Speed control DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1 of 2627

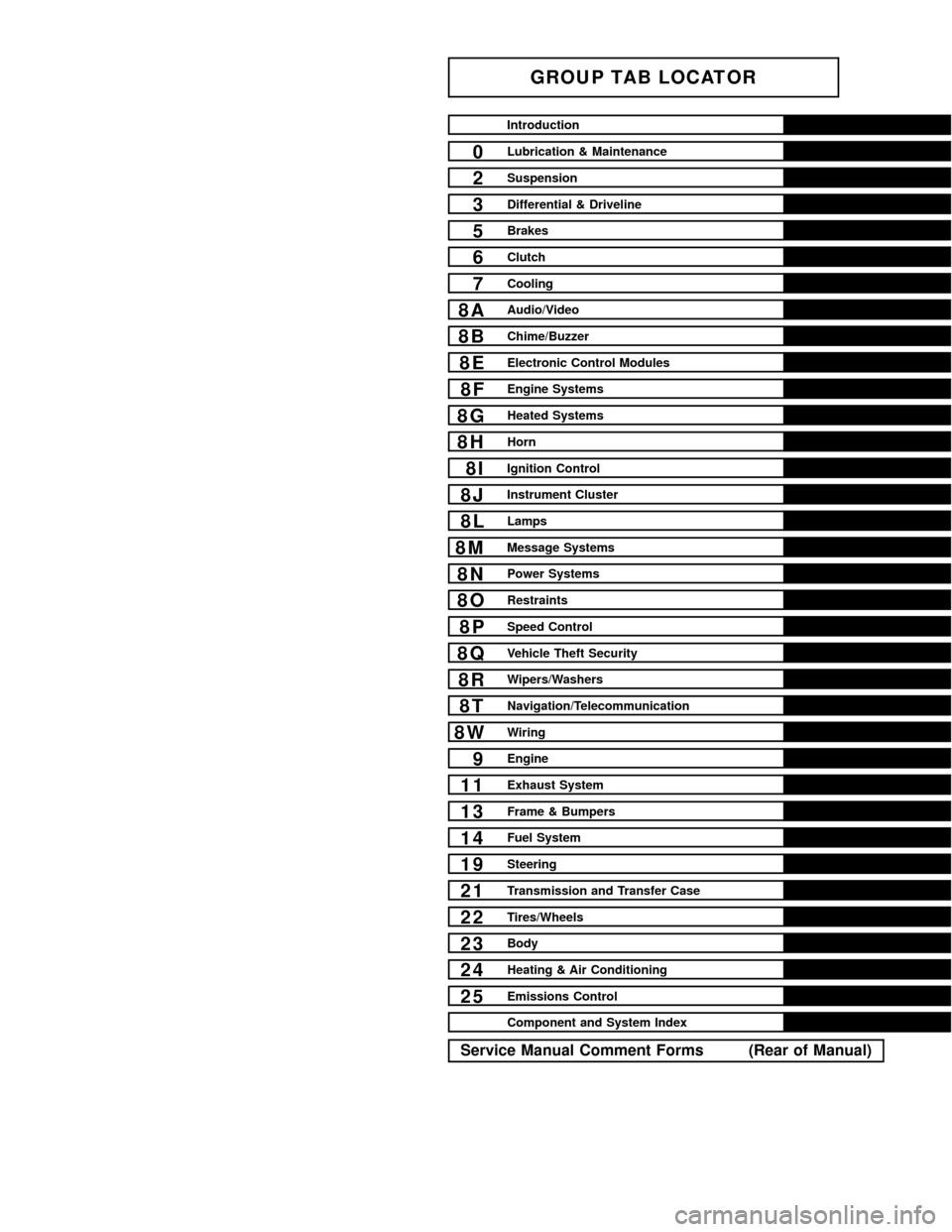

GROUP TAB LOCATOR

Introduction

0Lubrication & Maintenance

2Suspension

3Differential & Driveline

5Brakes

6Clutch

7Cooling

8AAudio/Video

8BChime/Buzzer

8EElectronic Control Modules

8FEngine Systems

8GHeated Systems

8HHorn

8IIgnition Control

8JInstrument Cluster

8LLamps

8MMessage Systems

8NPower Systems

8ORestraints

8PSpeed Control

8QVehicle Theft Security

8RWipers/Washers

8TNavigation/Telecommunication

8WWiring

9Engine

11Exhaust System

13Frame & Bumpers

14Fuel System

19Steering

21Transmission and Transfer Case

22Tires/Wheels

23Body

24Heating & Air Conditioning

25Emissions Control

Component and System Index

Service Manual Comment Forms (Rear of Manual)

Page 3 of 2627

POSITION INTERPRETATION CODE = DESCRIPTION

4 Gross Vehicle Weight Rating G = 5,001-6000 lbs.

H = 6,001-7,000 lbs.

J = 7,001-8,000 lbs.

K = 8,001-9,000 lbs.

L = 9,001-10,000 lbs.

M = 10,001-14,000 lbs.

W = Buses/Incomplete Vehicles with Hydraulic Brakes

5 Vehicle Line A = Ram Pickup 4X2

U = Ram Pickup 4X4

N = Ram Pickup 4X2 DX Family

6 Series 1 = 1500

2 = 2500

3 = 3500 Less Dual Rear Wheels

4 = 3500 With Dual Rear Wheels

5 = 4000 DX Family

7 Body Style 6 = Conventional Cab/Cab Chassis

8 = Quad Cab Full Rear Doors

8 Engine K = 3.7L 6 cyl. MPI Gasoline

N = 4.7L 8 cyl. MPI Gasoline

D = 5.7L 8 cyl. SMPI Gasoline

6 = 5.9L 6 cyl. Turbo Diesel 24v

C = 5.9L 6 cyl. Turbo Diesel High Output

9 Check Digit 0 through 9 or X

10 Model Year 4 = 2004

11 Plant Location S = Dodge City

G = Saltillo

J = St. Louis (North)

12 thru 17 Vehicle Build Sequence

VEHICLE EMISSION CONTROL

INFORMATION (VECI)

