horn DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1 of 2889

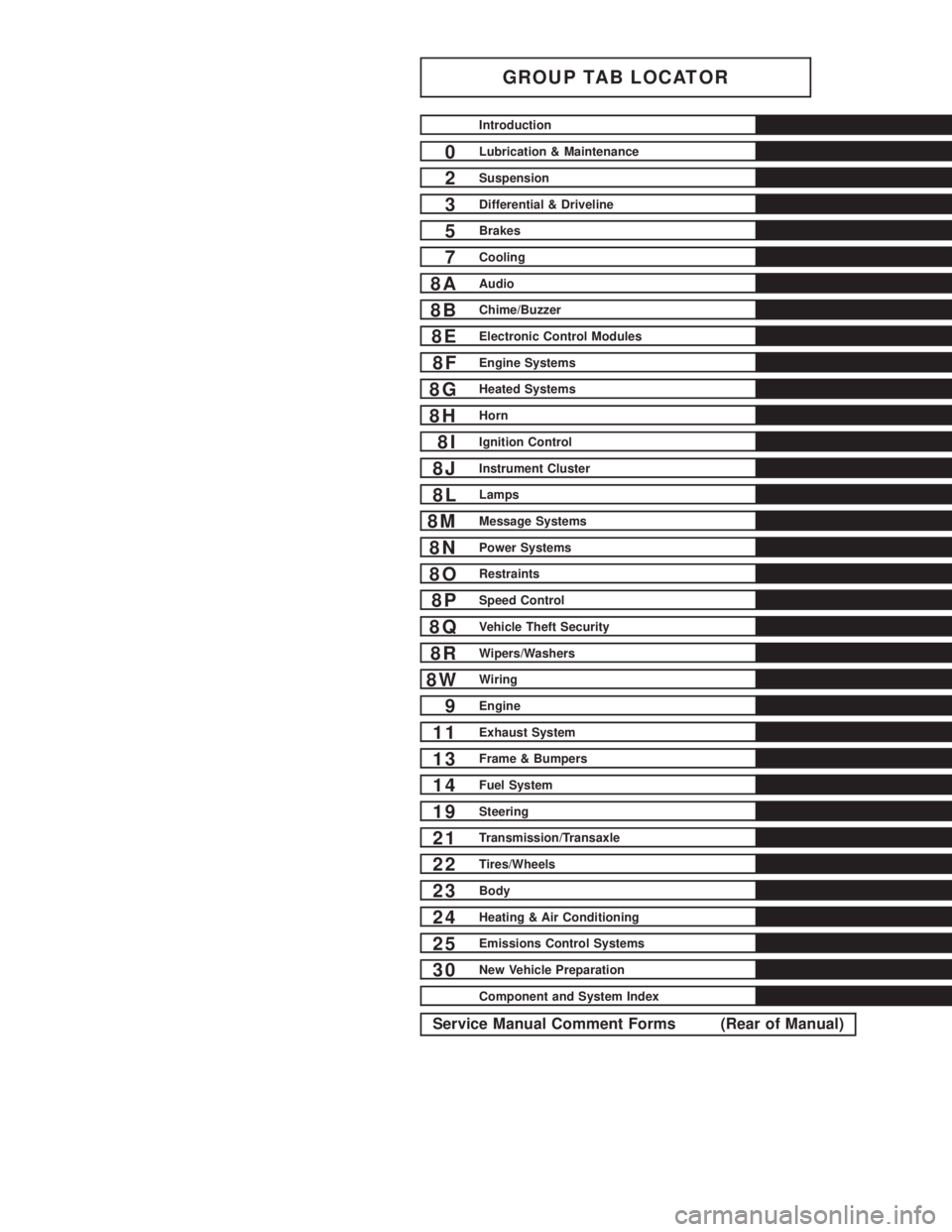

GROUP TAB LOCATOR

Introduction

0Lubrication & Maintenance

2Suspension

3Differential & Driveline

5Brakes

7Cooling

8AAudio

8BChime/Buzzer

8EElectronic Control Modules

8FEngine Systems

8GHeated Systems

8HHorn

8IIgnition Control

8JInstrument Cluster

8LLamps

8MMessage Systems

8NPower Systems

8ORestraints

8PSpeed Control

8QVehicle Theft Security

8RWipers/Washers

8WWiring

9Engine

11Exhaust System

13Frame & Bumpers

14Fuel System

19Steering

21Transmission/Transaxle

22Tires/Wheels

23Body

24Heating & Air Conditioning

25Emissions Control Systems

30New Vehicle Preparation

Component and System Index

Service Manual Comment Forms (Rear of Manual)

Page 7 of 2889

FASTENER USAGE

DESCRIPTION - FASTENER USAGE

WARNING: USE OF AN INCORRECT FASTENER

MAY RESULT IN COMPONENT DAMAGE OR PER-

SONAL INJURY.

Figure art, specifications and torque references in

this Service Manual are identified in metric and SAE

format.

During any maintenance or repair procedures, it is

important to salvage all fasteners (nuts, bolts, etc.)

for reassembly. If the fastener is not salvageable, a

fastener of equivalent specification must be used.

DESCRIPTION - THREADED HOLE REPAIR

Most stripped threaded holes can be repaired using

a Helicoilt. Follow the manufactures recommenda-

tions for application and repair procedures.

