steering DODGE RAM 2001 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 54 of 2889

(5) Install the steering knuckle on the lower ball

joint. Install the lower ball joint nut and tighten to:

²LD: 129 N´m (95 ft. lbs.)

²HD: 136 N´m (110 ft. lbs.)

(5) Install the lower ball joint cotter pin.

(6) Install the stabilizer bar link on the lower sus-

pension arm. Install the grommet, retainer and nut

and tighten to 37 N´m (27 ft. lbs.).

(7) Install the tie rod end on the steering knuckle

and tighten nut to 108 N´m (80 ft. lbs.). Install cotter

pin.

(8) Install the brake rotor and caliper assembly,

(Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/

ROTORS - INSTALLATION).

(9) Install the tire and wheel assembly, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

(10) Remove the support and lower the vehicle.

(11) Tighten the suspension arm crossmember

nuts to 169 N´m (125 ft. lbs.).

SHOCK

DESCRIPTION

The top of the shocks mounts on frame brackets

using grommets. The bottom of the shock is bolted to

the lower suspension arms.

OPERATION

The shock absorbers dampen jounce and rebound

of the vehicle over various road conditions.

DIAGNOSIS AND TESTING - SHOCK

A knocking or rattling noise from a shock absorber

may be caused by movement between mounting

bushings and metal brackets or attaching compo-

nents. These noises can usually be stopped by tight-

ening the attaching nuts. If the noise persists,

inspect for damaged and worn bushings, and attach-

ing components. Repair as necessary if any of these

conditions exist.

A squeaking noise from the shock absorber may be

caused by the hydraulic valving and may be intermit-

tent. This condition is not repairable and the shock

absorber must be replaced.

The shock absorbers are not refillable or adjust-

able. If a malfunction occurs, the shock absorber

must be replaced. To test a shock absorber, hold it in

an upright position and force the piston in and out of

the cylinder four or five times. The action throughout

each stroke should be smooth and even.

The shock absorber bushings do not require any

type of lubrication. Do not attempt to stop bushing

noise by lubricating them. Grease and mineral oil-

base lubricants will deteriorate the bushing.

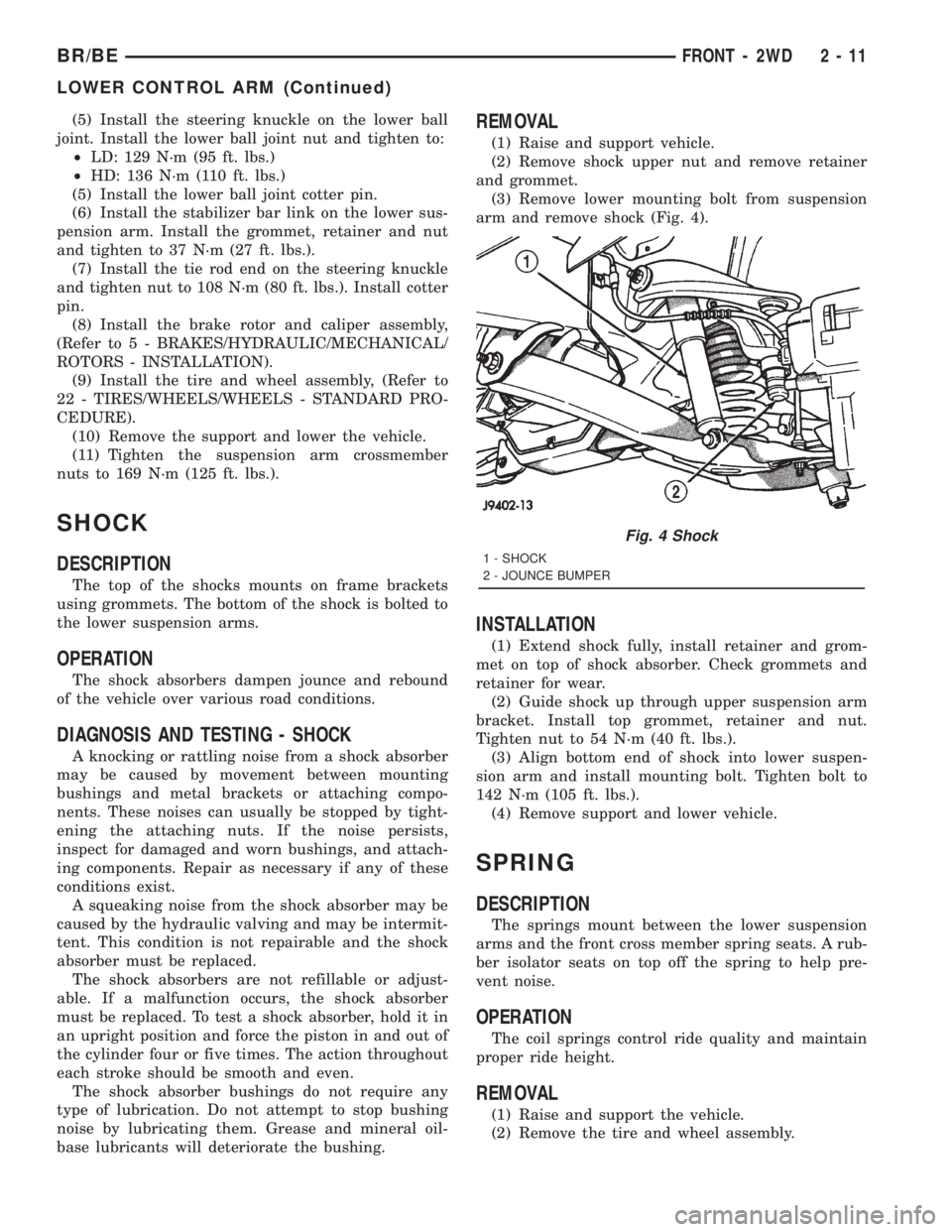

REMOVAL

(1) Raise and support vehicle.

(2) Remove shock upper nut and remove retainer

and grommet.

(3) Remove lower mounting bolt from suspension

arm and remove shock (Fig. 4).

INSTALLATION

(1) Extend shock fully, install retainer and grom-

met on top of shock absorber. Check grommets and

retainer for wear.

(2) Guide shock up through upper suspension arm

bracket. Install top grommet, retainer and nut.

Tighten nut to 54 N´m (40 ft. lbs.).

(3) Align bottom end of shock into lower suspen-

sion arm and install mounting bolt. Tighten bolt to

142 N´m (105 ft. lbs.).

(4) Remove support and lower vehicle.

SPRING

DESCRIPTION

The springs mount between the lower suspension

arms and the front cross member spring seats. A rub-

ber isolator seats on top off the spring to help pre-

vent noise.

OPERATION

The coil springs control ride quality and maintain

proper ride height.

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the tire and wheel assembly.