DESCRIPTION

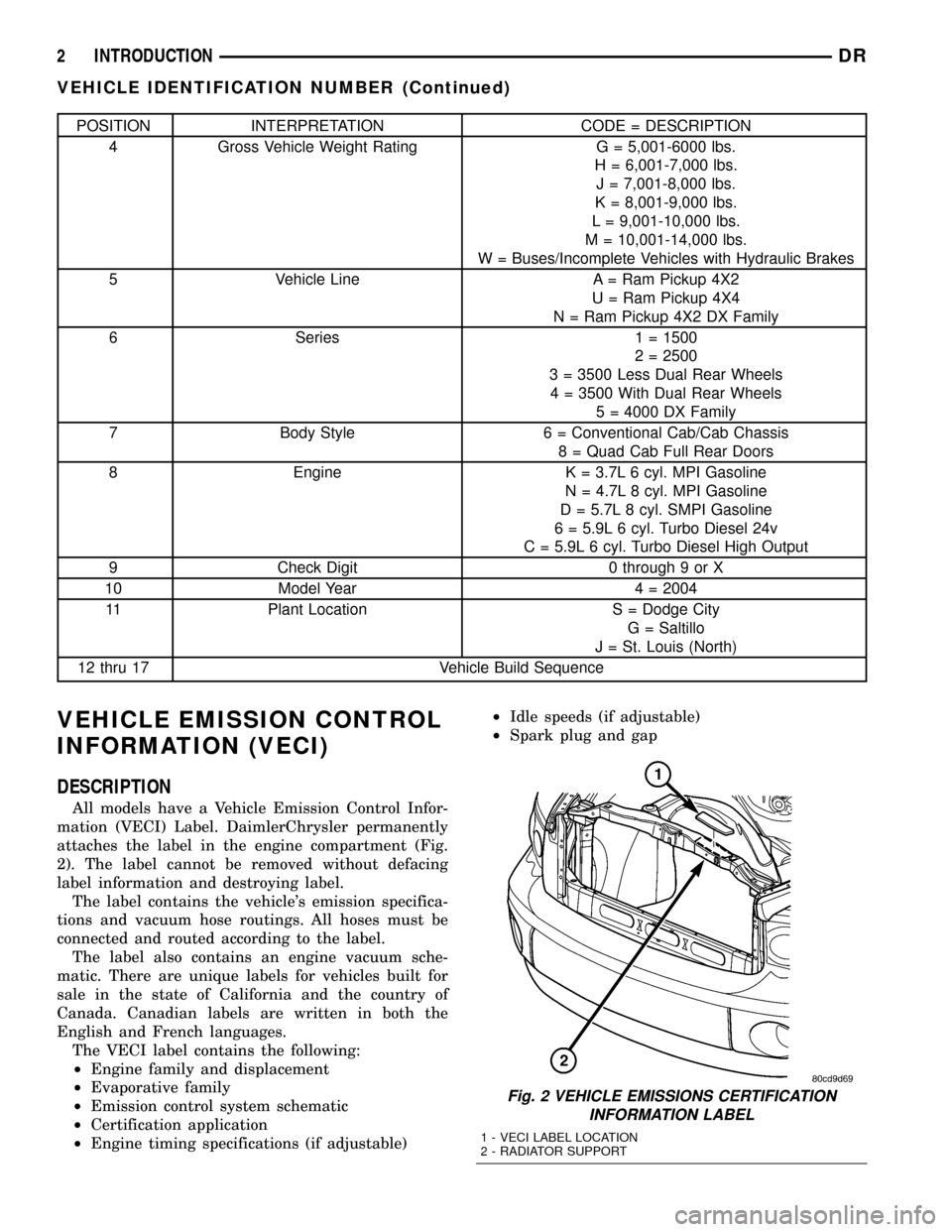

All models have a Vehicle Emission Control Infor-

mation (VECI) Label. DaimlerChrysler permanently

attaches the label in the engine compartment (Fig.

2). The label cannot be removed without defacing

label information and destroying label.

The label contains the vehicle's emission specifica-

tions and vacuum hose routings. All hoses must be

connected and routed according to the label.

The label also contains an engine vacuum sche-

matic. There are unique labels for vehicles built for

sale in the state of California and the country of

Canada. Canadian labels are written in both the

English and French languages.

The VECI label contains the following:

²Engine family and displacement

²Evaporative family

²Emission control system schematic

²Certification application

²Engine timing specifications (if adjustable)²Idle speeds (if adjustable)

²Spark plug and gap

Fig. 2 VEHICLE EMISSIONS CERTIFICATION

INFORMATION LABEL

1 - VECI LABEL LOCATION

2 - RADIATOR SUPPORT

2 INTRODUCTIONDR

VEHICLE IDENTIFICATION NUMBER (Continued)

Page 51 of 2627

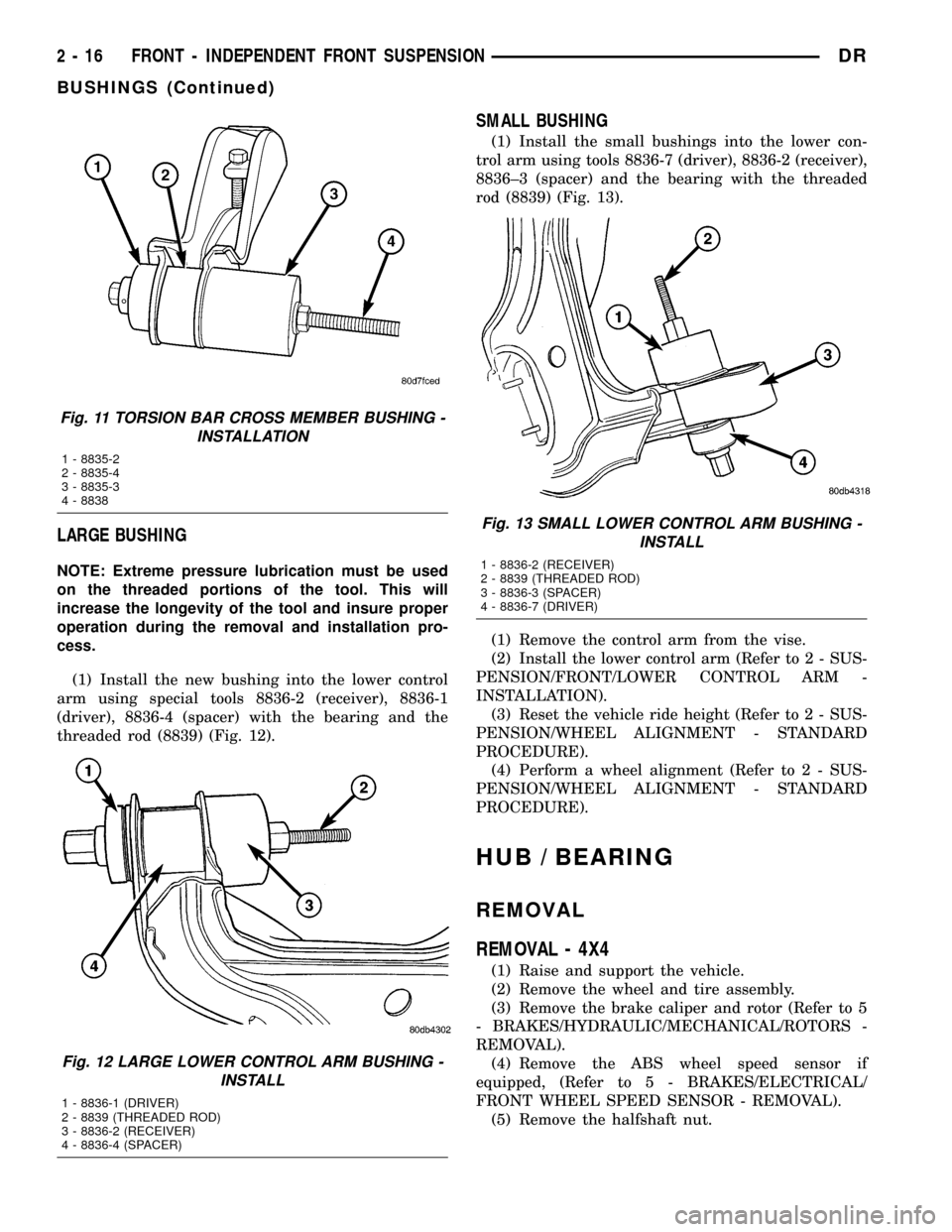

LARGE BUSHING

NOTE: Extreme pressure lubrication must be used

on the threaded portions of the tool. This will

increase the longevity of the tool and insure proper

operation during the removal and installation pro-

cess.

(1) Install the new bushing into the lower control

arm using special tools 8836-2 (receiver), 8836-1

(driver), 8836-4 (spacer) with the bearing and the

threaded rod (8839) (Fig. 12).

SMALL BUSHING

(1) Install the small bushings into the lower con-

trol arm using tools 8836-7 (driver), 8836-2 (receiver),

8836±3 (spacer) and the bearing with the threaded

rod (8839) (Fig. 13).

(1) Remove the control arm from the vise.

(2) Install the lower control arm (Refer to 2 - SUS-

PENSION/FRONT/LOWER CONTROL ARM -

INSTALLATION).

(3) Reset the vehicle ride height (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

(4) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

HUB / BEARING

REMOVAL

REMOVAL - 4X4

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assembly.

(3) Remove the brake caliper and rotor (Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

REMOVAL).

