ECO mode DODGE RAM 1500 GAS 2004 3.G Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: RAM 1500 GAS, Model: DODGE RAM 1500 GAS 2004 3.GPages: 429, PDF Size: 7.52 MB

Page 213 of 429

high gear. When the vehicle speed drops or during

acceleration when the transmission downshifts to second

gear, the clutch automatically disengages.

NOTE:The torque converter clutch will not engage

until the transmission fluid and engine coolant are warm

[usually after 1-3 miles (1.6 - 4.8 km) of driving]. Because

the engine speed is higher when the torque converter

clutch is not engaged, it may seem as if the transmission

is not shifting into Overdrive when cold. This is normal.

Pressing the ªTOW/HAULº button, when the transmis-

sion is sufficiently warm, will demonstrate that the

transmission is able to shift into and out of overdrive.

NOTE:If the vehicle has not been driven in several

days, the first few seconds of operation after shifting the

transmission into gear may seem sluggish. This is due tothe fluid partially draining from the torque converter into

the transmission. This condition is normal and will not

cause damage to the transmission. The torque converter

will refill within five seconds of shifting from Park into

any other gear position.

Manual Transmission Ð 5-Speed

NOTE:The parking brake should be engaged before

leaving the vehicle, especially on an incline.

Truck models with manual transmission are equipped

with a clutch interlocking ignition system. The clutch

pedal must be fully depressed to start the vehicle.

Fully depress the clutch pedal before shifting gears. As

you release the clutch pedal, lightly depress the accelera-

tor pedal.

