fuel additives DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 15 of 2889

It is even more important to look for gasoline with-

out MMT in Canada because MMT can be used at

levels higher than allowed in the United States.

MMT is prohibited in Federal and California refor-

mulated gasoline.

SULFUR IN GASOLINE

If you live in the northeast United States, your

vehicle may have been designed to meet California

low emission standards with Cleaner-Burning Cali-

fornia reformulated gasoline with low sulfur. If such

fuels are not available in states adopting California

emission standards, your vehicles will operate satis-

factorily on fuels meeting federal specifications, but

emission control system performance may be

adversely affected. Gasoline sold outside of California

is permitted to have higher sulfur levels which may

affect the performance of the vehicle's catalytic con-

verter. This may cause the Malfunction Indicator

Lamp (MIL), Check Engine or Service Engine Soon

light to illuminate. We recommend that you try a dif-

ferent brand of unleaded gasoline having lower sulfur

to determine if the problem is fuel related prior to

returning your vehicle to an authorized dealer for

service.

CAUTION: If the Malfunction Indicator Lamp (MIL),

Check Engine or Service Engine Soon light is flash-

ing, immediate service is required; see on-board

diagnostics system section.

MATERIALS ADDED TO FUEL

All gasoline sold in the United States and Canada

are required to contain effective detergent additives.

Use of additional detergents or other additives is not

needed under normal conditions.

FUEL SYSTEM CAUTIONS

CAUTION: Follow these guidelines to maintain your

vehicle's performance:

²The use of leaded gas is prohibited by Federal

law. Using leaded gasoline can impair engine perfor-

mance, damage the emission control system, and

could result in loss of warranty coverage.

²An out-of-tune engine, or certain fuel or ignition

malfunctions, can cause the catalytic converter to

overheat. If you notice a pungent burning odor or

some light smoke, your engine may be out of tune or

malfunctioning and may require immediate service.

Contact your dealer for service assistance.²When pulling a heavy load or driving a fully

loaded vehicle when the humidity is low and the tem-

perature is high, use a premium unleaded fuel to

help prevent spark knock. If spark knock persists,

lighten the load, or engine piston damage may result.

²The use of fuel additives which are now being

sold as octane enhancers is not recommended. Most

of these products contain high concentrations of

methanol. Fuel system damage or vehicle perfor-

mance problems resulting from the use of such fuels

or additives is not the responsibility of Daimler-

Chrysler Corporation and may not be covered under

the new vehicle warranty.

NOTE: Intentional tampering with emissions control

systems can result in civil penalties being assessed

against you.

DESCRIPTION - FUEL REQUIREMENTS -

DIESEL ENGINE

DESCRIPTION

WARNING: Do not use alcohol or gasoline as a fuel

blending agent. They can be unstable under certain

conditions and hazardous or explosive when mixed

with diesel fuel.

Use good quality diesel fuel from a reputable sup-

plier in your Dodge truck. For most year-round ser-

vice, number 2 diesel fuel meeting ASTM

specification D-975 will provide good performance. If

the vehicle is exposed to extreme cold (below 0ÉF/-

18ÉC), or is required to operate at colder-than-normal

conditions for prolonged periods, use climatized No. 2

diesel fuel or dilute the No. 2 diesel fuel with 50%

No. 1 diesel fuel. This will provide better protection

from fuel gelling or wax-plugging of the fuel filters.

Diesel fuel is seldom completely free of water. To

prevent fuel system trouble, including fuel line freez-

ing in winter, drain the accumulated water from the

fuel/water separator using the fuel/water separator

drain provided. If you buy good-quality fuel and fol-

low the cold-weather advice above, fuel conditioners

should not be required in your vehicle. If available in

your area, a high cetane ªpremiumº diesel fuel may

offer improved cold starting and warm-up perfor-

mance.

