change time DODGE RAM 2001 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1350 of 2889

is not required when a crankshaft and bearings are

replaced.

(1) Remove the oil pan and oil pickup tube (refer

to Oil Pan in this section for correct procedure).

(2) Remove the timing chain cover and gasket.

Remove and discard the front crankshaft oil seal and

cover gasket.

(3) Remove Transmission (refer to Group 21,

Transmission).

(4) Remove the rear seal retainer (refer to Crank-

shaft Rear Seal Retainer in this section for correct

procedure).

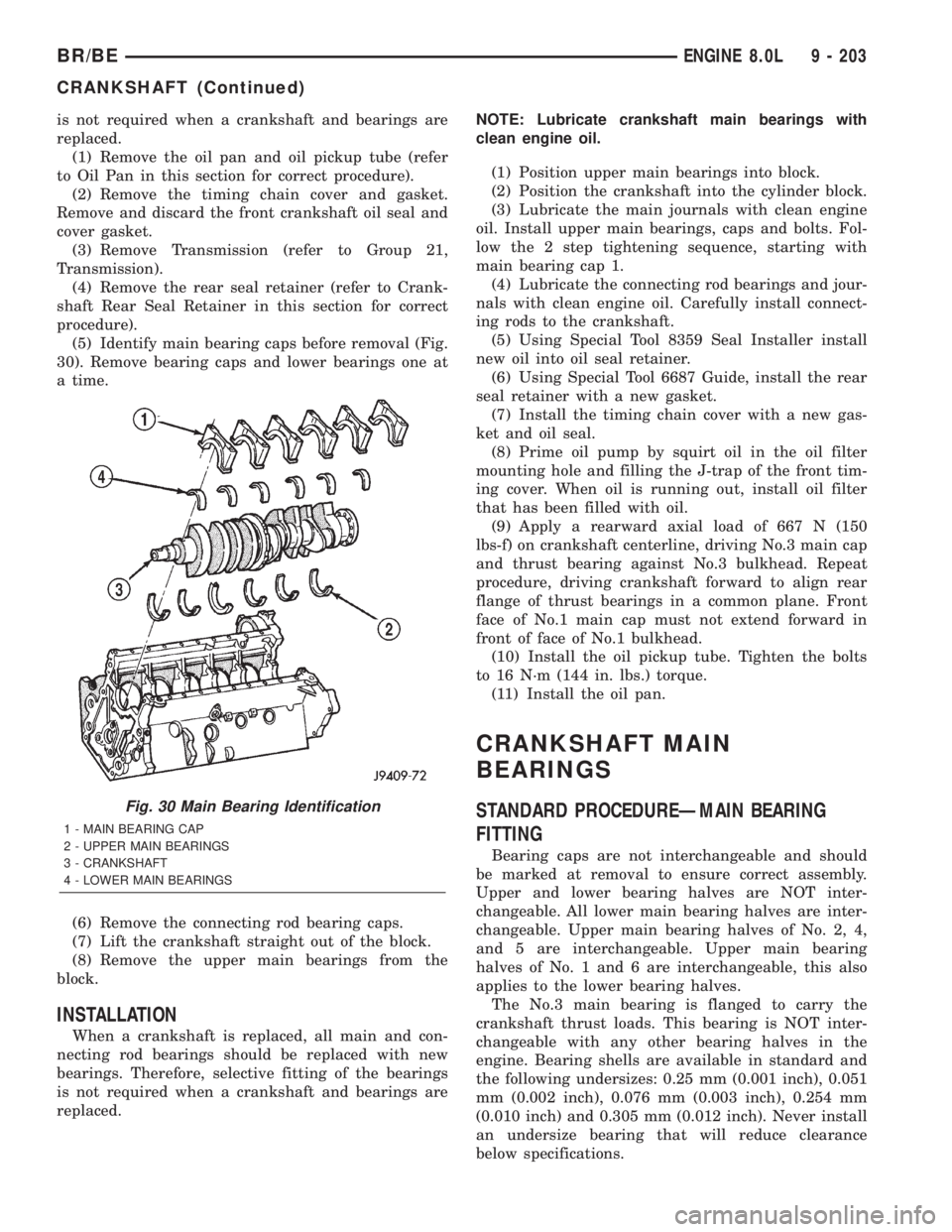

(5) Identify main bearing caps before removal (Fig.

30). Remove bearing caps and lower bearings one at

a time.

(6) Remove the connecting rod bearing caps.

(7) Lift the crankshaft straight out of the block.

(8) Remove the upper main bearings from the

block.

INSTALLATION

When a crankshaft is replaced, all main and con-

necting rod bearings should be replaced with new

bearings. Therefore, selective fitting of the bearings

is not required when a crankshaft and bearings are

replaced.NOTE: Lubricate crankshaft main bearings with

clean engine oil.

(1) Position upper main bearings into block.

(2) Position the crankshaft into the cylinder block.

(3) Lubricate the main journals with clean engine

oil. Install upper main bearings, caps and bolts. Fol-

low the 2 step tightening sequence, starting with

main bearing cap 1.

(4) Lubricate the connecting rod bearings and jour-

nals with clean engine oil. Carefully install connect-

ing rods to the crankshaft.

(5) Using Special Tool 8359 Seal Installer install

new oil into oil seal retainer.

(6) Using Special Tool 6687 Guide, install the rear

seal retainer with a new gasket.

(7) Install the timing chain cover with a new gas-

ket and oil seal.

(8) Prime oil pump by squirt oil in the oil filter

mounting hole and filling the J-trap of the front tim-

ing cover. When oil is running out, install oil filter

that has been filled with oil.

(9) Apply a rearward axial load of 667 N (150

lbs-f) on crankshaft centerline, driving No.3 main cap

and thrust bearing against No.3 bulkhead. Repeat

procedure, driving crankshaft forward to align rear

flange of thrust bearings in a common plane. Front

face of No.1 main cap must not extend forward in

front of face of No.1 bulkhead.

(10) Install the oil pickup tube. Tighten the bolts

to 16 N´m (144 in. lbs.) torque.

(11) Install the oil pan.

CRANKSHAFT MAIN

BEARINGS

STANDARD PROCEDUREÐMAIN BEARING

FITTING

Bearing caps are not interchangeable and should

be marked at removal to ensure correct assembly.

Upper and lower bearing halves are NOT inter-

changeable. All lower main bearing halves are inter-

changeable. Upper main bearing halves of No. 2, 4,

and 5 are interchangeable. Upper main bearing

halves of No. 1 and 6 are interchangeable, this also

applies to the lower bearing halves.

The No.3 main bearing is flanged to carry the

crankshaft thrust loads. This bearing is NOT inter-

changeable with any other bearing halves in the

engine. Bearing shells are available in standard and

the following undersizes: 0.25 mm (0.001 inch), 0.051

mm (0.002 inch), 0.076 mm (0.003 inch), 0.254 mm

(0.010 inch) and 0.305 mm (0.012 inch). Never install

an undersize bearing that will reduce clearance

below specifications.