STARTING AND OPERATING 213

5

Page 214 of 429

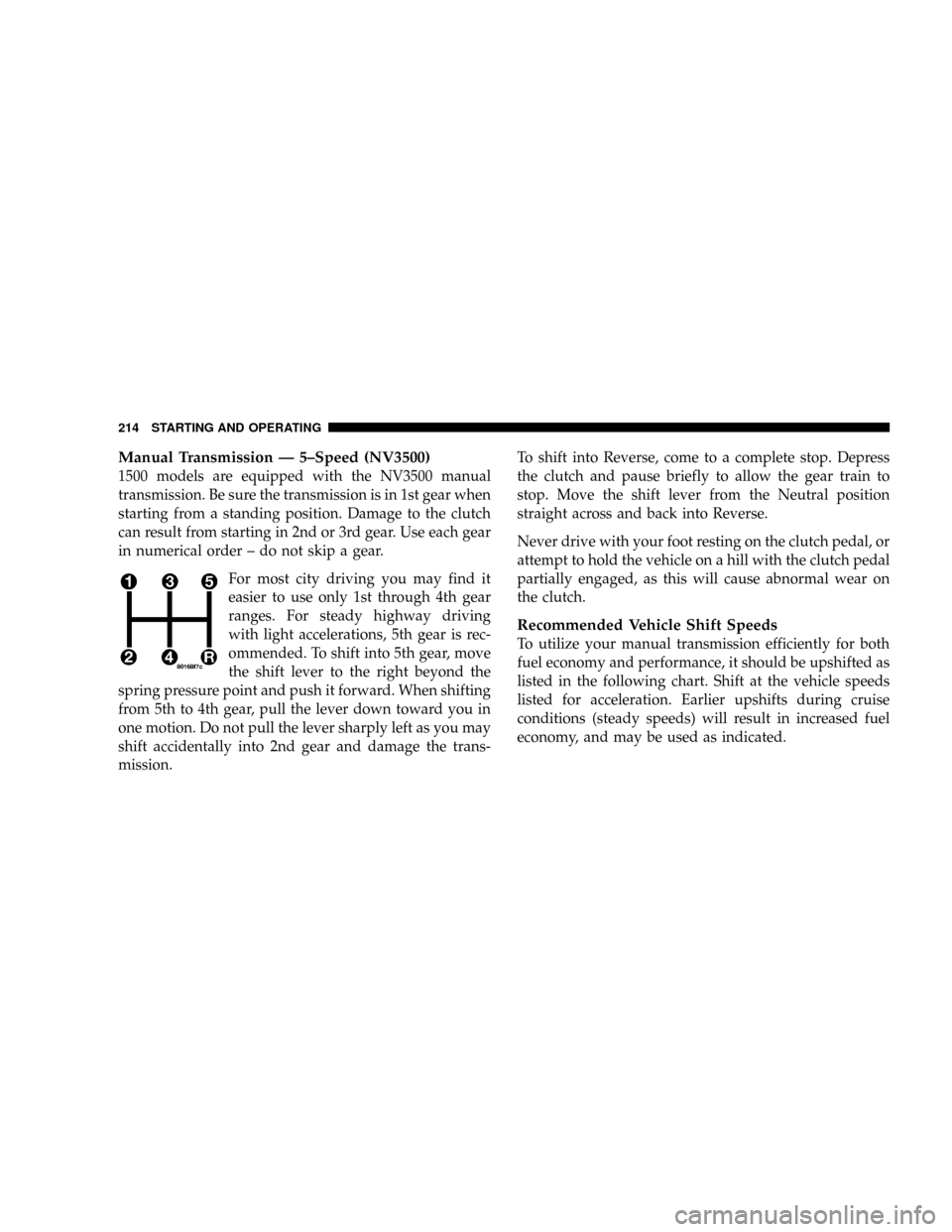

Manual Transmission Ð 5±Speed (NV3500)

1500 models are equipped with the NV3500 manual

transmission. Be sure the transmission is in 1st gear when

starting from a standing position. Damage to the clutch

can result from starting in 2nd or 3rd gear. Use each gear

in numerical order ± do not skip a gear.

For most city driving you may find it

easier to use only 1st through 4th gear

ranges. For steady highway driving

with light accelerations, 5th gear is rec-

ommended. To shift into 5th gear, move

the shift lever to the right beyond the

spring pressure point and push it forward. When shifting

from 5th to 4th gear, pull the lever down toward you in

one motion. Do not pull the lever sharply left as you may

shift accidentally into 2nd gear and damage the trans-

mission.To shift into Reverse, come to a complete stop. Depress

the clutch and pause briefly to allow the gear train to

stop. Move the shift lever from the Neutral position

straight across and back into Reverse.

Never drive with your foot resting on the clutch pedal, or

attempt to hold the vehicle on a hill with the clutch pedal

partially engaged, as this will cause abnormal wear on

the clutch.

Recommended Vehicle Shift Speeds

To utilize your manual transmission efficiently for both

fuel economy and performance, it should be upshifted as

listed in the following chart. Shift at the vehicle speeds

listed for acceleration. Earlier upshifts during cruise

conditions (steady speeds) will result in increased fuel

economy, and may be used as indicated.

214 STARTING AND OPERATING

Page 216 of 429

Never drive with your foot resting on the clutch pedal, or

attempt to hold the vehicle on a hill with the clutch pedal

partially engaged, as this will cause abnormal wear on

the clutch.