INTERNATIONAL VEHICLE

CONTROL & DISPLAY

SYMBOLS

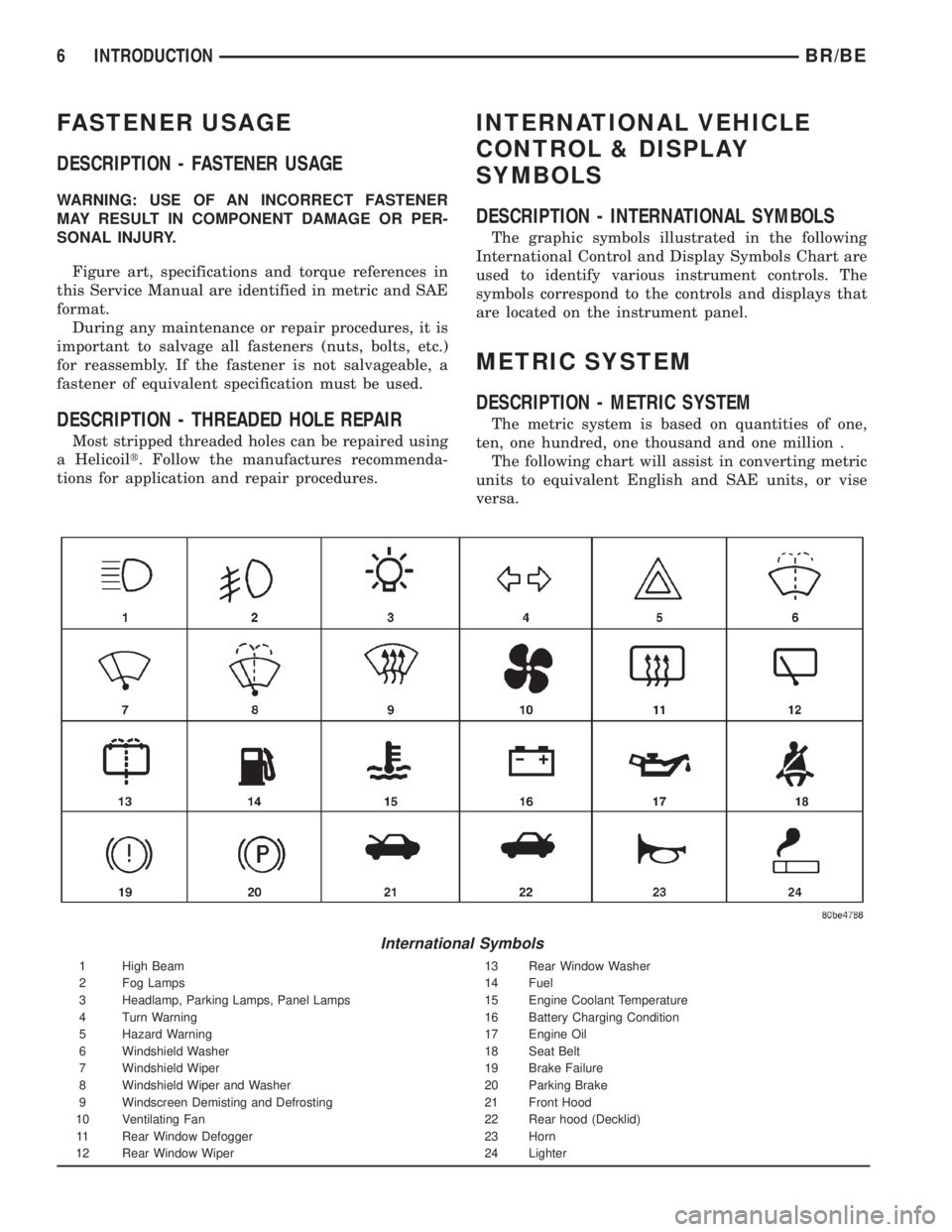

DESCRIPTION - INTERNATIONAL SYMBOLS

The graphic symbols illustrated in the following

International Control and Display Symbols Chart are

used to identify various instrument controls. The

symbols correspond to the controls and displays that

are located on the instrument panel.

METRIC SYSTEM

DESCRIPTION - METRIC SYSTEM

The metric system is based on quantities of one,

ten, one hundred, one thousand and one million .

The following chart will assist in converting metric

units to equivalent English and SAE units, or vise

versa.

International Symbols

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Windscreen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

6 INTRODUCTIONBR/BE

Page 453 of 2889

external connector receptacles that connect it to the

vehicle electrical system through one (base) or two

(high-line/premium) take outs with connectors from

the instrument panel wire harness.

The base version of the CTM is used on base mod-

els of this vehicle. It is also sometimes referred to as

the Integrated Electronic Module (IEM). The base

version of the CTM combines the functions of a

chime module and an intermittent wipe module in a

single unit. The high-line version of the CTM is used

on high-line vehicles. The high-line CTM provides all

of the functions of the base version of the CTM, but

also is used to control and integrate many additional

electronic functions and features included on high-

line models. The premium version of the CTM is the

same as the high-line version, but is used only on

models equipped with the heated seat option.

The high-line and premium versions of the CTM

utilize integrated circuitry and information carried

on the Chrysler Collision Detection (CCD) data bus

network along with many hard wired inputs to mon-

itor many sensor and switch inputs throughout the

vehicle. In response to those inputs, the internal cir-

cuitry and programming of the CTM allow it to con-

trol and integrate many electronic functions and

features of the vehicle through both hard wired out-

puts and the transmission of electronic message out-

puts to other electronic modules in the vehicle over

the CCD data bus.

The features that the CTM supports or controls

include the following:

²Automatic Door Lock- The high-line/premium

CTM provides an optional automatic door lock fea-

ture (also known as rolling door locks). This is a pro-

grammable feature.

²Central Locking- The high-line/premium CTM

provides an optional central locking/unlocking fea-

ture.

²Chimes- All versions of the CTM provide chime

service through an integral chime tone generator.

²Courtesy Lamps- The high-line/premium CTM

provides courtesy lamp control with timed load shed-

ding.

²Door Lock Inhibit- The high-line/premium

CTM provides a door lock inhibit feature.

²Enhanced Accident Response- The high-line/

premium CTM provides an optional enhanced acci-

dent response feature. This is a programmable

feature.

²Heated Seats- The premium CTM controls the

optional heated seat system by controlling the opera-

tion of the heated seat relay.

²Illuminated Entry- The high-line/premium

CTM provides a timed illuminated entry feature.²Intermittent Wipe Control- All versions of

the CTM provide control of the intermittent wipe

delay, and wipe-after-wash features.

²Panic Mode- The high-line/premium CTM pro-

vides support for the optional RKE system panic

mode features.

²Power Lock Control- The high-line/premium

CTM provides the optional power lock system fea-

tures, including support for the automatic door lock

and door lock inhibit modes.

²Programmable Features- The high-line/pre-

mium CTM provides support for certain programma-

ble features.

²Remote Keyless Entry- The high-line/pre-

mium CTM provides the optional Remote Keyless

Entry (RKE) system features, including support for

the RKE Lock (with optional horn chirp), Unlock,

Panic, and illuminated entry modes, as well as the

ability to be programmed to recognize up to four

RKE transmitters. The RKE horn chirp is a program-

mable feature.

²Remote Radio Switch Interface- The high-

line/premium CTM monitors and transmits the sta-

tus of the optional remote radio switches.

²Speed Sensitive Intermittent Wipe Control-

The high-line/premium CTM provides the speed sen-

sitive intermittent wipe feature.

²Vehicle Theft Alarm- The high-line/premium

CTM provides control of the optional Vehicle Theft

Alarm features, including support for the central

locking/unlocking mode.

Hard wired circuitry connects the CTM to the elec-

trical system of the vehicle. These hard wired circuits

are integral to several wire harnesses, which are

routed throughout the vehicle and retained by many

different methods. These circuits may be connected to

each other, to the vehicle electrical system and to the

CTM through the use of a combination of soldered

splices, splice block connectors, and many different

types of wire harness terminal connectors and insu-

lators. Refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, further

details on wire harness routing and retention, as well

as pin-out and location views for the various wire

harness connectors, splices and grounds.

All versions of the CTM for this model are serviced

only as a complete unit. Many of the electronic fea-

tures in the vehicle controlled or supported by the

high-line or premium versions of the CTM are pro-

grammable using the DRBIIItscan tool. In addition,

the high-line/premium CTM software is Flash com-

patible, which means it can be reprogrammed using

Flash reprogramming procedures. However, if any of

the CTM hardware components are damaged or

faulty, the entire CTM unit must be replaced. The

8E - 2 ELECTRONIC CONTROL MODULESBR/BE

BODY CONTROL/CENTRAL TIMER MODULE (Continued)

Page 455 of 2889

²Horn relay control - high-line/premium version

only

²VTSS indicator driver - high-line/premium ver-

sion only

²Wiper motor relay control

MESSAGING

The high-line/premium CTM uses the following

messages received from other electronic modules over

the CCD data bus:

²Airbag Deploy (ACM)

²Charging System Failure (PCM)

²Engine RPM (PCM)

²System Voltage (PCM)

²Vehicle Speed (PCM)

²Voltage Fault (PCM)

The high-line/premium CTM provides the following

messages to other electronic modules over the CCD

data bus:

²Engine Enable (PCM)

²Radio Seek Up (Radio)

²Radio Seek Down (Radio)

²Radio Volume Up (Radio)

²Radio Volume Down (Radio)

²Preset Scan (Radio)

DIAGNOSIS AND TESTING - CENTRAL TIMER

MODULE

The hard wired inputs to and outputs from the

Central Timer Module (CTM) may be diagnosed and

tested using conventional diagnostic tools and meth-

ods. Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds.

