differential DODGE RAM 2002 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 78 of 2255

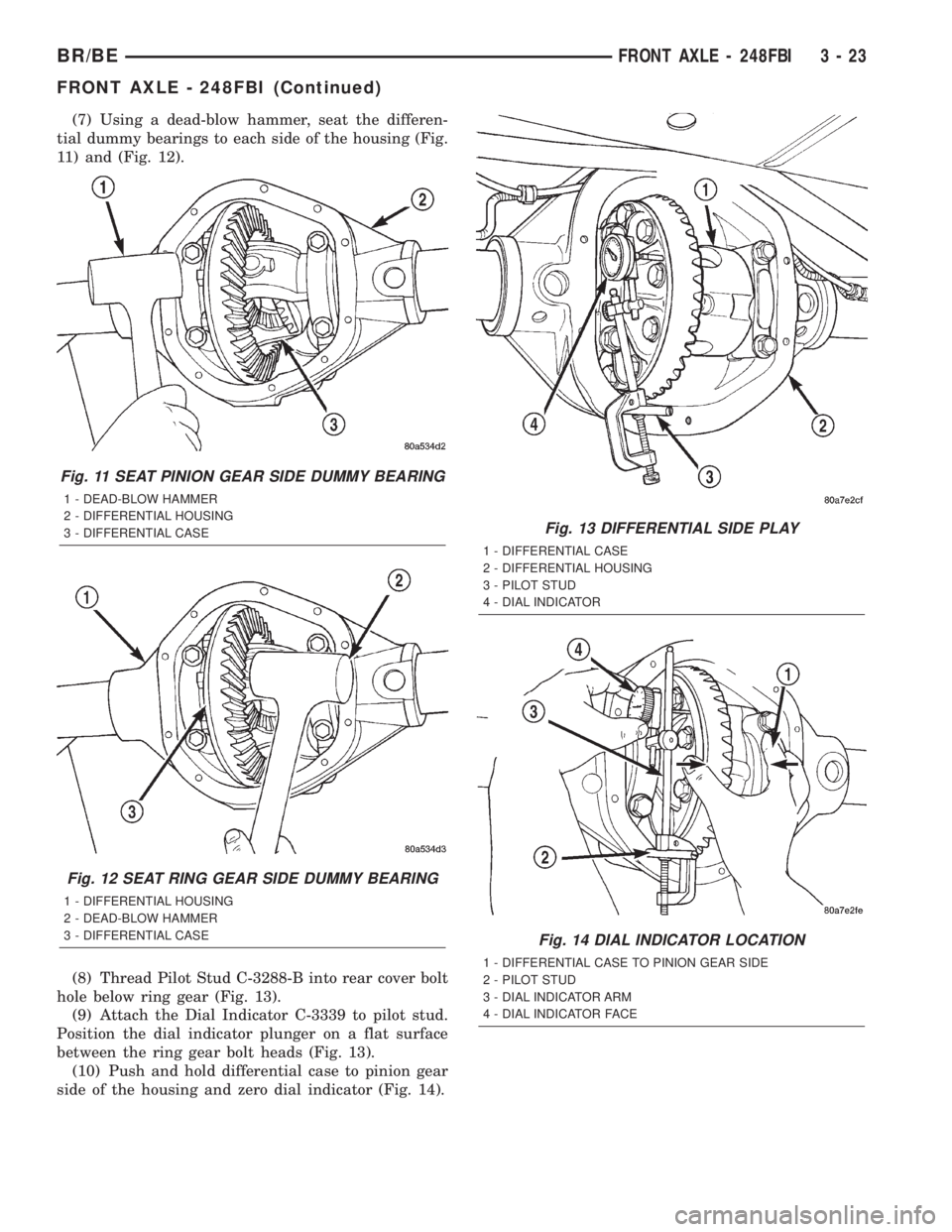

(7) Using a dead-blow hammer, seat the differen-

tial dummy bearings to each side of the housing (Fig.

11) and (Fig. 12).

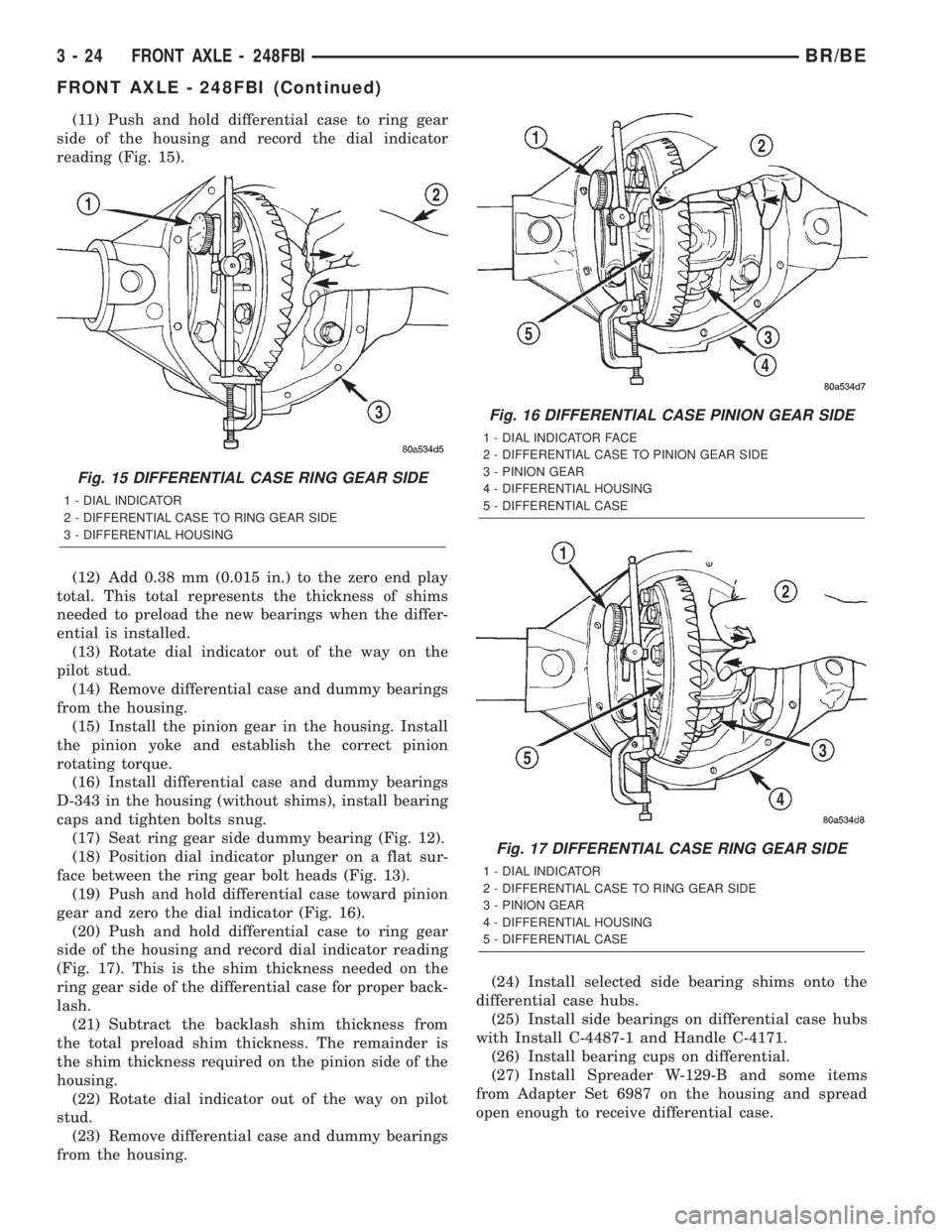

(8) Thread Pilot Stud C-3288-B into rear cover bolt

hole below ring gear (Fig. 13).

