Brake system DODGE RAM 1500 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 278 of 2627

(9)On vehicles equipped with adjustable

brake pedal.Reconnect the electrical connector to

the motor and the adjuster cable at the pedal.

(10) Install the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION).

(11) Reconnect the negative battery cable.

POWER BRAKE BOOSTER

DESCRIPTION

All models use a tandem diaphragm, power brake

booster.

NOTE: The power brake booster is not a repairable

component. The booster must be replaced as an

assembly if diagnosis indicates a malfunction has

occurred.

OPERATION

The booster unit consists of a single housing

divided into two by a tandem diaphragm. The outer

edge of the diaphragm is secured to the housing. The

booster push rod, which connects the booster to the

brake pedal and master cylinder, is attached to the

center of the diaphragm. A check valve is used in the

booster outlet connected to the engine intake mani-

fold. Power assist is generated by utilizing a combi-

nation of vacuum and atmospheric pressure to boost

brake assist.

REMOVAL

(1) Remove master cylinder. (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/MASTER CYLINDER -

REMOVAL).

(2) Disconnect vacuum line at booster.

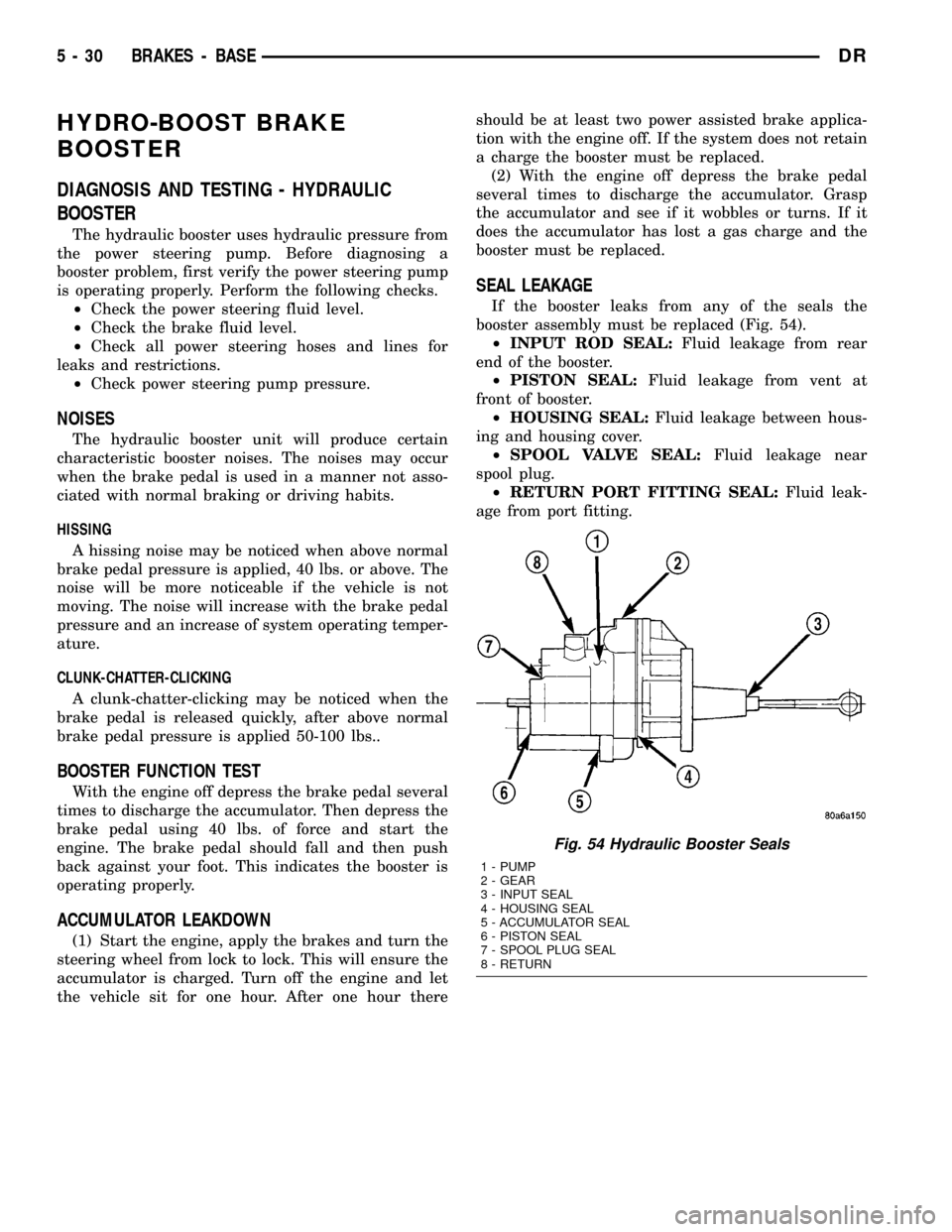

(3) Remove clip securing booster push rod to brake

pedal (Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/PEDAL - REMOVAL). (Fig. 53).

(4) Remove the nuts from the booster mounting

studs (Fig. 53).

(5) Remove the booster and gasket from front cowl

panel.

INSTALLATION

(1) Guide the booster studs into the cowl panel

holes and seat the booster on the panel (Fig. 53).

(2) Install and tighten new booster attaching nuts

to 28 N´m (250 in. lbs.).

(3) Install the booster push rod on brake pedal and

install clip (Fig. 53).

(4) Install the booster check valve if removed and

connect the vacuum hose to the check valve.

(5) Install the master cylinder. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/MASTER

CYLINDER - INSTALLATION).

(6) Fill and bleed the brake system. (Refer to 5 -

BRAKES - STANDARD PROCEDURE).

