Heat DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1682 of 2889

A leak at the front of the transmission will be from

either the front bearing retainer or retainer seal.

Lubricant may be seen dripping from the clutch

housing after extended operation. If the leak is

severe, it may also contaminate the clutch disc caus-

ing the disc to slip, grab and or chatter.

A correct lubricant level check can only be made

when the vehicle is level. Also allow the lubricant to

settle for a minute or so before checking. These rec-

ommendations will ensure an accurate check and

avoid an underfill or overfill condition. Always check

the lubricant level after any addition of fluid to avoid

an incorrect lubricant level condition.

HARD SHIFTING

Hard shifting is usually caused by a low lubricant

level, improper or contaminated lubricants. The con-

sequence of using non-recommended lubricants is

noise, excessive wear, internal bind and hard shift-

ing. Substantial lubricant leaks can result in gear,

shift rail, synchro, and bearing damage. If a leak

goes undetected for an extended period, the first indi-

cations of component damage are usually hard shift-

ing and noise.

Component damage, incorrect clutch adjustment or

damaged clutch pressure plate or disc are additional

probable causes of increased shift effort. Incorrect

adjustment or a worn/damaged pressure plate or disc

can cause incorrect release. If clutch problem is

advanced, gear clash during shifts can result. Worn

or damaged synchro rings can cause gear clash when

shifting into any forward gear. In some new or

rebuilt transmissions, new synchro rings may tend to

stick slightly causing hard or noisy shifts. In most

cases this condition will decline as the rings wear-in.

TRANSMISSION NOISE

Most manual transmissions make some noise dur-

ing normal operation. Rotating gears generate a mild

whine that is audible, but generally only at extreme

speeds.

Severe highly audible transmission noise is gener-

ally the initial indicator of a lubricant problem.

Insufficient, improper or contaminated lubricant will

promote rapid wear of gears, synchros, shift rails,

forks and bearings. The overheating caused by a

lubricant problem, can also lead to gear breakage.

REMOVAL

(1) Disconnect battery negative cable.

(2) Shift transmission into Neutral.

(3) Remove shift boot screws from floorpan and

slide boot upward on the shift lever.

(4) Remove shift lever extension from shift tower

and lever assembly.(5) Remove shift tower bolts holding tower to iso-

lator plate and transmission shift cover.

(6) Remove shift tower and isolator plate from

transmission shift cover.

(7) Raise and support vehicle.

(8) Remove skid plate, if equipped.

(9) Mark propeller shaft and axle yokes for instal-

lation reference and remove shaft/shafts.

(10) Remove exhaust system Y-pipe.

(11) Disconnect speed sensor and backup light

switch connectors.

(12) Support engine with safety stand and a wood

block.

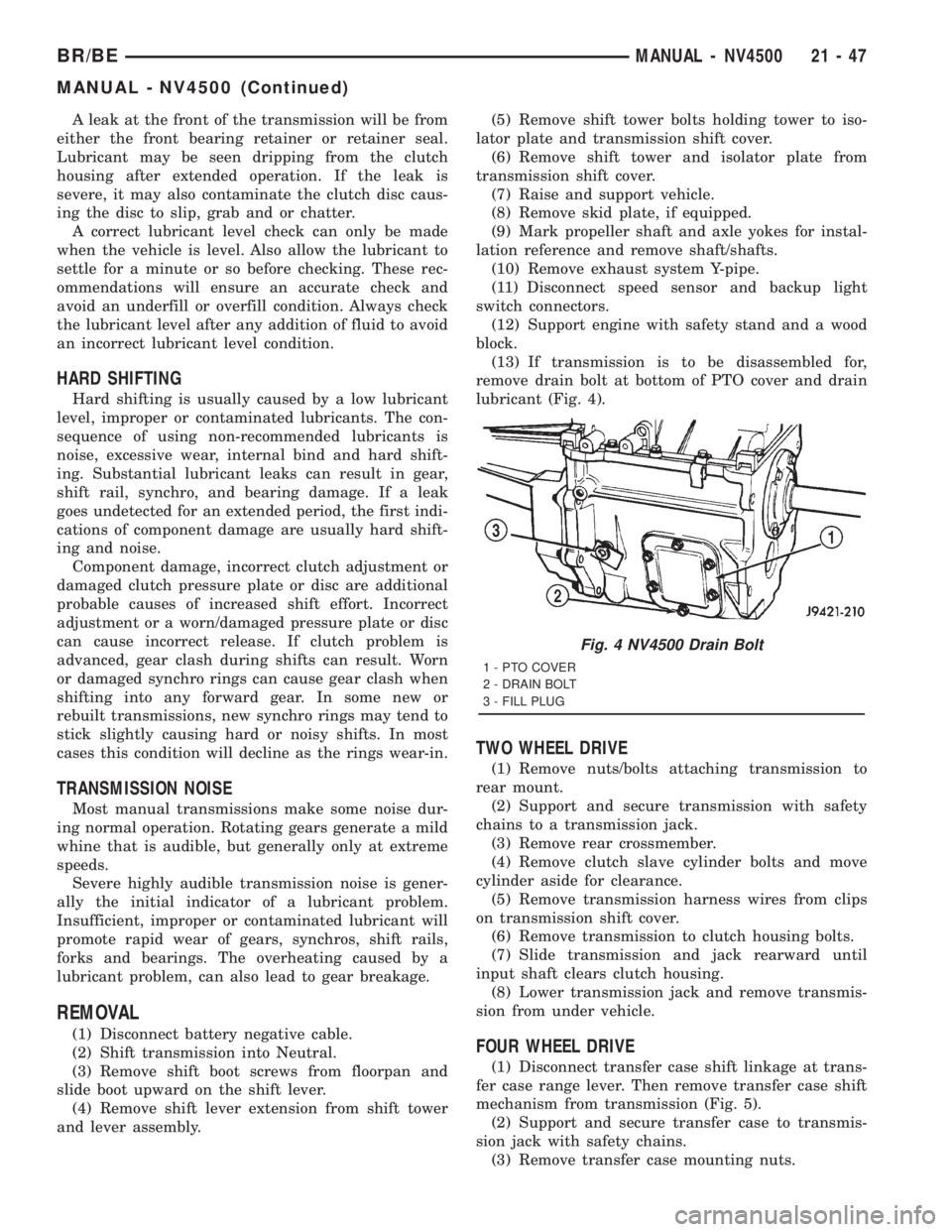

(13) If transmission is to be disassembled for,

remove drain bolt at bottom of PTO cover and drain

lubricant (Fig. 4).

TWO WHEEL DRIVE

(1) Remove nuts/bolts attaching transmission to

rear mount.

(2) Support and secure transmission with safety

chains to a transmission jack.

(3) Remove rear crossmember.

(4) Remove clutch slave cylinder bolts and move

cylinder aside for clearance.

(5) Remove transmission harness wires from clips

on transmission shift cover.

(6) Remove transmission to clutch housing bolts.

(7) Slide transmission and jack rearward until

input shaft clears clutch housing.

(8) Lower transmission jack and remove transmis-

sion from under vehicle.

FOUR WHEEL DRIVE

(1) Disconnect transfer case shift linkage at trans-

fer case range lever. Then remove transfer case shift

mechanism from transmission (Fig. 5).

