fuel cap DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 14 of 2889

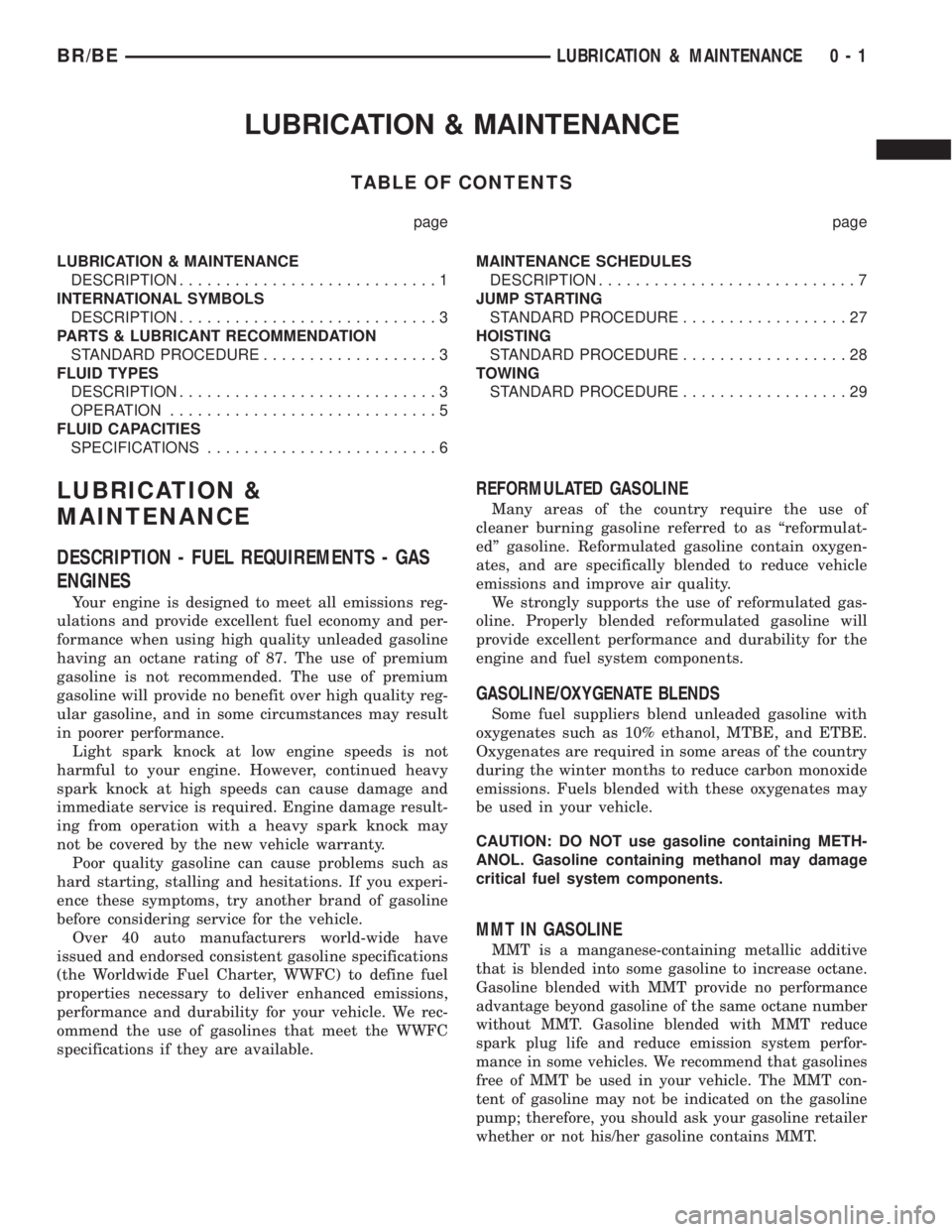

LUBRICATION & MAINTENANCE

TABLE OF CONTENTS

page page

LUBRICATION & MAINTENANCE

DESCRIPTION............................1

INTERNATIONAL SYMBOLS

DESCRIPTION............................3

PARTS & LUBRICANT RECOMMENDATION

STANDARD PROCEDURE...................3

FLUID TYPES

DESCRIPTION............................3

OPERATION.............................5

FLUID CAPACITIES

SPECIFICATIONS.........................6MAINTENANCE SCHEDULES

DESCRIPTION............................7

JUMP STARTING

STANDARD PROCEDURE..................27

HOISTING

STANDARD PROCEDURE..................28

TOWING

STANDARD PROCEDURE..................29

LUBRICATION &

MAINTENANCE

DESCRIPTION - FUEL REQUIREMENTS - GAS

ENGINES

Your engine is designed to meet all emissions reg-

ulations and provide excellent fuel economy and per-

formance when using high quality unleaded gasoline

having an octane rating of 87. The use of premium

gasoline is not recommended. The use of premium

gasoline will provide no benefit over high quality reg-

ular gasoline, and in some circumstances may result

in poorer performance.

Light spark knock at low engine speeds is not

harmful to your engine. However, continued heavy

spark knock at high speeds can cause damage and

immediate service is required. Engine damage result-

ing from operation with a heavy spark knock may

not be covered by the new vehicle warranty.

Poor quality gasoline can cause problems such as

hard starting, stalling and hesitations. If you experi-

ence these symptoms, try another brand of gasoline

before considering service for the vehicle.

Over 40 auto manufacturers world-wide have

issued and endorsed consistent gasoline specifications

(the Worldwide Fuel Charter, WWFC) to define fuel

properties necessary to deliver enhanced emissions,

performance and durability for your vehicle. We rec-

ommend the use of gasolines that meet the WWFC

specifications if they are available.

REFORMULATED GASOLINE

Many areas of the country require the use of

cleaner burning gasoline referred to as ªreformulat-

edº gasoline. Reformulated gasoline contain oxygen-

ates, and are specifically blended to reduce vehicle

emissions and improve air quality.

We strongly supports the use of reformulated gas-

oline. Properly blended reformulated gasoline will

provide excellent performance and durability for the

engine and fuel system components.

GASOLINE/OXYGENATE BLENDS

Some fuel suppliers blend unleaded gasoline with

oxygenates such as 10% ethanol, MTBE, and ETBE.

Oxygenates are required in some areas of the country

during the winter months to reduce carbon monoxide

emissions. Fuels blended with these oxygenates may

be used in your vehicle.

CAUTION: DO NOT use gasoline containing METH-

ANOL. Gasoline containing methanol may damage

critical fuel system components.

MMT IN GASOLINE

MMT is a manganese-containing metallic additive

that is blended into some gasoline to increase octane.

Gasoline blended with MMT provide no performance

advantage beyond gasoline of the same octane number

without MMT. Gasoline blended with MMT reduce

spark plug life and reduce emission system perfor-

mance in some vehicles. We recommend that gasolines

free of MMT be used in your vehicle. The MMT con-

tent of gasoline may not be indicated on the gasoline

pump; therefore, you should ask your gasoline retailer

whether or not his/her gasoline contains MMT.