Fig. 4 Shock

1 - SHOCK

2 - JOUNCE BUMPER

BR/BEFRONT - 2WD 2 - 11

LOWER CONTROL ARM (Continued)

Page 55 of 2889

(3) Remove the brake caliper assembly and rotor,

(Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/

ROTORS - REMOVAL).

(4) Remove the cotter pin and nut from the tie rod.

Remove the tie rod end from the steering knuckle

with Puller C-3894-A.

(5) Remove the stabilizer bar link from the lower

suspension arm.

(6) Support the lower suspension arm outboard

end with a jack. Place a jack under the arm in front

of the shock mount.

(7) Remove the cotter pin and nut from the lower

ball joint. Separate the ball joint with Remover

C-4150A.

(8) Remove the lower shock bolt from the suspen-

sion arm.

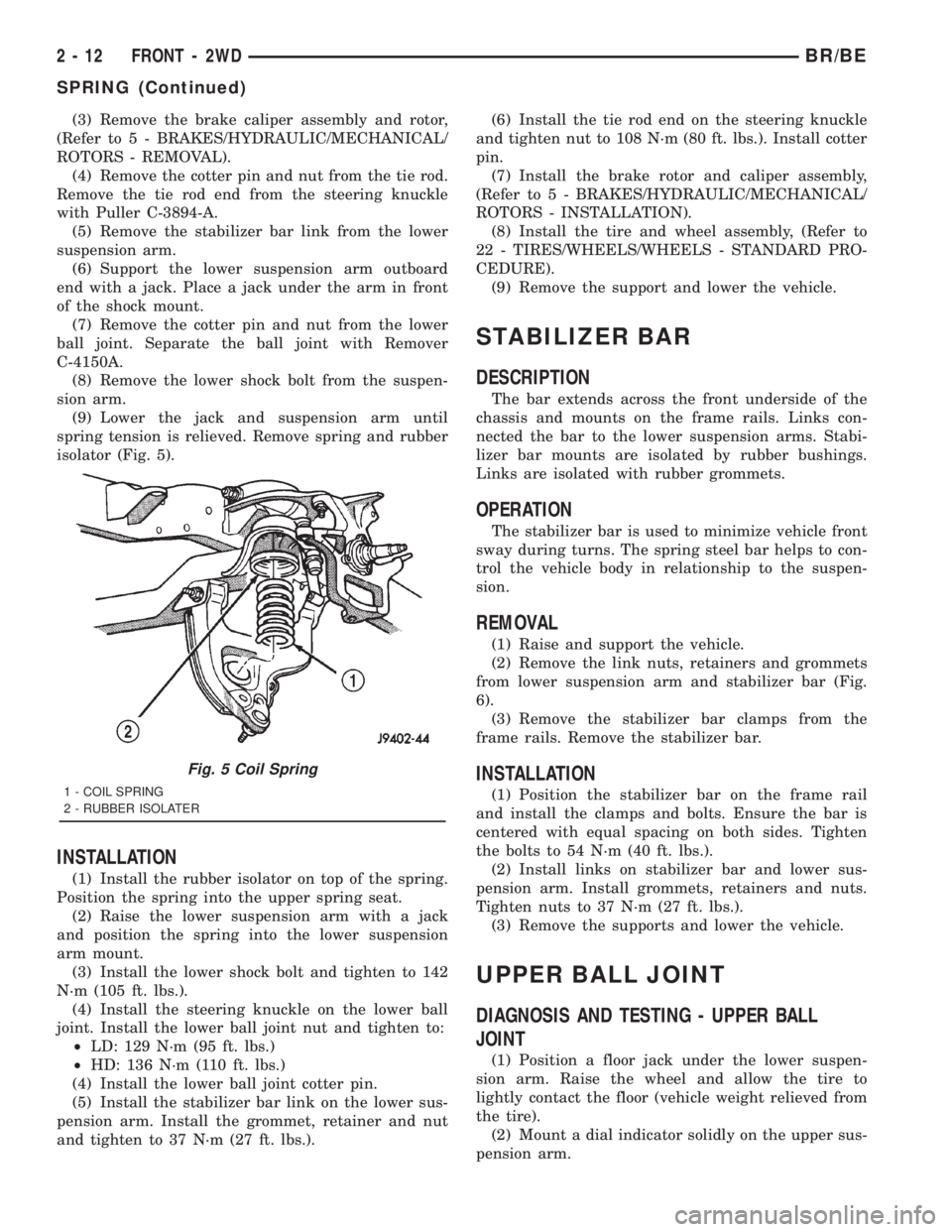

(9) Lower the jack and suspension arm until

spring tension is relieved. Remove spring and rubber

isolator (Fig. 5).

INSTALLATION

(1) Install the rubber isolator on top of the spring.

Position the spring into the upper spring seat.

(2) Raise the lower suspension arm with a jack

and position the spring into the lower suspension

arm mount.

(3) Install the lower shock bolt and tighten to 142

N´m (105 ft. lbs.).

(4) Install the steering knuckle on the lower ball

joint. Install the lower ball joint nut and tighten to:

²LD: 129 N´m (95 ft. lbs.)

²HD: 136 N´m (110 ft. lbs.)

(4) Install the lower ball joint cotter pin.

(5) Install the stabilizer bar link on the lower sus-

pension arm. Install the grommet, retainer and nut

and tighten to 37 N´m (27 ft. lbs.).(6) Install the tie rod end on the steering knuckle

and tighten nut to 108 N´m (80 ft. lbs.). Install cotter

pin.

(7) Install the brake rotor and caliper assembly,

(Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/

ROTORS - INSTALLATION).

(8) Install the tire and wheel assembly, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

(9) Remove the support and lower the vehicle.

