remote control DODGE RAM 2001 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 650 of 2889

POWER SYSTEMS

TABLE OF CONTENTS

page page

POWER LOCKS............................ 1

POWER MIRRORS........................ 10POWER SEAT SYSTEM..................... 15

POWER WINDOWS........................ 23

POWER LOCKS

TABLE OF CONTENTS

page page

POWER LOCKS

DESCRIPTION............................1

OPERATION.............................3

DIAGNOSIS AND TESTING..................4

POWER LOCK SYSTEM...................4

POWER LOCK & REMOTE KEYLESS

ENTRY SYSTEM.........................4

DOOR CYLINDER LOCK SWITCH

DESCRIPTION............................5

OPERATION.............................5

DIAGNOSIS AND TESTING..................5

DOOR CYLINDER LOCK SWITCH...........5

REMOVAL...............................6

INSTALLATION............................6

POWER LOCK MOTOR

DESCRIPTION............................6OPERATION.............................6

DIAGNOSIS AND TESTING..................7

POWER LOCK MOTOR...................7

REMOTE KEYLESS ENTRY TRANSMITTER

DESCRIPTION............................7

OPERATION.............................7

DIAGNOSIS AND TESTING..................7

REMOTE KEYLESS ENTRY TRANSMITTER....7

STANDARD PROCEDURE...................8

RKE TRANSMITTER PROGRAMMING........8

RKE TRANSMITTER BATTERIES............8

POWER LOCK SWITCH

DESCRIPTION............................8

OPERATION.............................8

DIAGNOSIS AND TESTING..................8

POWER LOCK SWITCH...................8

POWER LOCKS

DESCRIPTION - POWER LOCK SYSTEM

Two different power lock systems are offered as

optional factory-installed equipment on this model.

Both power lock systems are offered only on models

that are also equipped with power windows. On mod-

els without the optional Remote Keyless Entry (RKE)

system, a base version of the Central Timer Module

(CTM) is used. In this version of the power lock sys-

tem, the power lock switches provide the only control

over the operation of the power lock motors. On mod-

els with the optional RKE system, a high-line or pre-

mium version of the CTM is used to provide many

electronic features and conveniences that are not pos-

sible with the base version CTM. In this power lock

system, the power lock motors are controlled by the

microprocessor-based high-line or premium version ofthe CTM based upon the CTM programming and

electronic message inputs received from other elec-

tronic modules in the vehicle over the Chrysler Col-

lision Detection (CCD) data bus network, Radio

Frequency (RF) inputs received from the RKE trans-

mitters, as well as many hard wired inputs.

Both versions of the power lock system include the

following major components, which are described in

further detail elsewhere in this service manual:

²Power Lock Motors- A reversible electric

motor integral to the door latch of each front door

locks or unlocks the front door latch when provided

with the appropriate electrical inputs.

²Power Lock Switches- A power lock switch

integral to the power window/lock switch unit located

near the forward end of the arm rest on each front

door trim panel allows the power door lock system to

be operated by either the driver or the front seat pas-

senger.

BR/BEPOWER SYSTEMS 8N - 1

Page 652 of 2889

OPERATION - POWER LOCK SYSTEM

All versions of the power lock system allow both

doors to be locked or unlocked electrically by operat-

ing the power lock switch on either front door trim

panel. On vehicles that are also equipped with the

optional Remote Keyless Entry (RKE) system, both

doors may also be locked or unlocked using a key in

either front door lock cylinder, or by using the RKE

transmitter. On vehicles with the RKE system, if cer-

tain features have been electronically enabled, the

locks may also be operated automatically by the

high-line or premium Central Timer Module (CTM)

based upon various other inputs. Those features and

their inputs are:

²Automatic Door Lock- If enabled, the high-

line/premium CTM will automatically lock the doors

when it receives a message from the Powertrain Con-

trol Module (PCM) indicating that the vehicle speed

is about 24 kilometers-per-hour (15 miles-per-hour)

or greater. The CTM also monitors the door ajar

switches, and will not activate the automatic door

lock feature until both doors have been closed for at

least five seconds. If this feature is enabled and a

door is opened after the vehicle is moving, the CTM

will also lock the doors five seconds after both doors

are closed.

²Central Locking- Vehicles equipped with a

high-line/premium CTM also have a resistor-multi-

plexed door cylinder lock switch mounted to the back

of the door lock cylinder within each front door. The

CTM continually monitors the input from these

switches to provide the central locking/unlocking fea-

ture. The CTM will automatically lock or unlock both

front doors when either front door is locked or

unlocked using a key.

²Door Lock Inhibit- The high-line/premium

CTM receives inputs from the key-in ignition switch,

the headlamp switch, and the door ajar switches. The

logic within the CTM allows it to monitor these

inputs to provide a door lock inhibit feature. The

door lock inhibit feature prevents the power lock sys-

tem from being energized with a power lock switch

input if the driver door is open with the headlamps

on or the key still in the ignition switch. However,

the locks can still be operated with the manual door

lock button or with a key in the door lock cylinder,

and the power locks will still operate using the RKE

transmitter while the driver door is open with the

headlamps on or a key in the ignition.

²Enhanced Accident Response- If enabled,

the high-line/premium CTM provides an enhanced

accident response feature. This feature uses elec-

tronic message inputs received by the CTM from the

Airbag Control Module (ACM) to determine when an

airbag has been deployed. The CTM also monitors

the state of the power lock system and the vehiclespeed messages from the PCM in order to provide

this feature. If the airbag has been deployed and the

vehicle has stopped moving, the CTM will automati-

cally unlock the doors, prevent the doors from being

locked, and turn on the courtesy lamps inside the

vehicle. Of course, these responses are dependent

upon a functional battery and electrical circuitry fol-

lowing the impact.

All versions of the power lock system operate on

battery current received through a fused B(+) circuit

from a fuse in the Junction Block (JB) so that the

system remains functional, regardless of the ignition

switch position. Also, in both versions of the power

lock system, each power lock switch receives battery

current independent of the other. In vehicles with the

base version of the power lock system, the driver side

power lock switch receives ground through the body

wire harness. A single wire take out of the body wire

harness with an eyelet terminal connector is secured

by a ground screw to the lower left B-pillar (regular

cab, extended cab) or lower left quarter inner panel

(quad cab). The passenger side power lock switch

receives ground through the driver side power lock

switch in the base version of the power lock system.

