Washer pump DODGE RAM 1500 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1863 of 2627

DISASSEMBLY

(1) Clean exterior of transmission with suitable

solvent or pressure washer.

(2) Place transmission in vertical position.

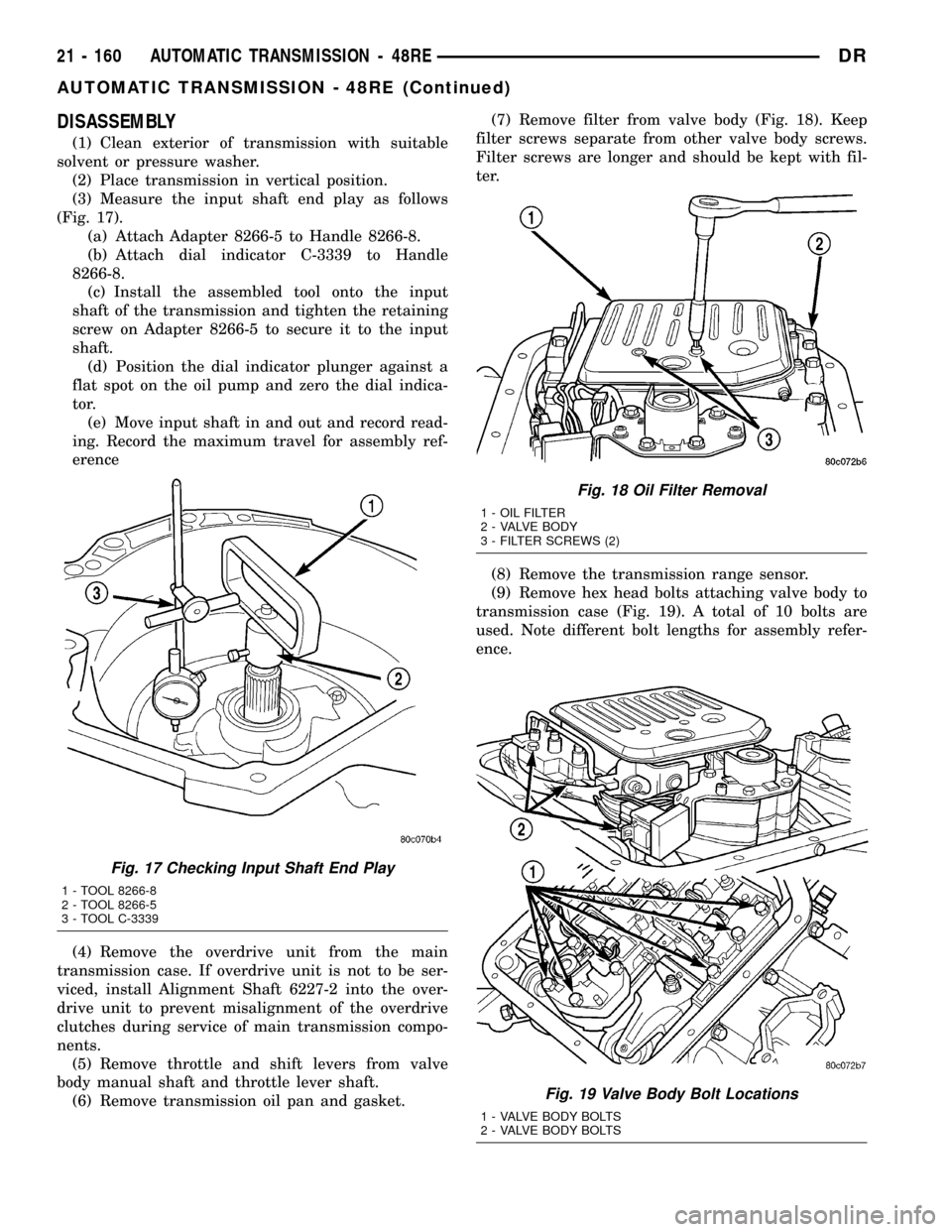

(3) Measure the input shaft end play as follows

(Fig. 17).

(a) Attach Adapter 8266-5 to Handle 8266-8.

(b) Attach dial indicator C-3339 to Handle

8266-8.

(c) Install the assembled tool onto the input

shaft of the transmission and tighten the retaining

screw on Adapter 8266-5 to secure it to the input

shaft.

(d) Position the dial indicator plunger against a

flat spot on the oil pump and zero the dial indica-

tor.

(e) Move input shaft in and out and record read-

ing. Record the maximum travel for assembly ref-

erence

(4) Remove the overdrive unit from the main

transmission case. If overdrive unit is not to be ser-

viced, install Alignment Shaft 6227-2 into the over-

drive unit to prevent misalignment of the overdrive

clutches during service of main transmission compo-

nents.

(5) Remove throttle and shift levers from valve

body manual shaft and throttle lever shaft.

(6) Remove transmission oil pan and gasket.(7) Remove filter from valve body (Fig. 18). Keep

filter screws separate from other valve body screws.

Filter screws are longer and should be kept with fil-

ter.

(8) Remove the transmission range sensor.

(9) Remove hex head bolts attaching valve body to

transmission case (Fig. 19). A total of 10 bolts are

used. Note different bolt lengths for assembly refer-

ence.

Fig. 19 Valve Body Bolt Locations

1 - VALVE BODY BOLTS

2 - VALVE BODY BOLTS

Fig. 17 Checking Input Shaft End Play

1 - TOOL 8266-8

2 - TOOL 8266-5

3 - TOOL C-3339

Fig. 18 Oil Filter Removal

1 - OIL FILTER

2 - VALVE BODY

3 - FILTER SCREWS (2)

21 - 160 AUTOMATIC TRANSMISSION - 48REDR

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 1870 of 2627

assembled. Verify that thrust washers, thrust plates

and seal rings are correctly positioned.

The planetary geartrain, front/rear clutch assem-

blies and oil pump are all much easier to install

when the transmission case is upright. Either tilt the

case upward with wood blocks, or cut a hole in the

bench large enough for the intermediate shaft and

rear support. Then lower the shaft and support into

the hole and support the rear of the case directly on

the bench.

