DODGE RAM 1500 GAS 2004 3.G Owners Manual

Manufacturer: DODGE, Model Year: 2004, Model line: RAM 1500 GAS, Model: DODGE RAM 1500 GAS 2004 3.GPages: 429, PDF Size: 7.52 MB

Page 301 of 429

CHANGING A FLAT TIRE

Removing The Spare Tire

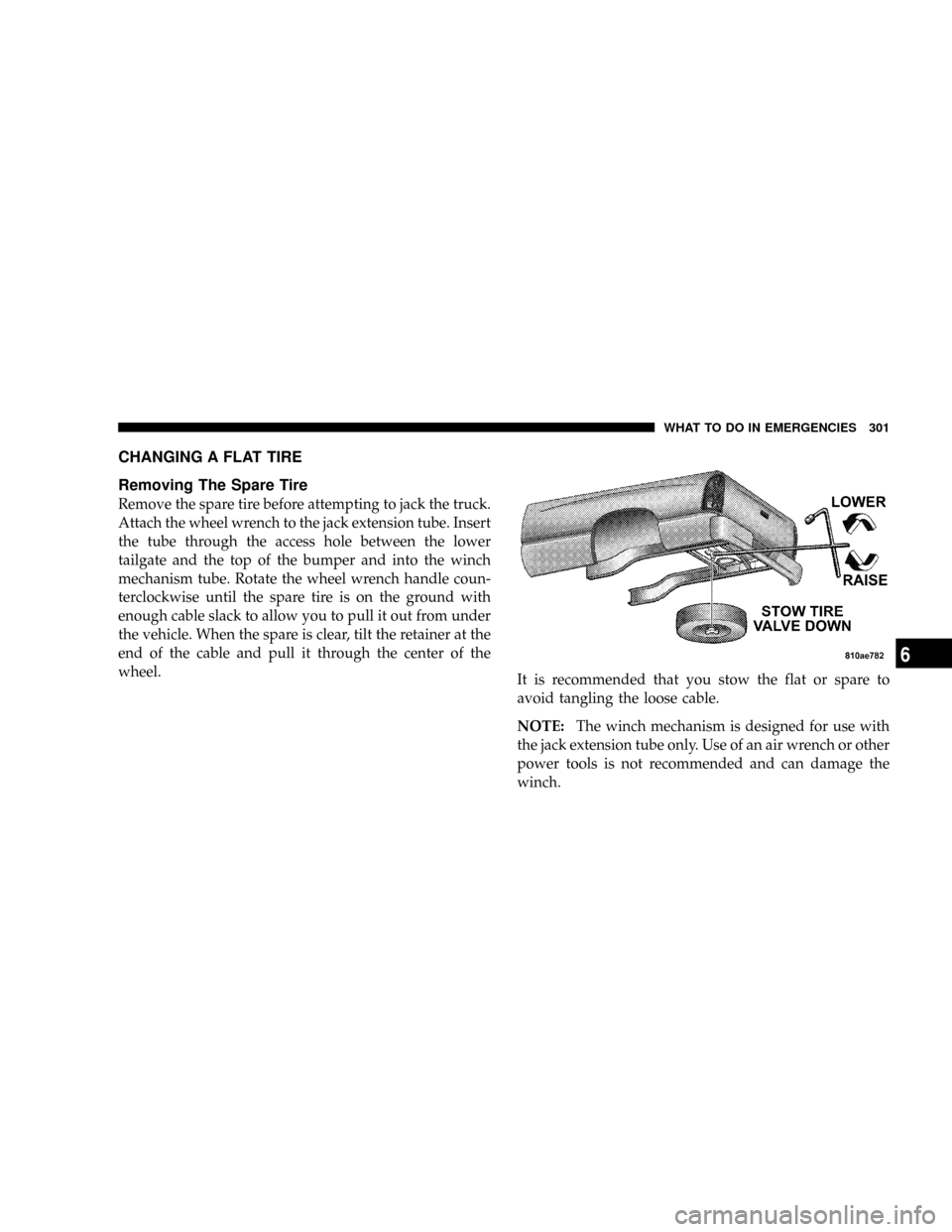

Remove the spare tire before attempting to jack the truck.

Attach the wheel wrench to the jack extension tube. Insert

the tube through the access hole between the lower

tailgate and the top of the bumper and into the winch

mechanism tube. Rotate the wheel wrench handle coun-

terclockwise until the spare tire is on the ground with

enough cable slack to allow you to pull it out from under

the vehicle. When the spare is clear, tilt the retainer at the

end of the cable and pull it through the center of the

wheel.

