steering DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 2831 of 2889

Check windshield washer solvent reservoir and fill

as necessary (Fig. 6).

NOTE: When using concentrated solvent such as

MoparTAll-Weather Windshield Washer Solution,

dilute per container directions.

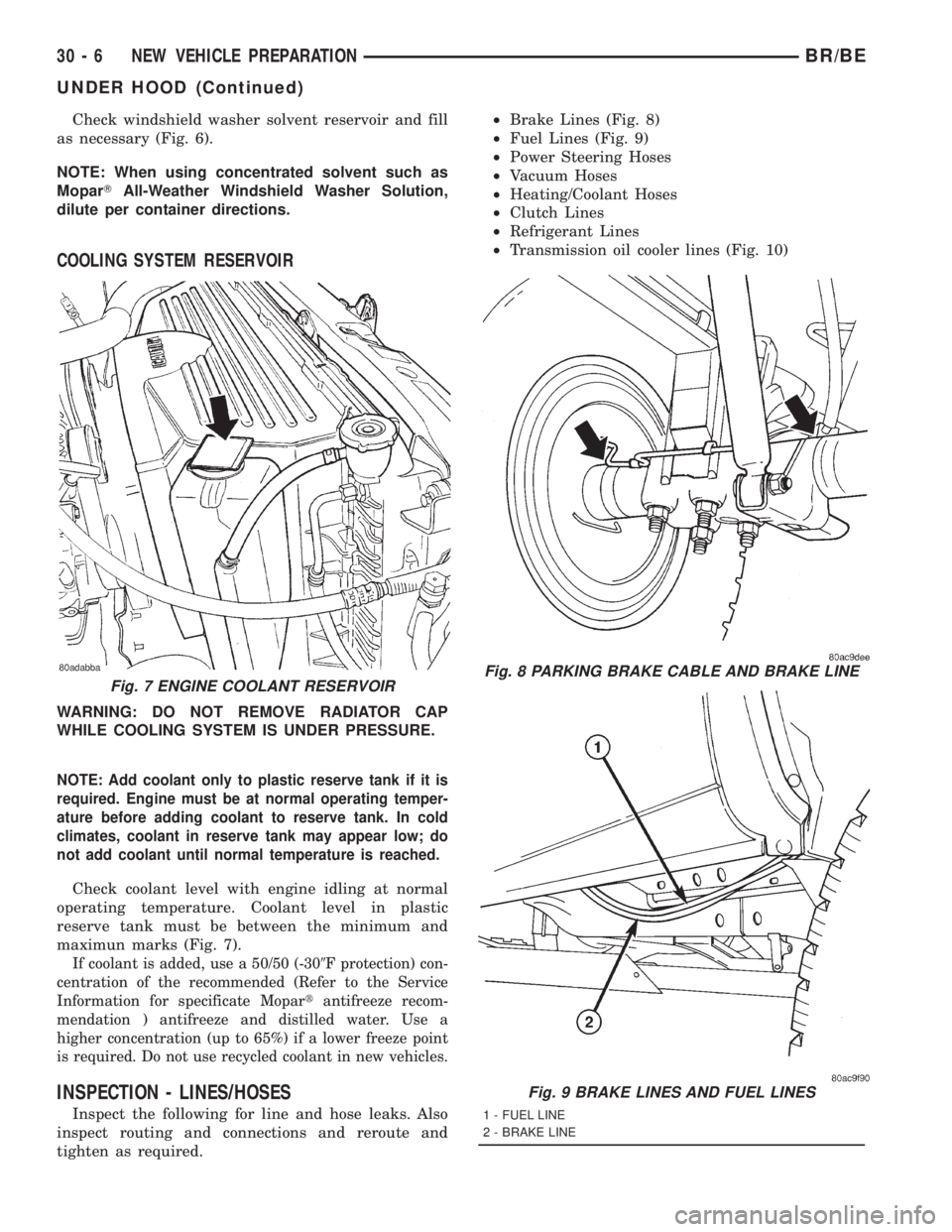

COOLING SYSTEM RESERVOIR

WARNING: DO NOT REMOVE RADIATOR CAP

WHILE COOLING SYSTEM IS UNDER PRESSURE.

NOTE: Add coolant only to plastic reserve tank if it is

required. Engine must be at normal operating temper-

ature before adding coolant to reserve tank. In cold

climates, coolant in reserve tank may appear low; do

not add coolant until normal temperature is reached.

Check coolant level with engine idling at normal

operating temperature. Coolant level in plastic

reserve tank must be between the minimum and

maximun marks (Fig. 7).

If coolant is added, use a 50/50 (-309F protection) con-

centration of the recommended (Refer to the Service

Information for specificate Mopartantifreeze recom-

mendation ) antifreeze and distilled water. Use a

higher concentration (up to 65%) if a lower freeze point

is required. Do not use recycled coolant in new vehicles.

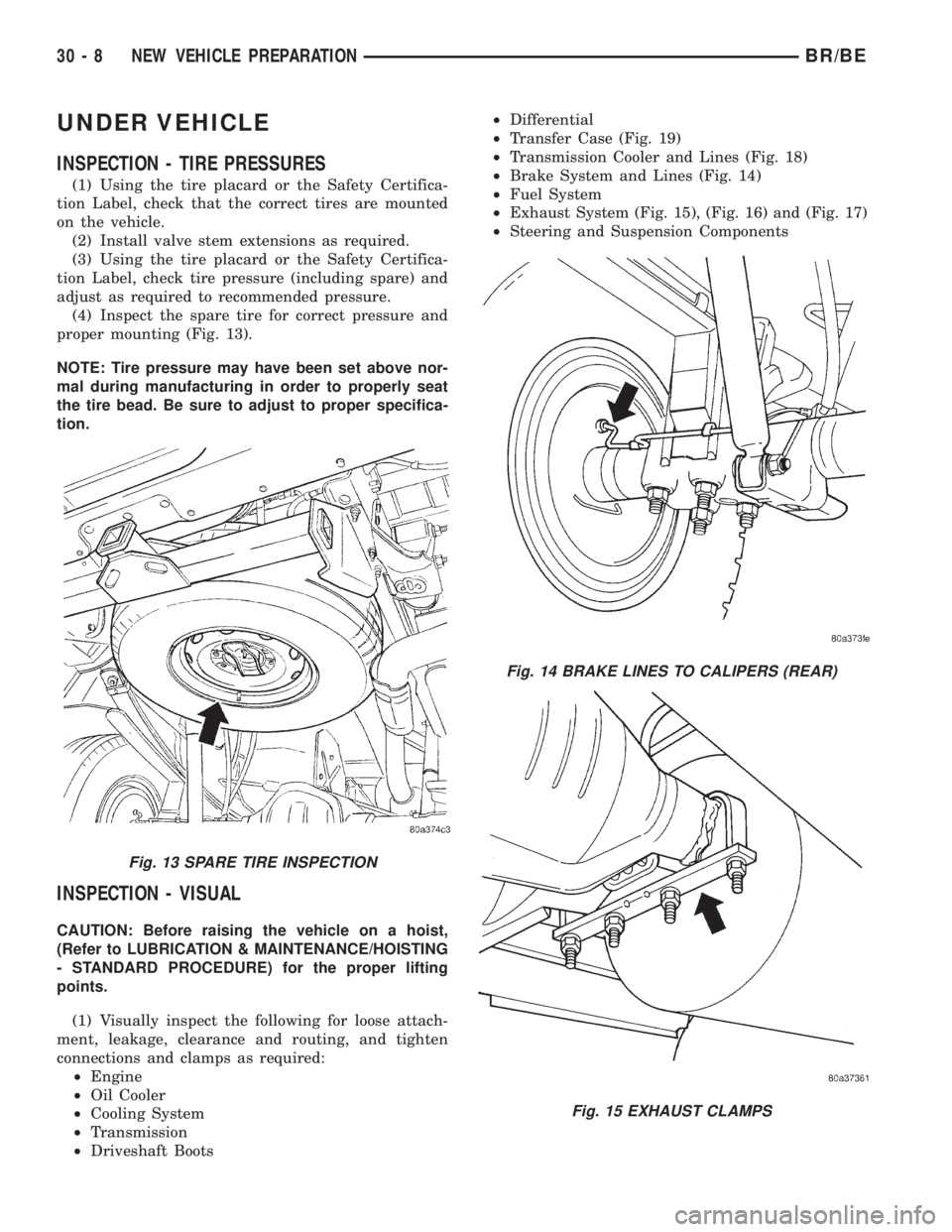

INSPECTION - LINES/HOSES

Inspect the following for line and hose leaks. Also

inspect routing and connections and reroute and

tighten as required.²Brake Lines (Fig. 8)

²Fuel Lines (Fig. 9)

²Power Steering Hoses

²Vacuum Hoses

²Heating/Coolant Hoses

²Clutch Lines

²Refrigerant Lines

²Transmission oil cooler lines (Fig. 10)

Fig. 7 ENGINE COOLANT RESERVOIRFig. 8 PARKING BRAKE CABLE AND BRAKE LINE

Fig. 9 BRAKE LINES AND FUEL LINES

1 - FUEL LINE

2 - BRAKE LINE

30 - 6 NEW VEHICLE PREPARATIONBR/BE

UNDER HOOD (Continued)

Page 2833 of 2889

UNDER VEHICLE

INSPECTION - TIRE PRESSURES

(1) Using the tire placard or the Safety Certifica-

tion Label, check that the correct tires are mounted

on the vehicle.

(2) Install valve stem extensions as required.

(3) Using the tire placard or the Safety Certifica-

tion Label, check tire pressure (including spare) and

adjust as required to recommended pressure.

(4) Inspect the spare tire for correct pressure and

proper mounting (Fig. 13).

NOTE: Tire pressure may have been set above nor-

mal during manufacturing in order to properly seat

the tire bead. Be sure to adjust to proper specifica-

tion.

INSPECTION - VISUAL

CAUTION: Before raising the vehicle on a hoist,

(Refer to LUBRICATION & MAINTENANCE/HOISTING

- STANDARD PROCEDURE) for the proper lifting

points.

(1) Visually inspect the following for loose attach-

ment, leakage, clearance and routing, and tighten

connections and clamps as required:

²Engine

²Oil Cooler

²Cooling System

²Transmission

²Driveshaft Boots²Differential

²Transfer Case (Fig. 19)

²Transmission Cooler and Lines (Fig. 18)

²Brake System and Lines (Fig. 14)

²Fuel System

²Exhaust System (Fig. 15), (Fig. 16) and (Fig. 17)

²Steering and Suspension Components

Fig. 13 SPARE TIRE INSPECTION

Fig. 14 BRAKE LINES TO CALIPERS (REAR)

Fig. 15 EXHAUST CLAMPS

30 - 8 NEW VEHICLE PREPARATIONBR/BE

Page 2840 of 2889

ROAD TEST

DESCRIPTION - ROAD TEST INSPECTION

The following items must be inspected during the

road test portion of the new vehicle inspection.

²Check neutral safety switch operation

²Check operation of shift/clutch interlock system

²Check operation of gauges and warning lights

²Check horn operation

²Check operation of turn signals and emergency

flashers

²Check all mirror adjustments, including day/

night function

²Check windshield wipers for proper wipe pattern

and intermittent mode (if equipped)

²Check washer spray pattern

²Check heater, defroster and air conditioning for

proper operation

²Check that the fan operates quietly

²Check the rear window defroster (if equipped)

²Leave air selection lever in the fresh air position

²Check the rear heater and air conditioning for

proper operation

²Check the rear air register locations

²Check that the indicator lamps operate properly

²Check the operation of the radio, cassette and/or

compact disc player, and that sound quality is good

²Ensure that the clock displays the correct time

²Check that the trip computer/maintenance

reminder operates in all modes

²Check all speed control functions

²Check the service brakes to ensure that they

stop the vehicle in a straight line, without noise,

shudder or vibration

²Check the brake warning light

²Check the parking brake operation

²Check the engine's performance

²Check the transmission's performance for

smooth, quiet operation. If the vehicle is a 4x4, check

that the transfer case shifts easily among all ranges

²Check Autostick function (if equipped)

²Check the vehicle's steering and handling

²The steering wheel should be centered when

traveling in a straight line

²The vehicle should not pull or vibrate

²Check for squeaks, rattles and wind noise

²Check any other vehicle aspects you believe are

important, but that may not be included on the New

Vehicle Preparation Form

²Fill fuel tank with specified grade of fuel

INSPECTION - FUEL

Fill fuel tank with specified grade of gasoline (reg-

ular, midgrade or premium).

