Crank DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 33 of 2627

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(7) Allow battery in disabled vehicle to charge to

at least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

onds, stop cranking engine and allow starter to cool

(15 min.), before cranking again.

DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

HOISTING

STANDARD PROCEDURE - HOISTING

Refer to the Owner's Manual for emergency vehicle

lifting procedures.

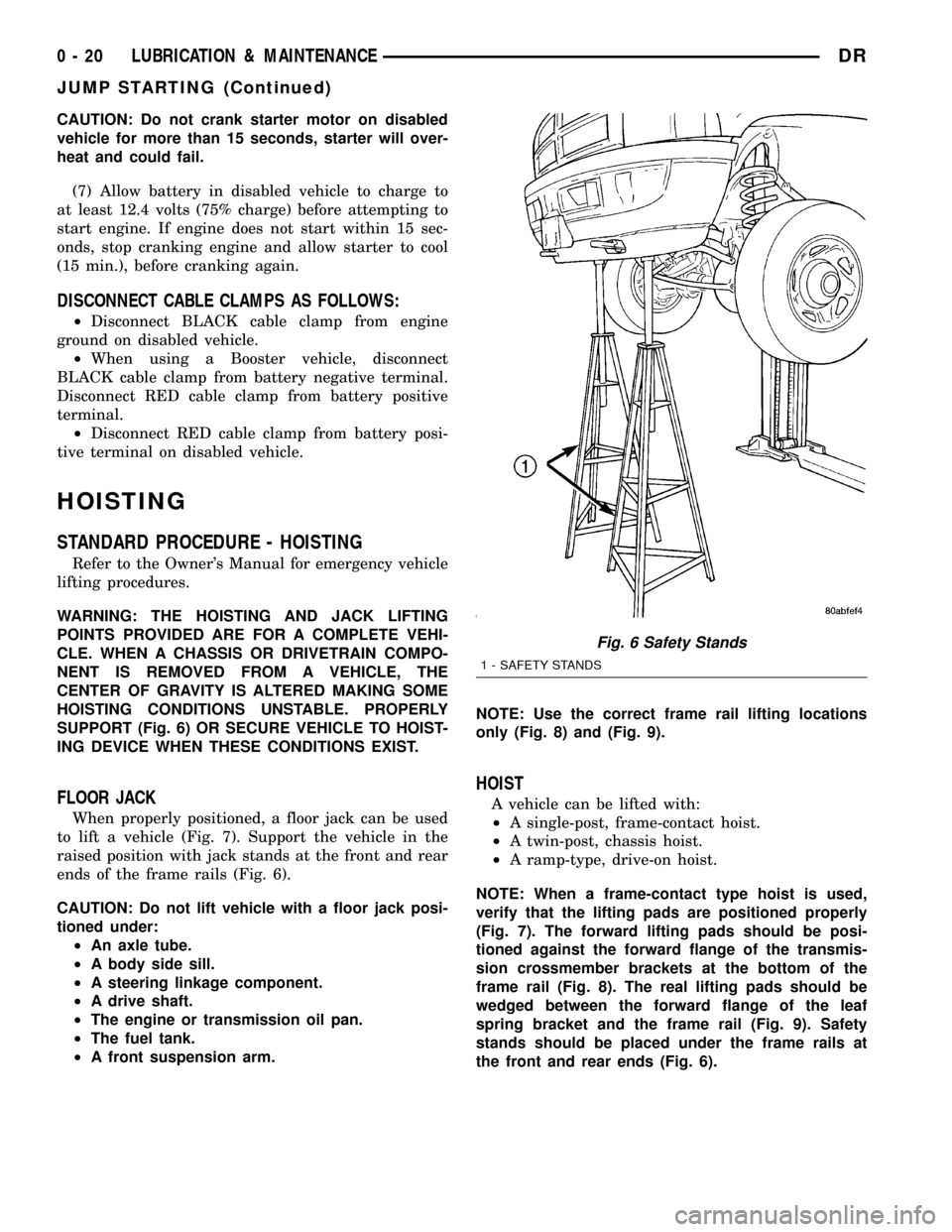

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VEHI-

CLE. WHEN A CHASSIS OR DRIVETRAIN COMPO-

NENT IS REMOVED FROM A VEHICLE, THE

CENTER OF GRAVITY IS ALTERED MAKING SOME

HOISTING CONDITIONS UNSTABLE. PROPERLY

SUPPORT (Fig. 6) OR SECURE VEHICLE TO HOIST-

ING DEVICE WHEN THESE CONDITIONS EXIST.

FLOOR JACK

When properly positioned, a floor jack can be used

to lift a vehicle (Fig. 7). Support the vehicle in the

raised position with jack stands at the front and rear

ends of the frame rails (Fig. 6).

CAUTION: Do not lift vehicle with a floor jack posi-

tioned under:

²An axle tube.

²A body side sill.

²A steering linkage component.

²A drive shaft.

²The engine or transmission oil pan.

²The fuel tank.

²A front suspension arm.NOTE: Use the correct frame rail lifting locations

only (Fig. 8) and (Fig. 9).

HOIST

A vehicle can be lifted with:

²A single-post, frame-contact hoist.

²A twin-post, chassis hoist.

²A ramp-type, drive-on hoist.

NOTE: When a frame-contact type hoist is used,

verify that the lifting pads are positioned properly

(Fig. 7). The forward lifting pads should be posi-

tioned against the forward flange of the transmis-

sion crossmember brackets at the bottom of the

frame rail (Fig. 8). The real lifting pads should be

wedged between the forward flange of the leaf

spring bracket and the frame rail (Fig. 9). Safety

stands should be placed under the frame rails at

the front and rear ends (Fig. 6).

Fig. 6 Safety Stands

1 - SAFETY STANDS

0 - 20 LUBRICATION & MAINTENANCEDR

JUMP STARTING (Continued)