Fig. 30 Main Bearing Identification

1 - MAIN BEARING CAP

2 - UPPER MAIN BEARINGS

3 - CRANKSHAFT

4 - LOWER MAIN BEARINGS

BR/BEENGINE 8.0L 9 - 203

CRANKSHAFT (Continued)

Page 1364 of 2889

OIL

STANDARD PROCEDUREÐENGINE OIL

OIL LEVEL INDICATOR (DIPSTICK)

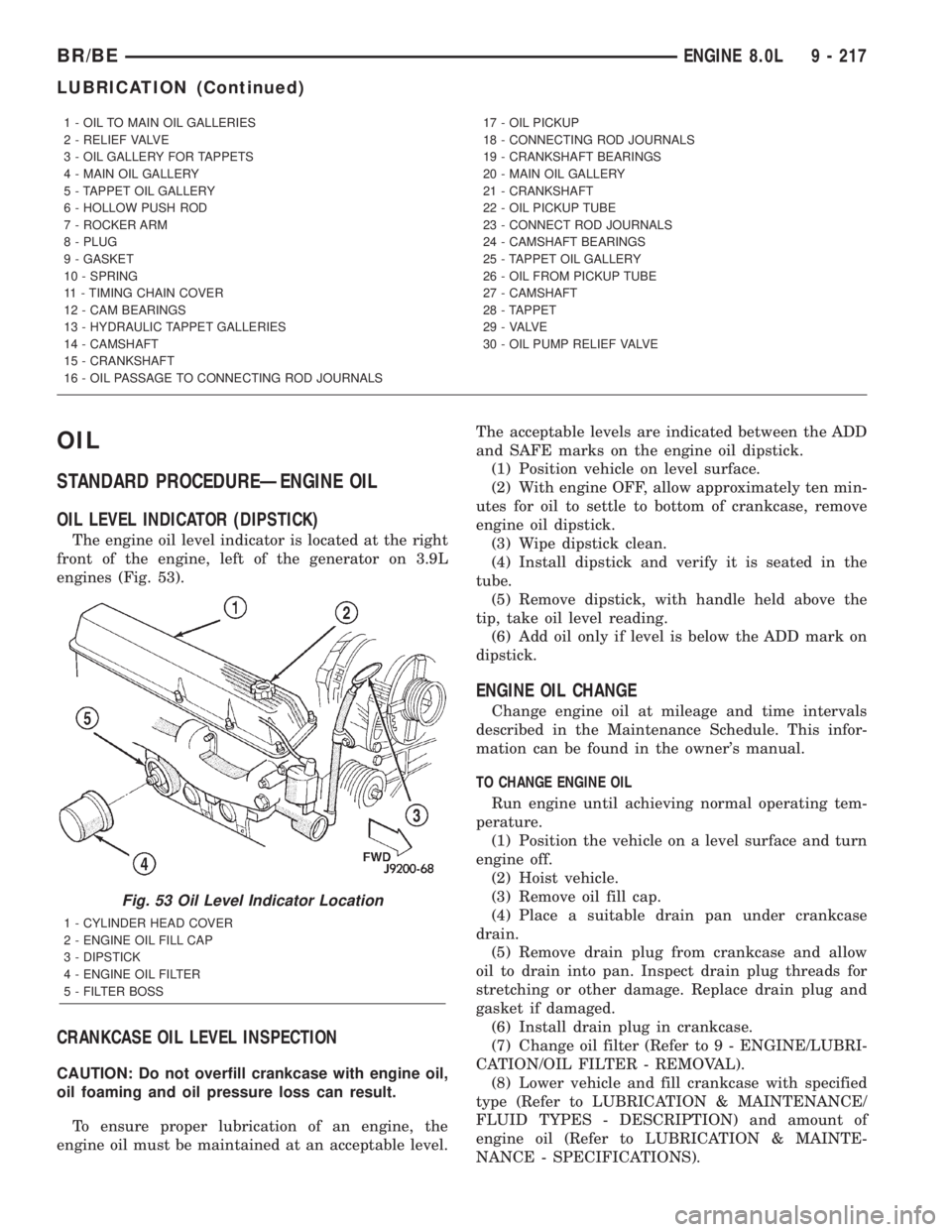

The engine oil level indicator is located at the right

front of the engine, left of the generator on 3.9L

engines (Fig. 53).

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil,

oil foaming and oil pressure loss can result.

To ensure proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.The acceptable levels are indicated between the ADD

and SAFE marks on the engine oil dipstick.

(1) Position vehicle on level surface.

(2) With engine OFF, allow approximately ten min-

utes for oil to settle to bottom of crankcase, remove

engine oil dipstick.

(3) Wipe dipstick clean.

(4) Install dipstick and verify it is seated in the

tube.

(5) Remove dipstick, with handle held above the

tip, take oil level reading.

(6) Add oil only if level is below the ADD mark on

dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in the Maintenance Schedule. This infor-

mation can be found in the owner's manual.

TO CHANGE ENGINE OIL

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Hoist vehicle.

(3) Remove oil fill cap.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug and

gasket if damaged.

(6) Install drain plug in crankcase.

(7) Change oil filter (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - REMOVAL).

(8) Lower vehicle and fill crankcase with specified

type (Refer to LUBRICATION & MAINTENANCE/

FLUID TYPES - DESCRIPTION) and amount of

engine oil (Refer to LUBRICATION & MAINTE-

NANCE - SPECIFICATIONS).

1 - OIL TO MAIN OIL GALLERIES

2 - RELIEF VALVE

3 - OIL GALLERY FOR TAPPETS

4 - MAIN OIL GALLERY

5 - TAPPET OIL GALLERY

6 - HOLLOW PUSH ROD

7 - ROCKER ARM

8 - PLUG

9 - GASKET

10 - SPRING

11 - TIMING CHAIN COVER

12 - CAM BEARINGS

13 - HYDRAULIC TAPPET GALLERIES

14 - CAMSHAFT

15 - CRANKSHAFT

16 - OIL PASSAGE TO CONNECTING ROD JOURNALS17 - OIL PICKUP

18 - CONNECTING ROD JOURNALS

19 - CRANKSHAFT BEARINGS

20 - MAIN OIL GALLERY

21 - CRANKSHAFT

22 - OIL PICKUP TUBE

23 - CONNECT ROD JOURNALS

24 - CAMSHAFT BEARINGS

25 - TAPPET OIL GALLERY

26 - OIL FROM PICKUP TUBE

27 - CAMSHAFT

28 - TAPPET

29 - VALVE

30 - OIL PUMP RELIEF VALVE

Fig. 53 Oil Level Indicator Location

1 - CYLINDER HEAD COVER

2 - ENGINE OIL FILL CAP

3 - DIPSTICK

4 - ENGINE OIL FILTER

5 - FILTER BOSS

BR/BEENGINE 8.0L 9 - 217

LUBRICATION (Continued)