BR/BELUBRICATION & MAINTENANCE 0 - 1

Page 19 of 2889

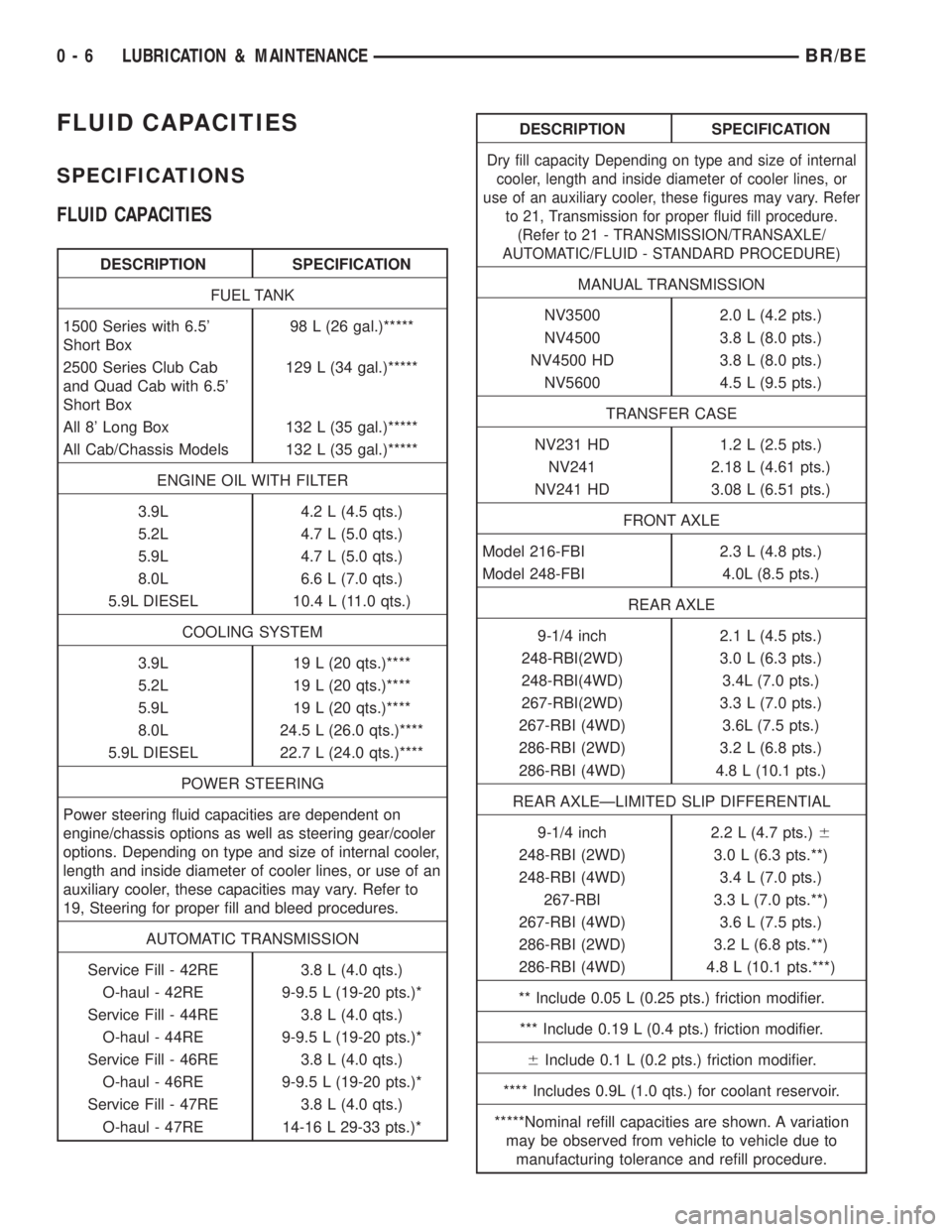

FLUID CAPACITIES

SPECIFICATIONS

FLUID CAPACITIES

DESCRIPTION SPECIFICATION

FUEL TANK

1500 Series with 6.5'

Short Box98 L (26 gal.)*****

2500 Series Club Cab

and Quad Cab with 6.5'

Short Box129 L (34 gal.)*****

All 8' Long Box 132 L (35 gal.)*****

All Cab/Chassis Models 132 L (35 gal.)*****

ENGINE OIL WITH FILTER

3.9L 4.2 L (4.5 qts.)

5.2L 4.7 L (5.0 qts.)

5.9L 4.7 L (5.0 qts.)

8.0L 6.6 L (7.0 qts.)

5.9L DIESEL 10.4 L (11.0 qts.)

COOLING SYSTEM

3.9L 19 L (20 qts.)****

5.2L 19 L (20 qts.)****

5.9L 19 L (20 qts.)****

8.0L 24.5 L (26.0 qts.)****

5.9L DIESEL 22.7 L (24.0 qts.)****

POWER STEERING

Power steering fluid capacities are dependent on

engine/chassis options as well as steering gear/cooler

options. Depending on type and size of internal cooler,

length and inside diameter of cooler lines, or use of an

auxiliary cooler, these capacities may vary. Refer to

19, Steering for proper fill and bleed procedures.

AUTOMATIC TRANSMISSION

Service Fill - 42RE 3.8 L (4.0 qts.)

O-haul - 42RE 9-9.5 L (19-20 pts.)*

Service Fill - 44RE 3.8 L (4.0 qts.)

O-haul - 44RE 9-9.5 L (19-20 pts.)*

Service Fill - 46RE 3.8 L (4.0 qts.)

O-haul - 46RE 9-9.5 L (19-20 pts.)*

Service Fill - 47RE 3.8 L (4.0 qts.)

O-haul - 47RE 14-16 L 29-33 pts.)*

DESCRIPTION SPECIFICATION

Dry fill capacity Depending on type and size of internal

cooler, length and inside diameter of cooler lines, or

use of an auxiliary cooler, these figures may vary. Refer

to 21, Transmission for proper fluid fill procedure.

(Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC/FLUID - STANDARD PROCEDURE)

MANUAL TRANSMISSION

NV3500 2.0 L (4.2 pts.)

NV4500 3.8 L (8.0 pts.)

NV4500 HD 3.8 L (8.0 pts.)

NV5600 4.5 L (9.5 pts.)

TRANSFER CASE

NV231 HD 1.2 L (2.5 pts.)

NV241 2.18 L (4.61 pts.)

NV241 HD 3.08 L (6.51 pts.)

FRONT AXLE

Model 216-FBI 2.3 L (4.8 pts.)

Model 248-FBI 4.0L (8.5 pts.)

REAR AXLE

9-1/4 inch 2.1 L (4.5 pts.)

248-RBI(2WD) 3.0 L (6.3 pts.)

248-RBI(4WD) 3.4L (7.0 pts.)

267-RBI(2WD) 3.3 L (7.0 pts.)

267-RBI (4WD) 3.6L (7.5 pts.)

286-RBI (2WD) 3.2 L (6.8 pts.)

286-RBI (4WD) 4.8 L (10.1 pts.)

REAR AXLEÐLIMITED SLIP DIFFERENTIAL

9-1/4 inch 2.2 L (4.7 pts.)6

248-RBI (2WD) 3.0 L (6.3 pts.**)

248-RBI (4WD) 3.4 L (7.0 pts.)

267-RBI 3.3 L (7.0 pts.**)

267-RBI (4WD) 3.6 L (7.5 pts.)

286-RBI (2WD) 3.2 L (6.8 pts.**)

286-RBI (4WD) 4.8 L (10.1 pts.***)

** Include 0.05 L (0.25 pts.) friction modifier.

*** Include 0.19 L (0.4 pts.) friction modifier.

6Include 0.1 L (0.2 pts.) friction modifier.

**** Includes 0.9L (1.0 qts.) for coolant reservoir.

*****Nominal refill capacities are shown. A variation

may be observed from vehicle to vehicle due to

manufacturing tolerance and refill procedure.