Page 280 of 2627

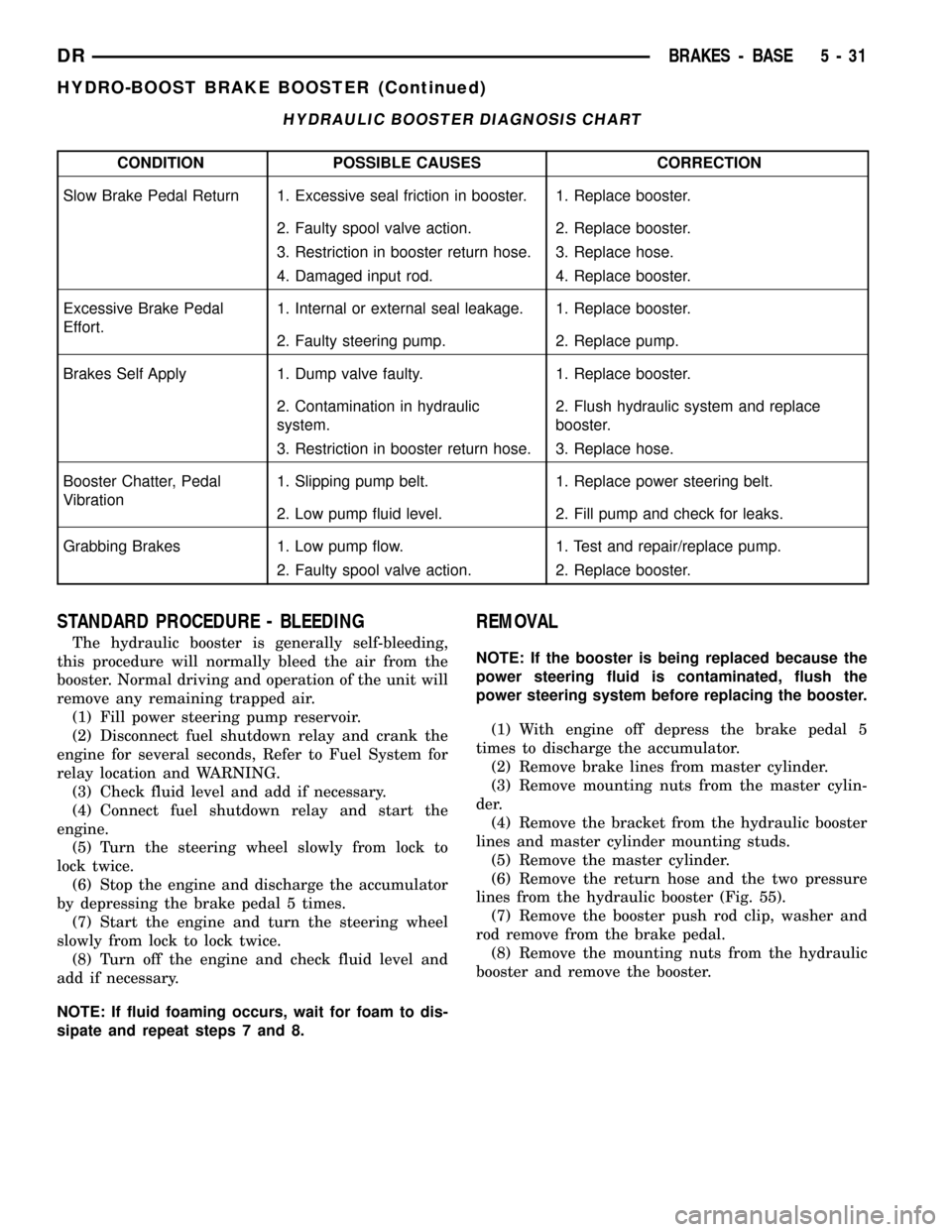

HYDRAULIC BOOSTER DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

Slow Brake Pedal Return 1. Excessive seal friction in booster. 1. Replace booster.

2. Faulty spool valve action. 2. Replace booster.

3. Restriction in booster return hose. 3. Replace hose.

4. Damaged input rod. 4. Replace booster.

Excessive Brake Pedal

Effort.1. Internal or external seal leakage. 1. Replace booster.

2. Faulty steering pump. 2. Replace pump.

Brakes Self Apply 1. Dump valve faulty. 1. Replace booster.

2. Contamination in hydraulic

system.2. Flush hydraulic system and replace

booster.

3. Restriction in booster return hose. 3. Replace hose.

Booster Chatter, Pedal

Vibration1. Slipping pump belt. 1. Replace power steering belt.

2. Low pump fluid level. 2. Fill pump and check for leaks.

Grabbing Brakes 1. Low pump flow. 1. Test and repair/replace pump.

2. Faulty spool valve action. 2. Replace booster.

STANDARD PROCEDURE - BLEEDING

The hydraulic booster is generally self-bleeding,

this procedure will normally bleed the air from the

booster. Normal driving and operation of the unit will

remove any remaining trapped air.

(1) Fill power steering pump reservoir.

(2) Disconnect fuel shutdown relay and crank the

engine for several seconds, Refer to Fuel System for

relay location and WARNING.

(3) Check fluid level and add if necessary.

(4) Connect fuel shutdown relay and start the

engine.

(5) Turn the steering wheel slowly from lock to

lock twice.

(6) Stop the engine and discharge the accumulator

by depressing the brake pedal 5 times.

(7) Start the engine and turn the steering wheel

slowly from lock to lock twice.

(8) Turn off the engine and check fluid level and

add if necessary.

NOTE: If fluid foaming occurs, wait for foam to dis-

sipate and repeat steps 7 and 8.

REMOVAL

NOTE: If the booster is being replaced because the

power steering fluid is contaminated, flush the

power steering system before replacing the booster.

(1) With engine off depress the brake pedal 5

times to discharge the accumulator.

(2) Remove brake lines from master cylinder.

(3) Remove mounting nuts from the master cylin-

der.

(4) Remove the bracket from the hydraulic booster

lines and master cylinder mounting studs.

(5) Remove the master cylinder.

(6) Remove the return hose and the two pressure

lines from the hydraulic booster (Fig. 55).

(7) Remove the booster push rod clip, washer and

rod remove from the brake pedal.

(8) Remove the mounting nuts from the hydraulic

booster and remove the booster.

DRBRAKES - BASE 5 - 31

HYDRO-BOOST BRAKE BOOSTER (Continued)

Page 303 of 2627

Engagement problems can cause slip, chatter/shud-

der and noisy operation. The causes may be clutch

disc contamination, wear, distortion or flywheel dam-

age.

CLUTCH MISALIGNMENT

Clutch components must be in proper alignment

with the crankshaft and transmission input shaft.

Misalignment caused by excessive runout or warpage

of any clutch component will cause grab, chatter and

improper clutch release.

CLUTCH COVER AND DISC RUNOUT

Check the clutch disc before installation. Axial

(face) runout of anewdisc should not exceed 0.50

mm (0.020 in.). Measure runout about 6 mm (1/4 in.)

from the outer edge of the disc facing. Obtain

another disc if runout is excessive.

Check condition of the clutch before installation. A

warped cover or diaphragm spring will cause grab

and incomplete release or engagement. Be careful

when handling the cover and disc. Impact can distort

the cover, diaphragm spring, release fingers and the

hub of the clutch disc.

Use an alignment tool when positioning the disc on

the flywheel. The tool prevents accidental misalign-

ment which could result in cover distortion and disc

damage.

A frequent cause of clutch cover distortion (and

consequent misalignment) is improper bolt tighten-

ing.

FLYWHEEL RUNOUT

Check flywheel runout whenever misalignment is

suspected. Flywheel runout should not exceed 0.08

mm (0.003 in.). Measure runout at the outer edge of

the flywheel face with a dial indicator.

Common causes of runout are:

²heat warpage

²improper machining

²incorrect bolt tightening

²improper seating on crankshaft flange shoulder

²foreign material on crankshaft flange

Flywheel machining is not recommended. The fly-

wheel clutch surface is machined to a unique contour

and machining will negate this feature. Minor fly-

wheel scoring can be cleaned up by hand with 180

grit emery or with turning equipment. Remove only

enough material to reduce scoring (approximately

0.001 - 0.003 in.). Heavy stock removal isnot rec-

ommended.Replace the flywheel if scoring is severe

and deeper than 0.076 mm (0.003 in.). Excessive

stock removal can result in flywheel cracking or

warpage after installation; it can also weaken the fly-

wheel and interfere with proper clutch release.

Clean the crankshaft flange before mounting the

flywheel. Dirt and grease on the flange surface may

cock the flywheel causing excessive runout. Use new

bolts when remounting a flywheel and secure the

bolts with Mopar Lock And Seal or equivalent.

Tighten flywheel bolts to specified torque only. Over-

tightening can distort the flywheel hub causing

runout.

