airbag DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 425 of 2889

Refer to Electrical, Restraints for more information

on the clockspring. Refer to Electrical, Body Control/

Central Control Module for more information on the

Central Timer Module. Refer to the appropriate wir-

ing information. The wiring information includes wir-

ing diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds. Following are general descriptions of

the remaining major components in the standard and

optional factory-installed audio systems.

OPERATION

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of each of the available audio systems.

CENTRAL TIMER MODULE

The high-line or premium Central Timer Module

(CTM) can also control some features of the audio

system when the vehicle is equipped with the

optional RAZ radio receiver and remote radio

switches. A high-line CTM is used on high-line ver-

sions of this vehicle. A premium CTM is used on

vehicles equipped with the optional heated seats. The

CTM combines the functions of a chime/buzzer mod-

ule, an intermittent wipe module, an illuminated

entry module, a remote keyless entry module, and a

vehicle theft security system module in a single unit.

The high-line or premium CTM also controls and

integrates many of the additional electronic functions

and features included on models with this option.The RAZ radio receiver with a remote radio switch

option is one of the features that the CTM controls.

The CTM is programmed to send switch status mes-

sages over the Chrysler Collision Detection (CCD)

data bus to control the volume, seek, and pre-set sta-

tion advance functions of the RAZ radio receiver. The

CTM monitors the status of the remote radio

switches located on the steering wheel through a

hard wired circuit. The CTM then sends the proper

switch status messages to the radio receiver. The

electronic circuitry within the radio receiver responds

to the switch status messages it receives by adjusting

the radio settings as requested.

Refer to Electrical, Body Control/Central Timer

Module for more information on the high-line CTM.

Refer to Remote Radio Switch in Description and

Operation for more information on this component.

In addition, radio receivers connected to the CCD

data bus have several audio system functions that

can be diagnosed using a DRBIIItscan tool. Refer to

the proper Diagnostic Procedures manual for more

information on DRBIIIttesting of the audio systems.

DIAGNOSIS AND TESTING - AUDIO

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

8A - 2 AUDIOBR/BE

AUDIO (Continued)

Page 428 of 2889

commercial radio stations in both the Amplitude

Modulating (AM) and Frequency Modulating (FM)

frequency ranges. These electromagnetic radio fre-

quency signals induce small electrical modulations

into the antenna as they move past the mast. The

antenna body transfers the weak electromagnetic

radio waves induced into the rigid antenna mast into

the center conductor of the flexible primary antenna

coaxial cable. The braided outer shield of the

antenna coaxial cable is grounded through both the

antenna body and the radio chassis, effectively

shielding the radio waves as they are conducted to

the radio. The radio then tunes and amplifies the

weak radio signals into stronger electrical signals in

order to operate the audio system speakers.

The antenna body includes an integral flange that

mates with and grounds the antenna body to the

underside of the fender panel sheet metal. Above the

fender panel, the antenna body has a short nipple

that is externally threaded to accept the antenna cap

nut. Inside the nipple is a plastic insulator tube, and

inside this insulator is an internally threaded metal

receptacle that accepts the adapter stud on the bot-

tom of the antenna mast. The antenna adapter

serves as an above fender interface to mount and

secure the antenna body to the vehicle. The antenna

adapter is a black molded plastic component that

provides a functional transition between the top of

the fender and the antenna cap nut, while concealing

the edges of the antenna mounting hole and protect-

ing the painted finish of the fender from marring as

the antenna cap nut is tightened. The adapter is

installed over and shrouds the threaded nipple of the

antenna body, which is installed from under and pro-

trudes through the top of the mounting hole in the

fender. The antenna cap nut is installed on top of the

antenna adapter and tightened onto the external

threads of the antenna body nipple to effectively

secure and ground the antenna body to the fender.

Three notches on the outer circumference of the cap

nut are engaged by matching projections of an

antenna nut wrench (Special Tool C-4816) to facili-

tate the removal and installation of this special fas-

tener. Proper tightening of the antenna cap nut is

critical to ensuring proper grounding of the antenna

body to the fender sheet metal, which is necessary

for clear radio signal reception.

A short length of coaxial cable serves as the pri-

mary antenna cable. The center conductor of the

cable is connected to the antenna mast receptacle.

The outer wire mesh of the cable is connected to and

grounded through the antenna body. One end of the

primary antenna cable is securely crimped to the

lower end of the antenna body, while the opposite

end features a simple push/pull-type male coaxial

cable connector that serves as the in-line connector tothe instrument panel (secondary) antenna coaxial

cable. The primary coaxial cable includes a grommet

that seals the cable to an entry hole in the right cowl

side outer panel where the cable passes into the pas-

senger compartment of the vehicle. The secondary

antenna cable has a push/pull-type male coaxial

cable connector on the radio end, and a push/pull-

type female coaxial cable connector on the opposite

end, which serves as the in-line connector to the pri-

mary antenna cable. In the passenger compartment

the primary cable is routed to the lower right side of

the instrument panel, where it is connected to the

secondary instrument panel antenna cable. The

instrument panel antenna cable is routed near the

instrument panel wire harness through the instru-

ment panel to the radio and is secured to the instru-

ment panel structural support with small metal

push-on retainers. This two-piece antenna cable

arrangement allows the instrument panel or the

antenna body and cable to be removed or installed

without disturbing the radio.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ANTENNA

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

The following four tests are used to diagnose the

antenna with an ohmmeter:

²Test 1- Mast to ground test

²Test 2- Tip-of-mast to tip-of-conductor test

²Test 3- Body ground to battery ground test

²Test 4- Body ground to coaxial shield test.

The ohmmeter test lead connections for each test

are shown in Antenna Tests (Fig. 1).

NOTE: This model has a two-piece antenna coaxial

cable. Tests 2 and 4 must be conducted in two

steps to isolate a coaxial cable problem; from the

coaxial cable connection under the right end of the

instrument panel near the right cowl side inner

panel to the antenna base, and then from the coax-

ial cable connection to the radio receiver chassis

connection.

BR/BEAUDIO 8A - 5

ANTENNA BODY & CABLE (Continued)

Page 434 of 2889

²Radio memory presets not working properly

²Volume changes with no remote radio switch

input

²Remote radio switch buttons taking on other

functions

²CD player skipping tracks

²Remote radio switch inoperative.

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

CAUTION: The speaker output of the radio receiver

is a ªfloating groundº system. Do not allow any

speaker lead to short to ground, as damage to the

radio receiver may result.

(1) Check the fused B(+) fuse in the junction block.

If OK, go to Step 2. If not OK, repair the shorted cir-

cuit or component as required and replace the faulty

fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the junction block. If OK, go to Step 3. If not OK,

repair the open fused B(+) circuit to the Power Dis-

tribution Center (PDC) as required.

(3) Check the fused ignition switch output (acc/

run) fuse in the junction block. If OK, go to Step 4. If

not OK, repair the shorted circuit or component as

required and replace the faulty fuse(s).

(4) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (acc/run) fuse in the junction block. If OK, go

to Step 5. If not OK, repair the open fused ignition

switch output (acc/run) circuit to the ignition switch

as required.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the radio receiver from the instrument

panel, but do not disconnect the wire harness connec-

tors. Check for continuity between the radio receiver

chassis and a good ground. There should be continu-

ity. If OK, go to Step 6. If not OK, repair the open

ground circuit to ground as required.(6) Connect the battery negative cable. Turn the

ignition switch to the On position. Check for battery

voltage at the fused ignition switch output (acc/run)

circuit cavity of the left (gray) radio wire harness

connector. If OK, go to Step 7. If not OK, repair the

open fused ignition switch output (acc/run) circuit to

the junction block fuse as required.