(9) Attach the Dial Indicator C-3339 to pilot stud.

Position the dial indicator plunger on a flat surface

between the ring gear bolt heads (Fig. 13).

(10) Push and hold differential case to pinion gear

side of the housing and zero dial indicator (Fig. 14).

Fig. 11 SEAT PINION GEAR SIDE DUMMY BEARING

1 - DEAD-BLOW HAMMER

2 - DIFFERENTIAL HOUSING

3 - DIFFERENTIAL CASE

Fig. 12 SEAT RING GEAR SIDE DUMMY BEARING

1 - DIFFERENTIAL HOUSING

2 - DEAD-BLOW HAMMER

3 - DIFFERENTIAL CASE

Fig. 13 DIFFERENTIAL SIDE PLAY

1 - DIFFERENTIAL CASE

2 - DIFFERENTIAL HOUSING

3 - PILOT STUD

4 - DIAL INDICATOR

Fig. 14 DIAL INDICATOR LOCATION

1 - DIFFERENTIAL CASE TO PINION GEAR SIDE

2 - PILOT STUD

3 - DIAL INDICATOR ARM

4 - DIAL INDICATOR FACE

BR/BEFRONT AXLE - 248FBI 3 - 23

FRONT AXLE - 248FBI (Continued)

Page 79 of 2255

(11) Push and hold differential case to ring gear

side of the housing and record the dial indicator

reading (Fig. 15).

(12) Add 0.38 mm (0.015 in.) to the zero end play

total. This total represents the thickness of shims

needed to preload the new bearings when the differ-

ential is installed.

(13) Rotate dial indicator out of the way on the

pilot stud.

(14) Remove differential case and dummy bearings

from the housing.

(15) Install the pinion gear in the housing. Install

the pinion yoke and establish the correct pinion

rotating torque.

(16) Install differential case and dummy bearings

D-343 in the housing (without shims), install bearing

caps and tighten bolts snug.

(17) Seat ring gear side dummy bearing (Fig. 12).

(18) Position dial indicator plunger on a flat sur-

face between the ring gear bolt heads (Fig. 13).

(19) Push and hold differential case toward pinion

gear and zero the dial indicator (Fig. 16).

(20) Push and hold differential case to ring gear

side of the housing and record dial indicator reading

(Fig. 17). This is the shim thickness needed on the

ring gear side of the differential case for proper back-

lash.

(21) Subtract the backlash shim thickness from

the total preload shim thickness. The remainder is

the shim thickness required on the pinion side of the

housing.

(22) Rotate dial indicator out of the way on pilot

stud.

(23) Remove differential case and dummy bearings

from the housing.(24) Install selected side bearing shims onto the

differential case hubs.

(25) Install side bearings on differential case hubs

with Install C-4487-1 and Handle C-4171.

(26) Install bearing cups on differential.

(27) Install Spreader W-129-B and some items

from Adapter Set 6987 on the housing and spread

open enough to receive differential case.

Fig. 15 DIFFERENTIAL CASE RING GEAR SIDE

1 - DIAL INDICATOR

2 - DIFFERENTIAL CASE TO RING GEAR SIDE

3 - DIFFERENTIAL HOUSING

Fig. 16 DIFFERENTIAL CASE PINION GEAR SIDE

1 - DIAL INDICATOR FACE

2 - DIFFERENTIAL CASE TO PINION GEAR SIDE

3 - PINION GEAR

4 - DIFFERENTIAL HOUSING

5 - DIFFERENTIAL CASE

Fig. 17 DIFFERENTIAL CASE RING GEAR SIDE

1 - DIAL INDICATOR

2 - DIFFERENTIAL CASE TO RING GEAR SIDE

3 - PINION GEAR

4 - DIFFERENTIAL HOUSING

5 - DIFFERENTIAL CASE

3 - 24 FRONT AXLE - 248FBIBR/BE

FRONT AXLE - 248FBI (Continued)

Page 80 of 2255

CAUTION: Never spread housing over 0.50 mm

(0.020 in.). The housing can be damaged if over-

spread.

(28) Install differential case into the housing.

(29) Remove spreader from the housing.

(30) Rotate differential case several times to seat

the side bearings.

