Brake system DODGE RAM 1500 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 561 of 2627

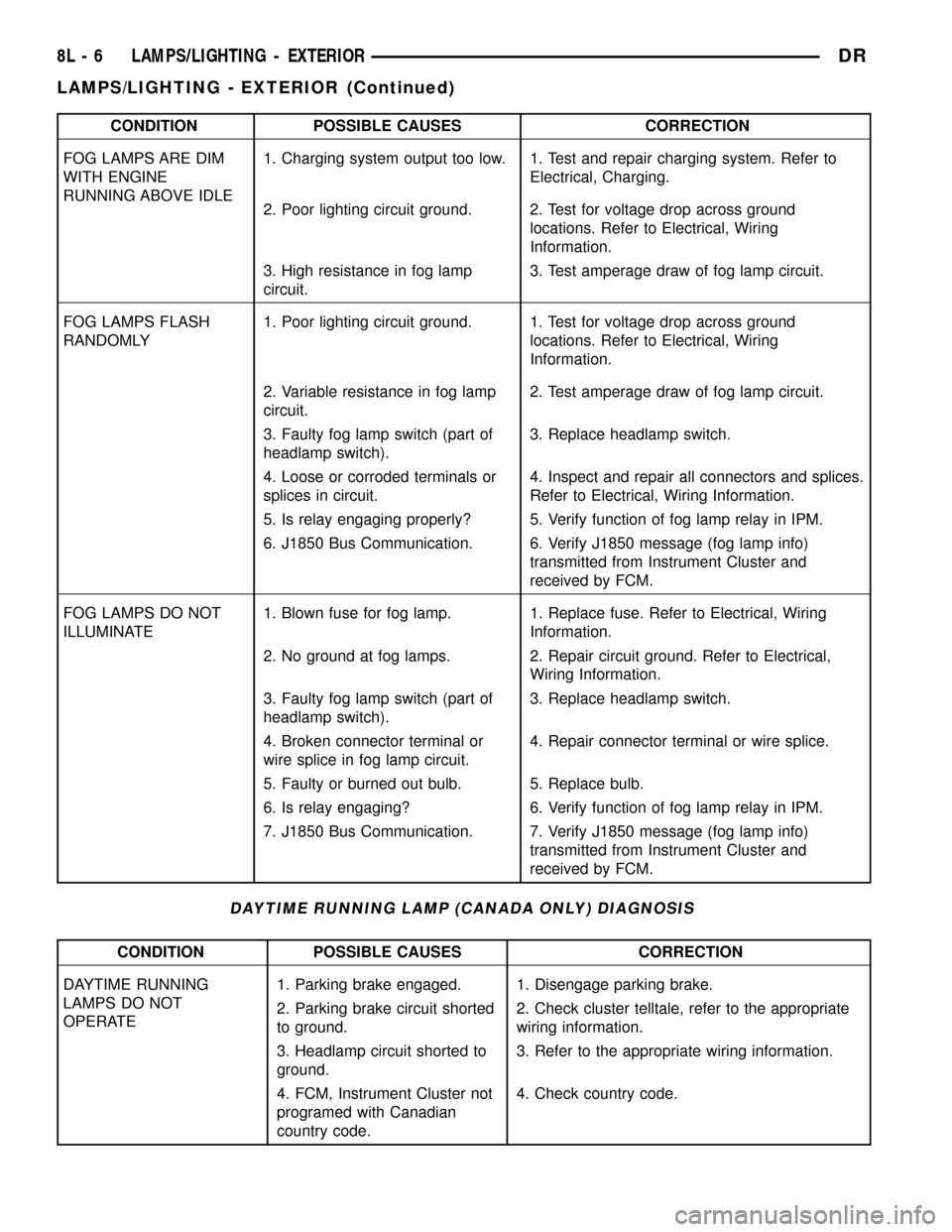

CONDITION POSSIBLE CAUSES CORRECTION

FOG LAMPS ARE DIM

WITH ENGINE

RUNNING ABOVE IDLE1. Charging system output too low. 1. Test and repair charging system. Refer to

Electrical, Charging.

2. Poor lighting circuit ground. 2. Test for voltage drop across ground

locations. Refer to Electrical, Wiring

Information.

3. High resistance in fog lamp

circuit.3. Test amperage draw of fog lamp circuit.

FOG LAMPS FLASH

RANDOMLY1. Poor lighting circuit ground. 1. Test for voltage drop across ground

locations. Refer to Electrical, Wiring

Information.

2. Variable resistance in fog lamp

circuit.2. Test amperage draw of fog lamp circuit.

3. Faulty fog lamp switch (part of

headlamp switch).3. Replace headlamp switch.

4. Loose or corroded terminals or

splices in circuit.4. Inspect and repair all connectors and splices.

Refer to Electrical, Wiring Information.

5. Is relay engaging properly? 5. Verify function of fog lamp relay in IPM.

6. J1850 Bus Communication. 6. Verify J1850 message (fog lamp info)

transmitted from Instrument Cluster and

received by FCM.

FOG LAMPS DO NOT

ILLUMINATE1. Blown fuse for fog lamp. 1. Replace fuse. Refer to Electrical, Wiring

Information.

2. No ground at fog lamps. 2. Repair circuit ground. Refer to Electrical,

Wiring Information.

3. Faulty fog lamp switch (part of

headlamp switch).3. Replace headlamp switch.

4. Broken connector terminal or

wire splice in fog lamp circuit.4. Repair connector terminal or wire splice.

5. Faulty or burned out bulb. 5. Replace bulb.

6. Is relay engaging? 6. Verify function of fog lamp relay in IPM.

7. J1850 Bus Communication. 7. Verify J1850 message (fog lamp info)

transmitted from Instrument Cluster and

received by FCM.

DAYTIME RUNNING LAMP (CANADA ONLY) DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

DAYTIME RUNNING

LAMPS DO NOT

OPERATE1. Parking brake engaged. 1. Disengage parking brake.

2. Parking brake circuit shorted

to ground.2. Check cluster telltale, refer to the appropriate

wiring information.

3. Headlamp circuit shorted to

ground.3. Refer to the appropriate wiring information.

4. FCM, Instrument Cluster not

programed with Canadian

country code.4. Check country code.

