Ignition switch replacemen DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 420 of 2627

(8) If the previous step is not performed, a Diag-

nostic Trouble Code (DTC) will be set.

(9) If necessary, use DRB IIItScan Tool to erase

any Diagnostic Trouble Codes (DTC's) from PCM.

Also use the DRB scan tool to reprogram new PCM

with vehicles original Vehicle Identification Number

(VIN) and original vehicle mileage.

SENTRY KEY IMMOBILIZER

MODULE

DESCRIPTION

The Sentry Key Immobilizer Module (SKIM) con-

tains a Radio Frequency (RF) transceiver and a cen-

tral processing unit, which includes the Sentry Key

Immobilizer System (SKIS) program logic. The SKIS

programming enables the SKIM to program and

retain in memory the codes of at least two, but no

more than eight electronically coded Sentry Key

transponders. The SKIS programming also enables

the SKIM to communicate over the Programmable

Communication Interface (PCI) bus network with the

Powertrain Control Module (PCM) or Electronic Con-

trol Module (ECM), depending on engine application,

and/or the DRBIIItscan tool.

OPERATION

The SKIM transmits and receives RF signals

through a tuned antenna enclosed within a molded

plastic ring that is integral to the SKIM housing.

When the SKIM is properly installed on the steering

column, the antenna ring is oriented around the igni-

tion lock cylinder housing. This antenna ring must be

located within eight millimeters (0.31 inches) of the

Sentry Key in order to ensure proper RF communica-

tion between the SKIM and the Sentry Key tran-

sponder.

For added system security, each SKIM is pro-

grammed with a unique ªSecret Keyº code and a

security code. The SKIM keeps the ªSecret Keyº code

in memory. The SKIM also sends the ªSecret Keyº

code to each of the programmed Sentry Key tran-

sponders. The security code is used by the assembly

plant to access the SKIS for initialization, or by the

dealer technician to access the system for service.

The SKIM also stores in its memory the Vehicle

Identification Number (VIN), which it learns through

a PCI bus message from the PCM (NGC) or ECM

(Cummins) during initialization.The SKIM and the PCM/ECM both use software

that includes a rolling code algorithm strategy, which

helps to reduce the possibility of unauthorized SKIS

disarming. The rolling code algorithm ensures secu-

rity by preventing an override of the SKIS through

the unauthorized substitution of the SKIM or the

PCM/ECM. However, the use of this strategy also

means that replacement of either the SKIM or the

PCM/ECM units will require a system initialization

procedure to restore system operation.

When the ignition switch is turned to the ON or

START positions, the SKIM transmits an RF signal

to excite the Sentry Key transponder. The SKIM then

listens for a return RF signal from the transponder

of the Sentry Key that is inserted in the ignition lock

cylinder. If the SKIM receives an RF signal with

valid ªSecret Keyº and transponder identification

codes, the SKIM sends a ªvalid keyº message to the

PCM/ECM over the PCI bus. If the SKIM receives an

invalid RF signal or no response, it sends ªinvalid

keyº messages to the PCM/ECM. The PCM/ECM will

enable or disable engine operation based upon the

status of the SKIM messages.

The SKIM also sends messages to the Instrument

Cluster which controls the VTSS indicator LED. The

SKIM sends messages to the Instrument Cluster to

turn the LED on for about three seconds when the

ignition switch is turned to the ON position as a bulb

test. After completion of the bulb test, the SKIM

sends bus messages to keep the LED off for a dura-

tion of about one second. Then the SKIM sends mes-

sages to turn the LED on or off based upon the

results of the SKIS self-tests. If the VTSS indicator

LED comes on and stays on after the bulb test, it

indicates that the SKIM has detected a system mal-

function and/or that the SKIS has become inopera-

tive.

If the SKIM detects an invalid key when the igni-

tion switch is turned to the ON position, it sends

messages to flash the VTSS indicator LED. The

SKIM can also send messages to flash the LED as an

indication to the customer that the SKIS has been

placed in it's ªCustomer Learnº programming mode.

See Sentry Key Immobilizer System Transponder

Programming in this section for more information on

the ªCustomer Learnº programming mode.

For diagnosis or initialization of the SKIM and the

PCM/ECM, a DRBIIItscan tool and the proper Pow-

ertrain Diagnostic Procedures manual are required.

The SKIM cannot be repaired and, if faulty or dam-

aged, the unit must be replaced.

DRELECTRONIC CONTROL MODULES 8E - 13

POWERTRAIN CONTROL MODULE (Continued)

Page 444 of 2627

erly install the stud adapters, or using stud adapters

that are dirty or worn-out may result in false test

readings.

(2) If testing the battery IN-THE-VEHICLE, make

certain all of the vehicle accessory loads are OFF,

including the ignition.The preferred test position

is at the battery terminal. If the battery is not

accessible, you may test using both the positive and

negative jumper posts. Select TESTING AT JUMPER

POST when connecting to that location.