(7) Turn the ignition switch to the Off position.

Check for battery voltage at the fused B(+) circuit

cavity of the left (gray) radio wire harness connector.

If OK, replace the faulty radio receiver. If not OK,

repair the open fused B(+) circuit to the junction

block fuse as required.

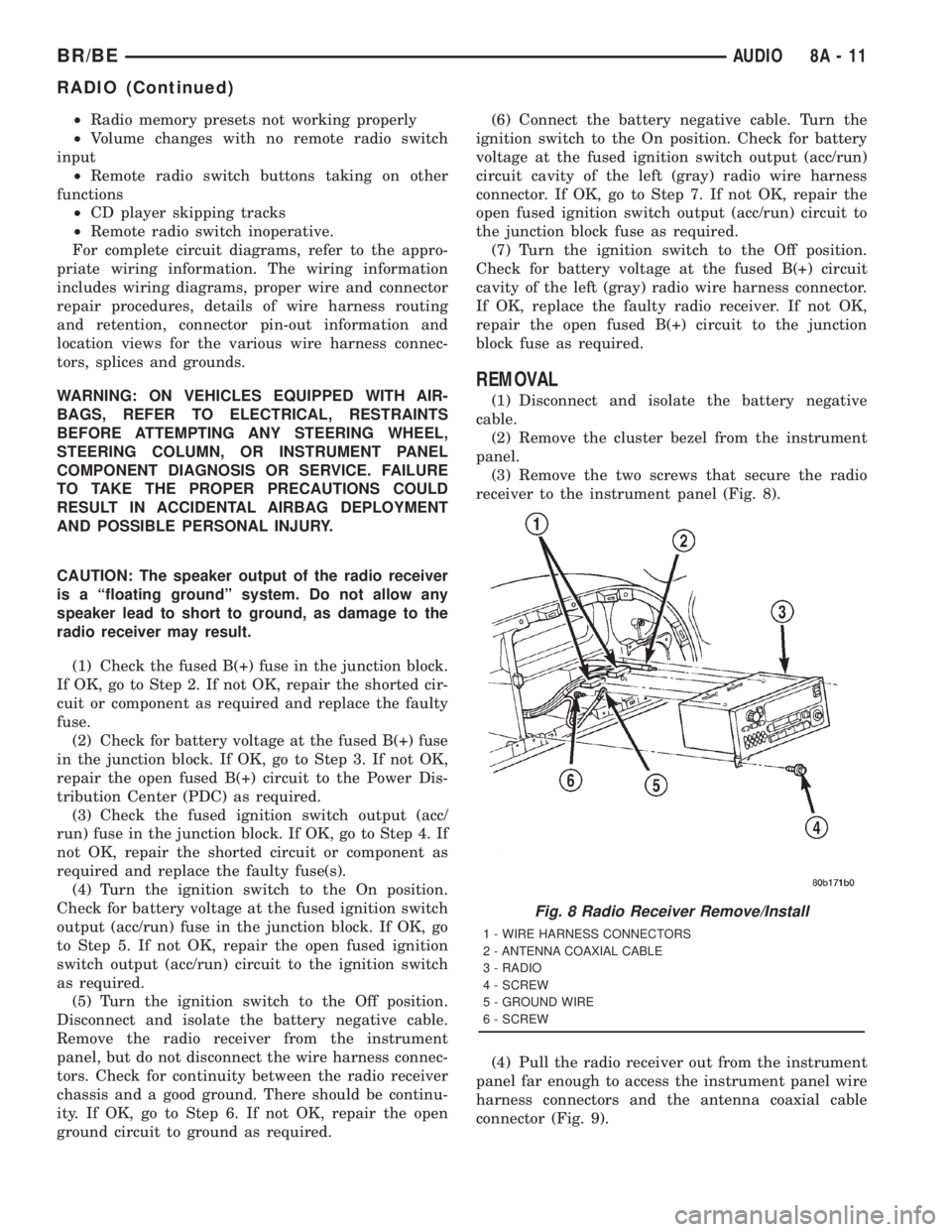

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cluster bezel from the instrument

panel.

(3) Remove the two screws that secure the radio

receiver to the instrument panel (Fig. 8).

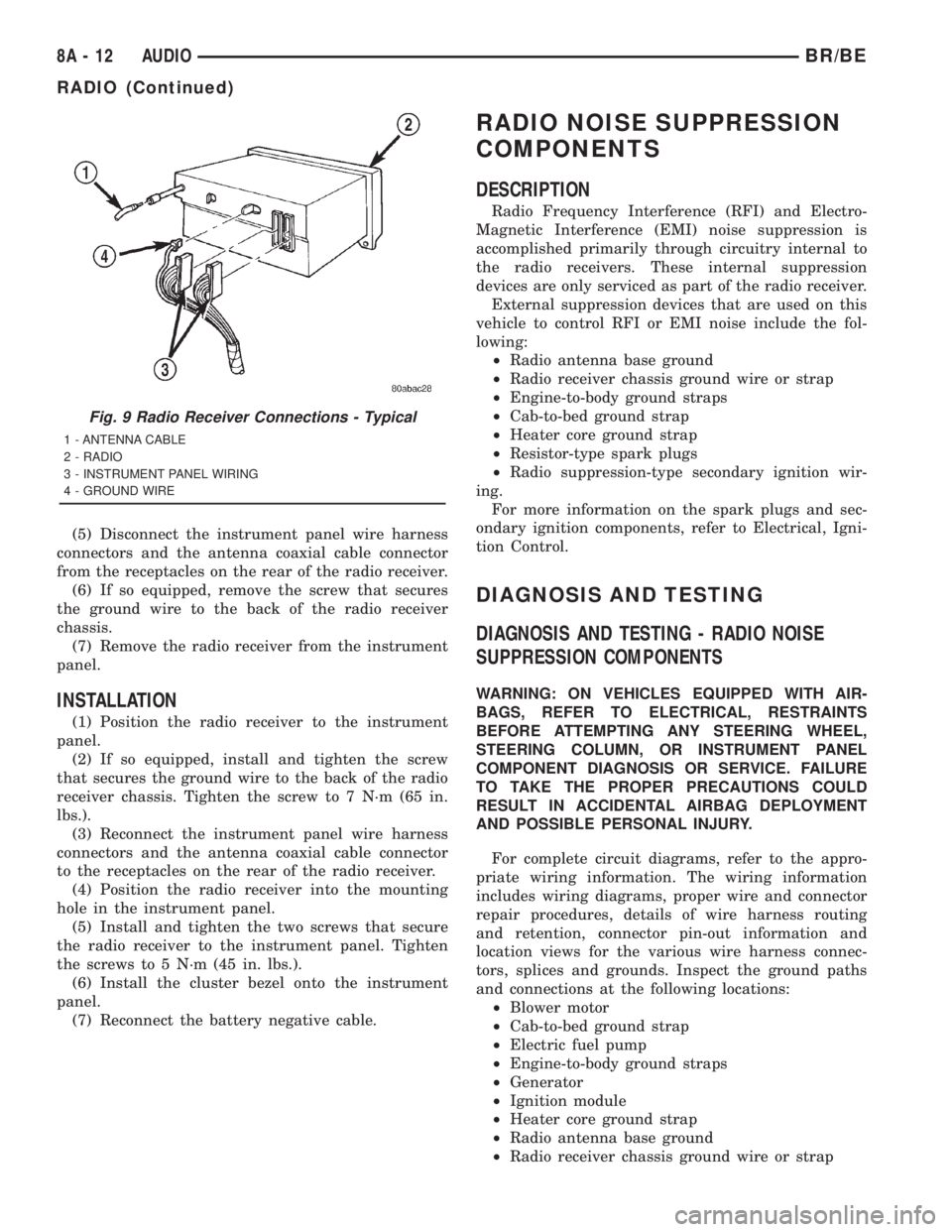

(4) Pull the radio receiver out from the instrument

panel far enough to access the instrument panel wire

harness connectors and the antenna coaxial cable

connector (Fig. 9).

