wheel alignment DODGE RAM 2001 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 245 of 2889

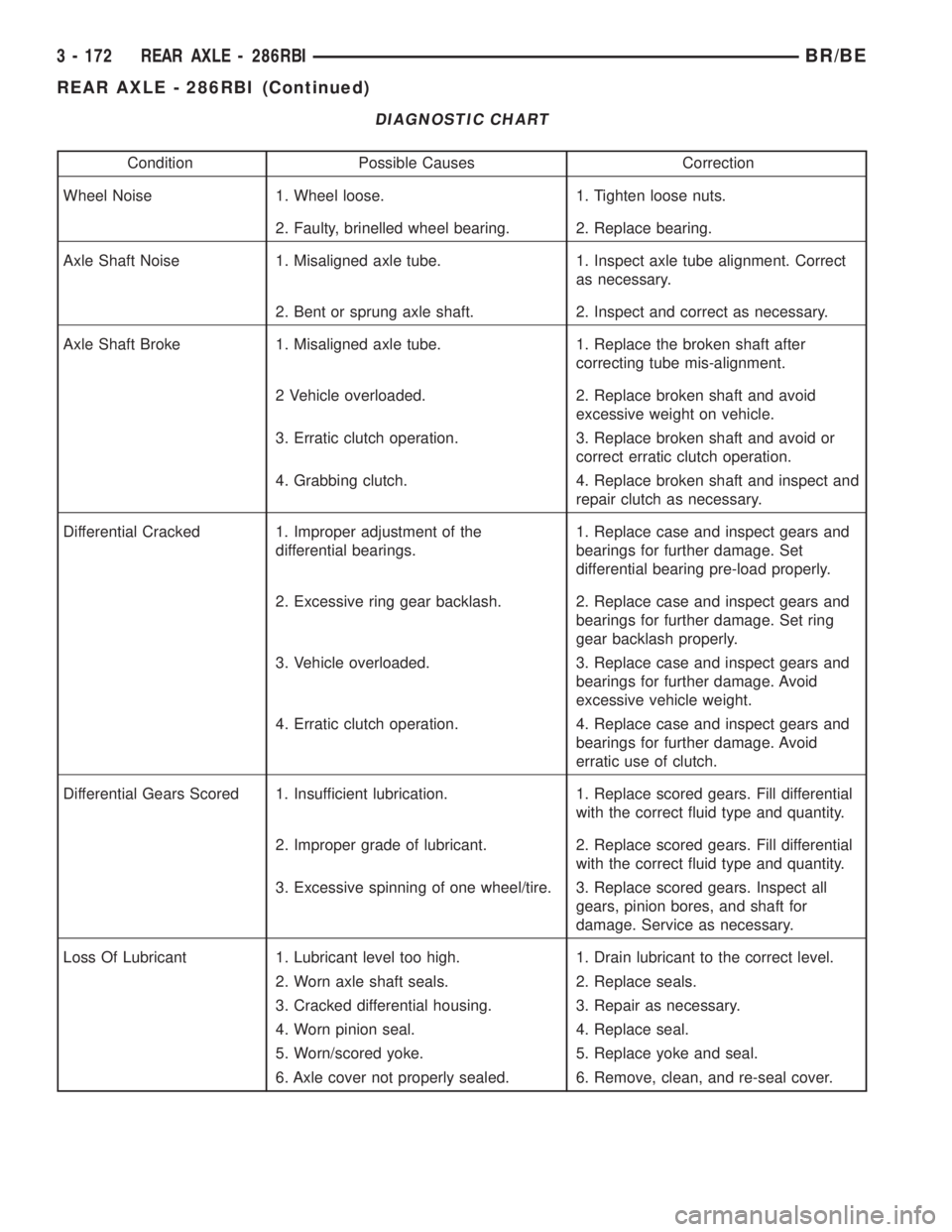

DIAGNOSTIC CHART

Condition Possible Causes Correction

Wheel Noise 1. Wheel loose. 1. Tighten loose nuts.

2. Faulty, brinelled wheel bearing. 2. Replace bearing.

Axle Shaft Noise 1. Misaligned axle tube. 1. Inspect axle tube alignment. Correct

as necessary.

2. Bent or sprung axle shaft. 2. Inspect and correct as necessary.

Axle Shaft Broke 1. Misaligned axle tube. 1. Replace the broken shaft after

correcting tube mis-alignment.

2 Vehicle overloaded. 2. Replace broken shaft and avoid

excessive weight on vehicle.

3. Erratic clutch operation. 3. Replace broken shaft and avoid or

correct erratic clutch operation.

4. Grabbing clutch. 4. Replace broken shaft and inspect and

repair clutch as necessary.

Differential Cracked 1. Improper adjustment of the

differential bearings.1. Replace case and inspect gears and

bearings for further damage. Set

differential bearing pre-load properly.

2. Excessive ring gear backlash. 2. Replace case and inspect gears and

bearings for further damage. Set ring

gear backlash properly.

3. Vehicle overloaded. 3. Replace case and inspect gears and

bearings for further damage. Avoid

excessive vehicle weight.

4. Erratic clutch operation. 4. Replace case and inspect gears and

bearings for further damage. Avoid

erratic use of clutch.

Differential Gears Scored 1. Insufficient lubrication. 1. Replace scored gears. Fill differential

with the correct fluid type and quantity.

2. Improper grade of lubricant. 2. Replace scored gears. Fill differential

with the correct fluid type and quantity.

3. Excessive spinning of one wheel/tire. 3. Replace scored gears. Inspect all

gears, pinion bores, and shaft for

damage. Service as necessary.

Loss Of Lubricant 1. Lubricant level too high. 1. Drain lubricant to the correct level.

2. Worn axle shaft seals. 2. Replace seals.

3. Cracked differential housing. 3. Repair as necessary.

4. Worn pinion seal. 4. Replace seal.

5. Worn/scored yoke. 5. Replace yoke and seal.

6. Axle cover not properly sealed. 6. Remove, clean, and re-seal cover.

3 - 172 REAR AXLE - 286RBIBR/BE

REAR AXLE - 286RBI (Continued)

