Washer pump DODGE RAM 1500 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1477 of 2627

(9) Install rocker housing and bolts. Tighten to 24

Nm (18 lb. ft.).

(10) Install fuel injector(Refer to 14 - FUEL SYS-

TEM/FUEL INJECTION/FUEL INJECTOR -

INSTALLATION).

(11) Install injector harness nuts. Tighten to 1.25

Nm (11 lb. in.).

(12) Install cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(13) Install wire harness P-clip to cylinder head

behind filter housing 24 N´m (18 ft. lbs.).

(14) Connect the IAT/MAP sensor connector.

(15) Install the fuel filter canister assembly and

torque mounting bolts to 24 N´m (18 ft. lbs.).

(16) Connect fuel lift pump, WIF sensor, and fuel

heater.

(17) Remove the engine lift bracket at rear of cyl-

inder head.

CAUTION: Failure to follow procedure will result in

fuel leaks and/or fuel system failure.

(18)Install the fuel rail and high pressure

fuel lines as follows:

(a) Hand tighten fuel rail bolts.

(b) Hand tighten fuel drain line to pressure lim-

iting valve. Hand tighten banjo bolt at fuel filter

housing.

(c) Hand tighten fuel rail-to-cylinder head high

pressure fuel lines.(d) Install fuel line brace bolts-to-intake mani-

fold finger tight.

(e) Hand tighten fuel pump to fuel rail line.

(f) Torque fuel line nuts at cylinder head to 30

Nm ( 22 ft. lbs.).

(g) Torque fuel line nuts at fuel rail to 30 Nm

(22 ft. lbs.)

(h) Using a back up wrench, torque fuel pump to

fuel rail line to 37 Nm (27 ft. lbs.). At injection

pump.

(i) Torque fuel pump to fuel rail line to 37 Nm

(27 ft. lbs.) at fuel rail.

(j) Torque fuel drain banjo bolt at pressure lim-

iting valve and front of fuel filter housing to 24 Nm

(18 ft. lbs.).

(k) Torque fuel line brace bolts to 24 N´m (18 ft.

lbs.).

(l) Torque rail bolts to 24 Nm (18 ft. lbs.).

(m) Connect fuel pressure sensor.

(19) Install the engine lift bracket at the rear of

cylinder head. Torque to 77 N´m (57 ft. lbs.).

(20) Reposition number 6 fuel line shield and

torque to 43 N´m (32 ft. lbs.).

(21) Install the fuel filter to injection pump low

pressure line. Inspect and replace sealing washers if

necessary. Torque banjo bolts to 24 N´m (18 ft. lbs.).

(22) Connect fuel return line at back of cylinder

head hand tight.

(23) Connect fuel return line at filter housing hand

tight.

(24) Torque banjo connections at cylinder head and

fuel filter housing to 24 Nm (18 ft. lbs.)

(25) Install bracket to rear of filter housing.

Torque to 24 Nm (18 ft. lbs.).

(26) Using new gaskets, install the intake grid

heater and air inlet housing. Torque bolts to 24 N´m

(18 ft. lbs.).

(27) Install wire harness P-clip and push on clip to

air inlet housing.

(28) Connect engine oil level indicator tube at fuel

filter housing and at air inlet housing.

(29) Connect the APPS connector.

(30) Install the APPS assembly to the cylinder

head bracket and torque bolts to 24 N´m (18 ft. lbs.).

(31) Install the throttle linkage cover.

(32) Install the charge air cooler-to-air inlet hous-

ing duct assembly. Torque all clamps to 11 N´m (100

in. lbs.).

(33) Connect intake grid heater wires.

(34) Secure engine harness to front of cylinder

head with bolt at four locations.

(35) Connect engine coolant temperature sensor

connector.

(36) Connect radiator upper hose to thermostat

housing.

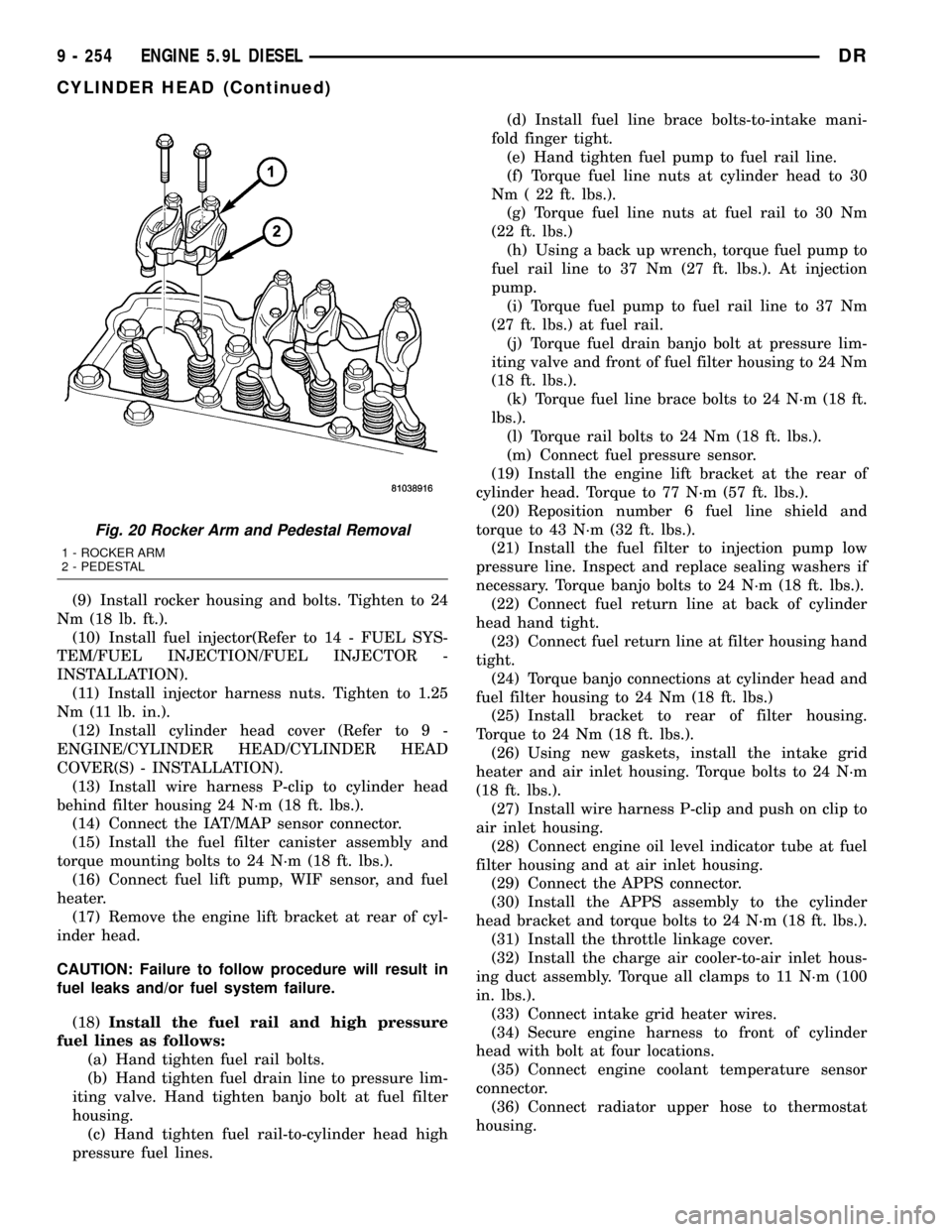

Fig. 20 Rocker Arm and Pedestal Removal

1 - ROCKER ARM

2 - PEDESTAL

9 - 254 ENGINE 5.9L DIESELDR

CYLINDER HEAD (Continued)

Page 1495 of 2627

(6) Remove the wooden dowel rods and rubber

bands from the tappets.

(7) Lubricate the push rods with engine oil and

install in their original location.Verify that they

are seated in the tappets.

(8) Lubricate the valve tips with engine oil and

install the crossheads in their original locations.

(9) Lubricate the crossheads and push rod sockets

with engine oil and install the rocker arms and ped-

estals in their original locations. Tighten bolts to 36

N´m (27 ft. lbs.) torque.

(10)Verify valve lash adjustment (Refer to 9 -

ENGINE/CYLINDER HEAD/INTAKE/EXHAUST

VALVES & SEATS - STANDARD PROCEDURE).

(11) Install the cylinder head cover and reusable

gasket (Refer to 9 - ENGINE/CYLINDER HEAD/

CYLINDER HEAD COVER(S) - INSTALLATION).

(12) Install gear housing cover (Refer to 9 -

ENGINE/VALVE TIMING/GEAR HOUSING COVER

- INSTALLATION). Install front crankshaft dust

seal.