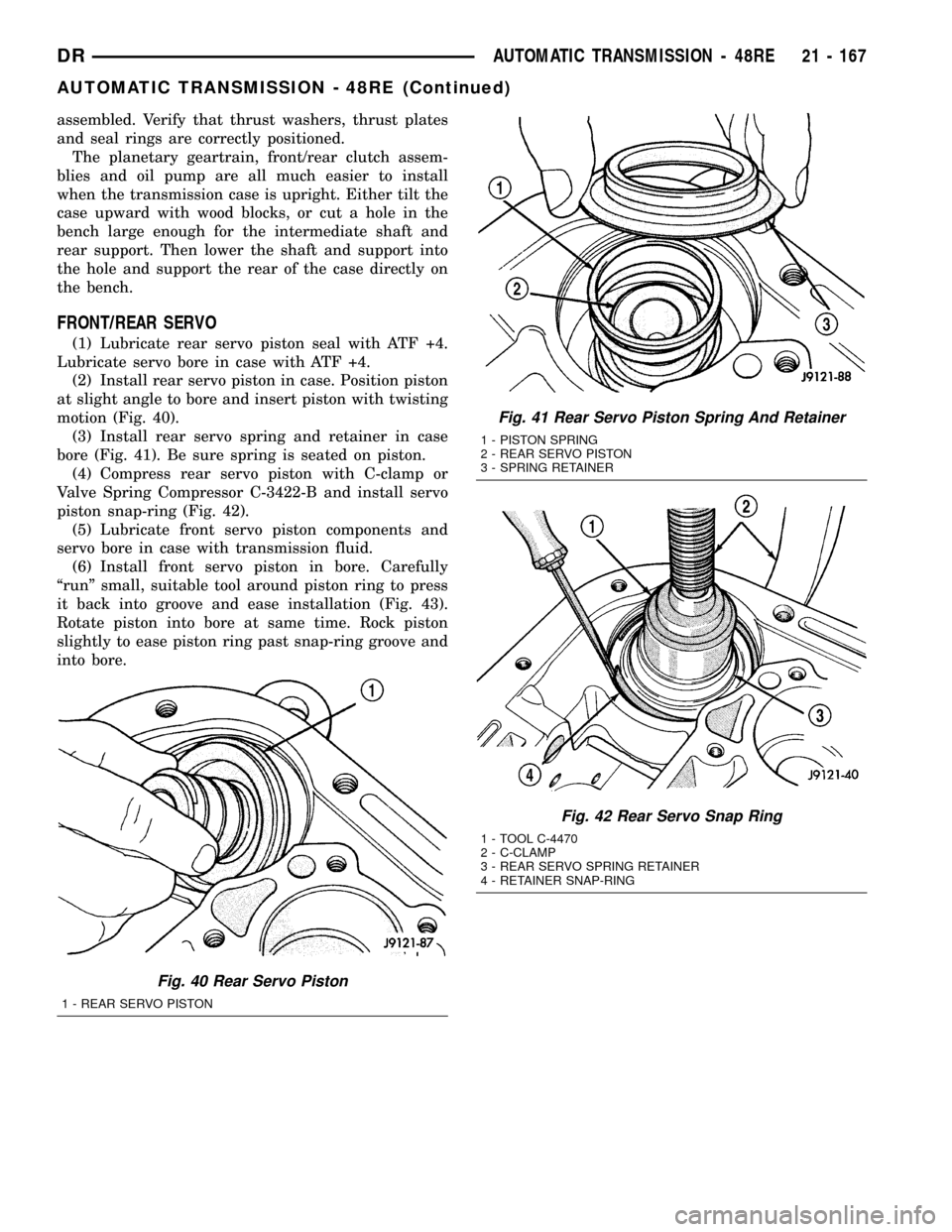

FRONT/REAR SERVO

(1) Lubricate rear servo piston seal with ATF +4.

Lubricate servo bore in case with ATF +4.

(2) Install rear servo piston in case. Position piston

at slight angle to bore and insert piston with twisting

motion (Fig. 40).

(3) Install rear servo spring and retainer in case

bore (Fig. 41). Be sure spring is seated on piston.

(4) Compress rear servo piston with C-clamp or

Valve Spring Compressor C-3422-B and install servo

piston snap-ring (Fig. 42).

(5) Lubricate front servo piston components and

servo bore in case with transmission fluid.

(6) Install front servo piston in bore. Carefully

ªrunº small, suitable tool around piston ring to press

it back into groove and ease installation (Fig. 43).

Rotate piston into bore at same time. Rock piston

slightly to ease piston ring past snap-ring groove and

into bore.

Fig. 40 Rear Servo Piston

1 - REAR SERVO PISTON

Fig. 41 Rear Servo Piston Spring And Retainer

1 - PISTON SPRING

2 - REAR SERVO PISTON

3 - SPRING RETAINER

Fig. 42 Rear Servo Snap Ring

1 - TOOL C-4470

2 - C-CLAMP

3 - REAR SERVO SPRING RETAINER

4 - RETAINER SNAP-RING

DRAUTOMATIC TRANSMISSION - 48RE 21 - 167

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 1874 of 2627

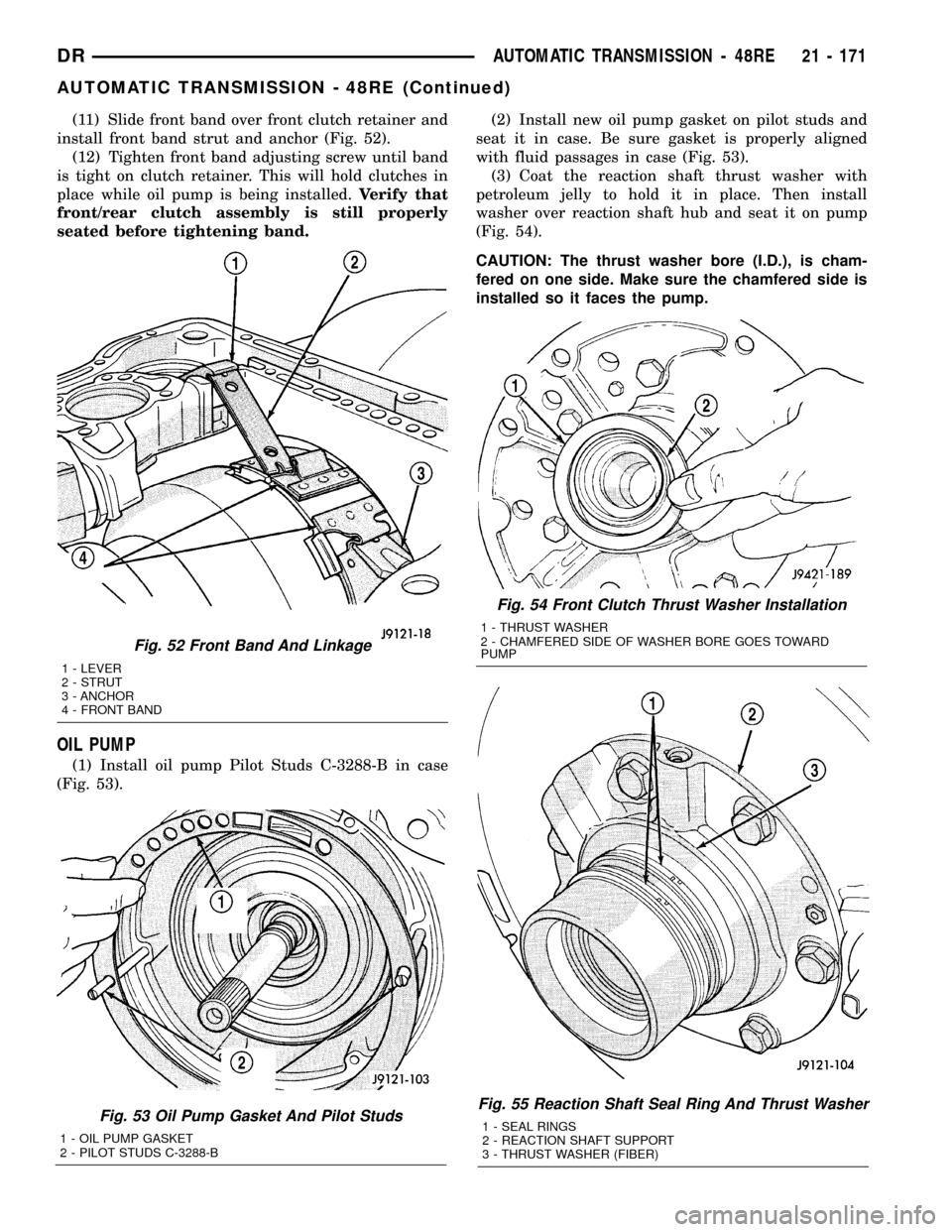

(11) Slide front band over front clutch retainer and

install front band strut and anchor (Fig. 52).