The base version power lock switches direct the

appropriate battery current and ground feeds to the

power lock motors. In the power lock system for vehi-

cles with the RKE system, the power lock switches

direct a battery current Lock or Unlock request sig-

nal to the high-line or premium CTM, and the CTM

energizes internal relays to direct the appropriate

battery current and ground feeds to the power lock

motors.

OPERATION - REMOTE KEYLESS ENTRY

SYSTEM

On vehicles with the Remote Keyless Entry (RKE)

system, the power locks can be operated remotely

using the RKE transmitter. If the vehicle is so

equipped, the RKE transmitter also arms and dis-

arms the factory-installed Vehicle Theft Security Sys-

tem (VTSS). Three small, recessed buttons on the

outside of the transmitter case labelled Lock, Unlock,

and Panic allow the user to choose the function that

is desired. The RKE transmitter then sends the

appropriate Radio Frequency (RF) signal. An RF

receiver that is integral to the high-line or premium

version of the Central Timer Module (CTM) receives

the transmitted signal, then uses its internal elec-

tronic programming to determine whether the

received signal is valid and what function has been

requested. If the signal is valid, the CTM provides

the programmed features.

Besides operating the power lock system and arm-

ing or disarming the VTSS, the RKE system also

controls the following features:

BR/BEPOWER LOCKS 8N - 3

POWER LOCKS (Continued)

Page 653 of 2889

²Horn Chirp- If this feature is enabled, the

CTM provides a horn chirp by internally pulling the

control coil of the horn relay to ground through a

hard wired circuit output.

²Illuminated Entry- The CTM provides illumi-

nated entry by internally controlling the current flow

to the courtesy lamps in the vehicle through a hard

wired output circuit.

²Panic Mode- The CTM provides the horn pulse

and headlight flash by internally pulling the control

coils of the horn relay and headlamp relay to ground

through hard wired circuit outputs. The CTM con-

trols the current flow to the courtesy lamps in the

vehicle through a hard wired output circuit. The

CTM also monitors the vehicle speed through elec-

tronic messages it receives from the Powertrain Con-

trol Module (PCM) over the Chrysler Collision

Detection (CCD) data bus network.

The RKE system operates on battery current received

through a fused B(+) circuit from a fuse in the Junction

Block (JB) so that the system remains functional,

regardless of the ignition switch position. The RKE sys-

tem can retain the vehicle access codes of up to four

RKE transmitters. The transmitter codes are retained

in RKE system memory, even if the battery is discon-

nected. If a transmitter is faulty or is lost, new trans-

mitter vehicle access codes can be programmed into the

system using a DRBIIItscan tool. Refer to the appro-

priate diagnostic information. Many of the electronic

features in the vehicle controlled or supported by the

high-line or premium versions of the CTM are program-

mable using the DRBIIItscan tool. In addition, the

high-line/premium CTM software is Flash compatible,

which means it can be reprogrammed using Flash

reprogramming procedures. However, if any of the CTM

hardware components are damaged or faulty, the entire

CTM unit must be replaced. The hard wired inputs or

outputs of the CTM can be diagnosed using conven-

tional diagnostic tools and methods; however, for diag-

nosis of the high-line or premium versions of the CTM

or the CCD data bus, the use of a DRBIIItscan tool is

required. Refer to the appropriate diagnostic informa-

tion.

DIAGNOSIS AND TESTING - POWER LOCK

SYSTEM

The following tests provide a preliminary diagnosis

for the power lock system usedonlyon vehicles

equipped with a base version of the Central Timer

Module (CTM). These testsdo notapply to the diag-

nosis of the power lock system used on vehicles

equipped with the optional Remote Keyless Entry

(RKE) system, which includes a high-line or premium

CTM. (Refer to 8 - ELECTRICAL/POWER LOCKS -

DIAGNOSIS AND TESTING - POWER LOCK &

REMOTE KEYLESS ENTRY SYSTEM). Refer to theappropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

PRELIMINARY TESTS

To begin this test, note the system operation while

you actuate both the Lock and Unlock functions with

the power lock switches. Then, proceed as follows:

²If the entire power lock system fails to function

with both of the power lock switches, check the fused

B(+) fuse in the Junction Block (JB). If the fuse is

OK, check the ground circuit between the driver side

power lock switch and ground (G301). If the ground

circuit is OK, proceed to the diagnosis of the power

lock motors. (Refer to 8 - ELECTRICAL/POWER

LOCKS/POWER LOCK MOTOR - DIAGNOSIS AND

TESTING).

²If the entire power lock system fails to function

with only one of the power lock switches, proceed to

diagnosis of the power lock switches. (Refer to 8 -

ELECTRICAL/POWER LOCKS/POWER LOCK

SWITCH - DIAGNOSIS AND TESTING).

²If only one power lock motor fails to operate

with both power lock switches, proceed to diagnosis

of the power lock motor. (Refer to 8 - ELECTRICAL/

POWER LOCKS/POWER LOCK MOTOR - DIAGNO-

SIS AND TESTING).

DIAGNOSIS AND TESTING - POWER LOCK &

REMOTE KEYLESS ENTRY SYSTEM

The following tests include a preliminary diagnosis

for the power lock system usedonlyon vehicles

equipped with the optional Remote Keyless Entry

(RKE) system, which includes a high-line or premium

Central Timer Module (CTM). These testsdo not

apply to the diagnosis of the power lock system on

vehicles equipped with a base version of the CTM.

(Refer to 8 - ELECTRICAL/POWER LOCKS - DIAG-

NOSIS AND TESTING - POWER LOCK SYSTEM).

These tests will help to diagnose the hard wired

components and circuits of the power lock system.

However, these tests may not prove conclusive in the

diagnosis of this system. In order to obtain conclusive

testing of the power lock and RKE system, the

Chrysler Collision Detection (CCD) data bus network

and all of the electronic modules that provide inputs

to, or receive outputs from the power lock and RKE

system components must be checked.