INSPECTION - OTHER

As part of DaimlerChrysler's Customer One philos-

ophy, the ªOtherº blank is provided on the New Vehi-

cle Preparation Form. This is designed to encourage

you to check any aspects of vehicle operation that

you believe are important to your customers, but that

do not appear elsewhere on the form.

INSPECTION - SQUEAKS, RATTLES AND WIND

NOISE

(1) Make sure that the instrument panel, glove

box, seats, steering wheel and column are free from

squeaks and rattles. Tighten any obvious loose fas-

teners.

(2) Check that the windows and doors are free

from squeaks, rattles and wind noise.

(3) Check that the vehicle exterior is free from

squeaks, rattles and noise, front and rear.

(4) Make sure that all interior panels are free from

squeaks and rattles.

INSPECTION - STEERING AND HANDLING

(1) Check that the power assist works properly (if

equipped). Steering should not require excessive

effort.

(2) Make sure the steering wheel does not vibrate

at idle or road speed.

(3) Ensure that the steering wheel is centered

when traveling straight ahead.

(4) Check that the vehicle does not drift to one

side.

(5) Make sure that the vehicle does not vibrate/

shake.

INSPECTION - TRANSMISSION/TRANSFER

CASE

AUTOMATIC TRANSMISSION

(1) Make sure that the park lock holds the vehicle

With the vehicle on a grade, put automatic trans-

mission in PARK and slowly release the service

brake to see if park lock holds. If it does not hold, the

transmission requires further service.

(2) Make sure shift lever operates easily/ smoothly

(Fig. 36).

Check for smooth shifting. Check for proper

upshifting and downshifting.

MANUAL TRANSMISSION

(1) Check that the shifter operates easily (Fig. 38).

(2) Make sure that the clutch operates smoothly

(Fig. 37).

(3) Look for proper synchronization.

The gears should not grind.

BR/BENEW VEHICLE PREPARATION 30 - 15

Page 2842 of 2889

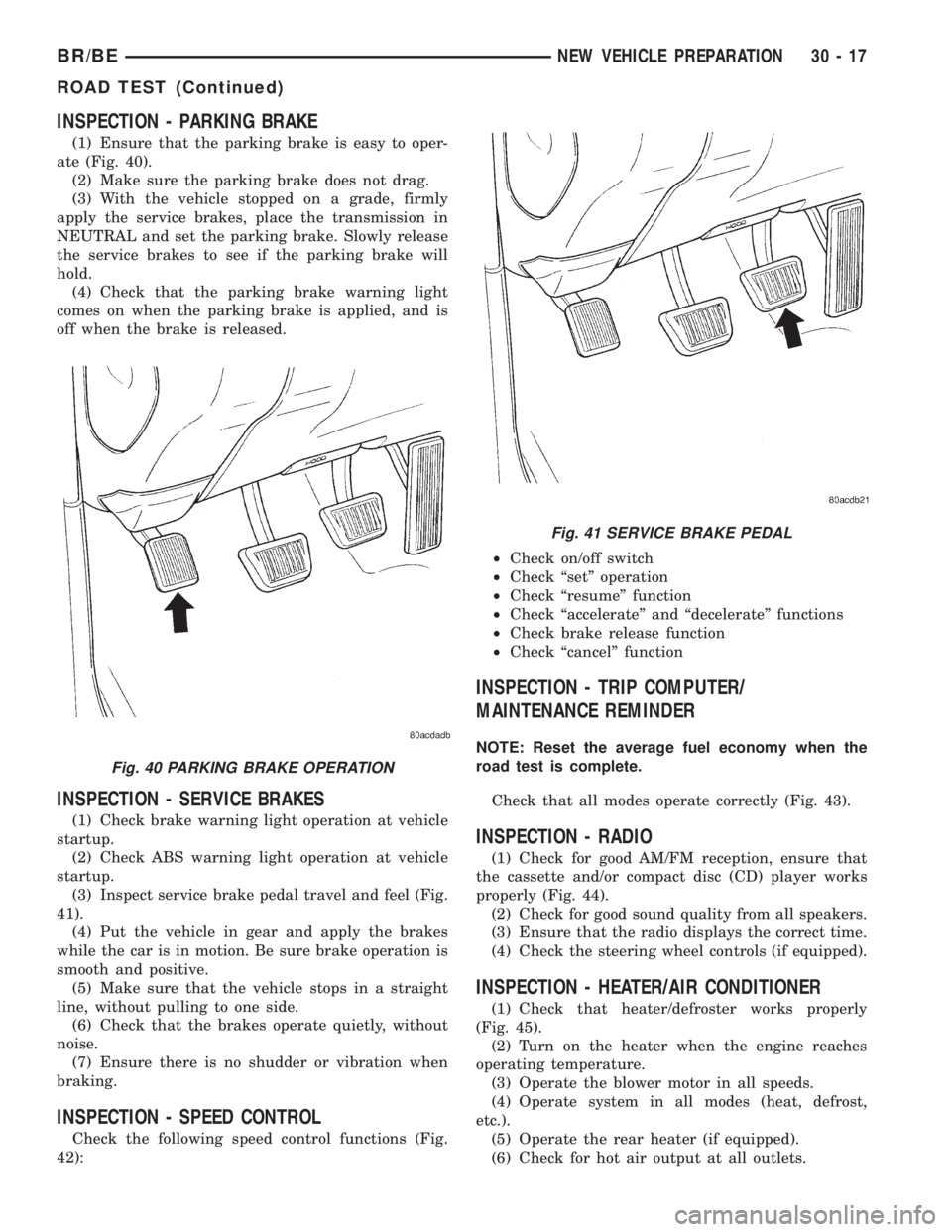

INSPECTION - PARKING BRAKE

(1) Ensure that the parking brake is easy to oper-

ate (Fig. 40).

(2) Make sure the parking brake does not drag.

(3) With the vehicle stopped on a grade, firmly

apply the service brakes, place the transmission in

NEUTRAL and set the parking brake. Slowly release

the service brakes to see if the parking brake will

hold.

(4) Check that the parking brake warning light

comes on when the parking brake is applied, and is

off when the brake is released.

INSPECTION - SERVICE BRAKES

(1) Check brake warning light operation at vehicle

startup.

(2) Check ABS warning light operation at vehicle

startup.

(3) Inspect service brake pedal travel and feel (Fig.

41).

(4) Put the vehicle in gear and apply the brakes

while the car is in motion. Be sure brake operation is

smooth and positive.

(5) Make sure that the vehicle stops in a straight

line, without pulling to one side.

(6) Check that the brakes operate quietly, without

noise.

(7) Ensure there is no shudder or vibration when

braking.

INSPECTION - SPEED CONTROL

Check the following speed control functions (Fig.

42):²Check on/off switch

²Check ªsetº operation

²Check ªresumeº function

²Check ªaccelerateº and ªdecelerateº functions

²Check brake release function

²Check ªcancelº function

INSPECTION - TRIP COMPUTER/

MAINTENANCE REMINDER

NOTE: Reset the average fuel economy when the

road test is complete.

Check that all modes operate correctly (Fig. 43).

INSPECTION - RADIO

(1) Check for good AM/FM reception, ensure that

the cassette and/or compact disc (CD) player works

properly (Fig. 44).

(2) Check for good sound quality from all speakers.

(3) Ensure that the radio displays the correct time.

(4) Check the steering wheel controls (if equipped).

INSPECTION - HEATER/AIR CONDITIONER

(1) Check that heater/defroster works properly

(Fig. 45).

(2) Turn on the heater when the engine reaches

operating temperature.

(3) Operate the blower motor in all speeds.

(4) Operate system in all modes (heat, defrost,

etc.).

(5) Operate the rear heater (if equipped).

(6) Check for hot air output at all outlets.

Fig. 40 PARKING BRAKE OPERATION

Fig. 41 SERVICE BRAKE PEDAL

BR/BENEW VEHICLE PREPARATION 30 - 17

ROAD TEST (Continued)