(13) Install the crankshaft damper with the speed

indicator ring (Refer to 9 - ENGINE/ENGINE

BLOCK/VIBRATION DAMPER - INSTALLATION).

(14) Install the fan support/hub assembly Refer to

(Refer to 7 - COOLING/ENGINE/RADIATOR FAN -

INSTALLATION).

(15) Install the power steering pump.

(16) Install accessory drive belt tensioner. Torque

bolt to 43 Nm (32 ft. lbs.).

(17) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(18) Install the charge air cooler (with a/c con-

denser and auxiliary transmission oil cooler, if

equipped) and tighten the mounting bolts to 2 N´m

(17 in. lbs.) torque.

(19) Connect charge air cooler inlet and outlet

pipes. Tighten clamps to 11 N´m (95 in. lbs.) torque.

(20) Install the radiator upper support panel.

(21) Close radiator petcock and lower the radiator

into the engine compartment. Tighten the mounting

bolts to 11 N´m (95 in. lbs.) torque.

(22) Raise vehicle on hoist.

(23) Connect radiator lower hose and install

clamp.

(24) Connect transmission auxiliary oil cooler lines

(if equipped).

(25) Lower vehicle.

(26) Install the fan shroud and tighten the mount-

ing screws to 6 N´m (50 in. lbs.) torque.

(27) Install the electronically controlled viscous

fan/drive assembly. Connect harness connector.(Refer

to 7 - COOLING/ENGINE/RADIATOR FAN -

INSTALLATION).(28) Install the coolant recovery and windshield

washer fluid reservoirs to the fan shroud.

(29) Connect the coolant recovery hose to the radi-

ator filler neck.

(30) Add engine coolant (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(31) Charge A/C system with refrigerant (if A/C

equipped) (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE).

(32) Connect the battery negative cables.

(33) Start engine and check for engine oil and cool-

ant leaks.

CONNECTING ROD BEARINGS

STANDARD PROCEDURE - CONNECTING ROD

BEARING AND CRANKSHAFT JOURNAL

CLEARANCE

(1) Measure the connecting rod bore with bearings

removedand the bolts tightened to 100 N´m (73 ft.

lbs.) torque..

(2) Measure the connecting rod bore with the bear-

ingsinstalledand the bolts tightened to 100 N´m

(73 ft. lbs.) torque.

Measure within 20É arc from each side of the part-

ing line. Also measure 90É from parting line.

Record the smallest and largest diameter.

Measure the diameter of the rod journal at the

location shown (Fig. 63). Calculate the average diam-

eter for each side of the journal.

Determine minimum bearing clearance by calculat-

ing the differance between the smallest connecting

rod bore diameter with the bearing installed and the

average diameter for each side of the crankshaft jour-

nal.

Determine the maximum bearing clearance by cal-

culating the difference between the largest connect-

ing rod bore diameter and the average diameter with

the bearing installed for each side of the crankshaft

journal.

DESCRIPTION MEASUREMENT

CONNECTING ROD

BORE, BEARINGS

REMOVEDMIN. 72.99 mm (2.874

in.)

MAX. 73.01 mm (2.875

in.)

CONNECTING ROD

BORE, BEARINGS

INSTALLEDMIN. 69.05 mm (2.719

in.)

MAX. 69.10 mm (2.720

in.)

9 - 272 ENGINE 5.9L DIESELDR

CAMSHAFT & BEARINGS (IN BLOCK) (Continued)

Page 1498 of 2627

CRANKSHAFT OIL SEAL - FRONT

REMOVAL

(1) Disconnect both battery negative cables.

(2) Raise vehicle on hoist.

(3) Partially drain engine coolant into container

suitable for re-use (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(4) Lower vehicle.

(5) Remove radiator upper hose.

(6) Disconnect coolant recovery bottle from radia-

tor filler neck and lift bottle off of fan shroud.

(7) Disconnect windshield washer pump supply

hose and electrical connections and lift washer bottle

off of fan shroud.

(8)

Remove the fan shroud-to-radiator mounting bolts.

(9)Remove viscous fan/drive assembly. (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(10) Remove cooling fan shroud and fan assembly

from the vehicle.

(11) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(12) Remove the cooling fan support/hub from the

front of the engine.

(13) Raise the vehicle on hoist.

(14) Remove the crankshaft damper and speed

indicator ring.

(15) Remove power steering pump.

(16) Remove accessory drive belt tensioner.

(17) Remove the gear cover-to-housing bolts and

gently pry the cover away from the housing, taking

care not to mar the gasket surfaces. Remove crank

seal dust shield with cover.

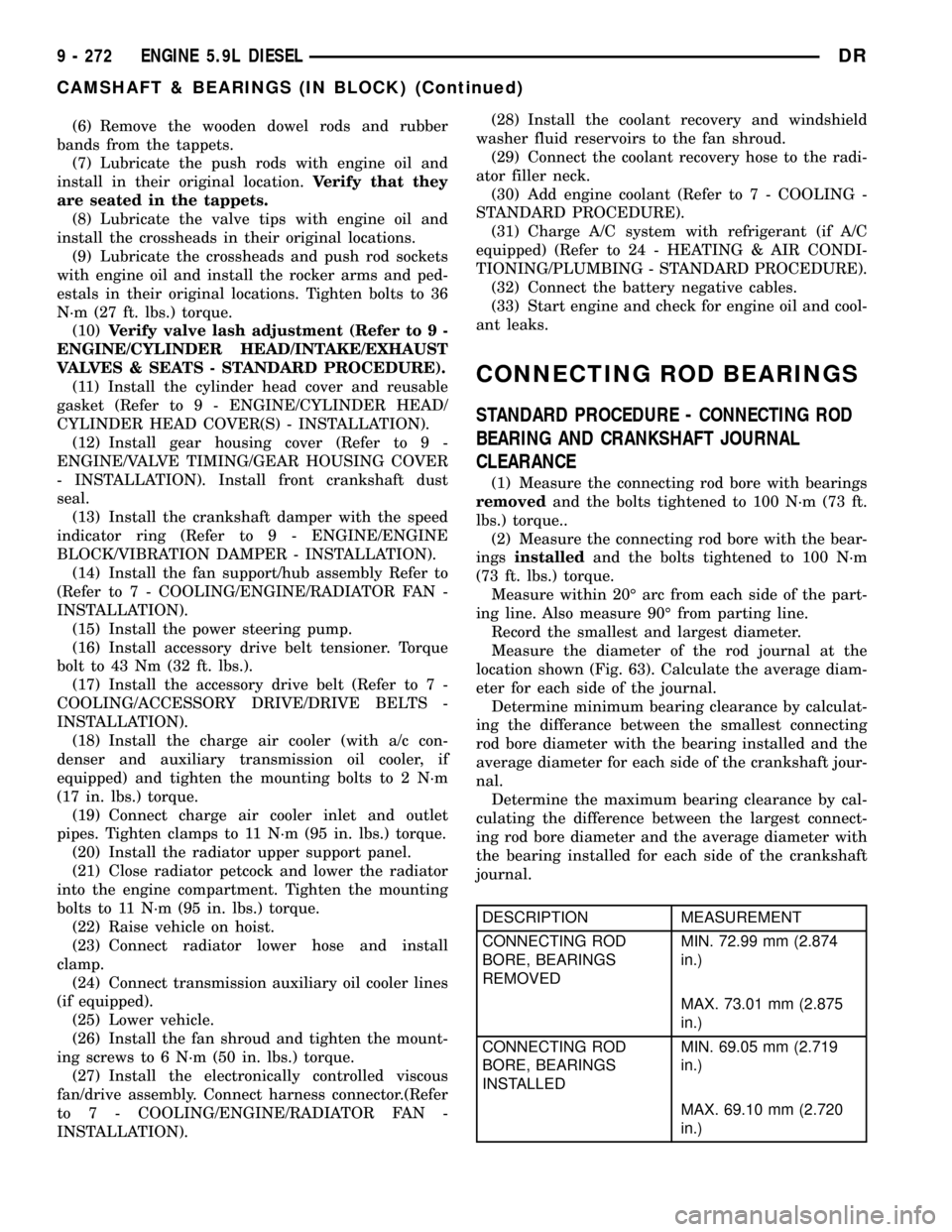

(18) Support the cover on a flat work surface with

wooden blocks (Fig. 68), and using a suitable punch

and hammer, drive the old seal out of the cover from

the back side of the cover to the front side (Fig. 68).