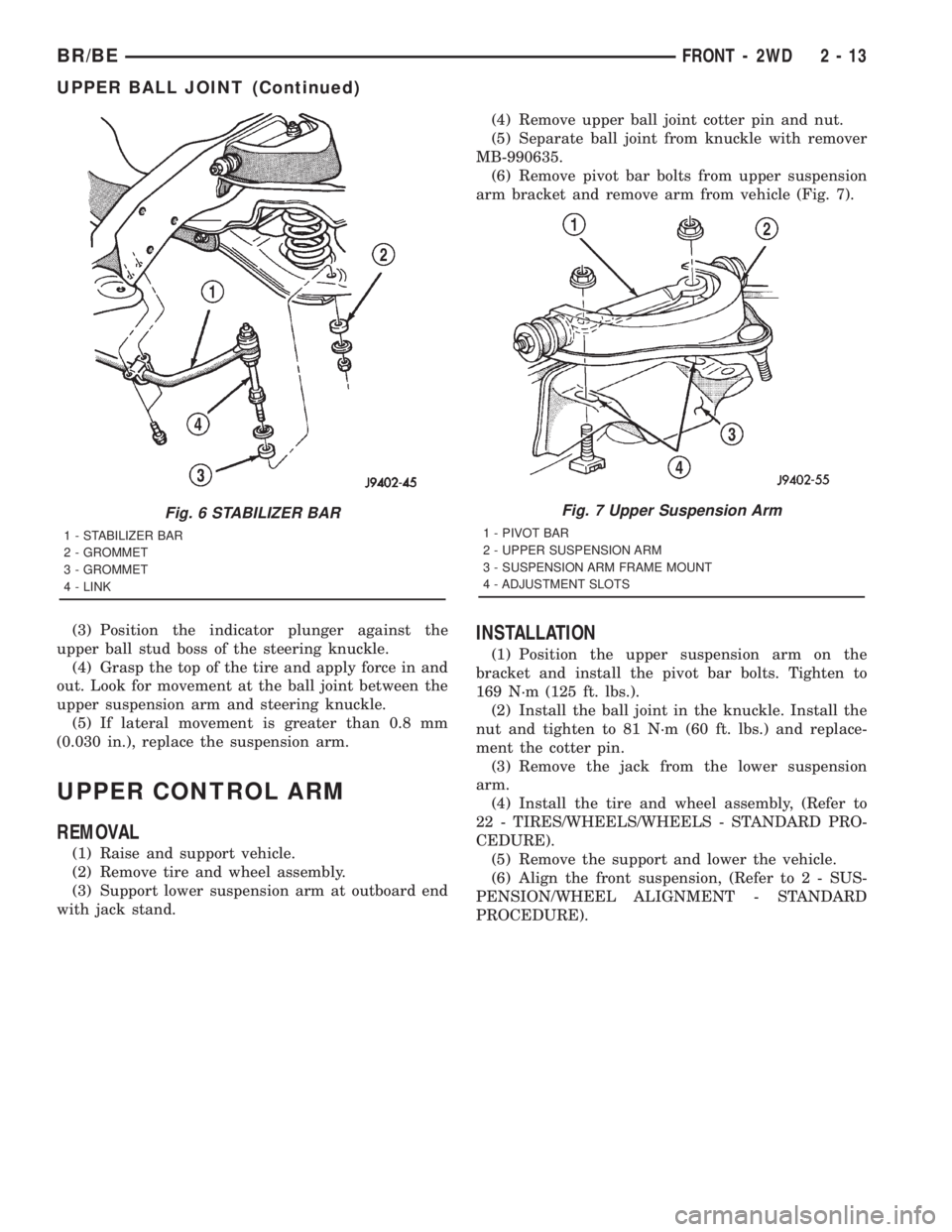

STABILIZER BAR

DESCRIPTION

The bar extends across the front underside of the

chassis and mounts on the frame rails. Links con-

nected the bar to the lower suspension arms. Stabi-

lizer bar mounts are isolated by rubber bushings.

Links are isolated with rubber grommets.

OPERATION

The stabilizer bar is used to minimize vehicle front

sway during turns. The spring steel bar helps to con-

trol the vehicle body in relationship to the suspen-

sion.

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the link nuts, retainers and grommets

from lower suspension arm and stabilizer bar (Fig.

6).

(3) Remove the stabilizer bar clamps from the

frame rails. Remove the stabilizer bar.

INSTALLATION

(1) Position the stabilizer bar on the frame rail

and install the clamps and bolts. Ensure the bar is

centered with equal spacing on both sides. Tighten

the bolts to 54 N´m (40 ft. lbs.).

(2) Install links on stabilizer bar and lower sus-

pension arm. Install grommets, retainers and nuts.

Tighten nuts to 37 N´m (27 ft. lbs.).

(3) Remove the supports and lower the vehicle.

UPPER BALL JOINT

DIAGNOSIS AND TESTING - UPPER BALL

JOINT

(1) Position a floor jack under the lower suspen-

sion arm. Raise the wheel and allow the tire to

lightly contact the floor (vehicle weight relieved from

the tire).

(2) Mount a dial indicator solidly on the upper sus-

pension arm.

Fig. 5 Coil Spring

1 - COIL SPRING

2 - RUBBER ISOLATER

2 - 12 FRONT - 2WDBR/BE

SPRING (Continued)

Page 56 of 2889

(3) Position the indicator plunger against the

upper ball stud boss of the steering knuckle.

(4) Grasp the top of the tire and apply force in and

out. Look for movement at the ball joint between the

upper suspension arm and steering knuckle.

(5) If lateral movement is greater than 0.8 mm

(0.030 in.), replace the suspension arm.