8L - 6 LAMPS/LIGHTING - EXTERIORDR

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 616 of 2627

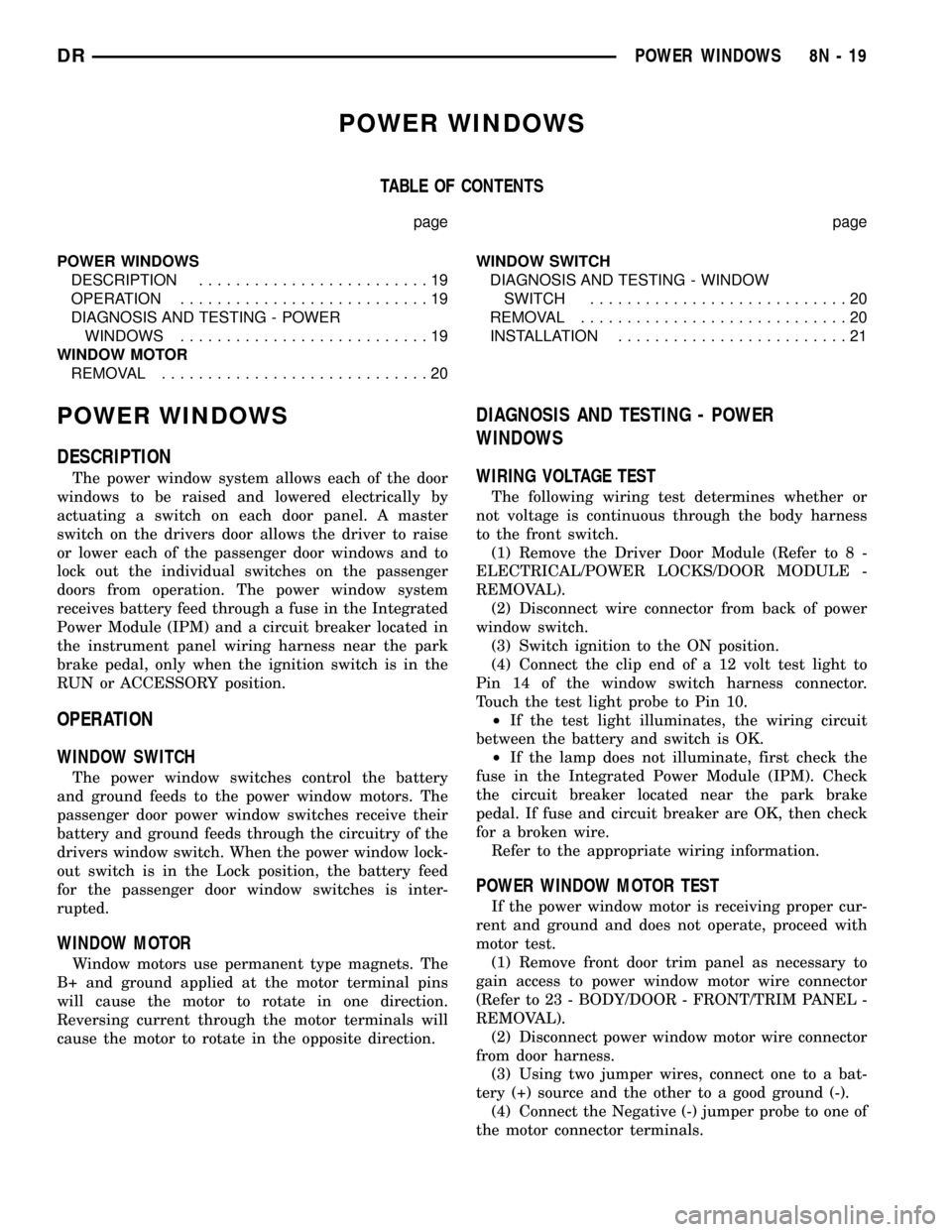

POWER WINDOWS

TABLE OF CONTENTS

page page

POWER WINDOWS

DESCRIPTION.........................19

OPERATION...........................19

DIAGNOSIS AND TESTING - POWER

WINDOWS...........................19

WINDOW MOTOR

REMOVAL.............................20WINDOW SWITCH

DIAGNOSIS AND TESTING - WINDOW

SWITCH............................20

REMOVAL.............................20

INSTALLATION.........................21

POWER WINDOWS

DESCRIPTION

The power window system allows each of the door

windows to be raised and lowered electrically by

actuating a switch on each door panel. A master

switch on the drivers door allows the driver to raise

or lower each of the passenger door windows and to

lock out the individual switches on the passenger

doors from operation. The power window system

receives battery feed through a fuse in the Integrated

Power Module (IPM) and a circuit breaker located in

the instrument panel wiring harness near the park

brake pedal, only when the ignition switch is in the

RUN or ACCESSORY position.

OPERATION

WINDOW SWITCH

The power window switches control the battery

and ground feeds to the power window motors. The

passenger door power window switches receive their

battery and ground feeds through the circuitry of the

drivers window switch. When the power window lock-

out switch is in the Lock position, the battery feed

for the passenger door window switches is inter-

rupted.

WINDOW MOTOR

Window motors use permanent type magnets. The

B+ and ground applied at the motor terminal pins

will cause the motor to rotate in one direction.

Reversing current through the motor terminals will

cause the motor to rotate in the opposite direction.

DIAGNOSIS AND TESTING - POWER

WINDOWS

WIRING VOLTAGE TEST

The following wiring test determines whether or

not voltage is continuous through the body harness

to the front switch.

(1) Remove the Driver Door Module (Refer to 8 -

ELECTRICAL/POWER LOCKS/DOOR MODULE -

REMOVAL).

(2) Disconnect wire connector from back of power

window switch.

(3) Switch ignition to the ON position.

(4) Connect the clip end of a 12 volt test light to

Pin 14 of the window switch harness connector.

Touch the test light probe to Pin 10.

²If the test light illuminates, the wiring circuit

between the battery and switch is OK.

²If the lamp does not illuminate, first check the

fuse in the Integrated Power Module (IPM). Check

the circuit breaker located near the park brake

pedal. If fuse and circuit breaker are OK, then check

for a broken wire.

Refer to the appropriate wiring information.

POWER WINDOW MOTOR TEST

If the power window motor is receiving proper cur-

rent and ground and does not operate, proceed with

motor test.

(1) Remove front door trim panel as necessary to

gain access to power window motor wire connector

(Refer to 23 - BODY/DOOR - FRONT/TRIM PANEL -

REMOVAL).

(2) Disconnect power window motor wire connector

from door harness.

(3) Using two jumper wires, connect one to a bat-

tery (+) source and the other to a good ground (-).

(4) Connect the Negative (-) jumper probe to one of

the motor connector terminals.