INSTALLATION

(1) Clean cover and housing gasket mating sur-

faces. Use a suitable scraper and be careful not to

damage the gear housing surface. Remove any old

sealer from the oil seal bore. Thoroughly clean the

front seal area of the crankshaft. The seal lip and the

sealing surface on the crankshaft must be free from

all oil residue to prevent seal leaks.

(2) Inspect the gear housing and cover for cracks

and replace if necessary. Carefully straighten any

bends or imperfections in the gear cover with a ball-

peen hammer on a flat surface. Inspect the crank-

shaft front journal for any grooves or nicks that

would affect the integrity of the new seal.

(3) Apply a bead of MopartStud & Bearing Mount

to the outside diameter of the seal. Do not lubricate

the inside diameter of the new seal.(4)

With the cover supported by wood blocks, install

the seal into the rear of the cover using crankshaft seal

installer Special Tool 8281 and driver handle C-4171

(Fig. 69). Strike the driver handle until the installation

tool bottoms out on the inside of the cover.

CAUTION: Do not distort or damage seal.

(5) Install the plastic seal pilot (provided with seal

kit) into the crankshaft seal.

Fig. 68 Removing Seal from Cover

1 - PUNCH

Fig. 69 Installing Seal Into Cover With Tool 8281

1 - SEAL INSTALLER 8281

2 - DRIVER HANDLE C4171

3 - SEAL

DRENGINE 5.9L DIESEL 9 - 275

Page 1522 of 2627

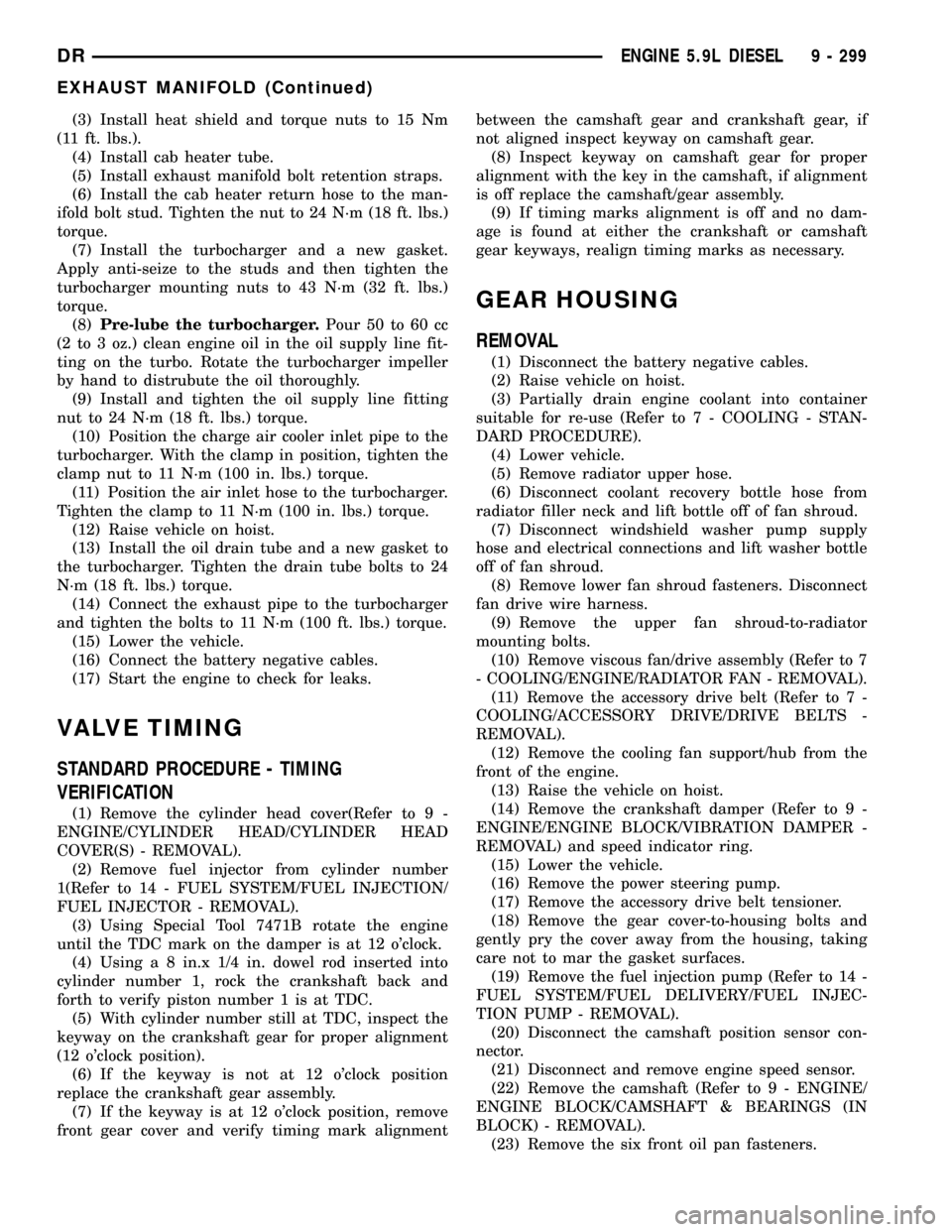

(3) Install heat shield and torque nuts to 15 Nm

(11 ft. lbs.).

(4) Install cab heater tube.

(5) Install exhaust manifold bolt retention straps.

(6) Install the cab heater return hose to the man-

ifold bolt stud. Tighten the nut to 24 N´m (18 ft. lbs.)

torque.

(7) Install the turbocharger and a new gasket.

Apply anti-seize to the studs and then tighten the

turbocharger mounting nuts to 43 N´m (32 ft. lbs.)

torque.

(8)Pre-lube the turbocharger.Pour 50 to 60 cc

(2 to 3 oz.) clean engine oil in the oil supply line fit-

ting on the turbo. Rotate the turbocharger impeller

by hand to distrubute the oil thoroughly.

(9) Install and tighten the oil supply line fitting

nut to 24 N´m (18 ft. lbs.) torque.

(10) Position the charge air cooler inlet pipe to the

turbocharger. With the clamp in position, tighten the

clamp nut to 11 N´m (100 in. lbs.) torque.

(11) Position the air inlet hose to the turbocharger.

Tighten the clamp to 11 N´m (100 in. lbs.) torque.

(12) Raise vehicle on hoist.

(13) Install the oil drain tube and a new gasket to

the turbocharger. Tighten the drain tube bolts to 24

N´m (18 ft. lbs.) torque.

(14) Connect the exhaust pipe to the turbocharger

and tighten the bolts to 11 N´m (100 ft. lbs.) torque.

(15) Lower the vehicle.

(16) Connect the battery negative cables.

(17) Start the engine to check for leaks.