(12) Tighten front band adjusting screw until band

is tight on clutch retainer. This will hold clutches in

place while oil pump is being installed.Verify that

front/rear clutch assembly is still properly

seated before tightening band.

OIL PUMP

(1) Install oil pump Pilot Studs C-3288-B in case

(Fig. 53).(2) Install new oil pump gasket on pilot studs and

seat it in case. Be sure gasket is properly aligned

with fluid passages in case (Fig. 53).

(3) Coat the reaction shaft thrust washer with

petroleum jelly to hold it in place. Then install

washer over reaction shaft hub and seat it on pump

(Fig. 54).

CAUTION: The thrust washer bore (I.D.), is cham-

fered on one side. Make sure the chamfered side is

installed so it faces the pump.

Fig. 53 Oil Pump Gasket And Pilot Studs

1 - OIL PUMP GASKET

2 - PILOT STUDS C-3288-B

Fig. 54 Front Clutch Thrust Washer Installation

1 - THRUST WASHER

2 - CHAMFERED SIDE OF WASHER BORE GOES TOWARD

PUMP

Fig. 55 Reaction Shaft Seal Ring And Thrust Washer

1 - SEAL RINGS

2 - REACTION SHAFT SUPPORT

3 - THRUST WASHER (FIBER)

Fig. 52 Front Band And Linkage

1 - LEVER

2 - STRUT

3 - ANCHOR

4 - FRONT BAND

DRAUTOMATIC TRANSMISSION - 48RE 21 - 171

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 1875 of 2627

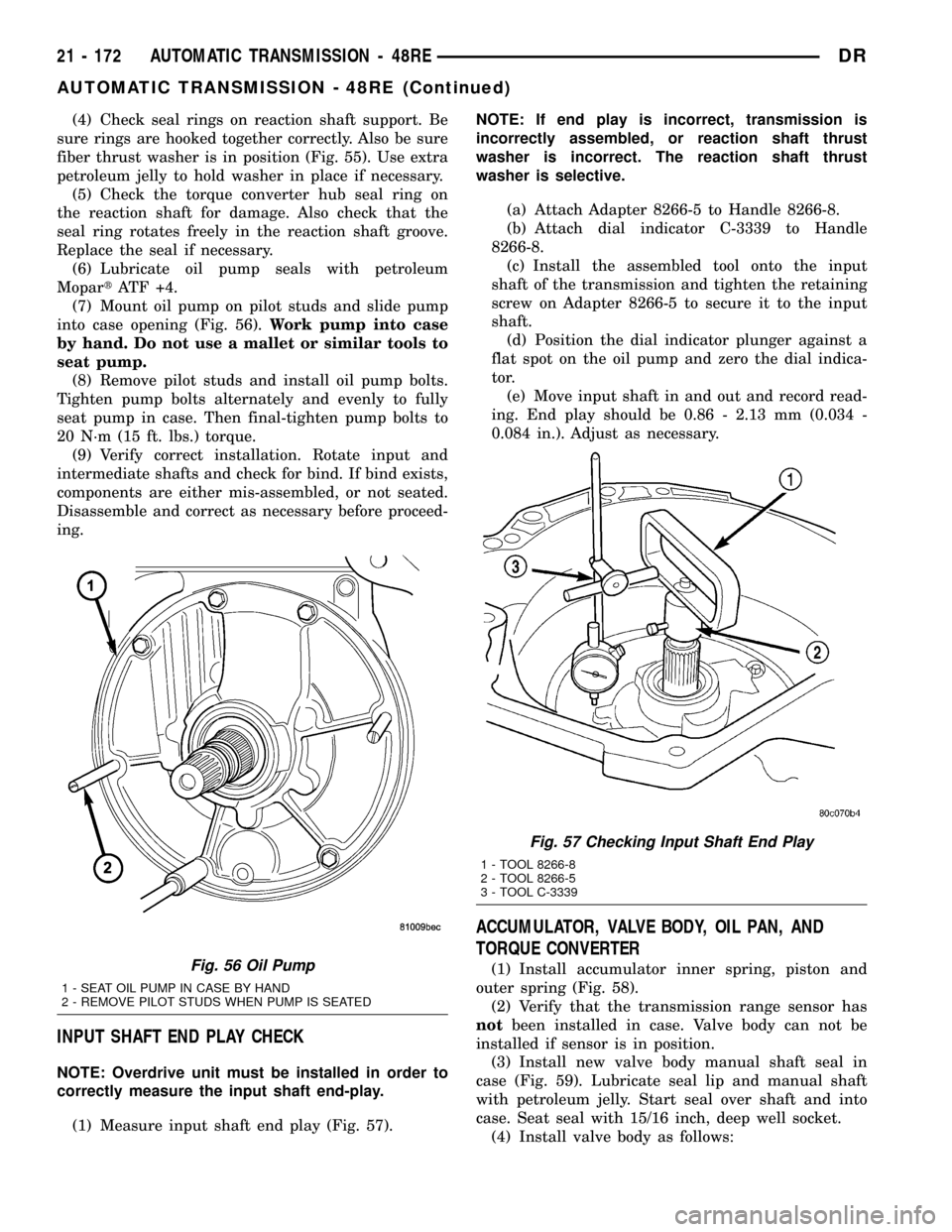

(4) Check seal rings on reaction shaft support. Be

sure rings are hooked together correctly. Also be sure

fiber thrust washer is in position (Fig. 55). Use extra

petroleum jelly to hold washer in place if necessary.

(5) Check the torque converter hub seal ring on

the reaction shaft for damage. Also check that the

seal ring rotates freely in the reaction shaft groove.

Replace the seal if necessary.

(6) Lubricate oil pump seals with petroleum

MopartATF +4.

(7) Mount oil pump on pilot studs and slide pump

into case opening (Fig. 56).Work pump into case

by hand. Do not use a mallet or similar tools to

seat pump.

(8) Remove pilot studs and install oil pump bolts.

Tighten pump bolts alternately and evenly to fully

seat pump in case. Then final-tighten pump bolts to

20 N´m (15 ft. lbs.) torque.

(9) Verify correct installation. Rotate input and

intermediate shafts and check for bind. If bind exists,

components are either mis-assembled, or not seated.

Disassemble and correct as necessary before proceed-

ing.

INPUT SHAFT END PLAY CHECK

NOTE: Overdrive unit must be installed in order to

correctly measure the input shaft end-play.

(1) Measure input shaft end play (Fig. 57).NOTE: If end play is incorrect, transmission is

incorrectly assembled, or reaction shaft thrust

washer is incorrect. The reaction shaft thrust

washer is selective.

(a) Attach Adapter 8266-5 to Handle 8266-8.

(b) Attach dial indicator C-3339 to Handle

8266-8.

