differential DODGE RAM 2002 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 123 of 2255

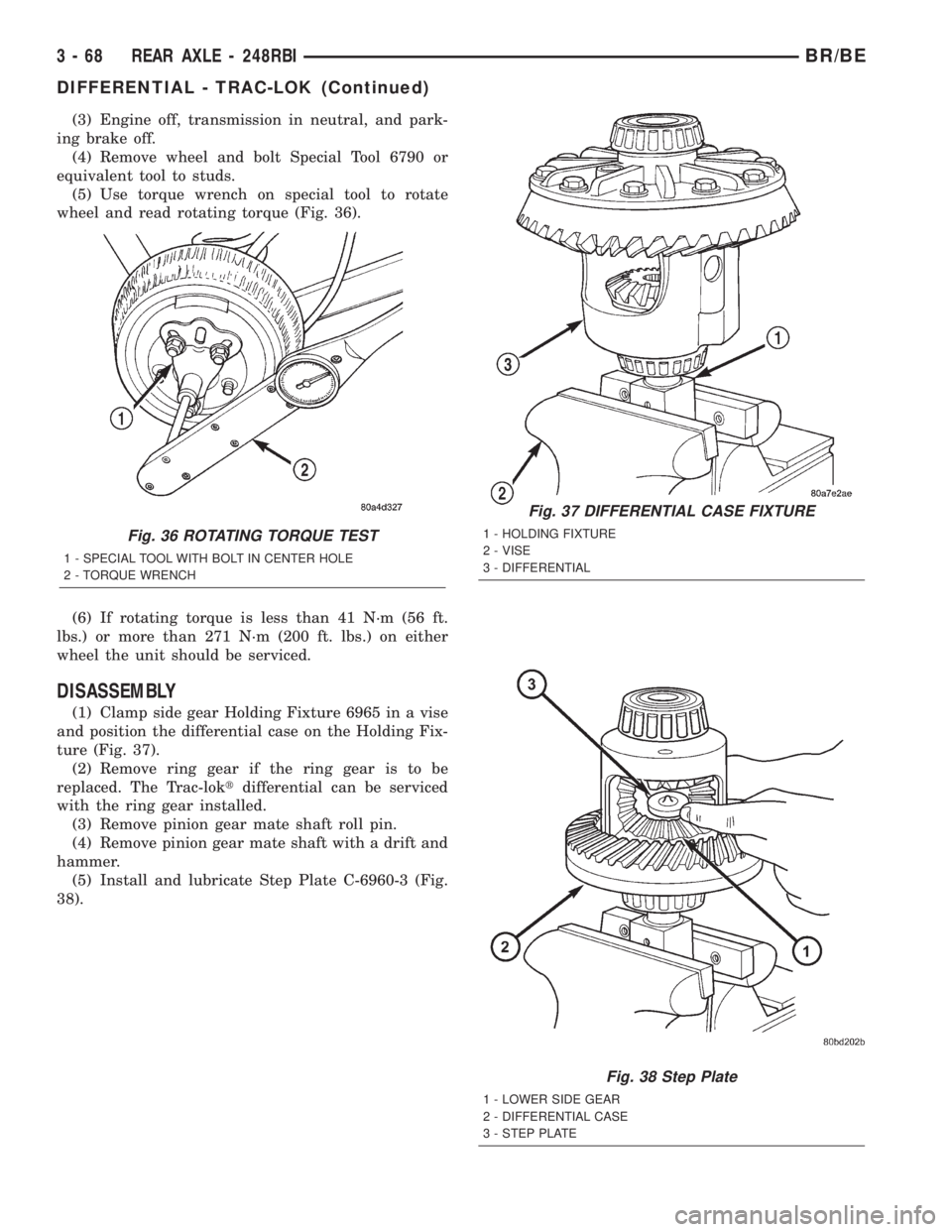

(3) Engine off, transmission in neutral, and park-

ing brake off.

(4) Remove wheel and bolt Special Tool 6790 or

equivalent tool to studs.

(5) Use torque wrench on special tool to rotate

wheel and read rotating torque (Fig. 36).

(6) If rotating torque is less than 41 N´m (56 ft.

lbs.) or more than 271 N´m (200 ft. lbs.) on either

wheel the unit should be serviced.