(4) Remove the ABS wheel speed sensor if

equipped, (Refer to 5 - BRAKES/ELECTRICAL/

FRONT WHEEL SPEED SENSOR - REMOVAL).

(5) Remove the halfshaft nut.

Fig. 11 TORSION BAR CROSS MEMBER BUSHING -

INSTALLATION

1 - 8835-2

2 - 8835-4

3 - 8835-3

4 - 8838

Fig. 12 LARGE LOWER CONTROL ARM BUSHING -

INSTALL

1 - 8836-1 (DRIVER)

2 - 8839 (THREADED ROD)

3 - 8836-2 (RECEIVER)

4 - 8836-4 (SPACER)

Fig. 13 SMALL LOWER CONTROL ARM BUSHING -

INSTALL

1 - 8836-2 (RECEIVER)

2 - 8839 (THREADED ROD)

3 - 8836-3 (SPACER)

4 - 8836-7 (DRIVER)

2 - 16 FRONT - INDEPENDENT FRONT SUSPENSIONDR

BUSHINGS (Continued)

Page 54 of 2627

(8) Remove the hub/bearing from the steering

knuckle (Refer to 2 - SUSPENSION/FRONT/HUB /

BEARING - REMOVAL).

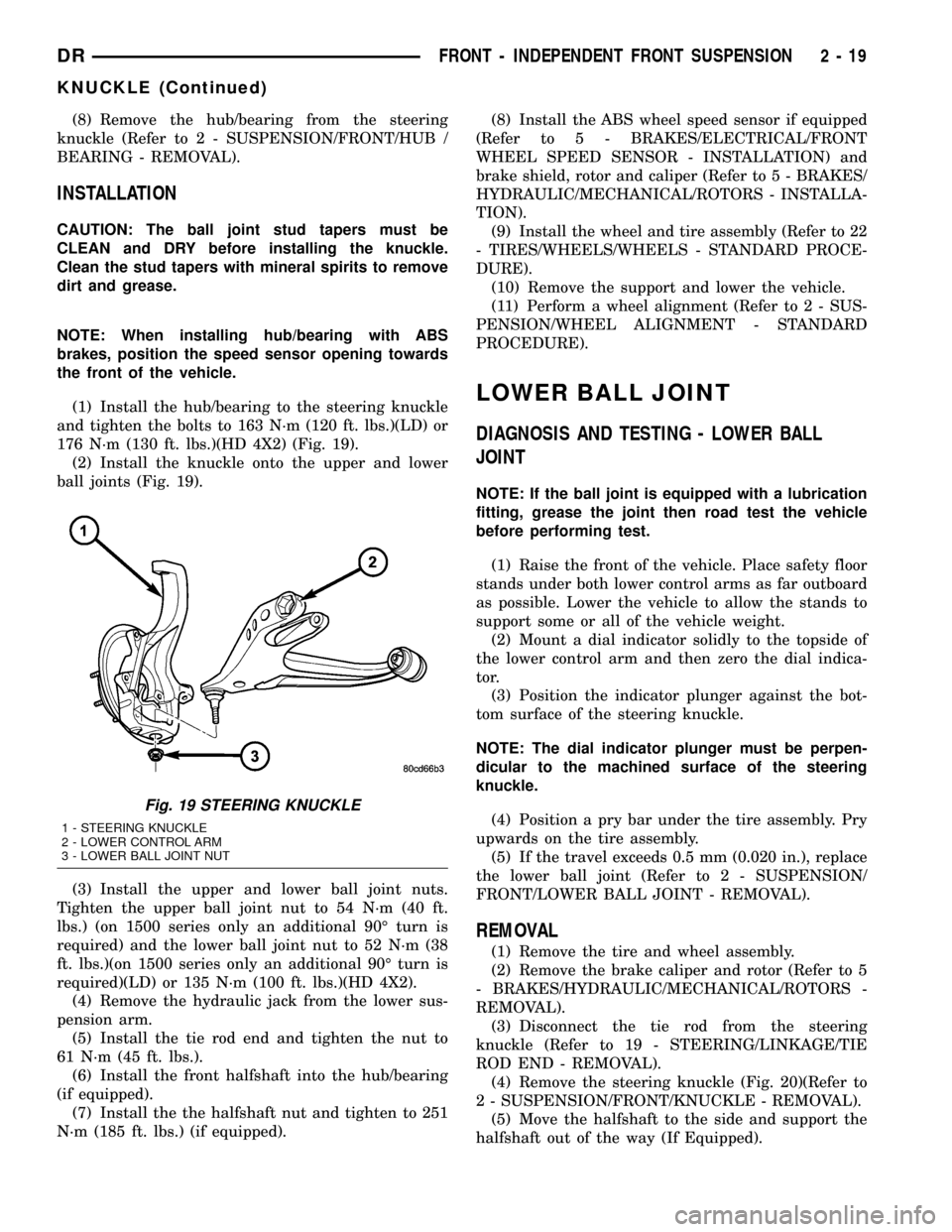

INSTALLATION

CAUTION: The ball joint stud tapers must be

CLEAN and DRY before installing the knuckle.

Clean the stud tapers with mineral spirits to remove

dirt and grease.

NOTE: When installing hub/bearing with ABS

brakes, position the speed sensor opening towards

the front of the vehicle.

(1) Install the hub/bearing to the steering knuckle

and tighten the bolts to 163 N´m (120 ft. lbs.)(LD) or

176 N´m (130 ft. lbs.)(HD 4X2) (Fig. 19).

(2) Install the knuckle onto the upper and lower

ball joints (Fig. 19).

(3) Install the upper and lower ball joint nuts.

Tighten the upper ball joint nut to 54 N´m (40 ft.

lbs.) (on 1500 series only an additional 90É turn is

required) and the lower ball joint nut to 52 N´m (38

ft. lbs.)(on 1500 series only an additional 90É turn is

required)(LD) or 135 N´m (100 ft. lbs.)(HD 4X2).

(4) Remove the hydraulic jack from the lower sus-

pension arm.

(5) Install the tie rod end and tighten the nut to

61 N´m (45 ft. lbs.).

(6) Install the front halfshaft into the hub/bearing

(if equipped).

(7) Install the the halfshaft nut and tighten to 251

N´m (185 ft. lbs.) (if equipped).(8) Install the ABS wheel speed sensor if equipped

(Refer to 5 - BRAKES/ELECTRICAL/FRONT

WHEEL SPEED SENSOR - INSTALLATION) and

brake shield, rotor and caliper (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/ROTORS - INSTALLA-

TION).

(9) Install the wheel and tire assembly (Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(10) Remove the support and lower the vehicle.

(11) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

LOWER BALL JOINT

DIAGNOSIS AND TESTING - LOWER BALL

JOINT

NOTE: If the ball joint is equipped with a lubrication

fitting, grease the joint then road test the vehicle

before performing test.

(1) Raise the front of the vehicle. Place safety floor

stands under both lower control arms as far outboard

as possible. Lower the vehicle to allow the stands to

support some or all of the vehicle weight.

(2) Mount a dial indicator solidly to the topside of

the lower control arm and then zero the dial indica-

tor.

(3) Position the indicator plunger against the bot-

tom surface of the steering knuckle.

NOTE: The dial indicator plunger must be perpen-

dicular to the machined surface of the steering

knuckle.

(4) Position a pry bar under the tire assembly. Pry

upwards on the tire assembly.

(5) If the travel exceeds 0.5 mm (0.020 in.), replace

the lower ball joint (Refer to 2 - SUSPENSION/

FRONT/LOWER BALL JOINT - REMOVAL).

REMOVAL

(1) Remove the tire and wheel assembly.

(2) Remove the brake caliper and rotor (Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

REMOVAL).

(3) Disconnect the tie rod from the steering

knuckle (Refer to 19 - STEERING/LINKAGE/TIE

ROD END - REMOVAL).