0 - 6 LUBRICATION & MAINTENANCEBR/BE

Page 343 of 2889

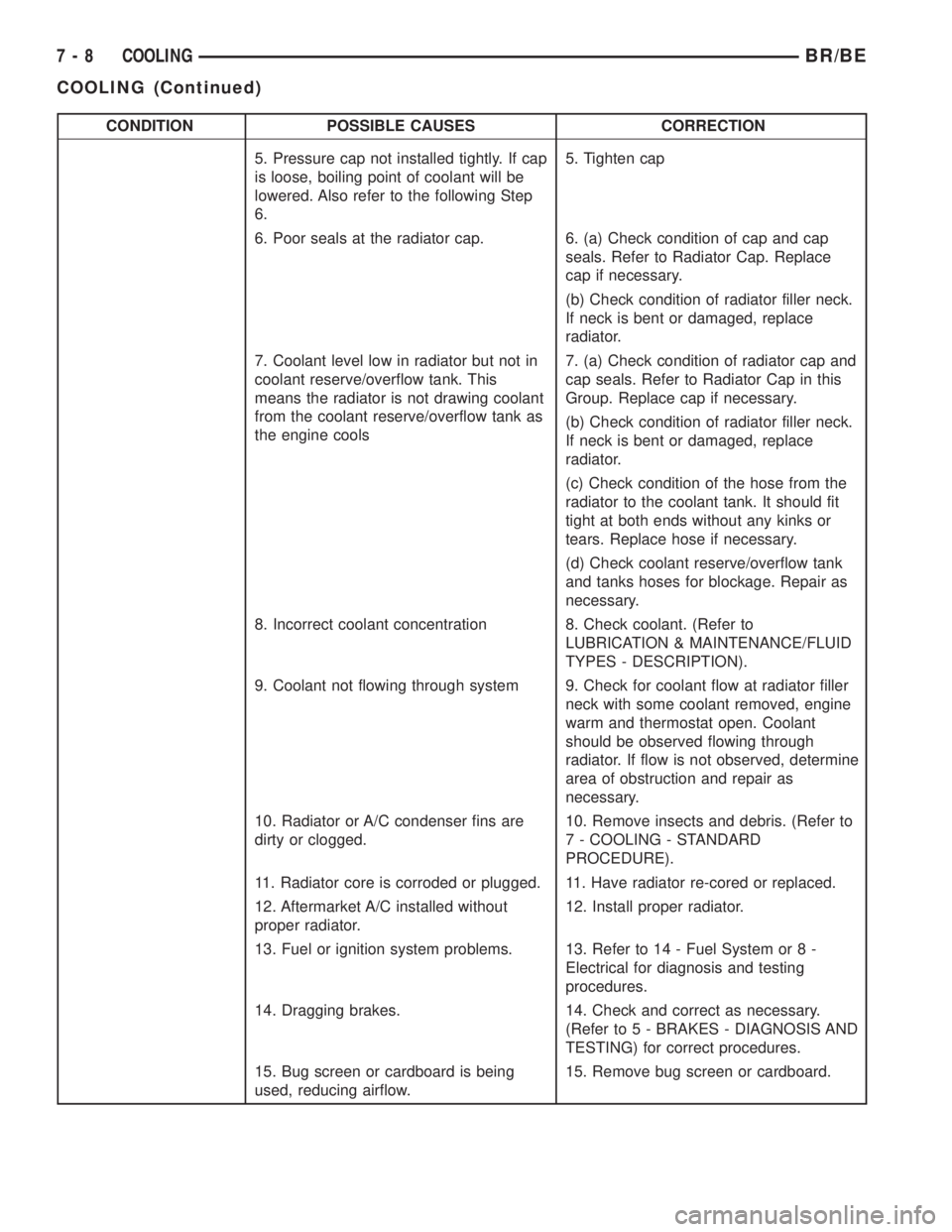

CONDITION POSSIBLE CAUSES CORRECTION

5. Pressure cap not installed tightly. If cap

is loose, boiling point of coolant will be

lowered. Also refer to the following Step

6.5. Tighten cap

6. Poor seals at the radiator cap. 6. (a) Check condition of cap and cap

seals. Refer to Radiator Cap. Replace

cap if necessary.

(b) Check condition of radiator filler neck.

If neck is bent or damaged, replace

radiator.

7. Coolant level low in radiator but not in

coolant reserve/overflow tank. This

means the radiator is not drawing coolant

from the coolant reserve/overflow tank as

the engine cools7. (a) Check condition of radiator cap and

cap seals. Refer to Radiator Cap in this

Group. Replace cap if necessary.

(b) Check condition of radiator filler neck.

If neck is bent or damaged, replace

radiator.

(c) Check condition of the hose from the

radiator to the coolant tank. It should fit

tight at both ends without any kinks or

tears. Replace hose if necessary.

(d) Check coolant reserve/overflow tank

and tanks hoses for blockage. Repair as

necessary.

8. Incorrect coolant concentration 8. Check coolant. (Refer to

LUBRICATION & MAINTENANCE/FLUID

TYPES - DESCRIPTION).

9. Coolant not flowing through system 9. Check for coolant flow at radiator filler

neck with some coolant removed, engine

warm and thermostat open. Coolant

should be observed flowing through

radiator. If flow is not observed, determine

area of obstruction and repair as

necessary.

10. Radiator or A/C condenser fins are

dirty or clogged.10. Remove insects and debris. (Refer to

7 - COOLING - STANDARD

PROCEDURE).

11. Radiator core is corroded or plugged. 11. Have radiator re-cored or replaced.

12. Aftermarket A/C installed without

proper radiator.12. Install proper radiator.

13. Fuel or ignition system problems. 13. Refer to 14 - Fuel System or 8 -

Electrical for diagnosis and testing

procedures.

14. Dragging brakes. 14. Check and correct as necessary.

(Refer to 5 - BRAKES - DIAGNOSIS AND

TESTING) for correct procedures.

15. Bug screen or cardboard is being

used, reducing airflow.15. Remove bug screen or cardboard.

7 - 8 COOLINGBR/BE

COOLING (Continued)

Page 447 of 2889

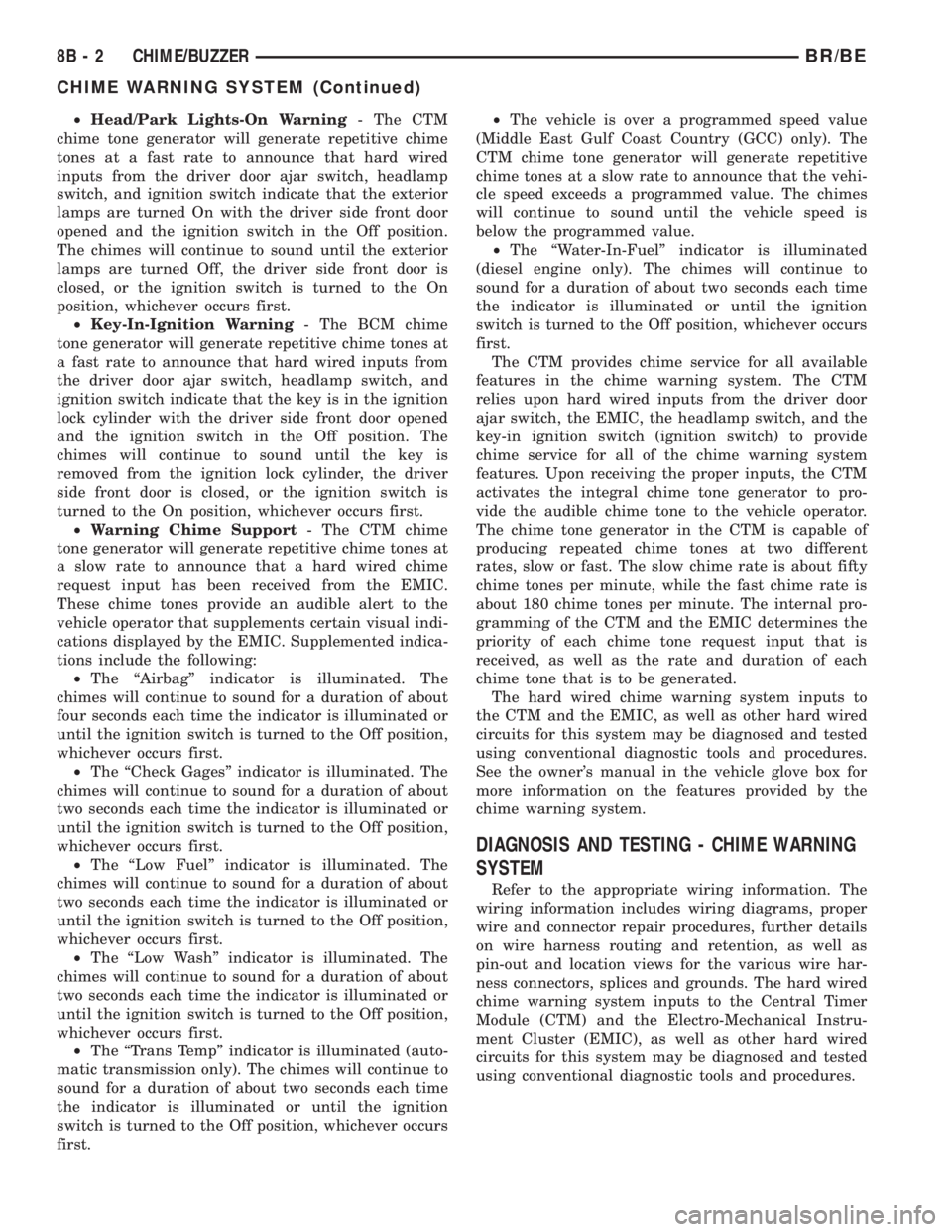

²Head/Park Lights-On Warning- The CTM

chime tone generator will generate repetitive chime

tones at a fast rate to announce that hard wired

inputs from the driver door ajar switch, headlamp

switch, and ignition switch indicate that the exterior

lamps are turned On with the driver side front door

opened and the ignition switch in the Off position.

