steering DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1204 of 2889

(8) Install water pump (Refer to 7 - COOLING/EN-

GINE/WATER PUMP - INSTALLATION).

(9) Install power steering pump (Refer to 19 -

STEERING/PUMP - INSTALLATION).

(10) Install the serpentine belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(11) Install the cooling system fan (Refer to 7 -

COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - INSTALLATION).

(12) Position the fan shroud and install the bolts.

Tighten the bolts to 11 N´m (95 in. lbs.) torque.

(13) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(14) Connect the negative cable to the battery.

TIMING BELT/CHAIN

TENSIONER

DESCRIPTION

The timing chain tensioner is a stamped steel con-

stant tension mechanical design. It is mounted to the

front of the engine, behind the timing chain drive.

OPERATION

The timing chain tension is maintained by routing

the timing chain through the tensioner assembly. A

nylon covered spring steel arm presses on the timing

chain maintaining the correct chain tension.

TIMING BELT/CHAIN AND

SPROCKETS

REMOVAL

(1) Disconnect battery negative cable.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

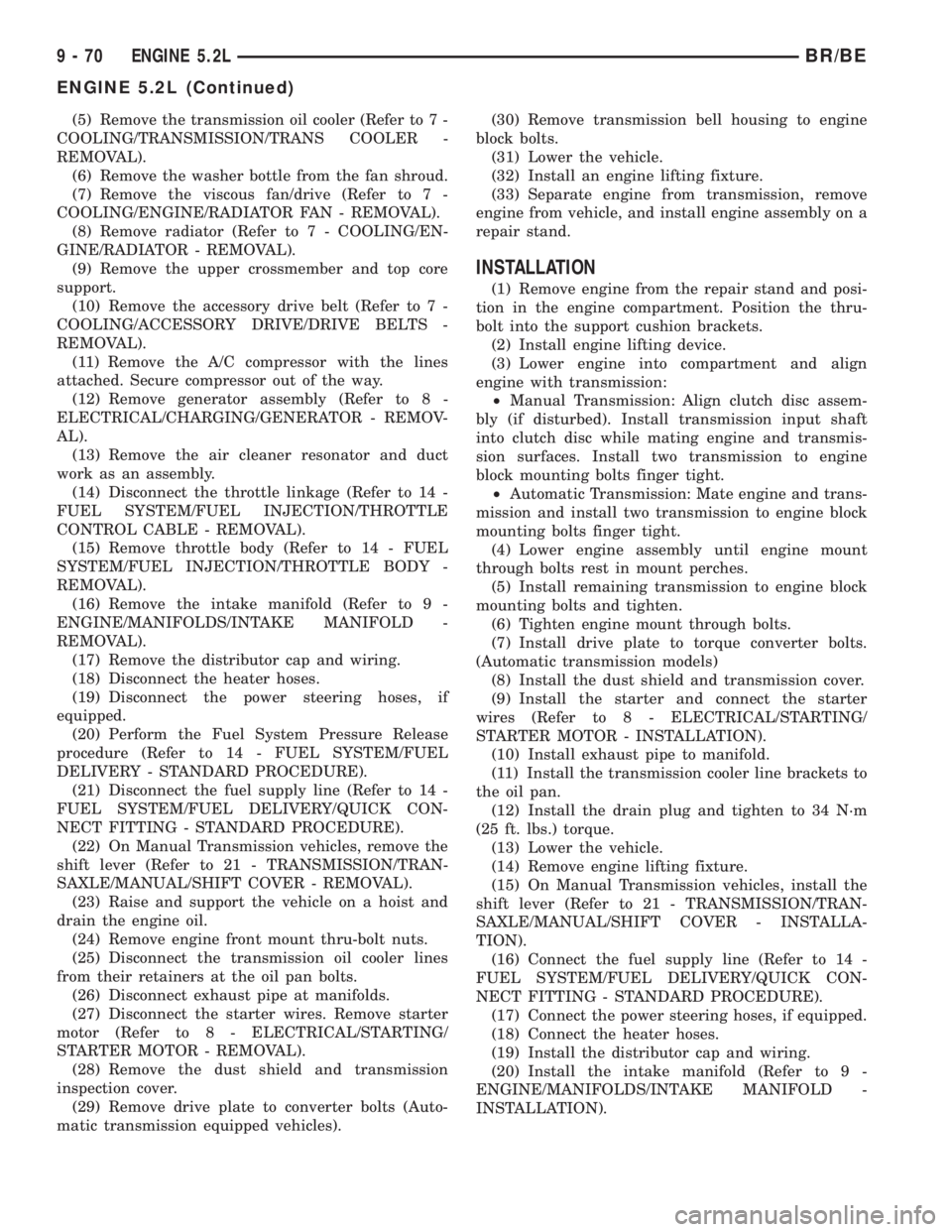

(4) Rotate crankshaft to align timing marks (Fig.

75) to #1 TDC.

(5) Remove camshaft sprocket attaching bolt and

remove timing chain with crankshaft and camshaft

sprockets.