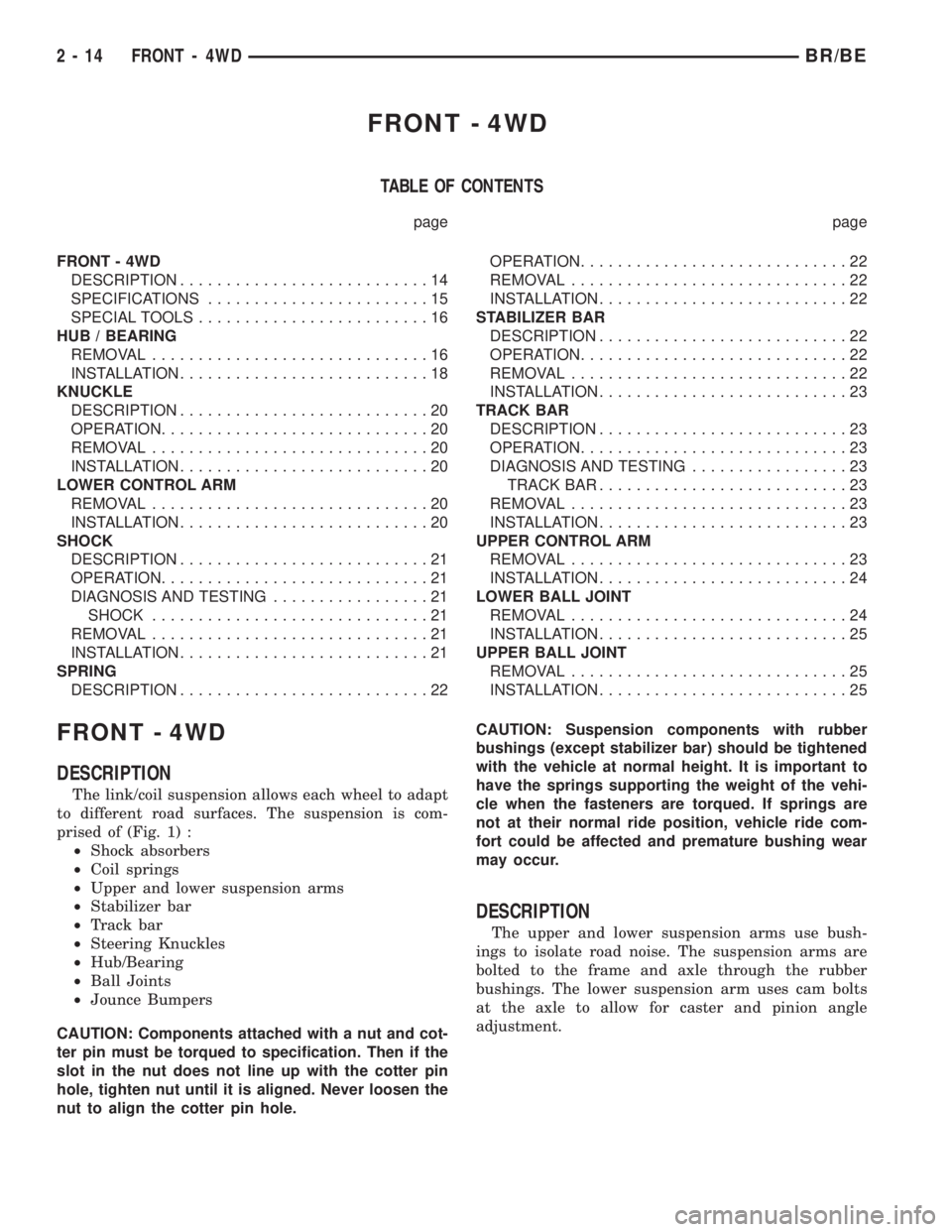

UPPER CONTROL ARM

REMOVAL

(1) Raise and support vehicle.

(2) Remove tire and wheel assembly.

(3) Support lower suspension arm at outboard end

with jack stand.(4) Remove upper ball joint cotter pin and nut.

(5) Separate ball joint from knuckle with remover

MB-990635.

(6) Remove pivot bar bolts from upper suspension

arm bracket and remove arm from vehicle (Fig. 7).

INSTALLATION

(1) Position the upper suspension arm on the

bracket and install the pivot bar bolts. Tighten to

169 N´m (125 ft. lbs.).

(2) Install the ball joint in the knuckle. Install the

nut and tighten to 81 N´m (60 ft. lbs.) and replace-

ment the cotter pin.

(3) Remove the jack from the lower suspension

arm.

(4) Install the tire and wheel assembly, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

(5) Remove the support and lower the vehicle.

(6) Align the front suspension, (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

Fig. 6 STABILIZER BAR

1 - STABILIZER BAR

2 - GROMMET

3 - GROMMET

4 - LINK

Fig. 7 Upper Suspension Arm

1 - PIVOT BAR

2 - UPPER SUSPENSION ARM

3 - SUSPENSION ARM FRAME MOUNT

4 - ADJUSTMENT SLOTS

BR/BEFRONT - 2WD 2 - 13

UPPER BALL JOINT (Continued)

Page 57 of 2889

FRONT - 4WD

TABLE OF CONTENTS

page page

FRONT - 4WD

DESCRIPTION...........................14

SPECIFICATIONS........................15

SPECIAL TOOLS.........................16

HUB / BEARING

REMOVAL..............................16

INSTALLATION...........................18

KNUCKLE

DESCRIPTION...........................20

OPERATION.............................20

REMOVAL..............................20

INSTALLATION...........................20

LOWER CONTROL ARM

REMOVAL..............................20

INSTALLATION...........................20

SHOCK

DESCRIPTION...........................21

OPERATION.............................21

DIAGNOSIS AND TESTING.................21

SHOCK..............................21

REMOVAL..............................21

INSTALLATION...........................21

SPRING

DESCRIPTION...........................22OPERATION.............................22

REMOVAL..............................22

INSTALLATION...........................22

STABILIZER BAR

DESCRIPTION...........................22

OPERATION.............................22

REMOVAL..............................22

INSTALLATION...........................23

TRACK BAR

DESCRIPTION...........................23

OPERATION.............................23

DIAGNOSIS AND TESTING.................23

TRACK BAR...........................23

REMOVAL..............................23

INSTALLATION...........................23

UPPER CONTROL ARM

REMOVAL..............................23

INSTALLATION...........................24

LOWER BALL JOINT

REMOVAL..............................24

INSTALLATION...........................25

UPPER BALL JOINT

REMOVAL..............................25

INSTALLATION...........................25

FRONT - 4WD

DESCRIPTION

The link/coil suspension allows each wheel to adapt

to different road surfaces. The suspension is com-

prised of (Fig. 1) :

²Shock absorbers

²Coil springs

²Upper and lower suspension arms

²Stabilizer bar

²Track bar

²Steering Knuckles

²Hub/Bearing

²Ball Joints

²Jounce Bumpers

CAUTION: Components attached with a nut and cot-

ter pin must be torqued to specification. Then if the

slot in the nut does not line up with the cotter pin

hole, tighten nut until it is aligned. Never loosen the

nut to align the cotter pin hole.CAUTION: Suspension components with rubber

bushings (except stabilizer bar) should be tightened

with the vehicle at normal height. It is important to

have the springs supporting the weight of the vehi-

cle when the fasteners are torqued. If springs are

not at their normal ride position, vehicle ride com-

fort could be affected and premature bushing wear

may occur.

DESCRIPTION

The upper and lower suspension arms use bush-

ings to isolate road noise. The suspension arms are

bolted to the frame and axle through the rubber

bushings. The lower suspension arm uses cam bolts

at the axle to allow for caster and pinion angle

adjustment.

2 - 14 FRONT - 4WDBR/BE

Page 59 of 2889

SPECIAL TOOLS

LINK/COIL SUSPENSION

HUB / BEARING

REMOVAL - 2500/3500

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assembly.