It is recommended that you stow the flat or spare to

avoid tangling the loose cable.

NOTE:The winch mechanism is designed for use with

the jack extension tube only. Use of an air wrench or other

power tools is not recommended and can damage the

winch.

WHAT TO DO IN EMERGENCIES 301

6

Page 302 of 429

Tire Changing Procedure

WARNING!

Getting under a jacked-up vehicle is dangerous. The

vehicle could slip off the jack and fall on you. You

could be crushed. Never get any part of your body

under a vehicle that is on a jack. Never start or run

the engine while the vehicle is on a jack. If you need

to get under a raised vehicle, take it to a service

center where it can be raised on a lift.

Do not raise this vehicle using a bumper jack. The jack is

designed as a tool for changing tires on this vehicle only.

It is not recommended that the jack be used for service

purposes or to lift more than one wheel at a time.

Preparations

Park the vehicle on a firm level surface, avoiding ice or

slippery areas. Set the parking brake and place the gear

selector in PARK (automatic transmission) or REVERSE

(manual transmission). On four-wheel drive vehicles,

shift the transfer case to the ª4Lº position.

WARNING!

Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off

the road to avoid the danger of being hit when

operating the jack or changing the wheel.

302 WHAT TO DO IN EMERGENCIES

Page 303 of 429

²Turn on the Hazard Warning Flasher.

²Block both the front and rear

of the wheel diagonally oppo-

site the jacking position. For

example, if the right front

wheel is being changed, block

the left rear wheel.

²Passengers should not remain in the vehicle when the

vehicle is being jacked.

Instructions

WARNING!

Carefully follow these tire changing warnings to help

prevent personal injury or damage to your vehicle:

²Always park on a firm, level surface as far from the

edge of the roadway as possible before raising the

vehicle.

²Block the wheel diagonally opposite the wheel to

be raised.

²Apply the parking brake firmly before jacking.

²Never start the engine with the vehicle on a jack.

²Do not let anyone sit in the vehicle when it is on a

jack.

²Do not get under the vehicle when it is on a jack.

²Only use the jack in the positions indicated.

²If working on or near a roadway, be extremely

careful of motor traffic.