(4) Remove the steering knuckle (Fig. 20)(Refer to

2 - SUSPENSION/FRONT/KNUCKLE - REMOVAL).

(5) Move the halfshaft to the side and support the

halfshaft out of the way (If Equipped).

Fig. 19 STEERING KNUCKLE

1 - STEERING KNUCKLE

2 - LOWER CONTROL ARM

3 - LOWER BALL JOINT NUT

DRFRONT - INDEPENDENT FRONT SUSPENSION 2 - 19

KNUCKLE (Continued)

Page 101 of 2627

HALF SHAFT

TABLE OF CONTENTS

page page

HALF SHAFT

CAUTION.............................20

DIAGNOSIS AND TESTING................20

REMOVAL.............................20

INSTALLATION.........................21

SPECIFICATIONS.......................21

SPECIAL TOOLS.......................21CV JOINT-OUTER

REMOVAL.............................22

INSTALLATION.........................23

CV JOINT-INNER

REMOVAL.............................25

INSTALLATION.........................25

HALF SHAFT

CAUTION

CAUTION:: Never grasp half shaft assembly by the

boots. This may cause the boot to pucker or crease

and reduce the service life of the boot.

Avoid over angulating or stroking the C/V joints

when handling the half shaft.

Half shafts exposed to battery acid, transmission

fluid, brake fluid, differential fluid or gasoline may

cause the boots to deteriorate. Failure to heed cau-

tion may result in damage.

DIAGNOSIS AND TESTING

Check inboard and outboard C/V joint for leaking

grease. This is a sign of boot or boot clamp damage.

NOISE/VIBRATION IN TURNS

A clicking noise or vibration in turns could be

caused by a damaged outer C/V or inner tripod joint

seal boot or seal boot clamps. This will result in the

loss/contamination of the joint grease, resulting in

inadequate lubrication of the joint. Noise could also

be caused by another component of the vehicle com-

ing in contact with the half shafts.

CLUNKING NOISE DURING ACCELERATION

This noise may be a damaged or worn C/V joint. A

torn boot or loose/missing clamp on the inner/outer

joint which has allowed the grease to be lost will

damage the C/V joint.

SHUDDER/VIBRATION DURING ACCELERATION

This could be a worn/damaged inner tripod joint or

a sticking tripod joint. Improper wheel alignment

may also cause a shudder or vibration.

VIBRATION AT HIGHWAY SPEEDS

This problem could be a result of out of balance

front tires or tire/wheel runout. Foreign material

(mud, etc.) packed on the backside of the wheel(s)

will also cause a vibration.

REMOVAL

(1) With vehicle in neutral, position vehicle on

hoist.

(2) Remove half shaft hub nut.

(3) Remove brake caliper and rotor.

(4) Position hydraulic jack under lower suspension

arm and raise jack to unload rebound bumper.

(5) Remove lower shock absorber bolt.

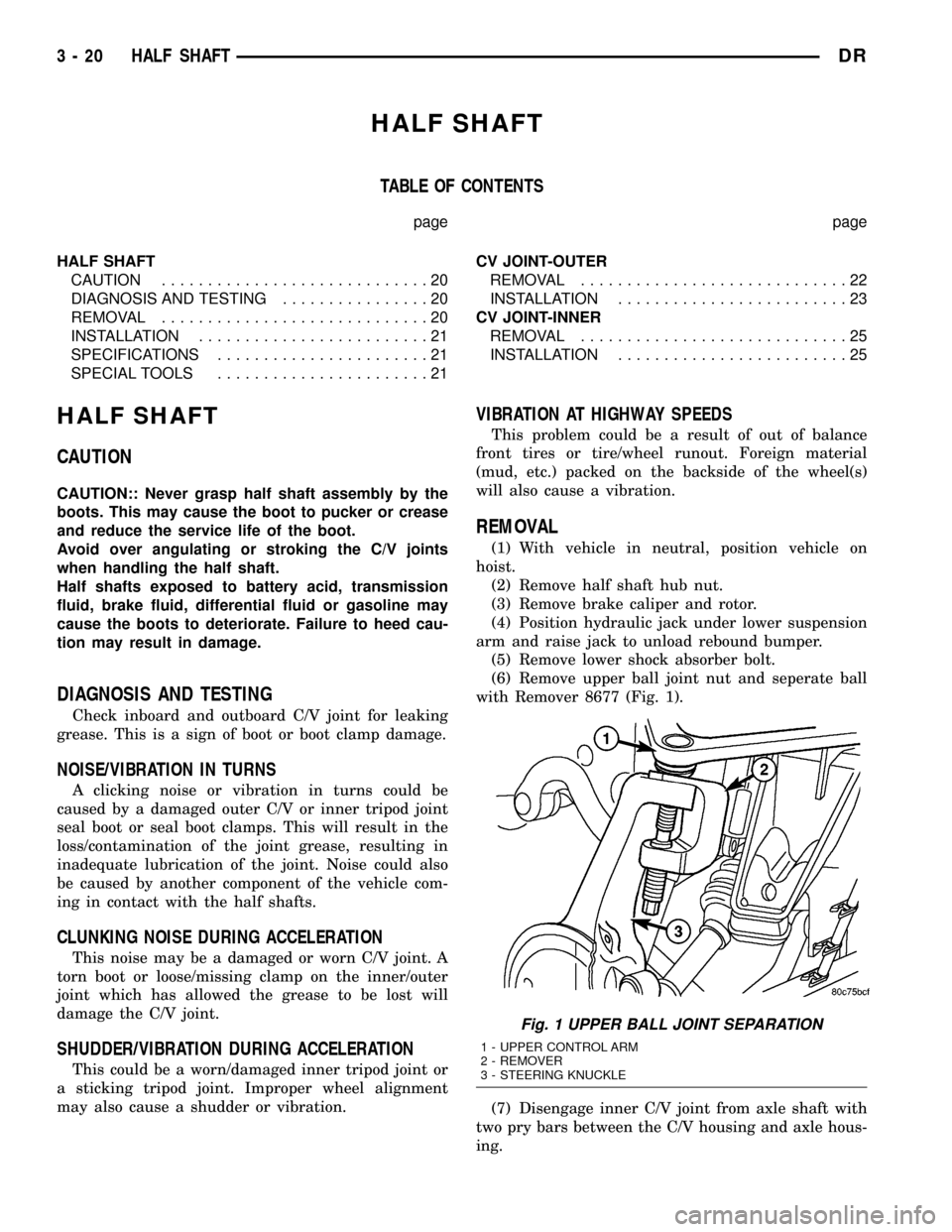

(6) Remove upper ball joint nut and seperate ball

with Remover 8677 (Fig. 1).

(7) Disengage inner C/V joint from axle shaft with

two pry bars between the C/V housing and axle hous-

ing.