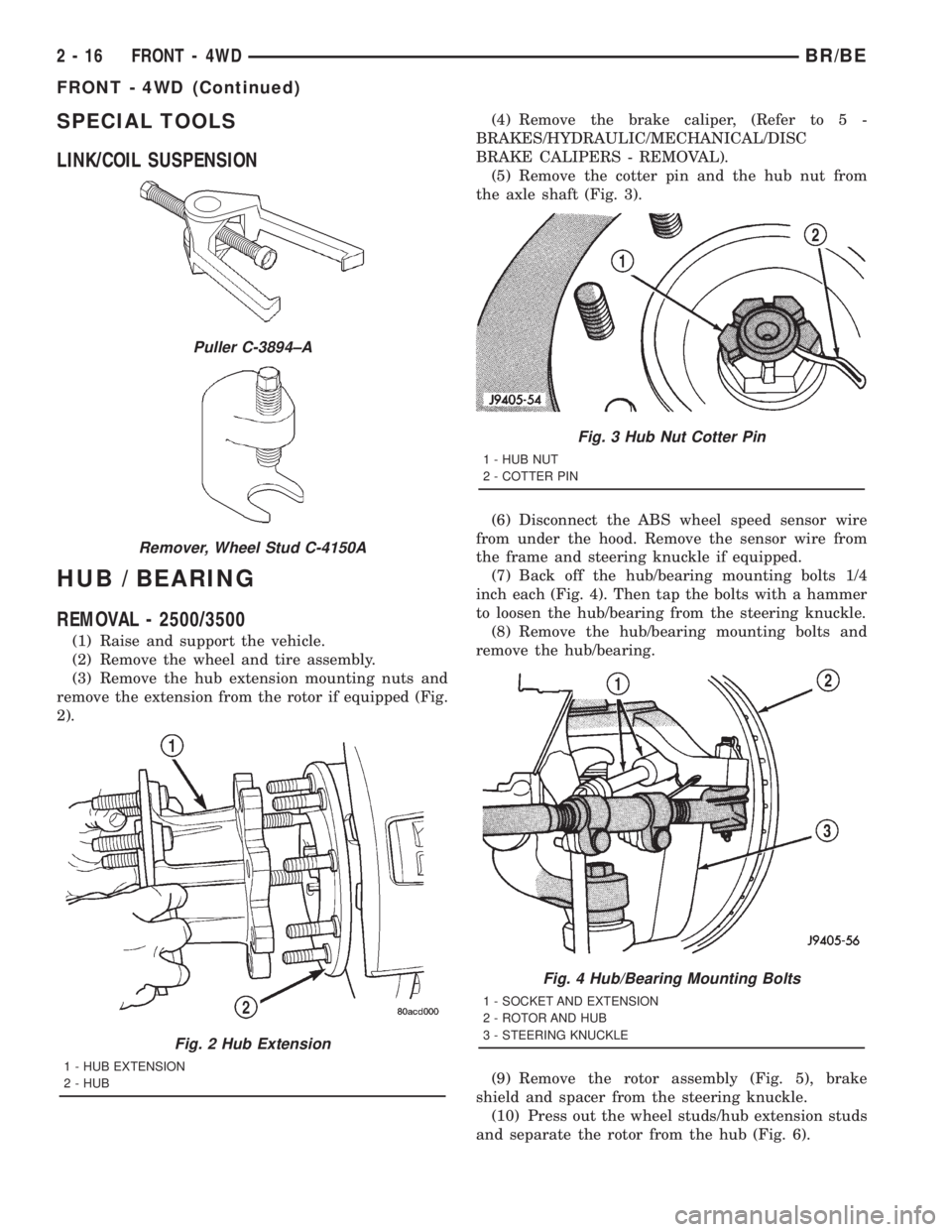

(3) Remove the hub extension mounting nuts and

remove the extension from the rotor if equipped (Fig.

2).(4) Remove the brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

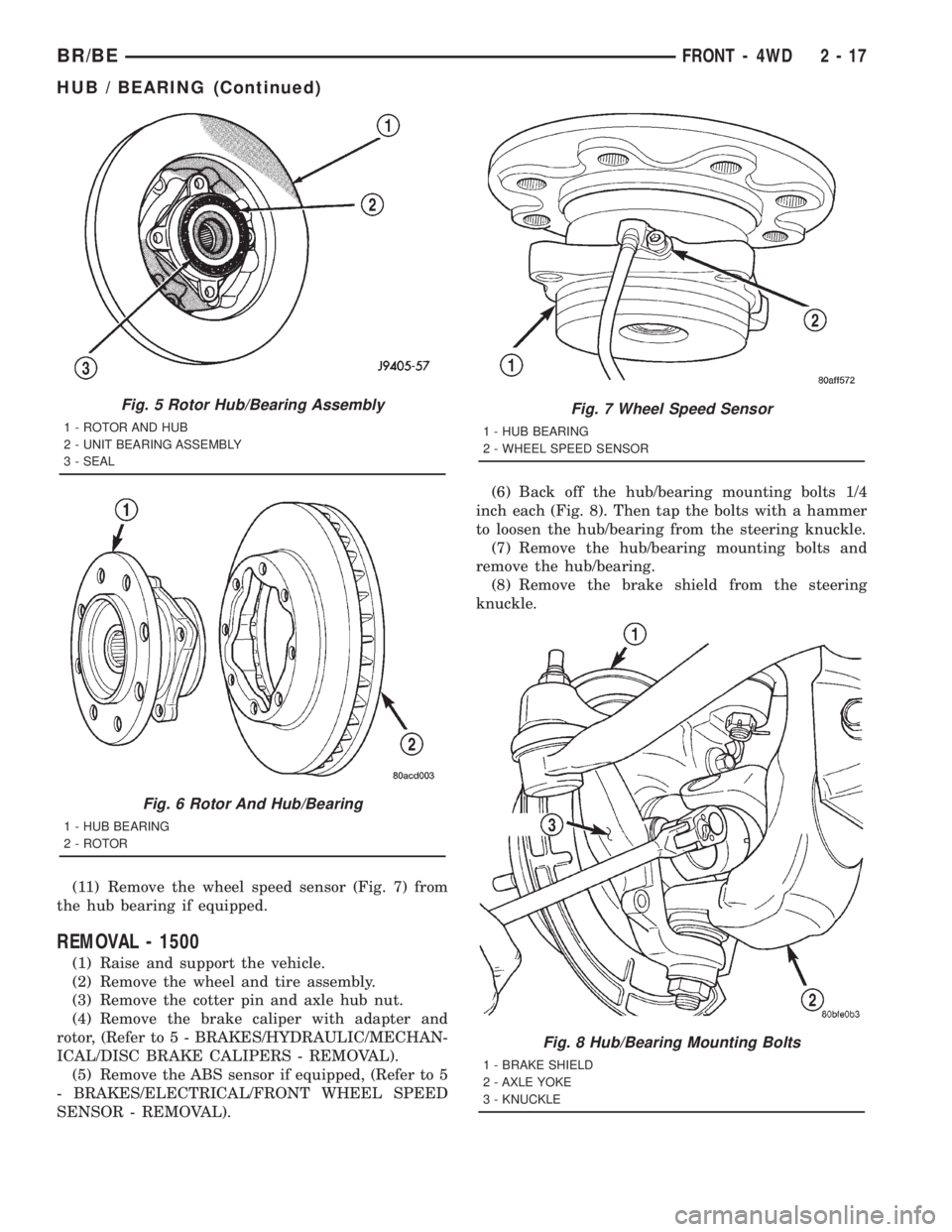

(5) Remove the cotter pin and the hub nut from

the axle shaft (Fig. 3).

(6) Disconnect the ABS wheel speed sensor wire

from under the hood. Remove the sensor wire from

the frame and steering knuckle if equipped.