(2) Support and secure transfer case to transmis-

sion jack with safety chains.

(3) Remove transfer case mounting nuts.

Fig. 4 NV4500 Drain Bolt

1 - PTO COVER

2 - DRAIN BOLT

3 - FILL PLUG

BR/BEMANUAL - NV4500 21 - 47

MANUAL - NV4500 (Continued)

Page 1699 of 2889

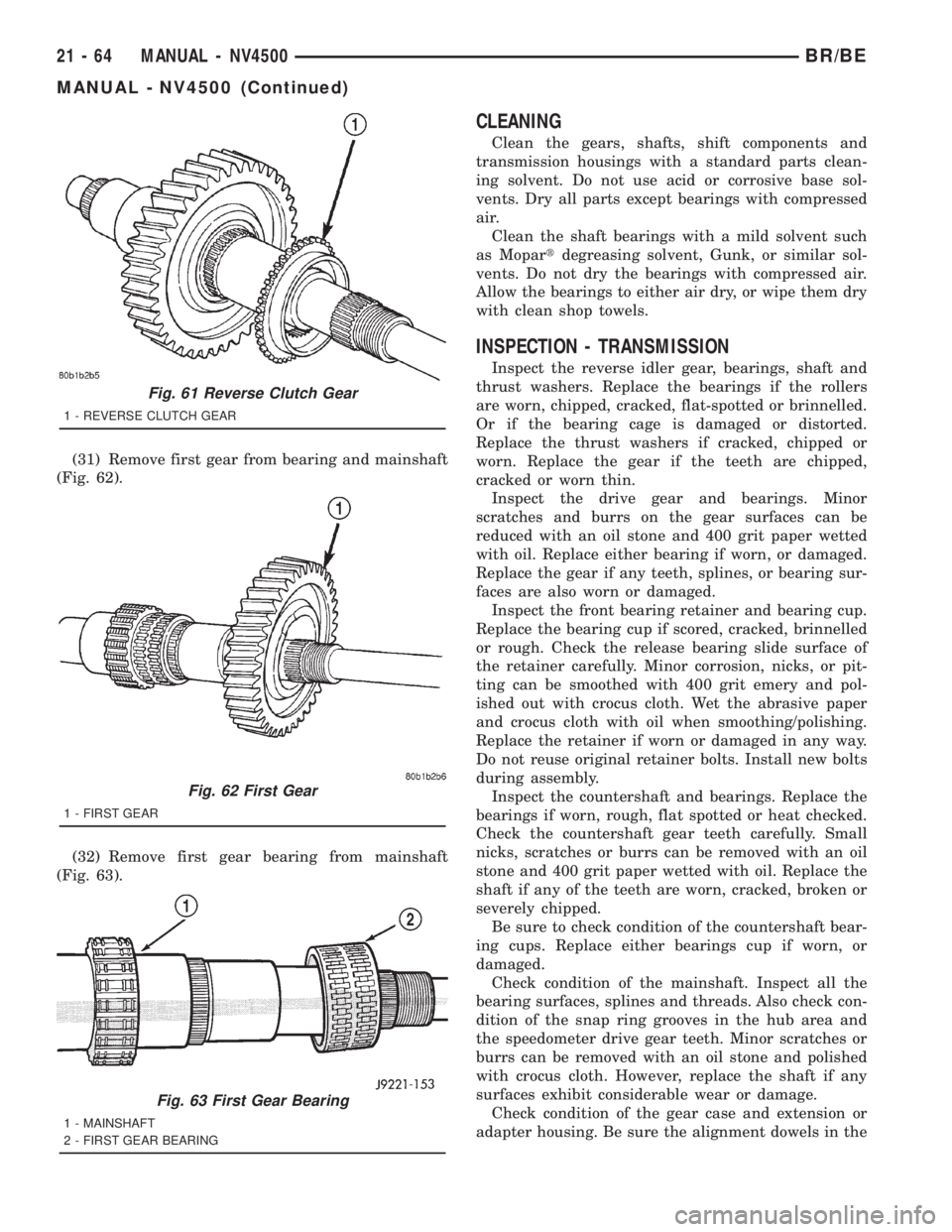

(31) Remove first gear from bearing and mainshaft

(Fig. 62).

(32) Remove first gear bearing from mainshaft

(Fig. 63).

CLEANING

Clean the gears, shafts, shift components and

transmission housings with a standard parts clean-

ing solvent. Do not use acid or corrosive base sol-

vents. Dry all parts except bearings with compressed

air.

Clean the shaft bearings with a mild solvent such

as Mopartdegreasing solvent, Gunk, or similar sol-

vents. Do not dry the bearings with compressed air.

Allow the bearings to either air dry, or wipe them dry

with clean shop towels.

INSPECTION - TRANSMISSION

Inspect the reverse idler gear, bearings, shaft and

thrust washers. Replace the bearings if the rollers

are worn, chipped, cracked, flat-spotted or brinnelled.

Or if the bearing cage is damaged or distorted.

Replace the thrust washers if cracked, chipped or

worn. Replace the gear if the teeth are chipped,

cracked or worn thin.

Inspect the drive gear and bearings. Minor

scratches and burrs on the gear surfaces can be

reduced with an oil stone and 400 grit paper wetted

with oil. Replace either bearing if worn, or damaged.

Replace the gear if any teeth, splines, or bearing sur-

faces are also worn or damaged.

Inspect the front bearing retainer and bearing cup.

Replace the bearing cup if scored, cracked, brinnelled

or rough. Check the release bearing slide surface of

the retainer carefully. Minor corrosion, nicks, or pit-

ting can be smoothed with 400 grit emery and pol-

ished out with crocus cloth. Wet the abrasive paper

and crocus cloth with oil when smoothing/polishing.

Replace the retainer if worn or damaged in any way.

Do not reuse original retainer bolts. Install new bolts

during assembly.

Inspect the countershaft and bearings. Replace the

bearings if worn, rough, flat spotted or heat checked.

Check the countershaft gear teeth carefully. Small

nicks, scratches or burrs can be removed with an oil

stone and 400 grit paper wetted with oil. Replace the

shaft if any of the teeth are worn, cracked, broken or

severely chipped.

Be sure to check condition of the countershaft bear-

ing cups. Replace either bearings cup if worn, or

damaged.

Check condition of the mainshaft. Inspect all the

bearing surfaces, splines and threads. Also check con-

dition of the snap ring grooves in the hub area and

the speedometer drive gear teeth. Minor scratches or

burrs can be removed with an oil stone and polished

with crocus cloth. However, replace the shaft if any

surfaces exhibit considerable wear or damage.

Check condition of the gear case and extension or

adapter housing. Be sure the alignment dowels in the

Fig. 61 Reverse Clutch Gear

1 - REVERSE CLUTCH GEAR

Fig. 62 First Gear

1 - FIRST GEAR

Fig. 63 First Gear Bearing

1 - MAINSHAFT

2 - FIRST GEAR BEARING

21 - 64 MANUAL - NV4500BR/BE

MANUAL - NV4500 (Continued)

Page 1729 of 2889

A leak at the front of the transmission will be from

either the front bearing retainer or retainer seal.

Lubricant may be seen dripping from the clutch

housing after extended operation. If the leak is

severe, it may also contaminate the clutch disc caus-

ing the disc to slip, grab and or chatter.