The chimes will continue to sound until the exterior

lamps are turned Off, the driver side front door is

closed, or the ignition switch is turned to the On

position, whichever occurs first.

²Key-In-Ignition Warning- The BCM chime

tone generator will generate repetitive chime tones at

a fast rate to announce that hard wired inputs from

the driver door ajar switch, headlamp switch, and

ignition switch indicate that the key is in the ignition

lock cylinder with the driver side front door opened

and the ignition switch in the Off position. The

chimes will continue to sound until the key is

removed from the ignition lock cylinder, the driver

side front door is closed, or the ignition switch is

turned to the On position, whichever occurs first.

²Warning Chime Support- The CTM chime

tone generator will generate repetitive chime tones at

a slow rate to announce that a hard wired chime

request input has been received from the EMIC.

These chime tones provide an audible alert to the

vehicle operator that supplements certain visual indi-

cations displayed by the EMIC. Supplemented indica-

tions include the following:

²The ªAirbagº indicator is illuminated. The

chimes will continue to sound for a duration of about

four seconds each time the indicator is illuminated or

until the ignition switch is turned to the Off position,

whichever occurs first.

²The ªCheck Gagesº indicator is illuminated. The

chimes will continue to sound for a duration of about

two seconds each time the indicator is illuminated or

until the ignition switch is turned to the Off position,

whichever occurs first.

²The ªLow Fuelº indicator is illuminated. The

chimes will continue to sound for a duration of about

two seconds each time the indicator is illuminated or

until the ignition switch is turned to the Off position,

whichever occurs first.

²The ªLow Washº indicator is illuminated. The

chimes will continue to sound for a duration of about

two seconds each time the indicator is illuminated or

until the ignition switch is turned to the Off position,

whichever occurs first.

²The ªTrans Tempº indicator is illuminated (auto-

matic transmission only). The chimes will continue to

sound for a duration of about two seconds each time

the indicator is illuminated or until the ignition

switch is turned to the Off position, whichever occurs

first.²The vehicle is over a programmed speed value

(Middle East Gulf Coast Country (GCC) only). The

CTM chime tone generator will generate repetitive

chime tones at a slow rate to announce that the vehi-

cle speed exceeds a programmed value. The chimes

will continue to sound until the vehicle speed is

below the programmed value.

²The ªWater-In-Fuelº indicator is illuminated

(diesel engine only). The chimes will continue to

sound for a duration of about two seconds each time

the indicator is illuminated or until the ignition

switch is turned to the Off position, whichever occurs

first.

The CTM provides chime service for all available

features in the chime warning system. The CTM

relies upon hard wired inputs from the driver door

ajar switch, the EMIC, the headlamp switch, and the

key-in ignition switch (ignition switch) to provide

chime service for all of the chime warning system

features. Upon receiving the proper inputs, the CTM

activates the integral chime tone generator to pro-

vide the audible chime tone to the vehicle operator.

The chime tone generator in the CTM is capable of

producing repeated chime tones at two different

rates, slow or fast. The slow chime rate is about fifty

chime tones per minute, while the fast chime rate is

about 180 chime tones per minute. The internal pro-

gramming of the CTM and the EMIC determines the

priority of each chime tone request input that is

received, as well as the rate and duration of each

chime tone that is to be generated.

The hard wired chime warning system inputs to

the CTM and the EMIC, as well as other hard wired

circuits for this system may be diagnosed and tested

using conventional diagnostic tools and procedures.

See the owner's manual in the vehicle glove box for

more information on the features provided by the

chime warning system.

DIAGNOSIS AND TESTING - CHIME WARNING

SYSTEM

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds. The hard wired

chime warning system inputs to the Central Timer

Module (CTM) and the Electro-Mechanical Instru-

ment Cluster (EMIC), as well as other hard wired

circuits for this system may be diagnosed and tested

using conventional diagnostic tools and procedures.

8B - 2 CHIME/BUZZERBR/BE

CHIME WARNING SYSTEM (Continued)

Page 492 of 2889

rosion or foreign material, then reassembled.

Following reassembly, check the voltage drop for the

battery cable connection and the battery cable again

to confirm repair.

When performing the voltage drop test, it is impor-

tant to remember that the voltage drop is giving an

indication of the resistance between the two points at

which the voltmeter probes are attached.EXAM-

PLE:When testing the resistance of the battery pos-

itive cable, touch the voltmeter leads to the battery

positive cable terminal clamp and to the battery pos-

itive cable eyelet terminal at the starter solenoid

B(+) terminal stud. If you probe the battery positive

terminal post and the battery positive cable eyelet

terminal at the starter solenoid B(+) terminal stud,

you are reading the combined voltage drop in the

battery positive cable terminal clamp-to-terminal

post connection and the battery positive cable.

VOLTAGE DROP TEST

WARNING: IF THE BATTERY SHOWS SIGNS OF

FREEZING, LEAKING, LOOSE POSTS, OR LOW

ELECTROLYTE LEVEL, DO NOT TEST, ASSIST-

BOOST, OR CHARGE. THE BATTERY MAY ARC

INTERNALLY AND EXPLODE. PERSONAL INJURY

AND/OR VEHICLE DAMAGE MAY RESULT.

WARNING: EXPLOSIVE HYDROGEN GAS FORMS IN

AND AROUND THE BATTERY. DO NOT SMOKE,

USE FLAME, OR CREATE SPARKS NEAR THE BAT-

TERY. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT.

WARNING: THE BATTERY CONTAINS SULFURIC

ACID, WHICH IS POISONOUS AND CAUSTIC. AVOID

CONTACT WITH THE SKIN, EYES, OR CLOTHING.

IN THE EVENT OF CONTACT, FLUSH WITH WATER

AND CALL A PHYSICIAN IMMEDIATELY. KEEP OUT

OF THE REACH OF CHILDREN.

WARNING: IF THE BATTERY IS EQUIPPED WITH

REMOVABLE CELL CAPS, BE CERTAIN THAT EACH

OF THE CELL CAPS IS IN PLACE AND TIGHT

BEFORE THE BATTERY IS RETURNED TO SER-

VICE. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT FROM LOOSE OR MISSING

CELL CAPS.

WARNING: MODELS EQUIPPED WITH THE DIESEL

ENGINE OPTION ALSO HAVE AN AUTOMATIC

SHUTDOWN (ASD) RELAY LOCATED IN THE

POWER DISTRIBUTION CENTER (PDC), IN THE

ENGINE COMPARTMENT. HOWEVER, REMOVAL OFTHE ASD RELAY MAY NOT PREVENT THE DIESEL

ENGINE FROM STARTING. BE CERTAIN TO ALSO

DISCONNECT THE FUEL SHUTDOWN SOLENOID

WIRE HARNESS CONNECTOR ON MODELS WITH A

DIESEL ENGINE. FAILURE TO DO SO MAY RESULT

IN PERSONAL INJURY.