Page 246 of 2889

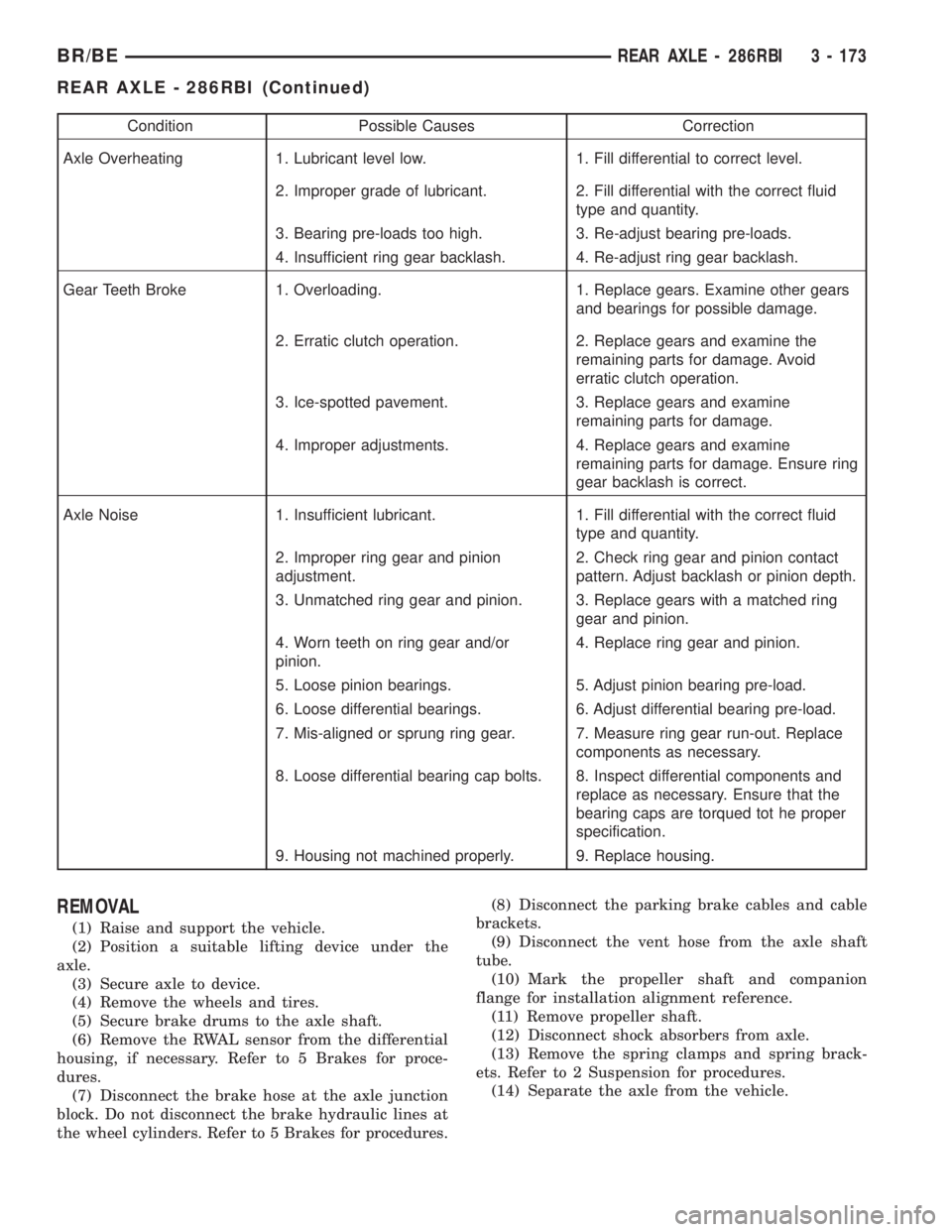

Condition Possible Causes Correction

Axle Overheating 1. Lubricant level low. 1. Fill differential to correct level.

2. Improper grade of lubricant. 2. Fill differential with the correct fluid

type and quantity.

3. Bearing pre-loads too high. 3. Re-adjust bearing pre-loads.

4. Insufficient ring gear backlash. 4. Re-adjust ring gear backlash.

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other gears

and bearings for possible damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure ring

gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct fluid

type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion contact

pattern. Adjust backlash or pinion depth.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched ring

gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out. Replace

components as necessary.

8. Loose differential bearing cap bolts. 8. Inspect differential components and

replace as necessary. Ensure that the

bearing caps are torqued tot he proper

specification.

9. Housing not machined properly. 9. Replace housing.

REMOVAL

(1) Raise and support the vehicle.

(2) Position a suitable lifting device under the

axle.

(3) Secure axle to device.

(4) Remove the wheels and tires.

(5) Secure brake drums to the axle shaft.

(6) Remove the RWAL sensor from the differential

housing, if necessary. Refer to 5 Brakes for proce-

dures.

(7) Disconnect the brake hose at the axle junction

block. Do not disconnect the brake hydraulic lines at

the wheel cylinders. Refer to 5 Brakes for procedures.(8) Disconnect the parking brake cables and cable

brackets.

(9) Disconnect the vent hose from the axle shaft

tube.

(10) Mark the propeller shaft and companion

flange for installation alignment reference.

(11) Remove propeller shaft.

(12) Disconnect shock absorbers from axle.

(13) Remove the spring clamps and spring brack-

ets. Refer to 2 Suspension for procedures.

(14) Separate the axle from the vehicle.

BR/BEREAR AXLE - 286RBI 3 - 173

REAR AXLE - 286RBI (Continued)

Page 317 of 2889

Oil contamination indicates a leak at either the

rear main seal or transmission input shaft. Oil leak-

age produces a residue of oil on the housing interior

and on the clutch cover and flywheel. Heat buildup

caused by slippage between the cover, disc and fly-

wheel, can sometimes bake the oil residue onto the

components. The glaze-like residue ranges in color

from amber to black.

Road splash contamination means dirt/water is

entering the clutch housing due to loose bolts, hous-

ing cracks or through hydraulic line openings. Driv-

ing through deep water puddles can force water/road

splash into the housing through such openings.

Clutch fluid leaks are usually from damaged slave

cylinder push rod seals.

IMPROPER RELEASE OR CLUTCH ENGAGEMENT

Clutch release or engagement problems are caused

by wear or damage to one or more clutch compo-

nents. A visual inspection of the release components

will usually reveal the problem part.

Release problems can result in hard shifting and

noise. Items to look for are: leaks at the clutch cylin-

ders and interconnecting line; loose slave cylinder

bolts; worn/loose release fork and pivot stud; dam-

aged release bearing; and a worn clutch disc, or pres-

sure plate.

Normal condensation in vehicles that are stored or

out of service for long periods of time can generate

enough corrosion to make the disc stick to the fly-

wheel, or pressure plate. If this condition is experi-

enced, correction only requires that the disc be

loosened manually through the inspection plate open-

ing.

Engagement problems usually result in slip, chat-

ter/shudder, and noisy operation. The primary causes

are clutch disc contamination; clutch disc wear; mis-

alignment, or distortion; flywheel damage; or a com-

bination of the foregoing. A visual inspection is

required to determine the part actually causing the

problem.

CLUTCH MISALIGNMENT

Clutch components must be in proper alignment

with the crankshaft and transmission input shaft.

Misalignment caused by excessive runout or warpage

of any clutch component will cause grab, chatter and

improper clutch release.

CLUTCH COVER AND DISC RUNOUT

Check the clutch disc before installation. Axial

(face) runout of anewdisc should not exceed 0.50

mm (0.020 in.). Measure runout about 6 mm (1/4 in.)

from the outer edge of the disc facing. Obtain

another disc if runout is excessive.Check condition of the clutch before installation. A

warped cover or diaphragm spring will cause grab

and incomplete release or engagement. Be careful

when handling the cover and disc. Impact can distort

the cover, diaphragm spring, release fingers and the

hub of the clutch disc.

Use an alignment tool when positioning the disc on

the flywheel. The tool prevents accidental misalign-

ment which could result in cover distortion and disc

damage.

A frequent cause of clutch cover distortion (and con-

sequent misalignment) is improper bolt tightening.

CLUTCH FLYWHEEL RUNOUT

Check flywheel runout whenever misalignment is

suspected. Flywheel runout should not exceed 0.08

mm (0.003 in.). Measure runout at the outer edge of

the flywheel face with a dial indicator. Mount the

indicator on the rear face of the engine block.

Common causes of runout are:

²heat warpage

²improper machining

²incorrect bolt tightening

²improper seating on crankshaft flange shoulder

²foreign material on crankshaft flange

Flywheel machining is not recommended. The fly-

wheel clutch surface is machined to a unique contour

and machining will negate this feature. However,

minor flywheel scoring can be cleaned up by hand with

180 grit emery, or with surface grinding equipment.

Remove only enough material to reduce scoring

(approximately 0.001 - 0.003 in.). Heavy stock removal

isnot recommended.