Fig. 1 UPPER BALL JOINT SEPARATION

1 - UPPER CONTROL ARM

2 - REMOVER

3 - STEERING KNUCKLE

3 - 20 HALF SHAFTDR

Page 294 of 2627

BRAKES - ABS

TABLE OF CONTENTS

page page

BRAKES - ABS

DESCRIPTION.........................45

OPERATION...........................45

STANDARD PROCEDURE - ABS BRAKE

BLEEDING...........................46

SPECIFICATIONS

TORQUE CHART......................46

FRONT WHEEL SPEED SENSOR

DESCRIPTION.........................47

OPERATION...........................47

REMOVAL.............................48

INSTALLATION.........................48

REAR WHEEL SPEED SENSOR

DIAGNOSIS AND TESTING - REAR WHEEL

ANTILOCK...........................48

REMOVAL.............................48

INSTALLATION.........................48TONE WHEEL

DIAGNOSIS AND TESTING - REAR WHEEL

SPEED SENSOR......................49

HYDRAULIC/MECHANICAL

DESCRIPTION - ELECTRONIC VARIABLE

BRAKE PROPORTIONING...............49

OPERATION - ELECTRONIC VARIABLE

BRAKE PROPORTIONING...............49

HCU (HYDRAULIC CONTROL UNIT)

DESCRIPTION.........................49

OPERATION...........................49

REMOVAL.............................50

INSTALLATION.........................50

R WA L VA LV E

DESCRIPTION.........................50

OPERATION...........................50

REMOVAL.............................51

INSTALLATION.........................51

BRAKES - ABS

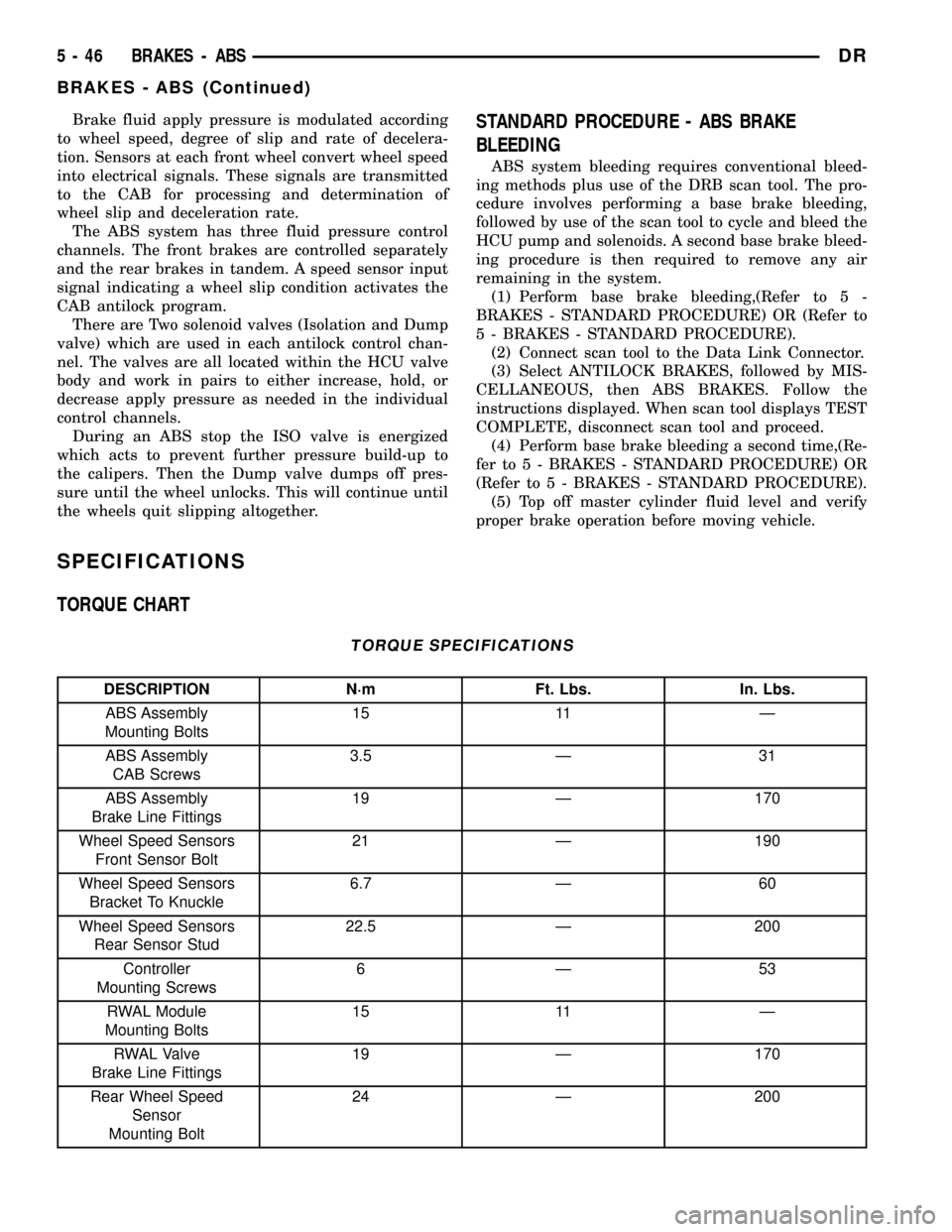

DESCRIPTION

The antilock brake system (ABS) is an electroni-

cally operated, three channel brake control system.

The vehicle has Electronic Variable Brake Propor-

tioning (EVBP) designed into the system which elim-

inates the combination/proportioning valve.

The system is designed to prevent wheel lockup

and maintain steering control during braking. Pre-

venting lockup is accomplished by modulating fluid

pressure to the wheel brake units.

The hydraulic system is a three channel design.

The front wheel brakes are controlled individually

and the rear wheel brakes in tandem. The ABS elec-

trical system is separate from other electrical circuits

in the vehicle. A specially programmed controller

antilock brake unit operates the system components.

ABS system major components include:

²Controller Antilock Brakes (CAB)

²Hydraulic Control Unit (HCU)

²Wheel Speed Sensors (WSS)

²ABS Warning Light

OPERATION

Battery voltage is supplied to the CAB. The CAB

performs a system initialization procedure at start

up. A check of the ABS motor is performed at 15miles per hour. Initialization consists of a static and

dynamic self check of system electrical components.

The static and dynamic checks occurs at ignition

start up. During the dynamic check, the CAB briefly

cycles solenoids to verify operation. An audible noise

may be heard during this self check. This noise

should be considered normal. The ABS motor and

pump are then checked at a speed of 15 mile per

hour.

If an ABS component exhibits a fault during ini-

tialization, the CAB illuminates the amber warning

light and registers a fault code in the microprocessor

memory.

The CAB monitors wheel speed sensor inputs con-

tinuously while the vehicle is in motion. However,

the CAB will not activate any ABS components as

long as sensor inputs indicate normal braking.

During normal braking, the master cylinder, power

booster and wheel brake units all function as they

would in a vehicle without ABS. The HCU compo-

nents are not activated.

The purpose of the antilock system is to prevent

wheel lockup. Preventing lockup helps maintain vehi-

cle braking action and steering control.

The antilock CAB activates the system whenever

sensor signals indicate periods of wheel slip.

The antilock system prevents lockup during a

wheel slip condition by modulating fluid apply pres-

sure to the wheel brake units.

DRBRAKES - ABS 5 - 45

Page 295 of 2627

Brake fluid apply pressure is modulated according

to wheel speed, degree of slip and rate of decelera-

tion. Sensors at each front wheel convert wheel speed

into electrical signals. These signals are transmitted

to the CAB for processing and determination of

wheel slip and deceleration rate.

The ABS system has three fluid pressure control

channels. The front brakes are controlled separately

and the rear brakes in tandem. A speed sensor input

signal indicating a wheel slip condition activates the

CAB antilock program.

There are Two solenoid valves (Isolation and Dump

valve) which are used in each antilock control chan-

nel. The valves are all located within the HCU valve

body and work in pairs to either increase, hold, or

decrease apply pressure as needed in the individual

control channels.

During an ABS stop the ISO valve is energized

which acts to prevent further pressure build-up to

the calipers. Then the Dump valve dumps off pres-

sure until the wheel unlocks. This will continue until

the wheels quit slipping altogether.STANDARD PROCEDURE - ABS BRAKE

BLEEDING

ABS system bleeding requires conventional bleed-

ing methods plus use of the DRB scan tool. The pro-

cedure involves performing a base brake bleeding,

followed by use of the scan tool to cycle and bleed the

HCU pump and solenoids. A second base brake bleed-

ing procedure is then required to remove any air

remaining in the system.

