Head bolt DODGE RAM 1500 1998 2.G Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1392 of 2627

SINGLE CAMSHAFT TIMING

NOTE: to adjust the timing on one camshaft, pre-

form the following procedure.

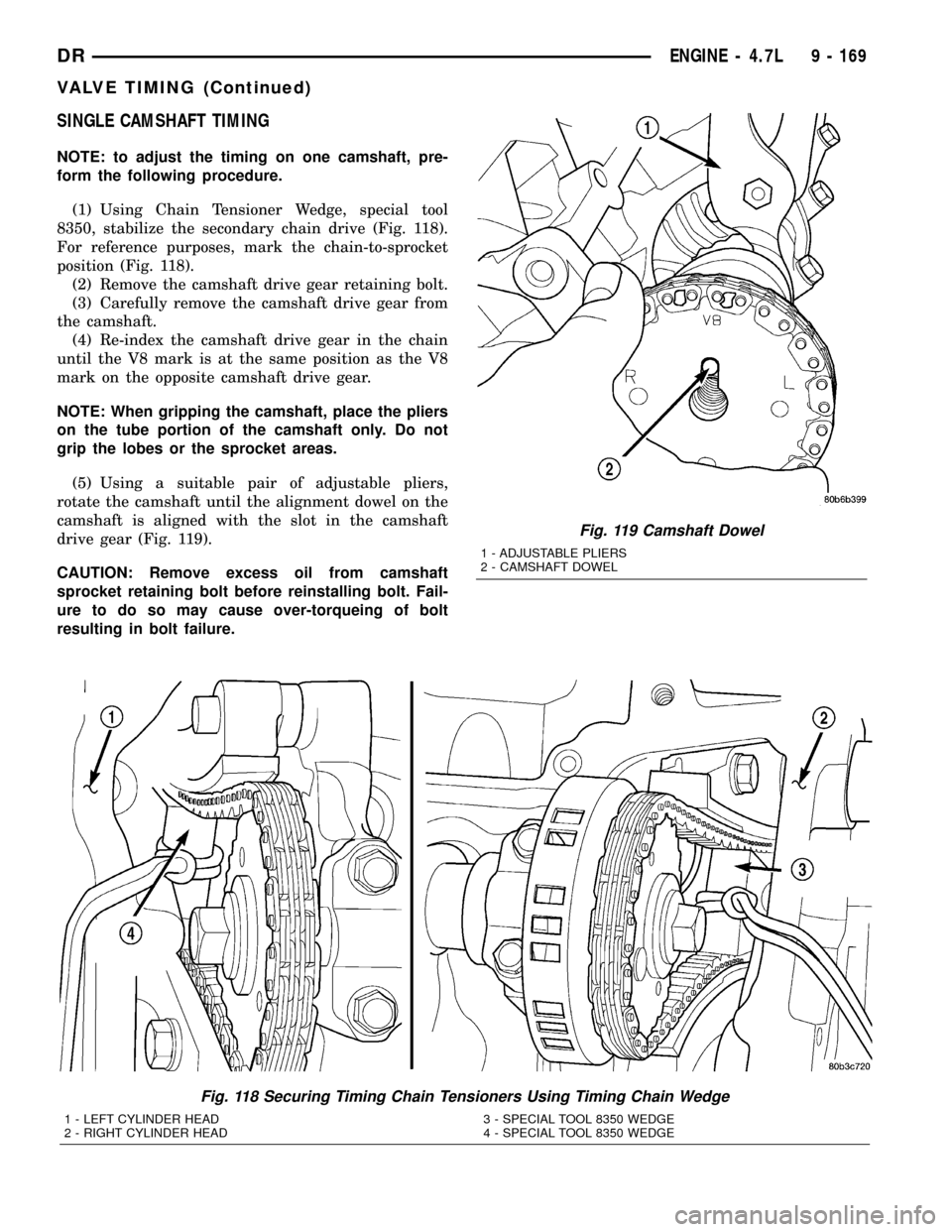

(1) Using Chain Tensioner Wedge, special tool

8350, stabilize the secondary chain drive (Fig. 118).

For reference purposes, mark the chain-to-sprocket

position (Fig. 118).

(2) Remove the camshaft drive gear retaining bolt.

(3) Carefully remove the camshaft drive gear from

the camshaft.

(4) Re-index the camshaft drive gear in the chain

until the V8 mark is at the same position as the V8

mark on the opposite camshaft drive gear.

NOTE: When gripping the camshaft, place the pliers

on the tube portion of the camshaft only. Do not

grip the lobes or the sprocket areas.