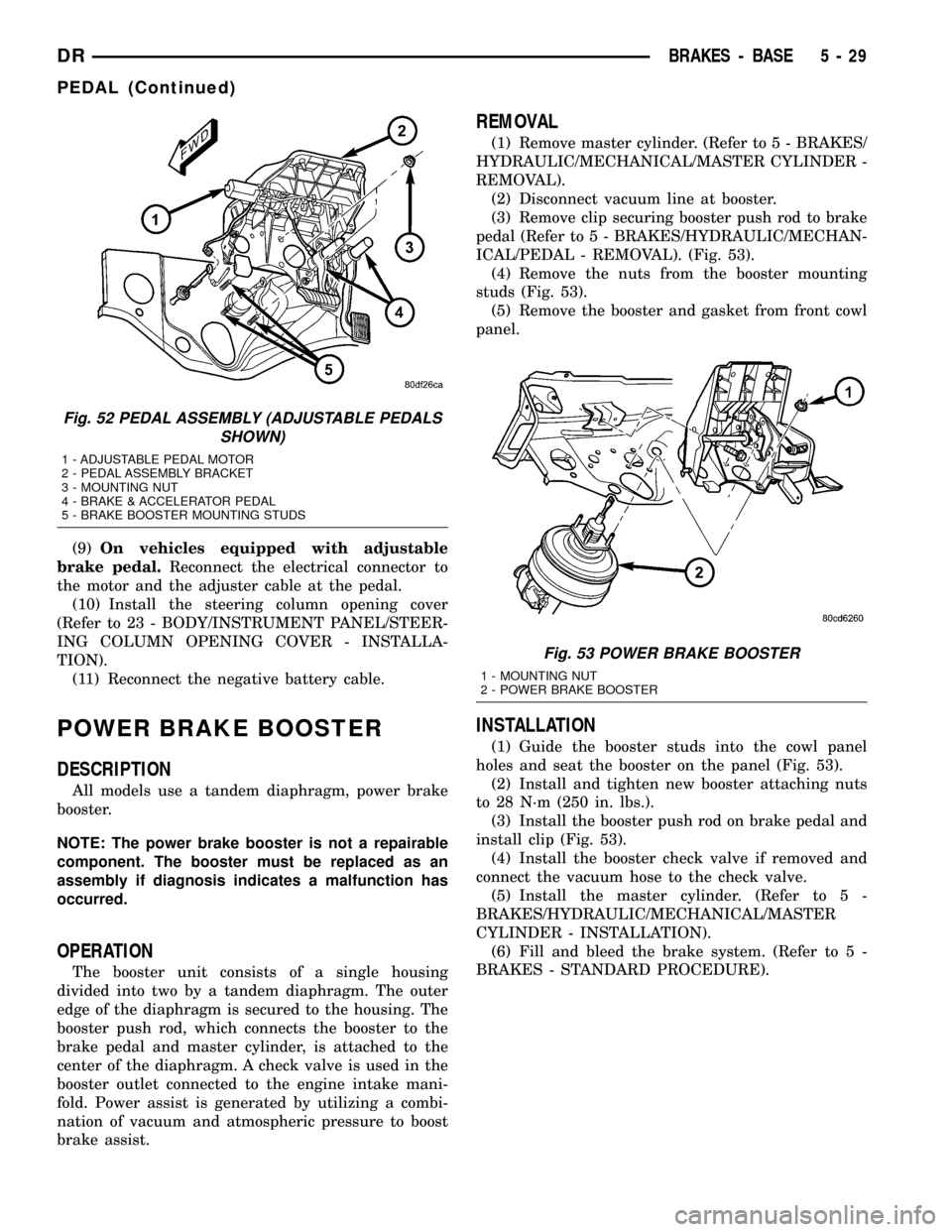

Fig. 52 PEDAL ASSEMBLY (ADJUSTABLE PEDALS

SHOWN)

1 - ADJUSTABLE PEDAL MOTOR

2 - PEDAL ASSEMBLY BRACKET

3 - MOUNTING NUT

4 - BRAKE & ACCELERATOR PEDAL

5 - BRAKE BOOSTER MOUNTING STUDS

Fig. 53 POWER BRAKE BOOSTER

1 - MOUNTING NUT

2 - POWER BRAKE BOOSTER

DRBRAKES - BASE 5 - 29

PEDAL (Continued)

Page 279 of 2627

HYDRO-BOOST BRAKE

BOOSTER

DIAGNOSIS AND TESTING - HYDRAULIC

BOOSTER

The hydraulic booster uses hydraulic pressure from

the power steering pump. Before diagnosing a

booster problem, first verify the power steering pump

is operating properly. Perform the following checks.

²Check the power steering fluid level.

²Check the brake fluid level.

²Check all power steering hoses and lines for

leaks and restrictions.

²Check power steering pump pressure.

NOISES

The hydraulic booster unit will produce certain

characteristic booster noises. The noises may occur

when the brake pedal is used in a manner not asso-

ciated with normal braking or driving habits.

HISSING

A hissing noise may be noticed when above normal

brake pedal pressure is applied, 40 lbs. or above. The

noise will be more noticeable if the vehicle is not

moving. The noise will increase with the brake pedal

pressure and an increase of system operating temper-

ature.

CLUNK-CHATTER-CLICKING

A clunk-chatter-clicking may be noticed when the

brake pedal is released quickly, after above normal

brake pedal pressure is applied 50-100 lbs..

BOOSTER FUNCTION TEST

With the engine off depress the brake pedal several

times to discharge the accumulator. Then depress the

brake pedal using 40 lbs. of force and start the

engine. The brake pedal should fall and then push

back against your foot. This indicates the booster is

operating properly.

ACCUMULATOR LEAKDOWN

(1) Start the engine, apply the brakes and turn the

steering wheel from lock to lock. This will ensure the

accumulator is charged. Turn off the engine and let

the vehicle sit for one hour. After one hour thereshould be at least two power assisted brake applica-

tion with the engine off. If the system does not retain

a charge the booster must be replaced.

(2) With the engine off depress the brake pedal

several times to discharge the accumulator. Grasp

the accumulator and see if it wobbles or turns. If it

does the accumulator has lost a gas charge and the

booster must be replaced.

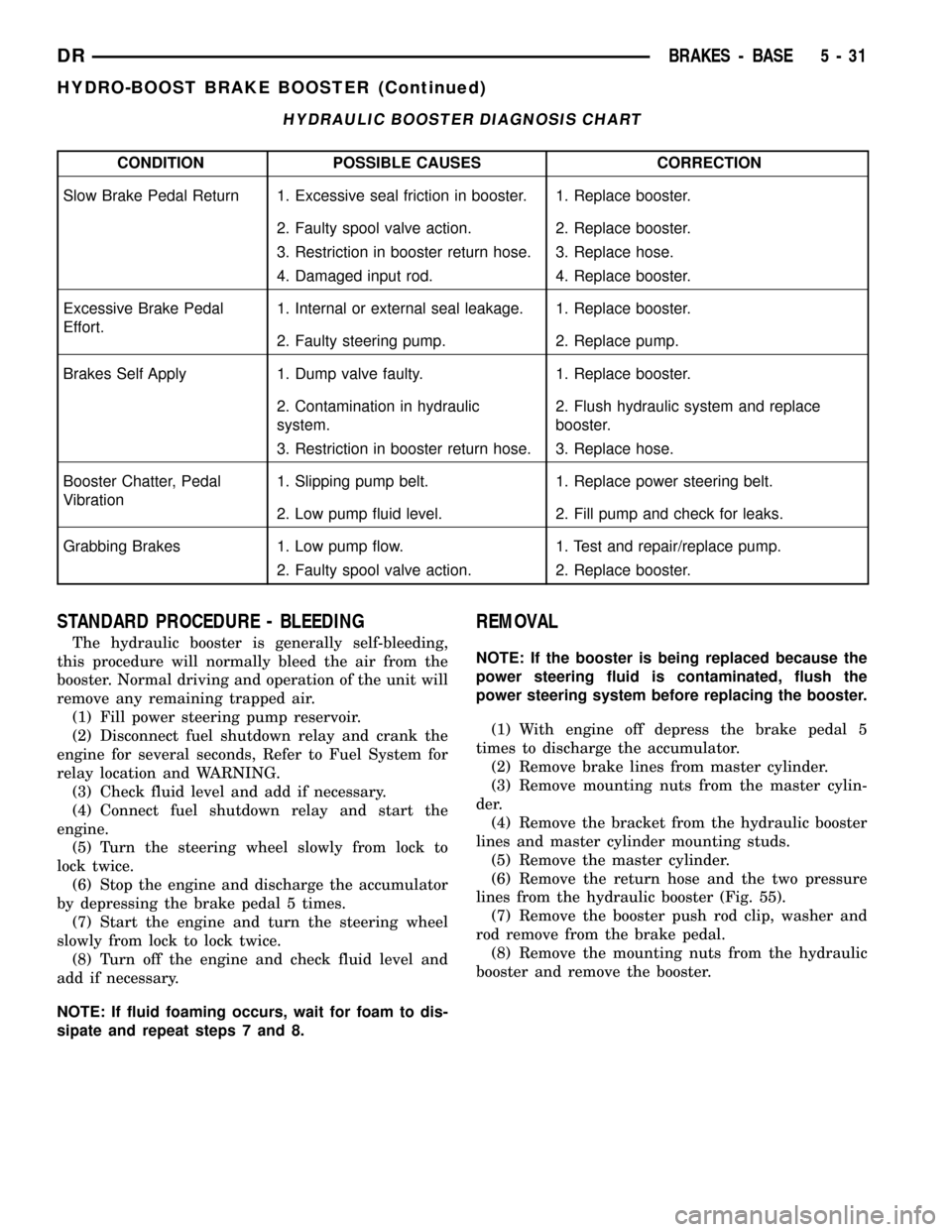

SEAL LEAKAGE

If the booster leaks from any of the seals the

booster assembly must be replaced (Fig. 54).