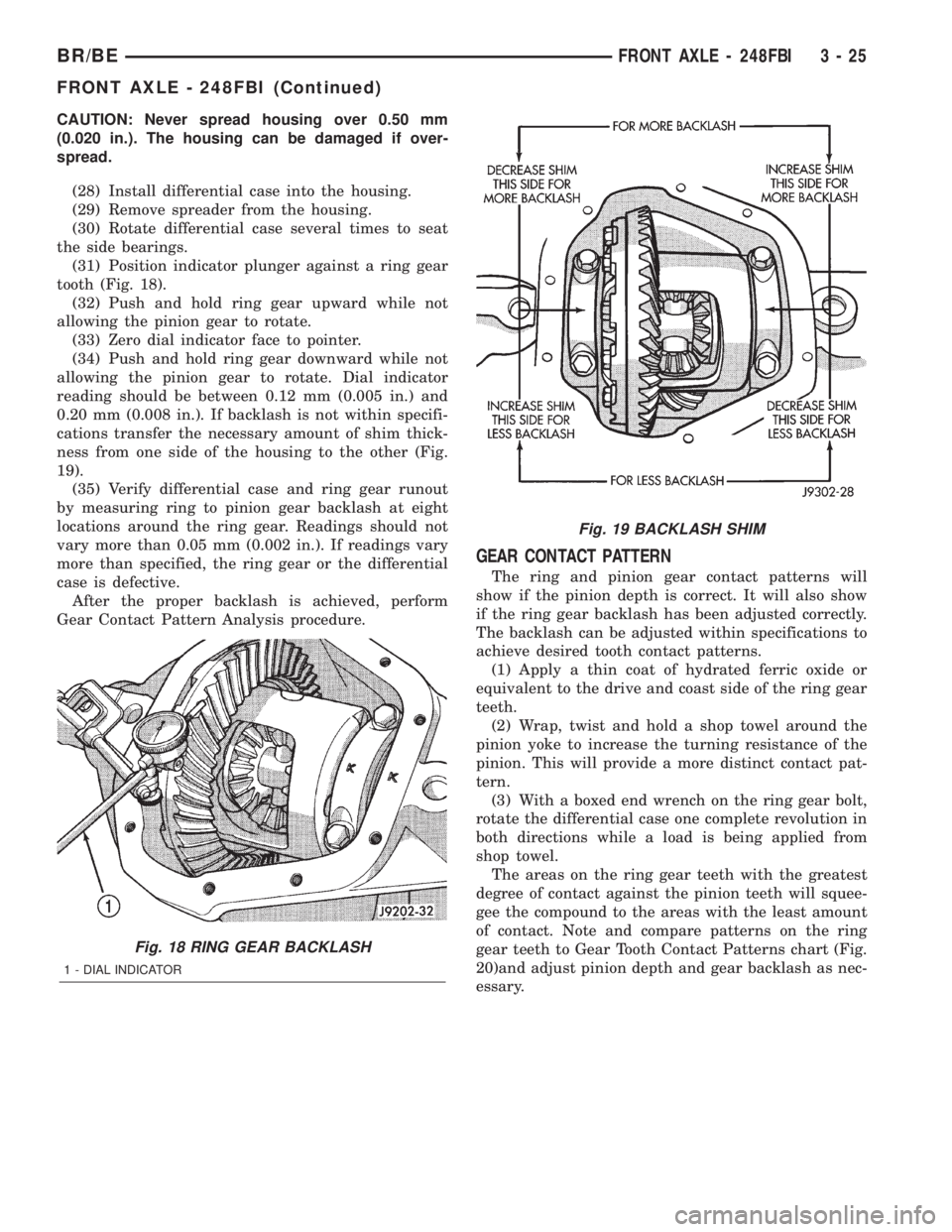

(31) Position indicator plunger against a ring gear

tooth (Fig. 18).

(32) Push and hold ring gear upward while not

allowing the pinion gear to rotate.

(33) Zero dial indicator face to pointer.

(34) Push and hold ring gear downward while not

allowing the pinion gear to rotate. Dial indicator

reading should be between 0.12 mm (0.005 in.) and

0.20 mm (0.008 in.). If backlash is not within specifi-

cations transfer the necessary amount of shim thick-

ness from one side of the housing to the other (Fig.

19).

(35) Verify differential case and ring gear runout

by measuring ring to pinion gear backlash at eight

locations around the ring gear. Readings should not

vary more than 0.05 mm (0.002 in.). If readings vary

more than specified, the ring gear or the differential

case is defective.

After the proper backlash is achieved, perform

Gear Contact Pattern Analysis procedure.

GEAR CONTACT PATTERN

The ring and pinion gear contact patterns will

show if the pinion depth is correct. It will also show

if the ring gear backlash has been adjusted correctly.

The backlash can be adjusted within specifications to

achieve desired tooth contact patterns.

(1) Apply a thin coat of hydrated ferric oxide or

equivalent to the drive and coast side of the ring gear

teeth.

(2) Wrap, twist and hold a shop towel around the

pinion yoke to increase the turning resistance of the

pinion. This will provide a more distinct contact pat-

tern.

(3) With a boxed end wrench on the ring gear bolt,

rotate the differential case one complete revolution in

both directions while a load is being applied from

shop towel.

The areas on the ring gear teeth with the greatest

degree of contact against the pinion teeth will squee-

gee the compound to the areas with the least amount

of contact. Note and compare patterns on the ring

gear teeth to Gear Tooth Contact Patterns chart (Fig.

20)and adjust pinion depth and gear backlash as nec-

essary.

Fig. 18 RING GEAR BACKLASH

1 - DIAL INDICATOR

Fig. 19 BACKLASH SHIM

BR/BEFRONT AXLE - 248FBI 3 - 25

FRONT AXLE - 248FBI (Continued)

Page 82 of 2255

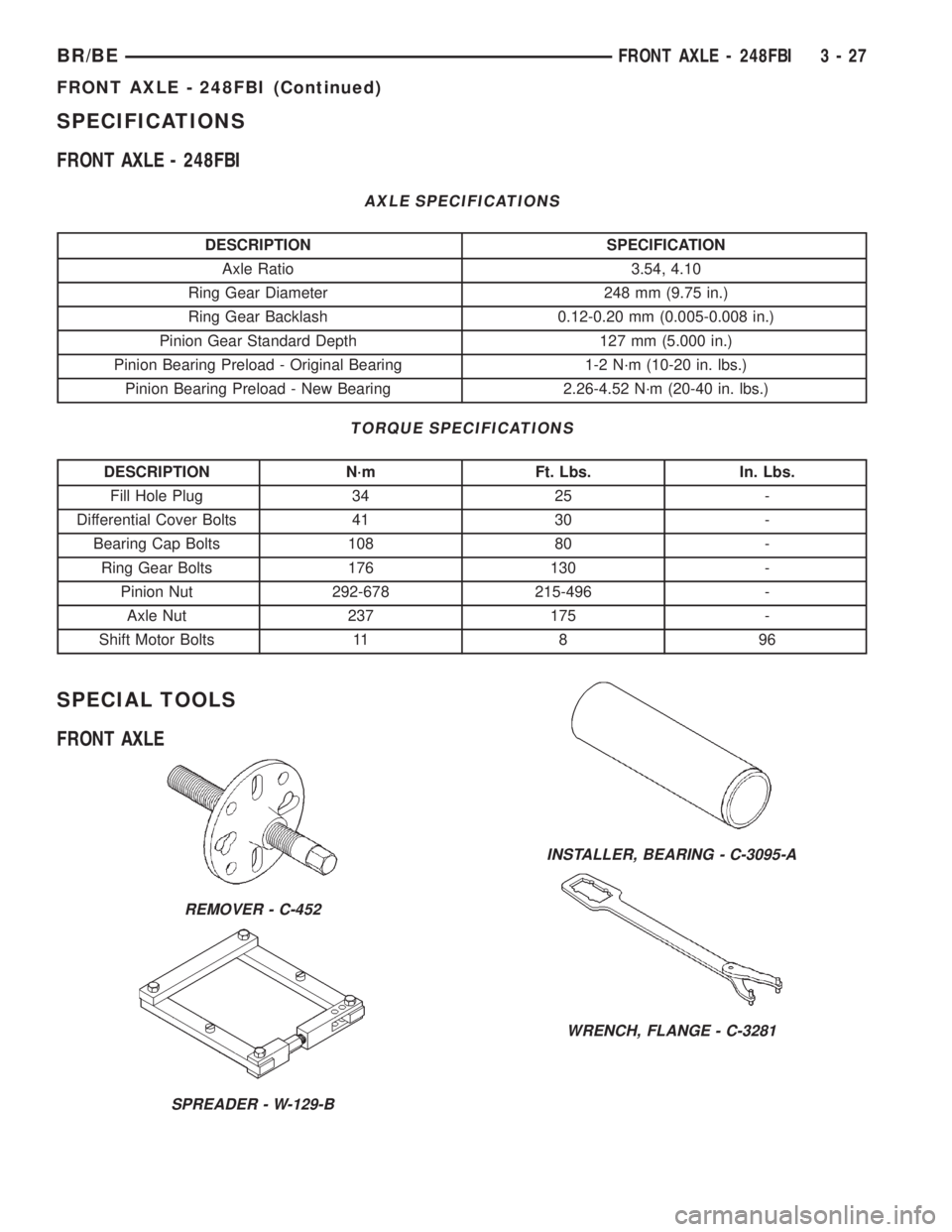

SPECIFICATIONS

FRONT AXLE - 248FBI

AXLE SPECIFICATIONS

DESCRIPTION SPECIFICATION

Axle Ratio 3.54, 4.10

Ring Gear Diameter 248 mm (9.75 in.)