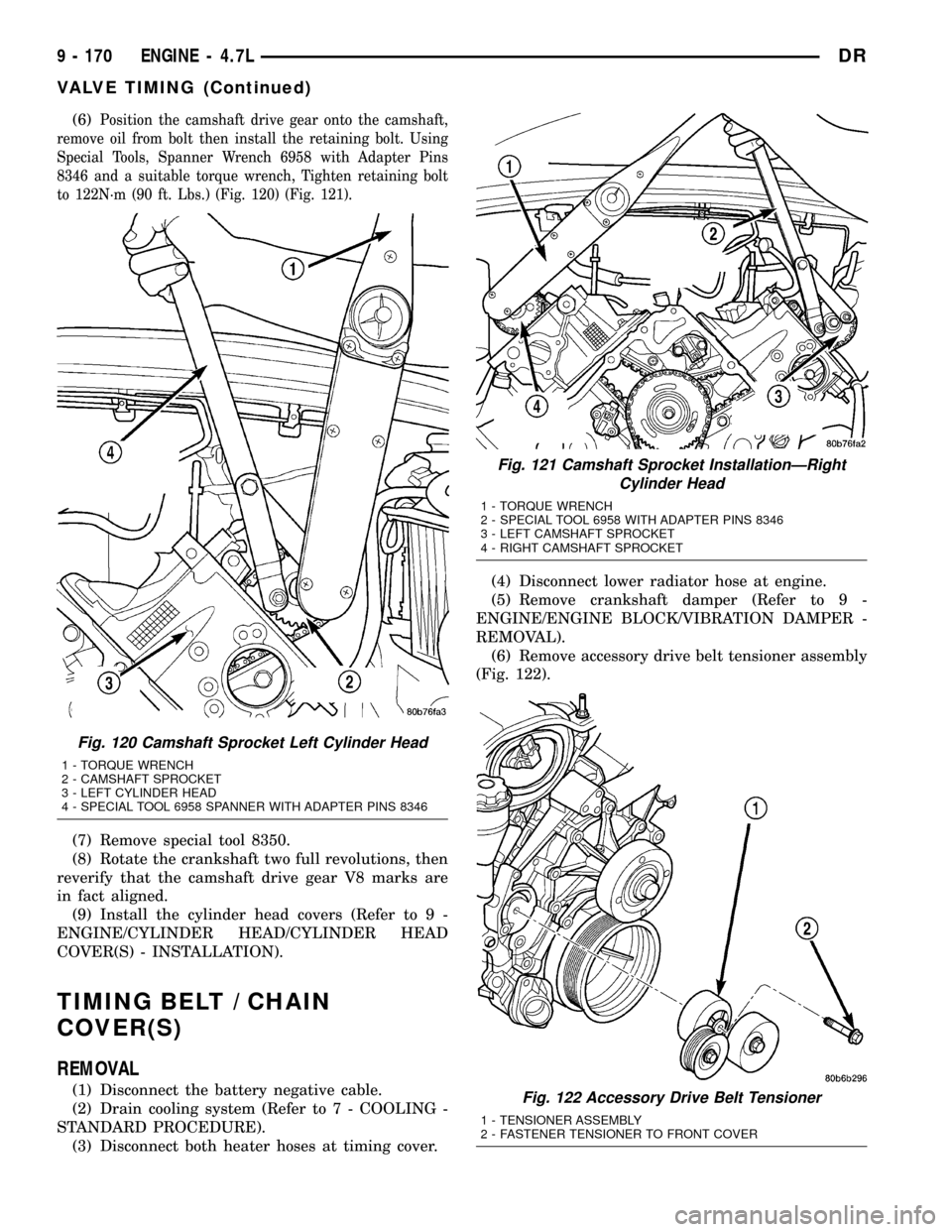

(5) Using a suitable pair of adjustable pliers,

rotate the camshaft until the alignment dowel on the

camshaft is aligned with the slot in the camshaft

drive gear (Fig. 119).

CAUTION: Remove excess oil from camshaft

sprocket retaining bolt before reinstalling bolt. Fail-

ure to do so may cause over-torqueing of bolt

resulting in bolt failure.

Fig. 118 Securing Timing Chain Tensioners Using Timing Chain Wedge

1 - LEFT CYLINDER HEAD

2 - RIGHT CYLINDER HEAD3 - SPECIAL TOOL 8350 WEDGE

4 - SPECIAL TOOL 8350 WEDGE

Fig. 119 Camshaft Dowel

1 - ADJUSTABLE PLIERS

2 - CAMSHAFT DOWEL

DRENGINE - 4.7L 9 - 169

VALVE TIMING (Continued)

Page 1393 of 2627

(6)Position the camshaft drive gear onto the camshaft,

remove oil from bolt then install the retaining bolt. Using

Special Tools, Spanner Wrench 6958 with Adapter Pins

8346 and a suitable torque wrench, Tighten retaining bolt

to 122N´m (90 ft. Lbs.) (Fig. 120) (Fig. 121).

(7) Remove special tool 8350.

(8) Rotate the crankshaft two full revolutions, then

reverify that the camshaft drive gear V8 marks are

in fact aligned.

(9) Install the cylinder head covers (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

TIMING BELT / CHAIN

COVER(S)

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Disconnect both heater hoses at timing cover.(4) Disconnect lower radiator hose at engine.

(5) Remove crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(6) Remove accessory drive belt tensioner assembly

(Fig. 122).

Fig. 120 Camshaft Sprocket Left Cylinder Head

1 - TORQUE WRENCH

2 - CAMSHAFT SPROCKET

3 - LEFT CYLINDER HEAD

4 - SPECIAL TOOL 6958 SPANNER WITH ADAPTER PINS 8346

Fig. 121 Camshaft Sprocket InstallationÐRight

Cylinder Head

1 - TORQUE WRENCH

2 - SPECIAL TOOL 6958 WITH ADAPTER PINS 8346

3 - LEFT CAMSHAFT SPROCKET

4 - RIGHT CAMSHAFT SPROCKET

Fig. 122 Accessory Drive Belt Tensioner

1 - TENSIONER ASSEMBLY

2 - FASTENER TENSIONER TO FRONT COVER

9 - 170 ENGINE - 4.7LDR

VALVE TIMING (Continued)

Page 1394 of 2627

(7) Remove the generator and A/C compressor.

CAUTION: The 4.7L engine uses an RTV sealer

instead of a gasket to seal the front cover to the

engine block, from the factory. For service, MoparT

Engine RTV sealant must be substituted.

NOTE: It is not necessary to remove the water

pump for timing cover removal.

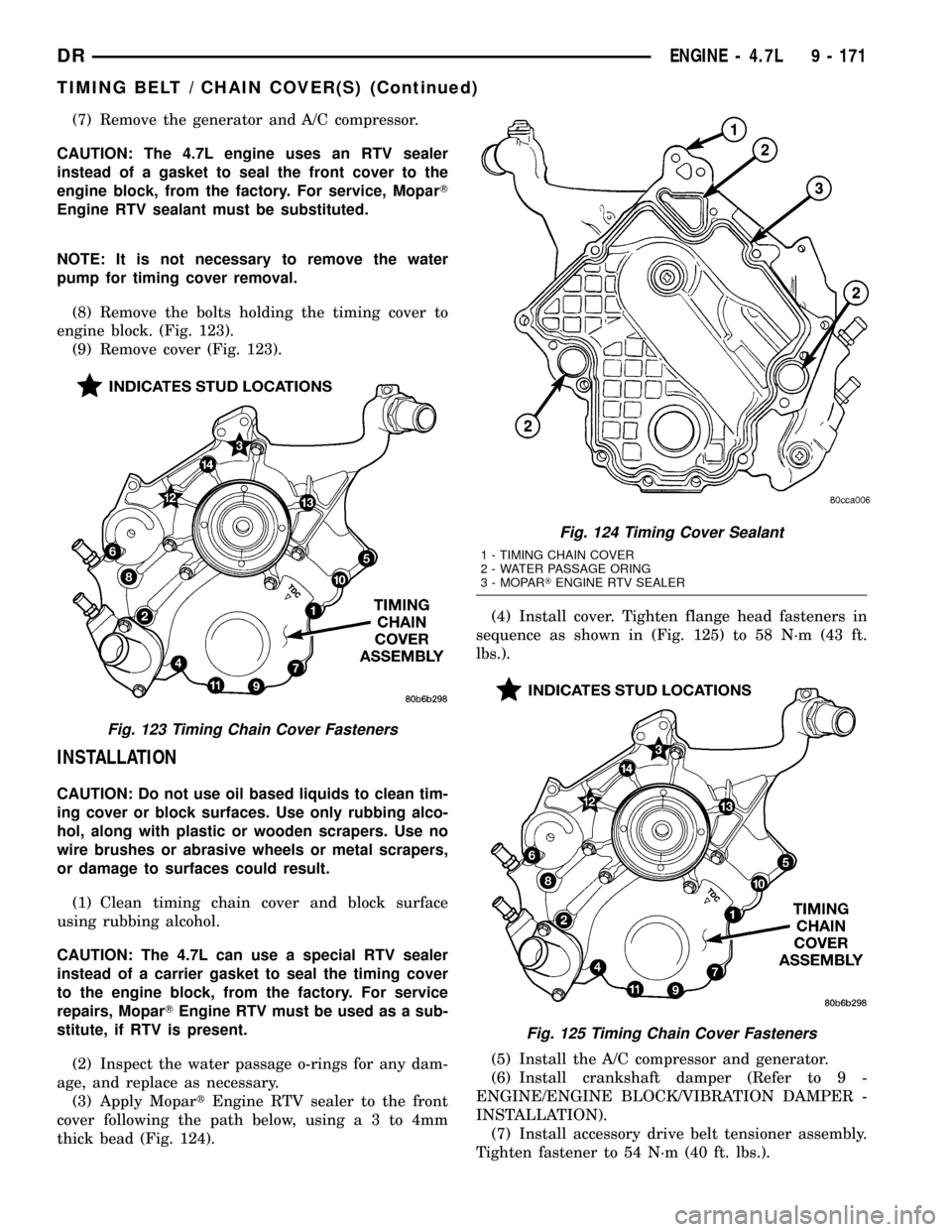

(8) Remove the bolts holding the timing cover to

engine block. (Fig. 123).

