Rear differential DODGE RAM 1500 1998 2.G Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 247 of 2627

(15) Rotate pinion several times then verify pinion

rotating torque again.

(16) Position the ring gear on differential case and

start twonewring gear bolts.

(17) Install the rest of thenewring gear bolts and

tighten them alternately to seat the ring gear.

(18) Torque ring gear bolts to 237 N´m (175 ft.

lbs.).

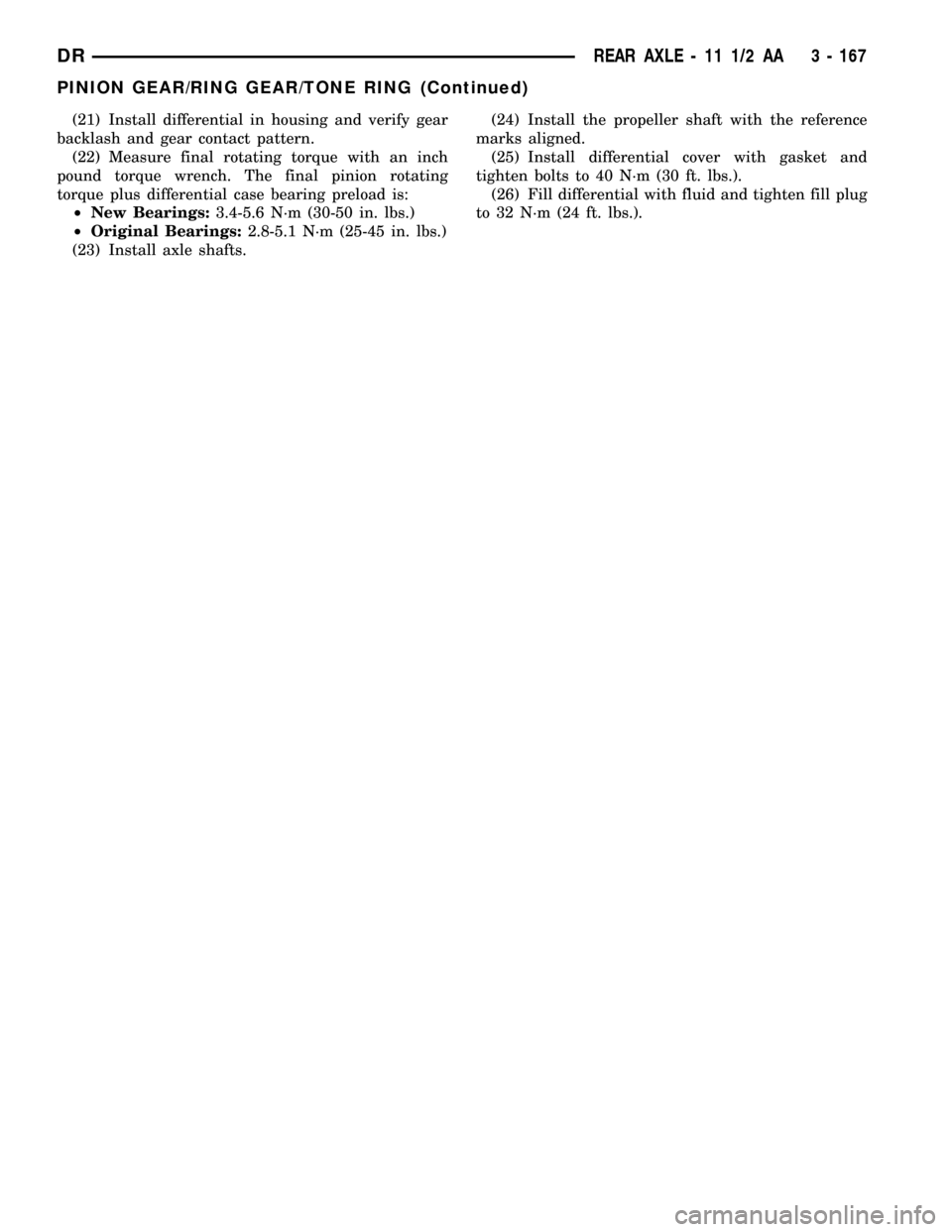

(19) If exciter ring was removed, position differen-

tial assembly on differential Plug 8965 (Fig. 64) and

place exciter ring on the differential case.

(20) Install the exciter ring on the differential case

evenly with a hammer and brass punch (Fig. 65).Drive the ring down until it is seated against the

ring gear.

CAUTION: Do not damage exciter ring teeth during

installation.