0 - 2 LUBRICATION & MAINTENANCEBR/BE

LUBRICATION & MAINTENANCE (Continued)

Page 554 of 2889

COLD FOULING/CARBON FOULING

Cold fouling is sometimes referred to as carbon

fouling. The deposits that cause cold fouling are basi-

cally carbon (Fig. 29). A dry, black deposit on one or

two plugs in a set may be caused by sticking valves

or defective spark plug cables. Cold (carbon) fouling

of the entire set of spark plugs may be caused by a

clogged air cleaner element or repeated short operat-

ing times (short trips).

WET FOULING OR GAS FOULING

A spark plug coated with excessive wet fuel or oil

is wet fouled. In older engines, worn piston rings,

leaking valve guide seals or excessive cylinder wear

can cause wet fouling. In new or recently overhauled

engines, wet fouling may occur before break-in (nor-

mal oil control) is achieved. This condition can usu-

ally be resolved by cleaning and reinstalling the

fouled plugs.

OIL OR ASH ENCRUSTED

If one or more spark plugs are oil or oil ash

encrusted (Fig. 30), evaluate engine condition for the

cause of oil entry into that particular combustion

chamber.

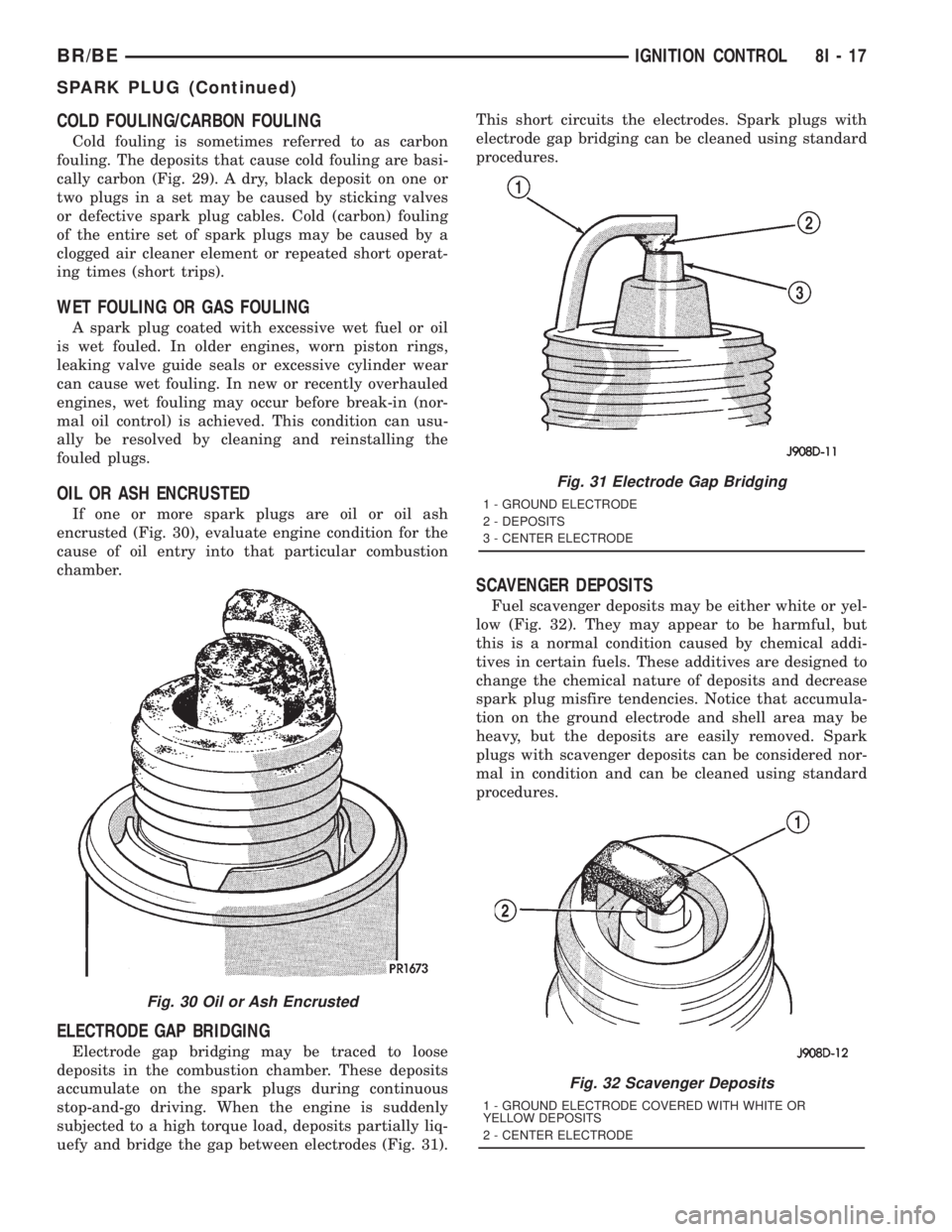

ELECTRODE GAP BRIDGING

Electrode gap bridging may be traced to loose

