Egr DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 18 of 2627

FLUID ADDITIVES

DaimlerChrysler strongly recommends against the

addition of any fluids to the transmission, other than

those automatic transmission fluids listed above.

Exceptions to this policy are the use of special dyes

to aid in detecting fluid leaks.

Various ªspecialº additives and supplements exist

that claim to improve shift feel and/or quality. These

additives and others also claim to improve converter

clutch operation and inhibit overheating, oxidation,

varnish, and sludge. These claims have not been sup-

ported to the satisfaction of DaimlerChrysler and

these additivesmust not be used.The use of trans-

mission ªsealersº should also be avoided, since they

may adversely affect the integrity of transmission

seals.

OPERATION - AUTOMATIC TRANSMISSION

FLUID

The automatic transmission fluid is selected based

upon several qualities. The fluid must provide a high

level of protection for the internal components by

providing a lubricating film between adjacent metal

components. The fluid must also be thermally stable

so that it can maintain a consistent viscosity through

a large temperature range. If the viscosity stays con-

stant through the temperature range of operation,

transmission operation and shift feel will remain con-

sistent. Transmission fluid must also be a good con-

ductor of heat. The fluid must absorb heat from the

internal transmission components and transfer that

heat to the transmission case.

FLUID CAPACITIES

SPECIFICATIONS

FLUID CAPACITIES

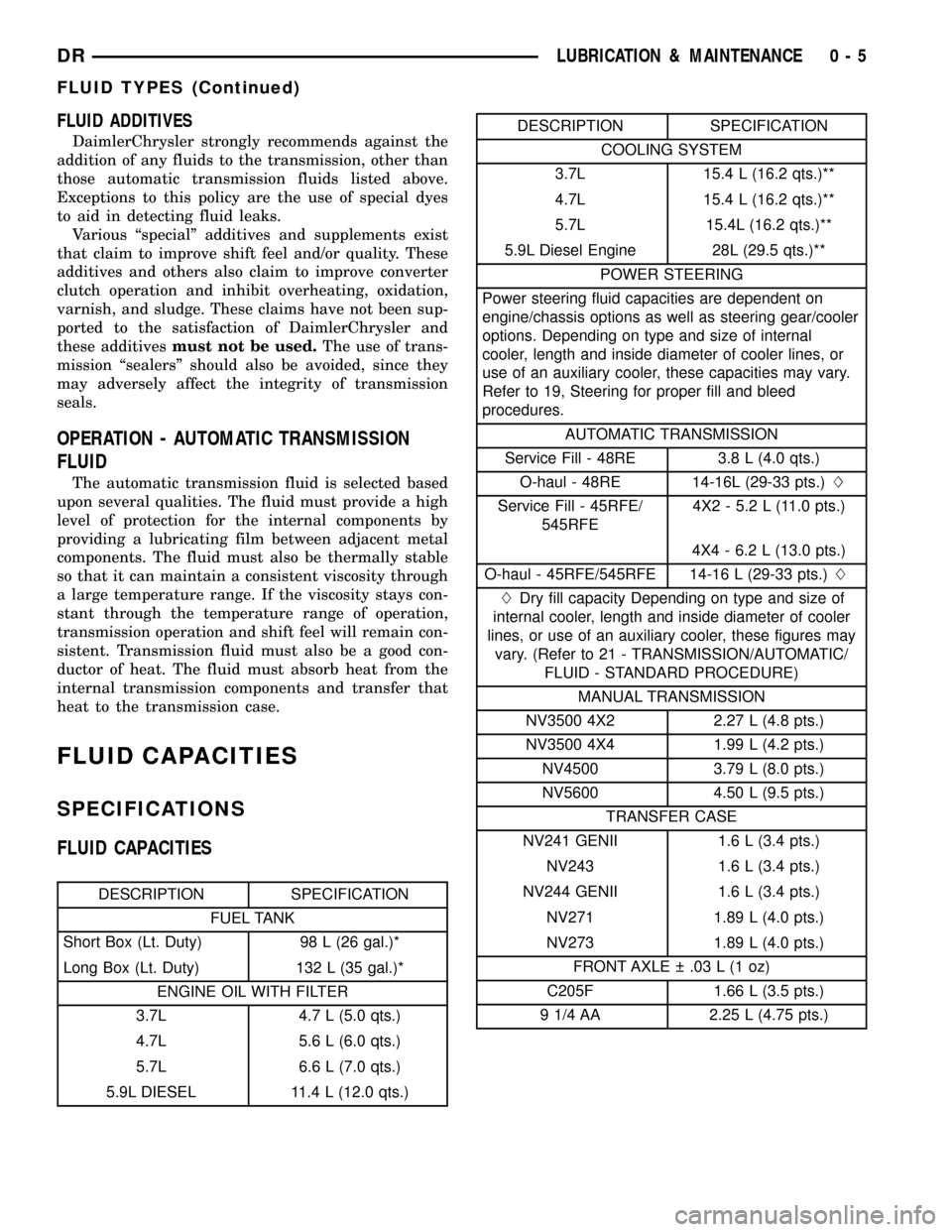

DESCRIPTION SPECIFICATION

FUEL TANK

Short Box (Lt. Duty) 98 L (26 gal.)*

Long Box (Lt. Duty) 132 L (35 gal.)*

ENGINE OIL WITH FILTER

3.7L 4.7 L (5.0 qts.)

4.7L 5.6 L (6.0 qts.)

5.7L 6.6 L (7.0 qts.)

5.9L DIESEL 11.4 L (12.0 qts.)

DESCRIPTION SPECIFICATION

COOLING SYSTEM

3.7L 15.4 L (16.2 qts.)**

4.7L 15.4 L (16.2 qts.)**

5.7L 15.4L (16.2 qts.)**

5.9L Diesel Engine 28L (29.5 qts.)**

POWER STEERING

Power steering fluid capacities are dependent on

engine/chassis options as well as steering gear/cooler

options. Depending on type and size of internal

cooler, length and inside diameter of cooler lines, or

use of an auxiliary cooler, these capacities may vary.

Refer to 19, Steering for proper fill and bleed

procedures.

AUTOMATIC TRANSMISSION

Service Fill - 48RE 3.8 L (4.0 qts.)

O-haul - 48RE 14-16L (29-33 pts.)L

Service Fill - 45RFE/

545RFE4X2 - 5.2 L (11.0 pts.)

4X4 - 6.2 L (13.0 pts.)

O-haul - 45RFE/545RFE 14-16 L (29-33 pts.)L

LDry fill capacity Depending on type and size of

internal cooler, length and inside diameter of cooler

lines, or use of an auxiliary cooler, these figures may

vary. (Refer to 21 - TRANSMISSION/AUTOMATIC/

FLUID - STANDARD PROCEDURE)

MANUAL TRANSMISSION

NV3500 4X2 2.27 L (4.8 pts.)

NV3500 4X4 1.99 L (4.2 pts.)

NV4500 3.79 L (8.0 pts.)

NV5600 4.50 L (9.5 pts.)

TRANSFER CASE

NV241 GENII 1.6 L (3.4 pts.)

NV243 1.6 L (3.4 pts.)

NV244 GENII 1.6 L (3.4 pts.)

NV271 1.89 L (4.0 pts.)

NV273 1.89 L (4.0 pts.)

FRONT AXLE .03 L (1 oz)

C205F 1.66 L (3.5 pts.)