(c) Install the assembled tool onto the input

shaft of the transmission and tighten the retaining

screw on Adapter 8266-5 to secure it to the input

shaft.

(d) Position the dial indicator plunger against a

flat spot on the oil pump and zero the dial indica-

tor.

(e) Move input shaft in and out and record read-

ing. End play should be 0.86 - 2.13 mm (0.034 -

0.084 in.). Adjust as necessary.

ACCUMULATOR, VALVE BODY, OIL PAN, AND

TORQUE CONVERTER

(1) Install accumulator inner spring, piston and

outer spring (Fig. 58).

(2) Verify that the transmission range sensor has

notbeen installed in case. Valve body can not be

installed if sensor is in position.

(3) Install new valve body manual shaft seal in

case (Fig. 59). Lubricate seal lip and manual shaft

with petroleum jelly. Start seal over shaft and into

case. Seat seal with 15/16 inch, deep well socket.

(4) Install valve body as follows:Fig. 56 Oil Pump

1 - SEAT OIL PUMP IN CASE BY HAND

2 - REMOVE PILOT STUDS WHEN PUMP IS SEATED

Fig. 57 Checking Input Shaft End Play

1 - TOOL 8266-8

2 - TOOL 8266-5

3 - TOOL C-3339

21 - 172 AUTOMATIC TRANSMISSION - 48REDR

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 1916 of 2627

OIL PUMP

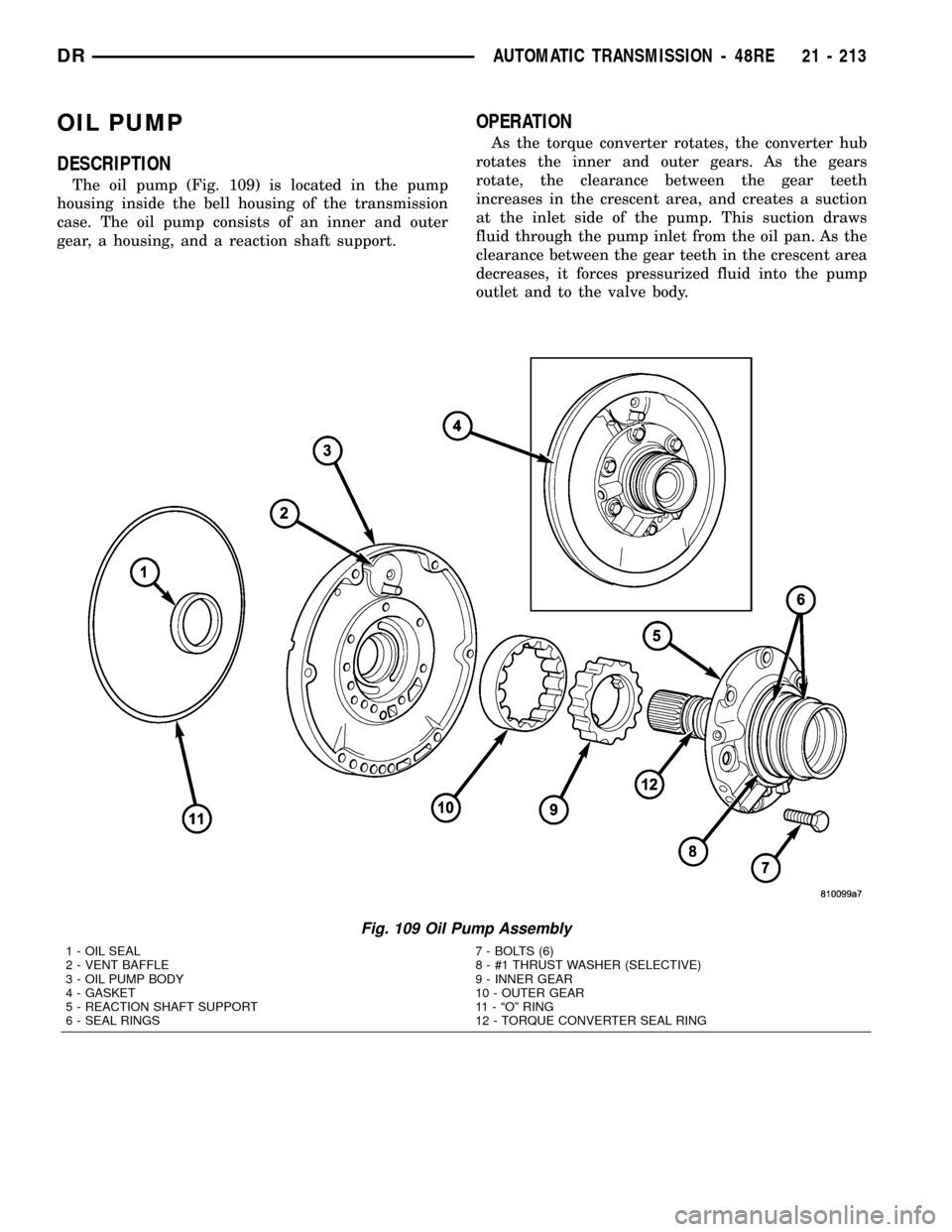

DESCRIPTION

The oil pump (Fig. 109) is located in the pump

housing inside the bell housing of the transmission

case. The oil pump consists of an inner and outer

gear, a housing, and a reaction shaft support.

OPERATION

As the torque converter rotates, the converter hub

rotates the inner and outer gears. As the gears

rotate, the clearance between the gear teeth

increases in the crescent area, and creates a suction

at the inlet side of the pump. This suction draws

fluid through the pump inlet from the oil pan. As the

clearance between the gear teeth in the crescent area

decreases, it forces pressurized fluid into the pump

outlet and to the valve body.

Fig. 109 Oil Pump Assembly

1 - OIL SEAL 7 - BOLTS (6)

2 - VENT BAFFLE 8 - #1 THRUST WASHER (SELECTIVE)