The most reliable, efficient, and accurate means to

diagnose the power lock and RKE system requires the

use of a DRBIIItscan tool. The DRBIIItscan tool can

provide confirmation that the CCD data bus is func-

tional, that all of the electronic modules are sending

8N - 4 POWER LOCKSBR/BE

POWER LOCKS (Continued)

Page 656 of 2889

DIAGNOSIS AND TESTING - POWER LOCK

MOTOR

On models with a base version of the Central

Timer Module (CTM), confirm proper power lock

switch operation before you proceed with this diagno-

sis. On models with a high-line or premium version

of the CTM, confirm proper power lock switch, power

lock switch output circuit, and CTM operation before

you proceed with this diagnosis. Remember, the

power lock switch controls the output to the power

lock motors on models with a base CTM, while the

CTM controls the output to the power lock motors on

models with a high-line or premium CTM. Refer to

the appropriate wiring information. The wiring infor-

mation includes wiring diagrams, proper wire and

connector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

(1) Check each power lock motor for correct opera-

tion while moving the power lock switch to both the

Lock and Unlock positions. If both of the power lock

motors are inoperative, go to Step 2. If one power

lock motor is inoperative, go to Step 3.

(2) If both of the power lock motors are inopera-

tive, the problem may be caused by one shorted

motor. Disconnecting a shorted power lock motor

from the power lock circuit will allow the good power

lock motors to operate. Disconnect the wire harness

connector from each power lock motor, one at a time,

and recheck both the lock and unlock functions by

operating the power lock switch. If both power lock

motors are still inoperative after the above test,

check for a short or open circuit between the power

lock motors and either the power lock switch (base

CTM) or the CTM (high-line or premium CTM). If

disconnecting one power lock motor causes the other

motor to become functional, go to Step 3 to test the

disconnected motor.

(3) Once it is determined which power lock motor

is inoperative, that motor can be tested as follows.

Disconnect the door wire harness connector from the

inoperative power lock motor. Apply 12 volts to the

lock and unlock driver circuit cavities of the power

lock motor pigtail wire connector to check its opera-

tion in one direction. Reverse the polarity to check

the motor operation in the opposite direction. If OK,

repair the shorted or open circuits between the power

lock motor and the power lock switch (base CTM) or

the CTM (high-line or premium CTM) as required. If

not OK, replace the faulty power lock motor.

REMOTE KEYLESS ENTRY

TRANSMITTER

DESCRIPTION

The Remote Keyless Entry (RKE) system Radio

Frequency (RF) transmitter is equipped with three

buttons, labeled Lock, Unlock, and Panic. It is also

equipped with a key ring and is designed to serve as

a key fob. The operating range of the transmitter

radio signal is up to 7 meters (23 feet) from the RKE

receiver. The RKE receiver is integral to the high-

line or premium Central Timer Module (CTM) in this

vehicle.

Each RKE transmitter has a different vehicle

access code, which must be programmed into the

memory of the RKE receiver in the vehicle in order

to operate the RKE system. The RKE receiver can

retain the access codes for up to four transmitters in

its memory. (Refer to 8 - ELECTRICAL/POWER

LOCKS/REMOTE KEYLESS ENTRY TRANSMIT-

TER - STANDARD PROCEDURE - RKE TRANS-

MITTER PROGRAMMING).

The RKE transmitter operates on two Duracell

DL2016, Panasonic CR2016 (or equivalent) batteries.

Typical battery life is from one to two years. The

RKE transmitter cannot be repaired and, if faulty or

damaged, it must be replaced.

OPERATION

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the Remote Keyless Entry (RKE) transmitters.

DIAGNOSIS AND TESTING - REMOTE KEYLESS

ENTRY TRANSMITTER

(1) Replace the Remote Keyless Entry (RKE)

transmitter batteries. (Refer to 8 - ELECTRICAL/

POWER LOCKS/REMOTE KEYLESS ENTRY

TRANSMITTER - STANDARD PROCEDURE - RKE

TRANSMITTER BATTERIES). Test each of the RKE

transmitter functions. If OK, discard the faulty bat-

teries. If not OK, go to Step 2.

(2) Program the suspect RKE transmitter and

another known good transmitter into the RKE

receiver. (Refer to 8 - ELECTRICAL/POWER

LOCKS/REMOTE KEYLESS ENTRY TRANSMIT-

TER - STANDARD PROCEDURE - RKE TRANS-

MITTER PROGRAMMING).

(3) Test the RKE system operation with both

transmitters. If both transmitters fail to operate the

power lock system, a DRBIIItscan tool is required

for further diagnosis of the RKE system. Refer to the

appropriate diagnostic information. If the known

good RKE transmitter operates the power locks and

BR/BEPOWER LOCKS 8N - 7

POWER LOCK MOTOR (Continued)

Page 657 of 2889

the suspect transmitter does not, replace the faulty

RKE transmitter.

NOTE: Be certain to perform the RKE Transmitter

Programming procedure again following this test.

This procedure will erase the access code of the

test transmitter from the RKE receiver.

STANDARD PROCEDURE - RKE TRANSMITTER

PROGRAMMING

To program the Remote Keyless Entry (RKE)

transmitter access codes into the RKE receiver in the

high-line or premium Central Timer Module (CTM)

requires the use of a DRBIIItscan tool. Refer to the

appropriate diagnostic information.

STANDARD PROCEDURE - RKE TRANSMITTER

BATTERIES

The Remote Keyless Entry (RKE) transmitter case

snaps open and shut for battery access. To replace

the RKE transmitter batteries:

(1) Using a trim stick or a thin coin, gently pry at

the notch in the center seam of the RKE transmitter

case halves located near the key ring until the two

halves unsnap.

(2) Lift the back half of the transmitter case off of

the RKE transmitter.

(3) Remove the two batteries from the RKE trans-

mitter.

(4) Replace the two batteries with new Duracell

DL2016, or their equivalent. Be certain that the bat-

teries are installed with their polarity correctly ori-

ented.

(5) Align the two RKE transmitter case halves

with each other, and squeeze them firmly and evenly

together using hand pressure until they snap back

into place.

POWER LOCK SWITCH

DESCRIPTION

The power lock system can be controlled by a two-

way momentary switch integral to the power window

and lock switch and bezel unit on the trim panel of

each front door. Each power lock switch is illumi-

nated by a Light-Emitting Diode (LED) that is inte-

gral to the switch paddle. The LED of each switch is

illuminated whenever the ignition switch is in the

On position.

The power lock switches and their LEDs cannot be

adjusted or repaired and, if faulty or damaged, the

entire power window and lock switch and bezel unit

must be replaced.