DRPOWER WINDOWS 8N - 19

Page 683 of 2627

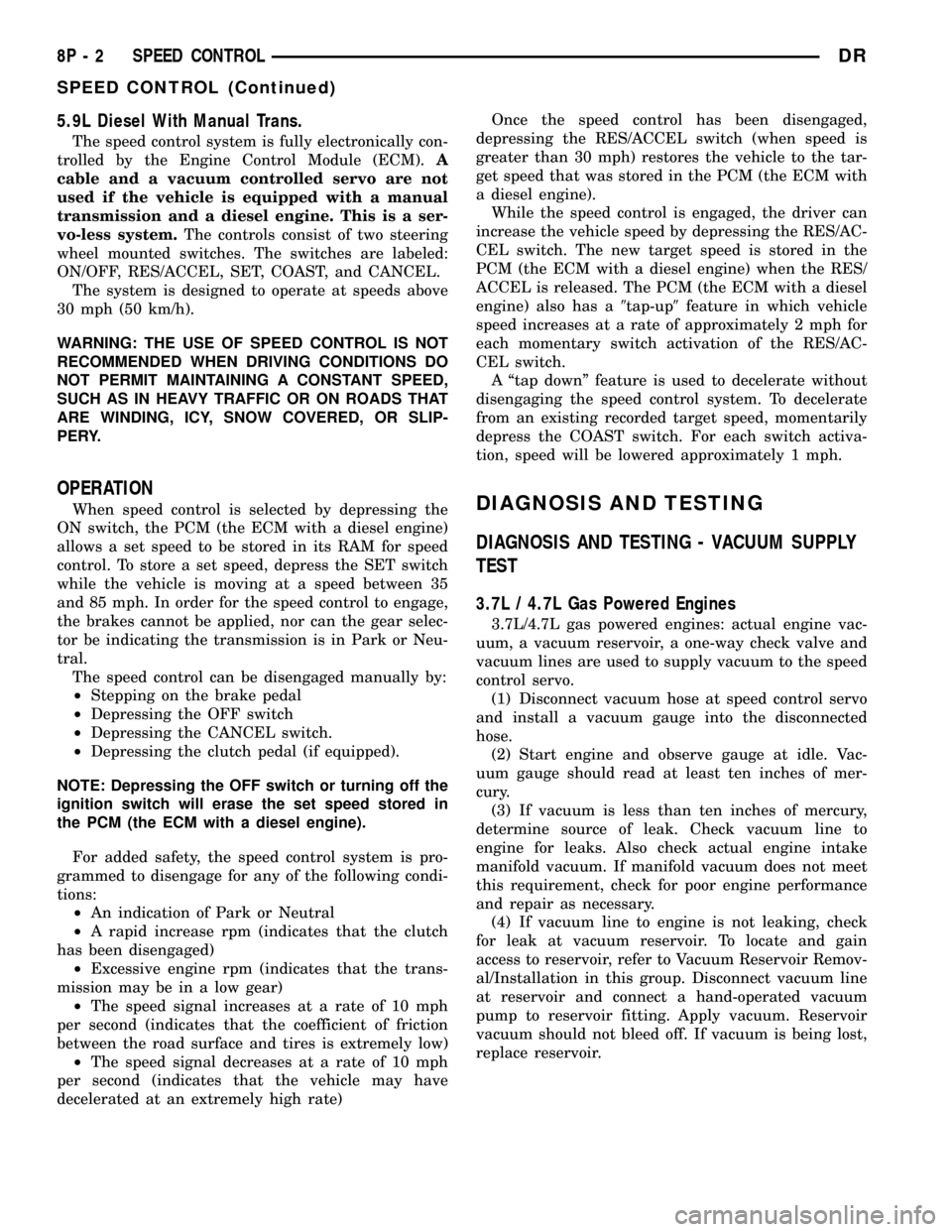

5.9L Diesel With Manual Trans.

The speed control system is fully electronically con-

trolled by the Engine Control Module (ECM).A

cable and a vacuum controlled servo are not

used if the vehicle is equipped with a manual

transmission and a diesel engine. This is a ser-

vo-less system.The controls consist of two steering

wheel mounted switches. The switches are labeled:

ON/OFF, RES/ACCEL, SET, COAST, and CANCEL.

The system is designed to operate at speeds above

30 mph (50 km/h).

WARNING: THE USE OF SPEED CONTROL IS NOT

RECOMMENDED WHEN DRIVING CONDITIONS DO

NOT PERMIT MAINTAINING A CONSTANT SPEED,

SUCH AS IN HEAVY TRAFFIC OR ON ROADS THAT

ARE WINDING, ICY, SNOW COVERED, OR SLIP-

PERY.

OPERATION

When speed control is selected by depressing the

ON switch, the PCM (the ECM with a diesel engine)

allows a set speed to be stored in its RAM for speed

control. To store a set speed, depress the SET switch

while the vehicle is moving at a speed between 35

and 85 mph. In order for the speed control to engage,

the brakes cannot be applied, nor can the gear selec-

tor be indicating the transmission is in Park or Neu-

tral.

The speed control can be disengaged manually by:

²Stepping on the brake pedal

²Depressing the OFF switch

²Depressing the CANCEL switch.

²Depressing the clutch pedal (if equipped).

NOTE: Depressing the OFF switch or turning off the

ignition switch will erase the set speed stored in

the PCM (the ECM with a diesel engine).

For added safety, the speed control system is pro-

grammed to disengage for any of the following condi-

tions:

²An indication of Park or Neutral

²A rapid increase rpm (indicates that the clutch

has been disengaged)

²Excessive engine rpm (indicates that the trans-

mission may be in a low gear)

²The speed signal increases at a rate of 10 mph

per second (indicates that the coefficient of friction

between the road surface and tires is extremely low)

²The speed signal decreases at a rate of 10 mph

per second (indicates that the vehicle may have

decelerated at an extremely high rate)Once the speed control has been disengaged,

depressing the RES/ACCEL switch (when speed is

greater than 30 mph) restores the vehicle to the tar-

get speed that was stored in the PCM (the ECM with

a diesel engine).

While the speed control is engaged, the driver can

increase the vehicle speed by depressing the RES/AC-

CEL switch. The new target speed is stored in the

PCM (the ECM with a diesel engine) when the RES/

ACCEL is released. The PCM (the ECM with a diesel

engine) also has a9tap-up9feature in which vehicle

speed increases at a rate of approximately 2 mph for

each momentary switch activation of the RES/AC-

CEL switch.

A ªtap downº feature is used to decelerate without

disengaging the speed control system. To decelerate

from an existing recorded target speed, momentarily

depress the COAST switch. For each switch activa-

tion, speed will be lowered approximately 1 mph.DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - VACUUM SUPPLY

TEST

3.7L / 4.7L Gas Powered Engines

3.7L/4.7L gas powered engines: actual engine vac-

uum, a vacuum reservoir, a one-way check valve and

vacuum lines are used to supply vacuum to the speed

control servo.

(1) Disconnect vacuum hose at speed control servo

and install a vacuum gauge into the disconnected

hose.

(2) Start engine and observe gauge at idle. Vac-

uum gauge should read at least ten inches of mer-

cury.

(3) If vacuum is less than ten inches of mercury,

determine source of leak. Check vacuum line to

engine for leaks. Also check actual engine intake

manifold vacuum. If manifold vacuum does not meet

this requirement, check for poor engine performance

and repair as necessary.

(4) If vacuum line to engine is not leaking, check

for leak at vacuum reservoir. To locate and gain

access to reservoir, refer to Vacuum Reservoir Remov-

al/Installation in this group. Disconnect vacuum line

at reservoir and connect a hand-operated vacuum

pump to reservoir fitting. Apply vacuum. Reservoir

vacuum should not bleed off. If vacuum is being lost,

replace reservoir.

8P - 2 SPEED CONTROLDR

SPEED CONTROL (Continued)

Page 684 of 2627

(5) Verify operation of one-way check valve and

check it for leaks.

(a) Locate one-way check valve. The valve is

located in vacuum line between vacuum reservoir

and engine vacuum source. Disconnect vacuum

hoses (lines) at each end of valve.

(b) Connect a hand-operated vacuum pump to

reservoir end of check valve. Apply vacuum. Vac-

uum should not bleed off. If vacuum is being lost,

replace one-way check valve.

(c) Connect a hand-operated vacuum pump to

vacuum source end of check valve. Apply vacuum.

Vacuum should flow through valve. If vacuum is

not flowing, replace one-way check valve. Seal the

fitting at opposite end of valve with a finger and

apply vacuum. If vacuum will not hold, diaphragm

within check valve has ruptured. Replace valve.

