rear brake shoes DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 68 of 2627

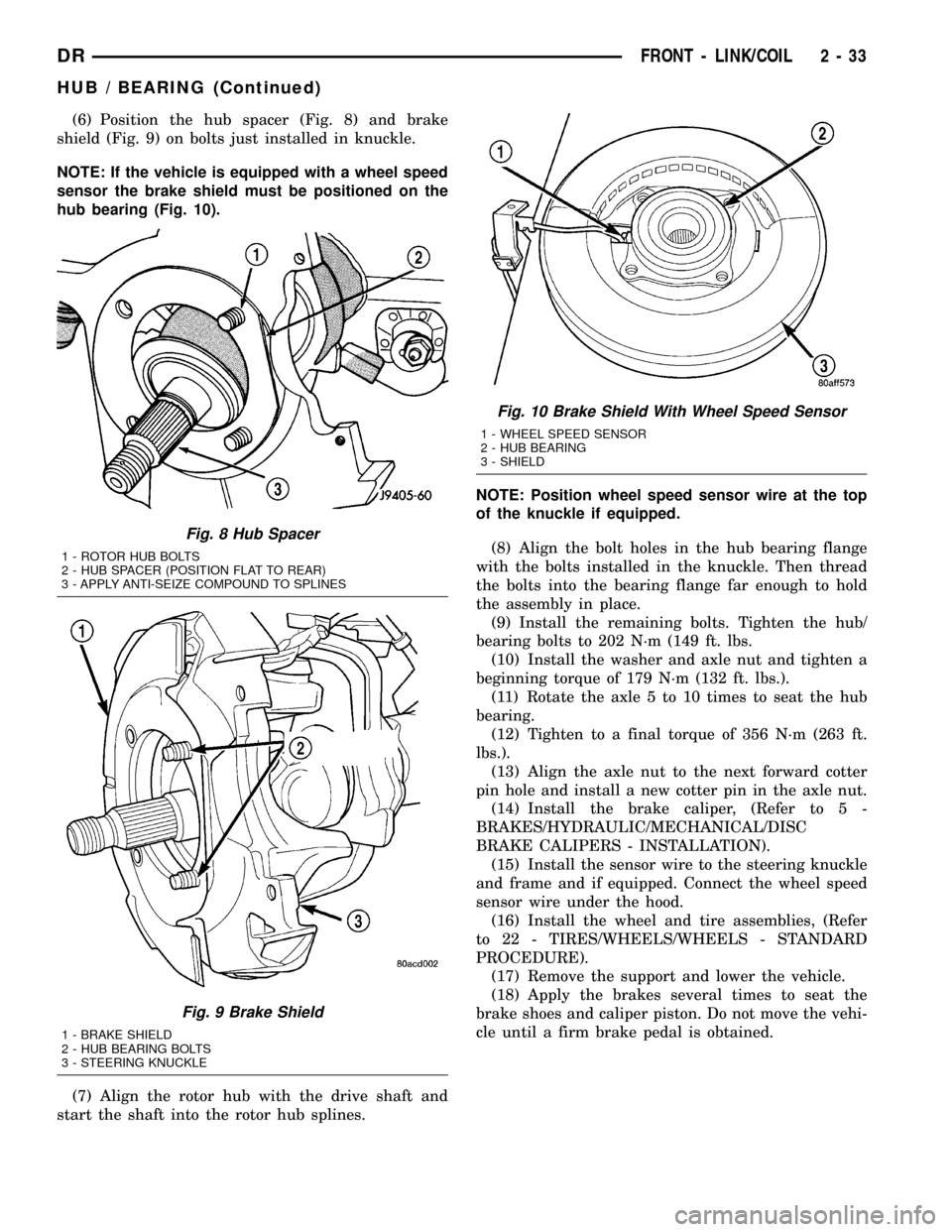

(6) Position the hub spacer (Fig. 8) and brake

shield (Fig. 9) on bolts just installed in knuckle.