WHAT TO DO IN EMERGENCIES 303

6

Page 304 of 429

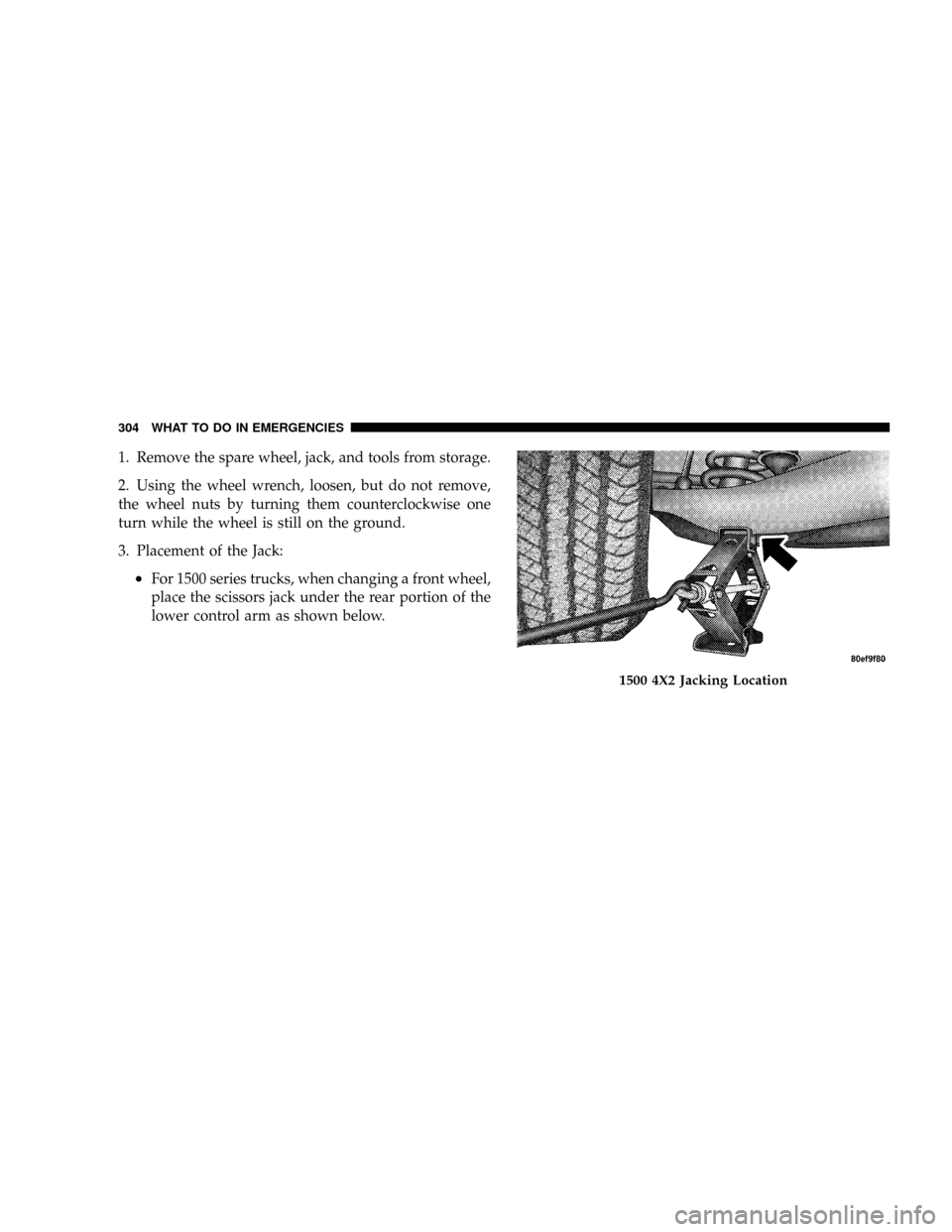

1. Remove the spare wheel, jack, and tools from storage.

2. Using the wheel wrench, loosen, but do not remove,

the wheel nuts by turning them counterclockwise one

turn while the wheel is still on the ground.

3. Placement of the Jack:

²For 1500 series trucks, when changing a front wheel,

place the scissors jack under the rear portion of the

lower control arm as shown below.