9 1/4 AA 2.25 L (4.75 pts.)

DRLUBRICATION & MAINTENANCE 0 - 5

FLUID TYPES (Continued)

Page 35 of 2627

A wooden crossbeam may be required for proper

connection when using the sling-type, front-end tow-

ing method.

SAFETY PRECAUTIONS

CAUTION: The following safety precautions must be

observed when towing a vehicle:

²Secure loose and protruding parts.

²Always use a safety chain system that is inde-

pendent of the lifting and towing equipment.

²Do not allow towing equipment to contact the

disabled vehicle's fuel tank.

²Do not allow anyone under the disabled vehicle

while it is lifted by the towing device.

²Do not allow passengers to ride in a vehicle

being towed.

²Always observe state and local laws regarding

towing regulations.

²Do not tow a vehicle in a manner that could

jeopardize the safety of the operator, pedestrians or

other motorists.

²Do not attach tow chains, T-hooks, J-hooks, or a

tow sling to a bumper, steering linkage, drive shafts

or a non-reinforced frame hole.

²Do not tow a heavily loaded vehicle. Damage to

the cab, cargo box or frame may result. Use a flatbed

device to transport a loaded vehicle.

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels removed,

install lug nuts to retain brake drums or rotors.

A towed vehicle should be raised until lifted wheels

are a minimum 100 mm (4 in) from the ground. Be

sure there is adequate ground clearance at the oppo-

site end of the vehicle, especially when towing over

rough terrain or steep rises in the road. If necessary,remove the wheels from the lifted end of the vehicle

and lower the vehicle closer to the ground, to

increase the ground clearance at the opposite end of

the vehicle. Install lug nuts on wheel attaching studs

to retain brake drums or rotors.

RAMP ANGLE

If a vehicle with flat-bed towing equipment is used,

the approach ramp angle should not exceed 15

degrees.

TOWING WHEN KEYS ARE NOT AVAILABLE

When the vehicle is locked and keys are not avail-

able, use a flat bed hauler. A Wheel-lift or Sling-type

device can be used on 4WD vehicles providedall the

wheels are lifted off the ground using tow dol-

lies.

FOUR-WHEEL-DRIVE VEHICLE TOWING

Chrysler Corporation recommends that a vehicle be

transported on a flat-bed device. A Wheel-lift or

Sling-type device can be used providedall the

wheels are lifted off the ground using tow dol-

lies.

WARNING: WHEN TOWING A DISABLED VEHICLE

AND THE DRIVE WHEELS ARE SECURED IN A

WHEEL LIFT OR TOW DOLLIES, ENSURE THE

TRANSMISSION IS IN THE PARK POSITION (AUTO-

MATIC TRANSMISSION) OR A FORWARD DRIVE

GEAR (MANUAL TRANSMISSION).

CAUTION: Many vehicles are equipped with air

dams, spoilers, and/or ground effect panels. To

avoid component damage, a wheel-lift towing vehi-

cle or a flat-bed hauling vehicle is recommended.

0 - 22 LUBRICATION & MAINTENANCEDR

TOWING (Continued)

Page 41 of 2627

(1) Start the engine and turn wheels both ways

before straightening the wheels. Center and Secure

the steering wheel and turn off engine.

(2) Loosen the adjustment sleeve clamp bolts.

(3) Adjust the right wheel toe position with the

drag link. Turn the sleeve until the right wheel is at

the correct TOE-IN position. Position clamp bolts to

their original position and tighten to specifications.

Make sure the toe setting does not change dur-

ing clamp tightening.

(4) Adjust left wheel toe position with tie rod at

left knuckle. Turn the sleeve until the left wheel is at

the correct TOE-IN position. Position clamp bolts to

their original position and tighten to specifications.

Make sure the toe setting does not change dur-

ing clamp tightening.

(5) Verify the right toe setting and a straight steer-

ing wheel.

(6) Road test the vehicle.

SPECIFICATIONS

ALIGNMENT

NOTE: All alignment specifications are in degrees.

SPECIFICATIONS

DESCRIP-

TIONSPECIFICATION

VEHICLE

1500WHEEL

BASECASTER

(4.0É

Min,

+.75É

Max)CAMBER

( .50É)TOTAL

TOE-IN

( .10É)

4X2 120.5 in 4.0É .0É .10É

4X2 140.5 in 4.2É .0É .10É

4X2 160.5 in 4.4É .0É .10É

VEHICLE

1500WHEEL

BASECASTER

(4.0É

Min,

+.75É

Min)CAMBER

( .50É)TOTAL

TOE-IN

( .10É)

4X4 120.5 in 4.2É .0É .10É

4X4 140.5 in 4.4É .0É .10É

4X4 160.5 in 4.6É .0É .10É

MAX

RT/LT

DIF-

FERENCE

4X2

1500Ð .40É .50É 0.06É

DESCRIP-

TIONSPECIFICATION

MAX

RT/LT

DIF-

FERENCE

4X4

1500Ð .40É .60É 0.06É

VEHICLE

4X2

2500 &

3500WHEEL

BASECASTER

(3.55É

Min,

+.75É

Max)CAMBER

( .50É)TOTAL

TOE-IN

(0.20É

.10É)

4X2

2500&3500140 4.0É 0.0É .10É

.05É

4X2

2500&3500160 4.3É 0.0É .10É

.05É

MAX

RT/LT

DIF-

FERENCE

4X2

2500&3500Ð 0.4É 0.6É 0.1É

VEHICLE

4X4

2500&3500WHEEL

BASECASTER

(4.0É

Min,

+.75É

Max)CAMBER

(.25É

.5É)TOTAL

TOE-IN

(0.20É

.10É)

4X4

2500&3500140 4.5É .25É .10É

.05É

4X4

2500&3500160 4.7É .25É .10É

.05É

MAX

RT/LT

DIF-

FERENCE

4X4

2500&3500Ð .5É .5É 0.1É

DESCRIP-

TIONREAR SPECIFICATION

CAMBER

(-.10É 0.35É)TOTAL TOE-IN

(0.30É 0.35É)

THRUST ANGLE 0É 0.4É

4X2

4X4

1500

THRUST ANGLE -0.2É 0.2É

4X2

4X4

2500&3500

2 - 6 WHEEL ALIGNMENTDR

WHEEL ALIGNMENT (Continued)

Page 62 of 2627

INSTALLATION

CAUTION: The left and right side torsion bars are

NOT interchangeable. The bars are identified and

stamped R or L, for right or left. The bars do not

have a front or rear end and can be installed with

either end facing forward.

(1) Insert torsion bar ends into anchor and suspen-

sion arm.

(2) Position the anchor in the frame crossmember.

(3) Install Special Tool - 8686 to the anchor and

the crossmember (Fig. 30).

(4) Increase the tension on the anchor in order to

load the torsion bar.

(5) Install the adjustment bolt and the adjuster

nut.

(6) Turn adjustment bolt clockwise the recorded

amount of turns.

(7) Remove tool - 8686 from the torsion bar cross-

member (Fig. 30).

(8) Install the transfer case skid plate (Refer to 13

- FRAME & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - INSTALLATION).

(9) Lower vehicle and adjust the front suspension

height (Refer to 2 - SUSPENSION/WHEEL ALIGN-

MENT - STANDARD PROCEDURE).

(10) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

UPPER BALL JOINT

DIAGNOSIS AND TESTING - UPPER BALL

JOINT

NOTE: If the ball joint is equipped with a lubrication

fitting, grease the joint then road test the vehicle

before performing test.