Page 1381 of 2889

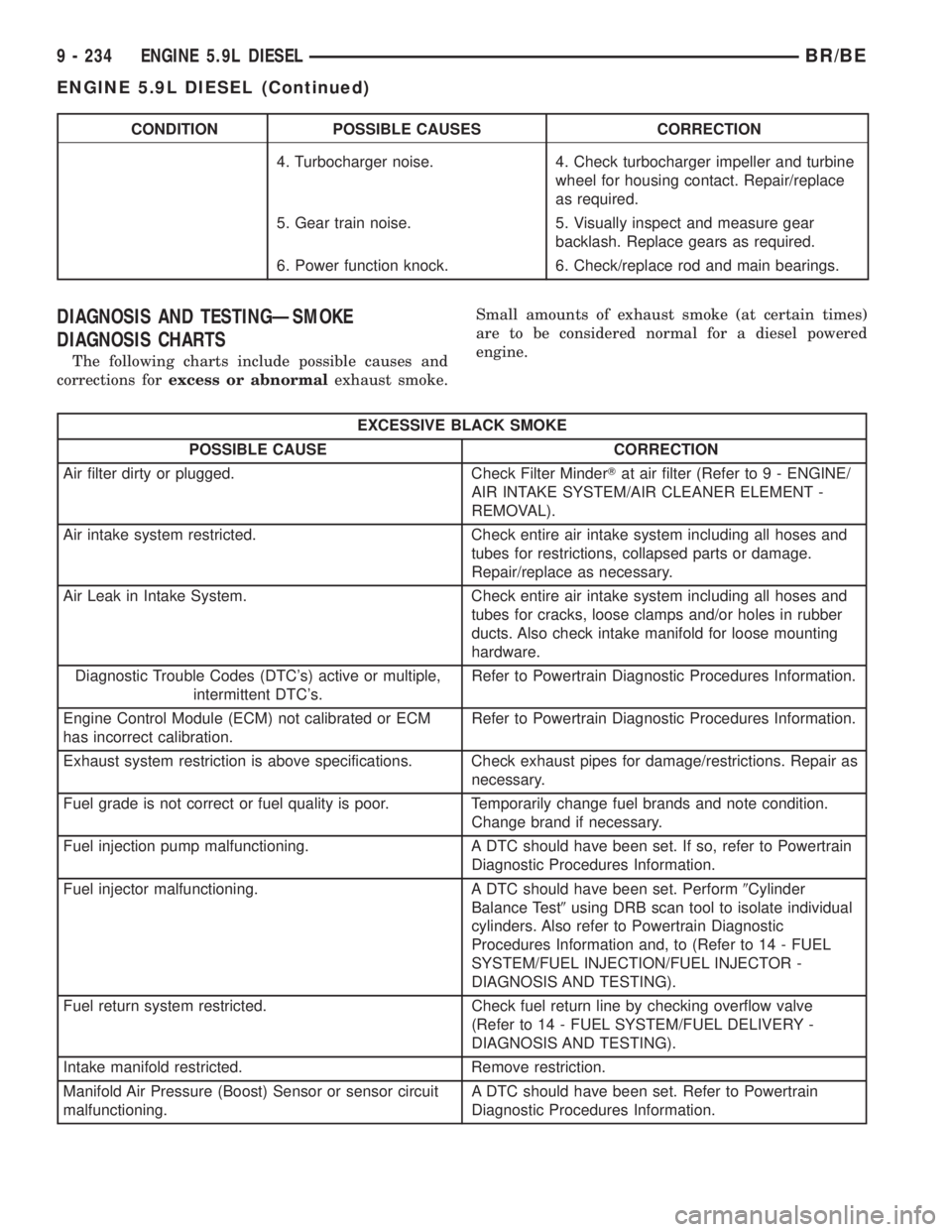

CONDITION POSSIBLE CAUSES CORRECTION

4. Turbocharger noise. 4. Check turbocharger impeller and turbine

wheel for housing contact. Repair/replace

as required.

5. Gear train noise. 5. Visually inspect and measure gear

backlash. Replace gears as required.

6. Power function knock. 6. Check/replace rod and main bearings.

DIAGNOSIS AND TESTINGÐSMOKE

DIAGNOSIS CHARTS

The following charts include possible causes and

corrections forexcess or abnormalexhaust smoke.Small amounts of exhaust smoke (at certain times)

are to be considered normal for a diesel powered

engine.

EXCESSIVE BLACK SMOKE

POSSIBLE CAUSE CORRECTION

Air filter dirty or plugged. Check Filter MinderTat air filter (Refer to 9 - ENGINE/

AIR INTAKE SYSTEM/AIR CLEANER ELEMENT -

REMOVAL).

Air intake system restricted. Check entire air intake system including all hoses and

tubes for restrictions, collapsed parts or damage.

Repair/replace as necessary.

Air Leak in Intake System. Check entire air intake system including all hoses and

tubes for cracks, loose clamps and/or holes in rubber

ducts. Also check intake manifold for loose mounting

hardware.

Diagnostic Trouble Codes (DTC's) active or multiple,

intermittent DTC's.Refer to Powertrain Diagnostic Procedures Information.

Engine Control Module (ECM) not calibrated or ECM

has incorrect calibration.Refer to Powertrain Diagnostic Procedures Information.

Exhaust system restriction is above specifications. Check exhaust pipes for damage/restrictions. Repair as

necessary.

Fuel grade is not correct or fuel quality is poor. Temporarily change fuel brands and note condition.

Change brand if necessary.

Fuel injection pump malfunctioning. A DTC should have been set. If so, refer to Powertrain

Diagnostic Procedures Information.

Fuel injector malfunctioning. A DTC should have been set. Perform9Cylinder

Balance Test9using DRB scan tool to isolate individual

cylinders. Also refer to Powertrain Diagnostic

Procedures Information and, to (Refer to 14 - FUEL

SYSTEM/FUEL INJECTION/FUEL INJECTOR -

DIAGNOSIS AND TESTING).

Fuel return system restricted. Check fuel return line by checking overflow valve

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

DIAGNOSIS AND TESTING).

Intake manifold restricted. Remove restriction.

Manifold Air Pressure (Boost) Sensor or sensor circuit

malfunctioning.A DTC should have been set. Refer to Powertrain

Diagnostic Procedures Information.

9 - 234 ENGINE 5.9L DIESELBR/BE

ENGINE 5.9L DIESEL (Continued)

Page 1389 of 2889

(23) Connect the transmission quick-connect oil

cooler lines to the radiator. Push together until an

audible ªclickº is heard. Verify connection by pulling

apart.

(24) Raise vehicle.

(25) Connect a/c compressor suction/discharge hose

(if a/c equipped).

(26) Install the radiator lower hose and clamps.

(27) Install the starter motor (Refer to 8 - ELEC-

TRICAL/STARTING/STARTER MOTOR - INSTAL-

LATION).

(28) Install the transmission and transfer case (if

equipped).

(29) Connect the exhaust pipe to the turbocharger

elbow (Fig. 3). Torque the bolts to 34 N´m (25 ft. lbs.)

torque.

(30) Connect the transmission auxiliary oil cooler

lines (if equipped).

(31) Lower the vehicle

(32) Connect the heater core supply and return

hoses.

(33) Install the cooling fan and shroud at the same

time (Refer to 7 - COOLING/ENGINE/RADIATOR

FAN - INSTALLATION).

(34) Install the coolant recovery bottle to the fan

shroud (Fig. 2) and connect the hose to the radiator

filler neck.

(35) Install the windshield washer bottle to the fan

shroud and connect the pump supply hose and elec-

trical connections.

(36) Install the radiator upper hose and clamps.

(37) Change oil filter and install new engine oil.

(38) Fill cooling system with coolant (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(39) Connect battery negative cables.

(40) Perform the fuel line air bleed procedure

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).

(41) Start engine and inspect for engine oil, cool-

ant, and fuel leaks.

INSTALLATIONÐCRANKCASE BREATHER

VAPOR CANISTER

(1) Position vapor canister with strap over stud on

engine front cover. Install retaining nut. Tighten nut

10 N´m ( 89 in. lbs.).

(2) If removed, position hose onto crankcase

breather, then position clamp.

(3) Position lower portion of hose into vapor canis-

ter, then install and tighten cap.

