differential DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 373 of 2255

BUS BIAS AND TERMINATION

The voltage network used by the CCD data bus to

transmit messages requires both bias and termina-

tion. At least one electronic control module on the

data bus must provide a voltage source for the CCD

data bus network known as bus bias, and there must

be at least one bus termination point for the data bus

circuit to be complete. However, while bias and ter-

mination are both required for data bus operation,

they both do not have to be within the same elec-

tronic control module. The CCD data bus is biased to

approximately 2.5 volts. With each of the electronic

control modules wired in parallel to the data bus, all

modules utilize the same bus bias. Therefore, based

upon vehicle options, the data bus can accommodate

two or twenty electronic control modules without

affecting bus voltage.

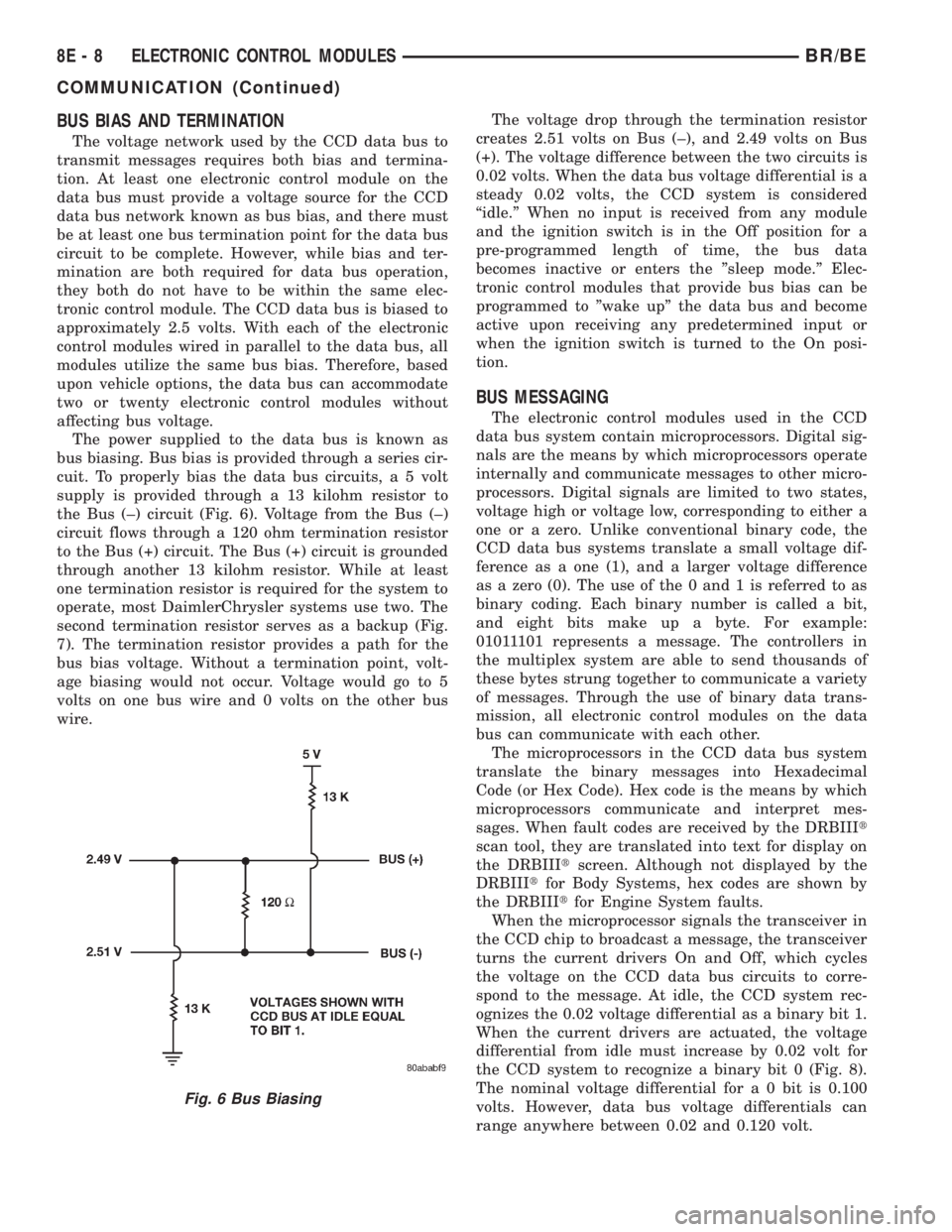

The power supplied to the data bus is known as

bus biasing. Bus bias is provided through a series cir-

cuit. To properly bias the data bus circuits, a 5 volt

supply is provided through a 13 kilohm resistor to

the Bus (±) circuit (Fig. 6). Voltage from the Bus (±)

circuit flows through a 120 ohm termination resistor

to the Bus (+) circuit. The Bus (+) circuit is grounded

through another 13 kilohm resistor. While at least

one termination resistor is required for the system to

operate, most DaimlerChrysler systems use two. The

second termination resistor serves as a backup (Fig.

7). The termination resistor provides a path for the

bus bias voltage. Without a termination point, volt-

age biasing would not occur. Voltage would go to 5

volts on one bus wire and 0 volts on the other bus

wire.The voltage drop through the termination resistor

creates 2.51 volts on Bus (±), and 2.49 volts on Bus

(+). The voltage difference between the two circuits is

0.02 volts. When the data bus voltage differential is a

steady 0.02 volts, the CCD system is considered

ªidle.º When no input is received from any module

and the ignition switch is in the Off position for a

pre-programmed length of time, the bus data

becomes inactive or enters the ºsleep mode.º Elec-

tronic control modules that provide bus bias can be

programmed to ºwake upº the data bus and become

active upon receiving any predetermined input or

when the ignition switch is turned to the On posi-

tion.

BUS MESSAGING

The electronic control modules used in the CCD

data bus system contain microprocessors. Digital sig-

nals are the means by which microprocessors operate

internally and communicate messages to other micro-

processors. Digital signals are limited to two states,

voltage high or voltage low, corresponding to either a

one or a zero. Unlike conventional binary code, the

CCD data bus systems translate a small voltage dif-

ference as a one (1), and a larger voltage difference

as a zero (0). The use of the 0 and 1 is referred to as

binary coding. Each binary number is called a bit,

and eight bits make up a byte. For example:

01011101 represents a message. The controllers in

the multiplex system are able to send thousands of

these bytes strung together to communicate a variety

of messages. Through the use of binary data trans-

mission, all electronic control modules on the data

bus can communicate with each other.

The microprocessors in the CCD data bus system

translate the binary messages into Hexadecimal

Code (or Hex Code). Hex code is the means by which

microprocessors communicate and interpret mes-

sages. When fault codes are received by the DRBIIIt

scan tool, they are translated into text for display on

the DRBIIItscreen. Although not displayed by the

DRBIIItfor Body Systems, hex codes are shown by

the DRBIIItfor Engine System faults.

