boot DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 82 of 2889

PROPELLER SHAFT - REAR

REMOVAL

(1) Raise and support vehicle on safety stands.

(2) Shift the transmission to the Neutral position.

(3) Using a suitable marker, mark a line across

the axle pinion yoke, or companion flange, and the

propeller shaft, or flange yoke for installation refer-

ence.

(4) Using a suitable marker, mark the outline of

the center bearing on the frame crossmember for

installation reference, if equipped.

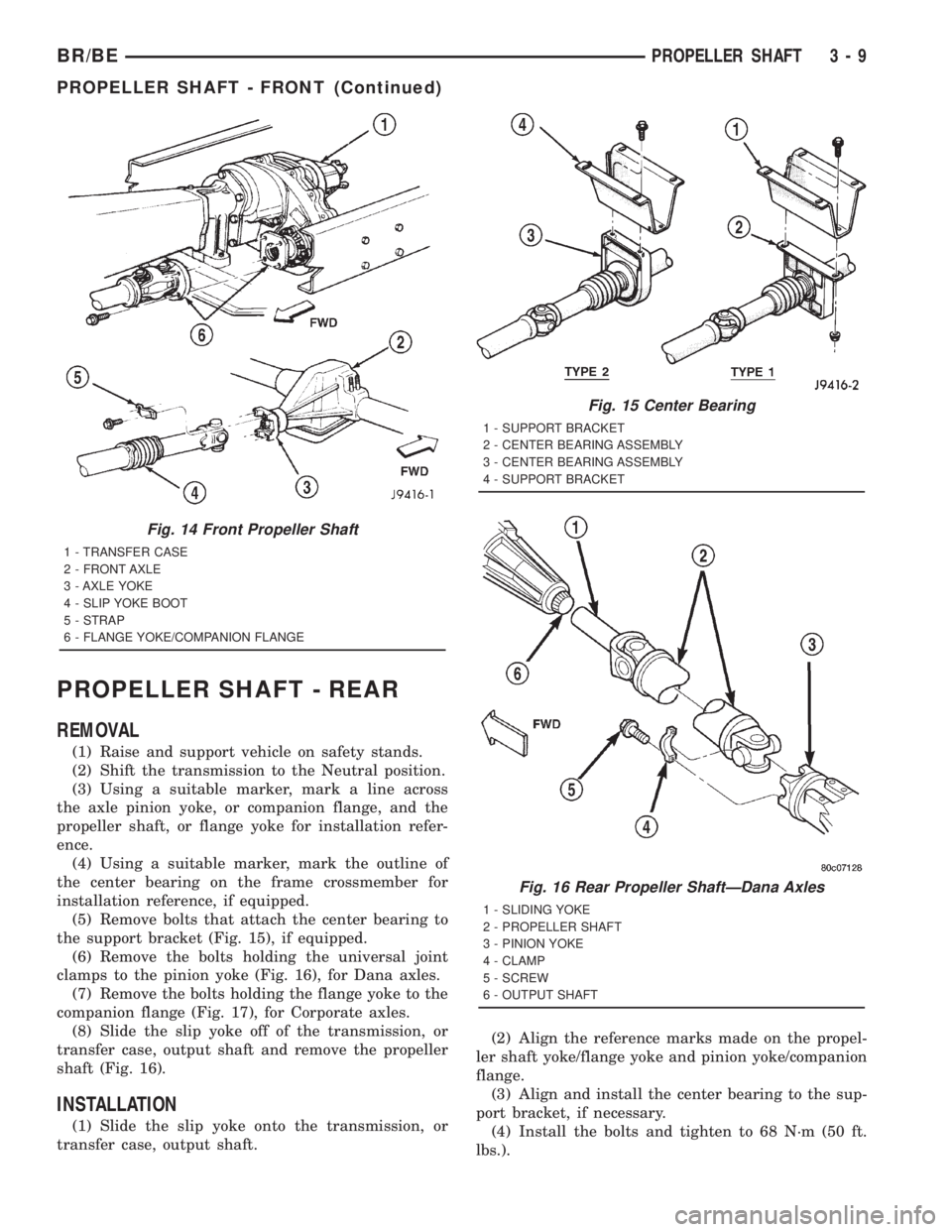

(5) Remove bolts that attach the center bearing to

the support bracket (Fig. 15), if equipped.

(6) Remove the bolts holding the universal joint

clamps to the pinion yoke (Fig. 16), for Dana axles.

(7) Remove the bolts holding the flange yoke to the

companion flange (Fig. 17), for Corporate axles.

(8) Slide the slip yoke off of the transmission, or

transfer case, output shaft and remove the propeller

shaft (Fig. 16).

INSTALLATION

(1) Slide the slip yoke onto the transmission, or

transfer case, output shaft.(2) Align the reference marks made on the propel-

ler shaft yoke/flange yoke and pinion yoke/companion

flange.

(3) Align and install the center bearing to the sup-

port bracket, if necessary.

(4) Install the bolts and tighten to 68 N´m (50 ft.

lbs.).

Fig. 14 Front Propeller Shaft

1 - TRANSFER CASE

2 - FRONT AXLE

3 - AXLE YOKE

4 - SLIP YOKE BOOT

5 - STRAP

6 - FLANGE YOKE/COMPANION FLANGE

Fig. 15 Center Bearing

1 - SUPPORT BRACKET

2 - CENTER BEARING ASSEMBLY

3 - CENTER BEARING ASSEMBLY

4 - SUPPORT BRACKET

Fig. 16 Rear Propeller ShaftÐDana Axles

1 - SLIDING YOKE

2 - PROPELLER SHAFT

3 - PINION YOKE

4 - CLAMP

5 - SCREW

6 - OUTPUT SHAFT

BR/BEPROPELLER SHAFT 3 - 9

PROPELLER SHAFT - FRONT (Continued)