Fig. 8 Radio Receiver Remove/Install

1 - WIRE HARNESS CONNECTORS

2 - ANTENNA COAXIAL CABLE

3 - RADIO

4 - SCREW

5 - GROUND WIRE

6 - SCREW

BR/BEAUDIO 8A - 11

RADIO (Continued)

Page 435 of 2889

(5) Disconnect the instrument panel wire harness

connectors and the antenna coaxial cable connector

from the receptacles on the rear of the radio receiver.

(6) If so equipped, remove the screw that secures

the ground wire to the back of the radio receiver

chassis.

(7) Remove the radio receiver from the instrument

panel.

INSTALLATION

(1) Position the radio receiver to the instrument

panel.

(2) If so equipped, install and tighten the screw

that secures the ground wire to the back of the radio

receiver chassis. Tighten the screw to 7 N´m (65 in.

lbs.).

(3) Reconnect the instrument panel wire harness

connectors and the antenna coaxial cable connector

to the receptacles on the rear of the radio receiver.

(4) Position the radio receiver into the mounting

hole in the instrument panel.

(5) Install and tighten the two screws that secure

the radio receiver to the instrument panel. Tighten

the screws to 5 N´m (45 in. lbs.).

(6) Install the cluster bezel onto the instrument

panel.

(7) Reconnect the battery negative cable.

RADIO NOISE SUPPRESSION

COMPONENTS

DESCRIPTION

Radio Frequency Interference (RFI) and Electro-

Magnetic Interference (EMI) noise suppression is

accomplished primarily through circuitry internal to

the radio receivers. These internal suppression

devices are only serviced as part of the radio receiver.

External suppression devices that are used on this

vehicle to control RFI or EMI noise include the fol-

lowing:

²Radio antenna base ground

²Radio receiver chassis ground wire or strap

²Engine-to-body ground straps

²Cab-to-bed ground strap

²Heater core ground strap

²Resistor-type spark plugs

²Radio suppression-type secondary ignition wir-

ing.

For more information on the spark plugs and sec-

ondary ignition components, refer to Electrical, Igni-

tion Control.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - RADIO NOISE

SUPPRESSION COMPONENTS

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds. Inspect the ground paths

and connections at the following locations:

²Blower motor

²Cab-to-bed ground strap

²Electric fuel pump

²Engine-to-body ground straps

²Generator

²Ignition module

²Heater core ground strap

²Radio antenna base ground

²Radio receiver chassis ground wire or strap

Fig. 9 Radio Receiver Connections - Typical

1 - ANTENNA CABLE

2 - RADIO

3 - INSTRUMENT PANEL WIRING

4 - GROUND WIRE

8A - 12 AUDIOBR/BE

RADIO (Continued)

Page 439 of 2889

manual in the vehicle glove box. For complete circuit

diagrams, refer to the appropriate wiring informa-

tion. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

details of wire harness routing and retention, connec-

tor pin-out information and location views for the

various wire harness connectors, splices and grounds.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - REMOTE

SWITCHES

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

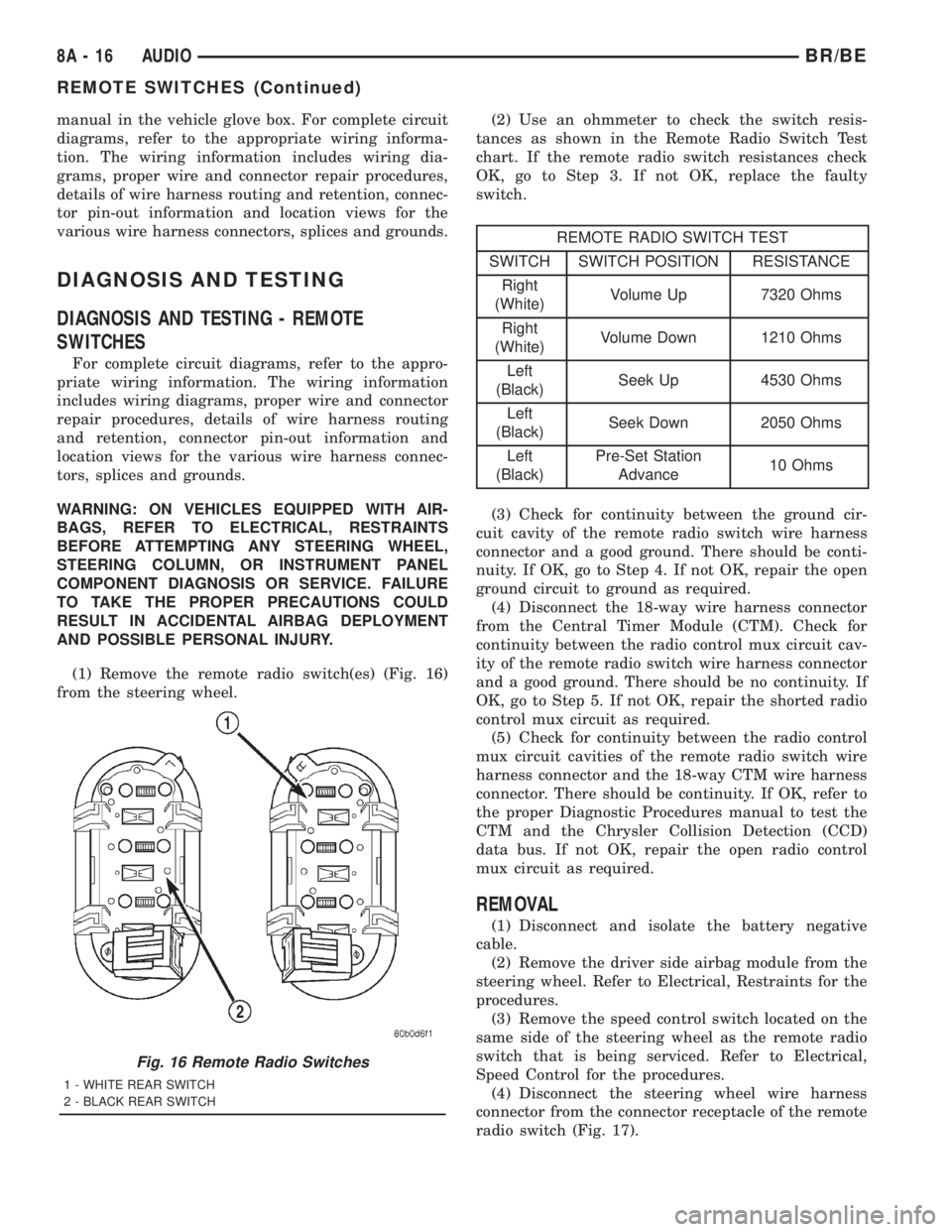

(1) Remove the remote radio switch(es) (Fig. 16)

from the steering wheel.(2) Use an ohmmeter to check the switch resis-

tances as shown in the Remote Radio Switch Test

chart. If the remote radio switch resistances check

OK, go to Step 3. If not OK, replace the faulty

switch.