The following operation will require a voltmeter

accurate to 1/10 (0.10) volt. Before performing this

test, be certain that the following procedures are

accomplished:

²The battery is fully-charged and load tested.

Refer toBattery Chargingin the index of this ser-

vice manual for the location of the proper battery

charging procedures. Refer toBatteryin the index of

this service manual for the location of the battery

diagnosis and testing procedures, including the

proper battery load test procedures.

²Fully engage the parking brake.

²If the vehicle is equipped with an automatic

transmission, place the gearshift selector lever in the

Park position. If the vehicle is equipped with a man-

ual transmission, place the gearshift selector lever in

the Neutral position and block the clutch pedal in the

fully depressed position.

²Verify that all lamps and accessories are turned

off.

²To prevent a gasoline engine from starting,

remove the Automatic ShutDown (ASD) relay. The

ASD relay is located in the Power Distribution Cen-

ter (PDC), in the engine compartment. See the fuse

and relay layout label affixed to the underside of the

PDC cover for ASD relay identification and location.

To prevent a diesel engine from starting, disconnect

the fuel shutdown solenoid wire harness connector

(Fig. 21).

(1) Connect the positive lead of the voltmeter to

the battery negative terminal post. Connect the neg-

ative lead of the voltmeter to the battery negative

cable terminal clamp (Fig. 22). Rotate and hold the

ignition switch in the Start position. Observe the

voltmeter. If voltage is detected, correct the poor con-

nection between the battery negative cable terminal

clamp and the battery negative terminal post.

NOTE: If the vehicle is equipped with a dual battery

system, Step 1 must be performed twice, once for

each battery.

(2) Connect the positive lead of the voltmeter to

the battery positive terminal post. Connect the nega-

tive lead of the voltmeter to the battery positive cable

terminal clamp (Fig. 23). Rotate and hold the ignition

switch in the Start position. Observe the voltmeter. If

voltage is detected, correct the poor connection

between the battery positive cable terminal clamp

and the battery positive terminal post.

BR/BEBATTERY SYSTEM 8F - 21

BATTERY CABLE (Continued)

Page 538 of 2889

IGNITION CONTROL

TABLE OF CONTENTS

page page

IGNITION CONTROL

DESCRIPTION............................1

OPERATION.............................1

SPECIFICATIONS.........................2

AUTOMATIC SHUT DOWN RELAY

DESCRIPTION............................3

OPERATION.............................3

DIAGNOSIS AND TESTING..................3

ASD AND FUEL PUMP RELAYS.............3

REMOVAL...............................4

INSTALLATION............................5

CAMSHAFT POSITION SENSOR

DESCRIPTION............................5

OPERATION.............................5

REMOVAL...............................7

INSTALLATION............................8

DISTRIBUTOR

DESCRIPTION...........................10

OPERATION.............................11

REMOVAL..............................11

INSTALLATION...........................11

DISTRIBUTOR CAP

DIAGNOSIS AND TESTING.................12

DISTRIBUTOR CAP.....................12DISTRIBUTOR ROTOR

DIAGNOSIS AND TESTING.................13

DISTRIBUTOR ROTOR...................13

IGNITION COIL

DESCRIPTION...........................13

OPERATION.............................14

REMOVAL..............................14

INSTALLATION...........................15

SPARK PLUG

DESCRIPTION...........................16

OPERATION.............................16

DIAGNOSIS AND TESTING.................16

SPARK PLUG CONDITIONS...............16

REMOVAL..............................18

CLEANING..............................19

INSTALLATION...........................19

SPARK PLUG CABLE

DESCRIPTION...........................19

OPERATION.............................19

DIAGNOSIS AND TESTING.................19

SPARK PLUG CABLES...................19

REMOVAL..............................20

INSTALLATION...........................20

IGNITION CONTROL

DESCRIPTION - 8.0L V-10

The ignition system used on the 8.0L V±10 engine

does not use a conventional mechanical distributor.

The system will be referred to as a distributor-less

ignition system.

DESCRIPTION - V-6/V-8

The ignition systems used on the 3.9L V-6, the

5.2L V-8 and the 5.9L V-8 are basically identical.

OPERATION - 8.0L V-10

The ignition coils are individually fired, but each

coil is a dual output. Refer to Ignition Coil for addi-

tional information.

The ignition system is controlled by the Powertrain

Control Module (PCM) on all engines.

The ignition system consists of:

²Spark Plugs

²Ignition Coil packs containing individual coils²Secondary Ignition Cables

²Powertrain Control Module (PCM)

²Also to be considered part of the ignition system

are certain inputs from the Crankshaft Position,

Camshaft Position, Throttle Position and MAP Sen-

sors

OPERATION - V-6/V-8

The ignition system is controlled by the Powertrain

Control Module (PCM) on all engines.

The ignition system consists of:

²Spark Plugs

²Ignition Coil

²Secondary Ignition Cables

²Distributor (contains rotor and camshaft position

sensor)

²Powertrain Control Module (PCM)

²Also to be considered part of the ignition system

are certain inputs from the Crankshaft Position,

Camshaft Position, Throttle Position and MAP Sen-

sors

BR/BEIGNITION CONTROL 8I - 1

Page 544 of 2889

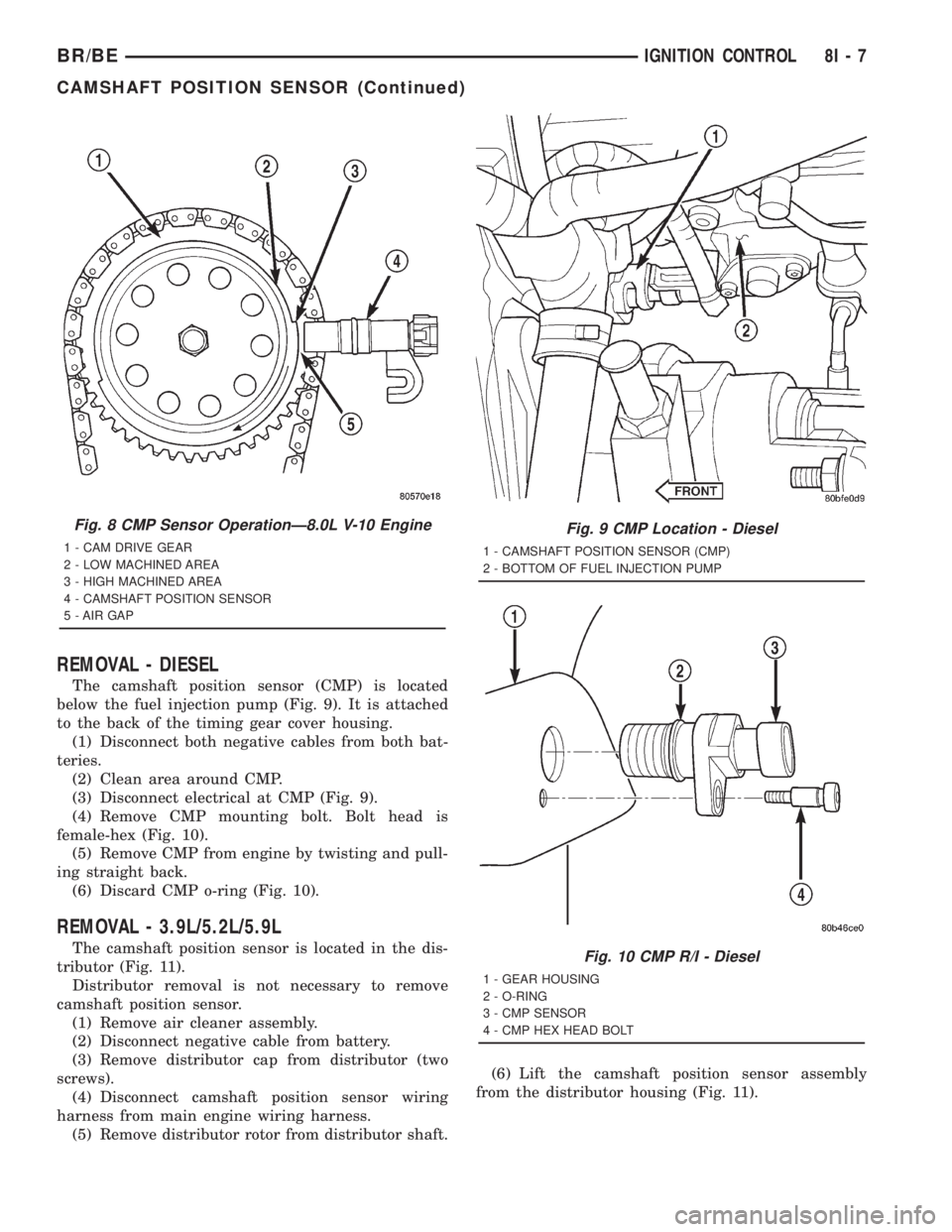

REMOVAL - DIESEL

The camshaft position sensor (CMP) is located

below the fuel injection pump (Fig. 9). It is attached

to the back of the timing gear cover housing.

