control arm DODGE RAM 2001 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1298 of 2889

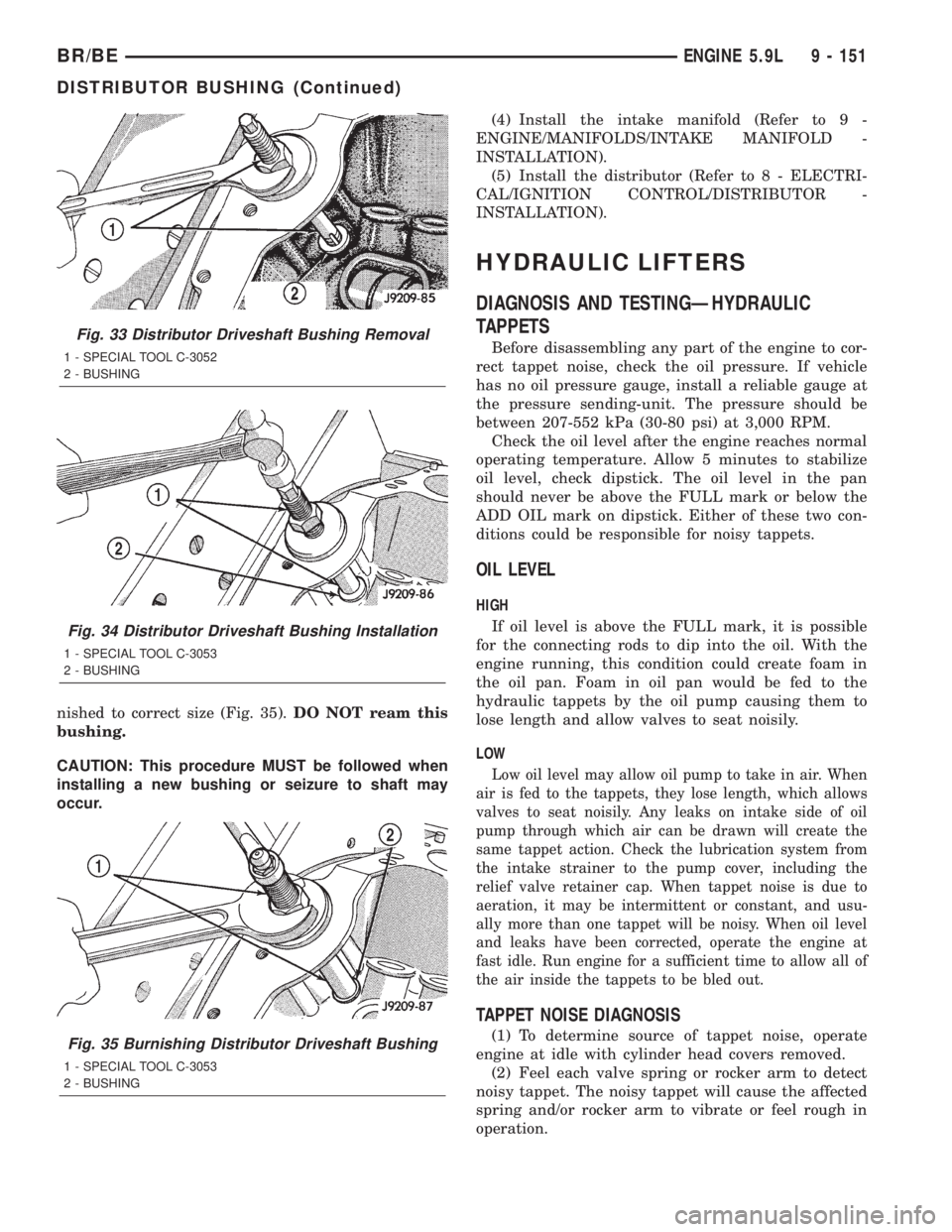

nished to correct size (Fig. 35).DO NOT ream this

bushing.

CAUTION: This procedure MUST be followed when

installing a new bushing or seizure to shaft may

occur.(4) Install the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

(5) Install the distributor (Refer to 8 - ELECTRI-

CAL/IGNITION CONTROL/DISTRIBUTOR -

INSTALLATION).

HYDRAULIC LIFTERS

DIAGNOSIS AND TESTINGÐHYDRAULIC

TAPPETS

Before disassembling any part of the engine to cor-

rect tappet noise, check the oil pressure. If vehicle

has no oil pressure gauge, install a reliable gauge at

the pressure sending-unit. The pressure should be

between 207-552 kPa (30-80 psi) at 3,000 RPM.

Check the oil level after the engine reaches normal

operating temperature. Allow 5 minutes to stabilize

oil level, check dipstick. The oil level in the pan

should never be above the FULL mark or below the

ADD OIL mark on dipstick. Either of these two con-

ditions could be responsible for noisy tappets.

OIL LEVEL

HIGH

If oil level is above the FULL mark, it is possible

for the connecting rods to dip into the oil. With the

engine running, this condition could create foam in

the oil pan. Foam in oil pan would be fed to the

hydraulic tappets by the oil pump causing them to

lose length and allow valves to seat noisily.

LOW

Low oil level may allow oil pump to take in air. When

air is fed to the tappets, they lose length, which allows

valves to seat noisily. Any leaks on intake side of oil

pump through which air can be drawn will create the

same tappet action. Check the lubrication system from

the intake strainer to the pump cover, including the

relief valve retainer cap. When tappet noise is due to

aeration, it may be intermittent or constant, and usu-

ally more than one tappet will be noisy. When oil level

and leaks have been corrected, operate the engine at

fast idle. Run engine for a sufficient time to allow all of

the air inside the tappets to be bled out.

TAPPET NOISE DIAGNOSIS

(1) To determine source of tappet noise, operate

engine at idle with cylinder head covers removed.

(2) Feel each valve spring or rocker arm to detect

noisy tappet. The noisy tappet will cause the affected

spring and/or rocker arm to vibrate or feel rough in

operation.

Fig. 33 Distributor Driveshaft Bushing Removal

1 - SPECIAL TOOL C-3052

2 - BUSHING

Fig. 34 Distributor Driveshaft Bushing Installation

1 - SPECIAL TOOL C-3053

2 - BUSHING

Fig. 35 Burnishing Distributor Driveshaft Bushing

1 - SPECIAL TOOL C-3053

2 - BUSHING

BR/BEENGINE 5.9L 9 - 151

DISTRIBUTOR BUSHING (Continued)

Page 1300 of 2889

(2) Install tappets and push rods in their original

positions. Ensure that the oil feed hole in the side of

the tappet body faces up (away from the crankshaft).

(3) Install aligning yokes with ARROW toward

camshaft.

(4) Install yoke retainer. Tighten the bolts to 23

N´m (200 in. lbs.) torque. Install intake manifold

(Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANI-

FOLD - INSTALLATION).

(5) Install push rods in original positions.

(6) Install rocker arms.

(7) Install cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(8) Install air cleaner assembly and air in-let hose.

(9) Start and operate engine. Warm up to normal

operating temperature.

CAUTION: To prevent damage to valve mechanism,

engine must not be run above fast idle until all

hydraulic tappets have filled with oil and have

become quiet.