²INPUT ROD SEAL:Fluid leakage from rear

end of the booster.

²PISTON SEAL:Fluid leakage from vent at

front of booster.

²HOUSING SEAL:Fluid leakage between hous-

ing and housing cover.

²SPOOL VALVE SEAL:Fluid leakage near

spool plug.

²RETURN PORT FITTING SEAL:Fluid leak-

age from port fitting.

Fig. 54 Hydraulic Booster Seals

1 - PUMP

2 - GEAR

3 - INPUT SEAL

4 - HOUSING SEAL

5 - ACCUMULATOR SEAL

6 - PISTON SEAL

7 - SPOOL PLUG SEAL

8 - RETURN

5 - 30 BRAKES - BASEDR

Page 280 of 2627

HYDRAULIC BOOSTER DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

Slow Brake Pedal Return 1. Excessive seal friction in booster. 1. Replace booster.

2. Faulty spool valve action. 2. Replace booster.

3. Restriction in booster return hose. 3. Replace hose.

4. Damaged input rod. 4. Replace booster.

Excessive Brake Pedal

Effort.1. Internal or external seal leakage. 1. Replace booster.

2. Faulty steering pump. 2. Replace pump.

Brakes Self Apply 1. Dump valve faulty. 1. Replace booster.

2. Contamination in hydraulic

system.2. Flush hydraulic system and replace

booster.

3. Restriction in booster return hose. 3. Replace hose.

Booster Chatter, Pedal

Vibration1. Slipping pump belt. 1. Replace power steering belt.

2. Low pump fluid level. 2. Fill pump and check for leaks.

Grabbing Brakes 1. Low pump flow. 1. Test and repair/replace pump.

2. Faulty spool valve action. 2. Replace booster.

STANDARD PROCEDURE - BLEEDING

The hydraulic booster is generally self-bleeding,

this procedure will normally bleed the air from the

booster. Normal driving and operation of the unit will

remove any remaining trapped air.

(1) Fill power steering pump reservoir.

(2) Disconnect fuel shutdown relay and crank the

engine for several seconds, Refer to Fuel System for

relay location and WARNING.

(3) Check fluid level and add if necessary.

(4) Connect fuel shutdown relay and start the

engine.

(5) Turn the steering wheel slowly from lock to

lock twice.

(6) Stop the engine and discharge the accumulator

by depressing the brake pedal 5 times.

(7) Start the engine and turn the steering wheel

slowly from lock to lock twice.

(8) Turn off the engine and check fluid level and

add if necessary.

NOTE: If fluid foaming occurs, wait for foam to dis-

sipate and repeat steps 7 and 8.

REMOVAL

NOTE: If the booster is being replaced because the

power steering fluid is contaminated, flush the

power steering system before replacing the booster.

(1) With engine off depress the brake pedal 5

times to discharge the accumulator.

(2) Remove brake lines from master cylinder.

(3) Remove mounting nuts from the master cylin-

der.

(4) Remove the bracket from the hydraulic booster

lines and master cylinder mounting studs.

(5) Remove the master cylinder.

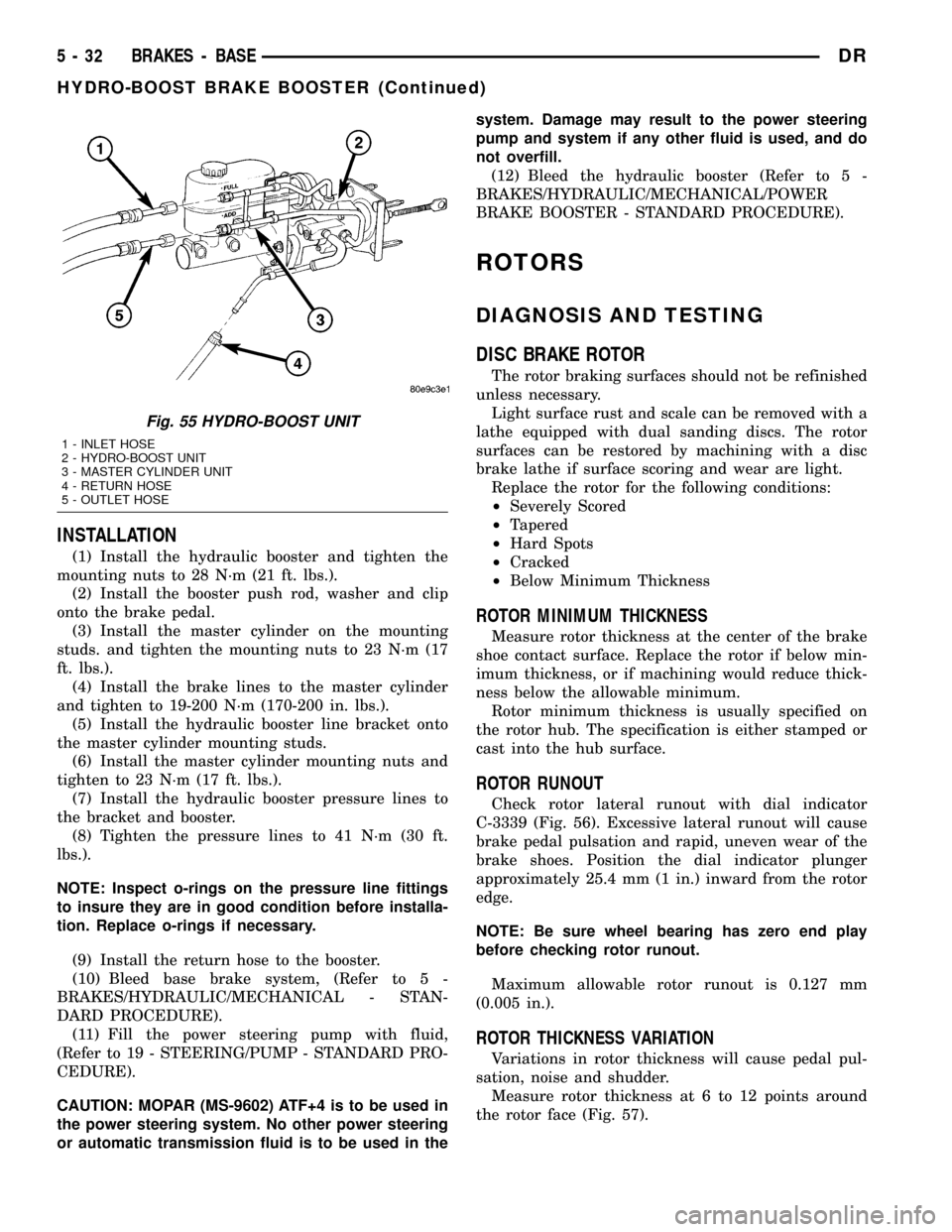

(6) Remove the return hose and the two pressure

lines from the hydraulic booster (Fig. 55).

(7) Remove the booster push rod clip, washer and

rod remove from the brake pedal.

(8) Remove the mounting nuts from the hydraulic

booster and remove the booster.

DRBRAKES - BASE 5 - 31

HYDRO-BOOST BRAKE BOOSTER (Continued)

Page 281 of 2627

INSTALLATION

(1) Install the hydraulic booster and tighten the

mounting nuts to 28 N´m (21 ft. lbs.).

(2) Install the booster push rod, washer and clip

onto the brake pedal.

