Exhaust DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1 of 2627

GROUP TAB LOCATOR

Introduction

0Lubrication & Maintenance

2Suspension

3Differential & Driveline

5Brakes

6Clutch

7Cooling

8AAudio/Video

8BChime/Buzzer

8EElectronic Control Modules

8FEngine Systems

8GHeated Systems

8HHorn

8IIgnition Control

8JInstrument Cluster

8LLamps

8MMessage Systems

8NPower Systems

8ORestraints

8PSpeed Control

8QVehicle Theft Security

8RWipers/Washers

8TNavigation/Telecommunication

8WWiring

9Engine

11Exhaust System

13Frame & Bumpers

14Fuel System

19Steering

21Transmission and Transfer Case

22Tires/Wheels

23Body

24Heating & Air Conditioning

25Emissions Control

Component and System Index

Service Manual Comment Forms (Rear of Manual)

Page 16 of 2627

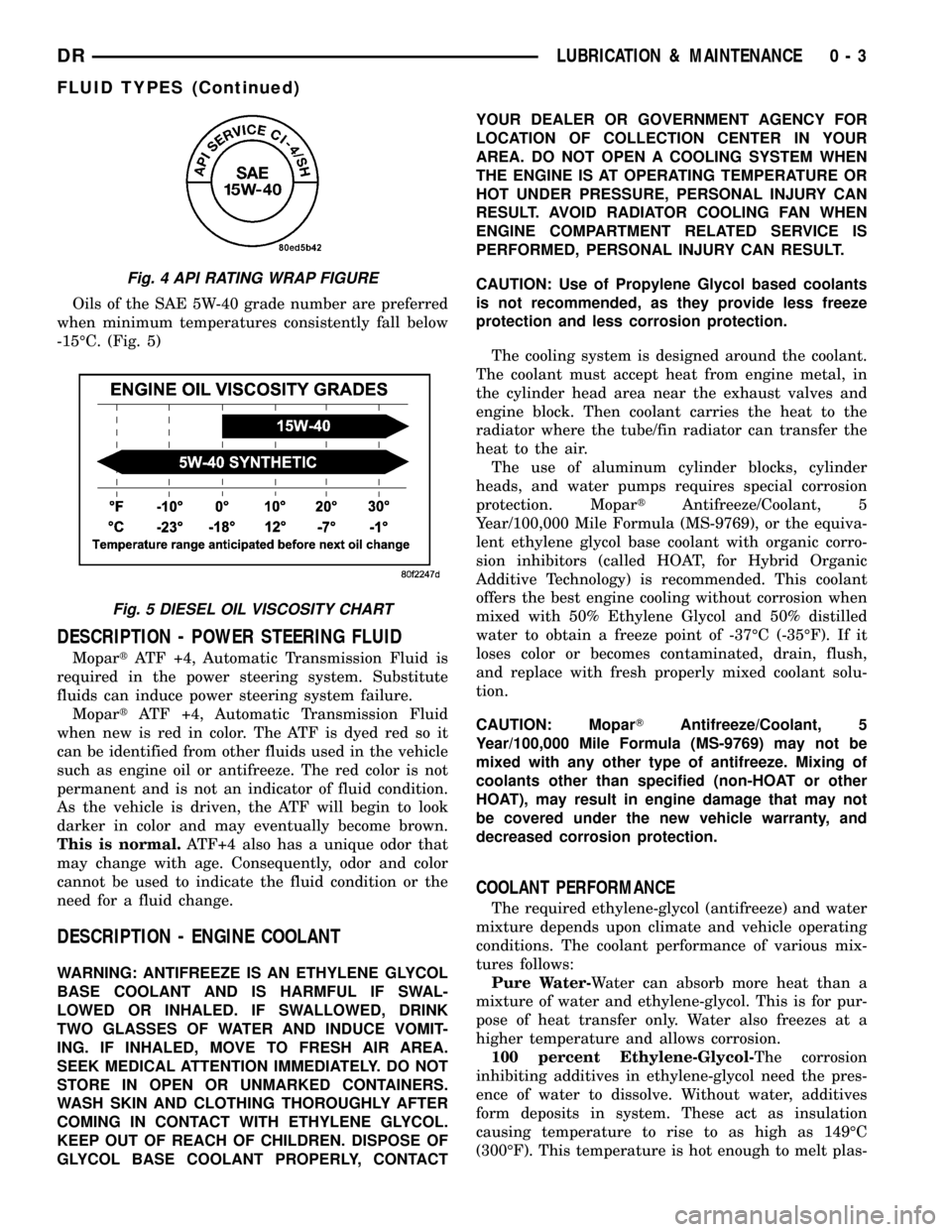

Oils of the SAE 5W-40 grade number are preferred

when minimum temperatures consistently fall below

-15ÉC. (Fig. 5)

DESCRIPTION - POWER STEERING FLUID

MopartATF +4, Automatic Transmission Fluid is

required in the power steering system. Substitute

fluids can induce power steering system failure.

MopartATF +4, Automatic Transmission Fluid

when new is red in color. The ATF is dyed red so it

can be identified from other fluids used in the vehicle

such as engine oil or antifreeze. The red color is not

permanent and is not an indicator of fluid condition.

As the vehicle is driven, the ATF will begin to look

darker in color and may eventually become brown.

This is normal.ATF+4 also has a unique odor that

may change with age. Consequently, odor and color

cannot be used to indicate the fluid condition or the

need for a fluid change.

DESCRIPTION - ENGINE COOLANT

WARNING: ANTIFREEZE IS AN ETHYLENE GLYCOL

BASE COOLANT AND IS HARMFUL IF SWAL-

LOWED OR INHALED. IF SWALLOWED, DRINK

TWO GLASSES OF WATER AND INDUCE VOMIT-

ING. IF INHALED, MOVE TO FRESH AIR AREA.

SEEK MEDICAL ATTENTION IMMEDIATELY. DO NOT

STORE IN OPEN OR UNMARKED CONTAINERS.

WASH SKIN AND CLOTHING THOROUGHLY AFTER

COMING IN CONTACT WITH ETHYLENE GLYCOL.

KEEP OUT OF REACH OF CHILDREN. DISPOSE OF

GLYCOL BASE COOLANT PROPERLY, CONTACTYOUR DEALER OR GOVERNMENT AGENCY FOR

LOCATION OF COLLECTION CENTER IN YOUR

AREA. DO NOT OPEN A COOLING SYSTEM WHEN

THE ENGINE IS AT OPERATING TEMPERATURE OR

HOT UNDER PRESSURE, PERSONAL INJURY CAN

RESULT. AVOID RADIATOR COOLING FAN WHEN

ENGINE COMPARTMENT RELATED SERVICE IS

PERFORMED, PERSONAL INJURY CAN RESULT.

CAUTION: Use of Propylene Glycol based coolants

is not recommended, as they provide less freeze

protection and less corrosion protection.

The cooling system is designed around the coolant.