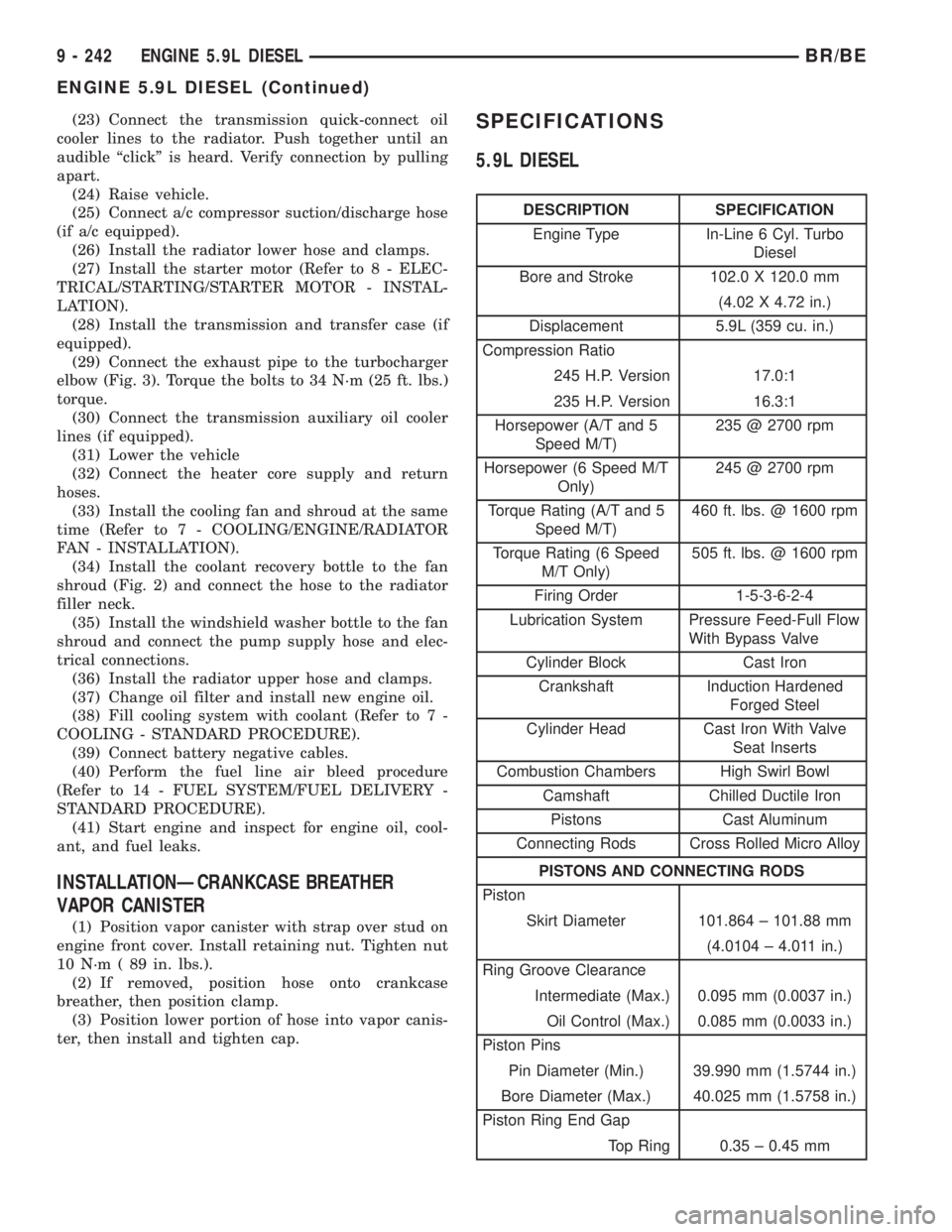

SPECIFICATIONS

5.9L DIESEL

DESCRIPTION SPECIFICATION

Engine Type In-Line 6 Cyl. Turbo

Diesel

Bore and Stroke 102.0 X 120.0 mm

(4.02 X 4.72 in.)

Displacement 5.9L (359 cu. in.)

Compression Ratio

245 H.P. Version 17.0:1

235 H.P. Version 16.3:1

Horsepower (A/T and 5

Speed M/T)235 @ 2700 rpm

Horsepower (6 Speed M/T

Only)245 @ 2700 rpm

Torque Rating (A/T and 5

Speed M/T)460 ft. lbs. @ 1600 rpm

Torque Rating (6 Speed

M/T Only)505 ft. lbs. @ 1600 rpm

Firing Order 1-5-3-6-2-4

Lubrication System Pressure Feed-Full Flow

With Bypass Valve

Cylinder Block Cast Iron

Crankshaft Induction Hardened

Forged Steel

Cylinder Head Cast Iron With Valve

Seat Inserts

Combustion Chambers High Swirl Bowl

Camshaft Chilled Ductile Iron

Pistons Cast Aluminum

Connecting Rods Cross Rolled Micro Alloy

PISTONS AND CONNECTING RODS

Piston

Skirt Diameter 101.864 ± 101.88 mm

(4.0104 ± 4.011 in.)

Ring Groove Clearance

Intermediate (Max.) 0.095 mm (0.0037 in.)

Oil Control (Max.) 0.085 mm (0.0033 in.)

Piston Pins

Pin Diameter (Min.) 39.990 mm (1.5744 in.)

Bore Diameter (Max.) 40.025 mm (1.5758 in.)

Piston Ring End Gap

Top Ring 0.35 ± 0.45 mm

9 - 242 ENGINE 5.9L DIESELBR/BE

ENGINE 5.9L DIESEL (Continued)

Page 1439 of 2889

LUBRICATION

DESCRIPTION

NOTE: Refer to (Fig. 148) and (Fig. 149) for circuit

illustrations.

A gear driven gerotor type oil pump is mounted

behind the front gear cover in the lower right portion

on the engine.

OPERATION

A gerotor style oil pump draws oil from the crank-

case through the suction tube and delivers it through

the block where it enters the oil cooler cover and

pressure regulator valve. When oil pressure exceeds

449 kPa (65 PSI), the valve opens exposing the dump

port, which routes excess oil back to the oil sump.

At the same time, oil is directed to a cast in pas-

sage in the oil cooler cover, leading to the oil cooler

element. As the oil travels through the element

plates, it is cooled by engine coolant traveling past

the outside of the plates. It is then routed to the oil

filter head and through a full flow oil filter. If a

plugged filter is encountered, the filter by-pass valve

opens, allowing unfiltered oil to lubricate the engine.

This condition can be avoided by frequent oil and fil-

ter changes, per the maintenance schedules found in

the owners manual. The by-pass valve is calibrated

to open when it sees a pressure drop of more than

344 kPa (50 psi) across the oil filter.The oil filter head then divides the oil between the

engine and the turbocharger. The turbocharger

receives filtered, cooled and pressurized oil through a

supply line from the filter head. The oil lubricates

the turbocharger and returns to the pan by way of a

drain tube connecting the bottom of the turbocharger

to a pressed in tube in the cylinder block.

Oil is then carried across the block to an angle

drilling which intersects the main oil rifle. The main

oil rifle runs the length of the block and delivers oil

to the crankshaft main journals and valve train. Oil

travels to the crankshaft through a series of transfer

drillings (one for each main bearing) and lubricates a

groove in the main bearing upper shell. From there

another drilling feeds the camshaft main journals.

The piston cooling nozzles are also supplied by the

main bearing upper shell. Crankshaft internal cross-

drillings supply oil to the connecting rod journals.

Another series of transfer drillings intersecting the

main oil rifle supply the valve train components. Oil

travels up the drilling, through a hole in the head

gasket, and through a drilling in the cylinder head

(one per cylinder), where it enters the rocker arm

pedestal and is divided between the intake and

exhaust rocker arm. Oil travels up and around the

rocker arm mounting bolt, and lubricates the rocker

shaft by cross drillings that intersect the mounting

bolt hole. Grooves at both ends of the rocker shaft

supply oil through the rocker arm where the oil trav-

els to the push rod and socket balls (Fig. 148) and

(Fig. 149).