A correct lubricant level check can only be made

when the vehicle is level. Also allow the lubricant to

settle for a minute or so before checking. These rec-

ommendations will ensure an accurate check and

avoid an underfill or overfill condition. Always check

the lubricant level after any addition of fluid to avoid

an incorrect lubricant level condition.

HARD SHIFTING

Hard shifting is usually caused by a low lubricant

level, improper or contaminated lubricants. The con-

sequence of using non-recommended lubricants is

noise, excessive wear, internal bind and hard shift-

ing. Substantial lubricant leaks can result in gear,

shift rail, synchro, and bearing damage. If a leak

goes undetected for an extended period, the first indi-

cations of component damage are usually hard shift-

ing and noise.

Component damage, incorrect clutch adjustment or

damaged clutch pressure plate or disc are additional

probable causes of increased shift effort. Incorrect

adjustment or a worn/damaged pressure plate or disc

can cause incorrect release. If clutch problem is

advanced, gear clash during shifts can result. Worn

or damaged synchro rings can cause gear clash when

shifting into any forward gear. In some new or

rebuilt transmissions, new synchro rings may tend to

stick slightly causing hard or noisy shifts. In most

cases this condition will decline as the rings wear-in.

TRANSMISSION NOISE

Most manual transmissions make some noise dur-

ing normal operation. Rotating gears generate a mild

whine that is audible, but generally only at extreme

speeds.

Severe highly audible transmission noise is gener-

ally the initial indicator of a lubricant problem.

Insufficient, improper or contaminated lubricant will

promote rapid wear of gears, synchros, shift rails,

forks and bearings. The overheating caused by a

lubricant problem, can also lead to gear breakage.

REMOVAL

NOTE: Use a heavy duty scissors style transmis-

sion jack for remove of the transmission.

(1) Disconnect battery negative cable.

(2) Shift transmission into Neutral.

(3) Remove screws attaching shift boot to floorpan.

Then slide boot upward on the shift lever.(4) Remove the bolts holding the shift tower to the

isolator plate and transmission gear case.

(5) Remove the shift tower and isolator plate from

the transmission gear case.

(6) Raise and support vehicle.

(7) Remove skid plate, if equipped.

(8) Mark propeller shaft/shafts and axle yokes for

installation reference.

(9) Remove propeller shaft.

(10) Disconnect and remove exhaust system as

necessary.

(11) Disconnect wires at backup light switch.

(12) Support engine with adjustable safety stand

and wood block.

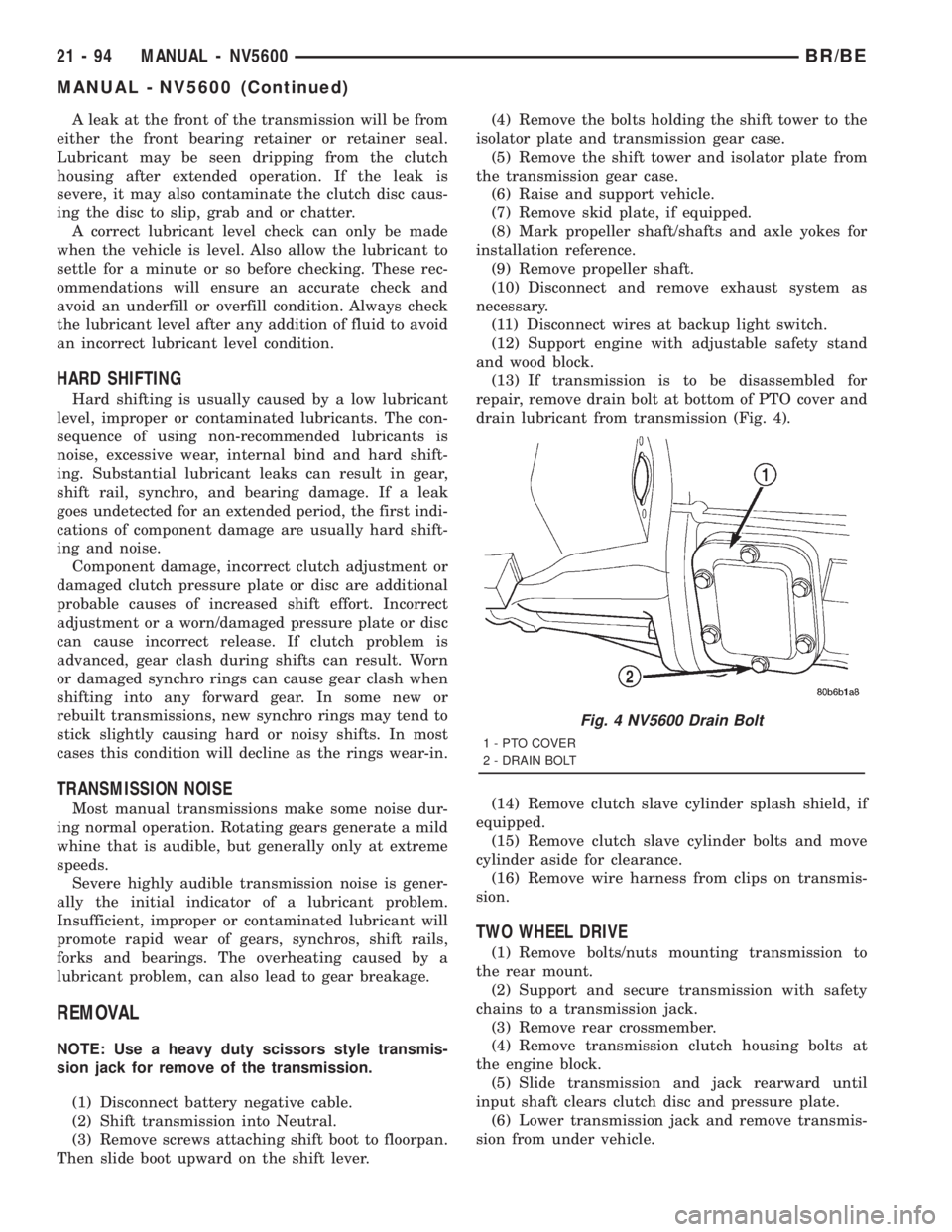

(13) If transmission is to be disassembled for

repair, remove drain bolt at bottom of PTO cover and

drain lubricant from transmission (Fig. 4).

(14) Remove clutch slave cylinder splash shield, if

equipped.

(15) Remove clutch slave cylinder bolts and move

cylinder aside for clearance.

(16) Remove wire harness from clips on transmis-

sion.

TWO WHEEL DRIVE

(1) Remove bolts/nuts mounting transmission to

the rear mount.

(2) Support and secure transmission with safety

chains to a transmission jack.

(3) Remove rear crossmember.

(4) Remove transmission clutch housing bolts at

the engine block.

(5) Slide transmission and jack rearward until

input shaft clears clutch disc and pressure plate.

(6) Lower transmission jack and remove transmis-

sion from under vehicle.