Replace the flywheel if scoring

is severe and deeper than 0.076 mm (0.003 in.).

Excessive stock removal can result in flywheel crack-

ing or warpage after installation; it can also weaken

the flywheel and interfere with proper clutch release.

Clean the crankshaft flange before mounting the

flywheel. Dirt and grease on the flange surface may

cock the flywheel causing excessive runout. Use new

bolts when remounting a flywheel and secure the

bolts with MopartLock And Seal. Tighten flywheel

bolts to specified torque only. Overtightening can dis-

tort the flywheel hub causing runout.

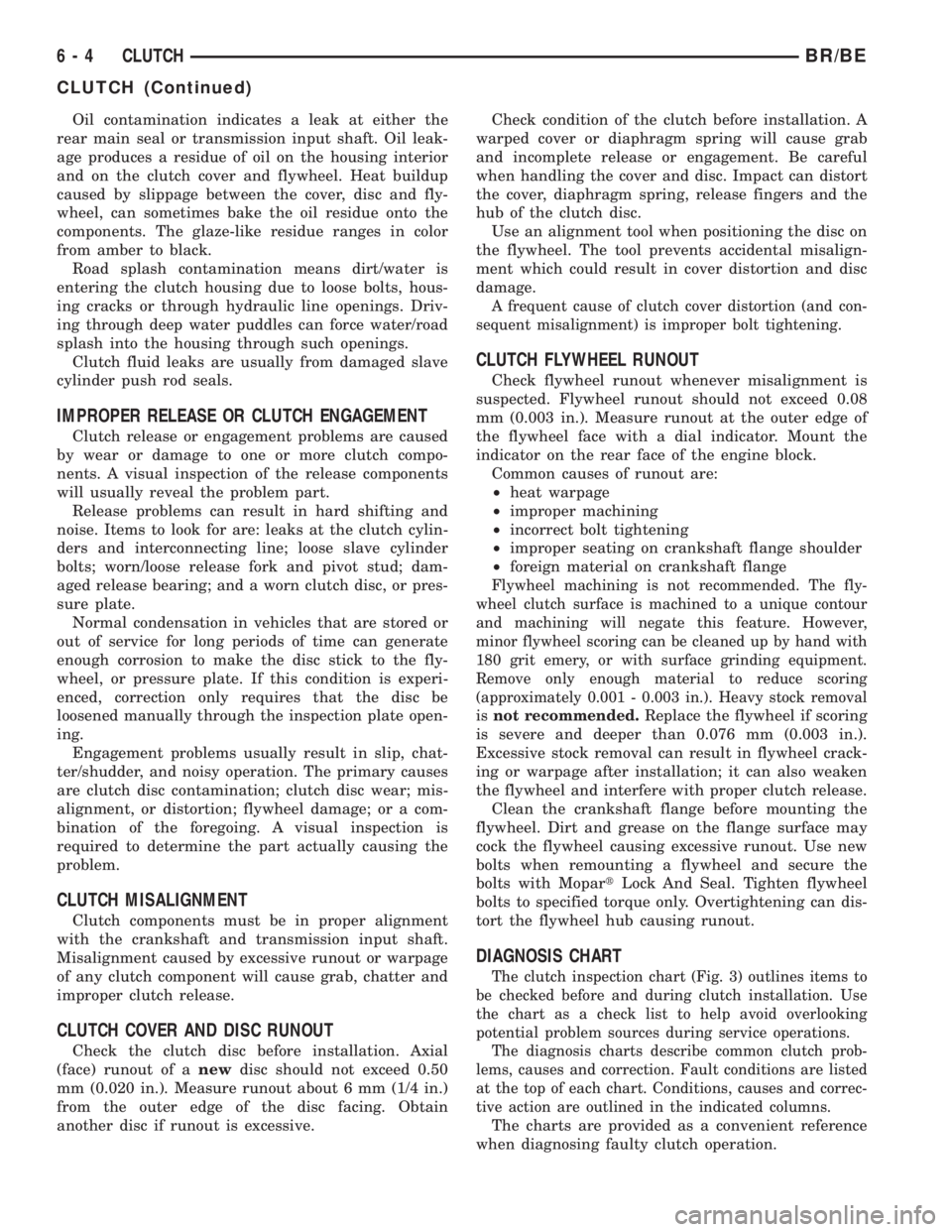

DIAGNOSIS CHART

The clutch inspection chart (Fig. 3) outlines items to

be checked before and during clutch installation. Use

the chart as a check list to help avoid overlooking

potential problem sources during service operations.

The diagnosis charts describe common clutch prob-

lems, causes and correction. Fault conditions are listed

at the top of each chart. Conditions, causes and correc-

tive action are outlined in the indicated columns.

The charts are provided as a convenient reference

when diagnosing faulty clutch operation.

6 - 4 CLUTCHBR/BE

CLUTCH (Continued)

Page 319 of 2889

CONDITION POSSIBLE CAUSES CORRECTION

Clutch disc binds on input shaft

splines.1. Clutch disc hub splines damaged

during installation.1. Clean, smooth, and lubricate hub

splines if possible. Replace disc if

necessary.

2. Input shaft splines rough,

damaged, or corroded.2. Clean, smooth, and lubricate

shaft splines if possible. Replace

input shaft if necessary.

Clutch disc rusted to flywheel and/or

pressure plate.1. Clutch not used for and extended

period of time (e.g. long term

vehicle storage).1. Sand rusted surfaces with 180

grit sanding paper. Replace clutch

cover and flywheel if necessary.

Pilot bearing seized, loose, or rollers

are worn.1. Bearing cocked during

installation.1. Install and lubricate a new

bearing.

2. Bearing defective. 2. Install and lubricate a new

bearing.

3. Bearing not lubricated. 3. Install and lubricate a new

bearing.

4. Clutch misalignment. 4. Inspect clutch and correct as

necessary. Install and lubricate a

new bearing.

Clutch will not disengage properly. 1. Low clutch fluid level. 1. Replace hydraulic linkage

assembly.

2. Clutch cover loose. 2. Follow proper bolt tightening

procedure.

3. Clutch disc bent or distorted. 3. Replace clutch disc.

4. Clutch cover diaphragm spring

bent or warped.4. Replace clutch cover.

5. Clutch disc installed backwards. 5. Remove and install clutch disc

correctly.

6. Release fork bent or fork pivot

loose or damaged.6. Replace fork or pivot as

necessary.

7. Clutch master or slave cylinder

failure.7. Replace hydraulic linkage

assembly.

Clutch pedal squeak. 1. Pivot pin loose. 1. Tighten pivot pin if possible.

Replace clutch pedal if necessary.

2. Master cylinder bushing not

lubricated.2. Lubricate master cylinder

bushing.

3. Pedal bushings worn out or

cracked.3. Replace and lubricate bushings.

Clutch master or slave cylinder

plunger dragging andùr binding1. Master or slave cylinder

components worn or corroded.1. Replace clutch hydraulic linkage

assembly.

Release bearing is noisy. 1. Release bearing defective or

damaged.1. Replace release bearing.