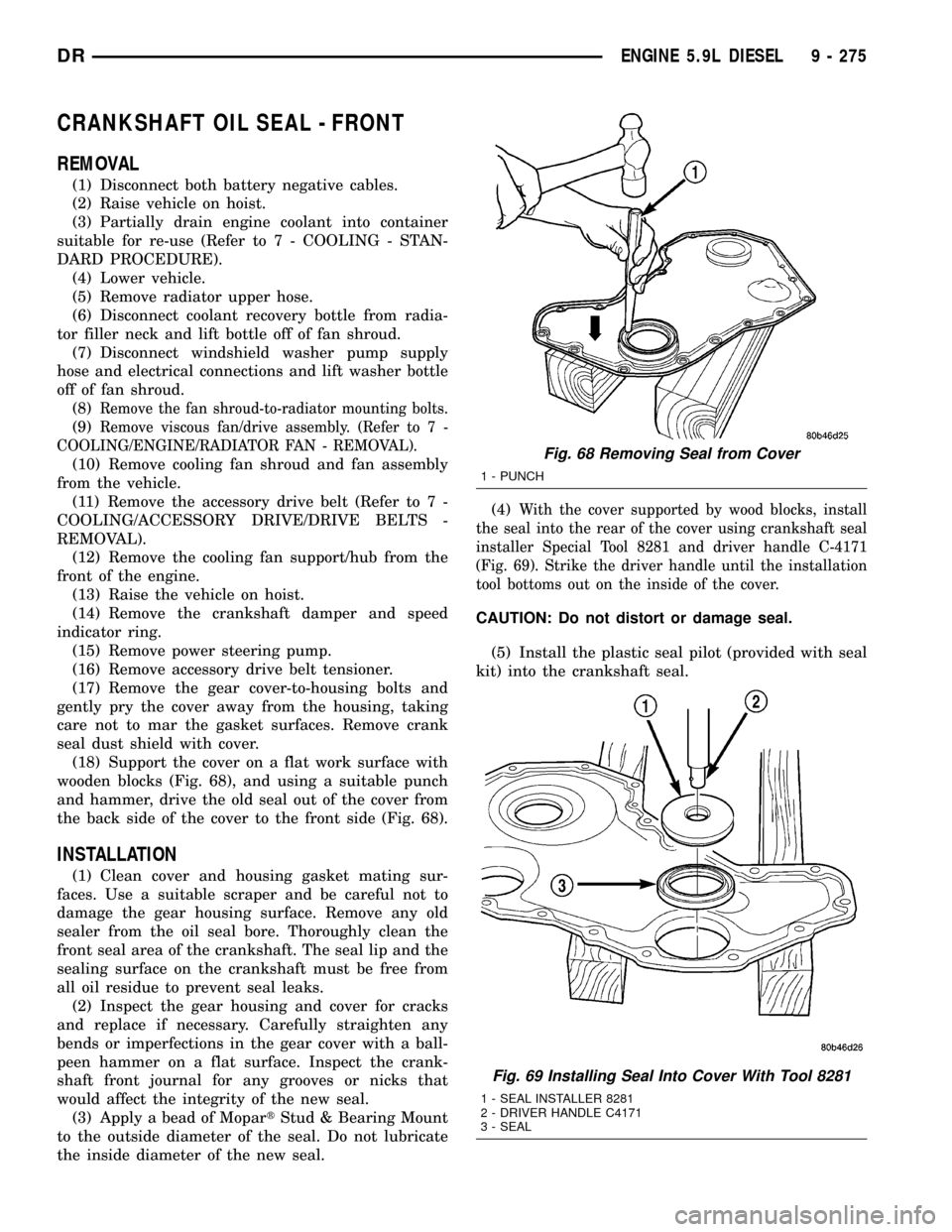

VALVE TIMING

STANDARD PROCEDURE - TIMING

VERIFICATION

(1) Remove the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(2) Remove fuel injector from cylinder number

1(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

FUEL INJECTOR - REMOVAL).

(3) Using Special Tool 7471B rotate the engine

until the TDC mark on the damper is at 12 o'clock.

(4) Using a 8 in.x 1/4 in. dowel rod inserted into

cylinder number 1, rock the crankshaft back and

forth to verify piston number 1 is at TDC.

(5) With cylinder number still at TDC, inspect the

keyway on the crankshaft gear for proper alignment

(12 o'clock position).

(6) If the keyway is not at 12 o'clock position

replace the crankshaft gear assembly.

(7) If the keyway is at 12 o'clock position, remove

front gear cover and verify timing mark alignmentbetween the camshaft gear and crankshaft gear, if

not aligned inspect keyway on camshaft gear.

(8) Inspect keyway on camshaft gear for proper

alignment with the key in the camshaft, if alignment

is off replace the camshaft/gear assembly.

(9) If timing marks alignment is off and no dam-

age is found at either the crankshaft or camshaft

gear keyways, realign timing marks as necessary.

GEAR HOUSING

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise vehicle on hoist.

(3) Partially drain engine coolant into container

suitable for re-use (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(4) Lower vehicle.

(5) Remove radiator upper hose.

(6) Disconnect coolant recovery bottle hose from

radiator filler neck and lift bottle off of fan shroud.

(7) Disconnect windshield washer pump supply

hose and electrical connections and lift washer bottle

off of fan shroud.

(8) Remove lower fan shroud fasteners. Disconnect

fan drive wire harness.

(9) Remove the upper fan shroud-to-radiator

mounting bolts.

(10) Remove viscous fan/drive assembly (Refer to 7

- COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(11) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(12) Remove the cooling fan support/hub from the

front of the engine.

(13) Raise the vehicle on hoist.

(14) Remove the crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL) and speed indicator ring.

(15) Lower the vehicle.

(16) Remove the power steering pump.

(17) Remove the accessory drive belt tensioner.

(18) Remove the gear cover-to-housing bolts and

gently pry the cover away from the housing, taking

care not to mar the gasket surfaces.

(19) Remove the fuel injection pump (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/FUEL INJEC-

TION PUMP - REMOVAL).

(20) Disconnect the camshaft position sensor con-

nector.

(21) Disconnect and remove engine speed sensor.

(22) Remove the camshaft (Refer to 9 - ENGINE/

ENGINE BLOCK/CAMSHAFT & BEARINGS (IN

BLOCK) - REMOVAL).

(23) Remove the six front oil pan fasteners.

DRENGINE 5.9L DIESEL 9 - 299

EXHAUST MANIFOLD (Continued)

Page 1524 of 2627

(23) Install the windshield washer reservoir to the

fan shroud and connect the washer pump supply

hose and electrical connection.

(24) Install the coolant recovery bottle to the fan

shroud and connect the hose to the radiator filler

neck.

(25) Install the radiator upper hose and clamps.

(26) Add engine oil.

(27) Add coolant (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(28) Connect the battery cables.

(29) Start engine and inspect for leaks.

GEAR HOUSING COVER

REMOVAL

(1) Disconnect both battery negative cables.

(2) Raise vehicle on hoist.

(3) Partially drain engine coolant into container

suitable for re-use (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(4) Lower vehicle.

(5) Remove radiator upper hose.

(6) Disconnect coolant recovery bottle hose from

radiator filler neck and lift bottle off of fan shroud.

(7) Disconnect windshield washer pump supply

hose and electrical connections and lift washer bottle

off of fan shroud.

(8) Remove viscous fan/drive assembly (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(9) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(10) Remove the cooling fan support/hub from the

front of the engine.

(11) Raise the vehicle on hoist.

(12) Remove power steering pump.

(13) Remove accessory drive belt tensioner.

(14) Remove the crankshaft damper and speed

indicator ring (Refer to 9 - ENGINE/ENGINE

BLOCK/VIBRATION DAMPER - REMOVAL).

(15) Lower the vehicle.

(16) Remove the gear cover-to-housing bolts and

gently pry the cover away from the housing, taking

care not to mar the gasket surfaces.

INSTALLATION

(1) Install a new front crankshaft oil seal.

(2) Obtain a seal pilot/installation tool from a

crankshaft front seal service kit and install the pilot

into the seal.

(3) Apply a bead of MopartSilicone Rubber Adhe-

sive Sealant or equivalent to the gear housing cover.