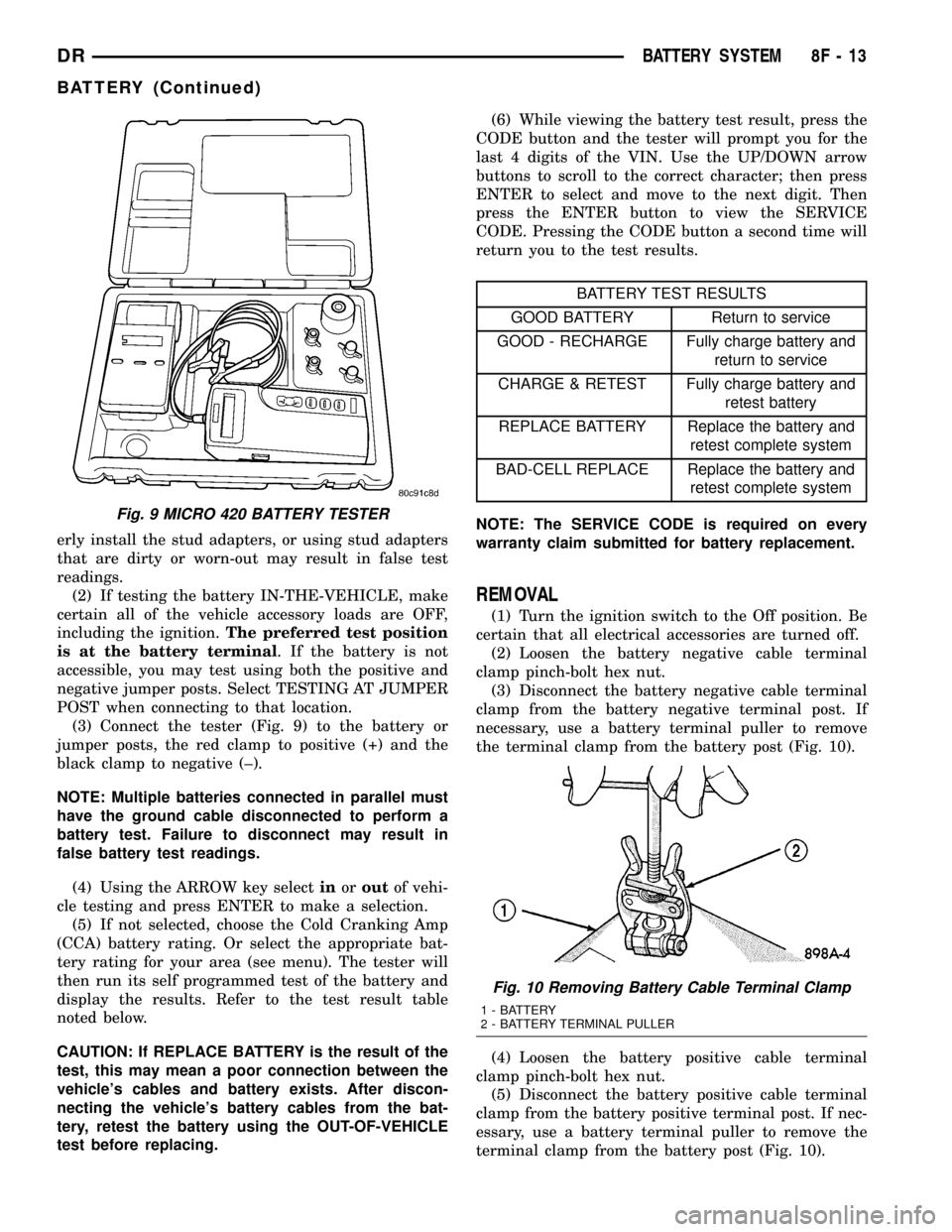

(3) Connect the tester (Fig. 9) to the battery or

jumper posts, the red clamp to positive (+) and the

black clamp to negative (±).

NOTE: Multiple batteries connected in parallel must

have the ground cable disconnected to perform a

battery test. Failure to disconnect may result in

false battery test readings.

(4) Using the ARROW key selectinoroutof vehi-

cle testing and press ENTER to make a selection.

(5) If not selected, choose the Cold Cranking Amp

(CCA) battery rating. Or select the appropriate bat-

tery rating for your area (see menu). The tester will

then run its self programmed test of the battery and

display the results. Refer to the test result table

noted below.

CAUTION: If REPLACE BATTERY is the result of the

test, this may mean a poor connection between the

vehicle's cables and battery exists. After discon-

necting the vehicle's battery cables from the bat-

tery, retest the battery using the OUT-OF-VEHICLE

test before replacing.(6) While viewing the battery test result, press the

CODE button and the tester will prompt you for the

last 4 digits of the VIN. Use the UP/DOWN arrow

buttons to scroll to the correct character; then press

ENTER to select and move to the next digit. Then

press the ENTER button to view the SERVICE

CODE. Pressing the CODE button a second time will

return you to the test results.

BATTERY TEST RESULTS

GOOD BATTERY Return to service

GOOD - RECHARGE Fully charge battery and

return to service

CHARGE & RETEST Fully charge battery and

retest battery

REPLACE BATTERY Replace the battery and

retest complete system

BAD-CELL REPLACE Replace the battery and

retest complete system

NOTE: The SERVICE CODE is required on every

warranty claim submitted for battery replacement.

REMOVAL

(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Loosen the battery negative cable terminal

clamp pinch-bolt hex nut.

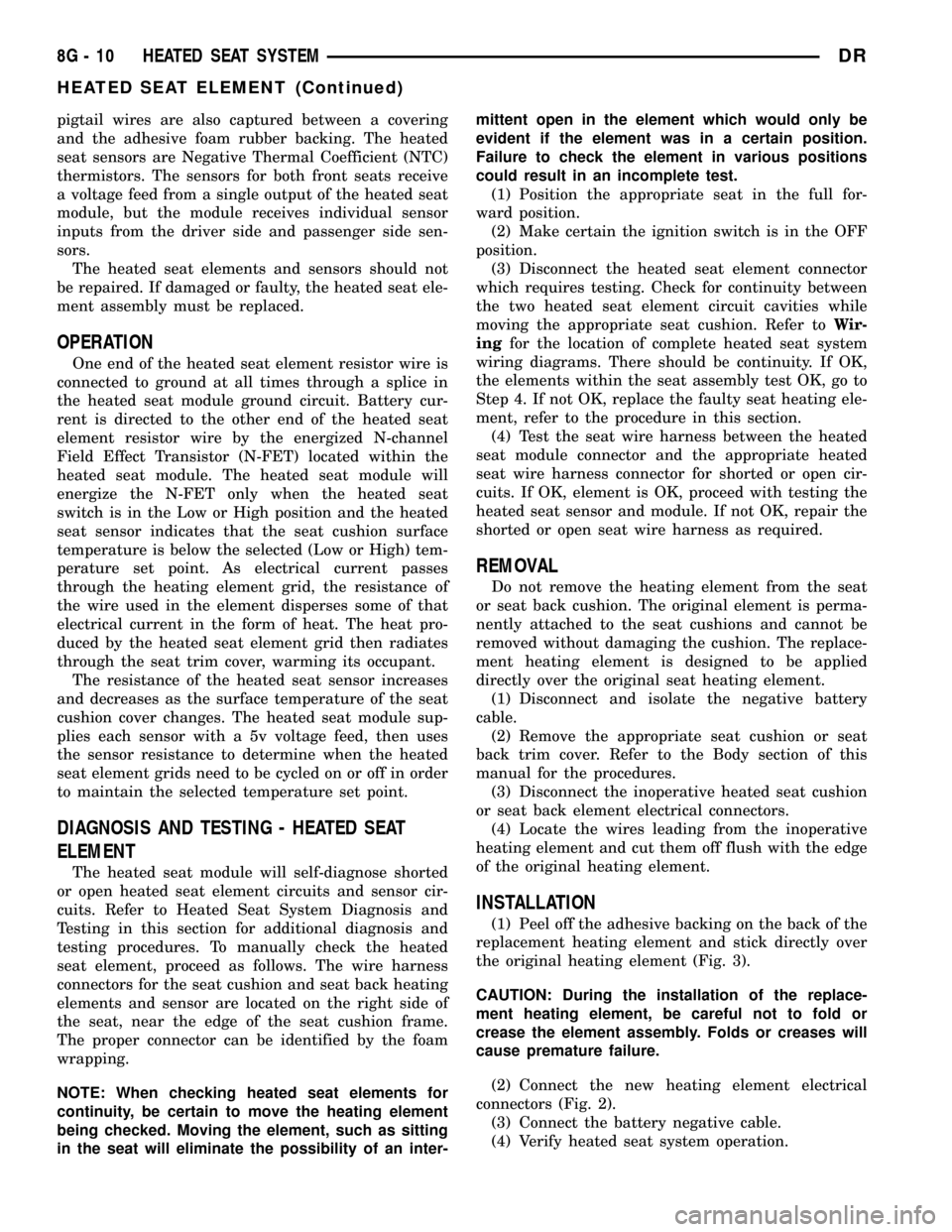

(3) Disconnect the battery negative cable terminal

clamp from the battery negative terminal post. If

necessary, use a battery terminal puller to remove

the terminal clamp from the battery post (Fig. 10).