However, conventional diagnostic methods may not

prove conclusive in the diagnosis of the high-line/pre-

mium CTM. In order to obtain conclusive testing of

the high-line/premium CTM, the Chrysler Collision

Detection (CCD) data bus network and all of the elec-

tronic modules that provide inputs to or receive out-

puts from the CTM must also be checked. The most

reliable, efficient, and accurate means to diagnose

the high-line/premium CTM, the CCD data bus net-

work, and the electronic modules that provide inputs

to or receive outputs from the high-line/premium

CTM requires the use of a DRBIIItscan tool and the

appropriate diagnostic information. The DRBIIIt

scan tool can provide confirmation that the CCD data

bus network is functional, that all of the electronic

modules are sending and receiving the proper mes-

sages over the CCD data bus, and that the CTM is

receiving the proper hard wired inputs and respond-ing with the proper hard wired outputs needed to

perform its many functions.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: The following tests may not prove conclu-

sive in the diagnosis of the high-line or premium

versions of the Central Timer Module (CTM). The

most reliable, efficient, and accurate means to diag-

nose the high-line or premium CTM requires the

use of a DRBIIITscan tool and the appropriate diag-

nostic information.

(1) Check the fused B(+) fuse (Fuse 13 - 10

ampere) in the Junction Block (JB). If OK, go to Step

2. If not OK, repair the shorted circuit or component

as required and replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

(Fuse 13 - 10 ampere) in the JB. If OK, go to Step 3.

If not OK, repair the open fused B(+) circuit between

the JB and the Power Distribution Center (PDC) as

required.

(3) For a base version CTM, check the fused igni-

tion switch output (st-run) fuse (Fuse 11 - 10 ampere)

in the JB. For a high-line/premium version CTM,

check the fused ignition switch output (run-acc) fuse

(Fuse6-25ampere) in the JB. If OK, go to Step 4. If

not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(4) Turn the ignition switch to the On position. For

a base version CTM, check for battery voltage at the

fused ignition switch output (st-run) fuse (Fuse 11 -

10 ampere) in the JB. For a high-line/premium ver-

sion CTM, check for battery voltage at the fused igni-

tion switch output (run-acc) fuse (Fuse6-25

ampere) in the JB. If OK, go to Step 5. If not OK,

repair the shorted circuit or component as required

and replace the faulty fuse.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the CTM from its mounting bracket to access

the CTM wire harness connector(s). Disconnect the

instrument panel wire harness connector(s) for the

8E - 4 ELECTRONIC CONTROL MODULESBR/BE

BODY CONTROL/CENTRAL TIMER MODULE (Continued)

Page 532 of 2889

HORN

TABLE OF CONTENTS

page page

HORN

DESCRIPTION............................1

OPERATION.............................1

HORN

DESCRIPTION............................2

OPERATION.............................2

DIAGNOSIS AND TESTING..................2

HORN................................2

REMOVAL...............................2

INSTALLATION............................3

HORN RELAY

DESCRIPTION............................3OPERATION.............................3

DIAGNOSIS AND TESTING..................3

HORN RELAY..........................3

REMOVAL...............................4

INSTALLATION............................4

HORN SWITCH

DESCRIPTION............................4

OPERATION.............................5

DIAGNOSIS AND TESTING..................5

HORN SWITCH.........................5

REMOVAL...............................5

HORN

DESCRIPTION

An electric horn system is standard factory-in-

stalled equipment on this model. Two horn systems

are offered on this model. The standard equipment

horn system features a single low-note electromag-

netic horn unit, while the optional dual horn system

features one low-note horn unit and one high-note

horn unit. Both horn systems use a non-switched

source of battery current so that the system will

remain functional, regardless of the ignition switch

position. The horn system includes the following com-

ponents:

²Clockspring

²High-line or premium Central Timer Module

(CTM)

²Horn(s)

²Horn relay

²Horn switch

(Refer to 8 - ELECTRICAL/RESTRAINTS/CLOCK-

SPRING - DESCRIPTION) for more information on

this component. (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/BODY CONTROL/

CENTRAL TIMER MODUL - DESCRIPTION) for

more information on this component. Refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds. Following are general

descriptions of the remaining major components in

the horn system.

OPERATION

Each horn system is activated by a horn switch

concealed beneath the driver side airbag module trim

cover in the center of the steering wheel. Depressing

the center of the driver side airbag module trim cover

closes the horn switch. Closing the horn switch acti-

vates the horn relay. The activated horn relay then

switches the battery current needed to energize the

horn(s).

Refer to the owner's manual in the vehicle glove

box for more information on the features, use and

operation of the horn system.

CENTRAL TIMER MODULE

The high-line or premium Central Timer Module

(CTM) can also operate the horn system. A high-line

CTM is used on high-line versions of this vehicle. A

premium CTM is used on vehicles equipped with the

optional heated seats. The CTM combines the func-

tions of a chime/buzzer module, an intermittent wipe

module, an illuminated entry module, a remote key-

less entry module, and a vehicle theft security sys-

tem module in a single unit.

The high-line or premium CTM also controls and

integrates many of the additional electronic functions

and features included on models with this option.

The horn relay is one of the hard wired outputs of

the CTM. The high-line or premium CTM is pro-

grammed to energize or de-energize the horn relay in

response to certain inputs from the Vehicle Theft

Security System (VTSS) and/or the Remote Keyless

Entry (RKE) system.

(Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/BODY CONTROL/CENTRAL

TIMER MODUL - DESCRIPTION) for more informa-

BR/BEHORN 8H - 1

Page 533 of 2889

tion on the high-line or premium CTM. (Refer to 8 -

ELECTRICAL/VEHICLE THEFT SECURITY - GEN-

ERAL INFORMATION) for more information on the

VTSS. (Refer to 8 - ELECTRICAL/POWER LOCKS -

GENERAL INFORMATION) for more information on

the RKE system.

HORN

DESCRIPTION

The standard single, low-note, electromagnetic dia-

phragm-type horn is secured with a bracket to the

right front fender wheel house extension in the

engine compartment. The high-note horn for the

optional dual-note horn system is connected in paral-

lel with and secured with a bracket just forward of

the low-note horn. Each horn is grounded through its

wire harness connector and circuit to a ground splice

joint connector, and receives battery feed through the

closed contacts of the horn relay.

The horns cannot be repaired or adjusted and, if

faulty or damaged, they must be individually replaced.