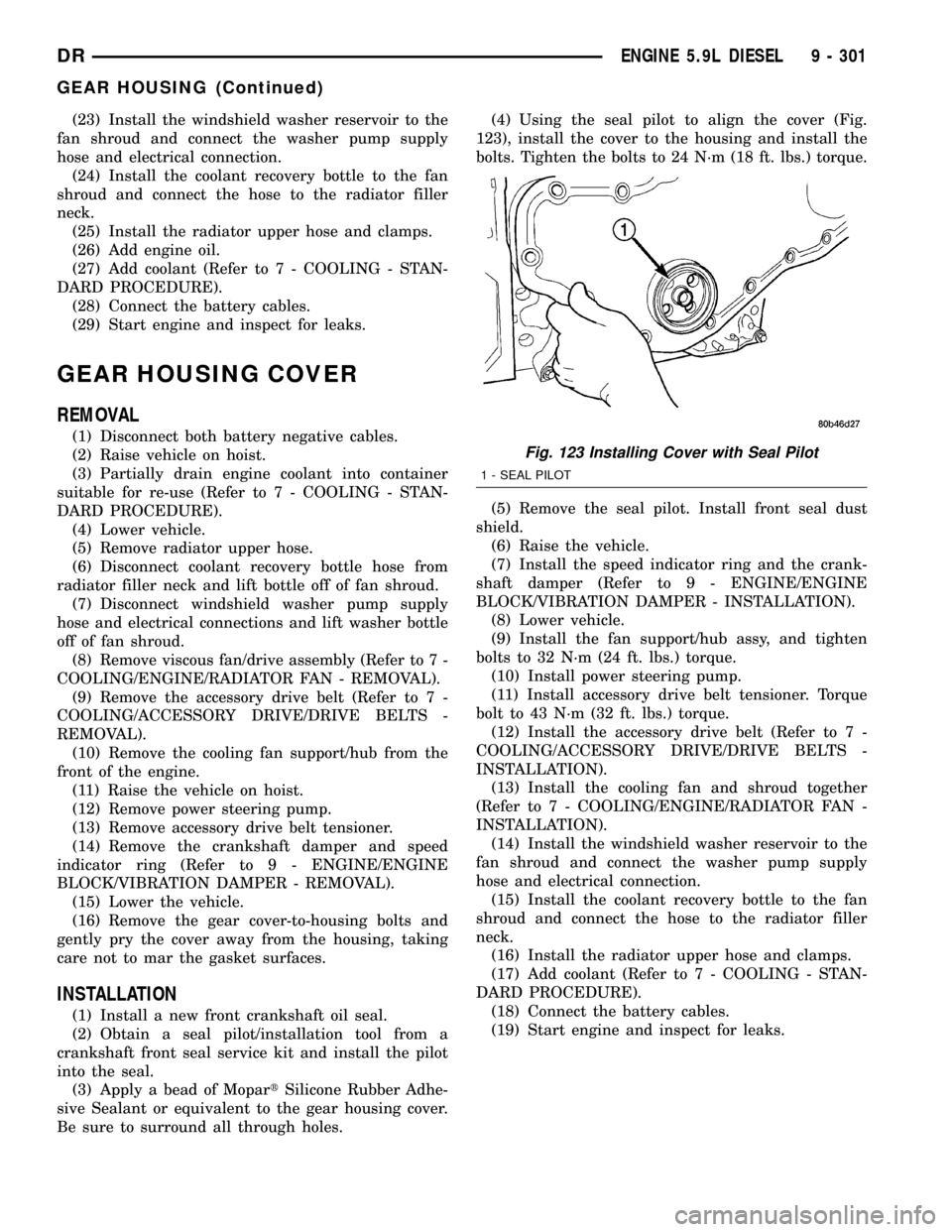

Be sure to surround all through holes.(4) Using the seal pilot to align the cover (Fig.

123), install the cover to the housing and install the

bolts. Tighten the bolts to 24 N´m (18 ft. lbs.) torque.

(5) Remove the seal pilot. Install front seal dust

shield.

(6) Raise the vehicle.

(7) Install the speed indicator ring and the crank-

shaft damper (Refer to 9 - ENGINE/ENGINE

BLOCK/VIBRATION DAMPER - INSTALLATION).

(8) Lower vehicle.

(9) Install the fan support/hub assy, and tighten

bolts to 32 N´m (24 ft. lbs.) torque.

(10) Install power steering pump.

(11) Install accessory drive belt tensioner. Torque

bolt to 43 N´m (32 ft. lbs.) torque.

(12) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(13) Install the cooling fan and shroud together

(Refer to 7 - COOLING/ENGINE/RADIATOR FAN -

INSTALLATION).

(14) Install the windshield washer reservoir to the

fan shroud and connect the washer pump supply

hose and electrical connection.

(15) Install the coolant recovery bottle to the fan

shroud and connect the hose to the radiator filler

neck.

(16) Install the radiator upper hose and clamps.

(17) Add coolant (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(18) Connect the battery cables.

(19) Start engine and inspect for leaks.

Fig. 123 Installing Cover with Seal Pilot

1 - SEAL PILOT

DRENGINE 5.9L DIESEL 9 - 301

GEAR HOUSING (Continued)

Page 1623 of 2627

REMOVAL

CAUTION: Cleanliness cannot be overemphasized

when handling or replacing diesel fuel system com-

ponents. This especially includes the fuel injectors,

high-pressure fuel lines and fuel injection pump.

Very tight tolerances are used with these parts. Dirt

contamination could cause rapid part wear and pos-

sible plugging of fuel injector nozzle tip holes. This

in turn could lead to possible engine misfire.

Always wash/clean any fuel system component

thoroughly before disassembly and then air dry.

Cap or cover any open part after disassembly.

Before assembly, examine each part for dirt, grease

or other contaminants and clean if necessary. When

installing new parts, lubricate them with clean

engine oil or clean diesel fuel only.

(1) Disconnect both negative battery cables at both

batteries. Cover and isolate ends of both cables.

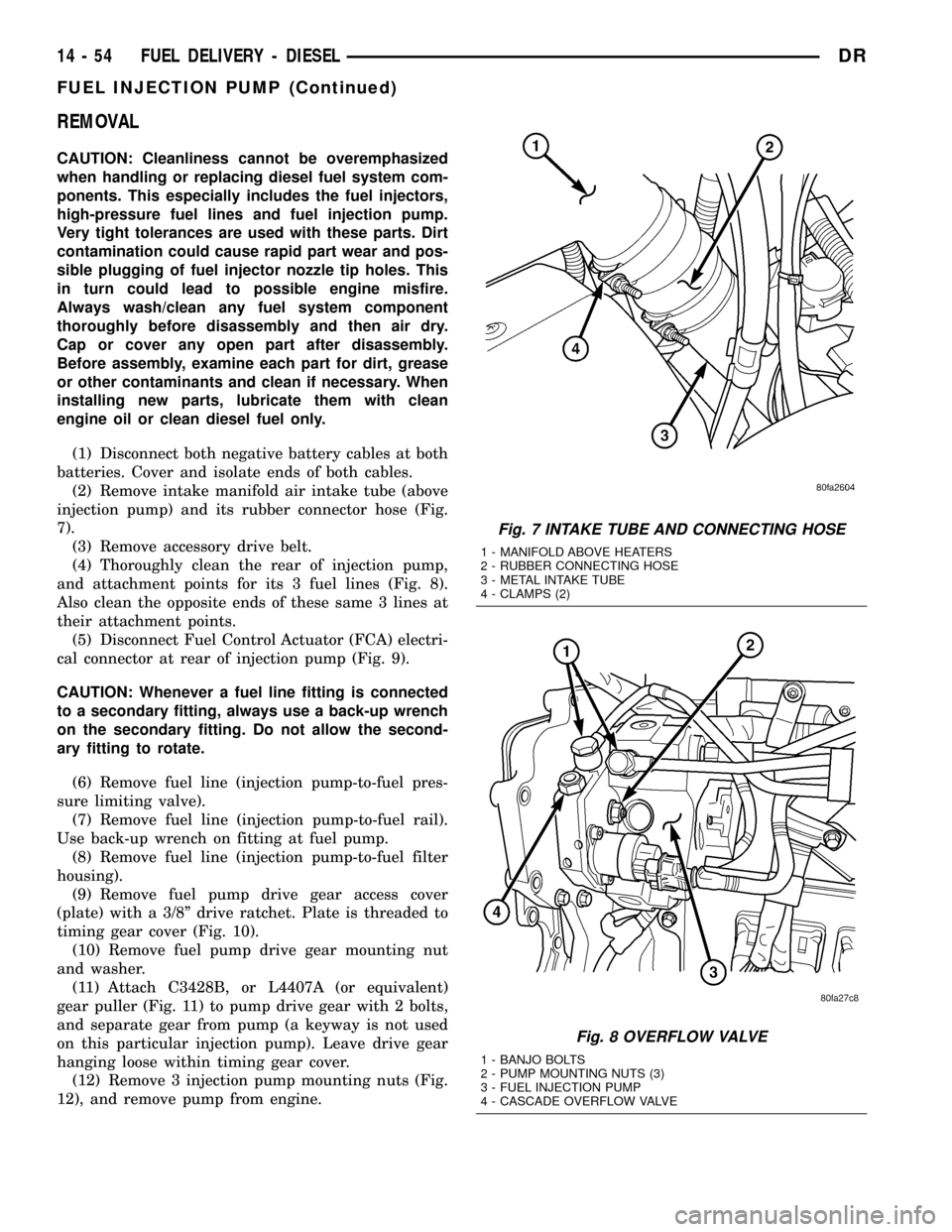

(2) Remove intake manifold air intake tube (above

injection pump) and its rubber connector hose (Fig.

7).

(3) Remove accessory drive belt.

(4) Thoroughly clean the rear of injection pump,

and attachment points for its 3 fuel lines (Fig. 8).

Also clean the opposite ends of these same 3 lines at

their attachment points.

(5) Disconnect Fuel Control Actuator (FCA) electri-

cal connector at rear of injection pump (Fig. 9).

CAUTION: Whenever a fuel line fitting is connected

to a secondary fitting, always use a back-up wrench

on the secondary fitting. Do not allow the second-

ary fitting to rotate.

(6) Remove fuel line (injection pump-to-fuel pres-

sure limiting valve).

(7) Remove fuel line (injection pump-to-fuel rail).

Use back-up wrench on fitting at fuel pump.

(8) Remove fuel line (injection pump-to-fuel filter

housing).

(9) Remove fuel pump drive gear access cover

(plate) with a 3/8º drive ratchet. Plate is threaded to

timing gear cover (Fig. 10).

(10) Remove fuel pump drive gear mounting nut

and washer.

(11) Attach C3428B, or L4407A (or equivalent)

gear puller (Fig. 11) to pump drive gear with 2 bolts,

and separate gear from pump (a keyway is not used

on this particular injection pump). Leave drive gear

hanging loose within timing gear cover.

(12) Remove 3 injection pump mounting nuts (Fig.

12), and remove pump from engine.