Ring Gear Backlash 0.12-0.20 mm (0.005-0.008 in.)

Pinion Gear Standard Depth 127 mm (5.000 in.)

Pinion Bearing Preload - Original Bearing 1-2 N´m (10-20 in. lbs.)

Pinion Bearing Preload - New Bearing 2.26-4.52 N´m (20-40 in. lbs.)

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Fill Hole Plug 34 25 -

Differential Cover Bolts 41 30 -

Bearing Cap Bolts 108 80 -

Ring Gear Bolts 176 130 -

Pinion Nut 292-678 215-496 -

Axle Nut 237 175 -

Shift Motor Bolts 11 8 96

SPECIAL TOOLS

FRONT AXLE

REMOVER - C-452

SPREADER - W-129-B

INSTALLER, BEARING - C-3095-A

WRENCH, FLANGE - C-3281

BR/BEFRONT AXLE - 248FBI 3 - 27

FRONT AXLE - 248FBI (Continued)

Page 84 of 2255

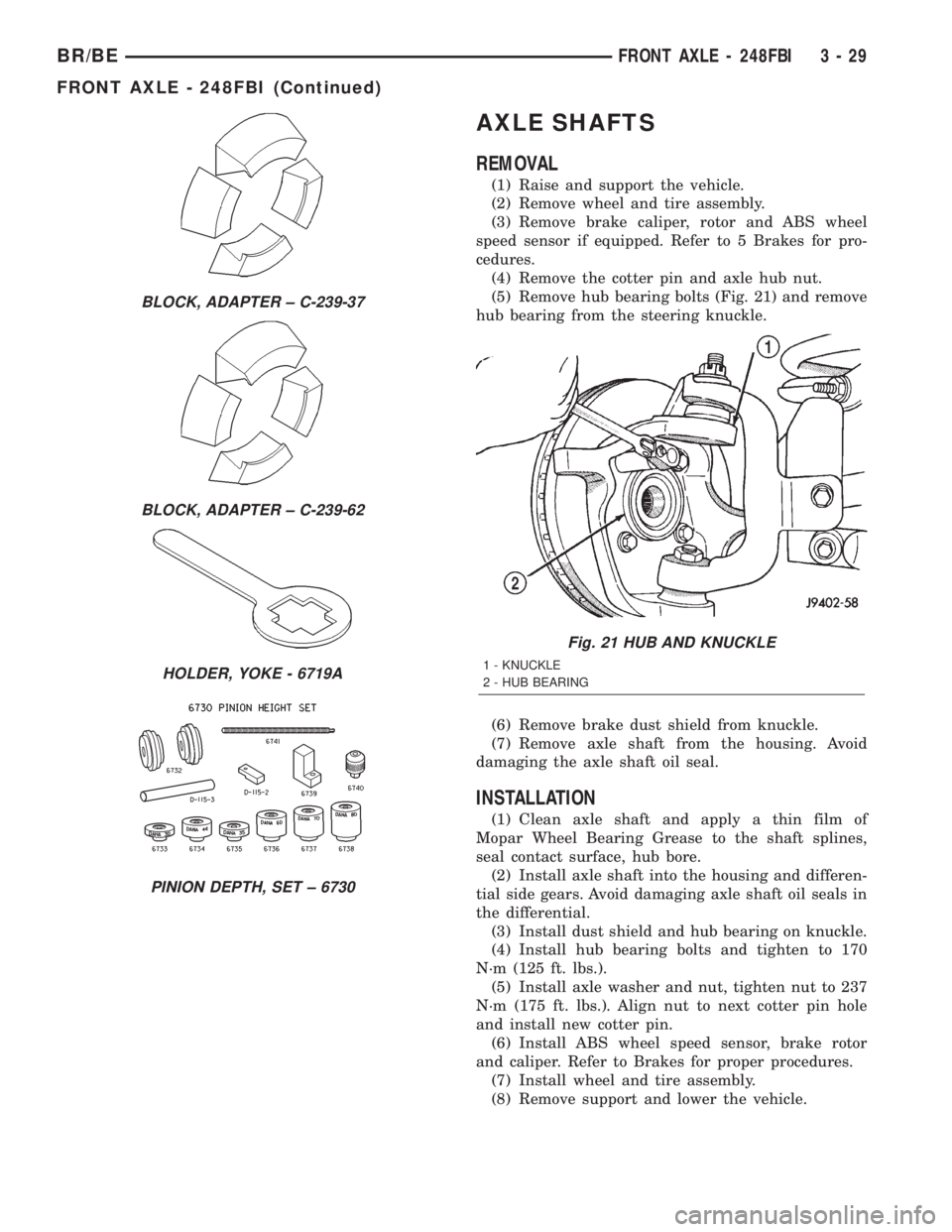

AXLE SHAFTS

REMOVAL

(1) Raise and support the vehicle.

(2) Remove wheel and tire assembly.

(3) Remove brake caliper, rotor and ABS wheel

speed sensor if equipped. Refer to 5 Brakes for pro-

cedures.

(4) Remove the cotter pin and axle hub nut.

(5) Remove hub bearing bolts (Fig. 21) and remove

hub bearing from the steering knuckle.

(6) Remove brake dust shield from knuckle.

(7) Remove axle shaft from the housing. Avoid

damaging the axle shaft oil seal.

INSTALLATION

(1) Clean axle shaft and apply a thin film of

Mopar Wheel Bearing Grease to the shaft splines,

seal contact surface, hub bore.

(2) Install axle shaft into the housing and differen-

tial side gears. Avoid damaging axle shaft oil seals in

the differential.

(3) Install dust shield and hub bearing on knuckle.

(4) Install hub bearing bolts and tighten to 170

N´m (125 ft. lbs.).

(5) Install axle washer and nut, tighten nut to 237

N´m (175 ft. lbs.). Align nut to next cotter pin hole

and install new cotter pin.

(6) Install ABS wheel speed sensor, brake rotor

and caliper. Refer to Brakes for proper procedures.

(7) Install wheel and tire assembly.

(8) Remove support and lower the vehicle.