Fig. 4 NV5600 Drain Bolt

1 - PTO COVER

2 - DRAIN BOLT

21 - 94 MANUAL - NV5600BR/BE

MANUAL - NV5600 (Continued)

Page 1735 of 2889

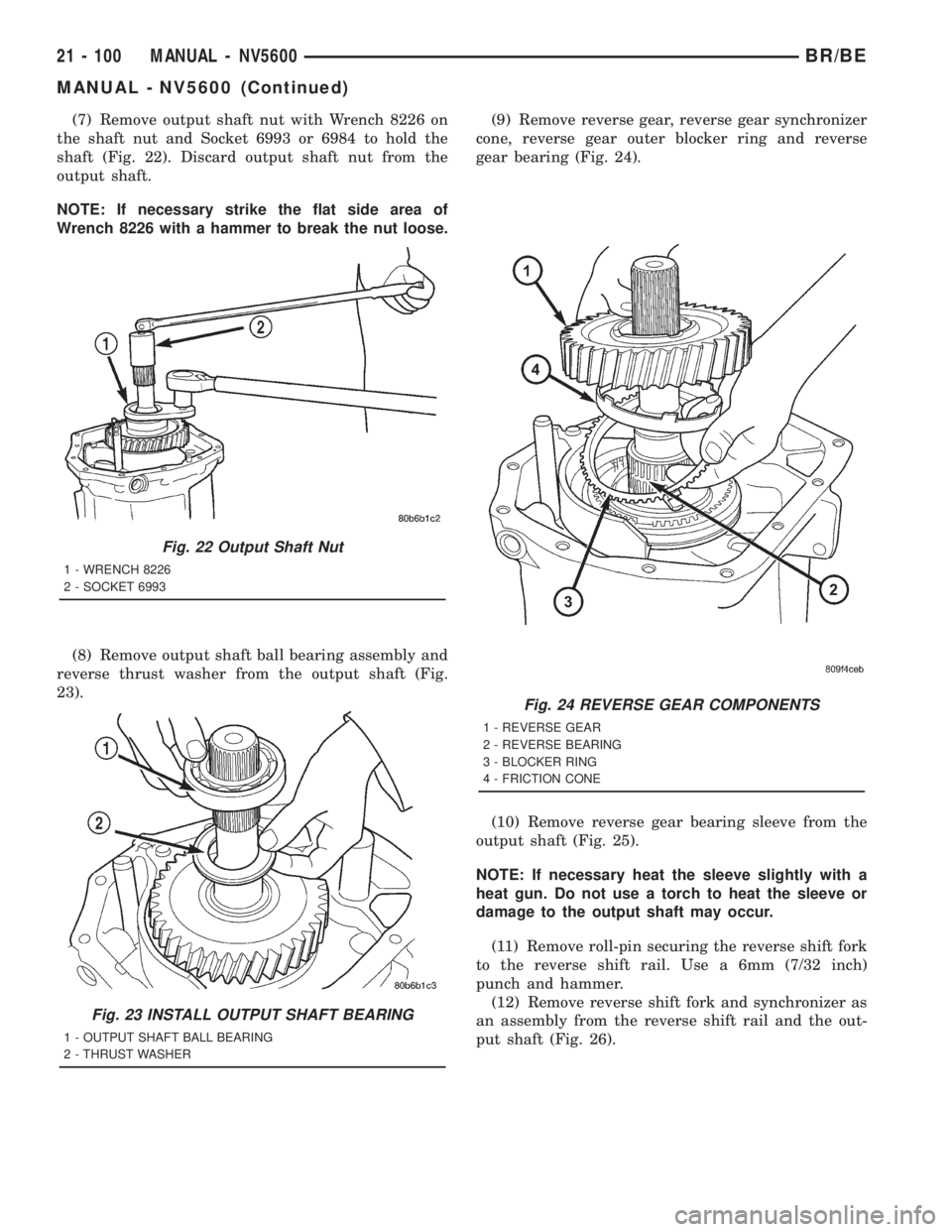

(7) Remove output shaft nut with Wrench 8226 on

the shaft nut and Socket 6993 or 6984 to hold the

shaft (Fig. 22). Discard output shaft nut from the

output shaft.

NOTE: If necessary strike the flat side area of

Wrench 8226 with a hammer to break the nut loose.

(8) Remove output shaft ball bearing assembly and

reverse thrust washer from the output shaft (Fig.

23).(9) Remove reverse gear, reverse gear synchronizer

cone, reverse gear outer blocker ring and reverse

gear bearing (Fig. 24).

(10) Remove reverse gear bearing sleeve from the

output shaft (Fig. 25).

NOTE: If necessary heat the sleeve slightly with a

heat gun. Do not use a torch to heat the sleeve or

damage to the output shaft may occur.

(11) Remove roll-pin securing the reverse shift fork

to the reverse shift rail. Use a 6mm (7/32 inch)

punch and hammer.

(12) Remove reverse shift fork and synchronizer as

an assembly from the reverse shift rail and the out-

put shaft (Fig. 26).

Fig. 22 Output Shaft Nut

1 - WRENCH 8226

2 - SOCKET 6993

Fig. 23 INSTALL OUTPUT SHAFT BEARING

1 - OUTPUT SHAFT BALL BEARING

2 - THRUST WASHER

Fig. 24 REVERSE GEAR COMPONENTS

1 - REVERSE GEAR

2 - REVERSE BEARING

3 - BLOCKER RING

4 - FRICTION CONE

21 - 100 MANUAL - NV5600BR/BE

MANUAL - NV5600 (Continued)

Page 1745 of 2889

and crocus cloth with oil when smoothing/polishing.

Replace the retainer if worn or damaged in any way.

Do not reuse original retainer bolts. Install new bolts

during assembly.

Inspect the countershaft and bearings. Replace the

bearings if worn, rough, flat spotted or heat checked.

Check the countershaft gear teeth carefully. Small

nicks, scratches or burrs can be removed with an oil

stone and 400 grit paper wetted with oil. Replace the

shaft if any of the teeth are worn, cracked, broken or

severely chipped.

Be sure to check condition of the countershaft bear-

ing cups. Replace either bearings cup if worn, or

damaged.

Check condition of the mainshaft. Inspect all the

bearing surfaces, splines and threads. Also check con-

dition of the snap ring grooves in the hub area and

the speedometer drive gear teeth. Minor scratches or

burrs can be removed with an oil stone and polished

with crocus cloth. However, replace the shaft if any

surfaces exhibit considerable wear or damage.

Check condition of the gear case and extension or

adapter housing. Be sure the alignment dowels in the

case top surface and in the housing/adapter are tight

and in good condition.

Run a tap through the gear case bolt holes if the

threads need minor cleanup. Helicoil inserts can be

used to repair seriously damaged threaded holes if

necessary.

Be sure all case and housing/adapter sealing and

mating surfaces are free of burrs and nicks. This is

especially important as gaskets are not used in the

transmission. Minor nicks and scratches on the seal-

ing surfaces can be dressed off with a fine tooth file

or oil stone.

Replace the gear case or housing/adapter if cracked

or broken. Do not attempt to repair this type of dam-

age by welding or brazing.

Check condition of the countershaft fifth gear com-

ponents. This includes the shift lug and rail located

in the gear case and the rail bushings.

Inspect the gear and hub assembly. Minor burrs

can be cleaned up with an oil stone. However, the

gear and hub assembly should be replaced if the

teeth or splines are excessively worn, or damaged.

The synchro sleeve should also be replaced if worn or

damaged in any way. Do not reuse synchro struts

that are worn or springs that are collapsed or

severely distorted. Replace worn distorted synchro

parts to avoid shift problems after assembly and

installation.