(1) Perform base brake bleeding,(Refer to 5 -

BRAKES - STANDARD PROCEDURE) OR (Refer to

5 - BRAKES - STANDARD PROCEDURE).

(2) Connect scan tool to the Data Link Connector.

(3) Select ANTILOCK BRAKES, followed by MIS-

CELLANEOUS, then ABS BRAKES. Follow the

instructions displayed. When scan tool displays TEST

COMPLETE, disconnect scan tool and proceed.

(4) Perform base brake bleeding a second time,(Re-

fer to 5 - BRAKES - STANDARD PROCEDURE) OR

(Refer to 5 - BRAKES - STANDARD PROCEDURE).

(5) Top off master cylinder fluid level and verify

proper brake operation before moving vehicle.

SPECIFICATIONS

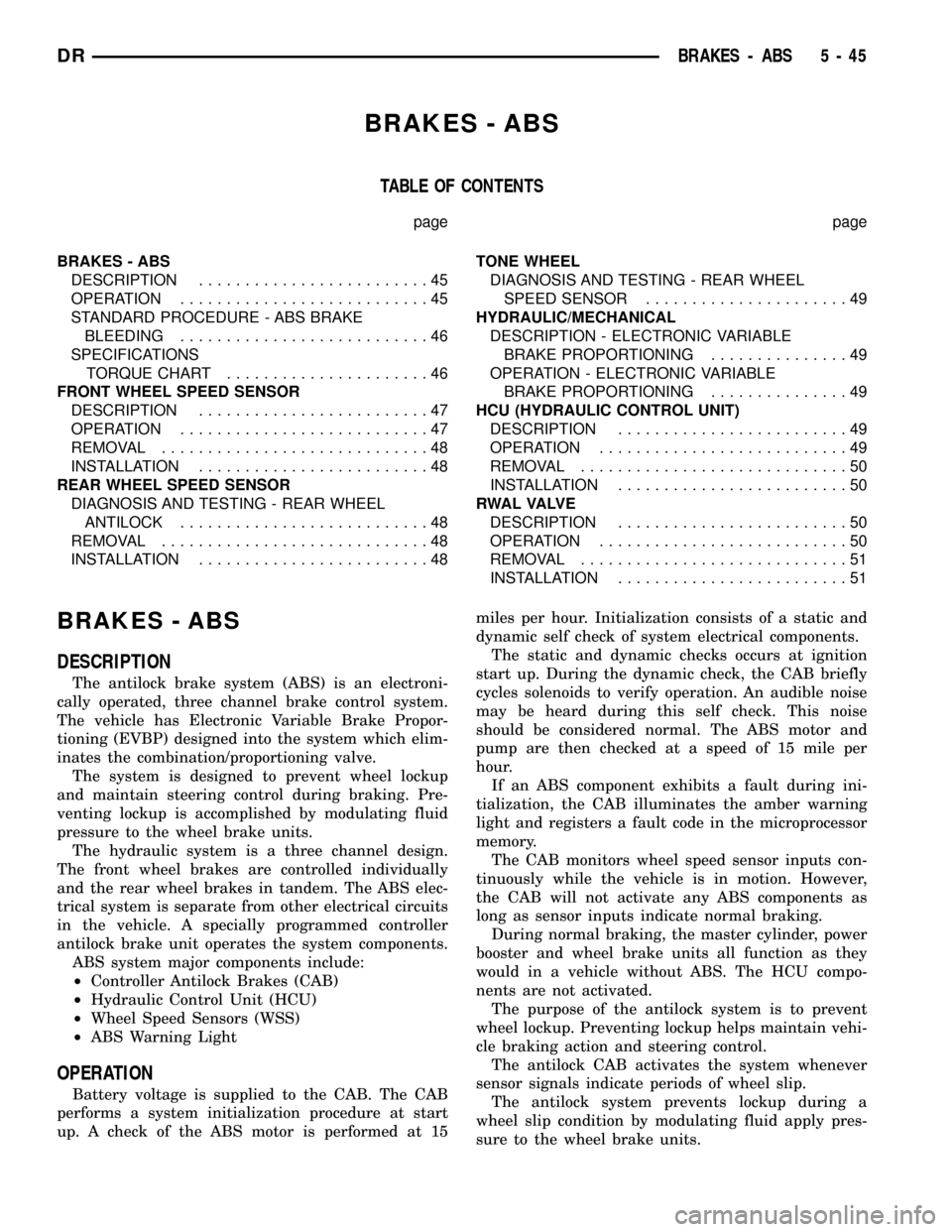

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

ABS Assembly

Mounting Bolts15 11 Ð

ABS Assembly

CAB Screws3.5 Ð 31

ABS Assembly

Brake Line Fittings19 Ð 170

Wheel Speed Sensors

Front Sensor Bolt21 Ð 190

Wheel Speed Sensors

Bracket To Knuckle6.7 Ð 60

Wheel Speed Sensors

Rear Sensor Stud22.5 Ð 200

Controller

Mounting Screws6Ð53

RWAL Module

Mounting Bolts15 11 Ð

RWAL Valve

Brake Line Fittings19 Ð 170

Rear Wheel Speed

Sensor

Mounting Bolt24 Ð 200

5 - 46 BRAKES - ABSDR

BRAKES - ABS (Continued)