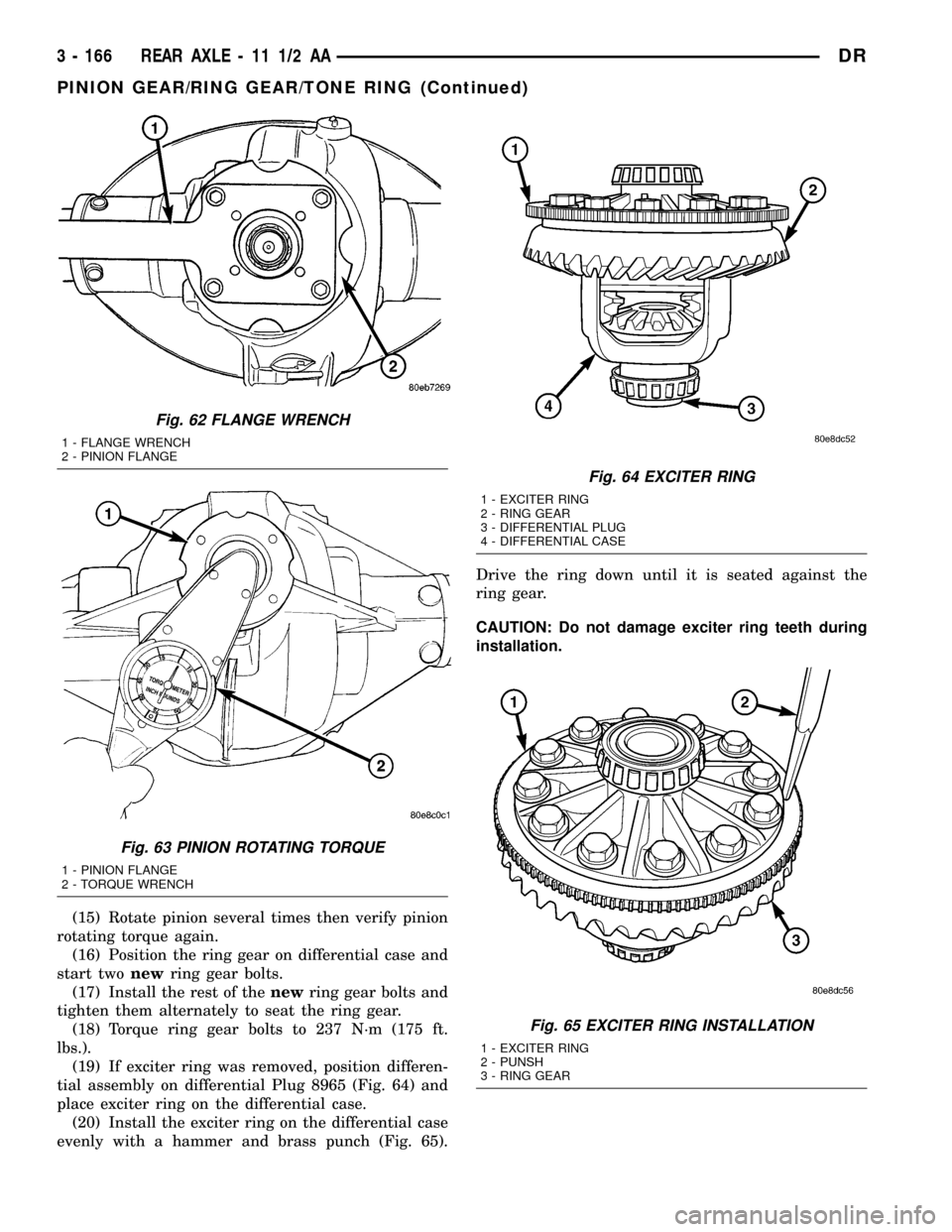

Fig. 62 FLANGE WRENCH

1 - FLANGE WRENCH

2 - PINION FLANGE

Fig. 63 PINION ROTATING TORQUE

1 - PINION FLANGE

2 - TORQUE WRENCH

Fig. 64 EXCITER RING

1 - EXCITER RING

2 - RING GEAR

3 - DIFFERENTIAL PLUG

4 - DIFFERENTIAL CASE

Fig. 65 EXCITER RING INSTALLATION

1 - EXCITER RING

2 - PUNSH

3 - RING GEAR

3 - 166 REAR AXLE - 11 1/2 AADR

PINION GEAR/RING GEAR/TONE RING (Continued)

Page 248 of 2627

(21) Install differential in housing and verify gear

backlash and gear contact pattern.

(22) Measure final rotating torque with an inch

pound torque wrench. The final pinion rotating

torque plus differential case bearing preload is:

²New Bearings:3.4-5.6 N´m (30-50 in. lbs.)

²Original Bearings:2.8-5.1 N´m (25-45 in. lbs.)

(23) Install axle shafts.(24) Install the propeller shaft with the reference

marks aligned.

(25) Install differential cover with gasket and

tighten bolts to 40 N´m (30 ft. lbs.).

(26) Fill differential with fluid and tighten fill plug

to 32 N´m (24 ft. lbs.).

DRREAR AXLE - 11 1/2 AA 3 - 167

PINION GEAR/RING GEAR/TONE RING (Continued)

Page 283 of 2627

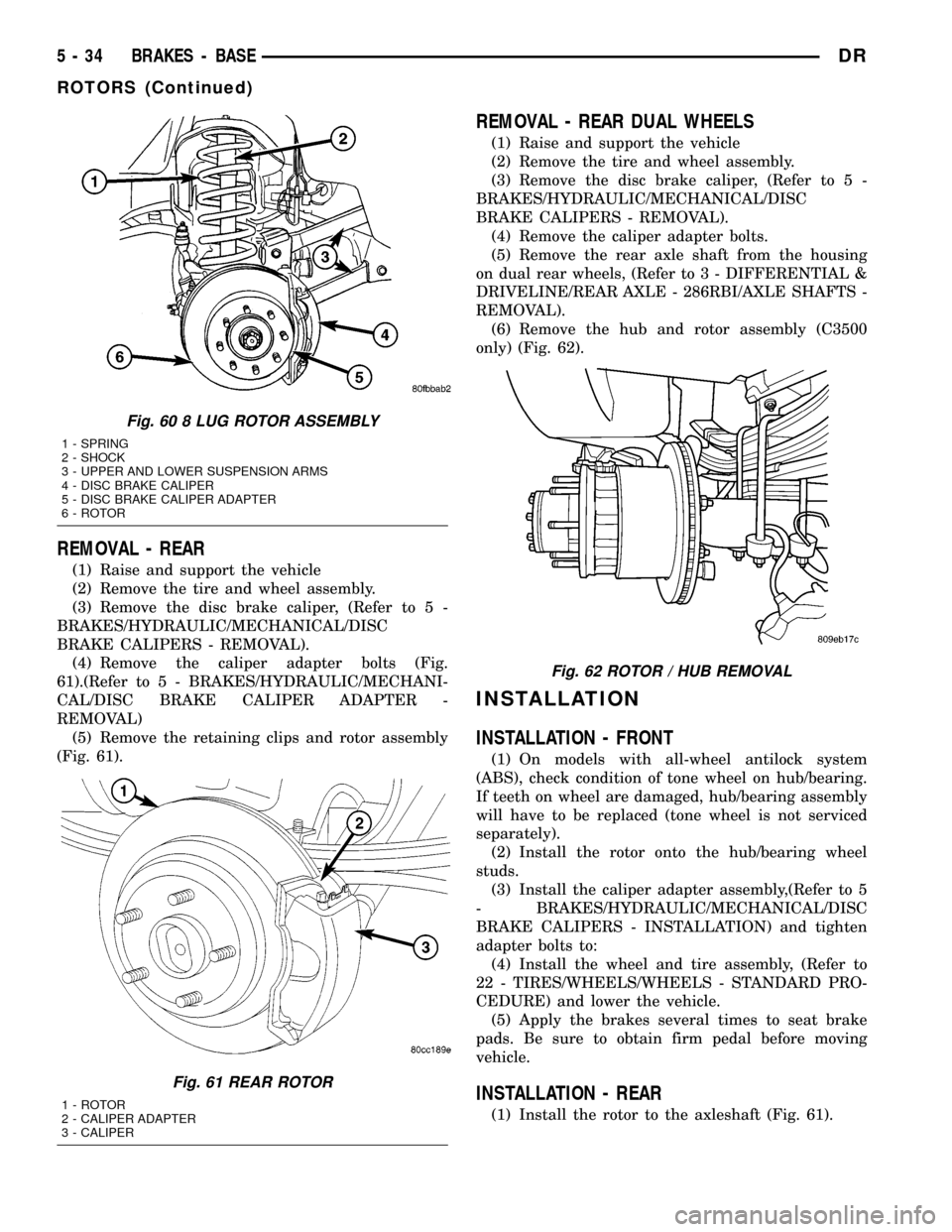

REMOVAL - REAR

(1) Raise and support the vehicle

(2) Remove the tire and wheel assembly.

(3) Remove the disc brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(4) Remove the caliper adapter bolts (Fig.

61).(Refer to 5 - BRAKES/HYDRAULIC/MECHANI-

CAL/DISC BRAKE CALIPER ADAPTER -

REMOVAL)

(5) Remove the retaining clips and rotor assembly

(Fig. 61).

REMOVAL - REAR DUAL WHEELS

(1) Raise and support the vehicle

(2) Remove the tire and wheel assembly.

(3) Remove the disc brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(4) Remove the caliper adapter bolts.

(5) Remove the rear axle shaft from the housing

on dual rear wheels, (Refer to 3 - DIFFERENTIAL &

DRIVELINE/REAR AXLE - 286RBI/AXLE SHAFTS -

REMOVAL).

(6) Remove the hub and rotor assembly (C3500

only) (Fig. 62).

INSTALLATION

INSTALLATION - FRONT

(1) On models with all-wheel antilock system

(ABS), check condition of tone wheel on hub/bearing.