BLOCK, ADAPTER ± C-239-37

BLOCK, ADAPTER ± C-239-62

HOLDER, YOKE - 6719A

PINION DEPTH, SET ± 6730

Fig. 21 HUB AND KNUCKLE

1 - KNUCKLE

2 - HUB BEARING

BR/BEFRONT AXLE - 248FBI 3 - 29

FRONT AXLE - 248FBI (Continued)

Page 86 of 2255

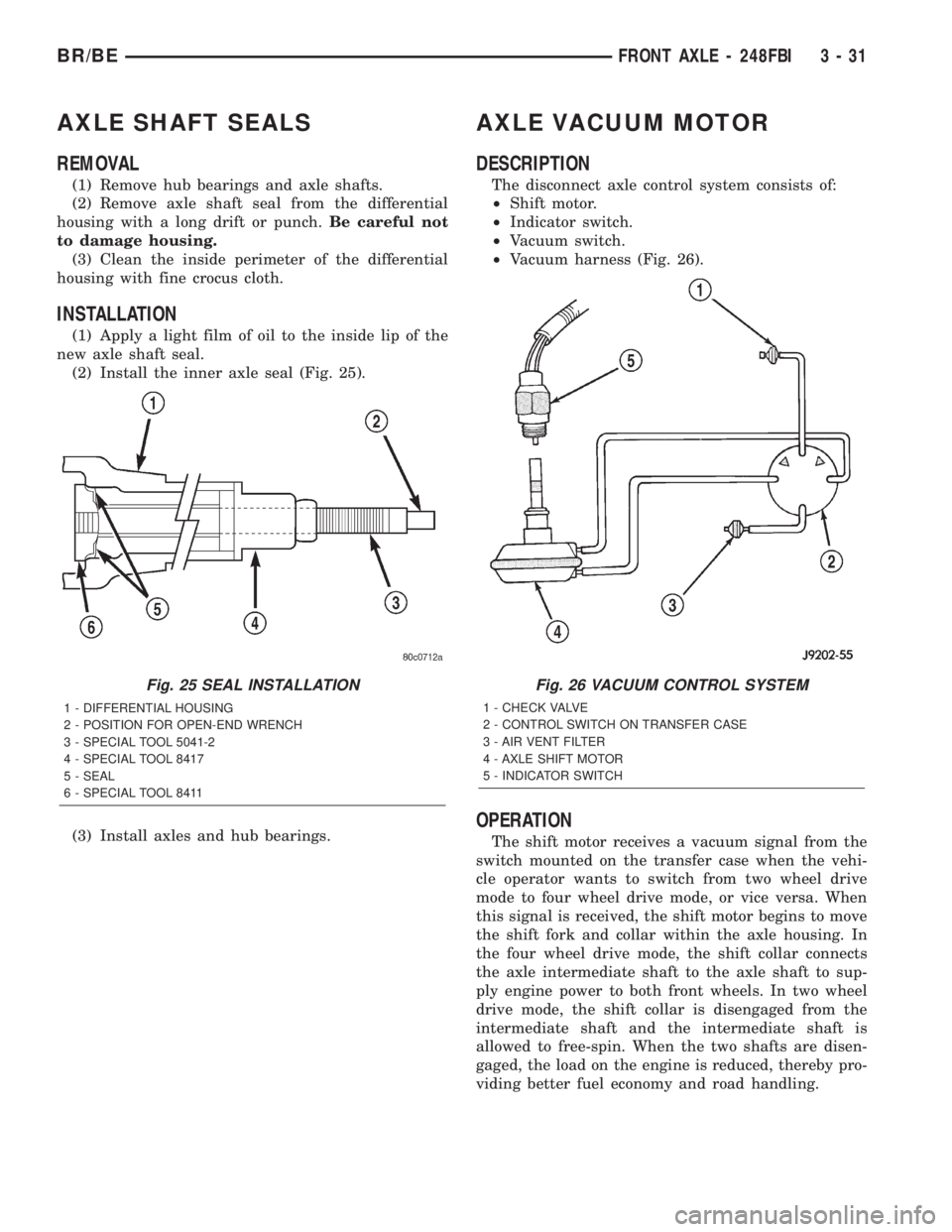

AXLE SHAFT SEALS

REMOVAL

(1) Remove hub bearings and axle shafts.

(2) Remove axle shaft seal from the differential

housing with a long drift or punch.Be careful not

to damage housing.

(3) Clean the inside perimeter of the differential

housing with fine crocus cloth.

INSTALLATION

(1) Apply a light film of oil to the inside lip of the

new axle shaft seal.

(2) Install the inner axle seal (Fig. 25).

(3) Install axles and hub bearings.

AXLE VACUUM MOTOR

DESCRIPTION

The disconnect axle control system consists of:

²Shift motor.

²Indicator switch.

²Vacuum switch.

²Vacuum harness (Fig. 26).

OPERATION

The shift motor receives a vacuum signal from the

switch mounted on the transfer case when the vehi-

cle operator wants to switch from two wheel drive

mode to four wheel drive mode, or vice versa. When

this signal is received, the shift motor begins to move

the shift fork and collar within the axle housing. In

the four wheel drive mode, the shift collar connects

the axle intermediate shaft to the axle shaft to sup-

ply engine power to both front wheels. In two wheel

drive mode, the shift collar is disengaged from the

intermediate shaft and the intermediate shaft is

allowed to free-spin. When the two shafts are disen-

gaged, the load on the engine is reduced, thereby pro-

viding better fuel economy and road handling.