The shift fork should be inspected for evidence of

wear and distortion. Check fit of the sleeve in the

fork to be sure the two parts fit and work smoothly.

Replace the fork if the roll pin holes are worn over-

size or damaged. Do not attempt to salvage a wornfork. It will cause shift problems later on. Replace

shift fork roll pins if necessary or if doubt exists

about their condition.

The bearings should be examined carefully for

wear, roughness, flat spots, pitting or other damage.

Replace the bearings if necessary.

Inspect the blocker ring and clutch gear. replace

either part if worn or damaged in any way. Also be

sure replacement parts fit properly before proceeding

with assembly.

Examine the 1-2 synchro hub and sleeve for wear

or damage. Replace sleeve and hub if the splines are

worn, chipped or damaged.

Replace the synchro struts if worn, or chipped. Also

replace the springs if collapsed, distorted or broken.

Inspect the mainshaft geartrain components.

Check teeth on all gears, hubs, clutch gears, stop

rings and clutch rings. The teeth must be in good

condition and not worn, cracked or chipped. Replace

any component that exhibits wear or damage.

Examine the synchro stop rings, clutch rings and

clutch gears. Replace any part that exhibits wear,

distortion or damage. Replace the clutch rings if the

friction material is burned, flaking off or worn.

Inspect all of the thrust washers and locating pins.

Replace the pins if bent or worn. Replace the wash-

ers if worn or the locating pin notches are distorted.

Check condition of the synchro struts and springs.

Replace these parts if worn, cracked or distorted.

ASSEMBLY

NOTE: Gaskets are not used in the transmission.

Use MoparTGasket Maker or equivalent on all gear

case and extension housing sealing surfaces.

OUTPUT SHAFT

(1) Place second gear on bench with the synchro

clutch ring up.

(2) Install second gear synchro inner blocker ring

onto second gear (Fig. 53).

(3) Install second gear synchro friction cone over

the blocker ring and onto second gear (Fig. 54).

(4) Install second gear synchro outer blocker ring

over the second gear synchro friction cone. Align one

of the lugs on the outer ring with a lug on the inner

ring (Fig. 55).

(5) Install 1-2 synchro assembly onto the second

gear assembly (Fig. 56).

(6) Reverse assembly on the bench.

21 - 110 MANUAL - NV5600BR/BE

MANUAL - NV5600 (Continued)

Page 1834 of 2889

FLUID AND FILTER

DIAGNOSIS AND TESTING - EFFECTS OF

INCORRECT FLUID LEVEL

A low fluid level allows the pump to take in air

along with the fluid. Air in the fluid will cause fluid

pressures to be low and develop slower than normal.

If the transmission is overfilled, the gears churn the

fluid into foam. This aerates the fluid and causing

the same conditions occurring with a low level. In

either case, air bubbles cause fluid overheating, oxi-

dation and varnish buildup which interferes with

valve and clutch operation. Foaming also causes fluid

expansion which can result in fluid overflow from the

transmission vent or fill tube. Fluid overflow can eas-

ily be mistaken for a leak if inspection is not careful.

DIAGNOSIS AND TESTING - CAUSES OF

BURNT FLUID

Burnt, discolored fluid is a result of overheating

which has two primary causes.

(1) A result of restricted fluid flow through the

main and/or auxiliary cooler. This condition is usu-

ally the result of a faulty or improperly installed

drainback valve, a damaged main cooler, or severe

restrictions in the coolers and lines caused by debris

or kinked lines.

(2) Heavy duty operation with a vehicle not prop-

erly equipped for this type of operation. Trailer tow-

ing or similar high load operation will overheat the

transmission fluid if the vehicle is improperly

equipped. Such vehicles should have an auxiliary

transmission fluid cooler, a heavy duty cooling sys-

tem, and the engine/axle ratio combination needed to

handle heavy loads.

DIAGNOSIS AND TESTING - FLUID

CONTAMINATION

Transmission fluid contamination is generally a

result of:

²adding incorrect fluid

²failure to clean dipstick and fill tube when

checking level

²engine coolant entering the fluid

²internal failure that generates debris

²

overheat that generates sludge (fluid breakdown)

²failure to reverse flush cooler and lines after repair

²failure to replace contaminated converter after

repair

The use of non-recommended fluids can result in

transmission failure. The usual results are erratic

shifts, slippage, abnormal wear and eventual failure

due to fluid breakdown and sludge formation. Avoid

this condition by using recommended fluids only.

The dipstick cap and fill tube should be wiped clean

before checking fluid level. Dirt, grease and other for-

eign material on the cap and tube could fall into the

tube if not removed beforehand. Take the time to wipe

the cap and tube clean before withdrawing the dipstick.

Engine coolant in the transmission fluid is gener-

ally caused by a cooler malfunction. The only remedy

is to replace the radiator as the cooler in the radiator

is not a serviceable part. If coolant has circulated

through the transmission, an overhaul is necessary.

The transmission cooler and lines should be

reverse flushed whenever a malfunction generates

sludge and/or debris. The torque converter should

also be replaced at the same time.

Failure to flush the cooler and lines will result in

recontamination. Flushing applies to auxiliary coolers

as well. The torque converter should also be replaced

whenever a failure generates sludge and debris. This is

necessary because normal converter flushing procedures

will not remove all contaminants.

STANDARD PROCEDURE - FLUID LEVEL

CHECK

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transmssion has too much fluid, the

geartrain churns up foam and cause the same condi-

tions which occur with a low fluid level.

In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can inter-

fere with normal valve, clutch, and accumulator opera-

tion. Foaming can also result in fluid escaping from the

transmission vent where it may be mistaken for a leak.

Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transmission recondition is

needed. Be sure to examine the fluid on the dipstick

closely. If there is any doubt about its condition,

drain out a sample for a double check.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

The transmission has a dipstick to check oil level.

It is located on the right side of the engine. Be sure

to wipe all dirt from dipstick handle before removing.

Fluid level is checked with the engine running at curb

idle speed, the transmission in NEUTRAL and the trans-

mission fluid at normal operating temperature.The

engine should be running at idle speed for at least

one minute, with the vehicle on level ground.

The transmission fluid level can be checked two

ways.