3 - OIL PUMP BODY 9 - INNER GEAR

4 - GASKET 10 - OUTER GEAR

5 - REACTION SHAFT SUPPORT 11 - ªOº RING

6 - SEAL RINGS 12 - TORQUE CONVERTER SEAL RING

DRAUTOMATIC TRANSMISSION - 48RE 21 - 213

Page 1917 of 2627

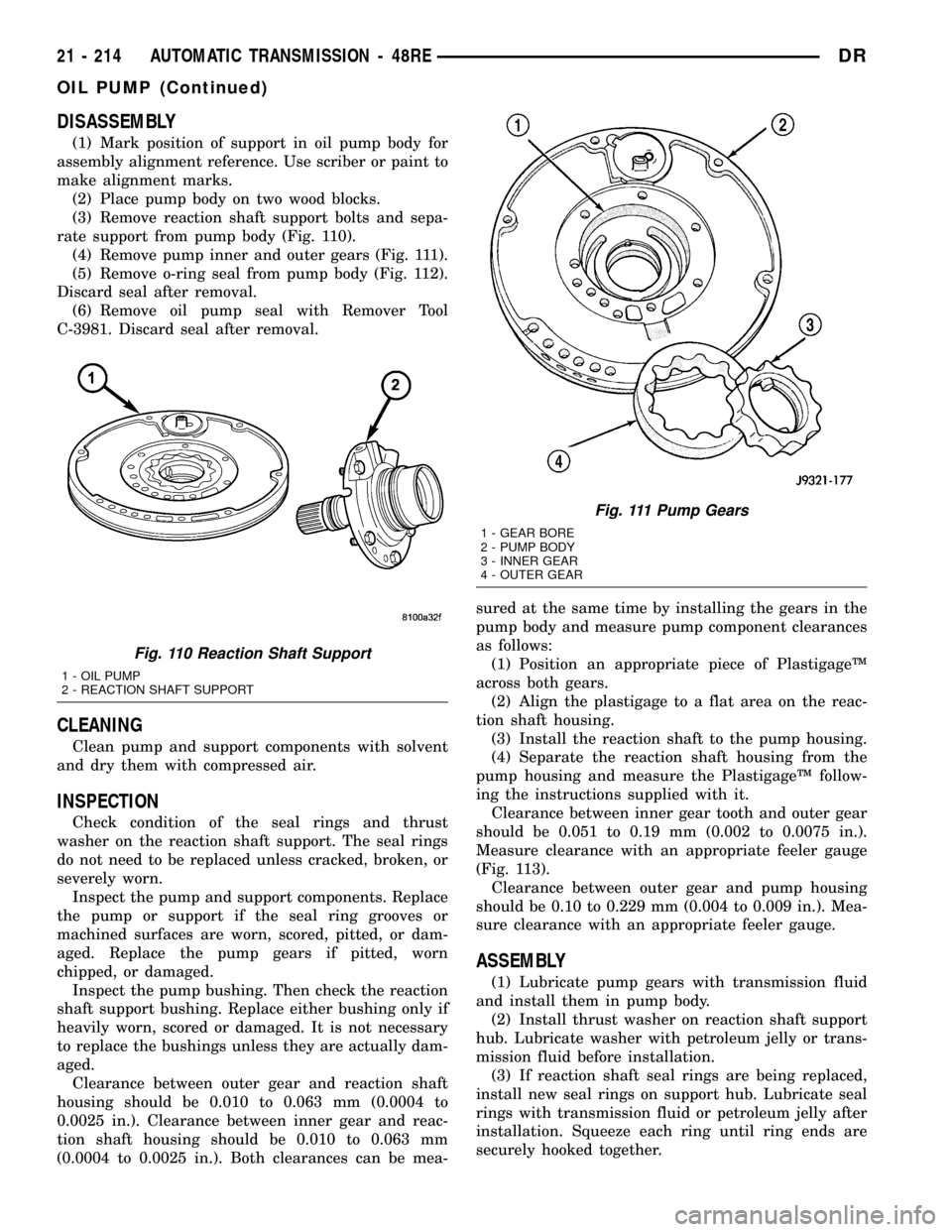

DISASSEMBLY

(1) Mark position of support in oil pump body for

assembly alignment reference. Use scriber or paint to

make alignment marks.

(2) Place pump body on two wood blocks.

(3) Remove reaction shaft support bolts and sepa-

rate support from pump body (Fig. 110).

(4) Remove pump inner and outer gears (Fig. 111).

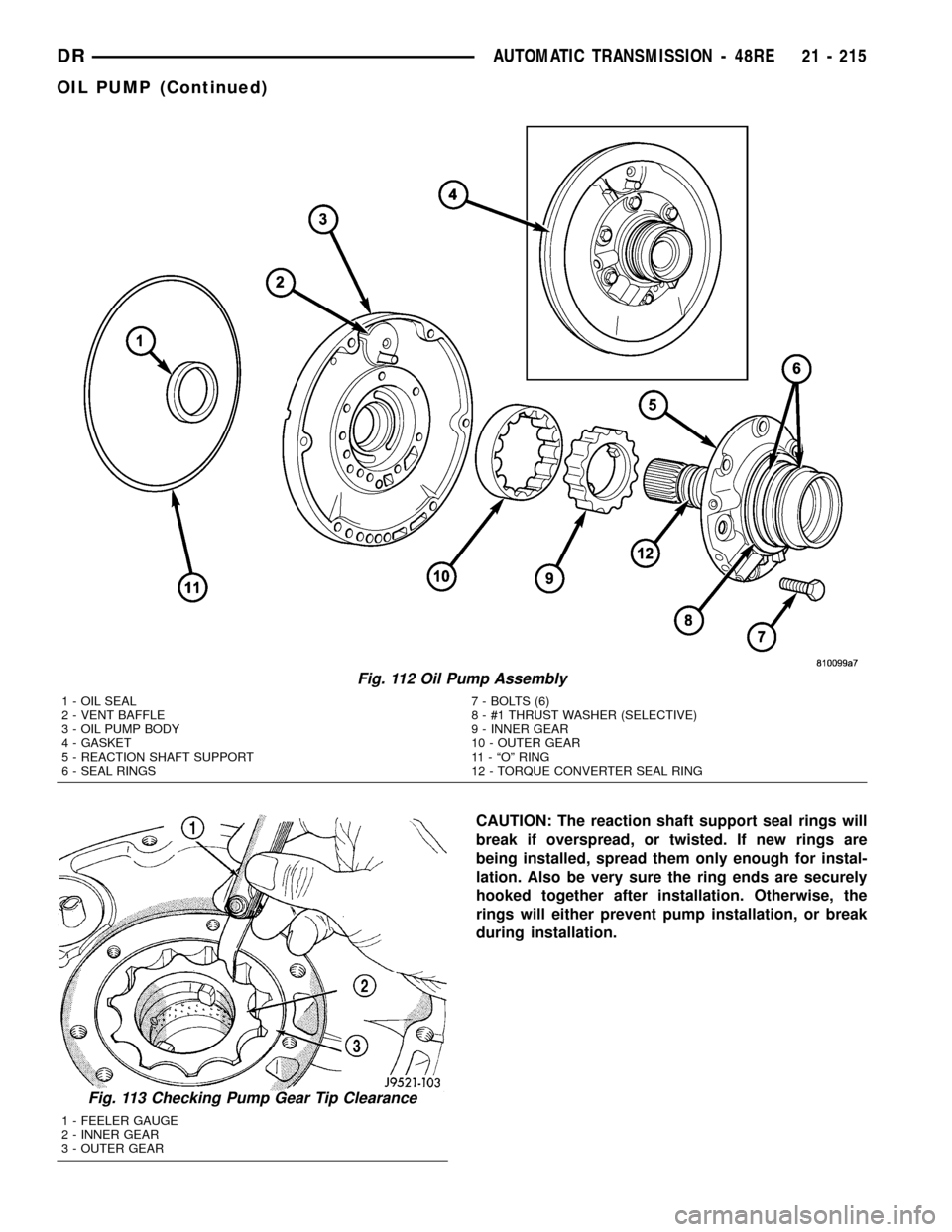

(5) Remove o-ring seal from pump body (Fig. 112).

Discard seal after removal.

(6) Remove oil pump seal with Remover Tool

C-3981. Discard seal after removal.

CLEANING

Clean pump and support components with solvent

and dry them with compressed air.

INSPECTION

Check condition of the seal rings and thrust

washer on the reaction shaft support. The seal rings

do not need to be replaced unless cracked, broken, or

severely worn.

Inspect the pump and support components. Replace

the pump or support if the seal ring grooves or

machined surfaces are worn, scored, pitted, or dam-

aged. Replace the pump gears if pitted, worn

chipped, or damaged.