6 - 6 CLUTCHBR/BE

CLUTCH (Continued)

Page 320 of 2889

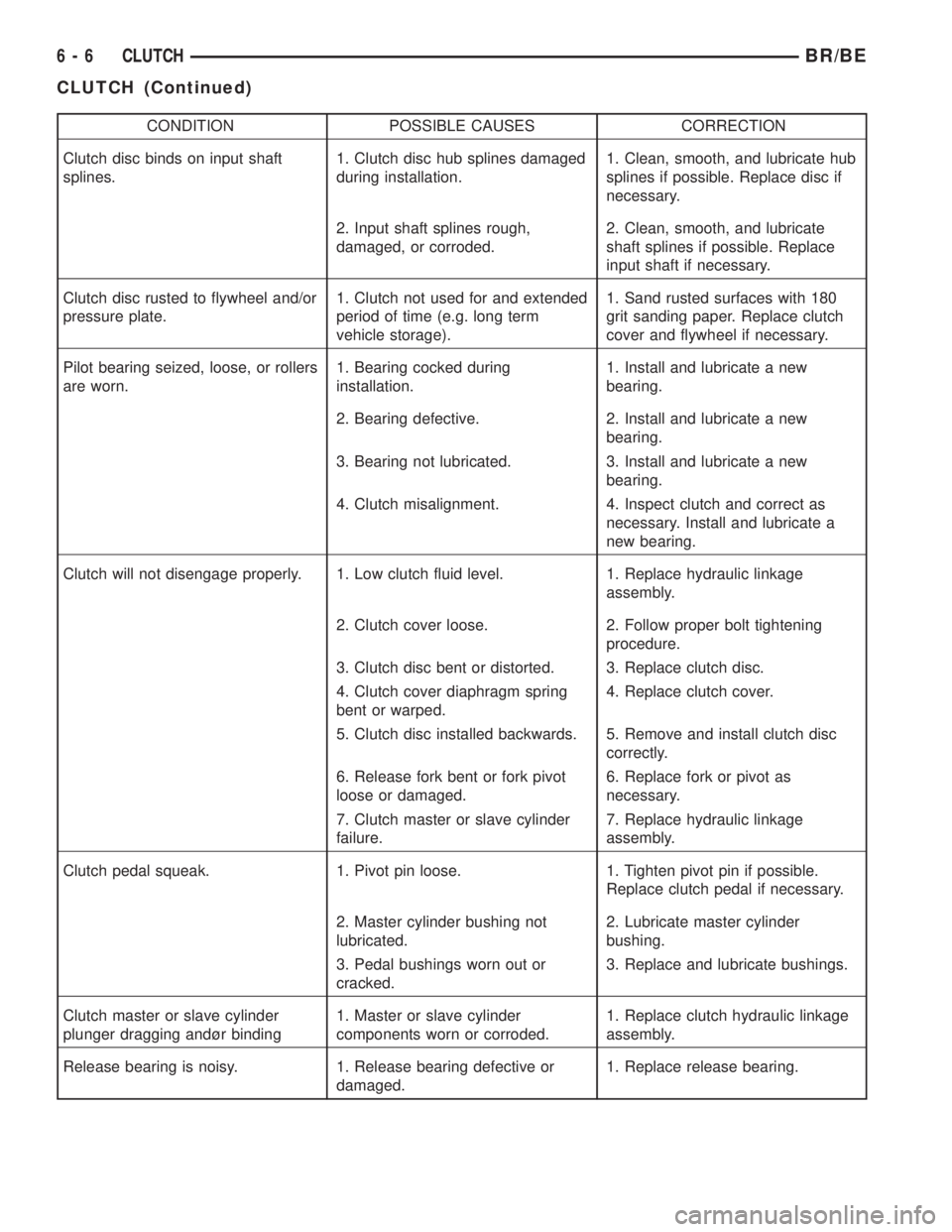

CONDITION POSSIBLE CAUSES CORRECTION

Contact surface of release bearing

damaged.1. Clutch cover incorrect or release

fingers bent or distorted.1. Replace clutch cover and release

bearing.

2. Release bearing defective or

damaged.2. Replace the release bearing.

3. Release bearing misaligned. 3. Check and correct runout of

clutch components. Check front

bearing sleeve for damage/

alignment. Repair as necessary.

Partial engagement of clutch disc.

One side of disc is worn and the

other side is glazed and lightly

worn.1. Clutch pressure plate position

incorrect.1. Replace clutch disc and cover.

2. Clutch cover, spring, or release

fingers bent or distorted.2. Replace clutch disc and cover.

3. Clutch disc damaged or

distorted.2. Replace clutch disc.

4. Clutch misalignment. 4. Check alignment and runout of

flywheel, disc, pressure plate, andùr

clutch housing. Correct as

necessary.

SPECIFICATIONS

SPECIFICATIONS - CLUTCH

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Nut, slave cylinder 19-26 14-19 170-230

Bolt, clutch cover-5/16 in. 23 17 -

Bolt, clutch cover-3/8 in. 41 30 -

Pivot, release bearing 23 17 -

Screw, fluid reservoir 5 - 40

CLUTCH DISC

DESCRIPTION

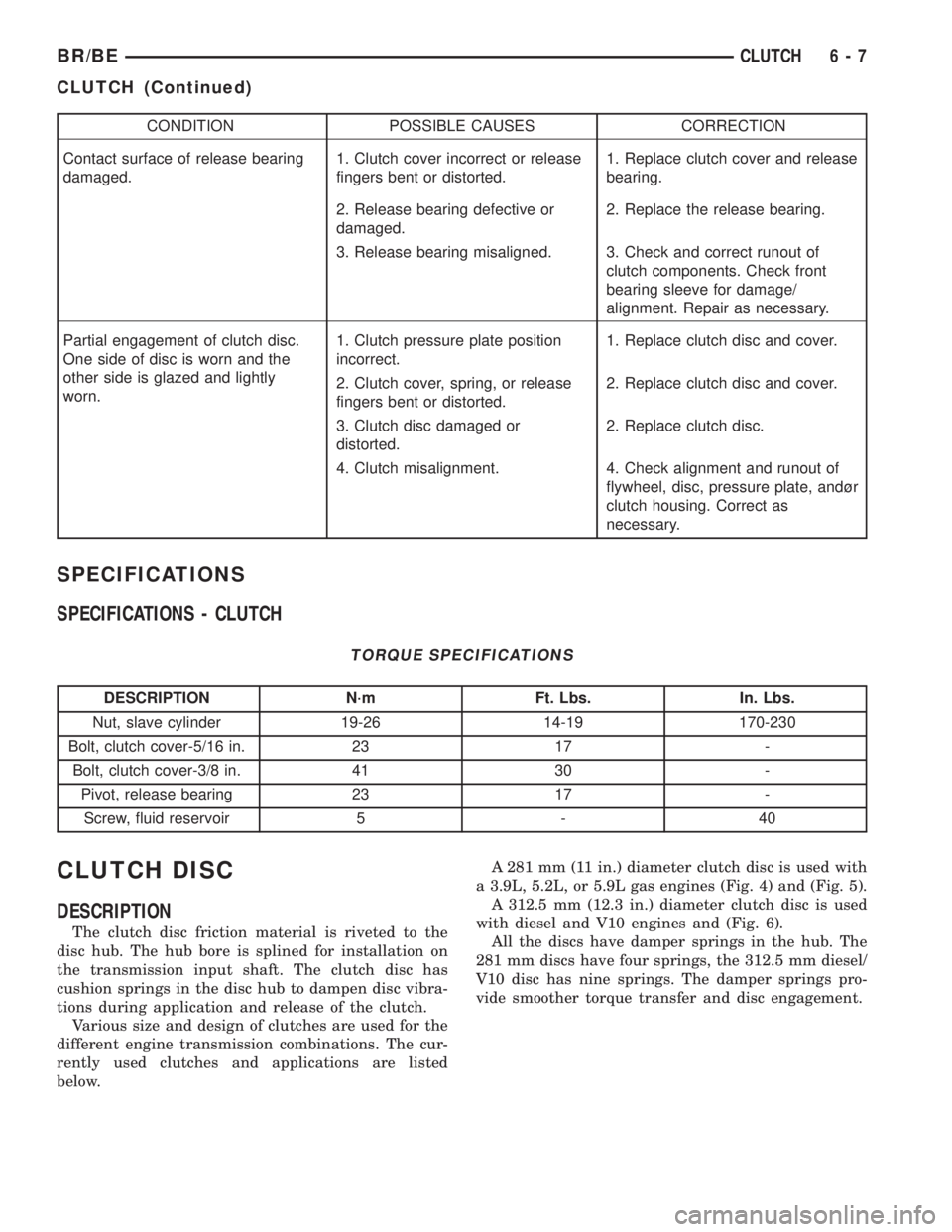

The clutch disc friction material is riveted to the

disc hub. The hub bore is splined for installation on

the transmission input shaft. The clutch disc has

cushion springs in the disc hub to dampen disc vibra-

tions during application and release of the clutch.