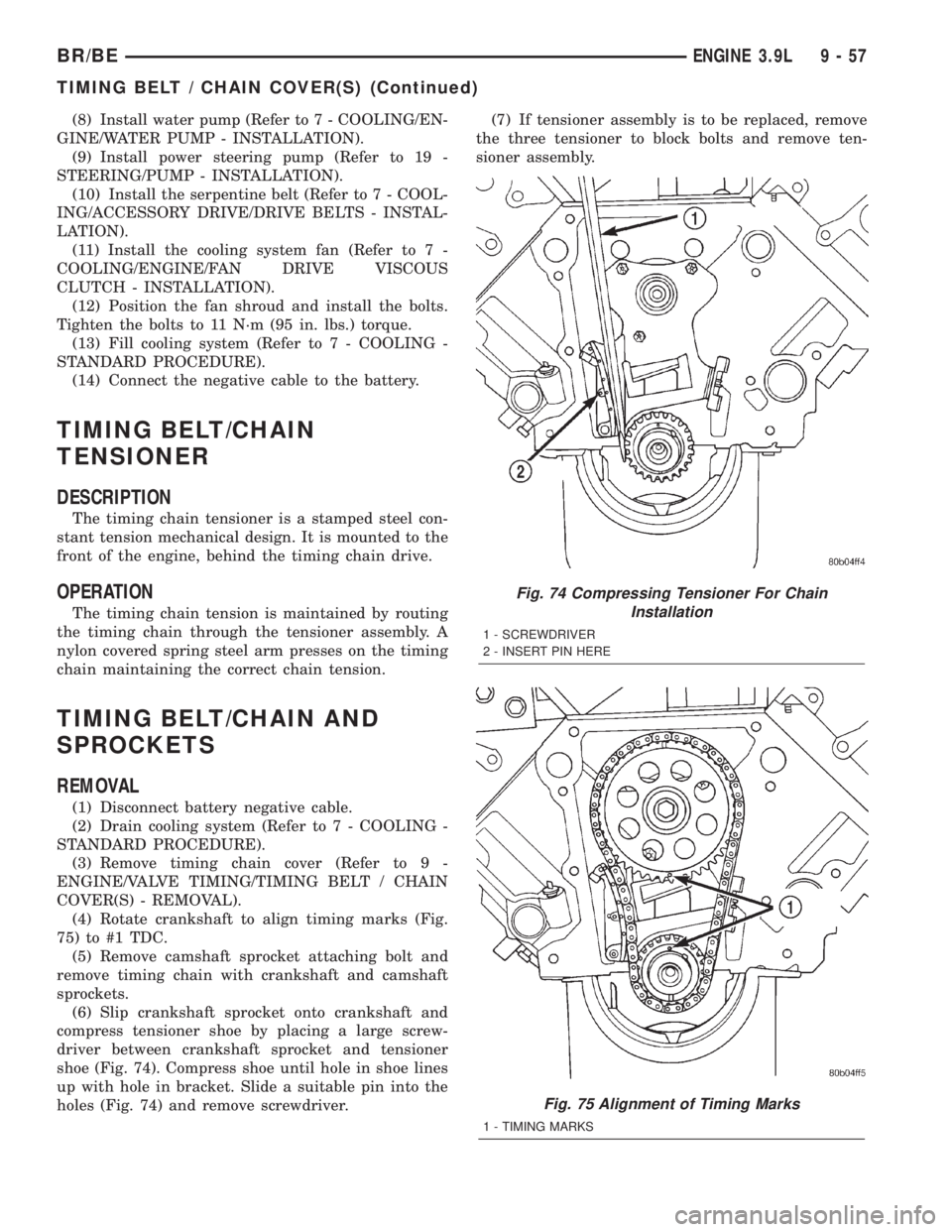

(6) Slip crankshaft sprocket onto crankshaft and

compress tensioner shoe by placing a large screw-

driver between crankshaft sprocket and tensioner

shoe (Fig. 74). Compress shoe until hole in shoe lines

up with hole in bracket. Slide a suitable pin into the

holes (Fig. 74) and remove screwdriver.(7) If tensioner assembly is to be replaced, remove

the three tensioner to block bolts and remove ten-

sioner assembly.

Fig. 74 Compressing Tensioner For Chain

Installation

1 - SCREWDRIVER

2 - INSERT PIN HERE

Fig. 75 Alignment of Timing Marks

1 - TIMING MARKS

BR/BEENGINE 3.9L 9 - 57

TIMING BELT / CHAIN COVER(S) (Continued)

Page 1217 of 2889

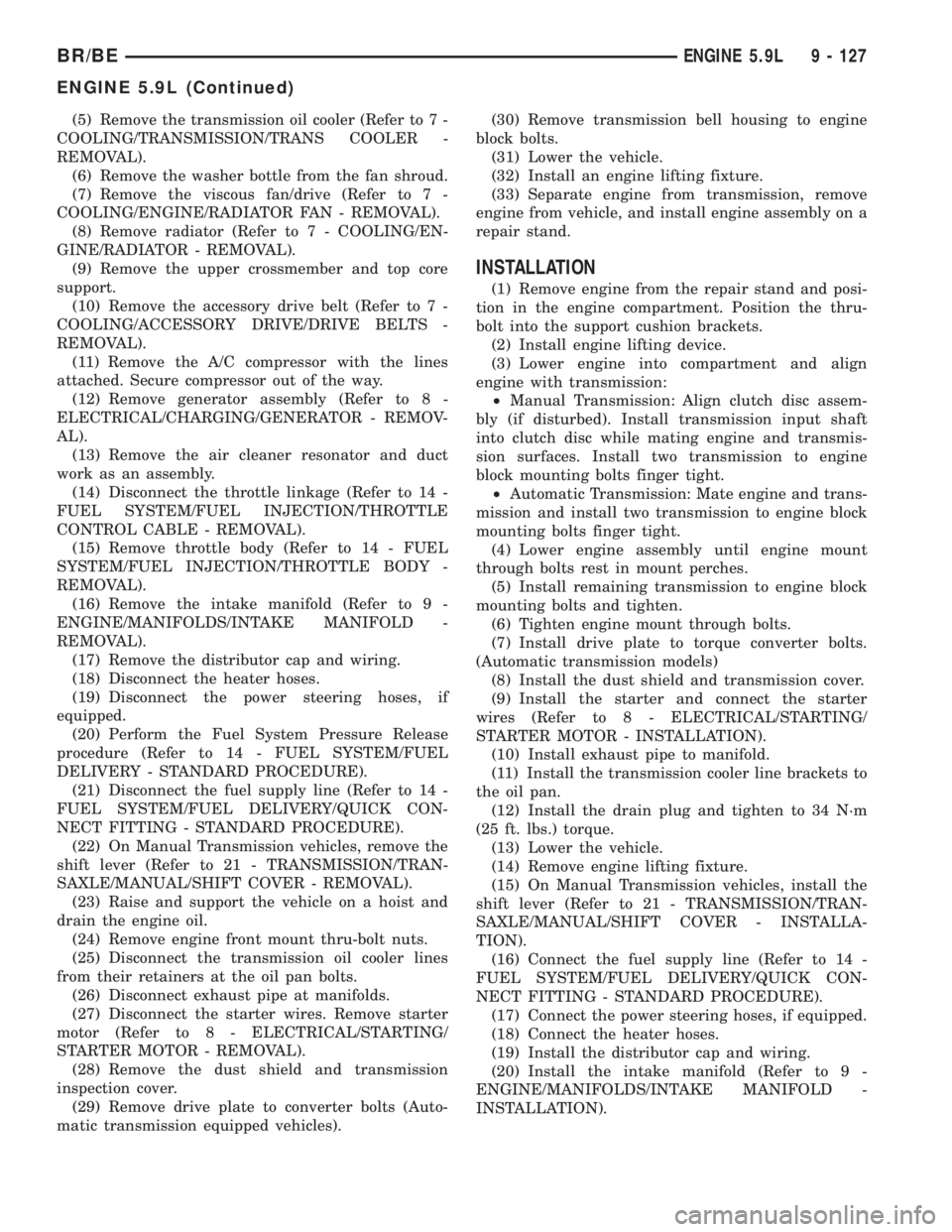

(5) Remove the transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

REMOVAL).

(6) Remove the washer bottle from the fan shroud.

(7) Remove the viscous fan/drive (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(8) Remove radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(9) Remove the upper crossmember and top core

support.

(10) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(11) Remove the A/C compressor with the lines

attached. Secure compressor out of the way.

(12) Remove generator assembly (Refer to 8 -

ELECTRICAL/CHARGING/GENERATOR - REMOV-

AL).

(13) Remove the air cleaner resonator and duct

work as an assembly.

(14) Disconnect the throttle linkage (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/THROTTLE

CONTROL CABLE - REMOVAL).

(15) Remove throttle body (Refer to 14 - FUEL

SYSTEM/FUEL INJECTION/THROTTLE BODY -

REMOVAL).

(16) Remove the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(17) Remove the distributor cap and wiring.

(18) Disconnect the heater hoses.

(19) Disconnect the power steering hoses, if

equipped.

(20) Perform the Fuel System Pressure Release

procedure (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY - STANDARD PROCEDURE).

(21) Disconnect the fuel supply line (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/QUICK CON-

NECT FITTING - STANDARD PROCEDURE).

(22) On Manual Transmission vehicles, remove the

shift lever (Refer to 21 - TRANSMISSION/TRAN-

SAXLE/MANUAL/SHIFT COVER - REMOVAL).

(23) Raise and support the vehicle on a hoist and

drain the engine oil.

(24) Remove engine front mount thru-bolt nuts.

(25) Disconnect the transmission oil cooler lines

from their retainers at the oil pan bolts.

(26) Disconnect exhaust pipe at manifolds.

(27) Disconnect the starter wires. Remove starter

motor (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - REMOVAL).

(28) Remove the dust shield and transmission

inspection cover.

(29) Remove drive plate to converter bolts (Auto-

matic transmission equipped vehicles).(30) Remove transmission bell housing to engine

block bolts.

(31) Lower the vehicle.

(32) Install an engine lifting fixture.

(33) Separate engine from transmission, remove

engine from vehicle, and install engine assembly on a

repair stand.

INSTALLATION

(1) Remove engine from the repair stand and posi-

tion in the engine compartment. Position the thru-

bolt into the support cushion brackets.

(2) Install engine lifting device.

(3) Lower engine into compartment and align

engine with transmission:

²Manual Transmission: Align clutch disc assem-

bly (if disturbed). Install transmission input shaft

into clutch disc while mating engine and transmis-

sion surfaces. Install two transmission to engine

block mounting bolts finger tight.

