lock DODGE RAM 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: RAM, Model: DODGE RAM 1999Pages: 1691, PDF Size: 40.34 MB

Page 1 of 1691

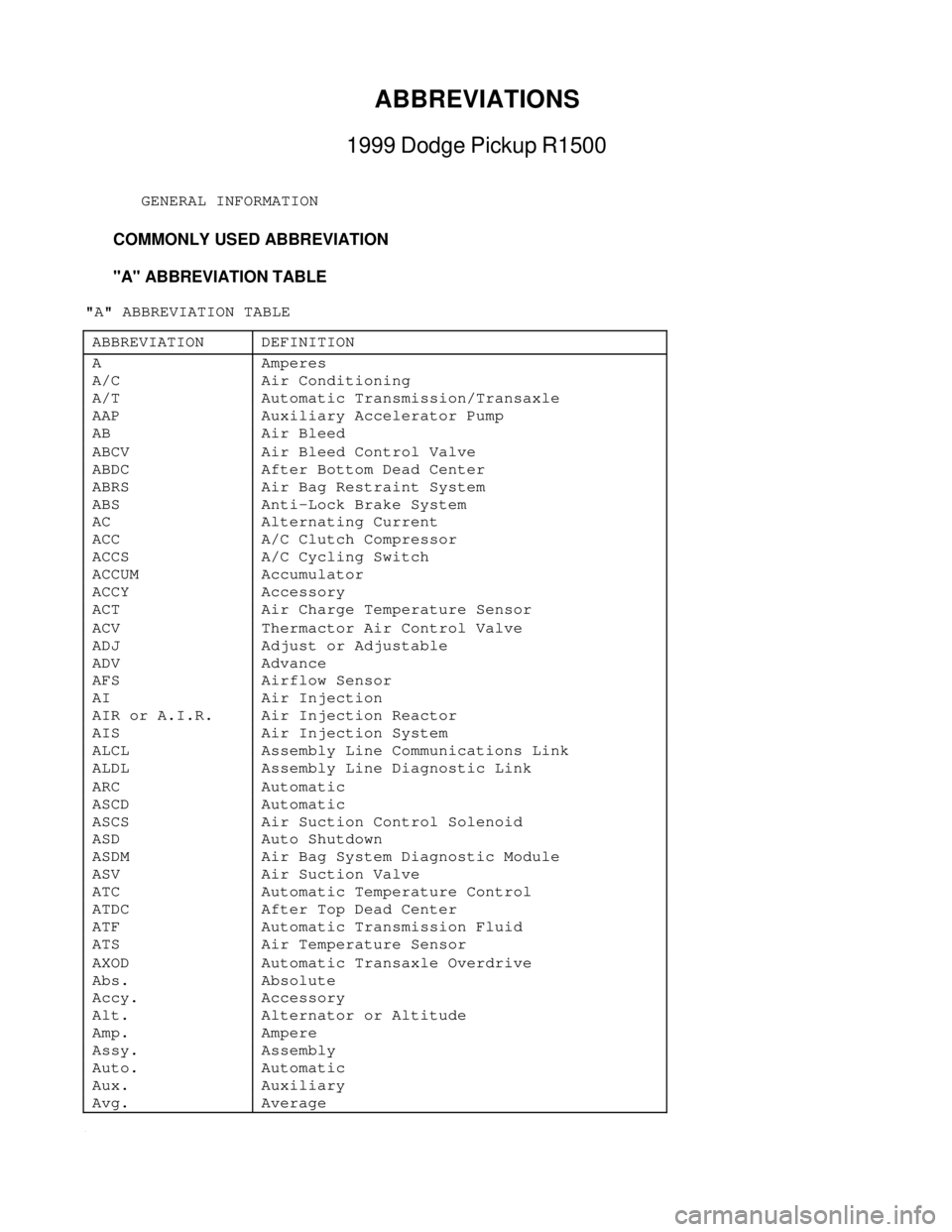

ABBREVIATIONS

1999 Dodge Pickup R1500

GENERAL INFORMATION

COMMONLY USED ABBREVIATION

"A" ABBREVIATION TABLE

"A" ABBREVIATION TABLE

ABBREVIATION DEFINITION A Amperes A/C Air Conditioning A/T Automatic Transmission/Transaxle AAP Auxiliary Accelerator Pump AB Air Bleed ABCV Air Bleed Control Valve ABDC After Bottom Dead Center ABRS Air Bag Restraint System ABS Anti-Lock Brake System AC Alternating Current ACC A/C Clutch Compressor ACCS A/C Cycling Switch ACCUM Accumulator ACCY Accessory ACT Air Charge Temperature Sensor ACV Thermactor Air Control Valve ADJ Adjust or Adjustable ADV Advance AFS Airflow Sensor AI Air Injection AIR or A.I.R. Air Injection Reactor AIS Air Injection System ALCL