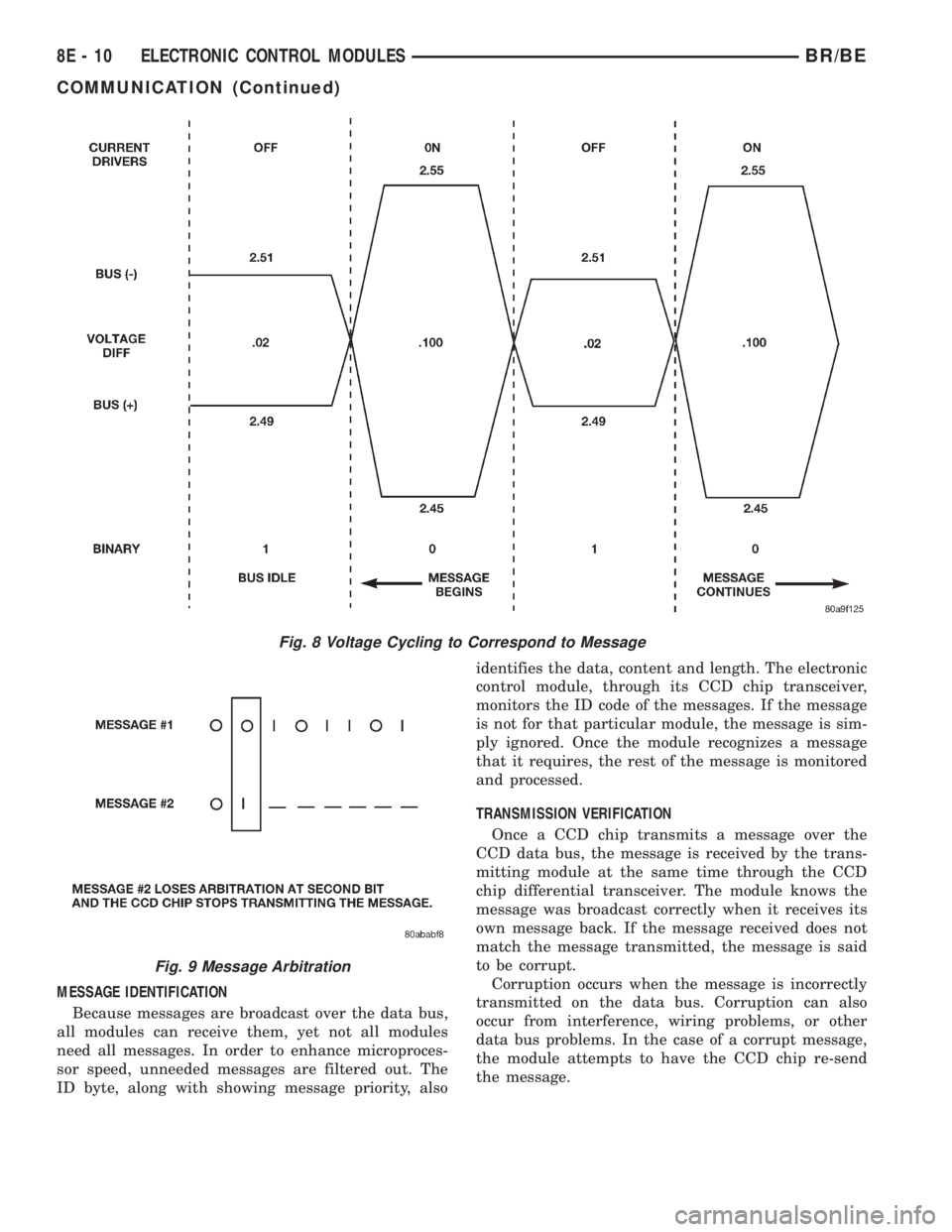

When the microprocessor signals the transceiver in

the CCD chip to broadcast a message, the transceiver

turns the current drivers On and Off, which cycles

the voltage on the CCD data bus circuits to corre-

spond to the message. At idle, the CCD system rec-

ognizes the 0.02 voltage differential as a binary bit 1.

When the current drivers are actuated, the voltage

differential from idle must increase by 0.02 volt for

the CCD system to recognize a binary bit 0 (Fig. 8).

The nominal voltage differential for a 0 bit is 0.100

volts. However, data bus voltage differentials can

range anywhere between 0.02 and 0.120 volt.

Fig. 6 Bus Biasing

8E - 8 ELECTRONIC CONTROL MODULESBR/BE

COMMUNICATION (Continued)

Page 375 of 2255

MESSAGE IDENTIFICATION

Because messages are broadcast over the data bus,

all modules can receive them, yet not all modules

need all messages. In order to enhance microproces-

sor speed, unneeded messages are filtered out. The

ID byte, along with showing message priority, alsoidentifies the data, content and length. The electronic

control module, through its CCD chip transceiver,

monitors the ID code of the messages. If the message

is not for that particular module, the message is sim-

ply ignored. Once the module recognizes a message

that it requires, the rest of the message is monitored

and processed.

TRANSMISSION VERIFICATION

Once a CCD chip transmits a message over the

CCD data bus, the message is received by the trans-

mitting module at the same time through the CCD

chip differential transceiver. The module knows the

message was broadcast correctly when it receives its

own message back. If the message received does not

match the message transmitted, the message is said

to be corrupt.

Corruption occurs when the message is incorrectly

transmitted on the data bus. Corruption can also

occur from interference, wiring problems, or other

data bus problems. In the case of a corrupt message,

the module attempts to have the CCD chip re-send

the message.

Fig. 8 Voltage Cycling to Correspond to Message

Fig. 9 Message Arbitration

8E - 10 ELECTRONIC CONTROL MODULESBR/BE

COMMUNICATION (Continued)

Page 376 of 2255

DIAGNOSIS AND TESTING - CCD DATA BUS

CCD BUS FAILURE

The CCD data bus can be monitored using the

DRBIIItscan tool. However, it is possible for the

data bus to pass all tests since the voltage parame-

ters will be in ªrangeª and false signals are being

sent. There are essentially 12 ªhard failuresª that

can occur with the CCD data bus:

²Bus Shorted to Battery

²Bus Shorted to 5 Volts

²Bus Shorted to Ground

²Bus (+) Shorted to Bus (±)

²Bus (±) and Bus (+) Open

²Bus (+) Open

²Bus (±) Open

²No Bus Bias

²Bus Bias Level Too High

²Bus Bias Level Too Low

²No Bus Termination

²Not Receiving Bus Messages Correctly

Refer to the appropriate diagnostic information for

details on how to diagnose these faults using a

DRBIIItscan tool.

BUS FAILURE VISUAL SYMPTOM DIAGNOSIS

The following visible symptoms or customer com-

plaints, alone or in combination, may indicate a CCD

data bus failure:

²Airbag Indicator and Malfunction Indicator

Lamp (MIL) Illuminated

²Instrument Cluster Gauges (All) Inoperative

²No Compass Mini-Trip Computer (CMTC) Oper-

ation (if equipped)