BR/BEAUTOMATIC TRANSMISSION - 42RE 21 - 199

Page 1890 of 2889

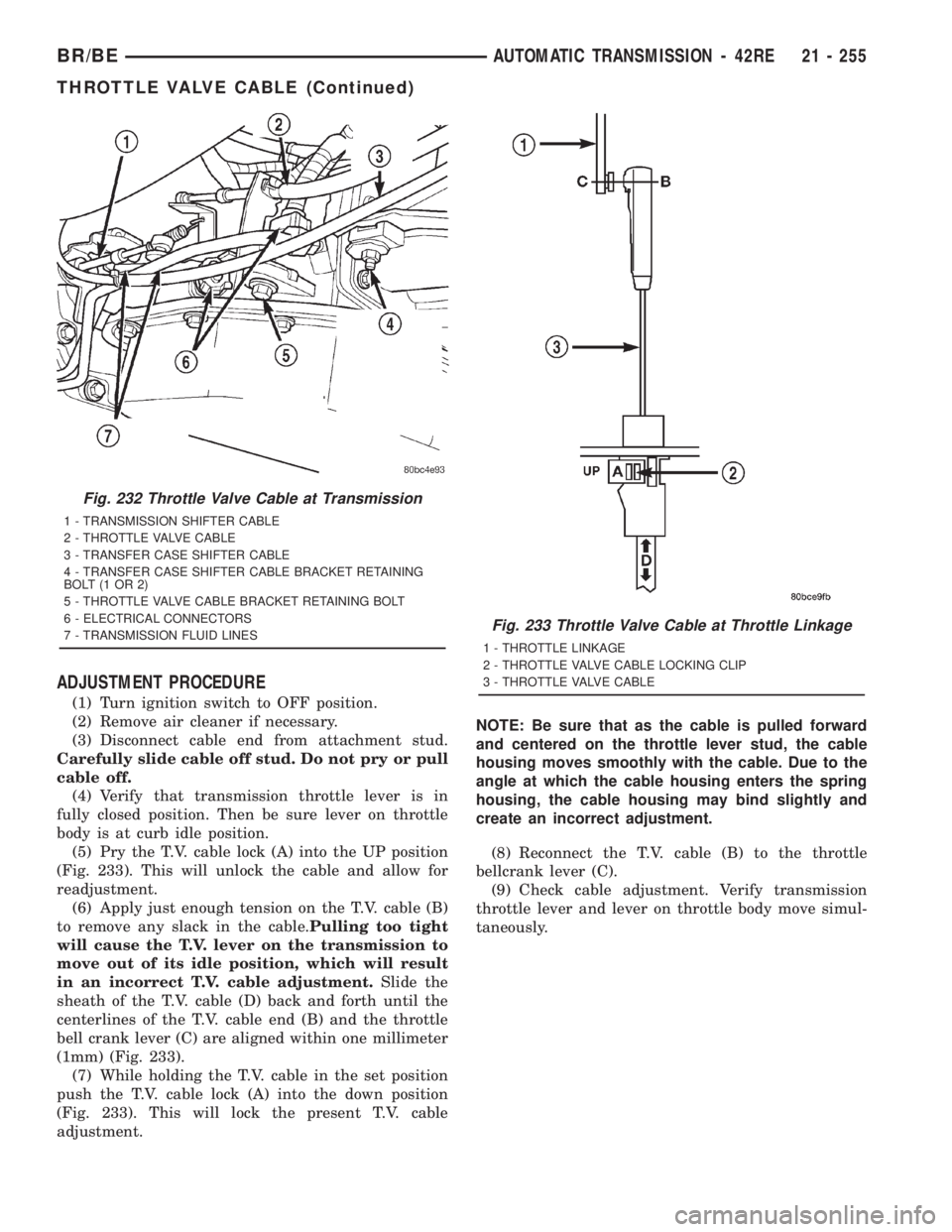

ADJUSTMENT PROCEDURE

(1) Turn ignition switch to OFF position.

(2) Remove air cleaner if necessary.

(3) Disconnect cable end from attachment stud.

Carefully slide cable off stud. Do not pry or pull

cable off.

(4) Verify that transmission throttle lever is in

fully closed position. Then be sure lever on throttle

body is at curb idle position.

(5) Pry the T.V. cable lock (A) into the UP position

(Fig. 233). This will unlock the cable and allow for

readjustment.

(6) Apply just enough tension on the T.V. cable (B)

to remove any slack in the cable.Pulling too tight

will cause the T.V. lever on the transmission to

move out of its idle position, which will result

in an incorrect T.V. cable adjustment.Slide the

sheath of the T.V. cable (D) back and forth until the

centerlines of the T.V. cable end (B) and the throttle

bell crank lever (C) are aligned within one millimeter

(1mm) (Fig. 233).

(7) While holding the T.V. cable in the set position

push the T.V. cable lock (A) into the down position

(Fig. 233). This will lock the present T.V. cable

adjustment.NOTE: Be sure that as the cable is pulled forward

and centered on the throttle lever stud, the cable

housing moves smoothly with the cable. Due to the

angle at which the cable housing enters the spring

housing, the cable housing may bind slightly and

create an incorrect adjustment.

(8) Reconnect the T.V. cable (B) to the throttle

bellcrank lever (C).

(9) Check cable adjustment. Verify transmission

throttle lever and lever on throttle body move simul-

taneously.

Fig. 232 Throttle Valve Cable at Transmission

1 - TRANSMISSION SHIFTER CABLE

2 - THROTTLE VALVE CABLE

3 - TRANSFER CASE SHIFTER CABLE

4 - TRANSFER CASE SHIFTER CABLE BRACKET RETAINING

BOLT(1OR2)

5 - THROTTLE VALVE CABLE BRACKET RETAINING BOLT

6 - ELECTRICAL CONNECTORS

7 - TRANSMISSION FLUID LINES

Fig. 233 Throttle Valve Cable at Throttle Linkage

1 - THROTTLE LINKAGE

2 - THROTTLE VALVE CABLE LOCKING CLIP

3 - THROTTLE VALVE CABLE

BR/BEAUTOMATIC TRANSMISSION - 42RE 21 - 255

THROTTLE VALVE CABLE (Continued)

Page 1897 of 2889

TORQUE CONVERTER

DRAINBACK VALVE

DESCRIPTION

The drainback valve is located in the transmission

cooler outlet (pressure) line.

OPERATION

The valve prevents fluid from draining from the

converter into the cooler and lines when the vehicle

is shut down for lengthy periods. Production valves

have a hose nipple at one end, while the opposite end

is threaded for a flare fitting. All valves have an

arrow (or similar mark) to indicate direction of flow

through the valve.

STANDARD PROCEDURE - TORQUE

CONVERTER DRAINBACK VALVE

The converter drainback check valve is located in

the cooler outlet (pressure) line near the radiator

tank. The valve prevents fluid drainback when the

vehicle is parked for lengthy periods. The valve check

ball is spring loaded and has an opening pressure of

approximately 2 psi.

The valve is serviced as an assembly; it is not

repairable. Do not clean the valve if restricted, or

contaminated by sludge, or debris. If the valve fails,

or if a transmission malfunction occurs that gener-

ates significant amounts of sludge and/or clutch par-

ticles and metal shavings, the valve must be

replaced.

The valve must be removed whenever the cooler

and lines are reverse flushed. The valve can be flow

tested when necessary. The procedure is exactly the

same as for flow testing a cooler.

If the valve is restricted, installed backwards, or in

the wrong line, it will cause an overheating condition

and possible transmission failure.

CAUTION: The drainback valve is a one-way flow

device. It must be properly oriented in terms of flow

direction for the cooler to function properly. The

valve must be installed in the pressure line. Other-

wise flow will be blocked and would cause an over-

heating condition and eventual transmission failure.