Fig. 25 SEAL INSTALLATION

1 - DIFFERENTIAL HOUSING

2 - POSITION FOR OPEN-END WRENCH

3 - SPECIAL TOOL 5041-2

4 - SPECIAL TOOL 8417

5 - SEAL

6 - SPECIAL TOOL 8411

Fig. 26 VACUUM CONTROL SYSTEM

1 - CHECK VALVE

2 - CONTROL SWITCH ON TRANSFER CASE

3 - AIR VENT FILTER

4 - AXLE SHIFT MOTOR

5 - INDICATOR SWITCH

BR/BEFRONT AXLE - 248FBI 3 - 31

Page 89 of 2255

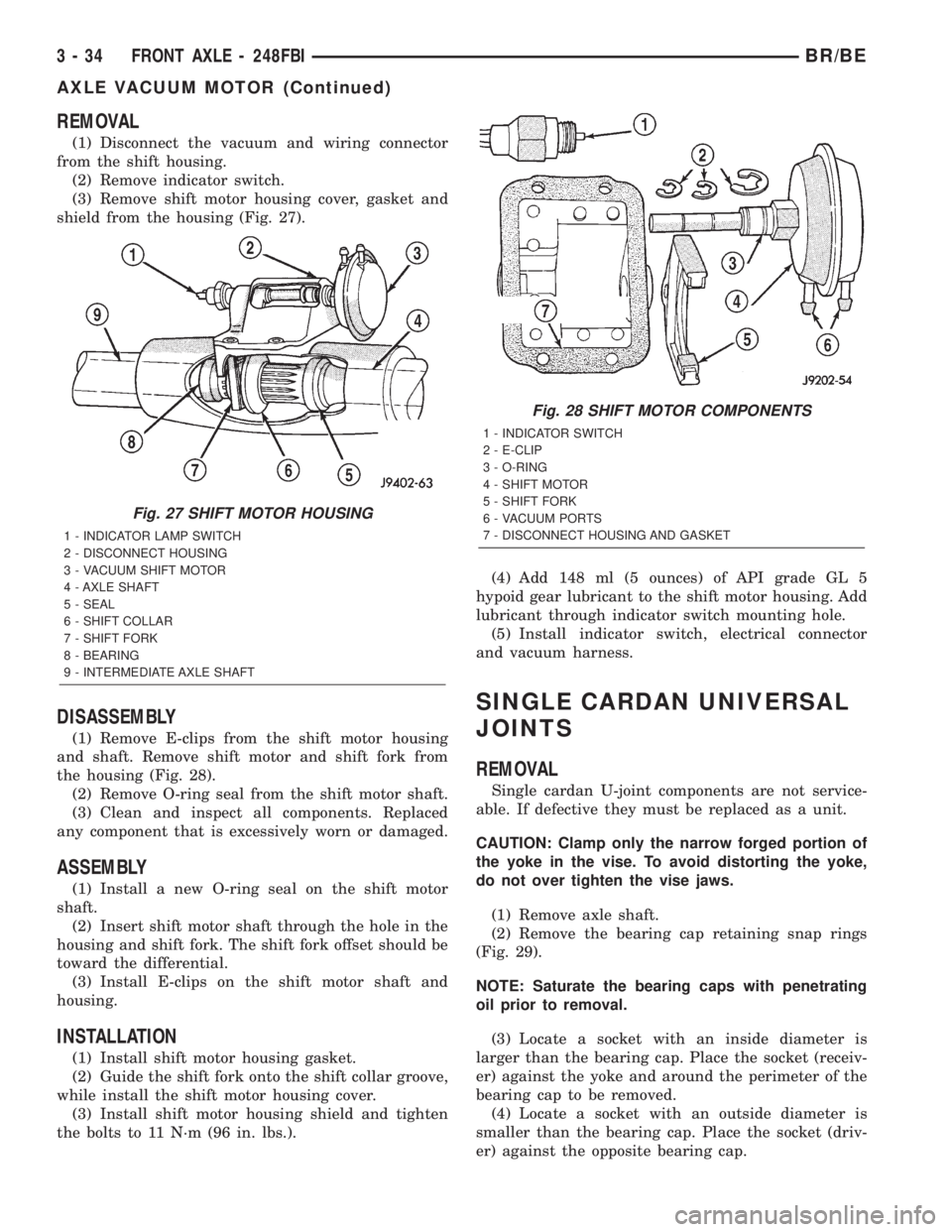

REMOVAL

(1) Disconnect the vacuum and wiring connector

from the shift housing.

(2) Remove indicator switch.

(3) Remove shift motor housing cover, gasket and

shield from the housing (Fig. 27).

DISASSEMBLY

(1) Remove E-clips from the shift motor housing

and shaft. Remove shift motor and shift fork from

the housing (Fig. 28).

(2) Remove O-ring seal from the shift motor shaft.

(3) Clean and inspect all components. Replaced

any component that is excessively worn or damaged.

ASSEMBLY

(1) Install a new O-ring seal on the shift motor

shaft.

(2) Insert shift motor shaft through the hole in the

housing and shift fork. The shift fork offset should be

toward the differential.

(3) Install E-clips on the shift motor shaft and

housing.

INSTALLATION

(1) Install shift motor housing gasket.

(2) Guide the shift fork onto the shift collar groove,

while install the shift motor housing cover.

(3) Install shift motor housing shield and tighten

the bolts to 11 N´m (96 in. lbs.).(4) Add 148 ml (5 ounces) of API grade GL 5

hypoid gear lubricant to the shift motor housing. Add

lubricant through indicator switch mounting hole.

(5) Install indicator switch, electrical connector

and vacuum harness.

SINGLE CARDAN UNIVERSAL

JOINTS

REMOVAL

Single cardan U-joint components are not service-

able. If defective they must be replaced as a unit.

CAUTION: Clamp only the narrow forged portion of

the yoke in the vise. To avoid distorting the yoke,

do not over tighten the vise jaws.

(1) Remove axle shaft.

(2) Remove the bearing cap retaining snap rings

(Fig. 29).

NOTE: Saturate the bearing caps with penetrating

oil prior to removal.

(3) Locate a socket with an inside diameter is

larger than the bearing cap. Place the socket (receiv-

er) against the yoke and around the perimeter of the

bearing cap to be removed.

(4) Locate a socket with an outside diameter is

smaller than the bearing cap. Place the socket (driv-

er) against the opposite bearing cap.

Fig. 27 SHIFT MOTOR HOUSING

1 - INDICATOR LAMP SWITCH

2 - DISCONNECT HOUSING

3 - VACUUM SHIFT MOTOR

4 - AXLE SHAFT

5 - SEAL

6 - SHIFT COLLAR

7 - SHIFT FORK

8 - BEARING

9 - INTERMEDIATE AXLE SHAFT

Fig. 28 SHIFT MOTOR COMPONENTS

1 - INDICATOR SWITCH

2 - E-CLIP

3 - O-RING

4 - SHIFT MOTOR

5 - SHIFT FORK

6 - VACUUM PORTS

7 - DISCONNECT HOUSING AND GASKET

3 - 34 FRONT AXLE - 248FBIBR/BE

AXLE VACUUM MOTOR (Continued)