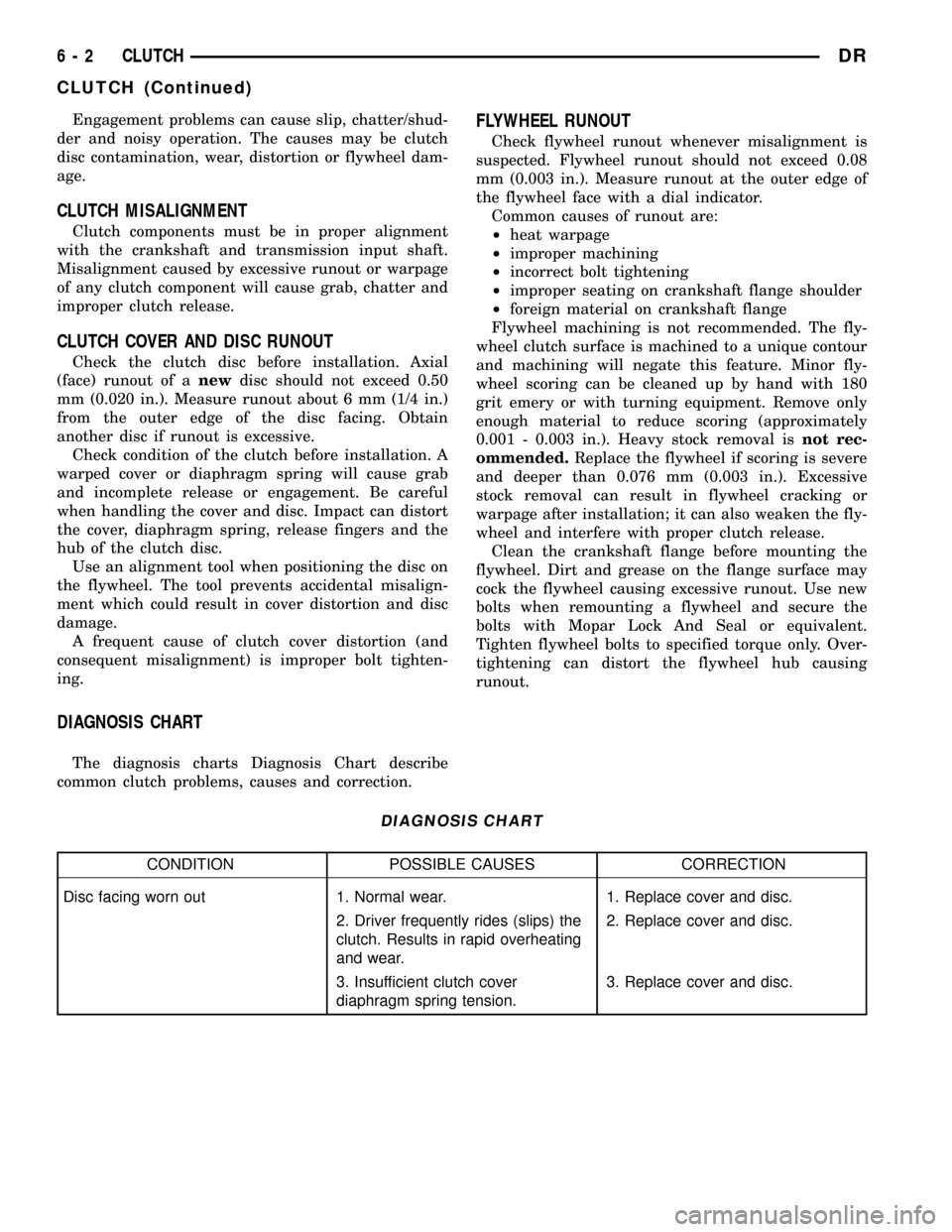

DIAGNOSIS CHART

The diagnosis charts Diagnosis Chart describe

common clutch problems, causes and correction.

DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

Disc facing worn out 1. Normal wear. 1. Replace cover and disc.

2. Driver frequently rides (slips) the

clutch. Results in rapid overheating

and wear.2. Replace cover and disc.

3. Insufficient clutch cover

diaphragm spring tension.3. Replace cover and disc.

6 - 2 CLUTCHDR

CLUTCH (Continued)

Page 306 of 2627

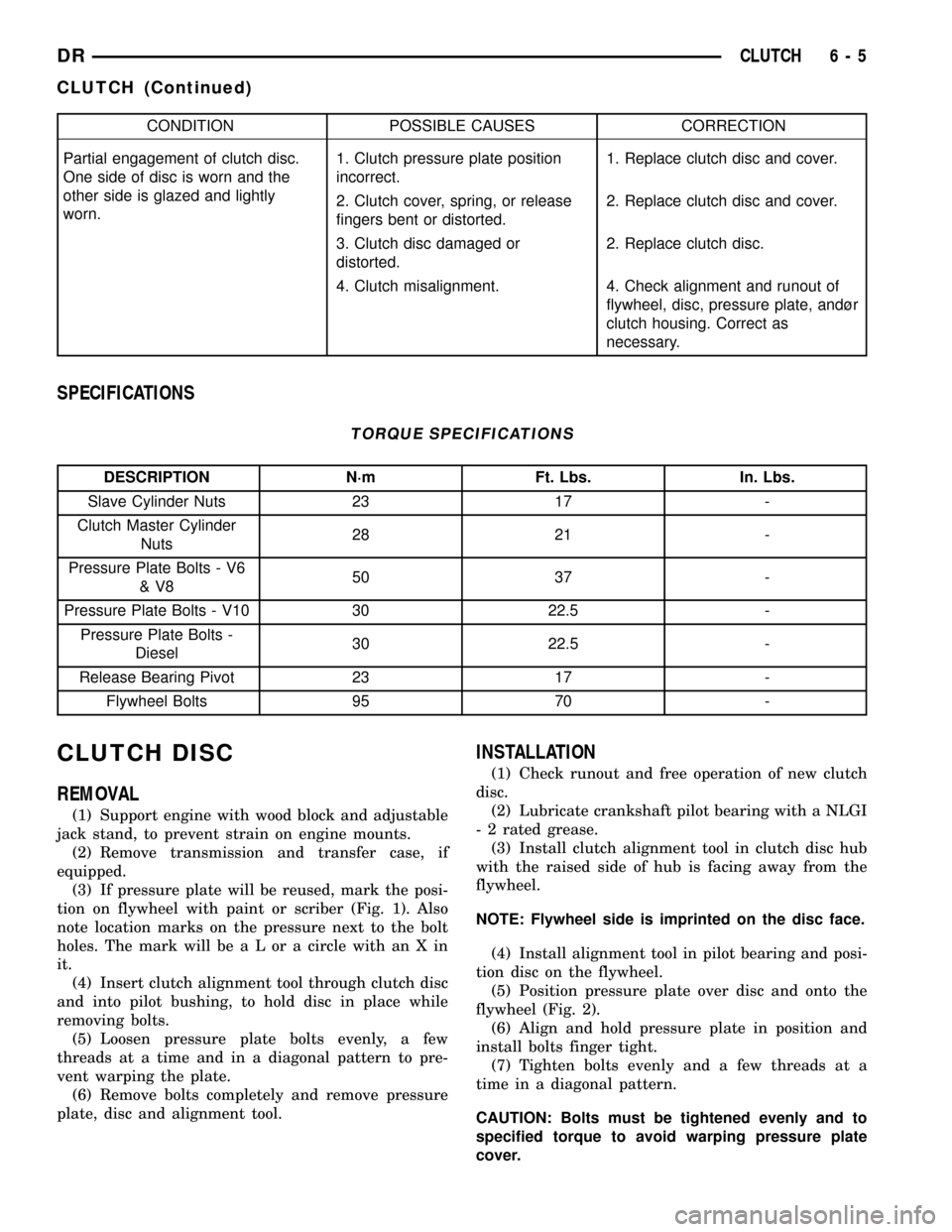

CONDITION POSSIBLE CAUSES CORRECTION

Partial engagement of clutch disc.

One side of disc is worn and the

other side is glazed and lightly

worn.1. Clutch pressure plate position

incorrect.1. Replace clutch disc and cover.

2. Clutch cover, spring, or release

fingers bent or distorted.2. Replace clutch disc and cover.

3. Clutch disc damaged or

distorted.2. Replace clutch disc.

4. Clutch misalignment. 4. Check alignment and runout of

flywheel, disc, pressure plate, andùr

clutch housing. Correct as

necessary.

SPECIFICATIONS

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Slave Cylinder Nuts 23 17 -

Clutch Master Cylinder

Nuts28 21 -

Pressure Plate Bolts - V6

&V850 37 -

Pressure Plate Bolts - V10 30 22.5 -

Pressure Plate Bolts -

Diesel30 22.5 -

Release Bearing Pivot 23 17 -

Flywheel Bolts 95 70 -

CLUTCH DISC

REMOVAL

(1) Support engine with wood block and adjustable

jack stand, to prevent strain on engine mounts.

(2) Remove transmission and transfer case, if

equipped.