The coolant must accept heat from engine metal, in

the cylinder head area near the exhaust valves and

engine block. Then coolant carries the heat to the

radiator where the tube/fin radiator can transfer the

heat to the air.

The use of aluminum cylinder blocks, cylinder

heads, and water pumps requires special corrosion

protection. MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769), or the equiva-

lent ethylene glycol base coolant with organic corro-

sion inhibitors (called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% Ethylene Glycol and 50% distilled

water to obtain a freeze point of -37ÉC (-35ÉF). If it

loses color or becomes contaminated, drain, flush,

and replace with fresh properly mixed coolant solu-

tion.

CAUTION: MoparTAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769) may not be

mixed with any other type of antifreeze. Mixing of

coolants other than specified (non-HOAT or other

HOAT), may result in engine damage that may not

be covered under the new vehicle warranty, and

decreased corrosion protection.

COOLANT PERFORMANCE

The required ethylene-glycol (antifreeze) and water

mixture depends upon climate and vehicle operating

conditions. The coolant performance of various mix-

tures follows:

Pure Water-Water can absorb more heat than a

mixture of water and ethylene-glycol. This is for pur-

pose of heat transfer only. Water also freezes at a

higher temperature and allows corrosion.

100 percent Ethylene-Glycol-The corrosion

inhibiting additives in ethylene-glycol need the pres-

ence of water to dissolve. Without water, additives

form deposits in system. These act as insulation

causing temperature to rise to as high as 149ÉC

(300ÉF). This temperature is hot enough to melt plas-

Fig. 4 API RATING WRAP FIGURE

Fig. 5 DIESEL OIL VISCOSITY CHART

DRLUBRICATION & MAINTENANCE 0 - 3

FLUID TYPES (Continued)

Page 19 of 2627

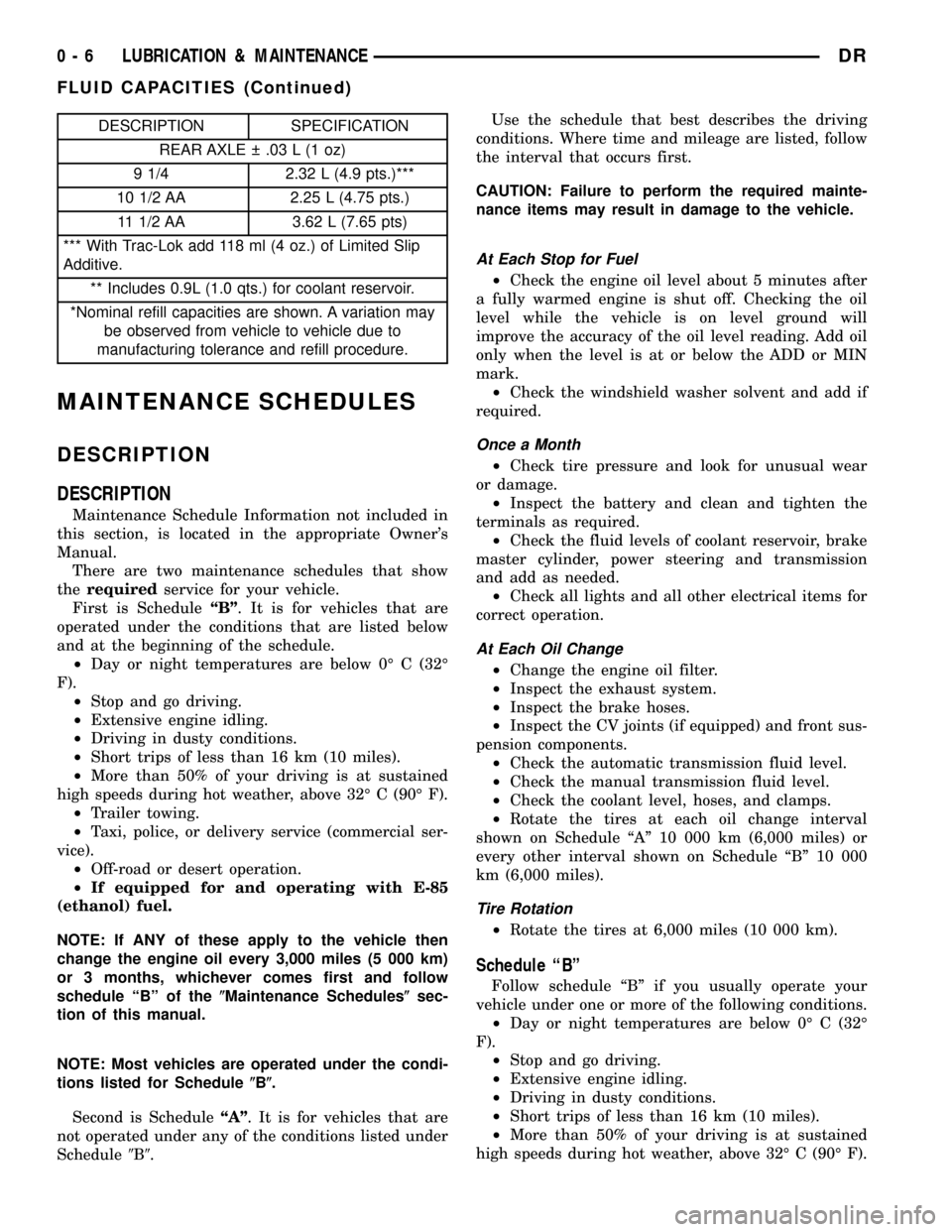

DESCRIPTION SPECIFICATION

REAR AXLE .03 L (1 oz)

9 1/4 2.32 L (4.9 pts.)***

10 1/2 AA 2.25 L (4.75 pts.)

11 1/2 AA 3.62 L (7.65 pts)

*** With Trac-Lok add 118 ml (4 oz.) of Limited Slip

Additive.

** Includes 0.9L (1.0 qts.) for coolant reservoir.

*Nominal refill capacities are shown. A variation may

be observed from vehicle to vehicle due to

manufacturing tolerance and refill procedure.

MAINTENANCE SCHEDULES

DESCRIPTION

DESCRIPTION

Maintenance Schedule Information not included in

this section, is located in the appropriate Owner's

Manual.

There are two maintenance schedules that show

therequiredservice for your vehicle.

First is ScheduleªBº. It is for vehicles that are

operated under the conditions that are listed below

and at the beginning of the schedule.

²Day or night temperatures are below 0É C (32É

F).

²Stop and go driving.

²Extensive engine idling.

²Driving in dusty conditions.

²Short trips of less than 16 km (10 miles).

²More than 50% of your driving is at sustained

high speeds during hot weather, above 32É C (90É F).

²Trailer towing.

²Taxi, police, or delivery service (commercial ser-

vice).

²Off-road or desert operation.

²If equipped for and operating with E-85

(ethanol) fuel.