(9) Remove cover (Fig. 123).

INSTALLATION

CAUTION: Do not use oil based liquids to clean tim-

ing cover or block surfaces. Use only rubbing alco-

hol, along with plastic or wooden scrapers. Use no

wire brushes or abrasive wheels or metal scrapers,

or damage to surfaces could result.

(1) Clean timing chain cover and block surface

using rubbing alcohol.

CAUTION: The 4.7L can use a special RTV sealer

instead of a carrier gasket to seal the timing cover

to the engine block, from the factory. For service

repairs, MoparTEngine RTV must be used as a sub-

stitute, if RTV is present.

(2) Inspect the water passage o-rings for any dam-

age, and replace as necessary.

(3) Apply MopartEngine RTV sealer to the front

cover following the path below, usinga3to4mm

thick bead (Fig. 124).(4) Install cover. Tighten flange head fasteners in

sequence as shown in (Fig. 125) to 58 N´m (43 ft.

lbs.).

(5) Install the A/C compressor and generator.

(6) Install crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION).

(7) Install accessory drive belt tensioner assembly.

Tighten fastener to 54 N´m (40 ft. lbs.).

Fig. 123 Timing Chain Cover Fasteners

Fig. 124 Timing Cover Sealant

1 - TIMING CHAIN COVER

2 - WATER PASSAGE ORING

3 - MOPARTENGINE RTV SEALER

Fig. 125 Timing Chain Cover Fasteners

DRENGINE - 4.7L 9 - 171

TIMING BELT / CHAIN COVER(S) (Continued)

Page 1399 of 2627

INSTALLATION

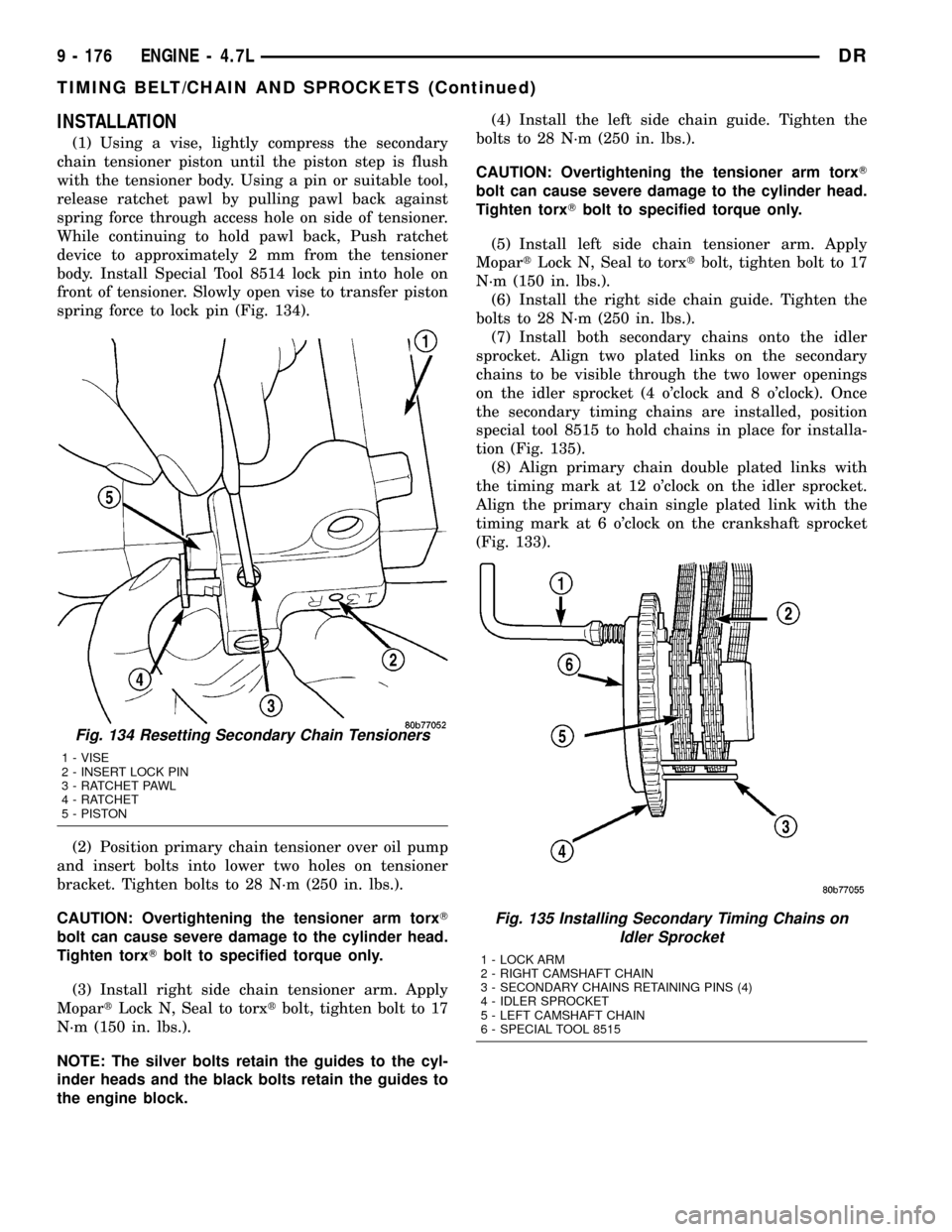

(1) Using a vise, lightly compress the secondary

chain tensioner piston until the piston step is flush

with the tensioner body. Using a pin or suitable tool,

release ratchet pawl by pulling pawl back against

spring force through access hole on side of tensioner.

While continuing to hold pawl back, Push ratchet

device to approximately 2 mm from the tensioner

body. Install Special Tool 8514 lock pin into hole on

front of tensioner. Slowly open vise to transfer piston

spring force to lock pin (Fig. 134).

(2) Position primary chain tensioner over oil pump

and insert bolts into lower two holes on tensioner

bracket. Tighten bolts to 28 N´m (250 in. lbs.).

CAUTION: Overtightening the tensioner arm torxT

bolt can cause severe damage to the cylinder head.

Tighten torxTbolt to specified torque only.

(3) Install right side chain tensioner arm. Apply

MopartLock N, Seal to torxtbolt, tighten bolt to 17

N´m (150 in. lbs.).