Various size and design of clutches are used for the

different engine transmission combinations. The cur-

rently used clutches and applications are listed

below.A 281 mm (11 in.) diameter clutch disc is used with

a 3.9L, 5.2L, or 5.9L gas engines (Fig. 4) and (Fig. 5).

A 312.5 mm (12.3 in.) diameter clutch disc is used

with diesel and V10 engines and (Fig. 6).

All the discs have damper springs in the hub. The

281 mm discs have four springs, the 312.5 mm diesel/

V10 disc has nine springs. The damper springs pro-

vide smoother torque transfer and disc engagement.

BR/BECLUTCH 6 - 7

CLUTCH (Continued)

Page 321 of 2889

OPERATION

The clutch disc is held onto the surface of the fly-

wheel by the force exerted by the pressure plate's

diaphragm spring. The friction material of the clutch

disc then transfers the engine torque from the fly-

wheel and pressure plate to the input shaft of the

transmission.

REMOVAL

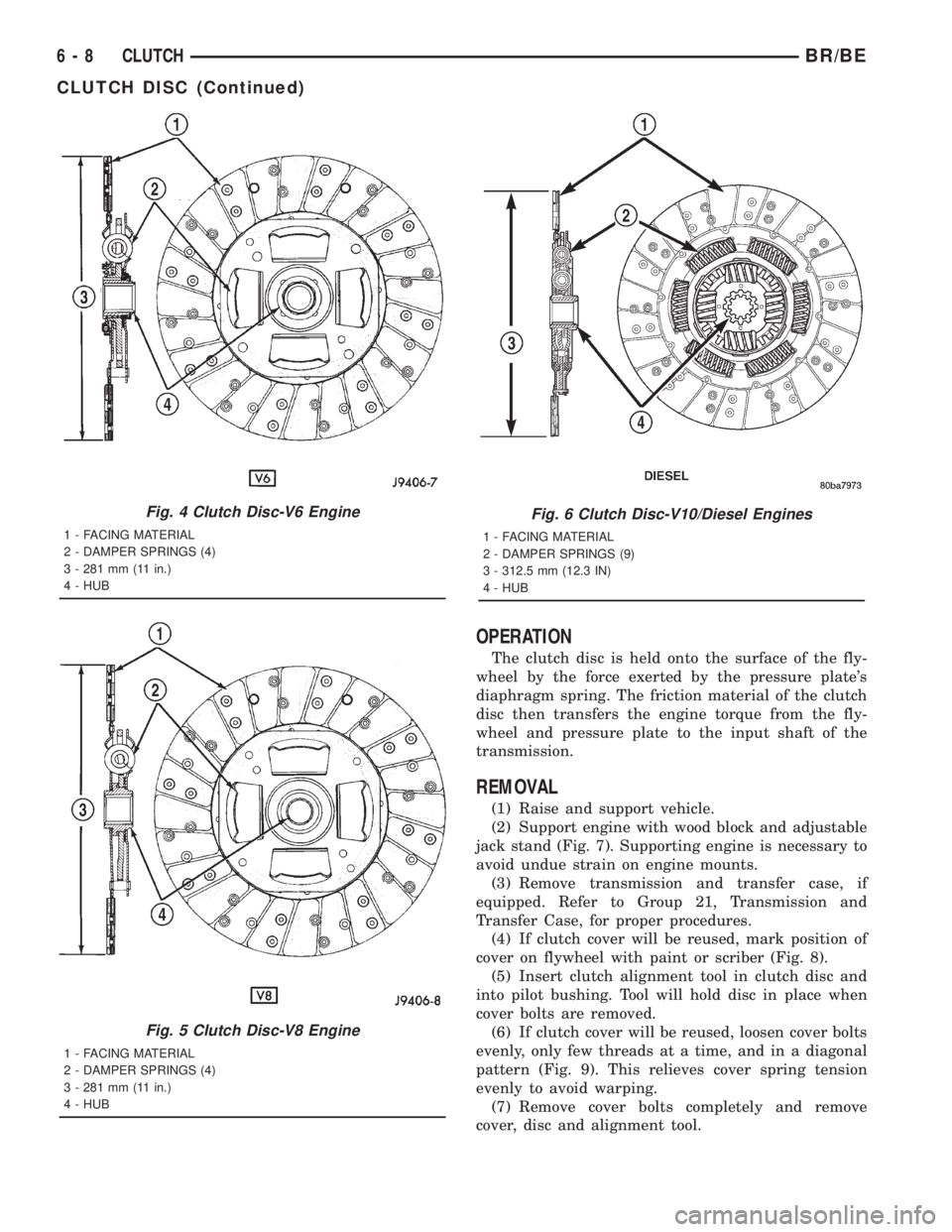

(1) Raise and support vehicle.

(2) Support engine with wood block and adjustable

jack stand (Fig. 7). Supporting engine is necessary to

avoid undue strain on engine mounts.

(3) Remove transmission and transfer case, if

equipped. Refer to Group 21, Transmission and

Transfer Case, for proper procedures.

(4) If clutch cover will be reused, mark position of

cover on flywheel with paint or scriber (Fig. 8).

(5) Insert clutch alignment tool in clutch disc and

into pilot bushing. Tool will hold disc in place when

cover bolts are removed.

(6) If clutch cover will be reused, loosen cover bolts

evenly, only few threads at a time, and in a diagonal

pattern (Fig. 9). This relieves cover spring tension

evenly to avoid warping.

(7) Remove cover bolts completely and remove

cover, disc and alignment tool.

Fig. 4 Clutch Disc-V6 Engine

1 - FACING MATERIAL

2 - DAMPER SPRINGS (4)

3 - 281 mm (11 in.)

4 - HUB

Fig. 5 Clutch Disc-V8 Engine

1 - FACING MATERIAL

2 - DAMPER SPRINGS (4)

3 - 281 mm (11 in.)

4 - HUB

Fig. 6 Clutch Disc-V10/Diesel Engines

1 - FACING MATERIAL

2 - DAMPER SPRINGS (9)

3 - 312.5 mm (12.3 IN)

4 - HUB

6 - 8 CLUTCHBR/BE

CLUTCH DISC (Continued)

Page 322 of 2889

INSTALLATION

(1) Check runout and free operation of new clutch

disc.

(2) Insert clutch alignment tool in clutch disc hub.

(3) Verify that disc hub is positioned correctly. The

raised side of hub is installed away from the fly-

wheel.

(4) Insert alignment tool in pilot bearing and posi-

tion disc on flywheel surface (Fig. 10).(5) Position clutch cover over disc and onto fly-

wheel (Fig. 10).