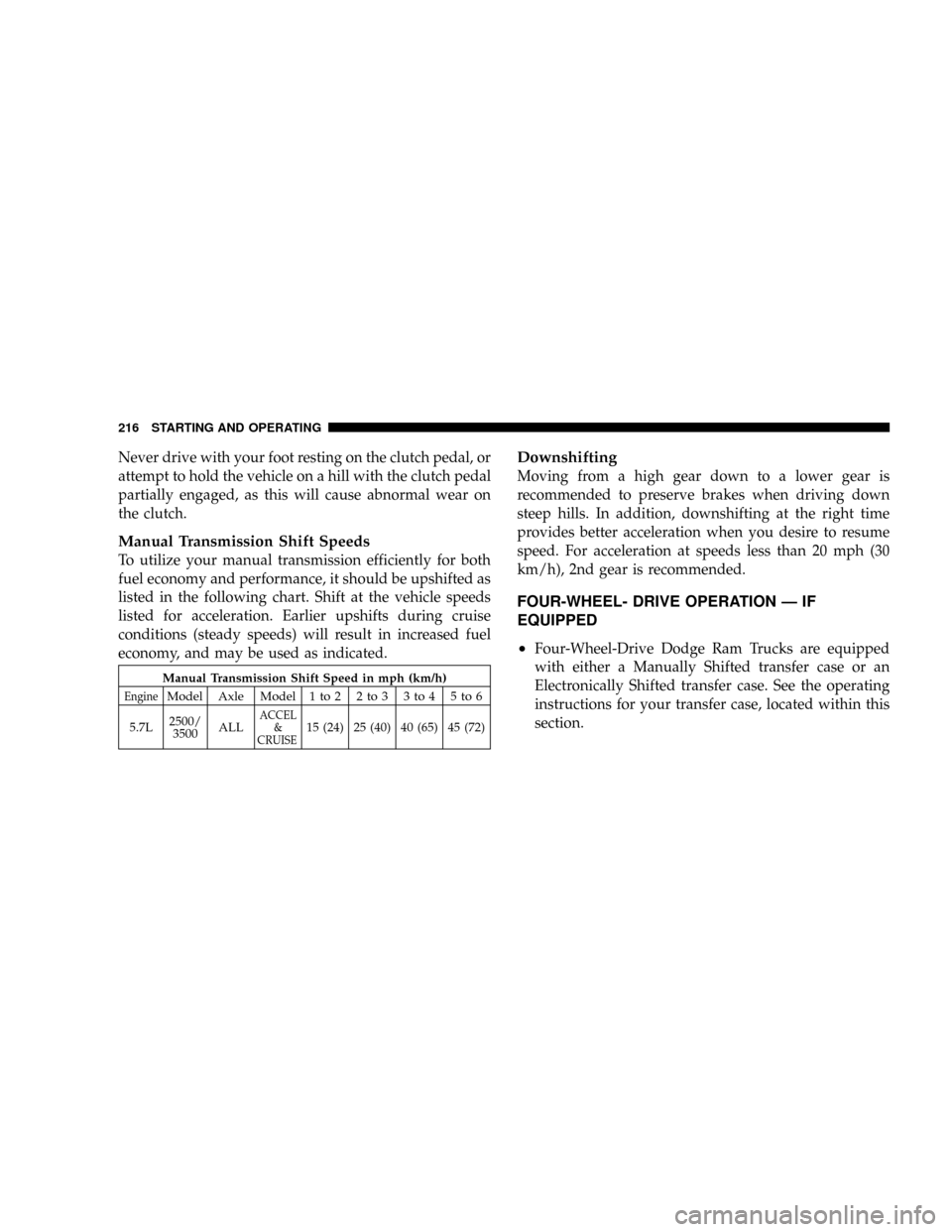

Manual Transmission Shift Speeds

To utilize your manual transmission efficiently for both

fuel economy and performance, it should be upshifted as

listed in the following chart. Shift at the vehicle speeds

listed for acceleration. Earlier upshifts during cruise

conditions (steady speeds) will result in increased fuel

economy, and may be used as indicated.

Manual Transmission Shift Speed in mph (km/h)

EngineModel Axle Model 1 to 2 2 to 3 3 to 4 5 to 6

5.7L2500/

3500ALL

ACCEL

&

CRUISE15 (24) 25 (40) 40 (65) 45 (72)

Downshifting

Moving from a high gear down to a lower gear is

recommended to preserve brakes when driving down

steep hills. In addition, downshifting at the right time

provides better acceleration when you desire to resume

speed. For acceleration at speeds less than 20 mph (30

km/h), 2nd gear is recommended.

FOUR-WHEEL- DRIVE OPERATION Ð IF

EQUIPPED

²

Four-Wheel-Drive Dodge Ram Trucks are equipped

with either a Manually Shifted transfer case or an

Electronically Shifted transfer case. See the operating

instructions for your transfer case, located within this

section.

216 STARTING AND OPERATING

Page 272 of 429

NOTE:Remember that everything put into or on the

trailer adds to the load on your vehicle. Also, additional

factory-installed options, or dealer-installed options,

must be considered as part of the total load on your

vehicle. Refer to the Certification label located at the

driver's door for the Gross Vehicle Weight Rating.

WARNING!

Improper towing can lead to an injury accident.