Page 2855 of 2889

CLUTCH RELAY - DIAGNOSIS AND

TESTING, A/C COMPRESSOR...........24-17

CLUTCH RELAY - INSTALLATION, A/C

COMPRESSOR.......................24-18

CLUTCH RELAY - OPERATION, A/C

COMPRESSOR.......................24-17

CLUTCH RELAY - REMOVAL, A/C

COMPRESSOR.......................24-18

CLUTCH RELEASE BEARING -

DESCRIPTION........................6-14

CLUTCH RELEASE BEARING -

INSTALLATION........................6-15

CLUTCH RELEASE BEARING -

OPERATION..........................6-14

CLUTCH RELEASE BEARING - REMOVAL . . . 6-15

COAT FINISH - DESCRIPTION, BASE

COAT/CLEAR.......................23-129

COAT FINISH - OPERATION, BASE

COAT/CLEAR.......................23-129

COAT HOOK - INSTALLATION..........23-125

COAT HOOK - REMOVAL..............23-124

COAT/CLEAR COAT FINISH -

DESCRIPTION, BASE.................23-129

COAT/CLEAR COAT FINISH - OPERATION,

BASE.............................23-129

CODE - DESCRIPTION, PAINT..........23-129

CODE PLATE - DESCRIPTION, BODY....Intro.-1

CODES - DESCRIPTION, DIAGNOSTIC

TROUBLE............................25-2

CODES, SPECIFICATIONS - 2001 BR

PAINT COLOR......................23-129

COIL - DIAGNOSIS AND TESTING, A/C

COMPRESSOR CLUTCH...............24-13

COIL RESISTANCE, 3.9L/5.2L/5.9L

ENGINES - IGNITION...................8I-3

COIL RESISTANCE, 8.0L V-10 ENGINE -

IGNITION............................8I-3

COLOR CODES, SPECIFICATIONS - 2001

BR PAINT..........................23-129

COLUMN - DESCRIPTION...............19-6

COLUMN - INSTALLATION...............19-8

COLUMN - REMOVAL..................19-7

COLUMN - SERVICE PRECAUTIONS.......19-6

COLUMN OPENING COVER -

INSTALLATION, STEERING............23-116

COLUMN OPENING COVER - REMOVAL,

STEERING.........................23-115

COMBINATION FLASHER - DESCRIPTION . . . 8L-7

COMBINATION FLASHER -

INSTALLATION........................8L-8

COMBINATION FLASHER - OPERATION....8L-7

COMBINATION FLASHER - REMOVAL......8L-8

COMBINATION VALVE - DESCRIPTION......5-9

COMBINATION VALVE - DIAGNOSIS AND

TESTING.............................5-9

COMBINATION VALVE - INSTALLATION.....5-10

COMBINATION VALVE - OPERATION........5-9

COMBINATION VALVE - REMOVAL........5-10

COMBUSTION PRESSURE LEAKAGE -

DIAGNOSIS AND TESTING, CYLINDER....9-124,

9-179,9-67,9-9

COMPASS - INSPECTION..............30-12

COMPASS CALIBRATION - STANDARD

PROCEDURE.........................8M-4

COMPASS DEMAGNETIZING -

STANDARD PROCEDURE...............8M-5

COMPASS MINI-TRIP COMPUTER -

DIAGNOSIS & TESTING...............8M-10

COMPASS VARIATION ADJUSTMENT -

STANDARD PROCEDURE...............8M-4

COMPASS/MINI-TRIP COMPUTER -

DESCRIPTION........................8M-8

COMPASS/MINI-TRIP COMPUTER -

INSTALLATION......................8M-11

COMPASS/MINI-TRIP COMPUTER -

OPERATION.........................8M-9

COMPASS/MINI-TRIP COMPUTER -

REMOVAL..........................8M-11

COMPRESSION PRESSURE - DIAGNOSIS

AND TESTING, CYLINDER . . 9-124,9-179,9-67,9-9

COMPRESSOR - DESCRIPTION, A/C......24-46

COMPRESSOR - DIAGNOSIS AND

TESTING, A/C

.......................24-46

COMPRESSOR - INSTALLATION, A/C

.....24-47

COMPRESSOR - OPERATION, A/C

........24-46

COMPRESSOR - REMOVAL, A/C

.........24-47

COMPRESSOR CLUTCH - DESCRIPTION,

A/C

................................24-13COMPRESSOR CLUTCH - INSPECTION,

A/C................................24-16

COMPRESSOR CLUTCH - INSTALLATION,

A/C................................24-16

COMPRESSOR CLUTCH - OPERATION,

A/C................................24-13

COMPRESSOR CLUTCH - REMOVAL, A/C . . 24-14

COMPRESSOR CLUTCH BREAK-IN -

STANDARD PROCEDURE, A/C...........24-13

COMPRESSOR CLUTCH COIL -

DIAGNOSIS AND TESTING, A/C..........24-13

COMPRESSOR CLUTCH RELAY -

DESCRIPTION, A/C...................24-17

COMPRESSOR CLUTCH RELAY -

DIAGNOSIS AND TESTING, A/C..........24-17

COMPRESSOR CLUTCH RELAY -

INSTALLATION, A/C...................24-18

COMPRESSOR CLUTCH RELAY -

OPERATION, A/C.....................24-17

COMPRESSOR CLUTCH RELAY -

REMOVAL, A/C......................24-18

COMPUTER - DESCRIPTION, COMPASS/

MINI-TRIP..........................8M-8

COMPUTER - DIAGNOSIS & TESTING,

COMPASS MINI-TRIP.................8M-10

COMPUTER - INSTALLATION, COMPASS/

MINI-TRIP.........................8M-11

COMPUTER - OPERATION, COMPASS/

MINI-TRIP..........................8M-9

COMPUTER - REMOVAL, COMPASS/

MINI-TRIP.........................8M-11

COMPUTER/MAINTENANCE REMINDER -

INSPECTION, TRIP...................30-17

CONDENSER - DESCRIPTION, A/C.......24-48

CONDENSER - INSTALLATION, A/C.......24-49

CONDENSER - OPERATION, A/C.........24-48

CONDENSER - REMOVAL, A/C..........24-49

CONDITIONER - DESCRIPTION, HEATER

AND AIR ............................24-1

CONDITIONER - INSPECTION,

HEATER/AIR.........................30-17

CONDITIONER - OPERATION, HEATER

AND AIR ............................24-1

CONDITIONING - INSTALLATION, WATER

PUMP BYPASS HOSE WITH AIR..........7-77

CONDITIONING - INSTALLATION, WATER

PUMP BYPASS HOSE WITHOUT AIR......7-78

CONDITIONING - REMOVAL, WATER

PUMP BYPASS HOSE WITH AIR..........7-74

CONDITIONING - REMOVAL, WATER

PUMP BYPASS HOSE WITHOUT AIR......7-77

CONDITIONS - DIAGNOSIS AND

TESTING, SPARK PLUG................8I-16

CONNECT FITTING - DESCRIPTION,

QUICK.............................14-22

CONNECTING ROD - CLEANING, PISTON . . 9-154,

9-209,9-285,9-41,9-98

CONNECTING ROD - CONNECTING

RODS, PISTON......................9-286

CONNECTING ROD - DESCRIPTION,

PISTON..........9-153,9-208,9-282,9-40,9-97

CONNECTING ROD - INSPECTION,

PISTON..........9-154,9-209,9-285,9-41,9-98

CONNECTING ROD - INSTALLATION,

PISTON..........9-154,9-210,9-287,9-41,9-98

CONNECTING ROD - REMOVAL, PISTON . . 9-154,

9-209,9-285,9-40,9-97

CONNECTING ROD BEARING AND

CRANKSHAFT JOURNAL CLEARANCE -

STANDARD PROCEDURE...............9-274

CONNECTING ROD BEARING FITTING -

STANDARD PROCEDURE......9-144,9-202,9-88

CONNECTING ROD BEARINGS -

STANDARD PROCEDURE-CONNECTING

ROD BEARING FITTING.................9-31

CONNECTING RODS, PISTON &

CONNECTING ROD...................9-286

CONNECTOR - AUGAT - INSTALLATION . 8W-01-8

CONNECTOR - AUGAT - REMOVAL.....8W-01-8

CONNECTOR - DESCRIPTION, DATA LINK . 8E-12

CONNECTOR - MOLEX - INSTALLATION . 8W-01-9

CONNECTOR - MOLEX - REMOVAL

....8W-01-9

CONNECTOR - OPERATION, DATA LINK

. . . 8E-12

CONNECTOR - THOMAS AND BETTS -

INSTALLATION

...................8W-01-10

CONNECTOR - THOMAS AND BETTS -

REMOVAL

........................8W-01-9

CONSOLE - DESCRIPTION, OVERHEAD

....8M-1CONSOLE - INSTALLATION, CENTER....23-122

CONSOLE - INSTALLATION, OVERHEAD . . . 8M-8

CONSOLE - OVERHEAD CONSOLE

ASSEMBLY, OVERHEAD................8M-7

CONSOLE - OVERHEAD CONSOLE

DISASSEMBLY, OVERHEAD.............8M-7

CONSOLE - REMOVAL, CENTER........23-122

CONSOLE - REMOVAL, OVERHEAD.......8M-6

CONSOLE ASSEMBLY, OVERHEAD

CONSOLE - OVERHEAD................8M-7

CONSOLE DISASSEMBLY, OVERHEAD

CONSOLE - OVERHEAD................8M-7

CONSOLE LID - INSTALLATION, CENTER . 23-132

CONSOLE LID - REMOVAL, CENTER.....23-131

CONSOLE SYSTEMS, SPECIAL TOOLS -

OVERHEAD..........................8M-8

CONTAINER - 3.9L/5.2L/5.9L/5.9L DIESEL

- DESCRIPTION, COOLANT RECOVERY.....7-41

CONTAINER - 3.9L/5.2L/5.9L/5.9L DIESEL

- INSTALLATION, COOLANT RECOVERY....7-41

CONTAINER - 3.9L/5.2L/5.9L/5.9L DIESEL

- OPERATION, COOLANT RECOVERY......7-41

CONTAINER - 3.9L/5.2L/5.9L/5.9L DIESEL

- REMOVAL, COOLANT RECOVERY........7-41

CONTAINER - 8.0L - DESCRIPTION,

COOLANT RECOVERY..................7-42

CONTAINER - 8.0L - OPERATION,

COOLANT RECOVERY..................7-42

CONTAMINATION - DIAGNOSIS AND

TESTING, BRAKE FLUID................5-14

CONTAMINATION - DIAGNOSIS AND

TESTING, FLUID....21-199,21-370,21-545,21-715

CONTINUITY - STANDARD PROCEDURE,

TESTING.........................8W-01-6

CONTROL - DESCRIPTION, A/C HEATER . . . 24-18

CONTROL - DIAGNOSIS AND TESTING,

A/C HEATER.........................24-19

CONTROL - INSPECTION, SPEED........30-17

CONTROL - INSTALLATION, A/C HEATER . . 24-20

CONTROL - OPERATION, A/C HEATER....24-18

CONTROL - REMOVAL, A/C HEATER......24-19

CONTROL ARM - INSTALLATION, LOWER . . 2-10,

2-20

CONTROL ARM - INSTALLATION, UPPER . . 2-13,

2-24

CONTROL ARM - REMOVAL, LOWER . . 2-10,2-20

CONTROL ARM - REMOVAL, UPPER . . 2-13,2-23

CONTROL CABLE - INSTALLATION,

THROTTLE....................14-105,14-50

CONTROL CABLE - REMOVAL,

THROTTLE....................14-104,14-50

CONTROL MODULE - DESCRIPTION,

AIRBAG.............................8O-6

CONTROL MODULE - INSTALLATION,

AIRBAG.............................8O-8

CONTROL MODULE - INSTALLATION,

ENGINE............................8E-14

CONTROL MODULE - INSTALLATION,

POWERTRAIN.......................8E-20

CONTROL MODULE - OPERATION,

AIRBAG.............................8O-6

CONTROL MODULE - REMOVAL, AIRBAG . . 8O-7

CONTROL MODULE - REMOVAL, ENGINE . . 8E-14

CONTROL MODULE - REMOVAL,

POWERTRAIN.......................8E-19

CONTROL MOTOR - DESCRIPTION, IDLE

AIR

...............................14-41

CONTROL MOTOR - OPERATION, IDLE

AIR

...............................14-41

CONTROL SERVO - DESCRIPTION,

SPEED

..............................8P-5

CONTROL SERVO - INSTALLATION,

SPEED

.............................8P-10

CONTROL SERVO - OPERATION, SPEED

. . . 8P-5

CONTROL SERVO - REMOVAL, SPEED

.....8P-6

CONTROL SWITCH - DESCRIPTION,

LUMBAR

...........................8N-17

CONTROL SWITCH - OPERATION,

LUMBAR

...........................8N-18

CONTROL SWITCH - REMOVAL,

LUMBAR

...........................8N-18

CONTROL SYSTEM - DESCRIPTION,

SPEED

..............................8P-1

CONTROL SYSTEM - OPERATION, SPEED

. . 8P-2

CONTROL SYSTEM - TORQUE, SPEED

.....8P-4

CONTROL/CENTRAL TIMER MODULE -

DESCRIPTION, BODY

..................8E-1

8 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2856 of 2889

CONTROL/CENTRAL TIMER MODULE -

INSTALLATION, BODY..................8E-6

CONTROL/CENTRAL TIMER MODULE -

OPERATION, BODY....................8E-3

CONTROL/CENTRAL TIMER MODULE -

REMOVAL, BODY......................8E-5

CONTROLLER ANTILOCK BRAKE -