5.7 Gas

Vacuum is not used for any part of the speed con-

trol system if equipped with a 5.7L V-8 engine.

5.9L Diesel Engine With Manual Trans.

Vacuum is not used for any part of the speed con-

trol system if equipped with a diesel engine and a

manual transmission.

5.9L Diesel Engines With Automatic Trans.

If equipped with a diesel powered engine and an

automatic transmission, an electric vacuum pump

and vacuum lines are used to supply vacuum to the

speed control servo. A vacuum reservoir is not used.

DIAGNOSIS AND TESTING - ROAD TEST

Perform a vehicle road test to verify reports of

speed control system malfunction. The road test

should include attention to the speedometer. Speed-ometer operation should be smooth and without flut-

ter at all speeds.

Flutter in the speedometer indicates a problem

which might cause surging in the speed control sys-

tem. The cause of any speedometer problems should

be corrected before proceeding. Refer to Instrument

Cluster for speedometer diagnosis.

If a road test verifies a system problem and the

speedometer operates properly, check for:

²A Diagnostic Trouble Code (DTC). If a DTC

exists, conduct tests per the Powertrain Diagnostic

Procedures service manual.

²A misadjusted brake (stop) lamp switch. This

could also cause an intermittent problem.

²Loose, damaged or corroded electrical connec-

tions at the servo (if used). Corrosion should be

removed from electrical terminals and a light coating

of Mopar MultiPurpose Grease, or equivalent,

applied.

²Leaking vacuum reservoir (if used).

²Loose or leaking vacuum hoses or connections (if

used).

²Defective one-way vacuum check valve (if used).

²Secure attachment of both ends of the speed con-

trol servo cable (if used).

²Smooth operation of throttle linkage (if used)

and throttle body air valve.

²Failed speed control servo (if used). Do the servo

vacuum test.

CAUTION: When test probing for voltage or conti-

nuity at electrical connectors, care must be taken

not to damage connector, terminals or seals. If

these components are damaged, intermittent or

complete system failure may occur.

SPECIFICATIONS

TORQUE - SPEED CONTROL

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Servo Mounting Bracket-

to-Servo Nuts7-60

Servo Mounting Bracket-

to-Battery Tray Screws4-30

Speed Control Switch

Mounting Screws1.7 - 15

Vacuum Reservoir

Mounting Nuts3-20

DRSPEED CONTROL 8P - 3

SPEED CONTROL (Continued)

Page 688 of 2627

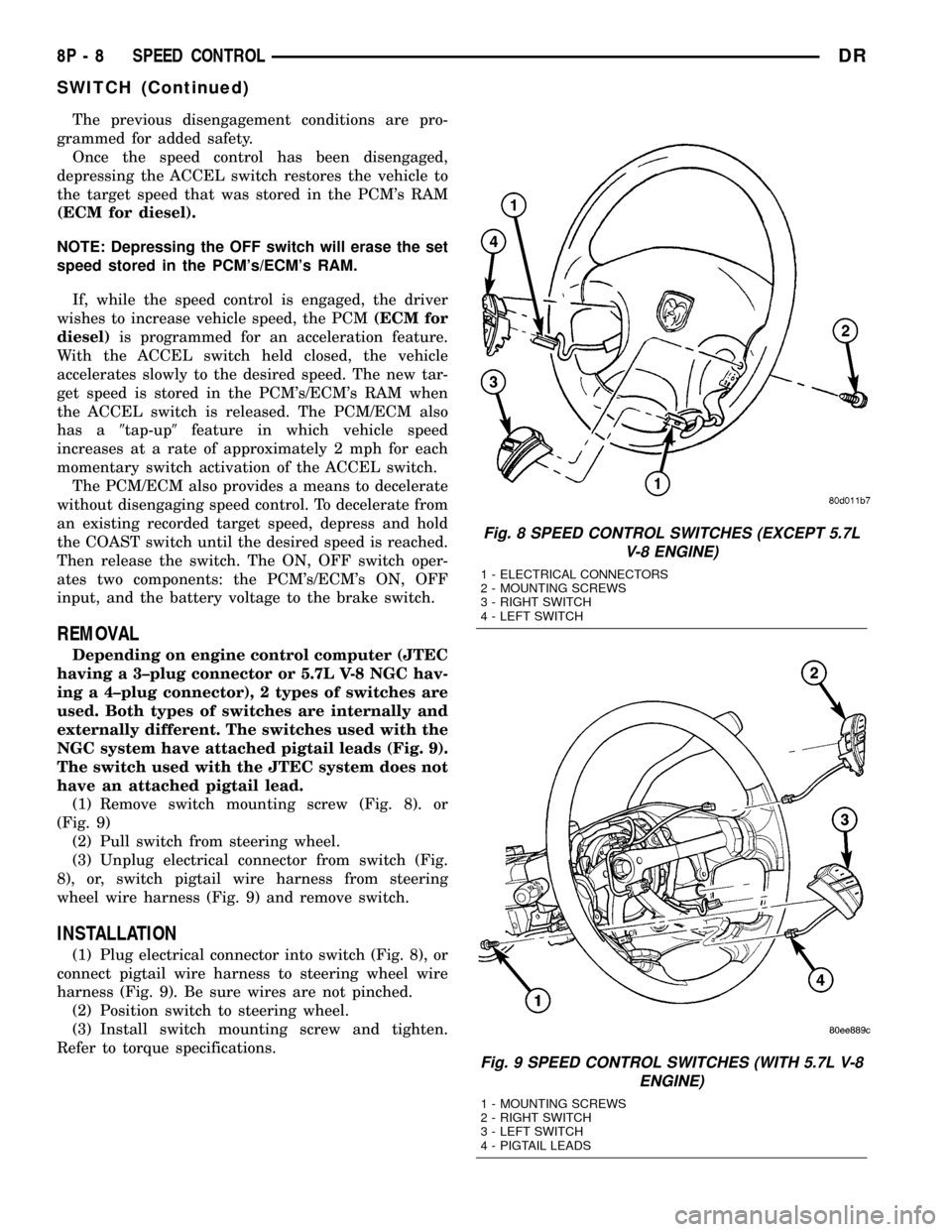

(11) Before starting engine, operate accelerator

pedal to check for any binding.

SWITCH

DESCRIPTION

Two separate switch pods operate the speed control

system. The steering-wheel-mounted switches use

multiplexed circuits to provide inputs to the PCM (to

the ECM for diesel) for ON, OFF, RESUME, ACCEL-

ERATE, SET, DECEL and CANCEL modes. Refer to

the owner's manual for more information on speed

control switch functions and setting procedures.

The individual switches cannot be repaired. If one

switch fails, the entire switch module must be

replaced.

Depending on engine control computer (JTEC

having a 3± plug connector or NGC having a 4±

plug connector), 2 types of switches are used.

Both types of switches are internally and exter-

nally different. The switch used with the NGC

system has an attached pigtail lead. The switch

used with the JTEC system does not have an

attached pigtail lead.

OPERATION

When speed control is selected by depressing the

ON, OFF switch, the PCM(ECM for diesel)allows

a set speed to be stored in its RAM for speed control.