NOTE: The silver bolts retain the guides to the cyl-

inder heads and the black bolts retain the guides to

the engine block.(4) Install the left side chain guide. Tighten the

bolts to 28 N´m (250 in. lbs.).

CAUTION: Overtightening the tensioner arm torxT

bolt can cause severe damage to the cylinder head.

Tighten torxTbolt to specified torque only.

(5) Install left side chain tensioner arm. Apply

MopartLock N, Seal to torxtbolt, tighten bolt to 17

N´m (150 in. lbs.).

(6) Install the right side chain guide. Tighten the

bolts to 28 N´m (250 in. lbs.).

(7) Install both secondary chains onto the idler

sprocket. Align two plated links on the secondary

chains to be visible through the two lower openings

on the idler sprocket (4 o'clock and 8 o'clock). Once

the secondary timing chains are installed, position

special tool 8515 to hold chains in place for installa-

tion (Fig. 135).

(8) Align primary chain double plated links with

the timing mark at 12 o'clock on the idler sprocket.

Align the primary chain single plated link with the

timing mark at 6 o'clock on the crankshaft sprocket

(Fig. 133).

Fig. 134 Resetting Secondary Chain Tensioners

1 - VISE

2 - INSERT LOCK PIN

3 - RATCHET PAWL

4 - RATCHET

5 - PISTON

Fig. 135 Installing Secondary Timing Chains on

Idler Sprocket

1 - LOCK ARM

2 - RIGHT CAMSHAFT CHAIN

3 - SECONDARY CHAINS RETAINING PINS (4)

4 - IDLER SPROCKET

5 - LEFT CAMSHAFT CHAIN

6 - SPECIAL TOOL 8515

9 - 176 ENGINE - 4.7LDR

TIMING BELT/CHAIN AND SPROCKETS (Continued)

Page 1400 of 2627

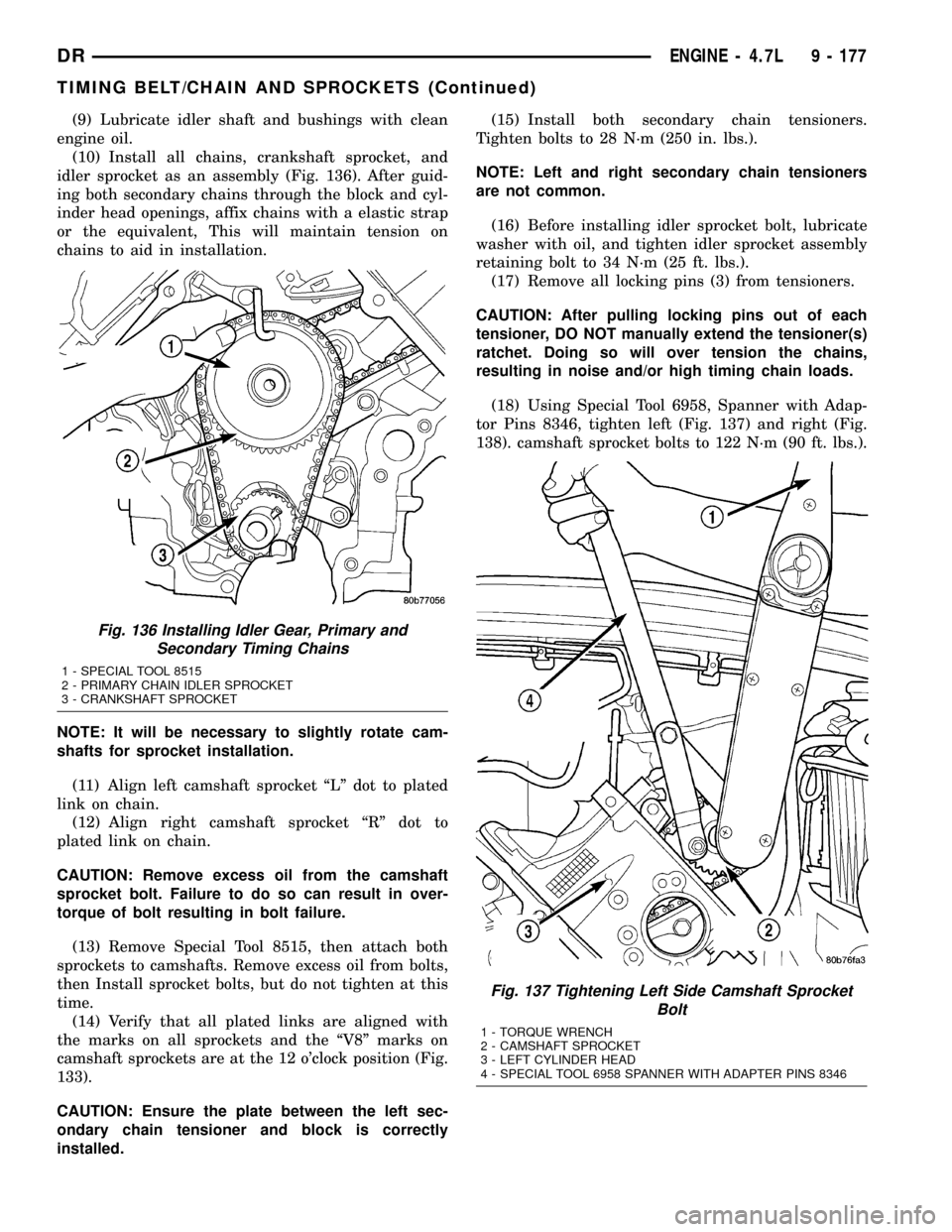

(9) Lubricate idler shaft and bushings with clean

engine oil.

(10) Install all chains, crankshaft sprocket, and

idler sprocket as an assembly (Fig. 136). After guid-

ing both secondary chains through the block and cyl-

inder head openings, affix chains with a elastic strap

or the equivalent, This will maintain tension on

chains to aid in installation.

NOTE: It will be necessary to slightly rotate cam-

shafts for sprocket installation.

(11) Align left camshaft sprocket ªLº dot to plated

link on chain.

(12) Align right camshaft sprocket ªRº dot to

plated link on chain.

CAUTION: Remove excess oil from the camshaft

sprocket bolt. Failure to do so can result in over-

torque of bolt resulting in bolt failure.

(13) Remove Special Tool 8515, then attach both

sprockets to camshafts. Remove excess oil from bolts,

then Install sprocket bolts, but do not tighten at this

time.

(14) Verify that all plated links are aligned with

the marks on all sprockets and the ªV8º marks on

camshaft sprockets are at the 12 o'clock position (Fig.

133).

CAUTION: Ensure the plate between the left sec-

ondary chain tensioner and block is correctly

installed.(15) Install both secondary chain tensioners.

Tighten bolts to 28 N´m (250 in. lbs.).

NOTE: Left and right secondary chain tensioners

are not common.

(16) Before installing idler sprocket bolt, lubricate

washer with oil, and tighten idler sprocket assembly

retaining bolt to 34 N´m (25 ft. lbs.).

(17) Remove all locking pins (3) from tensioners.