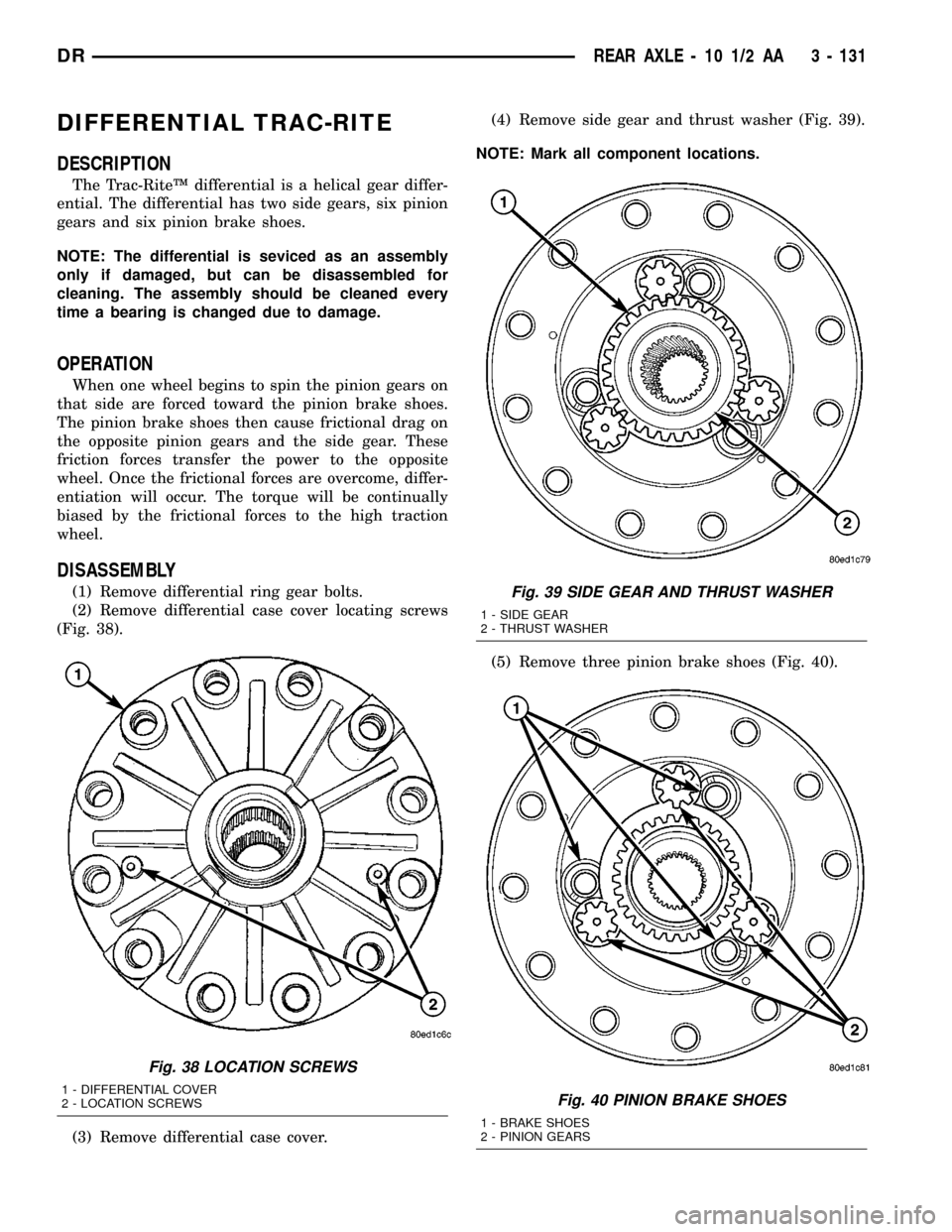

NOTE: If the vehicle is equipped with a wheel speed

sensor the brake shield must be positioned on the

hub bearing (Fig. 10).

(7) Align the rotor hub with the drive shaft and

start the shaft into the rotor hub splines.NOTE: Position wheel speed sensor wire at the top

of the knuckle if equipped.

(8) Align the bolt holes in the hub bearing flange

with the bolts installed in the knuckle. Then thread

the bolts into the bearing flange far enough to hold

the assembly in place.

(9) Install the remaining bolts. Tighten the hub/

bearing bolts to 202 N´m (149 ft. lbs.

(10) Install the washer and axle nut and tighten a

beginning torque of 179 N´m (132 ft. lbs.).

(11) Rotate the axle 5 to 10 times to seat the hub

bearing.

(12) Tighten to a final torque of 356 N´m (263 ft.

lbs.).

(13) Align the axle nut to the next forward cotter

pin hole and install a new cotter pin in the axle nut.

(14) Install the brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION).

(15) Install the sensor wire to the steering knuckle

and frame and if equipped. Connect the wheel speed

sensor wire under the hood.

(16) Install the wheel and tire assemblies, (Refer

to 22 - TIRES/WHEELS/WHEELS - STANDARD

PROCEDURE).

(17) Remove the support and lower the vehicle.

(18) Apply the brakes several times to seat the

brake shoes and caliper piston. Do not move the vehi-

cle until a firm brake pedal is obtained.

Fig. 8 Hub Spacer

1 - ROTOR HUB BOLTS

2 - HUB SPACER (POSITION FLAT TO REAR)

3 - APPLY ANTI-SEIZE COMPOUND TO SPLINES

Fig. 9 Brake Shield

1 - BRAKE SHIELD

2 - HUB BEARING BOLTS

3 - STEERING KNUCKLE

Fig. 10 Brake Shield With Wheel Speed Sensor

1 - WHEEL SPEED SENSOR

2 - HUB BEARING

3 - SHIELD

DRFRONT - LINK/COIL 2 - 33

HUB / BEARING (Continued)

Page 212 of 2627

DIFFERENTIAL TRAC-RITE

DESCRIPTION

The Trac-RiteŸ differential is a helical gear differ-

ential. The differential has two side gears, six pinion

gears and six pinion brake shoes.

NOTE: The differential is seviced as an assembly

only if damaged, but can be disassembled for

cleaning. The assembly should be cleaned every

time a bearing is changed due to damage.

OPERATION

When one wheel begins to spin the pinion gears on

that side are forced toward the pinion brake shoes.

The pinion brake shoes then cause frictional drag on

the opposite pinion gears and the side gear. These

friction forces transfer the power to the opposite

wheel. Once the frictional forces are overcome, differ-

entiation will occur. The torque will be continually

biased by the frictional forces to the high traction

wheel.