(1) Disconnect both negative cables from both bat-

teries.

(2) Clean area around CMP.

(3) Disconnect electrical at CMP (Fig. 9).

(4) Remove CMP mounting bolt. Bolt head is

female-hex (Fig. 10).

(5) Remove CMP from engine by twisting and pull-

ing straight back.

(6) Discard CMP o-ring (Fig. 10).

REMOVAL - 3.9L/5.2L/5.9L

The camshaft position sensor is located in the dis-

tributor (Fig. 11).

Distributor removal is not necessary to remove

camshaft position sensor.

(1) Remove air cleaner assembly.

(2) Disconnect negative cable from battery.

(3) Remove distributor cap from distributor (two

screws).

(4) Disconnect camshaft position sensor wiring

harness from main engine wiring harness.

(5) Remove distributor rotor from distributor shaft.(6) Lift the camshaft position sensor assembly

from the distributor housing (Fig. 11).

Fig. 8 CMP Sensor OperationÐ8.0L V-10 Engine

1 - CAM DRIVE GEAR

2 - LOW MACHINED AREA

3 - HIGH MACHINED AREA

4 - CAMSHAFT POSITION SENSOR

5 - AIR GAP

Fig. 9 CMP Location - Diesel

1 - CAMSHAFT POSITION SENSOR (CMP)

2 - BOTTOM OF FUEL INJECTION PUMP

Fig. 10 CMP R/I - Diesel

1 - GEAR HOUSING

2 - O-RING

3 - CMP SENSOR

4 - CMP HEX HEAD BOLT

BR/BEIGNITION CONTROL 8I - 7

CAMSHAFT POSITION SENSOR (Continued)

Page 548 of 2889

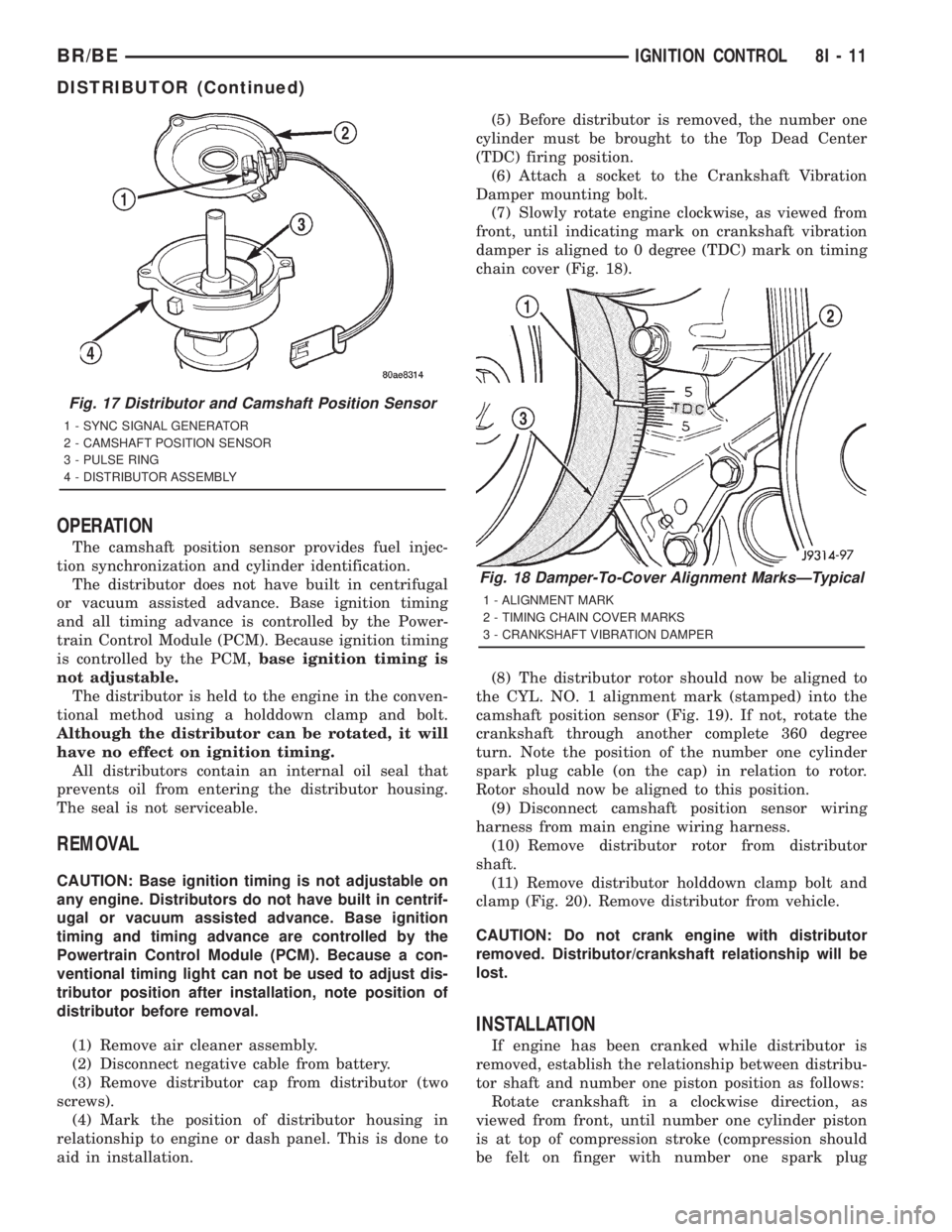

OPERATION

The camshaft position sensor provides fuel injec-

tion synchronization and cylinder identification.

The distributor does not have built in centrifugal

or vacuum assisted advance. Base ignition timing

and all timing advance is controlled by the Power-

train Control Module (PCM). Because ignition timing

is controlled by the PCM,base ignition timing is

not adjustable.

The distributor is held to the engine in the conven-

tional method using a holddown clamp and bolt.

Although the distributor can be rotated, it will

have no effect on ignition timing.

All distributors contain an internal oil seal that

prevents oil from entering the distributor housing.

The seal is not serviceable.

REMOVAL

CAUTION: Base ignition timing is not adjustable on

any engine. Distributors do not have built in centrif-

ugal or vacuum assisted advance. Base ignition

timing and timing advance are controlled by the

Powertrain Control Module (PCM). Because a con-

ventional timing light can not be used to adjust dis-

tributor position after installation, note position of

distributor before removal.

(1) Remove air cleaner assembly.

(2) Disconnect negative cable from battery.

(3) Remove distributor cap from distributor (two

screws).

(4) Mark the position of distributor housing in

relationship to engine or dash panel. This is done to

aid in installation.(5) Before distributor is removed, the number one

cylinder must be brought to the Top Dead Center

(TDC) firing position.

(6) Attach a socket to the Crankshaft Vibration

Damper mounting bolt.

(7) Slowly rotate engine clockwise, as viewed from

front, until indicating mark on crankshaft vibration

damper is aligned to 0 degree (TDC) mark on timing

chain cover (Fig. 18).