1500 4X2 Jacking Location

304 WHAT TO DO IN EMERGENCIES

Page 305 of 429

²For 2500/3500 4x2 series trucks, when changing a

front wheel, place the bottle jack under the frame

rail behind the wheel. Locate the jack as far forward

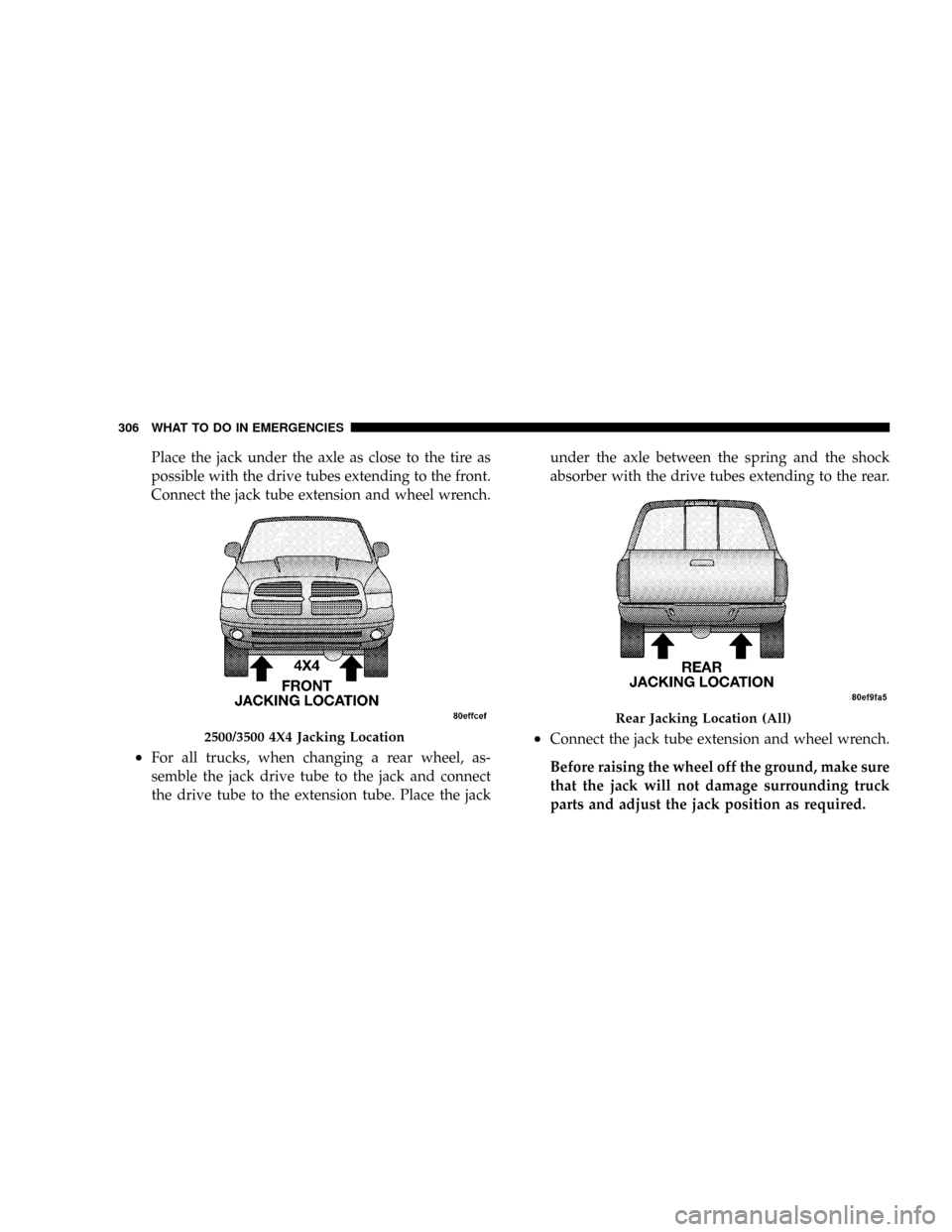

as possible on the straight part of the frame.²Operate the jack using the jack drive tube and the

wheel wrench. The tube extension, may be used, but

is not required.

²For 2500/3500 4x4 series trucks, when changing the

front wheel, assemble the jack drive tube to the jack

and connect the drive tube to the extension tube.