OPERATION

On models with a base version of the Central

Timer Module (CTM), the power lock switches are

hard-wired to the power lock motors. The power lock

switch provides the correct battery and ground feeds

to the power lock motors to lock or unlock the door

latches.

On models with a high-line or premium version of

the CTM, the power lock switch controls battery cur-

rent signals to the lock and unlock sense inputs of

the CTM. The CTM then relays the correct battery

and ground feeds to the power lock motors to lock or

unlock the door latches.

DIAGNOSIS AND TESTING - POWER LOCK

SWITCH

The Light-Emitting Diode (LED) illumination

lamps for all of the power window and lock switch

and bezel unit switch paddles receive battery current

through the power window circuit breaker in the

Junction Block (JB). If all of the LEDs are inopera-

tive in either or both power window and lock switch

and bezel units, be certain to diagnose the power

window system before replacing the switch unit.

(Refer to 8 - ELECTRICAL/POWER WINDOWS -

DIAGNOSIS AND TESTING). If only one LED in a

power window and lock switch and bezel unit is inop-

erative, replace the faulty switch and bezel unit.

Refer to the appropriate wiring information. The wir-

ing information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

(1) Check the fused B(+) fuse (Fuse 13 - 10

ampere) in the Junction Block (JB). If OK, go to Step

2. If not OK, repair the shorted circuit or component

as required and replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

(Fuse 13 - 10 ampere) in the JB. If OK, go to Step 3.

If not OK, repair the open fused B(+) circuit between

the JB and the Power Distribution Center (PDC) as

required.

(3) Disconnect and isolate the battery negative

cable. Remove the power window and lock switch and

bezel unit from the door trim panel. Disconnect the

door wire harness connector for the power window

and lock switch unit from the switch connector recep-

tacle.

(4) Reconnect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

door wire harness connector for the power window

and lock switch unit. If OK, go to Step 5. If not OK,

repair the open fused B(+) circuit between the power

window and lock switch unit and the JB as required.

8N - 8 POWER LOCKSBR/BE

REMOTE KEYLESS ENTRY TRANSMITTER (Continued)

Page 685 of 2889

(1) Position the child tether anchor (standard cab)

or child tether (club/quad cab) onto the cab back

panel (Fig. 7).

(2) Install and tighten the screw that secures the

child tether anchor (standard cab) or child tether

(club/quad cab) onto the cab back panel. Tighten the

screw to 13.5 N´m (120 in. lbs.).

(3) Reinstall the trim onto the inside of the cab

back panel. (Refer to 23 - BODY/INTERIOR/REAR

CLOSURE PANEL TRIM - INSTALLATION).

CLOCKSPRING

DESCRIPTION

The clockspring assembly is secured with two inte-

gral plastic latches onto the steering column lock

housing near the top of the steering column, behind

the steering wheel. The clockspring consists of a flat,

round molded plastic case with a stubby tail that

hangs below the steering column and contains a con-

nector receptacle and a long pigtail wire with connec-

tor that face toward the instrument panel. Within

the plastic housing is a spool-like molded plastic

rotor with a large exposed hub. The upper surface of

the rotor hub has a large center hole, two large flats,

two auto-locking tabs, and three short pigtail wires

with connectors that face toward the steering wheel.

The lower surface of the rotor hub has two integral

turn signal cancelling cam lobes. Within the plastic

case and wound around the rotor spool is a long rib-

bon-like tape that consists of several thin copper wire

leads sandwiched between two thin plastic mem-

branes. The outer end of the tape terminates at the

connector receptacle and pigtail wire that face the

instrument panel, while the inner end of the tape

terminates at the pigtail wires on the hub of the

clockspring rotor that face the steering wheel.

Service replacement clocksprings are shipped pre-

centered and with a piece of tape covering the

engaged auto-locking tabs. The auto-locking tabs

secure the centered clockspring rotor to the clock-

spring case during shipment, but these tabs are auto-

matically disengaged once the clockspring is installed

on the steering column. (Refer to 8 - ELECTRICAL/

RESTRAINTS/CLOCKSPRING - STANDARD PRO-

CEDURE - CLOCKSPRING CENTERING).

The clockspring cannot be repaired. If the clock-

spring is faulty, damaged, or if the driver airbag has

been deployed, the clockspring must be replaced.

OPERATION

The clockspring is a mechanical electrical circuit

component that is used to provide continuous electri-

cal continuity between the fixed instrument panel

wire harness and the electrical components mountedon or in the rotating steering wheel. On this model

the rotating electrical components include the driver

airbag, the horn switch, the speed control switches,

and the remote radio switches if the vehicle is so

equipped. The clockspring case is positioned and

secured to the upper steering column lock housing by

two integral plastic latches. The connector receptacle

on the tail of the fixed clockspring housing connect

the clockspring to the vehicle electrical system

through a take out with connector from the instru-

ment panel wire harness. The lower clockspring pig-

tail on the tail of the clockspring housing connect the

clockspring driver airbag circuits to a separate take

out and connector of the instrument panel wire har-

ness located near the lower instrument panel rein-

forcement, below the steering column. The

clockspring rotor is movable and is keyed to the hub

of the steering wheel by two large flats that are

molded into the rotor hub. The two lobes on the

lower surface of the clockspring rotor hub contact a

turn signal cancel actuator of the multi-function

switch to provide automatic turn signal cancellation.

The pigtail wires on the upper surface of the clock-

spring connect the clockspring to the horn switch, the

two speed control switches, and the remote radio

switches on vehicles that are so equipped.

Like the clockspring in a timepiece, the clockspring

tape has travel limits and can be damaged by being

wound too tightly during full stop-to-stop steering

wheel rotation. To prevent this from occurring, the

clockspring must be centered when it is installed on

the steering column. Centering the clockspring

indexes the clockspring spool to the movable steering

components so that the tape can operate within its

designed travel limits. However, if the clockspring is

removed from the steering column or if the steering

shaft is disconnected from the steering gear, the

clockspring spool can change position relative to the

movable steering components and must be re-cen-

tered following completion of the service or the tape

may be damaged. Service replacement clocksprings

are shipped pre-centered and with the auto-locking

tabs engaged. A piece of tape covers the auto-locking

tabs to discourage tampering. These auto-locking

tabs should not be disengaged until the clockspring

has been installed on the steering column. If this

shipping tape is removed or damaged, or if the auto-

locking tabs are disengaged before the clockspring is

installed on a steering column, the clockspring cen-

tering procedure must be performed. (Refer to 8 -

ELECTRICAL/RESTRAINTS/CLOCKSPRING -

STANDARD PROCEDURE - CLOCKSPRING CEN-

TERING).