(3) Install the master cylinder on the mounting

studs. and tighten the mounting nuts to 23 N´m (17

ft. lbs.).

(4) Install the brake lines to the master cylinder

and tighten to 19-200 N´m (170-200 in. lbs.).

(5) Install the hydraulic booster line bracket onto

the master cylinder mounting studs.

(6) Install the master cylinder mounting nuts and

tighten to 23 N´m (17 ft. lbs.).

(7) Install the hydraulic booster pressure lines to

the bracket and booster.

(8) Tighten the pressure lines to 41 N´m (30 ft.

lbs.).

NOTE: Inspect o-rings on the pressure line fittings

to insure they are in good condition before installa-

tion. Replace o-rings if necessary.

(9) Install the return hose to the booster.

(10) Bleed base brake system, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL - STAN-

DARD PROCEDURE).

(11) Fill the power steering pump with fluid,

(Refer to 19 - STEERING/PUMP - STANDARD PRO-

CEDURE).

CAUTION: MOPAR (MS-9602) ATF+4 is to be used in

the power steering system. No other power steering

or automatic transmission fluid is to be used in thesystem. Damage may result to the power steering

pump and system if any other fluid is used, and do

not overfill.

(12) Bleed the hydraulic booster (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/POWER

BRAKE BOOSTER - STANDARD PROCEDURE).

ROTORS

DIAGNOSIS AND TESTING

DISC BRAKE ROTOR

The rotor braking surfaces should not be refinished

unless necessary.

Light surface rust and scale can be removed with a

lathe equipped with dual sanding discs. The rotor

surfaces can be restored by machining with a disc

brake lathe if surface scoring and wear are light.

Replace the rotor for the following conditions:

²Severely Scored

²Tapered

²Hard Spots

²Cracked

²Below Minimum Thickness

ROTOR MINIMUM THICKNESS

Measure rotor thickness at the center of the brake

shoe contact surface. Replace the rotor if below min-

imum thickness, or if machining would reduce thick-

ness below the allowable minimum.

Rotor minimum thickness is usually specified on

the rotor hub. The specification is either stamped or

cast into the hub surface.

ROTOR RUNOUT

Check rotor lateral runout with dial indicator

C-3339 (Fig. 56). Excessive lateral runout will cause

brake pedal pulsation and rapid, uneven wear of the

brake shoes. Position the dial indicator plunger

approximately 25.4 mm (1 in.) inward from the rotor

edge.

NOTE: Be sure wheel bearing has zero end play

before checking rotor runout.

Maximum allowable rotor runout is 0.127 mm

(0.005 in.).

ROTOR THICKNESS VARIATION

Variations in rotor thickness will cause pedal pul-

sation, noise and shudder.

Measure rotor thickness at 6 to 12 points around

the rotor face (Fig. 57).

Fig. 55 HYDRO-BOOST UNIT

1 - INLET HOSE

2 - HYDRO-BOOST UNIT

3 - MASTER CYLINDER UNIT

4 - RETURN HOSE

5 - OUTLET HOSE

5 - 32 BRAKES - BASEDR

HYDRO-BOOST BRAKE BOOSTER (Continued)

Page 283 of 2627

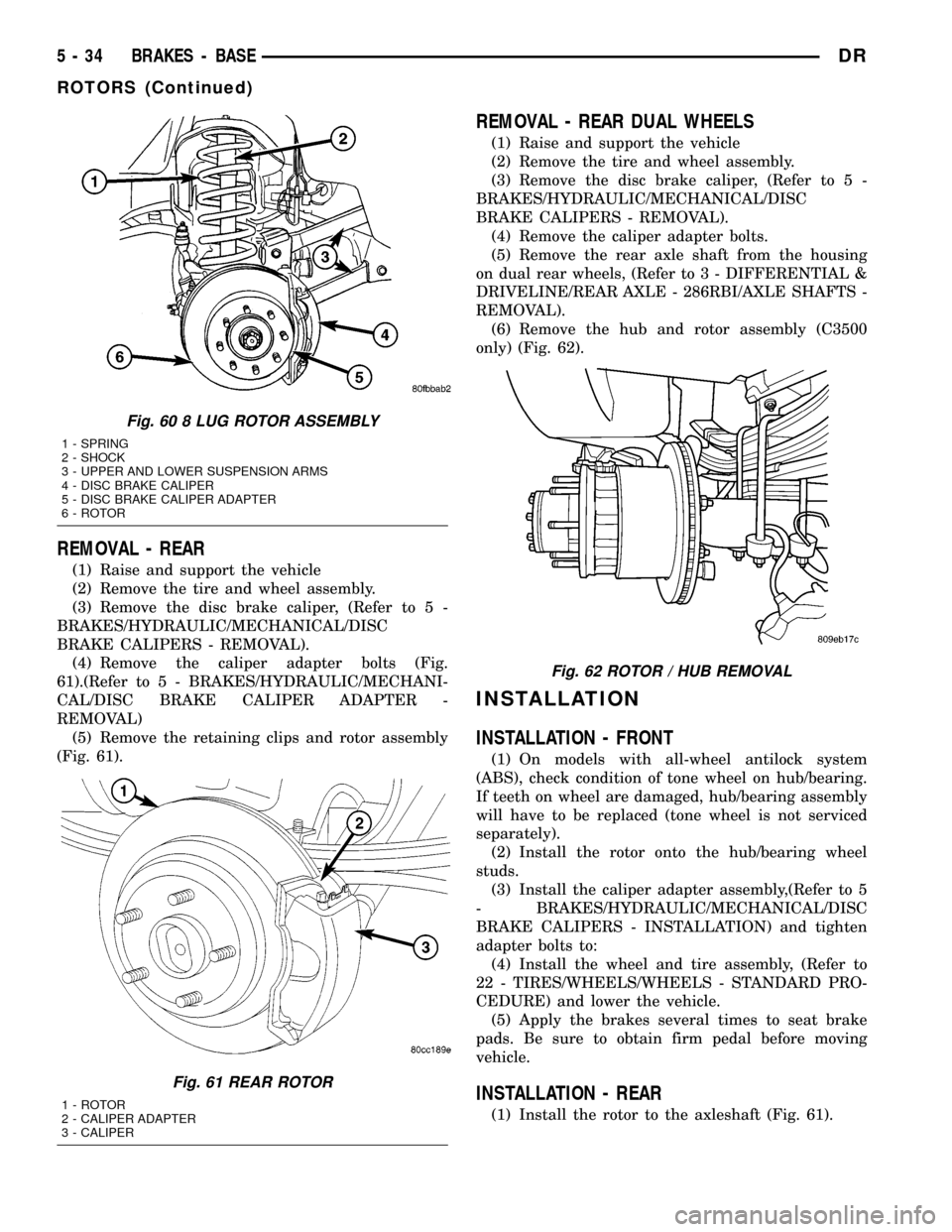

REMOVAL - REAR

(1) Raise and support the vehicle

(2) Remove the tire and wheel assembly.

(3) Remove the disc brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(4) Remove the caliper adapter bolts (Fig.

61).(Refer to 5 - BRAKES/HYDRAULIC/MECHANI-

CAL/DISC BRAKE CALIPER ADAPTER -

REMOVAL)

(5) Remove the retaining clips and rotor assembly

(Fig. 61).

REMOVAL - REAR DUAL WHEELS

(1) Raise and support the vehicle

(2) Remove the tire and wheel assembly.

(3) Remove the disc brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(4) Remove the caliper adapter bolts.

(5) Remove the rear axle shaft from the housing

on dual rear wheels, (Refer to 3 - DIFFERENTIAL &

DRIVELINE/REAR AXLE - 286RBI/AXLE SHAFTS -

REMOVAL).