REMOTE RADIO SWITCH TEST

SWITCH SWITCH POSITION RESISTANCE

Right

(White)Volume Up 7320 Ohms

Right

(White)Volume Down 1210 Ohms

Left

(Black)Seek Up 4530 Ohms

Left

(Black)Seek Down 2050 Ohms

Left

(Black)Pre-Set Station

Advance10 Ohms

(3) Check for continuity between the ground cir-

cuit cavity of the remote radio switch wire harness

connector and a good ground. There should be conti-

nuity. If OK, go to Step 4. If not OK, repair the open

ground circuit to ground as required.

(4) Disconnect the 18-way wire harness connector

from the Central Timer Module (CTM). Check for

continuity between the radio control mux circuit cav-

ity of the remote radio switch wire harness connector

and a good ground. There should be no continuity. If

OK, go to Step 5. If not OK, repair the shorted radio

control mux circuit as required.

(5) Check for continuity between the radio control

mux circuit cavities of the remote radio switch wire

harness connector and the 18-way CTM wire harness

connector. There should be continuity. If OK, refer to

the proper Diagnostic Procedures manual to test the

CTM and the Chrysler Collision Detection (CCD)

data bus. If not OK, repair the open radio control

mux circuit as required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the driver side airbag module from the

steering wheel. Refer to Electrical, Restraints for the

procedures.

(3) Remove the speed control switch located on the

same side of the steering wheel as the remote radio

switch that is being serviced. Refer to Electrical,

Speed Control for the procedures.

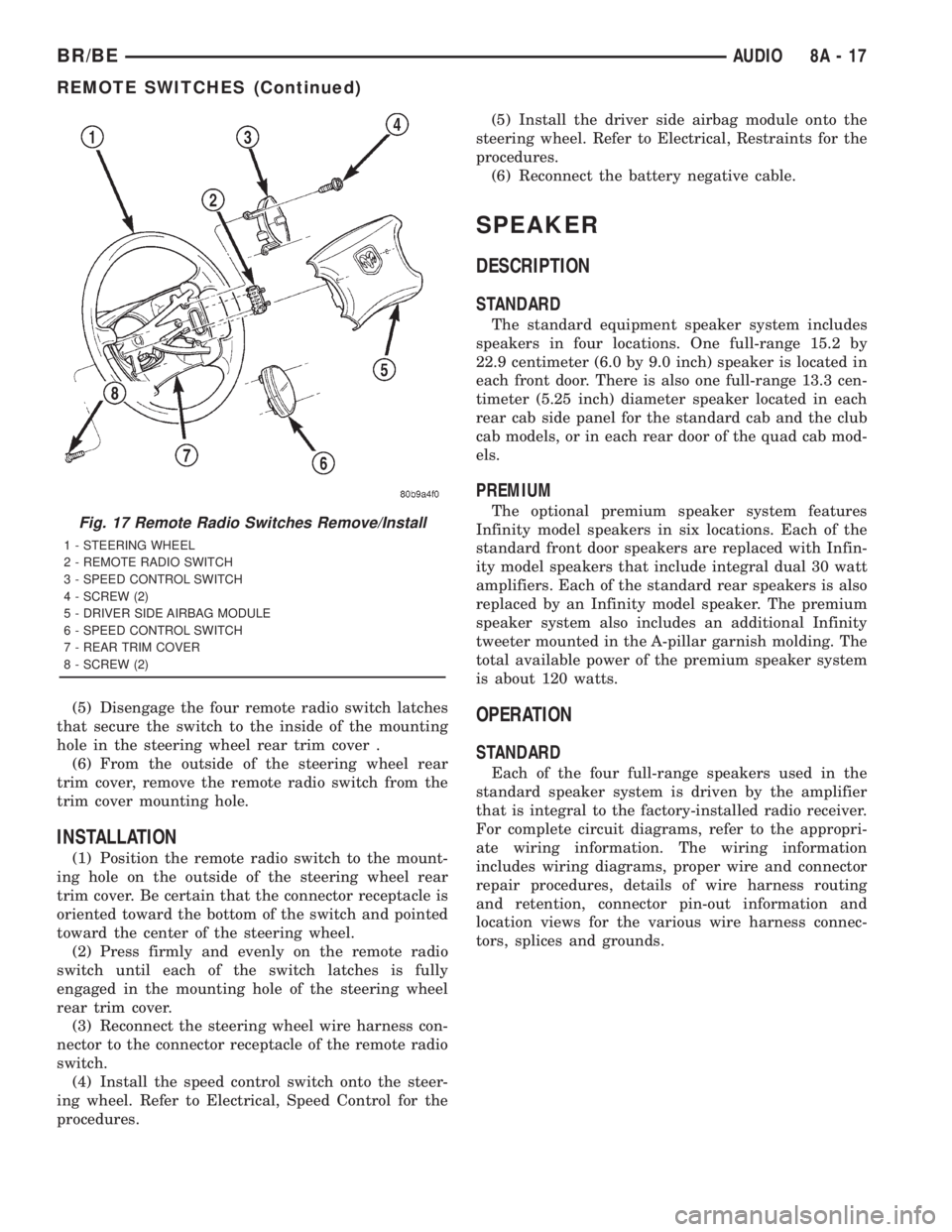

(4) Disconnect the steering wheel wire harness

connector from the connector receptacle of the remote

radio switch (Fig. 17).

Fig. 16 Remote Radio Switches

1 - WHITE REAR SWITCH

2 - BLACK REAR SWITCH

8A - 16 AUDIOBR/BE

REMOTE SWITCHES (Continued)

Page 440 of 2889

(5) Disengage the four remote radio switch latches

that secure the switch to the inside of the mounting

hole in the steering wheel rear trim cover .

(6) From the outside of the steering wheel rear

trim cover, remove the remote radio switch from the

trim cover mounting hole.

INSTALLATION

(1) Position the remote radio switch to the mount-

ing hole on the outside of the steering wheel rear

trim cover. Be certain that the connector receptacle is

oriented toward the bottom of the switch and pointed

toward the center of the steering wheel.

(2) Press firmly and evenly on the remote radio

switch until each of the switch latches is fully

engaged in the mounting hole of the steering wheel

rear trim cover.

(3) Reconnect the steering wheel wire harness con-

nector to the connector receptacle of the remote radio

switch.

(4) Install the speed control switch onto the steer-

ing wheel. Refer to Electrical, Speed Control for the

procedures.(5) Install the driver side airbag module onto the

steering wheel. Refer to Electrical, Restraints for the

procedures.

(6) Reconnect the battery negative cable.