If teeth on wheel are damaged, hub/bearing assembly

will have to be replaced (tone wheel is not serviced

separately).

(2) Install the rotor onto the hub/bearing wheel

studs.

(3) Install the caliper adapter assembly,(Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION) and tighten

adapter bolts to:

(4) Install the wheel and tire assembly, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE) and lower the vehicle.

(5) Apply the brakes several times to seat brake

pads. Be sure to obtain firm pedal before moving

vehicle.

INSTALLATION - REAR

(1) Install the rotor to the axleshaft (Fig. 61).

Fig. 60 8 LUG ROTOR ASSEMBLY

1 - SPRING

2 - SHOCK

3 - UPPER AND LOWER SUSPENSION ARMS

4 - DISC BRAKE CALIPER

5 - DISC BRAKE CALIPER ADAPTER

6 - ROTOR

Fig. 61 REAR ROTOR

1 - ROTOR

2 - CALIPER ADAPTER

3 - CALIPER

Fig. 62 ROTOR / HUB REMOVAL

5 - 34 BRAKES - BASEDR

ROTORS (Continued)

Page 284 of 2627

(2) Install the caliper adapter (Fig. 61) (Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - INSTALLATION).

(3) Install the caliper adapter bolts (Fig. 61) and

tighten the mounting bolts to 135 N´m (100 ft.lbs).

(4) Install the disc brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION).

(5) Install the tire and wheel assembly (Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(6) Lower the vehicle.

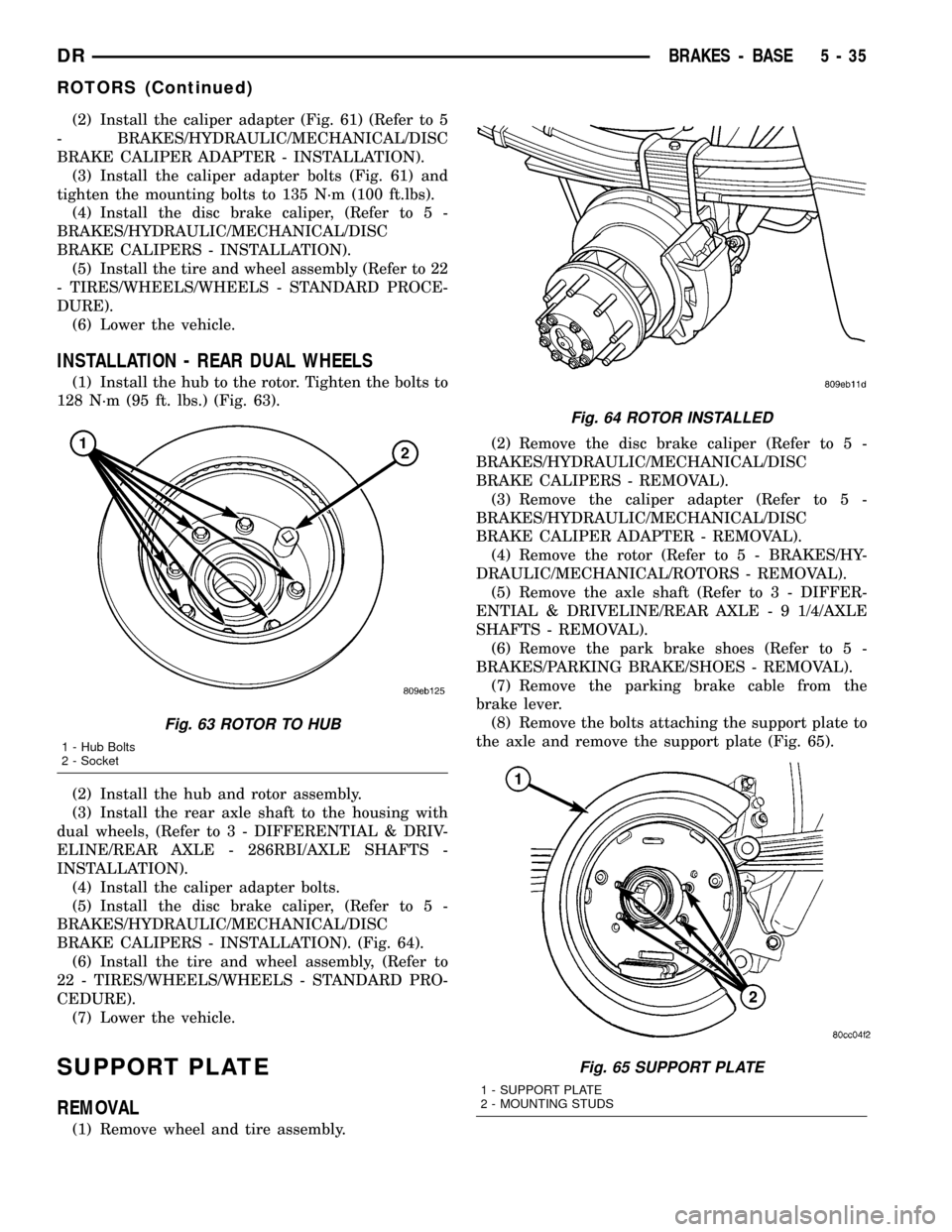

INSTALLATION - REAR DUAL WHEELS

(1) Install the hub to the rotor. Tighten the bolts to

128 N´m (95 ft. lbs.) (Fig. 63).

(2) Install the hub and rotor assembly.

(3) Install the rear axle shaft to the housing with

dual wheels, (Refer to 3 - DIFFERENTIAL & DRIV-

ELINE/REAR AXLE - 286RBI/AXLE SHAFTS -

INSTALLATION).

(4) Install the caliper adapter bolts.

(5) Install the disc brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION). (Fig. 64).

(6) Install the tire and wheel assembly, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

(7) Lower the vehicle.

SUPPORT PLATE

REMOVAL

(1) Remove wheel and tire assembly.(2) Remove the disc brake caliper (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(3) Remove the caliper adapter (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - REMOVAL).

(4) Remove the rotor (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ROTORS - REMOVAL).

(5) Remove the axle shaft (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/REAR AXLE - 9 1/4/AXLE

SHAFTS - REMOVAL).

(6) Remove the park brake shoes (Refer to 5 -

BRAKES/PARKING BRAKE/SHOES - REMOVAL).

(7) Remove the parking brake cable from the

brake lever.

(8) Remove the bolts attaching the support plate to

the axle and remove the support plate (Fig. 65).