Page 83 of 2889

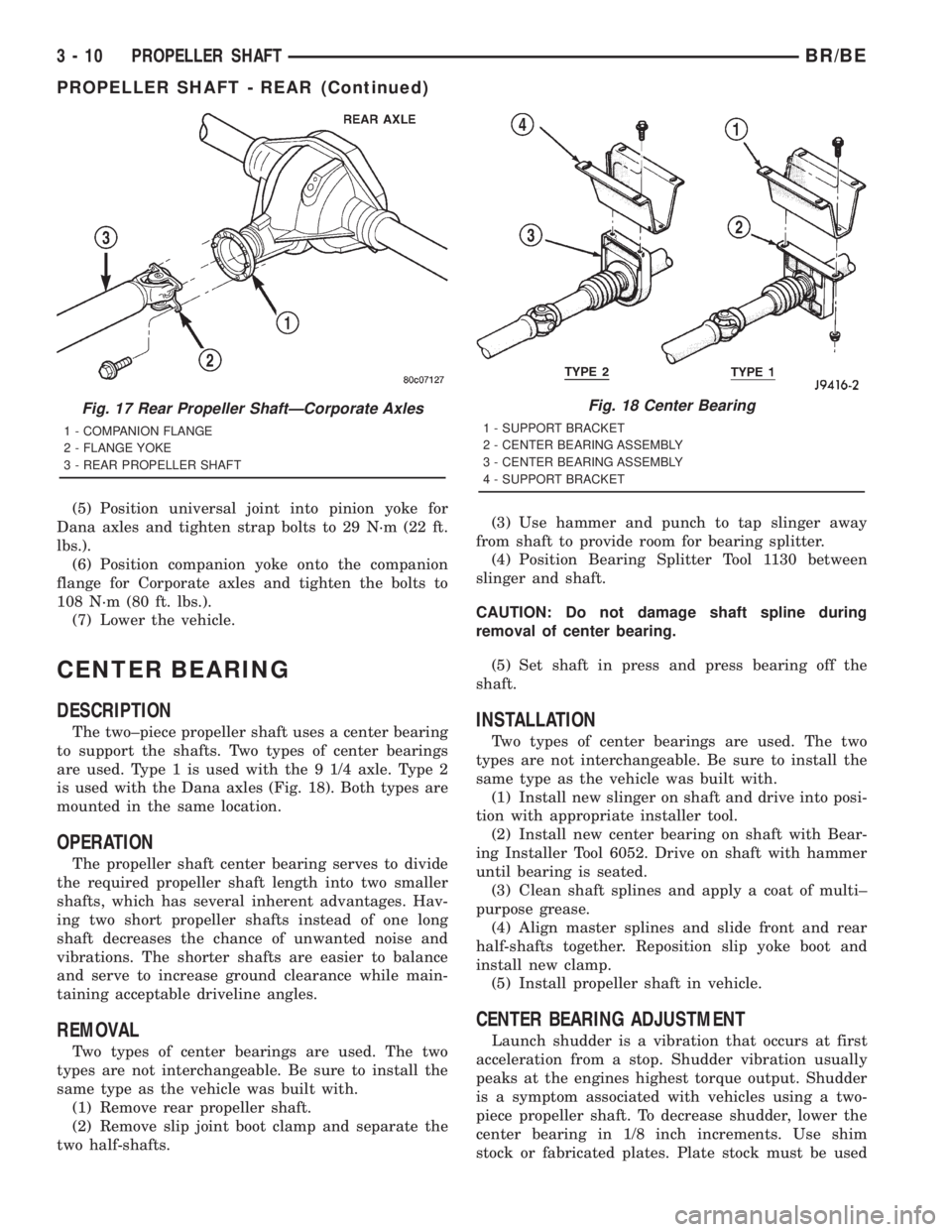

(5) Position universal joint into pinion yoke for

Dana axles and tighten strap bolts to 29 N´m (22 ft.

lbs.).

(6) Position companion yoke onto the companion

flange for Corporate axles and tighten the bolts to

108 N´m (80 ft. lbs.).

(7) Lower the vehicle.

CENTER BEARING

DESCRIPTION

The two±piece propeller shaft uses a center bearing

to support the shafts. Two types of center bearings

are used. Type 1 is used with the 9 1/4 axle. Type 2

is used with the Dana axles (Fig. 18). Both types are

mounted in the same location.

OPERATION

The propeller shaft center bearing serves to divide

the required propeller shaft length into two smaller

shafts, which has several inherent advantages. Hav-

ing two short propeller shafts instead of one long

shaft decreases the chance of unwanted noise and

vibrations. The shorter shafts are easier to balance

and serve to increase ground clearance while main-

taining acceptable driveline angles.

REMOVAL

Two types of center bearings are used. The two

types are not interchangeable. Be sure to install the

same type as the vehicle was built with.

(1) Remove rear propeller shaft.

(2) Remove slip joint boot clamp and separate the

two half-shafts.(3) Use hammer and punch to tap slinger away

from shaft to provide room for bearing splitter.

(4) Position Bearing Splitter Tool 1130 between

slinger and shaft.

CAUTION: Do not damage shaft spline during

removal of center bearing.

(5) Set shaft in press and press bearing off the

shaft.

INSTALLATION

Two types of center bearings are used. The two

types are not interchangeable. Be sure to install the

same type as the vehicle was built with.

(1) Install new slinger on shaft and drive into posi-

tion with appropriate installer tool.

(2) Install new center bearing on shaft with Bear-

ing Installer Tool 6052. Drive on shaft with hammer

until bearing is seated.

(3) Clean shaft splines and apply a coat of multi±

purpose grease.

(4) Align master splines and slide front and rear

half-shafts together. Reposition slip yoke boot and

install new clamp.

(5) Install propeller shaft in vehicle.

CENTER BEARING ADJUSTMENT

Launch shudder is a vibration that occurs at first

acceleration from a stop. Shudder vibration usually

peaks at the engines highest torque output. Shudder

is a symptom associated with vehicles using a two-

piece propeller shaft. To decrease shudder, lower the

center bearing in 1/8 inch increments. Use shim

stock or fabricated plates. Plate stock must be used

Fig. 17 Rear Propeller ShaftÐCorporate Axles

1 - COMPANION FLANGE

2 - FLANGE YOKE

3 - REAR PROPELLER SHAFT

Fig. 18 Center Bearing

1 - SUPPORT BRACKET

2 - CENTER BEARING ASSEMBLY

3 - CENTER BEARING ASSEMBLY

4 - SUPPORT BRACKET

3 - 10 PROPELLER SHAFTBR/BE

PROPELLER SHAFT - REAR (Continued)