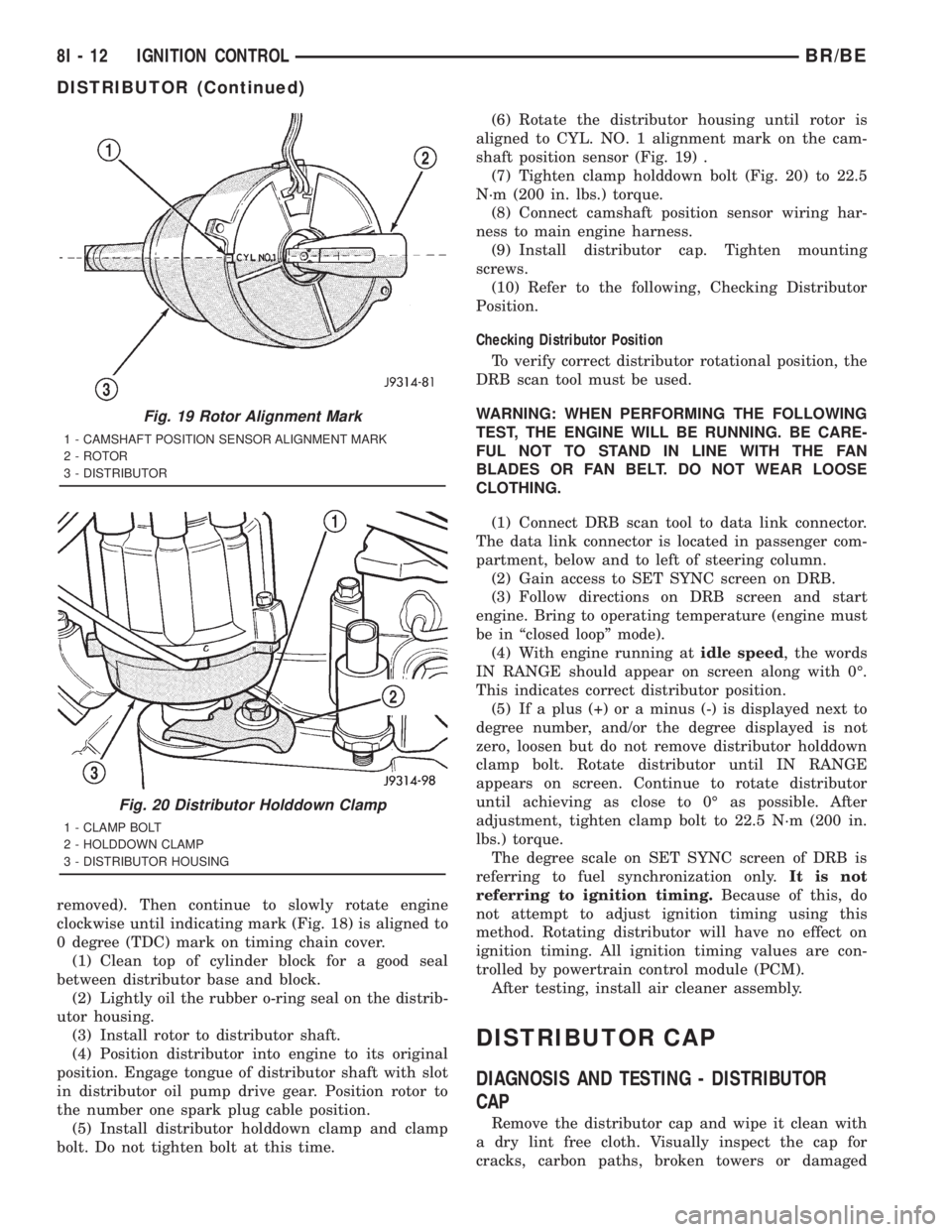

(8) The distributor rotor should now be aligned to

the CYL. NO. 1 alignment mark (stamped) into the

camshaft position sensor (Fig. 19). If not, rotate the

crankshaft through another complete 360 degree

turn. Note the position of the number one cylinder

spark plug cable (on the cap) in relation to rotor.

Rotor should now be aligned to this position.

(9) Disconnect camshaft position sensor wiring

harness from main engine wiring harness.

(10) Remove distributor rotor from distributor

shaft.

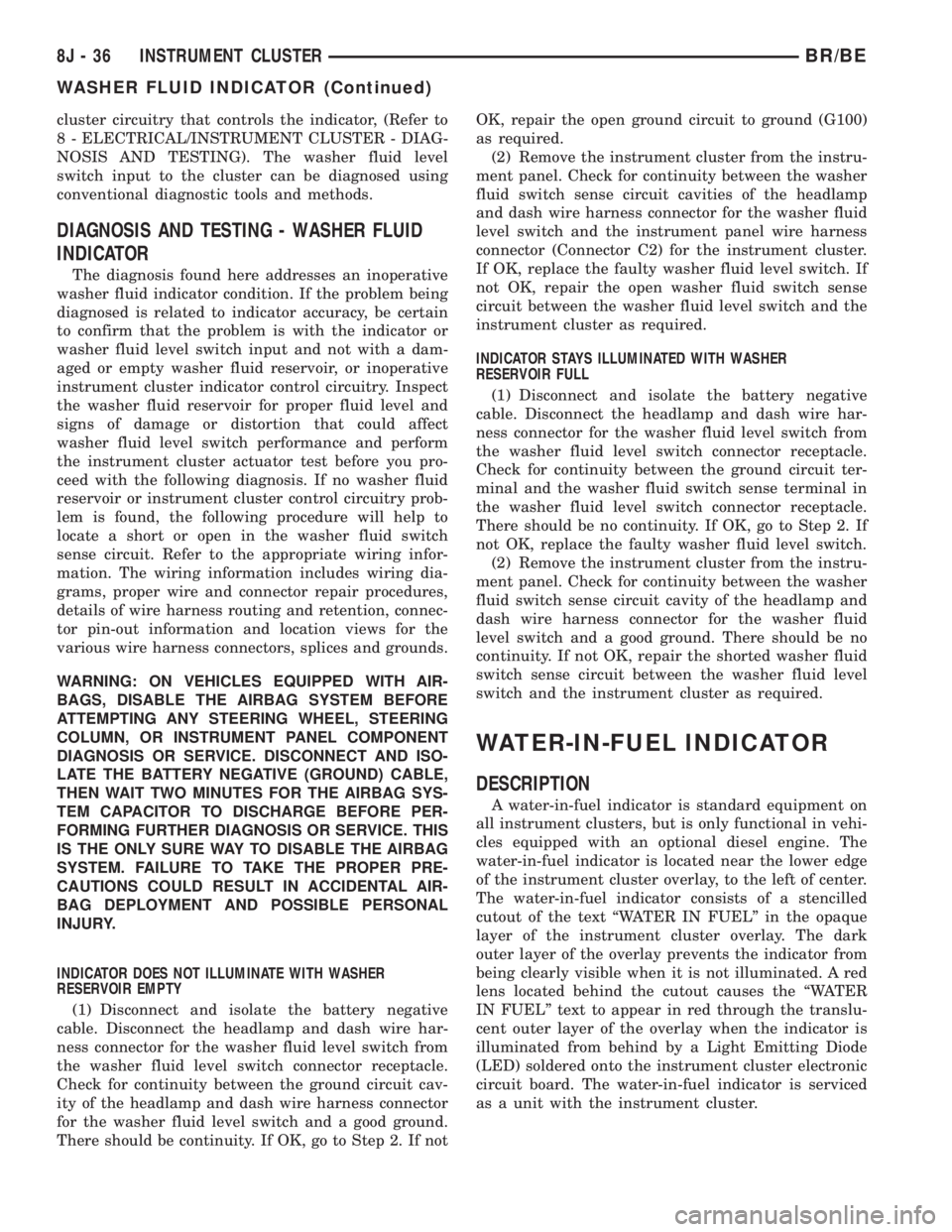

(11) Remove distributor holddown clamp bolt and

clamp (Fig. 20). Remove distributor from vehicle.

CAUTION: Do not crank engine with distributor

removed. Distributor/crankshaft relationship will be

lost.