Inspect the pump bushing. Then check the reaction

shaft support bushing. Replace either bushing only if

heavily worn, scored or damaged. It is not necessary

to replace the bushings unless they are actually dam-

aged.

Clearance between outer gear and reaction shaft

housing should be 0.010 to 0.063 mm (0.0004 to

0.0025 in.). Clearance between inner gear and reac-

tion shaft housing should be 0.010 to 0.063 mm

(0.0004 to 0.0025 in.). Both clearances can be mea-sured at the same time by installing the gears in the

pump body and measure pump component clearances

as follows:

(1) Position an appropriate piece of PlastigageŸ

across both gears.

(2) Align the plastigage to a flat area on the reac-

tion shaft housing.

(3) Install the reaction shaft to the pump housing.

(4) Separate the reaction shaft housing from the

pump housing and measure the PlastigageŸ follow-

ing the instructions supplied with it.

Clearance between inner gear tooth and outer gear

should be 0.051 to 0.19 mm (0.002 to 0.0075 in.).

Measure clearance with an appropriate feeler gauge

(Fig. 113).

Clearance between outer gear and pump housing

should be 0.10 to 0.229 mm (0.004 to 0.009 in.). Mea-

sure clearance with an appropriate feeler gauge.

ASSEMBLY

(1) Lubricate pump gears with transmission fluid

and install them in pump body.

(2) Install thrust washer on reaction shaft support

hub. Lubricate washer with petroleum jelly or trans-

mission fluid before installation.

(3) If reaction shaft seal rings are being replaced,

install new seal rings on support hub. Lubricate seal

rings with transmission fluid or petroleum jelly after

installation. Squeeze each ring until ring ends are

securely hooked together.

Fig. 110 Reaction Shaft Support

1 - OIL PUMP

2 - REACTION SHAFT SUPPORT

Fig. 111 Pump Gears

1 - GEAR BORE

2 - PUMP BODY

3 - INNER GEAR

4 - OUTER GEAR

21 - 214 AUTOMATIC TRANSMISSION - 48REDR

OIL PUMP (Continued)

Page 1918 of 2627

CAUTION: The reaction shaft support seal rings will

break if overspread, or twisted. If new rings are

being installed, spread them only enough for instal-

lation. Also be very sure the ring ends are securely

hooked together after installation. Otherwise, the

rings will either prevent pump installation, or break

during installation.

Fig. 112 Oil Pump Assembly

1 - OIL SEAL 7 - BOLTS (6)

2 - VENT BAFFLE 8 - #1 THRUST WASHER (SELECTIVE)

3 - OIL PUMP BODY 9 - INNER GEAR

4 - GASKET 10 - OUTER GEAR

5 - REACTION SHAFT SUPPORT 11 - ªOº RING

6 - SEAL RINGS 12 - TORQUE CONVERTER SEAL RING

Fig. 113 Checking Pump Gear Tip Clearance

1 - FEELER GAUGE

2 - INNER GEAR

3 - OUTER GEAR

DRAUTOMATIC TRANSMISSION - 48RE 21 - 215

OIL PUMP (Continued)

Page 1951 of 2627

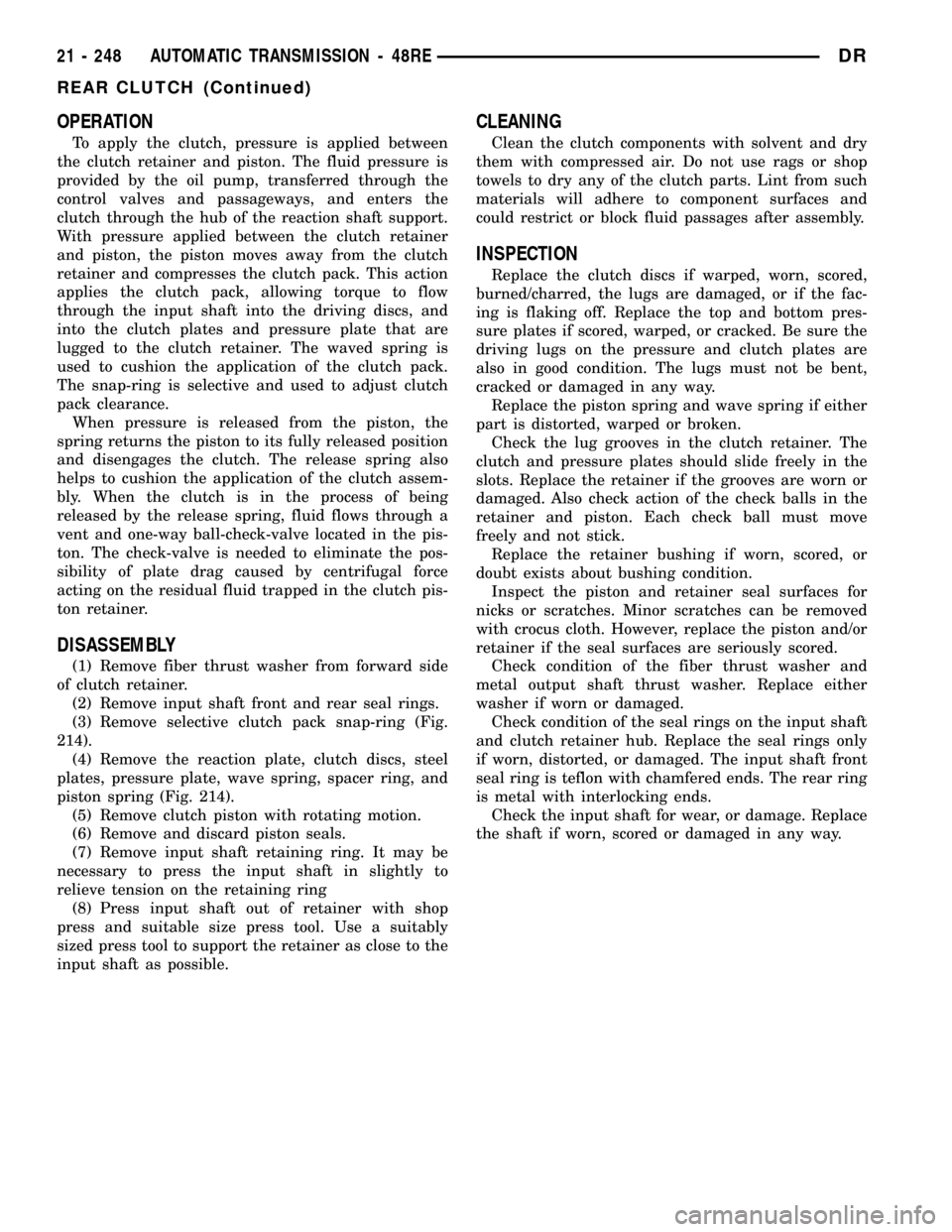

OPERATION

To apply the clutch, pressure is applied between

the clutch retainer and piston. The fluid pressure is

provided by the oil pump, transferred through the

control valves and passageways, and enters the

clutch through the hub of the reaction shaft support.