9 - 292 ENGINE 5.9L DIESELBR/BE

Page 1498 of 2889

(1) Be sure fuel tank contains fuel before starting

test. If tank is empty or near empty, amperage read-

ings will be incorrect.

(2) Obtain LCS adapter.

(3) Plug cable from LCS adapter into DRB scan

tool at SET 1 receptacle.

(4) Plug DRB into vehicle 16±way connector (data

link connector).

(5) Connect (-) and (+) test cable leads into LCS

adapter receptacles. Use10 amp (10A +)receptacle

and common (-) receptacles.

(6) Gain access to MAIN MENU on DRB screen.

(7) Press DVOM button on DRB.

(8) Using left/right arrow keys, highlight CHAN-

NEL 1 function on DRB screen.

(9) Press ENTER three times.

(10) Using up/down arrow keys, highlight RANGE

on DRB screen (screen will default to 2 amp scale).

(11) Press ENTER to change 2 amp scale to 10

amp scale.This step must be done to prevent

damage to DRB scan tool or LCS adapter

(blown fuse).

(12) Remove cover from Power Distribution Center

(PDC).

(13) Remove fuel pump relay from PDC. Refer to

label on PDC cover for relay location.

WARNING: BEFORE PROCEEDING TO NEXT STEP,

NOTE THE FUEL PUMP WILL BE ACTIVATED AND

SYSTEM PRESSURE WILL BE PRESENT. THIS WILL

OCCUR AFTER CONNECTING TEST LEADS FROM

LCS ADAPTER INTO FUEL PUMP RELAY CAVITIES.

THE FUEL PUMP WILL OPERATE EVEN WITH IGNI-

TION KEY IN OFF POSITION. BEFORE ATTACHING

TEST LEADS, BE SURE ALL FUEL LINES AND

FUEL SYSTEM COMPONENTS ARE CONNECTED.

CAUTION: To prevent possible damage to the vehi-

cle electrical system and LCS adapter, the test

leads must be connected into relay cavities exactly

as shown in following steps.

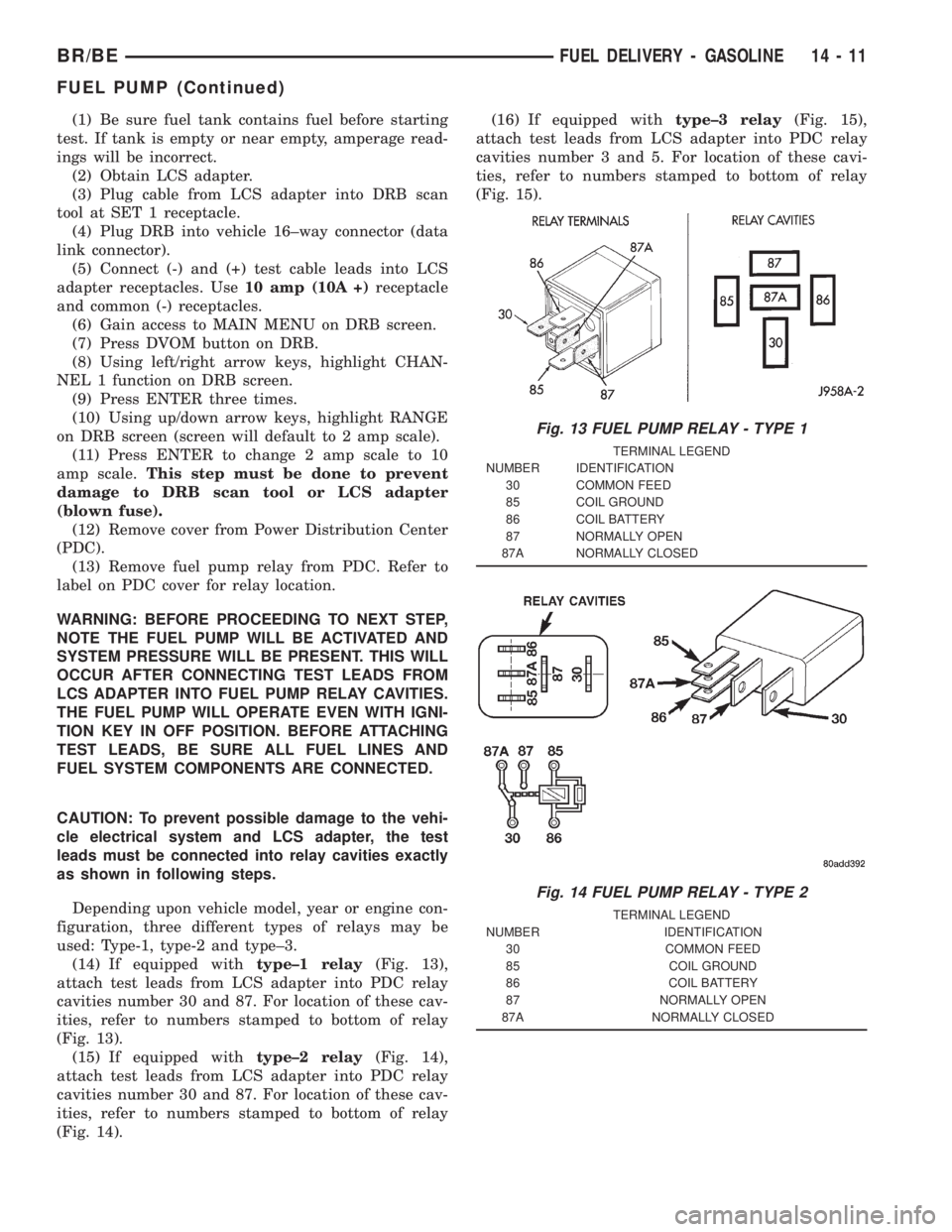

Depending upon vehicle model, year or engine con-

figuration, three different types of relays may be

used: Type-1, type-2 and type±3.

(14) If equipped withtype±1 relay(Fig. 13),

attach test leads from LCS adapter into PDC relay

cavities number 30 and 87. For location of these cav-

ities, refer to numbers stamped to bottom of relay

(Fig. 13).

(15) If equipped withtype±2 relay(Fig. 14),

attach test leads from LCS adapter into PDC relay

cavities number 30 and 87. For location of these cav-

ities, refer to numbers stamped to bottom of relay

(Fig. 14).(16) If equipped withtype±3 relay(Fig. 15),

attach test leads from LCS adapter into PDC relay

cavities number 3 and 5. For location of these cavi-

ties, refer to numbers stamped to bottom of relay

(Fig. 15).

Fig. 13 FUEL PUMP RELAY - TYPE 1

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

Fig. 14 FUEL PUMP RELAY - TYPE 2

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

BR/BEFUEL DELIVERY - GASOLINE 14 - 11

FUEL PUMP (Continued)

Page 1528 of 2889

(5) Install new plastic tie strap (Fig. 28) to secure

sensor pigtail harness to side of engine block. Thread

tie strap through casting hole on cylinder block.