Fig. 63 ROTOR TO HUB

1 - Hub Bolts

2 - Socket

Fig. 64 ROTOR INSTALLED

Fig. 65 SUPPORT PLATE

1 - SUPPORT PLATE

2 - MOUNTING STUDS

DRBRAKES - BASE 5 - 35

ROTORS (Continued)

Page 288 of 2627

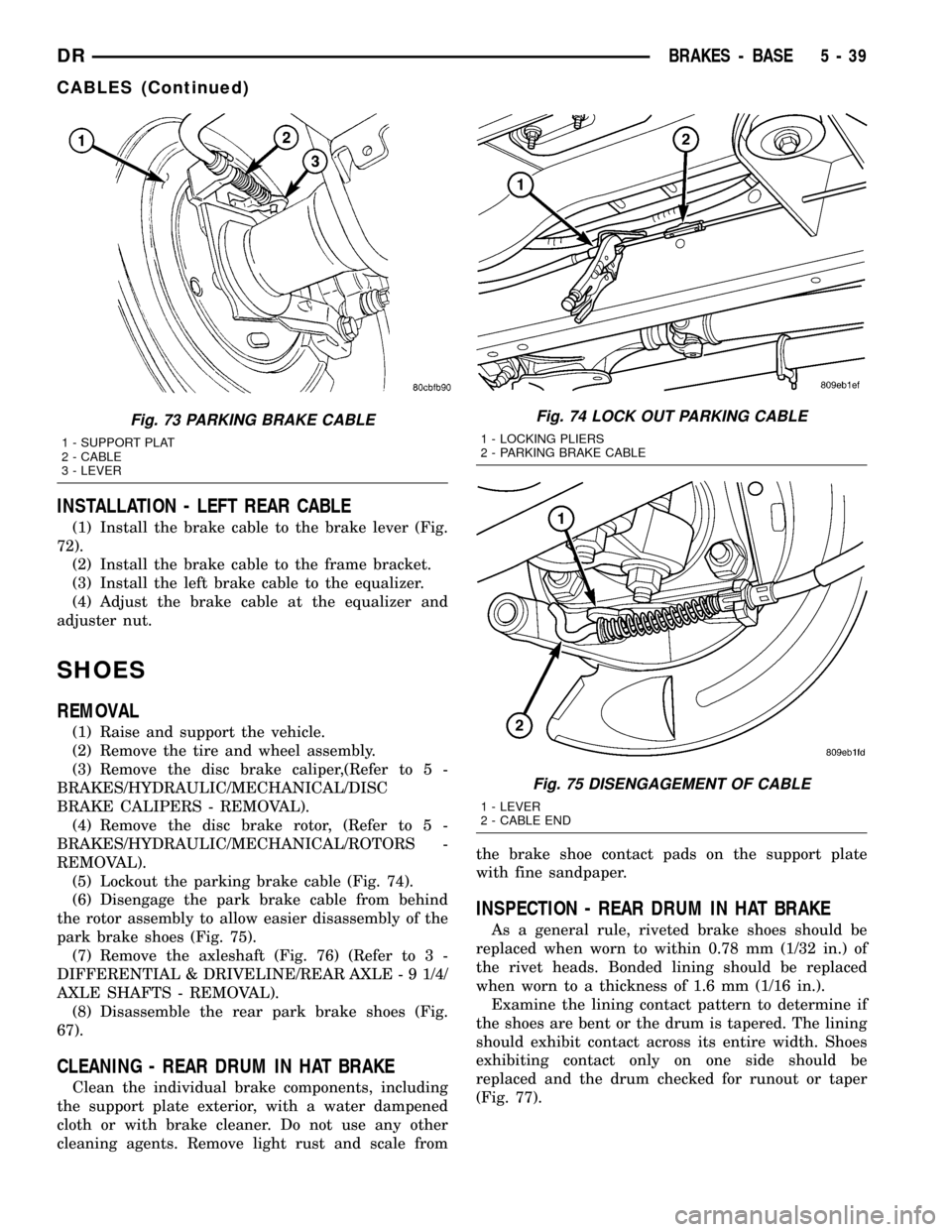

INSTALLATION - LEFT REAR CABLE

(1) Install the brake cable to the brake lever (Fig.

72).

(2) Install the brake cable to the frame bracket.

(3) Install the left brake cable to the equalizer.

(4) Adjust the brake cable at the equalizer and

adjuster nut.

SHOES

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the tire and wheel assembly.

(3) Remove the disc brake caliper,(Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(4) Remove the disc brake rotor, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

REMOVAL).

(5) Lockout the parking brake cable (Fig. 74).

(6) Disengage the park brake cable from behind

the rotor assembly to allow easier disassembly of the

park brake shoes (Fig. 75).

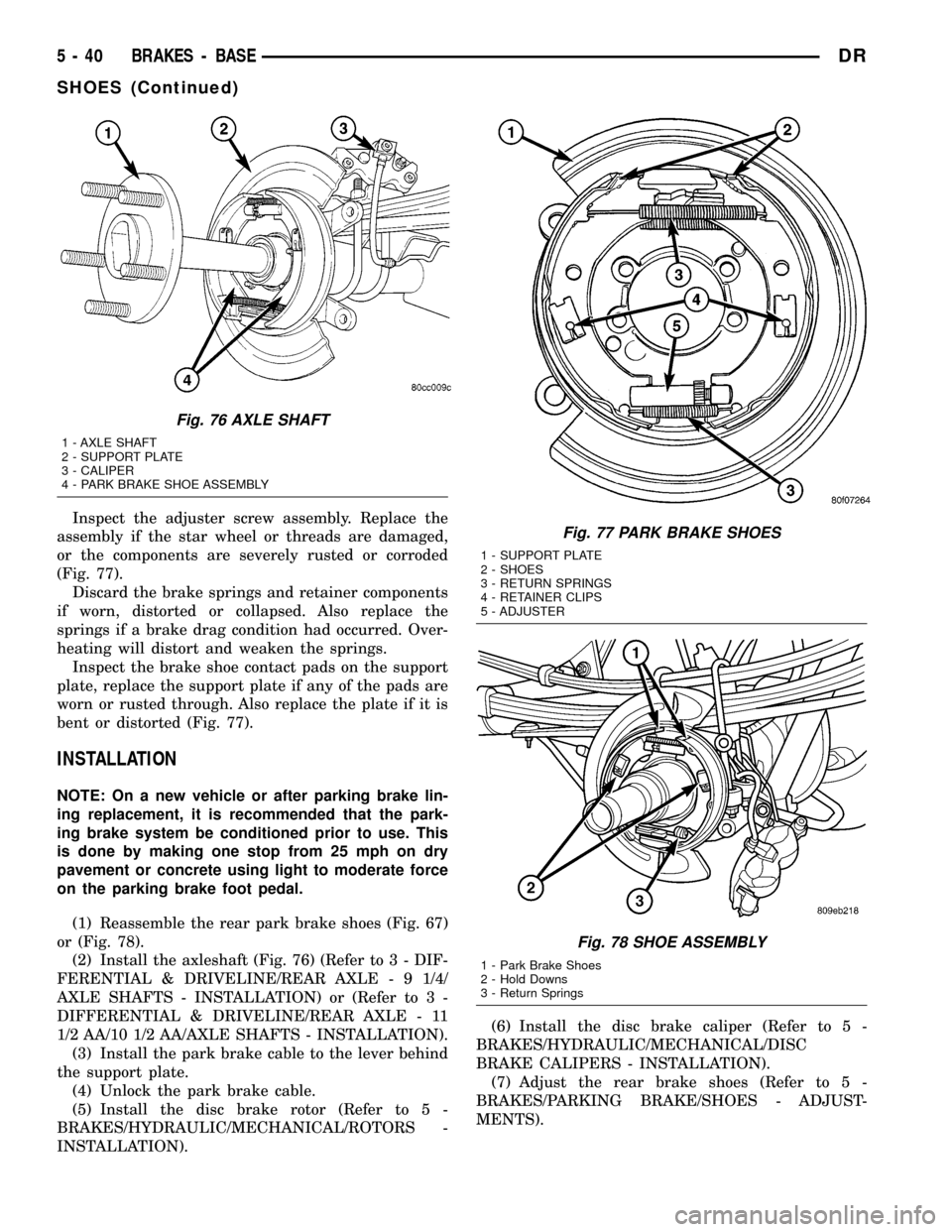

(7) Remove the axleshaft (Fig. 76) (Refer to 3 -

DIFFERENTIAL & DRIVELINE/REAR AXLE - 9 1/4/

AXLE SHAFTS - REMOVAL).