DISASSEMBLY

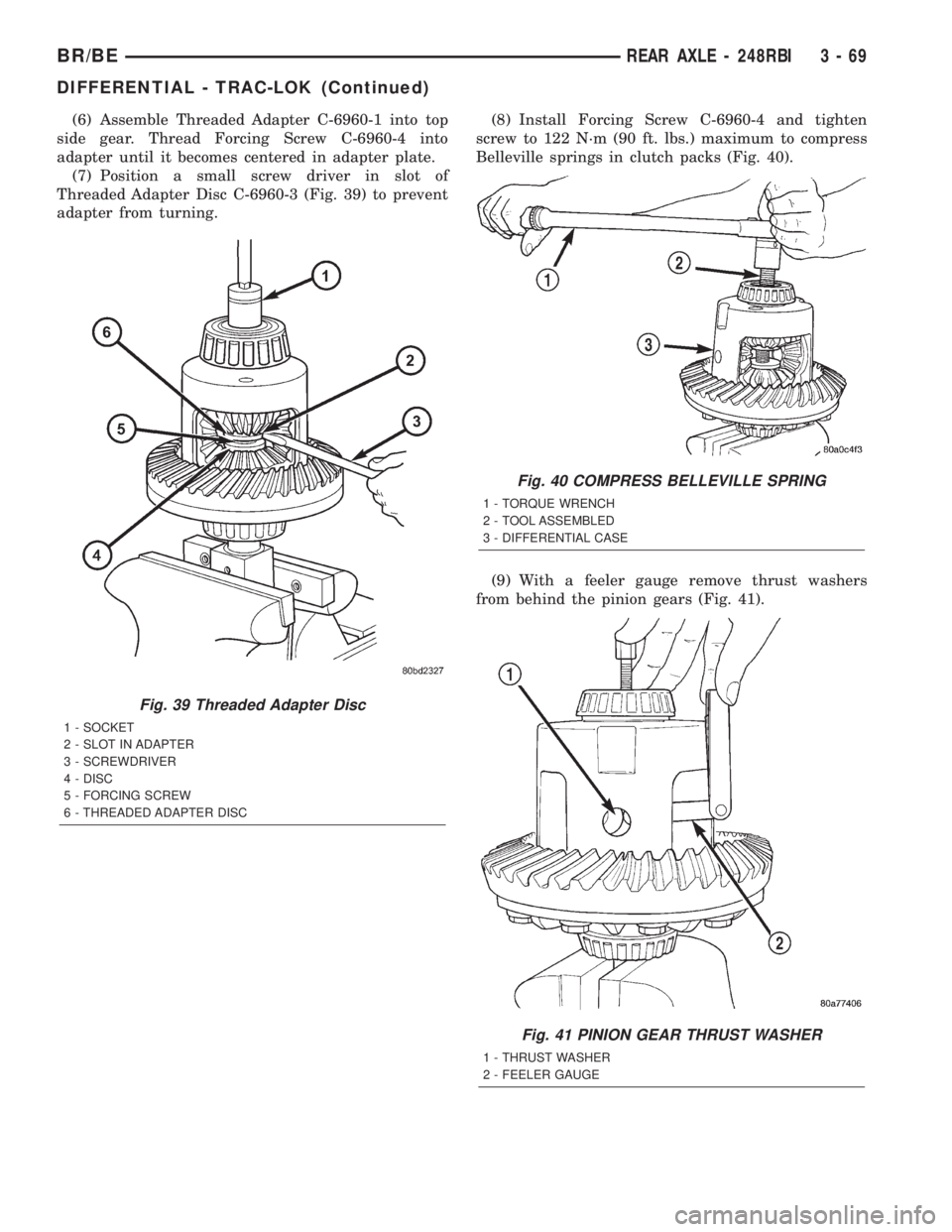

(1) Clamp side gear Holding Fixture 6965 in a vise

and position the differential case on the Holding Fix-

ture (Fig. 37).

(2) Remove ring gear if the ring gear is to be

replaced. The Trac-loktdifferential can be serviced

with the ring gear installed.

(3) Remove pinion gear mate shaft roll pin.

(4) Remove pinion gear mate shaft with a drift and

hammer.

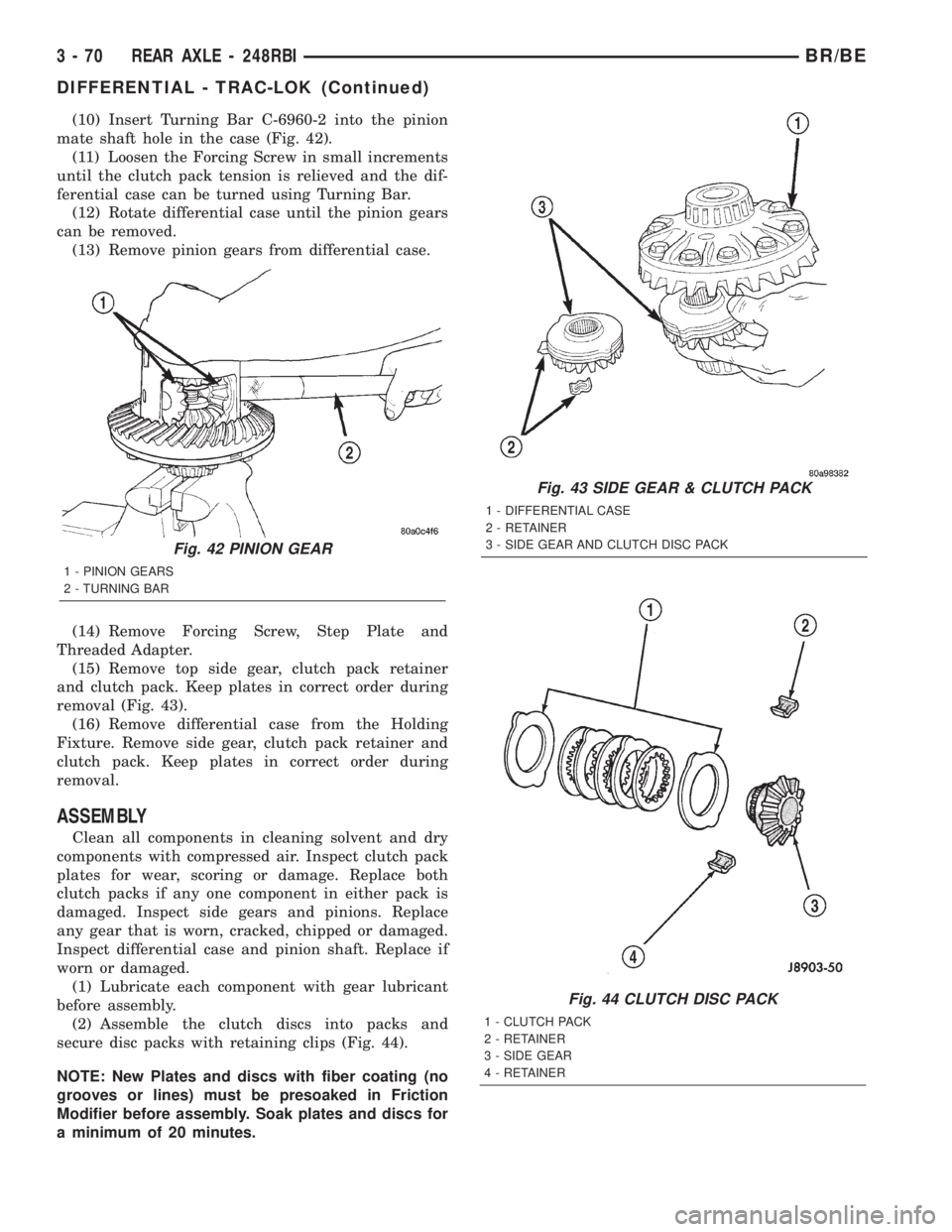

(5) Install and lubricate Step Plate C-6960-3 (Fig.

38).