²Automatic Transmission: Mate engine and trans-

mission and install two transmission to engine block

mounting bolts finger tight.

(4) Lower engine assembly until engine mount

through bolts rest in mount perches.

(5) Install remaining transmission to engine block

mounting bolts and tighten.

(6) Tighten engine mount through bolts.

(7) Install drive plate to torque converter bolts.

(Automatic transmission models)

(8) Install the dust shield and transmission cover.

(9) Install the starter and connect the starter

wires (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - INSTALLATION).

(10) Install exhaust pipe to manifold.

(11) Install the transmission cooler line brackets to

the oil pan.

(12) Install the drain plug and tighten to 34 N´m

(25 ft. lbs.) torque.

(13) Lower the vehicle.

(14) Remove engine lifting fixture.

(15) On Manual Transmission vehicles, install the

shift lever (Refer to 21 - TRANSMISSION/TRAN-

SAXLE/MANUAL/SHIFT COVER - INSTALLA-

TION).

(16) Connect the fuel supply line (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/QUICK CON-

NECT FITTING - STANDARD PROCEDURE).

(17) Connect the power steering hoses, if equipped.

(18) Connect the heater hoses.

(19) Install the distributor cap and wiring.

(20) Install the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

9 - 70 ENGINE 5.2LBR/BE

ENGINE 5.2L (Continued)

Page 1260 of 2889

Inspect mating surfaces of manifold for flatness

with a straight edge. Gasket surfaces must be flat

within 0.2 mm per 300 mm (0.008 inch per foot).

INSTALLATION

CAUTION: If the studs came out with the nuts when

removing the engine exhaust manifold, install new

studs. Apply sealer on the coarse thread ends.

Water leaks may develop at the studs if this precau-

tion is not taken.