CAUTION: After pulling locking pins out of each

tensioner, DO NOT manually extend the tensioner(s)

ratchet. Doing so will over tension the chains,

resulting in noise and/or high timing chain loads.

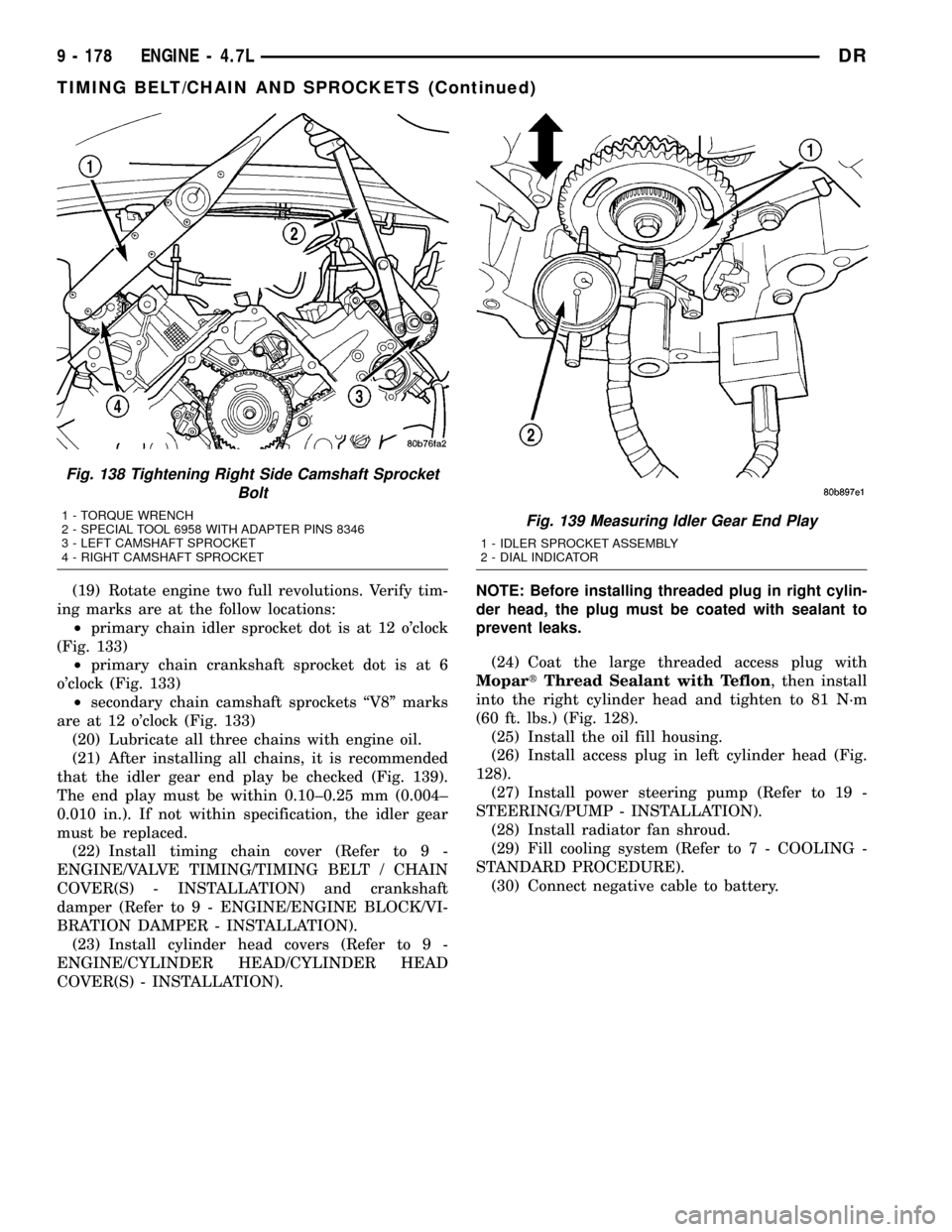

(18) Using Special Tool 6958, Spanner with Adap-

tor Pins 8346, tighten left (Fig. 137) and right (Fig.

138). camshaft sprocket bolts to 122 N´m (90 ft. lbs.).

Fig. 136 Installing Idler Gear, Primary and

Secondary Timing Chains

1 - SPECIAL TOOL 8515

2 - PRIMARY CHAIN IDLER SPROCKET

3 - CRANKSHAFT SPROCKET

Fig. 137 Tightening Left Side Camshaft Sprocket

Bolt

1 - TORQUE WRENCH

2 - CAMSHAFT SPROCKET

3 - LEFT CYLINDER HEAD

4 - SPECIAL TOOL 6958 SPANNER WITH ADAPTER PINS 8346

DRENGINE - 4.7L 9 - 177

TIMING BELT/CHAIN AND SPROCKETS (Continued)

Page 1401 of 2627

(19) Rotate engine two full revolutions. Verify tim-

ing marks are at the follow locations:

²primary chain idler sprocket dot is at 12 o'clock

(Fig. 133)

²primary chain crankshaft sprocket dot is at 6

o'clock (Fig. 133)

²secondary chain camshaft sprockets ªV8º marks

are at 12 o'clock (Fig. 133)

(20) Lubricate all three chains with engine oil.

(21) After installing all chains, it is recommended

that the idler gear end play be checked (Fig. 139).

The end play must be within 0.10±0.25 mm (0.004±

0.010 in.). If not within specification, the idler gear

must be replaced.

(22) Install timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION) and crankshaft

damper (Refer to 9 - ENGINE/ENGINE BLOCK/VI-

BRATION DAMPER - INSTALLATION).

(23) Install cylinder head covers (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).NOTE: Before installing threaded plug in right cylin-

der head, the plug must be coated with sealant to

prevent leaks.

(24) Coat the large threaded access plug with

MopartThread Sealant with Teflon, then install

into the right cylinder head and tighten to 81 N´m

(60 ft. lbs.) (Fig. 128).

(25) Install the oil fill housing.

(26) Install access plug in left cylinder head (Fig.

128).

(27) Install power steering pump (Refer to 19 -

STEERING/PUMP - INSTALLATION).

(28) Install radiator fan shroud.

(29) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(30) Connect negative cable to battery.