Fig. 36 ROTATING TORQUE TEST

1 - SPECIAL TOOL WITH BOLT IN CENTER HOLE

2 - TORQUE WRENCH

Fig. 37 DIFFERENTIAL CASE FIXTURE

1 - HOLDING FIXTURE

2 - VISE

3 - DIFFERENTIAL

Fig. 38 Step Plate

1 - LOWER SIDE GEAR

2 - DIFFERENTIAL CASE

3 - STEP PLATE

3 - 68 REAR AXLE - 248RBIBR/BE

DIFFERENTIAL - TRAC-LOK (Continued)

Page 124 of 2255

(6) Assemble Threaded Adapter C-6960-1 into top

side gear. Thread Forcing Screw C-6960-4 into

adapter until it becomes centered in adapter plate.

(7) Position a small screw driver in slot of

Threaded Adapter Disc C-6960-3 (Fig. 39) to prevent

adapter from turning.(8) Install Forcing Screw C-6960-4 and tighten

screw to 122 N´m (90 ft. lbs.) maximum to compress

Belleville springs in clutch packs (Fig. 40).

(9) With a feeler gauge remove thrust washers

from behind the pinion gears (Fig. 41).

Fig. 39 Threaded Adapter Disc

1 - SOCKET

2 - SLOT IN ADAPTER

3 - SCREWDRIVER

4 - DISC

5 - FORCING SCREW

6 - THREADED ADAPTER DISC

Fig. 40 COMPRESS BELLEVILLE SPRING

1 - TORQUE WRENCH

2 - TOOL ASSEMBLED

3 - DIFFERENTIAL CASE

Fig. 41 PINION GEAR THRUST WASHER

1 - THRUST WASHER

2 - FEELER GAUGE

BR/BEREAR AXLE - 248RBI 3 - 69

DIFFERENTIAL - TRAC-LOK (Continued)

Page 125 of 2255

(10) Insert Turning Bar C-6960-2 into the pinion

mate shaft hole in the case (Fig. 42).

(11) Loosen the Forcing Screw in small increments

until the clutch pack tension is relieved and the dif-

ferential case can be turned using Turning Bar.

(12) Rotate differential case until the pinion gears

can be removed.

(13) Remove pinion gears from differential case.

(14) Remove Forcing Screw, Step Plate and

Threaded Adapter.

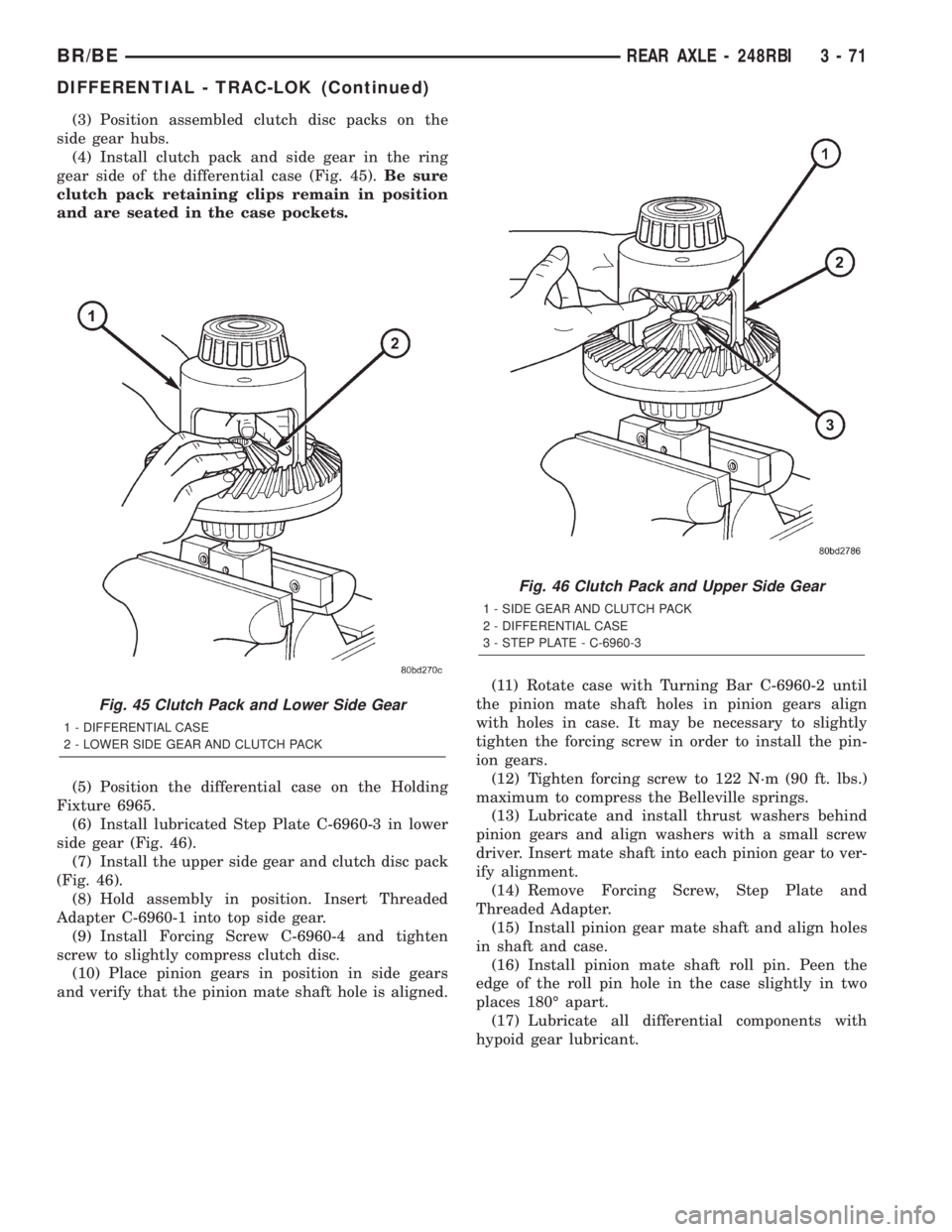

(15) Remove top side gear, clutch pack retainer

and clutch pack. Keep plates in correct order during

removal (Fig. 43).

(16) Remove differential case from the Holding

Fixture. Remove side gear, clutch pack retainer and

clutch pack. Keep plates in correct order during

removal.

ASSEMBLY

Clean all components in cleaning solvent and dry

components with compressed air. Inspect clutch pack

plates for wear, scoring or damage. Replace both

clutch packs if any one component in either pack is

damaged. Inspect side gears and pinions. Replace

any gear that is worn, cracked, chipped or damaged.