8O - 10 RESTRAINTSBR/BE

CHILD TETHER (Continued)

Page 686 of 2889

STANDARD PROCEDURE - CLOCKSPRING

CENTERING

The clockspring is designed to wind and unwind

when the steering wheel is rotated, but is only

designed to rotate the same number of turns (about

five complete rotations) as the steering wheel can be

turned from stop to stop. Centering the clockspring

indexes the clockspring tape to other steering compo-

nents so that it can operate within its designed

travel limits. The rotor of a centered clockspring can

be rotated two and one-half turns in either direction

from the centered position, without damaging the

clockspring tape.

However, if the clockspring is removed for service

or if the steering column is disconnected from the

steering gear, the clockspring tape can change posi-

tion relative to the other steering components. The

clockspring must then be re-centered following com-

pletion of such service or the clockspring tape may be

damaged. Service replacement clocksprings are

shipped pre-centered and with the auto-locking tabs

engaged (raised). These auto-locking tabs should not

be disengaged until the clockspring has been

installed on the steering column. If the auto-locking

tabs are disengaged before the clockspring is

installed on a steering column, the clockspring cen-

tering procedure must be performed.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

NOTE: Before starting this procedure, be certain to

turn the steering wheel until the front wheels are in

the straight-ahead position.

(1) Place the front wheels in the straight-ahead

position.