Assembly Line Communications Link ALDL Assembly Line Diagnostic Link ARC Automatic ASCD Automatic ASCS Air Suction Control Solenoid ASD Auto Shutdown ASDM Air Bag System Diagnostic Module ASV Air Suction Valve ATC Automatic Temperature Control ATDC After Top Dead Center ATF Automatic Transmission Fluid ATS Air Temperature Sensor AXOD Automatic Transaxle Overdrive Abs. Absolute Accy. Accessory Alt. Alternator or Altitude Amp. Ampere Assy. Assembly Auto. Automatic Aux. Auxiliary Avg. Average

3

Page 2 of 1691

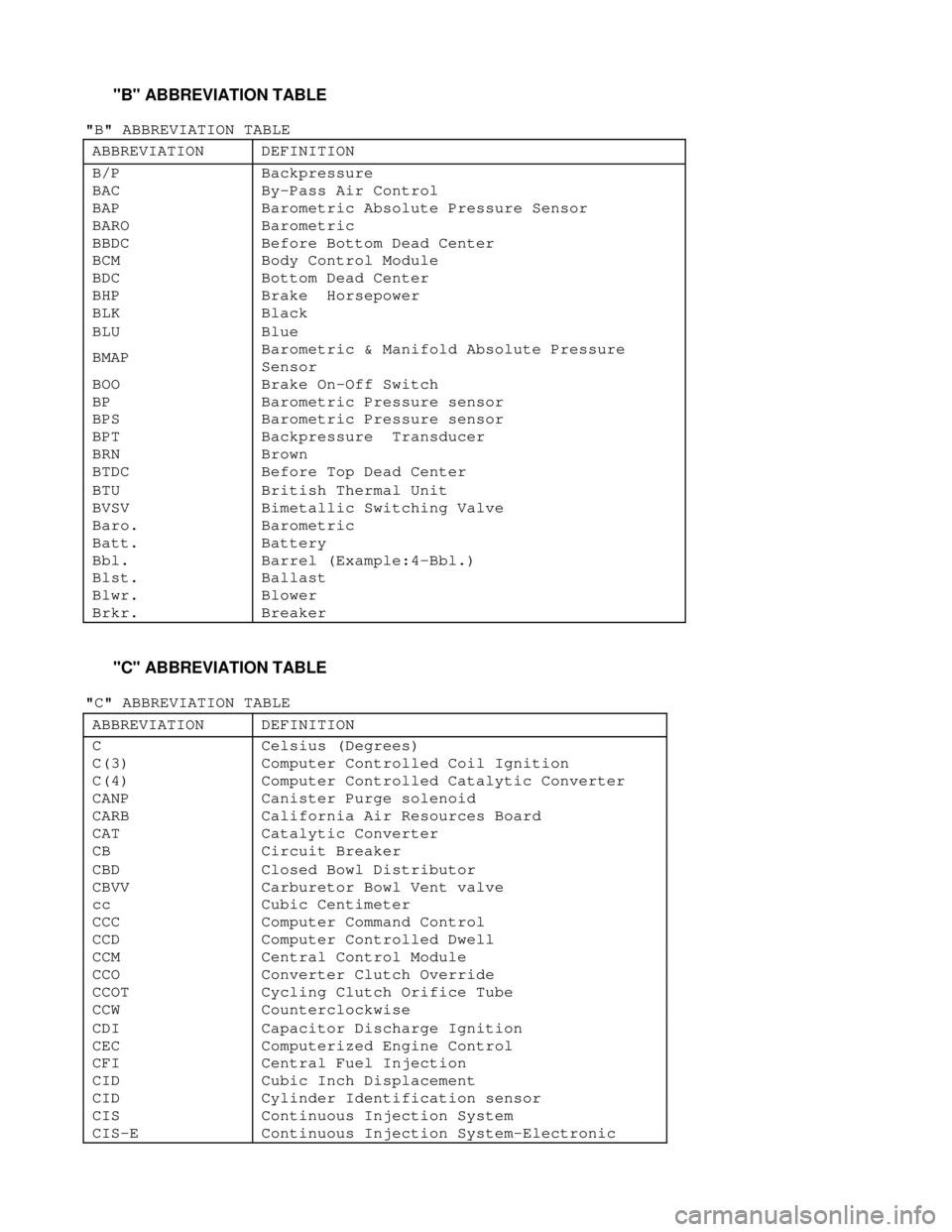

"B" ABBREVIATION TABLE

"B" ABBREVIATION TABLE

ABBREVIATION DEFINITION B/P Backpressure BAC By-Pass Air Control BAP Barometric Absolute Pressure Sensor BARO Barometric BBDC Before Bottom Dead Center BCM Body Control Module BDC Bottom Dead Center BHP Brake Horsepower BLK Black BLU Blue BMAP Barometric & Manifold Absolute Pressure