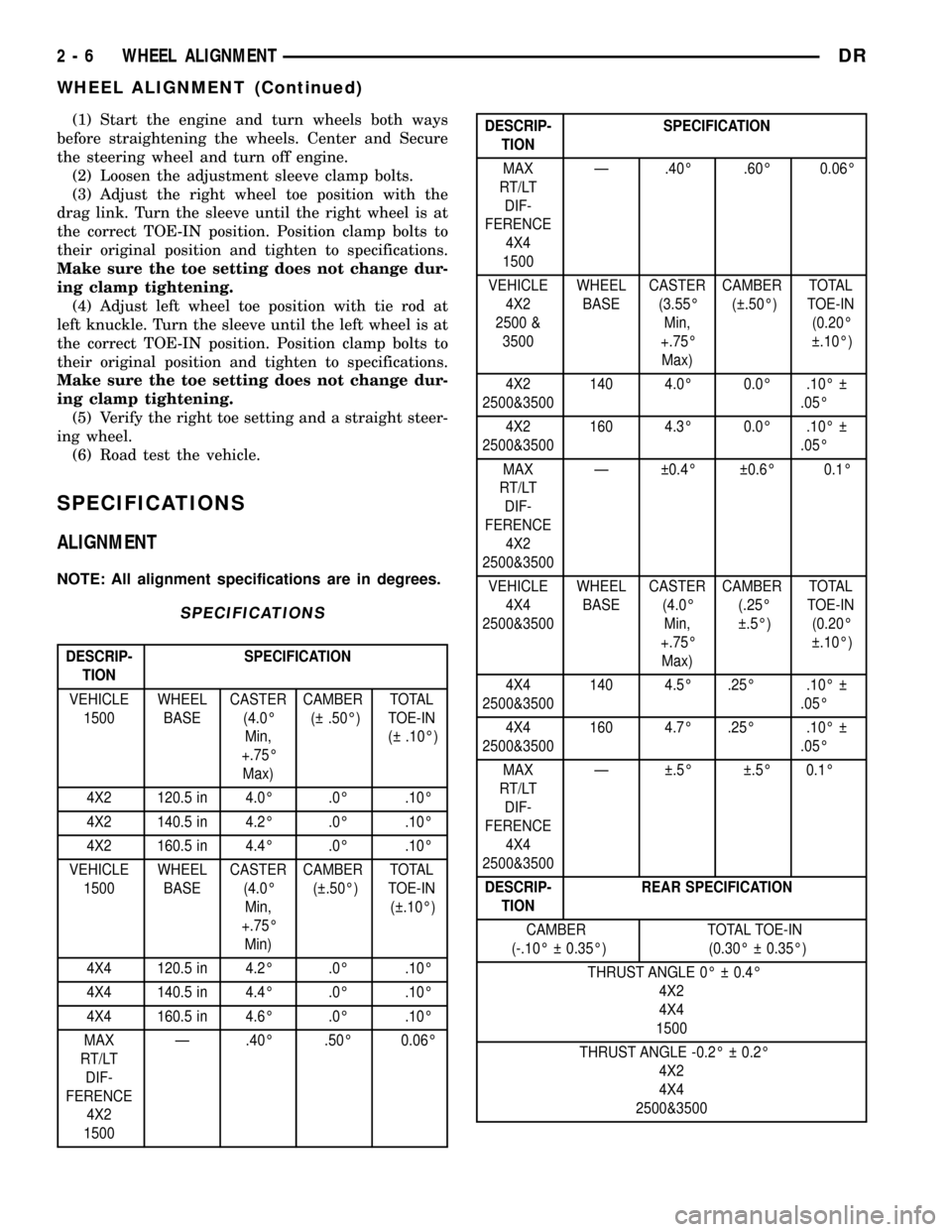

(1) Raise the front of the vehicle. Place safety floor

stands under both lower control arms as far outboard

as possible. Lower the vehicle to allow the stands to

support some or all of the vehicle weight.

(2) Remove the front tires.(3) Mount a dial indicator solidly to the frame and

then zero the dial indicator.

(4) Position dial indicator plunger on the topside of

the upper ball joint (Fig. 32).

NOTE: The dial indicator plunger must be perpen-

dicular to the machined surface of the ball joint

(Fig. 32).

NOTE: Use care not to pry or tear the ball joint

boot, when checking the free play.

(5) Position a pry bar between the steering

knuckle and the upper control arm. Pry upwards on

the upper control arm (Fig. 32).

(6) If the travel exceeds 0.5 mm (0.020 in.), replace

the upper control arm since the upper ball joint is

integral to the arm (Refer to 2 - SUSPENSION/

FRONT/UPPER CONTROL ARM - REMOVAL).

(7) If the upper ball joint is within specs reinstall

the front tires (Refer to 22 - TIRES/WHEELS/

WHEELS - STANDARD PROCEDURE).

Fig. 32 UPPER BALL JOINT PLAY

1 - DIAL INDICATOR

2 - UPPER CONTROL ARM

3-PRYBAR

4 - KNUCKLE

5 - BALL JOINT BOOT

DRFRONT - INDEPENDENT FRONT SUSPENSION 2 - 27

TORSION BAR (Continued)