SPEAKER

DESCRIPTION

STANDARD

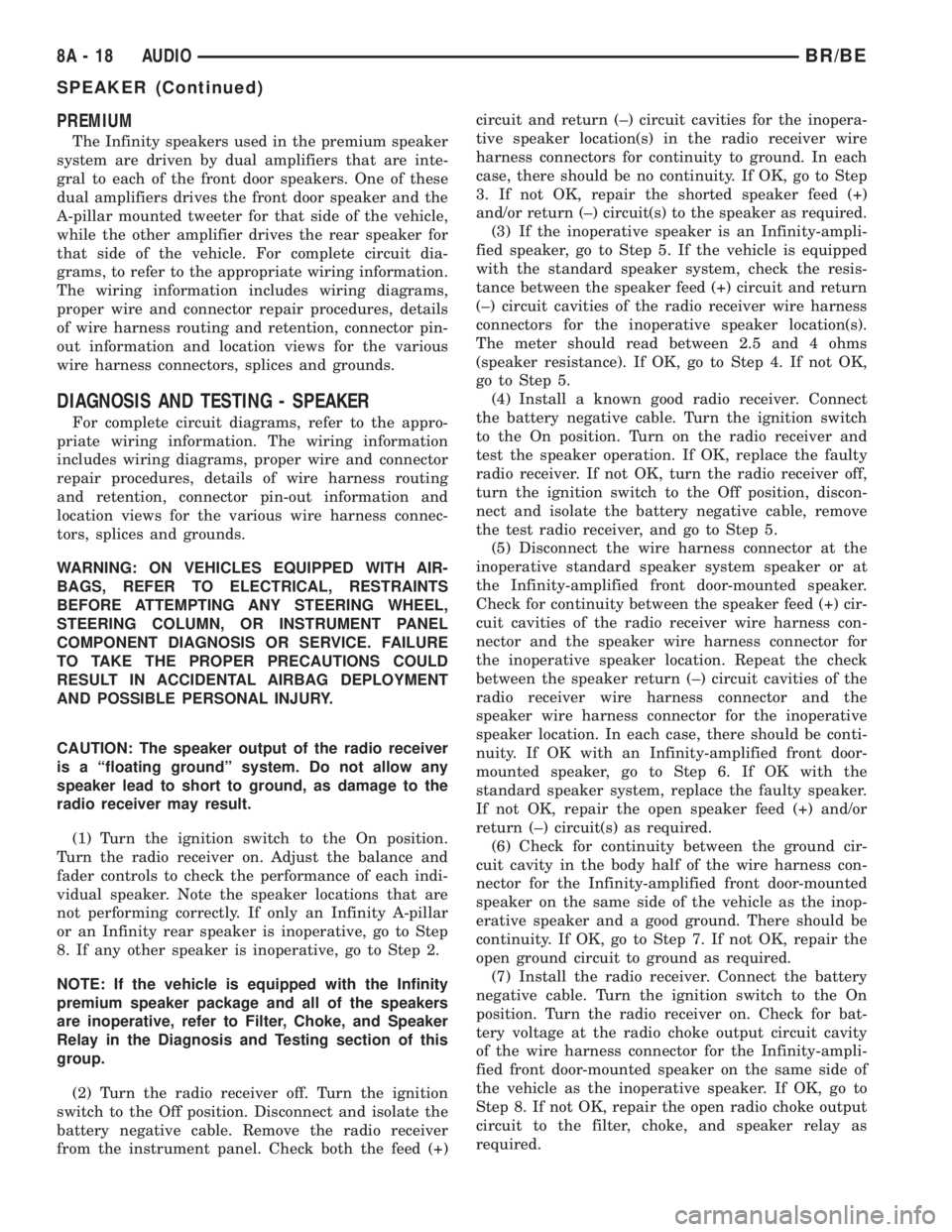

The standard equipment speaker system includes

speakers in four locations. One full-range 15.2 by

22.9 centimeter (6.0 by 9.0 inch) speaker is located in

each front door. There is also one full-range 13.3 cen-

timeter (5.25 inch) diameter speaker located in each

rear cab side panel for the standard cab and the club

cab models, or in each rear door of the quad cab mod-

els.

PREMIUM

The optional premium speaker system features

Infinity model speakers in six locations. Each of the

standard front door speakers are replaced with Infin-

ity model speakers that include integral dual 30 watt

amplifiers. Each of the standard rear speakers is also

replaced by an Infinity model speaker. The premium

speaker system also includes an additional Infinity

tweeter mounted in the A-pillar garnish molding. The

total available power of the premium speaker system

is about 120 watts.

OPERATION

STANDARD

Each of the four full-range speakers used in the

standard speaker system is driven by the amplifier

that is integral to the factory-installed radio receiver.

For complete circuit diagrams, refer to the appropri-

ate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

Fig. 17 Remote Radio Switches Remove/Install

1 - STEERING WHEEL

2 - REMOTE RADIO SWITCH

3 - SPEED CONTROL SWITCH

4 - SCREW (2)

5 - DRIVER SIDE AIRBAG MODULE

6 - SPEED CONTROL SWITCH

7 - REAR TRIM COVER

8 - SCREW (2)

BR/BEAUDIO 8A - 17

REMOTE SWITCHES (Continued)

Page 441 of 2889

PREMIUM

The Infinity speakers used in the premium speaker

system are driven by dual amplifiers that are inte-

gral to each of the front door speakers. One of these

dual amplifiers drives the front door speaker and the

A-pillar mounted tweeter for that side of the vehicle,

while the other amplifier drives the rear speaker for

that side of the vehicle. For complete circuit dia-

grams, to refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, details

of wire harness routing and retention, connector pin-

out information and location views for the various

wire harness connectors, splices and grounds.

DIAGNOSIS AND TESTING - SPEAKER

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

CAUTION: The speaker output of the radio receiver

is a ªfloating groundº system. Do not allow any

speaker lead to short to ground, as damage to the

radio receiver may result.

(1) Turn the ignition switch to the On position.

Turn the radio receiver on. Adjust the balance and

fader controls to check the performance of each indi-

vidual speaker. Note the speaker locations that are

not performing correctly. If only an Infinity A-pillar

or an Infinity rear speaker is inoperative, go to Step

8. If any other speaker is inoperative, go to Step 2.

NOTE: If the vehicle is equipped with the Infinity

premium speaker package and all of the speakers

are inoperative, refer to Filter, Choke, and Speaker

Relay in the Diagnosis and Testing section of this

group.

(2) Turn the radio receiver off. Turn the ignition

switch to the Off position. Disconnect and isolate the

battery negative cable. Remove the radio receiver

from the instrument panel. Check both the feed (+)circuit and return (±) circuit cavities for the inopera-

tive speaker location(s) in the radio receiver wire

harness connectors for continuity to ground. In each

case, there should be no continuity. If OK, go to Step

3. If not OK, repair the shorted speaker feed (+)

and/or return (±) circuit(s) to the speaker as required.

(3) If the inoperative speaker is an Infinity-ampli-

fied speaker, go to Step 5. If the vehicle is equipped

with the standard speaker system, check the resis-

tance between the speaker feed (+) circuit and return

(±) circuit cavities of the radio receiver wire harness

connectors for the inoperative speaker location(s).

The meter should read between 2.5 and 4 ohms

(speaker resistance). If OK, go to Step 4. If not OK,

go to Step 5.

(4) Install a known good radio receiver. Connect

the battery negative cable. Turn the ignition switch

to the On position. Turn on the radio receiver and

test the speaker operation. If OK, replace the faulty

radio receiver. If not OK, turn the radio receiver off,

turn the ignition switch to the Off position, discon-

nect and isolate the battery negative cable, remove

the test radio receiver, and go to Step 5.

(5) Disconnect the wire harness connector at the

inoperative standard speaker system speaker or at

the Infinity-amplified front door-mounted speaker.