To store a set speed, depress the SET switch while

the vehicle is moving at a speed between approxi-

mately 35 and 85 mph. In order for the speed control

to engage, the brakes cannot be applied, nor can the

gear selector be indicating the transmission is in

Park or Neutral.

The speed control can be disengaged manually by:

²Stepping on the brake pedal

²Depressing the OFF switch

²Depressing the CANCEL switch.

The speed control can be disengaged also by any of

the following conditions:

²An indication of Park or Neutral (auto. trans.)

²The VSS signal increases at a rate of 10 mph

per second (indicates that the co-efficient of friction

between the road surface and tires is extremely low)

²Depressing the clutch pedal (manual trans.).

²Excessive engine rpm (indicates that the trans-

mission may be in a low gear)

²The VSS signal decreases at a rate of 10 mph

per second (indicates that the vehicle may have

decelerated at an extremely high rate)

²If the actual speed is not within 20 mph of the

set speed

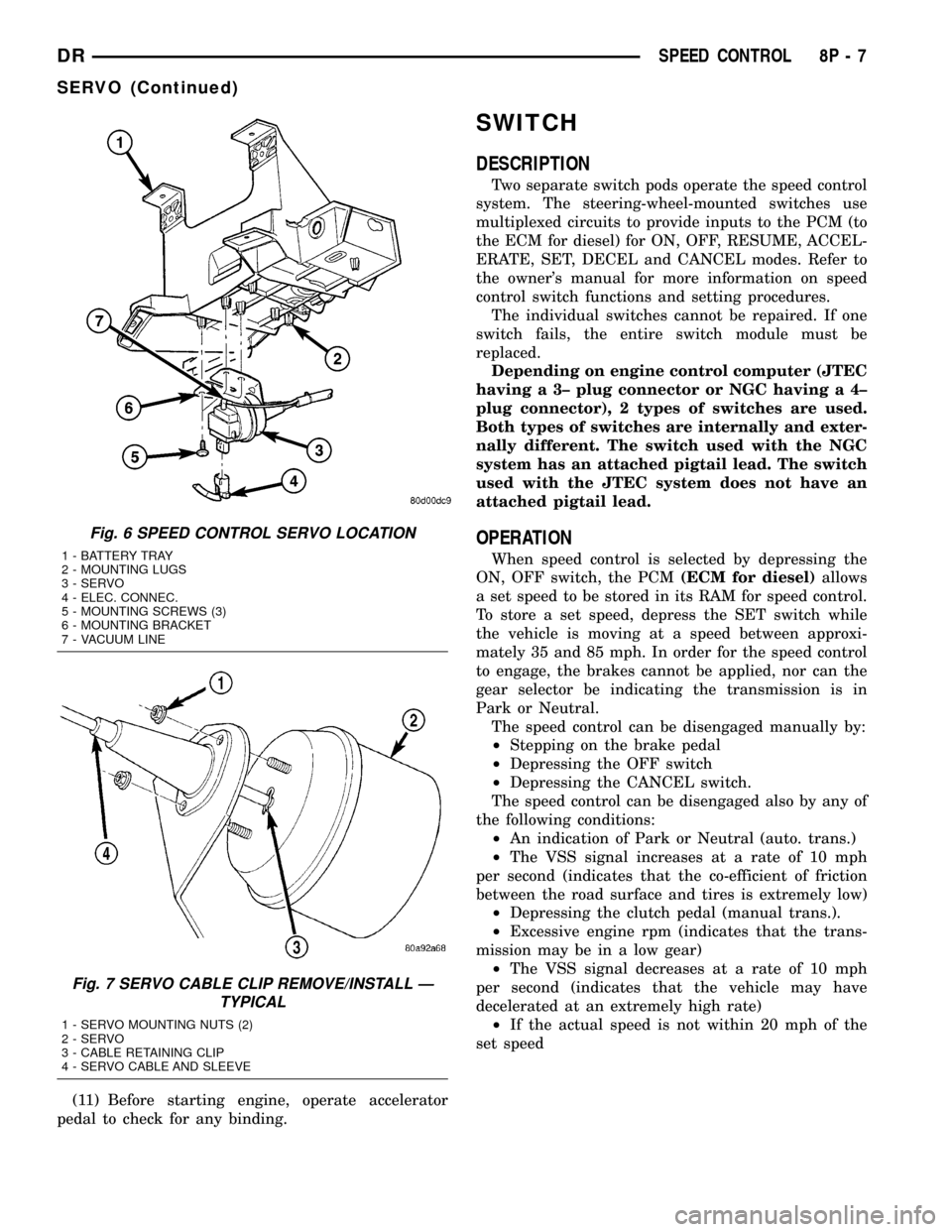

Fig. 6 SPEED CONTROL SERVO LOCATION

1 - BATTERY TRAY

2 - MOUNTING LUGS

3 - SERVO

4 - ELEC. CONNEC.

5 - MOUNTING SCREWS (3)

6 - MOUNTING BRACKET

7 - VACUUM LINE

Fig. 7 SERVO CABLE CLIP REMOVE/INSTALL Ð

TYPICAL

1 - SERVO MOUNTING NUTS (2)

2 - SERVO

3 - CABLE RETAINING CLIP

4 - SERVO CABLE AND SLEEVE

DRSPEED CONTROL 8P - 7

SERVO (Continued)

Page 689 of 2627

The previous disengagement conditions are pro-

grammed for added safety.

Once the speed control has been disengaged,

depressing the ACCEL switch restores the vehicle to

the target speed that was stored in the PCM's RAM

(ECM for diesel).

NOTE: Depressing the OFF switch will erase the set

speed stored in the PCM's/ECM's RAM.

If, while the speed control is engaged, the driver

wishes to increase vehicle speed, the PCM(ECM for

diesel)is programmed for an acceleration feature.

With the ACCEL switch held closed, the vehicle

accelerates slowly to the desired speed. The new tar-

get speed is stored in the PCM's/ECM's RAM when

the ACCEL switch is released. The PCM/ECM also

has a9tap-up9feature in which vehicle speed

increases at a rate of approximately 2 mph for each

momentary switch activation of the ACCEL switch.

The PCM/ECM also provides a means to decelerate

without disengaging speed control. To decelerate from

an existing recorded target speed, depress and hold

the COAST switch until the desired speed is reached.

Then release the switch. The ON, OFF switch oper-

ates two components: the PCM's/ECM's ON, OFF

input, and the battery voltage to the brake switch.