(6) Remove the hub and rotor assembly (C3500

only) (Fig. 62).

INSTALLATION

INSTALLATION - FRONT

(1) On models with all-wheel antilock system

(ABS), check condition of tone wheel on hub/bearing.

If teeth on wheel are damaged, hub/bearing assembly

will have to be replaced (tone wheel is not serviced

separately).

(2) Install the rotor onto the hub/bearing wheel

studs.

(3) Install the caliper adapter assembly,(Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION) and tighten

adapter bolts to:

(4) Install the wheel and tire assembly, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE) and lower the vehicle.

(5) Apply the brakes several times to seat brake

pads. Be sure to obtain firm pedal before moving

vehicle.

INSTALLATION - REAR

(1) Install the rotor to the axleshaft (Fig. 61).

Fig. 60 8 LUG ROTOR ASSEMBLY

1 - SPRING

2 - SHOCK

3 - UPPER AND LOWER SUSPENSION ARMS

4 - DISC BRAKE CALIPER

5 - DISC BRAKE CALIPER ADAPTER

6 - ROTOR

Fig. 61 REAR ROTOR

1 - ROTOR

2 - CALIPER ADAPTER

3 - CALIPER

Fig. 62 ROTOR / HUB REMOVAL

5 - 34 BRAKES - BASEDR

ROTORS (Continued)

Page 285 of 2627

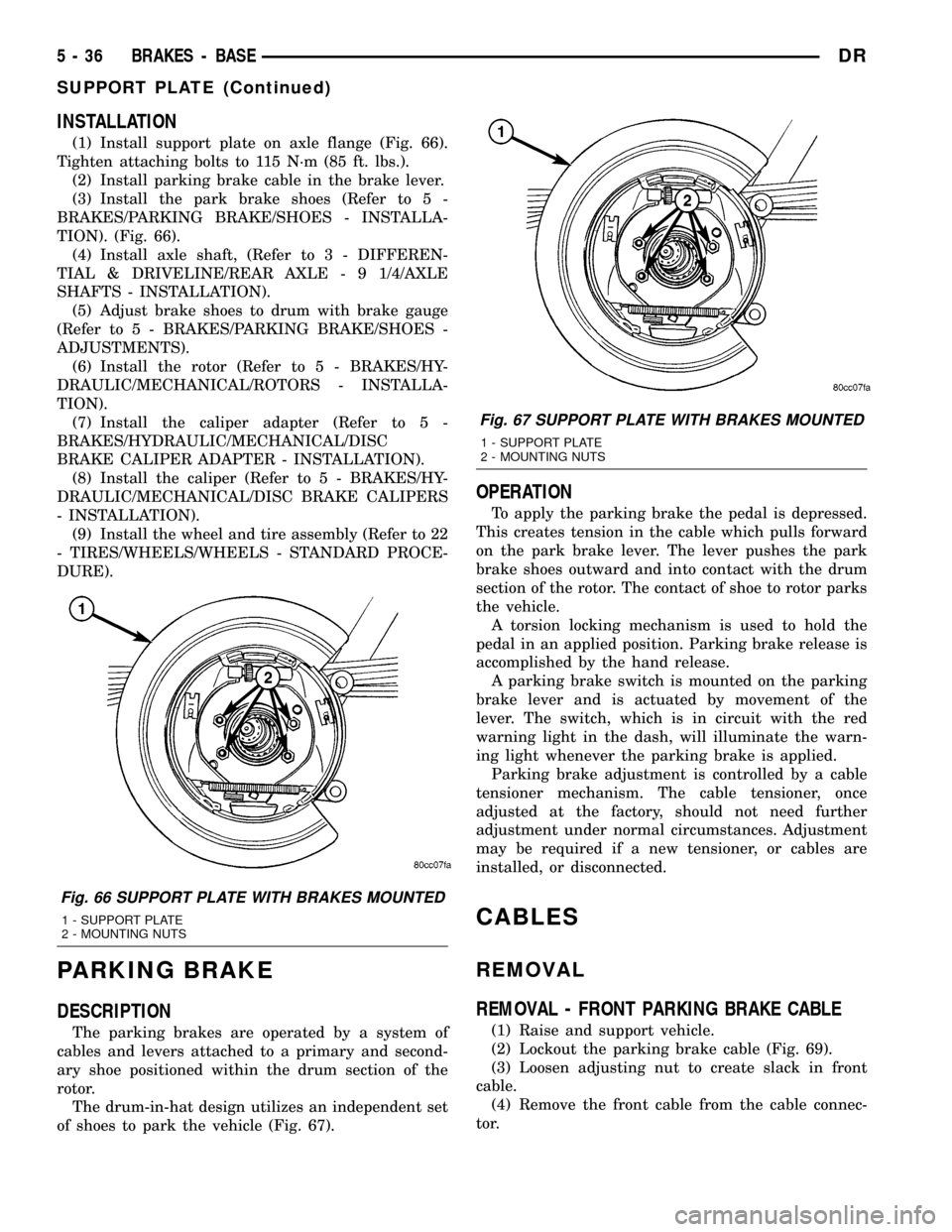

INSTALLATION

(1) Install support plate on axle flange (Fig. 66).

Tighten attaching bolts to 115 N´m (85 ft. lbs.).

(2) Install parking brake cable in the brake lever.

(3) Install the park brake shoes (Refer to 5 -

BRAKES/PARKING BRAKE/SHOES - INSTALLA-

TION). (Fig. 66).

(4) Install axle shaft, (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/REAR AXLE - 9 1/4/AXLE

SHAFTS - INSTALLATION).

(5) Adjust brake shoes to drum with brake gauge

(Refer to 5 - BRAKES/PARKING BRAKE/SHOES -

ADJUSTMENTS).

(6) Install the rotor (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ROTORS - INSTALLA-

TION).

(7) Install the caliper adapter (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - INSTALLATION).

(8) Install the caliper (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/DISC BRAKE CALIPERS

- INSTALLATION).

(9) Install the wheel and tire assembly (Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

PARKING BRAKE

DESCRIPTION

The parking brakes are operated by a system of

cables and levers attached to a primary and second-

ary shoe positioned within the drum section of the

rotor.

The drum-in-hat design utilizes an independent set

of shoes to park the vehicle (Fig. 67).

OPERATION

To apply the parking brake the pedal is depressed.

This creates tension in the cable which pulls forward

on the park brake lever. The lever pushes the park

brake shoes outward and into contact with the drum

section of the rotor. The contact of shoe to rotor parks

the vehicle.

A torsion locking mechanism is used to hold the

pedal in an applied position. Parking brake release is

accomplished by the hand release.

A parking brake switch is mounted on the parking

brake lever and is actuated by movement of the

lever. The switch, which is in circuit with the red

warning light in the dash, will illuminate the warn-

ing light whenever the parking brake is applied.

Parking brake adjustment is controlled by a cable

tensioner mechanism. The cable tensioner, once

adjusted at the factory, should not need further

adjustment under normal circumstances. Adjustment

may be required if a new tensioner, or cables are

installed, or disconnected.

CABLES

REMOVAL

REMOVAL - FRONT PARKING BRAKE CABLE

(1) Raise and support vehicle.

(2) Lockout the parking brake cable (Fig. 69).

(3) Loosen adjusting nut to create slack in front

cable.

(4) Remove the front cable from the cable connec-

tor.