Inspect differential case and pinion shaft. Replace if

worn or damaged.

(1) Lubricate each component with gear lubricant

before assembly.

(2) Assemble the clutch discs into packs and

secure disc packs with retaining clips (Fig. 44).

NOTE: New Plates and discs with fiber coating (no

grooves or lines) must be presoaked in Friction

Modifier before assembly. Soak plates and discs for

a minimum of 20 minutes.

Fig. 43 SIDE GEAR & CLUTCH PACK

1 - DIFFERENTIAL CASE

2 - RETAINER

3 - SIDE GEAR AND CLUTCH DISC PACK

Fig. 44 CLUTCH DISC PACK

1 - CLUTCH PACK

2 - RETAINER

3 - SIDE GEAR

4 - RETAINER

Fig. 42 PINION GEAR

1 - PINION GEARS

2 - TURNING BAR

3 - 70 REAR AXLE - 248RBIBR/BE

DIFFERENTIAL - TRAC-LOK (Continued)

Page 126 of 2255

(3) Position assembled clutch disc packs on the

side gear hubs.

(4) Install clutch pack and side gear in the ring

gear side of the differential case (Fig. 45).Be sure

clutch pack retaining clips remain in position

and are seated in the case pockets.

(5) Position the differential case on the Holding

Fixture 6965.

(6) Install lubricated Step Plate C-6960-3 in lower

side gear (Fig. 46).

(7) Install the upper side gear and clutch disc pack

(Fig. 46).

(8) Hold assembly in position. Insert Threaded

Adapter C-6960-1 into top side gear.

(9) Install Forcing Screw C-6960-4 and tighten

screw to slightly compress clutch disc.

(10) Place pinion gears in position in side gears

and verify that the pinion mate shaft hole is aligned.(11) Rotate case with Turning Bar C-6960-2 until

the pinion mate shaft holes in pinion gears align

with holes in case. It may be necessary to slightly

tighten the forcing screw in order to install the pin-

ion gears.

(12) Tighten forcing screw to 122 N´m (90 ft. lbs.)

maximum to compress the Belleville springs.

(13) Lubricate and install thrust washers behind

pinion gears and align washers with a small screw

driver. Insert mate shaft into each pinion gear to ver-

ify alignment.

(14) Remove Forcing Screw, Step Plate and

Threaded Adapter.

(15) Install pinion gear mate shaft and align holes

in shaft and case.

(16) Install pinion mate shaft roll pin. Peen the

edge of the roll pin hole in the case slightly in two

places 180É apart.

(17) Lubricate all differential components with

hypoid gear lubricant.

Fig. 45 Clutch Pack and Lower Side Gear

1 - DIFFERENTIAL CASE

2 - LOWER SIDE GEAR AND CLUTCH PACK

Fig. 46 Clutch Pack and Upper Side Gear

1 - SIDE GEAR AND CLUTCH PACK

2 - DIFFERENTIAL CASE

3 - STEP PLATE - C-6960-3

BR/BEREAR AXLE - 248RBI 3 - 71

DIFFERENTIAL - TRAC-LOK (Continued)

Page 127 of 2255

DIFFERENTIAL CASE

BEARINGS

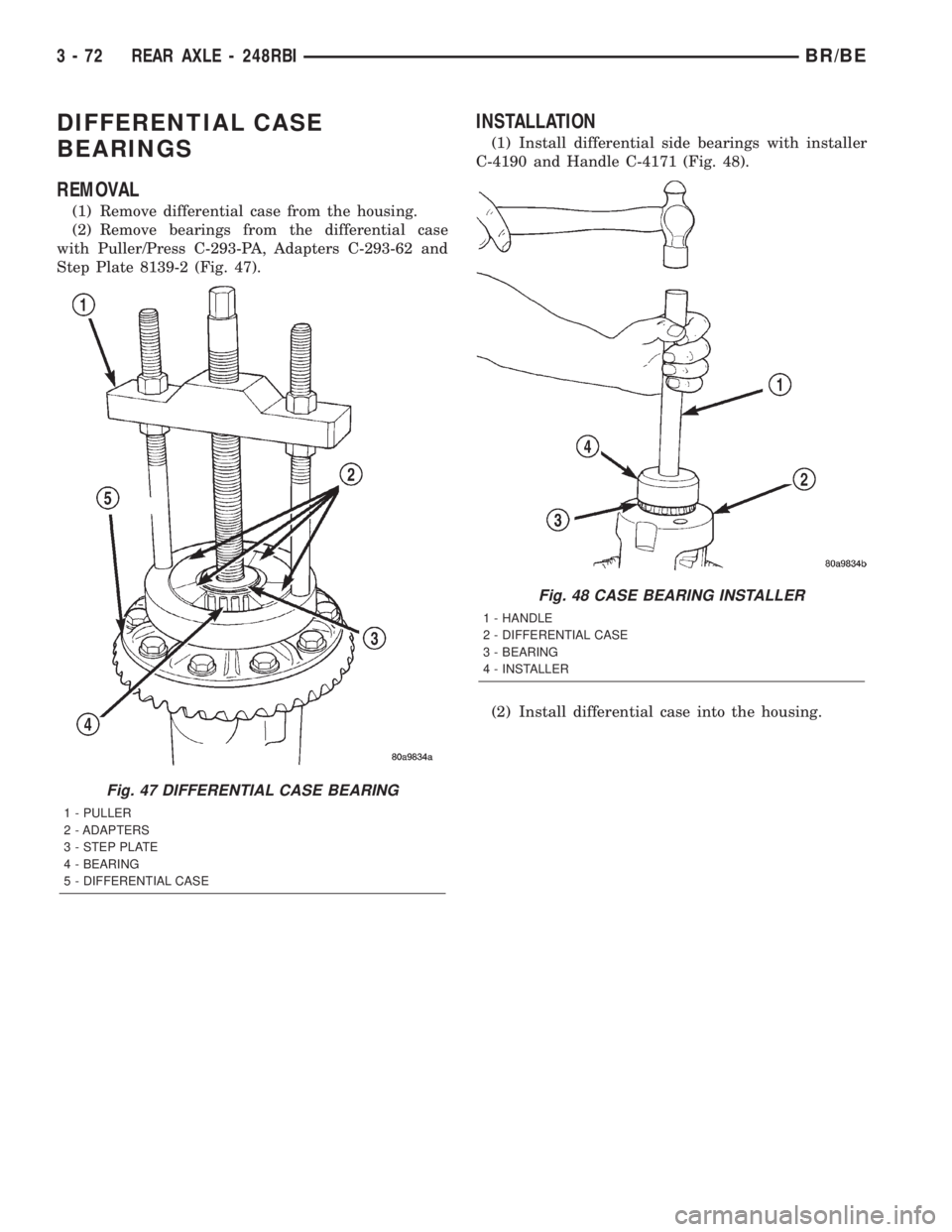

REMOVAL

(1) Remove differential case from the housing.