OPERATION

Within the two halves of the molded plastic horn

housing are a flexible diaphragm, a plunger, an elec-

tromagnetic coil and a set of contact points. The dia-

phragm is secured in suspension around its

perimeter by the mating surfaces of the horn hous-

ing. The plunger is secured to the center of the dia-

phragm and extends into the center of the

electromagnet. The contact points control the current

flow through the electromagnet.

When the horn is energized, electrical current

flows through the closed contact points to the electro-

magnet. The resulting electromagnetic field draws

the plunger and diaphragm toward it until that

movement mechanically opens the contact points.

When the contact points open, the electromagnetic

field collapses allowing the plunger and diaphragm to

return to their relaxed positions and closing the con-

tact points again. This cycle continues repeating at a

very rapid rate producing the vibration and move-

ment of air that creates the sound that is directed

through the horn outlet.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - HORN

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information andlocation views for the various wire harness connec-

tors, splices and grounds.

(1) Disconnect the wire harness connector(s) from

the horn connector receptacle(s). Measure the resis-

tance between the ground circuit cavity of the horn(s)

wire harness connector(s) and a good ground. There

should be no measurable resistance. If OK, go to Step

2. If not OK, repair the open ground circuit to ground

as required.

(2) Check for battery voltage at the horn relay out-

put circuit cavity of the horn(s) wire harness connec-

tor(s). There should be zero volts. If OK, go to Step 3.

If not OK, repair the shorted horn relay output cir-

cuit or replace the faulty horn relay as required.

(3) Depress the horn switch. There should now be

battery voltage at the horn relay output circuit cavity

of the horn(s) wire harness connector(s). If OK,

replace the faulty horn(s). If not OK, repair the open

horn relay output circuit to the horn relay as

required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Disconnect the wire harness connector(s) from

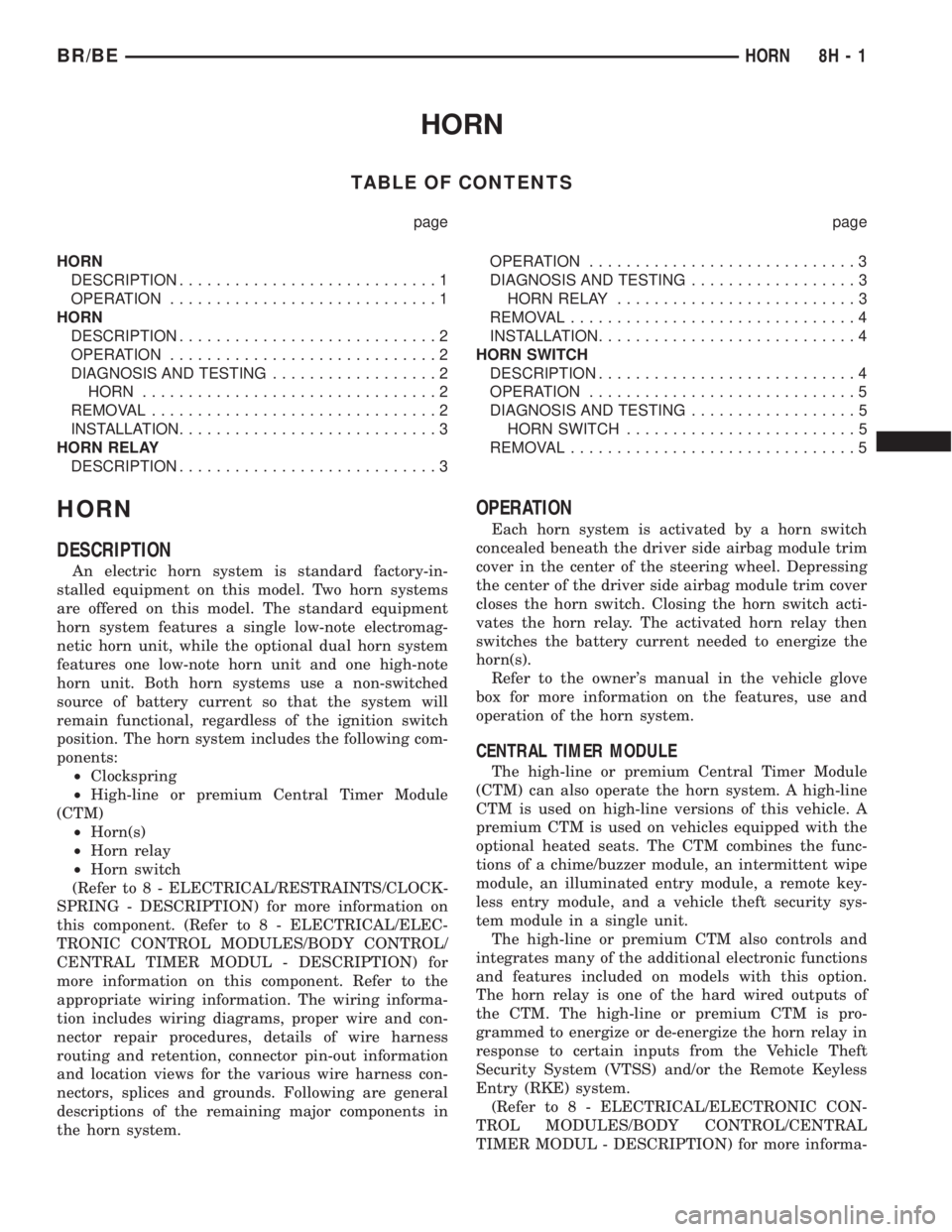

the horn connector receptacle(s) (Fig. 1) .

(3) Remove the screw that secures the horn and

mounting bracket unit(s) to the right fender wheel

house front extension.

(4) Remove the horn and mounting bracket unit(s)

from the right fender wheel house front extension.

Fig. 1 Horns Remove/Install

1 - WIRE HARNESS CONNECTOR

2 - SCREWS

3 - INNER FENDER

4 - LOW NOTE HORN

5 - WIRE HARNESS CONNECTOR

6 - WHEELHOUSE EXTENSION

7 - HIGH NOTE HORN

8H - 2 HORNBR/BE

HORN (Continued)

Page 534 of 2889

INSTALLATION

(1) Position the horn and mounting bracket unit(s)

onto the right fender wheel house front extension.

(2) Install and tighten the screw that secures the

horn and mounting bracket unit(s) to the right

fender wheel house front extension. Tighten the

screw to 11 N´m (95 in. lbs.).

(3) Reconnect the wire harness connector(s) to the

horn connector receptacle(s).

(4) Reconnect the battery negative cable.

HORN RELAY

DESCRIPTION

The horn relay is a electromechanical device that

switches battery current to the horn when the horn

switch grounds the relay coil. The horn relay is

located in the Power Distribution Center (PDC) in

the engine compartment. If a problem is encountered

with a continuously sounding horn, it can usually be

quickly resolved by removing the horn relay from the

PDC until further diagnosis is completed. See the

fuse and relay layout label affixed to the inside sur-

face of the PDC cover for horn relay identification

and location.