Page 298 of 2627

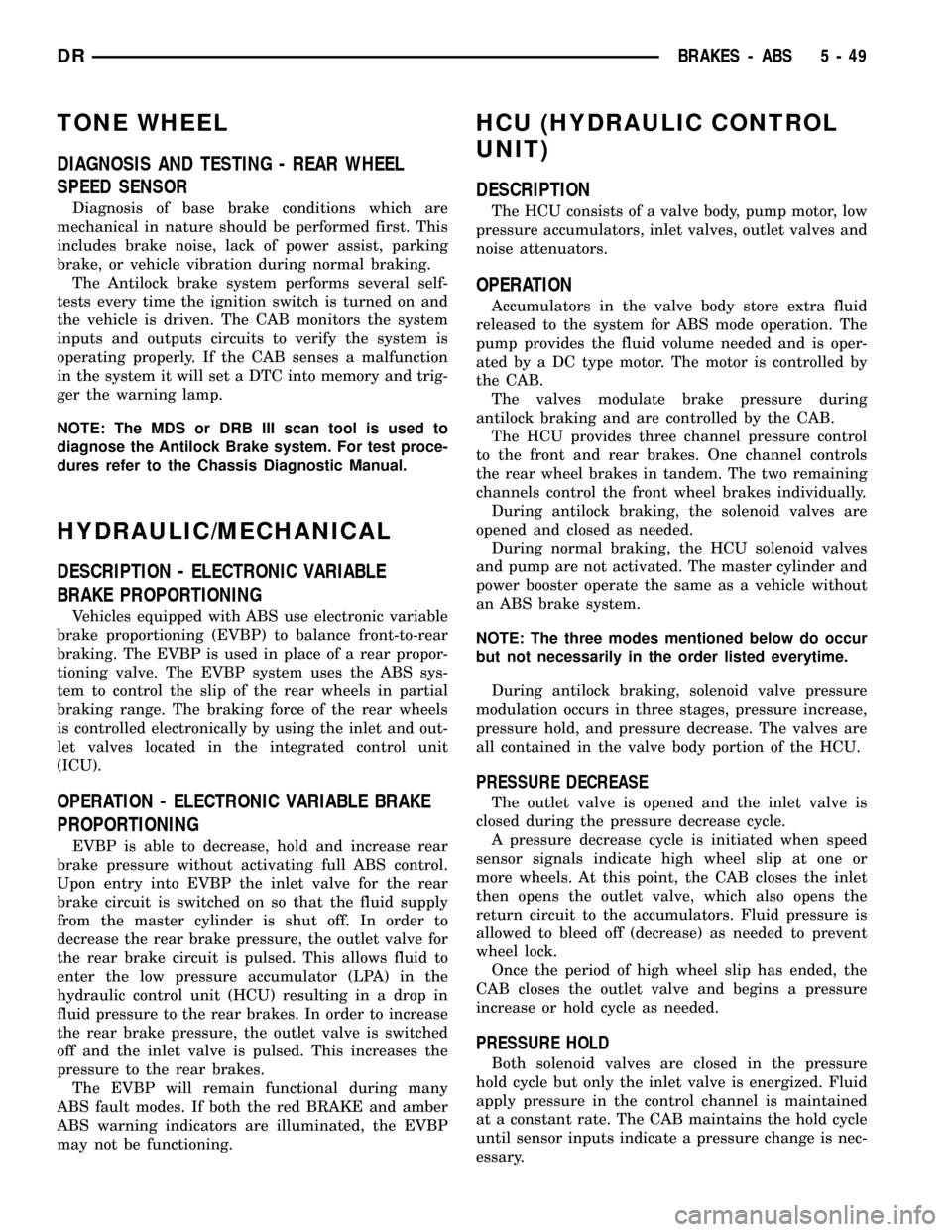

TONE WHEEL

DIAGNOSIS AND TESTING - REAR WHEEL

SPEED SENSOR

Diagnosis of base brake conditions which are

mechanical in nature should be performed first. This

includes brake noise, lack of power assist, parking

brake, or vehicle vibration during normal braking.

The Antilock brake system performs several self-

tests every time the ignition switch is turned on and

the vehicle is driven. The CAB monitors the system

inputs and outputs circuits to verify the system is

operating properly. If the CAB senses a malfunction

in the system it will set a DTC into memory and trig-

ger the warning lamp.

NOTE: The MDS or DRB III scan tool is used to

diagnose the Antilock Brake system. For test proce-

dures refer to the Chassis Diagnostic Manual.

HYDRAULIC/MECHANICAL

DESCRIPTION - ELECTRONIC VARIABLE

BRAKE PROPORTIONING

Vehicles equipped with ABS use electronic variable

brake proportioning (EVBP) to balance front-to-rear

braking. The EVBP is used in place of a rear propor-

tioning valve. The EVBP system uses the ABS sys-

tem to control the slip of the rear wheels in partial

braking range. The braking force of the rear wheels

is controlled electronically by using the inlet and out-

let valves located in the integrated control unit

(ICU).

OPERATION - ELECTRONIC VARIABLE BRAKE

PROPORTIONING

EVBP is able to decrease, hold and increase rear

brake pressure without activating full ABS control.

Upon entry into EVBP the inlet valve for the rear

brake circuit is switched on so that the fluid supply

from the master cylinder is shut off. In order to

decrease the rear brake pressure, the outlet valve for

the rear brake circuit is pulsed. This allows fluid to

enter the low pressure accumulator (LPA) in the

hydraulic control unit (HCU) resulting in a drop in

fluid pressure to the rear brakes. In order to increase

the rear brake pressure, the outlet valve is switched

off and the inlet valve is pulsed. This increases the

pressure to the rear brakes.

The EVBP will remain functional during many

ABS fault modes. If both the red BRAKE and amber

ABS warning indicators are illuminated, the EVBP

may not be functioning.

HCU (HYDRAULIC CONTROL

UNIT)

DESCRIPTION

The HCU consists of a valve body, pump motor, low

pressure accumulators, inlet valves, outlet valves and

noise attenuators.

OPERATION

Accumulators in the valve body store extra fluid

released to the system for ABS mode operation. The

pump provides the fluid volume needed and is oper-

ated by a DC type motor. The motor is controlled by

the CAB.

The valves modulate brake pressure during

antilock braking and are controlled by the CAB.

The HCU provides three channel pressure control

to the front and rear brakes. One channel controls

the rear wheel brakes in tandem. The two remaining

channels control the front wheel brakes individually.

During antilock braking, the solenoid valves are

opened and closed as needed.

During normal braking, the HCU solenoid valves

and pump are not activated. The master cylinder and

power booster operate the same as a vehicle without

an ABS brake system.

NOTE: The three modes mentioned below do occur

but not necessarily in the order listed everytime.

During antilock braking, solenoid valve pressure

modulation occurs in three stages, pressure increase,

pressure hold, and pressure decrease. The valves are

all contained in the valve body portion of the HCU.

PRESSURE DECREASE

The outlet valve is opened and the inlet valve is

closed during the pressure decrease cycle.

A pressure decrease cycle is initiated when speed

sensor signals indicate high wheel slip at one or

more wheels. At this point, the CAB closes the inlet

then opens the outlet valve, which also opens the

return circuit to the accumulators. Fluid pressure is

allowed to bleed off (decrease) as needed to prevent

wheel lock.

Once the period of high wheel slip has ended, the

CAB closes the outlet valve and begins a pressure

increase or hold cycle as needed.

PRESSURE HOLD

Both solenoid valves are closed in the pressure

hold cycle but only the inlet valve is energized. Fluid

apply pressure in the control channel is maintained

at a constant rate. The CAB maintains the hold cycle

until sensor inputs indicate a pressure change is nec-

essary.

DRBRAKES - ABS 5 - 49

Page 299 of 2627

PRESSURE INCREASE

The inlet valve is open and the outlet valve is

closed during the pressure increase cycle. The pres-

sure increase cycle is used to reapply thew brakes.

This cycle controls re-application of fluid apply pres-

sure.