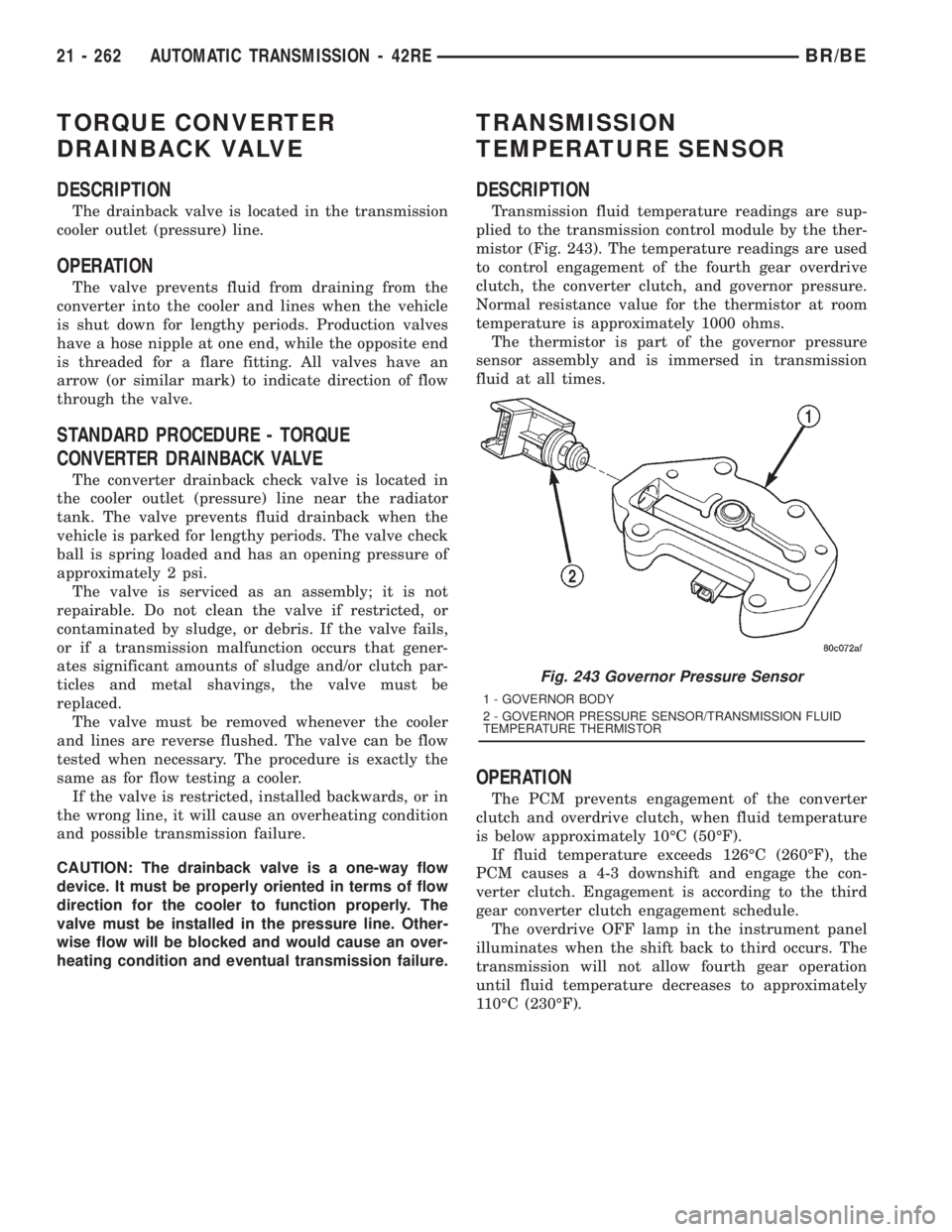

TRANSMISSION

TEMPERATURE SENSOR

DESCRIPTION

Transmission fluid temperature readings are sup-

plied to the transmission control module by the ther-

mistor (Fig. 243). The temperature readings are used

to control engagement of the fourth gear overdrive

clutch, the converter clutch, and governor pressure.

Normal resistance value for the thermistor at room

temperature is approximately 1000 ohms.

The thermistor is part of the governor pressure

sensor assembly and is immersed in transmission

fluid at all times.

OPERATION

The PCM prevents engagement of the converter

clutch and overdrive clutch, when fluid temperature

is below approximately 10ÉC (50ÉF).

If fluid temperature exceeds 126ÉC (260ÉF), the

PCM causes a 4-3 downshift and engage the con-

verter clutch. Engagement is according to the third

gear converter clutch engagement schedule.

The overdrive OFF lamp in the instrument panel

illuminates when the shift back to third occurs. The

transmission will not allow fourth gear operation

until fluid temperature decreases to approximately

110ÉC (230ÉF).