The horn relay is a International Standards Orga-

nization (ISO) micro-relay. Relays conforming to the

ISO specifications have common physical dimensions,

current capacities, terminal patterns, and terminal

functions. The ISO micro-relay terminal functions

are the same as a conventional ISO relay. However,

the ISO micro-relay terminal pattern (or footprint) is

different, the current capacity is lower, and the phys-

ical dimensions are smaller than those of the conven-

tional ISO relay.

The horn relay cannot be repaired or adjusted and,

if faulty or damaged, it must be replaced.

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one mov-

able) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When the elec-

tromagnetic coil is energized, it draws the movable

contact away from the normally closed fixed contact,

and holds it against the other (normally open) fixed

contact.

When the electromagnetic coil is de-energized,

spring pressure returns the movable contact to the

normally closed position. The resistor or diode is con-

nected in parallel with the electromagnetic coil in the

relay, and helps to dissipate voltage spikes that are

produced when the coil is de-energized.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - HORN RELAY

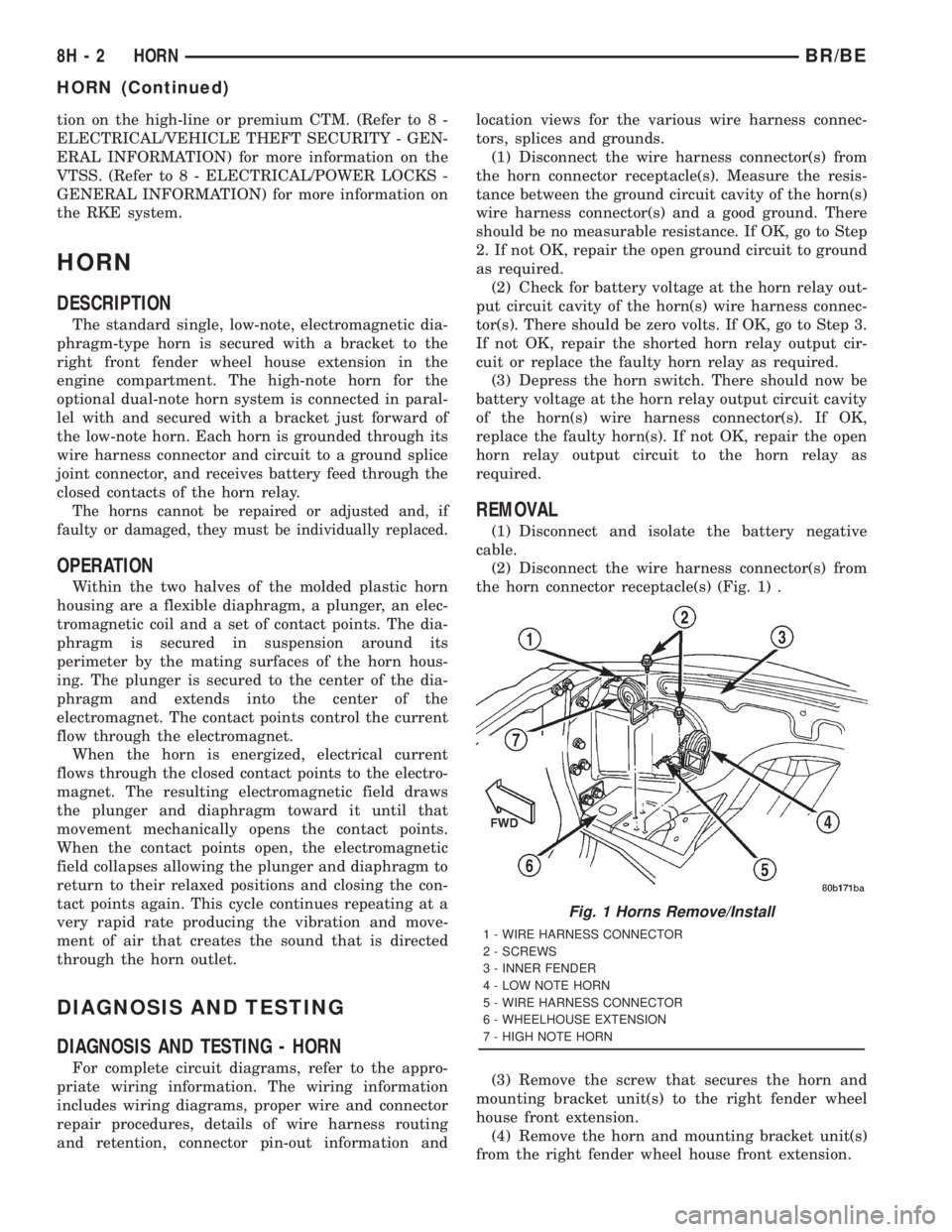

The horn relay (Fig. 2) is located in the Power Dis-

tribution Center (PDC) behind the battery on the

driver side of the engine compartment. If a problem

is encountered with a continuously sounding horn, it

can usually be quickly resolved by removing the horn

relay from the PDC until further diagnosis is com-

pleted. See the fuse and relay layout label affixed to

the inside surface of the PDC cover for horn relay

identification and location. For complete circuit dia-

grams, refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, details

of wire harness routing and retention, connector pin-

out information and location views for the various

wire harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Remove the horn relay from the PDC. (Refer to

8 - ELECTRICAL/HORN/HORN RELAY -

REMOVAL) for the procedures.

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 7565 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, perform the Relay Circuit Test that

follows. If not OK, replace the faulty relay.

RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the fuse in the PDC as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

BR/BEHORN 8H - 3

HORN (Continued)

Page 535 of 2889

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the horn(s). There should be continuity between

the cavity for relay terminal 87 and the horn relay

output circuit cavity of each horn wire harness con-

nector at all times. If OK, go to Step 4. If not OK,

repair the open circuit to the horn(s) as required.

(4) The coil battery terminal (86) is connected to

the electromagnet in the relay. It is connected to bat-

tery voltage and should be hot at all times. Check for

battery voltage at the cavity for relay terminal 86. If

OK, go to Step 5. If not OK, repair the open circuit to

the fuse in the PDC as required.

(5) The coil ground terminal (85) is connected to

the electromagnet in the relay. It is grounded

through the horn switch when the horn switch is

depressed. On vehicles equipped with the Vehicle

Theft Security System (VTSS), the horn relay coil

ground terminal can also be grounded by the Central

Timer Module (CTM) in response to certain inputs

related to the VTSS or Remote Keyless Entry (RKE)

system. Check for continuity to ground at the cavity

for relay terminal 85. There should be continuity

with the horn switch depressed, and no continuity

with the horn switch released. If not OK, (Refer to 8

- ELECTRICAL/HORN/HORN SWITCH - DIAGNO-

SIS AND TESTING).