(4) Loosen the battery positive cable terminal

clamp pinch-bolt hex nut.

(5) Disconnect the battery positive cable terminal

clamp from the battery positive terminal post. If nec-

essary, use a battery terminal puller to remove the

terminal clamp from the battery post (Fig. 10).

Fig. 9 MICRO 420 BATTERY TESTER

Fig. 10 Removing Battery Cable Terminal Clamp

1 - BATTERY

2 - BATTERY TERMINAL PULLER

DRBATTERY SYSTEM 8F - 13

BATTERY (Continued)

Page 479 of 2627

pigtail wires are also captured between a covering

and the adhesive foam rubber backing. The heated

seat sensors are Negative Thermal Coefficient (NTC)

thermistors. The sensors for both front seats receive

a voltage feed from a single output of the heated seat

module, but the module receives individual sensor

inputs from the driver side and passenger side sen-

sors.

The heated seat elements and sensors should not

be repaired. If damaged or faulty, the heated seat ele-

ment assembly must be replaced.

OPERATION

One end of the heated seat element resistor wire is

connected to ground at all times through a splice in

the heated seat module ground circuit. Battery cur-

rent is directed to the other end of the heated seat

element resistor wire by the energized N-channel

Field Effect Transistor (N-FET) located within the

heated seat module. The heated seat module will

energize the N-FET only when the heated seat

switch is in the Low or High position and the heated

seat sensor indicates that the seat cushion surface

temperature is below the selected (Low or High) tem-

perature set point. As electrical current passes

through the heating element grid, the resistance of

the wire used in the element disperses some of that

electrical current in the form of heat. The heat pro-

duced by the heated seat element grid then radiates

through the seat trim cover, warming its occupant.

The resistance of the heated seat sensor increases

and decreases as the surface temperature of the seat

cushion cover changes. The heated seat module sup-

plies each sensor with a 5v voltage feed, then uses

the sensor resistance to determine when the heated

seat element grids need to be cycled on or off in order

to maintain the selected temperature set point.

DIAGNOSIS AND TESTING - HEATED SEAT

ELEMENT

The heated seat module will self-diagnose shorted

or open heated seat element circuits and sensor cir-

cuits. Refer to Heated Seat System Diagnosis and

Testing in this section for additional diagnosis and

testing procedures. To manually check the heated

seat element, proceed as follows. The wire harness

connectors for the seat cushion and seat back heating

elements and sensor are located on the right side of

the seat, near the edge of the seat cushion frame.

The proper connector can be identified by the foam

wrapping.

NOTE: When checking heated seat elements for

continuity, be certain to move the heating element

being checked. Moving the element, such as sitting

in the seat will eliminate the possibility of an inter-mittent open in the element which would only be

evident if the element was in a certain position.

Failure to check the element in various positions

could result in an incomplete test.

(1) Position the appropriate seat in the full for-

ward position.

(2) Make certain the ignition switch is in the OFF

position.

(3) Disconnect the heated seat element connector

which requires testing. Check for continuity between

the two heated seat element circuit cavities while

moving the appropriate seat cushion. Refer toWir-

ingfor the location of complete heated seat system

wiring diagrams. There should be continuity. If OK,

the elements within the seat assembly test OK, go to

Step 4. If not OK, replace the faulty seat heating ele-

ment, refer to the procedure in this section.

(4) Test the seat wire harness between the heated

seat module connector and the appropriate heated

seat wire harness connector for shorted or open cir-

cuits. If OK, element is OK, proceed with testing the

heated seat sensor and module. If not OK, repair the

shorted or open seat wire harness as required.

REMOVAL

Do not remove the heating element from the seat

or seat back cushion. The original element is perma-

nently attached to the seat cushions and cannot be

removed without damaging the cushion. The replace-

ment heating element is designed to be applied

directly over the original seat heating element.

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the appropriate seat cushion or seat

back trim cover. Refer to the Body section of this

manual for the procedures.

(3) Disconnect the inoperative heated seat cushion

or seat back element electrical connectors.

(4) Locate the wires leading from the inoperative

heating element and cut them off flush with the edge

of the original heating element.

INSTALLATION

(1) Peel off the adhesive backing on the back of the

replacement heating element and stick directly over

the original heating element (Fig. 3).

CAUTION: During the installation of the replace-

ment heating element, be careful not to fold or

crease the element assembly. Folds or creases will

cause premature failure.

(2) Connect the new heating element electrical

connectors (Fig. 2).

(3) Connect the battery negative cable.

(4) Verify heated seat system operation.

8G - 10 HEATED SEAT SYSTEMDR

HEATED SEAT ELEMENT (Continued)

Page 514 of 2627

for more than about 1.6 kilometers (one mile) and

the vehicle speed remains greater than about twenty-

four kilometers-per-hour (fifteen miles-per-hour).

²Vacuum Fluorescent Display Synchroniza-

tion- The EMIC transmits electronic panel lamp

dimming level messages which allows all other elec-

tronic modules on the PCI data bus with Vacuum

Fluorescent Display (VFD) units to coordinate their

illumination intensity with that of the EMIC VFD

units.

²Vehicle Theft Security System- The EMIC

monitors inputs from the door cylinder lock

switch(es), the door ajar switches, the ignition

switch, and the Remote Keyless Entry (RKE) receiver

module, then provides electronic horn and lighting

request messages to the Front Control Module (FCM)

located on the Integrated Power Module (IPM) for

the appropriate VTSS alarm output features.

²Wiper/Washer System Control- The EMIC

provides electronic wiper and/or washer request mes-

sages to the Front Control Module (FCM) located on

the Integrated Power Module (IPM) for the appropri-

ate wiper and washer system features. (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS - DESCRIP-

TION).

The EMIC houses six analog gauges and has pro-

visions for up to twenty-three indicators (Fig. 3) or

(Fig. 4). The EMIC includes the following analog

gauges:

²Coolant Temperature Gauge

²Fuel Gauge

²Oil Pressure Gauge

²Speedometer

²Tachometer

²Voltage Gauge

Some of the EMIC indicators are automatically

configured when the EMIC is connected to the vehi-

cle electrical system for compatibility with certain

optional equipment or equipment required for regula-

tory purposes in certain markets. While each EMIC

may have provisions for indicators to support every

available option, the configurable indicators will not

be functional in a vehicle that does not have the

equipment that an indicator supports. The EMIC

includes provisions for the following indicators (Fig.