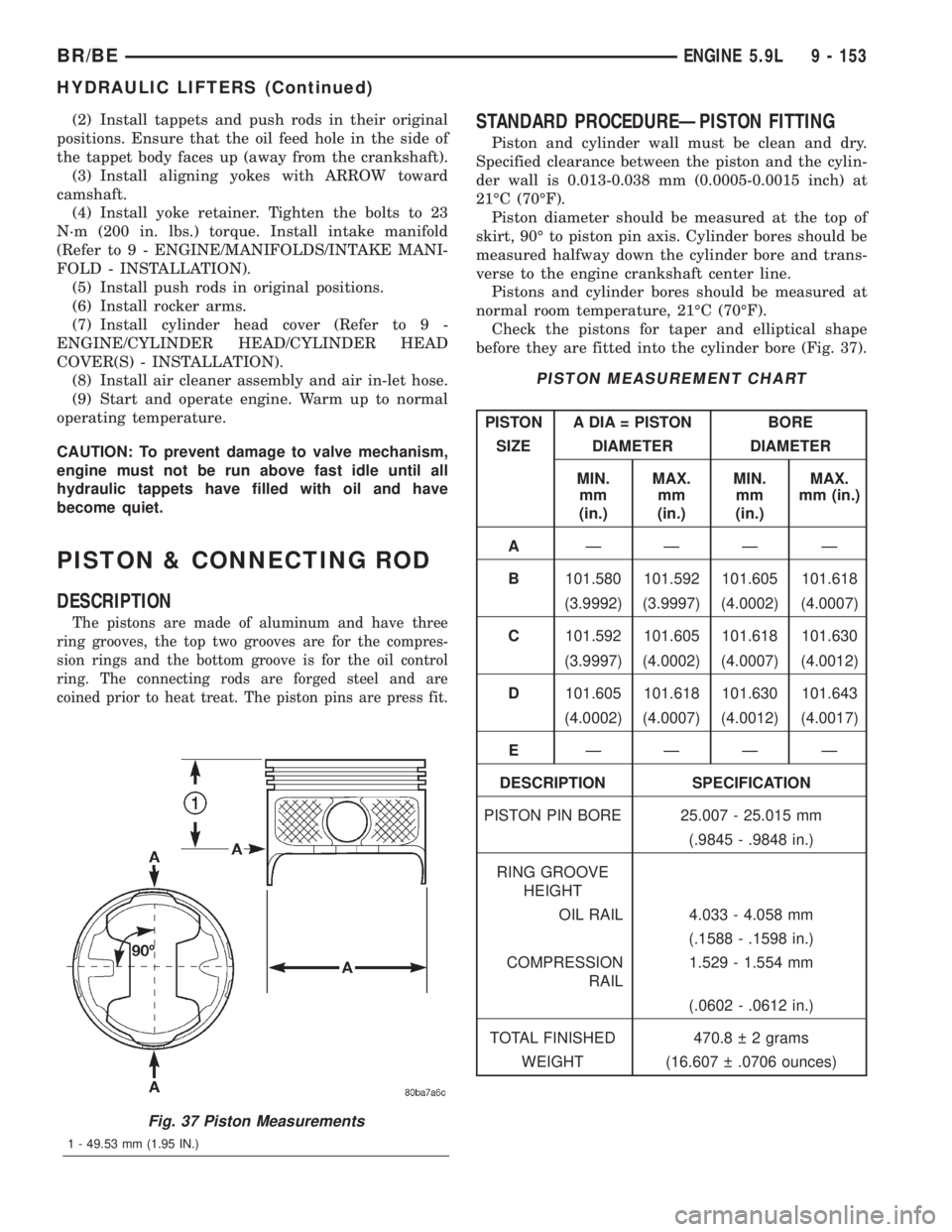

PISTON & CONNECTING ROD

DESCRIPTION

The pistons are made of aluminum and have three

ring grooves, the top two grooves are for the compres-

sion rings and the bottom groove is for the oil control

ring. The connecting rods are forged steel and are

coined prior to heat treat. The piston pins are press fit.

STANDARD PROCEDUREÐPISTON FITTING

Piston and cylinder wall must be clean and dry.

Specified clearance between the piston and the cylin-

der wall is 0.013-0.038 mm (0.0005-0.0015 inch) at

21ÉC (70ÉF).

Piston diameter should be measured at the top of

skirt, 90É to piston pin axis. Cylinder bores should be

measured halfway down the cylinder bore and trans-

verse to the engine crankshaft center line.

Pistons and cylinder bores should be measured at

normal room temperature, 21ÉC (70ÉF).

Check the pistons for taper and elliptical shape

before they are fitted into the cylinder bore (Fig. 37).

PISTON MEASUREMENT CHART

PISTON A DIA = PISTON BORE

SIZE DIAMETER DIAMETER

MIN. MAX. MIN. MAX.

mm

(in.)mm

(in.)mm

(in.)mm (in.)

AÐÐÐ Ð

B101.580 101.592 101.605 101.618

(3.9992) (3.9997) (4.0002) (4.0007)

C101.592 101.605 101.618 101.630

(3.9997) (4.0002) (4.0007) (4.0012)

D101.605 101.618 101.630 101.643

(4.0002) (4.0007) (4.0012) (4.0017)

EÐÐÐ Ð

DESCRIPTION SPECIFICATION

PISTON PIN BORE 25.007 - 25.015 mm

(.9845 - .9848 in.)

RING GROOVE

HEIGHT

OIL RAIL 4.033 - 4.058 mm

(.1588 - .1598 in.)

COMPRESSION

RAIL1.529 - 1.554 mm

(.0602 - .0612 in.)

TOTAL FINISHED 470.8 2 grams

WEIGHT (16.607 .0706 ounces)

Fig. 37 Piston Measurements

1 - 49.53 mm (1.95 IN.)

BR/BEENGINE 5.9L 9 - 153

HYDRAULIC LIFTERS (Continued)

Page 1315 of 2889

(9) Install closed crankcase ventilation and evapo-

ration control systems.

(10) Connect the coil wires.

(11) Connect the heat indicator sending unit wire.

(12) Connect the heater hoses and bypass hose.

(13) Install distributor cap and wires.

(14) Hook up the return spring.

(15) Connect the accelerator linkage (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/THROTTLE

CONTROL CABLE - INSTALLATION) and if so

equipped, the speed control and transmission kick-

down cables.

(16) Install the fuel lines (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE).

(17) Install the accessory drive bracket and A/C

compressor (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/A/C COMPRESSOR -

INSTALLATION).

(18) Install the generator and drive belt (Refer to 7

- COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION). Tighten generator mounting bolt

to 41 N´m (30 ft. lbs.) torque.

(19) Install the air cleaner.

(20) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(21) Connect the negative cable to the battery.