deposits in the combustion chamber. These deposits

accumulate on the spark plugs during continuous

stop-and-go driving. When the engine is suddenly

subjected to a high torque load, deposits partially liq-

uefy and bridge the gap between electrodes (Fig. 31).This short circuits the electrodes. Spark plugs with

electrode gap bridging can be cleaned using standard

procedures.

SCAVENGER DEPOSITS

Fuel scavenger deposits may be either white or yel-

low (Fig. 32). They may appear to be harmful, but

this is a normal condition caused by chemical addi-

tives in certain fuels. These additives are designed to

change the chemical nature of deposits and decrease

spark plug misfire tendencies. Notice that accumula-

tion on the ground electrode and shell area may be

heavy, but the deposits are easily removed. Spark

plugs with scavenger deposits can be considered nor-

mal in condition and can be cleaned using standard

procedures.

Fig. 30 Oil or Ash Encrusted

Fig. 31 Electrode Gap Bridging

1 - GROUND ELECTRODE

2 - DEPOSITS

3 - CENTER ELECTRODE

Fig. 32 Scavenger Deposits

1 - GROUND ELECTRODE COVERED WITH WHITE OR

YELLOW DEPOSITS

2 - CENTER ELECTRODE

BR/BEIGNITION CONTROL 8I - 17

SPARK PLUG (Continued)