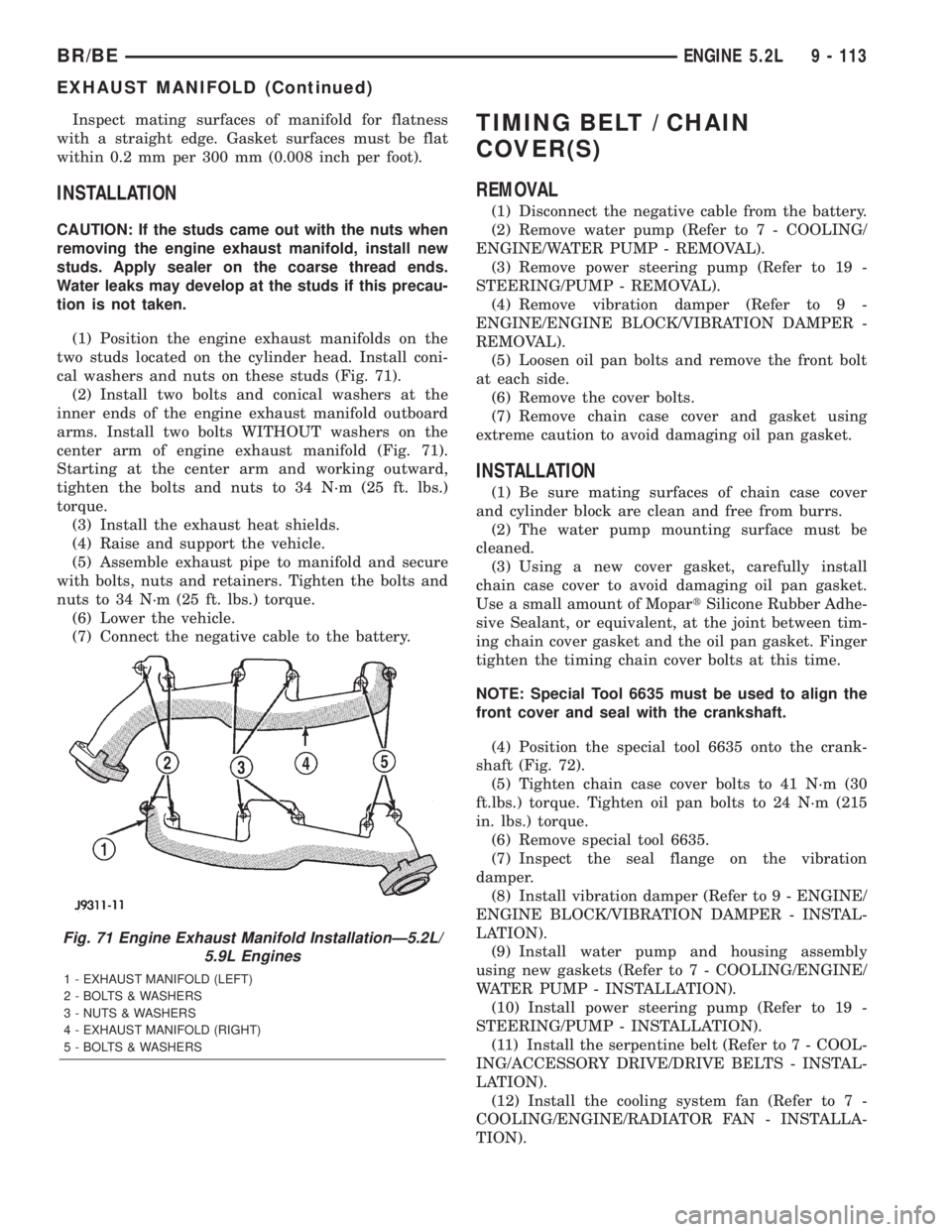

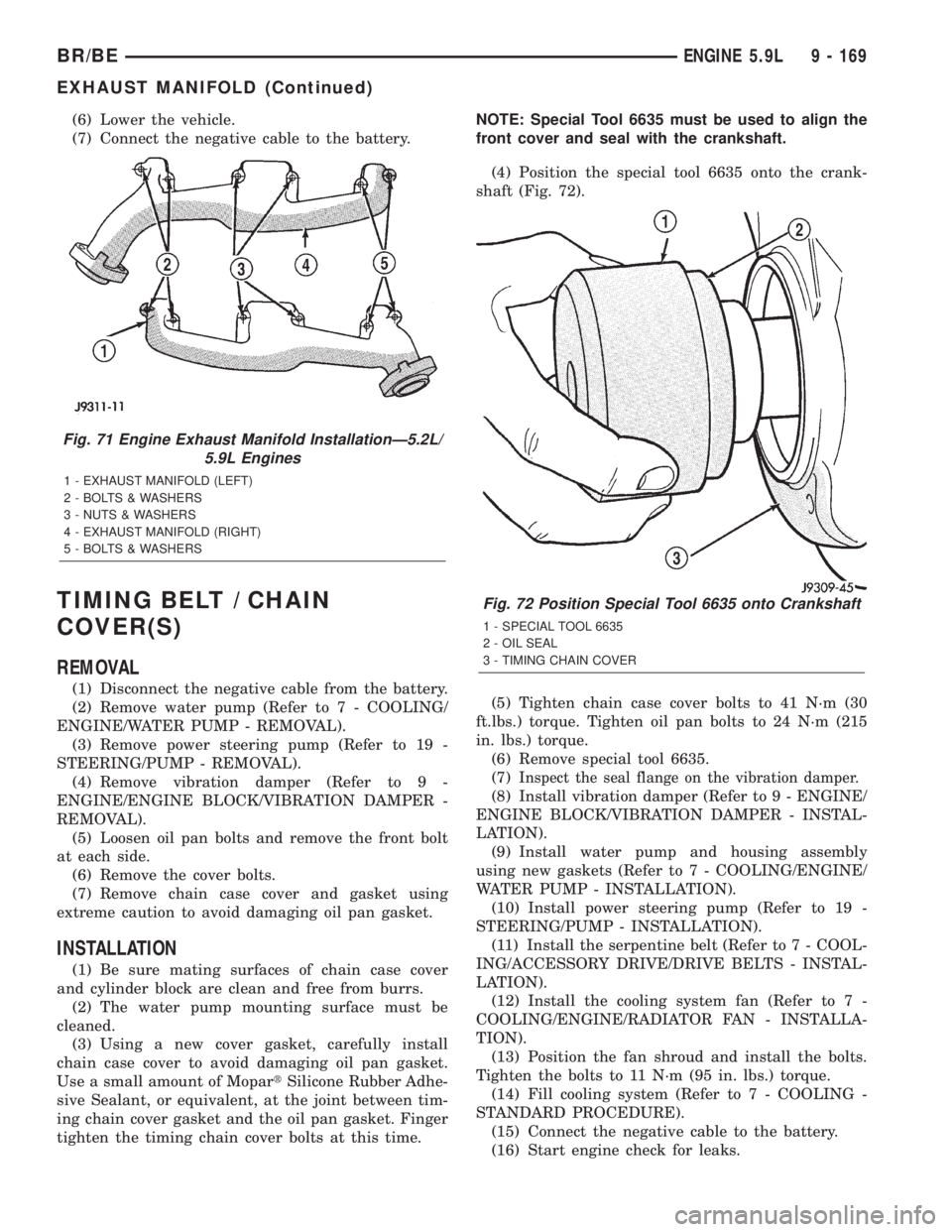

(1) Position the engine exhaust manifolds on the

two studs located on the cylinder head. Install coni-

cal washers and nuts on these studs (Fig. 71).

(2) Install two bolts and conical washers at the

inner ends of the engine exhaust manifold outboard

arms. Install two bolts WITHOUT washers on the

center arm of engine exhaust manifold (Fig. 71).

Starting at the center arm and working outward,

tighten the bolts and nuts to 34 N´m (25 ft. lbs.)

torque.

(3) Install the exhaust heat shields.

(4) Raise and support the vehicle.

(5) Assemble exhaust pipe to manifold and secure

with bolts, nuts and retainers. Tighten the bolts and

nuts to 34 N´m (25 ft. lbs.) torque.

(6) Lower the vehicle.

(7) Connect the negative cable to the battery.

TIMING BELT / CHAIN

COVER(S)

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Remove water pump (Refer to 7 - COOLING/

ENGINE/WATER PUMP - REMOVAL).

(3) Remove power steering pump (Refer to 19 -

STEERING/PUMP - REMOVAL).

(4) Remove vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(5) Loosen oil pan bolts and remove the front bolt

at each side.

(6) Remove the cover bolts.

(7) Remove chain case cover and gasket using

extreme caution to avoid damaging oil pan gasket.

INSTALLATION

(1) Be sure mating surfaces of chain case cover

and cylinder block are clean and free from burrs.

(2) The water pump mounting surface must be

cleaned.

(3) Using a new cover gasket, carefully install

chain case cover to avoid damaging oil pan gasket.

Use a small amount of MopartSilicone Rubber Adhe-

sive Sealant, or equivalent, at the joint between tim-

ing chain cover gasket and the oil pan gasket. Finger

tighten the timing chain cover bolts at this time.

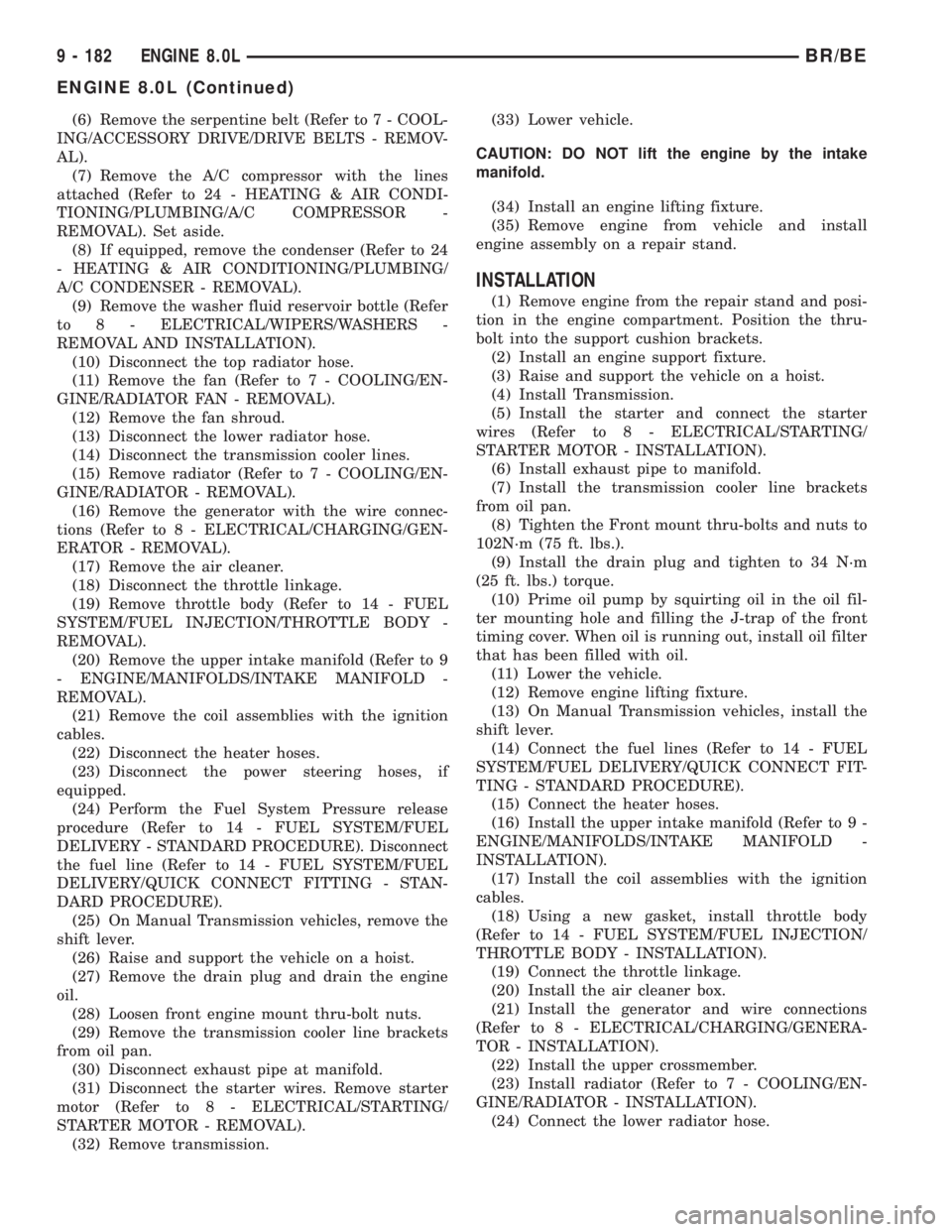

NOTE: Special Tool 6635 must be used to align the

front cover and seal with the crankshaft.

(4) Position the special tool 6635 onto the crank-

shaft (Fig. 72).

(5) Tighten chain case cover bolts to 41 N´m (30

ft.lbs.) torque. Tighten oil pan bolts to 24 N´m (215

in. lbs.) torque.

(6) Remove special tool 6635.

(7) Inspect the seal flange on the vibration

damper.

(8) Install vibration damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

(9) Install water pump and housing assembly

using new gaskets (Refer to 7 - COOLING/ENGINE/

WATER PUMP - INSTALLATION).

(10) Install power steering pump (Refer to 19 -

STEERING/PUMP - INSTALLATION).

(11) Install the serpentine belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(12) Install the cooling system fan (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - INSTALLA-

TION).

Fig. 71 Engine Exhaust Manifold InstallationÐ5.2L/

5.9L Engines

1 - EXHAUST MANIFOLD (LEFT)

2 - BOLTS & WASHERS

3 - NUTS & WASHERS

4 - EXHAUST MANIFOLD (RIGHT)

5 - BOLTS & WASHERS

BR/BEENGINE 5.2L 9 - 113

EXHAUST MANIFOLD (Continued)

Page 1274 of 2889

(5) Remove the transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

REMOVAL).