DESCRIPTION.......................8E-11

CONTROLLER ANTILOCK BRAKE -

INSTALLATION.......................8E-12

CONTROLLER ANTILOCK BRAKE -

OPERATION.........................8E-11

CONTROLLER ANTILOCK BRAKE -

REMOVAL..........................8E-12

CONTROLS - DIAGNOSIS AND TESTING,

OVERDRIVE

ELECTRICAL.....21-215,21-386,21-579,21-732

CONVERTER - 3.9L/5.2L/5.9L -

DESCRIPTION, CATALYTIC...............11-5

CONVERTER - 3.9L/5.2L/5.9L -

INSPECTION, CATALYTIC................11-5

CONVERTER - 3.9L/5.2L/5.9L -

INSTALLATION, CATALYTIC..............11-5

CONVERTER - 3.9L/5.2L/5.9L -

OPERATION, CATALYTIC................11-5

CONVERTER - 3.9L/5.2L/5.9L -

REMOVAL, CATALYTIC..................11-5

CONVERTER - 5.9L HEAVY DUTY/8.0L -

DESCRIPTION, CATALYTIC...............11-6

CONVERTER - 5.9L HEAVY DUTY/8.0L -

INSPECTION, CATALYTIC................11-7

CONVERTER - 5.9L HEAVY DUTY/8.0L -

INSTALLATION, CATALYTIC..............11-7

CONVERTER - 5.9L HEAVY DUTY/8.0L -

OPERATION, CATALYTIC................11-6

CONVERTER - 5.9L HEAVY DUTY/8.0L -

REMOVAL, CATALYTIC..................11-6

CONVERTER - DESCRIPTION,

TORQUE........21-256,21-427,21-600,21-773

CONVERTER - INSTALLATION,

TORQUE........21-261,21-432,21-605,21-778

CONVERTER - OPERATION,

TORQUE........21-260,21-430,21-604,21-777

CONVERTER - REMOVAL,

TORQUE........21-261,21-432,21-605,21-778

CONVERTER DRAINBACK VALVE -

DESCRIPTION,

TORQUE........21-262,21-432,21-605,21-778

CONVERTER DRAINBACK VALVE -

OPERATION,

TORQUE........21-262,21-432,21-605,21-778

CONVERTER DRAINBACK VALVE -

STANDARD PROCEDURE,

TORQUE........21-262,21-432,21-606,21-778

CONVERTER HOUSING FLUID LEAK -

DIAGNOSIS AND

TESTING........21-148,21-319,21-491,21-662

COOLANT - DESCRIPTION...............7-40

COOLANT - OPERATION

................7-40

COOLANT - STANDARD PROCEDURE,

ADDING ADDITIONAL

..................7-16

COOLANT FLOW - DIAGNOSIS AND

TESTING, RADIATOR

...........7-59,7-61,7-63

COOLANT LEVEL CHECK - STANDARD

PROCEDURE

.........................7-16

COOLANT RECOVERY CONTAINER -

3.9L/5.2L/5.9L/5.9L DIESEL -

DESCRIPTION

........................7-41

COOLANT RECOVERY CONTAINER -

3.9L/5.2L/5.9L/5.9L DIESEL -

INSTALLATION

........................7-41

COOLANT RECOVERY CONTAINER -

3.9L/5.2L/5.9L/5.9L DIESEL -

OPERATION

..........................7-41

COOLANT RECOVERY CONTAINER -

3.9L/5.2L/5.9L/5.9L DIESEL -

REMOVAL

...........................7-41

COOLANT RECOVERY CONTAINER - 8.0L

- DESCRIPTION

.......................7-42

COOLANT RECOVERY CONTAINER - 8.0L

- OPERATION

.........................7-42

COOLANT SELECTION-ADDITIVES -

STANDARD PROCEDURE

................7-17

COOLANT TEMP SENSOR - 3.9L/5.2L/

5.9L - DESCRIPTION, ENGINE

............7-48

COOLANT TEMP SENSOR - 3.9L/5.2L/

5.9L - INSTALLATION, ENGINE

...........7-48COOLANT TEMP SENSOR - 3.9L/5.2L/

5.9L - OPERATION, ENGINE.............7-48

COOLANT TEMP SENSOR - 3.9L/5.2L/

5.9L - REMOVAL, ENGINE...............7-48

COOLANT THERMOSTAT - 3.9L/5.2L/

5.9L - DESCRIPTION, ENGINE............7-49

COOLANT THERMOSTAT - 3.9L/5.2L/

5.9L - INSTALLATION, ENGINE...........7-50

COOLANT THERMOSTAT - 3.9L/5.2L/

5.9L - OPERATION, ENGINE.............7-49

COOLANT THERMOSTAT - 3.9L/5.2L/

5.9L - REMOVAL, ENGINE...............7-49

COOLANT THERMOSTAT - 5.9L DIESEL -

DESCRIPTION, ENGINE.................7-54

COOLANT THERMOSTAT - 5.9L DIESEL -

INSTALLATION, ENGINE................7-55

COOLANT THERMOSTAT - 5.9L DIESEL -

OPERATION, ENGINE...................7-54

COOLANT THERMOSTAT - 5.9L DIESEL -

REMOVAL, ENGINE....................7-55

COOLANT THERMOSTAT - 8.0L -

DESCRIPTION, ENGINE.................7-52

COOLANT THERMOSTAT - 8.0L -

INSTALLATION, ENGINE................7-53

COOLANT THERMOSTAT - 8.0L -

OPERATION, ENGINE...................7-52

COOLANT THERMOSTAT - 8.0L -

REMOVAL, ENGINE....................7-52

COOLER - 3.9L/5.2L/5.9L - ASSEMBLY,

TRANS..............................7-82

COOLER - 3.9L/5.2L/5.9L -

DESCRIPTION, TRANS.................7-79

COOLER - 3.9L/5.2L/5.9L -

DISASSEMBLY, TRANS...................7-81

COOLER - 3.9L/5.2L/5.9L -

INSTALLATION, TRANS.................7-82

COOLER - 3.9L/5.2L/5.9L - OPERATION,

TRANS..............................7-79

COOLER - 3.9L/5.2L/5.9L - REMOVAL,

TRANS..............................7-81

COOLER - 5.9L DIESEL - DESCRIPTION,

TRANS..............................7-85

COOLER - 5.9L DIESEL - INSTALLATION,

TRANS..............................7-88

COOLER - 5.9L DIESEL - OPERATION,

TRANS..............................7-85

COOLER - 8.0L - DESCRIPTION, TRANS....7-82

COOLER - 8.0L - INSTALLATION, TRANS . . . 7-85

COOLER - 8.0L - OPERATION, TRANS.....7-82

COOLER - 8.0L - REMOVAL, TRANS.......7-84

COOLER - INSTALLATION, AIR TO OIL.....7-88

COOLER & LINES - CLEANING AND

INSPECTION, OIL.....................9-296

COOLER - REMOVAL, AIR TO OIL.........7-87

COOLER - REMOVAL, WATER TO OIL......7-87

COOLER - STANDARD PROCEDURE,

FLUSHING COOLER AND TUBES -

WITHOUT RADIATOR IN-TANK

TRANSMISSION OIL...........7-80,7-83,7-86

COOLER - STANDARD PROCEDURE,

FLUSHING COOLERS AND TUBES -

WITH RADIATOR IN-TANK

TRANSMISSION OIL...........7-79,7-83,7-85

COOLER AND PLUMBING - CLEANING,

CHARGE AIR........................11-18

COOLER AND PLUMBING -

DESCRIPTION, CHARGE AIR............11-17

COOLER AND PLUMBING - INSPECTION,

CHARGE AIR........................11-18

COOLER AND PLUMBING -

INSTALLATION, CHARGE AIR...........11-18

COOLER AND PLUMBING - OPERATION,

CHARGE AIR........................11-17

COOLER AND PLUMBING - REMOVAL,

CHARGE AIR........................11-17

COOLER AND TUBES - WITHOUT

RADIATOR IN-TANK TRANSMISSION

OIL COOLER - STANDARD

PROCEDURE, FLUSHING

........7-80,7-83,7-86

COOLERS AND TUBES - WITH

RADIATOR IN-TANK TRANSMISSION

OIL COOLER - STANDARD

PROCEDURE, FLUSHING

........7-79,7-83,7-85

COOLING, SPECIAL TOOLS

..............7-18

COOLING SYSTEM - OPERATION

..........7-4

COOLING SYSTEM 3.9L/5.2L/5.9L/8.0L

ENGINES - STANDARD PROCEDURE,

DRAINING

...........................7-15COOLING SYSTEM 3.9L/5.2L/5.9L/8.0L

ENGINES - STANDARD PROCEDURE,

REFILLING...........................7-15

COOLING SYSTEM 5.9L DIESEL ENGINE

- STANDARD PROCEDURE, DRAINING.....7-15

COOLING SYSTEM 5.9L DIESEL ENGINE

- STANDARD PROCEDURE, REFILLING.....7-15

COOLING SYSTEM CLEANING/REVERSE

FLUSHING - STANDARD PROCEDURE.....7-16

COOLING SYSTEM DIESEL ENGINE -

DIAGNOSIS AND TESTING..............7-12

COOLING SYSTEM FLOW - 3.9L/5.2L/

5.9L ENGINE - DESCRIPTION.............7-1

COOLING SYSTEM FLOW - 5.9L DIESEL

- DESCRIPTION........................7-1

COOLING SYSTEM GAS ENGINE -

DIAGNOSIS AND TESTING...............7-7

COOLING SYSTEM LEAKS - DIAGNOSIS

AND TESTING.........................7-5

COOLING SYSTEM REQUIREMENTS -

DESCRIPTION........................24-1

CORE - DESCRIPTION, HEATER.........24-55

CORE - INSTALLATION, HEATER.........24-56

CORE - OPERATION, HEATER...........24-55

CORE - REMOVAL, HEATER............24-56

CORE GROUND STRAP - INSTALLATION,

HEATER............................8A-15

CORE GROUND STRAP - REMOVAL,

HEATER............................8A-14

CORNER SEAL - INSTALLATION, FRONT

DOOR UPPER......................23-154

CORNER SEAL - REMOVAL, FRONT

DOOR UPPER........................23-154

COUPLERS - DESCRIPTION, A/C LINE....24-40

COUPLERS - OPERATION, A/C LINE......24-41

COUPLERS - STANDARD PROCEDURE,

A/C LINE...........................24-43

COVER - INSTALLATION, CENTER SEAT

ARMREST/LATCH...................23-132

COVER - INSTALLATION, COWL TRIM . . . 23-120

COVER - INSTALLATION, GEAR HOUSING . 9-307

COVER - INSTALLATION, INSTRUMENT

PANEL TOP........................23-115

COVER - INSTALLATION, SEAT BACK....23-137

COVER - INSTALLATION, SEAT CUSHION . 23-139

COVER - INSTALLATION, SHIFT . . . 21-133,21-90

COVER - INSTALLATION, STANCHION....23-143

COVER - INSTALLATION, STEERING

COLUMN OPENING..................23-116

COVER - REMOVAL, CENTER SEAT

ARMREST/LATCH...................23-132

COVER - REMOVAL, COWL TRIM.......23-119

COVER - REMOVAL, GEAR HOUSING.....9-306

COVER - REMOVAL, INSTRUMENT

PANEL TOP........................23-114

COVER - REMOVAL, SEAT BACK........23-137

COVER - REMOVAL, SEAT CUSHION.....23-139

COVER - REMOVAL, SHIFT.......21-132,21-90

COVER - REMOVAL, STANCHION.......23-143

COVER - REMOVAL, STEERING COLUMN

OPENING..........................23-115

COVER - REMOVAL, WHEEL............22-12

COVER - SPLIT BENCH - INSTALLATION,

SEAT BACK........................23-138

COVER - SPLIT BENCH - INSTALLATION,

SEAT CUSHION.....................23-140

COVER - SPLIT BENCH - REMOVAL,

SEAT BACK........................23-137

COVER - SPLIT BENCH - REMOVAL,

SEAT CUSHION.....................23-139

COVER GASKET - DESCRIPTION,

CYLINDER...........................9-79

COVER GASKET - DESCRIPTION,

CYLINDER HEAD......................9-22

COVER GASKET - OPERATION,

CYLINDER HEAD......................9-22

COVER INSTALLED - INSTALLATION,

FRONT OIL SEAL - FRONT.............9-205

COVER INSTALLED - REMOVAL, FRONT

OIL SEAL - FRONT

...................9-204

COVER REMOVED - INSTALLATION,

FRONT OIL SEAL - FRONT

.............9-205

COVER REMOVED - REMOVAL, FRONT

OIL SEAL - FRONT

...................9-204

COVER(S) - CLEANING, CYLINDER HEAD

. 9-138,

9-194,9-24,9-253,9-81

COVER(S) - DESCRIPTION, CYLINDER

HEAD

..............................9-194

BR/BEINDEX 9

Description Group-Page Description Group-Page Description Group-Page

Page 2861 of 2889

FAN - 3.9L/5.2L/5.9L/8.0L -

INSTALLATION, RADIATOR..............7-43

FAN - 3.9L/5.2L/5.9L/8.0L - REMOVAL,

RADIATOR...........................7-42

FAN - 5.9L DIESEL - CLEANING,

RADIATOR...........................7-44

FAN - 5.9L DIESEL - INSPECTION,

RADIATOR...........................7-44

FAN - 5.9L DIESEL - INSTALLATION,

RADIATOR...........................7-45

FAN - 5.9L DIESEL - REMOVAL,

RADIATOR...........................7-44

FAN DRIVE - DIAGNOSIS AND TESTING,

VISCOUS........................7-56,7-58

FAN DRIVE VISCOUS CLUTCH -

3.9L/5.2L/5.9L/8.0L - DESCRIPTION.......7-56