NOTE: If ANY of these apply to the vehicle then

change the engine oil every 3,000 miles (5 000 km)

or 3 months, whichever comes first and follow

schedule ªBº of the(Maintenance Schedules(sec-

tion of this manual.

NOTE: Most vehicles are operated under the condi-

tions listed for Schedule(B(.

Second is ScheduleªAº. It is for vehicles that are

not operated under any of the conditions listed under

Schedule9B9.Use the schedule that best describes the driving

conditions. Where time and mileage are listed, follow

the interval that occurs first.

CAUTION: Failure to perform the required mainte-

nance items may result in damage to the vehicle.

At Each Stop for Fuel

²Check the engine oil level about 5 minutes after

a fully warmed engine is shut off. Checking the oil

level while the vehicle is on level ground will

improve the accuracy of the oil level reading. Add oil

only when the level is at or below the ADD or MIN

mark.

²Check the windshield washer solvent and add if

required.

Once a Month

²Check tire pressure and look for unusual wear

or damage.

²Inspect the battery and clean and tighten the

terminals as required.

²Check the fluid levels of coolant reservoir, brake

master cylinder, power steering and transmission

and add as needed.

²Check all lights and all other electrical items for

correct operation.

At Each Oil Change

²Change the engine oil filter.

²Inspect the exhaust system.

²Inspect the brake hoses.

²Inspect the CV joints (if equipped) and front sus-

pension components.

²Check the automatic transmission fluid level.

²Check the manual transmission fluid level.

²Check the coolant level, hoses, and clamps.

²Rotate the tires at each oil change interval

shown on Schedule ªAº 10 000 km (6,000 miles) or

every other interval shown on Schedule ªBº 10 000

km (6,000 miles).

Tire Rotation

²Rotate the tires at 6,000 miles (10 000 km).

Schedule ªBº

Follow schedule ªBº if you usually operate your

vehicle under one or more of the following conditions.

²Day or night temperatures are below 0É C (32É

F).

²Stop and go driving.

²Extensive engine idling.

²Driving in dusty conditions.

²Short trips of less than 16 km (10 miles).

²More than 50% of your driving is at sustained

high speeds during hot weather, above 32É C (90É F).

0 - 6 LUBRICATION & MAINTENANCEDR

FLUID CAPACITIES (Continued)

Page 26 of 2627

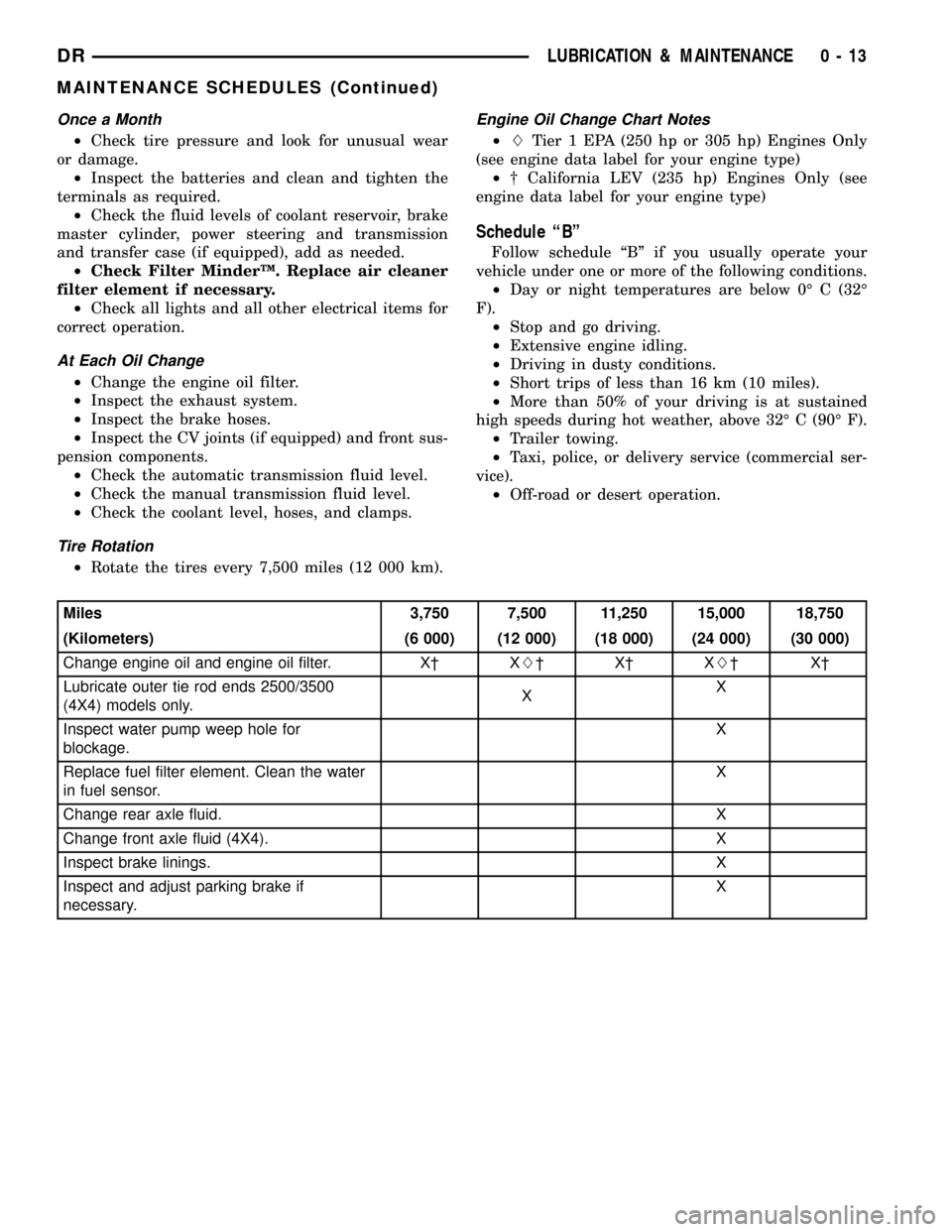

Once a Month

²Check tire pressure and look for unusual wear

or damage.

²Inspect the batteries and clean and tighten the

terminals as required.

²Check the fluid levels of coolant reservoir, brake

master cylinder, power steering and transmission

and transfer case (if equipped), add as needed.

²Check Filter MinderŸ. Replace air cleaner

filter element if necessary.

²Check all lights and all other electrical items for

correct operation.

At Each Oil Change

²Change the engine oil filter.

²Inspect the exhaust system.

²Inspect the brake hoses.

²Inspect the CV joints (if equipped) and front sus-

pension components.

²Check the automatic transmission fluid level.

²Check the manual transmission fluid level.

²Check the coolant level, hoses, and clamps.

Tire Rotation

²Rotate the tires every 7,500 miles (12 000 km).

Engine Oil Change Chart Notes

²LTier 1 EPA (250 hp or 305 hp) Engines Only

(see engine data label for your engine type)

²² California LEV (235 hp) Engines Only (see

engine data label for your engine type)

Schedule ªBº

Follow schedule ªBº if you usually operate your

vehicle under one or more of the following conditions.