Check for continuity between the speaker feed (+) cir-

cuit cavities of the radio receiver wire harness con-

nector and the speaker wire harness connector for

the inoperative speaker location. Repeat the check

between the speaker return (±) circuit cavities of the

radio receiver wire harness connector and the

speaker wire harness connector for the inoperative

speaker location. In each case, there should be conti-

nuity. If OK with an Infinity-amplified front door-

mounted speaker, go to Step 6. If OK with the

standard speaker system, replace the faulty speaker.

If not OK, repair the open speaker feed (+) and/or

return (±) circuit(s) as required.

(6) Check for continuity between the ground cir-

cuit cavity in the body half of the wire harness con-

nector for the Infinity-amplified front door-mounted

speaker on the same side of the vehicle as the inop-

erative speaker and a good ground. There should be

continuity. If OK, go to Step 7. If not OK, repair the

open ground circuit to ground as required.

(7) Install the radio receiver. Connect the battery

negative cable. Turn the ignition switch to the On

position. Turn the radio receiver on. Check for bat-

tery voltage at the radio choke output circuit cavity

of the wire harness connector for the Infinity-ampli-

fied front door-mounted speaker on the same side of

the vehicle as the inoperative speaker. If OK, go to

Step 8. If not OK, repair the open radio choke output

circuit to the filter, choke, and speaker relay as

required.

8A - 18 AUDIOBR/BE

SPEAKER (Continued)

Page 447 of 2889

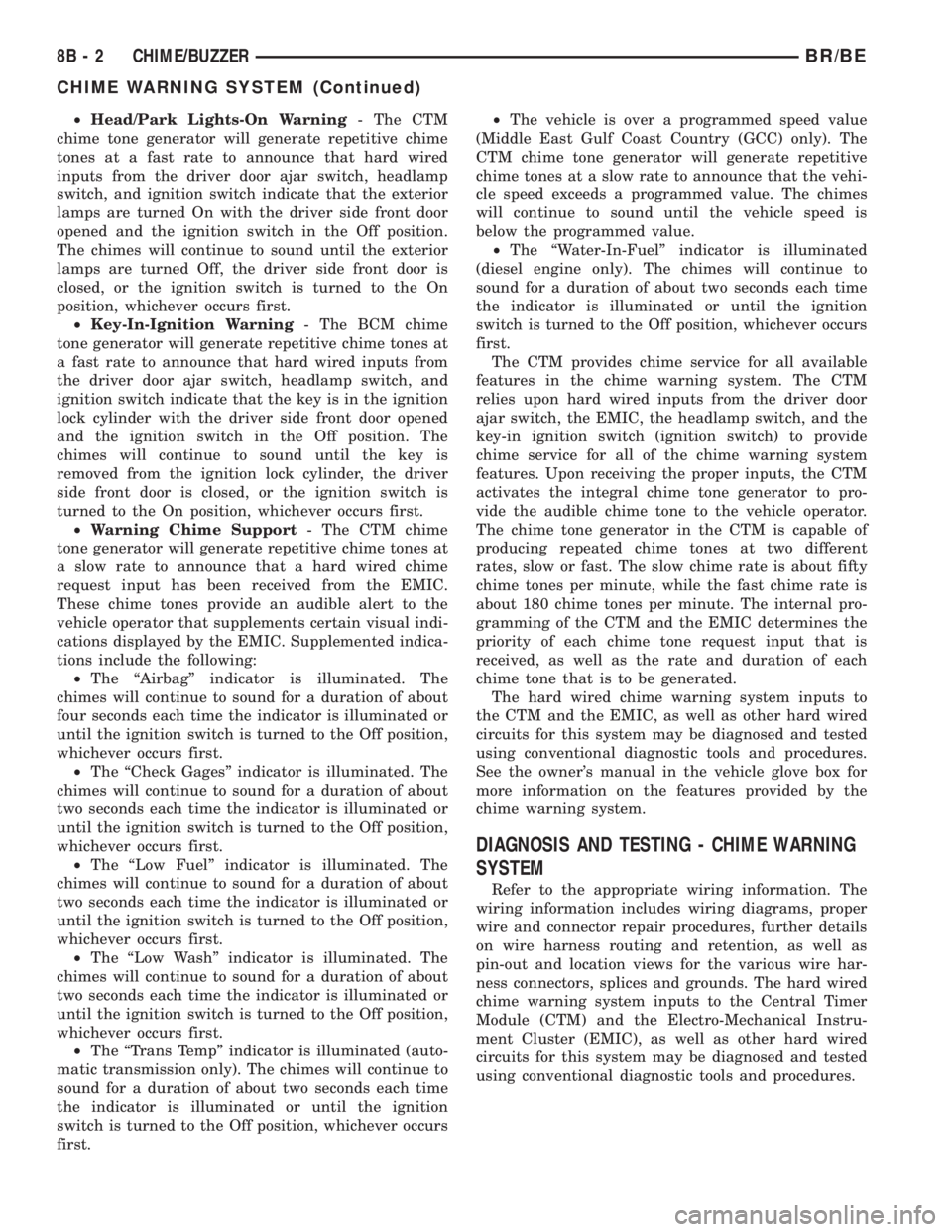

²Head/Park Lights-On Warning- The CTM

chime tone generator will generate repetitive chime

tones at a fast rate to announce that hard wired

inputs from the driver door ajar switch, headlamp

switch, and ignition switch indicate that the exterior

lamps are turned On with the driver side front door

opened and the ignition switch in the Off position.

The chimes will continue to sound until the exterior

lamps are turned Off, the driver side front door is

closed, or the ignition switch is turned to the On

position, whichever occurs first.

²Key-In-Ignition Warning- The BCM chime

tone generator will generate repetitive chime tones at

a fast rate to announce that hard wired inputs from

the driver door ajar switch, headlamp switch, and

ignition switch indicate that the key is in the ignition

lock cylinder with the driver side front door opened

and the ignition switch in the Off position. The

chimes will continue to sound until the key is

removed from the ignition lock cylinder, the driver

side front door is closed, or the ignition switch is

turned to the On position, whichever occurs first.

²Warning Chime Support- The CTM chime

tone generator will generate repetitive chime tones at

a slow rate to announce that a hard wired chime

request input has been received from the EMIC.

These chime tones provide an audible alert to the

vehicle operator that supplements certain visual indi-

cations displayed by the EMIC. Supplemented indica-

tions include the following:

²The ªAirbagº indicator is illuminated. The

chimes will continue to sound for a duration of about

four seconds each time the indicator is illuminated or

until the ignition switch is turned to the Off position,

whichever occurs first.

²The ªCheck Gagesº indicator is illuminated. The

chimes will continue to sound for a duration of about

two seconds each time the indicator is illuminated or

until the ignition switch is turned to the Off position,

whichever occurs first.

²The ªLow Fuelº indicator is illuminated. The

chimes will continue to sound for a duration of about

two seconds each time the indicator is illuminated or

until the ignition switch is turned to the Off position,

whichever occurs first.

²The ªLow Washº indicator is illuminated. The

chimes will continue to sound for a duration of about

two seconds each time the indicator is illuminated or

until the ignition switch is turned to the Off position,

whichever occurs first.