(6) Remove the washer bottle from the fan shroud.

(7) Remove the viscous fan/drive (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(8) Remove radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(9) Remove the upper crossmember and top core

support.

(10) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(11) Remove the A/C compressor with the lines

attached. Secure compressor out of the way.

(12) Remove generator assembly (Refer to 8 -

ELECTRICAL/CHARGING/GENERATOR - REMOV-

AL).

(13) Remove the air cleaner resonator and duct

work as an assembly.

(14) Disconnect the throttle linkage (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/THROTTLE

CONTROL CABLE - REMOVAL).

(15) Remove throttle body (Refer to 14 - FUEL

SYSTEM/FUEL INJECTION/THROTTLE BODY -

REMOVAL).

(16) Remove the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(17) Remove the distributor cap and wiring.

(18) Disconnect the heater hoses.

(19) Disconnect the power steering hoses, if

equipped.

(20) Perform the Fuel System Pressure Release

procedure (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY - STANDARD PROCEDURE).

(21) Disconnect the fuel supply line (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/QUICK CON-

NECT FITTING - STANDARD PROCEDURE).

(22) On Manual Transmission vehicles, remove the

shift lever (Refer to 21 - TRANSMISSION/TRAN-

SAXLE/MANUAL/SHIFT COVER - REMOVAL).

(23) Raise and support the vehicle on a hoist and

drain the engine oil.

(24) Remove engine front mount thru-bolt nuts.

(25) Disconnect the transmission oil cooler lines

from their retainers at the oil pan bolts.

(26) Disconnect exhaust pipe at manifolds.

(27) Disconnect the starter wires. Remove starter

motor (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - REMOVAL).

(28) Remove the dust shield and transmission

inspection cover.

(29) Remove drive plate to converter bolts (Auto-

matic transmission equipped vehicles).(30) Remove transmission bell housing to engine

block bolts.

(31) Lower the vehicle.

(32) Install an engine lifting fixture.

(33) Separate engine from transmission, remove

engine from vehicle, and install engine assembly on a

repair stand.

INSTALLATION

(1) Remove engine from the repair stand and posi-

tion in the engine compartment. Position the thru-

bolt into the support cushion brackets.

(2) Install engine lifting device.

(3) Lower engine into compartment and align

engine with transmission:

²Manual Transmission: Align clutch disc assem-

bly (if disturbed). Install transmission input shaft

into clutch disc while mating engine and transmis-

sion surfaces. Install two transmission to engine

block mounting bolts finger tight.

²Automatic Transmission: Mate engine and trans-

mission and install two transmission to engine block

mounting bolts finger tight.

(4) Lower engine assembly until engine mount

through bolts rest in mount perches.

(5) Install remaining transmission to engine block

mounting bolts and tighten.

(6) Tighten engine mount through bolts.

(7) Install drive plate to torque converter bolts.

(Automatic transmission models)

(8) Install the dust shield and transmission cover.

(9) Install the starter and connect the starter

wires (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - INSTALLATION).

(10) Install exhaust pipe to manifold.

(11) Install the transmission cooler line brackets to

the oil pan.

(12) Install the drain plug and tighten to 34 N´m

(25 ft. lbs.) torque.

(13) Lower the vehicle.

(14) Remove engine lifting fixture.

(15) On Manual Transmission vehicles, install the

shift lever (Refer to 21 - TRANSMISSION/TRAN-

SAXLE/MANUAL/SHIFT COVER - INSTALLA-

TION).

(16) Connect the fuel supply line (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/QUICK CON-

NECT FITTING - STANDARD PROCEDURE).

(17) Connect the power steering hoses, if equipped.

(18) Connect the heater hoses.

(19) Install the distributor cap and wiring.

(20) Install the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

BR/BEENGINE 5.9L 9 - 127

ENGINE 5.9L (Continued)

Page 1316 of 2889

(6) Lower the vehicle.

(7) Connect the negative cable to the battery.

TIMING BELT / CHAIN

COVER(S)

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Remove water pump (Refer to 7 - COOLING/

ENGINE/WATER PUMP - REMOVAL).

(3) Remove power steering pump (Refer to 19 -

STEERING/PUMP - REMOVAL).

(4) Remove vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(5) Loosen oil pan bolts and remove the front bolt

at each side.

(6) Remove the cover bolts.

(7) Remove chain case cover and gasket using

extreme caution to avoid damaging oil pan gasket.

INSTALLATION

(1) Be sure mating surfaces of chain case cover

and cylinder block are clean and free from burrs.

(2) The water pump mounting surface must be

cleaned.

(3) Using a new cover gasket, carefully install

chain case cover to avoid damaging oil pan gasket.

Use a small amount of MopartSilicone Rubber Adhe-

sive Sealant, or equivalent, at the joint between tim-

ing chain cover gasket and the oil pan gasket. Finger

tighten the timing chain cover bolts at this time.NOTE: Special Tool 6635 must be used to align the

front cover and seal with the crankshaft.

(4) Position the special tool 6635 onto the crank-

shaft (Fig. 72).

(5) Tighten chain case cover bolts to 41 N´m (30

ft.lbs.) torque. Tighten oil pan bolts to 24 N´m (215

in. lbs.) torque.

(6) Remove special tool 6635.

(7)

Inspect the seal flange on the vibration damper.

(8) Install vibration damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

(9) Install water pump and housing assembly

using new gaskets (Refer to 7 - COOLING/ENGINE/

WATER PUMP - INSTALLATION).

(10) Install power steering pump (Refer to 19 -

STEERING/PUMP - INSTALLATION).

(11) Install the serpentine belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(12) Install the cooling system fan (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - INSTALLA-

TION).

(13) Position the fan shroud and install the bolts.

Tighten the bolts to 11 N´m (95 in. lbs.) torque.

(14) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(15) Connect the negative cable to the battery.

(16) Start engine check for leaks.

Fig. 71 Engine Exhaust Manifold InstallationÐ5.2L/

5.9L Engines

1 - EXHAUST MANIFOLD (LEFT)

2 - BOLTS & WASHERS

3 - NUTS & WASHERS

4 - EXHAUST MANIFOLD (RIGHT)

5 - BOLTS & WASHERS

Fig. 72 Position Special Tool 6635 onto Crankshaft

1 - SPECIAL TOOL 6635

2 - OIL SEAL

3 - TIMING CHAIN COVER

BR/BEENGINE 5.9L 9 - 169

EXHAUST MANIFOLD (Continued)

Page 1329 of 2889

(6) Remove the serpentine belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - REMOV-

AL).

(7) Remove the A/C compressor with the lines

attached (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/A/C COMPRESSOR -

REMOVAL). Set aside.

(8) If equipped, remove the condenser (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING/

A/C CONDENSER - REMOVAL).

(9) Remove the washer fluid reservoir bottle (Refer

to 8 - ELECTRICAL/WIPERS/WASHERS -

REMOVAL AND INSTALLATION).

(10) Disconnect the top radiator hose.

(11) Remove the fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - REMOVAL).

(12) Remove the fan shroud.

(13) Disconnect the lower radiator hose.

(14) Disconnect the transmission cooler lines.

(15) Remove radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(16) Remove the generator with the wire connec-

tions (Refer to 8 - ELECTRICAL/CHARGING/GEN-

ERATOR - REMOVAL).

(17) Remove the air cleaner.

(18) Disconnect the throttle linkage.

(19) Remove throttle body (Refer to 14 - FUEL

SYSTEM/FUEL INJECTION/THROTTLE BODY -

REMOVAL).

(20) Remove the upper intake manifold (Refer to 9

- ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(21) Remove the coil assemblies with the ignition

cables.

(22) Disconnect the heater hoses.