CONTROLLER ANTILOCK

BRAKE

DESCRIPTION

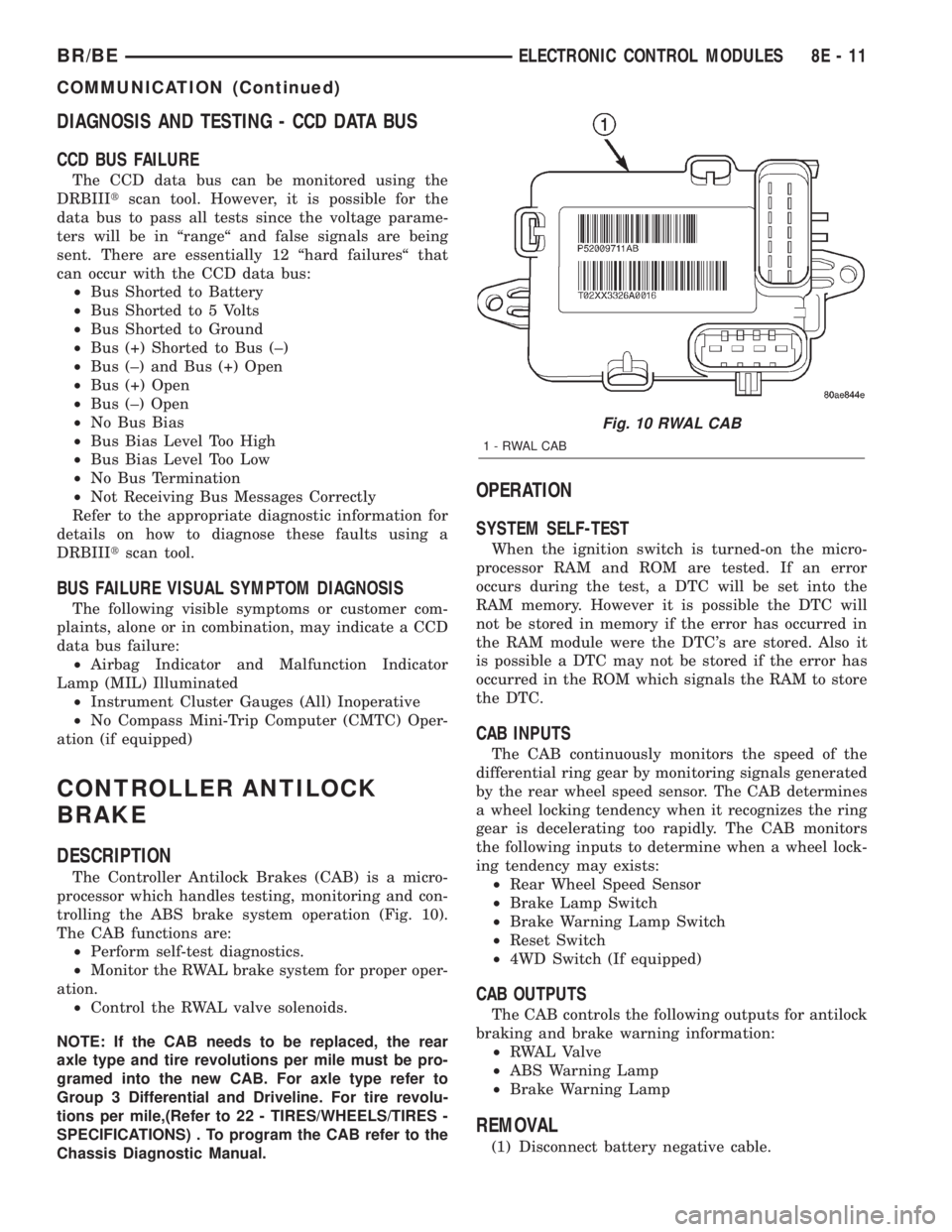

The Controller Antilock Brakes (CAB) is a micro-

processor which handles testing, monitoring and con-

trolling the ABS brake system operation (Fig. 10).

The CAB functions are:

²Perform self-test diagnostics.

²Monitor the RWAL brake system for proper oper-

ation.

²Control the RWAL valve solenoids.

NOTE: If the CAB needs to be replaced, the rear

axle type and tire revolutions per mile must be pro-

gramed into the new CAB. For axle type refer to

Group 3 Differential and Driveline. For tire revolu-

tions per mile,(Refer to 22 - TIRES/WHEELS/TIRES -

SPECIFICATIONS) . To program the CAB refer to the

Chassis Diagnostic Manual.

OPERATION

SYSTEM SELF-TEST

When the ignition switch is turned-on the micro-

processor RAM and ROM are tested. If an error

occurs during the test, a DTC will be set into the

RAM memory. However it is possible the DTC will

not be stored in memory if the error has occurred in

the RAM module were the DTC's are stored. Also it

is possible a DTC may not be stored if the error has

occurred in the ROM which signals the RAM to store

the DTC.

CAB INPUTS

The CAB continuously monitors the speed of the

differential ring gear by monitoring signals generated

by the rear wheel speed sensor. The CAB determines

a wheel locking tendency when it recognizes the ring

gear is decelerating too rapidly. The CAB monitors

the following inputs to determine when a wheel lock-

ing tendency may exists:

²Rear Wheel Speed Sensor

²Brake Lamp Switch

²Brake Warning Lamp Switch

²Reset Switch

²4WD Switch (If equipped)

CAB OUTPUTS

The CAB controls the following outputs for antilock

braking and brake warning information:

²RWAL Valve

²ABS Warning Lamp

²Brake Warning Lamp

REMOVAL

(1) Disconnect battery negative cable.

Fig. 10 RWAL CAB

1-RWALCAB

BR/BEELECTRONIC CONTROL MODULES 8E - 11

COMMUNICATION (Continued)

Page 508 of 2255

disconnect mechanism, (Refer to 3 - DIFFERENTIAL

& DRIVELINE/FRONT AXLE/AXLE VACUUM

MOTOR - OPERATION). The four-wheel drive switch

input to the instrument cluster circuitry can be diag-

nosed using conventional diagnostic tools and meth-

ods.

DIAGNOSIS AND TESTING - FOUR-WHEEL

DRIVE INDICATOR

The diagnosis found here addresses an inoperative

four-wheel drive indicator condition. If the problem

being diagnosed is related to indicator accuracy, be

certain to confirm that the problem is with the indi-

cator and not with a damaged or inoperative front

axle disconnect mechanism. (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/FRONT AXLE/AXLE VACUUM

MOTOR - DIAGNOSIS AND TESTING). If no front

axle disconnect problem is found, the following proce-

dure will help locate a short or open in the four-

wheel drive switch input to the instrument cluster.

Refer to the appropriate wiring information. The wir-

ing information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

INDICATOR DOES NOT ILLUMINATE WITH FOUR-WHEEL

DRIVE MODE SELECTED

(1) Disconnect and isolate the battery negative

cable. Disconnect the engine wire harness connector

for the four-wheel drive switch from the switch con-

nector receptacle. Check for continuity between the

ground circuit cavity of the engine wire harness con-

nector for the four-wheel drive switch and a good

ground. There should be continuity. If OK, go to Step

2. If not OK, repair the open ground circuit to ground

(G100) as required.

(2) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Install a jumper

wire between the 4WD switch sense circuit cavity ofthe engine wire harness connector for the four-wheel

drive switch and a good ground. The four-wheel drive

indicator should light. If OK, replace the faulty four-

wheel drive switch. If not OK, go to Step 3.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the instrument cluster from the instrument

panel. Check for continuity between the 4WD switch

sense circuit cavities of the instrument panel wire

harness connector (Connector C2) for the instrument

cluster and the engine wire harness connector for the

four-wheel drive switch. There should be continuity.

If OK, replace the faulty instrument cluster. If not

OK, repair the open 4WD switch sense circuit

between the instrument cluster and the four-wheel

drive switch as required.

INDICATOR STAYS ILLUMINATED WITH FOUR-WHEEL DRIVE

MODE NOT SELECTED

(1) Disconnect and isolate the battery negative

cable. Disconnect the engine wire harness connector

for the four-wheel drive switch from the switch con-

nector receptacle. Check for continuity between the

ground circuit terminal and the 4WD switch sense

circuit terminal in the four-wheel drive switch con-

nector receptacle. There should be no continuity. If

OK, repair the shorted 4WD switch sense circuit

between the four-wheel drive switch and the instru-

ment cluster as required. If not OK, replace the

faulty four-wheel drive switch.