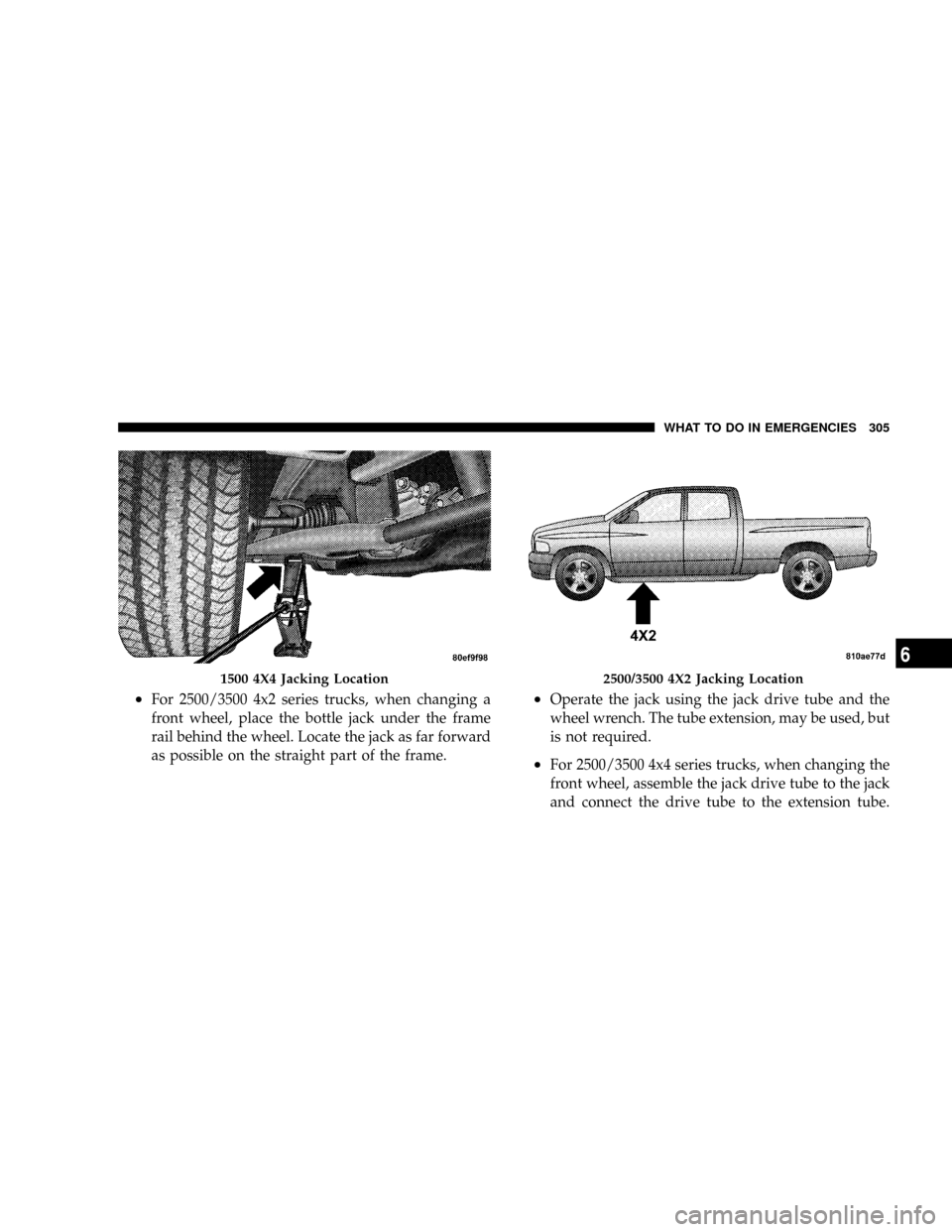

1500 4X4 Jacking Location2500/3500 4X2 Jacking Location

WHAT TO DO IN EMERGENCIES 305

6

Page 306 of 429

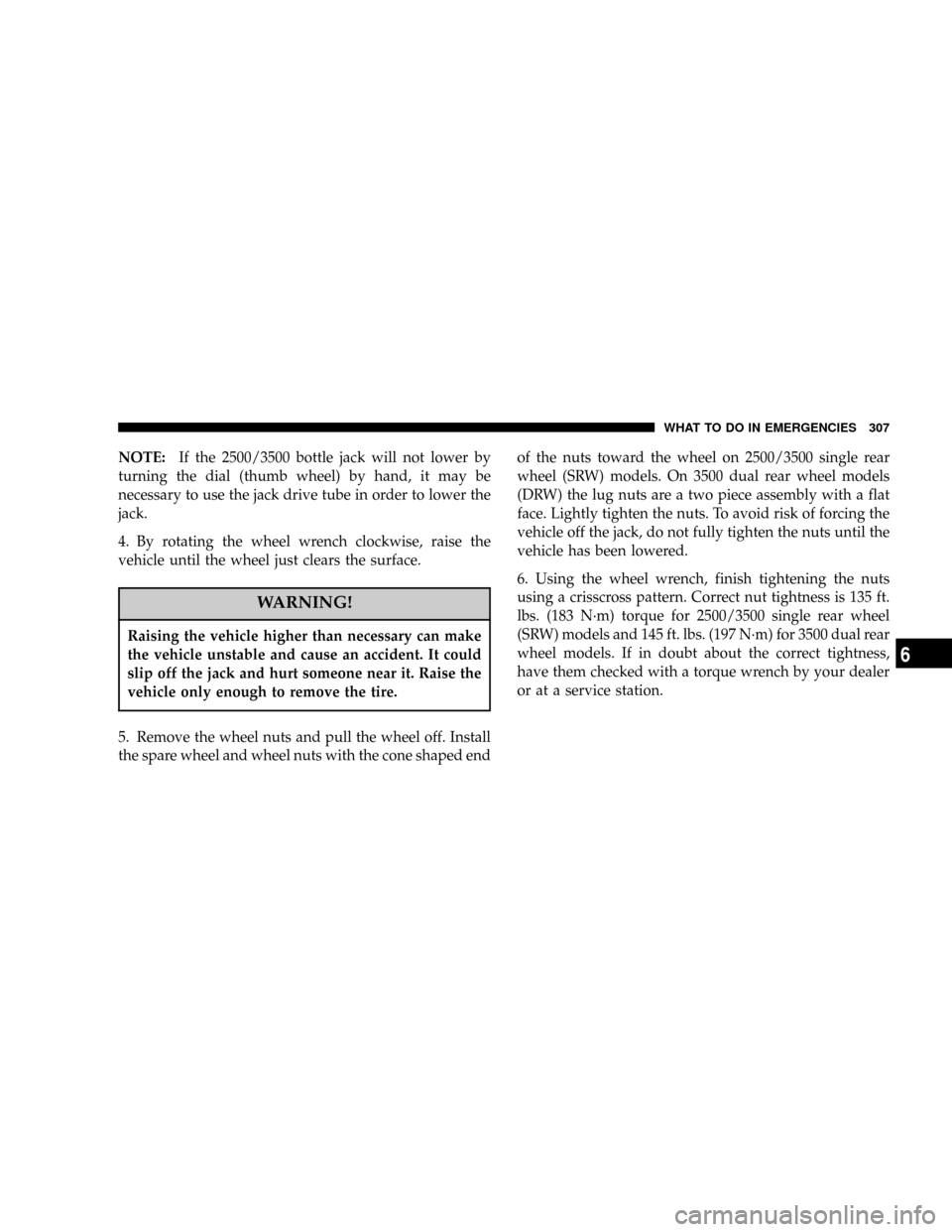

Place the jack under the axle as close to the tire as

possible with the drive tubes extending to the front.

Connect the jack tube extension and wheel wrench.

²For all trucks, when changing a rear wheel, as-

semble the jack drive tube to the jack and connect

the drive tube to the extension tube. Place the jackunder the axle between the spring and the shock

absorber with the drive tubes extending to the rear.

²Connect the jack tube extension and wheel wrench.

Before raising the wheel off the ground, make sure

that the jack will not damage surrounding truck

parts and adjust the jack position as required.2500/3500 4X4 Jacking Location

Rear Jacking Location (All)

306 WHAT TO DO IN EMERGENCIES

Page 307 of 429

NOTE:If the 2500/3500 bottle jack will not lower by

turning the dial (thumb wheel) by hand, it may be

necessary to use the jack drive tube in order to lower the

jack.

4. By rotating the wheel wrench clockwise, raise the

vehicle until the wheel just clears the surface.

WARNING!

Raising the vehicle higher than necessary can make

the vehicle unstable and cause an accident. It could

slip off the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

5. Remove the wheel nuts and pull the wheel off. Install

the spare wheel and wheel nuts with the cone shaped endof the nuts toward the wheel on 2500/3500 single rear

wheel (SRW) models. On 3500 dual rear wheel models

(DRW) the lug nuts are a two piece assembly with a flat

face. Lightly tighten the nuts. To avoid risk of forcing the

vehicle off the jack, do not fully tighten the nuts until the

vehicle has been lowered.

6. Using the wheel wrench, finish tightening the nuts

using a crisscross pattern. Correct nut tightness is 135 ft.

lbs. (183 N´m) torque for 2500/3500 single rear wheel

(SRW) models and 145 ft. lbs. (197 N´m) for 3500 dual rear