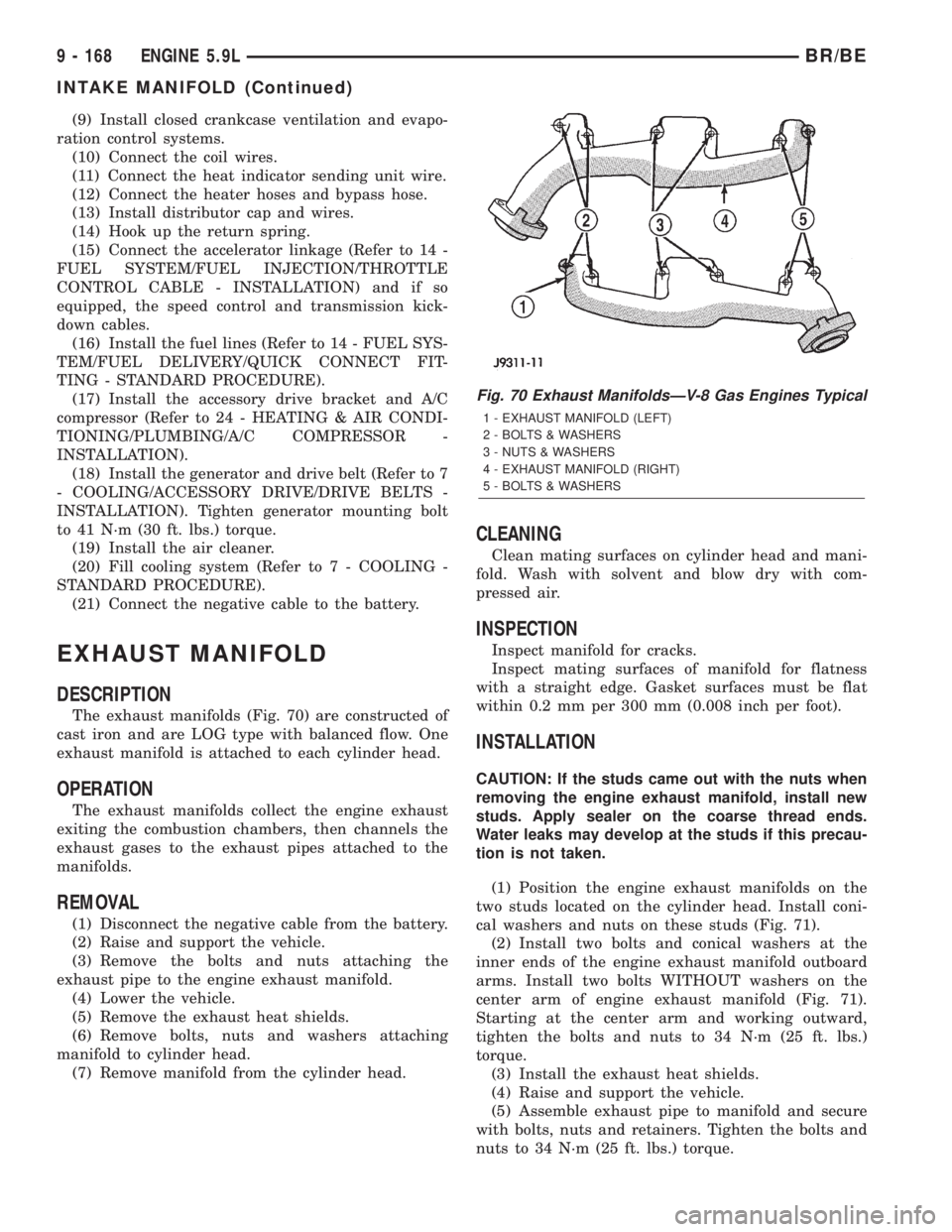

EXHAUST MANIFOLD

DESCRIPTION

The exhaust manifolds (Fig. 70) are constructed of

cast iron and are LOG type with balanced flow. One

exhaust manifold is attached to each cylinder head.

OPERATION

The exhaust manifolds collect the engine exhaust

exiting the combustion chambers, then channels the

exhaust gases to the exhaust pipes attached to the

manifolds.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Raise and support the vehicle.

(3) Remove the bolts and nuts attaching the

exhaust pipe to the engine exhaust manifold.

(4) Lower the vehicle.

(5) Remove the exhaust heat shields.

(6) Remove bolts, nuts and washers attaching

manifold to cylinder head.

(7) Remove manifold from the cylinder head.

CLEANING

Clean mating surfaces on cylinder head and mani-

fold. Wash with solvent and blow dry with com-

pressed air.

INSPECTION

Inspect manifold for cracks.

Inspect mating surfaces of manifold for flatness

with a straight edge. Gasket surfaces must be flat

within 0.2 mm per 300 mm (0.008 inch per foot).

INSTALLATION

CAUTION: If the studs came out with the nuts when

removing the engine exhaust manifold, install new

studs. Apply sealer on the coarse thread ends.

Water leaks may develop at the studs if this precau-

tion is not taken.

(1) Position the engine exhaust manifolds on the

two studs located on the cylinder head. Install coni-

cal washers and nuts on these studs (Fig. 71).

(2) Install two bolts and conical washers at the

inner ends of the engine exhaust manifold outboard

arms. Install two bolts WITHOUT washers on the

center arm of engine exhaust manifold (Fig. 71).

Starting at the center arm and working outward,

tighten the bolts and nuts to 34 N´m (25 ft. lbs.)

torque.

(3) Install the exhaust heat shields.

(4) Raise and support the vehicle.

(5) Assemble exhaust pipe to manifold and secure

with bolts, nuts and retainers. Tighten the bolts and

nuts to 34 N´m (25 ft. lbs.) torque.

Fig. 70 Exhaust ManifoldsÐV-8 Gas Engines Typical

1 - EXHAUST MANIFOLD (LEFT)

2 - BOLTS & WASHERS

3 - NUTS & WASHERS

4 - EXHAUST MANIFOLD (RIGHT)

5 - BOLTS & WASHERS

9 - 168 ENGINE 5.9LBR/BE

INTAKE MANIFOLD (Continued)

Page 1322 of 2889

CONDITION POSSIBLE CAUSES CORRECTION

7. Intake manifold vacuum leak 7. Inspect intake manifold gasket and

vacuum hoses (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE

MANIFOLD - DIAGNOSIS AND

TESTING).

ENGINE MISSES ON

ACCELERATION1. Worn or incorrectly gapped spark

plugs1. Replace spark plugs or clean and

set gap. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG -

CLEANING)

2. Spark plug cables defective or

crossed2. Replace or rewire secondary

ignition cables. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL/

SPARK PLUG CABLE - REMOVAL)

3. Dirt in fuel system 3. Clean fuel system

4. Burned, warped or pitted valves 4. Install new valves

5. Faulty coil 5. Test and replace as necessary

(Refer to 8 - ELECTRICAL/IGNITION

CONTROL/IGNITION COIL -

REMOVAL)

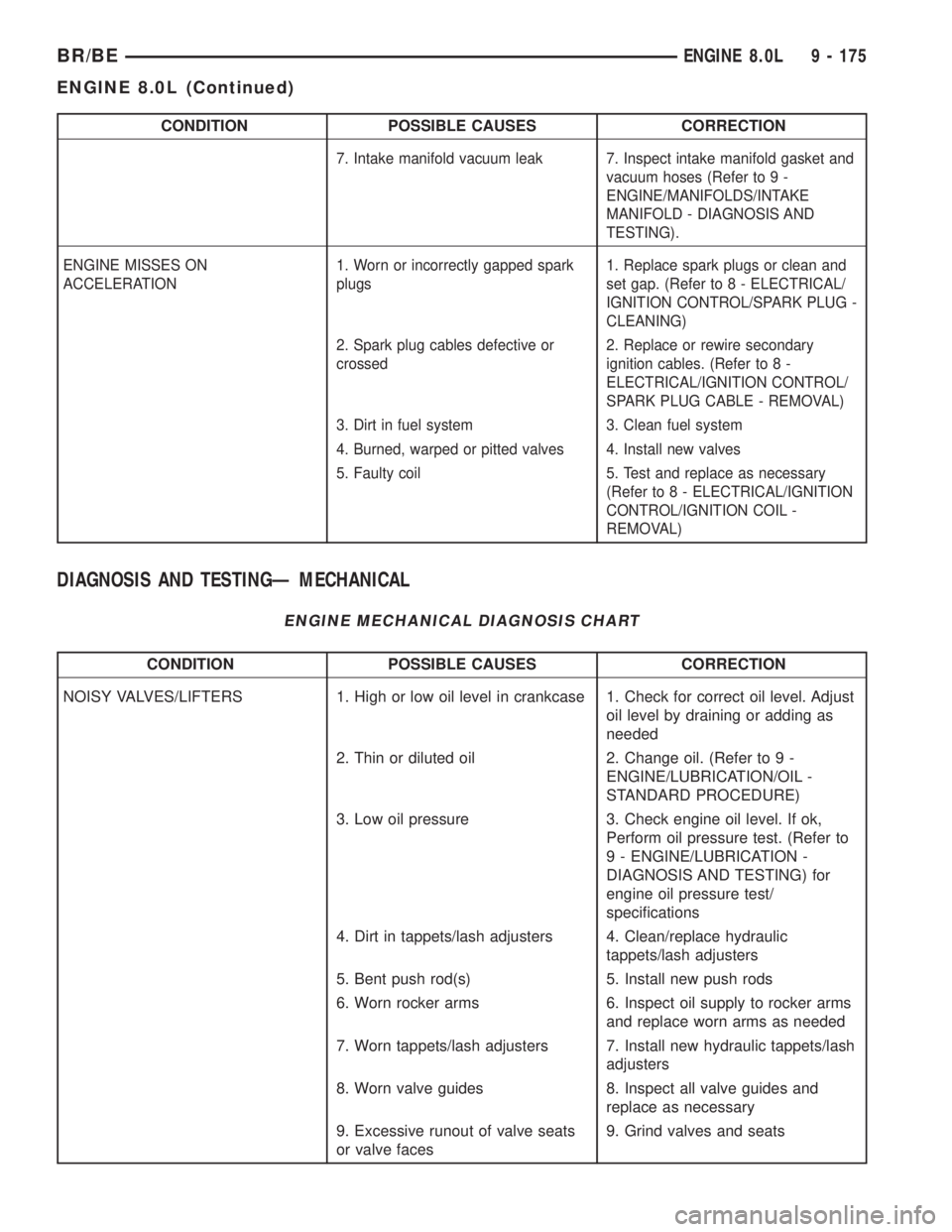

DIAGNOSIS AND TESTINGÐ MECHANICAL

ENGINE MECHANICAL DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

NOISY VALVES/LIFTERS 1. High or low oil level in crankcase 1. Check for correct oil level. Adjust

oil level by draining or adding as

needed

2. Thin or diluted oil 2. Change oil. (Refer to 9 -

ENGINE/LUBRICATION/OIL -

STANDARD PROCEDURE)