INSTALLATION

If engine has been cranked while distributor is

removed, establish the relationship between distribu-

tor shaft and number one piston position as follows:

Rotate crankshaft in a clockwise direction, as

viewed from front, until number one cylinder piston

is at top of compression stroke (compression should

be felt on finger with number one spark plug

Fig. 17 Distributor and Camshaft Position Sensor

1 - SYNC SIGNAL GENERATOR

2 - CAMSHAFT POSITION SENSOR

3 - PULSE RING

4 - DISTRIBUTOR ASSEMBLY

Fig. 18 Damper-To-Cover Alignment MarksÐTypical

1 - ALIGNMENT MARK

2 - TIMING CHAIN COVER MARKS

3 - CRANKSHAFT VIBRATION DAMPER

BR/BEIGNITION CONTROL 8I - 11

DISTRIBUTOR (Continued)

Page 549 of 2889

removed). Then continue to slowly rotate engine

clockwise until indicating mark (Fig. 18) is aligned to

0 degree (TDC) mark on timing chain cover.

(1) Clean top of cylinder block for a good seal

between distributor base and block.

(2) Lightly oil the rubber o-ring seal on the distrib-

utor housing.

(3) Install rotor to distributor shaft.

(4) Position distributor into engine to its original

position. Engage tongue of distributor shaft with slot

in distributor oil pump drive gear. Position rotor to

the number one spark plug cable position.

(5) Install distributor holddown clamp and clamp

bolt. Do not tighten bolt at this time.(6) Rotate the distributor housing until rotor is

aligned to CYL. NO. 1 alignment mark on the cam-

shaft position sensor (Fig. 19) .

(7) Tighten clamp holddown bolt (Fig. 20) to 22.5

N´m (200 in. lbs.) torque.

(8) Connect camshaft position sensor wiring har-

ness to main engine harness.

(9) Install distributor cap. Tighten mounting

screws.

(10) Refer to the following, Checking Distributor

Position.

Checking Distributor Position

To verify correct distributor rotational position, the

DRB scan tool must be used.

WARNING: WHEN PERFORMING THE FOLLOWING

TEST, THE ENGINE WILL BE RUNNING. BE CARE-

FUL NOT TO STAND IN LINE WITH THE FAN

BLADES OR FAN BELT. DO NOT WEAR LOOSE

CLOTHING.

(1) Connect DRB scan tool to data link connector.

The data link connector is located in passenger com-

partment, below and to left of steering column.

(2) Gain access to SET SYNC screen on DRB.

(3) Follow directions on DRB screen and start

engine. Bring to operating temperature (engine must

be in ªclosed loopº mode).

(4) With engine running atidle speed, the words

IN RANGE should appear on screen along with 0É.

This indicates correct distributor position.

(5) If a plus (+) or a minus (-) is displayed next to

degree number, and/or the degree displayed is not

zero, loosen but do not remove distributor holddown

clamp bolt. Rotate distributor until IN RANGE

appears on screen. Continue to rotate distributor

until achieving as close to 0É as possible. After

adjustment, tighten clamp bolt to 22.5 N´m (200 in.

lbs.) torque.

The degree scale on SET SYNC screen of DRB is

referring to fuel synchronization only.It is not

referring to ignition timing.Because of this, do

not attempt to adjust ignition timing using this

method. Rotating distributor will have no effect on

ignition timing. All ignition timing values are con-

trolled by powertrain control module (PCM).

After testing, install air cleaner assembly.

DISTRIBUTOR CAP

DIAGNOSIS AND TESTING - DISTRIBUTOR

CAP

Remove the distributor cap and wipe it clean with

a dry lint free cloth. Visually inspect the cap for

cracks, carbon paths, broken towers or damaged

Fig. 19 Rotor Alignment Mark

1 - CAMSHAFT POSITION SENSOR ALIGNMENT MARK

2 - ROTOR

3 - DISTRIBUTOR

Fig. 20 Distributor Holddown Clamp

1 - CLAMP BOLT

2 - HOLDDOWN CLAMP

3 - DISTRIBUTOR HOUSING

8I - 12 IGNITION CONTROLBR/BE

DISTRIBUTOR (Continued)

Page 595 of 2889

cluster circuitry that controls the indicator, (Refer to

8 - ELECTRICAL/INSTRUMENT CLUSTER - DIAG-

NOSIS AND TESTING). The washer fluid level

switch input to the cluster can be diagnosed using

conventional diagnostic tools and methods.

DIAGNOSIS AND TESTING - WASHER FLUID

INDICATOR

The diagnosis found here addresses an inoperative

washer fluid indicator condition. If the problem being

diagnosed is related to indicator accuracy, be certain

to confirm that the problem is with the indicator or

washer fluid level switch input and not with a dam-

aged or empty washer fluid reservoir, or inoperative

instrument cluster indicator control circuitry. Inspect

the washer fluid reservoir for proper fluid level and

signs of damage or distortion that could affect

washer fluid level switch performance and perform

the instrument cluster actuator test before you pro-

ceed with the following diagnosis. If no washer fluid

reservoir or instrument cluster control circuitry prob-

lem is found, the following procedure will help to

locate a short or open in the washer fluid switch

sense circuit. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

details of wire harness routing and retention, connec-

tor pin-out information and location views for the

various wire harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

INDICATOR DOES NOT ILLUMINATE WITH WASHER

RESERVOIR EMPTY

(1) Disconnect and isolate the battery negative

cable. Disconnect the headlamp and dash wire har-

ness connector for the washer fluid level switch from

the washer fluid level switch connector receptacle.

Check for continuity between the ground circuit cav-

ity of the headlamp and dash wire harness connector

for the washer fluid level switch and a good ground.

There should be continuity. If OK, go to Step 2. If notOK, repair the open ground circuit to ground (G100)

as required.

(2) Remove the instrument cluster from the instru-

ment panel. Check for continuity between the washer

fluid switch sense circuit cavities of the headlamp

and dash wire harness connector for the washer fluid

level switch and the instrument panel wire harness

connector (Connector C2) for the instrument cluster.

If OK, replace the faulty washer fluid level switch. If

not OK, repair the open washer fluid switch sense

circuit between the washer fluid level switch and the

instrument cluster as required.

INDICATOR STAYS ILLUMINATED WITH WASHER

RESERVOIR FULL

(1) Disconnect and isolate the battery negative

cable. Disconnect the headlamp and dash wire har-

ness connector for the washer fluid level switch from

the washer fluid level switch connector receptacle.

Check for continuity between the ground circuit ter-

minal and the washer fluid switch sense terminal in

the washer fluid level switch connector receptacle.

There should be no continuity. If OK, go to Step 2. If

not OK, replace the faulty washer fluid level switch.

(2) Remove the instrument cluster from the instru-

ment panel. Check for continuity between the washer

fluid switch sense circuit cavity of the headlamp and

dash wire harness connector for the washer fluid

level switch and a good ground. There should be no

continuity. If not OK, repair the shorted washer fluid

switch sense circuit between the washer fluid level

switch and the instrument cluster as required.

WATER-IN-FUEL INDICATOR

DESCRIPTION

A water-in-fuel indicator is standard equipment on

all instrument clusters, but is only functional in vehi-

cles equipped with an optional diesel engine. The

water-in-fuel indicator is located near the lower edge

of the instrument cluster overlay, to the left of center.

The water-in-fuel indicator consists of a stencilled

cutout of the text ªWATER IN FUELº in the opaque

layer of the instrument cluster overlay. The dark

outer layer of the overlay prevents the indicator from

being clearly visible when it is not illuminated. A red

lens located behind the cutout causes the ªWATER

IN FUELº text to appear in red through the translu-

cent outer layer of the overlay when the indicator is

illuminated from behind by a Light Emitting Diode

(LED) soldered onto the instrument cluster electronic

circuit board. The water-in-fuel indicator is serviced

as a unit with the instrument cluster.

8J - 36 INSTRUMENT CLUSTERBR/BE

WASHER FLUID INDICATOR (Continued)