With pressure applied between the clutch retainer

and piston, the piston moves away from the clutch

retainer and compresses the clutch pack. This action

applies the clutch pack, allowing torque to flow

through the input shaft into the driving discs, and

into the clutch plates and pressure plate that are

lugged to the clutch retainer. The waved spring is

used to cushion the application of the clutch pack.

The snap-ring is selective and used to adjust clutch

pack clearance.

When pressure is released from the piston, the

spring returns the piston to its fully released position

and disengages the clutch. The release spring also

helps to cushion the application of the clutch assem-

bly. When the clutch is in the process of being

released by the release spring, fluid flows through a

vent and one-way ball-check-valve located in the pis-

ton. The check-valve is needed to eliminate the pos-

sibility of plate drag caused by centrifugal force

acting on the residual fluid trapped in the clutch pis-

ton retainer.

DISASSEMBLY

(1) Remove fiber thrust washer from forward side

of clutch retainer.

(2) Remove input shaft front and rear seal rings.

(3) Remove selective clutch pack snap-ring (Fig.

214).

(4) Remove the reaction plate, clutch discs, steel

plates, pressure plate, wave spring, spacer ring, and

piston spring (Fig. 214).

(5) Remove clutch piston with rotating motion.

(6) Remove and discard piston seals.

(7) Remove input shaft retaining ring. It may be

necessary to press the input shaft in slightly to

relieve tension on the retaining ring

(8) Press input shaft out of retainer with shop

press and suitable size press tool. Use a suitably

sized press tool to support the retainer as close to the

input shaft as possible.

CLEANING

Clean the clutch components with solvent and dry

them with compressed air. Do not use rags or shop

towels to dry any of the clutch parts. Lint from such

materials will adhere to component surfaces and

could restrict or block fluid passages after assembly.

INSPECTION

Replace the clutch discs if warped, worn, scored,

burned/charred, the lugs are damaged, or if the fac-

ing is flaking off. Replace the top and bottom pres-

sure plates if scored, warped, or cracked. Be sure the

driving lugs on the pressure and clutch plates are

also in good condition. The lugs must not be bent,

cracked or damaged in any way.

Replace the piston spring and wave spring if either

part is distorted, warped or broken.

Check the lug grooves in the clutch retainer. The

clutch and pressure plates should slide freely in the

slots. Replace the retainer if the grooves are worn or

damaged. Also check action of the check balls in the

retainer and piston. Each check ball must move

freely and not stick.

Replace the retainer bushing if worn, scored, or

doubt exists about bushing condition.

Inspect the piston and retainer seal surfaces for

nicks or scratches. Minor scratches can be removed

with crocus cloth. However, replace the piston and/or

retainer if the seal surfaces are seriously scored.

Check condition of the fiber thrust washer and

metal output shaft thrust washer. Replace either

washer if worn or damaged.

Check condition of the seal rings on the input shaft

and clutch retainer hub. Replace the seal rings only

if worn, distorted, or damaged. The input shaft front

seal ring is teflon with chamfered ends. The rear ring

is metal with interlocking ends.

Check the input shaft for wear, or damage. Replace

the shaft if worn, scored or damaged in any way.

21 - 248 AUTOMATIC TRANSMISSION - 48REDR

REAR CLUTCH (Continued)

Page 1961 of 2627

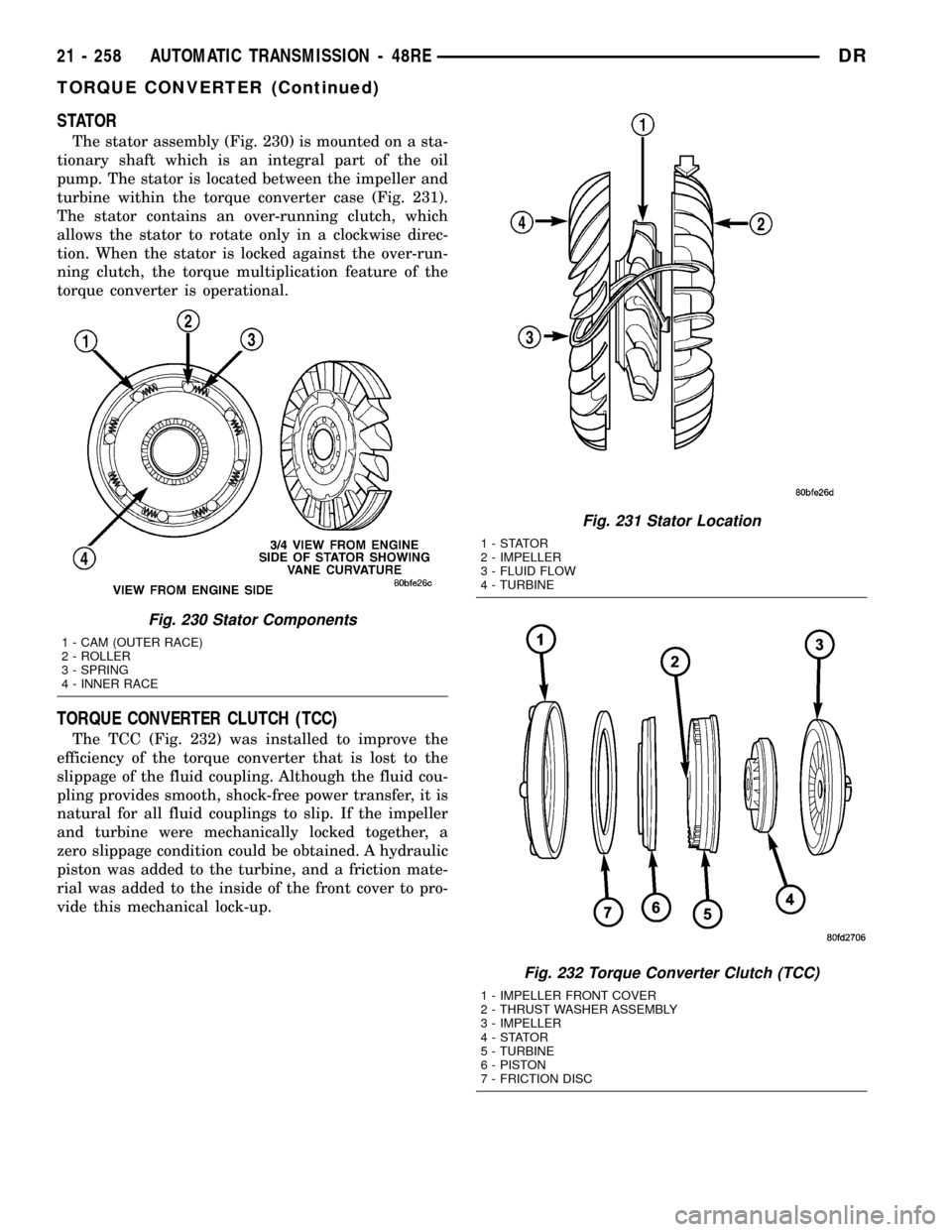

STATOR

The stator assembly (Fig. 230) is mounted on a sta-

tionary shaft which is an integral part of the oil

pump. The stator is located between the impeller and

turbine within the torque converter case (Fig. 231).

The stator contains an over-running clutch, which

allows the stator to rotate only in a clockwise direc-

tion. When the stator is locked against the over-run-

ning clutch, the torque multiplication feature of the

torque converter is operational.