wheel models. If in doubt about the correct tightness,

have them checked with a torque wrench by your dealer

or at a service station.

WHAT TO DO IN EMERGENCIES 307

6

Page 308 of 429

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could injure someone in the vehicle.

Always stow the jack parts and the extra tire and

wheel in the places provided.

7. Install wheel center cap and remove wheel blocks. Do

not install chrome or aluminum wheel center caps on the

spare wheel. This may result in cap damage.

8. Lower the jack to its fully closed position. If the bottle

jack will not lower by turning the dial (thumb wheel) by

hand, it may be necessary to use the jack drive tube in

order to lower the jack. Stow the replaced tire, jack, and

tools as previously described.

9. Adjust the tire pressure when possible.NOTE:Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated wheel nuts.

Hub Caps

The hub caps must be removed before raising the vehicle

off the ground.

For 2500/3500 single rear wheel (SRW) models, use the

blade on the end of the lug wrench to pry the cap off.

On 3500 models with dual rear wheels (DRW), you must

first remove the hub caps. The jack handle driver has a

hook at one end that will fit in the pry off notch of the

rear hub caps. Position the hook and pull out on the

ratchet firmly. The cap should pop off. The wheel skins

can now be removed. For the front hub cap on 3500

models use the blade on the end of the lug wrench to pry

the caps off. The wheel skin can now be removed.

You must use the flat end of the lug wrench to pry off the

wheel skins. Insert the flat tip completely and using a

308 WHAT TO DO IN EMERGENCIES

Page 309 of 429

back and forth motion, loosen the wheel skin. Repeat this

procedure around the tire until the skin pops off.

Replace the wheel skins first using a rubber mallet. When

replacing the hub caps, tilt the cap retainer over the

lugnut bolt circle and strike the high side down with a

rubber mallet. Be sure that the hub caps and wheel skins

are firmly seated around the wheel.