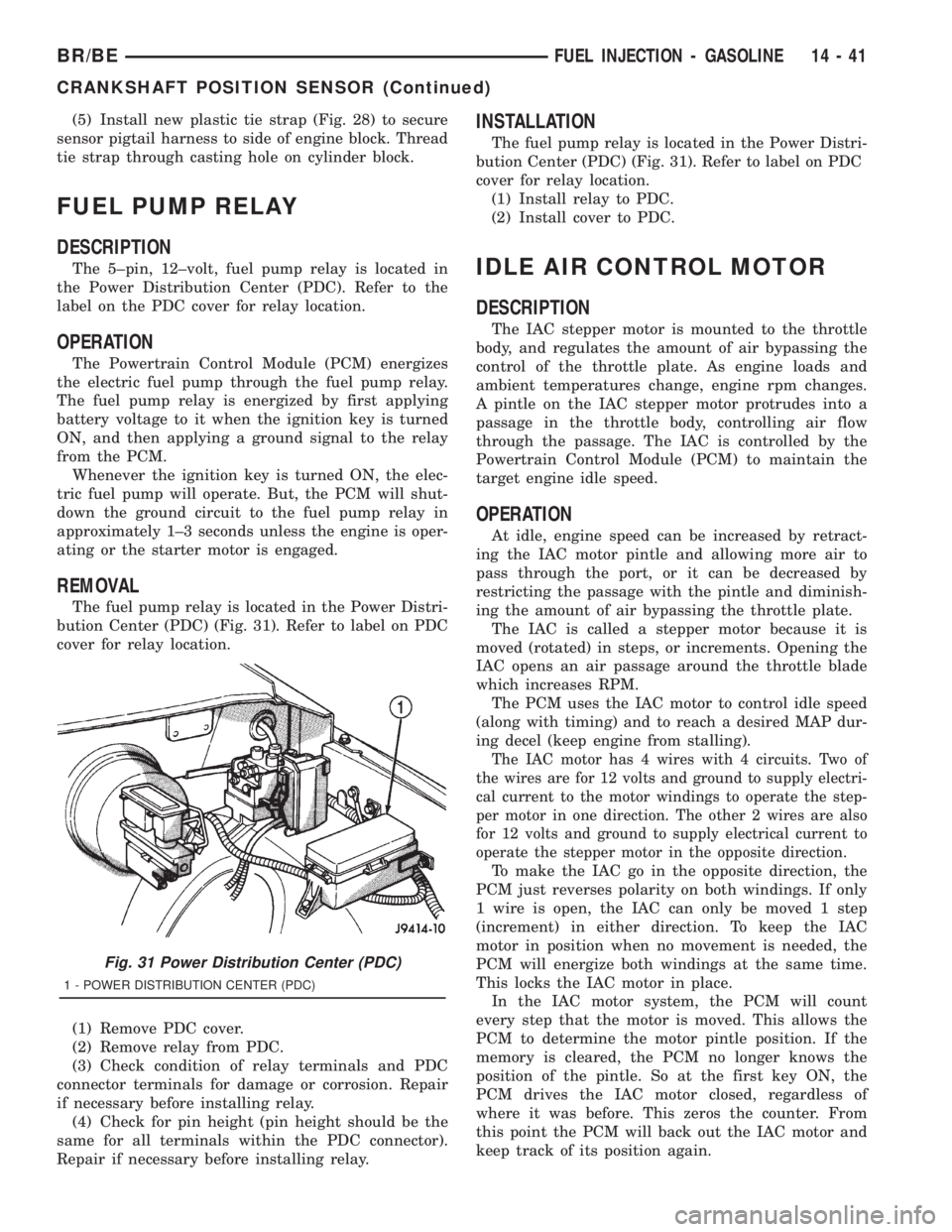

FUEL PUMP RELAY

DESCRIPTION

The 5±pin, 12±volt, fuel pump relay is located in

the Power Distribution Center (PDC). Refer to the

label on the PDC cover for relay location.

OPERATION

The Powertrain Control Module (PCM) energizes

the electric fuel pump through the fuel pump relay.

The fuel pump relay is energized by first applying

battery voltage to it when the ignition key is turned

ON, and then applying a ground signal to the relay

from the PCM.

Whenever the ignition key is turned ON, the elec-

tric fuel pump will operate. But, the PCM will shut-

down the ground circuit to the fuel pump relay in

approximately 1±3 seconds unless the engine is oper-

ating or the starter motor is engaged.

REMOVAL

The fuel pump relay is located in the Power Distri-

bution Center (PDC) (Fig. 31). Refer to label on PDC

cover for relay location.

(1) Remove PDC cover.

(2) Remove relay from PDC.

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

The fuel pump relay is located in the Power Distri-

bution Center (PDC) (Fig. 31). Refer to label on PDC

cover for relay location.

(1) Install relay to PDC.

(2) Install cover to PDC.

IDLE AIR CONTROL MOTOR

DESCRIPTION

The IAC stepper motor is mounted to the throttle

body, and regulates the amount of air bypassing the

control of the throttle plate. As engine loads and

ambient temperatures change, engine rpm changes.

A pintle on the IAC stepper motor protrudes into a

passage in the throttle body, controlling air flow

through the passage. The IAC is controlled by the

Powertrain Control Module (PCM) to maintain the

target engine idle speed.

OPERATION

At idle, engine speed can be increased by retract-

ing the IAC motor pintle and allowing more air to

pass through the port, or it can be decreased by

restricting the passage with the pintle and diminish-

ing the amount of air bypassing the throttle plate.

The IAC is called a stepper motor because it is

moved (rotated) in steps, or increments. Opening the

IAC opens an air passage around the throttle blade

which increases RPM.

The PCM uses the IAC motor to control idle speed

(along with timing) and to reach a desired MAP dur-

ing decel (keep engine from stalling).

The IAC motor has 4 wires with 4 circuits. Two of

the wires are for 12 volts and ground to supply electri-

cal current to the motor windings to operate the step-

per motor in one direction. The other 2 wires are also

for 12 volts and ground to supply electrical current to

operate the stepper motor in the opposite direction.

To make the IAC go in the opposite direction, the

PCM just reverses polarity on both windings. If only

1 wire is open, the IAC can only be moved 1 step

(increment) in either direction. To keep the IAC

motor in position when no movement is needed, the

PCM will energize both windings at the same time.

This locks the IAC motor in place.

In the IAC motor system, the PCM will count

every step that the motor is moved. This allows the

PCM to determine the motor pintle position. If the

memory is cleared, the PCM no longer knows the

position of the pintle. So at the first key ON, the

PCM drives the IAC motor closed, regardless of

where it was before. This zeros the counter. From

this point the PCM will back out the IAC motor and

keep track of its position again.

Fig. 31 Power Distribution Center (PDC)

1 - POWER DISTRIBUTION CENTER (PDC)

BR/BEFUEL INJECTION - GASOLINE 14 - 41

CRANKSHAFT POSITION SENSOR (Continued)

Page 1529 of 2889

When engine rpm is above idle speed, the IAC is

used for the following:

²Off-idle dashpot (throttle blade will close quickly

but idle speed will not stop quickly)

²Deceleration air flow control

²A/C compressor load control (also opens the pas-

sage slightly before the compressor is engaged so

that the engine rpm does not dip down when the

compressor engages)

²Power steering load control

The PCM can control polarity of the circuit to con-

trol direction of the stepper motor.

IAC Stepper Motor Program:The PCM is also

equipped with a memory program that records the

number of steps the IAC stepper motor most recently

advanced to during a certain set of parameters. For

example: The PCM was attempting to maintain a

1000 rpm target during a cold start-up cycle. The last

recorded number of steps for that may have been

125. That value would be recorded in the memory

cell so that the next time the PCM recognizes the

identical conditions, the PCM recalls that 125 steps

were required to maintain the target. This program

allows for greater customer satisfaction due to

greater control of engine idle.