Fig. 66 SUPPORT PLATE WITH BRAKES MOUNTED

1 - SUPPORT PLATE

2 - MOUNTING NUTS

Fig. 67 SUPPORT PLATE WITH BRAKES MOUNTED

1 - SUPPORT PLATE

2 - MOUNTING NUTS

5 - 36 BRAKES - BASEDR

SUPPORT PLATE (Continued)

Page 289 of 2627

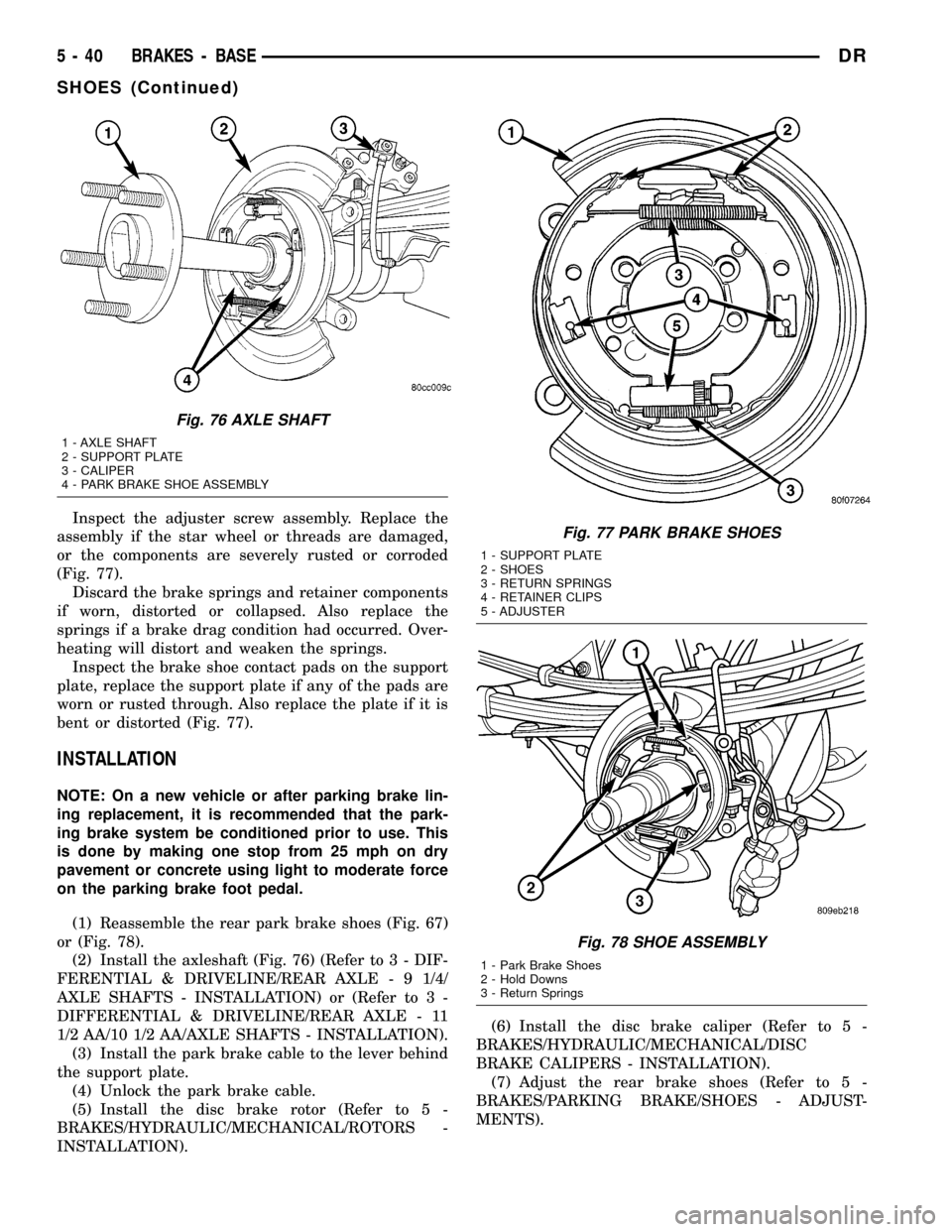

Inspect the adjuster screw assembly. Replace the

assembly if the star wheel or threads are damaged,

or the components are severely rusted or corroded

(Fig. 77).

Discard the brake springs and retainer components

if worn, distorted or collapsed. Also replace the

springs if a brake drag condition had occurred. Over-

heating will distort and weaken the springs.

Inspect the brake shoe contact pads on the support

plate, replace the support plate if any of the pads are

worn or rusted through. Also replace the plate if it is

bent or distorted (Fig. 77).

INSTALLATION

NOTE: On a new vehicle or after parking brake lin-

ing replacement, it is recommended that the park-

ing brake system be conditioned prior to use. This

is done by making one stop from 25 mph on dry

pavement or concrete using light to moderate force

on the parking brake foot pedal.

(1) Reassemble the rear park brake shoes (Fig. 67)

or (Fig. 78).

(2) Install the axleshaft (Fig. 76) (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/REAR AXLE - 9 1/4/

AXLE SHAFTS - INSTALLATION) or (Refer to 3 -

DIFFERENTIAL & DRIVELINE/REAR AXLE - 11

1/2 AA/10 1/2 AA/AXLE SHAFTS - INSTALLATION).

(3) Install the park brake cable to the lever behind

the support plate.

(4) Unlock the park brake cable.

(5) Install the disc brake rotor (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

INSTALLATION).(6) Install the disc brake caliper (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION).

(7) Adjust the rear brake shoes (Refer to 5 -

BRAKES/PARKING BRAKE/SHOES - ADJUST-

MENTS).

Fig. 76 AXLE SHAFT

1 - AXLE SHAFT

2 - SUPPORT PLATE

3 - CALIPER

4 - PARK BRAKE SHOE ASSEMBLY

Fig. 77 PARK BRAKE SHOES

1 - SUPPORT PLATE

2 - SHOES

3 - RETURN SPRINGS

4 - RETAINER CLIPS

5 - ADJUSTER

Fig. 78 SHOE ASSEMBLY

1 - Park Brake Shoes

2 - Hold Downs

3 - Return Springs

5 - 40 BRAKES - BASEDR

SHOES (Continued)

Page 291 of 2627

(12) Rotate rotor to verify that the park brake

shoes are not dragging on the brake drum. If park

brake shoes are dragging, remove rotor and back off

star wheel adjuster one notch and recheck for brake

shoe drag against drum. Continue with the previous

step until brake shoes are not dragging on brake

drum.

(13) Install disc brake caliper on caliper adapter

(Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/

DISC BRAKE CALIPERS - INSTALLATION).

(14) Install wheel and tire.

(15) Tighten the wheel mounting nuts in the

proper sequence until all nuts are torqued to half the

specified torque. Then repeat the tightening sequence

to the full specified torque of 180 N´m (135 ft. lbs.)

1500 & 2500 Series or 195 N´m (145 ft. lbs.) 3500

Series.

(16) Lower vehicle.

(17) Apply and release the park brake pedal one

time. This will seat and correctly adjust the park

brake cables.

CAUTION: Before moving vehicle, pump brake

pedal several times to ensure the vehicle has a firm

enough pedal to stop the vehicle.

NOTE: On a new vehicle or after parking brake lin-

ing replacement, it is recommended that the park-

ing brake system be conditioned prior to use. This

is done by making one stop from 25 mph on dry

pavement or concrete using light to moderate force

on the parking brake foot pedal.

(18) Road test the vehicle to ensure proper func-

tion of the vehicle's brake system.