Page 275 of 2889

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Park Brake Pedal

Assembly

Mounting Bolts/Nuts28 21 250

Hub/Bearing

LD 4x2 Spindle Nut251 185 Ð

Hub/Bearing

HD 4x2 Spindle Nut380 280 Ð

Hub/Bearing

4x4 Hub/Bearing Bolts170 125 Ð

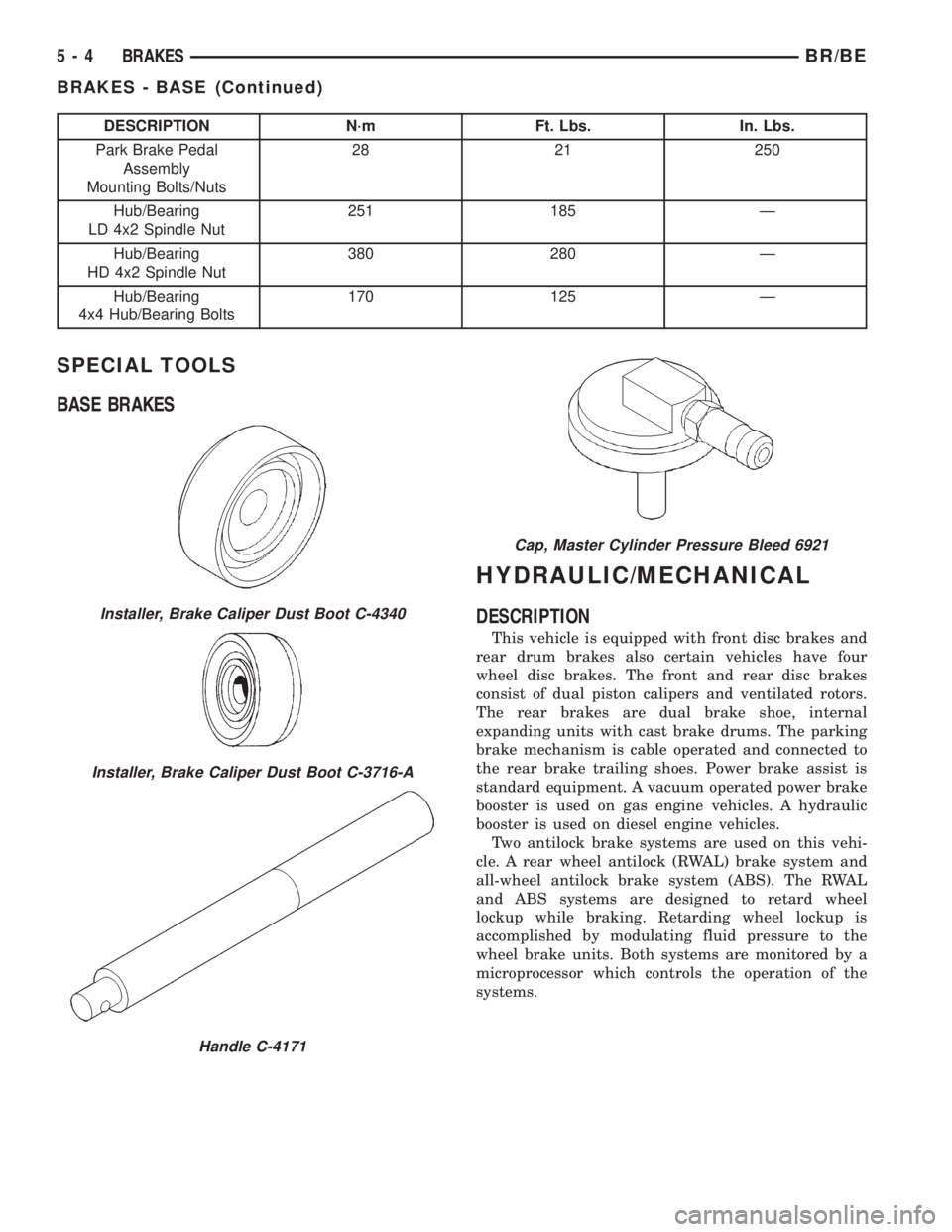

SPECIAL TOOLS

BASE BRAKES

HYDRAULIC/MECHANICAL

DESCRIPTION

This vehicle is equipped with front disc brakes and

rear drum brakes also certain vehicles have four

wheel disc brakes. The front and rear disc brakes

consist of dual piston calipers and ventilated rotors.

The rear brakes are dual brake shoe, internal

expanding units with cast brake drums. The parking

brake mechanism is cable operated and connected to

the rear brake trailing shoes. Power brake assist is

standard equipment. A vacuum operated power brake

booster is used on gas engine vehicles. A hydraulic

booster is used on diesel engine vehicles.

Two antilock brake systems are used on this vehi-

cle. A rear wheel antilock (RWAL) brake system and

all-wheel antilock brake system (ABS). The RWAL

and ABS systems are designed to retard wheel

lockup while braking. Retarding wheel lockup is

accomplished by modulating fluid pressure to the

wheel brake units. Both systems are monitored by a

microprocessor which controls the operation of the

systems.

Installer, Brake Caliper Dust Boot C-4340

Installer, Brake Caliper Dust Boot C-3716-A

Handle C-4171

Cap, Master Cylinder Pressure Bleed 6921

5 - 4 BRAKESBR/BE

BRAKES - BASE (Continued)

Page 282 of 2889

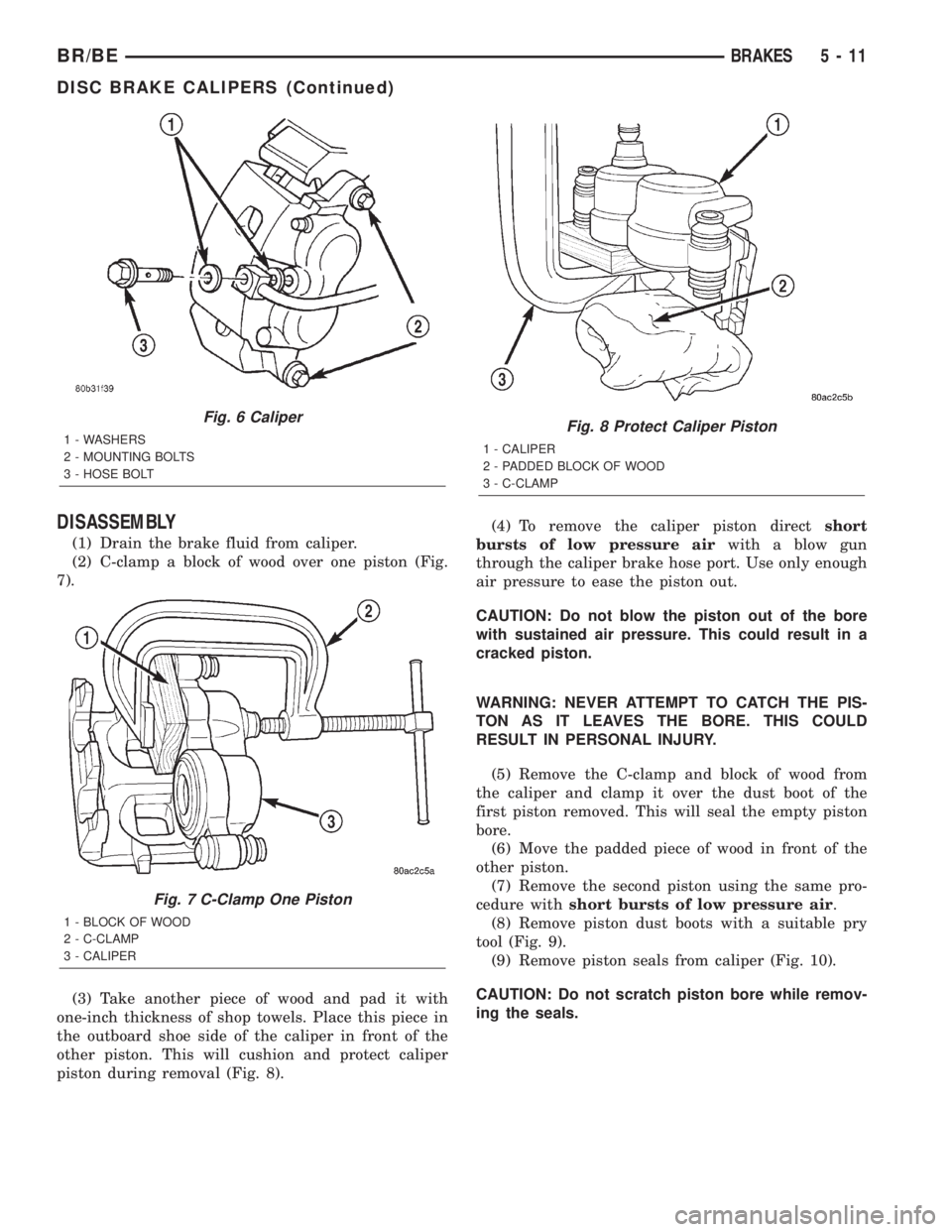

DISASSEMBLY

(1) Drain the brake fluid from caliper.

(2) C-clamp a block of wood over one piston (Fig.

7).

(3) Take another piece of wood and pad it with

one-inch thickness of shop towels. Place this piece in

the outboard shoe side of the caliper in front of the

other piston. This will cushion and protect caliper

piston during removal (Fig. 8).(4) To remove the caliper piston directshort

bursts of low pressure airwith a blow gun

through the caliper brake hose port. Use only enough

air pressure to ease the piston out.

CAUTION: Do not blow the piston out of the bore

with sustained air pressure. This could result in a

cracked piston.

WARNING: NEVER ATTEMPT TO CATCH THE PIS-

TON AS IT LEAVES THE BORE. THIS COULD

RESULT IN PERSONAL INJURY.

(5) Remove the C-clamp and block of wood from

the caliper and clamp it over the dust boot of the

first piston removed. This will seal the empty piston

bore.

(6) Move the padded piece of wood in front of the

other piston.

(7) Remove the second piston using the same pro-

cedure withshort bursts of low pressure air.