Follow these guidelines to make your trailer towing

as safe as possible:

Perform the maintenance listed in the ªMaintenance

Schedulesº section of this manual (Section 8). When

towing a trailer, never exceed the Gross Axle Weight

Rating (GAWR), or Gross Combined Vehicle Weight

(GCVW).

CAUTION!

When hauling cargo or towing a trailer, do not

overload your vehicle or trailer. Overloading can

cause a loss of control, poor performance or damage

to brakes, axle, engine, transmission, steering, sus-

pension, body structure or tires.

Axle Lubricant and Trailer Towing

1500 Models

²

1500 Modelrear axles are trailer tow ready. Limited

slip rear axles on 1500 models require the use of a

limited slip additive (refer to the ªRecommended

Fluids, Lubricants, and Genuine Partsº section.)

²The limited slip additive is included with the factory

fill.

²If the axle fluid is changed, 4 oz. (118 ml) of limited slip

additive must be added.

272 STARTING AND OPERATING

Page 273 of 429

2500/3500 Models

²

The Axles on 2500/3500 Modelsare trailer tow ready

andDO NOT REQUIREany special axle lubes or

additives.

Trailer Towing Recommendations

²

All trailer hitches should be professionally installed on

your vehicle.

²Safety chains must always be used between your

vehicle and trailer.

²Donotinterconnect the hydraulic brake system or

vacuum system of your vehicle with that of the trailer.

This could cause inadequate braking and possible

personal injury. An electrically±actuated electric trailer

brake controller is recommended.

²Trailer brakes are recommended for trailers over 1000

lbs (454 kg) and are required for trailers in excess of

2,000 lbs (907 kg)

²Use an approved wiring harness connector on the

trailer. Standard equipment on all RAM pickup mod-

els provides a 4-way trailer tow connector located

under the bumper. This connector contains the follow-

ing vehicle circuits: park/tail lamps, left stop/turn

lamp, right stop/turn lamp, and ground. With the

optional Trailer Tow Prep package a 7-way connector

is provided with the following additional circuits:

backup lamp, trailer battery and electric brake.

NOTE:Connect trailer lighting and brakes using factory

harnesses only. Do not cut or splice wiring to the brake

circuits.

STARTING AND OPERATING 273

5

Page 280 of 429

If your vehicle has an automatic transmission and you

tow a trailer frequently, change transmission fluid and

filter every 30,000 miles (48 000 km)

SNOWPLOW

Snowplow Prep Packages are available as a factory

installed option. These packages include components

necessary to equip your vehicle with a snowplow.

Dodge Ram 1500 Models

NOTE:Do not use Dodge Ram 1500 Models for snow-

plow applications.

WARNING!

On 1500 Models, snowplows, winches, and other

aftermarket equipment should not be added to the

front end of your vehicle. The airbag crash sensors

may be affected by the change in the front end

structure. The airbags could deploy unexpectedly or

could fail to deploy during a collision resulting in

serious injury or death.

CAUTION!

Using 1500 Model vehicles for snowplow applica-

tions can cause damage to the vehicle.

NOTE:Before installation of a snowplow it is highly

recommended that the owner / installer obtain and

follow the recommendations contained within the Dodge

280 STARTING AND OPERATING

Page 290 of 429

during the 1 second time, then all of the mode position

indicator lights will flash continuously until all require-

ments are met or until the Neutral (N) button is released.

NOTE:The ignition key must be ON for a shift to take

place and for the position indicator lights to be operable.

If the key is not ON, the shift will not take place and no

position indicator lights will be on or flashing.

NOTE:Flashing neutral (N) position indicator light

indicates that shift requirements have not been met.WARNING!

You or others could be injured if you leave the

vehicle unattended with the transfer case in the

Neutral (N) position without first fully engaging the

parking brake. The transfer case Neutral (N) position

disengages both the front and rear driveshafts from

the powertrain and will allow the vehicle to move

despite the transmission position. The parking

brake should always be applied when the driver is

not in the vehicle.

290 STARTING AND OPERATING

Page 292 of 429

If you experience unusual vibration after driving in mud,

slush or similar conditions, check the wheels for im-

pacted material. Impacted foreign material can cause a

wheel imbalance. Removing the foreign material from

the wheels will correct the situation.