²Day or night temperatures are below 0É C (32É

F).

²Stop and go driving.

²Extensive engine idling.

²Driving in dusty conditions.

²Short trips of less than 16 km (10 miles).

²More than 50% of your driving is at sustained

high speeds during hot weather, above 32É C (90É F).

²Trailer towing.

²Taxi, police, or delivery service (commercial ser-

vice).

²Off-road or desert operation.

Miles 3,750 7,500 11,250 15,000 18,750

(Kilometers) (6 000) (12 000) (18 000) (24 000) (30 000)

Change engine oil and engine oil filter. X² XL²X²XL²X²

Lubricate outer tie rod ends 2500/3500

(4X4) models only.XX

Inspect water pump weep hole for

blockage.X

Replace fuel filter element. Clean the water

in fuel sensor.X

Change rear axle fluid. X

Change front axle fluid (4X4). X

Inspect brake linings.X

Inspect and adjust parking brake if

necessary.X

DRLUBRICATION & MAINTENANCE 0 - 13

MAINTENANCE SCHEDULES (Continued)

Page 72 of 2627

KNUCKLE

REMOVAL

(1) Remove the hub bearing (Refer to 2 - SUSPEN-

SION/FRONT/HUB / BEARING - REMOVAL).

(2) Remove tie-rod or drag link end from the steer-

ing knuckle arm.

(3) Remove the ABS sensor wire and bracket from

knuckle. Refer to Brakes, for proper procedures.

(4) Remove the cotter pin from the upper ball stud

nut. Remove the upper and lower ball stud nuts.

(5) Strike the steering knuckle with a brass ham-

mer to loosen.

(6) Remove knuckle from axle tube yokes.

INSTALLATION

(1) Position the steering knuckle on the ball studs.

(2) Install and tighten lower ball stud nut to 47

N´m (35 ft. lbs.) torque. Do not install cotter pin at

this time.

(3) Install and tighten upper ball stud nut to 94

N´m (70 ft. lbs.) torque. Advance nut to next slot to

line up hole and install new cotter pin.

(4) Retorque lower ball stud nut to 190±217 N´m

(140±160 ft. lbs.) torque. Advance nut to next slot to

line up hole and install new cotter pin.

(5) Install the hub bearing (Refer to 2 - SUSPEN-

SION/FRONT/HUB / BEARING - INSTALLATION).

(6) Install tie-rod or drag link end onto the steer-

ing knuckle arm.

(7) Install the ABS sensor wire and bracket to the

knuckle. Refer to Brakes, for proper procedure.

UPPER SUSPENSION ARM

REMOVAL

REMOVAL - LEFT

(1) Raise and support the vehicle.

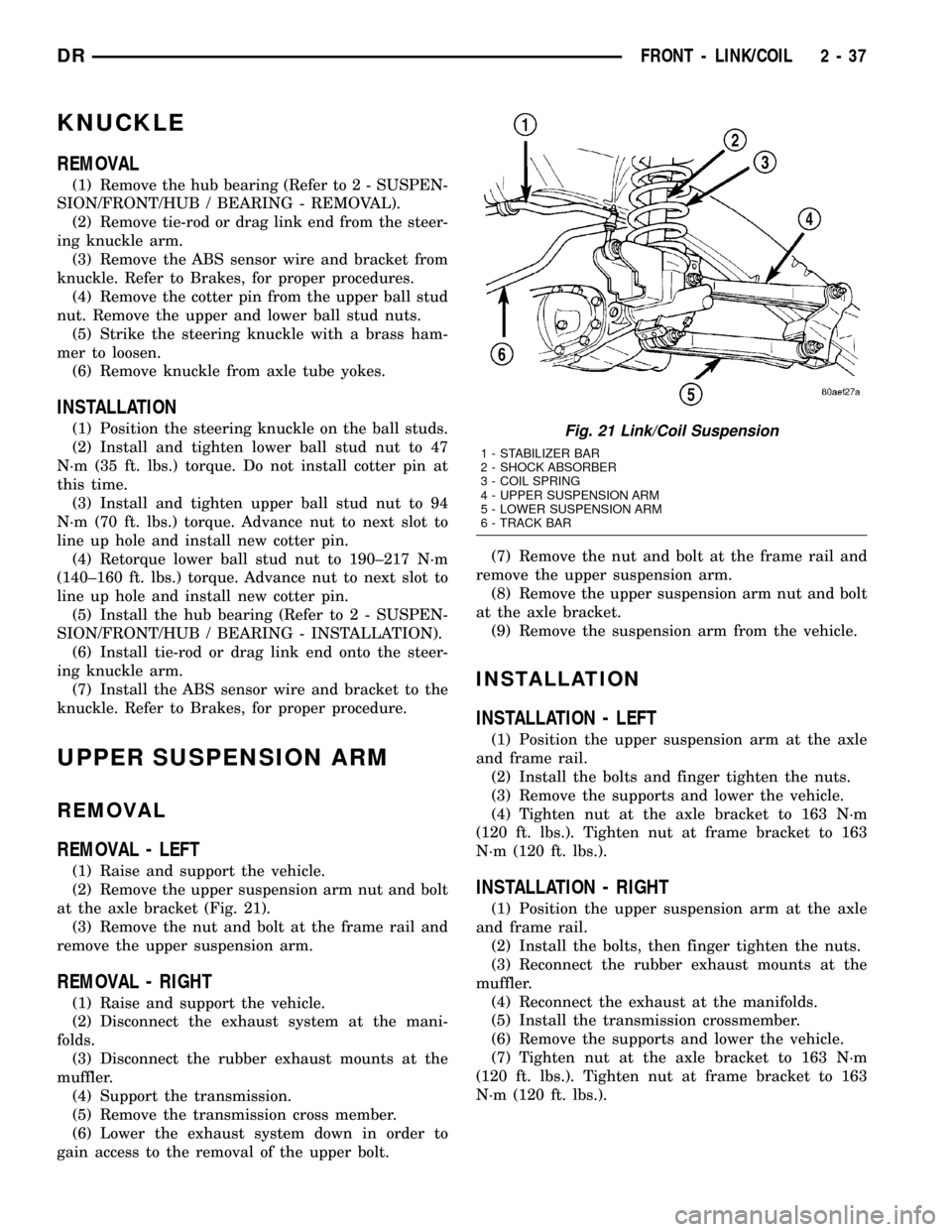

(2) Remove the upper suspension arm nut and bolt

at the axle bracket (Fig. 21).

(3) Remove the nut and bolt at the frame rail and

remove the upper suspension arm.

REMOVAL - RIGHT

(1) Raise and support the vehicle.

(2) Disconnect the exhaust system at the mani-

folds.

(3) Disconnect the rubber exhaust mounts at the

muffler.

(4) Support the transmission.

(5) Remove the transmission cross member.