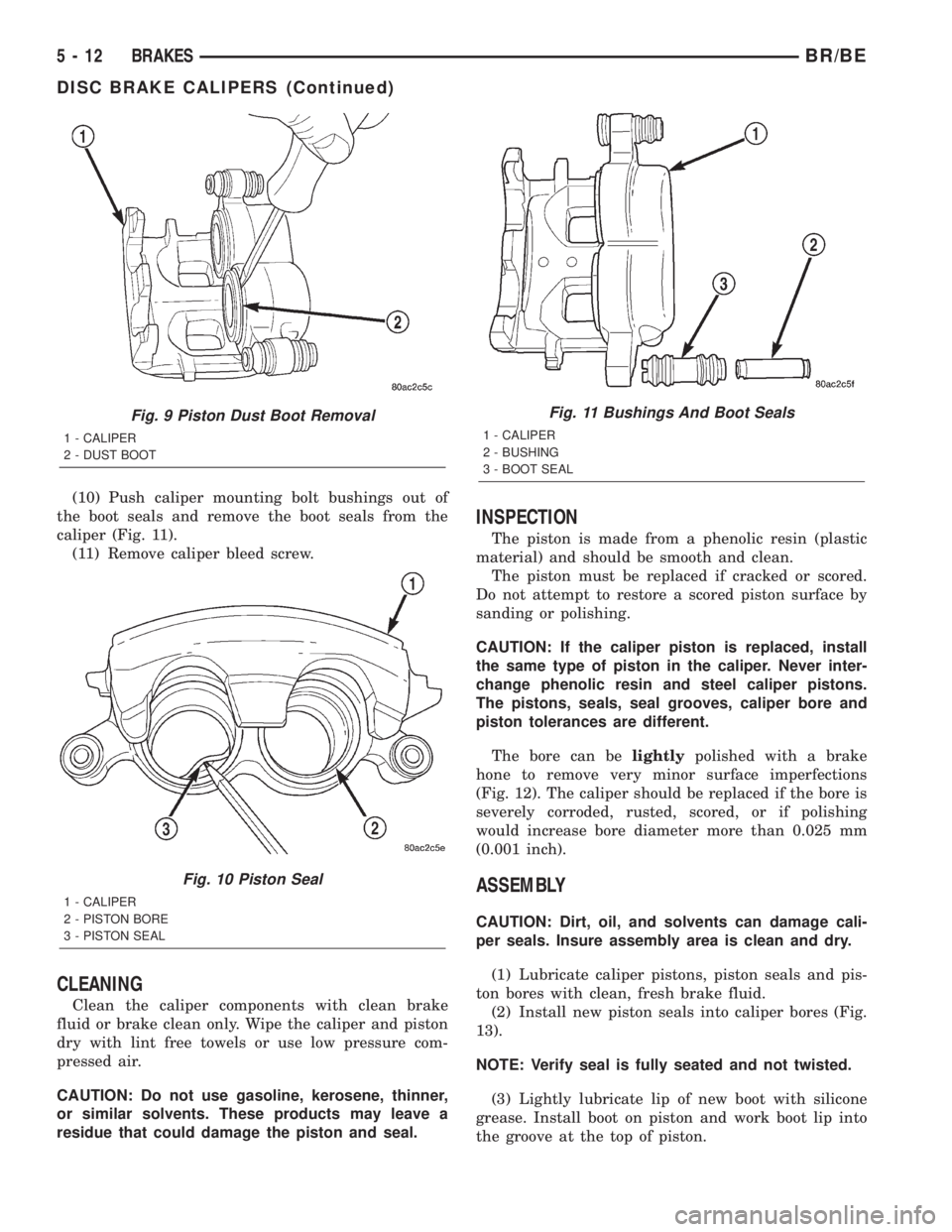

(8) Remove piston dust boots with a suitable pry

tool (Fig. 9).

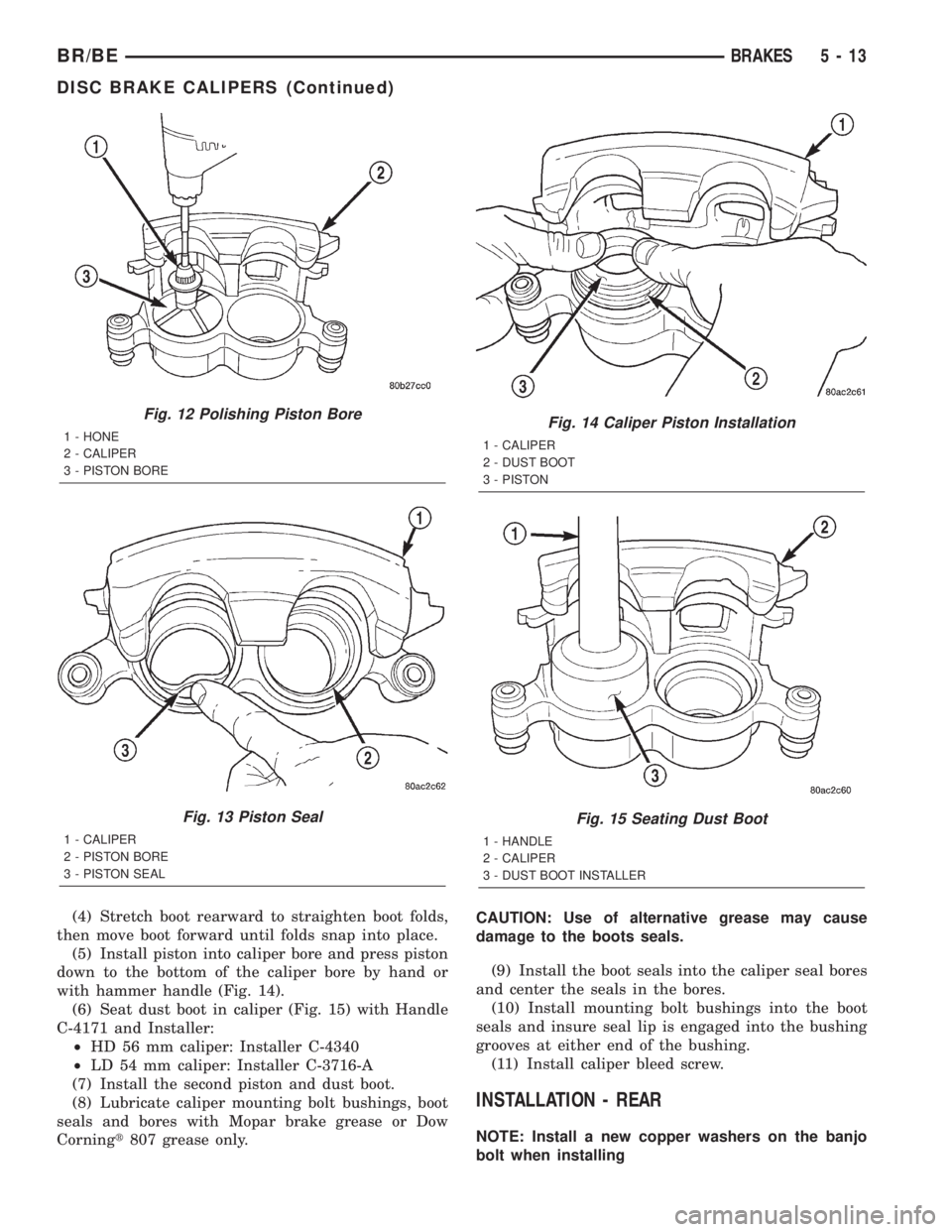

(9) Remove piston seals from caliper (Fig. 10).

CAUTION: Do not scratch piston bore while remov-

ing the seals.