(23) Disconnect the power steering hoses, if

equipped.

(24) Perform the Fuel System Pressure release

procedure (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY - STANDARD PROCEDURE). Disconnect

the fuel line (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/QUICK CONNECT FITTING - STAN-

DARD PROCEDURE).

(25) On Manual Transmission vehicles, remove the

shift lever.

(26) Raise and support the vehicle on a hoist.

(27) Remove the drain plug and drain the engine

oil.

(28) Loosen front engine mount thru-bolt nuts.

(29) Remove the transmission cooler line brackets

from oil pan.

(30) Disconnect exhaust pipe at manifold.

(31) Disconnect the starter wires. Remove starter

motor (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - REMOVAL).

(32) Remove transmission.(33) Lower vehicle.

CAUTION: DO NOT lift the engine by the intake

manifold.

(34) Install an engine lifting fixture.

(35) Remove engine from vehicle and install

engine assembly on a repair stand.

INSTALLATION

(1) Remove engine from the repair stand and posi-

tion in the engine compartment. Position the thru-

bolt into the support cushion brackets.

(2) Install an engine support fixture.

(3) Raise and support the vehicle on a hoist.

(4) Install Transmission.

(5) Install the starter and connect the starter

wires (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - INSTALLATION).

(6) Install exhaust pipe to manifold.

(7) Install the transmission cooler line brackets

from oil pan.

(8) Tighten the Front mount thru-bolts and nuts to

102N´m (75 ft. lbs.).

(9) Install the drain plug and tighten to 34 N´m

(25 ft. lbs.) torque.

(10) Prime oil pump by squirting oil in the oil fil-

ter mounting hole and filling the J-trap of the front

timing cover. When oil is running out, install oil filter

that has been filled with oil.

(11) Lower the vehicle.

(12) Remove engine lifting fixture.

(13) On Manual Transmission vehicles, install the

shift lever.

(14) Connect the fuel lines (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE).

(15) Connect the heater hoses.

(16) Install the upper intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

(17) Install the coil assemblies with the ignition

cables.

(18) Using a new gasket, install throttle body

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE BODY - INSTALLATION).

(19) Connect the throttle linkage.

(20) Install the air cleaner box.

(21) Install the generator and wire connections

(Refer to 8 - ELECTRICAL/CHARGING/GENERA-

TOR - INSTALLATION).

(22) Install the upper crossmember.

(23) Install radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - INSTALLATION).

(24) Connect the lower radiator hose.

9 - 182 ENGINE 8.0LBR/BE

ENGINE 8.0L (Continued)

Page 1330 of 2889

(25) Install the transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

INSTALLATION).

(26) Connect the transmission cooler lines.

(27) Connect the power steering hoses, if equipped.

(28) Install the fan shroud.

(29) Install the fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - INSTALLATION).

(30) Connect the top radiator hose.

(31) Install the washer fluid reservoir bottle (Refer

to 8 - ELECTRICAL/WIPERS/WASHERS - INSTAL-

LATION).

(32) If equipped, install the condenser (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING/

A/C CONDENSER - INSTALLATION).

(33) Install the A/C compressor with the lines

attached (Refer to 24 - HEATING & AIR CONDI-TIONING/PLUMBING/A/C COMPRESSOR -

INSTALLATION).

(34) Install the serpentine belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(35) Evacuate (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE) and charge the air conditioning system, if

equipped (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE).

(36) Add coolant to the cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(37) Install the battery.

(38) Warm engine and adjust as required.

(39) Road test vehicle.

BR/BEENGINE 8.0L 9 - 183

ENGINE 8.0L (Continued)

Page 1386 of 2889

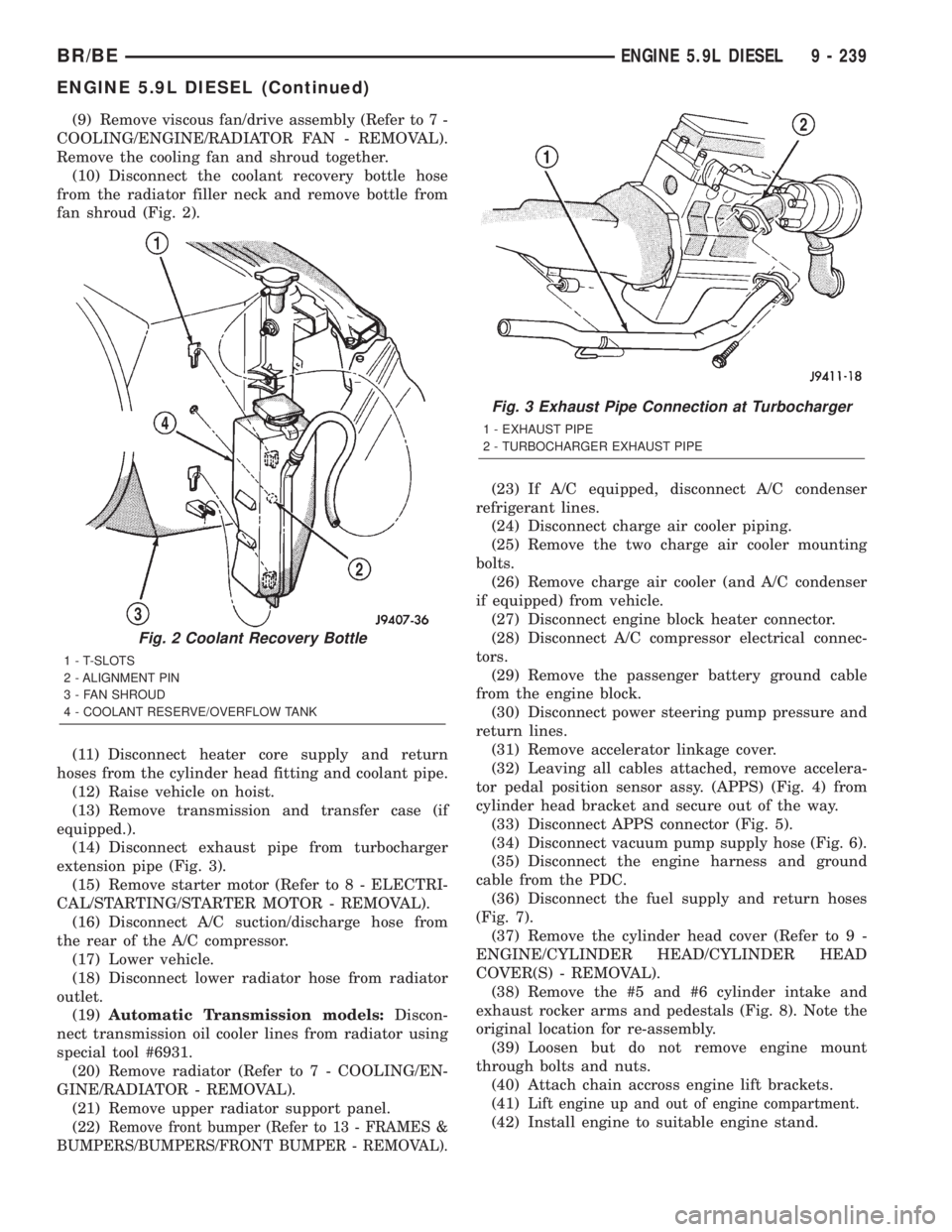

(9) Remove viscous fan/drive assembly (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - REMOVAL).

Remove the cooling fan and shroud together.

(10) Disconnect the coolant recovery bottle hose

from the radiator filler neck and remove bottle from

fan shroud (Fig. 2).

(11) Disconnect heater core supply and return

hoses from the cylinder head fitting and coolant pipe.

(12) Raise vehicle on hoist.

(13) Remove transmission and transfer case (if

equipped.).

(14) Disconnect exhaust pipe from turbocharger

extension pipe (Fig. 3).

(15) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL).