Sensor BOO Brake On-Off Switch BP Barometric Pressure sensor BPS Barometric Pressure sensor BPT Backpressure Transducer BRN Brown BTDC Before Top Dead Center BTU British Thermal Unit BVSV Bimetallic Switching Valve Baro. Barometric Batt. Battery Bbl. Barrel (Example:4-Bbl.) Blst. Ballast Blwr. Blower Brkr. Breaker

"C" ABBREVIATION TABLE

"C" ABBREVIATION TABLE

ABBREVIATION DEFINITION C Celsius (Degrees) C(3) Computer Controlled Coil Ignition C(4) Computer Controlled Catalytic Converter CANP Canister Purge solenoid CARB California Air Resources Board CAT Catalytic Converter CB Circuit Breaker CBD Closed Bowl Distributor CBVV Carburetor Bowl Vent valve cc Cubic Centimeter CCC Computer Command Control CCD Computer Controlled Dwell CCM Central Control Module CCO Converter Clutch Override CCOT Cycling Clutch Orifice Tube CCW Counterclockwise CDI Capacitor Discharge Ignition CEC Computerized Engine Control CFI Central Fuel Injection CID Cubic Inch Displacement CID Cylinder Identification sensor CIS Continuous Injection System CIS-E Continuous Injection System-Electronic