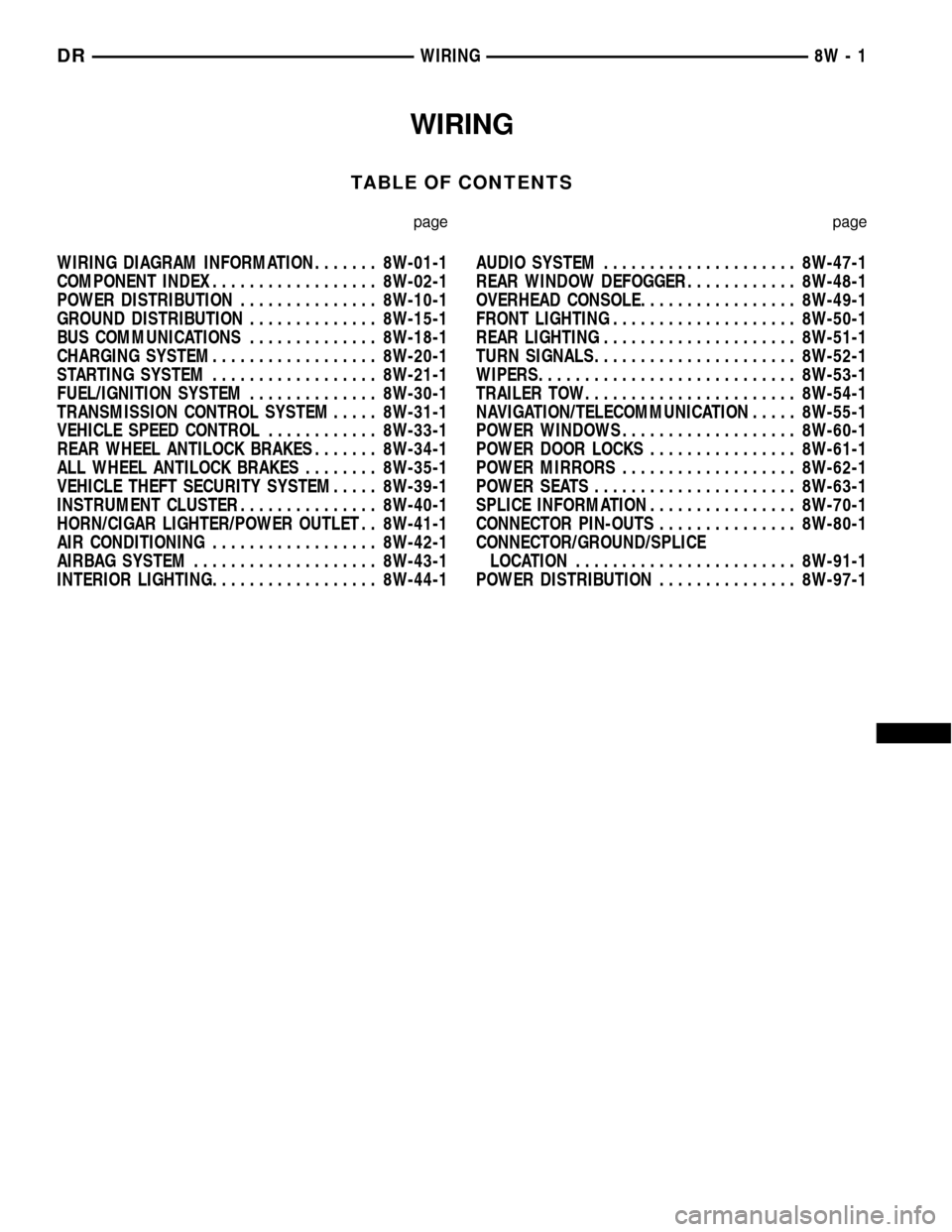

REMOVAL

Depending on engine control computer (JTEC

having a 3±plug connector or 5.7L V-8 NGC hav-

ing a 4±plug connector), 2 types of switches are

used. Both types of switches are internally and

externally different. The switches used with the

NGC system have attached pigtail leads (Fig. 9).

The switch used with the JTEC system does not

have an attached pigtail lead.

(1) Remove switch mounting screw (Fig. 8). or

(Fig. 9)

(2) Pull switch from steering wheel.

(3) Unplug electrical connector from switch (Fig.

8), or, switch pigtail wire harness from steering

wheel wire harness (Fig. 9) and remove switch.

INSTALLATION

(1) Plug electrical connector into switch (Fig. 8), or

connect pigtail wire harness to steering wheel wire

harness (Fig. 9). Be sure wires are not pinched.

(2) Position switch to steering wheel.

(3) Install switch mounting screw and tighten.

Refer to torque specifications.

Fig. 8 SPEED CONTROL SWITCHES (EXCEPT 5.7L

V-8 ENGINE)

1 - ELECTRICAL CONNECTORS

2 - MOUNTING SCREWS

3 - RIGHT SWITCH

4 - LEFT SWITCH

Fig. 9 SPEED CONTROL SWITCHES (WITH 5.7L V-8

ENGINE)

1 - MOUNTING SCREWS

2 - RIGHT SWITCH

3 - LEFT SWITCH

4 - PIGTAIL LEADS

8P - 8 SPEED CONTROLDR

SWITCH (Continued)