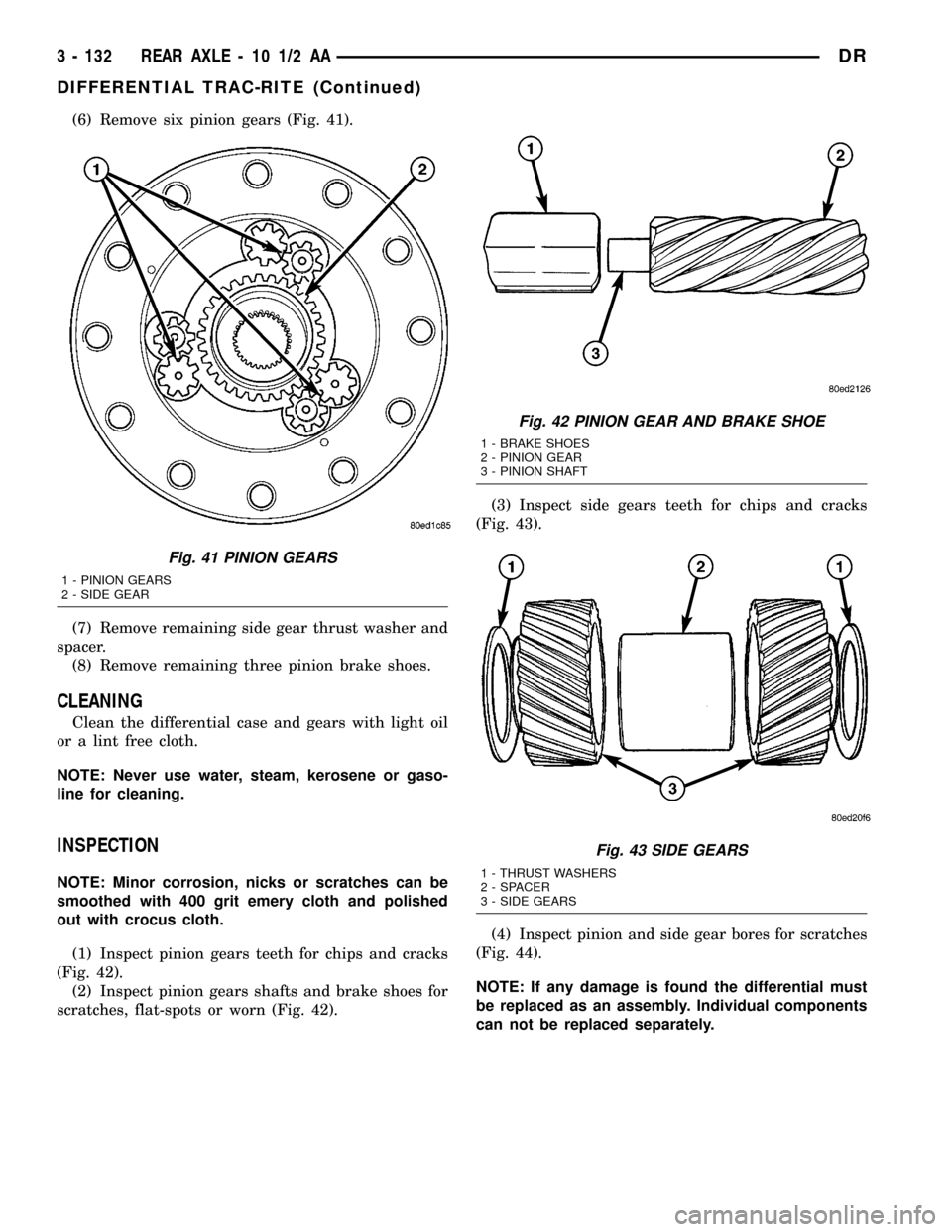

DISASSEMBLY

(1) Remove differential ring gear bolts.

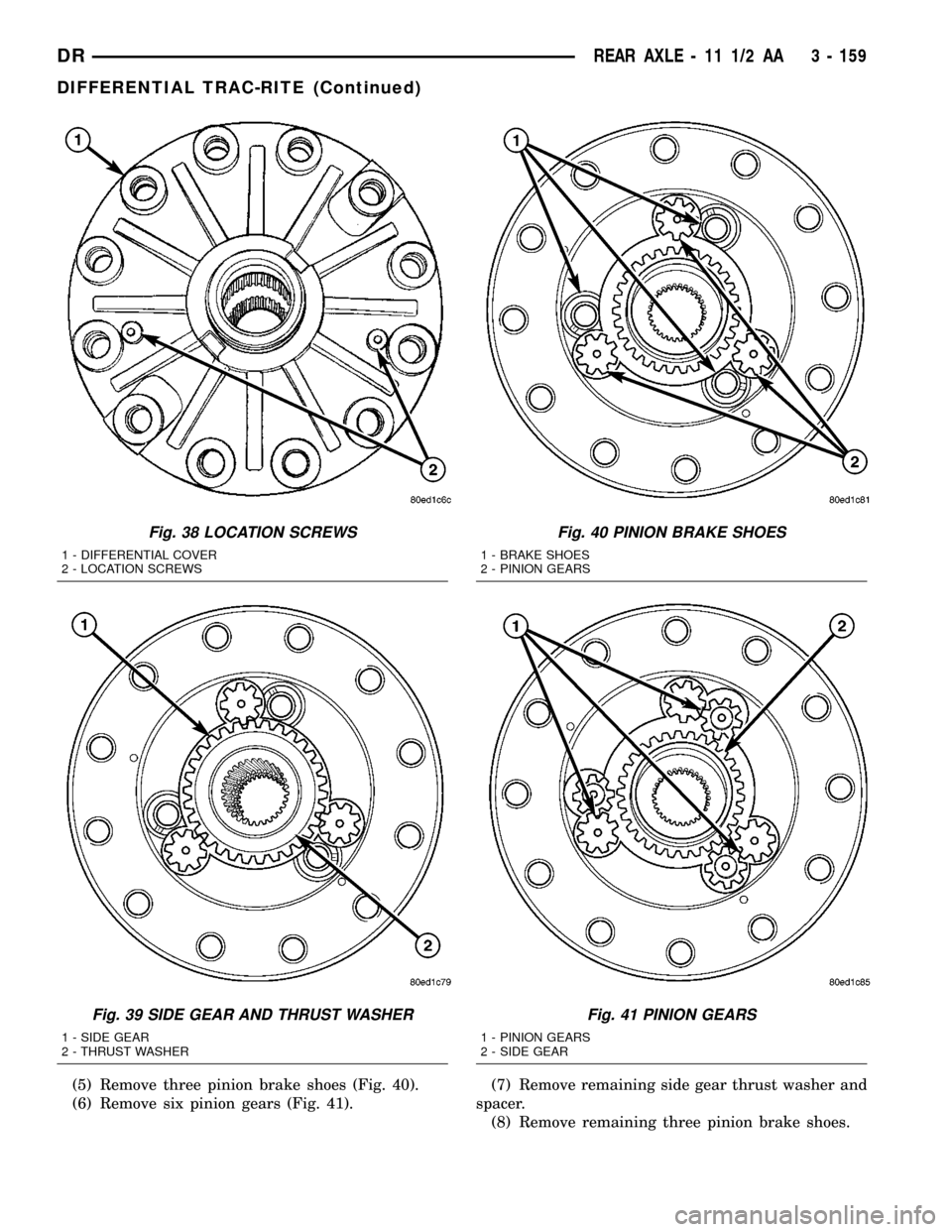

(2) Remove differential case cover locating screws

(Fig. 38).

(3) Remove differential case cover.(4) Remove side gear and thrust washer (Fig. 39).

NOTE: Mark all component locations.

(5) Remove three pinion brake shoes (Fig. 40).