(8) Disassemble the rear park brake shoes (Fig.

67).

CLEANING - REAR DRUM IN HAT BRAKE

Clean the individual brake components, including

the support plate exterior, with a water dampened

cloth or with brake cleaner. Do not use any other

cleaning agents. Remove light rust and scale fromthe brake shoe contact pads on the support plate

with fine sandpaper.

INSPECTION - REAR DRUM IN HAT BRAKE

As a general rule, riveted brake shoes should be

replaced when worn to within 0.78 mm (1/32 in.) of

the rivet heads. Bonded lining should be replaced

when worn to a thickness of 1.6 mm (1/16 in.).

Examine the lining contact pattern to determine if

the shoes are bent or the drum is tapered. The lining

should exhibit contact across its entire width. Shoes

exhibiting contact only on one side should be

replaced and the drum checked for runout or taper

(Fig. 77).

Fig. 73 PARKING BRAKE CABLE

1 - SUPPORT PLAT

2 - CABLE

3 - LEVER

Fig. 74 LOCK OUT PARKING CABLE

1 - LOCKING PLIERS

2 - PARKING BRAKE CABLE

Fig. 75 DISENGAGEMENT OF CABLE

1 - LEVER

2 - CABLE END

DRBRAKES - BASE 5 - 39

CABLES (Continued)

Page 289 of 2627

Inspect the adjuster screw assembly. Replace the

assembly if the star wheel or threads are damaged,

or the components are severely rusted or corroded

(Fig. 77).

Discard the brake springs and retainer components

if worn, distorted or collapsed. Also replace the

springs if a brake drag condition had occurred. Over-

heating will distort and weaken the springs.

Inspect the brake shoe contact pads on the support

plate, replace the support plate if any of the pads are

worn or rusted through. Also replace the plate if it is

bent or distorted (Fig. 77).

INSTALLATION

NOTE: On a new vehicle or after parking brake lin-

ing replacement, it is recommended that the park-

ing brake system be conditioned prior to use. This

is done by making one stop from 25 mph on dry

pavement or concrete using light to moderate force

on the parking brake foot pedal.

(1) Reassemble the rear park brake shoes (Fig. 67)

or (Fig. 78).

(2) Install the axleshaft (Fig. 76) (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/REAR AXLE - 9 1/4/

AXLE SHAFTS - INSTALLATION) or (Refer to 3 -

DIFFERENTIAL & DRIVELINE/REAR AXLE - 11

1/2 AA/10 1/2 AA/AXLE SHAFTS - INSTALLATION).

(3) Install the park brake cable to the lever behind

the support plate.

(4) Unlock the park brake cable.

(5) Install the disc brake rotor (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

INSTALLATION).(6) Install the disc brake caliper (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION).

(7) Adjust the rear brake shoes (Refer to 5 -

BRAKES/PARKING BRAKE/SHOES - ADJUST-

MENTS).

Fig. 76 AXLE SHAFT

1 - AXLE SHAFT

2 - SUPPORT PLATE

3 - CALIPER

4 - PARK BRAKE SHOE ASSEMBLY

Fig. 77 PARK BRAKE SHOES

1 - SUPPORT PLATE

2 - SHOES

3 - RETURN SPRINGS

4 - RETAINER CLIPS

5 - ADJUSTER

Fig. 78 SHOE ASSEMBLY

1 - Park Brake Shoes

2 - Hold Downs

3 - Return Springs

5 - 40 BRAKES - BASEDR

SHOES (Continued)

Page 297 of 2627

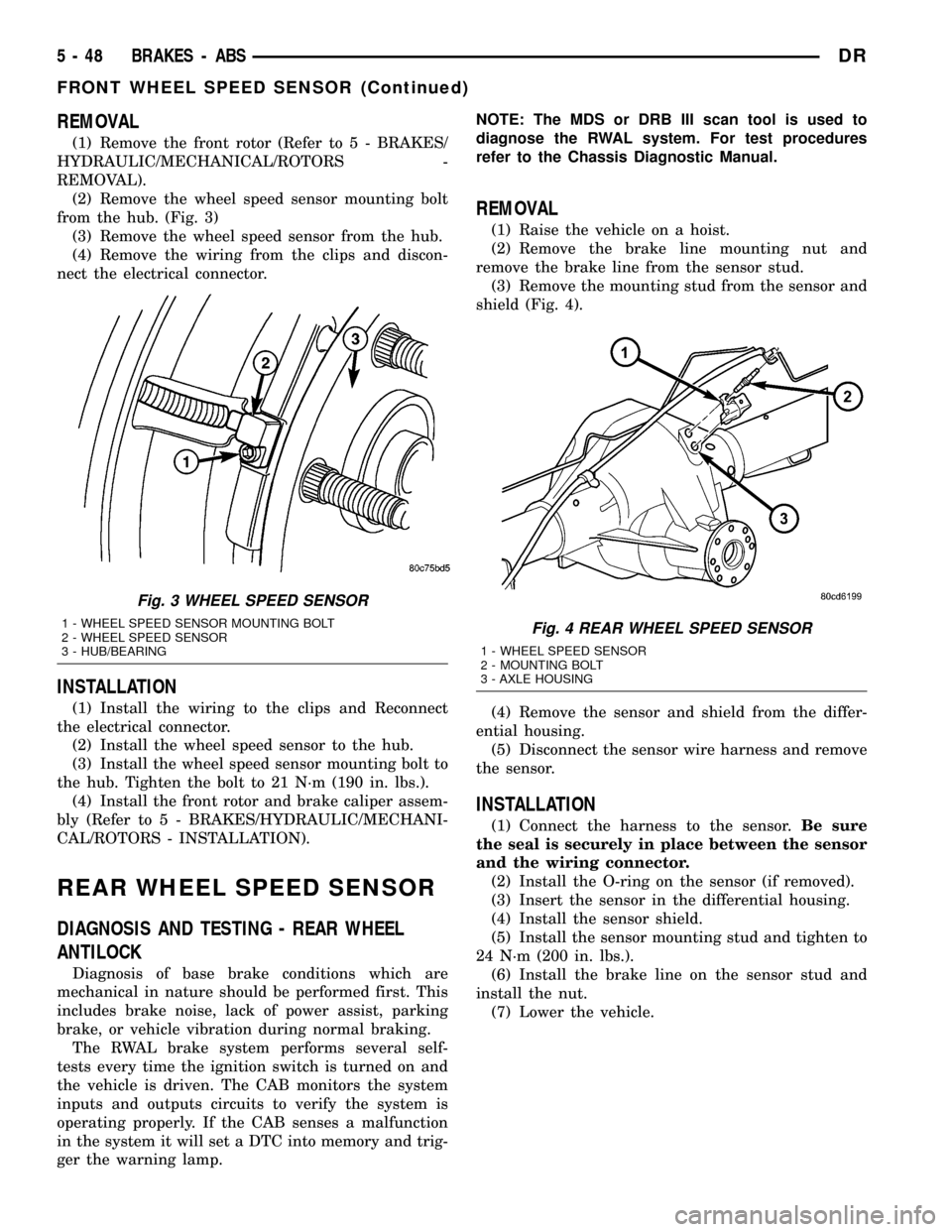

REMOVAL

(1) Remove the front rotor (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/ROTORS -

REMOVAL).