Page 3 of 1691

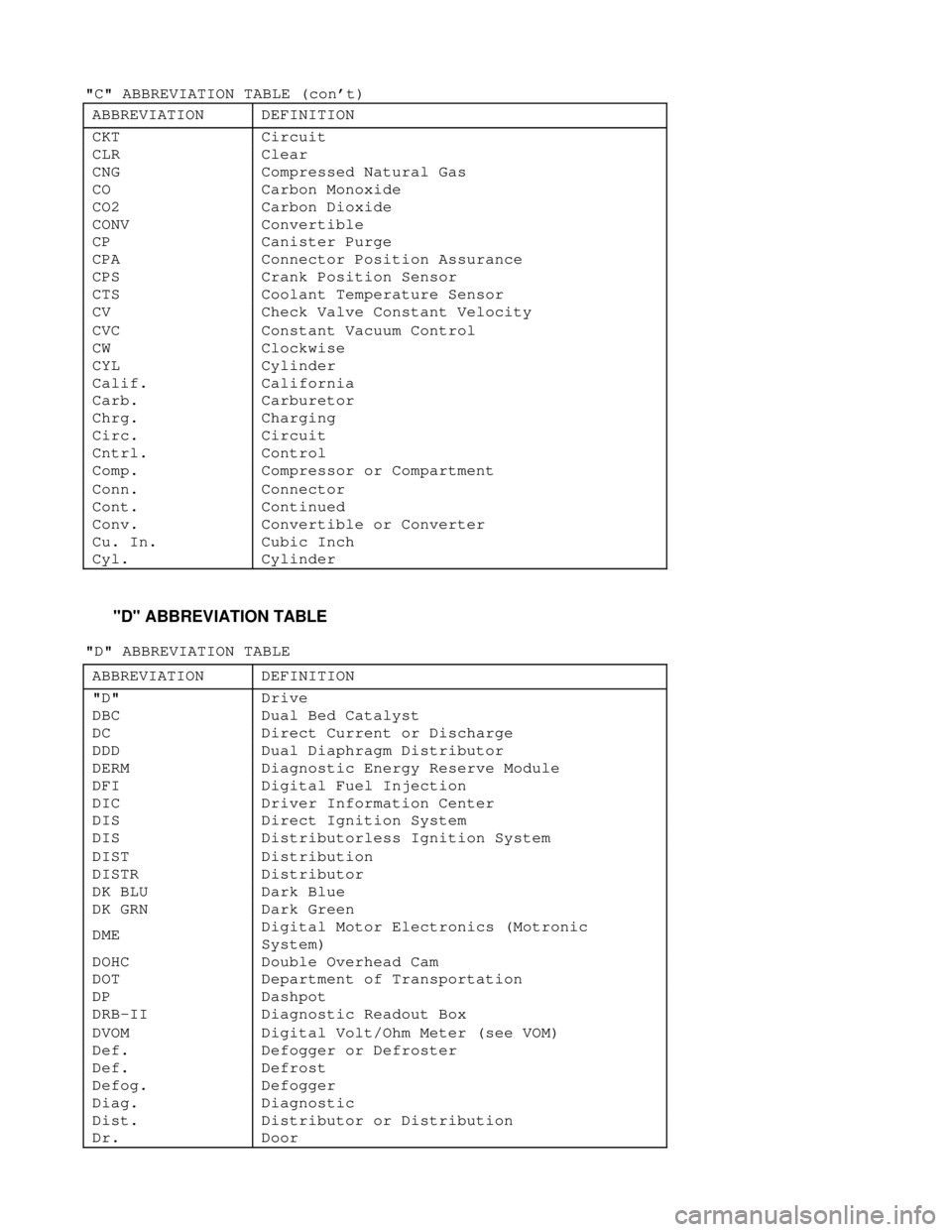

"C" ABBREVIATION TABLE (con’t)

ABBREVIATION DEFINITION CKT Circuit CLR Clear CNG Compressed Natural Gas CO Carbon Monoxide CO2 Carbon Dioxide CONV Convertible CP Canister Purge CPA Connector Position Assurance CPS Crank Position Sensor CTS Coolant Temperature Sensor CV Check Valve Constant Velocity CVC Constant Vacuum Control CW Clockwise CYL Cylinder Calif. California Carb. Carburetor Chrg. Charging Circ. Circuit Cntrl. Control Comp. Compressor or Compartment Conn. Connector Cont. Continued Conv. Convertible or Converter Cu. In. Cubic Inch Cyl. Cylinder

"D" ABBREVIATION TABLE

"D" ABBREVIATION TABLE

ABBREVIATION DEFINITION "D" Drive DBC Dual Bed Catalyst DC Direct Current or Discharge DDD Dual Diaphragm Distributor DERM Diagnostic Energy Reserve Module DFI Digital Fuel Injection DIC Driver Information Center DIS Direct Ignition System DIS Distributorless Ignition System DIST Distribution DISTR Distributor DK BLU Dark Blue DK GRN Dark Green DME Digital Motor Electronics (Motronic

System) DOHC Double Overhead Cam DOT Department of Transportation DP Dashpot DRB-II Diagnostic Readout Box DVOM Digital Volt/Ohm Meter (see VOM) Def. Defogger or Defroster Def. Defrost Defog. Defogger Diag. Diagnostic Dist. Distributor or Distribution Dr. Door