(2) Remove the clockspring from the steering col-

umn. (Refer to 8 - ELECTRICAL/RESTRAINTS/

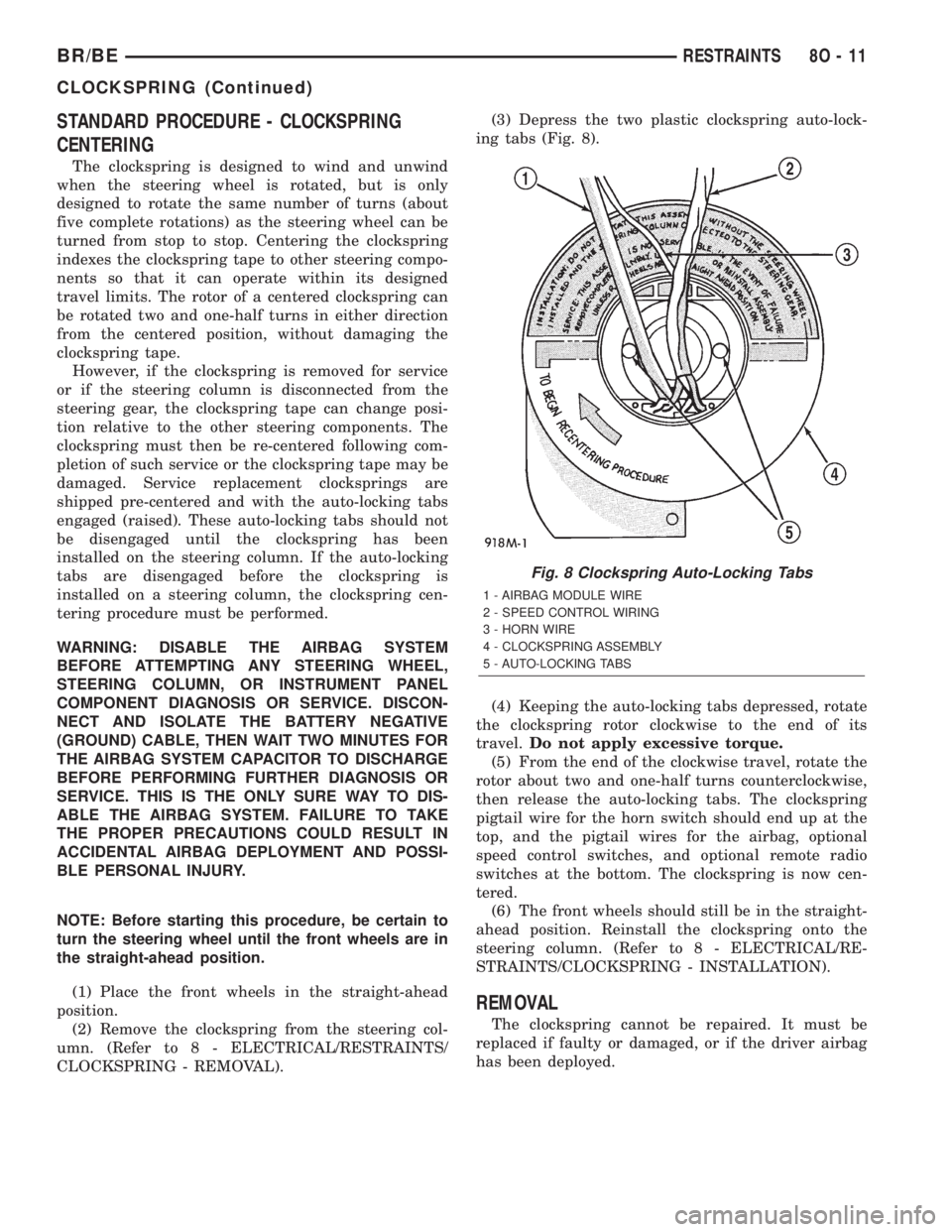

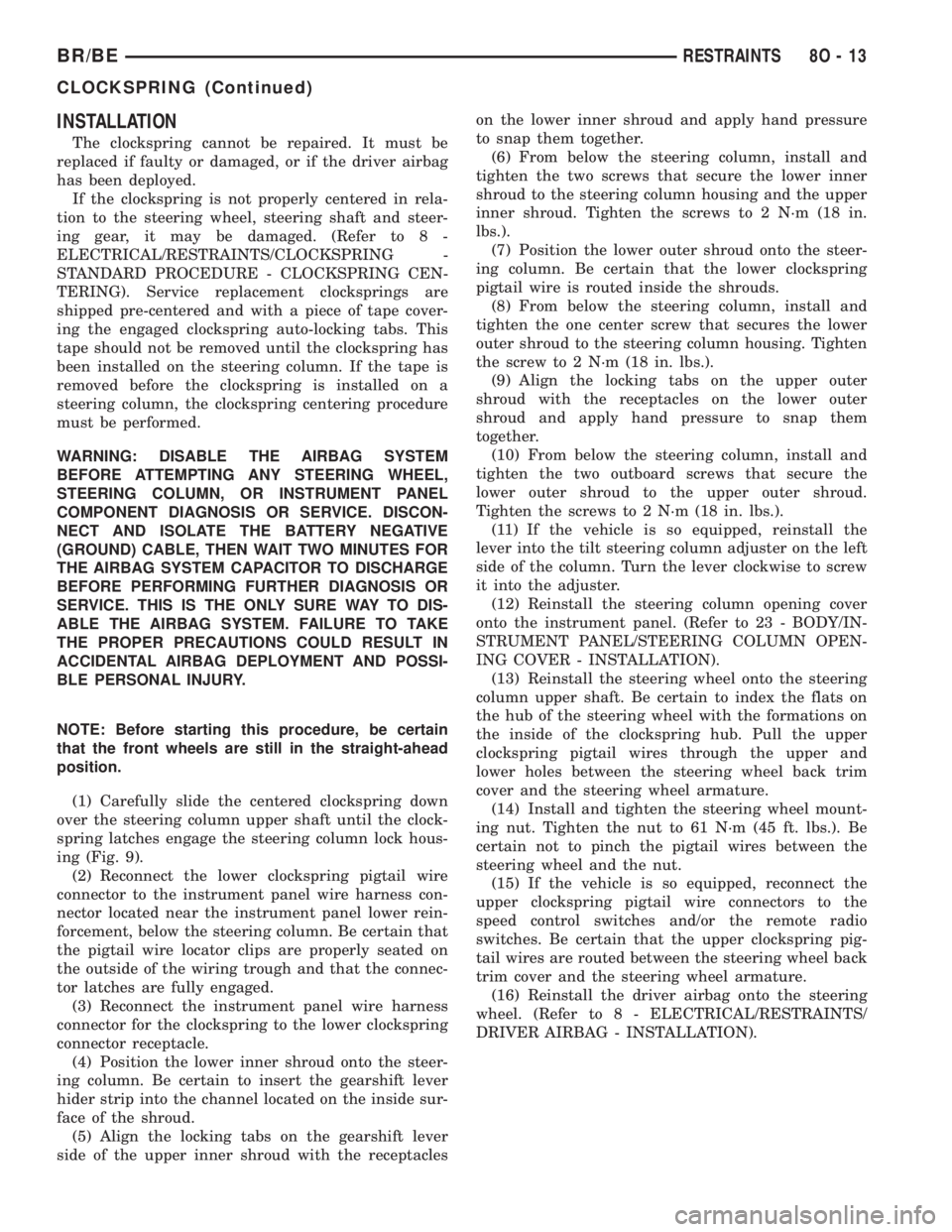

CLOCKSPRING - REMOVAL).(3) Depress the two plastic clockspring auto-lock-

ing tabs (Fig. 8).

(4) Keeping the auto-locking tabs depressed, rotate

the clockspring rotor clockwise to the end of its

travel.Do not apply excessive torque.

(5) From the end of the clockwise travel, rotate the

rotor about two and one-half turns counterclockwise,

then release the auto-locking tabs. The clockspring

pigtail wire for the horn switch should end up at the

top, and the pigtail wires for the airbag, optional

speed control switches, and optional remote radio

switches at the bottom. The clockspring is now cen-

tered.

(6) The front wheels should still be in the straight-

ahead position. Reinstall the clockspring onto the

steering column. (Refer to 8 - ELECTRICAL/RE-

STRAINTS/CLOCKSPRING - INSTALLATION).

REMOVAL

The clockspring cannot be repaired. It must be

replaced if faulty or damaged, or if the driver airbag

has been deployed.

Fig. 8 Clockspring Auto-Locking Tabs

1 - AIRBAG MODULE WIRE

2 - SPEED CONTROL WIRING

3 - HORN WIRE

4 - CLOCKSPRING ASSEMBLY

5 - AUTO-LOCKING TABS

BR/BERESTRAINTS 8O - 11

CLOCKSPRING (Continued)

Page 687 of 2889

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

NOTE: Before starting this procedure, be certain to

turn the steering wheel until the front wheels are in

the straight-ahead position.

(1) Place the front wheels in the straight-ahead

position.

(2) Remove the driver airbag from the steering

wheel. (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - REMOVAL).

(3) If the vehicle is so equipped, disconnect the

clockspring pigtail wire connectors from the speed

control switches and the remote radio switches

located within the hub cavity of the steering wheel.

(4) Remove the nut that secures the steering wheel

armature to the steering column upper shaft, which

is located within the hub cavity of the steering wheel.

(5) Pull the steering wheel off of the steering col-

umn upper shaft spline using a steering wheel puller

(Special Tool C-3428-B).

(6) Remove the steering column opening cover

from the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - REMOVAL).

(7) If the vehicle is so equipped, unscrew the lever

from the tilt steering column adjuster mechanism

located on the left side of the column just below the

multi-function switch control stalk. Turn the lever

counterclockwise to unscrew it from the adjuster.