Fig. 6 Caliper

1 - WASHERS

2 - MOUNTING BOLTS

3 - HOSE BOLT

Fig. 7 C-Clamp One Piston

1 - BLOCK OF WOOD

2 - C-CLAMP

3 - CALIPER

Fig. 8 Protect Caliper Piston

1 - CALIPER

2 - PADDED BLOCK OF WOOD

3 - C-CLAMP

BR/BEBRAKES 5 - 11

DISC BRAKE CALIPERS (Continued)

Page 283 of 2889

(10) Push caliper mounting bolt bushings out of

the boot seals and remove the boot seals from the

caliper (Fig. 11).

(11) Remove caliper bleed screw.

CLEANING

Clean the caliper components with clean brake

fluid or brake clean only. Wipe the caliper and piston

dry with lint free towels or use low pressure com-

pressed air.

CAUTION: Do not use gasoline, kerosene, thinner,

or similar solvents. These products may leave a

residue that could damage the piston and seal.

INSPECTION

The piston is made from a phenolic resin (plastic

material) and should be smooth and clean.

The piston must be replaced if cracked or scored.

Do not attempt to restore a scored piston surface by

sanding or polishing.

CAUTION: If the caliper piston is replaced, install

the same type of piston in the caliper. Never inter-

change phenolic resin and steel caliper pistons.

The pistons, seals, seal grooves, caliper bore and

piston tolerances are different.

The bore can belightlypolished with a brake

hone to remove very minor surface imperfections

(Fig. 12). The caliper should be replaced if the bore is

severely corroded, rusted, scored, or if polishing

would increase bore diameter more than 0.025 mm

(0.001 inch).

ASSEMBLY

CAUTION: Dirt, oil, and solvents can damage cali-

per seals. Insure assembly area is clean and dry.

(1) Lubricate caliper pistons, piston seals and pis-

ton bores with clean, fresh brake fluid.

(2) Install new piston seals into caliper bores (Fig.

13).

NOTE: Verify seal is fully seated and not twisted.

(3) Lightly lubricate lip of new boot with silicone

grease. Install boot on piston and work boot lip into

the groove at the top of piston.

Fig. 9 Piston Dust Boot Removal

1 - CALIPER

2 - DUST BOOT

Fig. 10 Piston Seal

1 - CALIPER

2 - PISTON BORE

3 - PISTON SEAL

Fig. 11 Bushings And Boot Seals

1 - CALIPER

2 - BUSHING

3 - BOOT SEAL

5 - 12 BRAKESBR/BE

DISC BRAKE CALIPERS (Continued)

Page 284 of 2889

(4) Stretch boot rearward to straighten boot folds,

then move boot forward until folds snap into place.

(5) Install piston into caliper bore and press piston

down to the bottom of the caliper bore by hand or

with hammer handle (Fig. 14).

(6) Seat dust boot in caliper (Fig. 15) with Handle

C-4171 and Installer:

²HD 56 mm caliper: Installer C-4340

²LD 54 mm caliper: Installer C-3716-A

(7) Install the second piston and dust boot.

(8) Lubricate caliper mounting bolt bushings, boot

seals and bores with Mopar brake grease or Dow

Corningt807 grease only.CAUTION: Use of alternative grease may cause

damage to the boots seals.

(9) Install the boot seals into the caliper seal bores

and center the seals in the bores.

(10) Install mounting bolt bushings into the boot

seals and insure seal lip is engaged into the bushing

grooves at either end of the bushing.

(11) Install caliper bleed screw.

INSTALLATION - REAR

NOTE: Install a new copper washers on the banjo

bolt when installing

Fig. 12 Polishing Piston Bore

1 - HONE

2 - CALIPER

3 - PISTON BORE

Fig. 13 Piston Seal

1 - CALIPER

2 - PISTON BORE

3 - PISTON SEAL

Fig. 14 Caliper Piston Installation

1 - CALIPER

2 - DUST BOOT

3 - PISTON

Fig. 15 Seating Dust Boot

1 - HANDLE

2 - CALIPER

3 - DUST BOOT INSTALLER

BR/BEBRAKES 5 - 13

DISC BRAKE CALIPERS (Continued)

Page 302 of 2889

(4) Bleed base brake system, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL - STAN-

DARD PROCEDURE)

WHEEL CYLINDERS

REMOVAL

(1) Raise vehicle and remove tire and wheel

assembly.

(2) Remove brake drum.

(3) Lift adjuster lever away from adjuster screw.

Then turn screw star wheel until screw is fully

retracted.

(4) Remove brake shoe return springs, adjuster

spring and adjuster screw. Move upper ends of brake

shoes apart to provide removal clearance for wheel

cylinder links.

(5) Disconnect brake line from wheel cylinder.

(6) Remove wheel cylinder attaching screws and

remove cylinder from support plate

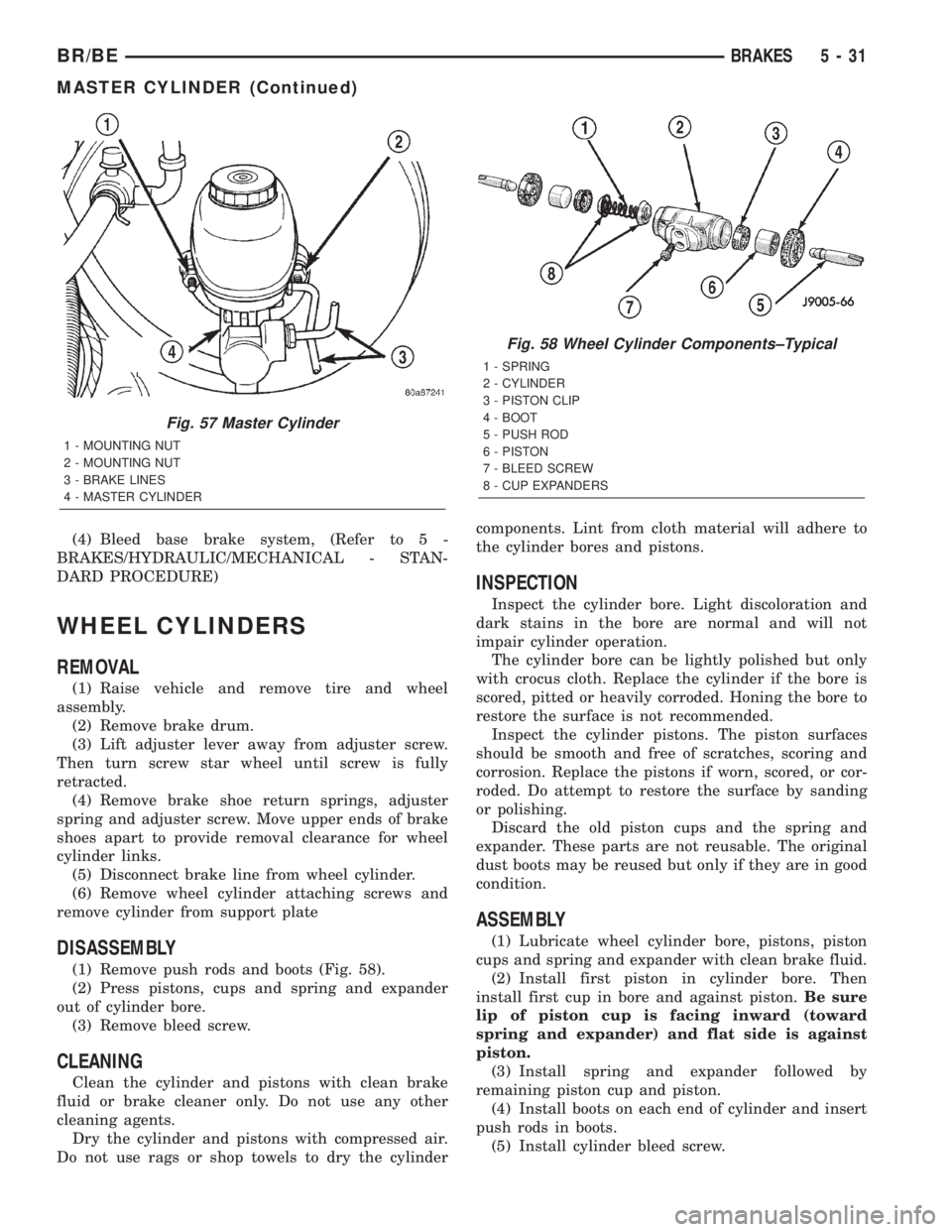

DISASSEMBLY

(1) Remove push rods and boots (Fig. 58).