Page 4 of 1691

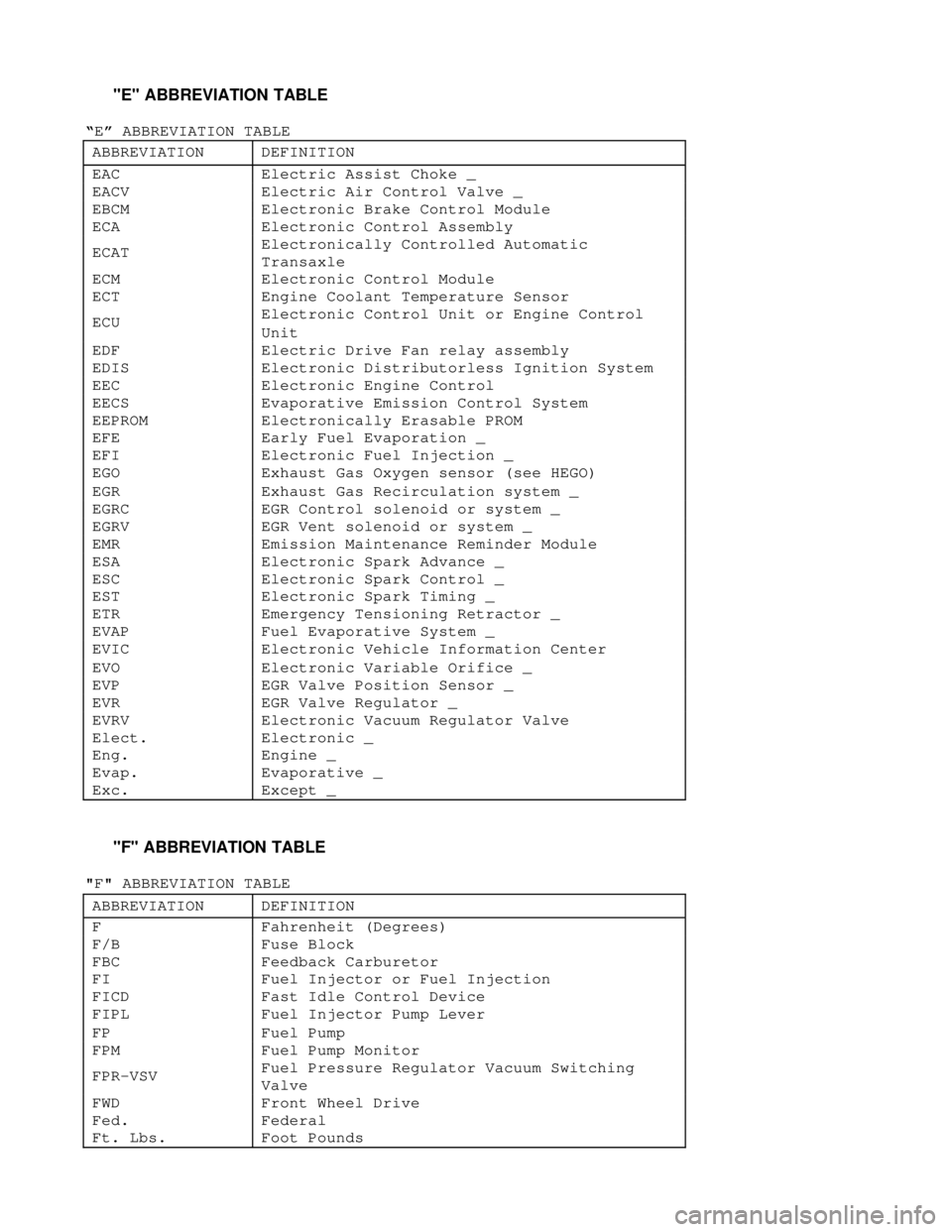

"E" ABBREVIATION TABLE

“E” ABBREVIATION TABLE

ABBREVIATION DEFINITION EAC Electric Assist Choke _ EACV Electric Air Control Valve _ EBCM Electronic Brake Control Module ECA Electronic Control Assembly ECAT Electronically Controlled Automatic

Transaxle ECM Electronic Control Module ECT Engine Coolant Temperature Sensor ECU Electronic Control Unit or Engine Control

Unit EDF Electric Drive Fan relay assembly EDIS Electronic Distributorless Ignition System EEC Electronic Engine Control EECS Evaporative Emission Control System EEPROM Electronically Erasable PROM EFE Early Fuel Evaporation _ EFI Electronic Fuel Injection _ EGO Exhaust Gas Oxygen sensor (see HEGO) EGR Exhaust Gas Recirculation system _ EGRC EGR Control solenoid or system _ EGRV EGR Vent solenoid or system _ EMR Emission Maintenance Reminder Module ESA Electronic Spark Advance _ ESC Electronic Spark Control _ EST Electronic Spark Timing _ ETR Emergency Tensioning Retractor _ EVAP Fuel Evaporative System _ EVIC Electronic Vehicle Information Center EVO Electronic Variable Orifice _ EVP EGR Valve Position Sensor _ EVR EGR Valve Regulator _ EVRV Electronic Vacuum Regulator Valve Elect. Electronic _ Eng. Engine _ Evap. Evaporative _ Exc. Except _

"F" ABBREVIATION TABLE

"F" ABBREVIATION TABLE

ABBREVIATION DEFINITION F Fahrenheit (Degrees) F/B Fuse Block FBC Feedback Carburetor FI Fuel Injector or Fuel Injection FICD Fast Idle Control Device FIPL Fuel Injector Pump Lever FP Fuel Pump FPM Fuel Pump Monitor FPR-VSV Fuel Pressure Regulator Vacuum Switching

Valve FWD Front Wheel Drive Fed. Federal Ft. Lbs. Foot Pounds

Page 6 of 1691

"I" ABBREVIATION TABLE (con’t)

ABBREVIATION DEFINITION ISA Idle Speed Actuator ISC Idle Speed Control ISS Idle Stop Solenoid ITS Idle Tracking Switch IVSV Idle Vacuum Switching Valve Ign. Ignition In. Inches Inj. Injector

"J" ABBREVIATION TABLE

"J" ABBREVIATION TABLE

ABBREVIATION DEFINITION J/B Junction Block

"K" ABBREVIATION TABLE

"K" ABBREVIATION TABLE

ABBREVIATION DEFINITION k/ohms 1000 ohms (kilo as in k/ohms) kg Kilograms (weight) kg/cm Kilograms Per Square Centimeter KAM Keep Alive Memory KAPWR Keep Alive Power KM/H Kilometers Per Hour KOEO Key On Engine Off KOER Key On Engine Running KS Knock Sensor