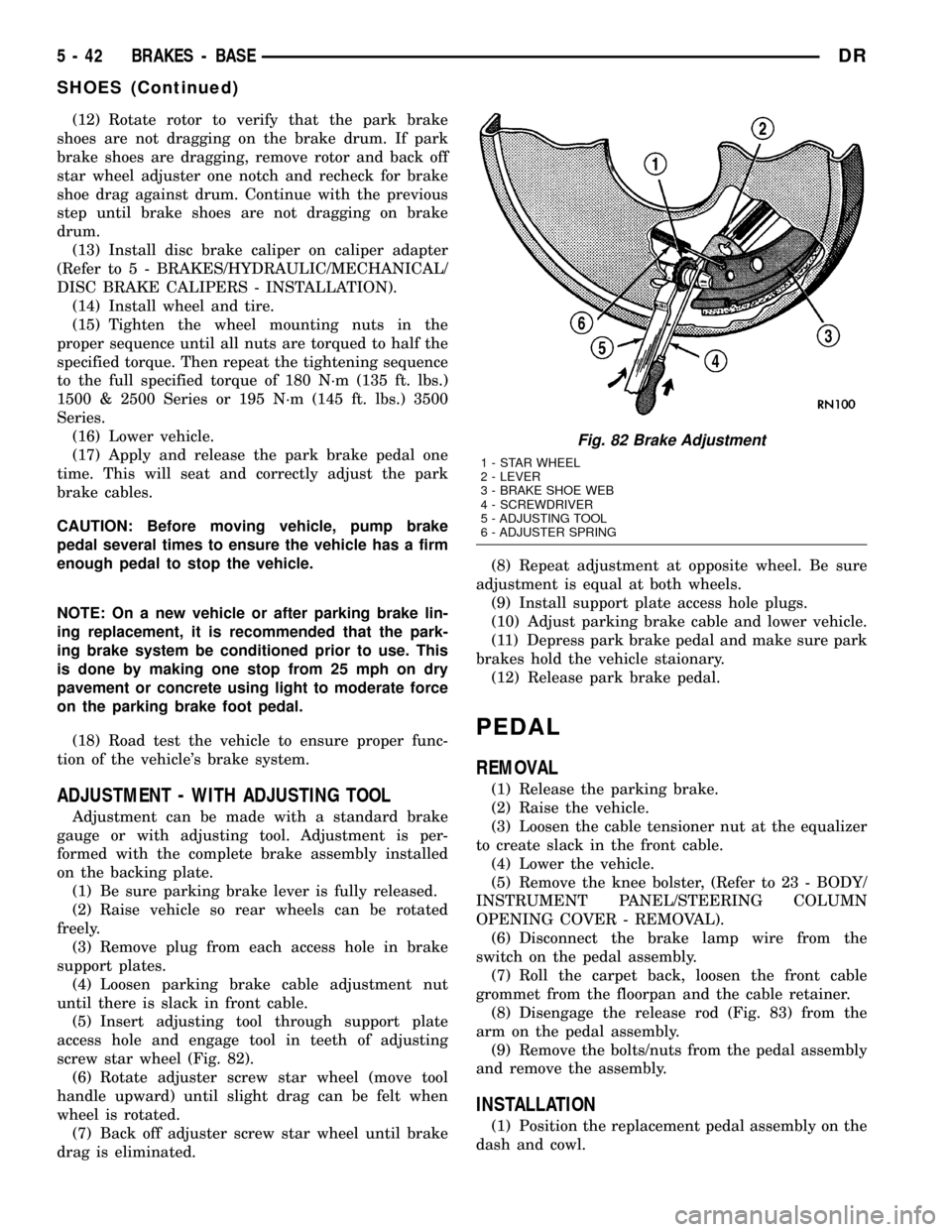

ADJUSTMENT - WITH ADJUSTING TOOL

Adjustment can be made with a standard brake

gauge or with adjusting tool. Adjustment is per-

formed with the complete brake assembly installed

on the backing plate.

(1) Be sure parking brake lever is fully released.

(2) Raise vehicle so rear wheels can be rotated

freely.

(3) Remove plug from each access hole in brake

support plates.

(4) Loosen parking brake cable adjustment nut

until there is slack in front cable.

(5) Insert adjusting tool through support plate

access hole and engage tool in teeth of adjusting

screw star wheel (Fig. 82).

(6) Rotate adjuster screw star wheel (move tool

handle upward) until slight drag can be felt when

wheel is rotated.

(7) Back off adjuster screw star wheel until brake

drag is eliminated.(8) Repeat adjustment at opposite wheel. Be sure

adjustment is equal at both wheels.

(9) Install support plate access hole plugs.

(10) Adjust parking brake cable and lower vehicle.

(11) Depress park brake pedal and make sure park

brakes hold the vehicle staionary.

(12) Release park brake pedal.

PEDAL

REMOVAL

(1) Release the parking brake.

(2) Raise the vehicle.

(3) Loosen the cable tensioner nut at the equalizer

to create slack in the front cable.

(4) Lower the vehicle.

(5) Remove the knee bolster, (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - REMOVAL).

(6) Disconnect the brake lamp wire from the

switch on the pedal assembly.

(7) Roll the carpet back, loosen the front cable

grommet from the floorpan and the cable retainer.

(8) Disengage the release rod (Fig. 83) from the

arm on the pedal assembly.

(9) Remove the bolts/nuts from the pedal assembly

and remove the assembly.

INSTALLATION

(1) Position the replacement pedal assembly on the

dash and cowl.

Fig. 82 Brake Adjustment

1 - STAR WHEEL

2 - LEVER

3 - BRAKE SHOE WEB

4 - SCREWDRIVER

5 - ADJUSTING TOOL

6 - ADJUSTER SPRING

5 - 42 BRAKES - BASEDR

SHOES (Continued)

Page 294 of 2627

BRAKES - ABS

TABLE OF CONTENTS

page page

BRAKES - ABS

DESCRIPTION.........................45

OPERATION...........................45

STANDARD PROCEDURE - ABS BRAKE

BLEEDING...........................46

SPECIFICATIONS

TORQUE CHART......................46

FRONT WHEEL SPEED SENSOR

DESCRIPTION.........................47

OPERATION...........................47

REMOVAL.............................48

INSTALLATION.........................48

REAR WHEEL SPEED SENSOR

DIAGNOSIS AND TESTING - REAR WHEEL

ANTILOCK...........................48

REMOVAL.............................48

INSTALLATION.........................48TONE WHEEL

DIAGNOSIS AND TESTING - REAR WHEEL

SPEED SENSOR......................49

HYDRAULIC/MECHANICAL

DESCRIPTION - ELECTRONIC VARIABLE

BRAKE PROPORTIONING...............49

OPERATION - ELECTRONIC VARIABLE

BRAKE PROPORTIONING...............49

HCU (HYDRAULIC CONTROL UNIT)

DESCRIPTION.........................49

OPERATION...........................49

REMOVAL.............................50

INSTALLATION.........................50

R WA L VA LV E

DESCRIPTION.........................50

OPERATION...........................50

REMOVAL.............................51

INSTALLATION.........................51

BRAKES - ABS

DESCRIPTION

The antilock brake system (ABS) is an electroni-

cally operated, three channel brake control system.

The vehicle has Electronic Variable Brake Propor-

tioning (EVBP) designed into the system which elim-

inates the combination/proportioning valve.

The system is designed to prevent wheel lockup

and maintain steering control during braking. Pre-

venting lockup is accomplished by modulating fluid

pressure to the wheel brake units.

The hydraulic system is a three channel design.

The front wheel brakes are controlled individually

and the rear wheel brakes in tandem. The ABS elec-

trical system is separate from other electrical circuits

in the vehicle. A specially programmed controller

antilock brake unit operates the system components.

ABS system major components include:

²Controller Antilock Brakes (CAB)

²Hydraulic Control Unit (HCU)

²Wheel Speed Sensors (WSS)

²ABS Warning Light

OPERATION

Battery voltage is supplied to the CAB. The CAB

performs a system initialization procedure at start

up. A check of the ABS motor is performed at 15miles per hour. Initialization consists of a static and

dynamic self check of system electrical components.