Page 92 of 2255

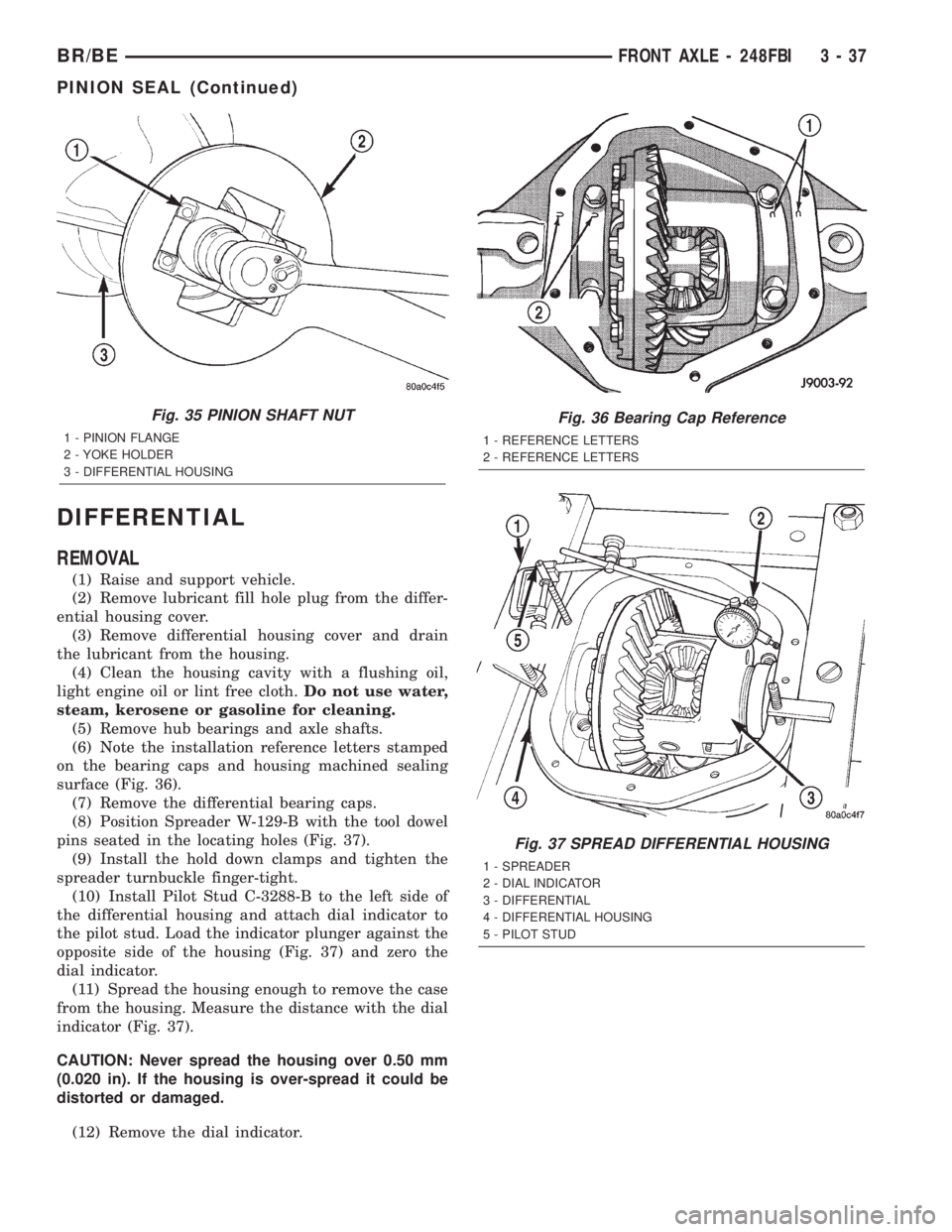

DIFFERENTIAL

REMOVAL

(1) Raise and support vehicle.

(2) Remove lubricant fill hole plug from the differ-

ential housing cover.

(3) Remove differential housing cover and drain

the lubricant from the housing.

(4) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.Do not use water,

steam, kerosene or gasoline for cleaning.

(5) Remove hub bearings and axle shafts.

(6) Note the installation reference letters stamped

on the bearing caps and housing machined sealing

surface (Fig. 36).

(7) Remove the differential bearing caps.

(8) Position Spreader W-129-B with the tool dowel

pins seated in the locating holes (Fig. 37).

(9) Install the hold down clamps and tighten the

spreader turnbuckle finger-tight.

(10) Install Pilot Stud C-3288-B to the left side of

the differential housing and attach dial indicator to

the pilot stud. Load the indicator plunger against the

opposite side of the housing (Fig. 37) and zero the

dial indicator.

(11) Spread the housing enough to remove the case

from the housing. Measure the distance with the dial

indicator (Fig. 37).

CAUTION: Never spread the housing over 0.50 mm

(0.020 in). If the housing is over-spread it could be

distorted or damaged.

(12) Remove the dial indicator.

Fig. 35 PINION SHAFT NUT

1 - PINION FLANGE

2 - YOKE HOLDER

3 - DIFFERENTIAL HOUSING

Fig. 36 Bearing Cap Reference

1 - REFERENCE LETTERS

2 - REFERENCE LETTERS

Fig. 37 SPREAD DIFFERENTIAL HOUSING

1 - SPREADER

2 - DIAL INDICATOR

3 - DIFFERENTIAL

4 - DIFFERENTIAL HOUSING

5 - PILOT STUD

BR/BEFRONT AXLE - 248FBI 3 - 37

PINION SEAL (Continued)

Page 93 of 2255

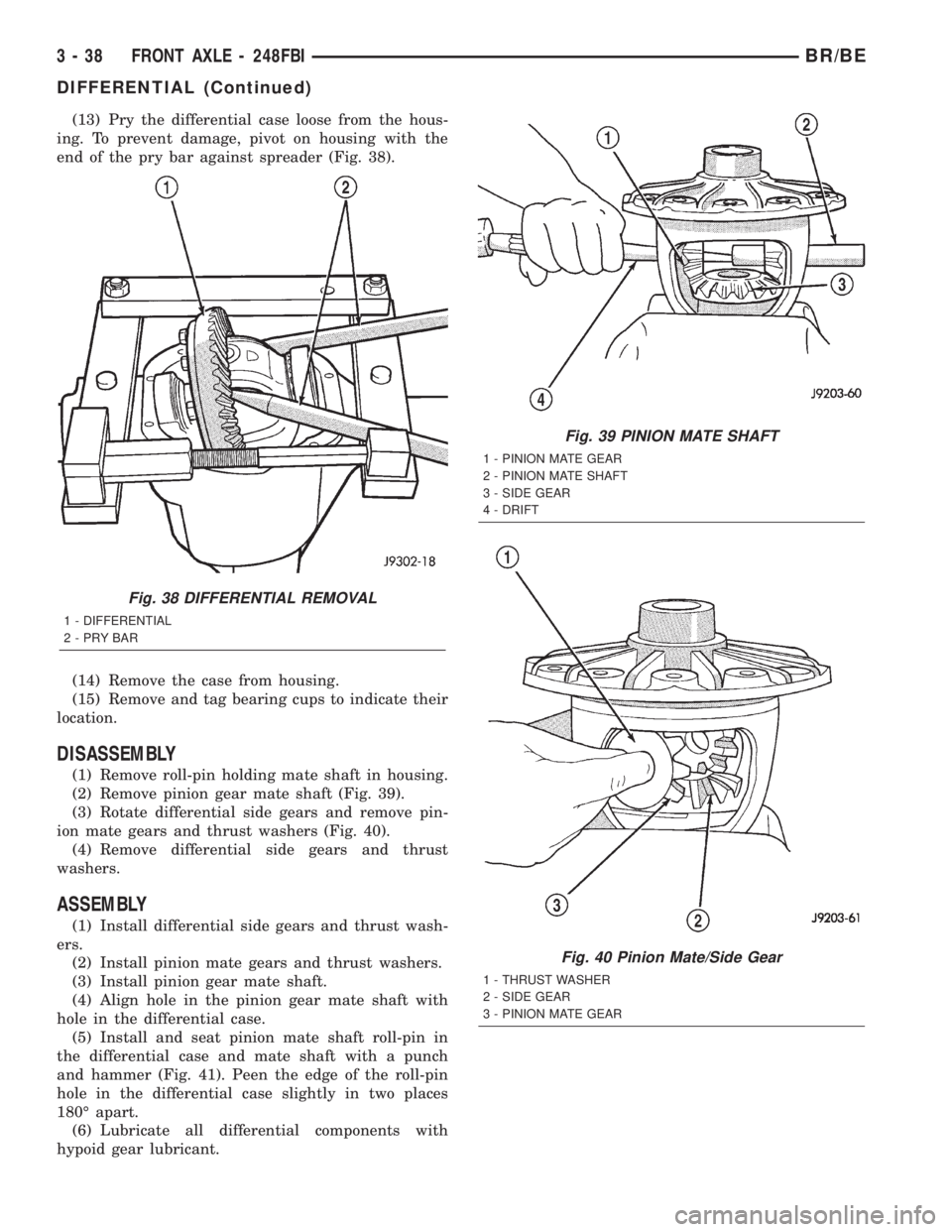

(13) Pry the differential case loose from the hous-

ing. To prevent damage, pivot on housing with the

end of the pry bar against spreader (Fig. 38).