(3) If pressure plate will be reused, mark the posi-

tion on flywheel with paint or scriber (Fig. 1). Also

note location marks on the pressure next to the bolt

holes. The mark will be a L or a circle with an X in

it.

(4) Insert clutch alignment tool through clutch disc

and into pilot bushing, to hold disc in place while

removing bolts.

(5) Loosen pressure plate bolts evenly, a few

threads at a time and in a diagonal pattern to pre-

vent warping the plate.

(6) Remove bolts completely and remove pressure

plate, disc and alignment tool.

INSTALLATION

(1) Check runout and free operation of new clutch

disc.

(2) Lubricate crankshaft pilot bearing with a NLGI

- 2 rated grease.

(3) Install clutch alignment tool in clutch disc hub

with the raised side of hub is facing away from the

flywheel.

NOTE: Flywheel side is imprinted on the disc face.

(4) Install alignment tool in pilot bearing and posi-

tion disc on the flywheel.

(5) Position pressure plate over disc and onto the

flywheel (Fig. 2).

(6) Align and hold pressure plate in position and

install bolts finger tight.

(7) Tighten bolts evenly and a few threads at a

time in a diagonal pattern.

CAUTION: Bolts must be tightened evenly and to

specified torque to avoid warping pressure plate

cover.

DRCLUTCH 6 - 5

CLUTCH (Continued)

Page 308 of 2627

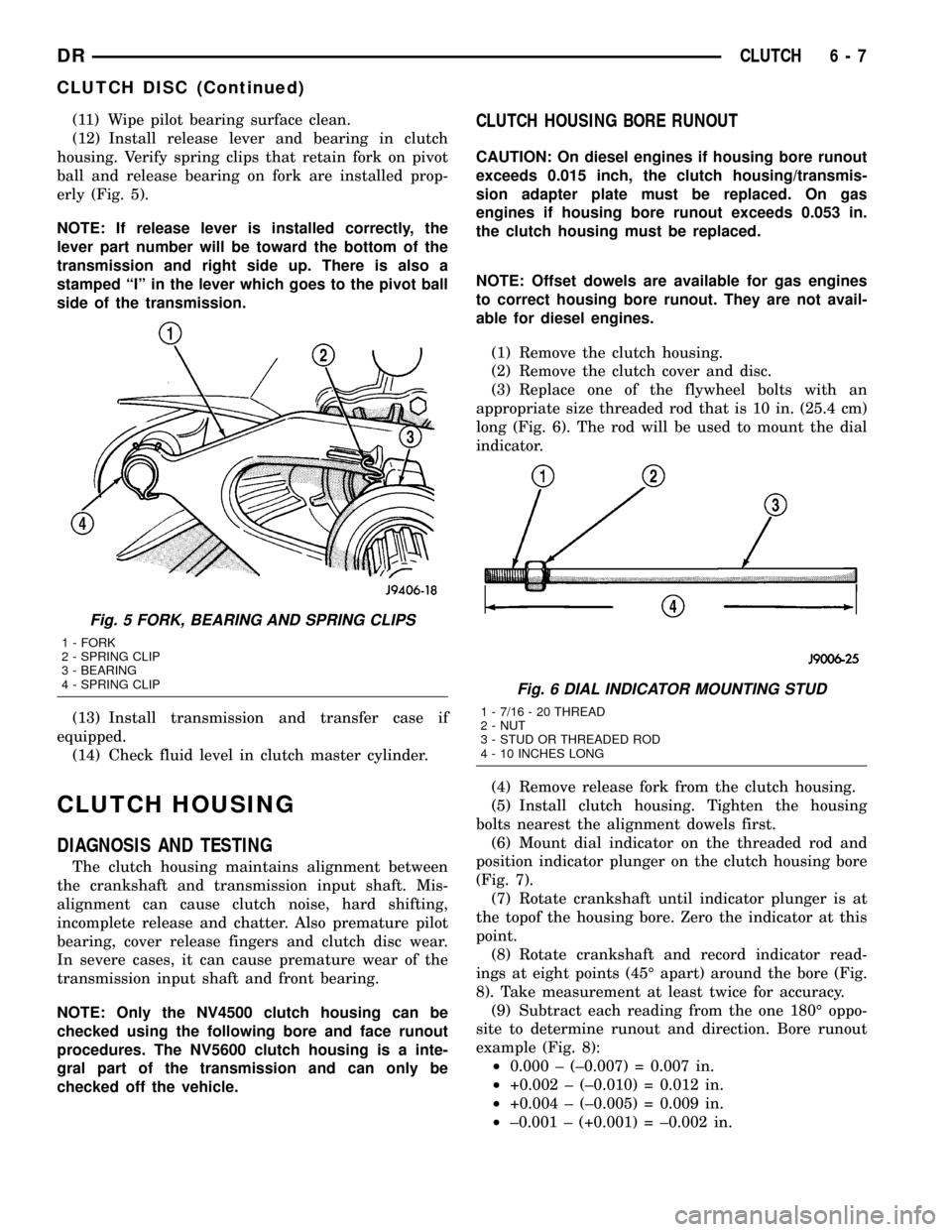

(11) Wipe pilot bearing surface clean.

(12) Install release lever and bearing in clutch

housing. Verify spring clips that retain fork on pivot

ball and release bearing on fork are installed prop-

erly (Fig. 5).

NOTE: If release lever is installed correctly, the

lever part number will be toward the bottom of the

transmission and right side up. There is also a

stamped ªIº in the lever which goes to the pivot ball

side of the transmission.

(13) Install transmission and transfer case if

equipped.

(14) Check fluid level in clutch master cylinder.

CLUTCH HOUSING

DIAGNOSIS AND TESTING

The clutch housing maintains alignment between

the crankshaft and transmission input shaft. Mis-

alignment can cause clutch noise, hard shifting,

incomplete release and chatter. Also premature pilot

bearing, cover release fingers and clutch disc wear.

In severe cases, it can cause premature wear of the

transmission input shaft and front bearing.

NOTE: Only the NV4500 clutch housing can be

checked using the following bore and face runout

procedures. The NV5600 clutch housing is a inte-

gral part of the transmission and can only be

checked off the vehicle.

CLUTCH HOUSING BORE RUNOUT

CAUTION: On diesel engines if housing bore runout

exceeds 0.015 inch, the clutch housing/transmis-

sion adapter plate must be replaced. On gas

engines if housing bore runout exceeds 0.053 in.

the clutch housing must be replaced.

NOTE: Offset dowels are available for gas engines

to correct housing bore runout. They are not avail-

able for diesel engines.