(16) Disconnect A/C suction/discharge hose from

the rear of the A/C compressor.

(17) Lower vehicle.

(18) Disconnect lower radiator hose from radiator

outlet.

(19)Automatic Transmission models:Discon-

nect transmission oil cooler lines from radiator using

special tool #6931.

(20) Remove radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(21) Remove upper radiator support panel.

(22)

Remove front bumper (Refer to 13 - FRAMES &

BUMPERS/BUMPERS/FRONT BUMPER - REMOVAL).

(23) If A/C equipped, disconnect A/C condenser

refrigerant lines.

(24) Disconnect charge air cooler piping.

(25) Remove the two charge air cooler mounting

bolts.

(26) Remove charge air cooler (and A/C condenser

if equipped) from vehicle.

(27) Disconnect engine block heater connector.

(28) Disconnect A/C compressor electrical connec-

tors.

(29) Remove the passenger battery ground cable

from the engine block.

(30) Disconnect power steering pump pressure and

return lines.

(31) Remove accelerator linkage cover.

(32) Leaving all cables attached, remove accelera-

tor pedal position sensor assy. (APPS) (Fig. 4) from

cylinder head bracket and secure out of the way.

(33) Disconnect APPS connector (Fig. 5).

(34) Disconnect vacuum pump supply hose (Fig. 6).

(35) Disconnect the engine harness and ground

cable from the PDC.

(36) Disconnect the fuel supply and return hoses

(Fig. 7).

(37) Remove the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

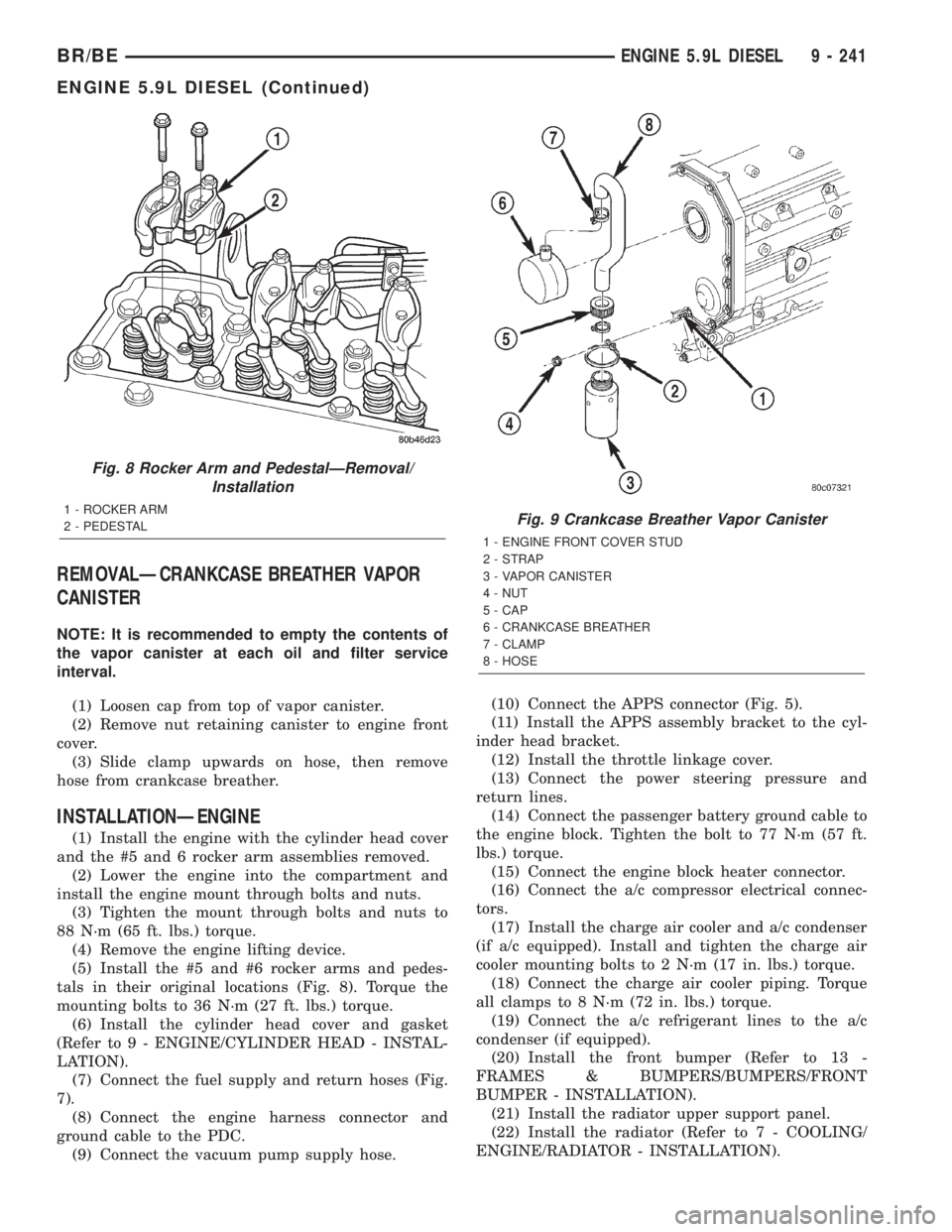

COVER(S) - REMOVAL).

(38) Remove the #5 and #6 cylinder intake and

exhaust rocker arms and pedestals (Fig. 8). Note the

original location for re-assembly.

(39) Loosen but do not remove engine mount

through bolts and nuts.

(40) Attach chain accross engine lift brackets.

(41)

Lift engine up and out of engine compartment.

(42) Install engine to suitable engine stand.

Fig. 2 Coolant Recovery Bottle

1 - T-SLOTS

2 - ALIGNMENT PIN

3 - FAN SHROUD

4 - COOLANT RESERVE/OVERFLOW TANK

Fig. 3 Exhaust Pipe Connection at Turbocharger

1 - EXHAUST PIPE

2 - TURBOCHARGER EXHAUST PIPE

BR/BEENGINE 5.9L DIESEL 9 - 239

ENGINE 5.9L DIESEL (Continued)