Fig. 243 Governor Pressure Sensor

1 - GOVERNOR BODY

2 - GOVERNOR PRESSURE SENSOR/TRANSMISSION FLUID

TEMPERATURE THERMISTOR

21 - 262 AUTOMATIC TRANSMISSION - 42REBR/BE

Page 1903 of 2889

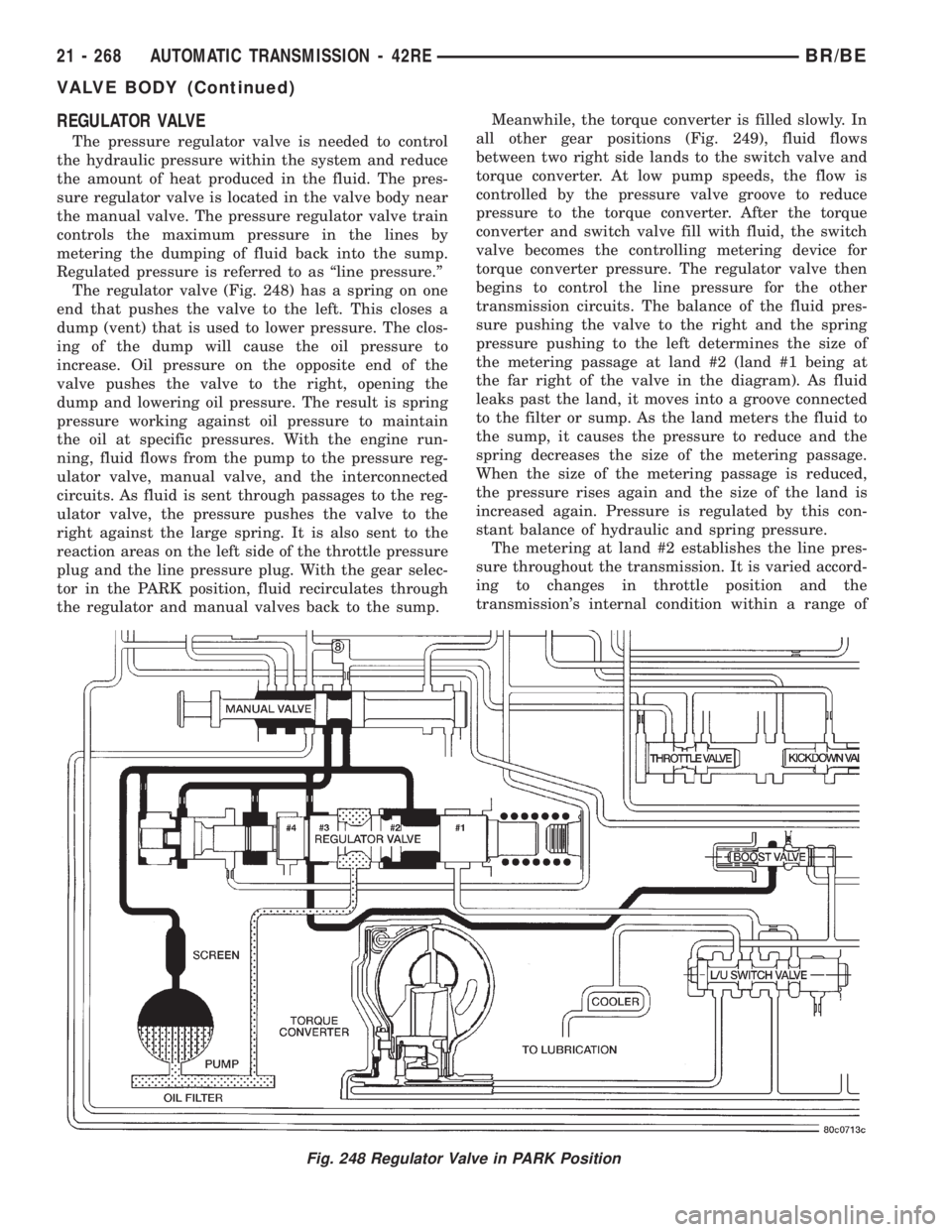

REGULATOR VALVE

The pressure regulator valve is needed to control

the hydraulic pressure within the system and reduce

the amount of heat produced in the fluid. The pres-

sure regulator valve is located in the valve body near

the manual valve. The pressure regulator valve train

controls the maximum pressure in the lines by

metering the dumping of fluid back into the sump.

Regulated pressure is referred to as ªline pressure.º

The regulator valve (Fig. 248) has a spring on one

end that pushes the valve to the left. This closes a

dump (vent) that is used to lower pressure. The clos-

ing of the dump will cause the oil pressure to

increase. Oil pressure on the opposite end of the

valve pushes the valve to the right, opening the

dump and lowering oil pressure. The result is spring

pressure working against oil pressure to maintain

the oil at specific pressures. With the engine run-

ning, fluid flows from the pump to the pressure reg-

ulator valve, manual valve, and the interconnected

circuits. As fluid is sent through passages to the reg-

ulator valve, the pressure pushes the valve to the

right against the large spring. It is also sent to the

reaction areas on the left side of the throttle pressure

plug and the line pressure plug. With the gear selec-

tor in the PARK position, fluid recirculates through

the regulator and manual valves back to the sump.Meanwhile, the torque converter is filled slowly. In

all other gear positions (Fig. 249), fluid flows

between two right side lands to the switch valve and

torque converter. At low pump speeds, the flow is

controlled by the pressure valve groove to reduce

pressure to the torque converter. After the torque

converter and switch valve fill with fluid, the switch

valve becomes the controlling metering device for

torque converter pressure. The regulator valve then

begins to control the line pressure for the other

transmission circuits. The balance of the fluid pres-

sure pushing the valve to the right and the spring

pressure pushing to the left determines the size of

the metering passage at land #2 (land #1 being at

the far right of the valve in the diagram). As fluid

leaks past the land, it moves into a groove connected

to the filter or sump. As the land meters the fluid to

the sump, it causes the pressure to reduce and the

spring decreases the size of the metering passage.

When the size of the metering passage is reduced,

the pressure rises again and the size of the land is

increased again. Pressure is regulated by this con-

stant balance of hydraulic and spring pressure.

The metering at land #2 establishes the line pres-

sure throughout the transmission. It is varied accord-

ing to changes in throttle position and the

transmission's internal condition within a range of

Fig. 248 Regulator Valve in PARK Position

21 - 268 AUTOMATIC TRANSMISSION - 42REBR/BE

VALVE BODY (Continued)

Page 2005 of 2889

FLUID AND FILTER

DIAGNOSIS AND TESTING - EFFECTS OF

INCORRECT FLUID LEVEL

A low fluid level allows the pump to take in air

along with the fluid. Air in the fluid will cause fluid

pressures to be low and develop slower than normal.

If the transmission is overfilled, the gears churn the

fluid into foam. This aerates the fluid and causing

the same conditions occurring with a low level. In

either case, air bubbles cause fluid overheating, oxi-

dation and varnish buildup which interferes with

valve and clutch operation. Foaming also causes fluid

expansion which can result in fluid overflow from the

transmission vent or fill tube. Fluid overflow can eas-

ily be mistaken for a leak if inspection is not careful.

DIAGNOSIS AND TESTING - CAUSES OF

BURNT FLUID

Burnt, discolored fluid is a result of overheating

which has two primary causes.

(1)

A result of restricted fluid flow through the main

and/or auxiliary cooler. This condition is usually the

result of a faulty or improperly installed drainback

valve, a damaged main cooler, or severe restrictions in

the coolers and lines caused by debris or kinked lines.

(2) Heavy duty operation with a vehicle not prop-

erly equipped for this type of operation. Trailer tow-

ing or similar high load operation will overheat the

transmission fluid if the vehicle is improperly

equipped. Such vehicles should have an auxiliary

transmission fluid cooler, a heavy duty cooling sys-

tem, and the engine/axle ratio combination needed to

handle heavy loads.

DIAGNOSIS AND TESTING - FLUID

CONTAMINATION

Transmission fluid contamination is generally a

result of:

²adding incorrect fluid

²failure to clean dipstick and fill tube when

checking level

²engine coolant entering the fluid

²internal failure that generates debris

²

overheat that generates sludge (fluid breakdown)

²failure to reverse flush cooler and lines after repair

²failure to replace contaminated converter after

repair

The use of non-recommended fluids can result in

transmission failure. The usual results are erratic

shifts, slippage, abnormal wear and eventual failure

due to fluid breakdown and sludge formation. Avoid

this condition by using recommended fluids only.

The dipstick cap and fill tube should be wiped

clean before checking fluid level. Dirt, grease andother foreign material on the cap and tube could fall

into the tube if not removed beforehand. Take the

time to wipe the cap and tube clean before withdraw-

ing the dipstick.

Engine coolant in the transmission fluid is gener-

ally caused by a cooler malfunction. The only remedy

is to replace the radiator as the cooler in the radiator

is not a serviceable part. If coolant has circulated

through the transmission, an overhaul is necessary.

The transmission cooler and lines should be

reverse flushed whenever a malfunction generates

sludge and/or debris. The torque converter should

also be replaced at the same time.

Failure to flush the cooler and lines will result in

recontamination. Flushing applies to auxiliary coolers

as well. The torque converter should also be replaced

whenever a failure generates sludge and debris. This is

necessary because normal converter flushing procedures

will not remove all contaminants.

STANDARD PROCEDURE - FLUID LEVEL

CHECK

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transmssion has too much fluid, the

geartrain churns up foam and cause the same condi-

tions which occur with a low fluid level.

In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can

interfere with normal valve, clutch, and accumulator

operation. Foaming can also result in fluid escaping

from the transmission vent where it may be mis-

taken for a leak.

Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transmission recondition is

needed. Be sure to examine the fluid on the dipstick

closely. If there is any doubt about its condition,

drain out a sample for a double check.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

The transmission has a dipstick to check oil level.

It is located on the right side of the engine. Be sure

to wipe all dirt from dipstick handle before removing.

Fluid level is checked with the engine running at

curb idle speed, the transmission in NEUTRAL and the

transmission fluid at normal operating temperature.

The engine should be running at idle speed for at

least one minute, with the vehicle on level

ground.

The transmission fluid level can be checked two ways.

21 - 370 AUTOMATIC TRANSMISSION - 44REBR/BE