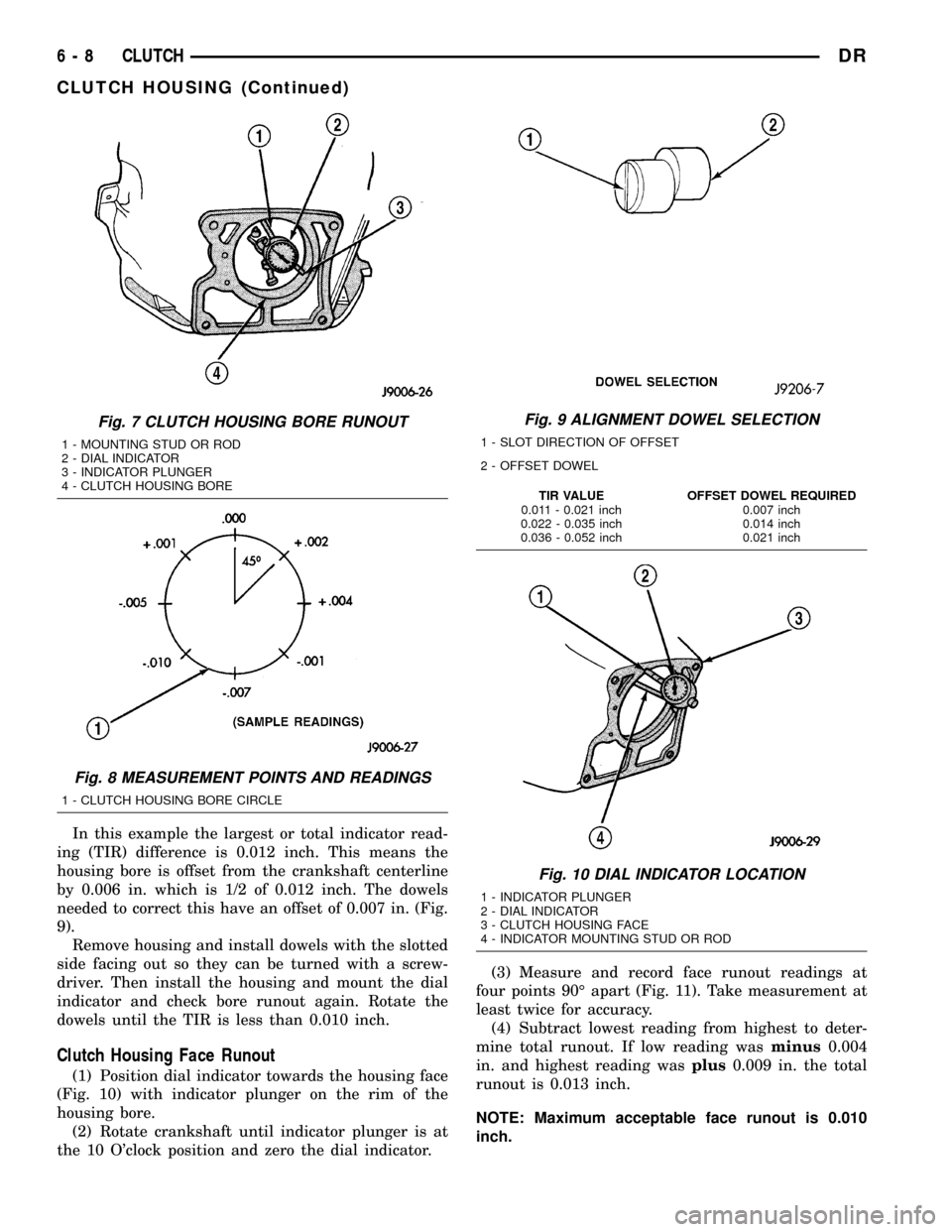

(1) Remove the clutch housing.

(2) Remove the clutch cover and disc.

(3) Replace one of the flywheel bolts with an

appropriate size threaded rod that is 10 in. (25.4 cm)

long (Fig. 6). The rod will be used to mount the dial

indicator.

(4) Remove release fork from the clutch housing.

(5) Install clutch housing. Tighten the housing

bolts nearest the alignment dowels first.

(6) Mount dial indicator on the threaded rod and

position indicator plunger on the clutch housing bore

(Fig. 7).

(7) Rotate crankshaft until indicator plunger is at

the topof the housing bore. Zero the indicator at this

point.

(8) Rotate crankshaft and record indicator read-

ings at eight points (45É apart) around the bore (Fig.

8). Take measurement at least twice for accuracy.

(9) Subtract each reading from the one 180É oppo-

site to determine runout and direction. Bore runout

example (Fig. 8):

²0.000 ± (±0.007) = 0.007 in.

²+0.002 ± (±0.010) = 0.012 in.

²+0.004 ± (±0.005) = 0.009 in.

²±0.001 ± (+0.001) = ±0.002 in.

Fig. 5 FORK, BEARING AND SPRING CLIPS

1 - FORK

2 - SPRING CLIP

3 - BEARING

4 - SPRING CLIP

Fig. 6 DIAL INDICATOR MOUNTING STUD

1 - 7/16 - 20 THREAD

2 - NUT

3 - STUD OR THREADED ROD

4 - 10 INCHES LONG

DRCLUTCH 6 - 7

CLUTCH DISC (Continued)

Page 309 of 2627

In this example the largest or total indicator read-

ing (TIR) difference is 0.012 inch. This means the

housing bore is offset from the crankshaft centerline

by 0.006 in. which is 1/2 of 0.012 inch. The dowels

needed to correct this have an offset of 0.007 in. (Fig.

9).

Remove housing and install dowels with the slotted

side facing out so they can be turned with a screw-

driver. Then install the housing and mount the dial

indicator and check bore runout again. Rotate the

dowels until the TIR is less than 0.010 inch.

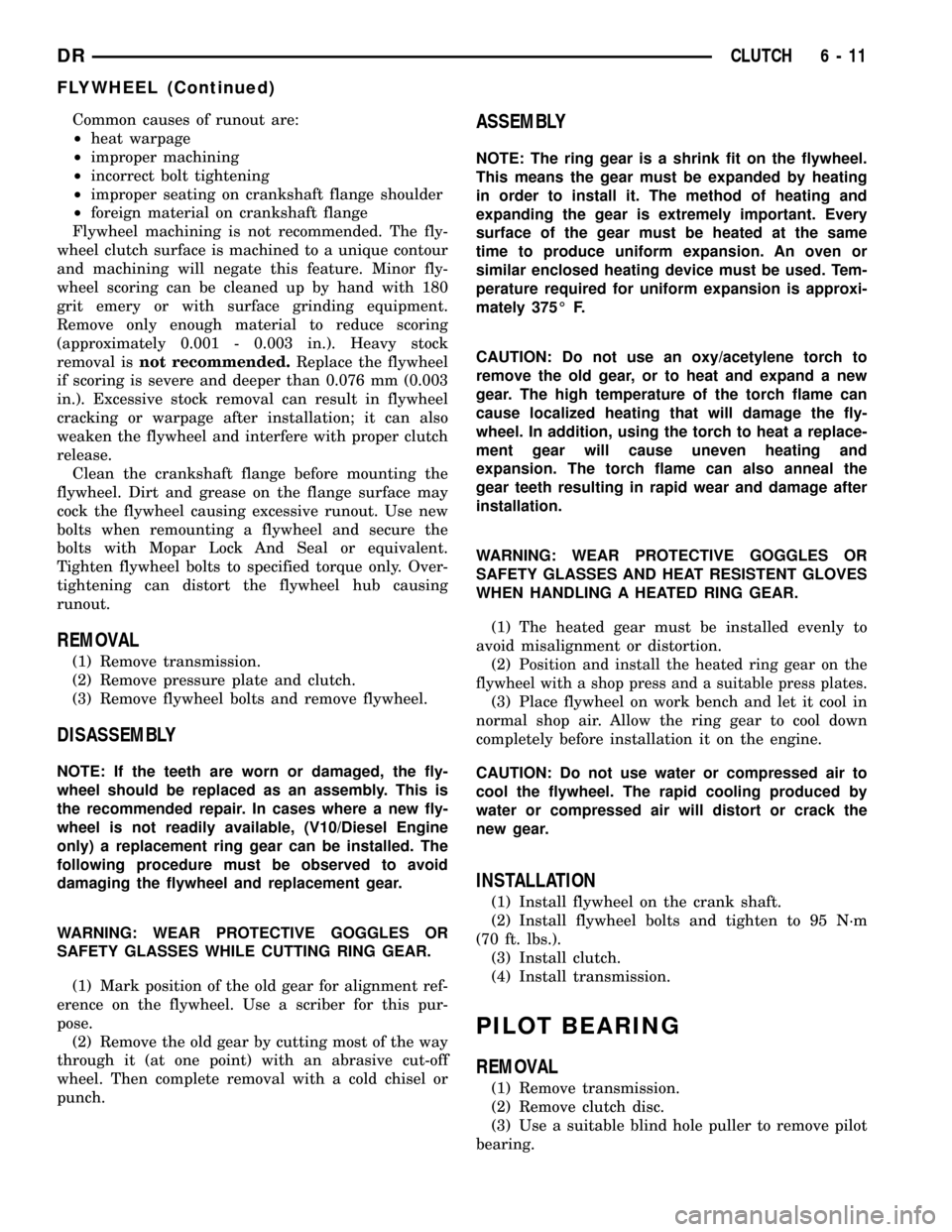

Clutch Housing Face Runout

(1) Position dial indicator towards the housing face

(Fig. 10) with indicator plunger on the rim of the

housing bore.