Fig. 7 INTAKE TUBE AND CONNECTING HOSE

1 - MANIFOLD ABOVE HEATERS

2 - RUBBER CONNECTING HOSE

3 - METAL INTAKE TUBE

4 - CLAMPS (2)

Fig. 8 OVERFLOW VALVE

1 - BANJO BOLTS

2 - PUMP MOUNTING NUTS (3)

3 - FUEL INJECTION PUMP

4 - CASCADE OVERFLOW VALVE

14 - 54 FUEL DELIVERY - DIESELDR

FUEL INJECTION PUMP (Continued)

Page 1625 of 2627

This will ensure proper gear-to-shaft tighten-

ing.

(5) Clean pump gear and pump shaft at machined

tapers with an evaporative type cleaner such as

brake cleaner.

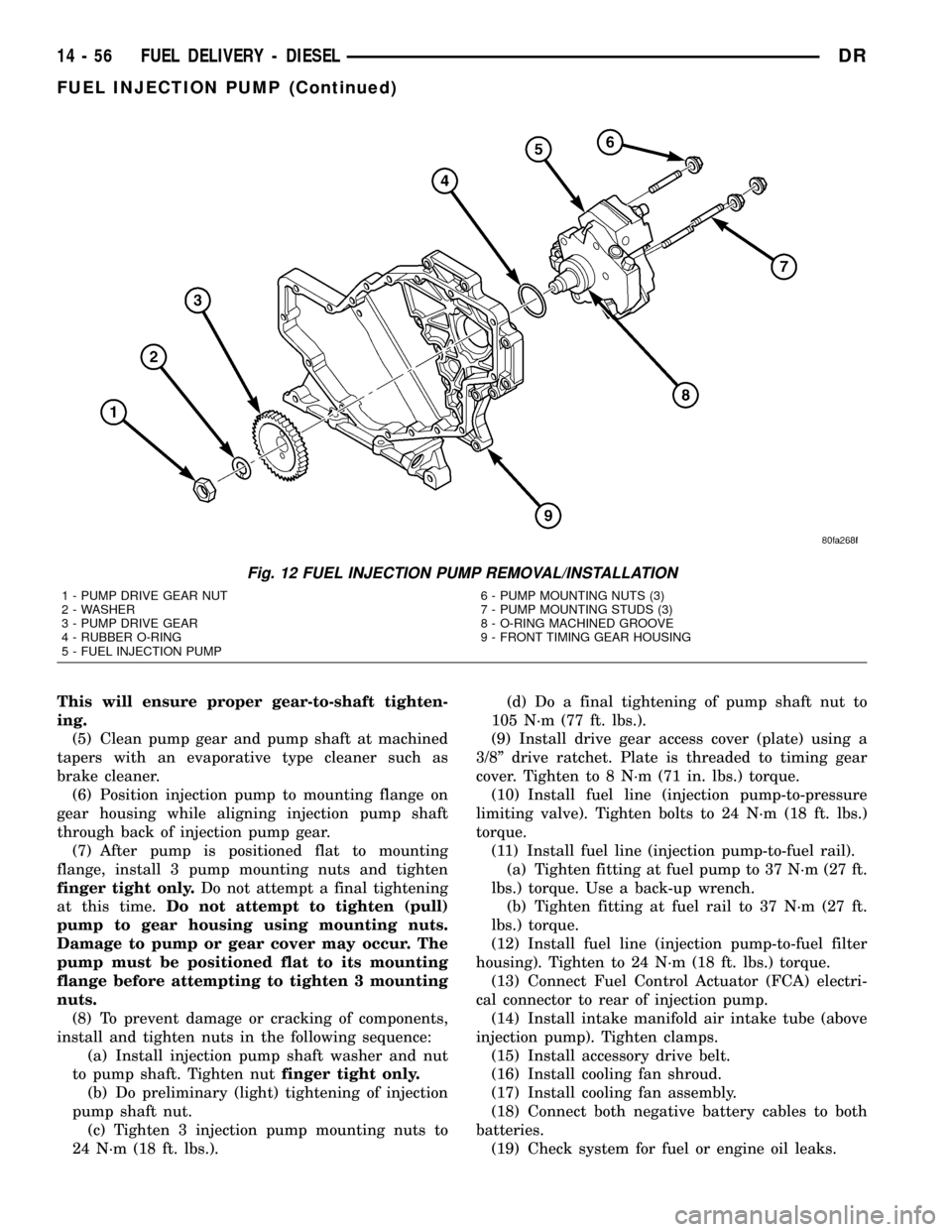

(6) Position injection pump to mounting flange on

gear housing while aligning injection pump shaft

through back of injection pump gear.

(7) After pump is positioned flat to mounting

flange, install 3 pump mounting nuts and tighten

finger tight only.Do not attempt a final tightening

at this time.Do not attempt to tighten (pull)

pump to gear housing using mounting nuts.

Damage to pump or gear cover may occur. The

pump must be positioned flat to its mounting

flange before attempting to tighten 3 mounting

nuts.

(8) To prevent damage or cracking of components,

install and tighten nuts in the following sequence:

(a) Install injection pump shaft washer and nut

to pump shaft. Tighten nutfinger tight only.

(b) Do preliminary (light) tightening of injection

pump shaft nut.

(c) Tighten 3 injection pump mounting nuts to

24 N´m (18 ft. lbs.).(d) Do a final tightening of pump shaft nut to

105 N´m (77 ft. lbs.).

(9) Install drive gear access cover (plate) using a

3/8º drive ratchet. Plate is threaded to timing gear

cover. Tighten to 8 N´m (71 in. lbs.) torque.

(10) Install fuel line (injection pump-to-pressure

limiting valve). Tighten bolts to 24 N´m (18 ft. lbs.)

torque.

(11) Install fuel line (injection pump-to-fuel rail).

(a) Tighten fitting at fuel pump to 37 N´m (27 ft.

lbs.) torque. Use a back-up wrench.

(b) Tighten fitting at fuel rail to 37 N´m (27 ft.

lbs.) torque.

(12) Install fuel line (injection pump-to-fuel filter

housing). Tighten to 24 N´m (18 ft. lbs.) torque.

(13) Connect Fuel Control Actuator (FCA) electri-

cal connector to rear of injection pump.

(14) Install intake manifold air intake tube (above

injection pump). Tighten clamps.

(15) Install accessory drive belt.

(16) Install cooling fan shroud.

(17) Install cooling fan assembly.

(18) Connect both negative battery cables to both

batteries.

(19) Check system for fuel or engine oil leaks.

Fig. 12 FUEL INJECTION PUMP REMOVAL/INSTALLATION

1 - PUMP DRIVE GEAR NUT

2 - WASHER

3 - PUMP DRIVE GEAR

4 - RUBBER O-RING

5 - FUEL INJECTION PUMP6 - PUMP MOUNTING NUTS (3)

7 - PUMP MOUNTING STUDS (3)

8 - O-RING MACHINED GROOVE

9 - FRONT TIMING GEAR HOUSING

14 - 56 FUEL DELIVERY - DIESELDR

FUEL INJECTION PUMP (Continued)

Page 1630 of 2627

INSTALLATION

(1) Inspect fuel pressure sensor sealing surface.

(2) Lubricate sensor threads with clean diesel fuel.

(3) Install sensor into fuel rail.

(4) To prevent leaks, sensormustbe tightened to

prescribed torque. Refer to Torque Specifications.

(5) Connect electrical connector to sensor.

(6) Start engine and check for fuel leaks.