REMOVAL

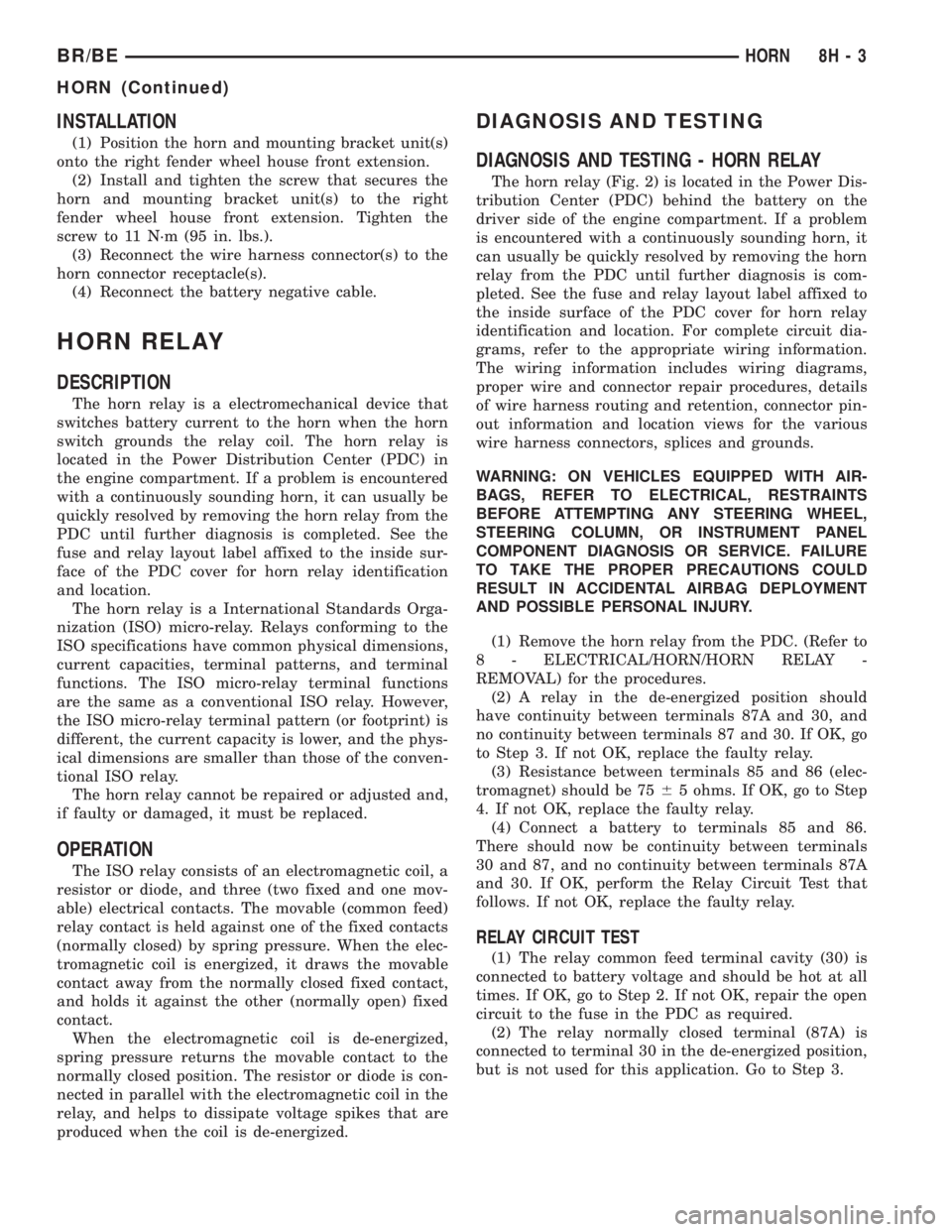

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Power Distribution

Center (PDC) (Fig. 3) .(3) See the fuse and relay layout label affixed to

the underside of the PDC cover for horn relay iden-

tification and location.

(4) Remove the horn relay from the PDC.

INSTALLATION

(1) See the fuse and relay layout label affixed to

the underside of the PDC cover for the proper horn

relay location.

(2) Position the horn relay in the proper receptacle

in the PDC.

(3) Align the horn relay terminals with the termi-

nal cavities in the PDC receptacle.

(4) Push down firmly on the horn relay until the

terminals are fully seated in the terminal cavities in

the PDC receptacle.

(5) Install the cover onto the PDC.

(6) Reconnect the battery negative cable.