(2) Remove bearings from the differential case

with Puller/Press C-293-PA, Adapters C-293-62 and

Step Plate 8139-2 (Fig. 47).

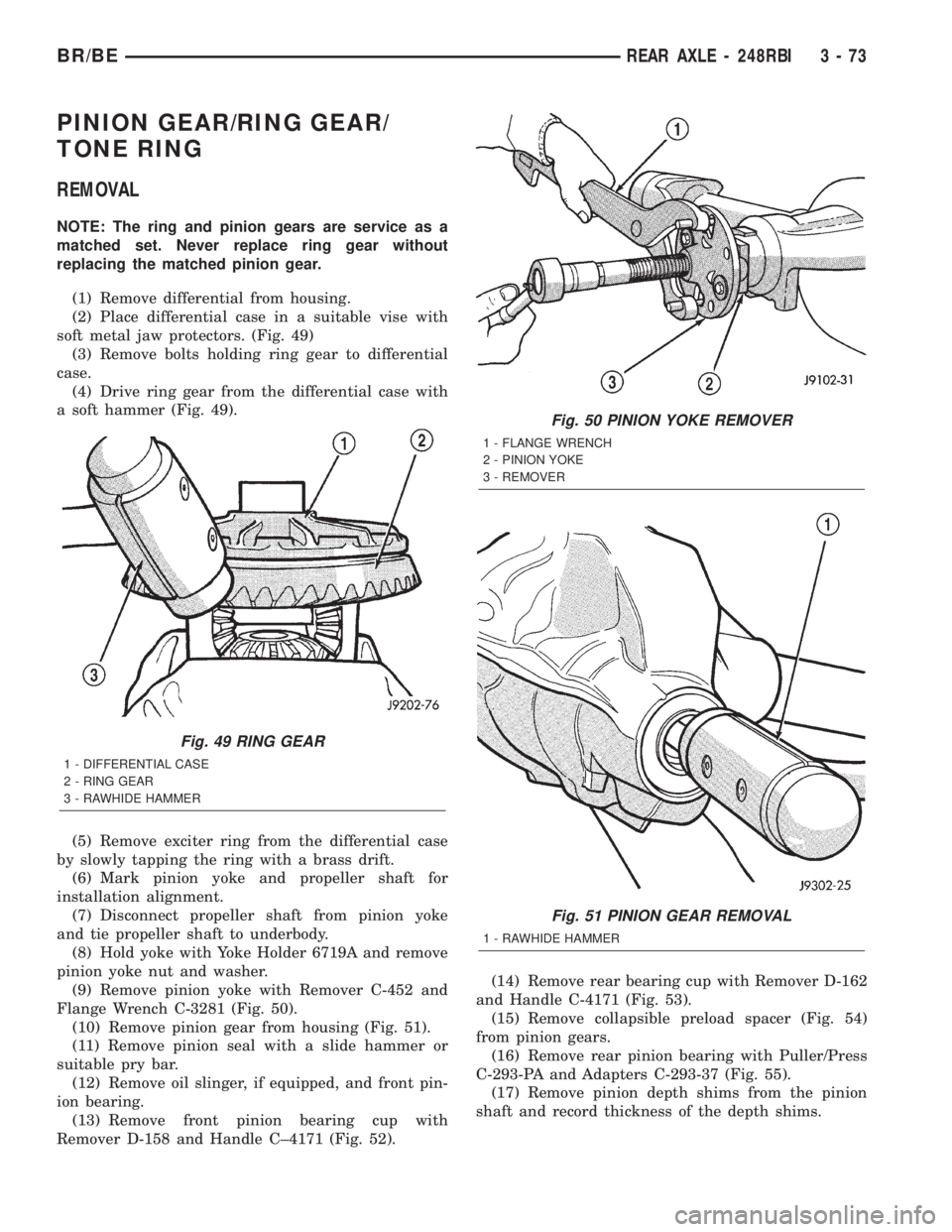

INSTALLATION

(1) Install differential side bearings with installer

C-4190 and Handle C-4171 (Fig. 48).

(2) Install differential case into the housing.

Fig. 47 DIFFERENTIAL CASE BEARING

1 - PULLER

2 - ADAPTERS

3 - STEP PLATE

4 - BEARING

5 - DIFFERENTIAL CASE

Fig. 48 CASE BEARING INSTALLER

1 - HANDLE

2 - DIFFERENTIAL CASE

3 - BEARING

4 - INSTALLER

3 - 72 REAR AXLE - 248RBIBR/BE

Page 128 of 2255

PINION GEAR/RING GEAR/

TONE RING

REMOVAL

NOTE: The ring and pinion gears are service as a

matched set. Never replace ring gear without

replacing the matched pinion gear.

(1) Remove differential from housing.

(2) Place differential case in a suitable vise with

soft metal jaw protectors. (Fig. 49)

(3) Remove bolts holding ring gear to differential

case.

(4) Drive ring gear from the differential case with

a soft hammer (Fig. 49).

(5) Remove exciter ring from the differential case

by slowly tapping the ring with a brass drift.

(6) Mark pinion yoke and propeller shaft for

installation alignment.

(7) Disconnect propeller shaft from pinion yoke

and tie propeller shaft to underbody.

(8) Hold yoke with Yoke Holder 6719A and remove

pinion yoke nut and washer.

(9) Remove pinion yoke with Remover C-452 and

Flange Wrench C-3281 (Fig. 50).