SPEEDOMETER

DESCRIPTION

A speedometer is standard equipment on all instru-

ment clusters. The speedometer is located just to the

right of the tachometer near the center of the instru-

ment cluster. The speedometer consists of a movable

gauge needle or pointer controlled by the instrument

cluster circuitry and a fixed 210 degree primary scale

on the gauge dial face that reads left-to-right either

from 0 to 120 mph, or from 0 to 200 km/h, depending

upon the market for which the vehicle is manufac-

tured. Each version also has a secondary inner scale

on the gauge dial face that provides the equivalent

opposite units from the primary scale. Text appearing

on the cluster overlay just below the hub of the

speedometer needle abbreviates the unit of measure

for the primary scale in all upper case letters (i.e.:

MPH or KM/H), followed by the unit of measure for

the secondary scale in all lower case letters (i.e.: mph

or km/h). The speedometer graphics are white (pri-

mary scale) and red (secondary scale) against a black

field, making them clearly visible within the instru-

ment cluster in daylight. When illuminated from

behind by the panel lamps dimmer controlled cluster

BR/BEINSTRUMENT CLUSTER 8J - 29

SHIFT INDICATOR (TRANSFER CASE) (Continued)

Page 1392 of 2255

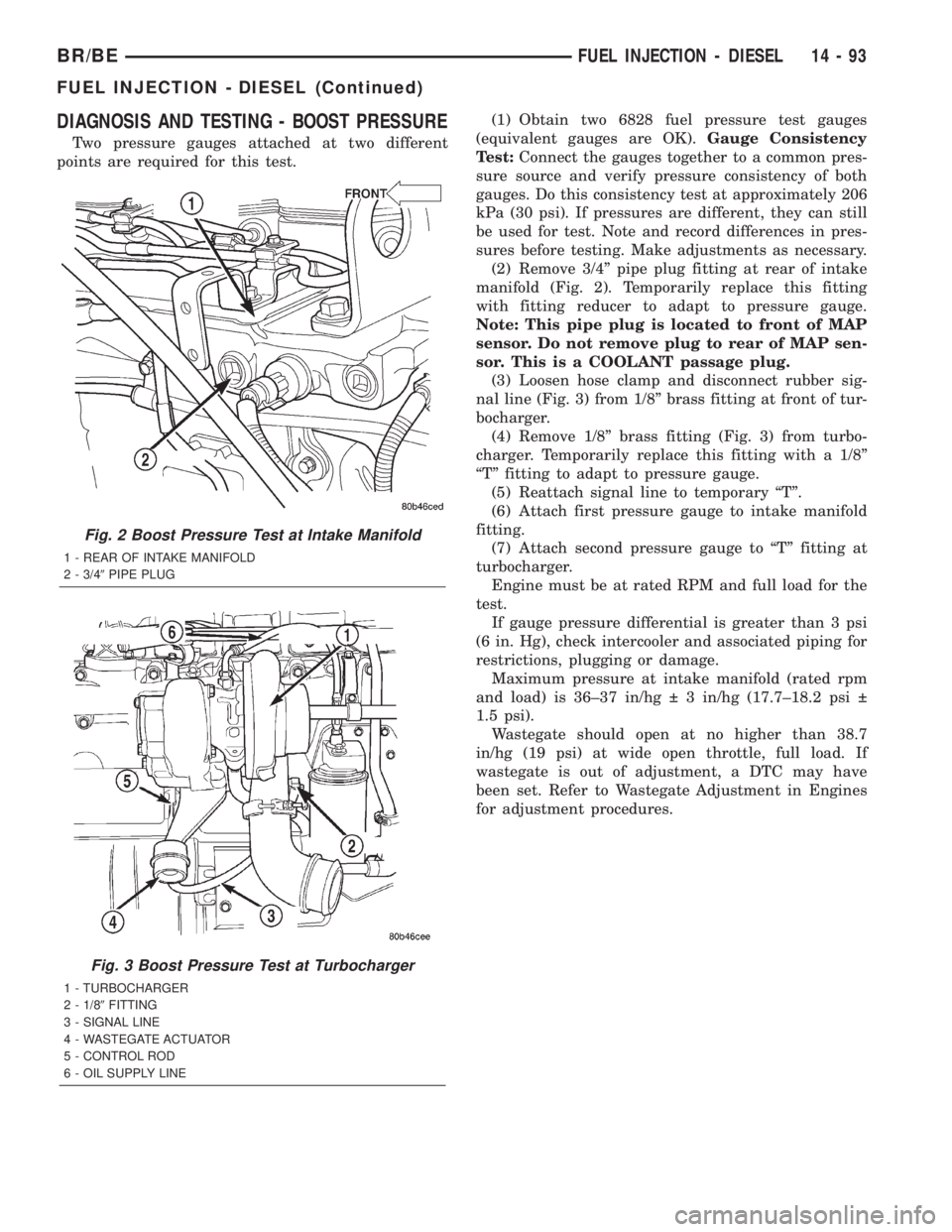

DIAGNOSIS AND TESTING - BOOST PRESSURE

Two pressure gauges attached at two different

points are required for this test.(1) Obtain two 6828 fuel pressure test gauges

(equivalent gauges are OK).Gauge Consistency

Test:Connect the gauges together to a common pres-

sure source and verify pressure consistency of both

gauges. Do this consistency test at approximately 206

kPa (30 psi). If pressures are different, they can still

be used for test. Note and record differences in pres-

sures before testing. Make adjustments as necessary.

(2) Remove 3/4º pipe plug fitting at rear of intake

manifold (Fig. 2). Temporarily replace this fitting

with fitting reducer to adapt to pressure gauge.

Note: This pipe plug is located to front of MAP

sensor. Do not remove plug to rear of MAP sen-

sor. This is a COOLANT passage plug.