(6) Align and hold clutch cover in position and

install cover bolts finger tight.

(7) Tighten cover bolts evenly and a few threads at

a time. Cover bolts must be tightened evenly and to

specified torque to avoid distorting cover.

(8) Tighten clutch cover bolts to following:

²5/16 in. diameter bolts to 23 N´m (17 ft. lbs.).

²3/8 in. diameter bolts to 41 N´m (30 ft. lbs.).

Fig. 7 Supporting Engine With Jack Stand And

Wood BlockÐDiesel Model Shown

1 - WOOD BLOCK

2 - ADJUSTABLE JACK STAND

Fig. 8 Marking Clutch Cover Position

1 - FLYWHEEL

2 - ALIGNMENT MARKS (SCRIBE OR PAINT)

3 - CLUTCH COVER

Fig. 9 Clutch Cover Bolt Loosening/Tightening

Pattern

Fig. 10 Clutch Disc And Cover Alignment/

Installation

1 - FLYWHEEL

2 - CLUTCH COVER AND DISC

3 - CLUTCH DISC ALIGNMENT TOOL

BR/BECLUTCH 6 - 9

CLUTCH DISC (Continued)

Page 324 of 2889

CLUTCH HOUSING

DIAGNOSIS AND TESTING - CLUTCH HOUSING

Clutch housing alignment is important to proper

clutch operation. The housing maintains alignment

between the crankshaft and transmission input

shaft. Misalignment can cause clutch noise, hard

shifting, incomplete release and chatter. It can also

result in premature wear of the pilot bearing, cover

release fingers and clutch disc. In severe cases, mis-

alignment can also cause premature wear of the

transmission input shaft and front bearing.

Housing misalignment is generally caused by

incorrect seating on the engine or transmission, loose

housing bolts, missing alignment dowels, or housing

damage. Infrequently, misalignment may also be

caused by housing mounting surfaces that are not

completely parallel. Misalignment can be corrected

with shims.

CHECKING RUNOUT

Only the NV4500 clutch housing can be

checked using the following bore and face

runout procedures. The NV3500 and NV5600

clutch housings are an integral part of the

transmission and can only be checked off the

vehicle.