FUEL PRESSURE LIMITING

VA LV E

DESCRIPTION

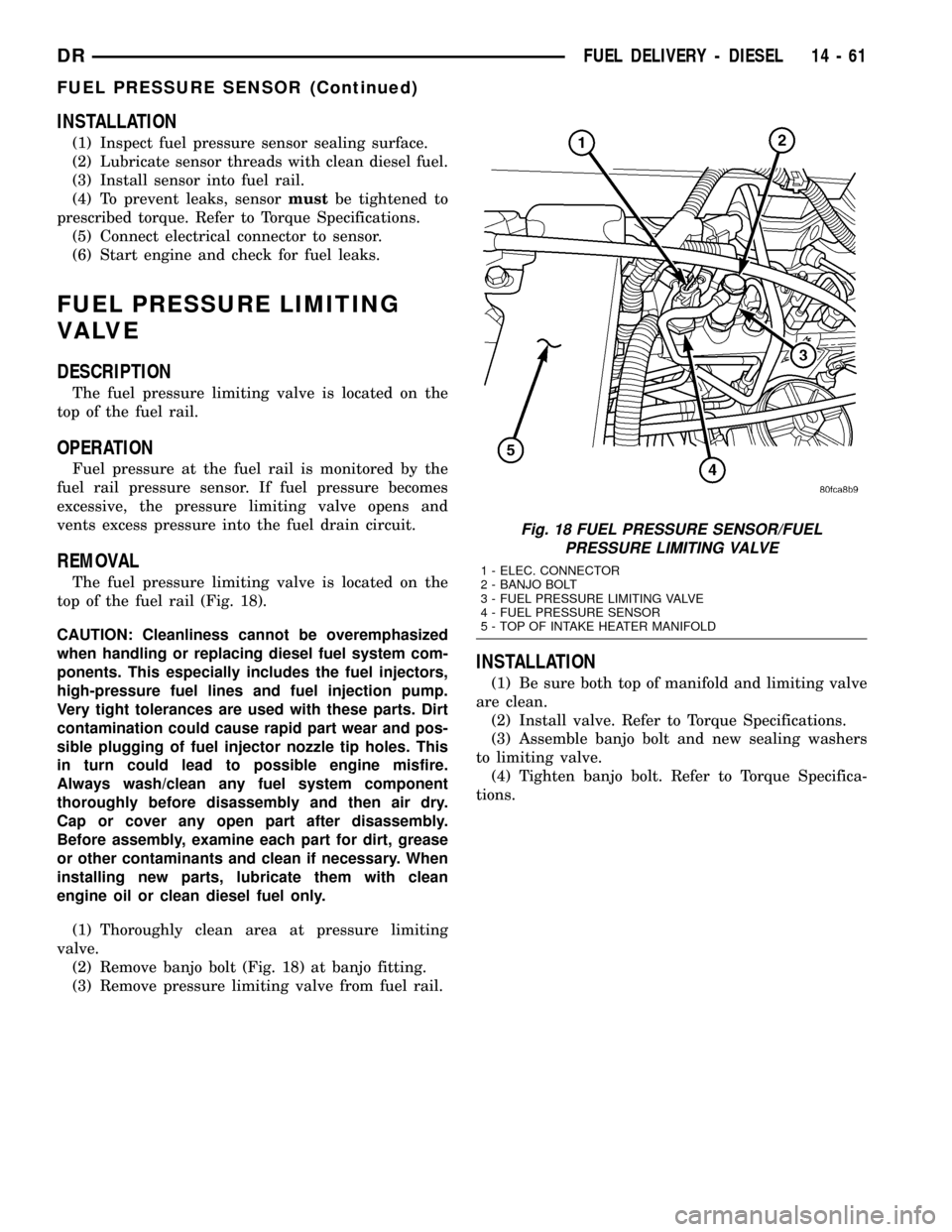

The fuel pressure limiting valve is located on the

top of the fuel rail.

OPERATION

Fuel pressure at the fuel rail is monitored by the

fuel rail pressure sensor. If fuel pressure becomes

excessive, the pressure limiting valve opens and

vents excess pressure into the fuel drain circuit.

REMOVAL

The fuel pressure limiting valve is located on the

top of the fuel rail (Fig. 18).

CAUTION: Cleanliness cannot be overemphasized

when handling or replacing diesel fuel system com-

ponents. This especially includes the fuel injectors,

high-pressure fuel lines and fuel injection pump.

Very tight tolerances are used with these parts. Dirt

contamination could cause rapid part wear and pos-

sible plugging of fuel injector nozzle tip holes. This

in turn could lead to possible engine misfire.

Always wash/clean any fuel system component

thoroughly before disassembly and then air dry.

Cap or cover any open part after disassembly.

Before assembly, examine each part for dirt, grease

or other contaminants and clean if necessary. When

installing new parts, lubricate them with clean

engine oil or clean diesel fuel only.

(1) Thoroughly clean area at pressure limiting

valve.

(2) Remove banjo bolt (Fig. 18) at banjo fitting.

(3) Remove pressure limiting valve from fuel rail.

INSTALLATION

(1) Be sure both top of manifold and limiting valve

are clean.

(2) Install valve. Refer to Torque Specifications.

(3) Assemble banjo bolt and new sealing washers

to limiting valve.

(4) Tighten banjo bolt. Refer to Torque Specifica-

tions.

Fig. 18 FUEL PRESSURE SENSOR/FUEL

PRESSURE LIMITING VALVE

1 - ELEC. CONNECTOR

2 - BANJO BOLT

3 - FUEL PRESSURE LIMITING VALVE

4 - FUEL PRESSURE SENSOR

5 - TOP OF INTAKE HEATER MANIFOLD

DRFUEL DELIVERY - DIESEL 14 - 61

FUEL PRESSURE SENSOR (Continued)

Page 1643 of 2627

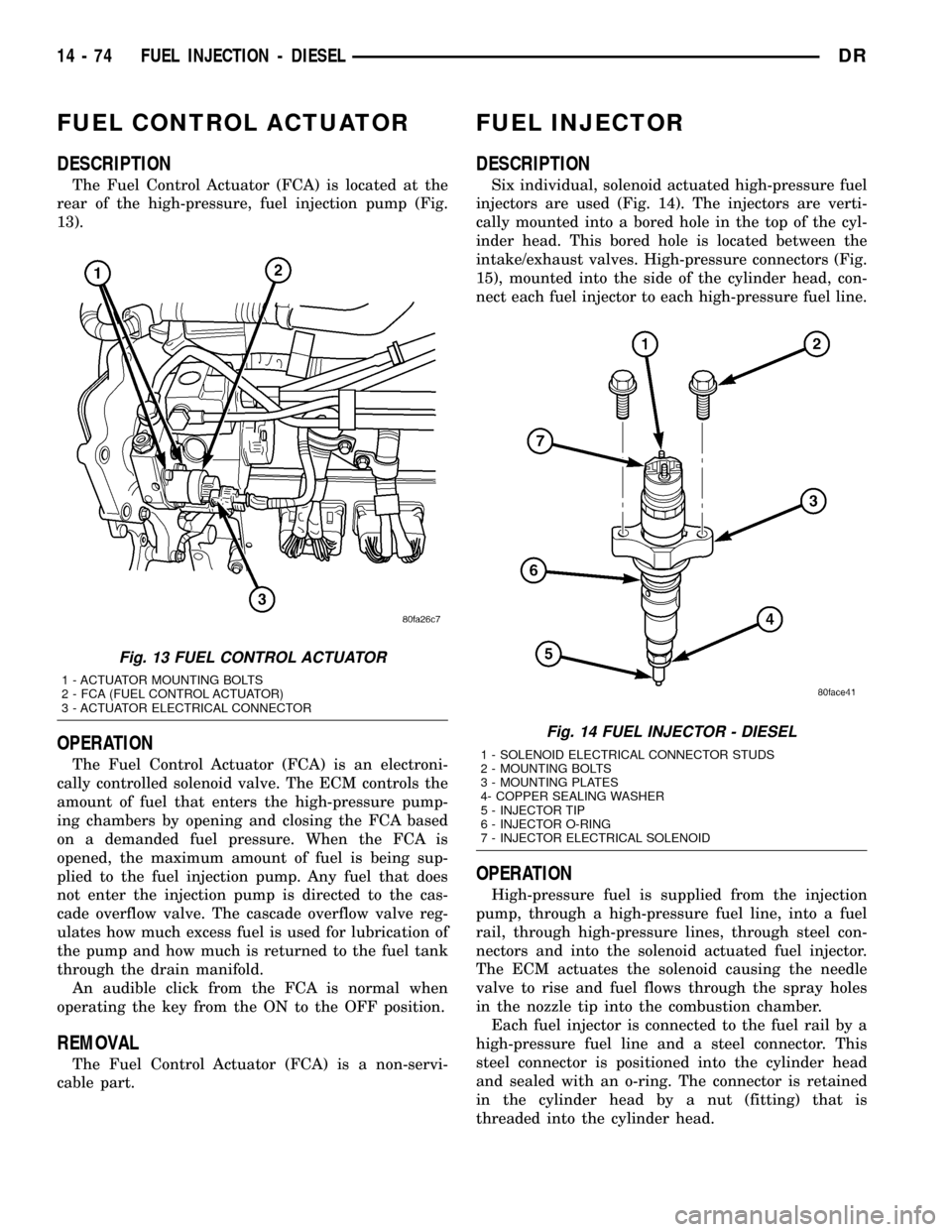

FUEL CONTROL ACTUATOR

DESCRIPTION

The Fuel Control Actuator (FCA) is located at the

rear of the high-pressure, fuel injection pump (Fig.

13).