FAN DRIVE VISCOUS CLUTCH -

3.9L/5.2L/5.9L/8.0L - OPERATION.........7-56

FAN DRIVE VISCOUS CLUTCH - 5.9L

DIESEL - DESCRIPTION................7-57

FAN DRIVE VISCOUS CLUTCH - 5.9L

DIESEL - OPERATION..................7-57

FASCIA - ADJUSTMENT, FRONT..........13-2

FASCIA - INSTALLATION, FRONT.........13-2

FASCIA - INSTALLATION, FRONT LOWER . . . 13-3

FASCIA - REMOVAL, FRONT.............13-2

FASCIA - REMOVAL, FRONT LOWER......13-3

FASCIA-SPORT - INSTALLATION, FRONT . . . 13-3

FASCIA-SPORT - REMOVAL, FRONT.......13-3

FASTENER IDENTIFICATION -

DESCRIPTION......................Intro.-3

FASTENER USAGE - DESCRIPTION......Intro.-6

FASTENERS - DESCRIPTION, PUSH-IN.....23-1

FEATURES - DESCRIPTION,

PROGRAMMABLE ELECTRONIC.........30-20

FEATURES - OPERATION,

PROGRAMMABLE ELECTRONIC.........30-20

FENDER - INSTALLATION, LEFT FRONT . . . 23-93

FENDER - INSTALLATION, REAR.........23-95

FENDER - INSTALLATION, RIGHT FRONT . . 23-94

FENDER - REMOVAL, LEFT FRONT.......23-92

FENDER - REMOVAL, REAR............23-95

FENDER - REMOVAL, RIGHT FRONT......23-94

FILL - STANDARD PROCEDURE,

TRANSMISSION . . . 21-201,21-372,21-547,21-718

FILL DOOR - INSTALLATION, FUEL.......23-95

FILL DOOR - REMOVAL, FUEL..........23-95

FILLER CAP - DESCRIPTION, FUEL.......25-33

FILLER CAP - OPERATION, FUEL........25-33

FILLER CAP - REMOVAL/INSTALLATION,

FUEL..............................25-33

FILTER - DESCRIPTION, PCV...........25-35

FILTER - INSTALLATION, AIR PUMP......25-29

FILTER - INSTALLATION, INLET..........14-22

FILTER - INSTALLATION, OIL . 9-105,9-161,9-218,

9-296,9-48

FILTER - REMOVAL, AIR PUMP.........25-29

FILTER - REMOVAL, INLET.............14-22

FILTER - REMOVAL, OIL.....9-105,9-161,9-218,

9-296,9-48

FILTER - STANDARD PROCEDURES,

WATER DRAINING AT FUEL............14-56

FILTER / WATER SEPARATOR -

DESCRIPTION, FUEL..................14-59

FILTER / WATER SEPARATOR -

INSTALLATION, FUEL.................14-61

FILTER / WATER SEPARATOR -

OPERATION, FUEL....................14-59

FILTER / WATER SEPARATOR -

REMOVAL, FUEL.....................14-60

FILTER REPLACEMENT - STANDARD

PROCEDURE, FLUID.....21-201,21-372,21-547,

21-717

FILTER/PRESSURE REGULATOR -

DESCRIPTION, FUEL...................14-5

FILTER/PRESSURE REGULATOR -

INSTALLATION, FUEL..................14-6

FILTER/PRESSURE REGULATOR -

OPERATION, FUEL.....................14-5

FILTER/PRESSURE REGULATOR -

REMOVAL, FUEL

......................14-5

FINAL STEPS - NEW VEHICLE

PREPARATION FORM

.................30-22

FINISH - DESCRIPTION, BASE

COAT/CLEAR COAT

..................23-129

FINISH - INSPECTION, FIT

........30-10,30-12

FINISH - OPERATION, BASE COAT/CLEAR

COAT

.............................23-129FIRING ORDER, 3.9L V-6 ENGINE -

ENGINE..............................8I-2

FIRING ORDER, 5.2L/5.9L V-8 ENGINES -

ENGINE..............................8I-2

FIRING ORDER, DIESEL - FUEL

INJECTOR..........................14-58

FIT AND FINISH - INSPECTION.....30-10,30-12

FITTING - DESCRIPTION, QUICK

CONNECT...........................14-22

FITTING - STANDARD PROCEDURE,

CONNECTING ROD BEARING . . 9-144,9-202,9-88

FITTING - STANDARD PROCEDURE,

CRANKSHAFT MAIN BEARING......9-146,9-90

FITTING - STANDARD PROCEDURE,

MAIN BEARING..................9-203,9-33

FITTING - STANDARD PROCEDURE,

PISTON...............9-153,9-208,9-40,9-97

FITTING - STANDARD PROCEDURE,

PISTON RING...............9-154,9-41,9-98

FITTING, CONNECTING ROD BEARINGS -

STANDARD PROCEDURE-CONNECTING

ROD BEARING........................9-31

FITTING PISTON RINGS - STANDARD

PROCEDURE........................9-211

FITTING, PISTON RINGS - STANDARD

PROCEDURE-PISTON RING.............9-288

FITTINGS - STANDARD PROCEDURES,

QUICK-CONNECT.....................14-22

FIXED ORIFICE TUBE - DIAGNOSIS AND

TESTING...........................24-54

FLAG - INSTALLATION, SIDE VIEW

MIRROR...........................23-74

FLAG - REMOVAL, SIDE VIEW MIRROR . . . 23-74

FLARING - STANDARD PROCEDURE,

DOUBLE INVERTED.....................5-8

FLARING - STANDARD PROCEDURE, ISO....5-8

FLASHER - DESCRIPTION, COMBINATION . . 8L-7

FLASHER - INSTALLATION,

COMBINATION........................8L-8

FLASHER - OPERATION, COMBINATION....8L-7

FLASHER - REMOVAL, COMBINATION.....8L-8

FLOOR MATS - INSTALLATION, CARPETS . 23-123

FLOOR MATS - REMOVAL, CARPETS....23-123

FLOOR SHIFT BOOT - INSTALLATION,

4WD .............................23-122

FLOOR SHIFT BOOT - REMOVAL, 4WD . . . 23-122

FLOOR STOWAGE TRAY -

INSTALLATION, REAR................23-121

FLOOR STOWAGE TRAY - REMOVAL,

REAR.............................23-121

FLOW - 3.9L/5.2L/5.9L ENGINE -

DESCRIPTION, COOLING SYSTEM.........7-1

FLOW - 5.9L DIESEL - DESCRIPTION,

COOLING SYSTEM.....................7-1

FLOW - DIAGNOSIS AND TESTING,

RADIATOR COOLANT..........7-59,7-61,7-63

FLOW AND PRESSURE - DIAGNOSIS

AND TESTING, POWER STEERING........19-4

FLUID - DESCRIPTION, AUTOMATIC

TRANSMISSION.......................0-5

FLUID - DESCRIPTION, TRANSFER CASE....0-5

FLUID - DIAGNOSIS AND TESTING,

CAUSES OF BURNT.....21-199,21-370,21-545,

21-715

FLUID - OPERATION, AUTOMATIC

TRANSMISSION.......................0-5

FLUID AND FILTER REPLACEMENT -

STANDARD PROCEDURE . 21-201,21-372,21-547,

21-717

FLUID CAPACITIES, SPECIFICATIONS.......0-6

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING....21-199,21-370,21-545,21-715

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING, BRAKE..................5-14

FLUID DRAIN AND REFILL - STANDARD

PROCEDURE...........21-851,21-885,21-922

FLUID INDICATOR - DESCRIPTION,

WASHER

...........................8J-35

FLUID INDICATOR - DIAGNOSIS AND

TESTING, WASHER

...................8J-36

FLUID INDICATOR - OPERATION,

WASHER

...........................8J-35

FLUID LEAK - DIAGNOSIS AND TESTING,

CONVERTER HOUSING

. . . 21-148,21-319,21-491,

21-662

FLUID LEVEL - DIAGNOSIS AND

TESTING, EFFECTS OF INCORRECT

.....21-199,

21-370,21-545,21-715FLUID LEVEL - STANDARD PROCEDURE,

BRAKE..............................5-14

FLUID LEVEL CHECK - STANDARD

PROCEDURE.....21-199,21-370,21-545,21-715

FLUID LEVEL SWITCH - DESCRIPTION,

WASHER............................8R-7

FLUID LEVEL SWITCH - INSTALLATION,

WASHER............................8R-8

FLUID LEVEL SWITCH - OPERATION,

WASHER............................8R-7

FLUID LEVEL SWITCH - REMOVAL,

WASHER............................8R-8

FLUID LEVELS - INSPECTION............30-4

FLUID RESERVOIR - INSTALLATION.......5-15

FLUID RESERVOIR - REMOVAL..........5-15

FLUID, SPECIFICATIONS - BRAKE.........5-15

FLUID TYPES - DESCRIPTION.............0-5

FLUSH MEASUREMENTS,

SPECIFICATIONS - BODY GAP..........23-56

FLUSHING - STANDARD PROCEDURE,

COOLING SYSTEM CLEANING/

REVERSE............................7-16

FLUSHING COOLER AND TUBES -

WITHOUT RADIATOR IN-TANK

TRANSMISSION OIL COOLER -

STANDARD PROCEDURE.......7-80,7-83,7-86

FLUSHING COOLERS AND TUBES - WITH

RADIATOR IN-TANK TRANSMISSION

OIL COOLER - STANDARD

PROCEDURE.................7-79,7-83,7-85

FLUSHING POWER STEERING SYSTEM -

STANDARD PROCEDURE...............19-32

FLYWHEEL - ASSEMBLY................6-17

FLYWHEEL - DESCRIPTION..............6-16

FLYWHEEL - DIAGNOSIS AND TESTING....6-17

FLYWHEEL - DISASSEMBLY.............6-17

FLYWHEEL - OPERATION...............6-16

FOG LAMP - DIAGNOSIS AND TESTING....8L-9

FOG LAMP - INSTALLATION............8L-11

FOG LAMP - REMOVAL................8L-11

FOG LAMP UNIT - ADJUSTMENTS.......8L-12

FOG LAMP UNIT - INSTALLATION........8L-12

FOG LAMP UNIT - REMOVAL...........8L-11

FORE/AFT - ADJUSTMENT, FRONT DOOR . . 23-68

FORM, FINAL STEPS - NEW VEHICLE

PREPARATION.......................30-22

FORM-IN-PLACE GASKETS & SEALERS -

STANDARD PROCEDURE.....9-11,9-125,9-180,

9-237,9-68

FOUR-WHEEL DRIVE INDICATOR -

DIAGNOSIS AND TESTING..............8J-29

FRAME - DESCRIPTION.................13-6

FRAME - FRAME SERVICE..............13-6

FRAME - INSTALLATION, GRILLE........23-92

FRAME - REMOVAL, GRILLE............23-91

FRAME DIMENSION, SPECIFICATIONS.....13-7

FRAME SERVICE, FRAME...............13-6

FRONT - 2WD - DESCRIPTION.........2-7,2-8

FRONT - 4WD - DESCRIPTION...........2-14

FRONT - DESCRIPTION, CRANKSHAFT

OIL SEAL...................9-147,9-34,9-91

FRONT - INSTALLATION............5-14,5-27

FRONT - INSTALLATION...............22-12

FRONT - INSTALLATION, 1500/2500.......5-22

FRONT - INSTALLATION, 3500...........5-22

FRONT - INSTALLATION, CRANKSHAFT

OIL SEAL..............9-148,9-277,9-34,9-91

FRONT - INSTALLATION, PROPELLER

SHAFT...............................3-8

FRONT - OPERATION, CRANKSHAFT OIL

SEAL......................9-147,9-34,9-91

FRONT - REMOVAL................5-10,5-24

FRONT - REMOVAL, 1500/2500..........5-21

FRONT - REMOVAL, 3500...............5-22

FRONT - REMOVAL, CRANKSHAFT OIL

SEAL.................9-147,9-276,9-34,9-91

FRONT - REMOVAL, PROPELLER SHAFT....3-8

FRONT AIR DAM - INSTALLATION........13-2

FRONT AIR DAM - REMOVAL............13-1

FRONT AXLE - 216FBI - ADJUSTMENTS....3-17

FRONT AXLE - 216FBI - DESCRIPTION.....3-12

FRONT AXLE - 216FBI - INSTALLATION....3-17

FRONT AXLE - 216FBI - OPERATION......3-12

FRONT AXLE - 216FBI - REMOVAL

........3-16

FRONT AXLE - 248FBI - ADJUSTMENTS

....3-50

FRONT AXLE - 248FBI - DESCRIPTION

.....3-45

FRONT AXLE - 248FBI - INSTALLATION

....3-50

FRONT AXLE - 248FBI - OPERATION

......3-45

14 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2863 of 2889

FUEL TRANSFER PUMP - OPERATION....14-79

FUEL TRANSFER PUMP - REMOVAL......14-83

FUEL TRANSFER PUMP PRESSURE -

DIAGNOSIS AND TESTING.............14-80

FUSE - DESCRIPTION, GENERATOR

CARTRIDGE.......................8W-97-4

FUSE - DESCRIPTION, IOD...........8W-97-4

FUSE - INSTALLATION, GENERATOR

CARTRIDGE.......................8W-97-4

FUSE - INSTALLATION, IOD..........8W-97-5

FUSE - OPERATION, GENERATOR

CARTRIDGE.......................8W-97-4

FUSE - OPERATION, IOD.............8W-97-5

FUSE - REMOVAL, GENERATOR

CARTRIDGE.......................8W-97-4

FUSE - REMOVAL, IOD..............8W-97-5

FUSES POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR SHORT TO GROUND ON.........8W-01-7