3) or (Fig. 4):

²Airbag Indicator (with Airbag System only)

²Antilock Brake System (ABS) Indicator

(with ABS or Rear Wheel Anti-Lock [RWAL]

brakes only)

²Brake Indicator

²Cargo Lamp Indicator

²Check Gauges Indicator

²Cruise Indicator (with Speed Control only)

²Door Ajar Indicator²Electronic Throttle Control (ETC) Indicator

(with 5.7L Gasoline Engine only)

²Gear Selector Indicator (with Automatic

Transmission only)

²High Beam Indicator

²Lamp Out Indicator

²Low Fuel Indicator

²Malfunction Indicator Lamp (MIL)

²Seatbelt Indicator

²Security Indicator (with Sentry Key Immo-

bilizer & Vehicle Theft Security Systems only)

²Service Four-Wheel Drive Indicator (with

Four-Wheel Drive only)

²Tow/Haul Indicator (with Automatic Trans-

mission only)

²Transmission Overtemp Indicator (with

Automatic Transmission only)

²Turn Signal (Right and Left) Indicators

²Upshift Indicator (with Manual Transmis-

sion only)

²Washer Fluid Indicator

²Wait-To-Start Indicator (with Diesel Engine

only)

²Water-In-Fuel Indicator (with Diesel Engine

only)

Each indicator in the EMIC, except those located

within one of the VFD units, is illuminated by a ded-

icated LED that is soldered onto the EMIC electronic

circuit board. The LED units are not available for

service replacement and, if damaged or faulty, the

entire EMIC must be replaced. Cluster illumination

is accomplished by dimmable incandescent back

lighting, which illuminates the gauges for visibility

when the exterior lighting is turned on. Each of the

incandescent bulbs is secured by an integral bulb

holder to the electronic circuit board from the back of

the cluster housing.

Hard wired circuitry connects the EMIC to the

electrical system of the vehicle. These hard wired cir-

cuits are integral to several wire harnesses, which

are routed throughout the vehicle and retained by

many different methods. These circuits may be con-

nected to each other, to the vehicle electrical system

and to the EMIC through the use of a combination of

soldered splices, splice block connectors, and many

different types of wire harness terminal connectors

and insulators. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

The EMIC modules for this model are serviced only

as complete units. The EMIC module cannot be

adjusted or repaired. If a gauge, an LED indicator, a

VFD unit, the electronic circuit board, the circuit

DRINSTRUMENT CLUSTER 8J - 5

INSTRUMENT CLUSTER (Continued)

Page 520 of 2627

CAUTION: Instrument clusters used in this model

automatically configure themselves for compatibil-

ity with the features and optional equipment in the

vehicle in which they are initially installed. The

instrument cluster is programmed to do this by

embedding the Vehicle Identification Number (VIN)

and other information critical to proper cluster

operation into electronic memory. This embedded

information is learned through electronic messages

received from other electronic modules in the vehi-

cle over the Programmable Communications Inter-

face (PCI) data bus, and through certain hard wired

inputs received when the cluster is connected to

the vehicle electrically. Once configured, the instru-

ment cluster memory may be irreparably damaged

and certain irreversible configuration errors may

occur if the cluster is connected electrically to

another vehicle; or, if an electronic module from

another vehicle is connected that provides data to

the instrument cluster (including odometer values)

that conflicts with that which was previously

learned and stored. Therefore, the practice of

exchanging (swapping) instrument clusters and

other electronic modules in this vehicle with those

removed from another vehicle must always be

avoided. Failure to observe this caution may result

in instrument cluster damage, which is not reim-

bursable under the terms of the product warranty.

Service replacement instrument clusters are pro-

vided with the correct VIN, and the certified odom-

eter and engine hours values embedded into cluster

memory, but will otherwise be automatically config-

ured for compatibility with the features and optional

equipment in the vehicle in which they are initially

installed.

NOTE: Certain indicators in this instrument cluster

are automatically configured. This feature allows

those indicators to be activated or deactivated for

compatibility with certain optional equipment. If the

problem being diagnosed involves improper illumi-

nation of the cruise indicator, the electronic throttle

control indicator, the service four-wheel drive indi-

cator, the tow/haul indicator, the transmission over-

temp indicator, the upshift indicator, the security

indicator or the gear selector indicator, disconnect

and isolate the battery negative cable. After about

five minutes, reconnect the battery negative cable

and turn the ignition switch to the On position. The

instrument cluster should automatically relearn the

equipment in the vehicle and properly configure the

configurable indicators accordingly.PRELIMINARY DIAGNOSIS

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

(1) Check the fused B(+) fuse (Fuse 51 - 20

ampere) in the Integrated Power Module (IPM). If

OK, go to Step 2. If not OK, repair the shorted circuit

or component as required and replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

(Fuse 51 - 20 ampere) in the IPM. If OK, go to Step

3. If not OK, repair the open fused B(+) circuit

between the IPM and the battery as required.

(3) Disconnect and isolate the battery negative

cable. Remove the instrument cluster. Reconnect the

battery negative cable. Check for battery voltage at

the fused B(+) circuit cavity of the instrument panel

wire harness connector (Connector C1) for the instru-

ment cluster. If OK, go to Step 4. If not OK, repair

the open fused B(+) circuit between the instrument

cluster and the IPM as required.

(4) Check for continuity between the signal ground

circuit cavity of the instrument panel wire harness

connector (Connector C1) for the instrument cluster

and a good ground. There should be continuity. If

OK, refer to ACTUATOR TEST. If not OK, repair the

open ground circuit to ground (G202) as required.

DRINSTRUMENT CLUSTER 8J - 11

INSTRUMENT CLUSTER (Continued)

Page 581 of 2627

LAMPS/LIGHTING - INTERIOR

TABLE OF CONTENTS

page page

DOME LAMP

DESCRIPTION.........................26

OPERATION...........................26

REMOVAL.............................26

INSTALLATION.........................26

DOOR AJAR SWITCH

DESCRIPTION.........................27

OPERATION...........................27GLOVE BOX LAMP/SWITCH

REMOVAL.............................27

INSTALLATION.........................28

READING LAMP

DESCRIPTION.........................28

OPERATION...........................28

REMOVAL.............................28

INSTALLATION.........................29

DOME LAMP

DESCRIPTION

The dome lamp is controlled by the instrument

cluster which provides power at all times, regardless

of the ignition switch position. The ground circuit for

the lamp is switched through the integral dome lamp

switch or through the door ajar switches via the

instrument cluster.