Page 85 of 2627

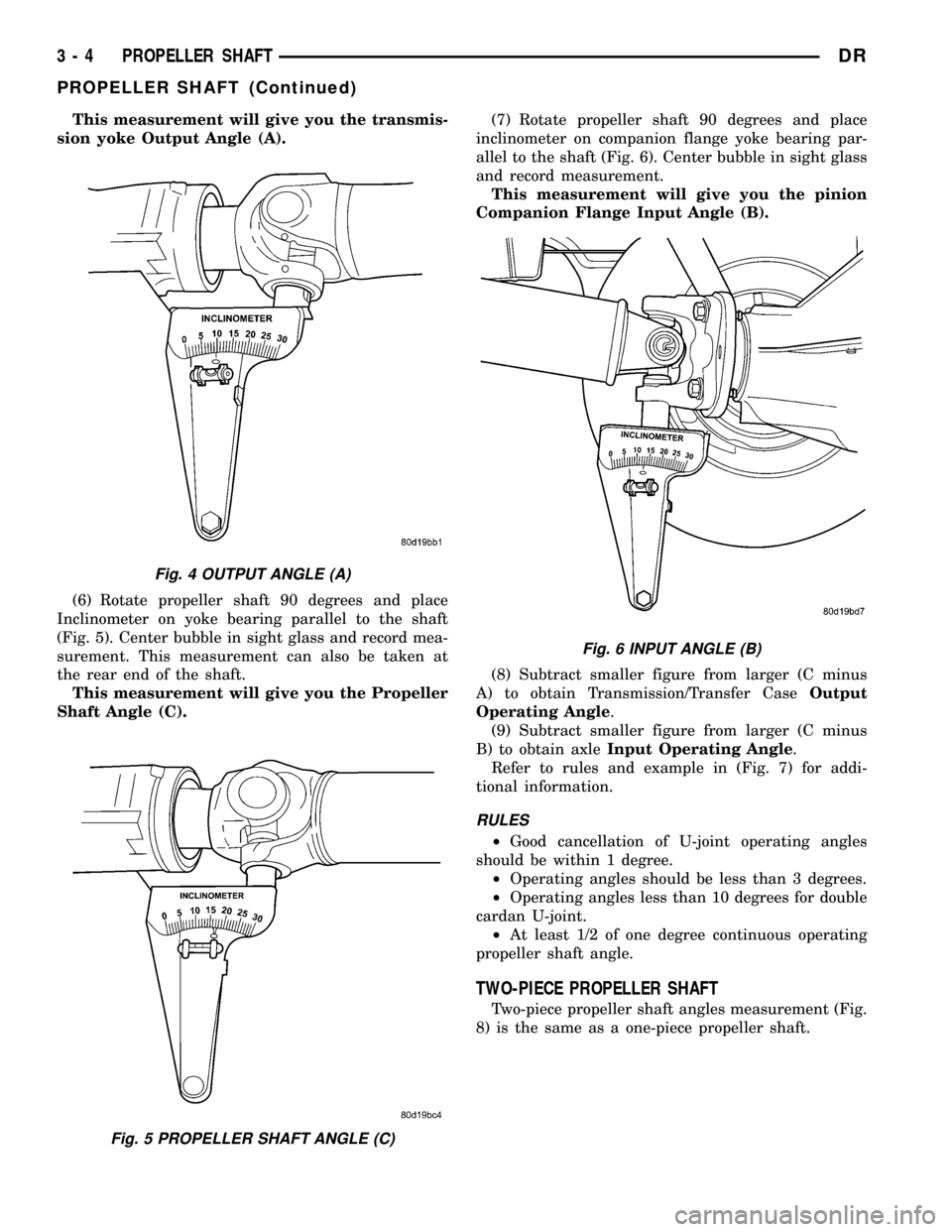

This measurement will give you the transmis-

sion yoke Output Angle (A).

(6) Rotate propeller shaft 90 degrees and place

Inclinometer on yoke bearing parallel to the shaft

(Fig. 5). Center bubble in sight glass and record mea-

surement. This measurement can also be taken at

the rear end of the shaft.

This measurement will give you the Propeller

Shaft Angle (C).(7) Rotate propeller shaft 90 degrees and place

inclinometer on companion flange yoke bearing par-

allel to the shaft (Fig. 6). Center bubble in sight glass

and record measurement.

This measurement will give you the pinion

Companion Flange Input Angle (B).

(8) Subtract smaller figure from larger (C minus

A) to obtain Transmission/Transfer CaseOutput

Operating Angle.

(9) Subtract smaller figure from larger (C minus

B) to obtain axleInput Operating Angle.

Refer to rules and example in (Fig. 7) for addi-

tional information.

RULES

²Good cancellation of U-joint operating angles

should be within 1 degree.

²Operating angles should be less than 3 degrees.

²Operating angles less than 10 degrees for double

cardan U-joint.

²At least 1/2 of one degree continuous operating

propeller shaft angle.

TWO-PIECE PROPELLER SHAFT

Two-piece propeller shaft angles measurement (Fig.

8) is the same as a one-piece propeller shaft.

Fig. 4 OUTPUT ANGLE (A)

Fig. 5 PROPELLER SHAFT ANGLE (C)

Fig. 6 INPUT ANGLE (B)

3 - 4 PROPELLER SHAFTDR

PROPELLER SHAFT (Continued)

Page 168 of 2627

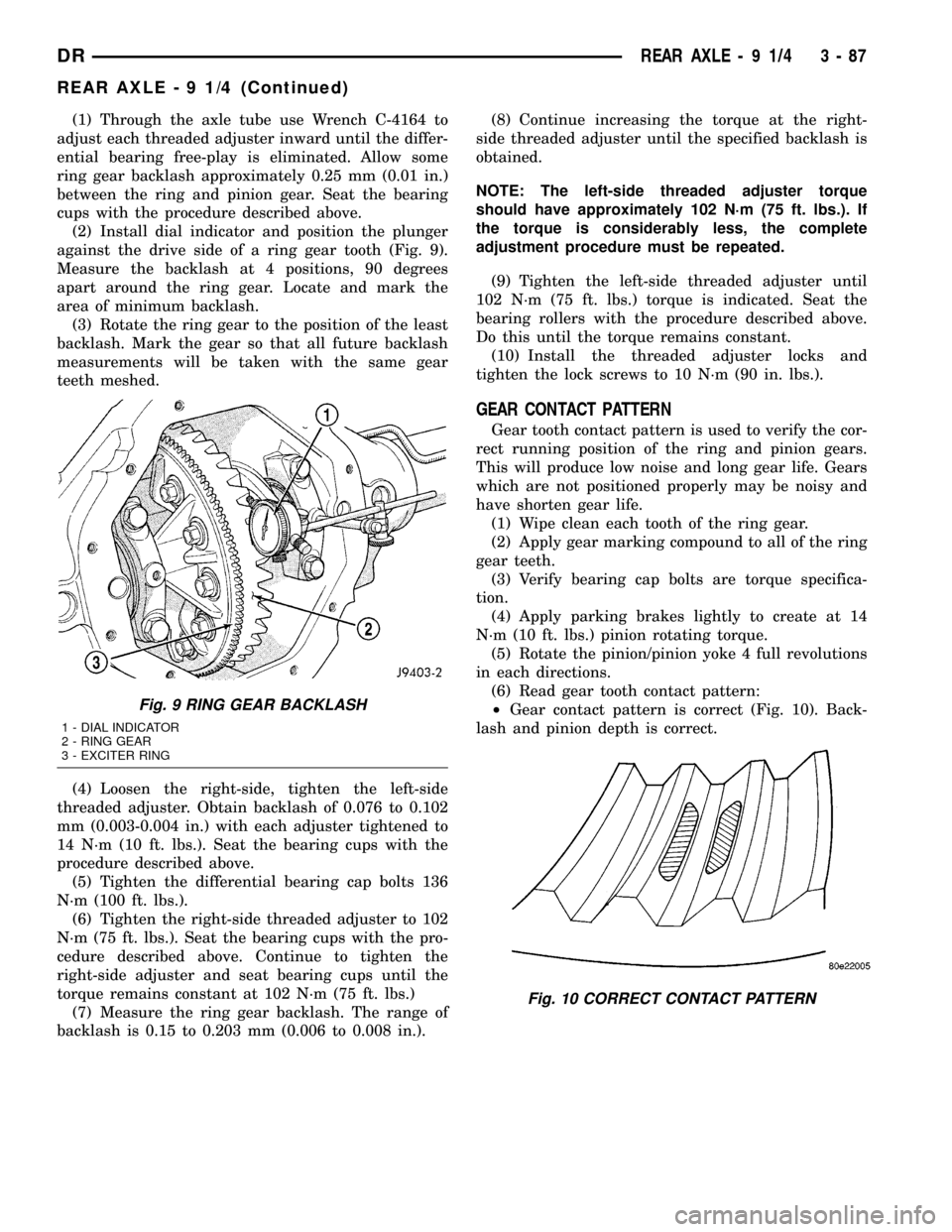

(1) Through the axle tube use Wrench C-4164 to

adjust each threaded adjuster inward until the differ-

ential bearing free-play is eliminated. Allow some

ring gear backlash approximately 0.25 mm (0.01 in.)

between the ring and pinion gear. Seat the bearing

cups with the procedure described above.

(2) Install dial indicator and position the plunger

against the drive side of a ring gear tooth (Fig. 9).