(6) Lower the exhaust system down in order to

gain access to the removal of the upper bolt.(7) Remove the nut and bolt at the frame rail and

remove the upper suspension arm.

(8) Remove the upper suspension arm nut and bolt

at the axle bracket.

(9) Remove the suspension arm from the vehicle.

INSTALLATION

INSTALLATION - LEFT

(1) Position the upper suspension arm at the axle

and frame rail.

(2) Install the bolts and finger tighten the nuts.

(3) Remove the supports and lower the vehicle.

(4) Tighten nut at the axle bracket to 163 N´m

(120 ft. lbs.). Tighten nut at frame bracket to 163

N´m (120 ft. lbs.).

INSTALLATION - RIGHT

(1) Position the upper suspension arm at the axle

and frame rail.

(2) Install the bolts, then finger tighten the nuts.

(3) Reconnect the rubber exhaust mounts at the

muffler.

(4) Reconnect the exhaust at the manifolds.

(5) Install the transmission crossmember.

(6) Remove the supports and lower the vehicle.

(7) Tighten nut at the axle bracket to 163 N´m

(120 ft. lbs.). Tighten nut at frame bracket to 163

N´m (120 ft. lbs.).

Fig. 21 Link/Coil Suspension

1 - STABILIZER BAR

2 - SHOCK ABSORBER

3 - COIL SPRING

4 - UPPER SUSPENSION ARM

5 - LOWER SUSPENSION ARM

6 - TRACK BAR

DRFRONT - LINK/COIL 2 - 37

Page 87 of 2627

SPECIFICATIONS

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Center Bearing Bolts 54 40 -

Transfer Case Flange

Bolts88 65 -

LD - Front Pinion Flange

Bolts11 5 8 5 -

HD - Front Pinion Flange

Bolts28 21 -

Rear Pinion Flange Bolts 115 85 -

Rear Pinion Yoke Bolts 29 22 -

SPECIAL TOOLSPROPELLER SHAFT- LD

FRONT

REMOVAL

(1) With vehicle in neutral, position vehicle on

hoist.

(2) Remove exhaust crossover pipe.

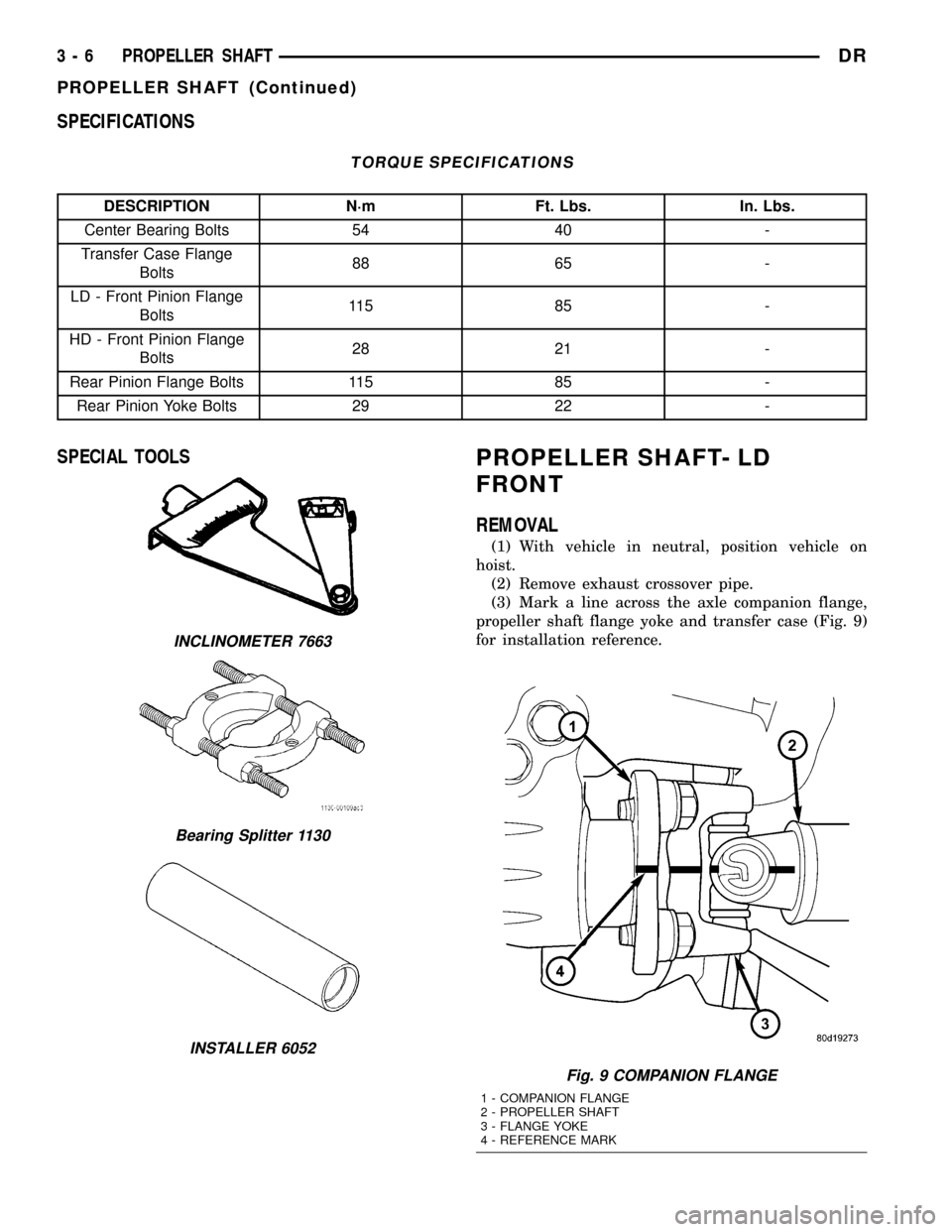

(3) Mark a line across the axle companion flange,

propeller shaft flange yoke and transfer case (Fig. 9)

for installation reference.