3. Low oil pressure 3. Check engine oil level. If ok,

Perform oil pressure test. (Refer to

9 - ENGINE/LUBRICATION -

DIAGNOSIS AND TESTING) for

engine oil pressure test/

specifications

4. Dirt in tappets/lash adjusters 4. Clean/replace hydraulic

tappets/lash adjusters

5. Bent push rod(s) 5. Install new push rods

6. Worn rocker arms 6. Inspect oil supply to rocker arms

and replace worn arms as needed

7. Worn tappets/lash adjusters 7. Install new hydraulic tappets/lash

adjusters

8. Worn valve guides 8. Inspect all valve guides and

replace as necessary

9. Excessive runout of valve seats

or valve faces9. Grind valves and seats

BR/BEENGINE 8.0L 9 - 175

ENGINE 8.0L (Continued)

Page 1339 of 2889

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

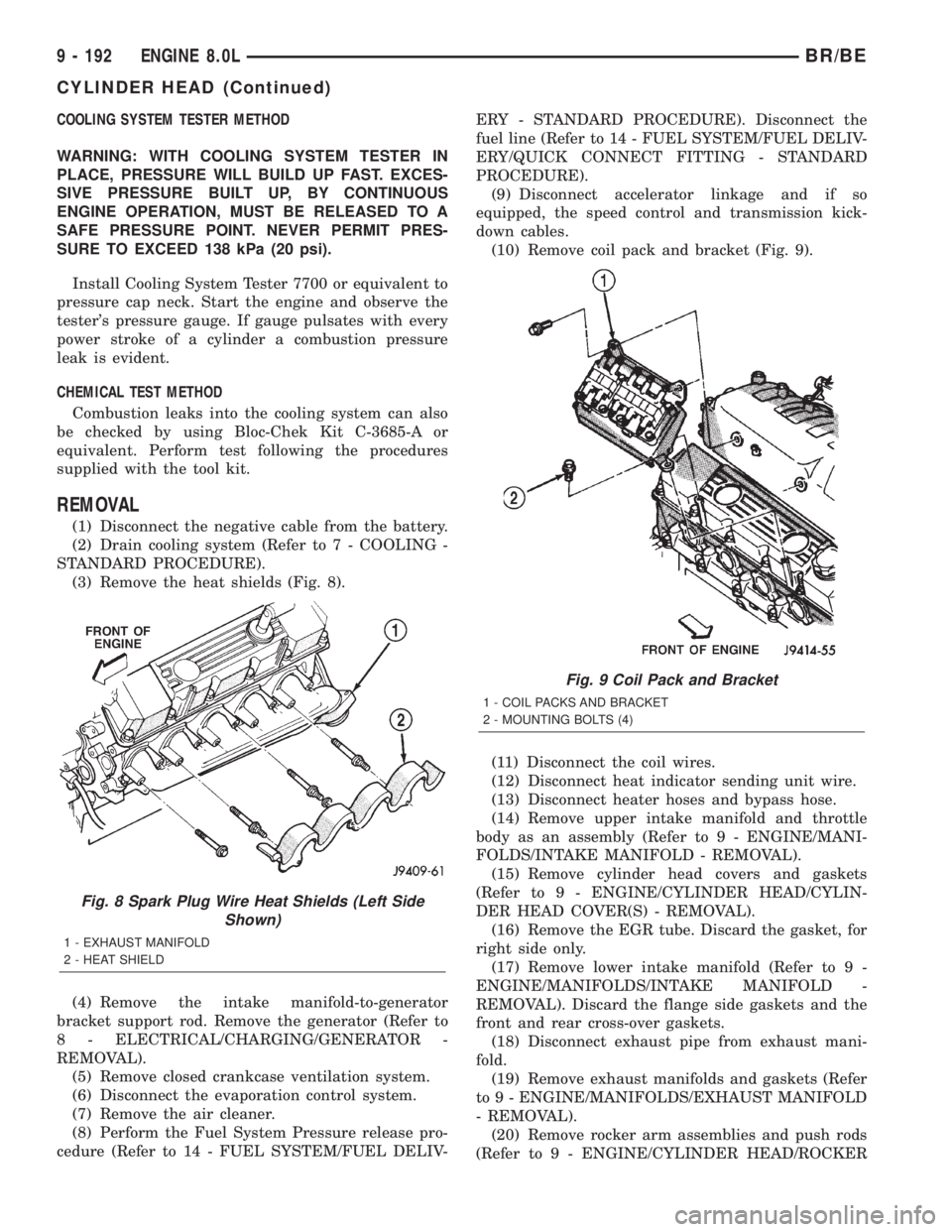

(3) Remove the heat shields (Fig. 8).

(4) Remove the intake manifold-to-generator

bracket support rod. Remove the generator (Refer to

8 - ELECTRICAL/CHARGING/GENERATOR -

REMOVAL).

(5) Remove closed crankcase ventilation system.

(6) Disconnect the evaporation control system.

(7) Remove the air cleaner.

(8) Perform the Fuel System Pressure release pro-

cedure (Refer to 14 - FUEL SYSTEM/FUEL DELIV-ERY - STANDARD PROCEDURE). Disconnect the

fuel line (Refer to 14 - FUEL SYSTEM/FUEL DELIV-

ERY/QUICK CONNECT FITTING - STANDARD

PROCEDURE).

(9) Disconnect accelerator linkage and if so

equipped, the speed control and transmission kick-

down cables.

(10) Remove coil pack and bracket (Fig. 9).

(11) Disconnect the coil wires.

(12) Disconnect heat indicator sending unit wire.

(13) Disconnect heater hoses and bypass hose.

(14) Remove upper intake manifold and throttle

body as an assembly (Refer to 9 - ENGINE/MANI-

FOLDS/INTAKE MANIFOLD - REMOVAL).

(15) Remove cylinder head covers and gaskets

(Refer to 9 - ENGINE/CYLINDER HEAD/CYLIN-

DER HEAD COVER(S) - REMOVAL).

(16) Remove the EGR tube. Discard the gasket, for

right side only.

(17) Remove lower intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL). Discard the flange side gaskets and the

front and rear cross-over gaskets.

(18) Disconnect exhaust pipe from exhaust mani-

fold.

(19) Remove exhaust manifolds and gaskets (Refer

to 9 - ENGINE/MANIFOLDS/EXHAUST MANIFOLD

- REMOVAL).

(20) Remove rocker arm assemblies and push rods

(Refer to 9 - ENGINE/CYLINDER HEAD/ROCKER

Fig. 8 Spark Plug Wire Heat Shields (Left Side

Shown)

1 - EXHAUST MANIFOLD

2 - HEAT SHIELD

Fig. 9 Coil Pack and Bracket

1 - COIL PACKS AND BRACKET

2 - MOUNTING BOLTS (4)

9 - 192 ENGINE 8.0LBR/BE

CYLINDER HEAD (Continued)

Page 1340 of 2889

ARM / ADJUSTER ASSY - REMOVAL). Identify to

ensure installation in original locations.

(21) Remove the head bolts from each cylinder

head and remove cylinder heads. Discard the cylin-

der head gasket.

(22) Remove spark plugs.

CLEANING

Clean all surfaces of cylinder block and cylinder

heads. Be sure material does not fall into the lifters

and surrounding valley.

Clean cylinder block front and rear gasket surfaces

using a suitable solvent.

Clean the exhaust manifold to cylinder head mat-

ing areas.

INSPECTION

Inspect all surfaces with a straightedge if there is

any reason to suspect leakage. The out-of-flatness

specifications are 0.0007 mm/mm (0.0004 inch/inch),

0.127 mm/152 mm (0.005 inch/6 inches) any direction

or 0.254 mm (0.010 inch) overall across head. If

exceeded, either replace head or lightly machine the

head surface.

The cylinder head surface finish should be

1.78-4.57 microns (15-80 microinches).

Inspect push rods. Replace worn or bent rods.