GAP AND FLUSH MEASUREMENTS,

SPECIFICATIONS - BODY...............23-56

GAS ENGINE - DIAGNOSIS AND TESTING . . 11-4

GAS ENGINE - DIAGNOSIS AND

TESTING, COOLING SYSTEM.............7-7

GAS ENGINES - DESCRIPTION,

COMPONENT MONITORS..............25-18

GAS ENGINES - DESCRIPTION, FUEL

REQUIREMENTS.......................0-1

GAS ENGINES - INSTALLATION..........8P-4

GAS ENGINES - OPERATION............25-18

GAS ENGINES - OPERATION, NON-

MONITORED CIRCUITS................25-22

GAS ENGINES - OPERATION, PCM.......8E-17

GAS ENGINES - REMOVAL..............8P-4

GAS ENGINES - SPECIFICATIONS, FUEL

SYSTEM PRESSURE...................14-4

GAS FUEL INJECTION - SPECIFICATIONS,

TORQUE............................14-35

GASKET - DESCRIPTION, CYLINDER

COVER..............................9-79

GASKET - DESCRIPTION, CYLINDER

HEAD COVER.........................9-22

GASKET - OPERATION, CYLINDER HEAD

COVER..............................9-22

GASKET FAILURE - DIAGNOSIS AND

TESTING, CYLINDER HEAD . . . 9-136,9-191,9-22,

9-79

GASKETS & SEALERS - STANDARD

PROCEDURE, FORM-IN-PLACE.....9-11,9-125,

9-180,9-237,9-68

GASOLINE - NEGATIVE CABLE

INSTALLATION.......................8F-24

GASOLINE - NEGATIVE CABLE REMOVAL . . 8F-23

GASOLINE - POSITIVE CABLE

INSTALLATION.......................8F-23

GASOLINE - POSITIVE CABLE REMOVAL . . 8F-23

GASOLINE ENGINE - INSTALLATION......19-35

GASOLINE ENGINE - REMOVAL.........19-33

GAUGE - DESCRIPTION, ENGINE

TEMPERATURE......................8J-19

GAUGE - DESCRIPTION, FUEL...........8J-20

GAUGE - DESCRIPTION, OIL PRESSURE . . 8J-25

GAUGE - DESCRIPTION, VOLTAGE.......8J-33

GAUGE - OPERATION, ENGINE

TEMPERATURE......................8J-19

GAUGE - OPERATION, FUEL............8J-20

GAUGE - OPERATION, OIL PRESSURE....8J-26

GAUGE - OPERATION, VOLTAGE.........8J-34

GAUGE SENDING UNIT - DIAGNOSIS

AND TESTING, FUEL...................14-8

GAUGES - DIAGNOSIS AND TESTING,

PRESSURE..........................22-7

GAUGES INDICATOR - DESCRIPTION,

CHECK.............................8J-17

GAUGES INDICATOR - OPERATION,

CHECK.............................8J-17

GAUGES/WARNING LIGHTS -

INSPECTION........................30-19

GEAR - ADJUSTMENTS................19-16

GEAR - DESCRIPTION.................19-14

GEAR - INSTALLATION................19-16

GEAR - INSTALLATION, PINION

GEAR/RING

......................3-42,3-74

GEAR - OPERATION

...................19-14

GEAR - REMOVAL

....................19-16

GEAR - REMOVAL, PINION GEAR/RING

....3-40,

3-72

GEAR HOUSING - INSTALLATION

........9-305GEAR HOUSING - REMOVAL............9-304

GEAR HOUSING COVER - INSTALLATION . . 9-307

GEAR HOUSING COVER - REMOVAL.....9-306

GEAR HOUSING PLUG - INSTALLATION,

STEERING..........................19-27

GEAR HOUSING PLUG - REMOVAL,

STEERING..........................19-27

GEAR LEAKAGE - DIAGNOSIS AND

TESTING, POWER STEERING...........19-14

GEAR SELECTOR INDICATOR -

DESCRIPTION.......................8J-21

GEAR SELECTOR INDICATOR -

OPERATION.........................8J-21

GEAR SHIFT LEVER - INSTALLATION.....19-13

GEAR SHIFT LEVER - REMOVAL.........19-13

GEAR, SPECIAL TOOLS - POWER

STEERING..........................19-20

GEAR, SPECIFICATIONS - POWER

STEERING..........................19-19

GEAR/RING GEAR - INSTALLATION,

PINION.........................3-42,3-74

GEAR/RING GEAR - REMOVAL, PINION....3-40,

3-72

GEAR/RING GEAR/TONE RING -

INSTALLATION, PINION . 3-105,3-137,3-166,3-195

GEAR/RING GEAR/TONE RING -

REMOVAL, PINION....3-103,3-135,3-165,3-193

GEAR/TONE RING - INSTALLATION,

PINION GEAR/RING....3-105,3-137,3-166,3-195

GEAR/TONE RING - REMOVAL, PINION

GEAR/RING..........3-103,3-135,3-165,3-193

GEARTRAIN/OUTPUT SHAFT -

ASSEMBLY, PLANETARY . . 21-241,21-412,21-588,

21-760

GEARTRAIN/OUTPUT SHAFT -

DESCRIPTION, PLANETARY.....21-240,21-410,

21-585,21-757

GEARTRAIN/OUTPUT SHAFT -

DISASSEMBLY, PLANETARY.....21-240,21-411,

21-586,21-757

GEARTRAIN/OUTPUT SHAFT -

INSPECTION, PLANETARY......21-241,21-411,

21-587,21-760

GEARTRAIN/OUTPUT SHAFT -

OPERATION,

PLANETARY......21-240,21-410,21-585,21-757

GENERAL - WARNINGS.............8W-01-5

GENERATOR - DESCRIPTION...........8F-29

GENERATOR - INSTALLATION...........8F-30

GENERATOR - OPERATION.............8F-29

GENERATOR - REMOVAL...............8F-30

GENERATOR CARTRIDGE FUSE -

DESCRIPTION.....................8W-97-4

GENERATOR CARTRIDGE FUSE -

INSTALLATION....................8W-97-4

GENERATOR CARTRIDGE FUSE -

OPERATION.......................8W-97-4

GENERATOR CARTRIDGE FUSE -

REMOVAL........................8W-97-4

GENERATOR RATINGS, SPECIFICATIONS . . 8F-28

GENERATOR/CHARGING SYSTEM -

SPECIFICATIONS, TORQUE.............8F-28

GLASS - DESCRIPTION, STATIONARY....23-145

GLASS - INSTALLATION, BACKLITE VENT . 23-147

GLASS - INSTALLATION, DOOR.........23-69

GLASS - INSTALLATION, SIDE VIEW

MIRROR...........................23-98

GLASS - OPERATION, STATIONARY.....23-145

GLASS - REMOVAL, BACKLITE VENT....23-147

GLASS - REMOVAL, DOOR.............23-69

GLASS - REMOVAL, SIDE VIEW MIRROR . . 23-98

GLASS RUN CHANNEL - INSTALLATION . . . 23-70

GLASS RUN CHANNEL - REMOVAL......23-70

GLASS RUN WEATHERSTRIP -

INSTALLATION, FRONT DOOR..........23-154

GLASS RUN WEATHERSTRIP -

REMOVAL, FRONT DOOR.............23-153

GLOVE BOX - ASSEMBLY.............23-112

GLOVE BOX - DISASSEMBLY..........23-112

GLOVE BOX - INSTALLATION..........23-113

GLOVE BOX - REMOVAL

..............23-112

GLOVE BOX LAMP AND SWITCH -

INSTALLATION

.......................8L-35

GLOVE BOX LAMP AND SWITCH -

REMOVAL

..........................8L-35

GLOVE BOX LATCH STRIKER -

INSTALLATION

......................23-113

GLOVE BOX LATCH STRIKER - REMOVAL

. 23-113GLOVE BOX OPENING UPPER TRIM -

INSTALLATION......................23-114

GLOVE BOX OPENING UPPER TRIM -

REMOVAL.........................23-114

GOVERNOR - DESCRIPTION,

ELECTRONIC.....21-194,21-365,21-540,21-710

GOVERNOR - INSTALLATION,

ELECTRONIC.....21-197,21-367,21-543,21-713

GOVERNOR - OPERATION, ELECTRONIC . 21-194,

21-365,21-541,21-711

GOVERNOR - REMOVAL, ELECTRONIC . . 21-196,

21-367,21-542,21-712

GRAB HANDLE - INSTALLATION,

A-PILLAR..........................23-119

GRAB HANDLE - REMOVAL, A-PILLAR . . . 23-119

GRADING - STANDARD PROCEDURE,

PISTON............................9-282

GRID - DESCRIPTION, HEATED MIRROR . . . 8G-4

GRID - DIAGNOSIS AND TESTING,

HEATED MIRROR.....................8G-4

GRID - OPERATION, HEATED MIRROR.....8G-4

GRILLE - INSTALLATION...............23-91

GRILLE - INSTALLATION, COWL.........23-90

GRILLE - REMOVAL..................23-91

GRILLE - REMOVAL, COWL............23-90

GRILLE FRAME - INSTALLATION.........23-92

GRILLE FRAME - REMOVAL............23-91

GRILLES - INSTALLATION, DEMISTER....24-32

GRILLES - REMOVAL, DEMISTER........24-31

GROUND - DESCRIPTION, SIGNAL........8E-17

GROUND - STANDARD PROCEDURE,

TESTING FOR A SHORT TO..........8W-01-6

GROUND ON FUSES POWERING

SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR SHORT TO . 8W-01-7

GROUND STRAP - INSTALLATION,

CAB-TO- BED........................8A-14

GROUND STRAP - INSTALLATION,

ENGINE-TO-BODY....................8A-13

GROUND STRAP - INSTALLATION,

HEATER CORE.......................8A-15

GROUND STRAP - REMOVAL, CAB-TO-

BED ...............................8A-14

GROUND STRAP - REMOVAL,

ENGINE-TO-BODY....................8A-13

GROUND STRAP - REMOVAL, HEATER

CORE..............................8A-14

GROUNDS - DESCRIPTION, POWER......8E-17

GUIDES AND SPRINGS - STANDARD

PROCEDURE, VALVES.........9-138,9-25,9-82

HANDLE - INSTALLATION, A-PILLAR

GRAB.............................23-119

HANDLE - INSTALLATION, ASSIST......23-124

HANDLE - INSTALLATION, EXTERIOR.....23-70

HANDLE - INSTALLATION, LATCH........23-65

HANDLE - INSTALLATION, SHUTFACE.....23-83

HANDLE - REMOVAL, A-PILLAR GRAB . . . 23-119

HANDLE - REMOVAL, ASSIST..........23-124

HANDLE - REMOVAL, EXTERIOR........23-70

HANDLE - REMOVAL, LATCH...........23-65

HANDLE - REMOVAL, SHUTFACE........23-83

HANDLE ACTUATOR - INSTALLATION,

INSIDE........................23-71,23-80

HANDLE ACTUATOR - REMOVAL,

INSIDE

........................23-71,23-80

HANDLE ESCUTCHEON - INSTALLATION

. . 23-63

HANDLE ESCUTCHEON - REMOVAL

......23-63

HANDLING - INSPECTION, STEERING

.....30-15

HANDLING NON-DEPLOYED AIRBAGS -

STANDARD PROCEDURE

...............8O-4

HARNESS - DIAGNOSIS AND TESTING,

WIRING

..........................8W-01-5

HAT PARK BRAKE SHOES - 2500/3500 -

INSTALLATION, REAR DRUM IN

..........5-42

HAT PARK BRAKE SHOES - 2500/3500 -

REMOVAL, REAR DRUM IN

..............5-41

HAZARD WARNING SYSTEM -

DESCRIPTION, TURN SIGNAL

............8L-2

HAZARD WARNING SYSTEM -

DIAGNOSIS AND TESTING, TURN

SIGNAL

.............................8L-3

HAZARD WARNING SYSTEM -

OPERATION, TURN SIGNAL

.............8L-2

HEAD - CLEANING, CYLINDER

. 9-137,9-193,9-23,

9-248,9-80

HEAD - DESCRIPTION, CYLINDER

. . 9-136,9-191,

9-22,9-246,9-79

16 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2865 of 2889

HORN RELAY - DIAGNOSIS AND

TESTING............................8H-3

HORN RELAY - OPERATION.............8H-3

HORN SWITCH - DESCRIPTION..........8H-4

HORN SWITCH - DIAGNOSIS AND

TESTING............................8H-5

HORN SWITCH - OPERATION............8H-5

HOSE - OPERATION, CRANKCASE VENT . . . 25-32

HOSE CLAMPS - DESCRIPTION...........7-2

HOSE CLAMPS - OPERATION.............7-2

HOSE WITH AIR CONDITIONING -

INSTALLATION, WATER PUMP BYPASS....7-77

HOSE WITH AIR CONDITIONING -

REMOVAL, WATER PUMP BYPASS........7-74

HOSE WITHOUT AIR CONDITIONING -