(2) Press pistons, cups and spring and expander

out of cylinder bore.

(3) Remove bleed screw.

CLEANING

Clean the cylinder and pistons with clean brake

fluid or brake cleaner only. Do not use any other

cleaning agents.

Dry the cylinder and pistons with compressed air.

Do not use rags or shop towels to dry the cylindercomponents. Lint from cloth material will adhere to

the cylinder bores and pistons.

INSPECTION

Inspect the cylinder bore. Light discoloration and

dark stains in the bore are normal and will not

impair cylinder operation.

The cylinder bore can be lightly polished but only

with crocus cloth. Replace the cylinder if the bore is

scored, pitted or heavily corroded. Honing the bore to

restore the surface is not recommended.

Inspect the cylinder pistons. The piston surfaces

should be smooth and free of scratches, scoring and

corrosion. Replace the pistons if worn, scored, or cor-

roded. Do attempt to restore the surface by sanding

or polishing.

Discard the old piston cups and the spring and

expander. These parts are not reusable. The original

dust boots may be reused but only if they are in good

condition.

ASSEMBLY

(1) Lubricate wheel cylinder bore, pistons, piston

cups and spring and expander with clean brake fluid.

(2) Install first piston in cylinder bore. Then

install first cup in bore and against piston.Be sure

lip of piston cup is facing inward (toward

spring and expander) and flat side is against

piston.

(3) Install spring and expander followed by

remaining piston cup and piston.

(4) Install boots on each end of cylinder and insert

push rods in boots.

(5) Install cylinder bleed screw.

Fig. 57 Master Cylinder

1 - MOUNTING NUT

2 - MOUNTING NUT

3 - BRAKE LINES

4 - MASTER CYLINDER

Fig. 58 Wheel Cylinder Components±Typical

1 - SPRING

2 - CYLINDER

3 - PISTON CLIP

4 - BOOT

5 - PUSH ROD

6 - PISTON

7 - BLEED SCREW

8 - CUP EXPANDERS

BR/BEBRAKES 5 - 31

MASTER CYLINDER (Continued)

Page 326 of 2889

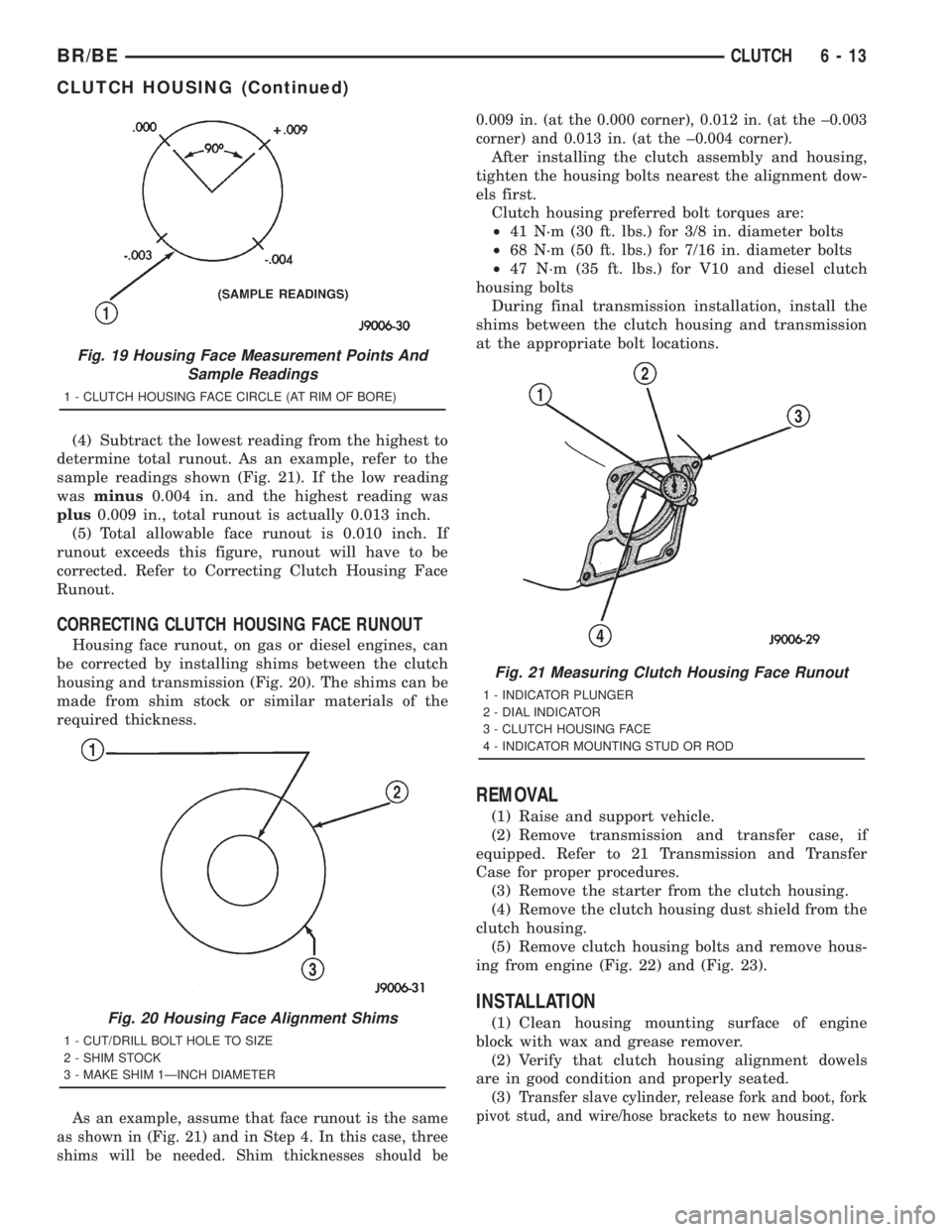

(4) Subtract the lowest reading from the highest to

determine total runout. As an example, refer to the

sample readings shown (Fig. 21). If the low reading

wasminus0.004 in. and the highest reading was

plus0.009 in., total runout is actually 0.013 inch.

(5) Total allowable face runout is 0.010 inch. If

runout exceeds this figure, runout will have to be

corrected. Refer to Correcting Clutch Housing Face

Runout.

CORRECTING CLUTCH HOUSING FACE RUNOUT

Housing face runout, on gas or diesel engines, can

be corrected by installing shims between the clutch

housing and transmission (Fig. 20). The shims can be

made from shim stock or similar materials of the

required thickness.