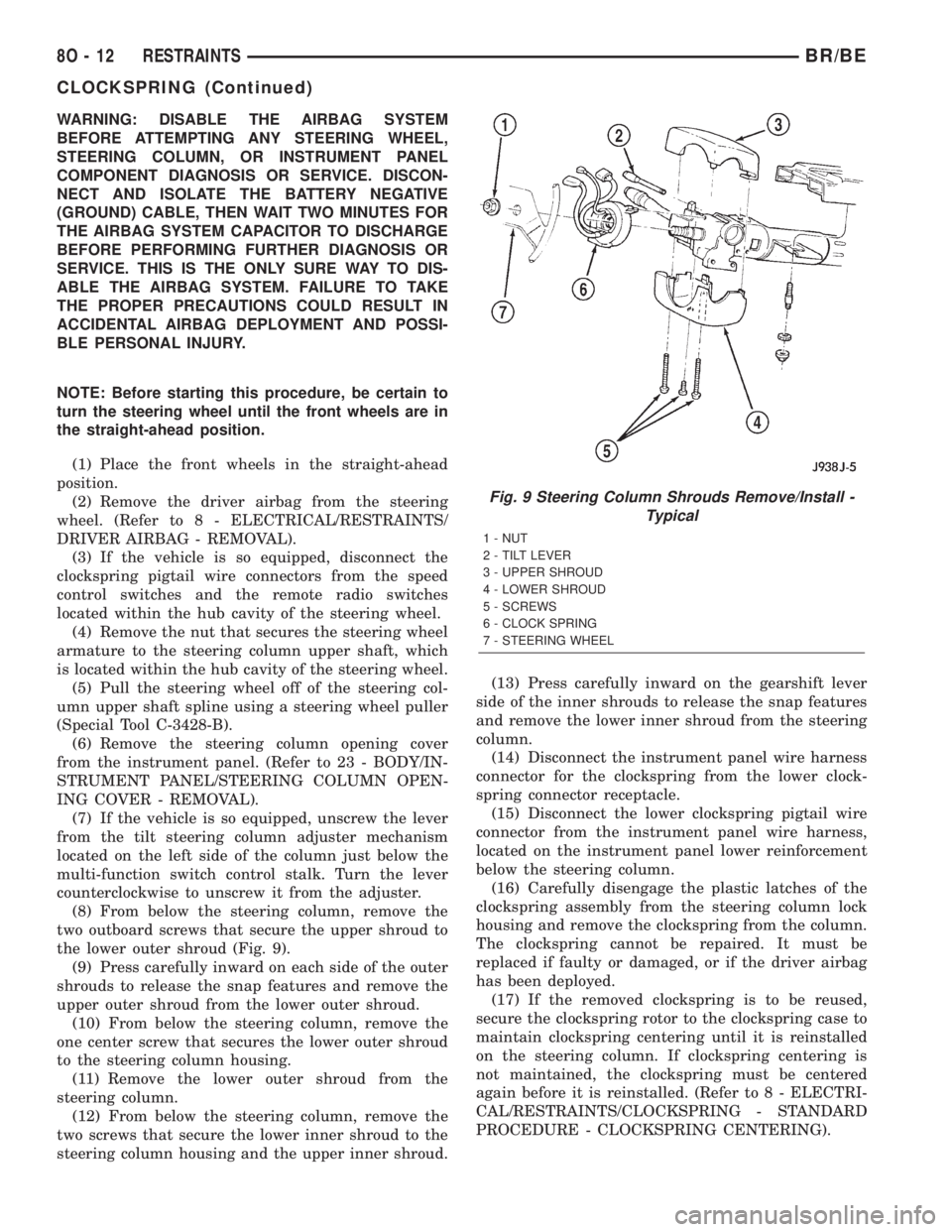

(8) From below the steering column, remove the

two outboard screws that secure the upper shroud to

the lower outer shroud (Fig. 9).

(9) Press carefully inward on each side of the outer

shrouds to release the snap features and remove the

upper outer shroud from the lower outer shroud.

(10) From below the steering column, remove the

one center screw that secures the lower outer shroud

to the steering column housing.

(11) Remove the lower outer shroud from the

steering column.

(12) From below the steering column, remove the

two screws that secure the lower inner shroud to the

steering column housing and the upper inner shroud.(13) Press carefully inward on the gearshift lever

side of the inner shrouds to release the snap features

and remove the lower inner shroud from the steering

column.

(14) Disconnect the instrument panel wire harness

connector for the clockspring from the lower clock-

spring connector receptacle.

(15) Disconnect the lower clockspring pigtail wire

connector from the instrument panel wire harness,

located on the instrument panel lower reinforcement

below the steering column.

(16) Carefully disengage the plastic latches of the

clockspring assembly from the steering column lock

housing and remove the clockspring from the column.

The clockspring cannot be repaired. It must be

replaced if faulty or damaged, or if the driver airbag

has been deployed.

(17) If the removed clockspring is to be reused,

secure the clockspring rotor to the clockspring case to

maintain clockspring centering until it is reinstalled

on the steering column. If clockspring centering is

not maintained, the clockspring must be centered

again before it is reinstalled. (Refer to 8 - ELECTRI-

CAL/RESTRAINTS/CLOCKSPRING - STANDARD

PROCEDURE - CLOCKSPRING CENTERING).

Fig. 9 Steering Column Shrouds Remove/Install -

Typical

1 - NUT

2 - TILT LEVER

3 - UPPER SHROUD

4 - LOWER SHROUD

5 - SCREWS

6 - CLOCK SPRING

7 - STEERING WHEEL

8O - 12 RESTRAINTSBR/BE

CLOCKSPRING (Continued)

Page 688 of 2889

INSTALLATION

The clockspring cannot be repaired. It must be

replaced if faulty or damaged, or if the driver airbag

has been deployed.

If the clockspring is not properly centered in rela-

tion to the steering wheel, steering shaft and steer-

ing gear, it may be damaged. (Refer to 8 -

ELECTRICAL/RESTRAINTS/CLOCKSPRING -

STANDARD PROCEDURE - CLOCKSPRING CEN-

TERING). Service replacement clocksprings are

shipped pre-centered and with a piece of tape cover-

ing the engaged clockspring auto-locking tabs. This

tape should not be removed until the clockspring has

been installed on the steering column. If the tape is

removed before the clockspring is installed on a

steering column, the clockspring centering procedure

must be performed.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

NOTE: Before starting this procedure, be certain

that the front wheels are still in the straight-ahead

position.

(1) Carefully slide the centered clockspring down

over the steering column upper shaft until the clock-

spring latches engage the steering column lock hous-

ing (Fig. 9).

(2) Reconnect the lower clockspring pigtail wire

connector to the instrument panel wire harness con-

nector located near the instrument panel lower rein-

forcement, below the steering column. Be certain that

the pigtail wire locator clips are properly seated on

the outside of the wiring trough and that the connec-

tor latches are fully engaged.

(3) Reconnect the instrument panel wire harness

connector for the clockspring to the lower clockspring

connector receptacle.

(4) Position the lower inner shroud onto the steer-

ing column. Be certain to insert the gearshift lever

hider strip into the channel located on the inside sur-

face of the shroud.

(5) Align the locking tabs on the gearshift lever

side of the upper inner shroud with the receptacleson the lower inner shroud and apply hand pressure

to snap them together.