INSTALLATION, WATER PUMP BYPASS....7-78

HOSE WITHOUT AIR CONDITIONING -

REMOVAL, WATER PUMP BYPASS........7-77

HOSES - PRESSURE - DESCRIPTION.....19-37

HOSES - PRESSURE - OPERATION.......19-37

HOSES - RETURN - DESCRIPTION.......19-37

HOSES - RETURN - OPERATION.........19-37

HOSES/LINES/TUBES PRECAUTIONS -

CAUTION, REFRIGERANT..............24-42

HOSES/TUBES - DESCRIPTION, WASHER . . 8R-8

HOSES/TUBES - OPERATION, WASHER....8R-8

HOUSING - ASSEMBLY, HVAC...........24-36

HOUSING - DIAGNOSIS AND TESTING,

CLUTCH.............................6-11

HOUSING - DISASSEMBLY, HVAC........24-36

HOUSING - INSTALLATION, CLUTCH......6-13

HOUSING - INSTALLATION, GEAR........9-305

HOUSING - INSTALLATION, HVAC........24-37

HOUSING - INSTALLATION, LOCK

CYLINDER..........................19-11

HOUSING - REMOVAL, CLUTCH..........6-13

HOUSING - REMOVAL, GEAR...........9-304

HOUSING - REMOVAL, HVAC...........24-35

HOUSING - REMOVAL, LOCK CYLINDER . . 19-10

HOUSING BUSHING - INSTALLATION,

EXTENSION......21-198,21-369,21-544,21-714

HOUSING BUSHING - REMOVAL,

EXTENSION......21-198,21-369,21-544,21-714

HOUSING BUSHING AND SEAL -

INSTALLATION, EXTENSION.....21-850,21-885,

21-921

HOUSING BUSHING AND SEAL -

REMOVAL, EXTENSION . . . 21-850,21-885,21-921

HOUSING COVER - INSTALLATION, GEAR . 9-307

HOUSING COVER - REMOVAL, GEAR.....9-306

HOUSING FLUID LEAK - DIAGNOSIS AND

TESTING, CONVERTER . . . 21-148,21-319,21-491,

21-662

HOUSING INLET BAFFLE -

INSTALLATION, HVAC.................24-37

HOUSING INLET BAFFLE - REMOVAL,

HVAC..............................24-36

HOUSING PLUG - INSTALLATION,

STEERING GEAR.....................19-27

HOUSING PLUG - REMOVAL, STEERING

GEAR..............................19-27

HOUSING SEAL - INSTALLATION,

ADAPTER.....................21-132,21-87

HOUSING SEAL - INSTALLATION,

EXTENSION......21-132,21-198,21-369,21-544,

21-715,21-87

HOUSING SEAL - REMOVAL, ADAPTER . . 21-132,

21-87

HOUSING SEAL - REMOVAL,

EXTENSION......21-132,21-198,21-369,21-544,

21-714,21-87

HOW TO USE WIRING DIAGRAMS -

DESCRIPTION.....................8W-01-1

H.P. - DESCRIPTION, FUEL PUMP 235....14-66

H.P. - DESCRIPTION, FUEL PUMP 245....14-65

HUB / BEARING - INSTALLATION..........2-9

HUB / BEARING - REMOVAL..............2-9

HVAC HOUSING - ASSEMBLY...........24-36

HVAC HOUSING - DISASSEMBLY........24-36

HVAC HOUSING - INSTALLATION........24-37

HVAC HOUSING - REMOVAL

............24-35

HVAC HOUSING INLET BAFFLE -

INSTALLATION

.......................24-37

HVAC HOUSING INLET BAFFLE -

REMOVAL

..........................24-36

HVAC SYSTEM AIRFLOW - DESCRIPTION

. 24-31

HYDRAULIC BOOSTER - DIAGNOSIS

AND TESTING

........................5-17HYDRAULIC LIFTERS - CLEANING . . 9-152,9-208

HYDRAULIC LIFTERS - INSTALLATION . . . 9-152,

9-208

HYDRAULIC LIFTERS - REMOVAL . . . 9-152,9-207

HYDRAULIC LIFTERS (CAM IN BLOCK) -

CLEANING.......................9-39,9-96

HYDRAULIC LIFTERS (CAM IN BLOCK) -

INSTALLATION....................9-39,9-96

HYDRAULIC LIFTERS (CAM IN BLOCK) -

REMOVAL.......................9-39,9-96

HYDRAULIC PRESSURE TEST -

DIAGNOSIS AND TESTING......21-144,21-315,

21-487,21-658

HYDRAULIC SCHEMATICS, SCHEMATICS

AND DIAGRAMS . . 21-174,21-345,21-520,21-690

HYDRAULIC TAPPETS - DIAGNOSIS AND

TESTING..............9-151,9-206,9-38,9-95

HYDRAULIC/MECHANICAL -

DESCRIPTION.........................5-4

HYDRAULIC/MECHANICAL - WARNING.....5-5

HYDROMETER TEST - STANDARD

PROCEDURE........................8F-12

HYDROSTATIC LOCK - STANDARD

PROCEDURE......9-11,9-125,9-181,9-238,9-68

IDENTIFICATION - DESCRIPTION,

FASTENER.........................Intro.-3

IDENTIFICATION LAMP - INSTALLATION,

OUTBOARD.........................8L-29

IDENTIFICATION LAMP - REMOVAL,

OUTBOARD.........................8L-28

IDENTIFICATION NUMBER -

DESCRIPTION, VEHICLE.............Intro.-10

IDENTIFICATION PLATE - DESCRIPTION,

EQUIPMENT......................Intro.-12

IDLE AIR CONTROL MOTOR -

DESCRIPTION.......................14-41

IDLE AIR CONTROL MOTOR -

OPERATION.........................14-41

I.F.S. - STANDARD PROCEDURES,

ALIGNMENT...........................2-2

IGNITION - SPECIFICATIONS, TORQUE.....8I-2

IGNITION CIRCUIT SENSE -

DESCRIPTION.......................8E-17

IGNITION CIRCUIT SENSE - OPERATION . . 8E-19

IGNITION COIL RESISTANCE, 3.9L/5.2L/

5.9L ENGINES........................8I-3

IGNITION COIL RESISTANCE, 8.0L V-10

ENGINE..............................8I-3

IGNITION SWITCH - DESCRIPTION.......19-11

IGNITION SWITCH - DESCRIPTION,

KEY-IN..............................19-9

IGNITION SWITCH - DIAGNOSIS AND

TESTING...........................19-11

IGNITION SWITCH - INSTALLATION......19-12

IGNITION SWITCH - OPERATION........19-11

IGNITION SWITCH - REMOVAL..........19-12

IGNITION SWITCH AND KEY LOCK

CYLINDER - DIAGNOSIS AND TESTING . . . 19-10

IGNITION TIMING, SPECIFICATIONS.......8I-3

IGNITION-OFF DRAW TEST - STANDARD

PROCEDURE........................8F-15

IMPORTANCE OF CAREFUL NEW

VEHICLE PREPARATION -

DESCRIPTION, THE....................30-1

INCH - INSTALLATION, 12 1/8...........5-28

INCH - INSTALLATION, REAR BRAKE

SHOES-11...........................5-27

INCH - REMOVAL, 12 1/8...............5-26

INCH - REMOVAL, REAR BRAKE

SHOES-11...........................5-25

INCORRECT FLUID LEVEL - DIAGNOSIS

AND TESTING, EFFECTS OF.....21-199,21-370,

21-545,21-715

INDEPENDENT FRONT SUSPENSION,

SPECIAL TOOLS.......................2-9

INDICATOR - DESCRIPTION, ABS........8J-14

INDICATOR - DESCRIPTION, AIRBAG.....8J-15

INDICATOR - DESCRIPTION, BRAKE/

PARK BRAKE........................8J-16

INDICATOR - DESCRIPTION, CHECK

GAUGES............................8J-17

INDICATOR - DESCRIPTION, CRUISE

.....8J-18

INDICATOR - DESCRIPTION, GEAR

SELECTOR

..........................8J-21

INDICATOR - DESCRIPTION, HIGH BEAM

. . 8J-21

INDICATOR - DESCRIPTION, LOW FUEL

. . . 8J-23

INDICATOR - DESCRIPTION, OVERDRIVE

OFF

...............................8J-27INDICATOR - DESCRIPTION, SEATBELT . . . 8J-27

INDICATOR - DESCRIPTION, SERVICE

REMINDER..........................8J-28

INDICATOR - DESCRIPTION,

TRANSMISSION OVERTEMP............8J-31

INDICATOR - DESCRIPTION, UPSHIFT....8J-33

INDICATOR - DESCRIPTION, VTSS........8Q-3

INDICATOR - DESCRIPTION, WAIT-TO-

START .............................8J-34

INDICATOR - DESCRIPTION, WASHER

FLUID..............................8J-35

INDICATOR - DESCRIPTION, WATER-IN-

FUEL..............................8J-36

INDICATOR - DIAGNOSIS AND TESTING,

BRAKE.............................8J-16

INDICATOR - DIAGNOSIS AND TESTING,

FOUR-WHEEL DRIVE..................8J-29

INDICATOR - DIAGNOSIS AND TESTING,

HIGH BEAM.........................8J-22

INDICATOR - DIAGNOSIS AND TESTING,

VTSS...............................8Q-3

INDICATOR - DIAGNOSIS AND TESTING,

WASHER FLUID......................8J-36

INDICATOR - OPERATION, ABS..........8J-14

INDICATOR - OPERATION, AIRBAG.......8J-15

INDICATOR - OPERATION, BRAKE/PARK

BRAKE.............................8J-16

INDICATOR - OPERATION, CHECK

GAUGES............................8J-17

INDICATOR - OPERATION, CRUISE.......8J-18

INDICATOR - OPERATION, GEAR

SELECTOR...........................8J-21

INDICATOR - OPERATION, HIGH BEAM....8J-22

INDICATOR - OPERATION, LOW FUEL.....8J-23

INDICATOR - OPERATION, OVERDRIVE

OFF ...............................8J-27

INDICATOR - OPERATION, SEATBELT.....8J-27

INDICATOR - OPERATION, SERVICE

REMINDER..........................8J-28

INDICATOR - OPERATION,

TRANSMISSION OVERTEMP............8J-31

INDICATOR - OPERATION, UPSHIFT......8J-33

INDICATOR - OPERATION, VTSS.........8Q-3

INDICATOR - OPERATION, WAIT-TO-

START .............................8J-35

INDICATOR - OPERATION, WASHER

FLUID..............................8J-35

INDICATOR - OPERATION, WATER-IN-

FUEL..............................8J-37

INDICATOR LAMP (MIL) - DESCRIPTION,

MALFUNCTION.......................8J-24

INDICATOR LAMP (MIL) - OPERATION,

MALFUNCTION.......................8J-24

INDICATOR TEST - STANDARD

PROCEDURE, BUILT-IN................8F-11

INDICATOR (TRANSFER CASE) -

DESCRIPTION, SHIFT.................8J-29

INDICATOR (TRANSFER CASE) -

OPERATION, SHIFT...................8J-29

INDICATORS - DESCRIPTION, TURN

SIGNAL............................8J-32

INDICATORS - DIAGNOSIS AND

TESTING, TREAD WEAR................22-7

INDICATORS - DIAGNOSIS AND

TESTING, TURN SIGNAL...............8J-32

INDICATORS - OPERATION, TURN

SIGNAL............................8J-32

INITIAL OPERATION - STANDARD

PROCEDURE, POWER STEERING

PUMP

.............................19-31

INJECTION - SPECIFICATIONS, TORQUE -

GAS FUEL

..........................14-35

INJECTION PUMP - DESCRIPTION, AIR

. . . 25-28

INJECTION PUMP - DIAGNOSIS AND

TESTING, AIR

.......................25-28

INJECTION PUMP - INSTALLATION, AIR

. . . 25-29

INJECTION PUMP - INSTALLATION, FUEL

. 14-71

INJECTION PUMP - OPERATION, AIR

.....25-28

INJECTION PUMP - OPERATION, FUEL

....14-66

INJECTION PUMP - REMOVAL, AIR

......25-29

INJECTION PUMP - REMOVAL, FUEL

.....14-68

INJECTION PUMP DATA PLATE,

SPECIFICATIONS - FUEL

...............14-73

INJECTION PUMP RELAY -

DESCRIPTION, FUEL

..................14-99

INJECTION PUMP RELAY - OPERATION,

FUEL

..............................14-99

18 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2866 of 2889

INJECTION PUMP TIMING - DIAGNOSIS

AND TESTING, FUEL..................14-66

INJECTION SYSTEM - DESCRIPTION, AIR . 25-25

INJECTION SYSTEM - DESCRIPTION,

DIESEL FUEL........................14-87