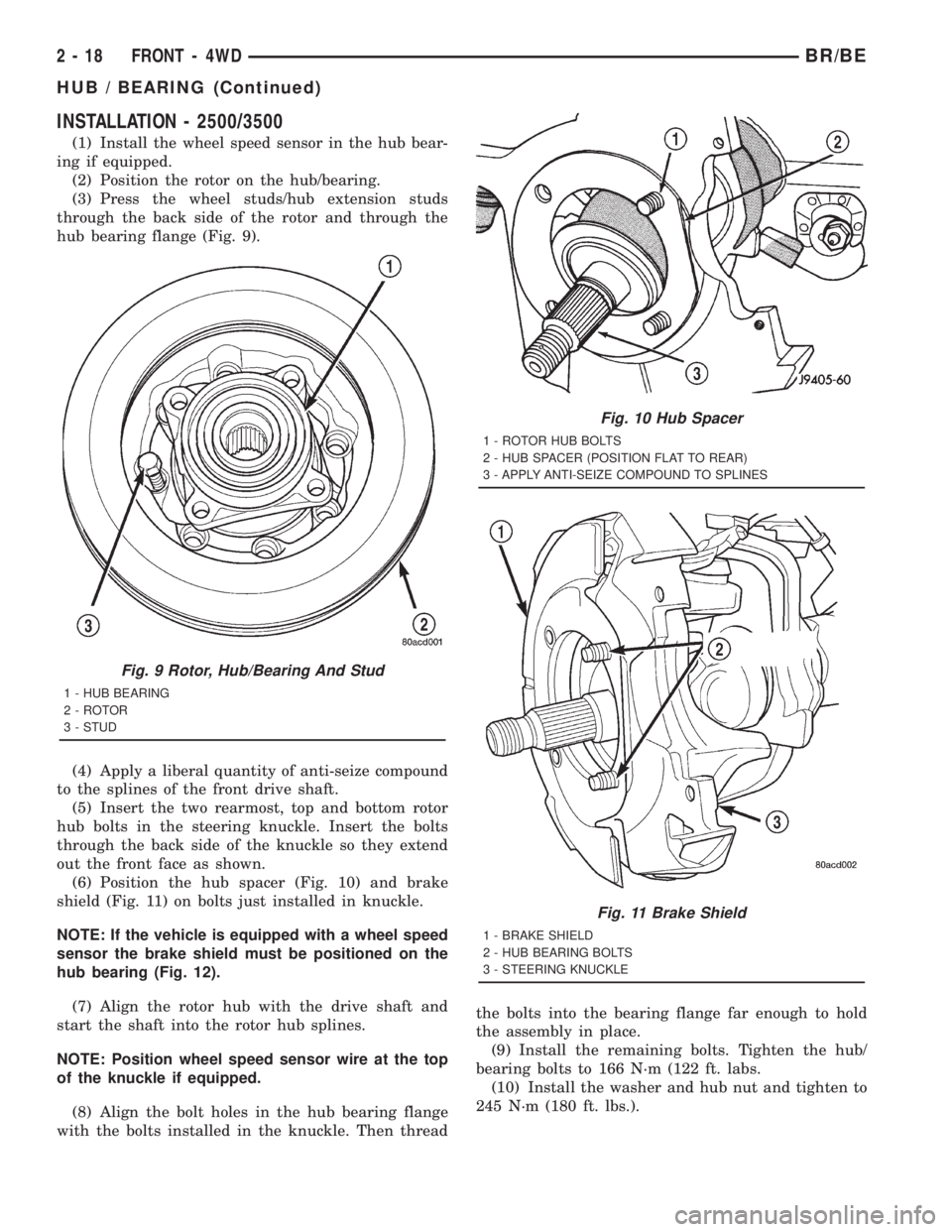

(7) Back off the hub/bearing mounting bolts 1/4

inch each (Fig. 4). Then tap the bolts with a hammer

to loosen the hub/bearing from the steering knuckle.

(8) Remove the hub/bearing mounting bolts and

remove the hub/bearing.

(9) Remove the rotor assembly (Fig. 5), brake

shield and spacer from the steering knuckle.

(10) Press out the wheel studs/hub extension studs

and separate the rotor from the hub (Fig. 6).

Puller C-3894±A

Remover, Wheel Stud C-4150A

Fig. 2 Hub Extension

1 - HUB EXTENSION

2 - HUB

Fig. 3 Hub Nut Cotter Pin

1 - HUB NUT

2 - COTTER PIN

Fig. 4 Hub/Bearing Mounting Bolts

1 - SOCKET AND EXTENSION

2 - ROTOR AND HUB

3 - STEERING KNUCKLE

2 - 16 FRONT - 4WDBR/BE

FRONT - 4WD (Continued)

Page 60 of 2889

(11) Remove the wheel speed sensor (Fig. 7) from

the hub bearing if equipped.

REMOVAL - 1500

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assembly.

(3) Remove the cotter pin and axle hub nut.

(4) Remove the brake caliper with adapter and

rotor, (Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/DISC BRAKE CALIPERS - REMOVAL).