Another function of the memory program, which

occurs when the power steering switch (if equipped),

or the A/C request circuit, requires that the IAC step-

per motor control engine rpm, is the recording of the

last targeted steps into the memory cell. The PCM

can anticipate A/C compressor loads. This is accom-

plished by delaying compressor operation for approx-

imately 0.5 seconds until the PCM moves the IAC

stepper motor to the recorded steps that were loaded

into the memory cell. Using this program helps elim-

inate idle-quality changes as loads change. Finally,

the PCM incorporates a9No-Load9engine speed lim-

iter of approximately 1800 - 2000 rpm, when it rec-

ognizes that the TPS is indicating an idle signal and

IAC motor cannot maintain engine idle.

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the IAC motor through the PCM.

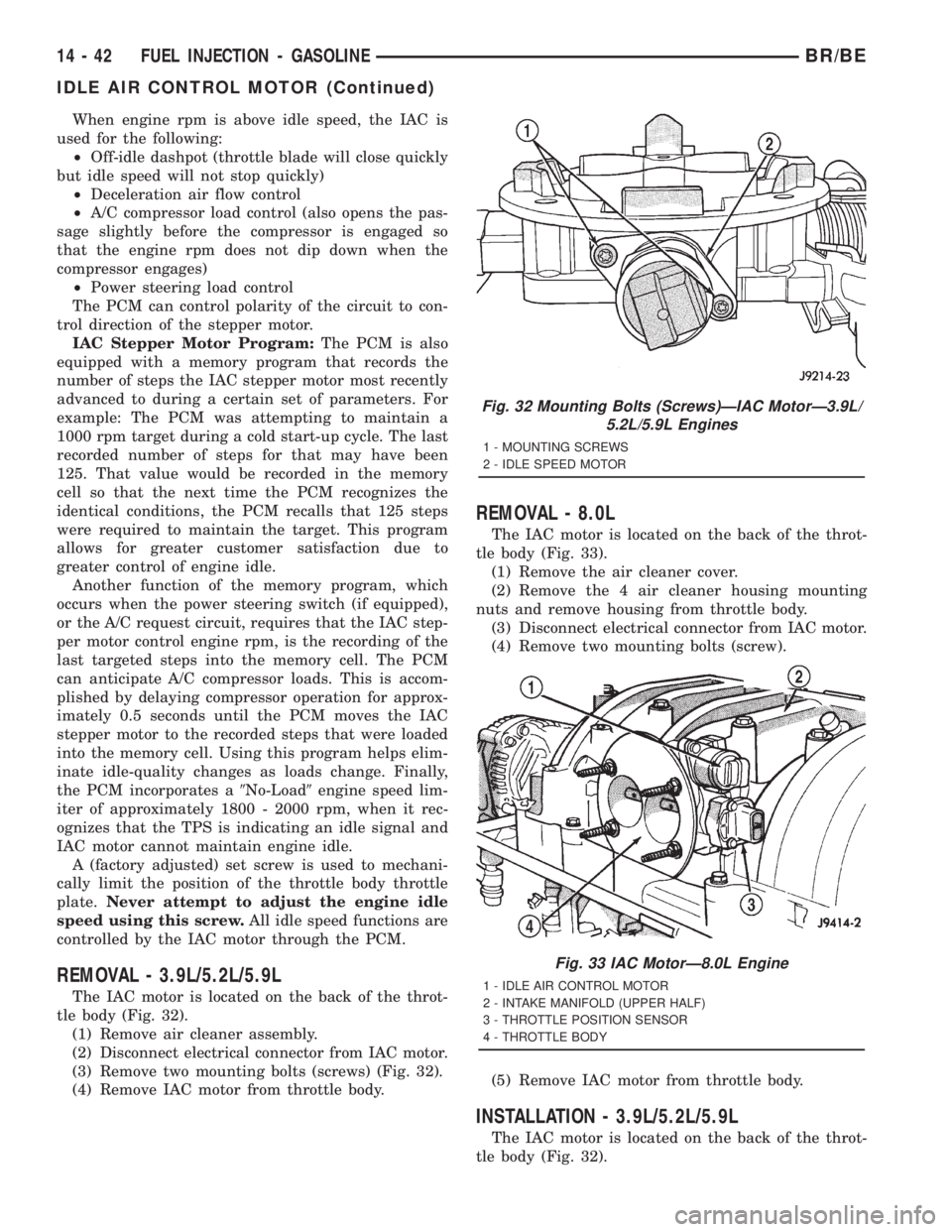

REMOVAL - 3.9L/5.2L/5.9L

The IAC motor is located on the back of the throt-

tle body (Fig. 32).

(1) Remove air cleaner assembly.

(2) Disconnect electrical connector from IAC motor.

(3) Remove two mounting bolts (screws) (Fig. 32).

(4) Remove IAC motor from throttle body.

REMOVAL - 8.0L

The IAC motor is located on the back of the throt-

tle body (Fig. 33).

(1) Remove the air cleaner cover.

(2) Remove the 4 air cleaner housing mounting

nuts and remove housing from throttle body.

(3) Disconnect electrical connector from IAC motor.

(4) Remove two mounting bolts (screw).

(5) Remove IAC motor from throttle body.

INSTALLATION - 3.9L/5.2L/5.9L

The IAC motor is located on the back of the throt-

tle body (Fig. 32).

Fig. 32 Mounting Bolts (Screws)ÐIAC MotorÐ3.9L/

5.2L/5.9L Engines

1 - MOUNTING SCREWS

2 - IDLE SPEED MOTOR

Fig. 33 IAC MotorÐ8.0L Engine

1 - IDLE AIR CONTROL MOTOR

2 - INTAKE MANIFOLD (UPPER HALF)

3 - THROTTLE POSITION SENSOR

4 - THROTTLE BODY

14 - 42 FUEL INJECTION - GASOLINEBR/BE

IDLE AIR CONTROL MOTOR (Continued)

Page 1531 of 2889

(1) Install sensor to intake manifold. Tighten to

12±15 N´m (110±130 in. lbs.) torque.

(2) Install electrical connector.

(3) Install air cleaner.

INSTALLATION - 8.0L

The intake manifold air temperature sensor is

located in the side of the intake manifold near the

front of throttle body (Fig. 35).

(1) Install sensor to intake manifold. Tighten to

12±15 N´m (110±130 in. lbs.) torque.

(2) Install electrical connector.

MANIFOLD ABSOLUTE

PRESSURE SENSOR

DESCRIPTION - 3.9L/5.2L/5.9L/8.0L

On 3.9L/5.2L/5.9L engines, the MAP sensor is

mounted on the side of the engine throttle body. The

sensor is connected to the throttle body with a rubber

L-shaped fitting.

On the 8.0L 10±cylinder engine, the MAP sensor is

mounted into the right side of the intake manifold.

OPERATION - 3.9L/5.2L/5.9L/8.0L

The MAP sensor is used as an input to the Power-

train Control Module (PCM). It contains a silicon

based sensing unit to provide data on the manifold

vacuum that draws the air/fuel mixture into the com-

bustion chamber. The PCM requires this information

to determine injector pulse width and spark advance.

When manifold absolute pressure (MAP) equals

Barometric pressure, the pulse width will be at max-

imum.

A 5 volt reference is supplied from the PCM and

returns a voltage signal to the PCM that reflects

manifold pressure. The zero pressure reading is 0.5V

and full scale is 4.5V. For a pressure swing of 0±15

psi, the voltage changes 4.0V. To operate the sensor,

it is supplied a regulated 4.8 to 5.1 volts. Ground is

provided through the low-noise, sensor return circuit

at the PCM.