(2) Remove the wheel speed sensor mounting bolt

from the hub. (Fig. 3)

(3) Remove the wheel speed sensor from the hub.

(4) Remove the wiring from the clips and discon-

nect the electrical connector.

INSTALLATION

(1) Install the wiring to the clips and Reconnect

the electrical connector.

(2) Install the wheel speed sensor to the hub.

(3) Install the wheel speed sensor mounting bolt to

the hub. Tighten the bolt to 21 N´m (190 in. lbs.).

(4) Install the front rotor and brake caliper assem-

bly (Refer to 5 - BRAKES/HYDRAULIC/MECHANI-

CAL/ROTORS - INSTALLATION).

REAR WHEEL SPEED SENSOR

DIAGNOSIS AND TESTING - REAR WHEEL

ANTILOCK

Diagnosis of base brake conditions which are

mechanical in nature should be performed first. This

includes brake noise, lack of power assist, parking

brake, or vehicle vibration during normal braking.

The RWAL brake system performs several self-

tests every time the ignition switch is turned on and

the vehicle is driven. The CAB monitors the system

inputs and outputs circuits to verify the system is

operating properly. If the CAB senses a malfunction

in the system it will set a DTC into memory and trig-

ger the warning lamp.NOTE: The MDS or DRB III scan tool is used to

diagnose the RWAL system. For test procedures

refer to the Chassis Diagnostic Manual.

REMOVAL

(1) Raise the vehicle on a hoist.

(2) Remove the brake line mounting nut and

remove the brake line from the sensor stud.

(3) Remove the mounting stud from the sensor and

shield (Fig. 4).

(4) Remove the sensor and shield from the differ-

ential housing.

(5) Disconnect the sensor wire harness and remove

the sensor.

INSTALLATION

(1) Connect the harness to the sensor.Be sure

the seal is securely in place between the sensor

and the wiring connector.

(2) Install the O-ring on the sensor (if removed).

(3) Insert the sensor in the differential housing.

(4) Install the sensor shield.

(5) Install the sensor mounting stud and tighten to

24 N´m (200 in. lbs.).

(6) Install the brake line on the sensor stud and

install the nut.

(7) Lower the vehicle.

Fig. 3 WHEEL SPEED SENSOR

1 - WHEEL SPEED SENSOR MOUNTING BOLT

2 - WHEEL SPEED SENSOR

3 - HUB/BEARINGFig. 4 REAR WHEEL SPEED SENSOR

1 - WHEEL SPEED SENSOR

2 - MOUNTING BOLT

3 - AXLE HOUSING

5 - 48 BRAKES - ABSDR

FRONT WHEEL SPEED SENSOR (Continued)

Page 1878 of 2627

(13) Install bolts attaching converter housing to

engine.

(14) Install rear support.

(15) Install the rear transmission crossmember.

(16) Lower transmission onto crossmember and

install bolts attaching transmission mount to cross-

member.

(17) Remove engine support fixture.

(18) Install the transfer case, if equipped.

(19) Install crankshaft position sensor. (Refer to 14

- FUEL SYSTEM/FUEL INJECTION/CRANKSHAFT

POSITION SENSOR - INSTALLATION)

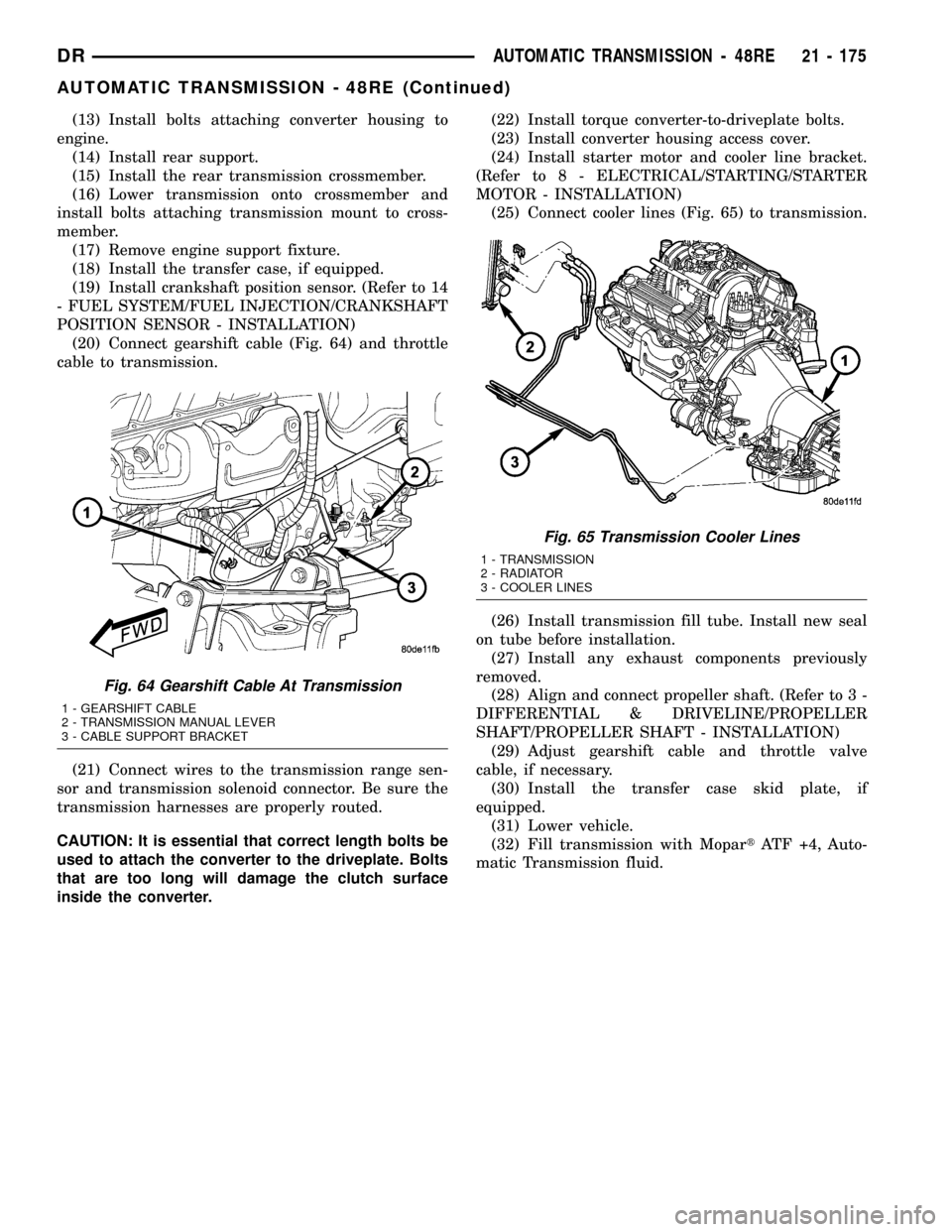

(20) Connect gearshift cable (Fig. 64) and throttle

cable to transmission.