INJECTION SYSTEM - OPERATION, AIR . . . 25-27

INJECTION SYSTEM - TORQUE, AIR......25-28

INJECTOR - DESCRIPTION, FUEL . . . 14-53,14-93

INJECTOR - INSTALLATION, FUEL . . 14-53,14-98

INJECTOR - OPERATION, FUEL.....14-53,14-94

INJECTOR - REMOVAL, FUEL......14-53,14-96

INJECTOR FIRING ORDER, DIESEL -

FUEL..............................14-58

INJECTOR TEST - DIAGNOSIS AND

TESTING, FUEL.................14-53,14-95

INLET BAFFLE - INSTALLATION, HVAC

HOUSING...........................24-37

INLET BAFFLE - REMOVAL, HVAC

HOUSING...........................24-36

INLET FILTER - INSTALLATION..........14-22

INLET FILTER - REMOVAL..............14-22

INNER BELT WEATHERSTRIP -

INSTALLATION, FRONT DOOR..........23-154

INNER BELT WEATHERSTRIP -

REMOVAL, FRONT DOOR.............23-154

IN/OUT - ADJUSTMENT, FRONT DOOR....23-69

INPUT - DESCRIPTION, VEHICLE SPEED . . . 8P-1

INPUT - OPERATION, ASD SENSE - PCM . . . 8I-3

INSIDE HANDLE ACTUATOR -

INSTALLATION...................23-71,23-80

INSIDE HANDLE ACTUATOR - REMOVAL . . 23-71,

23-80

INSPECTION - DESCRIPTION, ROAD

TEST..............................30-15

INSPECTION - DIAGNOSIS AND

TESTING, WHEEL....................22-10

INSPECTION - INFORMATION LABELS -

STANDARD PROCEDURE...............30-22

INSPECTION, 3.9L/5.2L/5.9L ENGINES -

VISUAL............................14-28

INSPECTION, 8.0L ENGINE - VISUAL.....14-32

INSPECTION, A/C COMPRESSOR

CLUTCH............................24-16

INSPECTION, ACCUMULATOR . . . 21-192,21-363,

21-538,21-708

INSPECTION, AUTOMATIC

TRANSMISSION - 42RE...............21-165

INSPECTION, AUTOMATIC

TRANSMISSION - 44RE...............21-337

INSPECTION, AUTOMATIC

TRANSMISSION - 46RE...............21-510

INSPECTION, AUTOMATIC

TRANSMISSION - 47RE...............21-681

INSPECTION, BATTERY.................30-7

INSPECTION, BATTERY SYSTEM..........8F-5

INSPECTION, BODY SEALING...........30-10

INSPECTION, CAMSHAFT & BEARINGS

(IN BLOCK).........................9-272

INSPECTION, CATALYTIC CONVERTER -

3.9L/5.2L/5.9L........................11-5

INSPECTION, CATALYTIC CONVERTER -

5.9L HEAVY DUTY/8.0L.................11-7

INSPECTION, CHARGE AIR COOLER AND

PLUMBING.........................11-18

INSPECTION, COMPASS...............30-12

INSPECTION, CROSSHEADS............9-250

INSPECTION, CYLINDER HEAD....9-137,9-193,

9-23,9-250,9-80

INSPECTION, CYLINDER HEAD COVER(S) . 9-138,

9-194,9-24,9-253,9-81

INSPECTION, DISC BRAKE CALIPERS......5-12

INSPECTION, DOORS AND DOOR LOCKS . . 30-11

INSPECTION, DRUM...................5-33

INSPECTION, ENGINE BLOCK . 9-142,9-200,9-267,

9-28,9-86

INSPECTION, ENGINE PERFORMANCE....30-16

INSPECTION, EXHAUST MANIFOLD . 9-112,9-168,

9-225,9-304,9-55

INSPECTION, EXHAUST PIPE -

3.9L/5.2L/5.9L........................11-7

INSPECTION, EXHAUST PIPE - 5.9L

DIESEL

.............................11-9

INSPECTION, EXHAUST PIPE - 5.9L

HEAVY DUTY/8.0L

.....................11-9

INSPECTION, FIT AND FINISH

......30-10,30-12

INSPECTION, FLUID LEVELS

.............30-4

INSPECTION, FRONT CLUTCH

. . . 21-205,21-376,

21-550,21-721INSPECTION, FRONT SERVO....21-207,21-378,

21-553,21-723

INSPECTION, FUEL...................30-15

INSPECTION, GAUGES/WARNING LIGHTS . 30-19

INSPECTION, HEATER/AIR CONDITIONER . . 30-17

INSPECTION, HOOD LATCH/SAFETY

CATCH ..............................30-4

INSPECTION, HORN..................30-19

INSPECTION, INTAKE MANIFOLD . . . 9-110,9-166,

9-223,9-302,9-53

INSPECTION, INTAKE/EXHAUST VALVES

& SEATS ..............9-141,9-198,9-27,9-84

INSPECTION, KEYLESS ENTRY..........30-11

INSPECTION, LIGHTS AND SWITCHES....30-12

INSPECTION, LINES/HOSES.............30-6

INSPECTION, MANUAL - NV3500........21-15

INSPECTION, MEASURING TIMING

CHAIN STRETCH.......9-114,9-170,9-227,9-58

INSPECTION, MIRROR................30-19

INSPECTION, NEUTRAL SAFETY SWITCH . . 30-19

INSPECTION, OIL COOLER & LINES -

CLEANING..........................9-296

INSPECTION, OIL PAN . 9-106,9-162,9-219,9-297,

9-49

INSPECTION, OIL PRESSURE RELIEF

VALVE .............................9-297

INSPECTION, OIL PUMP....9-107,9-163,9-220,

9-299,9-50

INSPECTION, OIL PUMP . . 21-211,21-382,21-557,

21-728

INSPECTION, OTHER..................30-15

INSPECTION, OVERDRIVE UNIT . . 21-224,21-394,

21-569,21-741

INSPECTION, OVERRUNNING CLUTCH

CAM/OVERDRIVE PISTON RETAINER....21-236,

21-406,21-580,21-752

INSPECTION, PARKING BRAKE..........30-17

INSPECTION, PISTON & CONNECTING

ROD ............9-154,9-209,9-285,9-41,9-98

INSPECTION, PLANETARY GEARTRAIN/

OUTPUT SHAFT . . . 21-241,21-411,21-587,21-760

INSPECTION, PUSHRODS..............9-250

INSPECTION, RADIATOR - 3.9L/5.2L/5.9L . . . 7-61

INSPECTION, RADIATOR - 5.9L DIESEL....7-65

INSPECTION, RADIATOR - 8.0L..........7-62

INSPECTION, RADIATOR FAN -

3.9L/5.2L/5.9L/8.0L....................7-43

INSPECTION, RADIATOR FAN - 5.9L

DIESEL.............................7-44

INSPECTION, RADIATOR PRESSURE CAP . . . 7-66

INSPECTION, RADIO..................30-17

INSPECTION, REAR CLUTCH....21-248,21-419,

21-593,21-765

INSPECTION, RECEIVING...............30-3

INSPECTION, ROCKER ARM / ADJUSTER

ASSY..............................9-262

INSPECTION, SEAT BELTS, SHOULDER

BELTS, RETRACTORS AND HEAD

RESTRAINTS........................30-12

INSPECTION, SEATS..................30-13

INSPECTION, SERVICE BRAKES.........30-17

INSPECTION, SHIFT/CLUTCH INTERLOCK

SYSTEM............................30-19

INSPECTION, SOLID LIFTERS/TAPPETS . . . 9-281

INSPECTION, SPEED CONTROL.........30-17

INSPECTION, SQUEAKS, RATTLES AND

WIND NOISE........................30-15

INSPECTION, STEERING AND HANDLING

. . 30-15

INSPECTION, TAILPIPE - 3.9L/5.2L/5.9L

. . . 11-11

INSPECTION, TAILPIPE - 5.9L DIESEL

....11-12

INSPECTION, TAILPIPE - 5.9L HEAVY

DUTY/8.0L

..........................11-12

INSPECTION, TIRE PRESSURES

..........30-8

INSPECTION, TRANSFER CASE -

NV231HD

..........................21-832

INSPECTION, TRANSFER CASE -

NV241HD

..........................21-902

INSPECTION, TRANSFER CASE -

NV241LD

..........................21-867

INSPECTION, TRANSMISSION

.....21-109,21-64

INSPECTION, TRANSMISSION/TRANSFER

CASE

..............................30-15

INSPECTION, TRIP COMPUTER/

MAINTENANCE REMINDER

.............30-17

INSPECTION, TURBOCHARGER

..........11-16

INSPECTION, TURN AND EMERGENCY

SIGNALS

...........................30-19INSPECTION, VALVE BODY......21-293,21-465,

21-637,21-809

INSPECTION, VIBRATION DAMPER.......9-289

INSPECTION, VISUAL..................30-8

INSPECTION, WATER PUMP -

3.9L/5.2L/5.9L........................7-69

INSPECTION, WATER PUMP - 5.9L

DIESEL.............................7-73

INSPECTION, WATER PUMP - 8.0L........7-72

INSPECTION, WHEEL CYLINDERS........5-31

INSPECTION, WINDOWS, DOORS AND

LOCKS.............................30-14

INSPECTION WINDSHIELD WIPERS/

WASHERS, ROAD TEST................30-18

INSPECTION, WIPER & WASHER

SYSTEM............................8R-6

INSPECTION, WIRING..................30-7

INSTALLED - INSTALLATION, FRONT OIL

SEAL - FRONT COVER.................9-205

INSTALLED - REMOVAL, FRONT OIL

SEAL - FRONT COVER.................9-204

INSTRUMENT CLUSTER - ASSEMBLY.....8J-13

INSTRUMENT CLUSTER - DESCRIPTION . . . 8J-2

INSTRUMENT CLUSTER - DIAGNOSIS

AND TESTING........................8J-6

INSTRUMENT CLUSTER - DISASSEMBLY . . 8J-11

INSTRUMENT CLUSTER - INSTALLATION . . 8J-14

INSTRUMENT CLUSTER - OPERATION.....8J-3

INSTRUMENT CLUSTER - REMOVAL.....8J-10

INSTRUMENT PANEL ANTENNA CABLE -

INSTALLATION.......................8A-10

INSTRUMENT PANEL ANTENNA CABLE -

REMOVAL...........................8A-9

INSTRUMENT PANEL DEMISTER DUCTS

- REMOVAL.........................24-37

INSTRUMENT PANEL DUCTS - REMOVAL . 24-37

INSTRUMENT PANEL SYSTEM -

DESCRIPTION......................23-104

INSTRUMENT PANEL SYSTEM -

INSTALLATION......................23-107

INSTRUMENT PANEL SYSTEM -

OPERATION........................23-105

INSTRUMENT PANEL SYSTEM -

REMOVAL.........................23-106

INSTRUMENT PANEL TOP COVER -

INSTALLATION......................23-115

INSTRUMENT PANEL TOP COVER -

REMOVAL.........................23-114

INTAKE AIR HEATER - DESCRIPTION....14-100

INTAKE AIR HEATER - INSTALLATION....14-101

INTAKE AIR HEATER - OPERATION......14-100

INTAKE AIR HEATER - REMOVAL.......14-100

INTAKE AIR HEATER RELAY -

DESCRIPTION......................14-101

INTAKE AIR HEATER RELAY -

INSTALLATION......................14-102

INTAKE AIR HEATER RELAY -

OPERATION........................14-102

INTAKE AIR HEATER RELAY - REMOVAL . 14-102

INTAKE MANIFOLD - CLEANING

....9-110,9-166,

9-223,9-302,9-53

INTAKE MANIFOLD - DESCRIPTION

. 9-109,9-165,

9-222,9-52

INTAKE MANIFOLD - INSPECTION

. . 9-110,9-166,

9-223,9-302,9-53

INTAKE MANIFOLD - INSTALLATION

.....9-111,

9-166,9-223,9-302,9-53

INTAKE MANIFOLD - OPERATION

. . 9-109,9-165,

9-52

INTAKE MANIFOLD - REMOVAL

....9-110,9-166,

9-222,9-301,9-53

INTAKE MANIFOLD LEAKAGE -

DIAGNOSIS AND TESTING

. . . 9-110,9-165,9-222,

9-53

INTAKE/EXHAUST VALVES & SEATS -

CLEANING

.............9-140,9-198,9-27,9-84

INTAKE/EXHAUST VALVES & SEATS -

DESCRIPTION

.....9-138,9-195,9-25,9-253,9-81

INTAKE/EXHAUST VALVES & SEATS -

INSPECTION

...........9-141,9-198,9-27,9-84

INTAKE/EXHAUST VALVES & SEATS -

INSTALLATION

.........9-141,9-260,9-28,9-85

INTAKE/EXHAUST VALVES & SEATS -

REMOVAL

.............9-140,9-258,9-27,9-84

INTAKE/EXHAUST VALVES & SEATS -

STANDARD PROCEDURE-

VALVES,GUIDES AND SPRINGS

.........9-253

BR/BEINDEX 19

Description Group-Page Description Group-Page Description Group-Page