Fig. 38 LOCATION SCREWS

1 - DIFFERENTIAL COVER

2 - LOCATION SCREWS

Fig. 39 SIDE GEAR AND THRUST WASHER

1 - SIDE GEAR

2 - THRUST WASHER

Fig. 40 PINION BRAKE SHOES

1 - BRAKE SHOES

2 - PINION GEARS

DRREAR AXLE - 10 1/2 AA 3 - 131

Page 213 of 2627

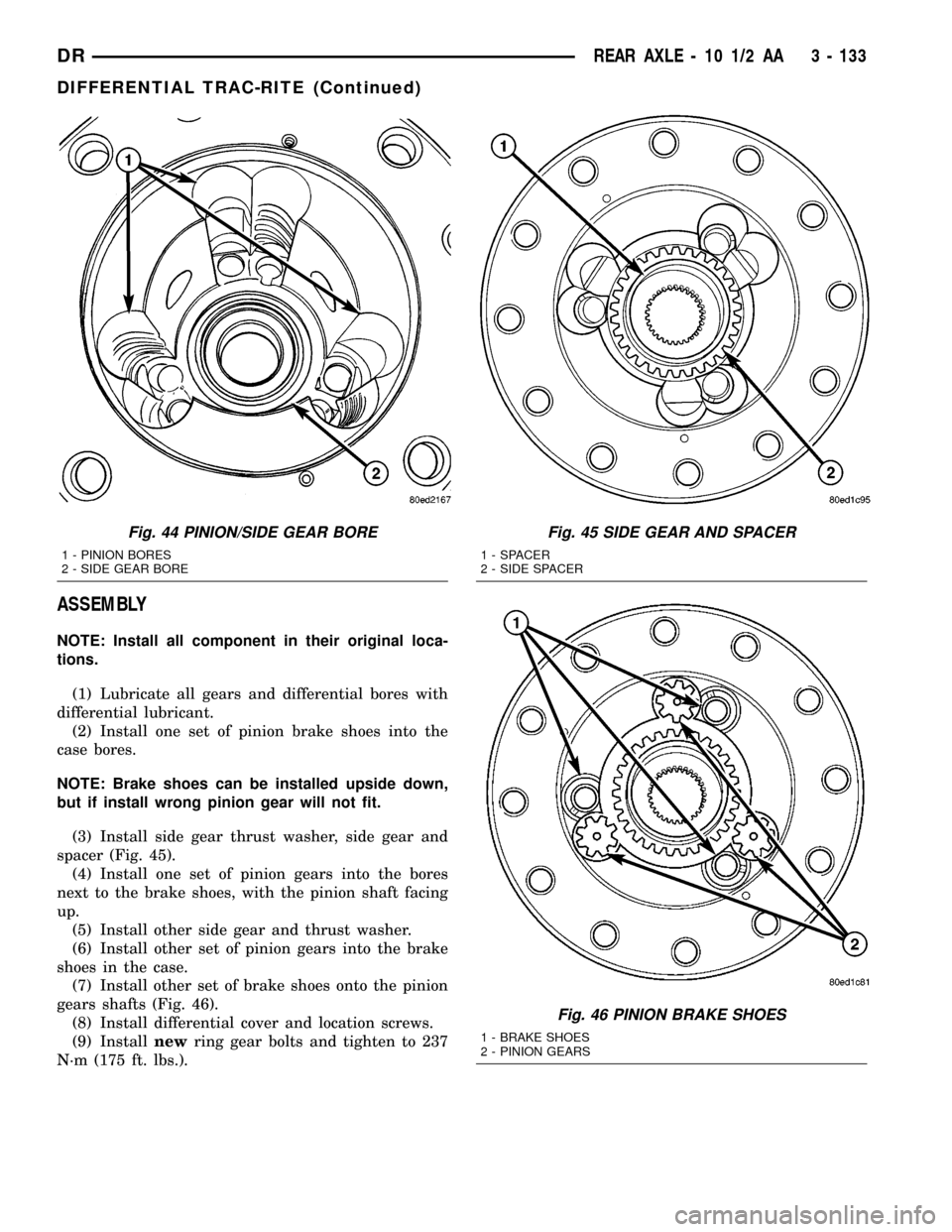

(6) Remove six pinion gears (Fig. 41).

(7) Remove remaining side gear thrust washer and

spacer.

(8) Remove remaining three pinion brake shoes.

CLEANING

Clean the differential case and gears with light oil

or a lint free cloth.

NOTE: Never use water, steam, kerosene or gaso-

line for cleaning.

INSPECTION

NOTE: Minor corrosion, nicks or scratches can be

smoothed with 400 grit emery cloth and polished

out with crocus cloth.