HORN SWITCH

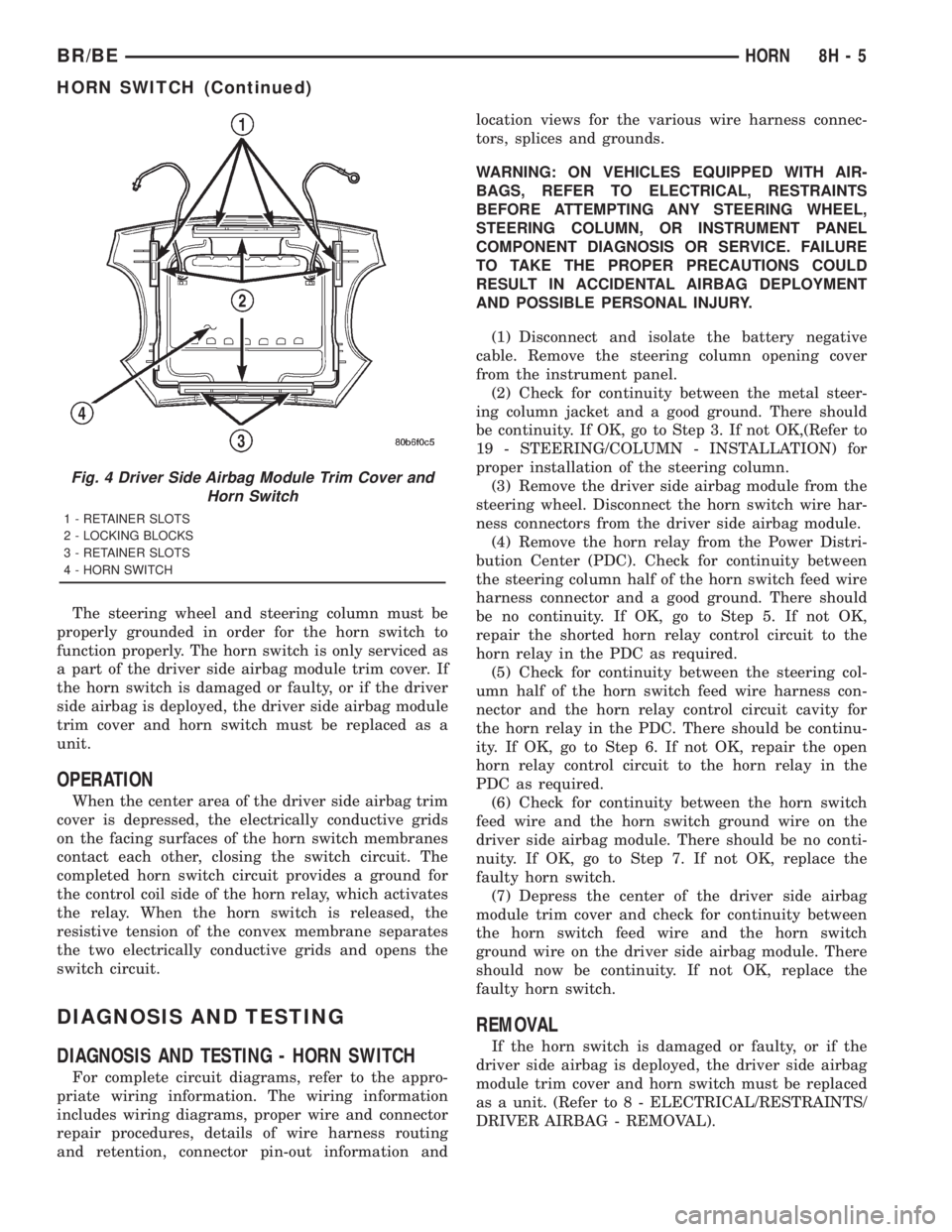

DESCRIPTION

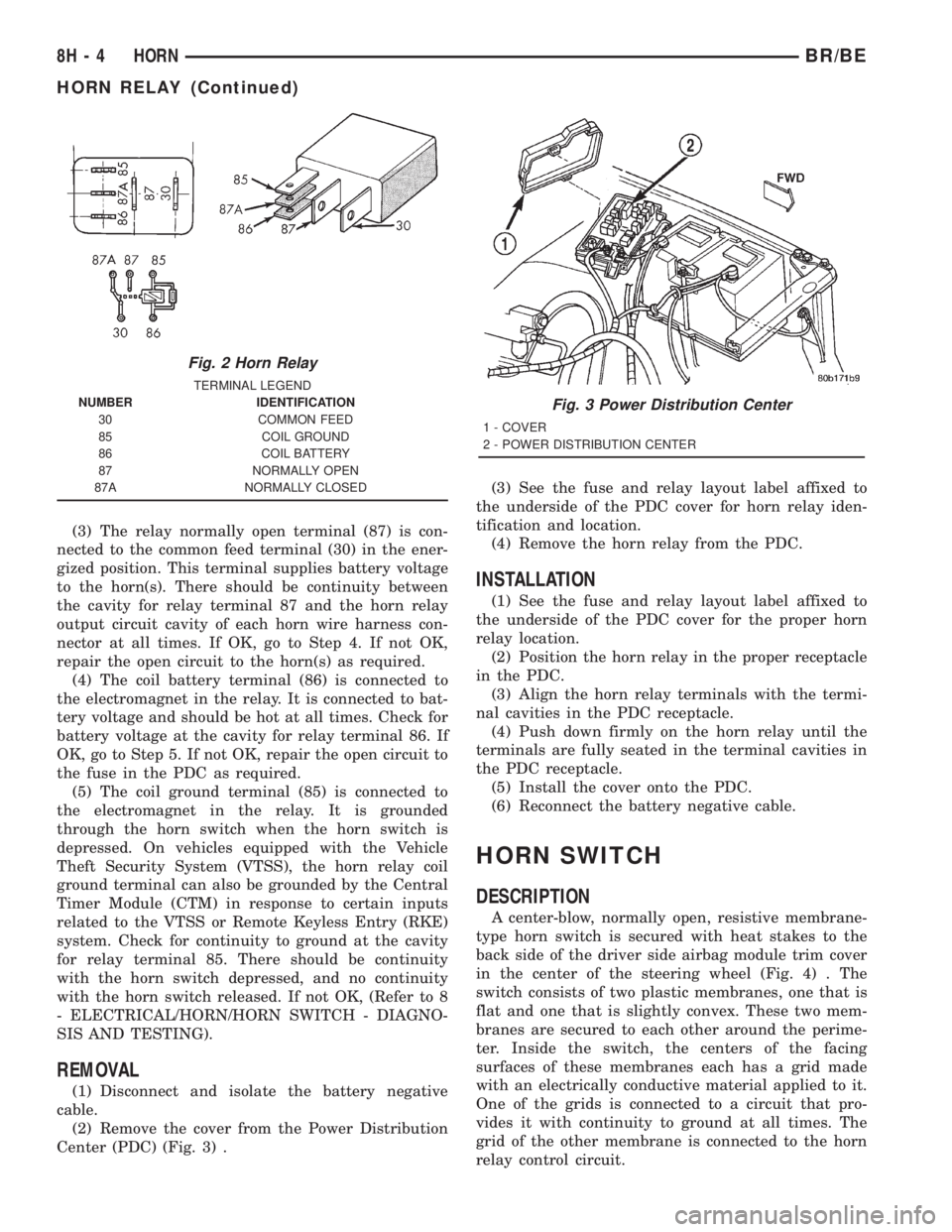

A center-blow, normally open, resistive membrane-

type horn switch is secured with heat stakes to the

back side of the driver side airbag module trim cover

in the center of the steering wheel (Fig. 4) . The

switch consists of two plastic membranes, one that is

flat and one that is slightly convex. These two mem-

branes are secured to each other around the perime-

ter. Inside the switch, the centers of the facing

surfaces of these membranes each has a grid made

with an electrically conductive material applied to it.

One of the grids is connected to a circuit that pro-

vides it with continuity to ground at all times. The

grid of the other membrane is connected to the horn

relay control circuit.

Fig. 2 Horn Relay

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

Fig. 3 Power Distribution Center

1 - COVER

2 - POWER DISTRIBUTION CENTER

8H - 4 HORNBR/BE

HORN RELAY (Continued)

Page 536 of 2889

The steering wheel and steering column must be

properly grounded in order for the horn switch to

function properly. The horn switch is only serviced as

a part of the driver side airbag module trim cover. If

the horn switch is damaged or faulty, or if the driver

side airbag is deployed, the driver side airbag module

trim cover and horn switch must be replaced as a

unit.

OPERATION

When the center area of the driver side airbag trim

cover is depressed, the electrically conductive grids

on the facing surfaces of the horn switch membranes

contact each other, closing the switch circuit. The

completed horn switch circuit provides a ground for

the control coil side of the horn relay, which activates

the relay. When the horn switch is released, the

resistive tension of the convex membrane separates

the two electrically conductive grids and opens the

switch circuit.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - HORN SWITCH

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information andlocation views for the various wire harness connec-

tors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable. Remove the steering column opening cover

from the instrument panel.

(2) Check for continuity between the metal steer-

ing column jacket and a good ground. There should

be continuity. If OK, go to Step 3. If not OK,(Refer to

19 - STEERING/COLUMN - INSTALLATION) for

proper installation of the steering column.

(3) Remove the driver side airbag module from the

steering wheel. Disconnect the horn switch wire har-

ness connectors from the driver side airbag module.

(4) Remove the horn relay from the Power Distri-

bution Center (PDC). Check for continuity between

the steering column half of the horn switch feed wire

harness connector and a good ground. There should

be no continuity. If OK, go to Step 5. If not OK,

repair the shorted horn relay control circuit to the

horn relay in the PDC as required.

(5) Check for continuity between the steering col-

umn half of the horn switch feed wire harness con-

nector and the horn relay control circuit cavity for

the horn relay in the PDC. There should be continu-

ity. If OK, go to Step 6. If not OK, repair the open

horn relay control circuit to the horn relay in the

PDC as required.

(6) Check for continuity between the horn switch

feed wire and the horn switch ground wire on the

driver side airbag module. There should be no conti-

nuity. If OK, go to Step 7. If not OK, replace the

faulty horn switch.