Measure the backlash at 4 positions, 90 degrees

apart around the ring gear. Locate and mark the

area of minimum backlash.

(3) Rotate the ring gear to the position of the least

backlash. Mark the gear so that all future backlash

measurements will be taken with the same gear

teeth meshed.

(4) Loosen the right-side, tighten the left-side

threaded adjuster. Obtain backlash of 0.076 to 0.102

mm (0.003-0.004 in.) with each adjuster tightened to

14 N´m (10 ft. lbs.). Seat the bearing cups with the

procedure described above.

(5) Tighten the differential bearing cap bolts 136

N´m (100 ft. lbs.).

(6) Tighten the right-side threaded adjuster to 102

N´m (75 ft. lbs.). Seat the bearing cups with the pro-

cedure described above. Continue to tighten the

right-side adjuster and seat bearing cups until the

torque remains constant at 102 N´m (75 ft. lbs.)

(7) Measure the ring gear backlash. The range of

backlash is 0.15 to 0.203 mm (0.006 to 0.008 in.).(8) Continue increasing the torque at the right-

side threaded adjuster until the specified backlash is

obtained.

NOTE: The left-side threaded adjuster torque

should have approximately 102 N´m (75 ft. lbs.). If

the torque is considerably less, the complete

adjustment procedure must be repeated.

(9) Tighten the left-side threaded adjuster until

102 N´m (75 ft. lbs.) torque is indicated. Seat the

bearing rollers with the procedure described above.

Do this until the torque remains constant.

(10) Install the threaded adjuster locks and

tighten the lock screws to 10 N´m (90 in. lbs.).

GEAR CONTACT PATTERN

Gear tooth contact pattern is used to verify the cor-

rect running position of the ring and pinion gears.

This will produce low noise and long gear life. Gears

which are not positioned properly may be noisy and

have shorten gear life.

(1) Wipe clean each tooth of the ring gear.

(2) Apply gear marking compound to all of the ring

gear teeth.

(3) Verify bearing cap bolts are torque specifica-

tion.

(4) Apply parking brakes lightly to create at 14

N´m (10 ft. lbs.) pinion rotating torque.

(5) Rotate the pinion/pinion yoke 4 full revolutions

in each directions.

(6) Read gear tooth contact pattern:

²Gear contact pattern is correct (Fig. 10). Back-

lash and pinion depth is correct.

Fig. 9 RING GEAR BACKLASH

1 - DIAL INDICATOR

2 - RING GEAR

3 - EXCITER RING

Fig. 10 CORRECT CONTACT PATTERN

DRREAR AXLE - 9 1/4 3 - 87

REAR AXLE - 9 1/4 (Continued)

Page 276 of 2627

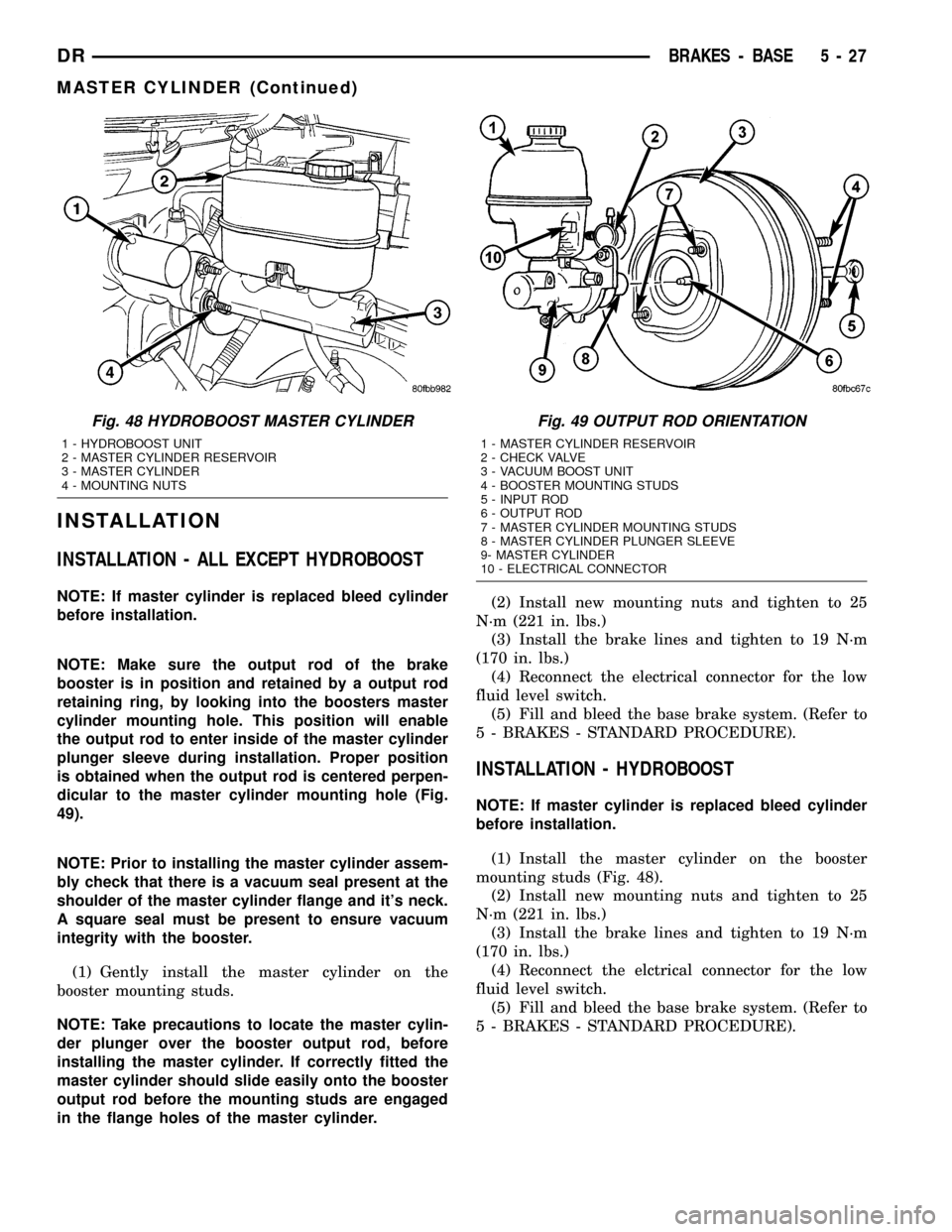

INSTALLATION

INSTALLATION - ALL EXCEPT HYDROBOOST

NOTE: If master cylinder is replaced bleed cylinder

before installation.

NOTE: Make sure the output rod of the brake

booster is in position and retained by a output rod

retaining ring, by looking into the boosters master

cylinder mounting hole. This position will enable

the output rod to enter inside of the master cylinder

plunger sleeve during installation. Proper position

is obtained when the output rod is centered perpen-

dicular to the master cylinder mounting hole (Fig.

49).

NOTE: Prior to installing the master cylinder assem-

bly check that there is a vacuum seal present at the

shoulder of the master cylinder flange and it's neck.

A square seal must be present to ensure vacuum

integrity with the booster.

(1) Gently install the master cylinder on the

booster mounting studs.

NOTE: Take precautions to locate the master cylin-

der plunger over the booster output rod, before

installing the master cylinder. If correctly fitted the

master cylinder should slide easily onto the booster

output rod before the mounting studs are engaged

in the flange holes of the master cylinder.(2) Install new mounting nuts and tighten to 25

N´m (221 in. lbs.)