Fig. 138 Tightening Right Side Camshaft Sprocket

Bolt

1 - TORQUE WRENCH

2 - SPECIAL TOOL 6958 WITH ADAPTER PINS 8346

3 - LEFT CAMSHAFT SPROCKET

4 - RIGHT CAMSHAFT SPROCKETFig. 139 Measuring Idler Gear End Play

1 - IDLER SPROCKET ASSEMBLY

2 - DIAL INDICATOR

9 - 178 ENGINE - 4.7LDR

TIMING BELT/CHAIN AND SPROCKETS (Continued)

Page 1418 of 2627

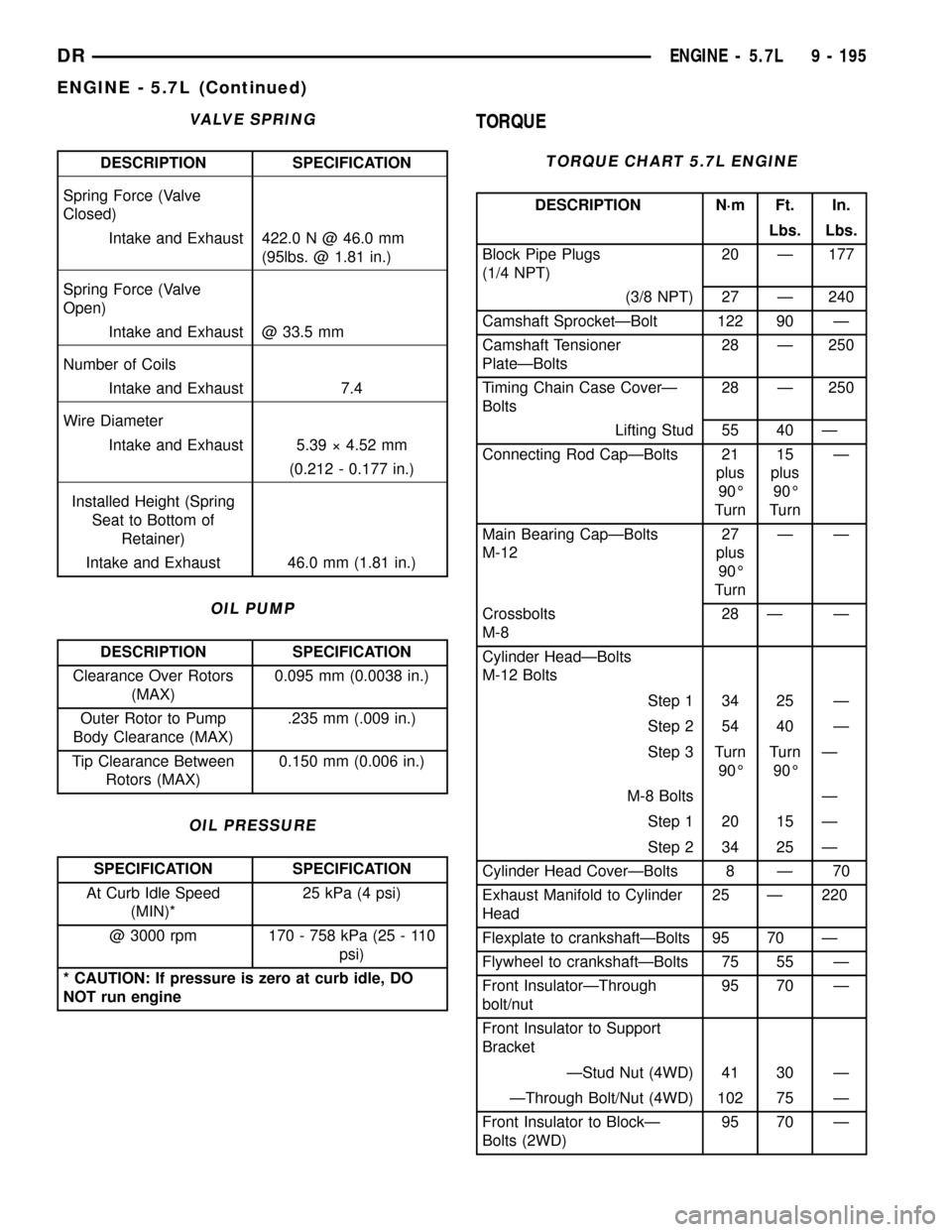

VALVE SPRING

DESCRIPTION SPECIFICATION

Spring Force (Valve

Closed)

Intake and Exhaust 422.0 N @ 46.0 mm

(95lbs. @ 1.81 in.)

Spring Force (Valve

Open)

Intake and Exhaust @ 33.5 mm

Number of Coils

Intake and Exhaust 7.4

Wire Diameter

Intake and Exhaust 5.39 ý 4.52 mm

(0.212 - 0.177 in.)

Installed Height (Spring

Seat to Bottom of

Retainer)

Intake and Exhaust 46.0 mm (1.81 in.)

OIL PUMP

DESCRIPTION SPECIFICATION

Clearance Over Rotors

(MAX)0.095 mm (0.0038 in.)

Outer Rotor to Pump

Body Clearance (MAX).235 mm (.009 in.)

Tip Clearance Between

Rotors (MAX)0.150 mm (0.006 in.)

OIL PRESSURE

SPECIFICATION SPECIFICATION

At Curb Idle Speed

(MIN)*25 kPa (4 psi)

@ 3000 rpm 170 - 758 kPa (25 - 110

psi)

* CAUTION: If pressure is zero at curb idle, DO

NOT run engine

TORQUE

TORQUE CHART 5.7L ENGINE

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

Block Pipe Plugs

(1/4 NPT)20 Ð 177

(3/8 NPT) 27 Ð 240

Camshaft SprocketÐBolt 122 90 Ð

Camshaft Tensioner

PlateÐBolts28 Ð 250

Timing Chain Case CoverÐ

Bolts28 Ð 250

Lifting Stud 55 40 Ð

Connecting Rod CapÐBolts 21

plus

90É

Turn15

plus

90É

TurnÐ

Main Bearing CapÐBolts

M-1227

plus

90É

TurnÐÐ

Crossbolts

M-828 Ð Ð

Cylinder HeadÐBolts

M-12 Bolts

Step 1 34 25 Ð

Step 2 54 40 Ð

Step 3 Turn

90ÉTurn

90ÉÐ

M-8 Bolts Ð

Step 1 20 15 Ð

Step 2 34 25 Ð

Cylinder Head CoverÐBolts 8 Ð 70

Exhaust Manifold to Cylinder

Head25 Ð 220

Flexplate to crankshaftÐBolts 95 70 Ð

Flywheel to crankshaftÐBolts 75 55 Ð

Front InsulatorÐThrough

bolt/nut95 70 Ð

Front Insulator to Support

Bracket

ÐStud Nut (4WD) 41 30 Ð

ÐThrough Bolt/Nut (4WD) 102 75 Ð

Front Insulator to BlockÐ

Bolts (2WD)95 70 Ð

DRENGINE - 5.7L 9 - 195

ENGINE - 5.7L (Continued)