(10) Remove pinion gear from housing (Fig. 51).

(11) Remove pinion seal with a slide hammer or

suitable pry bar.

(12) Remove oil slinger, if equipped, and front pin-

ion bearing.

(13) Remove front pinion bearing cup with

Remover D-158 and Handle C±4171 (Fig. 52).(14) Remove rear bearing cup with Remover D-162

and Handle C-4171 (Fig. 53).

(15) Remove collapsible preload spacer (Fig. 54)

from pinion gears.

(16) Remove rear pinion bearing with Puller/Press

C-293-PA and Adapters C-293-37 (Fig. 55).

(17) Remove pinion depth shims from the pinion

shaft and record thickness of the depth shims.

Fig. 49 RING GEAR

1 - DIFFERENTIAL CASE

2 - RING GEAR

3 - RAWHIDE HAMMER

Fig. 50 PINION YOKE REMOVER

1 - FLANGE WRENCH

2 - PINION YOKE

3 - REMOVER

Fig. 51 PINION GEAR REMOVAL

1 - RAWHIDE HAMMER

BR/BEREAR AXLE - 248RBI 3 - 73

Page 131 of 2255

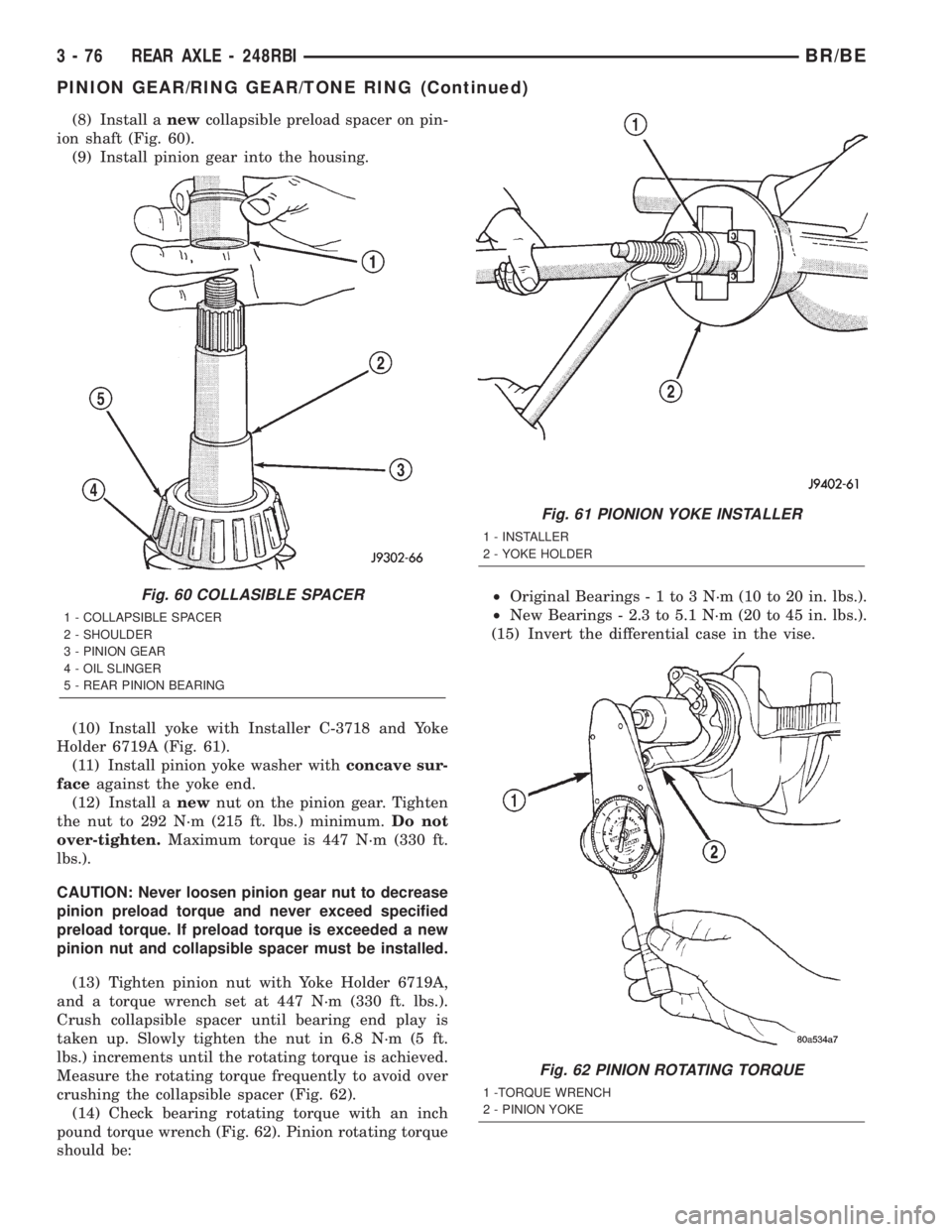

(8) Install anewcollapsible preload spacer on pin-

ion shaft (Fig. 60).

(9) Install pinion gear into the housing.

(10) Install yoke with Installer C-3718 and Yoke

Holder 6719A (Fig. 61).

(11) Install pinion yoke washer withconcave sur-

faceagainst the yoke end.

(12) Install anewnut on the pinion gear. Tighten

the nut to 292 N´m (215 ft. lbs.) minimum.Do not

over-tighten.Maximum torque is 447 N´m (330 ft.

lbs.).

CAUTION: Never loosen pinion gear nut to decrease

pinion preload torque and never exceed specified

preload torque. If preload torque is exceeded a new

pinion nut and collapsible spacer must be installed.

(13) Tighten pinion nut with Yoke Holder 6719A,

and a torque wrench set at 447 N´m (330 ft. lbs.).

Crush collapsible spacer until bearing end play is

taken up. Slowly tighten the nut in 6.8 N´m (5 ft.

lbs.) increments until the rotating torque is achieved.

Measure the rotating torque frequently to avoid over

crushing the collapsible spacer (Fig. 62).

(14) Check bearing rotating torque with an inch

pound torque wrench (Fig. 62). Pinion rotating torque

should be:²Original Bearings-1to3N´m(10to20in.lbs.).

²New Bearings - 2.3 to 5.1 N´m (20 to 45 in. lbs.).