(3) Install the brake lines and tighten to 19 N´m

(170 in. lbs.)

(4) Reconnect the electrical connector for the low

fluid level switch.

(5) Fill and bleed the base brake system. (Refer to

5 - BRAKES - STANDARD PROCEDURE).

INSTALLATION - HYDROBOOST

NOTE: If master cylinder is replaced bleed cylinder

before installation.

(1) Install the master cylinder on the booster

mounting studs (Fig. 48).

(2) Install new mounting nuts and tighten to 25

N´m (221 in. lbs.)

(3) Install the brake lines and tighten to 19 N´m

(170 in. lbs.)

(4) Reconnect the elctrical connector for the low

fluid level switch.

(5) Fill and bleed the base brake system. (Refer to

5 - BRAKES - STANDARD PROCEDURE).

Fig. 48 HYDROBOOST MASTER CYLINDER

1 - HYDROBOOST UNIT

2 - MASTER CYLINDER RESERVOIR

3 - MASTER CYLINDER

4 - MOUNTING NUTS

Fig. 49 OUTPUT ROD ORIENTATION

1 - MASTER CYLINDER RESERVOIR

2 - CHECK VALVE

3 - VACUUM BOOST UNIT

4 - BOOSTER MOUNTING STUDS

5 - INPUT ROD

6 - OUTPUT ROD

7 - MASTER CYLINDER MOUNTING STUDS

8 - MASTER CYLINDER PLUNGER SLEEVE

9- MASTER CYLINDER

10 - ELECTRICAL CONNECTOR

DRBRAKES - BASE 5 - 27

MASTER CYLINDER (Continued)

Page 295 of 2627

Brake fluid apply pressure is modulated according

to wheel speed, degree of slip and rate of decelera-

tion. Sensors at each front wheel convert wheel speed

into electrical signals. These signals are transmitted

to the CAB for processing and determination of

wheel slip and deceleration rate.

The ABS system has three fluid pressure control

channels. The front brakes are controlled separately

and the rear brakes in tandem. A speed sensor input

signal indicating a wheel slip condition activates the

CAB antilock program.

There are Two solenoid valves (Isolation and Dump

valve) which are used in each antilock control chan-

nel. The valves are all located within the HCU valve

body and work in pairs to either increase, hold, or

decrease apply pressure as needed in the individual

control channels.

During an ABS stop the ISO valve is energized

which acts to prevent further pressure build-up to

the calipers. Then the Dump valve dumps off pres-

sure until the wheel unlocks. This will continue until

the wheels quit slipping altogether.STANDARD PROCEDURE - ABS BRAKE

BLEEDING

ABS system bleeding requires conventional bleed-

ing methods plus use of the DRB scan tool. The pro-

cedure involves performing a base brake bleeding,

followed by use of the scan tool to cycle and bleed the

HCU pump and solenoids. A second base brake bleed-

ing procedure is then required to remove any air

remaining in the system.

(1) Perform base brake bleeding,(Refer to 5 -

BRAKES - STANDARD PROCEDURE) OR (Refer to

5 - BRAKES - STANDARD PROCEDURE).

(2) Connect scan tool to the Data Link Connector.

(3) Select ANTILOCK BRAKES, followed by MIS-

CELLANEOUS, then ABS BRAKES. Follow the

instructions displayed. When scan tool displays TEST

COMPLETE, disconnect scan tool and proceed.

(4) Perform base brake bleeding a second time,(Re-

fer to 5 - BRAKES - STANDARD PROCEDURE) OR

(Refer to 5 - BRAKES - STANDARD PROCEDURE).

(5) Top off master cylinder fluid level and verify

proper brake operation before moving vehicle.

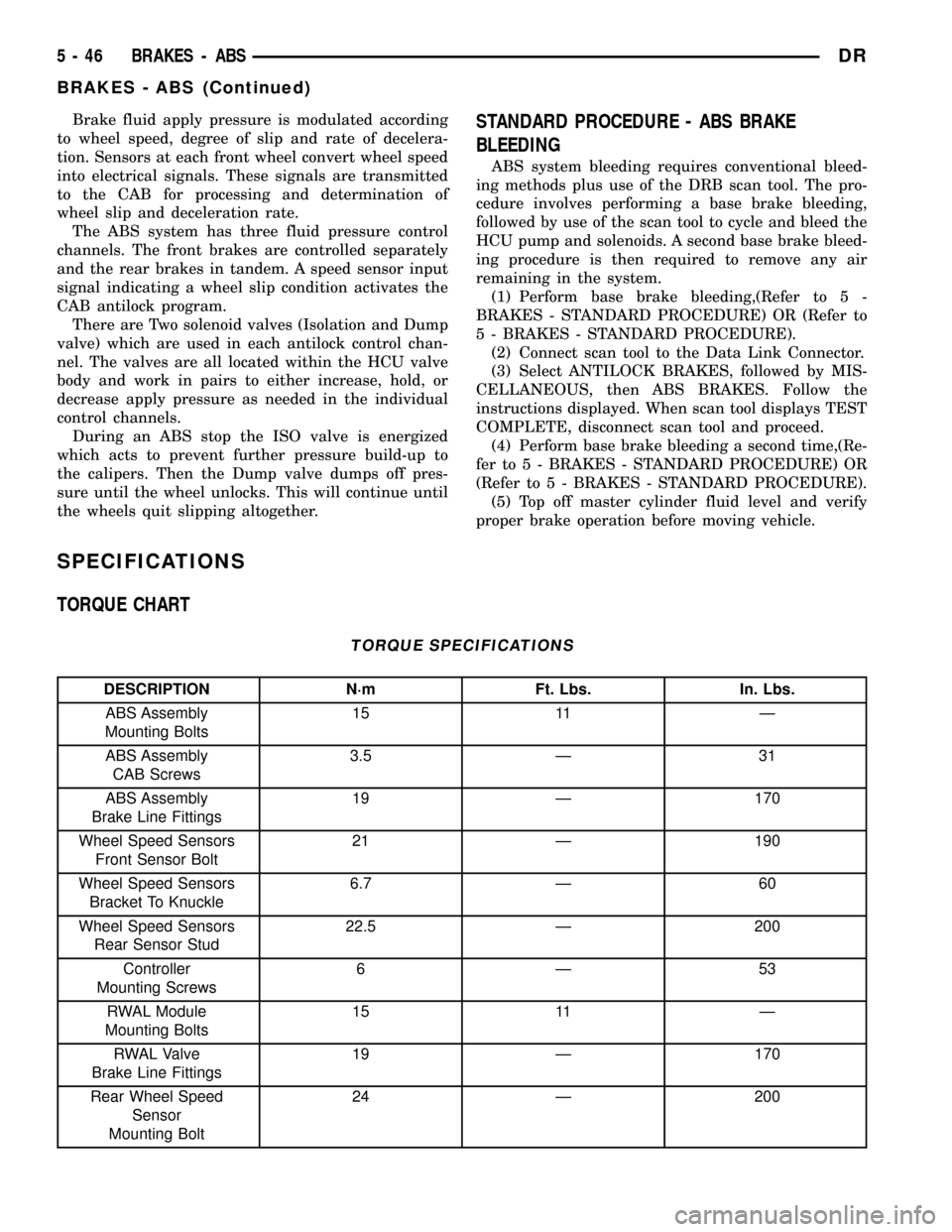

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

ABS Assembly

Mounting Bolts15 11 Ð

ABS Assembly

CAB Screws3.5 Ð 31

ABS Assembly

Brake Line Fittings19 Ð 170

Wheel Speed Sensors

Front Sensor Bolt21 Ð 190

Wheel Speed Sensors

Bracket To Knuckle6.7 Ð 60

Wheel Speed Sensors

Rear Sensor Stud22.5 Ð 200

Controller

Mounting Screws6Ð53

RWAL Module

Mounting Bolts15 11 Ð

RWAL Valve

Brake Line Fittings19 Ð 170

Rear Wheel Speed

Sensor

Mounting Bolt24 Ð 200

5 - 46 BRAKES - ABSDR

BRAKES - ABS (Continued)

Page 298 of 2627

TONE WHEEL

DIAGNOSIS AND TESTING - REAR WHEEL

SPEED SENSOR

Diagnosis of base brake conditions which are

mechanical in nature should be performed first. This

includes brake noise, lack of power assist, parking

brake, or vehicle vibration during normal braking.