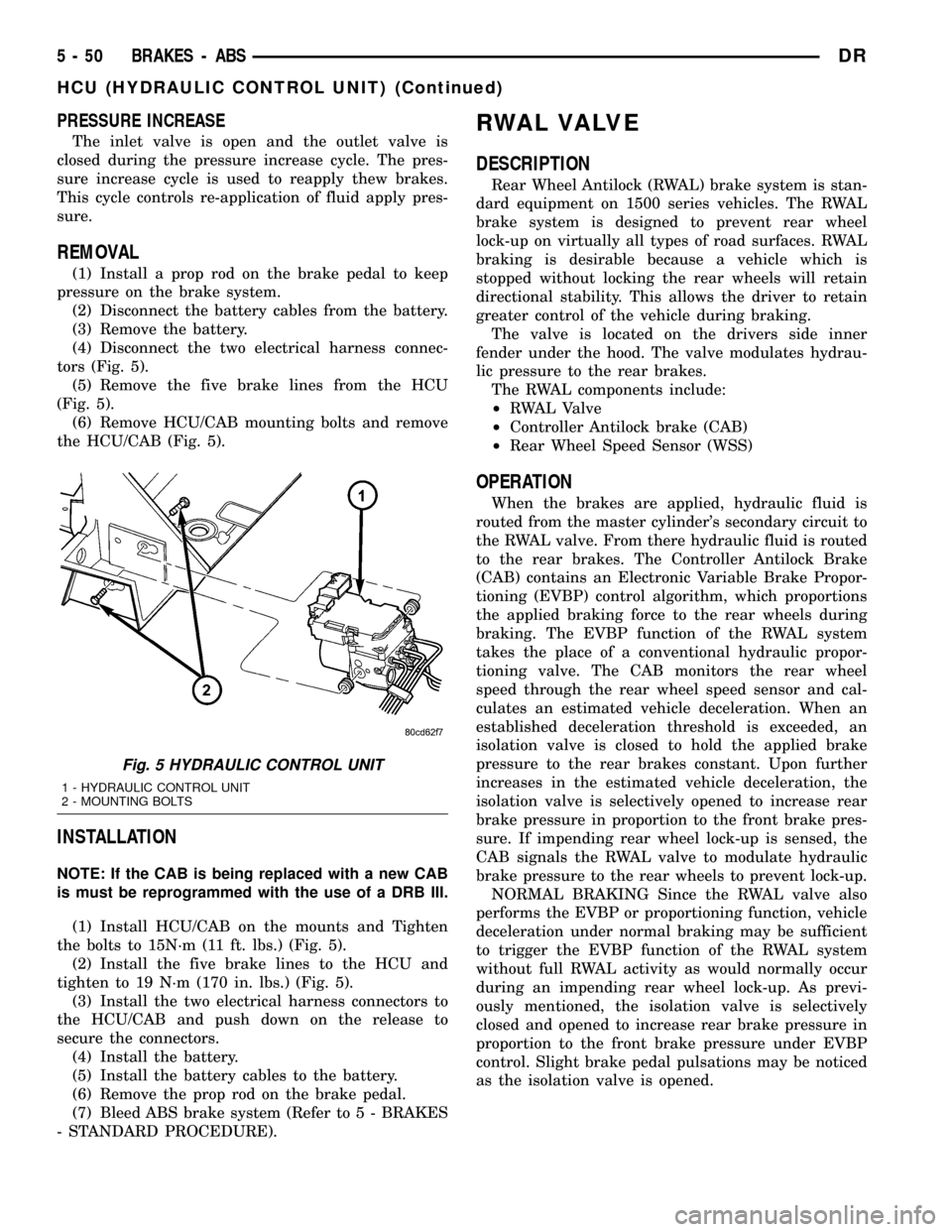

REMOVAL

(1) Install a prop rod on the brake pedal to keep

pressure on the brake system.

(2) Disconnect the battery cables from the battery.

(3) Remove the battery.

(4) Disconnect the two electrical harness connec-

tors (Fig. 5).

(5) Remove the five brake lines from the HCU

(Fig. 5).

(6) Remove HCU/CAB mounting bolts and remove

the HCU/CAB (Fig. 5).

INSTALLATION

NOTE: If the CAB is being replaced with a new CAB

is must be reprogrammed with the use of a DRB III.

(1) Install HCU/CAB on the mounts and Tighten

the bolts to 15N´m (11 ft. lbs.) (Fig. 5).

(2) Install the five brake lines to the HCU and

tighten to 19 N´m (170 in. lbs.) (Fig. 5).

(3) Install the two electrical harness connectors to

the HCU/CAB and push down on the release to

secure the connectors.

(4) Install the battery.

(5) Install the battery cables to the battery.

(6) Remove the prop rod on the brake pedal.

(7) Bleed ABS brake system (Refer to 5 - BRAKES

- STANDARD PROCEDURE).

RWAL VALVE

DESCRIPTION

Rear Wheel Antilock (RWAL) brake system is stan-

dard equipment on 1500 series vehicles. The RWAL

brake system is designed to prevent rear wheel

lock-up on virtually all types of road surfaces. RWAL

braking is desirable because a vehicle which is

stopped without locking the rear wheels will retain

directional stability. This allows the driver to retain

greater control of the vehicle during braking.

The valve is located on the drivers side inner

fender under the hood. The valve modulates hydrau-

lic pressure to the rear brakes.

The RWAL components include:

²RWAL Valve

²Controller Antilock brake (CAB)

²Rear Wheel Speed Sensor (WSS)

OPERATION

When the brakes are applied, hydraulic fluid is

routed from the master cylinder's secondary circuit to

the RWAL valve. From there hydraulic fluid is routed

to the rear brakes. The Controller Antilock Brake

(CAB) contains an Electronic Variable Brake Propor-

tioning (EVBP) control algorithm, which proportions

the applied braking force to the rear wheels during

braking. The EVBP function of the RWAL system

takes the place of a conventional hydraulic propor-

tioning valve. The CAB monitors the rear wheel

speed through the rear wheel speed sensor and cal-

culates an estimated vehicle deceleration. When an

established deceleration threshold is exceeded, an

isolation valve is closed to hold the applied brake

pressure to the rear brakes constant. Upon further

increases in the estimated vehicle deceleration, the

isolation valve is selectively opened to increase rear

brake pressure in proportion to the front brake pres-

sure. If impending rear wheel lock-up is sensed, the

CAB signals the RWAL valve to modulate hydraulic

brake pressure to the rear wheels to prevent lock-up.

NORMAL BRAKING Since the RWAL valve also

performs the EVBP or proportioning function, vehicle

deceleration under normal braking may be sufficient

to trigger the EVBP function of the RWAL system

without full RWAL activity as would normally occur

during an impending rear wheel lock-up. As previ-

ously mentioned, the isolation valve is selectively

closed and opened to increase rear brake pressure in

proportion to the front brake pressure under EVBP

control. Slight brake pedal pulsations may be noticed

as the isolation valve is opened.

Fig. 5 HYDRAULIC CONTROL UNIT

1 - HYDRAULIC CONTROL UNIT

2 - MOUNTING BOLTS

5 - 50 BRAKES - ABSDR

HCU (HYDRAULIC CONTROL UNIT) (Continued)

Page 320 of 2627

OPERATION

OPERATION - COOLING SYSTEM

The cooling system regulates engine operating tem-

perature. It allows the engine to reach normal oper-

ating temperature as quickly as possible. It also

maintains normal operating temperature and pre-

vents overheating.

The cooling system also provides a means of heat-

ing the passenger compartment and cooling the auto-

matic transmission fluid (if equipped). The cooling

system is pressurized and uses a centrifugal water

pump to circulate coolant throughout the system.

All engines utilize an ambient overflow bottle for

coolant recovery/reserve.

An optional factory installed maximum duty cool-

ing package is available on most models. This pack-

age will provide additional cooling capacity for

vehicles used under extreme conditions such as

trailer towing in high ambient temperatures.

OPERATION - HOSE CLAMPS

The spring type hose clamp applies constant ten-

sion on a hose connection. To remove a spring type

hose clamp, only use constant tension clamp pliers

designed to compress the hose clamp.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐON-BOARD

DIAGNOSTICS (OBD)

COOLING SYSTEM RELATED DIAGNOSTICS

The Engine Control Module (ECM) has been pro-

grammed to monitor certain cooling system compo-

nents:

²If the engine has remained cool for too long a

period, such as with a stuck open thermostat, a Diag-

nostic Trouble Code (DTC) can be set.

²If an open or shorted condition has developed in

the electronically controlled viscous fan clutch circuit,

a Diagnostic Trouble Code (DTC) can be set.

²If fan speed is not detected a DTC will be set.

²Coolant temperature sensor circuit problems can

set a DTC.

If the problem is sensed in a monitored circuit

often enough to indicated an actual problem, a DTC

is stored. The DTC will be stored in the ECM mem-

ory for eventual display to the service technician.

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

ACCESSING DIAGNOSTIC TROUBLE CODES

To read DTC's and to obtain cooling system data,

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

ERASING TROUBLE CODES

After the problem has been repaired, use the

DRBIIItscan tool to erase a DTC. Refer to the

appropriate Powertrain Diagnostic Procedures ser-

vice information for operation of the DRBIIItscan

tool.

DIAGNOSIS AND TESTING - COOLING SYSTEM

- TESTING FOR LEAKS

ULTRAVIOLET LIGHT METHOD

A leak detection additive is available through the

parts department that can be added to cooling sys-

tem. The additive is highly visible under ultraviolet

light (black light). Pour one ounce of additive into

cooling system. Place heater control unit in HEAT

position. Start and operate the engine until the radi-

ator upper hose is warm to the touch. Aim the com-

mercially available black light tool at the components

to be checked. If leaks are present, the black light

will cause the additive to glow a bright green color.

The black light can be used in conjunction with a

pressure tester to determine if any external leaks

exist (Fig. 5).

Fig. 4 Spring Clamp Size Location

1 - SPRING CLAMP SIZE LOCATION

DRCOOLING 7 - 5

COOLING (Continued)