Page 2878 of 2889

SEAT TRACK ADJUSTER - REMOVAL....23-143

SEATBELT INDICATOR - DESCRIPTION....8J-27

SEATBELT INDICATOR - OPERATION......8J-27

SEATS - CLEANING, INTAKE/EXHAUST

VALVES ...............9-140,9-198,9-27,9-84

SEATS - DESCRIPTION...............23-131

SEATS - DESCRIPTION, INTAKE/

EXHAUST VALVES . . 9-138,9-195,9-25,9-253,9-81

SEATS - INSPECTION.................30-13

SEATS - INSPECTION, INTAKE/EXHAUST

VALVES ...............9-141,9-198,9-27,9-84

SEATS - INSTALLATION, INTAKE/

EXHAUST VALVES.......9-141,9-260,9-28,9-85

SEATS - OPERATION.................23-131

SEATS - REMOVAL, INTAKE/EXHAUST

VALVES ...............9-140,9-258,9-27,9-84

SEATS - STANDARD PROCEDURE-

VALVES,GUIDES AND SPRINGS,

INTAKE/EXHAUST VALVES..............9-253

SEATS - VALVE SERVICE, INTAKE/

EXHAUST VALVES....................9-195

SECOND WEATHERSTRIP -

INSTALLATION, FRONT DOOR..........23-155

SECOND WEATHERSTRIP - REMOVAL,

FRONT DOOR......................23-154

SECURITY - DESCRIPTION, VEHICLE

THEFT..............................8Q-1

SECURITY - OPERATION, VEHICLE THEFT . . 8Q-2

SECURITY SYSTEM - DIAGNOSIS AND

TESTING, VEHICLE THEFT..............8Q-3

SELECTION-ADDITIVES - STANDARD

PROCEDURE, COOLANT..................7-17

SELECTOR INDICATOR - DESCRIPTION,

GEAR..............................8J-21

SELECTOR INDICATOR - OPERATION,

GEAR..............................8J-21

SENDING UNIT - DIAGNOSIS AND

TESTING, FUEL GAUGE.................14-8

SENDING UNIT / SENSOR -

DESCRIPTION, FUEL LEVEL........14-7,14-73

SENDING UNIT / SENSOR -

INSTALLATION, FUEL LEVEL.............14-9

SENDING UNIT / SENSOR - OPERATION,

FUEL LEVEL.....................14-7,14-73

SENDING UNIT / SENSOR - REMOVAL,

FUEL LEVEL..........................14-8

SENSE - DESCRIPTION, IGNITION

CIRCUIT............................8E-17

SENSE - OPERATION, IGNITION CIRCUIT . . 8E-19

SENSE - PCM INPUT - OPERATION, ASD . . . 8I-3

SENSOR - 3.9L/5.2L/5.9L -

DESCRIPTION, ENGINE COOLANT

TEMP...............................7-48

SENSOR - 3.9L/5.2L/5.9L -

INSTALLATION, ENGINE COOLANT

TEMP...............................7-48

SENSOR - 3.9L/5.2L/5.9L - OPERATION,

ENGINE COOLANT TEMP................7-48

SENSOR - 3.9L/5.2L/5.9L - REMOVAL,

ENGINE COOLANT TEMP................7-48

SENSOR - DESCRIPTION, ACCELERATOR

PEDAL POSITION....................14-91

SENSOR - DESCRIPTION, AMBIENT

TEMP.............................8M-11

SENSOR - DESCRIPTION, BATTERY

TEMPERATURE......................8F-29

SENSOR - DESCRIPTION, FUEL LEVEL

SENDING UNIT..................14-7,14-73

SENSOR - DESCRIPTION, FUEL

TEMPERATURE......................14-99

SENSOR - DESCRIPTION, O2...........14-46

SENSOR - DESCRIPTION, SPEED . 21-253,21-424,

21-597,21-770

SENSOR - DESCRIPTION, THROTTLE

POSITION..........................14-51

SENSOR - DESCRIPTION,

TRANSMISSION TEMPERATURE . 21-262,21-433,

21-606,21-779

SENSOR - DESCRIPTION, WATER IN

FUEL

..............................14-85

SENSOR - DIAGNOSIS & TESTING,

AMBIENT TEMPERATURE

..............8M-12

SENSOR - DIAGNOSIS & TESTING,

HEATED SEAT ELEMENT

...............8G-11

SENSOR - INSTALLATION,

ACCELERATOR PEDAL POSITION

........14-93