INCLINOMETER 7663

Bearing Splitter 1130

INSTALLER 6052

Fig. 9 COMPANION FLANGE

1 - COMPANION FLANGE

2 - PROPELLER SHAFT

3 - FLANGE YOKE

4 - REFERENCE MARK

3 - 6 PROPELLER SHAFTDR

PROPELLER SHAFT (Continued)

Page 88 of 2627

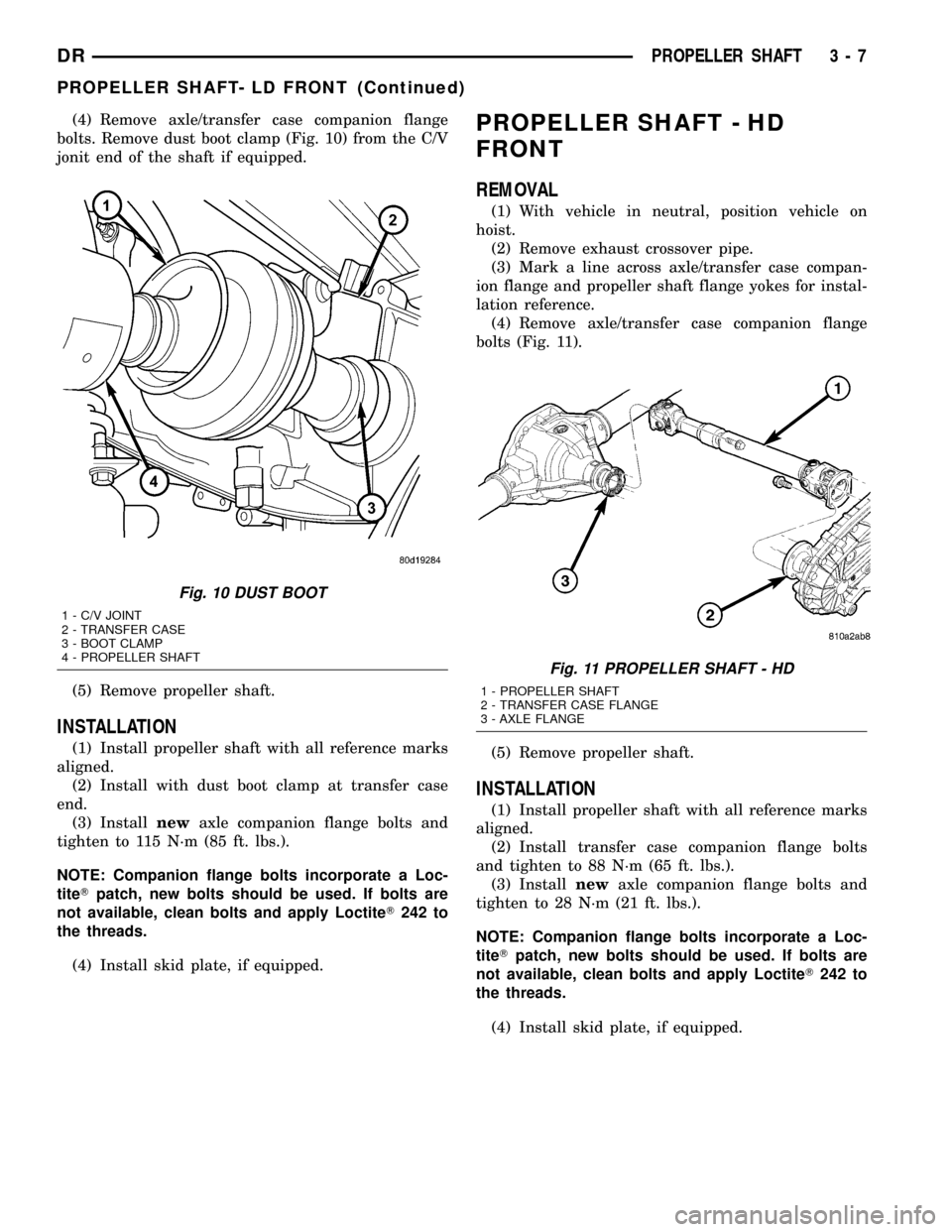

(4) Remove axle/transfer case companion flange

bolts. Remove dust boot clamp (Fig. 10) from the C/V

jonit end of the shaft if equipped.

(5) Remove propeller shaft.

INSTALLATION

(1) Install propeller shaft with all reference marks

aligned.

(2) Install with dust boot clamp at transfer case

end.

(3) Installnewaxle companion flange bolts and

tighten to 115 N´m (85 ft. lbs.).

NOTE: Companion flange bolts incorporate a Loc-

titeTpatch, new bolts should be used. If bolts are

not available, clean bolts and apply LoctiteT242 to

the threads.

(4) Install skid plate, if equipped.

PROPELLER SHAFT - HD

FRONT

REMOVAL

(1) With vehicle in neutral, position vehicle on

hoist.

(2) Remove exhaust crossover pipe.

(3) Mark a line across axle/transfer case compan-

ion flange and propeller shaft flange yokes for instal-

lation reference.

(4) Remove axle/transfer case companion flange

bolts (Fig. 11).

(5) Remove propeller shaft.

INSTALLATION

(1) Install propeller shaft with all reference marks

aligned.

(2) Install transfer case companion flange bolts

and tighten to 88 N´m (65 ft. lbs.).

(3) Installnewaxle companion flange bolts and

tighten to 28 N´m (21 ft. lbs.).

NOTE: Companion flange bolts incorporate a Loc-

titeTpatch, new bolts should be used. If bolts are

not available, clean bolts and apply LoctiteT242 to

the threads.

(4) Install skid plate, if equipped.

Fig. 10 DUST BOOT

1 - C/V JOINT

2 - TRANSFER CASE

3 - BOOT CLAMP

4 - PROPELLER SHAFT

Fig. 11 PROPELLER SHAFT - HD

1 - PROPELLER SHAFT

2 - TRANSFER CASE FLANGE

3 - AXLE FLANGE

DRPROPELLER SHAFT 3 - 7

PROPELLER SHAFT- LD FRONT (Continued)

Page 112 of 2627

REMOVAL

(1) With vehicle in neutral, position vehicle on

hoist.

(2) Remove axle half shafts.

(3) Remove exhaust crossover.

(4) Mark front propeller shaft and remove shaft.