The dome lamp lens and bulb are available for ser-

vice replacement. If either of the lamp switch or bulb

holders is faulty or damaged, the dome lamp assem-

bly must be replaced.

For service of the dome lamp bulb, refer to the

appropriate wiring information.

OPERATION

The dome lamp is activated by the door ajar

switches via the instrument cluster. When all of the

doors are closed, the lamp can be activated by

depressing the lens. When any door is open, depress-

ing the lamp lense to activate the lamp switch will

not turn the lamps off.

The instrument cluster monitors the door ajar

switches. When a door is open the instrument cluster

grounds the low side drivers to turn on the lamp.

Upon closing all doors, the instrument cluster ini-

tiates a 30 second timer. If any of the doors are

opened during the ªtime outº cycle, the instrument

cluster will reset the timer until all doors are closed.

The instrument cluster will faid to off when the doors

are closed and the ignition is turned ON, the time

out expires or the power locks are activated.

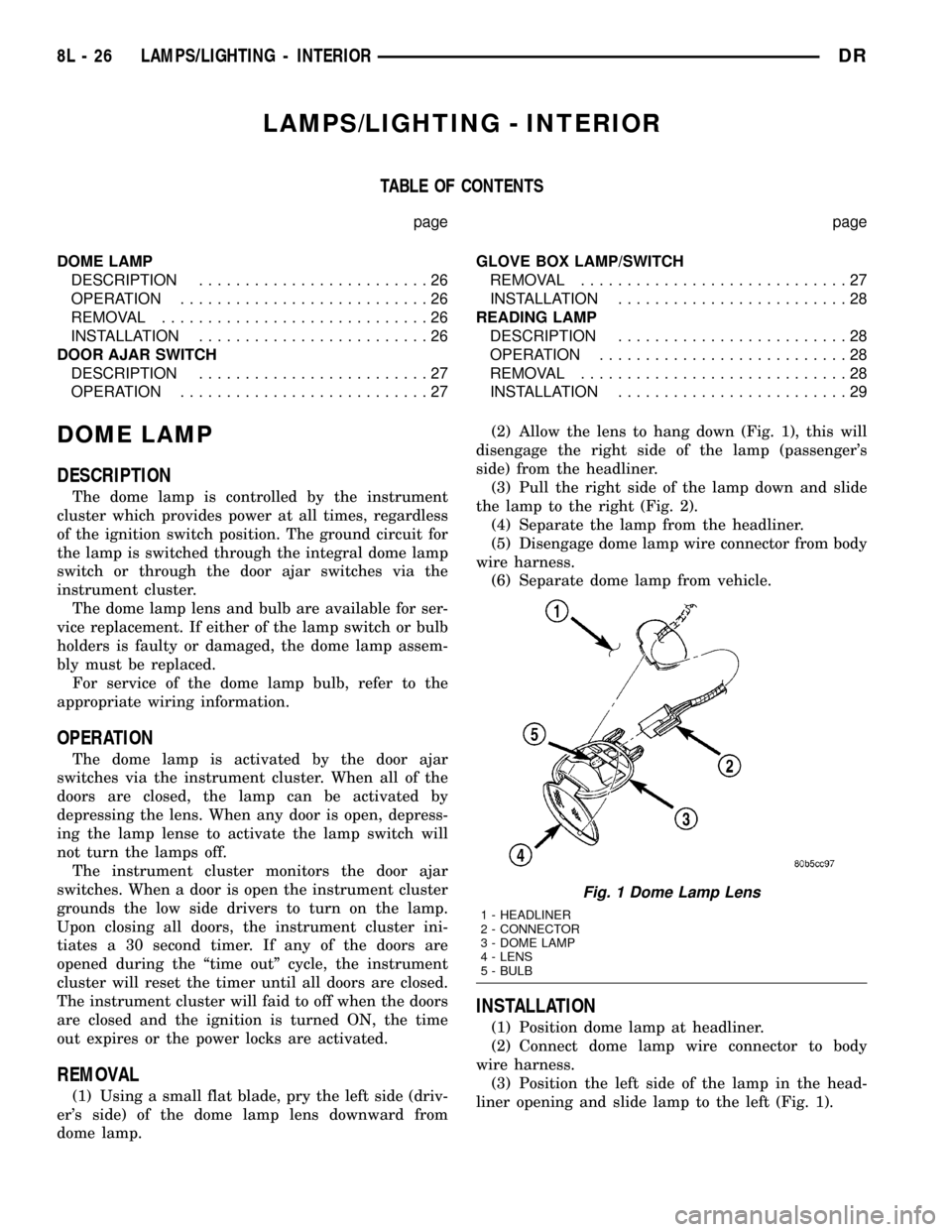

REMOVAL

(1) Using a small flat blade, pry the left side (driv-

er's side) of the dome lamp lens downward from

dome lamp.(2) Allow the lens to hang down (Fig. 1), this will

disengage the right side of the lamp (passenger's

side) from the headliner.

(3) Pull the right side of the lamp down and slide

the lamp to the right (Fig. 2).

(4) Separate the lamp from the headliner.

(5) Disengage dome lamp wire connector from body

wire harness.

(6) Separate dome lamp from vehicle.

INSTALLATION

(1) Position dome lamp at headliner.

(2) Connect dome lamp wire connector to body

wire harness.

(3) Position the left side of the lamp in the head-

liner opening and slide lamp to the left (Fig. 1).

Fig. 1 Dome Lamp Lens

1 - HEADLINER

2 - CONNECTOR

3 - DOME LAMP

4 - LENS

5 - BULB

8L - 26 LAMPS/LIGHTING - INTERIORDR

Page 583 of 2627

INSTALLATION

(1) Reach through the glove box opening and

behind the glove box lamp and switch mounting

bracket to feed the instrument panel wire harness

connectors out through the hole in the glove box

lamp and switch housing mounting bracket.

(2) Position the glove box lamp and switch unit to

the instrument panel.

(3) Reconnect the instrument panel wire harness

connector to the connector receptacle on the back of

the glove box lamp and switch unit.

(4) Push the glove box lamp and switch unit into

the hole in the mounting bracket on the instrument

panel glove box opening upper reinforcement.

(5) Install the glove box onto the instrument panel.

(Refer to 23 - BODY/INSTRUMENT PANEL/GLOVE

BOX - INSTALLATION) for the procedures.

(6) Close the glove box.

(7) Reconnect the battery negative cable.

READING LAMP

DESCRIPTION

The overhead console in this vehicle is equipped

with two individual reading and courtesy lamps. The

lamp lenses are the only visible components of these

lamps. Each lamp has its own switch, bulb, reflector

and lens within the overhead console.

The overhead console reading and courtesy lamps

are controlled by the instrument cluster which pro-

vides power at all times, regardless of the ignition

switch position. The ground circuit for the lamps is

switched through the integral reading and courtesy

lamp switches or through the door ajar switches.