(7) Depress the center of the driver side airbag

module trim cover and check for continuity between

the horn switch feed wire and the horn switch

ground wire on the driver side airbag module. There

should now be continuity. If not OK, replace the

faulty horn switch.

REMOVAL

If the horn switch is damaged or faulty, or if the

driver side airbag is deployed, the driver side airbag

module trim cover and horn switch must be replaced

as a unit. (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - REMOVAL).

Fig. 4 Driver Side Airbag Module Trim Cover and

Horn Switch

1 - RETAINER SLOTS

2 - LOCKING BLOCKS

3 - RETAINER SLOTS

4 - HORN SWITCH

BR/BEHORN 8H - 5

HORN SWITCH (Continued)

Page 620 of 2889

(1) Disconnect and isolate the battery negative

cable.

(2) Remove four screws attaching rear ID lamps to

tailgate (Fig. 23).

(3) Separate ID lamps from tailgate.

(4) Disengage ID lamp wire connector from body

wire harness.

(5) Separate ID lamp from vehicle.

INSTALLATION

(1) Position ID lamp on vehicle.

(2) Engage ID lamp wire connector to body wire

harness.

(3) Install screws attaching rear ID lamps to tail-

gate.

(4) Connect the battery negative cable.

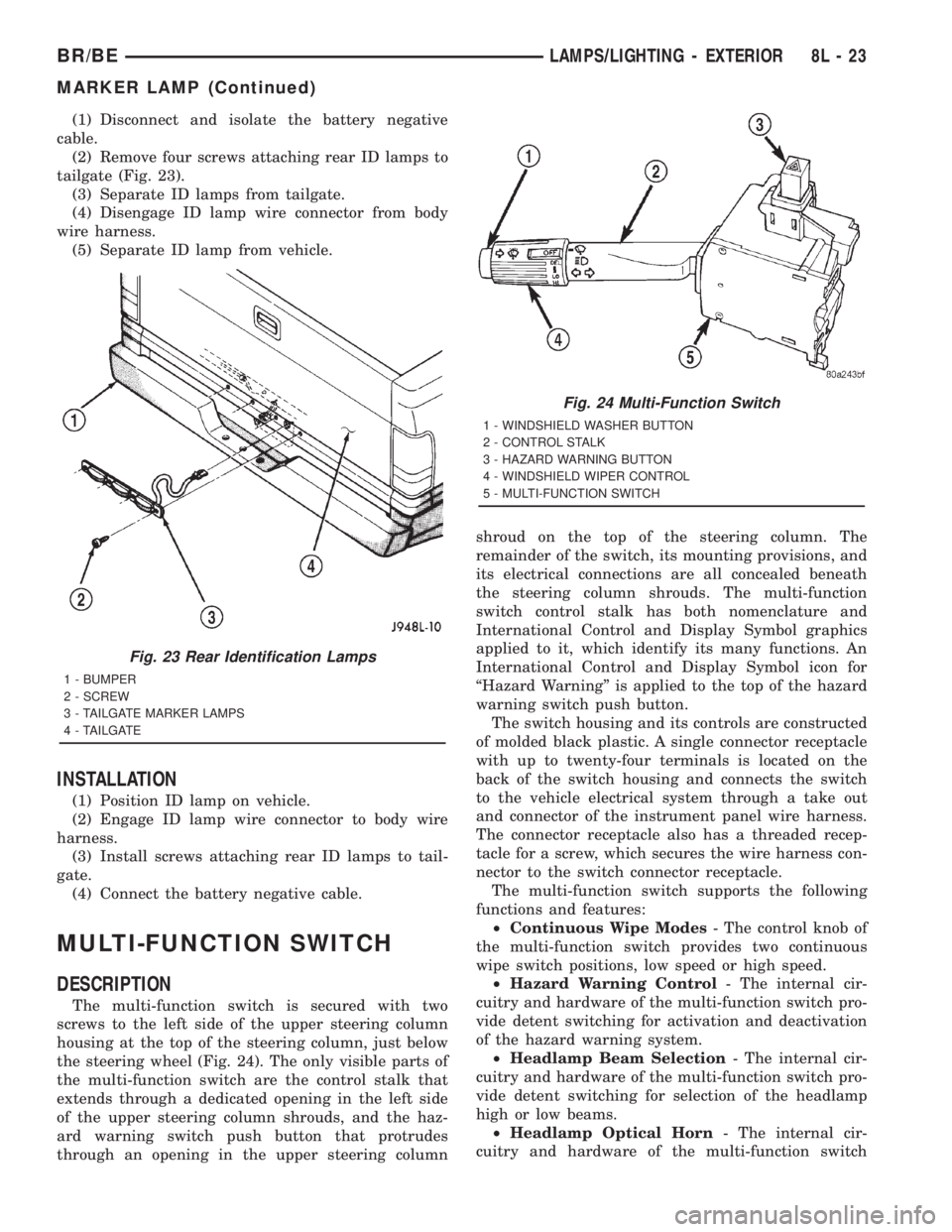

MULTI-FUNCTION SWITCH

DESCRIPTION

The multi-function switch is secured with two

screws to the left side of the upper steering column

housing at the top of the steering column, just below

the steering wheel (Fig. 24). The only visible parts of

the multi-function switch are the control stalk that

extends through a dedicated opening in the left side

of the upper steering column shrouds, and the haz-

ard warning switch push button that protrudes

through an opening in the upper steering columnshroud on the top of the steering column. The

remainder of the switch, its mounting provisions, and

its electrical connections are all concealed beneath

the steering column shrouds. The multi-function

switch control stalk has both nomenclature and

International Control and Display Symbol graphics

applied to it, which identify its many functions. An

International Control and Display Symbol icon for

ªHazard Warningº is applied to the top of the hazard

warning switch push button.

The switch housing and its controls are constructed

of molded black plastic. A single connector receptacle

with up to twenty-four terminals is located on the

back of the switch housing and connects the switch

to the vehicle electrical system through a take out

and connector of the instrument panel wire harness.

The connector receptacle also has a threaded recep-

tacle for a screw, which secures the wire harness con-

nector to the switch connector receptacle.

The multi-function switch supports the following

functions and features:

²Continuous Wipe Modes- The control knob of

the multi-function switch provides two continuous

wipe switch positions, low speed or high speed.

²Hazard Warning Control- The internal cir-

cuitry and hardware of the multi-function switch pro-

vide detent switching for activation and deactivation

of the hazard warning system.

²Headlamp Beam Selection- The internal cir-

cuitry and hardware of the multi-function switch pro-

vide detent switching for selection of the headlamp

high or low beams.

²Headlamp Optical Horn- The internal cir-

cuitry and hardware of the multi-function switch

Fig. 23 Rear Identification Lamps

1 - BUMPER

2 - SCREW

3 - TAILGATE MARKER LAMPS

4 - TAILGATE

Fig. 24 Multi-Function Switch

1 - WINDSHIELD WASHER BUTTON

2 - CONTROL STALK

3 - HAZARD WARNING BUTTON

4 - WINDSHIELD WIPER CONTROL

5 - MULTI-FUNCTION SWITCH

BR/BELAMPS/LIGHTING - EXTERIOR 8L - 23

MARKER LAMP (Continued)