(21) Connect wires to the transmission range sen-

sor and transmission solenoid connector. Be sure the

transmission harnesses are properly routed.

CAUTION: It is essential that correct length bolts be

used to attach the converter to the driveplate. Bolts

that are too long will damage the clutch surface

inside the converter.(22) Install torque converter-to-driveplate bolts.

(23) Install converter housing access cover.

(24) Install starter motor and cooler line bracket.

(Refer to 8 - ELECTRICAL/STARTING/STARTER

MOTOR - INSTALLATION)

(25) Connect cooler lines (Fig. 65) to transmission.

(26) Install transmission fill tube. Install new seal

on tube before installation.

(27) Install any exhaust components previously

removed.

(28) Align and connect propeller shaft. (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - INSTALLATION)

(29) Adjust gearshift cable and throttle valve

cable, if necessary.

(30) Install the transfer case skid plate, if

equipped.

(31) Lower vehicle.

(32) Fill transmission with MopartATF +4, Auto-

matic Transmission fluid.

Fig. 64 Gearshift Cable At Transmission

1 - GEARSHIFT CABLE

2 - TRANSMISSION MANUAL LEVER

3 - CABLE SUPPORT BRACKET

Fig. 65 Transmission Cooler Lines

1 - TRANSMISSION

2 - RADIATOR

3 - COOLER LINES

DRAUTOMATIC TRANSMISSION - 48RE 21 - 175

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 1921 of 2627

OVERDRIVE UNIT

REMOVAL

(1) Shift transmission into PARK.

(2) Raise vehicle.

(3) Remove transfer case, if equipped.

(4) Mark propeller shaft universal joint(s) and axle

pinion yoke, or the companion flange and flange

yoke, for alignment reference at installation, if neces-

sary.

(5) Disconnect and remove the rear propeller shaft,

if necessary. (Refer to 3 - DIFFERENTIAL & DRIV-

ELINE/PROPELLER SHAFT/PROPELLER SHAFT -

REMOVAL)

(6) Remove transmission oil pan, remove gasket,

drain oil and reinstall pan.

(7) If overdrive unit had malfunctioned, or if fluid

is contaminated, remove entire transmission. If diag-

nosis indicated overdrive problems only, remove just

the overdrive unit.

(8) Support transmission with transmission jack.

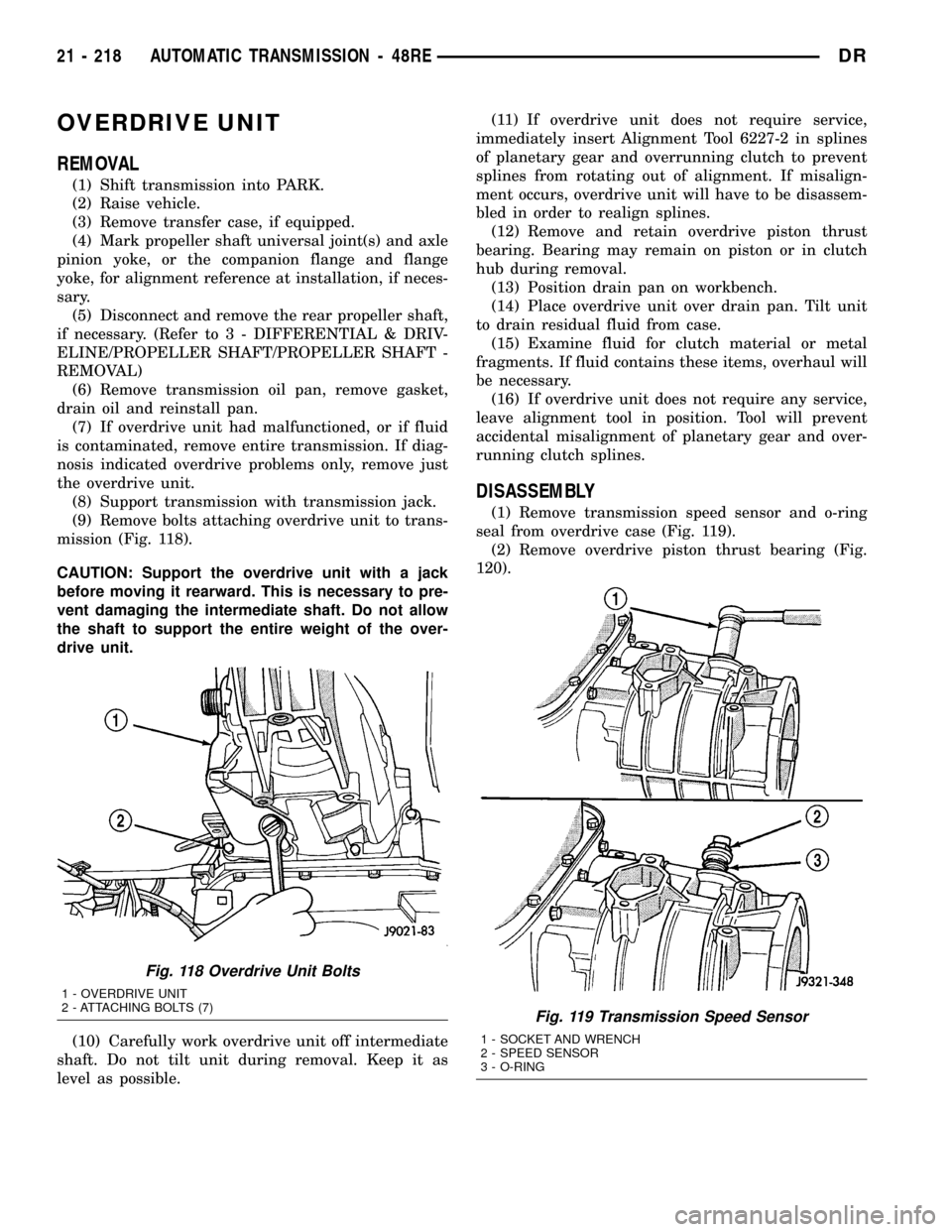

(9) Remove bolts attaching overdrive unit to trans-

mission (Fig. 118).

CAUTION: Support the overdrive unit with a jack

before moving it rearward. This is necessary to pre-

vent damaging the intermediate shaft. Do not allow

the shaft to support the entire weight of the over-

drive unit.

(10) Carefully work overdrive unit off intermediate

shaft. Do not tilt unit during removal. Keep it as

level as possible.(11) If overdrive unit does not require service,

immediately insert Alignment Tool 6227-2 in splines

of planetary gear and overrunning clutch to prevent

splines from rotating out of alignment. If misalign-

ment occurs, overdrive unit will have to be disassem-

bled in order to realign splines.

(12) Remove and retain overdrive piston thrust

bearing. Bearing may remain on piston or in clutch

hub during removal.

(13) Position drain pan on workbench.

(14) Place overdrive unit over drain pan. Tilt unit

to drain residual fluid from case.