(15) Invert the differential case in the vise.

Fig. 60 COLLASIBLE SPACER

1 - COLLAPSIBLE SPACER

2 - SHOULDER

3 - PINION GEAR

4 - OIL SLINGER

5 - REAR PINION BEARING

Fig. 61 PIONION YOKE INSTALLER

1 - INSTALLER

2 - YOKE HOLDER

Fig. 62 PINION ROTATING TORQUE

1 -TORQUE WRENCH

2 - PINION YOKE

3 - 76 REAR AXLE - 248RBIBR/BE

PINION GEAR/RING GEAR/TONE RING (Continued)

Page 132 of 2255

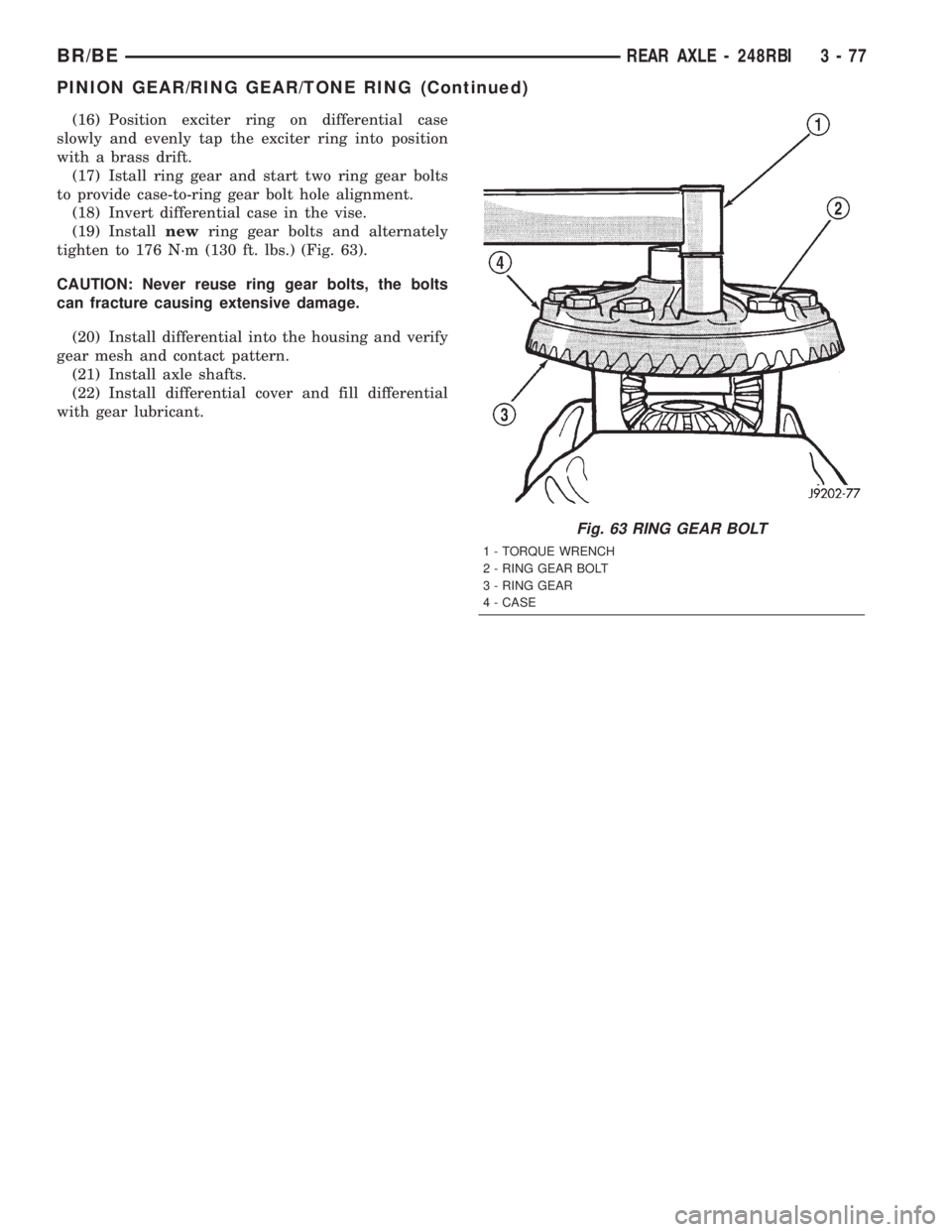

(16) Position exciter ring on differential case

slowly and evenly tap the exciter ring into position

with a brass drift.

(17) Istall ring gear and start two ring gear bolts

to provide case-to-ring gear bolt hole alignment.

(18) Invert differential case in the vise.

(19) Installnewring gear bolts and alternately

tighten to 176 N´m (130 ft. lbs.) (Fig. 63).

CAUTION: Never reuse ring gear bolts, the bolts

can fracture causing extensive damage.

(20) Install differential into the housing and verify

gear mesh and contact pattern.

(21) Install axle shafts.

(22) Install differential cover and fill differential

with gear lubricant.

Fig. 63 RING GEAR BOLT

1 - TORQUE WRENCH

2 - RING GEAR BOLT

3 - RING GEAR

4 - CASE

BR/BEREAR AXLE - 248RBI 3 - 77

PINION GEAR/RING GEAR/TONE RING (Continued)

Page 133 of 2255

REAR AXLE - 267RBI

TABLE OF CONTENTS

page page

REAR AXLE - 267RBI

DESCRIPTION.........................78

OPERATION...........................78

DIAGNOSIS AND TESTING - AXLE..........80

REMOVAL.............................82

INSTALLATION.........................82

ADJUSTMENTS........................83

SPECIFICATIONS

REAR AXLE - 267RBI..................91

SPECIAL TOOLS

REAR AXLE - 267RBI..................91

AXLE SHAFTS

REMOVAL.............................94

INSTALLATION.........................94

AXLE BEARINGS

REMOVAL.............................94

INSTALLATION.........................94

PINION SEAL

REMOVAL.............................94INSTALLATION.........................95

DIFFERENTIAL

REMOVAL.............................96

DISASSEMBLY.........................97

ASSEMBLY............................97

INSTALLATION.........................97

DIFFERENTIAL - POWR-LOK

DIAGNOSIS AND TESTING - POWR-LOKT....99

DISASSEMBLY.........................99

ASSEMBLY............................99

DIFFERENTIAL CASE BEARINGS

REMOVAL............................102

INSTALLATION........................102

PINION GEAR/RING GEAR/TONE RING

REMOVAL............................103

INSTALLATION........................104

REAR AXLE - 267RBI

DESCRIPTION

The Rear Beam-design Iron (RBI) axle housings

consist of an iron center casting (differential housing)

with axle shaft tubes extending from either side. The

tubes are pressed into the differential housing and

welded. The axles are full-floating axle shafts, sup-

ported by the axle housing tubes. The full-float shafts

are retained by bolts attached to the hub.