OPERATION

The Fuel Control Actuator (FCA) is an electroni-

cally controlled solenoid valve. The ECM controls the

amount of fuel that enters the high-pressure pump-

ing chambers by opening and closing the FCA based

on a demanded fuel pressure. When the FCA is

opened, the maximum amount of fuel is being sup-

plied to the fuel injection pump. Any fuel that does

not enter the injection pump is directed to the cas-

cade overflow valve. The cascade overflow valve reg-

ulates how much excess fuel is used for lubrication of

the pump and how much is returned to the fuel tank

through the drain manifold.

An audible click from the FCA is normal when

operating the key from the ON to the OFF position.

REMOVAL

The Fuel Control Actuator (FCA) is a non-servi-

cable part.

FUEL INJECTOR

DESCRIPTION

Six individual, solenoid actuated high-pressure fuel

injectors are used (Fig. 14). The injectors are verti-

cally mounted into a bored hole in the top of the cyl-

inder head. This bored hole is located between the

intake/exhaust valves. High-pressure connectors (Fig.

15), mounted into the side of the cylinder head, con-

nect each fuel injector to each high-pressure fuel line.

OPERATION

High-pressure fuel is supplied from the injection

pump, through a high-pressure fuel line, into a fuel

rail, through high-pressure lines, through steel con-

nectors and into the solenoid actuated fuel injector.

The ECM actuates the solenoid causing the needle

valve to rise and fuel flows through the spray holes

in the nozzle tip into the combustion chamber.

Each fuel injector is connected to the fuel rail by a

high-pressure fuel line and a steel connector. This

steel connector is positioned into the cylinder head

and sealed with an o-ring. The connector is retained

in the cylinder head by a nut (fitting) that is

threaded into the cylinder head.

Fig. 13 FUEL CONTROL ACTUATOR

1 - ACTUATOR MOUNTING BOLTS

2 - FCA (FUEL CONTROL ACTUATOR)

3 - ACTUATOR ELECTRICAL CONNECTOR

Fig. 14 FUEL INJECTOR - DIESEL

1 - SOLENOID ELECTRICAL CONNECTOR STUDS

2 - MOUNTING BOLTS

3 - MOUNTING PLATES

4- COPPER SEALING WASHER

5 - INJECTOR TIP

6 - INJECTOR O-RING

7 - INJECTOR ELECTRICAL SOLENOID

14 - 74 FUEL INJECTION - DIESELDR

Page 1676 of 2627

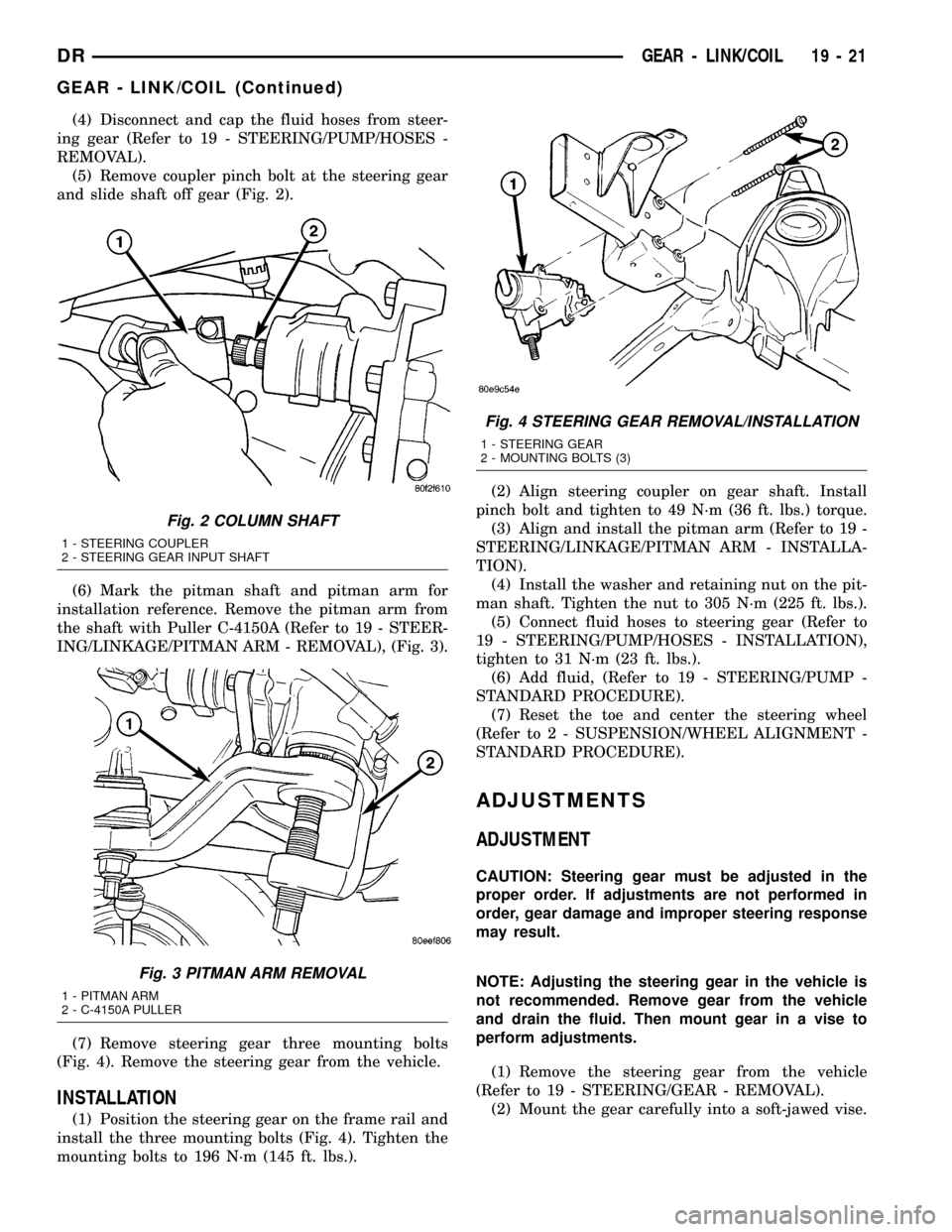

(4) Disconnect and cap the fluid hoses from steer-

ing gear (Refer to 19 - STEERING/PUMP/HOSES -

REMOVAL).

(5) Remove coupler pinch bolt at the steering gear

and slide shaft off gear (Fig. 2).

(6) Mark the pitman shaft and pitman arm for

installation reference. Remove the pitman arm from

the shaft with Puller C-4150A (Refer to 19 - STEER-

ING/LINKAGE/PITMAN ARM - REMOVAL), (Fig. 3).

(7) Remove steering gear three mounting bolts

(Fig. 4). Remove the steering gear from the vehicle.

INSTALLATION

(1) Position the steering gear on the frame rail and

install the three mounting bolts (Fig. 4). Tighten the

mounting bolts to 196 N´m (145 ft. lbs.).(2) Align steering coupler on gear shaft. Install

pinch bolt and tighten to 49 N´m (36 ft. lbs.) torque.

(3) Align and install the pitman arm (Refer to 19 -

STEERING/LINKAGE/PITMAN ARM - INSTALLA-

TION).

(4) Install the washer and retaining nut on the pit-

man shaft. Tighten the nut to 305 N´m (225 ft. lbs.).

(5) Connect fluid hoses to steering gear (Refer to

19 - STEERING/PUMP/HOSES - INSTALLATION),

tighten to 31 N´m (23 ft. lbs.).

(6) Add fluid, (Refer to 19 - STEERING/PUMP -

STANDARD PROCEDURE).

(7) Reset the toe and center the steering wheel

(Refer to 2 - SUSPENSION/WHEEL ALIGNMENT -

STANDARD PROCEDURE).

ADJUSTMENTS

ADJUSTMENT

CAUTION: Steering gear must be adjusted in the

proper order. If adjustments are not performed in

order, gear damage and improper steering response

may result.

NOTE: Adjusting the steering gear in the vehicle is

not recommended. Remove gear from the vehicle

and drain the fluid. Then mount gear in a vise to

perform adjustments.

(1) Remove the steering gear from the vehicle

(Refer to 19 - STEERING/GEAR - REMOVAL).

(2) Mount the gear carefully into a soft-jawed vise.

Fig. 2 COLUMN SHAFT

1 - STEERING COUPLER

2 - STEERING GEAR INPUT SHAFT

Fig. 3 PITMAN ARM REMOVAL

1 - PITMAN ARM

2 - C-4150A PULLER

Fig. 4 STEERING GEAR REMOVAL/INSTALLATION

1 - STEERING GEAR

2 - MOUNTING BOLTS (3)

DRGEAR - LINK/COIL 19 - 21

GEAR - LINK/COIL (Continued)