Inspect rocker arms. Replace if worn or scored.

INSTALLATION

(1) Position the new cylinder head gaskets onto

the cylinder block.

(2) Position the cylinder heads onto head gaskets

and cylinder block.

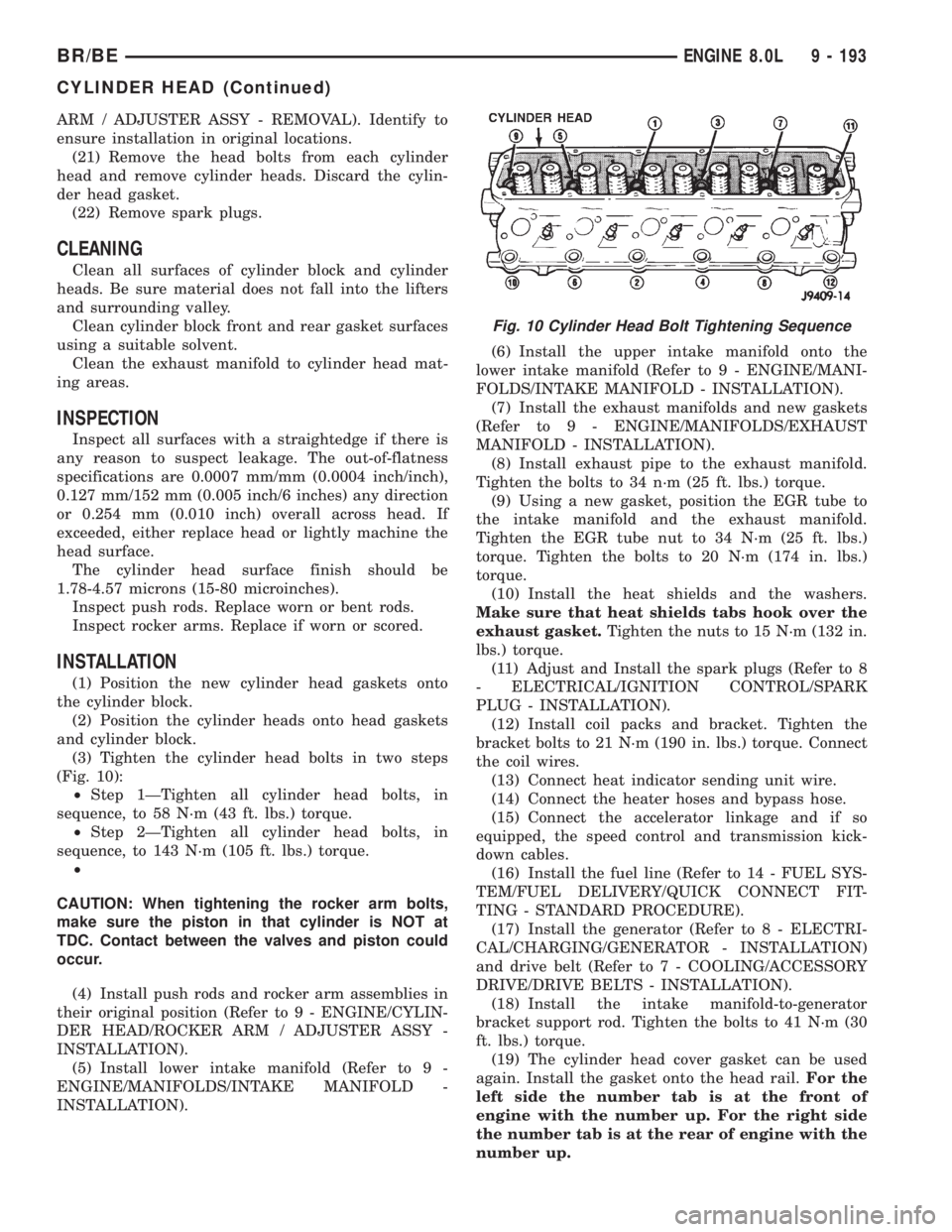

(3) Tighten the cylinder head bolts in two steps

(Fig. 10):

²Step 1ÐTighten all cylinder head bolts, in

sequence, to 58 N´m (43 ft. lbs.) torque.

²Step 2ÐTighten all cylinder head bolts, in

sequence, to 143 N´m (105 ft. lbs.) torque.

²

CAUTION: When tightening the rocker arm bolts,

make sure the piston in that cylinder is NOT at

TDC. Contact between the valves and piston could

occur.

(4) Install push rods and rocker arm assemblies in

their original position (Refer to 9 - ENGINE/CYLIN-

DER HEAD/ROCKER ARM / ADJUSTER ASSY -

INSTALLATION).

(5) Install lower intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).(6) Install the upper intake manifold onto the

lower intake manifold (Refer to 9 - ENGINE/MANI-

FOLDS/INTAKE MANIFOLD - INSTALLATION).

(7) Install the exhaust manifolds and new gaskets

(Refer to 9 - ENGINE/MANIFOLDS/EXHAUST

MANIFOLD - INSTALLATION).

(8) Install exhaust pipe to the exhaust manifold.

Tighten the bolts to 34 n´m (25 ft. lbs.) torque.

(9) Using a new gasket, position the EGR tube to

the intake manifold and the exhaust manifold.

Tighten the EGR tube nut to 34 N´m (25 ft. lbs.)

torque. Tighten the bolts to 20 N´m (174 in. lbs.)

torque.

(10) Install the heat shields and the washers.

Make sure that heat shields tabs hook over the

exhaust gasket.Tighten the nuts to 15 N´m (132 in.

lbs.) torque.

(11) Adjust and Install the spark plugs (Refer to 8

- ELECTRICAL/IGNITION CONTROL/SPARK

PLUG - INSTALLATION).

(12) Install coil packs and bracket. Tighten the

bracket bolts to 21 N´m (190 in. lbs.) torque. Connect

the coil wires.

(13) Connect heat indicator sending unit wire.

(14) Connect the heater hoses and bypass hose.

(15) Connect the accelerator linkage and if so

equipped, the speed control and transmission kick-

down cables.

(16) Install the fuel line (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE).

(17) Install the generator (Refer to 8 - ELECTRI-

CAL/CHARGING/GENERATOR - INSTALLATION)

and drive belt (Refer to 7 - COOLING/ACCESSORY

DRIVE/DRIVE BELTS - INSTALLATION).

(18) Install the intake manifold-to-generator

bracket support rod. Tighten the bolts to 41 N´m (30

ft. lbs.) torque.

(19) The cylinder head cover gasket can be used

again. Install the gasket onto the head rail.For the

left side the number tab is at the front of

engine with the number up. For the right side

the number tab is at the rear of engine with the

number up.

Fig. 10 Cylinder Head Bolt Tightening Sequence

BR/BEENGINE 8.0L 9 - 193

CYLINDER HEAD (Continued)

Page 1344 of 2889

(3) Inspect the valve seat with Prussian blue to

determine where the valve contacts the seat. To do

this, coat valve seat LIGHTLY with Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to the top edge of valve face, lower valve seat

with a 15É stone. If the blue is transferred to bottom

edge of valve face raise valve seat with a 60É stone.

(4) When seat is properly positioned the width of

valve seats should be 1.016-1.524 mm (0.040-0.060

inch).