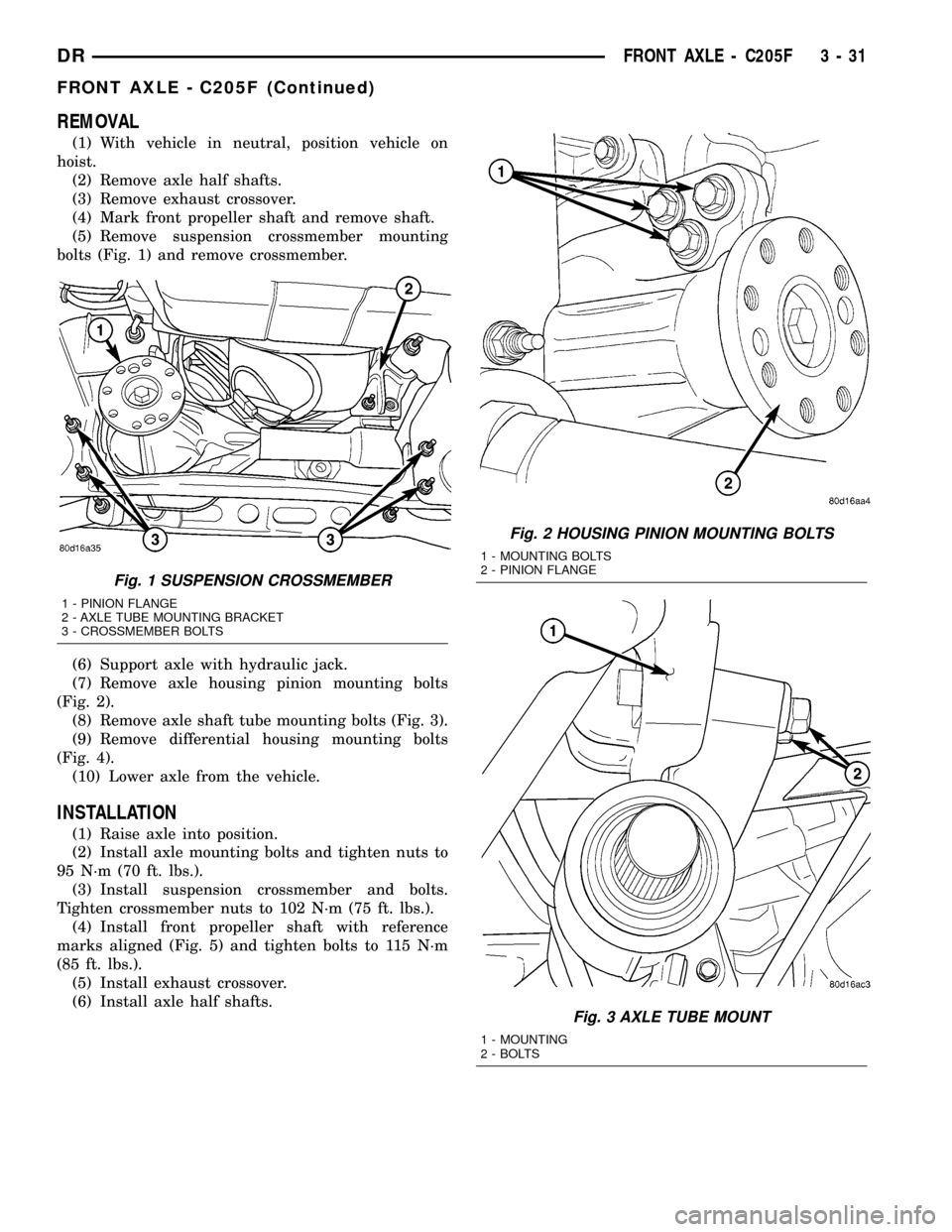

(5) Remove suspension crossmember mounting

bolts (Fig. 1) and remove crossmember.

(6) Support axle with hydraulic jack.

(7) Remove axle housing pinion mounting bolts

(Fig. 2).

(8) Remove axle shaft tube mounting bolts (Fig. 3).

(9) Remove differential housing mounting bolts

(Fig. 4).

(10) Lower axle from the vehicle.

INSTALLATION

(1) Raise axle into position.

(2) Install axle mounting bolts and tighten nuts to

95 N´m (70 ft. lbs.).

(3) Install suspension crossmember and bolts.

Tighten crossmember nuts to 102 N´m (75 ft. lbs.).

(4) Install front propeller shaft with reference

marks aligned (Fig. 5) and tighten bolts to 115 N´m

(85 ft. lbs.).

(5) Install exhaust crossover.

(6) Install axle half shafts.

Fig. 1 SUSPENSION CROSSMEMBER

1 - PINION FLANGE

2 - AXLE TUBE MOUNTING BRACKET

3 - CROSSMEMBER BOLTS

Fig. 2 HOUSING PINION MOUNTING BOLTS

1 - MOUNTING BOLTS

2 - PINION FLANGE

Fig. 3 AXLE TUBE MOUNT

1 - MOUNTING

2 - BOLTS

DRFRONT AXLE - C205F 3 - 31

FRONT AXLE - C205F (Continued)

Page 321 of 2627

PRESSURE TESTER METHOD

The engine should be at normal operating temper-

ature. Recheck the system cold if the cause of coolant

loss is not located during the warm engine examina-

tion.

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING.

Carefully remove the radiator pressure cap from

the filler neck and check the coolant level. Push

down on the cap to disengage it from the stop tabs.

Wipe the inside of the filler neck and examine the

lower inside sealing seat for nicks, cracks, paint, dirt

and solder residue. Inspect the radiator-to- reserve/

overflow tank hose for internal obstructions. Insert a

wire through the hose to be sure it is not obstructed.

Inspect the cams on the outside of the filler neck.

If the cams are damaged, seating of the pressure cap

valve and tester seal will be affected.

Attach pressure tester (7700 or an equivalent) to

radiator filler neck.

Operate the tester pump to apply 103.4 kPa (15

psi) pressure to the system. If the hoses enlarge

excessively or bulges while testing, replace as neces-

sary. Observe the gauge pointer and determine the

condition of the cooling system according to following

criteria:

Holds Steady:If the pointer remains steady for

two minutes, serious coolant leaks are not present in

system. However, there could be an internal leakthat does not appear with normal system test pres-

sure. If it is certain that coolant is being lost and

leaks cannot be detected, inspect for interior leakage

or perform Internal Leakage Test. Refer to INTER-

NAL LEAKAGE INSPECTION.

Drops Slowly:Indicates a small leak or seepage

is occurring. Examine all of the connections for seep-

age or slight leakage with a flashlight. Inspect the

radiator, hoses, gasket edges and heater. Seal the

small leak holes with a Sealer Lubricant (or equiva-

lent). Repair the leak holes and inspect the system

again with pressure applied.

Drops Quickly:Indicates that serious leakage is

occurring. Examine the system for external leakage.

If leaks are not visible, inspect for internal leakage.

Large radiator leak holes should be repaired by a

reputable radiator repair shop.

INTERNAL LEAKAGE INSPECTION

Remove the engine oil pan drain plug and drain a

small amount of engine oil. If coolant is present in

the pan, it will drain first because it is heavier than

oil. An alternative method is to operate engine for a

short period to churn the oil. After this is done,

remove the engine dipstick and inspect for water

globules. Also inspect the transmission dipstick for

water globules and transmission fluid cooler for leak-

age.

WARNING: WITH RADIATOR PRESSURE TESTER

TOOL INSTALLED ON RADIATOR, DO NOT ALLOW

PRESSURE TO EXCEED 145 kPa (21 PSI). PRES-

SURE WILL BUILD UP QUICKLY IF A COMBUSTION

LEAK IS PRESENT. TO RELEASE PRESSURE,

ROCK TESTER FROM SIDE TO SIDE. WHEN

REMOVING TESTER, DO NOT TURN TESTER MORE

THAN 1/2 TURN IF SYSTEM IS UNDER PRESSURE.

Operate the engine without the pressure cap on

the radiator until the thermostat opens. Attach a

Pressure Tester to the filler neck. If pressure builds

up quickly it indicates a combustion leak exists. This

is usually the result of a cylinder head gasket leak or

crack in engine. Repair as necessary.

If there is not an immediate pressure increase,

pump the Pressure Tester. Do this until indicated

pressure is within system range of 110 kPa (16 psi).

Fluctuation of the gauge pointer indicates compres-

sion or combustion leakage into cooling system.

Because the vehicle is equipped with a catalytic

converter,do notshort out cylinders to isolate com-

pression leak.