(2) Rotate crankshaft until indicator plunger is at

the 10 O'clock position and zero the dial indicator.(3) Measure and record face runout readings at

four points 90É apart (Fig. 11). Take measurement at

least twice for accuracy.

(4) Subtract lowest reading from highest to deter-

mine total runout. If low reading wasminus0.004

in. and highest reading wasplus0.009 in. the total

runout is 0.013 inch.

NOTE: Maximum acceptable face runout is 0.010

inch.

Fig. 7 CLUTCH HOUSING BORE RUNOUT

1 - MOUNTING STUD OR ROD

2 - DIAL INDICATOR

3 - INDICATOR PLUNGER

4 - CLUTCH HOUSING BORE

Fig. 8 MEASUREMENT POINTS AND READINGS

1 - CLUTCH HOUSING BORE CIRCLE

Fig. 9 ALIGNMENT DOWEL SELECTION

1 - SLOT DIRECTION OF OFFSET

2 - OFFSET DOWEL

TIR VALUE OFFSET DOWEL REQUIRED

0.011 - 0.021 inch 0.007 inch

0.022 - 0.035 inch 0.014 inch

0.036 - 0.052 inch 0.021 inch

Fig. 10 DIAL INDICATOR LOCATION

1 - INDICATOR PLUNGER

2 - DIAL INDICATOR

3 - CLUTCH HOUSING FACE

4 - INDICATOR MOUNTING STUD OR ROD

6 - 8 CLUTCHDR

CLUTCH HOUSING (Continued)

Page 312 of 2627

Common causes of runout are:

²heat warpage

²improper machining

²incorrect bolt tightening

²improper seating on crankshaft flange shoulder

²foreign material on crankshaft flange

Flywheel machining is not recommended. The fly-

wheel clutch surface is machined to a unique contour

and machining will negate this feature. Minor fly-

wheel scoring can be cleaned up by hand with 180

grit emery or with surface grinding equipment.

Remove only enough material to reduce scoring

(approximately 0.001 - 0.003 in.). Heavy stock

removal isnot recommended.Replace the flywheel

if scoring is severe and deeper than 0.076 mm (0.003

in.). Excessive stock removal can result in flywheel

cracking or warpage after installation; it can also

weaken the flywheel and interfere with proper clutch

release.

Clean the crankshaft flange before mounting the

flywheel. Dirt and grease on the flange surface may

cock the flywheel causing excessive runout. Use new

bolts when remounting a flywheel and secure the

bolts with Mopar Lock And Seal or equivalent.

Tighten flywheel bolts to specified torque only. Over-

tightening can distort the flywheel hub causing

runout.

REMOVAL

(1) Remove transmission.

(2) Remove pressure plate and clutch.

(3) Remove flywheel bolts and remove flywheel.

DISASSEMBLY

NOTE: If the teeth are worn or damaged, the fly-

wheel should be replaced as an assembly. This is

the recommended repair. In cases where a new fly-

wheel is not readily available, (V10/Diesel Engine

only) a replacement ring gear can be installed. The

following procedure must be observed to avoid

damaging the flywheel and replacement gear.

WARNING: WEAR PROTECTIVE GOGGLES OR

SAFETY GLASSES WHILE CUTTING RING GEAR.

(1) Mark position of the old gear for alignment ref-

erence on the flywheel. Use a scriber for this pur-

pose.

(2) Remove the old gear by cutting most of the way

through it (at one point) with an abrasive cut-off

wheel. Then complete removal with a cold chisel or

punch.

ASSEMBLY

NOTE: The ring gear is a shrink fit on the flywheel.

This means the gear must be expanded by heating

in order to install it. The method of heating and

expanding the gear is extremely important. Every

surface of the gear must be heated at the same

time to produce uniform expansion. An oven or

similar enclosed heating device must be used. Tem-

perature required for uniform expansion is approxi-

mately 375É F.

CAUTION: Do not use an oxy/acetylene torch to

remove the old gear, or to heat and expand a new

gear. The high temperature of the torch flame can

cause localized heating that will damage the fly-

wheel. In addition, using the torch to heat a replace-

ment gear will cause uneven heating and

expansion. The torch flame can also anneal the

gear teeth resulting in rapid wear and damage after

installation.

WARNING: WEAR PROTECTIVE GOGGLES OR

SAFETY GLASSES AND HEAT RESISTENT GLOVES

WHEN HANDLING A HEATED RING GEAR.

(1) The heated gear must be installed evenly to

avoid misalignment or distortion.

(2)

Position and install the heated ring gear on the

flywheel with a shop press and a suitable press plates.

(3) Place flywheel on work bench and let it cool in

normal shop air. Allow the ring gear to cool down

completely before installation it on the engine.

CAUTION: Do not use water or compressed air to

cool the flywheel. The rapid cooling produced by

water or compressed air will distort or crack the

new gear.

INSTALLATION

(1) Install flywheel on the crank shaft.

(2) Install flywheel bolts and tighten to 95 N´m

(70 ft. lbs.).

(3) Install clutch.

(4) Install transmission.

PILOT BEARING

REMOVAL

(1) Remove transmission.

(2) Remove clutch disc.

(3) Use a suitable blind hole puller to remove pilot

bearing.

DRCLUTCH 6 - 11

FLYWHEEL (Continued)

Page 338 of 2627

INSTALLATION

(1) Install tensioner on to the mounting bracket.

Tighten bolt to 41 N´m (30 ft. lbs.).