Page 726 of 2627

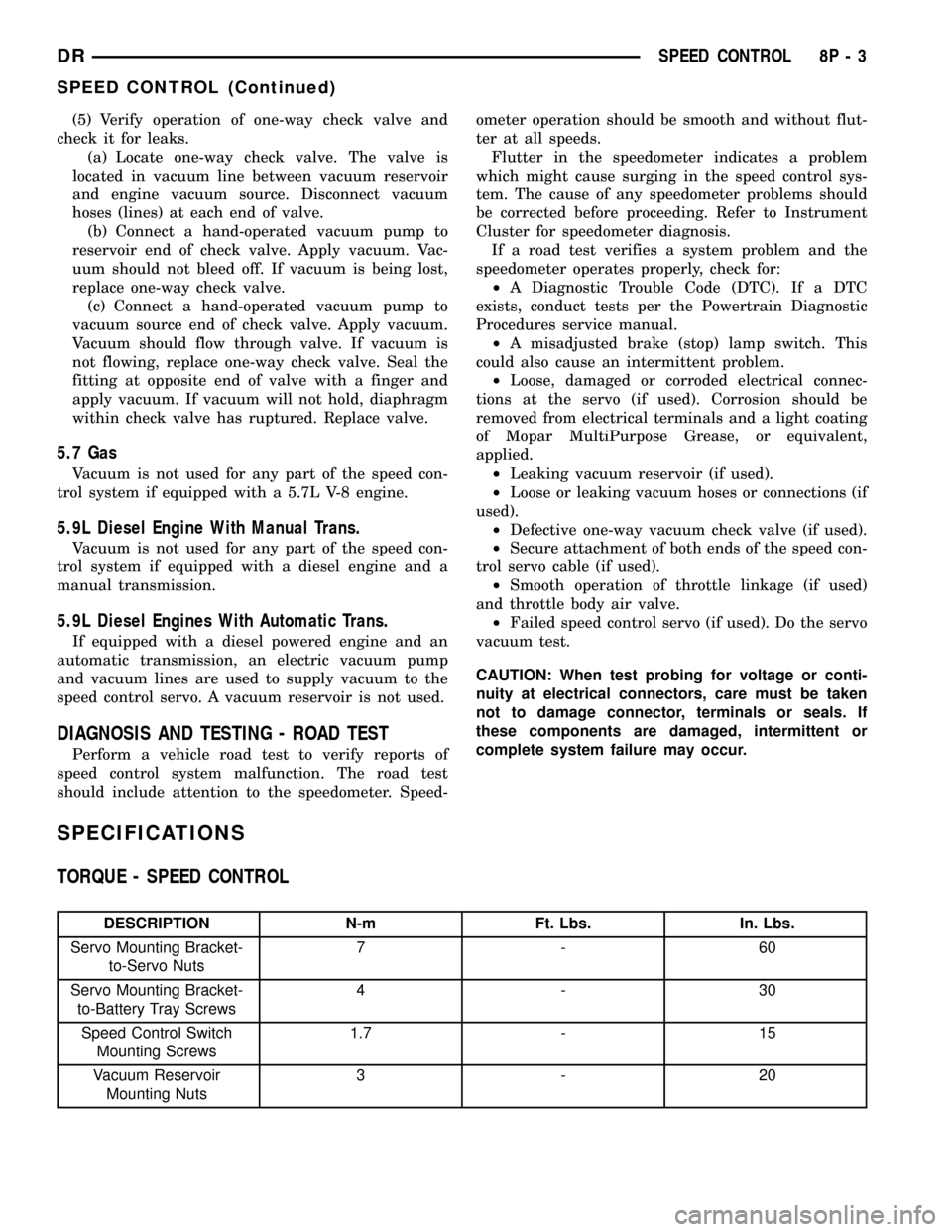

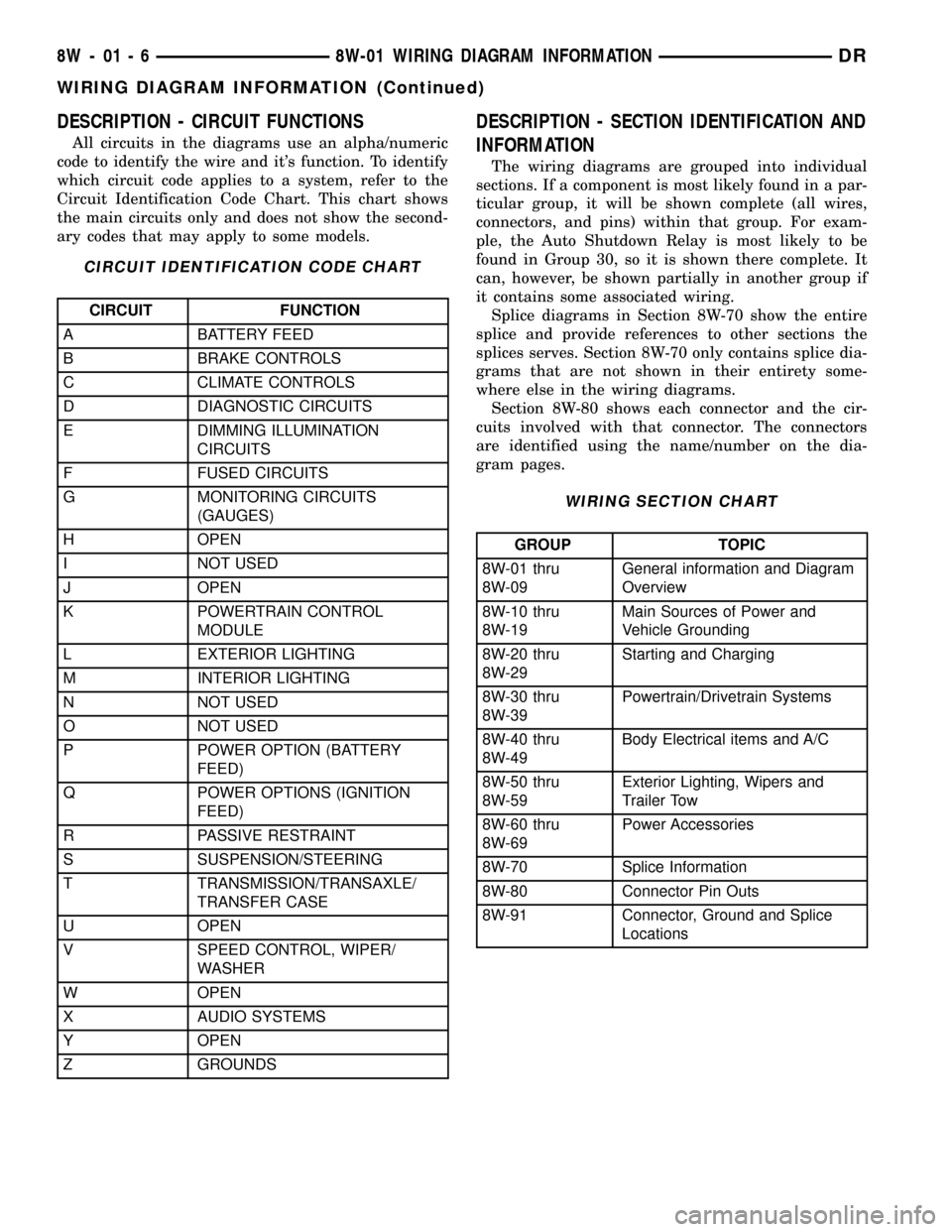

WIRING

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION....... 8W-01-1

COMPONENT INDEX.................. 8W-02-1

POWER DISTRIBUTION............... 8W-10-1

GROUND DISTRIBUTION.............. 8W-15-1

BUS COMMUNICATIONS.............. 8W-18-1

CHARGING SYSTEM.................. 8W-20-1

STARTING SYSTEM.................. 8W-21-1

FUEL/IGNITION SYSTEM.............. 8W-30-1

TRANSMISSION CONTROL SYSTEM..... 8W-31-1

VEHICLE SPEED CONTROL............ 8W-33-1

REAR WHEEL ANTILOCK BRAKES....... 8W-34-1

ALL WHEEL ANTILOCK BRAKES........ 8W-35-1

VEHICLE THEFT SECURITY SYSTEM..... 8W-39-1

INSTRUMENT CLUSTER............... 8W-40-1

HORN/CIGAR LIGHTER/POWER OUTLET . . 8W-41-1

AIR CONDITIONING.................. 8W-42-1

AIRBAG SYSTEM.................... 8W-43-1

INTERIOR LIGHTING.................. 8W-44-1AUDIO SYSTEM..................... 8W-47-1

REAR WINDOW DEFOGGER............ 8W-48-1

OVERHEAD CONSOLE................. 8W-49-1

FRONT LIGHTING.................... 8W-50-1

REAR LIGHTING..................... 8W-51-1

TURN SIGNALS...................... 8W-52-1

WIPERS............................ 8W-53-1

TRAILER TOW....................... 8W-54-1

NAVIGATION/TELECOMMUNICATION..... 8W-55-1

POWER WINDOWS................... 8W-60-1

POWER DOOR LOCKS................ 8W-61-1

POWER MIRRORS................... 8W-62-1

POWER SEATS...................... 8W-63-1

SPLICE INFORMATION................ 8W-70-1

CONNECTOR PIN-OUTS............... 8W-80-1

CONNECTOR/GROUND/SPLICE

LOCATION........................ 8W-91-1

POWER DISTRIBUTION............... 8W-97-1 DRWIRING 8W - 1

Page 733 of 2627

DESCRIPTION - CIRCUIT FUNCTIONS

All circuits in the diagrams use an alpha/numeric

code to identify the wire and it's function. To identify

which circuit code applies to a system, refer to the

Circuit Identification Code Chart. This chart shows

the main circuits only and does not show the second-

ary codes that may apply to some models.