²The ªTrans Tempº indicator is illuminated (auto-

matic transmission only). The chimes will continue to

sound for a duration of about two seconds each time

the indicator is illuminated or until the ignition

switch is turned to the Off position, whichever occurs

first.²The vehicle is over a programmed speed value

(Middle East Gulf Coast Country (GCC) only). The

CTM chime tone generator will generate repetitive

chime tones at a slow rate to announce that the vehi-

cle speed exceeds a programmed value. The chimes

will continue to sound until the vehicle speed is

below the programmed value.

²The ªWater-In-Fuelº indicator is illuminated

(diesel engine only). The chimes will continue to

sound for a duration of about two seconds each time

the indicator is illuminated or until the ignition

switch is turned to the Off position, whichever occurs

first.

The CTM provides chime service for all available

features in the chime warning system. The CTM

relies upon hard wired inputs from the driver door

ajar switch, the EMIC, the headlamp switch, and the

key-in ignition switch (ignition switch) to provide

chime service for all of the chime warning system

features. Upon receiving the proper inputs, the CTM

activates the integral chime tone generator to pro-

vide the audible chime tone to the vehicle operator.

The chime tone generator in the CTM is capable of

producing repeated chime tones at two different

rates, slow or fast. The slow chime rate is about fifty

chime tones per minute, while the fast chime rate is

about 180 chime tones per minute. The internal pro-

gramming of the CTM and the EMIC determines the

priority of each chime tone request input that is

received, as well as the rate and duration of each

chime tone that is to be generated.

The hard wired chime warning system inputs to

the CTM and the EMIC, as well as other hard wired

circuits for this system may be diagnosed and tested

using conventional diagnostic tools and procedures.

See the owner's manual in the vehicle glove box for

more information on the features provided by the

chime warning system.

DIAGNOSIS AND TESTING - CHIME WARNING

SYSTEM

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds. The hard wired

chime warning system inputs to the Central Timer

Module (CTM) and the Electro-Mechanical Instru-

ment Cluster (EMIC), as well as other hard wired

circuits for this system may be diagnosed and tested

using conventional diagnostic tools and procedures.

8B - 2 CHIME/BUZZERBR/BE

CHIME WARNING SYSTEM (Continued)

Page 448 of 2889

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

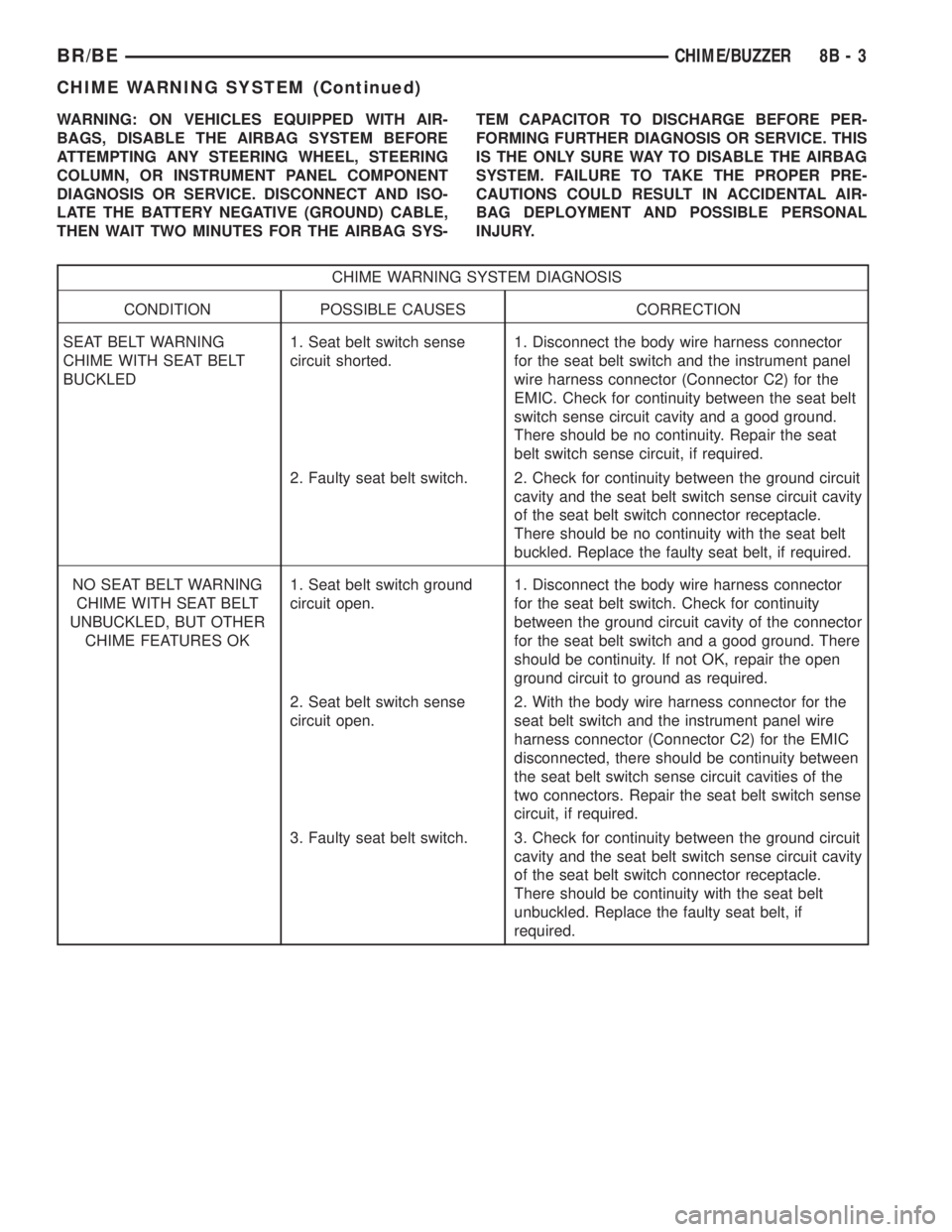

CHIME WARNING SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

SEAT BELT WARNING

CHIME WITH SEAT BELT

BUCKLED1. Seat belt switch sense

circuit shorted.1. Disconnect the body wire harness connector

for the seat belt switch and the instrument panel

wire harness connector (Connector C2) for the

EMIC. Check for continuity between the seat belt

switch sense circuit cavity and a good ground.

There should be no continuity. Repair the seat

belt switch sense circuit, if required.

2. Faulty seat belt switch. 2. Check for continuity between the ground circuit

cavity and the seat belt switch sense circuit cavity

of the seat belt switch connector receptacle.

There should be no continuity with the seat belt

buckled. Replace the faulty seat belt, if required.

NO SEAT BELT WARNING

CHIME WITH SEAT BELT

UNBUCKLED, BUT OTHER

CHIME FEATURES OK1. Seat belt switch ground

circuit open.1. Disconnect the body wire harness connector

for the seat belt switch. Check for continuity

between the ground circuit cavity of the connector

for the seat belt switch and a good ground. There

should be continuity. If not OK, repair the open

ground circuit to ground as required.

2. Seat belt switch sense

circuit open.2. With the body wire harness connector for the

seat belt switch and the instrument panel wire

harness connector (Connector C2) for the EMIC

disconnected, there should be continuity between

the seat belt switch sense circuit cavities of the

two connectors. Repair the seat belt switch sense

circuit, if required.

3. Faulty seat belt switch. 3. Check for continuity between the ground circuit

cavity and the seat belt switch sense circuit cavity

of the seat belt switch connector receptacle.

There should be continuity with the seat belt

unbuckled. Replace the faulty seat belt, if

required.