TRACTION

When driving on wet or slushy roads, it is possible for a

wedge of water to build up between the tire and road

surface. This is known as hydroplaning and may cause

partial or complete loss of vehicle control and stopping

ability. To reduce this possibility, the following precau-

tions should be observed:

1. Slow down during rainstorms or when roads are

slushy.

2. Slow down if road has standing water or puddles.

3. Replace tires when tread wear indicators first become

visible.4. Keep tires properly inflated.

5. Maintain sufficient distance between your vehicle and

the car in front to avoid a collision in a sudden stop.

EQUIPMENT IDENTIFICATION PLATE

The equipment Identification Plate is located on the hood

inner surface.

The following information about your vehicle is dis-

played on this plate: Model, Wheelbase, Vehicle Identifi-

cation Number, Truck Order Number, and code numbers

with descriptions of all production and special equip-

ment on the truck as shipped from the factory.

NOTE:Always refer to the Equipment Identification

Plate When Ordering Parts.

292 STARTING AND OPERATING

Page 340 of 429

apparent, and/or the system is not functioning as antici-

pated. Coordinate inspection efforts through a certified

DaimlerChrysler Dealership.9

WARNING!

Fluid level should be checked on a level surface and

with the engine off to prevent injury from moving

parts and to insure accurate fluid level reading. Do

not overfill. Use only manufacturers recommended

power steering fluid.

If necessary, add fluid to restore to the proper indicated

level. With a clean cloth, wipe any spilled fluid from all

surfaces. Refer to Recommended Fluids, Lubricants, and

Genuine Parts for correct fluid type.

Front Suspension Ball Joints

4 x 2 Models

The ball joints and seals should be inspected whenever

the vehicle is serviced for other reasons.

The ball joints originally supplied with the vehicle are

permanently lubricated at the factory and do not require

service. However, if the seals on the ball joints are

damaged, the joints should be replaced. Serviceable

replacement ball joints are available.

Front suspension ball joints should be replaced only by a

qualified service technician using tools specially de-

signed for this purpose. Damage to the joints and/or

suspension components may result if improper replace-

ment procedures are used.

If seals are damaged the ball joints should be replaced to

prevent leakage or contamination of the grease.

340 MAINTAINING YOUR VEHICLE

Page 350 of 429

Clutch Linkage

If the clutch pedal linkage begins to squeak or grunt, the

clutch pedal pivot bushings should be lubricated. Refer

to Recommended Fluids, Lubricants and Genuine Parts

for the correct lubricant type.

Propeller Shaft Universal Joints

Cross Type (No fittings) ÐRelubrication of this type of

universal joint is not required. The seals should be

inspected for external leaks or damage. If external leaks

or damage is evident, the universal joint should be

replaced.

Rear Axle And 4x4 Front Driving Axle Fluid Level

Refer to Recommended Fluids, Lubricants and Genuine

Parts for the correct Fluid type. For normal service,

periodic fluid level checks are not required. When the

vehicle is serviced for other reasons the exterior surfaces

of the axle assembly should be inspected. If gear oil

leakage is suspected inspect the fluid level.This inspection should be made with the vehicle in a level

position. The fluid level should be even with the bottom

of the fill hole for the Manufacturer's C205F HD Front

Axles. The fluid level should be 5/8º (16 mm) below on

9 1/4º Manufacturer's Rear Axles.

For all 2500/3500 Model axles, the fluid level should be

1/4º 1/4º (6.4 mm 6.4 mm) below the fill hole on the

9.25º Front and 3/4º 1/4º (19 mm 6.4 mm) on 10.5º

Rear axles. The 11.5º Rear Axle level should be 1/4º

1/4º (6.4 mm 6.4 mm) below the fill hole.

Drain and Refill

Vehicles operated in normal service do not have regularly

scheduled oil changes. If fluid has become contaminated

with water or to provide the correct viscosity grade, drain

and refill.

Lubricant Selection

Refer to Recommended Fluids, Lubricants and Genuine

Parts for correct fluid type.

350 MAINTAINING YOUR VEHICLE