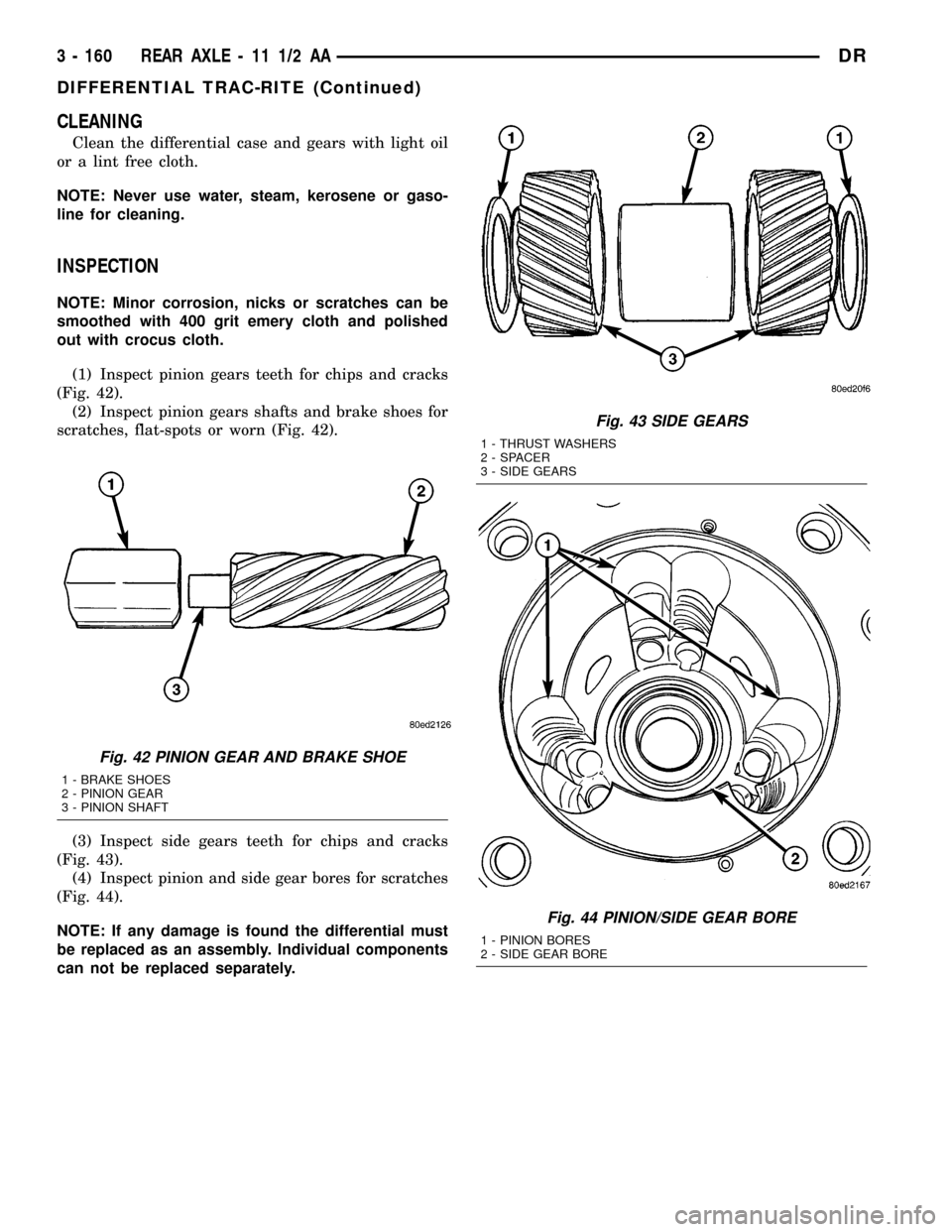

(1) Inspect pinion gears teeth for chips and cracks

(Fig. 42).

(2) Inspect pinion gears shafts and brake shoes for

scratches, flat-spots or worn (Fig. 42).(3) Inspect side gears teeth for chips and cracks

(Fig. 43).

(4) Inspect pinion and side gear bores for scratches

(Fig. 44).

NOTE: If any damage is found the differential must

be replaced as an assembly. Individual components

can not be replaced separately.

Fig. 41 PINION GEARS

1 - PINION GEARS

2 - SIDE GEAR

Fig. 42 PINION GEAR AND BRAKE SHOE

1 - BRAKE SHOES

2 - PINION GEAR

3 - PINION SHAFT

Fig. 43 SIDE GEARS

1 - THRUST WASHERS

2 - SPACER

3 - SIDE GEARS

3 - 132 REAR AXLE - 10 1/2 AADR

DIFFERENTIAL TRAC-RITE (Continued)

Page 214 of 2627

ASSEMBLY

NOTE: Install all component in their original loca-

tions.

(1) Lubricate all gears and differential bores with

differential lubricant.

(2) Install one set of pinion brake shoes into the

case bores.

NOTE: Brake shoes can be installed upside down,

but if install wrong pinion gear will not fit.

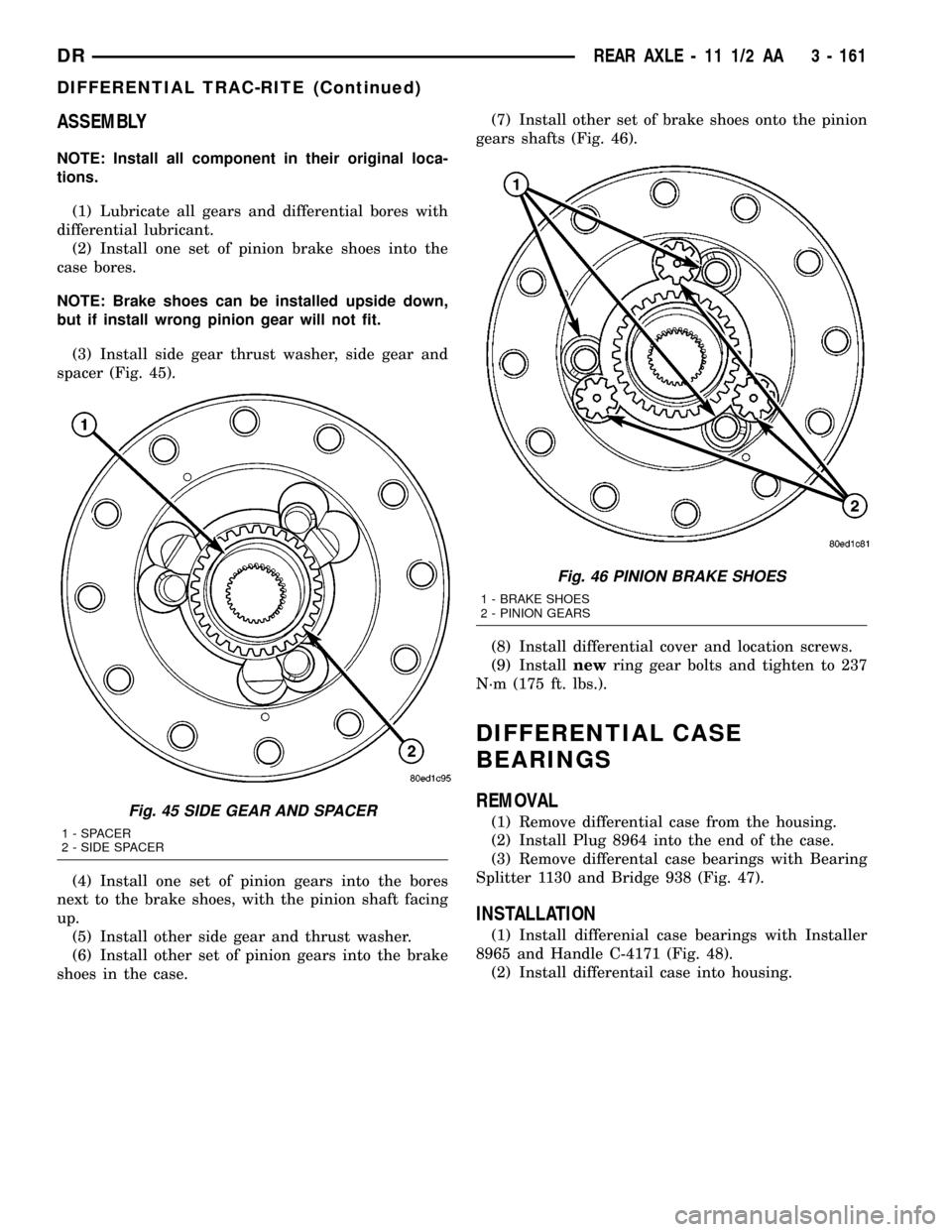

(3) Install side gear thrust washer, side gear and

spacer (Fig. 45).