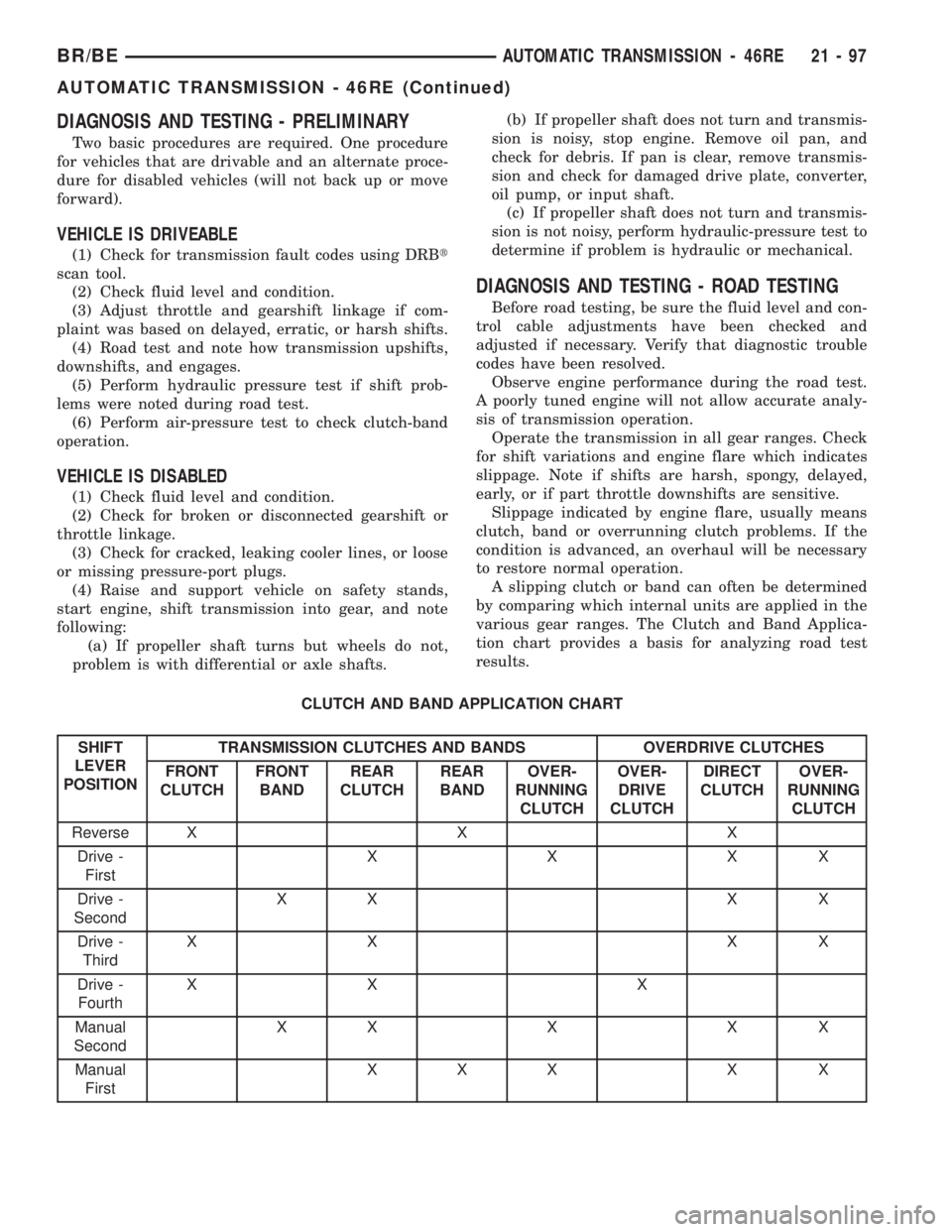

(3) Loosen hose clamp and disconnect rubber sig-

nal line (Fig. 3) from 1/8º brass fitting at front of tur-

bocharger.

(4) Remove 1/8º brass fitting (Fig. 3) from turbo-

charger. Temporarily replace this fitting with a 1/8º

ªTº fitting to adapt to pressure gauge.

(5) Reattach signal line to temporary ªTº.

(6) Attach first pressure gauge to intake manifold

fitting.

(7) Attach second pressure gauge to ªTº fitting at

turbocharger.

Engine must be at rated RPM and full load for the

test.

If gauge pressure differential is greater than 3 psi

(6 in. Hg), check intercooler and associated piping for

restrictions, plugging or damage.

Maximum pressure at intake manifold (rated rpm

and load) is 36±37 in/hg 3 in/hg (17.7±18.2 psi

1.5 psi).

Wastegate should open at no higher than 38.7

in/hg (19 psi) at wide open throttle, full load. If

wastegate is out of adjustment, a DTC may have

been set. Refer to Wastegate Adjustment in Engines

for adjustment procedures.

Fig. 2 Boost Pressure Test at Intake Manifold

1 - REAR OF INTAKE MANIFOLD

2 - 3/49PIPE PLUG

Fig. 3 Boost Pressure Test at Turbocharger

1 - TURBOCHARGER

2 - 1/89FITTING

3 - SIGNAL LINE

4 - WASTEGATE ACTUATOR

5 - CONTROL ROD

6 - OIL SUPPLY LINE

BR/BEFUEL INJECTION - DIESEL 14 - 93

FUEL INJECTION - DIESEL (Continued)

Page 1550 of 2255

DIAGNOSIS AND TESTING - PRELIMINARY

Two basic procedures are required. One procedure

for vehicles that are drivable and an alternate proce-

dure for disabled vehicles (will not back up or move

forward).

VEHICLE IS DRIVEABLE

(1) Check for transmission fault codes using DRBt

scan tool.

(2) Check fluid level and condition.

(3) Adjust throttle and gearshift linkage if com-

plaint was based on delayed, erratic, or harsh shifts.

(4) Road test and note how transmission upshifts,

downshifts, and engages.

(5) Perform hydraulic pressure test if shift prob-

lems were noted during road test.

(6) Perform air-pressure test to check clutch-band

operation.

VEHICLE IS DISABLED

(1) Check fluid level and condition.

(2) Check for broken or disconnected gearshift or

throttle linkage.

(3) Check for cracked, leaking cooler lines, or loose

or missing pressure-port plugs.

(4) Raise and support vehicle on safety stands,

start engine, shift transmission into gear, and note

following:

(a) If propeller shaft turns but wheels do not,

problem is with differential or axle shafts.(b) If propeller shaft does not turn and transmis-

sion is noisy, stop engine. Remove oil pan, and

check for debris. If pan is clear, remove transmis-

sion and check for damaged drive plate, converter,

oil pump, or input shaft.

(c) If propeller shaft does not turn and transmis-

sion is not noisy, perform hydraulic-pressure test to

determine if problem is hydraulic or mechanical.

DIAGNOSIS AND TESTING - ROAD TESTING

Before road testing, be sure the fluid level and con-

trol cable adjustments have been checked and

adjusted if necessary. Verify that diagnostic trouble

codes have been resolved.

Observe engine performance during the road test.

A poorly tuned engine will not allow accurate analy-

sis of transmission operation.

Operate the transmission in all gear ranges. Check

for shift variations and engine flare which indicates

slippage. Note if shifts are harsh, spongy, delayed,

early, or if part throttle downshifts are sensitive.

Slippage indicated by engine flare, usually means

clutch, band or overrunning clutch problems. If the

condition is advanced, an overhaul will be necessary

to restore normal operation.

A slipping clutch or band can often be determined

by comparing which internal units are applied in the

various gear ranges. The Clutch and Band Applica-

tion chart provides a basis for analyzing road test

results.

CLUTCH AND BAND APPLICATION CHART

SHIFT

LEVER

POSITIONTRANSMISSION CLUTCHES AND BANDS OVERDRIVE CLUTCHES

FRONT

CLUTCHFRONT

BANDREAR

CLUTCHREAR

BANDOVER-

RUNNING

CLUTCHOVER-

DRIVE

CLUTCHDIRECT

CLUTCHOVER-

RUNNING

CLUTCH

Reverse X X X

Drive -

FirstXXXX

Drive -

SecondXX X X

Drive -

ThirdXX XX

Drive -

FourthXX X

Manual

SecondXXXXX

Manual

FirstXXX X X

BR/BEAUTOMATIC TRANSMISSION - 46RE 21 - 97

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 1567 of 2255

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR

Damaged or worn threads in the aluminum trans-

mission case and valve body can be repaired by the

use of Heli-CoilsŸ, or equivalent. This repair con-

sists of drilling out the worn-out damaged threads.

Then tap the hole with a special Heli-CoilŸ tap, or

equivalent, and installing a Heli-CoilŸ insert, or

equivalent, into the hole. This brings the hole back to

its original thread size.

Heli-CoilŸ, or equivalent, tools and inserts are

readily available from most automotive parts suppli-

ers.

REMOVAL

The overdrive unit can be removed and serviced

separately. It is not necessary to remove the entire

transmission assembly to perform overdrive unit

repairs.

(1) Disconnect battery negative cable.

(2) Disconnect and lower or remove necessary

exhaust components.