(14) Remove the case from housing.

(15) Remove and tag bearing cups to indicate their

location.

DISASSEMBLY

(1) Remove roll-pin holding mate shaft in housing.

(2) Remove pinion gear mate shaft (Fig. 39).

(3) Rotate differential side gears and remove pin-

ion mate gears and thrust washers (Fig. 40).

(4) Remove differential side gears and thrust

washers.

ASSEMBLY

(1) Install differential side gears and thrust wash-

ers.

(2) Install pinion mate gears and thrust washers.

(3) Install pinion gear mate shaft.

(4) Align hole in the pinion gear mate shaft with

hole in the differential case.

(5) Install and seat pinion mate shaft roll-pin in

the differential case and mate shaft with a punch

and hammer (Fig. 41). Peen the edge of the roll-pin

hole in the differential case slightly in two places

180É apart.

(6) Lubricate all differential components with

hypoid gear lubricant.

Fig. 38 DIFFERENTIAL REMOVAL

1 - DIFFERENTIAL

2-PRYBAR

Fig. 39 PINION MATE SHAFT

1 - PINION MATE GEAR

2 - PINION MATE SHAFT

3 - SIDE GEAR

4 - DRIFT

Fig. 40 Pinion Mate/Side Gear

1 - THRUST WASHER

2 - SIDE GEAR

3 - PINION MATE GEAR

3 - 38 FRONT AXLE - 248FBIBR/BE

DIFFERENTIAL (Continued)

Page 94 of 2255

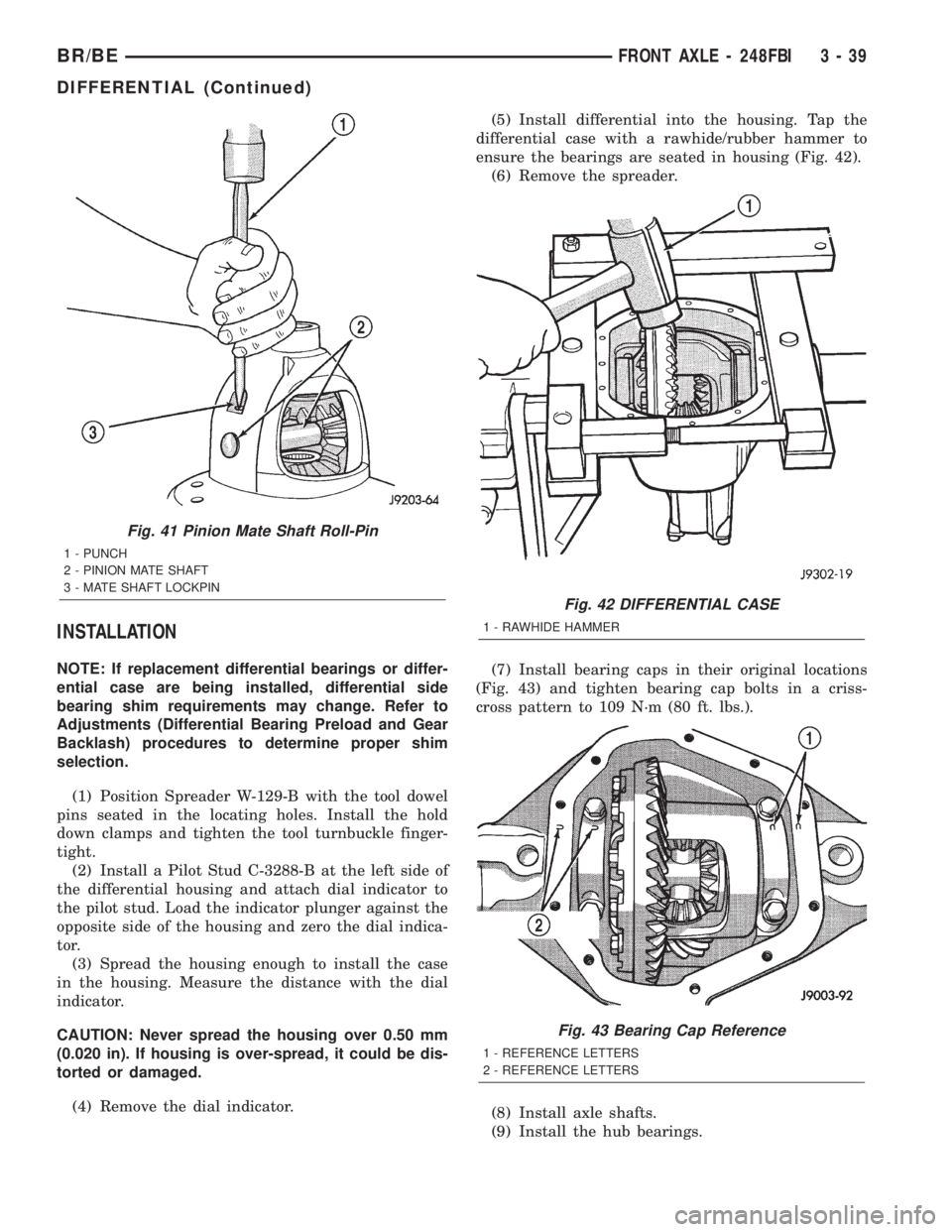

INSTALLATION

NOTE: If replacement differential bearings or differ-

ential case are being installed, differential side

bearing shim requirements may change. Refer to

Adjustments (Differential Bearing Preload and Gear

Backlash) procedures to determine proper shim

selection.

(1) Position Spreader W-129-B with the tool dowel

pins seated in the locating holes. Install the hold

down clamps and tighten the tool turnbuckle finger-

tight.

(2) Install a Pilot Stud C-3288-B at the left side of

the differential housing and attach dial indicator to

the pilot stud. Load the indicator plunger against the

opposite side of the housing and zero the dial indica-

tor.

(3) Spread the housing enough to install the case

in the housing. Measure the distance with the dial

indicator.

CAUTION: Never spread the housing over 0.50 mm

(0.020 in). If housing is over-spread, it could be dis-

torted or damaged.

(4) Remove the dial indicator.(5) Install differential into the housing. Tap the

differential case with a rawhide/rubber hammer to

ensure the bearings are seated in housing (Fig. 42).

(6) Remove the spreader.

(7) Install bearing caps in their original locations

(Fig. 43) and tighten bearing cap bolts in a criss-

cross pattern to 109 N´m (80 ft. lbs.).

(8) Install axle shafts.

(9) Install the hub bearings.

Fig. 41 Pinion Mate Shaft Roll-Pin

1 - PUNCH

2 - PINION MATE SHAFT

3 - MATE SHAFT LOCKPIN

Fig. 42 DIFFERENTIAL CASE

1 - RAWHIDE HAMMER

Fig. 43 Bearing Cap Reference

1 - REFERENCE LETTERS

2 - REFERENCE LETTERS

BR/BEFRONT AXLE - 248FBI 3 - 39

DIFFERENTIAL (Continued)