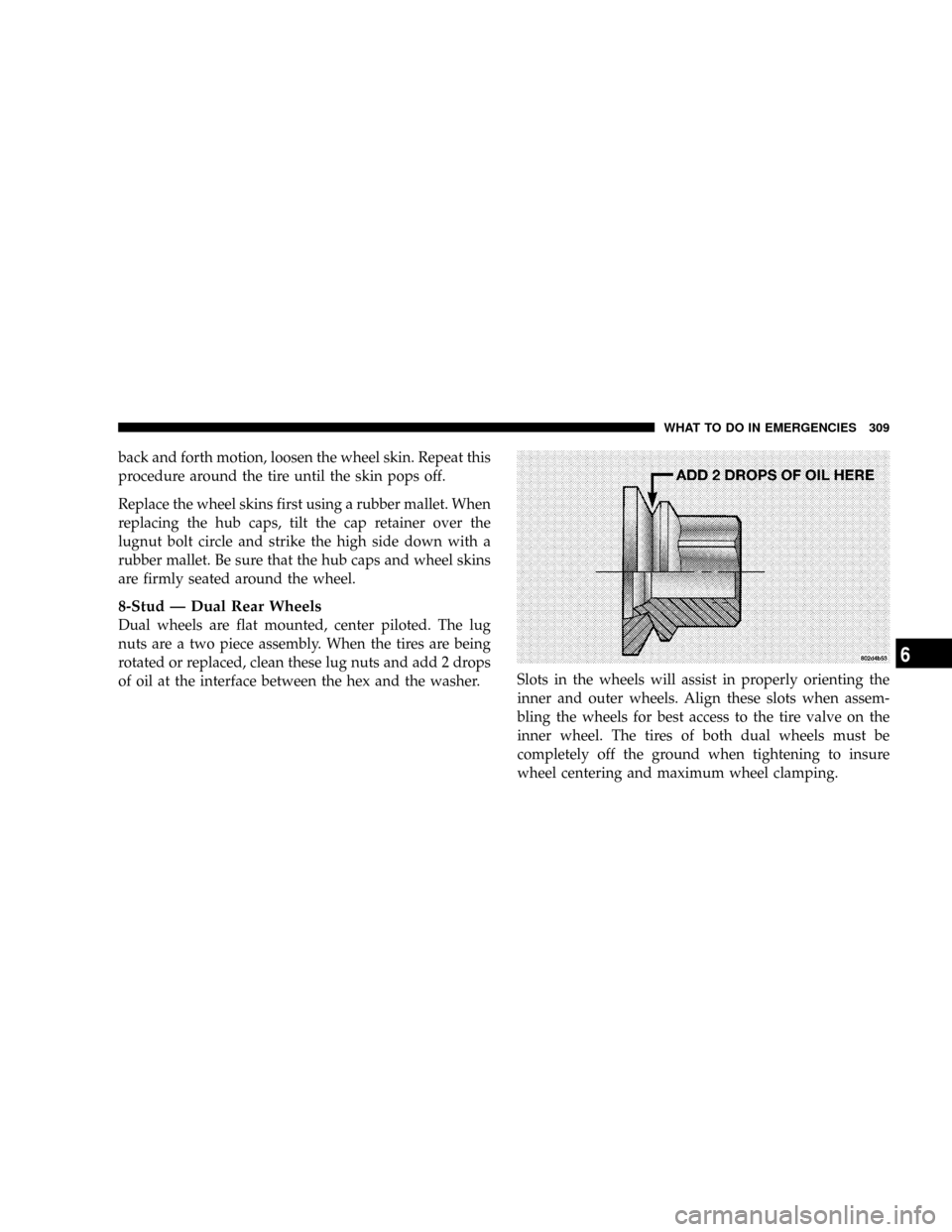

8-Stud Ð Dual Rear Wheels

Dual wheels are flat mounted, center piloted. The lug

nuts are a two piece assembly. When the tires are being

rotated or replaced, clean these lug nuts and add 2 drops

of oil at the interface between the hex and the washer.Slots in the wheels will assist in properly orienting the

inner and outer wheels. Align these slots when assem-

bling the wheels for best access to the tire valve on the

inner wheel. The tires of both dual wheels must be

completely off the ground when tightening to insure

wheel centering and maximum wheel clamping.