If the needle on dial of the pressure tester does not

fluctuate, race engine a few times to check for an

abnormal amount of coolant or steam. This would be

emitting from exhaust pipe. Coolant or steam from

Fig. 5 Leak Detection Using Black Light - Typical

1 - TYPICAL BLACK LIGHT TOOL

7 - 6 COOLINGDR

COOLING (Continued)

Page 322 of 2627

exhaust pipe may indicate a faulty cylinder head gas-

ket, cracked engine cylinder block or cylinder head.

A convenient check for exhaust gas leakage into

cooling system is provided by a commercially avail-

able Block Leak Check tool. Follow manufacturers

instructions when using this product.

COMBUSTION LEAKAGE TEST - WITHOUT

PRESSURE TESTER

DO NOT WASTE reusable coolant. If the solution

is clean, drain the coolant into a clean container for

reuse.

WARNING: DO NOT REMOVE CYLINDER BLOCK

DRAIN PLUGS OR LOOSEN RADIATOR DRAIN-

COCK WITH SYSTEM HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM COOLANT CAN OCCUR.

Drain sufficient coolant to allow thermostat

removal. (Refer to 7 - COOLING/ENGINE/ENGINECOOLANT THERMOSTAT - REMOVAL). Remove

accessory drive belt (Refer to 7 - COOLING/ACCES-

SORY DRIVE/DRIVE BELTS - REMOVAL).

Add coolant to radiator to bring level to within 6.3

mm (1/4 in) of the top of the thermostat housing.

CAUTION: Avoid overheating. Do not operate

engine for an excessive period of time. Open drain-

cock immediately after test to eliminate boil over.

Start engine and accelerate rapidly three times, to

approximately 3000 rpm while observing coolant. If

internal engine combustion gases are leaking into

cooling system, bubbles will appear in coolant. If bub-

bles do not appear, internal combustion gas leakage

is not present.

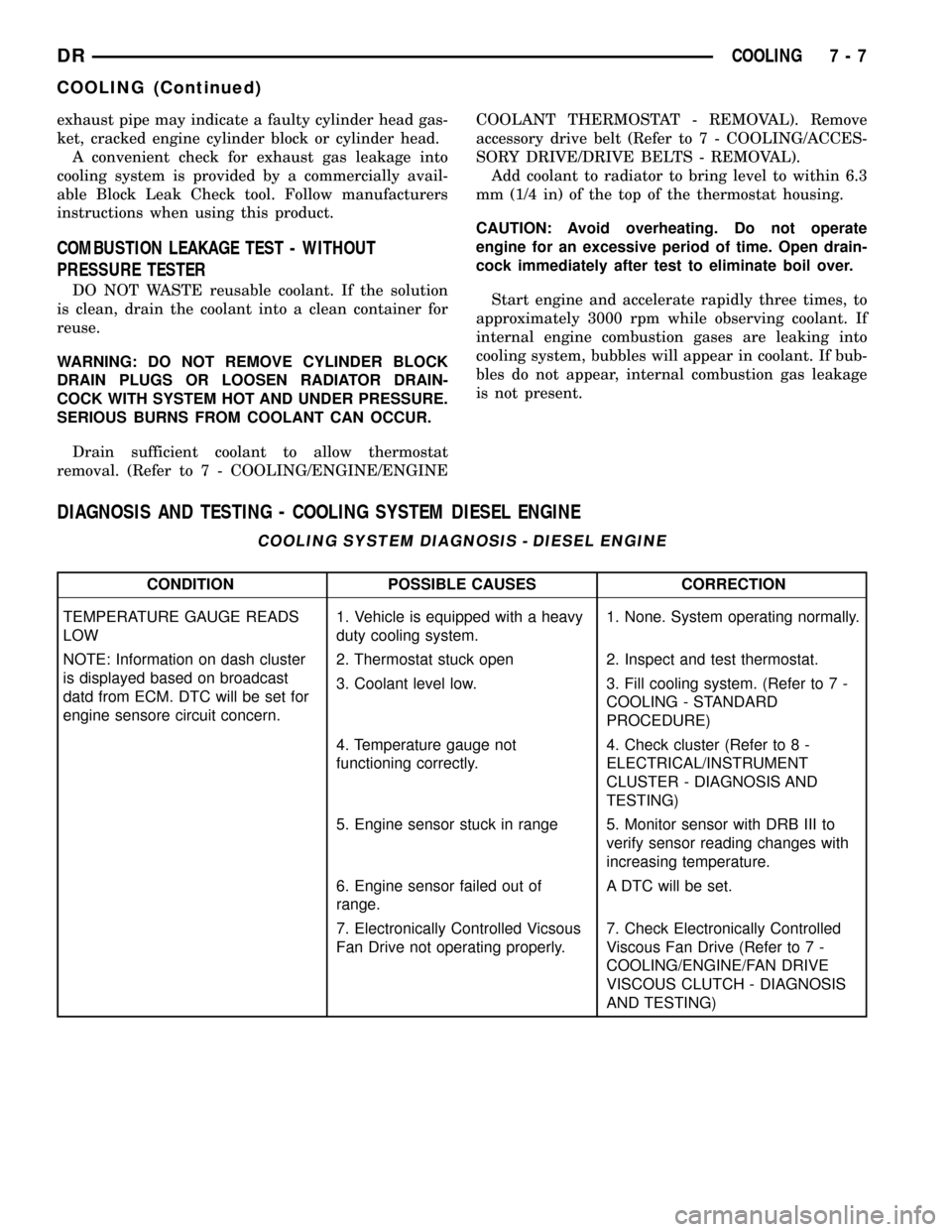

DIAGNOSIS AND TESTING - COOLING SYSTEM DIESEL ENGINE

COOLING SYSTEM DIAGNOSIS - DIESEL ENGINE

CONDITION POSSIBLE CAUSES CORRECTION

TEMPERATURE GAUGE READS

LOW1. Vehicle is equipped with a heavy

duty cooling system.1. None. System operating normally.

NOTE: Information on dash cluster

is displayed based on broadcast

datd from ECM. DTC will be set for

engine sensore circuit concern.2. Thermostat stuck open 2. Inspect and test thermostat.

3. Coolant level low. 3. Fill cooling system. (Refer to 7 -

COOLING - STANDARD

PROCEDURE)

4. Temperature gauge not

functioning correctly.4. Check cluster (Refer to 8 -

ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND

TESTING)

5. Engine sensor stuck in range 5. Monitor sensor with DRB III to

verify sensor reading changes with

increasing temperature.

6. Engine sensor failed out of

range.A DTC will be set.

7. Electronically Controlled Vicsous

Fan Drive not operating properly.7. Check Electronically Controlled

Viscous Fan Drive (Refer to 7 -

COOLING/ENGINE/FAN DRIVE

VISCOUS CLUTCH - DIAGNOSIS

AND TESTING)

DRCOOLING 7 - 7

COOLING (Continued)