Each lamp is designed and aimed to provide illumi-

nation that will be directed only to that side of the

vehicle on which the lamp is located.

The reading and courtesy lamp lenses and bulbs

are available for service replacement. The reading

and courtesy lamp switches, bulb holders and wiring

are only available as part of the overhead console

wire harness. If either of the lamp switches or bulb

holders is faulty or damaged, the entire overhead

console wire harness assembly must be replaced.

For service of the reading and courtesy lamp bulbs,

refer to the appropriate wiring information.

OPERATION

All reading and courtesy lamps located in the over-

head console are activated by the door ajar switches

via the instrument cluster. When all of the doors are

closed, these lamps can be individually activated by

depressing the corresponding lens. When any door is

open, depressing the lamp lenses to activate the lamp

switches will not turn the lamps off.The instrument cluster monitors the door ajar

switches. When a door is open the instrument cluster

grounds the low side drivers to turn on the lamps.

Upon closing all doors, the instrument cluster ini-

tiates a 30 second timer. If any of the doors are

opened during the ªtime outº cycle, the instrument

cluster will reset the timer until all doors are closed.

The instrument cluster will faid to off when the doors

are closed and the ignition is turned ON, the time

out expires or the power locks are activated.

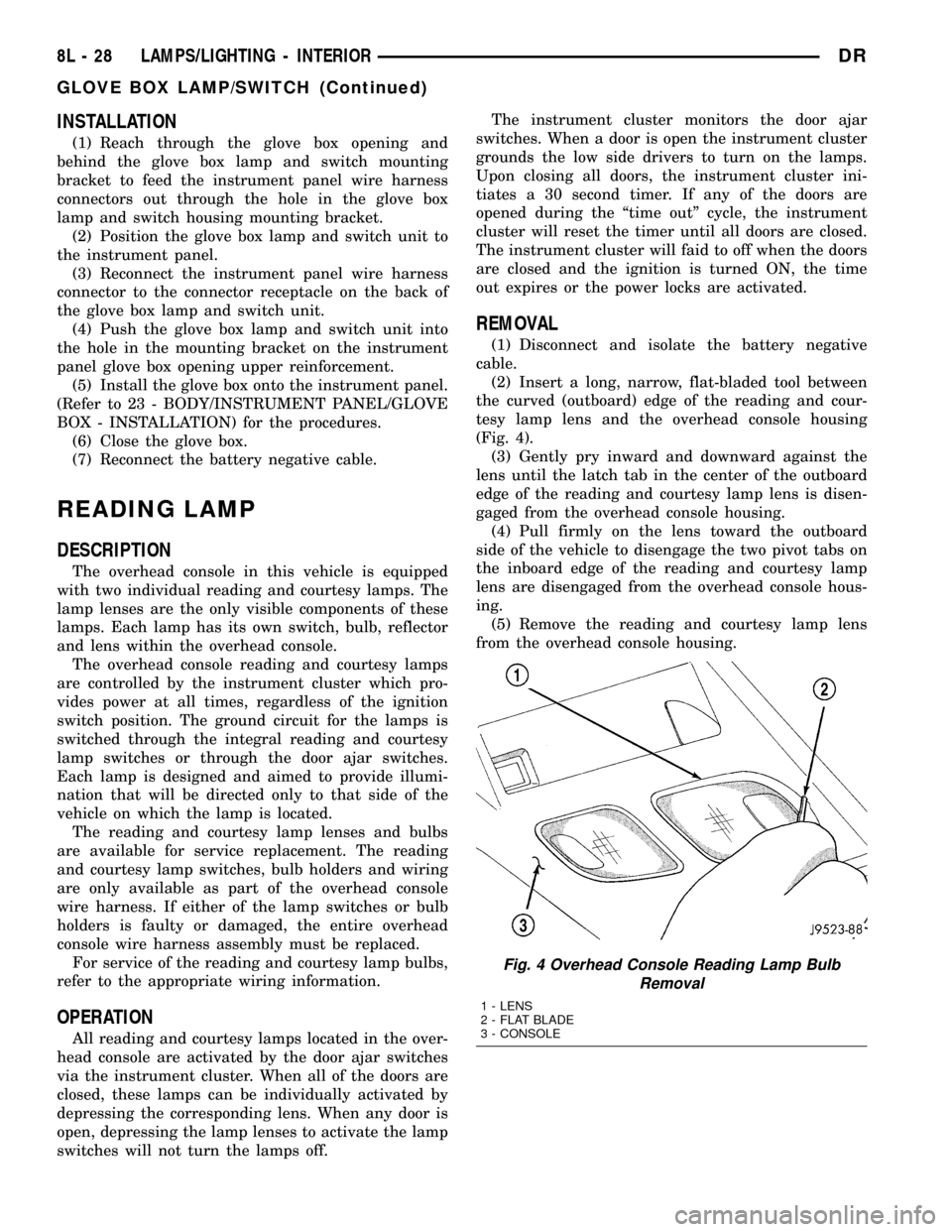

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Insert a long, narrow, flat-bladed tool between

the curved (outboard) edge of the reading and cour-

tesy lamp lens and the overhead console housing

(Fig. 4).

(3) Gently pry inward and downward against the

lens until the latch tab in the center of the outboard

edge of the reading and courtesy lamp lens is disen-

gaged from the overhead console housing.

(4) Pull firmly on the lens toward the outboard

side of the vehicle to disengage the two pivot tabs on

the inboard edge of the reading and courtesy lamp

lens are disengaged from the overhead console hous-

ing.

(5) Remove the reading and courtesy lamp lens

from the overhead console housing.

Fig. 4 Overhead Console Reading Lamp Bulb

Removal

1 - LENS

2 - FLAT BLADE

3 - CONSOLE

8L - 28 LAMPS/LIGHTING - INTERIORDR

GLOVE BOX LAMP/SWITCH (Continued)

Page 588 of 2627

SELF-DIAGNOSTIC TEST

A self-diagnostic test is built-in to the module to

determine that the electronics module is operating

properly, and that all the J1850 PCI data bus mes-

sages are being received for proper operation. To per-

form the self-diagnostic test proceed as follows:

(1) With the ignition switch in the Off position,

simultaneously depress and hold theSTEP and

RESET buttons.

(2) Turn the ignition switch to the On position.

(3) Following completion of the test, the electronics

module will display one of the following messages:

a.Pass Self Test (EVIC only), PASS (CMTC)-

The electronics module is working properly.

b.Failed Self Test (EVIC only), FAIL (CMTC)-

The electronics module has an internal failure. The

electronics module is faulty and must be replaced.

c.Failed J1850 Communication (EVIC only),

BUS (CMTC)- The electronics module is not receiv-

ing proper message input through the J1850 PCI

data bus circuit. This can result from one or more

faulty electronic modules in the vehicle, or from a

faulty PCI data bus. The use of a DRB IIItscan tool

and the proper Diagnostic Procedures manual are

required for further diagnosis.