SENSOR - INSTALLATION, AMBIENT

TEMP

.............................8M-13SENSOR - INSTALLATION, BATTERY

TEMPERATURE......................8F-29

SENSOR - INSTALLATION, FUEL LEVEL

SENDING UNIT.......................14-9

SENSOR - INSTALLATION, MAP........14-104

SENSOR - INSTALLATION, O2...........14-48

SENSOR - OPERATION, ACCELERATOR

PEDAL POSITION....................14-91

SENSOR - OPERATION, AMBIENT TEMP . . 8M-11

SENSOR - OPERATION, BATTERY

TEMPERATURE......................8F-29

SENSOR - OPERATION, FUEL LEVEL

SENDING UNIT..................14-7,14-73

SENSOR - OPERATION, FUEL

TEMPERATURE.....................14-100

SENSOR - OPERATION, O2.............14-46

SENSOR - OPERATION, SPEED . . 21-253,21-424,

21-597,21-770

SENSOR - OPERATION, THROTTLE

POSITION..........................14-51

SENSOR - OPERATION, TRANSMISSION

TEMPERATURE . . . 21-262,21-433,21-606,21-779

SENSOR - OPERATION, WATER IN FUEL . . 14-85

SENSOR - REMOVAL, ACCELERATOR

PEDAL POSITION....................14-91

SENSOR - REMOVAL, AMBIENT TEMP . . . 8M-12

SENSOR - REMOVAL, BATTERY

TEMPERATURE......................8F-29

SENSOR - REMOVAL, FUEL LEVEL

SENDING UNIT.......................14-8

SENSOR - REMOVAL, O2..............14-47

SENSOR - REMOVAL, WATER IN FUEL....14-85

SENSOR RETURN - DESCRIPTION.......8E-17

SENSOR/SWITCH - DESCRIPTION, OIL

PRESSURE.....................9-298,9-49

SENSOR/SWITCH - INSTALLATION, OIL

PRESSURE.........................9-299

SENSOR/SWITCH - OPERATION, OIL

PRESSURE.....................9-298,9-49

SENSOR/SWITCH - REMOVAL, OIL

PRESSURE.........................9-298

SEPARATOR - DESCRIPTION, FUEL

FILTER / WATER .....................14-59

SEPARATOR - INSTALLATION, FUEL

FILTER / WATER .....................14-61

SEPARATOR - OPERATION, FUEL FILTER

/ WATER ...........................14-59

SEPARATOR - REMOVAL, FUEL FILTER /

WATER.............................14-60

SERIES - INSTALLATION, REAR PARK

BRAKE CABLES - 1500.................5-39

SERIES - REMOVAL, REAR PARK BRAKE

CABLES - 1500.......................5-37

SERIES WITH DRUM BRAKES -

INSTALLATION, REAR PARK BRAKE

CABLE 2500/3500.....................5-39

SERIES WITH DRUM BRAKES -

REMOVAL, REAR PARK BRAKE

CABLES 2500/3500....................5-38

SERVO - ASSEMBLY, FRONT....21-208,21-379,

21-553,21-723

SERVO - ASSEMBLY, REAR.....21-251,21-422,

21-595,21-768

SERVO - CLEANING, FRONT

....21-207,21-378,

21-552,21-723

SERVO - CLEANING, REAR

.....21-251,21-422,

21-594,21-768

SERVO - DESCRIPTION, FRONT

. . 21-206,21-377,

21-551,21-722

SERVO - DESCRIPTION, REAR

. . . 21-250,21-421,

21-594,21-767

SERVO - DESCRIPTION, SPEED

CONTROL

...........................8P-5

SERVO - DISASSEMBLY, FRONT

. 21-207,21-378,

21-552,21-723

SERVO - DISASSEMBLY, REAR

. . 21-251,21-421,

21-594,21-768

SERVO - INSPECTION, FRONT

. . . 21-207,21-378,

21-553,21-723

SERVO - INSTALLATION, SPEED

CONTROL

..........................8P-10

SERVO - OPERATION, FRONT

. . . 21-207,21-377,

21-552,21-723

SERVO - OPERATION, REAR

....21-250,21-421,

21-594,21-767

SERVO - OPERATION, SPEED CONTROL

. . . 8P-5

SERVO - REMOVAL, SPEED CONTROL