(4) Install one set of pinion gears into the bores

next to the brake shoes, with the pinion shaft facing

up.

(5) Install other side gear and thrust washer.

(6) Install other set of pinion gears into the brake

shoes in the case.

(7) Install other set of brake shoes onto the pinion

gears shafts (Fig. 46).

(8) Install differential cover and location screws.

(9) Installnewring gear bolts and tighten to 237

N´m (175 ft. lbs.).

Fig. 44 PINION/SIDE GEAR BORE

1 - PINION BORES

2 - SIDE GEAR BORE

Fig. 45 SIDE GEAR AND SPACER

1 - SPACER

2 - SIDE SPACER

Fig. 46 PINION BRAKE SHOES

1 - BRAKE SHOES

2 - PINION GEARS

DRREAR AXLE - 10 1/2 AA 3 - 133

DIFFERENTIAL TRAC-RITE (Continued)

Page 239 of 2627

(5) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zero

backlash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(6) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 until they make contact with the differential

bearings/cups.

(7) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

(8) Install ring gear side adjuster lock and bolt. Do

not tighten adjuster lock bolt at this time.

(9) Tighten pinion gear side adjuster firmly

against the differential case bearing cup.

(10) Rotate the pinion several times to seat the dif-

ferential bearings.

(11) Loosen pinion gear side adjuster until it is no

longer in contact with the bearing cup.

(12) Tighten pinion gear side adjuster until it just

makes contact with the bearing cup.

(13) Tighten pinion gear side adjuster an addi-

tional:

²New Bearings6 Adjuster Holes

²Original Bearings4 Adjuster Holes

(14) Install pinion gear side adjuster lock and bolt.

Do not tighten adjuster lock bolt at this time.

(15) Tighten bearing cap bolts to 281 N´m (207 ft.

lbs.).

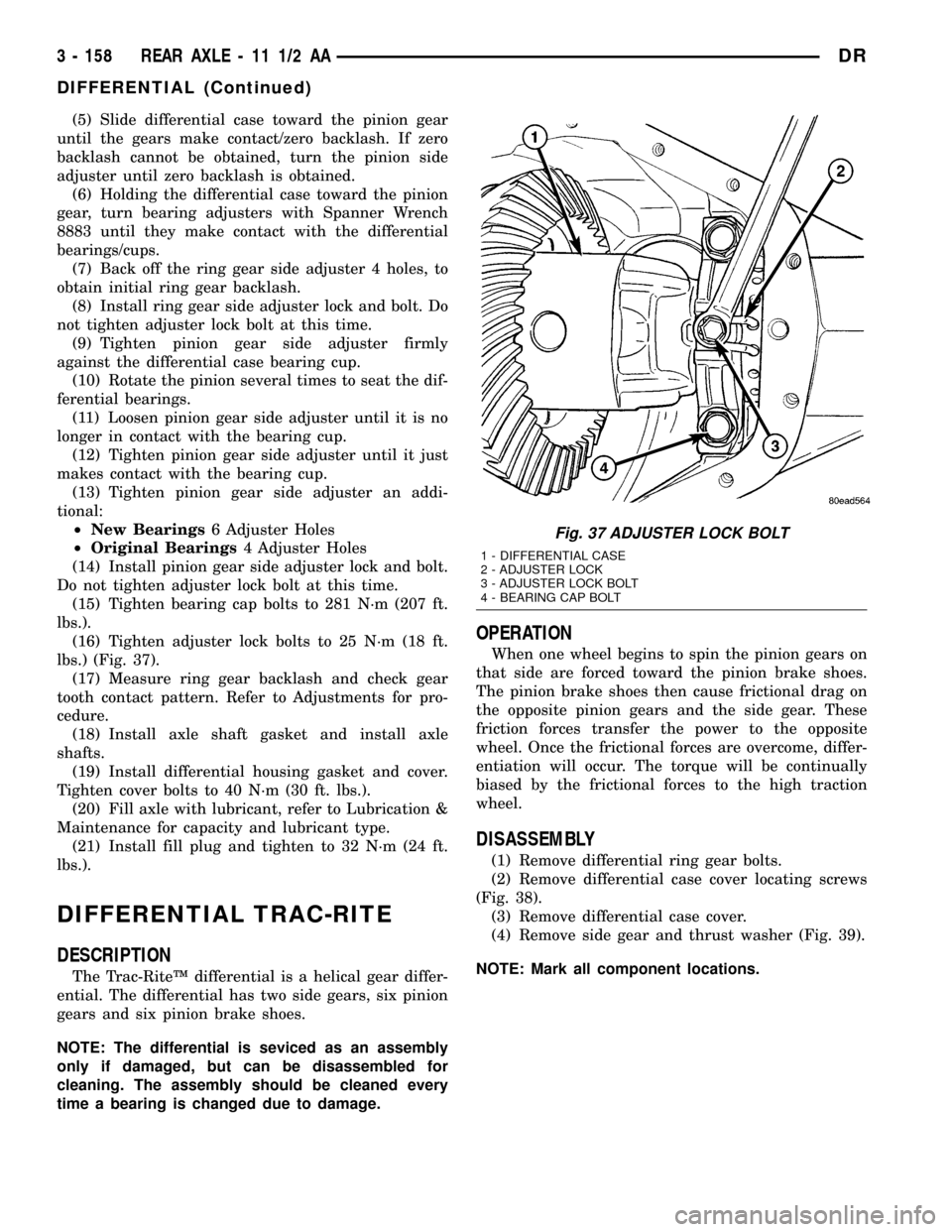

(16) Tighten adjuster lock bolts to 25 N´m (18 ft.

lbs.) (Fig. 37).