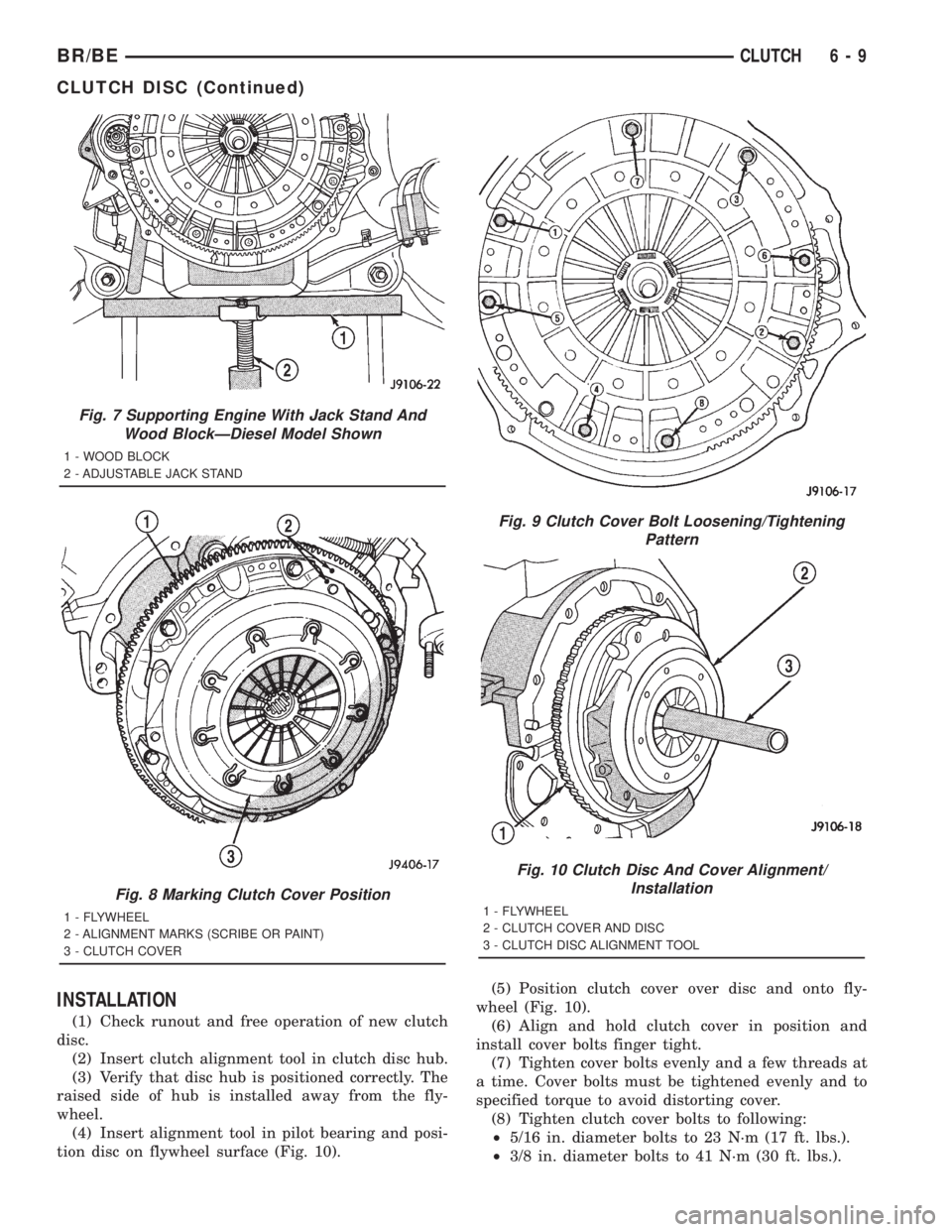

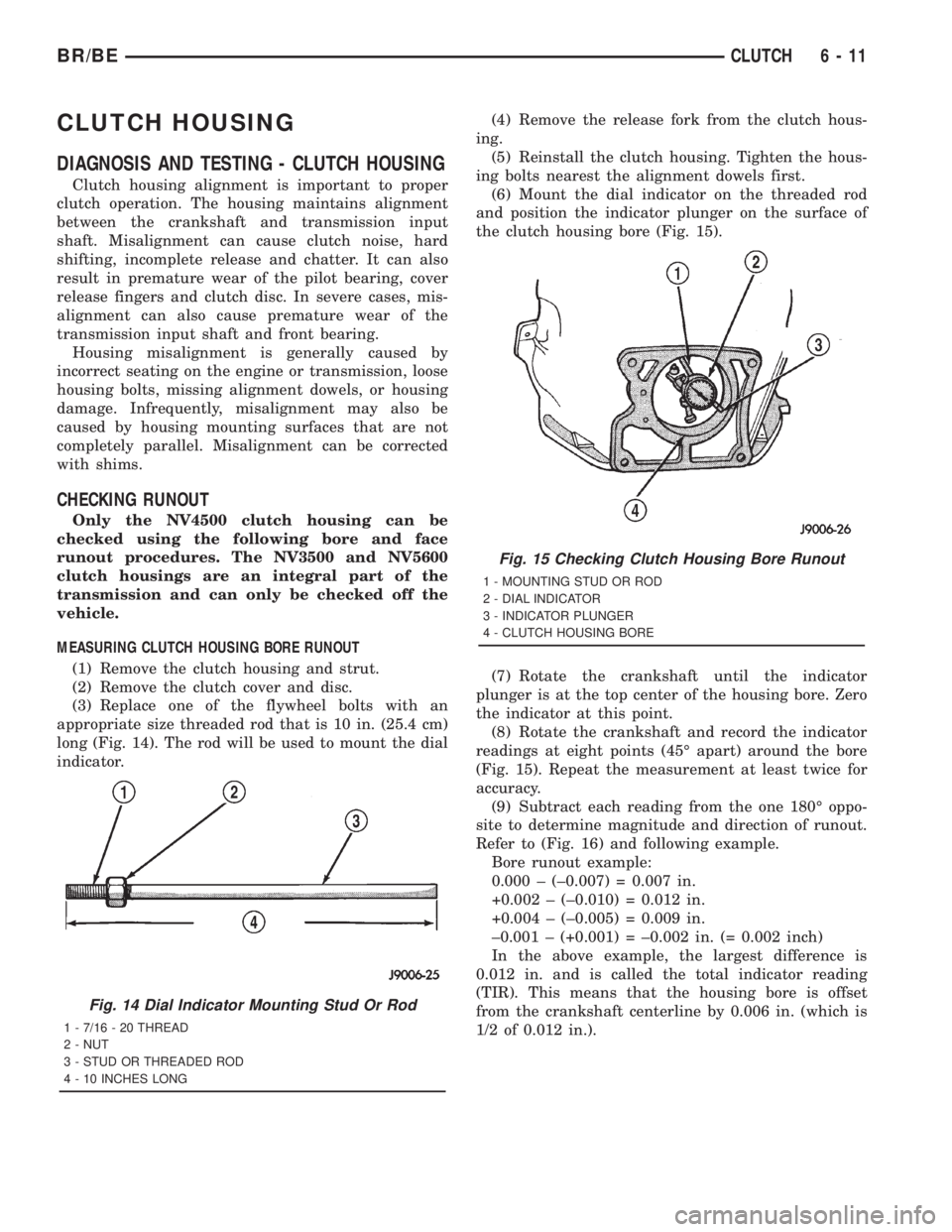

MEASURING CLUTCH HOUSING BORE RUNOUT

(1) Remove the clutch housing and strut.

(2) Remove the clutch cover and disc.

(3) Replace one of the flywheel bolts with an

appropriate size threaded rod that is 10 in. (25.4 cm)

long (Fig. 14). The rod will be used to mount the dial

indicator.(4) Remove the release fork from the clutch hous-

ing.

(5) Reinstall the clutch housing. Tighten the hous-

ing bolts nearest the alignment dowels first.

(6) Mount the dial indicator on the threaded rod

and position the indicator plunger on the surface of

the clutch housing bore (Fig. 15).

(7) Rotate the crankshaft until the indicator

plunger is at the top center of the housing bore. Zero

the indicator at this point.

(8) Rotate the crankshaft and record the indicator

readings at eight points (45É apart) around the bore

(Fig. 15). Repeat the measurement at least twice for

accuracy.

(9) Subtract each reading from the one 180É oppo-

site to determine magnitude and direction of runout.

Refer to (Fig. 16) and following example.

Bore runout example:

0.000 ± (±0.007) = 0.007 in.

+0.002 ± (±0.010) = 0.012 in.

+0.004 ± (±0.005) = 0.009 in.

±0.001 ± (+0.001) = ±0.002 in. (= 0.002 inch)

In the above example, the largest difference is

0.012 in. and is called the total indicator reading

(TIR). This means that the housing bore is offset

from the crankshaft centerline by 0.006 in. (which is

1/2 of 0.012 in.).

Fig. 14 Dial Indicator Mounting Stud Or Rod

1 - 7/16 - 20 THREAD

2 - NUT

3 - STUD OR THREADED ROD

4 - 10 INCHES LONG

Fig. 15 Checking Clutch Housing Bore Runout

1 - MOUNTING STUD OR ROD

2 - DIAL INDICATOR

3 - INDICATOR PLUNGER

4 - CLUTCH HOUSING BORE

BR/BECLUTCH 6 - 11

Page 330 of 2889

shaft speeds and releasing the energy back into the

system when the crankshaft slows down.

DIAGNOSIS AND TESTING - FLYWHEEL

Check flywheel runout whenever misalignment is

suspected. Flywheel runout should not exceed 0.08

mm (0.003 in.). Measure runout at the outer edge of

the flywheel face with a dial indicator. Mount the

indicator on a stud installed in place of one of the fly-

wheel bolts.

Common causes of runout are:

²heat warpage

²improper machining

²incorrect bolt tightening

²improper seating on crankshaft flange shoulder

²foreign material on crankshaft flange

Flywheel machining is not recommended. The fly-

wheel clutch surface is machined to a unique contour

and machining will negate this feature. However,

minor flywheel scoring can be cleaned up by hand with

180 grit emery, or with surface grinding equipment.

Remove only enough material to reduce scoring

(approximately 0.001 - 0.003 in.). Heavy stock removal

isnot recommended.

Replace the flywheel if scoring

is severe and deeper than 0.076 mm (0.003 in.).

Excessive stock removal can result in flywheel crack-

ing or warpage after installation; it can also weaken

the flywheel and interfere with proper clutch release.

Clean the crankshaft flange before mounting the

flywheel. Dirt and grease on the flange surface may

cock the flywheel causing excessive runout. Use new

bolts when remounting a flywheel and secure the

bolts with MopartLock And Seal. Tighten flywheel

bolts to specified torque only. Overtightening can dis-

tort the flywheel hub causing runout.

DISASSEMBLY

NOTE: If the teeth are worn or damaged, the fly-

wheel should be replaced as an assembly. This is

the recommended and preferred method of repair.

In cases where a new flywheel is not readily avail-

able, (V10/Diesel Engine only) a replacement ring

gear can be installed. The following procedure must

be observed to avoid damaging the flywheel and

replacement gear.

WARNING: WEAR PROTECTIVE GOGGLES OR

SAFETY GLASSES WHILE CUTTING RING GEAR.

(1) Mark position of the old gear for alignment ref-

erence on the flywheel. Use a scriber for this pur-

pose.

(2) Remove the old gear by cutting most of the way

through it (at one point) with an abrasive cut-off

wheel. Then complete removal with a cold chisel or

punch.

ASSEMBLY

NOTE: The ring gear is a shrink fit on the flywheel.

This means the gear must be expanded by heating

in order to install it. The method of heating and

expanding the gear is extremely important. Every

surface of the gear must be heated at the same

time to produce uniform expansion. An oven or

similar enclosed heating device must be used. Tem-

perature required for uniform expansion is approxi-

mately 375É F.

CAUTION: Do not use an oxy/acetylene torch to

remove the old gear, or to heat and expand a new

gear. The high temperature of the torch flame can

cause localized heating that will damage the fly-

wheel. In addition, using the torch to heat a replace-

ment gear will cause uneven heating and

expansion. The torch flame can also anneal the

gear teeth resulting in rapid wear and damage after

installation.

WARNING: WEAR PROTECTIVE GOGGLES OR

SAFETY GLASSES AND HEAT RESISTENT GLOVES

WHEN HANDLING A HEATED RING GEAR.

(1) The heated gear must be installed evenly to

avoid misalignment or distortion.

(2) Position and install the heated ring gear on the

flywheel with a shop press and a suitable press

plates.

(3) Place flywheel on work bench and let it cool in

normal shop air. Allow the ring gear to cool down

completely before installation it on the engine.