NOTE: If the compass functions, but accuracy is

suspect, it may be necessary to perform a variation

adjustment. This procedure allows the compass

unit to accommodate variations in the earth's mag-

netic field strength, based on geographic location.

Refer to Compass Variation Adjustment in the Stan-

dard Procedures section of this group.

NOTE: If the compass reading displays dashes, and

only ªCALº appears in the display, demagnetizing

may be necessary to remove excessive residual

magnetic fields from the vehicle. Refer to Compass

Demagnetizing in the Standard Procedures section

of this group.

STANDARD PROCEDURE

STANDARD PROCEDURE - READING/

COURTESY LAMP REPLACEMENT

(1) Open hood, disconnect and isolate the negative

battery cable.

(2) Remove the reading/courtesy lamp lens. Using

a trim stick, gently pry the forward edge of the read-

ing/courtesy lamp lens outward.

(3) Remove the reading/courtesy lamp socket from

the overhead console. Rotate the reading/courtesy

lamp socket one quarter turn counter clockwise.

(4) Remove the lamp and socket assembly.(5) Reverse the above procedure to install.

STANDARD PROCEDURE - MODULE LENS

REPLACEMENT

(1) Remove the overhead console (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE -

REMOVAL).

(2) Remove the electronics module from the over-

head console. Refer to the procedure later in this sec-

tion.

(3) Unsnap the lens from the module and replace

lens as necessary.

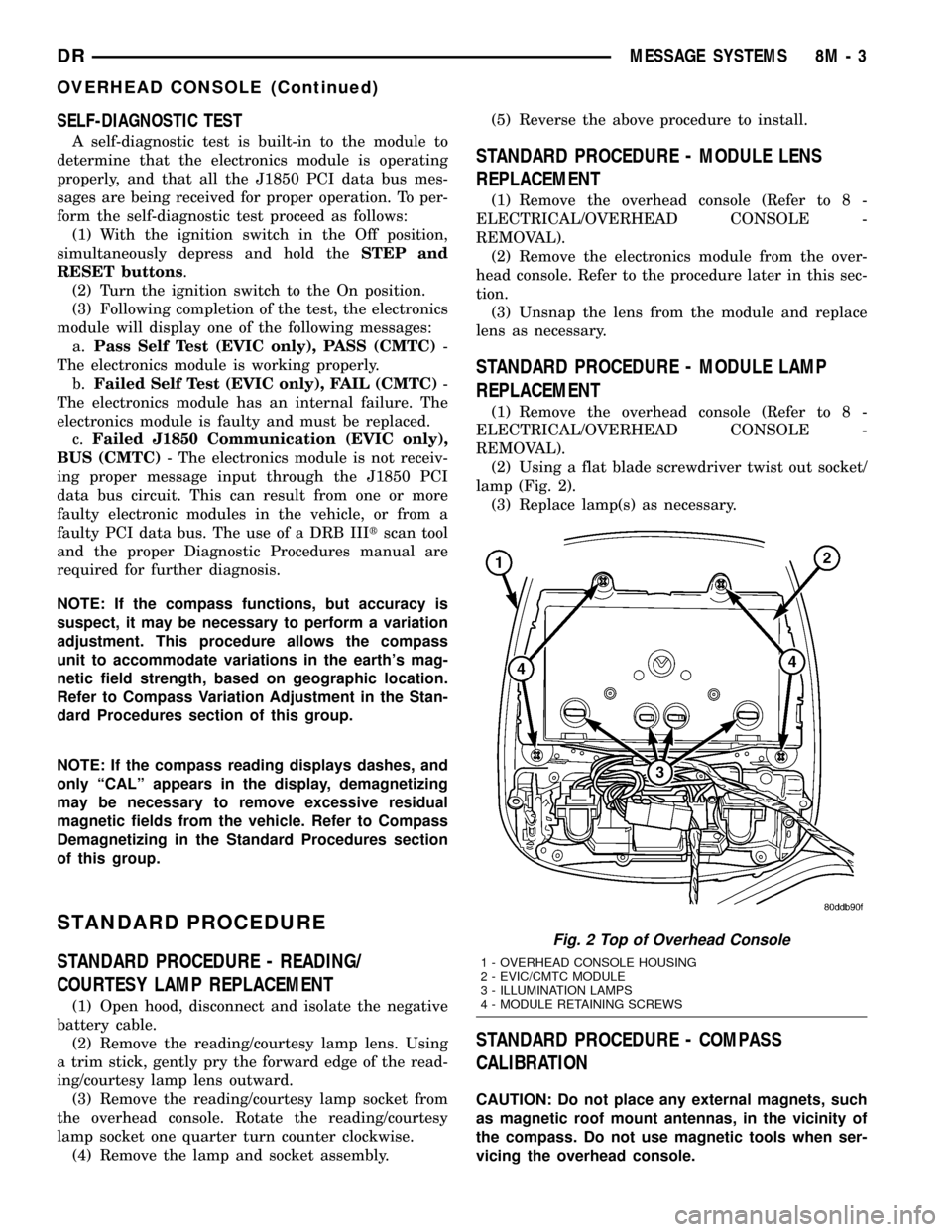

STANDARD PROCEDURE - MODULE LAMP

REPLACEMENT

(1) Remove the overhead console (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE -

REMOVAL).

(2) Using a flat blade screwdriver twist out socket/

lamp (Fig. 2).

(3) Replace lamp(s) as necessary.

STANDARD PROCEDURE - COMPASS

CALIBRATION

CAUTION: Do not place any external magnets, such

as magnetic roof mount antennas, in the vicinity of

the compass. Do not use magnetic tools when ser-

vicing the overhead console.

Fig. 2 Top of Overhead Console

1 - OVERHEAD CONSOLE HOUSING

2 - EVIC/CMTC MODULE

3 - ILLUMINATION LAMPS

4 - MODULE RETAINING SCREWS

DRMESSAGE SYSTEMS 8M - 3

OVERHEAD CONSOLE (Continued)

Page 589 of 2627

The electronic compass unit features a self-cali-

brating design, which simplifies the calibration pro-

cedure. This feature automatically updates the

compass calibration while the vehicle is being driven.

This allows the compass unit to compensate for small

changes in the residual magnetism that the vehicle

may acquire during normal use. If the compass read-

ings appear to be erratic or out of calibration, per-

form the following calibration procedure. Also, new

service replacement Electronic Modules (EVIC,

CMTC) must have their compass calibrated using

this procedure. Do not attempt to calibrate the com-

pass near large metal objects such as other vehicles,

large buildings, or bridges; or, near overhead or

underground power lines.