(17) Measure ring gear backlash and check gear

tooth contact pattern. Refer to Adjustments for pro-

cedure.

(18) Install axle shaft gasket and install axle

shafts.

(19) Install differential housing gasket and cover.

Tighten cover bolts to 40 N´m (30 ft. lbs.).

(20) Fill axle with lubricant, refer to Lubrication &

Maintenance for capacity and lubricant type.

(21) Install fill plug and tighten to 32 N´m (24 ft.

lbs.).

DIFFERENTIAL TRAC-RITE

DESCRIPTION

The Trac-RiteŸ differential is a helical gear differ-

ential. The differential has two side gears, six pinion

gears and six pinion brake shoes.

NOTE: The differential is seviced as an assembly

only if damaged, but can be disassembled for

cleaning. The assembly should be cleaned every

time a bearing is changed due to damage.

OPERATION

When one wheel begins to spin the pinion gears on

that side are forced toward the pinion brake shoes.

The pinion brake shoes then cause frictional drag on

the opposite pinion gears and the side gear. These

friction forces transfer the power to the opposite

wheel. Once the frictional forces are overcome, differ-

entiation will occur. The torque will be continually

biased by the frictional forces to the high traction

wheel.

DISASSEMBLY

(1) Remove differential ring gear bolts.

(2) Remove differential case cover locating screws

(Fig. 38).

(3) Remove differential case cover.

(4) Remove side gear and thrust washer (Fig. 39).

NOTE: Mark all component locations.

Fig. 37 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

3 - 158 REAR AXLE - 11 1/2 AADR

DIFFERENTIAL (Continued)

Page 240 of 2627

(5) Remove three pinion brake shoes (Fig. 40).

(6) Remove six pinion gears (Fig. 41).(7) Remove remaining side gear thrust washer and

spacer.

(8) Remove remaining three pinion brake shoes.

Fig. 38 LOCATION SCREWS

1 - DIFFERENTIAL COVER

2 - LOCATION SCREWS

Fig. 39 SIDE GEAR AND THRUST WASHER

1 - SIDE GEAR

2 - THRUST WASHER

Fig. 40 PINION BRAKE SHOES

1 - BRAKE SHOES

2 - PINION GEARS

Fig. 41 PINION GEARS

1 - PINION GEARS

2 - SIDE GEAR

DRREAR AXLE - 11 1/2 AA 3 - 159

DIFFERENTIAL TRAC-RITE (Continued)

Page 241 of 2627

CLEANING

Clean the differential case and gears with light oil

or a lint free cloth.

NOTE: Never use water, steam, kerosene or gaso-

line for cleaning.

INSPECTION

NOTE: Minor corrosion, nicks or scratches can be

smoothed with 400 grit emery cloth and polished

out with crocus cloth.

(1) Inspect pinion gears teeth for chips and cracks

(Fig. 42).

(2) Inspect pinion gears shafts and brake shoes for

scratches, flat-spots or worn (Fig. 42).

(3) Inspect side gears teeth for chips and cracks

(Fig. 43).

(4) Inspect pinion and side gear bores for scratches

(Fig. 44).

NOTE: If any damage is found the differential must

be replaced as an assembly. Individual components

can not be replaced separately.

Fig. 42 PINION GEAR AND BRAKE SHOE

1 - BRAKE SHOES

2 - PINION GEAR

3 - PINION SHAFT

Fig. 43 SIDE GEARS

1 - THRUST WASHERS

2 - SPACER

3 - SIDE GEARS

Fig. 44 PINION/SIDE GEAR BORE

1 - PINION BORES

2 - SIDE GEAR BORE

3 - 160 REAR AXLE - 11 1/2 AADR

DIFFERENTIAL TRAC-RITE (Continued)

Page 242 of 2627

ASSEMBLY

NOTE: Install all component in their original loca-

tions.

(1) Lubricate all gears and differential bores with

differential lubricant.

(2) Install one set of pinion brake shoes into the

case bores.

NOTE: Brake shoes can be installed upside down,

but if install wrong pinion gear will not fit.

(3) Install side gear thrust washer, side gear and

spacer (Fig. 45).

(4) Install one set of pinion gears into the bores

next to the brake shoes, with the pinion shaft facing

up.

(5) Install other side gear and thrust washer.

(6) Install other set of pinion gears into the brake

shoes in the case.(7) Install other set of brake shoes onto the pinion

gears shafts (Fig. 46).

(8) Install differential cover and location screws.

(9) Installnewring gear bolts and tighten to 237

N´m (175 ft. lbs.).

DIFFERENTIAL CASE

BEARINGS

REMOVAL

(1) Remove differential case from the housing.

(2) Install Plug 8964 into the end of the case.

(3) Remove differental case bearings with Bearing

Splitter 1130 and Bridge 938 (Fig. 47).

INSTALLATION

(1) Install differenial case bearings with Installer

8965 and Handle C-4171 (Fig. 48).

(2) Install differentail case into housing.

Fig. 45 SIDE GEAR AND SPACER

1 - SPACER

2 - SIDE SPACER

Fig. 46 PINION BRAKE SHOES

1 - BRAKE SHOES

2 - PINION GEARS

DRREAR AXLE - 11 1/2 AA 3 - 161

DIFFERENTIAL TRAC-RITE (Continued)