TORQUE CONVERTER CLUTCH (TCC)

The TCC (Fig. 232) was installed to improve the

efficiency of the torque converter that is lost to the

slippage of the fluid coupling. Although the fluid cou-

pling provides smooth, shock-free power transfer, it is

natural for all fluid couplings to slip. If the impeller

and turbine were mechanically locked together, a

zero slippage condition could be obtained. A hydraulic

piston was added to the turbine, and a friction mate-

rial was added to the inside of the front cover to pro-

vide this mechanical lock-up.

Fig. 230 Stator Components

1 - CAM (OUTER RACE)

2 - ROLLER

3 - SPRING

4 - INNER RACE

Fig. 231 Stator Location

1-STATOR

2 - IMPELLER

3 - FLUID FLOW

4 - TURBINE

Fig. 232 Torque Converter Clutch (TCC)

1 - IMPELLER FRONT COVER

2 - THRUST WASHER ASSEMBLY

3 - IMPELLER

4-STATOR

5 - TURBINE

6 - PISTON

7 - FRICTION DISC

21 - 258 AUTOMATIC TRANSMISSION - 48REDR

TORQUE CONVERTER (Continued)

Page 2093 of 2627

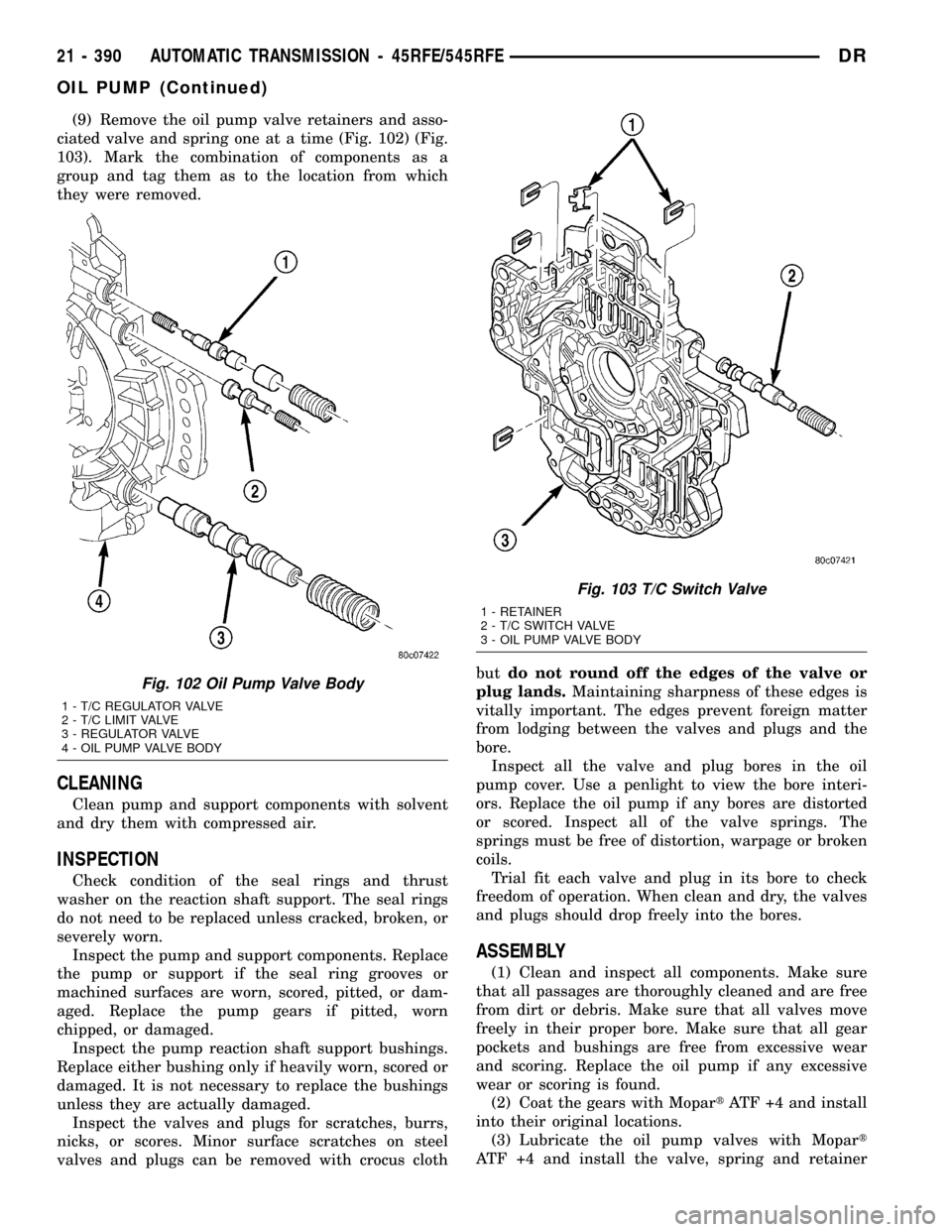

(9) Remove the oil pump valve retainers and asso-

ciated valve and spring one at a time (Fig. 102) (Fig.

103). Mark the combination of components as a

group and tag them as to the location from which

they were removed.

CLEANING

Clean pump and support components with solvent

and dry them with compressed air.

INSPECTION

Check condition of the seal rings and thrust

washer on the reaction shaft support. The seal rings

do not need to be replaced unless cracked, broken, or

severely worn.

Inspect the pump and support components. Replace

the pump or support if the seal ring grooves or

machined surfaces are worn, scored, pitted, or dam-

aged. Replace the pump gears if pitted, worn

chipped, or damaged.

Inspect the pump reaction shaft support bushings.

Replace either bushing only if heavily worn, scored or

damaged. It is not necessary to replace the bushings

unless they are actually damaged.

Inspect the valves and plugs for scratches, burrs,

nicks, or scores. Minor surface scratches on steel

valves and plugs can be removed with crocus clothbutdo not round off the edges of the valve or

plug lands.Maintaining sharpness of these edges is

vitally important. The edges prevent foreign matter

from lodging between the valves and plugs and the

bore.

Inspect all the valve and plug bores in the oil

pump cover. Use a penlight to view the bore interi-

ors. Replace the oil pump if any bores are distorted

or scored. Inspect all of the valve springs. The

springs must be free of distortion, warpage or broken

coils.

Trial fit each valve and plug in its bore to check

freedom of operation. When clean and dry, the valves

and plugs should drop freely into the bores.

ASSEMBLY

(1) Clean and inspect all components. Make sure

that all passages are thoroughly cleaned and are free

from dirt or debris. Make sure that all valves move

freely in their proper bore. Make sure that all gear

pockets and bushings are free from excessive wear

and scoring. Replace the oil pump if any excessive

wear or scoring is found.

(2) Coat the gears with MopartATF +4 and install

into their original locations.

(3) Lubricate the oil pump valves with Mopart

ATF +4 and install the valve, spring and retainer

Fig. 102 Oil Pump Valve Body

1 - T/C REGULATOR VALVE

2 - T/C LIMIT VALVE

3 - REGULATOR VALVE

4 - OIL PUMP VALVE BODY

Fig. 103 T/C Switch Valve

1 - RETAINER

2 - T/C SWITCH VALVE

3 - OIL PUMP VALVE BODY

21 - 390 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

OIL PUMP (Continued)