(2) Install tensioner and bracket assembly

(3) Install accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

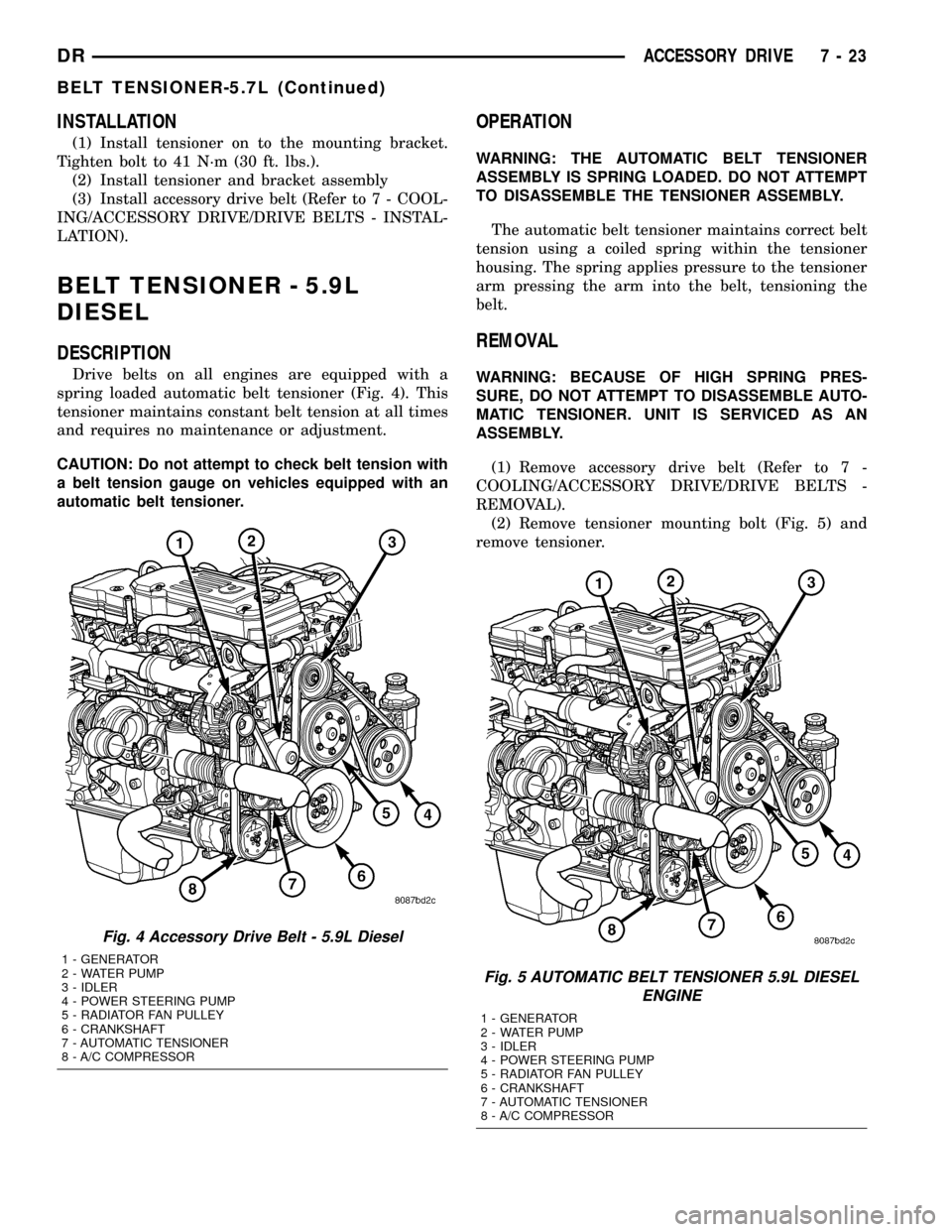

BELT TENSIONER - 5.9L

DIESEL

DESCRIPTION

Drive belts on all engines are equipped with a

spring loaded automatic belt tensioner (Fig. 4). This

tensioner maintains constant belt tension at all times

and requires no maintenance or adjustment.

CAUTION: Do not attempt to check belt tension with

a belt tension gauge on vehicles equipped with an

automatic belt tensioner.

OPERATION

WARNING: THE AUTOMATIC BELT TENSIONER

ASSEMBLY IS SPRING LOADED. DO NOT ATTEMPT

TO DISASSEMBLE THE TENSIONER ASSEMBLY.

The automatic belt tensioner maintains correct belt

tension using a coiled spring within the tensioner

housing. The spring applies pressure to the tensioner

arm pressing the arm into the belt, tensioning the

belt.

REMOVAL

WARNING: BECAUSE OF HIGH SPRING PRES-

SURE, DO NOT ATTEMPT TO DISASSEMBLE AUTO-

MATIC TENSIONER. UNIT IS SERVICED AS AN

ASSEMBLY.

(1) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(2) Remove tensioner mounting bolt (Fig. 5) and

remove tensioner.

Fig. 4 Accessory Drive Belt - 5.9L Diesel

1 - GENERATOR

2 - WATER PUMP

3 - IDLER

4 - POWER STEERING PUMP

5 - RADIATOR FAN PULLEY

6 - CRANKSHAFT

7 - AUTOMATIC TENSIONER

8 - A/C COMPRESSOR

Fig. 5 AUTOMATIC BELT TENSIONER 5.9L DIESEL

ENGINE

1 - GENERATOR

2 - WATER PUMP

3 - IDLER

4 - POWER STEERING PUMP

5 - RADIATOR FAN PULLEY

6 - CRANKSHAFT

7 - AUTOMATIC TENSIONER

8 - A/C COMPRESSOR

DRACCESSORY DRIVE 7 - 23

BELT TENSIONER-5.7L (Continued)

Page 341 of 2627

CONDITION POSSIBLE CAUSES CORRECTION

CORD EDGE FAILURE

(Tensile member exposed at edges

of belt or separated from belt body)1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Belt contacting stationary object 2. Replace belt

3. Pulley(s) out of tolerance 3. Replace pulley

4. Insufficient adhesion between

tensile member and rubber matrix4. Replace belt

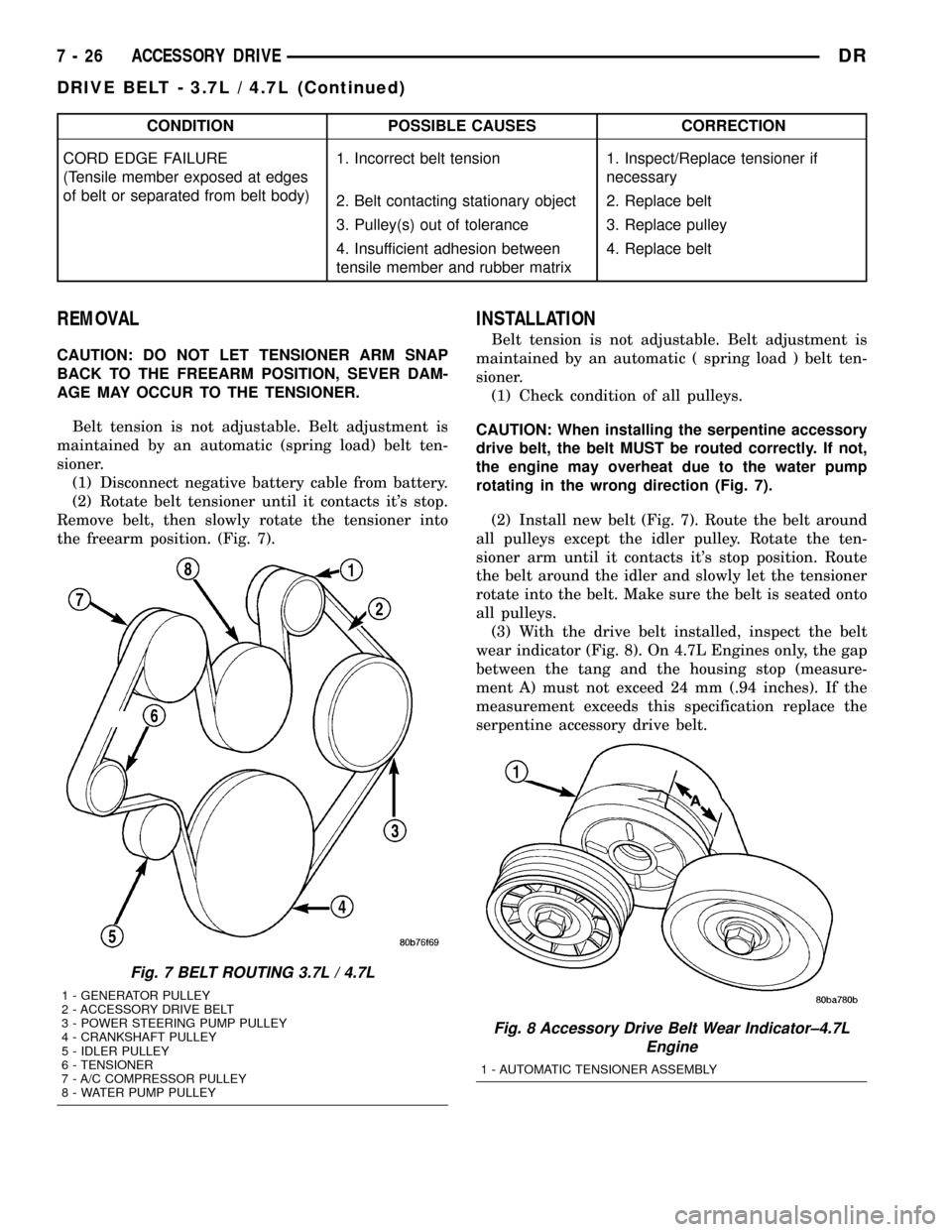

REMOVAL

CAUTION: DO NOT LET TENSIONER ARM SNAP

BACK TO THE FREEARM POSITION, SEVER DAM-

AGE MAY OCCUR TO THE TENSIONER.

Belt tension is not adjustable. Belt adjustment is

maintained by an automatic (spring load) belt ten-

sioner.

(1) Disconnect negative battery cable from battery.

(2) Rotate belt tensioner until it contacts it's stop.