As an example, assume that face runout is the same

as shown in (Fig. 21) and in Step 4. In this case, three

shims will be needed. Shim thicknesses should be0.009 in. (at the 0.000 corner), 0.012 in. (at the ±0.003

corner) and 0.013 in. (at the ±0.004 corner).

After installing the clutch assembly and housing,

tighten the housing bolts nearest the alignment dow-

els first.

Clutch housing preferred bolt torques are:

²41 N´m (30 ft. lbs.) for 3/8 in. diameter bolts

²68 N´m (50 ft. lbs.) for 7/16 in. diameter bolts

²47 N´m (35 ft. lbs.) for V10 and diesel clutch

housing bolts

During final transmission installation, install the

shims between the clutch housing and transmission

at the appropriate bolt locations.

REMOVAL

(1) Raise and support vehicle.

(2) Remove transmission and transfer case, if

equipped. Refer to 21 Transmission and Transfer

Case for proper procedures.

(3) Remove the starter from the clutch housing.

(4) Remove the clutch housing dust shield from the

clutch housing.

(5) Remove clutch housing bolts and remove hous-

ing from engine (Fig. 22) and (Fig. 23).

INSTALLATION

(1) Clean housing mounting surface of engine

block with wax and grease remover.

(2) Verify that clutch housing alignment dowels

are in good condition and properly seated.

(3)

Transfer slave cylinder, release fork and boot, fork

pivot stud, and wire/hose brackets to new housing.

Fig. 19 Housing Face Measurement Points And

Sample Readings

1 - CLUTCH HOUSING FACE CIRCLE (AT RIM OF BORE)

Fig. 20 Housing Face Alignment Shims

1 - CUT/DRILL BOLT HOLE TO SIZE

2 - SHIM STOCK

3 - MAKE SHIM 1ÐINCH DIAMETER

Fig. 21 Measuring Clutch Housing Face Runout

1 - INDICATOR PLUNGER

2 - DIAL INDICATOR

3 - CLUTCH HOUSING FACE

4 - INDICATOR MOUNTING STUD OR ROD

BR/BECLUTCH 6 - 13

CLUTCH HOUSING (Continued)

Page 511 of 2889

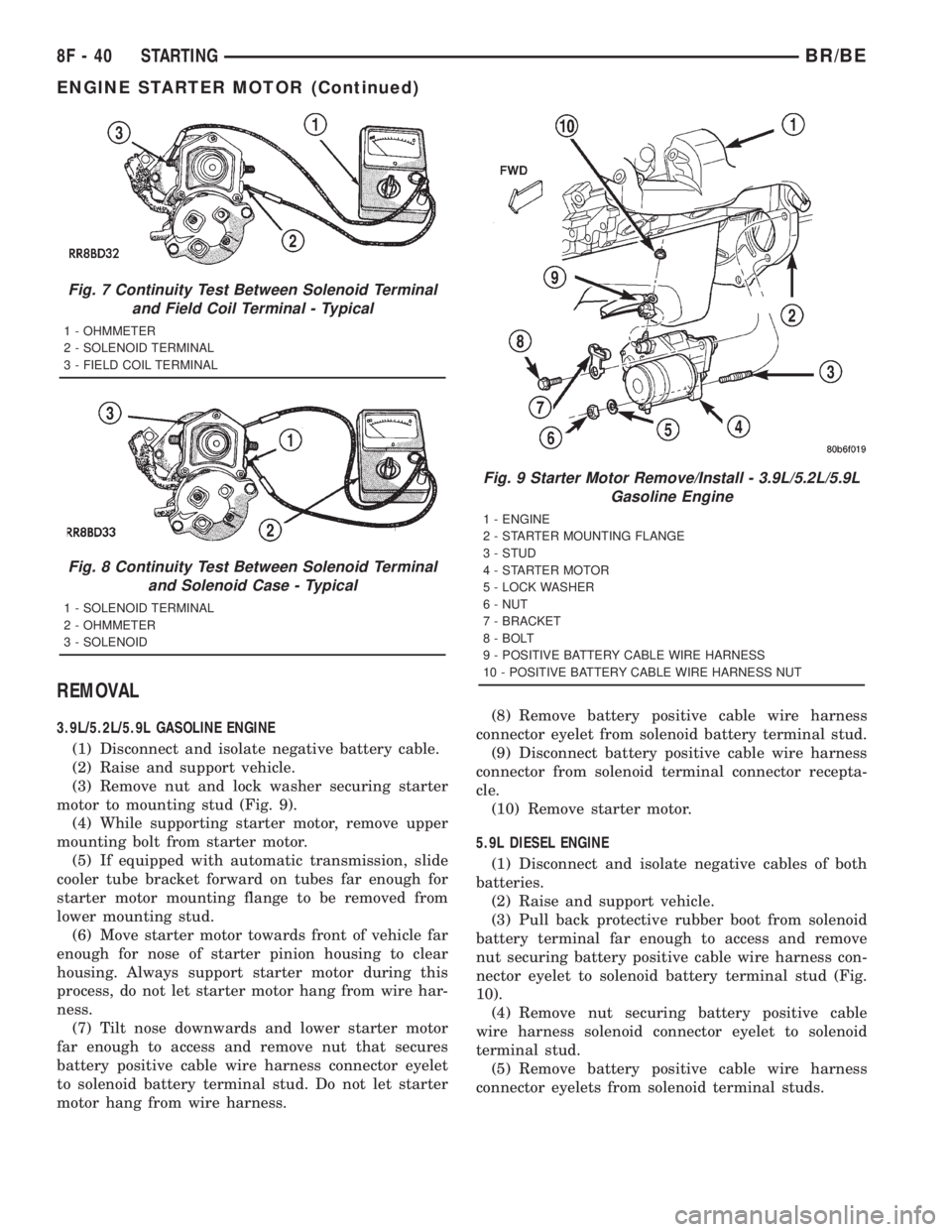

REMOVAL

3.9L/5.2L/5.9L GASOLINE ENGINE

(1) Disconnect and isolate negative battery cable.

(2) Raise and support vehicle.

(3) Remove nut and lock washer securing starter

motor to mounting stud (Fig. 9).

(4) While supporting starter motor, remove upper

mounting bolt from starter motor.

(5) If equipped with automatic transmission, slide

cooler tube bracket forward on tubes far enough for

starter motor mounting flange to be removed from

lower mounting stud.

(6) Move starter motor towards front of vehicle far

enough for nose of starter pinion housing to clear

housing. Always support starter motor during this

process, do not let starter motor hang from wire har-

ness.

(7) Tilt nose downwards and lower starter motor

far enough to access and remove nut that secures

battery positive cable wire harness connector eyelet

to solenoid battery terminal stud. Do not let starter

motor hang from wire harness.(8) Remove battery positive cable wire harness

connector eyelet from solenoid battery terminal stud.

(9) Disconnect battery positive cable wire harness

connector from solenoid terminal connector recepta-

cle.

(10) Remove starter motor.

5.9L DIESEL ENGINE

(1) Disconnect and isolate negative cables of both

batteries.

(2) Raise and support vehicle.

(3) Pull back protective rubber boot from solenoid

battery terminal far enough to access and remove

nut securing battery positive cable wire harness con-

nector eyelet to solenoid battery terminal stud (Fig.

10).

(4) Remove nut securing battery positive cable

wire harness solenoid connector eyelet to solenoid

terminal stud.

(5) Remove battery positive cable wire harness

connector eyelets from solenoid terminal studs.