CIRCUIT IDENTIFICATION CODE CHART

CIRCUIT FUNCTION

A BATTERY FEED

B BRAKE CONTROLS

C CLIMATE CONTROLS

D DIAGNOSTIC CIRCUITS

E DIMMING ILLUMINATION

CIRCUITS

F FUSED CIRCUITS

G MONITORING CIRCUITS

(GAUGES)

H OPEN

I NOT USED

J OPEN

K POWERTRAIN CONTROL

MODULE

L EXTERIOR LIGHTING

M INTERIOR LIGHTING

N NOT USED

O NOT USED

P POWER OPTION (BATTERY

FEED)

Q POWER OPTIONS (IGNITION

FEED)

R PASSIVE RESTRAINT

S SUSPENSION/STEERING

T TRANSMISSION/TRANSAXLE/

TRANSFER CASE

U OPEN

V SPEED CONTROL, WIPER/

WASHER

W OPEN

X AUDIO SYSTEMS

Y OPEN

Z GROUNDS

DESCRIPTION - SECTION IDENTIFICATION AND

INFORMATION

The wiring diagrams are grouped into individual

sections. If a component is most likely found in a par-

ticular group, it will be shown complete (all wires,

connectors, and pins) within that group. For exam-

ple, the Auto Shutdown Relay is most likely to be

found in Group 30, so it is shown there complete. It

can, however, be shown partially in another group if

it contains some associated wiring.

Splice diagrams in Section 8W-70 show the entire

splice and provide references to other sections the

splices serves. Section 8W-70 only contains splice dia-

grams that are not shown in their entirety some-

where else in the wiring diagrams.

Section 8W-80 shows each connector and the cir-

cuits involved with that connector. The connectors

are identified using the name/number on the dia-

gram pages.

WIRING SECTION CHART

GROUP TOPIC

8W-01 thru

8W-09General information and Diagram

Overview

8W-10 thru

8W-19Main Sources of Power and

Vehicle Grounding

8W-20 thru

8W-29Starting and Charging

8W-30 thru

8W-39Powertrain/Drivetrain Systems

8W-40 thru

8W-49Body Electrical items and A/C

8W-50 thru

8W-59Exterior Lighting, Wipers and

Trailer Tow

8W-60 thru

8W-69Power Accessories

8W-70 Splice Information

8W-80 Connector Pin Outs

8W-91 Connector, Ground and Splice

Locations

8W - 01 - 6 8W-01 WIRING DIAGRAM INFORMATIONDR

WIRING DIAGRAM INFORMATION (Continued)

Page 734 of 2627

DESCRIPTION - CONNECTOR, GROUND AND

SPLICE INFORMATION

CAUTION: Not all connectors are serviced. Some

connectors are serviced only with a harness. A typ-

ical example might be the Supplemental Restraint

System connectors. Always check parts availability

before attempting a repair.

IDENTIFICATION

In-line connectors are identified by a number, as

follows:

²In-line connectors located in the engine compart-

ment are C100 series numbers

²In-line connectors located in the Instrument

Panel area are C200 series numbers.

²In-line connectors located in the body are C300

series numbers.

²Jumper harness connectors are C400 series

numbers.

²Grounds and ground connectors are identified

with a ªGº and follow the same series numbering as

the in-line connectors.

²Splices are identified with an ªSº and follow the

same series numbering as the in-line connectors.

²Component connectors are identified by the com-

ponent name instead of a number. Multiple connec-

tors on a component use a C1, C2, etc. identifier.

LOCATIONS

Section 8W-91 contains connector/ground/splice

location illustrations. The illustrations contain the

connector name (or number)/ground number/splice

number and component identification. Connector/

ground/splice location charts in section 8W-91 refer-

ence the figure numbers of the illustrations.

The abbreviation T/O is used in the component

location section to indicate a point in which the wir-

ing harness branches out to a component. The abbre-

viation N/S means Not Shown in the illustrations

WARNING

WARNINGS - GENERAL

WARNINGSprovide information to prevent per-

sonal injury and vehicle damage. Below is a list of

general warnings that should be followed any time a

vehicle is being serviced.

WARNING: ALWAYS WEAR SAFETY GLASSES FOR

EYE PROTECTION.

WARNING: USE SAFETY STANDS ANYTIME A PRO-

CEDURE REQUIRES BEING UNDER A VEHICLE.WARNING: BE SURE THAT THE IGNITION SWITCH

ALWAYS IS IN THE OFF POSITION, UNLESS THE

PROCEDURE REQUIRES IT TO BE ON.

WARNING: SET THE PARKING BRAKE WHEN

WORKING ON ANY VEHICLE. AN AUTOMATIC

TRANSMISSION SHOULD BE IN PARK. A MANUAL

TRANSMISSION SHOULD BE IN NEUTRAL.

WARNING: OPERATE THE ENGINE ONLY IN A

WELL-VENTILATED AREA.

WARNING: KEEP AWAY FROM MOVING PARTS

WHEN THE ENGINE IS RUNNING, ESPECIALLY THE

FAN AND BELTS.

WARNING: TO PREVENT SERIOUS BURNS, AVOID

CONTACT WITH HOT PARTS SUCH AS THE RADIA-

TOR, EXHAUST MANIFOLD(S), TAIL PIPE, CATA-

LYTIC CONVERTER AND MUFFLER.

WARNING: DO NOT ALLOW FLAME OR SPARKS

NEAR THE BATTERY. GASES ARE ALWAYS

PRESENT IN AND AROUND THE BATTERY.

WARNING: ALWAYS REMOVE RINGS, WATCHES,

LOOSE HANGING JEWELRY AND AVOID LOOSE

CLOTHING.

DIAGNOSIS AND TESTING - WIRING HARNESS

TROUBLESHOOTING TOOLS

When diagnosing a problem in an electrical circuit

there are several common tools necessary. These tools

are listed and explained below.

²Jumper Wire - This is a test wire used to con-

nect two points of a circuit. It can be used to bypass

an open in a circuit.

WARNING: NEVER USE A JUMPER WIRE ACROSS

A LOAD, SUCH AS A MOTOR, CONNECTED

BETWEEN A BATTERY FEED AND GROUND.

²Voltmeter - Used to check for voltage on a cir-

cuit. Always connect the black lead to a known good

ground and the red lead to the positive side of the

circuit.

CAUTION: Most of the electrical components used

in today's vehicles are Solid State. When checking

voltages in these circuits, use a meter with a 10 -

megohm or greater impedance rating.

DR8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 7

WIRING DIAGRAM INFORMATION (Continued)

Page 828 of 2627

8W-21 STARTING SYSTEM

Component Page

Auxiliary Battery.................... 8W-21-3

Battery.......................... 8W-21-2, 3

Clutch Interlock Brake Switch.......... 8W-21-4

Engine Control Module................ 8W-21-4

Fuse 14.......................... 8W-21-2, 3

G104.............................. 8W-21-4

Ignition Switch.................... 8W-21-2, 3Component Page

Integrated Power Module.......... 8W-21-2, 3, 4

Powertrain Control Module............ 8W-21-2

Starter Motor..................... 8W-21-2, 3

Starter Motor Relay................ 8W-21-2, 3

Transfer Case Control Module.......... 8W-21-4

Transmission Range Sensor............ 8W-21-4

DR8W-21 STARTING SYSTEM 8W - 21 - 1