"L" ABBREVIATION TABLE

"L" ABBREVIATION TABLE

ABBREVIATION DEFINITION L Liter(s) L/D Light Duty LCD Liquid Crystal Display LED Light Emitting Diode LH Left Hand LOS Limited Operation Strategy LT BLU Light Blue LT GRN Light Green LUS Lock-Up Solenoid Lbs. Pounds Lt(s). Light(s) Lugg. Luggage

Page 9 of 1691

"R" ABBREVIATION TABLE

"R" ABBREVIATION TABLE

ABBREVIATION DEFINITION RABS Rear Anti-Lock Brake System RAC Remote Accessory Control RAM Random Access Memory RAP Retained Accessory Power RECIRC Recirculation RED Red RH Right hand ROM Read Only Memory RPM Revolutions Per Minute RVB Rear Vacuum Break RWAL Rear Wheel Anti-Lock Brake RWD Rear Wheel Drive Recirc. Recirculate or Recirculation Reg. Regulator Rly. Relay

"S" ABBREVIATION TABLE

"S" ABBREVIATION TABLE

ABBREVIATION DEFINITION SAW Spark Angle Word _ SBC Single Bed Converter _ SBEC Single Board Engine Controller _ SC Super Charged _ SCC Spark Control Computer _ SCS Air Suction Control Solenoid _ SDM Supplemental Restraint System Diagnostic Module _ SDU SRS Diagnostic Unit _ SEN Sensor _ SES Service Engine Soon _ SFI Sequential (Port) Fuel Injection _ SIG RTN Signal Return circuit _ SIL Shift Indicator Light _ SIR Supplemental Inflatable Restraint _ SMEC Single Module Engine Controller _ SOHC Single Overhead Cam _ SOL or SoL Solenoid _ SPFI Sequential Port Fuel Injection _ SPK Spark Control _ SPOUT Spark Output Signal _ SRS Supplemental Restraint System (Air Bag) _ SS 3/4-4/3 Shift Solenoid circuit _ SSI Solid State Ignition _ STAR Self-Test Automatic Readout _ STI Self Test Input circuit _ STO Self-Test Output _ SUB-O2 Sub Oxygen Sensor _ Sen. Or Sens. Sensor _ Sol. Solenoid _ Sprchg. Supercharger _ Strg. Steering _ Susp. Suspension _ Sw. Switch _ Sys. System _

Page 17 of 1691

Use only NEW, moisture-free refrigerant oil in A/C systems.

Refrigerant oil is highly refined with a very low moisture content.

Oil container must be tightly closed when not in use, or moisture from

air will be absorbed into refrigerant oil.

Refrigerant R-134a systems use Polyalkylene Glycol (PAG)

refrigerant oil. Using a mineral oil based lubricant with R-134a

systems will result in A/C compressor failure due to lack of proper

lubrication.

All compressors have different lubrication requirements and

use different Polyalkylene Glycol (PAG) refrigerant oils. Use only the\

specified PAG refrigerant oil for the appropriate system and A/C

compressor. Always check the underhood A/C specification label or A/C

compressor label before adding refrigerant oil to A/C

compressor/system. See listing of refrigerant oils currently available

from the vehicle manufacturers.

NOTE: PAG oil absorbs moisture very rapidly, 2.3-5.6 percent by

weight as compared to a mineral oil absorption rate of .005

percent by weight.

CHRYSLER CORP., JEEP & EAGLE

Use ND-8 PAG oil, SUN PAG 56 oil, SP-10 PAG oil, or SP-20 PAG

oil.

FORD MOTOR CO.

Use YN-12B or YN-12C PAG Refrigerant Oil (specification WSH-

M1C231-B) or SP-20 PAG Oil (specification WST-M1C231-B2).

GENERAL MOTORS

On all models except Saturn, use PAG Refrigerant Oil (Part

No. 12345923). On Saturn, use Saturn PAG refrigerant oil.

SERVICING PRECAUTIONS

DISCHARGING SYSTEM

Discharge A/C system, using approved refrigerant

recovery/recycling equipment before loosening any fittings. Follow

refrigerant recovery/recycling equipment manufacturer's instructions.

DISCONNECTING LINES & FITTINGS

After system is discharged, carefully clean area around all

fittings to be opened. Always use 2 wrenches when loosening or

tightening fittings. Some refrigerant lines are connected with a

spring-lock coupling. Special tools may be required to disconnect

lines. To prevent dirt and moisture from entering system, cap all

openings as soon as lines are removed. DO NOT remove service valve

caps until ready to connect lines and fittings.

NOTE: All R-134a based systems use 1/2-16 ACME threaded fittings.

Ensure all replacement parts match the connections of the

system being worked on.