Fig. 7 Continuity Test Between Solenoid Terminal

and Field Coil Terminal - Typical

1 - OHMMETER

2 - SOLENOID TERMINAL

3 - FIELD COIL TERMINAL

Fig. 8 Continuity Test Between Solenoid Terminal

and Solenoid Case - Typical

1 - SOLENOID TERMINAL

2 - OHMMETER

3 - SOLENOID

Fig. 9 Starter Motor Remove/Install - 3.9L/5.2L/5.9L

Gasoline Engine

1 - ENGINE

2 - STARTER MOUNTING FLANGE

3 - STUD

4 - STARTER MOTOR

5 - LOCK WASHER

6 - NUT

7 - BRACKET

8 - BOLT

9 - POSITIVE BATTERY CABLE WIRE HARNESS

10 - POSITIVE BATTERY CABLE WIRE HARNESS NUT

8F - 40 STARTINGBR/BE

ENGINE STARTER MOTOR (Continued)

Page 513 of 2889

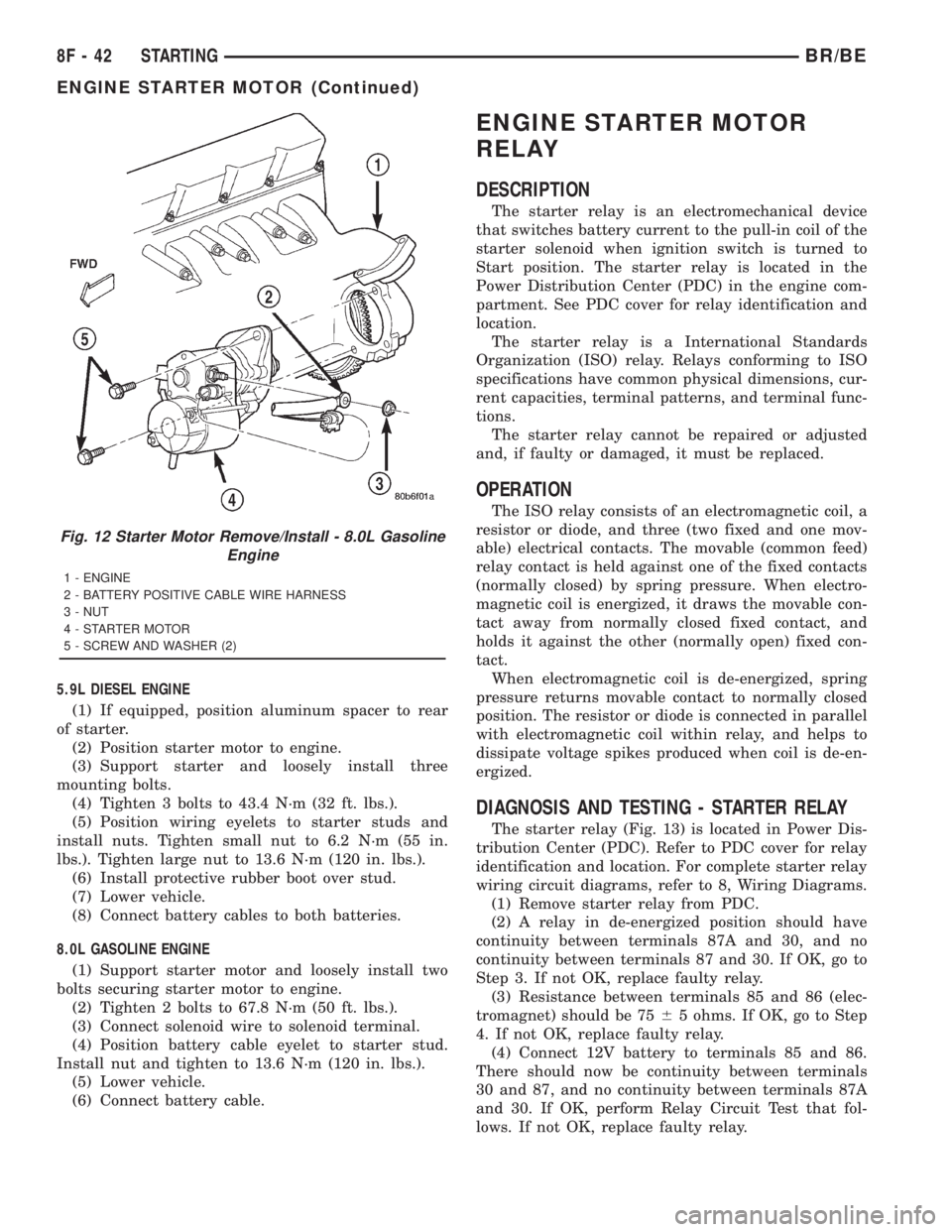

5.9L DIESEL ENGINE

(1) If equipped, position aluminum spacer to rear

of starter.

(2) Position starter motor to engine.

(3) Support starter and loosely install three

mounting bolts.

(4) Tighten 3 bolts to 43.4 N´m (32 ft. lbs.).

(5) Position wiring eyelets to starter studs and

install nuts. Tighten small nut to 6.2 N´m (55 in.

lbs.). Tighten large nut to 13.6 N´m (120 in. lbs.).

(6) Install protective rubber boot over stud.

(7) Lower vehicle.

(8) Connect battery cables to both batteries.

8.0L GASOLINE ENGINE

(1) Support starter motor and loosely install two

bolts securing starter motor to engine.

(2) Tighten 2 bolts to 67.8 N´m (50 ft. lbs.).

(3) Connect solenoid wire to solenoid terminal.

(4) Position battery cable eyelet to starter stud.

Install nut and tighten to 13.6 N´m (120 in. lbs.).

(5) Lower vehicle.

(6) Connect battery cable.

ENGINE STARTER MOTOR

RELAY

DESCRIPTION

The starter relay is an electromechanical device

that switches battery current to the pull-in coil of the

starter solenoid when ignition switch is turned to

Start position. The starter relay is located in the

Power Distribution Center (PDC) in the engine com-

partment. See PDC cover for relay identification and

location.

The starter relay is a International Standards

Organization (ISO) relay. Relays conforming to ISO

specifications have common physical dimensions, cur-

rent capacities, terminal patterns, and terminal func-

tions.

The starter relay cannot be repaired or adjusted

and, if faulty or damaged, it must be replaced.

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one mov-

able) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When electro-

magnetic coil is energized, it draws the movable con-

tact away from normally closed fixed contact, and

holds it against the other (normally open) fixed con-

tact.

When electromagnetic coil is de-energized, spring

pressure returns movable contact to normally closed

position. The resistor or diode is connected in parallel

with electromagnetic coil within relay, and helps to

dissipate voltage spikes produced when coil is de-en-

ergized.

DIAGNOSIS AND TESTING - STARTER RELAY

The starter relay (Fig. 13) is located in Power Dis-

tribution Center (PDC). Refer to PDC cover for relay

identification and location. For complete starter relay

wiring circuit diagrams, refer to 8, Wiring Diagrams.

(1) Remove starter relay from PDC.

(2) A relay in de-energized position should have

continuity between terminals 87A and 30, and no

continuity between terminals 87 and 30. If OK, go to

Step 3. If not OK, replace faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 7565 ohms. If OK, go to Step

4. If not OK, replace faulty relay.

(4) Connect 12V battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, perform Relay Circuit Test that fol-

lows. If not OK, replace faulty relay.

Fig. 12 Starter Motor Remove/Install - 8.0L Gasoline

Engine

1 - ENGINE

2 - BATTERY POSITIVE CABLE WIRE HARNESS

3 - NUT

4 - STARTER MOTOR

5 - SCREW AND WASHER (2)

8F - 42 STARTINGBR/BE

ENGINE STARTER MOTOR (Continued)