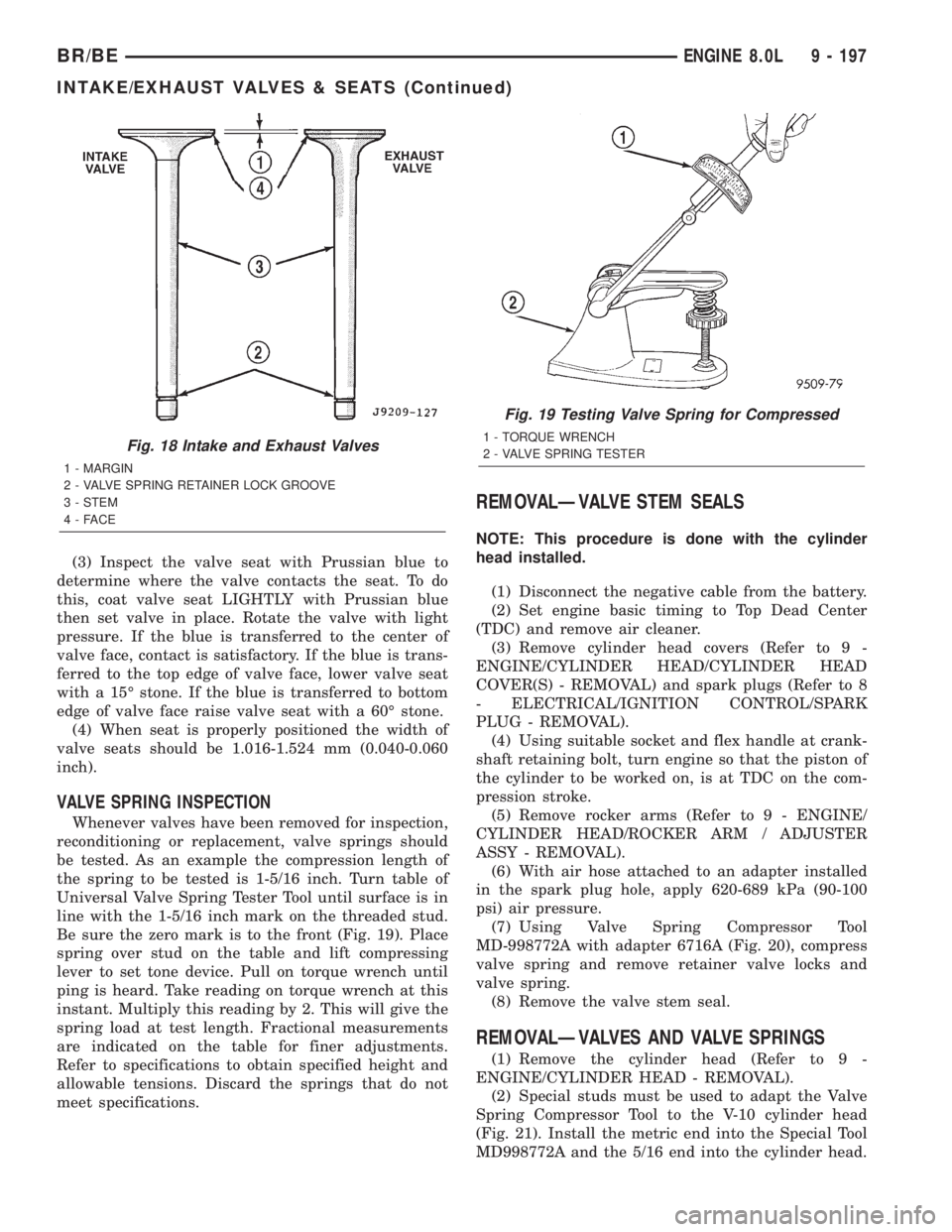

VALVE SPRING INSPECTION

Whenever valves have been removed for inspection,

reconditioning or replacement, valve springs should

be tested. As an example the compression length of

the spring to be tested is 1-5/16 inch. Turn table of

Universal Valve Spring Tester Tool until surface is in

line with the 1-5/16 inch mark on the threaded stud.

Be sure the zero mark is to the front (Fig. 19). Place

spring over stud on the table and lift compressing

lever to set tone device. Pull on torque wrench until

ping is heard. Take reading on torque wrench at this

instant. Multiply this reading by 2. This will give the

spring load at test length. Fractional measurements

are indicated on the table for finer adjustments.

Refer to specifications to obtain specified height and

allowable tensions. Discard the springs that do not

meet specifications.

REMOVALÐVALVE STEM SEALS

NOTE: This procedure is done with the cylinder

head installed.

(1) Disconnect the negative cable from the battery.

(2) Set engine basic timing to Top Dead Center

(TDC) and remove air cleaner.

(3) Remove cylinder head covers (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL) and spark plugs (Refer to 8

- ELECTRICAL/IGNITION CONTROL/SPARK

PLUG - REMOVAL).

(4) Using suitable socket and flex handle at crank-

shaft retaining bolt, turn engine so that the piston of

the cylinder to be worked on, is at TDC on the com-

pression stroke.

(5) Remove rocker arms (Refer to 9 - ENGINE/

CYLINDER HEAD/ROCKER ARM / ADJUSTER

ASSY - REMOVAL).

(6) With air hose attached to an adapter installed

in the spark plug hole, apply 620-689 kPa (90-100

psi) air pressure.

(7) Using Valve Spring Compressor Tool

MD-998772A with adapter 6716A (Fig. 20), compress

valve spring and remove retainer valve locks and

valve spring.

(8) Remove the valve stem seal.

REMOVALÐVALVES AND VALVE SPRINGS

(1) Remove the cylinder head (Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

(2) Special studs must be used to adapt the Valve

Spring Compressor Tool to the V-10 cylinder head

(Fig. 21). Install the metric end into the Special Tool

MD998772A and the 5/16 end into the cylinder head.

Fig. 18 Intake and Exhaust Valves

1 - MARGIN

2 - VALVE SPRING RETAINER LOCK GROOVE

3 - STEM

4-FACE

Fig. 19 Testing Valve Spring for Compressed

1 - TORQUE WRENCH

2 - VALVE SPRING TESTER

BR/BEENGINE 8.0L 9 - 197

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1346 of 2889

(4) Compress valve spring and install retainer

valve locks.

(5) Remove air hose and adapter from spark plug

hole.

(6) Remove Valve Spring Compressor and Adapter

Studs.

(7) Install rocker arms (Refer to 9 - ENGINE/CYL-

INDER HEAD/ROCKER ARM / ADJUSTER ASSY -

INSTALLATION).