CONNECTING LINES & FITTINGS

Always use new a gasket or "O" rings when connecting lines or

Page 29 of 1691

Removal

1) Discharge A/C system, using approved refrigerant

recovery/recycling equipment. Remove compressor. Using a spanner

wrench or clutch holder, remove clutch plate bolt. Discard bolt.

Thread an 8-mm bolt into clutch plate and remove clutch plate and

shims.

2) Remove shaft felt seal. Using low pressure compressed air

and a lint-free cloth, thoroughly clean seal inside and outside of

compressor nose area. Using Snap Ring Remover (T89P-19623-DH), rotate

eye of snap ring. Pull up snap ring while holding snap ring at an

angle.

3) Position Shaft Seal Remover (T89P-19623-BH) over

compressor shaft. Push shaft seal remover downward against seal.

Ensure end of shaft seal remover engages inside of seal.

4) Rotate shaft seal remover handle clockwise to expand

remover tip inside seal. Pull shaft seal from compressor.

Installation

1) Lubricate shaft seal protector and shaft seal with

refrigerant oil. Replacement Seal Kit (19D665) includes Shaft Seal

Protector (T94P-19623-F).

2) Coat shaft seal and protector with clean refrigerant oil.

Install shaft seal on shaft seal protector so lip of seal is toward

large end of shaft seal protector. Install shaft seal protector onto

compressor shaft.

3) Using Shaft Seal Replacer (T89P-19623-AH), slowly push

shaft seal down until it is seated. Remove shaft seal installer and

protector. Install new shaft seal snap ring. Rotate compressor shaft

about 10 revolutions and leak test shaft seal installation.

4) Install new shaft seal felt. Install clutch plate. Install

new clutch plate bolt, and tighten it to 98-123 INCH lbs. (11-14 N.m).\

5) Using a feeler gauge, measure air gap (in 3 places)

between clutch plate and pulley assembly mating surface. Air gap

should be 0.014-0.033" (0.36-0.84 mm). If air gap is not as specified,\

add or remove shims as necessary.

HARRISON HD6/HT6 & HD6/HR-6HE 6-CYL., V5 5-CYL. & V7 7-CYL.

CLUTCH ASSEMBLY

CAUTION: DO NOT hammer on compressor shaft to remove clutch plate, as

compressor damage will result.

Removal

1) Remove compressor from vehicle. Place compressor in

Holding Fixture (HD6/HT6 and HD6/HR-6HE compressor use J-33026; on V5

or V7 compressor use J-34992 or J-41790). On V5 or V7 compressor,

remove dust cover (if equipped). Use Clutch Plate Spanner (J-33027-A)\

to hold clutch plate and remove compressor shaft nut using Shaft Nut

Socket (J-33022). See Fig. 2 or 3.

2) On all compressors, using Clutch Plate Remover/Installer

(J-33013-B), remove compressor clutch plate and hub. See Fig. 2 or 3.

Hold remover body and turn center screw into remover body to remove

clutch plate and hub. Ensure forcing tip on remover/installer center

screw is flat or end of shaft/axial plate will be damaged. Remove

shaft key.

3) Remove snap ring. Install Puller Guide (J-33023-A) on

front head. Position Pulley and Bearing Puller (J-41552 for HD6/HT6

and HD6/HR-6HE or J-33020 for V5 or V7 compressor) into inner circle

of slots on pulley assembly. Turn puller clockwise in slots. Tighten

puller and remove pulley assembly.

Page 33 of 1691

NOTE: It is not necessary to replace shaft seal because of a small

amount of oil found on adjacent surfaces. A small amount of

oil is normal for lubrication purposes. Shaft seal should

only be replaced after a confirmed refrigerant leak is

found.

Removal

1) Discharge A/C system, using approved refrigerant

recovery/recycling equipment. Loosen and reposition compressor in

mounting bracket. Remove clutch plate and hub assembly. See CLUTCH

ASSEMBLY. See Fig. 2 or 3.

2) Remove shaft seal snap ring. Ensure all surfaces around

seal are clean. Insert Shaft Seal Remover/Installer (J-23128-A) into

shaft seal. Rotate handle clockwise to seat seal remover/installer in

seal. Remove shaft seal. Using "O" Ring Remover (J-9553-01), remove

"O" ring. Ensure shaft and inside of compressor neck are clean and

free of foreign material. Thoroughly clean "O" ring groove in front

head.

Installation

1) Install Shaft Seal Protector (J-34614) over compressor

shaft. With shaft seal protector in place, lubricate "O" ring with

refrigerant oil and install it on "O" Ring Installer (J-33011).

2) Insert "O" ring installer in compressor until it bottoms.

Move slide on "O" ring installer downward until "O" ring is released

into groove. Rotate installer to seat "O" ring. Remove "O" ring

installer.