Page 1422 of 2627

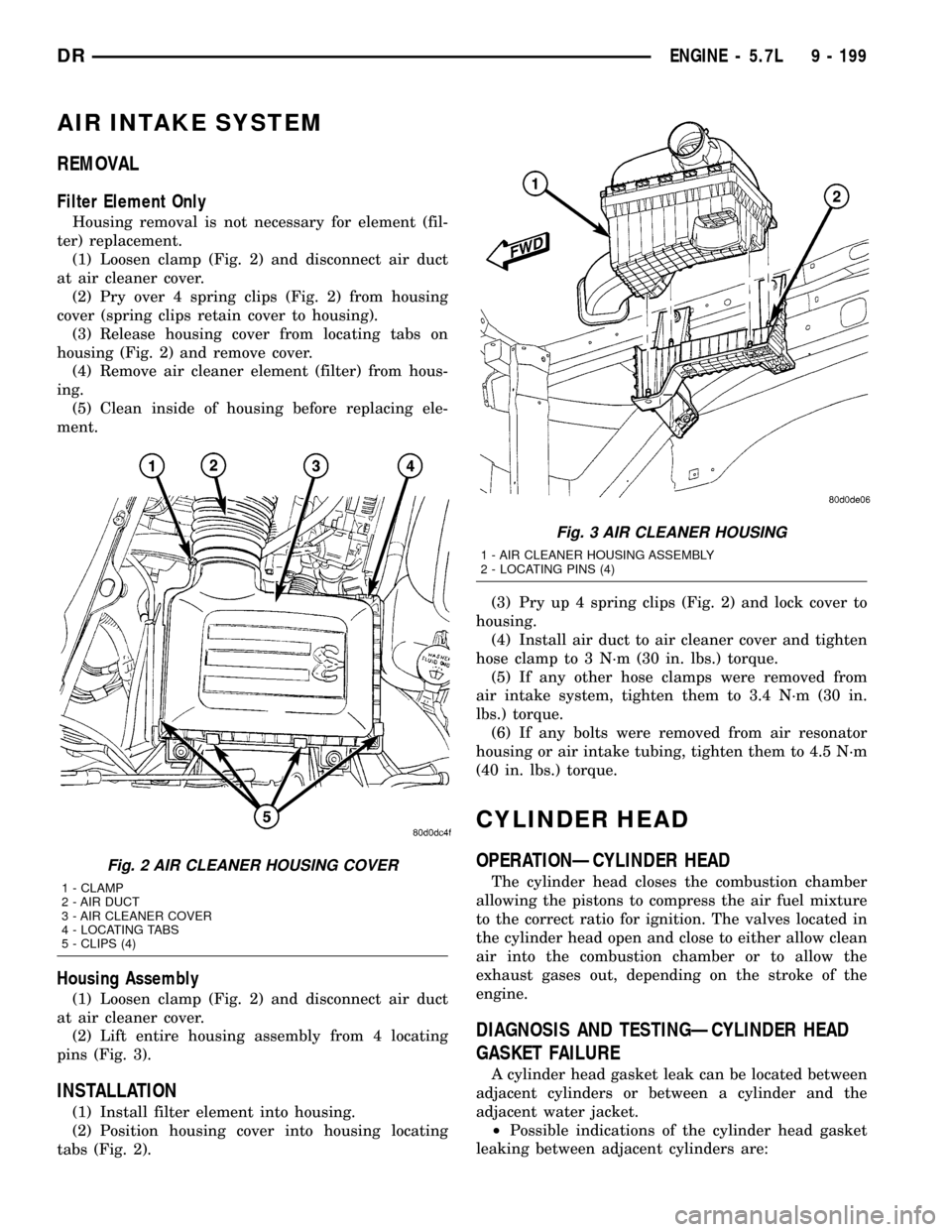

AIR INTAKE SYSTEM

REMOVAL

Filter Element Only

Housing removal is not necessary for element (fil-

ter) replacement.

(1) Loosen clamp (Fig. 2) and disconnect air duct

at air cleaner cover.

(2) Pry over 4 spring clips (Fig. 2) from housing

cover (spring clips retain cover to housing).

(3) Release housing cover from locating tabs on

housing (Fig. 2) and remove cover.

(4) Remove air cleaner element (filter) from hous-

ing.

(5) Clean inside of housing before replacing ele-

ment.

Housing Assembly

(1) Loosen clamp (Fig. 2) and disconnect air duct

at air cleaner cover.

(2) Lift entire housing assembly from 4 locating

pins (Fig. 3).

INSTALLATION

(1) Install filter element into housing.

(2) Position housing cover into housing locating

tabs (Fig. 2).(3) Pry up 4 spring clips (Fig. 2) and lock cover to

housing.

(4) Install air duct to air cleaner cover and tighten

hose clamp to 3 N´m (30 in. lbs.) torque.

(5) If any other hose clamps were removed from

air intake system, tighten them to 3.4 N´m (30 in.

lbs.) torque.

(6) If any bolts were removed from air resonator

housing or air intake tubing, tighten them to 4.5 N´m

(40 in. lbs.) torque.

CYLINDER HEAD

OPERATIONÐCYLINDER HEAD

The cylinder head closes the combustion chamber

allowing the pistons to compress the air fuel mixture

to the correct ratio for ignition. The valves located in

the cylinder head open and close to either allow clean

air into the combustion chamber or to allow the

exhaust gases out, depending on the stroke of the

engine.

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET FAILURE

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

²Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

Fig. 2 AIR CLEANER HOUSING COVER

1 - CLAMP

2 - AIR DUCT

3 - AIR CLEANER COVER

4 - LOCATING TABS

5 - CLIPS (4)

Fig. 3 AIR CLEANER HOUSING

1 - AIR CLEANER HOUSING ASSEMBLY

2 - LOCATING PINS (4)

DRENGINE - 5.7L 9 - 199

Page 1423 of 2627

þ Loss of engine power

þ Engine misfiring

þ Poor fuel economy

²Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

þ Engine overheating

þ Loss of coolant

þ Excessive steam (white smoke) emitting from

exhaust

þ Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test in this

section. An engine cylinder head gasket leaking

between adjacent cylinders will result in approxi-

mately a 50±70% reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain cooling system.

(3) Remove the air cleaner resonator and duct

work.

(4) Remove the generator.

(5) Remove closed crankcase ventilation system.

(6) Disconnect the evaporation control system.

(7) Perform the Fuel System Pressure Release pro-

cedure (Refer to 14 - FUEL SYSTEM/FUEL DELIV-

ERY - STANDARD PROCEDURE). Disconnect the

fuel supply line (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/QUICK CONNECT FITTING - STAN-

DARD PROCEDURE).

(8) Disconnect heater hoses.

(9) Remove cylinder head covers and gaskets.

(10) Remove intake manifold and throttle body as

an assembly.

(11) Remove rocker arm assemblies and push rods.

Identify to ensure installation in original locations.

(12) Remove the head bolts from each cylinder

head and remove cylinder heads. Discard the cylin-

der head gasket.

CLEANING

Clean all surfaces of cylinder block and cylinder

heads.

Clean cylinder block front and rear gasket surfaces

using a suitable solvent.

INSPECTION

(1) Inspect the cylinder head for out-of-flatness,

using a straightedge and a feeler gauge. If tolerances

exceed 0.0508 mm (0.002 in.) replace the cylinder

head.

(2) Inspect the valve seats for damage. Service the

valve seats as necessary.

(3) Inspect the valve guides for wear, cracks or

looseness. If either condition exist, replace the cylin-

der head.

(4) Inspect pushrods. Replace worn or bent push-

rods.

INSTALLATION

(1) Clean all surfaces of cylinder block and cylin-

der heads.

(2) Clean cylinder block front and rear gasket sur-

faces using a suitable solvent.

CAUTION: The head gaskets are not interchange-

able between left and right sides. They are marked

ªLº and ªRº to indicate left and right sides.