(15) Examine fluid for clutch material or metal

fragments. If fluid contains these items, overhaul will

be necessary.

(16) If overdrive unit does not require any service,

leave alignment tool in position. Tool will prevent

accidental misalignment of planetary gear and over-

running clutch splines.

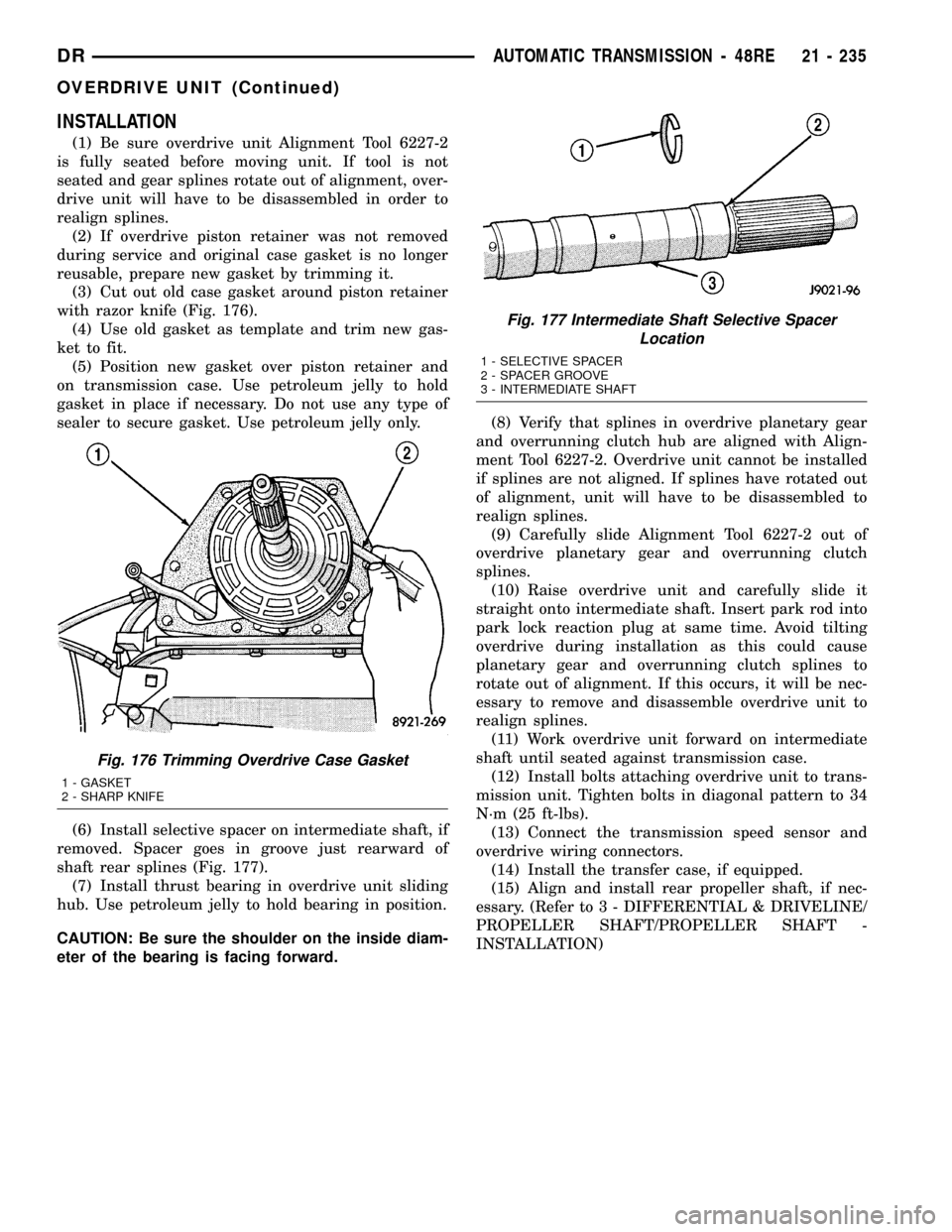

DISASSEMBLY

(1) Remove transmission speed sensor and o-ring

seal from overdrive case (Fig. 119).

(2) Remove overdrive piston thrust bearing (Fig.

120).

Fig. 118 Overdrive Unit Bolts

1 - OVERDRIVE UNIT

2 - ATTACHING BOLTS (7)

Fig. 119 Transmission Speed Sensor

1 - SOCKET AND WRENCH

2 - SPEED SENSOR

3 - O-RING

21 - 218 AUTOMATIC TRANSMISSION - 48REDR

Page 1938 of 2627

INSTALLATION

(1) Be sure overdrive unit Alignment Tool 6227-2

is fully seated before moving unit. If tool is not

seated and gear splines rotate out of alignment, over-

drive unit will have to be disassembled in order to

realign splines.

(2) If overdrive piston retainer was not removed

during service and original case gasket is no longer

reusable, prepare new gasket by trimming it.

(3) Cut out old case gasket around piston retainer

with razor knife (Fig. 176).

(4) Use old gasket as template and trim new gas-

ket to fit.

(5) Position new gasket over piston retainer and

on transmission case. Use petroleum jelly to hold

gasket in place if necessary. Do not use any type of

sealer to secure gasket. Use petroleum jelly only.

(6) Install selective spacer on intermediate shaft, if

removed. Spacer goes in groove just rearward of

shaft rear splines (Fig. 177).

(7) Install thrust bearing in overdrive unit sliding

hub. Use petroleum jelly to hold bearing in position.

CAUTION: Be sure the shoulder on the inside diam-

eter of the bearing is facing forward.(8) Verify that splines in overdrive planetary gear

and overrunning clutch hub are aligned with Align-

ment Tool 6227-2. Overdrive unit cannot be installed

if splines are not aligned. If splines have rotated out

of alignment, unit will have to be disassembled to

realign splines.

(9) Carefully slide Alignment Tool 6227-2 out of

overdrive planetary gear and overrunning clutch

splines.

(10) Raise overdrive unit and carefully slide it

straight onto intermediate shaft. Insert park rod into

park lock reaction plug at same time. Avoid tilting

overdrive during installation as this could cause

planetary gear and overrunning clutch splines to

rotate out of alignment. If this occurs, it will be nec-

essary to remove and disassemble overdrive unit to

realign splines.

(11) Work overdrive unit forward on intermediate

shaft until seated against transmission case.

(12) Install bolts attaching overdrive unit to trans-

mission unit. Tighten bolts in diagonal pattern to 34

N´m (25 ft-lbs).

(13) Connect the transmission speed sensor and

overdrive wiring connectors.

(14) Install the transfer case, if equipped.

(15) Align and install rear propeller shaft, if nec-

essary. (Refer to 3 - DIFFERENTIAL & DRIVELINE/

PROPELLER SHAFT/PROPELLER SHAFT -

INSTALLATION)

Fig. 176 Trimming Overdrive Case Gasket

1 - GASKET

2 - SHARP KNIFE

Fig. 177 Intermediate Shaft Selective Spacer

Location

1 - SELECTIVE SPACER

2 - SPACER GROOVE

3 - INTERMEDIATE SHAFT

DRAUTOMATIC TRANSMISSION - 48RE 21 - 235

OVERDRIVE UNIT (Continued)