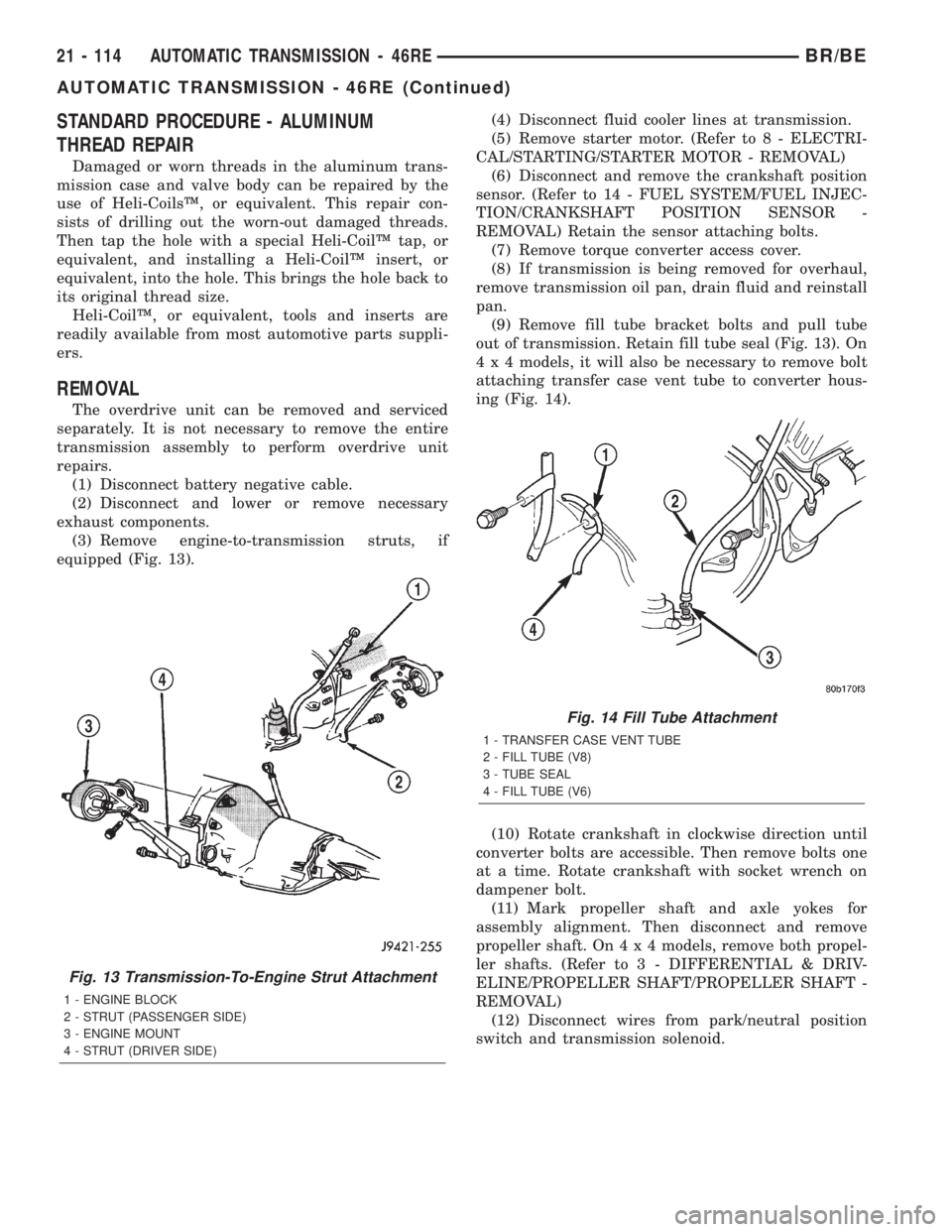

(3) Remove engine-to-transmission struts, if

equipped (Fig. 13).(4) Disconnect fluid cooler lines at transmission.

(5) Remove starter motor. (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

(6) Disconnect and remove the crankshaft position

sensor. (Refer to 14 - FUEL SYSTEM/FUEL INJEC-

TION/CRANKSHAFT POSITION SENSOR -

REMOVAL) Retain the sensor attaching bolts.

(7) Remove torque converter access cover.

(8) If transmission is being removed for overhaul,

remove transmission oil pan, drain fluid and reinstall

pan.

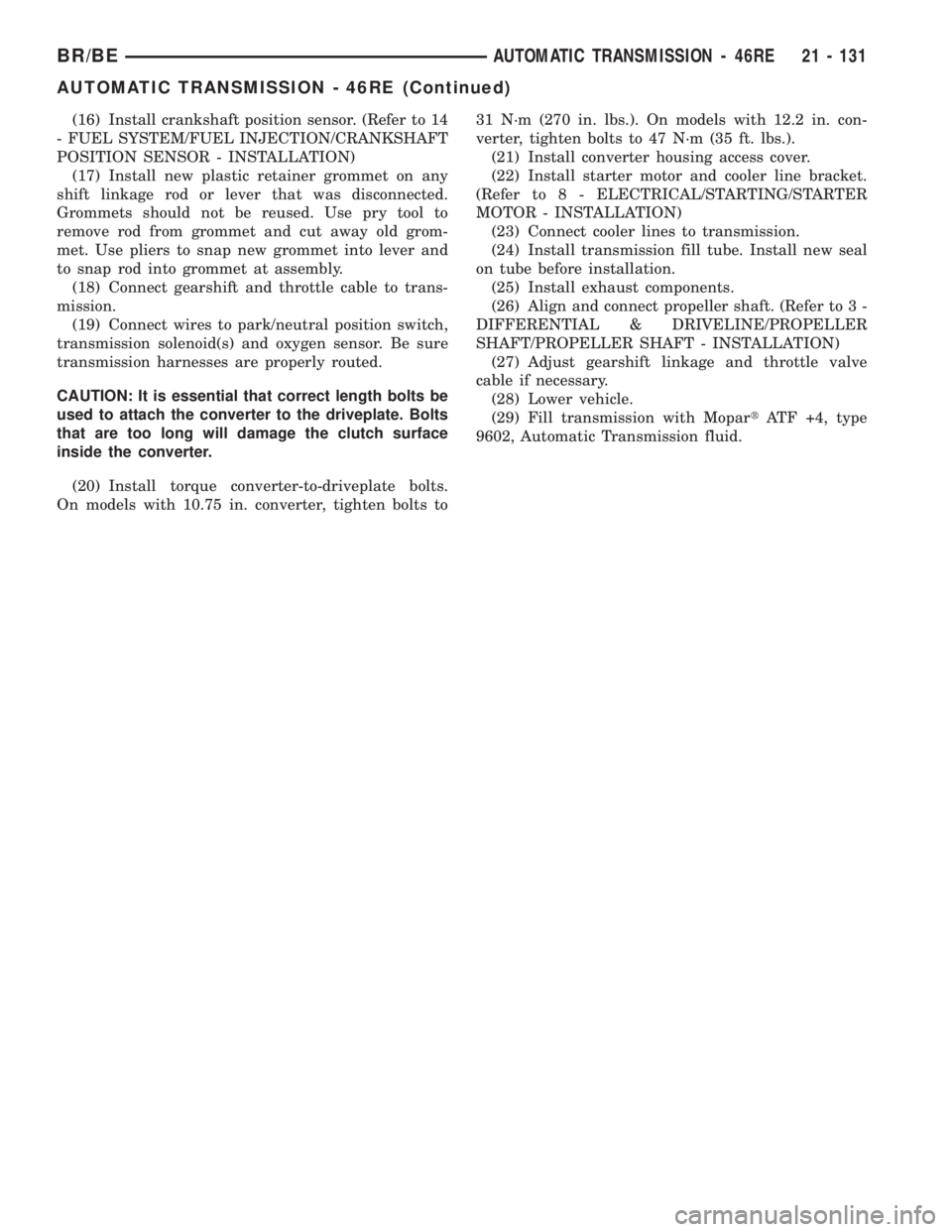

(9) Remove fill tube bracket bolts and pull tube

out of transmission. Retain fill tube seal (Fig. 13). On

4 x 4 models, it will also be necessary to remove bolt

attaching transfer case vent tube to converter hous-

ing (Fig. 14).

(10) Rotate crankshaft in clockwise direction until

converter bolts are accessible. Then remove bolts one

at a time. Rotate crankshaft with socket wrench on

dampener bolt.