(3) Position new cylinder head gaskets onto the

cylinder block.

9 - 200 ENGINE - 5.7LDR

CYLINDER HEAD (Continued)

Page 1424 of 2627

CAUTION: The head gaskets are marked ªTOPº to

indicate which side goes up.

(4) Position cylinder heads onto head gaskets and

cylinder block.

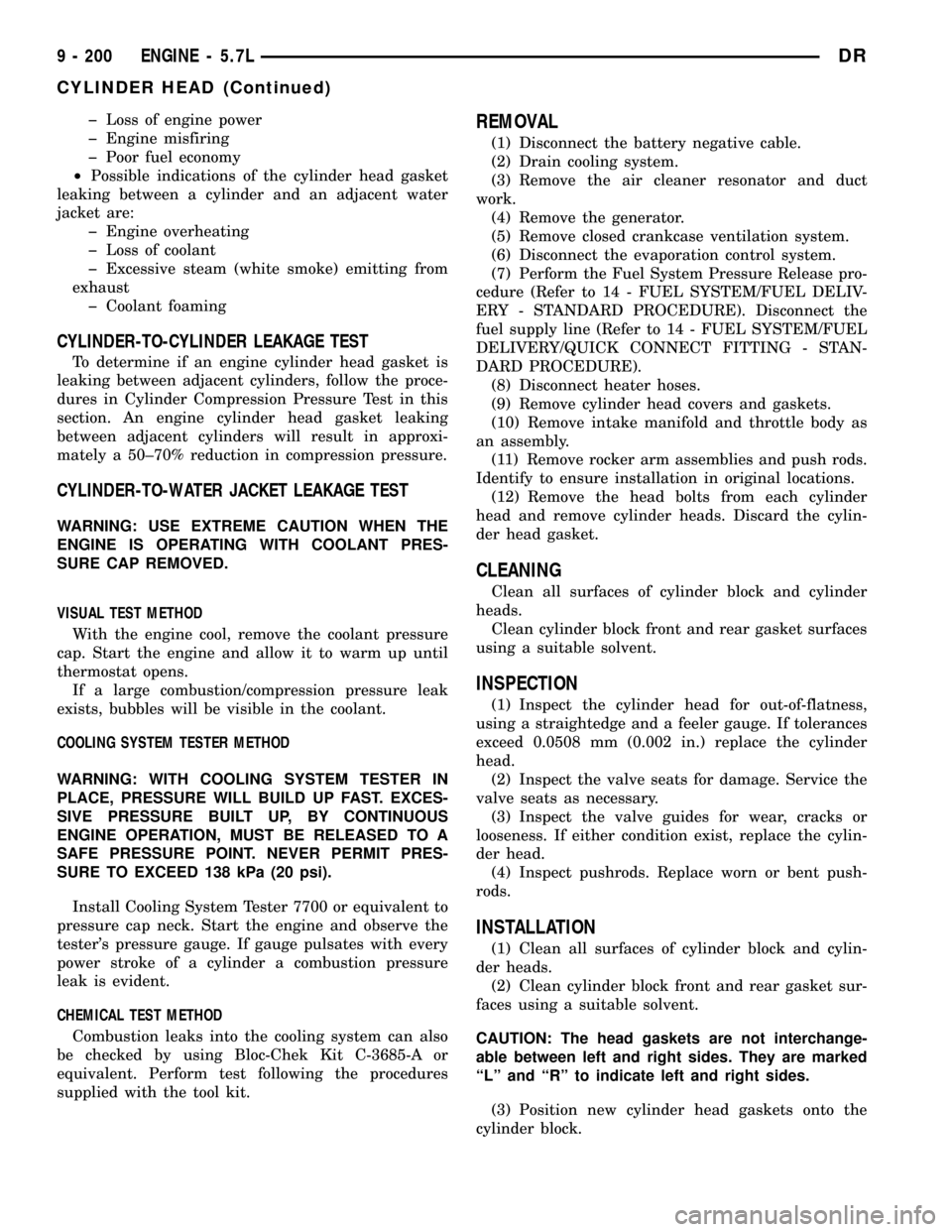

(5) Tighten the cylinder head bolts in three steps

(Fig. 4):

²Step 1Ð Snug tighten M12 cylinder head bolts,

in sequence, to 34 N´m (25 ft. lbs.) and M8 bolts to

20 N´m (15 ft. lbs.) torque.

²Step 2Ð Tighten M12 cylinder head bolts, in

sequence, to 54 N´m (40 ft. lbs.) and verify M8 bolts

to 20 N´m (15 ft. lbs.) torque..

²Step 3Ð Turn M12 cylinder head bolts, in

sequence, 90 degrees and tighten M8 bolts to 34 N´m

(25 ft. lbs.) torque.

(6) Install push rods and rocker arm assemblies in

their original position.

(7) Install the intake manifold and throttle body

assembly.

(8) If required, adjust spark plugs to specifications.

Install the plugs.

(9) Connect the heater hoses.

(10) Install the fuel supply line.

(11) Install the generator and drive belt.

(12) Install cylinder head covers(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(13) Connect the evaporation control system.

(14) Install the air cleaner.

(15) Fill cooling system.

(16) Connect the negative cable to the battery.

(17) Start engine check for leaks.CYLINDER HEAD COVER(S)

REMOVAL

(1) Disconnect battery negative cable.

(2) Disconnect coil on plug connectors.

CAUTION: The ground straps must be installed in

the same location as removed. The covers are

machined to accept the ground straps in those

locations only.

(3) Remove cylinder head cover retaining bolts,

and ground straps.

(4) Remove cylinder head cover.

NOTE: The gasket may be used again, provided no

cuts, tears, or deformation has occurred.

INSTALLATION

CAUTION: Do not use harsh cleaners to clean the

cylinder head covers. Severe damage to covers

may occur.

CAUTION: DO NOT allow other components includ-

ing the wire harness to rest on or against the

engine cylinder head cover. Prolonged contact with

other objects may wear a hole in the cylinder head

cover.

(1) Clean cylinder head cover and both sealing sur-

faces. Inspect and replace gasket as necessary.

(2)

Install cylinder head cover and hand start all fas-

teners. Verify that all double ended studs are in the cor-

rect location and install left and right ground straps.

CAUTION: The ground straps must be installed in

the same location as removed. The covers are

machined to accept the ground straps in those

locations only.

NOTE: The right hand ground strap is located on

the front inboard stud. The left hand ground strap

is located on the rear inboard stud.

(3) Tighten cylinder head cover bolts and double

ended studs to 8 N´m (70 in. lbs). Begin torque

sequence in the middle of head cover and torque

bolts moving outward in a crisscross pattern from top

to bottom.

(4) Install ignition coil on plug, and torque fasten-

ers to 12 N´m (105 in. lbs)

(5) Connect, ignition coil electrical connectors.

(6) Install PCV hose.

(7) Connect battery negative cable.

Fig. 4 CYLINDER HEAD TIGHTENING SEQUENCE

DRENGINE - 5.7L 9 - 201

CYLINDER HEAD (Continued)