The static and dynamic checks occurs at ignition

start up. During the dynamic check, the CAB briefly

cycles solenoids to verify operation. An audible noise

may be heard during this self check. This noise

should be considered normal. The ABS motor and

pump are then checked at a speed of 15 mile per

hour.

If an ABS component exhibits a fault during ini-

tialization, the CAB illuminates the amber warning

light and registers a fault code in the microprocessor

memory.

The CAB monitors wheel speed sensor inputs con-

tinuously while the vehicle is in motion. However,

the CAB will not activate any ABS components as

long as sensor inputs indicate normal braking.

During normal braking, the master cylinder, power

booster and wheel brake units all function as they

would in a vehicle without ABS. The HCU compo-

nents are not activated.

The purpose of the antilock system is to prevent

wheel lockup. Preventing lockup helps maintain vehi-

cle braking action and steering control.

The antilock CAB activates the system whenever

sensor signals indicate periods of wheel slip.

The antilock system prevents lockup during a

wheel slip condition by modulating fluid apply pres-

sure to the wheel brake units.

DRBRAKES - ABS 5 - 45

Page 295 of 2627

Brake fluid apply pressure is modulated according

to wheel speed, degree of slip and rate of decelera-

tion. Sensors at each front wheel convert wheel speed

into electrical signals. These signals are transmitted

to the CAB for processing and determination of

wheel slip and deceleration rate.

The ABS system has three fluid pressure control

channels. The front brakes are controlled separately

and the rear brakes in tandem. A speed sensor input

signal indicating a wheel slip condition activates the

CAB antilock program.

There are Two solenoid valves (Isolation and Dump

valve) which are used in each antilock control chan-

nel. The valves are all located within the HCU valve

body and work in pairs to either increase, hold, or

decrease apply pressure as needed in the individual

control channels.

During an ABS stop the ISO valve is energized

which acts to prevent further pressure build-up to

the calipers. Then the Dump valve dumps off pres-

sure until the wheel unlocks. This will continue until

the wheels quit slipping altogether.STANDARD PROCEDURE - ABS BRAKE

BLEEDING

ABS system bleeding requires conventional bleed-

ing methods plus use of the DRB scan tool. The pro-

cedure involves performing a base brake bleeding,

followed by use of the scan tool to cycle and bleed the

HCU pump and solenoids. A second base brake bleed-

ing procedure is then required to remove any air

remaining in the system.

(1) Perform base brake bleeding,(Refer to 5 -

BRAKES - STANDARD PROCEDURE) OR (Refer to

5 - BRAKES - STANDARD PROCEDURE).

(2) Connect scan tool to the Data Link Connector.

(3) Select ANTILOCK BRAKES, followed by MIS-

CELLANEOUS, then ABS BRAKES. Follow the

instructions displayed. When scan tool displays TEST

COMPLETE, disconnect scan tool and proceed.

(4) Perform base brake bleeding a second time,(Re-

fer to 5 - BRAKES - STANDARD PROCEDURE) OR

(Refer to 5 - BRAKES - STANDARD PROCEDURE).

(5) Top off master cylinder fluid level and verify

proper brake operation before moving vehicle.

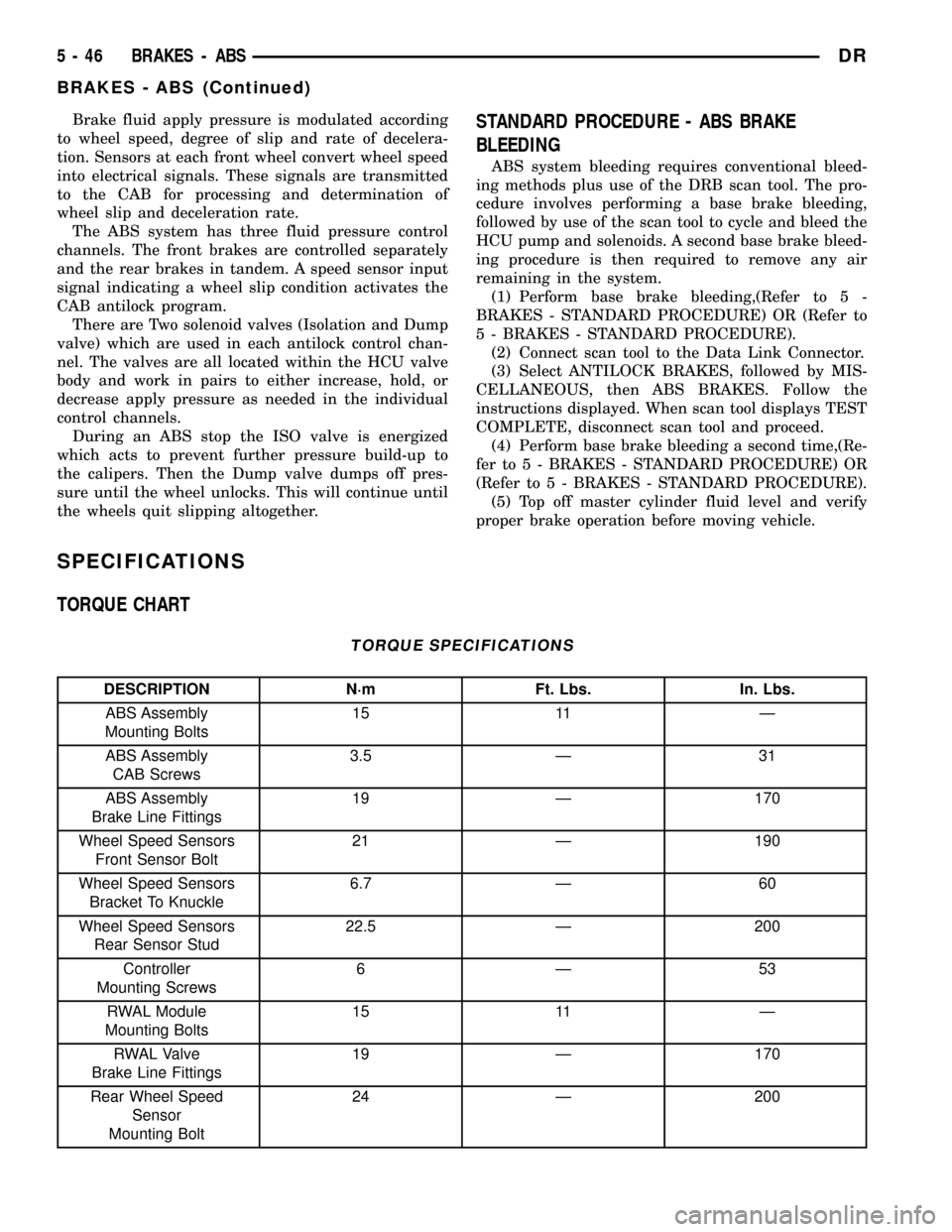

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

ABS Assembly

Mounting Bolts15 11 Ð

ABS Assembly

CAB Screws3.5 Ð 31

ABS Assembly

Brake Line Fittings19 Ð 170

Wheel Speed Sensors

Front Sensor Bolt21 Ð 190

Wheel Speed Sensors

Bracket To Knuckle6.7 Ð 60

Wheel Speed Sensors

Rear Sensor Stud22.5 Ð 200

Controller

Mounting Screws6Ð53

RWAL Module

Mounting Bolts15 11 Ð

RWAL Valve

Brake Line Fittings19 Ð 170

Rear Wheel Speed

Sensor

Mounting Bolt24 Ð 200

5 - 46 BRAKES - ABSDR

BRAKES - ABS (Continued)