(5) Remove the ABS sensor if equipped, (Refer to 5

- BRAKES/ELECTRICAL/FRONT WHEEL SPEED

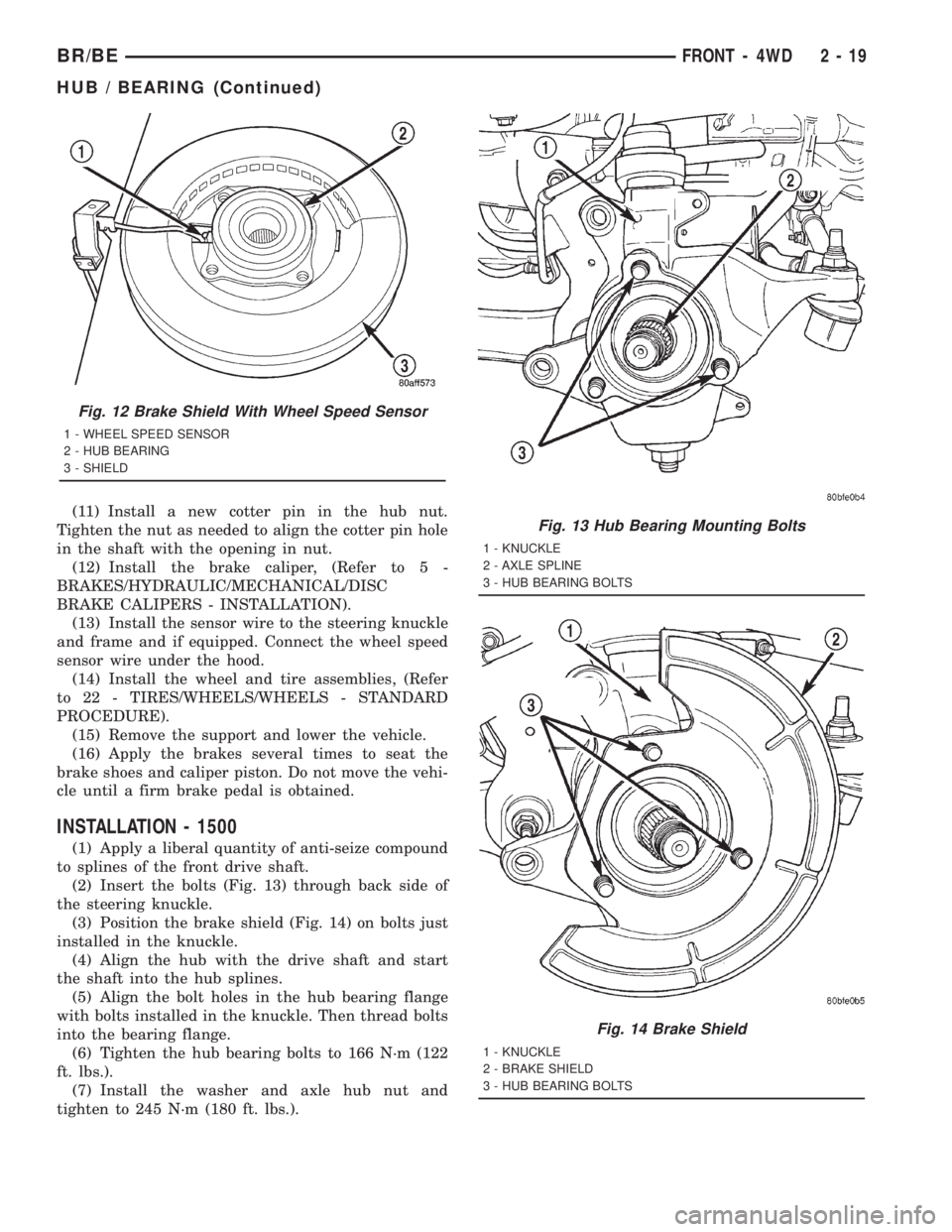

SENSOR - REMOVAL).(6) Back off the hub/bearing mounting bolts 1/4

inch each (Fig. 8). Then tap the bolts with a hammer

to loosen the hub/bearing from the steering knuckle.

(7) Remove the hub/bearing mounting bolts and

remove the hub/bearing.

(8) Remove the brake shield from the steering

knuckle.

Fig. 5 Rotor Hub/Bearing Assembly

1 - ROTOR AND HUB

2 - UNIT BEARING ASSEMBLY

3 - SEAL

Fig. 6 Rotor And Hub/Bearing

1 - HUB BEARING

2 - ROTOR

Fig. 7 Wheel Speed Sensor

1 - HUB BEARING

2 - WHEEL SPEED SENSOR

Fig. 8 Hub/Bearing Mounting Bolts

1 - BRAKE SHIELD

2 - AXLE YOKE

3 - KNUCKLE

BR/BEFRONT - 4WD 2 - 17

HUB / BEARING (Continued)

Page 61 of 2889

INSTALLATION - 2500/3500

(1) Install the wheel speed sensor in the hub bear-

ing if equipped.

(2) Position the rotor on the hub/bearing.

(3) Press the wheel studs/hub extension studs

through the back side of the rotor and through the

hub bearing flange (Fig. 9).

(4) Apply a liberal quantity of anti-seize compound

to the splines of the front drive shaft.

(5) Insert the two rearmost, top and bottom rotor

hub bolts in the steering knuckle. Insert the bolts

through the back side of the knuckle so they extend

out the front face as shown.

(6) Position the hub spacer (Fig. 10) and brake

shield (Fig. 11) on bolts just installed in knuckle.

NOTE: If the vehicle is equipped with a wheel speed

sensor the brake shield must be positioned on the

hub bearing (Fig. 12).

(7) Align the rotor hub with the drive shaft and

start the shaft into the rotor hub splines.

NOTE: Position wheel speed sensor wire at the top

of the knuckle if equipped.

(8) Align the bolt holes in the hub bearing flange

with the bolts installed in the knuckle. Then threadthe bolts into the bearing flange far enough to hold

the assembly in place.

(9) Install the remaining bolts. Tighten the hub/

bearing bolts to 166 N´m (122 ft. labs.

(10) Install the washer and hub nut and tighten to

245 N´m (180 ft. lbs.).

Fig. 9 Rotor, Hub/Bearing And Stud

1 - HUB BEARING

2 - ROTOR

3 - STUD

Fig. 10 Hub Spacer

1 - ROTOR HUB BOLTS

2 - HUB SPACER (POSITION FLAT TO REAR)

3 - APPLY ANTI-SEIZE COMPOUND TO SPLINES

Fig. 11 Brake Shield

1 - BRAKE SHIELD

2 - HUB BEARING BOLTS

3 - STEERING KNUCKLE

2 - 18 FRONT - 4WDBR/BE

HUB / BEARING (Continued)

Page 62 of 2889

(11) Install a new cotter pin in the hub nut.

Tighten the nut as needed to align the cotter pin hole

in the shaft with the opening in nut.

(12) Install the brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION).

(13) Install the sensor wire to the steering knuckle

and frame and if equipped. Connect the wheel speed

sensor wire under the hood.

(14) Install the wheel and tire assemblies, (Refer

to 22 - TIRES/WHEELS/WHEELS - STANDARD

PROCEDURE).

(15) Remove the support and lower the vehicle.

(16) Apply the brakes several times to seat the

brake shoes and caliper piston. Do not move the vehi-

cle until a firm brake pedal is obtained.

INSTALLATION - 1500

(1) Apply a liberal quantity of anti-seize compound

to splines of the front drive shaft.

(2) Insert the bolts (Fig. 13) through back side of

the steering knuckle.

(3) Position the brake shield (Fig. 14) on bolts just

installed in the knuckle.

(4) Align the hub with the drive shaft and start

the shaft into the hub splines.

(5) Align the bolt holes in the hub bearing flange

with bolts installed in the knuckle. Then thread bolts

into the bearing flange.

(6) Tighten the hub bearing bolts to 166 N´m (122

ft. lbs.).

(7) Install the washer and axle hub nut and

tighten to 245 N´m (180 ft. lbs.).

Fig. 12 Brake Shield With Wheel Speed Sensor

1 - WHEEL SPEED SENSOR

2 - HUB BEARING

3 - SHIELD

Fig. 13 Hub Bearing Mounting Bolts

1 - KNUCKLE

2 - AXLE SPLINE

3 - HUB BEARING BOLTS

Fig. 14 Brake Shield

1 - KNUCKLE

2 - BRAKE SHIELD

3 - HUB BEARING BOLTS

BR/BEFRONT - 4WD 2 - 19

HUB / BEARING (Continued)

Page 63 of 2889

(8) Install a new cotter pin in hub nut. Tighten the

nut as needed to align cotter pin hole in shaft with

the opening in the nut.

(9) Install the rotor, brake caliper with adapter,

(Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/

DISC BRAKE CALIPERS - INSTALLATION).

(10) Install the ABS wheel speed sensor if

equipped, (Refer to 5 - BRAKES/ELECTRICAL/

FRONT WHEEL SPEED SENSOR - INSTALLA-

TION).