3) Lubricate shaft seal with refrigerant oil. Install shaft

seal onto Seal Installer (J-23128-A). Install shaft seal so flared

side of lip seal is installed toward compressor. Expand seal using

shaft seal remover/installer. Install shaft seal on Seal Protector (J-

34614). Place seal protector over shaft.

4) Push shaft seal into compressor using a rotary motion

until seal bottoms. Install new snap ring with flat side against seal.

Install clutch plate and hub assembly onto compressor shaft. See

CLUTCH ASSEMBLY.

NIPPONDENSO 10-CYLINDER

CLUTCH ASSEMBLY

Removal & Installation (Metro & Tracker)

1) Discharge A/C system, using approved refrigerant

recovery/recycling equipment. Remove A/C compressor. Drain, measure

and discard refrigerant oil from compressor.

2) Using Clutch Plate Holder/Remover (J-41384) remove clutch\

plate nut, washer and clutch plate from compressor drive shaft. Remove

clutch pulley snap ring and shim. Using a plastic mallet, gently tap

and remove clutch pulley. Remove clutch coil wire retainer from

compressor. Remove clutch coil snap ring and clutch coil. See Fig. 4.

3) Install clutch coil and snap ring. Attach clutch coil wire

retainer to compressor. Install clutch pulley, snap ring and shim.

Install clutch plate to compressor shaft. Measure air gap between

clutch pulley and clutch plate.

4) Air gap should be 0.014-0.026" (0.35-0.65 mm). Add or

remove shims as necessary. Install compressor shaft nut and washer.

Tighten compressor shaft nut to 11-15 ft. lbs. (15-20 N.m). After

repairs, add NEW refrigerant oil to compressor equal to amount

drained. To complete installation, reverse removal procedure.

SHAFT SEAL

Page 37 of 1691

Ford Motor Co. (Taurus 3.4L SHO)

1) Discharge A/C system, using approved refrigerant

recovery/recycling equipment. Remove A/C compressor. Drain and measure

oil from compressor.

2) Remove pulley assembly. Using Spanner Wrench (T81P-19623-

MH), remove shaft nut and lock washer. Using a steering wheel puller,

remove clutch plate, shaft key and shim. Remove snap ring and pulley

assembly, by hand. If necessary, use a 3-jaw puller to remove pulley

assembly. Remove clutch coil wire from retaining brace on compressor.

Remove snap ring and clutch coil. See Fig. 1.

Installation

1) Install clutch coil. Ensure hole on back of clutch coil is

aligned with pin on compressor head. Install snap ring with beveled

side facing outward. Install clutch coil wire into retaining brace.

2) Slip pulley assembly onto compressor shaft and install

snap ring with beveled side facing outward. Install shim and shaft

key. Align clutch plate with shaft key and install clutch plate. Use

Hub Driven Plate Replacer (T80L-19703-F), if necessary. Using spanner

wrench, install lock washer and shaft nut. Tighten shaft nut to 10-14

ft. lbs. (14-19 N.m).

3) Using a feeler gauge, measure air gap between clutch plate

and pulley assembly at 3 equally spaced locations. Rotate pulley 180

degrees and measure air gap at 3 locations again. Air gap should be 0.

016-0.027" (0.41-0.69 mm). If air gap is not within specification, add\

or remove shims to obtain correct air gap.

4) Add correct amount of refrigerant oil to compressor and

install compressor. See COMPRESSOR REFRIGERANT OIL CHECKING. Evacuate

and charge A/C system. Perform leak test.

SANDEN MSC90-C SCROLL

CLUTCH ASSEMBLY

Removal

1) Discharge A/C system, using approved refrigerant

recovery/recycling equipment. Remove compressor. Drain oil from

compressor, and measure amount drained.

2) Remove pulley assembly. Using Spanner (MB991367) and Pins\

(MB991386), remove shaft nut. Remove clutch plate, snap ring and rotor\

assembly. Remove snap ring and clutch coil. See Fig. 6.

Installation

1) Install clutch coil. Ensure projection on back of clutch

coil is aligned with pin hole in compressor body. Install snap ring so

that tapered surface is facing outward.

2) Install rotor assembly and snap ring. Align match mark of

clutch plate with match mark of compressor shaft spline and install

clutch plate. Using spanner and pins, install shaft nut.

3) Using a feeler gauge, check air gap between clutch plate

and rotor assembly at more than one place. Air gap should be 0.016-0.

024" (0.40-0.60 mm). If air gap is not within specification, add or

remove shims as necessary. Install pulley assembly.

4) Add same amount of refrigerant oil to compressor as was

drained from it. Install A/C compressor. Evacuate and charge A/C

system. Perform leak test.