.....8P-6SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR SHORT TO

GROUND ON FUSES POWERING......8W-01-7

SHAFT - ASSEMBLY, PLANETARY

GEARTRAIN/OUTPUT....21-241,21-412,21-588,

21-760

SHAFT - DESCRIPTION, PLANETARY

GEARTRAIN/OUTPUT....21-240,21-410,21-585,

21-757

SHAFT - DESCRIPTION, PROPELLER.......3-1

SHAFT - DIAGNOSIS AND TESTING,

PROPELLER...........................3-3

SHAFT - DISASSEMBLY, PLANETARY

GEARTRAIN/OUTPUT....21-240,21-411,21-586,

21-757

SHAFT - FRONT - INSTALLATION,

PROPELLER...........................3-8

SHAFT - FRONT - REMOVAL,

PROPELLER...........................3-8

SHAFT - INSPECTION, PLANETARY

GEARTRAIN/OUTPUT....21-241,21-411,21-587,

21-760

SHAFT - INSTALLATION, PITMAN........19-23

SHAFT - INSTALLATION, WORM.........19-29

SHAFT - OPERATION, PLANETARY

GEARTRAIN/OUTPUT....21-240,21-410,21-585,

21-757

SHAFT - OPERATION, PROPELLER.........3-1

SHAFT - REAR - INSTALLATION,

PROPELLER...........................3-9

SHAFT - REAR - REMOVAL, PROPELLER....3-9

SHAFT - REMOVAL, PITMAN............19-22

SHAFT - REMOVAL, WORM............19-27

SHAFT - STANDARD PROCEDURES,

PROPELLER...........................3-5

SHAFT FRONT BEARING -

INSTALLATION, OUTPUT . 21-213,21-384,21-560,

21-730

SHAFT FRONT BEARING - REMOVAL,

OUTPUT.........21-213,21-384,21-559,21-730

SHAFT REAR BEARING - INSTALLATION,

OUTPUT.........21-213,21-384,21-560,21-731

SHAFT REAR BEARING - REMOVAL,

OUTPUT.........21-213,21-384,21-560,21-731

SHAFT SEAL - INSTALLATION, FRONT

OUTPUT...............21-852,21-886,21-922

SHAFT SEAL - INSTALLATION, PITMAN . . . 19-24

SHAFT SEAL - REMOVAL, FRONT

OUTPUT...............21-851,21-886,21-922

SHAFT SEAL - REMOVAL, PITMAN.......19-23

SHAFT SEALS - INSTALLATION, AXLE . 3-29,3-61,

3-94

SHAFT SEALS - REMOVAL, AXLE . 3-29,3-61,3-94

SHAFT, SPECIAL TOOLS - PROPELLER......3-8

SHAFT, SPECIFICATIONS - PROPELLER.....3-8

SHAFTS - INSTALLATION, AXLE....3-125,3-156,

3-185,3-28,3-60,3-93

SHAFTS - INTERMEDIATE -

INSTALLATION, AXLE..................3-28

SHAFTS - INTERMEDIATE - REMOVAL,

AXLE...............................3-28

SHAFTS - REMOVAL, AXLE . . 3-125,3-156,3-185,

3-28,3-60,3-93

SHIELD - INSTALLATION, REAR SPLASH . . 23-96

SHIELD - REMOVAL, REAR SPLASH......23-96

SHIELDS - DESCRIPTION, HEAT.........11-10

SHIELDS - INSTALLATION, FRONT END

SPLASH

............................23-92

SHIELDS - INSTALLATION, HEAT

........11-10

SHIELDS - REMOVAL, FRONT END

SPLASH

............................23-92

SHIELDS - REMOVAL, HEAT

............11-10

SHIFT BOOT - INSTALLATION, 4WD

FLOOR

............................23-122

SHIFT BOOT - MANUAL TRANSMISSION

- INSTALLATION

....................23-122

SHIFT BOOT - MANUAL TRANSMISSION

- REMOVAL

........................23-122

SHIFT BOOT - REMOVAL, 4WD FLOOR

. . . 23-122

SHIFT COVER - INSTALLATION

....21-133,21-90

SHIFT COVER - REMOVAL

.......21-132,21-90

SHIFT INDICATOR (TRANSFER CASE) -

DESCRIPTION

.......................8J-29

SHIFT INDICATOR (TRANSFER CASE) -

OPERATION

.........................8J-29

SHIFT LEVER - ADJUSTMENT

. . . 21-853,21-888,

21-925

BR/BEINDEX 31

Description Group-Page Description Group-Page Description Group-Page