(11) Mark propeller shaft and axle yokes for

assembly alignment. Then disconnect and remove

propeller shaft. On4x4models, remove both propel-

ler shafts. (Refer to 3 - DIFFERENTIAL & DRIV-

ELINE/PROPELLER SHAFT/PROPELLER SHAFT -

REMOVAL)

(12) Disconnect wires from park/neutral position

switch and transmission solenoid.

Fig. 13 Transmission-To-Engine Strut Attachment

1 - ENGINE BLOCK

2 - STRUT (PASSENGER SIDE)

3 - ENGINE MOUNT

4 - STRUT (DRIVER SIDE)

Fig. 14 Fill Tube Attachment

1 - TRANSFER CASE VENT TUBE

2 - FILL TUBE (V8)

3 - TUBE SEAL

4 - FILL TUBE (V6)

21 - 114 AUTOMATIC TRANSMISSION - 46REBR/BE

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 1584 of 2255

(16) Install crankshaft position sensor. (Refer to 14

- FUEL SYSTEM/FUEL INJECTION/CRANKSHAFT

POSITION SENSOR - INSTALLATION)

(17) Install new plastic retainer grommet on any

shift linkage rod or lever that was disconnected.

Grommets should not be reused. Use pry tool to

remove rod from grommet and cut away old grom-

met. Use pliers to snap new grommet into lever and

to snap rod into grommet at assembly.

(18) Connect gearshift and throttle cable to trans-

mission.

(19) Connect wires to park/neutral position switch,

transmission solenoid(s) and oxygen sensor. Be sure

transmission harnesses are properly routed.

CAUTION: It is essential that correct length bolts be

used to attach the converter to the driveplate. Bolts

that are too long will damage the clutch surface

inside the converter.

(20) Install torque converter-to-driveplate bolts.

On models with 10.75 in. converter, tighten bolts to31 N´m (270 in. lbs.). On models with 12.2 in. con-

verter, tighten bolts to 47 N´m (35 ft. lbs.).

(21) Install converter housing access cover.

(22) Install starter motor and cooler line bracket.

(Refer to 8 - ELECTRICAL/STARTING/STARTER

MOTOR - INSTALLATION)

(23) Connect cooler lines to transmission.

(24) Install transmission fill tube. Install new seal

on tube before installation.

(25) Install exhaust components.

(26) Align and connect propeller shaft. (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - INSTALLATION)

(27) Adjust gearshift linkage and throttle valve

cable if necessary.

(28) Lower vehicle.

(29) Fill transmission with MopartATF +4, type

9602, Automatic Transmission fluid.

BR/BEAUTOMATIC TRANSMISSION - 46RE 21 - 131

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 1626 of 2255

OVERDRIVE UNIT

REMOVAL

(1) Shift transmission into PARK.

(2) Raise vehicle.

(3) Remove transfer case, if equipped.

(4) Mark propeller shaft universal joint(s) and axle

pinion yoke, or the companion flange and flange

yoke, for alignment reference at installation, if necc-

esary.

(5) Disconnect and remove the rear propeller shaft,

if necessary. (Refer to 3 - DIFFERENTIAL & DRIV-

ELINE/PROPELLER SHAFT/PROPELLER SHAFT -

REMOVAL)

(6) Remove transmission oil pan, remove gasket,

drain oil and reinstall pan.

(7) If overdrive unit had malfunctioned, or if fluid

is contaminated, remove entire transmission. If diag-

nosis indicated overdrive problems only, remove just

the overdrive unit.

(8) Support transmission with transmission jack.

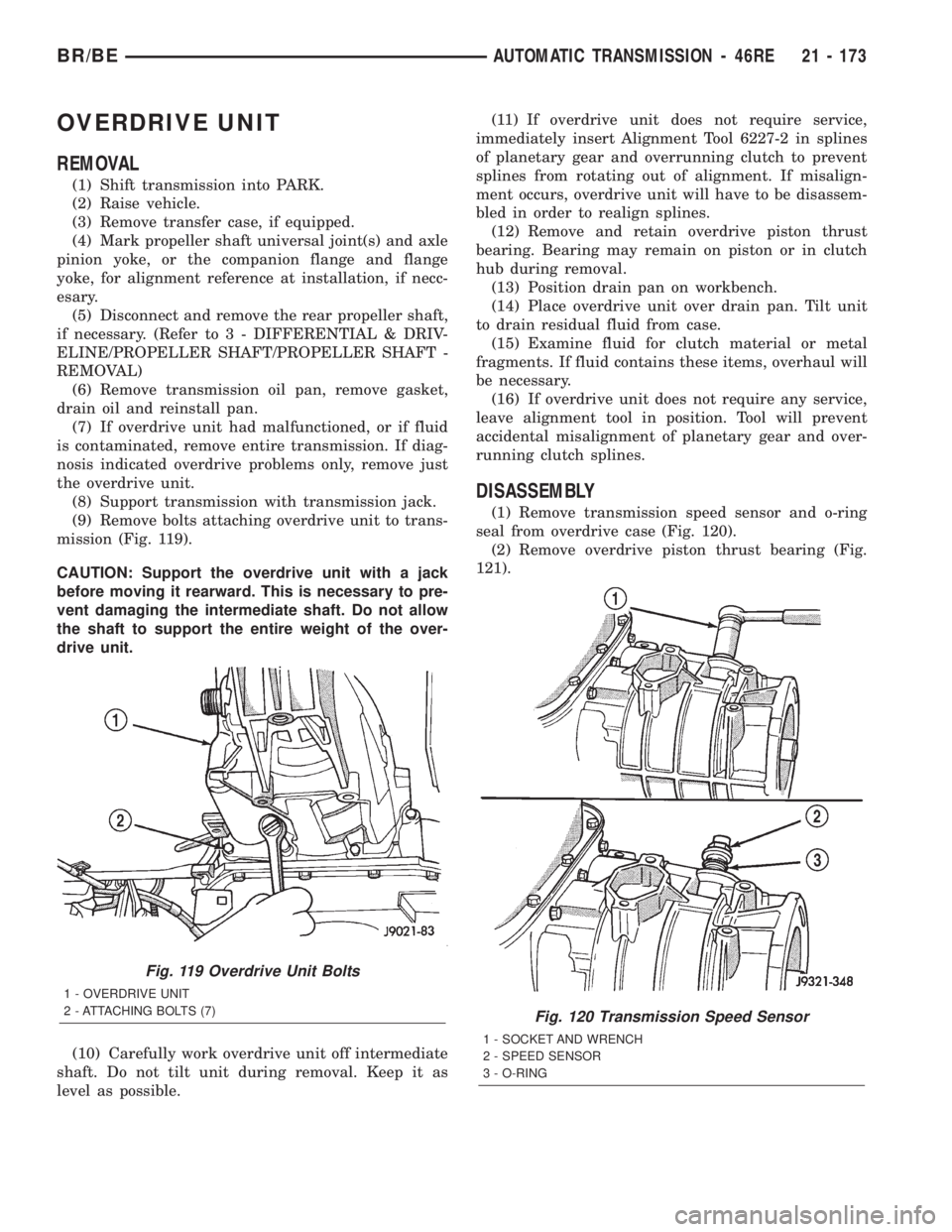

(9) Remove bolts attaching overdrive unit to trans-

mission (Fig. 119).

CAUTION: Support the overdrive unit with a jack

before moving it rearward. This is necessary to pre-

vent damaging the intermediate shaft. Do not allow

the shaft to support the entire weight of the over-

drive unit.

(10) Carefully work overdrive unit off intermediate

shaft. Do not tilt unit during removal. Keep it as

level as possible.(11) If overdrive unit does not require service,

immediately insert Alignment Tool 6227-2 in splines

of planetary gear and overrunning clutch to prevent

splines from rotating out of alignment. If misalign-

ment occurs, overdrive unit will have to be disassem-

bled in order to realign splines.