Page 1388 of 2889

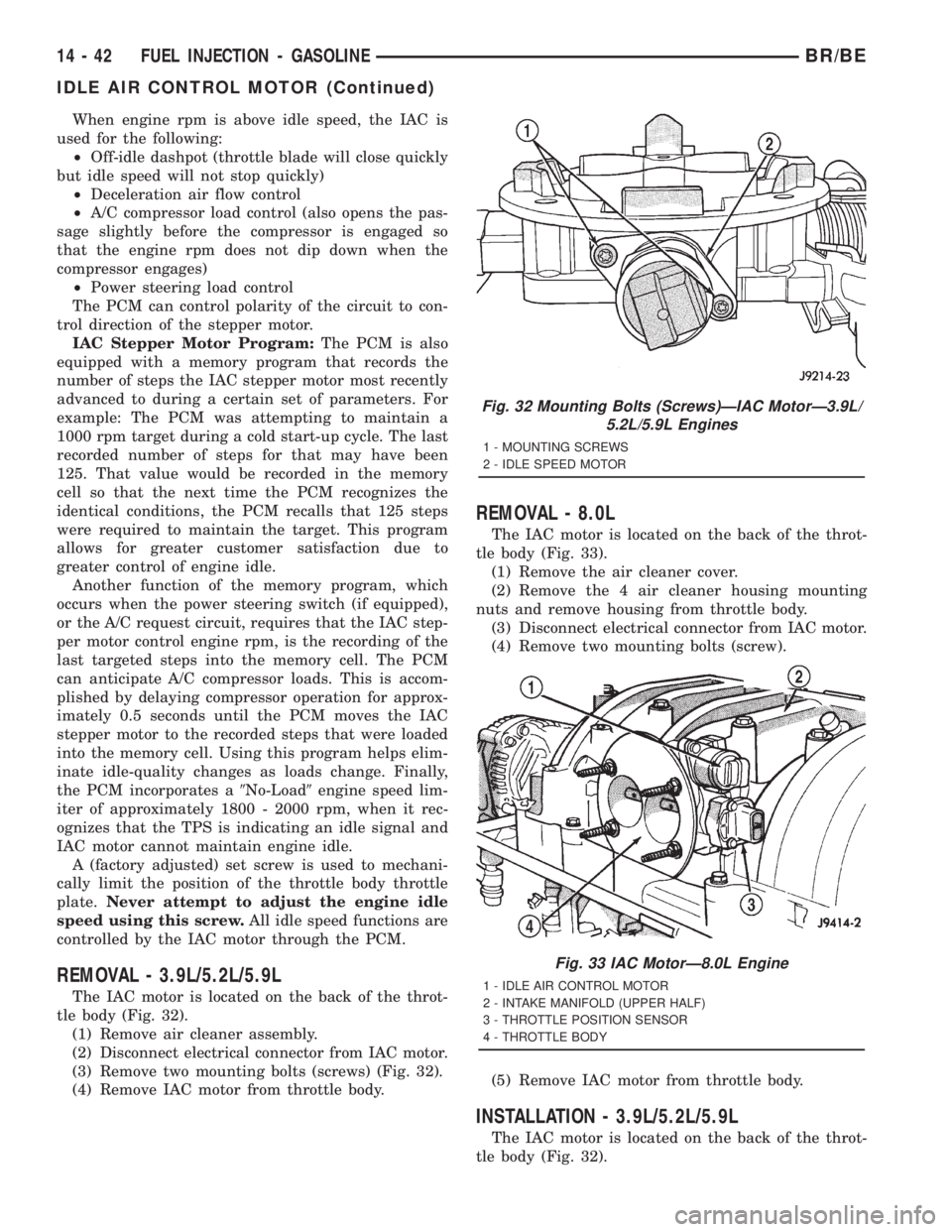

REMOVALÐCRANKCASE BREATHER VAPOR

CANISTER

NOTE: It is recommended to empty the contents of

the vapor canister at each oil and filter service

interval.

(1) Loosen cap from top of vapor canister.

(2) Remove nut retaining canister to engine front

cover.

(3) Slide clamp upwards on hose, then remove

hose from crankcase breather.

INSTALLATIONÐENGINE

(1) Install the engine with the cylinder head cover

and the #5 and 6 rocker arm assemblies removed.

(2) Lower the engine into the compartment and

install the engine mount through bolts and nuts.

(3) Tighten the mount through bolts and nuts to

88 N´m (65 ft. lbs.) torque.

(4) Remove the engine lifting device.

(5) Install the #5 and #6 rocker arms and pedes-

tals in their original locations (Fig. 8). Torque the

mounting bolts to 36 N´m (27 ft. lbs.) torque.

(6) Install the cylinder head cover and gasket

(Refer to 9 - ENGINE/CYLINDER HEAD - INSTAL-

LATION).

(7) Connect the fuel supply and return hoses (Fig.

7).

(8) Connect the engine harness connector and

ground cable to the PDC.

(9) Connect the vacuum pump supply hose.(10) Connect the APPS connector (Fig. 5).

(11) Install the APPS assembly bracket to the cyl-

inder head bracket.

(12) Install the throttle linkage cover.

(13) Connect the power steering pressure and

return lines.

(14) Connect the passenger battery ground cable to

the engine block. Tighten the bolt to 77 N´m (57 ft.

lbs.) torque.

(15) Connect the engine block heater connector.

(16) Connect the a/c compressor electrical connec-

tors.

(17) Install the charge air cooler and a/c condenser

(if a/c equipped). Install and tighten the charge air

cooler mounting bolts to 2 N´m (17 in. lbs.) torque.

(18) Connect the charge air cooler piping. Torque

all clamps to 8 N´m (72 in. lbs.) torque.

(19) Connect the a/c refrigerant lines to the a/c

condenser (if equipped).

(20) Install the front bumper (Refer to 13 -

FRAMES & BUMPERS/BUMPERS/FRONT

BUMPER - INSTALLATION).

(21) Install the radiator upper support panel.

(22) Install the radiator (Refer to 7 - COOLING/

ENGINE/RADIATOR - INSTALLATION).

Fig. 8 Rocker Arm and PedestalÐRemoval/

Installation

1 - ROCKER ARM

2 - PEDESTALFig. 9 Crankcase Breather Vapor Canister

1 - ENGINE FRONT COVER STUD

2 - STRAP

3 - VAPOR CANISTER

4 - NUT

5 - CAP

6 - CRANKCASE BREATHER

7 - CLAMP

8 - HOSE

BR/BEENGINE 5.9L DIESEL 9 - 241

ENGINE 5.9L DIESEL (Continued)

Page 1529 of 2889

When engine rpm is above idle speed, the IAC is

used for the following:

²Off-idle dashpot (throttle blade will close quickly

but idle speed will not stop quickly)

²Deceleration air flow control

²A/C compressor load control (also opens the pas-

sage slightly before the compressor is engaged so

that the engine rpm does not dip down when the

compressor engages)

²Power steering load control

The PCM can control polarity of the circuit to con-

trol direction of the stepper motor.

IAC Stepper Motor Program:The PCM is also

equipped with a memory program that records the

number of steps the IAC stepper motor most recently

advanced to during a certain set of parameters. For

example: The PCM was attempting to maintain a

1000 rpm target during a cold start-up cycle. The last

recorded number of steps for that may have been

125. That value would be recorded in the memory

cell so that the next time the PCM recognizes the

identical conditions, the PCM recalls that 125 steps

were required to maintain the target. This program

allows for greater customer satisfaction due to

greater control of engine idle.

Another function of the memory program, which

occurs when the power steering switch (if equipped),

or the A/C request circuit, requires that the IAC step-

per motor control engine rpm, is the recording of the

last targeted steps into the memory cell. The PCM

can anticipate A/C compressor loads. This is accom-

plished by delaying compressor operation for approx-

imately 0.5 seconds until the PCM moves the IAC

stepper motor to the recorded steps that were loaded

into the memory cell. Using this program helps elim-

inate idle-quality changes as loads change. Finally,

the PCM incorporates a9No-Load9engine speed lim-

iter of approximately 1800 - 2000 rpm, when it rec-

ognizes that the TPS is indicating an idle signal and

IAC motor cannot maintain engine idle.

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the IAC motor through the PCM.

REMOVAL - 3.9L/5.2L/5.9L

The IAC motor is located on the back of the throt-

tle body (Fig. 32).

(1) Remove air cleaner assembly.

(2) Disconnect electrical connector from IAC motor.

(3) Remove two mounting bolts (screws) (Fig. 32).

(4) Remove IAC motor from throttle body.

REMOVAL - 8.0L

The IAC motor is located on the back of the throt-

tle body (Fig. 33).

(1) Remove the air cleaner cover.

(2) Remove the 4 air cleaner housing mounting

nuts and remove housing from throttle body.

(3) Disconnect electrical connector from IAC motor.

(4) Remove two mounting bolts (screw).

(5) Remove IAC motor from throttle body.

INSTALLATION - 3.9L/5.2L/5.9L

The IAC motor is located on the back of the throt-

tle body (Fig. 32).

Fig. 32 Mounting Bolts (Screws)ÐIAC MotorÐ3.9L/

5.2L/5.9L Engines

1 - MOUNTING SCREWS

2 - IDLE SPEED MOTOR

Fig. 33 IAC MotorÐ8.0L Engine

1 - IDLE AIR CONTROL MOTOR

2 - INTAKE MANIFOLD (UPPER HALF)

3 - THROTTLE POSITION SENSOR

4 - THROTTLE BODY

14 - 42 FUEL INJECTION - GASOLINEBR/BE

IDLE AIR CONTROL MOTOR (Continued)