BR/BECHIME/BUZZER 8B - 3

CHIME WARNING SYSTEM (Continued)

Page 455 of 2889

²Horn relay control - high-line/premium version

only

²VTSS indicator driver - high-line/premium ver-

sion only

²Wiper motor relay control

MESSAGING

The high-line/premium CTM uses the following

messages received from other electronic modules over

the CCD data bus:

²Airbag Deploy (ACM)

²Charging System Failure (PCM)

²Engine RPM (PCM)

²System Voltage (PCM)

²Vehicle Speed (PCM)

²Voltage Fault (PCM)

The high-line/premium CTM provides the following

messages to other electronic modules over the CCD

data bus:

²Engine Enable (PCM)

²Radio Seek Up (Radio)

²Radio Seek Down (Radio)

²Radio Volume Up (Radio)

²Radio Volume Down (Radio)

²Preset Scan (Radio)

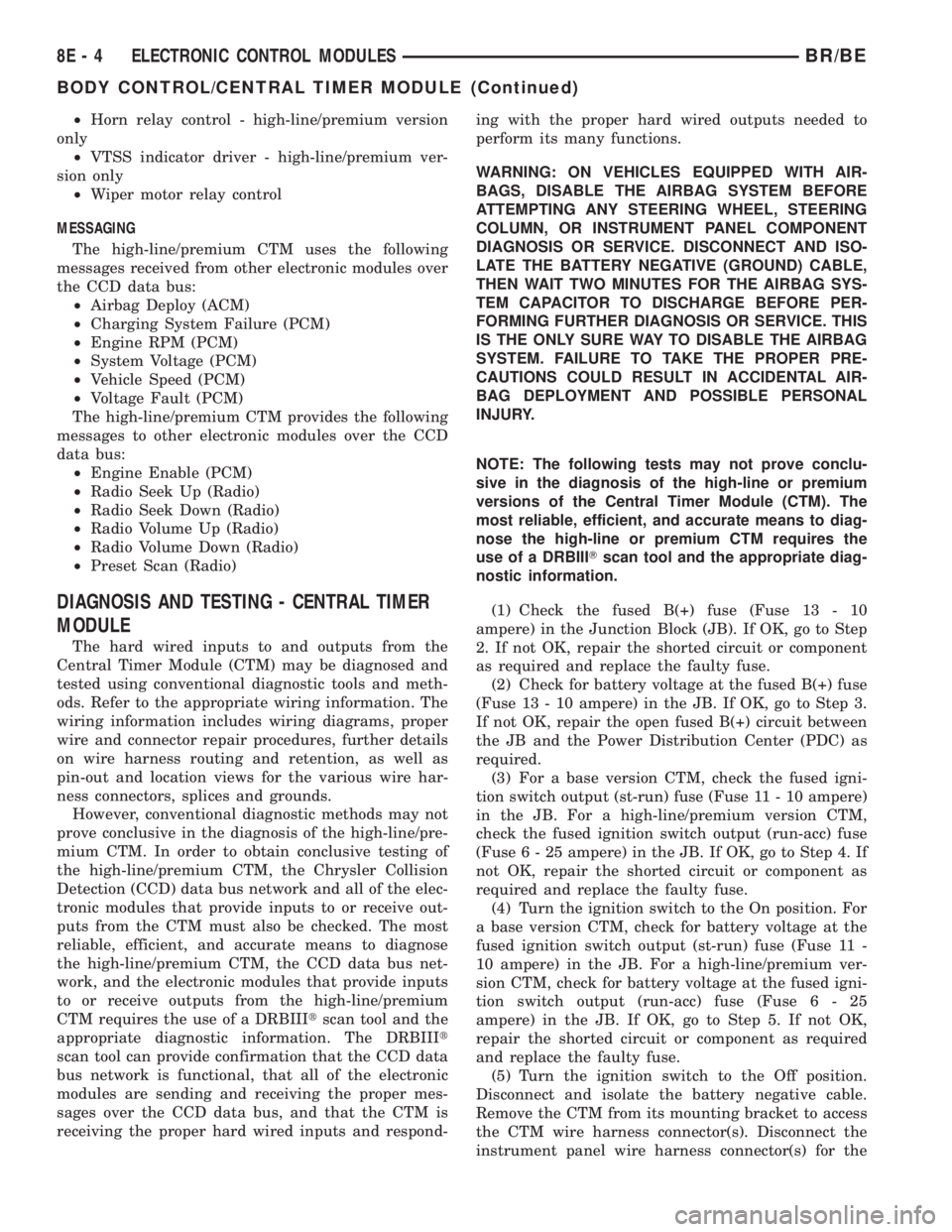

DIAGNOSIS AND TESTING - CENTRAL TIMER

MODULE

The hard wired inputs to and outputs from the

Central Timer Module (CTM) may be diagnosed and

tested using conventional diagnostic tools and meth-

ods. Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds.

However, conventional diagnostic methods may not

prove conclusive in the diagnosis of the high-line/pre-

mium CTM. In order to obtain conclusive testing of

the high-line/premium CTM, the Chrysler Collision

Detection (CCD) data bus network and all of the elec-

tronic modules that provide inputs to or receive out-

puts from the CTM must also be checked. The most

reliable, efficient, and accurate means to diagnose

the high-line/premium CTM, the CCD data bus net-

work, and the electronic modules that provide inputs

to or receive outputs from the high-line/premium

CTM requires the use of a DRBIIItscan tool and the

appropriate diagnostic information. The DRBIIIt

scan tool can provide confirmation that the CCD data

bus network is functional, that all of the electronic

modules are sending and receiving the proper mes-

sages over the CCD data bus, and that the CTM is

receiving the proper hard wired inputs and respond-ing with the proper hard wired outputs needed to

perform its many functions.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: The following tests may not prove conclu-

sive in the diagnosis of the high-line or premium

versions of the Central Timer Module (CTM). The

most reliable, efficient, and accurate means to diag-

nose the high-line or premium CTM requires the

use of a DRBIIITscan tool and the appropriate diag-

nostic information.

(1) Check the fused B(+) fuse (Fuse 13 - 10

ampere) in the Junction Block (JB). If OK, go to Step

2. If not OK, repair the shorted circuit or component

as required and replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

(Fuse 13 - 10 ampere) in the JB. If OK, go to Step 3.

If not OK, repair the open fused B(+) circuit between

the JB and the Power Distribution Center (PDC) as

required.

(3) For a base version CTM, check the fused igni-

tion switch output (st-run) fuse (Fuse 11 - 10 ampere)

in the JB. For a high-line/premium version CTM,

check the fused ignition switch output (run-acc) fuse

(Fuse6-25ampere) in the JB. If OK, go to Step 4. If

not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(4) Turn the ignition switch to the On position. For

a base version CTM, check for battery voltage at the

fused ignition switch output (st-run) fuse (Fuse 11 -

10 ampere) in the JB. For a high-line/premium ver-

sion CTM, check for battery voltage at the fused igni-

tion switch output (run-acc) fuse (Fuse6-25

ampere) in the JB. If OK, go to Step 5. If not OK,

repair the shorted circuit or component as required

and replace the faulty fuse.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the CTM from its mounting bracket to access

the CTM wire harness connector(s). Disconnect the

instrument panel wire harness connector(s) for the

8E - 4 ELECTRONIC CONTROL MODULESBR/BE

BODY CONTROL/CENTRAL TIMER MODULE (Continued)