The MAP sensor input is the number one contrib-

utor to fuel injector pulse width. The most important

function of the MAP sensor is to determine baromet-

ric pressure. The PCM needs to know if the vehicle is

at sea level or at a higher altitude, because the air

density changes with altitude. It will also help to cor-

rect for varying barometric pressure. Barometric

pressure and altitude have a direct inverse correla-

tion; as altitude goes up, barometric goes down. At

key-on, the PCM powers up and looks at MAP volt-

age, and based upon the voltage it sees, it knows the

current barometric pressure (relative to altitude).

Once the engine starts, the PCM looks at the voltageagain, continuously every 12 milliseconds, and com-

pares the current voltage to what it was at key-on.

The difference between current voltage and what it

was at key-on, is manifold vacuum.

During key-on (engine not running) the sensor

reads (updates) barometric pressure. A normal range

can be obtained by monitoring a known good sensor.

As the altitude increases, the air becomes thinner

(less oxygen). If a vehicle is started and driven to a

very different altitude than where it was at key-on,

the barometric pressure needs to be updated. Any

time the PCM sees Wide Open Throttle (WOT), based

upon Throttle Position Sensor (TPS) angle and RPM,

it will update barometric pressure in the MAP mem-

ory cell. With periodic updates, the PCM can make

its calculations more effectively.

The PCM uses the MAP sensor input to aid in cal-

culating the following:

²Manifold pressure

²Barometric pressure

²Engine load

²Injector pulse-width

²Spark-advance programs

²Shift-point strategies (certain automatic trans-

missions only)

²Idle speed

²Decel fuel shutoff

The MAP sensor signal is provided from a single

piezoresistive element located in the center of a dia-

phragm. The element and diaphragm are both made

of silicone. As manifold pressure changes, the dia-

phragm moves causing the element to deflect, which

stresses the silicone. When silicone is exposed to

stress, its resistance changes. As manifold vacuum

increases, the MAP sensor input voltage decreases

proportionally. The sensor also contains electronics

that condition the signal and provide temperature

compensation.

The PCM recognizes a decrease in manifold pres-

sure by monitoring a decrease in voltage from the

reading stored in the barometric pressure memory

cell. The MAP sensor is a linear sensor; meaning as

pressure changes, voltage changes proportionately.

The range of voltage output from the sensor is usu-

ally between 4.6 volts at sea level to as low as 0.3

volts at 26 in. of Hg. Barometric pressure is the pres-

sure exerted by the atmosphere upon an object. At

sea level on a standard day, no storm, barometric

pressure is approximately 29.92 in Hg. For every 100

feet of altitude, barometric pressure drops .10 in. Hg.

If a storm goes through it can change barometric

pressure from what should be present for that alti-

tude. You should know what the average pressure

and corresponding barometric pressure is for your

area.

14 - 44 FUEL INJECTION - GASOLINEBR/BE

INTAKE AIR TEMPERATURE SENSOR (Continued)

Page 1533 of 2889

(3) Install MAP sensor mounting bolts (screws).

Tighten screws to 3 N´m (25 in. lbs.) torque.

(4) Install air cleaner.

INSTALLATION - 8.0L

The MAP sensor is mounted into the right upper

side of the intake manifold (Fig. 38). A rubber gasket

is used to seal the sensor to the intake manifold. The

rubber gasket is part of the sensor and is not ser-

viced separately.

(1) Check the condition of the sensor seal. Clean

the sensor and lubricate the rubber gasket with clean

engine oil.

(2) Clean the sensor opening in the intake mani-

fold.

(3) Install the sensor into the intake manifold.

(4) Install sensor mounting bolts. Tighten bolts to

2 N´m (20 in. lbs.) torque.

(5) Install the electrical connector to sensor.

O2 SENSOR

DESCRIPTION

The Oxygen Sensors (O2S) are attached to, and

protrude into the vehicle exhaust system. Depending

on the emission package, the vehicle may use a total

of either 2 or 4 sensors.

3.9L/5.2L/Light Duty 5.9L Engine:Four sensors

are used: 2 upstream (referred to as 1/1 and 2/1) and

2 downstream (referred to as 1/2 and 2/2). With this

emission package, the right upstream sensor (2/1) is

located in the right exhaust downpipe just before the

mini-catalytic convertor. The left upstream sensor

(1/1) is located in the left exhaust downpipe just

before the mini-catalytic convertor. The right down-

stream sensor (2/2) is located in the right exhaust

downpipe just after the mini-catalytic convertor, and

before the main catalytic convertor. The left down-

stream sensor (1/2) is located in the left exhaust

downpipe just after the mini-catalytic convertor, and

before the main catalytic convertor.

Medium and Heavy Duty 8.0L V-10 Engine:

Four sensors are used (2 upstream, 1 pre-catalyst

and 1 post-catalyst). With this emission package, the

1/1 upstream sensor (left side) is located in the left

exhaust downpipe before both the pre-catalyst sensor

(1/2), and the main catalytic convertor. The 2/1

upstream sensor (right side) is located in the right

exhaust downpipe before both the pre-catalyst sensor

(1/2), and the main catalytic convertor. The pre-cata-

lyst sensor (1/2) is located after the 1/1 and 2/1 sen-

sors, and just before the main catalytic convertor.

The post-catalyst sensor (1/3) is located just after the

main catalytic convertor.Heavy Duty 5.9L Engine:Two sensors are used.

They arebothreferred to as upstream sensors (left

side is referred to as 1/1 and right side is referred to

as 2/1). With this emission package, a sensor is

located in each of the exhaust downpipes before the

main catalytic convertor.

OPERATION

An O2 sensor is a galvanic battery that provides

the PCM with a voltage signal (0-1 volt) inversely

proportional to the amount of oxygen in the exhaust.

In other words, if the oxygen content is low, the volt-

age output is high; if the oxygen content is high the

output voltage is low. The PCM uses this information

to adjust injector pulse-width to achieve the

14.7±to±1 air/fuel ratio necessary for proper engine

operation and to control emissions.

The O2 sensor must have a source of oxygen from

outside of the exhaust stream for comparison. Cur-

rent O2 sensors receive their fresh oxygen (outside

air) supply through the wire harness. This is why it

is important to never solder an O2 sensor connector,

or pack the connector with grease.

Four wires (circuits) are used on each O2 sensor: a

12±volt feed circuit for the sensor heating element; a

ground circuit for the heater element; a low-noise

sensor return circuit to the PCM, and an input cir-

cuit from the sensor back to the PCM to detect sen-

sor operation.

Oxygen Sensor Heaters/Heater Relays:

Depending on the emissions package, the heating ele-

ments within the sensors will be supplied voltage

from either the ASD relay, or 2 separate oxygen sen-

sor relays. Refer to 8, Wiring Diagrams to determine

which relays are used.

The O2 sensor uses a Positive Thermal Co-efficient

(PTC) heater element. As temperature increases,

resistance increases. At ambient temperatures

around 70ÉF, the resistance of the heating element is

approximately 4.5 ohms. As the sensor's temperature

increases, resistance in the heater element increases.

This allows the heater to maintain the optimum

operating temperature of approximately 930É-1100ÉF

(500É-600É C). Although the sensors operate the

same, there are physical differences, due to the envi-

ronment that they operate in, that keep them from

being interchangeable.

Maintaining correct sensor temperature at all times

allows the system to enter into closed loop operation

sooner. Also, it allows the system to remain in closed

loop operation during periods of extended idle.

In Closed Loop operation, the PCM monitors cer-

tain O2 sensor input(s) along with other inputs, and

adjusts the injector pulse width accordingly. During

Open Loop operation, the PCM ignores the O2 sensor

input. The PCM adjusts injector pulse width based

14 - 46 FUEL INJECTION - GASOLINEBR/BE

MANIFOLD ABSOLUTE PRESSURE SENSOR (Continued)