Page 250 of 2627

BRAKES

TABLE OF CONTENTS

page page

BRAKES - BASE........................... 1BRAKES - ABS........................... 45

BRAKES - BASE

TABLE OF CONTENTS

page page

BRAKES - BASE

DIAGNOSIS AND TESTING - BASE BRAKE

SYSTEM.............................2

STANDARD PROCEDURE

STANDARD PROCEDURE - MANUAL

BLEEDING............................5

STANDARD PROCEDURE - PRESSURE

BLEEDING............................5

SPECIAL TOOLS

BASE BRAKES........................5

ADJUSTABLE PEDAL SWITCH

REMOVAL.............................6

INSTALLATION..........................6

ADJUSTABLE PEDAL MOTOR

DESCRIPTION..........................6

REMOVAL.............................7

INSTALLATION..........................7

HYDRAULIC/MECHANICAL

SPECIFICATIONS

SPECIFICATIONS - TORQUE CHART.......8

BASE BRAKE........................10

BRAKE LINES

STANDARD PROCEDURE

STANDARD PROCEDURE - DOUBLE

INVERTED FLARING...................10

STANDARD PROCEDURE - ISO FLARING . . 11

REMOVAL

REMOVAL - REAR BRAKE HOSE.........11

REMOVAL - REAR TUBE / HOSE

ASSEMBLY..........................12

REMOVAL - FRONT HOSE..............12

INSTALLATION

INSTALLATION - REAR BRAKE HOSE......12

INSTALLATION - REAR TUBE / HOSE

ASSEMBLY..........................13

INSTALLATION - FRONT BRAKE HOSE....13BRAKE PADS/SHOES

REMOVAL

REMOVAL - FRONT....................13

REMOVAL - REAR.....................14

INSTALLATION

INSTALLATION - FRONT................16

INSTALLATION - REAR.................16

DISC BRAKE CALIPERS

DESCRIPTION.........................16

OPERATION...........................16

REMOVAL

REMOVAL - FRONT....................17

REMOVAL - REAR.....................17

DISASSEMBLY.........................18

INSPECTION..........................19

ASSEMBLY............................20

INSTALLATION

INSTALLATION - FRONT................21

INSTALLATION - REAR.................21

DISC BRAKE CALIPER ADAPTER

REMOVAL

REMOVAL - FRONT....................21

REMOVAL - REAR.....................21

INSTALLATION

INSTALLATION - FRONT................22

INSTALLATION - REAR.................22

DISC BRAKE CALIPER ADAPTER MOUNT

REMOVAL - REAR......................22

INSTALLATION.........................22

FLUID

DIAGNOSIS AND TESTING - BRAKE FLUID

CONTAMINATION.....................23

STANDARD PROCEDURE - BRAKE FLUID

LEVEL..............................23

SPECIFICATIONS

BRAKE FLUID........................23

DRBRAKES 5 - 1

Page 251 of 2627

FLUID RESERVOIR

REMOVAL.............................23

INSTALLATION.........................24

BRAKE JUNCTION BLOCK

REMOVAL.............................24

INSTALLATION.........................24

MASTER CYLINDER

DESCRIPTION.........................24

OPERATION...........................25

DIAGNOSIS AND TESTING - MASTER

CYLINDER/POWER BOOSTER...........25

STANDARD PROCEDURE - MASTER

CYLINDER BLEEDING..................26

REMOVAL

REMOVAL - ALL EXCEPT HYDROBOOST . . . 26

REMOVAL - HYDROBOOST.............26

INSTALLATION

INSTALLATION - ALL EXCEPT

HYDROBOOST.......................27

INSTALLATION - HYDROBOOST..........27

PEDAL

DESCRIPTION.........................28

OPERATION...........................28

REMOVAL.............................28

INSTALLATION.........................28

POWER BRAKE BOOSTER

DESCRIPTION.........................29

OPERATION...........................29

REMOVAL.............................29

INSTALLATION.........................29

HYDRO-BOOST BRAKE BOOSTER

DIAGNOSIS AND TESTING - HYDRAULIC

BOOSTER...........................30

STANDARD PROCEDURE - BLEEDING......31

REMOVAL.............................31

INSTALLATION.........................32

ROTORS

DIAGNOSIS AND TESTING

DISC BRAKE ROTOR..................32

REMOVAL

REMOVAL - FRONT....................33

REMOVAL - REAR.....................34REMOVAL - REAR DUAL WHEELS........34

INSTALLATION

INSTALLATION - FRONT................34

INSTALLATION - REAR.................34

INSTALLATION - REAR DUAL WHEELS....35

SUPPORT PLATE

REMOVAL.............................35

INSTALLATION.........................36

PARKING BRAKE

DESCRIPTION.........................36

OPERATION...........................36

CABLES

REMOVAL

REMOVAL - FRONT PARKING BRAKE

CABLE..............................36

REMOVAL - REAR PARK BRAKE CABLE . . . 37

REMOVAL - RIGHT REAR CABLE.........37

REMOVAL - LEFT REAR CABLE..........38

INSTALLATION

INSTALLATION - FRONT PARKING BRAKE

CABLE..............................38

INSTALLATION - REAR PARK BRAKE

CABLE..............................38

INSTALLATION - RIGHT REAR CABLE.....38

INSTALLATION - LEFT REAR CABLE......39

SHOES

REMOVAL.............................39

CLEANING - REAR DRUM IN HAT BRAKE....39

INSPECTION - REAR DRUM IN HAT BRAKE . . 39

INSTALLATION.........................40

ADJUSTMENTS

ADJUSTMENT - PARKING BRAKE SHOES . . 41

ADJUSTMENT - WITH ADJUSTING TOOL . . . 42

PEDAL

REMOVAL.............................42

INSTALLATION.........................42

CABLE TENSIONER

ADJUSTMENTS

ADJUSTMENT........................43

RELEASE HANDLE

REMOVAL.............................44

INSTALLATION.........................44

BRAKES - BASE

DIAGNOSIS AND TESTING - BASE BRAKE

SYSTEM

Base brake components consist of the brake pads,

calipers, brake drum in hat rotor in the rear, rotors,

brake lines, master cylinder, booster, and parking

brake components.

Brake diagnosis involves determining if the prob-

lem is related to a mechanical, hydraulic, or vacuum

operated component.

The first diagnosis step is the preliminary check.

PRELIMINARY BRAKE CHECK

(1) Check condition of tires and wheels. Damaged

wheels and worn, damaged, or underinflated tires

can cause pull, shudder, vibration, and a condition

similar to grab.

(2) If complaint was based on noise when braking,

check suspension components. Jounce front and rear

of vehicle and listen for noise that might be caused

by loose, worn or damaged suspension or steering

components.

(3) Inspect brake fluid level and condition. Note

that the brake reservoir fluid level will decrease in

proportion to normal lining wear.Also note that

brake fluid tends to darken over time. This is

5 - 2 BRAKES - BASEDR