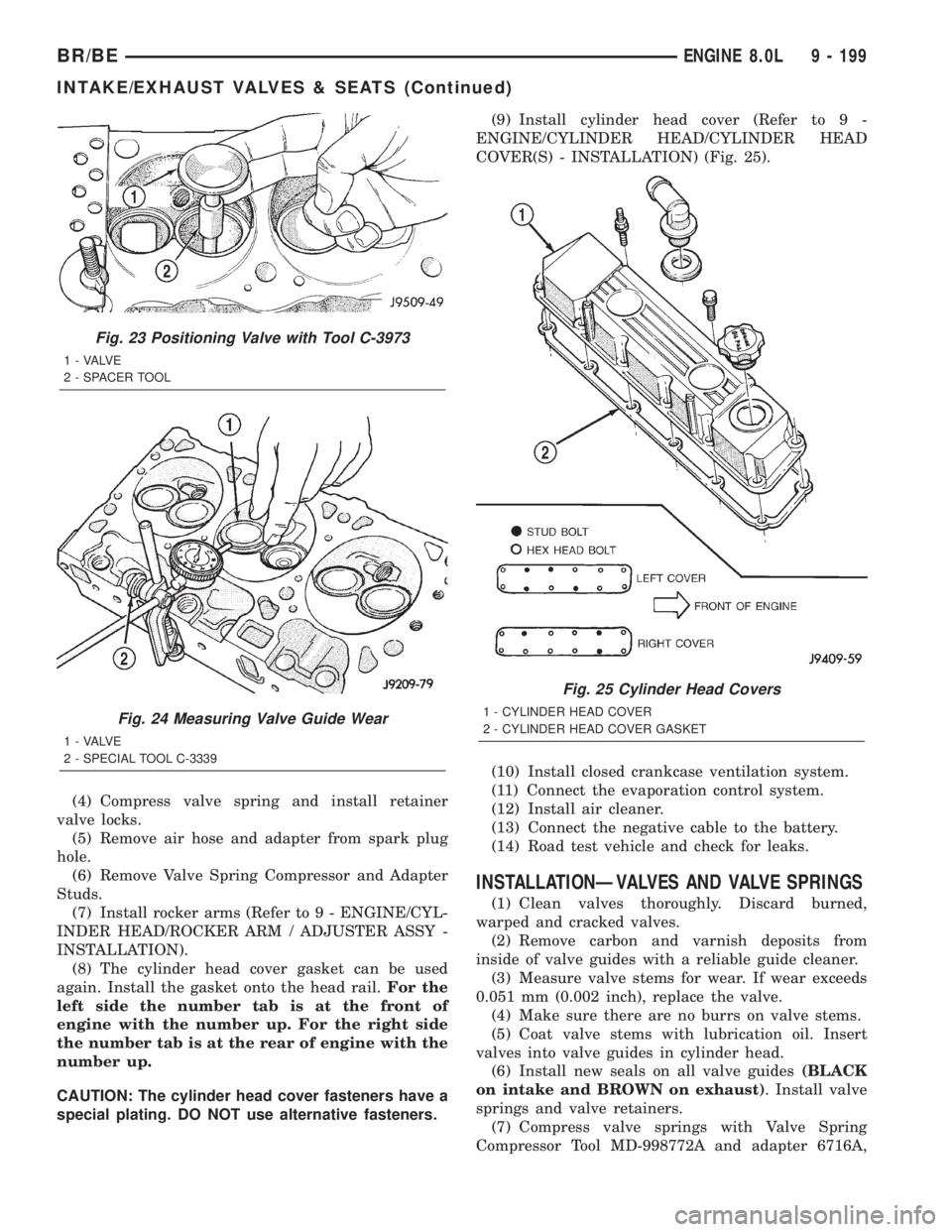

(8) The cylinder head cover gasket can be used

again. Install the gasket onto the head rail.For the

left side the number tab is at the front of

engine with the number up. For the right side

the number tab is at the rear of engine with the

number up.

CAUTION: The cylinder head cover fasteners have a

special plating. DO NOT use alternative fasteners.(9) Install cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION) (Fig. 25).

(10) Install closed crankcase ventilation system.

(11) Connect the evaporation control system.

(12) Install air cleaner.

(13) Connect the negative cable to the battery.

(14) Road test vehicle and check for leaks.

INSTALLATIONÐVALVES AND VALVE SPRINGS

(1) Clean valves thoroughly. Discard burned,

warped and cracked valves.

(2) Remove carbon and varnish deposits from

inside of valve guides with a reliable guide cleaner.

(3) Measure valve stems for wear. If wear exceeds

0.051 mm (0.002 inch), replace the valve.

(4) Make sure there are no burrs on valve stems.

(5) Coat valve stems with lubrication oil. Insert

valves into valve guides in cylinder head.

(6) Install new seals on all valve guides(BLACK

on intake and BROWN on exhaust). Install valve

springs and valve retainers.

(7) Compress valve springs with Valve Spring

Compressor Tool MD-998772A and adapter 6716A,

Fig. 23 Positioning Valve with Tool C-3973

1 - VALVE

2 - SPACER TOOL

Fig. 24 Measuring Valve Guide Wear

1 - VALVE

2 - SPECIAL TOOL C-3339

Fig. 25 Cylinder Head Covers

1 - CYLINDER HEAD COVER

2 - CYLINDER HEAD COVER GASKET

BR/BEENGINE 8.0L 9 - 199

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1390 of 2889

DESCRIPTION SPECIFICATION

(0.014 ± 0.0177 in.)

Intermediate 0.85 ± 1.15 mm

(0.0334 ± 0.0452 in.)

Oil Control 0.250 ± 0.550 mm

(0.010 ± 0.0215 in.)

Connecting Rods

Pin Bore Diameter (Max.) 40.042 mm (1.5764 in.)

Side Clearance 0.100 ± 0.330 mm

(0.004 ± 0.013 in.)

CYLINDER HEAD

Overall Flatness End to

End (Max.)0.30 mm (0.012 in.)

Overall Flatness Side to

Side (Max.)0.076 mm (0.003 in.)

Intake Valve Seat Angle 30É

Exhaust Valve Seat Angle 45É

Valve Seat Width

(Min.) 1.49 mm (0.059 in.)

(Max.) 1.80 mm (0.071 in.)

Valve Margin (Min.) 0.72 mm (0.031 in.)

OIL PRESSURE

At Idle 69 kPa (10 psi)

At 2,500 rpm 207 kPa (30 psi)

Regulating Valve Opening

Pressure448 kPa (65 psi)

Oil Filter Bypass Pressure

Setting344.75 kPa (50 psi)TORQUE

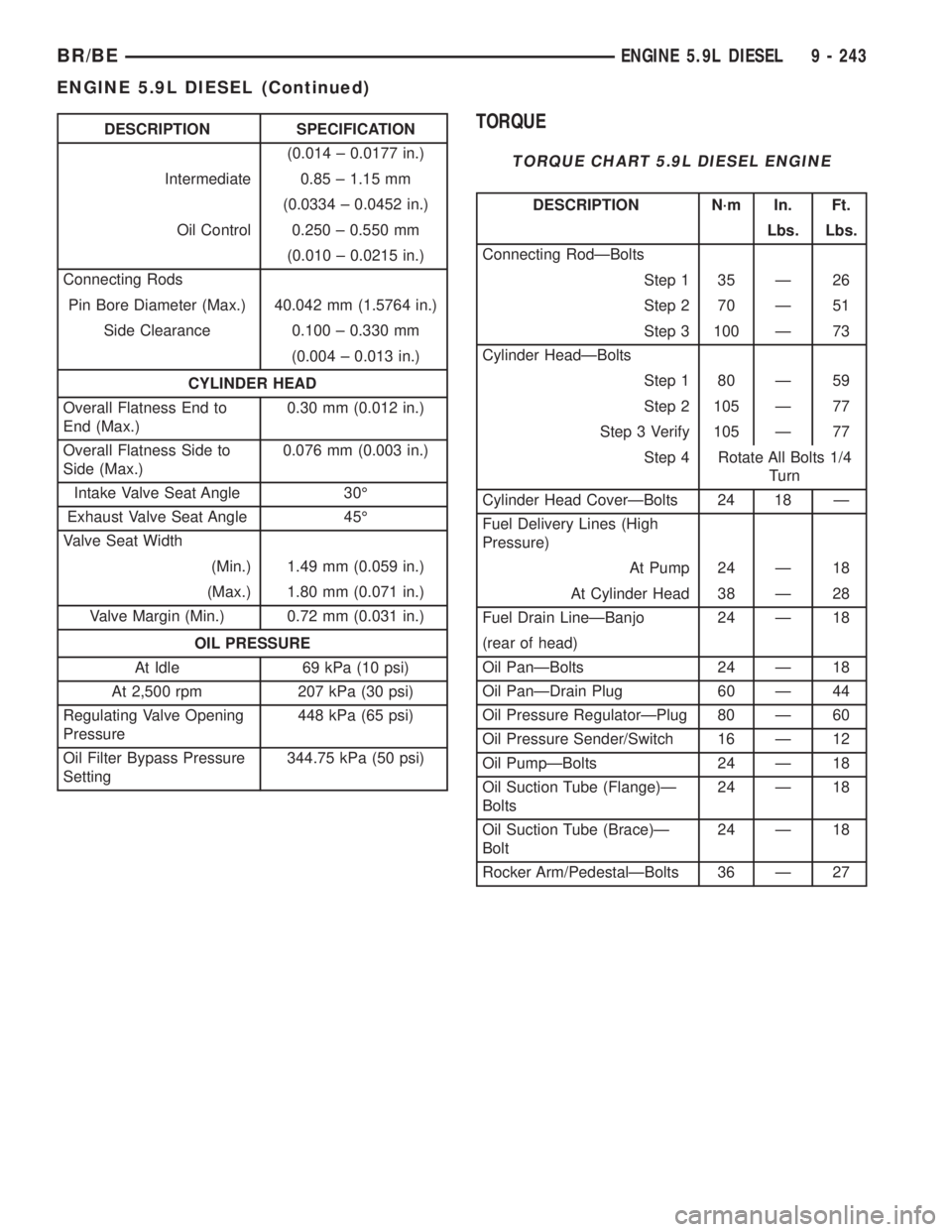

TORQUE CHART 5.9L DIESEL ENGINE

DESCRIPTION N´m In. Ft.

Lbs. Lbs.