WHAT TO DO IN EMERGENCIES 309

6

Page 310 of 429

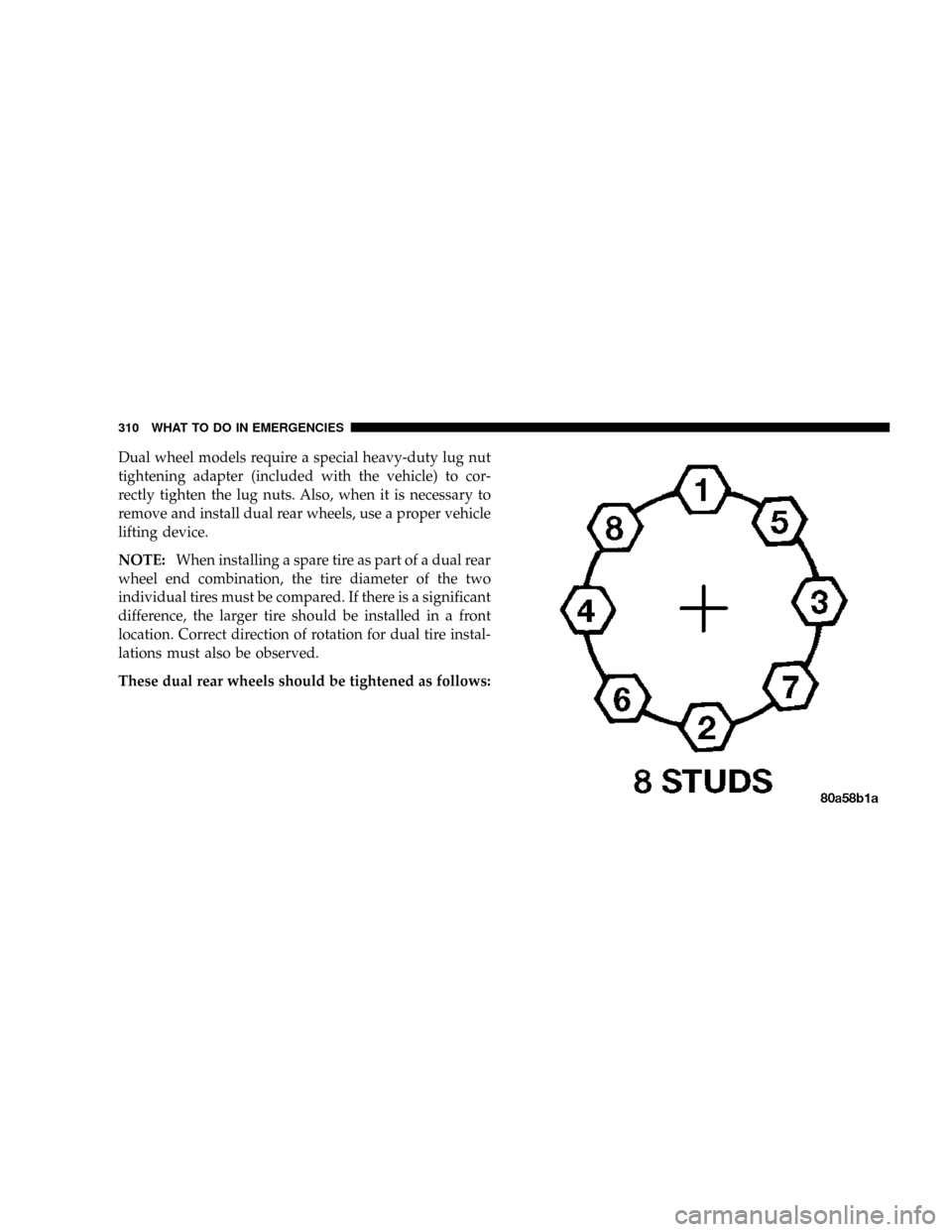

Dual wheel models require a special heavy-duty lug nut

tightening adapter (included with the vehicle) to cor-

rectly tighten the lug nuts. Also, when it is necessary to

remove and install dual rear wheels, use a proper vehicle

lifting device.

NOTE:When installing a spare tire as part of a dual rear

wheel end combination, the tire diameter of the two

individual tires must be compared. If there is a significant

difference, the larger tire should be installed in a front

location. Correct direction of rotation for dual tire instal-

lations must also be observed.

These dual rear wheels should be tightened as follows:

310 WHAT TO DO IN EMERGENCIES