CAUTION: Do not use water or compressed air to

cool the flywheel. The rapid cooling produced by

water or compressed air will distort or crack the

new gear.

PILOT BEARING

DESCRIPTION

Vehicles equipped with a manual transmission uti-

lize a pilot bearing. This bearing is located in the

back of the engine crankshaft. Depending on the type

of engine or application, the pilot bearing can be a

solid soft metallic bushing or a fully caged needle

bearing. The pilot bearing's main functions are to

support the transmission input shaft, maintain

proper alignment of the clutch assembly and allow

the transmission main shaft to rotate at a different

speed than the engine mounted crankshaft.

BR/BECLUTCH 6 - 17

FLYWHEEL (Continued)

Page 1178 of 2889

(8) Turn crankshaft and camshaft to line up with

keyway location in crankshaft sprocket and in cam-

shaft sprocket.

(9) Lift sprockets and chain (keep sprockets tight

against the chain in position as described).

(10) Slide both sprockets evenly over their respec-

tive shafts and use a straightedge to check alignment

of timing marks (Fig. 22).

(11) Install the camshaft bolt/cup washer. Tighten

bolt to 68 N´m (50 ft. lbs.) torque.

(12) Measure camshaft end play (Fig. 23). (Refer to

9 - ENGINE - SPECIFICATIONS) for proper clear-

ance. If not within limits, install a new timing chain

tensioner.

(13) Each tappet reused must be installed in the

same position at which it was removed.When cam-

shaft is replaced, all of the tappets must be

replaced.Install hydraulic tappets (Refer to 9 -

ENGINE/ENGINE BLOCK/HYDRAULIC LIFTERS

(CAM IN BLOCK) - INSTALLATION).

(14) Install timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(15) Install intake manifold (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - INSTALLA-

TION).

(16) Install distributor.

(17) Install cylinder head covers (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(18) Install radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - INSTALLATION).

(19) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(20) Connect battery negative cable.

(21) Start engine and check for leaks.

CONNECTING ROD BEARINGS

STANDARD PROCEDURE-CONNECTING ROD

BEARING FITTING

Fit all rods on a bank until completed. DO NOT

alternate from one bank to another, because connect-

ing rods and pistons are not interchangeable from

one bank to another.

The bearing caps are not interchangeable and

should be marked at removal to ensure correct

assembly.

Each bearing cap has a small V-groove across the

parting face. When installing the lower bearing shell,

be certain that the V-groove in the shell is in line

with the V-groove in the cap. This provides lubrica-

tion of the cylinder wall in the opposite bank.The bearing shells must be installed so that the

tangs are in the machined grooves in the rods and

caps.

Limits of taper or out-of-round on any crankshaft

journals should be held to 0.025 mm (0.001 in.).

Bearings are available in 0.025 mm (0.001 in.), 0.051

mm (0.002 in.), 0.076 mm (0.003 in.), 0.254 mm

(0.010 in.) and 0.305 mm (0.012 in.) undersize.

Install the bearings in pairs. DO NOT use a new

bearing half with an old bearing half. DO NOT

file the rods or bearing caps.

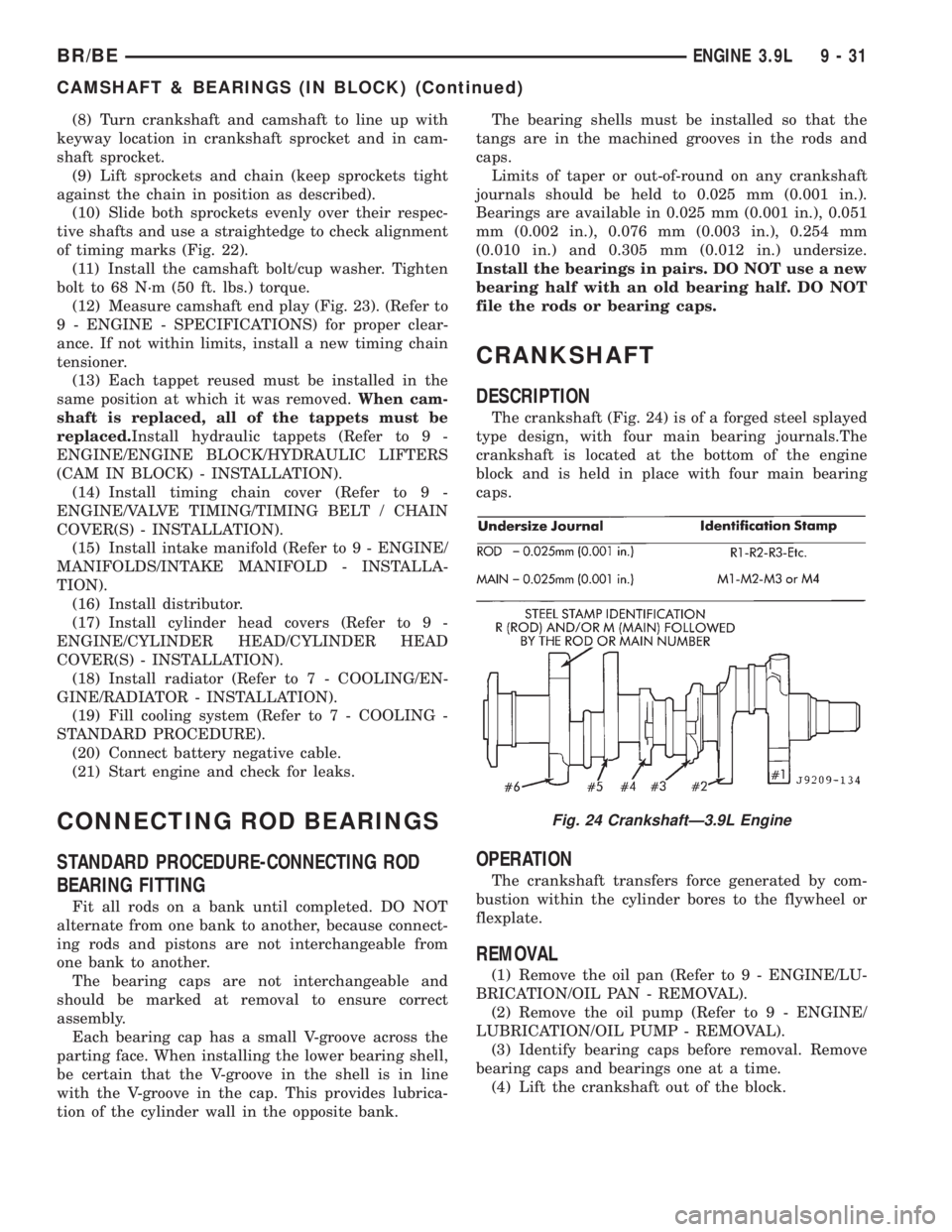

CRANKSHAFT

DESCRIPTION

The crankshaft (Fig. 24) is of a forged steel splayed

type design, with four main bearing journals.The

crankshaft is located at the bottom of the engine

block and is held in place with four main bearing

caps.

OPERATION

The crankshaft transfers force generated by com-

bustion within the cylinder bores to the flywheel or

flexplate.

REMOVAL

(1) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(2) Remove the oil pump (Refer to 9 - ENGINE/

LUBRICATION/OIL PUMP - REMOVAL).

(3) Identify bearing caps before removal. Remove

bearing caps and bearings one at a time.

(4) Lift the crankshaft out of the block.

Fig. 24 CrankshaftÐ3.9L Engine

BR/BEENGINE 3.9L 9 - 31

CAMSHAFT & BEARINGS (IN BLOCK) (Continued)