(11) Install the wheel and tire assemblies, (Refer

to 22 - TIRES/WHEELS/WHEELS - STANDARD

PROCEDURE).

(12) Remove the support and lower the vehicle.

(13) Apply the brakes several times to seat the

brake shoes and the caliper piston. Do not move the

vehicle until a firm brake pedal is obtained.

KNUCKLE

DESCRIPTION

The knuckles are a single casting with legs

machined for the upper and lower ball joints. The

knuckles also has machined mounting locations for

the front brake calipers adapters and hub bearing

assembly.

OPERATION

The steering knuckles pivots between the upper

and lower ball joints. The steering linkage is

attached to the knuckles controls vehicle steering.

REMOVAL

(1) Remove hub bearing and axle shaft.

(2) Remove tie-rod or drag link end from the steer-

ing knuckle arm.

(3) Remove the ABS sensor wire and bracket from

knuckle.

(4) Remove the cotter pin from the upper ball stud

nut. Remove the upper and lower ball stud nuts.

(5) Strike the steering knuckle with a brass ham-

mer to loosen. Remove knuckle from axle tube yokes.

REMOVAL

(1) Remove hub bearing and axle shaft.

(2) Remove tie-rod or drag link end from the steer-

ing knuckle arm.

(3) Remove the ABS sensor wire and bracket from

knuckle. Refer to Brakes, for proper procedures.

(4) Remove the cotter pin from the upper ball stud

nut. Remove the upper and lower ball stud nuts.

(5) Strike the steering knuckle with a brass ham-

mer to loosen.

(6) Remove knuckle from axle tube yokes.

INSTALLATION

(1) Position the steering knuckle on the ball studs.

(2) Install and tighten lower ball stud nut to 108

N´m (80 ft. lbs.) torque. Advance nut to next slot to

line up hole and install new cotter pin.

(3) Install and tighten upper ball stud nut to 101

N´m (75 ft. lbs.) torque. Advance nut to next slot to

line up hole and install new cotter pin.

(4) Install the hub bearing and axle shaft.

(5) Install tie-rod or drag link end onto the steer-

ing knuckle arm.

(6) Install the ABS sensor wire and bracket to the

knuckle. Refer to Brakes, for proper procedures.

INSTALLATION

(1) Position the steering knuckle on the ball studs.

(2) Install and tighten lower ball stud nut to 47

N´m (35 ft. lbs.) torque. Do not install cotter pin at

this time.

(3) Install and tighten upper ball stud nut to 94

N´m (70 ft. lbs.) torque. Advance nut to next slot to

line up hole and install new cotter pin.

(4) Retorque lower ball stud nut to 190±217 N´m

(140±160 ft. lbs.) torque. Advance nut to next slot to

line up hole and install new cotter pin.

(5) Install the hub bearing and axle shaft.

(6) Install tie-rod or drag link end onto the steer-

ing knuckle arm.

(7) Install the ABS sensor wire and bracket to the

knuckle. Refer to Brakes, for proper procedure.

LOWER CONTROL ARM

REMOVAL

(1) Raise and support the vehicle.

(2) Paint or scribe alignment marks on the cam

adjusters and suspension arm for installation refer-

ence (Fig. 15).

(3) Remove the lower suspension arm nut, cam

and cam bolt from the axle.

(4) Remove the nut and bolt from the frame rail

bracket and remove the lower suspension arm (Fig.

22).

INSTALLATION

(1) Position the lower suspension arm at the axle

bracket and frame rail bracket.

(2) Install the rear bolt and finger tighten the nut.

(3) Install the cam bolt, cam and nut in the axle

and align the reference marks.

(4) Remove support and lower the vehicle.

(5) Tighten cam nut at the axle bracket to 190

N´m (140 ft. lbs.). Tighten rear nut at the frame

bracket to 190 N´m (140 ft. lbs.).

2 - 20 FRONT - 4WDBR/BE

HUB / BEARING (Continued)

Page 69 of 2889

REAR

TABLE OF CONTENTS

page page

REAR

DESCRIPTION...........................26

DIAGNOSIS AND TESTING.................26

SPRING AND SHOCK....................26

SPECIFICATIONS........................27

SPECIAL TOOLS.........................28

BUSHINGS

REMOVAL..............................28

INSTALLATION...........................28

JOUNCE BUMPER

DESCRIPTION...........................28

OPERATION.............................28

SHOCK

DESCRIPTION...........................28OPERATION.............................28

REMOVAL..............................28

INSTALLATION...........................28

SPRING

DESCRIPTION...........................28

OPERATION.............................28

REMOVAL..............................28

INSTALLATION...........................29

STABILIZER BAR

DESCRIPTION...........................30

OPERATION.............................30

REMOVAL..............................30

INSTALLATION...........................30

REAR

DESCRIPTION

The rear suspension is comprised of:

²Shock Absorbers

²Jounce Bumpers

²Stabilizer Bar (optional)

²Leaf Springs

²Drive Axle

CAUTION: A vehicle should always be loaded so

the vehicle weight center-line is located immedi-

ately forward of the rear axle. Correct vehicle load-

ing provides proper front tire-to-road contact. This

results in maximum vehicle handling stability and

safety. Incorrect vehicle weight distribution can

cause excessive tire tread wear, spring fatigue or

failure, and erratic steering.

CAUTION: Suspension components with rubber/ure-

thane bushings (except stabilizer bar) should be

tightened with the vehicle at normal ride height. It is

important to have the springs supporting the weight

of the vehicle when the fasteners are torqued. If

springs are not at their normal ride position, vehicle

ride comfort could be affected and premature bush-

ing wear may occur.

DIAGNOSIS AND TESTING - SPRING AND

SHOCK

A knocking or rattling noise from a shock absorber

may be caused by movement between mounting

bushings and metal brackets or attaching compo-

nents. These noises can usually be stopped by tight-

ening the attaching nuts. If the noise persists,

inspect for damaged and worn bushings, and attach-

ing components. Repair as necessary if any of these

conditions exist.

A squeaking noise from the shock absorber may be

caused by the hydraulic valving and may be intermit-

tent. This condition is not repairable and the shock

absorber must be replaced.

The shock absorbers are not refillable or adjust-

able. If a malfunction occurs, the shock absorber

must be replaced. To test a shock absorber, hold it in

an upright position and force the piston in and out of

the cylinder four or five times. The action throughout

each stroke should be smooth and even.

The spring eye and shock absorber bushings do not

require any type of lubrication. Do not attempt to

stop spring bushing noise by lubricating them.

Grease and mineral oil-base lubricants will deterio-

rate the bushing rubber.

If the vehicle is used for severe, off-road operation,

the springs should be examined periodically. Check

for broken and shifted leafs, loose and missing clips,

and broken center bolts. Refer to Spring and Shock

Absorber Diagnosis chart for additional information.

2 - 26 REARBR/BE