Remove belt, then slowly rotate the tensioner into

the freearm position. (Fig. 7).

INSTALLATION

Belt tension is not adjustable. Belt adjustment is

maintained by an automatic ( spring load ) belt ten-

sioner.

(1) Check condition of all pulleys.

CAUTION: When installing the serpentine accessory

drive belt, the belt MUST be routed correctly. If not,

the engine may overheat due to the water pump

rotating in the wrong direction (Fig. 7).

(2) Install new belt (Fig. 7). Route the belt around

all pulleys except the idler pulley. Rotate the ten-

sioner arm until it contacts it's stop position. Route

the belt around the idler and slowly let the tensioner

rotate into the belt. Make sure the belt is seated onto

all pulleys.

(3) With the drive belt installed, inspect the belt

wear indicator (Fig. 8). On 4.7L Engines only, the gap

between the tang and the housing stop (measure-

ment A) must not exceed 24 mm (.94 inches). If the

measurement exceeds this specification replace the

serpentine accessory drive belt.

Fig. 7 BELT ROUTING 3.7L / 4.7L

1 - GENERATOR PULLEY

2 - ACCESSORY DRIVE BELT

3 - POWER STEERING PUMP PULLEY

4 - CRANKSHAFT PULLEY

5 - IDLER PULLEY

6 - TENSIONER

7 - A/C COMPRESSOR PULLEY

8 - WATER PUMP PULLEY

Fig. 8 Accessory Drive Belt Wear Indicator±4.7L

Engine

1 - AUTOMATIC TENSIONER ASSEMBLY

7 - 26 ACCESSORY DRIVEDR

DRIVE BELT - 3.7L / 4.7L (Continued)

Page 344 of 2627

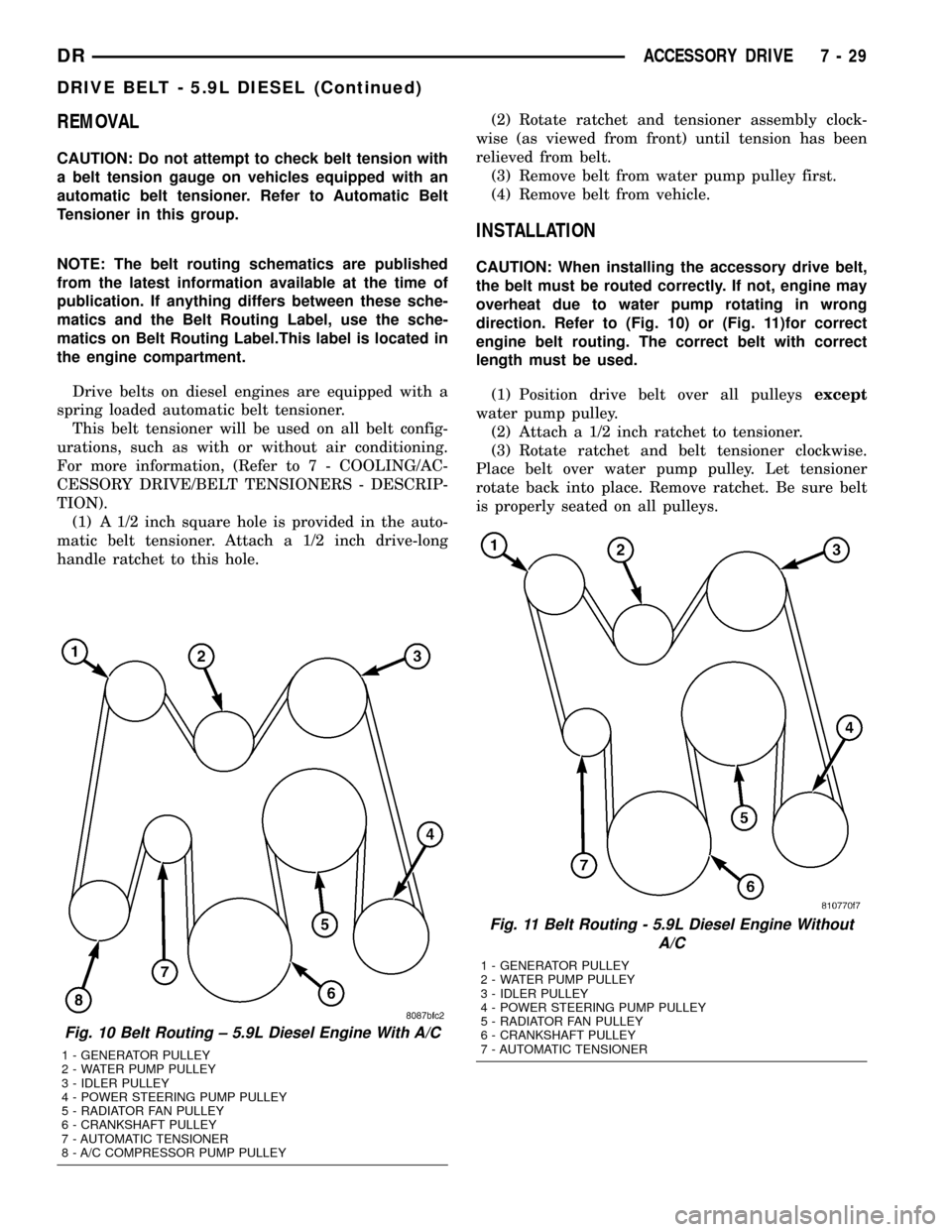

REMOVAL

CAUTION: Do not attempt to check belt tension with

a belt tension gauge on vehicles equipped with an

automatic belt tensioner. Refer to Automatic Belt

Tensioner in this group.

NOTE: The belt routing schematics are published

from the latest information available at the time of

publication. If anything differs between these sche-

matics and the Belt Routing Label, use the sche-

matics on Belt Routing Label.This label is located in

the engine compartment.

Drive belts on diesel engines are equipped with a

spring loaded automatic belt tensioner.

This belt tensioner will be used on all belt config-

urations, such as with or without air conditioning.

For more information, (Refer to 7 - COOLING/AC-

CESSORY DRIVE/BELT TENSIONERS - DESCRIP-

TION).

(1) A 1/2 inch square hole is provided in the auto-

matic belt tensioner. Attach a 1/2 inch drive-long

handle ratchet to this hole.(2) Rotate ratchet and tensioner assembly clock-

wise (as viewed from front) until tension has been

relieved from belt.

(3) Remove belt from water pump pulley first.

(4) Remove belt from vehicle.

INSTALLATION

CAUTION: When installing the accessory drive belt,

the belt must be routed correctly. If not, engine may

overheat due to water pump rotating in wrong

direction. Refer to (Fig. 10) or (Fig. 11)for correct

engine belt routing. The correct belt with correct

length must be used.

(1) Position drive belt over all pulleysexcept

water pump pulley.

(2) Attach a 1/2 inch ratchet to tensioner.

(3) Rotate ratchet and belt tensioner clockwise.

Place belt over water pump pulley. Let tensioner

rotate back into place. Remove ratchet. Be sure belt

is properly seated on all pulleys.

Fig. 10 Belt Routing ± 5.9L Diesel Engine With A/C

1 - GENERATOR PULLEY

2 - WATER PUMP PULLEY

3 - IDLER PULLEY

4 - POWER STEERING PUMP PULLEY

5 - RADIATOR FAN PULLEY

6 - CRANKSHAFT PULLEY

7 - AUTOMATIC TENSIONER

8 - A/C COMPRESSOR PUMP PULLEY

Fig. 11 Belt Routing - 5.9L Diesel Engine Without

A/C

1 - GENERATOR PULLEY

2 - WATER PUMP PULLEY

3 - IDLER PULLEY

4 - POWER STEERING PUMP PULLEY

5 - RADIATOR FAN PULLEY

6 - CRANKSHAFT PULLEY

7 - AUTOMATIC TENSIONER

DRACCESSORY DRIVE 7 - 29

DRIVE BELT - 5.9L DIESEL (Continued)