The Antilock brake system performs several self-

tests every time the ignition switch is turned on and

the vehicle is driven. The CAB monitors the system

inputs and outputs circuits to verify the system is

operating properly. If the CAB senses a malfunction

in the system it will set a DTC into memory and trig-

ger the warning lamp.

NOTE: The MDS or DRB III scan tool is used to

diagnose the Antilock Brake system. For test proce-

dures refer to the Chassis Diagnostic Manual.

HYDRAULIC/MECHANICAL

DESCRIPTION - ELECTRONIC VARIABLE

BRAKE PROPORTIONING

Vehicles equipped with ABS use electronic variable

brake proportioning (EVBP) to balance front-to-rear

braking. The EVBP is used in place of a rear propor-

tioning valve. The EVBP system uses the ABS sys-

tem to control the slip of the rear wheels in partial

braking range. The braking force of the rear wheels

is controlled electronically by using the inlet and out-

let valves located in the integrated control unit

(ICU).

OPERATION - ELECTRONIC VARIABLE BRAKE

PROPORTIONING

EVBP is able to decrease, hold and increase rear

brake pressure without activating full ABS control.

Upon entry into EVBP the inlet valve for the rear

brake circuit is switched on so that the fluid supply

from the master cylinder is shut off. In order to

decrease the rear brake pressure, the outlet valve for

the rear brake circuit is pulsed. This allows fluid to

enter the low pressure accumulator (LPA) in the

hydraulic control unit (HCU) resulting in a drop in

fluid pressure to the rear brakes. In order to increase

the rear brake pressure, the outlet valve is switched

off and the inlet valve is pulsed. This increases the

pressure to the rear brakes.

The EVBP will remain functional during many

ABS fault modes. If both the red BRAKE and amber

ABS warning indicators are illuminated, the EVBP

may not be functioning.

HCU (HYDRAULIC CONTROL

UNIT)

DESCRIPTION

The HCU consists of a valve body, pump motor, low

pressure accumulators, inlet valves, outlet valves and

noise attenuators.

OPERATION

Accumulators in the valve body store extra fluid

released to the system for ABS mode operation. The

pump provides the fluid volume needed and is oper-

ated by a DC type motor. The motor is controlled by

the CAB.

The valves modulate brake pressure during

antilock braking and are controlled by the CAB.

The HCU provides three channel pressure control

to the front and rear brakes. One channel controls

the rear wheel brakes in tandem. The two remaining

channels control the front wheel brakes individually.

During antilock braking, the solenoid valves are

opened and closed as needed.

During normal braking, the HCU solenoid valves

and pump are not activated. The master cylinder and

power booster operate the same as a vehicle without

an ABS brake system.

NOTE: The three modes mentioned below do occur

but not necessarily in the order listed everytime.

During antilock braking, solenoid valve pressure

modulation occurs in three stages, pressure increase,

pressure hold, and pressure decrease. The valves are

all contained in the valve body portion of the HCU.

PRESSURE DECREASE

The outlet valve is opened and the inlet valve is

closed during the pressure decrease cycle.

A pressure decrease cycle is initiated when speed

sensor signals indicate high wheel slip at one or

more wheels. At this point, the CAB closes the inlet

then opens the outlet valve, which also opens the

return circuit to the accumulators. Fluid pressure is

allowed to bleed off (decrease) as needed to prevent

wheel lock.

Once the period of high wheel slip has ended, the

CAB closes the outlet valve and begins a pressure

increase or hold cycle as needed.

PRESSURE HOLD

Both solenoid valves are closed in the pressure

hold cycle but only the inlet valve is energized. Fluid

apply pressure in the control channel is maintained

at a constant rate. The CAB maintains the hold cycle

until sensor inputs indicate a pressure change is nec-

essary.

DRBRAKES - ABS 5 - 49

Page 314 of 2627

(2) Apply a light coating of grease to the inside

diameter of the master cylinder push rod eye.

(3) Install clutch master cylinder on dash panel

and tighten clutch master cylinder nuts to 28 N´m

(21 ft. lbs.).

(4) Install clutch master cylinder push rod pin.

(5) Connect clutch pedal position interlock switch

wires.

(6) Install plastic clip securing hydraulic line to

the dash panel into the lower dash panel flange.

(7) Install plastic clip securing hydraulic line to

the dash panel onto the upper dash panel stud.

(8) Raise vehicle.

(9) Install slave cylinder and verify cylinder rod is

properly seated in release lever.

(10) Install and tighten slave cylinder nuts to 23

N´m (17 ft. lbs.).

(11) Ifnewclutch linkage is being installed, con-

nect the clutch hydraulic line to the clutch slave cyl-

inder.

CAUTION: Once the clutch hydraulic line is con-

nected to the slave cylinder, it should never be dis-

connected.

(12) Lower vehicle.

(13) Operate linkage several times to verify proper

operation.