NOTE: Whenever the compass is calibrated manu-

ally, the variance number must also be reset. Refer

to Compass Variation Adjustment in this group.

To calibrate the compass manually proceed as fol-

lows:

(1) Turn the ignition switch to the On position. If

the compass/temperature data is not currently being

displayed, momentarily depress and release the C/T

push button to reach the compass/temperature dis-

play.

(2) Depress the RESET push button and hold the

button down until ªCALº appears in the display. This

takes about ten seconds, and appears about five sec-

onds after ªVAR = XXº is displayed.

(3) Release the RESET push button.

(4) Drive the vehicle on a level surface, away from

large metal objects and power lines, through three or

more complete turns at between five and eight kilo-

meters-per-hour (three and five miles-per-hour) in

not less than 48 seconds. The ªCALº message will

disappear from the display to indicate that the com-

pass is now calibrated.

NOTE: If the ªCALº message remains in the display,

either there is excessive magnetism near the com-

pass, or the unit is faulty. Repeat the calibration

procedure one more time.

NOTE: If the wrong direction is still indicated in the

compass display, the area selected for calibration

may be too close to a strong magnetic field. Repeat

the calibration procedure in another location.STANDARD PROCEDURE - COMPASS

DEMAGNETIZING

A degaussing tool (Special Tool 6029) is used to

demagnetize, or degauss, the overhead console for-

ward mounting screw and the roof panel above the

overhead console. Equivalent units must be rated as

continuous duty for 110/115 volts and 60 Hz. They

must also have a field strength of over 350 gauss at 7

millimeters (0.25 inch) beyond the tip of the probe.

To demagnetize the roof panel and the overhead

console forward mounting screw, proceed as follows:

(1) Be certain that the ignition switch is in the Off

position, before you begin the demagnetizing proce-

dure.

(2) Connect the degaussing tool to an electrical

outlet, while keeping the tool at least 61 centimeters

(2 feet) away from the compass unit.

(3) Slowly approach the head of the overhead con-

sole mounting screw with the degaussing tool con-

nected.

(4) Contact the head of the screw with the plastic

coated tip of the degaussing tool for about two sec-

onds.

(5) With the degaussing tool still energized, slowly

back it away from the screw. When the tip of the tool

is at least 61 centimeters (2 feet) from the screw

head, disconnect the tool.

(6) Place a piece of paper approximately 22 by 28

centimeters (8.5 by 11 inches), oriented on the vehicle

lengthwise from front to rear, on the center line of

the roof at the windshield header (Fig. 3). The pur-

pose of the paper is to protect the roof panel from

scratches, and to define the area to be demagnetized.

(7) Connect the degaussing tool to an electrical

outlet, while keeping the tool at least 61 centimeters

(2 feet) away from the compass unit.

(8) Slowly approach the center line of the roof

panel at the windshield header, with the degaussing

tool connected.

(9) Contact the roof panel with the plastic coated

tip of the degaussing tool. Be sure that the template

is in place to avoid scratching the roof panel. Using a

slow, back-and-forth sweeping motion, and allowing

13 millimeters (0.50 inch) between passes, move the

tool at least 11 centimeters (4 inches) to each side of

the roof center line, and 28 centimeters (11 inches)

back from the windshield header.

(10) With the degaussing tool still energized,

slowly back it away from the roof panel. When the

tip of the tool is at least 61 centimeters (2 feet) from

the roof panel, disconnect the tool.

(11) Calibrate the compass and adjust the compass

variance (Refer to 8 - ELECTRICAL/OVERHEAD

CONSOLE - STANDARD PROCEDURE).

8M - 4 MESSAGE SYSTEMSDR

OVERHEAD CONSOLE (Continued)

Page 624 of 2627

Airbag Control Module (ACM). An airbag indicator in

the ElectroMechanical Instrument Cluster (EMIC)

illuminates for about six seconds as a bulb test each

time the ignition switch is turned to the On or Start

positions. Following the bulb test, the airbag indica-

tor is turned on or off by the ACM to indicate the

status of the supplemental restraint system. If the

airbag indicator comes on at any time other than

during the bulb test, it indicates that there is a prob-

lem in the supplemental restraint system electrical

circuits. Such a problem may cause airbags not to

deploy when required, or to deploy when not

required.

Deployment of the supplemental restraints

depends upon the angle and severity of an impact.

Deployment is not based upon vehicle speed; rather,

deployment is based upon the rate of deceleration as

measured by the forces of gravity (G force) upon the

impact sensors. When an impact is severe enough,

the microprocessor in the ACM signals the inflator of

the appropriate airbag units to deploy their airbag

cushions. The outboard front seat belt tensioners are

provided with a deployment signal by the ACM in

conjunction with the driver and passenger front air-

bags. During a frontal vehicle impact, the knee block-

ers work in concert with properly fastened and

adjusted seat belts to restrain both the driver and

the front seat passenger in the proper position for an

airbag deployment. The knee blockers also absorb

and distribute the crash energy from the driver and

the front seat passenger to the structure of the

instrument panel. The seat belt tensioner removes

the slack from the outboard front seat belts to pro-

vide further assurance that the driver and front seat

passenger are properly positioned and restrained for

an airbag deployment.

Typically, the vehicle occupants recall more about

the events preceding and following a collision than

they do of an airbag deployment itself. This is

because the airbag deployment and deflation occur

very rapidly. In a typical 48 kilometer-per-hour (30

mile-per-hour) barrier impact, from the moment of

impact until the airbags are fully inflated takes

about 40 milliseconds. Within one to two seconds

from the moment of impact, the airbags are almost

entirely deflated. The times cited for these events are

approximations, which apply only to a barrier impact

at the given speed. Actual times will vary somewhat,

depending upon the vehicle speed, impact angle,

severity of the impact, and the type of collision.

When the ACM monitors a problem in any of the

supplemental restraint system circuits or compo-

nents, including the seat belt tensioners, it stores a

fault code or Diagnostic Trouble Code (DTC) in its

memory circuit and sends an electronic message to

the EMIC to turn on the airbag indicator. Propertesting of the supplemental restraint system compo-

nents, the Programmable Communications Interface

(PCI) data bus, the electronic message inputs to and

outputs from the EMIC or the ACM, as well as the

retrieval or erasure of a DTC from the ACM or EMIC

requires the use of a DRBIIItscan tool. Refer to the

appropriate diagnostic information.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of all of the factory-installed passive restraints.

WARNING

WARNINGS - RESTRAINT SYSTEM

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, DURING AND FOLLOWING ANY SEAT BELT

OR CHILD RESTRAINT ANCHOR SERVICE, CARE-

FULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLA-

TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

DRRESTRAINTS 8O - 5

RESTRAINTS (Continued)