Connecting RodÐBolts

Step 1 35 Ð 26

Step 2 70 Ð 51

Step 3 100 Ð 73

Cylinder HeadÐBolts

Step 1 80 Ð 59

Step 2 105 Ð 77

Step 3 Verify 105 Ð 77

Step 4 Rotate All Bolts 1/4

Turn

Cylinder Head CoverÐBolts 24 18 Ð

Fuel Delivery Lines (High

Pressure)

At Pump 24 Ð 18

At Cylinder Head 38 Ð 28

Fuel Drain LineÐBanjo 24 Ð 18

(rear of head)

Oil PanÐBolts 24 Ð 18

Oil PanÐDrain Plug 60 Ð 44

Oil Pressure RegulatorÐPlug 80 Ð 60

Oil Pressure Sender/Switch 16 Ð 12

Oil PumpÐBolts 24 Ð 18

Oil Suction Tube (Flange)Ð

Bolts24 Ð 18

Oil Suction Tube (Brace)Ð

Bolt24 Ð 18

Rocker Arm/PedestalÐBolts 36 Ð 27

BR/BEENGINE 5.9L DIESEL 9 - 243

ENGINE 5.9L DIESEL (Continued)

Page 1489 of 2889

FUEL DELIVERY - GASOLINE

DESCRIPTION - FUEL DELIVERY SYSTEM

The fuel delivery system consists of:

²the fuel pump module containing the electric

fuel pump, fuel filter/fuel pressure regulator, rollover

valve (certain modules), fuel gauge sending unit (fuel

level sensor) and a separate fuel filter located at bot-

tom of pump module

²fuel tubes/lines/hoses

²quick-connect fittings

²fuel injector rail

²fuel injectors

²fuel tank

²fuel tank filler/vent tube assembly

²fuel tank filler tube cap

²accelerator pedal

²throttle cable

OPERATION - FUEL DELIVERY SYSTEM

Fuel is returned through the fuel pump module

and back into the fuel tank through the fuel filter/

fuel pressure regulator. A separate fuel return line

from the engine to the tank is not used with any gas-

oline powered engine.

The fuel tank assembly consists of: the fuel tank,

fuel pump module assembly, fuel pump module lock-

nut/gasket and rollover valve(s) (refer to 25, Emis-

sion Control System for rollover valve information).

A fuel filler/vent tube assembly using a pressure/

vacuum, 1/4 turn fuel filler cap is used. The fuel

filler tube contains a flap door located below the fuel

fill cap.

Also to be considered part of the fuel system is the

evaporation control system. This is designed to

reduce the emission of fuel vapors into the atmo-

sphere. The description and function of the Evapora-

tive Control System is found in 25, Emission Control

Systems.

Both fuel filters (at bottom of fuel pump module

and within fuel pressure regulator) are designed for

extended service. They do not require normal sched-

uled maintenance. Filters should only be replaced if

a diagnostic procedure indicates to do so.

DIAGNOSIS AND TESTING - FUEL PRESSURE

LEAK DOWN TEST

Use this test in conjunction with the Fuel Pump

Pressure Test and Fuel Pump Capacity Test.

Check Valve Operation:The electric fuel pump

outlet contains a one-way check valve to prevent fuel

flow back into the tank and to maintain fuel supply

line pressure (engine warm) when pump is not oper-

ational. It is also used to keep the fuel supply line

full of gasoline when pump is not operational. Afterthe vehicle has cooled down, fuel pressure may drop

to 0 psi (cold fluid contracts), but liquid gasoline will

remain in fuel supply line between the check valve

and fuel injectors.Fuel pressure that has

dropped to 0 psi on a cooled down vehicle

(engine off) is a normal condition.When the elec-

tric fuel pump is activated, fuel pressure should

immediately(1±2 seconds) rise to specification.

Abnormally long periods of cranking to restart a

hotengine that has been shut down for a short

period of time may be caused by:

²Fuel pressure bleeding past a fuel injector(s).

²Fuel pressure bleeding past the check valve in

the fuel pump module.

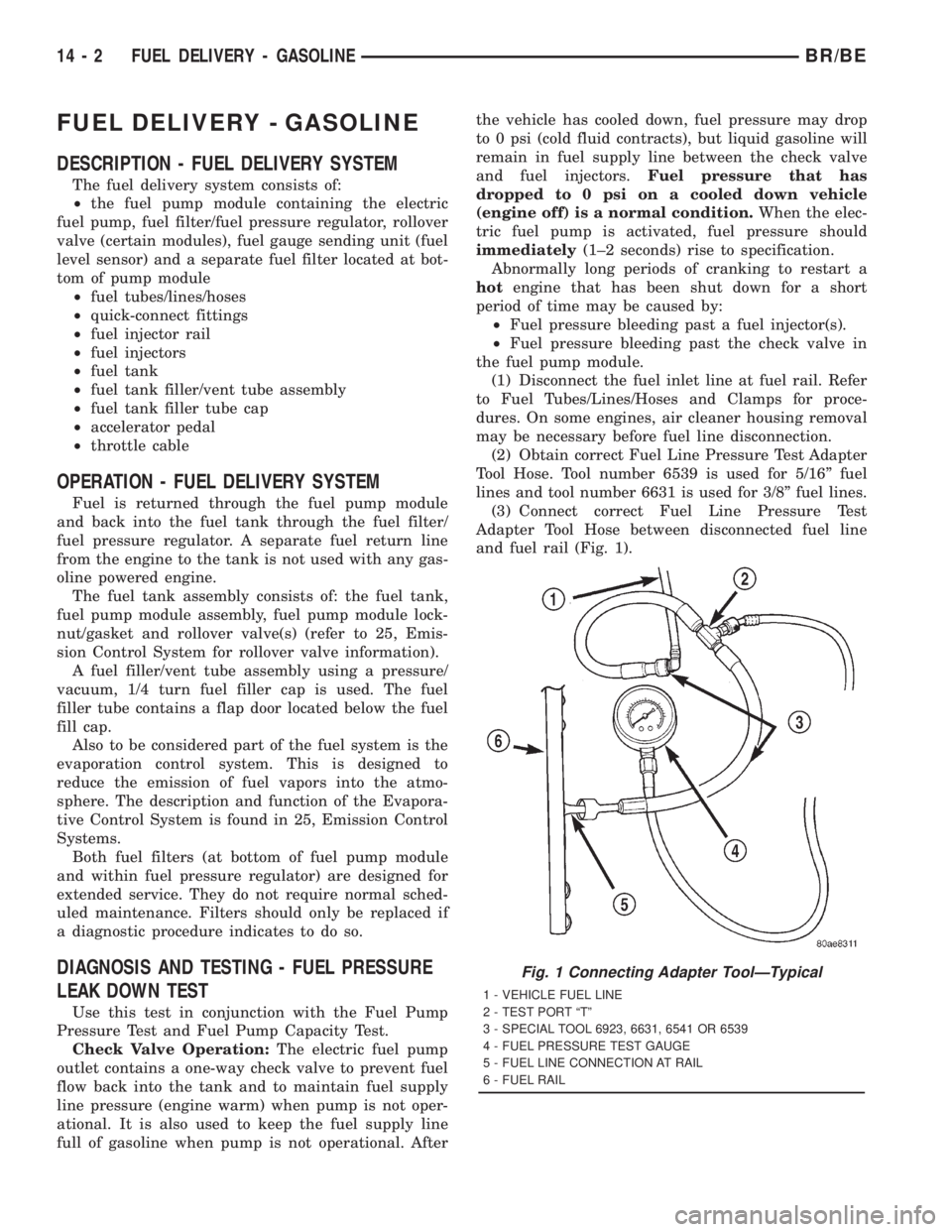

(1) Disconnect the fuel inlet line at fuel rail. Refer

to Fuel Tubes/Lines/Hoses and Clamps for proce-

dures. On some engines, air cleaner housing removal

may be necessary before fuel line disconnection.

(2) Obtain correct Fuel Line Pressure Test Adapter

Tool Hose. Tool number 6539 is used for 5/16º fuel

lines and tool number 6631 is used for 3/8º fuel lines.

(3) Connect correct Fuel Line Pressure Test

Adapter Tool Hose between disconnected fuel line

and fuel rail (Fig. 1).

Fig. 1 Connecting Adapter ToolÐTypical

1 - VEHICLE FUEL LINE

2 - TEST PORT ªTº

3 - SPECIAL TOOL 6923, 6631, 6541 OR 6539

4 - FUEL PRESSURE TEST GAUGE

5 - FUEL LINE CONNECTION AT RAIL

6 - FUEL RAIL

14 - 2 FUEL DELIVERY - GASOLINEBR/BE