CLUTCH PEDAL POSITION

SWITCH

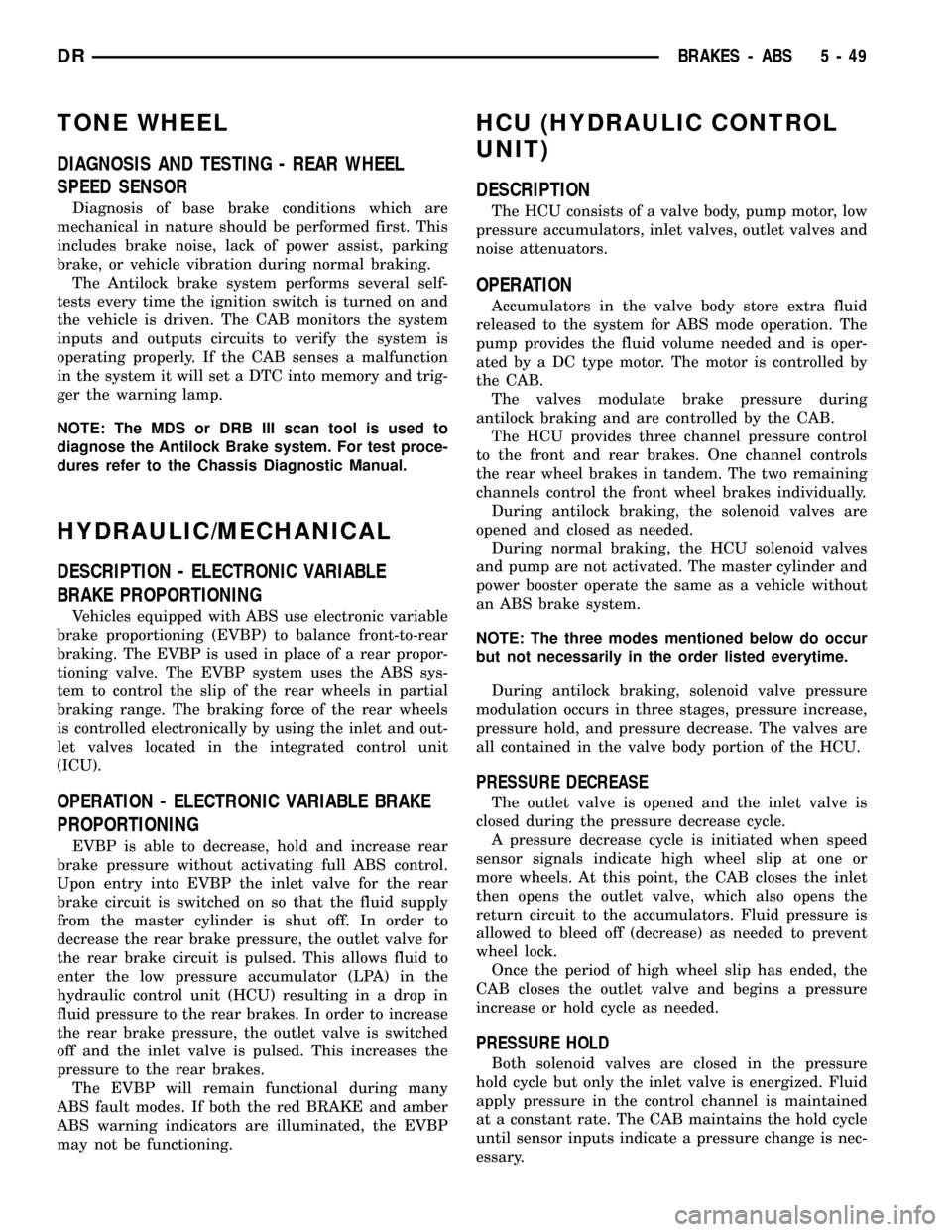

DESCRIPTION

A clutch pedal position switch (CPPS) is mounted

on the clutch master cylinder push rod (Fig. 20). The

wiring harness connector is inside of the vehicle

under the left side of the instrument panel.

NOTE: Switch is serviced with clutch master cylin-

der.

OPERATION

The clutch pedal position switch is used to prevent

starter motor engagement unless the clutch pedal is

depressed. An input from this switch is also used to

either shut down/prevent operation of the speed con-

trol system when pedal is depressed. The position

switch is an integral part of the clutch master cylin-

der push rod.

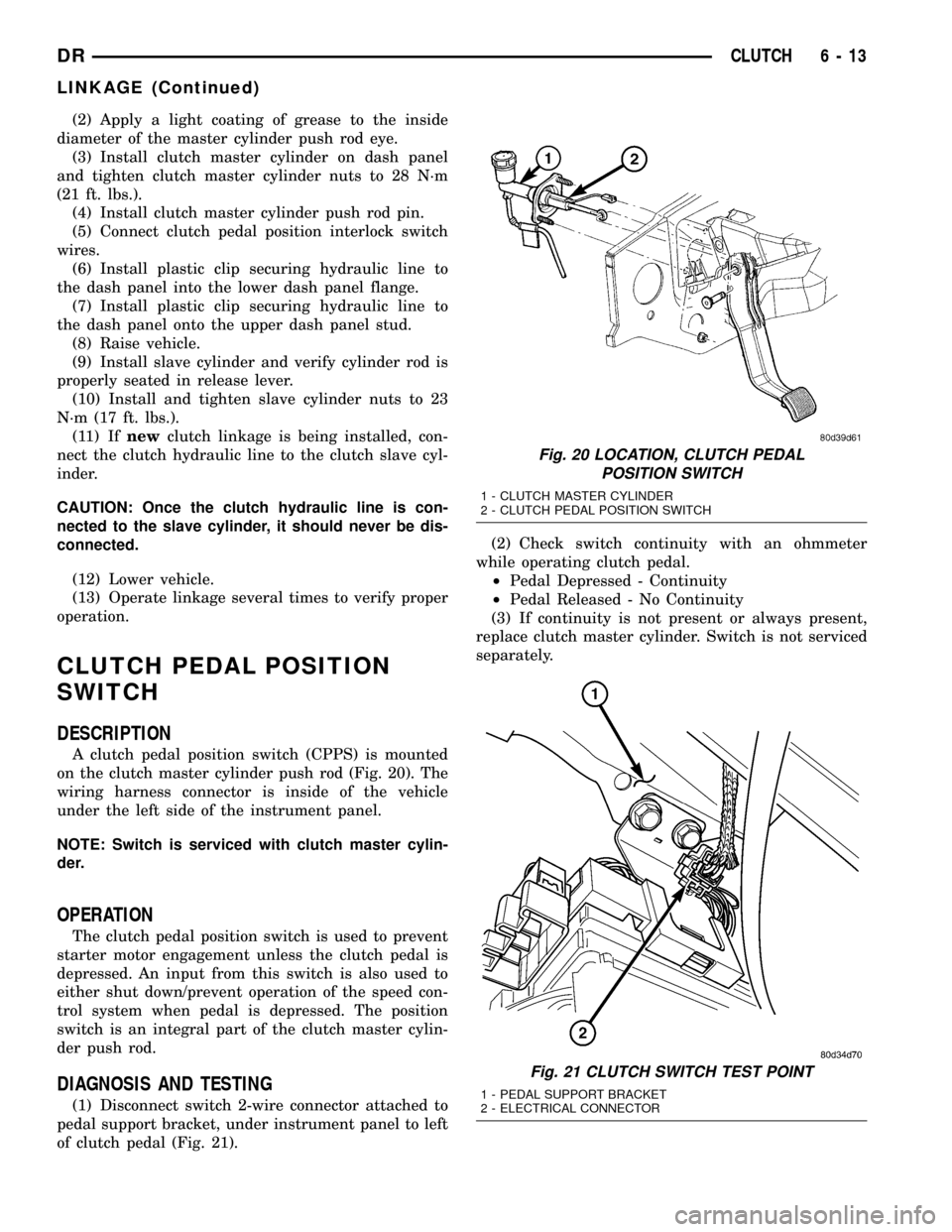

DIAGNOSIS AND TESTING

(1) Disconnect switch 2-wire connector attached to

pedal support bracket, under instrument panel to left

of clutch pedal (Fig. 21).(2) Check switch continuity with an ohmmeter

while operating clutch pedal.

²Pedal Depressed - Continuity

²Pedal Released - No Continuity

(3) If continuity is not present or always present,

replace clutch master cylinder. Switch is not serviced

separately.

Fig. 20 LOCATION, CLUTCH PEDAL

POSITION SWITCH

1 - CLUTCH MASTER CYLINDER

2 - CLUTCH PEDAL POSITION SWITCH

Fig. 21 CLUTCH SWITCH TEST POINT

1 - PEDAL SUPPORT BRACKET

2 - ELECTRICAL CONNECTOR

DRCLUTCH 6 - 13

LINKAGE (Continued)