(6) From below the steering column, install and

tighten the two screws that secure the lower inner

shroud to the steering column housing and the upper

inner shroud. Tighten the screws to 2 N´m (18 in.

lbs.).

(7) Position the lower outer shroud onto the steer-

ing column. Be certain that the lower clockspring

pigtail wire is routed inside the shrouds.

(8) From below the steering column, install and

tighten the one center screw that secures the lower

outer shroud to the steering column housing. Tighten

the screw to 2 N´m (18 in. lbs.).

(9) Align the locking tabs on the upper outer

shroud with the receptacles on the lower outer

shroud and apply hand pressure to snap them

together.

(10) From below the steering column, install and

tighten the two outboard screws that secure the

lower outer shroud to the upper outer shroud.

Tighten the screws to 2 N´m (18 in. lbs.).

(11) If the vehicle is so equipped, reinstall the

lever into the tilt steering column adjuster on the left

side of the column. Turn the lever clockwise to screw

it into the adjuster.

(12) Reinstall the steering column opening cover

onto the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - INSTALLATION).

(13) Reinstall the steering wheel onto the steering

column upper shaft. Be certain to index the flats on

the hub of the steering wheel with the formations on

the inside of the clockspring hub. Pull the upper

clockspring pigtail wires through the upper and

lower holes between the steering wheel back trim

cover and the steering wheel armature.

(14) Install and tighten the steering wheel mount-

ing nut. Tighten the nut to 61 N´m (45 ft. lbs.). Be

certain not to pinch the pigtail wires between the

steering wheel and the nut.

(15) If the vehicle is so equipped, reconnect the

upper clockspring pigtail wire connectors to the

speed control switches and/or the remote radio

switches. Be certain that the upper clockspring pig-

tail wires are routed between the steering wheel back

trim cover and the steering wheel armature.

(16) Reinstall the driver airbag onto the steering

wheel. (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - INSTALLATION).

BR/BERESTRAINTS 8O - 13

CLOCKSPRING (Continued)

Page 720 of 2889

VEHICLE THEFT SECURITY

TABLE OF CONTENTS

page page

VEHICLE THEFT SECURITY

DESCRIPTION............................1

OPERATION.............................2

DIAGNOSIS AND TESTING..................3

VEHICLE THEFT SECURITY SYSTEM........3VTSS INDICATOR

DESCRIPTION............................3

OPERATION.............................3

DIAGNOSIS AND TESTING..................3

VTSS INDICATOR.......................3

VEHICLE THEFT SECURITY

DESCRIPTION

The Vehicle Theft Security System (VTSS) is an

available factory-installed option on this model when

it is also equipped with the high-line or premium

Central Timer Module (CTM). The VTSS is designed

to provide perimeter protection against unauthorized

use or tampering by monitoring the vehicle doors and

the ignition system. If unauthorized vehicle use or

tampering is detected, the system responds by puls-

ing the horn, flashing the headlamps, and preventing

the engine from operating.

The VTSS includes the following major compo-

nents, which are described in further detail else-

where in this service manual:

²Central Timer Module- The high-line or pre-

mium Central Timer Module (CTM) is located under

the driver side end of the instrument panel, inboard

of the instrument panel steering column opening.

The high-line or premium CTM contains a micropro-

cessor and software that allow it to provide many

electronic functions and features not available with

base version of the CTM, including the VTSS. The

CTM provides all of the proper VTSS features and

outputs based upon the monitored inputs. The CTM

circuitry monitors hard wired switch inputs, as well

as message inputs received from other vehicle elec-

tronic modules over the Chrysler Collision Detection

(CCD) data bus network. (Refer to 8 - ELECTRICAL/

ELECTRONIC CONTROL MODULES/BODY CON-

TROL/CENTRAL TIMER MODULE -

DESCRIPTION).

²Door Ajar Switch- A door ajar switch is

located on the hinge pillar of each front door in the

vehicle. These switches provide an input to the VTSS

indicating whether the door is opened or closed.

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

INTERIOR/DOOR AJAR SWITCH - DESCRIPTION).

²Door Cylinder Lock Switch- A door cylinder

lock switch is located on the back of each front door

lock cylinder. This switch provides an input to theVTSS indicating whether the system should remain

armed or be disarmed. (Refer to 8 - ELECTRICAL/

POWER LOCKS/DOOR CYLINDER LOCK SWITCH

- DESCRIPTION).

²Horn Relay- The horn relay is located in the

Power Distribution Center (PDC) in the engine com-

partment near the battery. The horn relay is nor-

mally activated by the horn switch to control the

sounding of the vehicle horn or horns. However, it

can also be activated by an output of the Central

Timer Module (CTM) to provide an audible indication

that unauthorized vehicle use or tampering has been

detected. (Refer to 8 - ELECTRICAL/HORN/HORN

RELAY - DESCRIPTION).

²Headlamp Relay- The headlamp relay (also

known as the security relay) is located in the Power

Distribution Center (PDC) in the engine compart-

ment near the battery. The headlamp relay is nor-

mally activated by the Central Timer Module (CTM)

based upon inputs from the Remote Keyless Entry

(RKE) panic mode feature. However, it can also be

activated by an output of the CTM to flash the head-

lamp low beams to provide a highly visible indication

that unauthorized vehicle use or tampering has been

detected. (Refer to 8 - ELECTRICAL/LAMPS/LIGHT-

ING - EXTERIOR/HEADLAMP RELAY - DESCRIP-

TION).

²VTSS Indicator- A red Light Emitting Diode

(LED) located on the lower surface of the overhead

console near the windshield is illuminated by an out-

put of the Central Timer Module (CTM) to indicate

the status of the VTSS. This LED is integral to the

electronic circuit board for the Compass Mini-Trip

Computer (CMTC). (Refer to 8 - ELECTRICAL/

OVERHEAD CONSOLE/COMPASS/MINI-TRIP

COMPUTER - DESCRIPTION).

The engine no-run feature of the VTSS relies upon

communication between the high-line or premium

CTM and the Powertrain Control Module (PCM) over

the Chrysler Collision Detection (CCD) data bus net-

work.

Hard wired circuitry connects many of the VTSS

components to each other through the electrical sys-

BR/BEVEHICLE THEFT SECURITY 8Q - 1