(12) Remove and retain overdrive piston thrust

bearing. Bearing may remain on piston or in clutch

hub during removal.

(13) Position drain pan on workbench.

(14) Place overdrive unit over drain pan. Tilt unit

to drain residual fluid from case.

(15) Examine fluid for clutch material or metal

fragments. If fluid contains these items, overhaul will

be necessary.

(16) If overdrive unit does not require any service,

leave alignment tool in position. Tool will prevent

accidental misalignment of planetary gear and over-

running clutch splines.

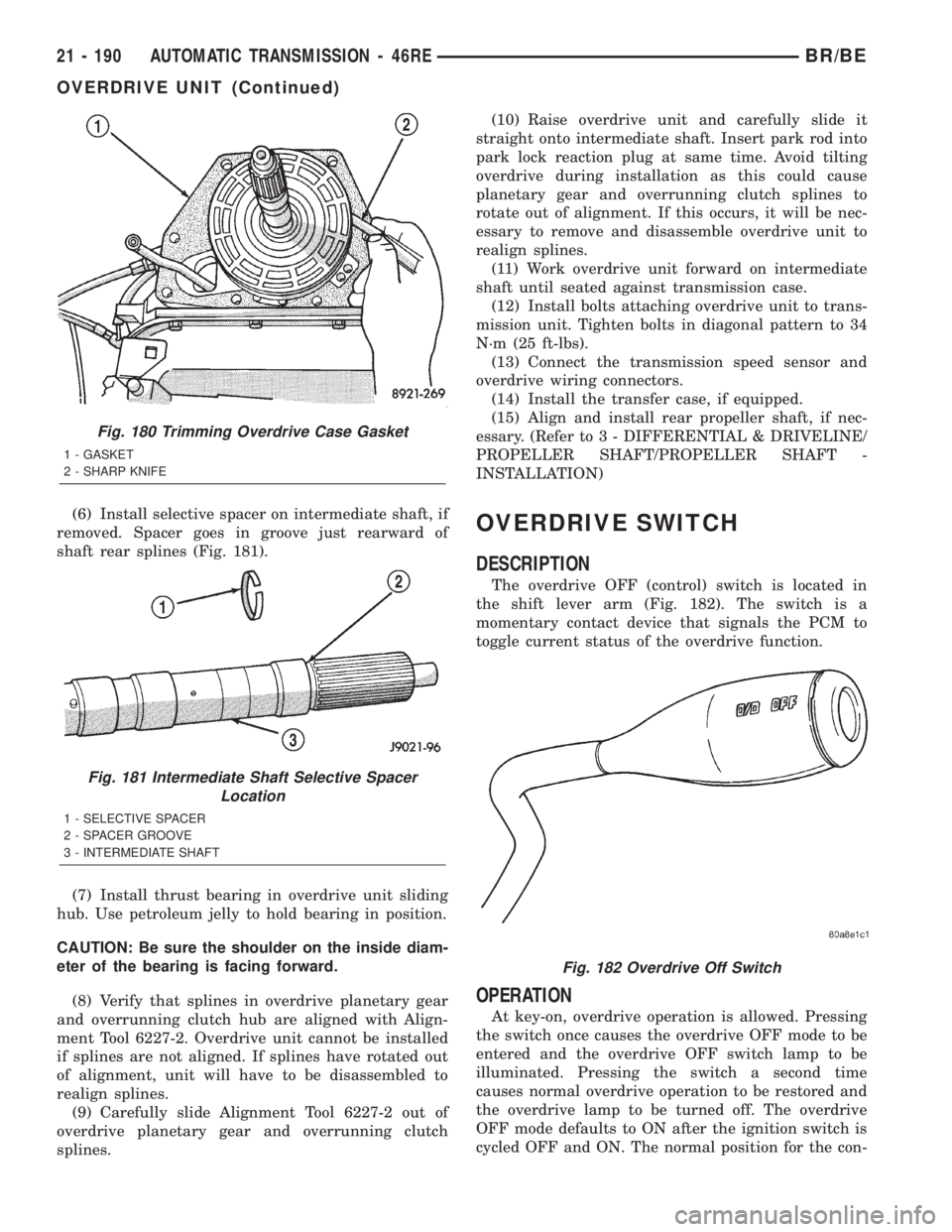

DISASSEMBLY

(1) Remove transmission speed sensor and o-ring

seal from overdrive case (Fig. 120).

(2) Remove overdrive piston thrust bearing (Fig.

121).

Fig. 119 Overdrive Unit Bolts

1 - OVERDRIVE UNIT

2 - ATTACHING BOLTS (7)

Fig. 120 Transmission Speed Sensor

1 - SOCKET AND WRENCH

2 - SPEED SENSOR

3 - O-RING

BR/BEAUTOMATIC TRANSMISSION - 46RE 21 - 173

Page 1643 of 2255

(6) Install selective spacer on intermediate shaft, if

removed. Spacer goes in groove just rearward of

shaft rear splines (Fig. 181).

(7) Install thrust bearing in overdrive unit sliding

hub. Use petroleum jelly to hold bearing in position.

CAUTION: Be sure the shoulder on the inside diam-

eter of the bearing is facing forward.

(8) Verify that splines in overdrive planetary gear

and overrunning clutch hub are aligned with Align-

ment Tool 6227-2. Overdrive unit cannot be installed

if splines are not aligned. If splines have rotated out

of alignment, unit will have to be disassembled to

realign splines.

(9) Carefully slide Alignment Tool 6227-2 out of

overdrive planetary gear and overrunning clutch

splines.(10) Raise overdrive unit and carefully slide it

straight onto intermediate shaft. Insert park rod into

park lock reaction plug at same time. Avoid tilting

overdrive during installation as this could cause

planetary gear and overrunning clutch splines to

rotate out of alignment. If this occurs, it will be nec-

essary to remove and disassemble overdrive unit to

realign splines.

(11) Work overdrive unit forward on intermediate

shaft until seated against transmission case.

(12) Install bolts attaching overdrive unit to trans-

mission unit. Tighten bolts in diagonal pattern to 34

N´m (25 ft-lbs).

(13) Connect the transmission speed sensor and

overdrive wiring connectors.

(14) Install the transfer case, if equipped.

(15) Align and install rear propeller shaft, if nec-

essary. (Refer to 3 - DIFFERENTIAL & DRIVELINE/

PROPELLER SHAFT/PROPELLER SHAFT -

INSTALLATION)OVERDRIVE SWITCH

DESCRIPTION

The overdrive OFF (control) switch is located in

the shift lever arm (Fig. 182). The switch is a

momentary contact device that signals the PCM to

toggle current status of the overdrive function.

OPERATION

At key-on, overdrive operation is allowed. Pressing

the switch once causes the overdrive OFF mode to be

entered and the overdrive OFF switch lamp to be

illuminated. Pressing the switch a second time

causes normal overdrive operation to be restored and

the overdrive lamp to be turned off. The overdrive

OFF mode defaults to ON after the ignition switch is

cycled OFF and ON. The normal position for the con-

Fig. 180 Trimming Overdrive Case Gasket

1 - GASKET

2 - SHARP KNIFE

Fig. 181 Intermediate Shaft Selective Spacer

Location

1 - SELECTIVE SPACER

2 - SPACER GROOVE

3 - INTERMEDIATE SHAFT

Fig. 182 Overdrive Off Switch

21 - 190 AUTOMATIC TRANSMISSION - 46REBR/BE

OVERDRIVE UNIT (Continued)