The differential case for the standard differential is

a one-piece design. Differential bearing preload and

ring gear backlash are adjusted by the use of shims

located between the differential bearing cones and

case. Pinion bearing preload is set and maintained by

the use of a solid shims. The differential cover pro-

vides a means for inspection and service.

Axles equipped with a Powr-loktdifferential are

optional. The differential has a two-piece differentialcase. The differential contains four pinion gears and

a two-piece pinion mate cross shaft to provide

increased torque to the non-slipping wheel through a

ramping motion in addition to the standard Trac-lokt

components.

OPERATION

STANDARD DIFFERENTIAL

The axle receives power from the transmission/

transfer case through the rear propeller shaft. The

rear propeller shaft is connected to the pinion gear

which rotates the differential through the gear mesh

with the ring gear bolted to the differential case. The

engine power is transmitted to the axle shafts

through the pinion mate and side gears. The side

gears are splined to the axle shafts.

3 - 78 REAR AXLE - 267RBIBR/BE

Page 134 of 2255

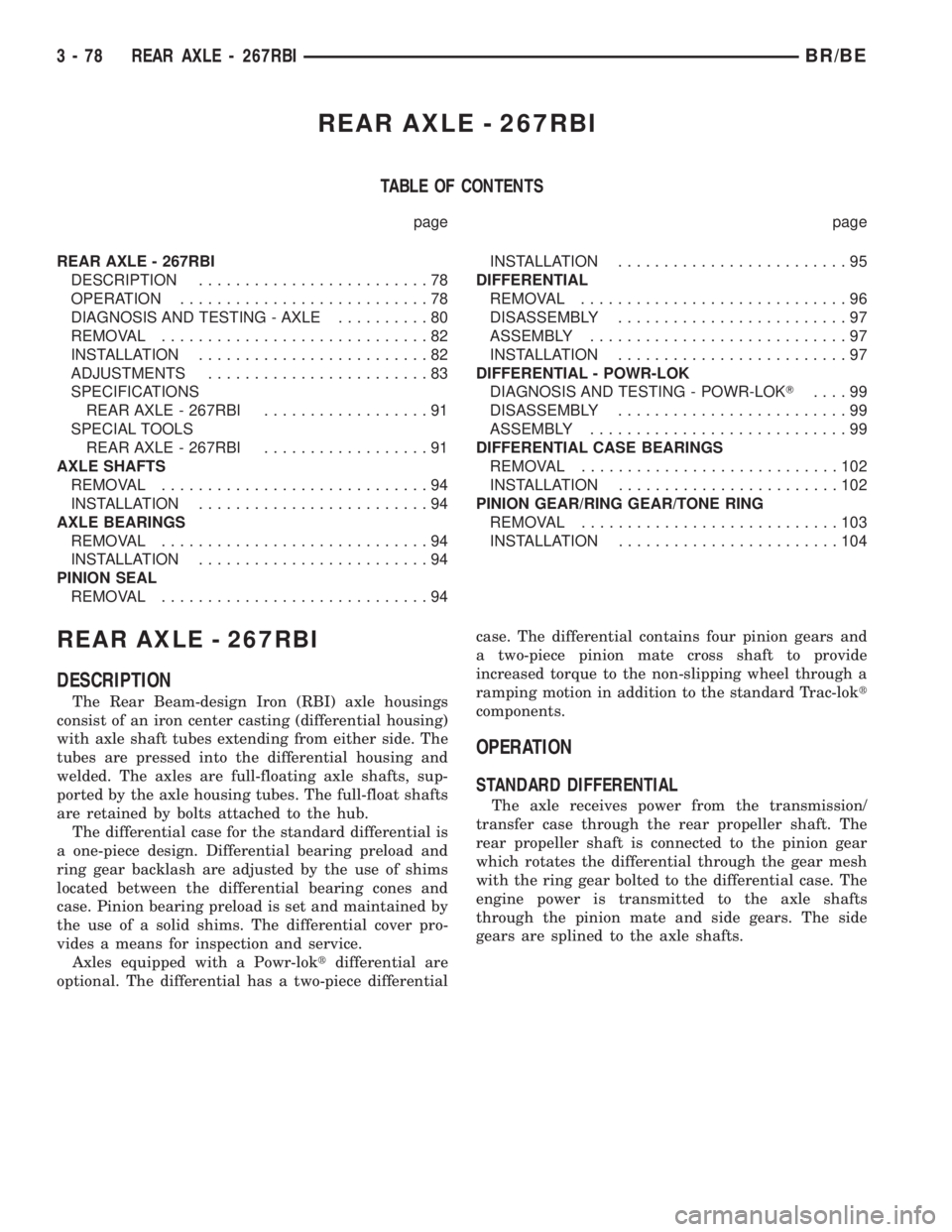

During straight-ahead driving, the differential pin-

ion gears do not rotate on the pinion mate shaft. This

occurs because input torque applied to the gears is

divided and distributed equally between the two side

gears. As a result, the pinion gears revolve with the

pinion mate shaft but do not rotate around it (Fig. 1).

When turning corners, the outside wheel must

travel a greater distance than the inside wheel to

complete a turn. The difference must be compensated

for to prevent the tires from scuffing and skidding

through turns. To accomplish this, the differential

allows the axle shafts to turn at unequal speeds (Fig.

2). In this instance, the input torque applied to the

pinion gears is not divided equally. The pinion gears

now rotate around the pinion mate shaft in opposite

directions. This allows the side gear and axle shaft

attached to the outside wheel to rotate at a faster

speed.

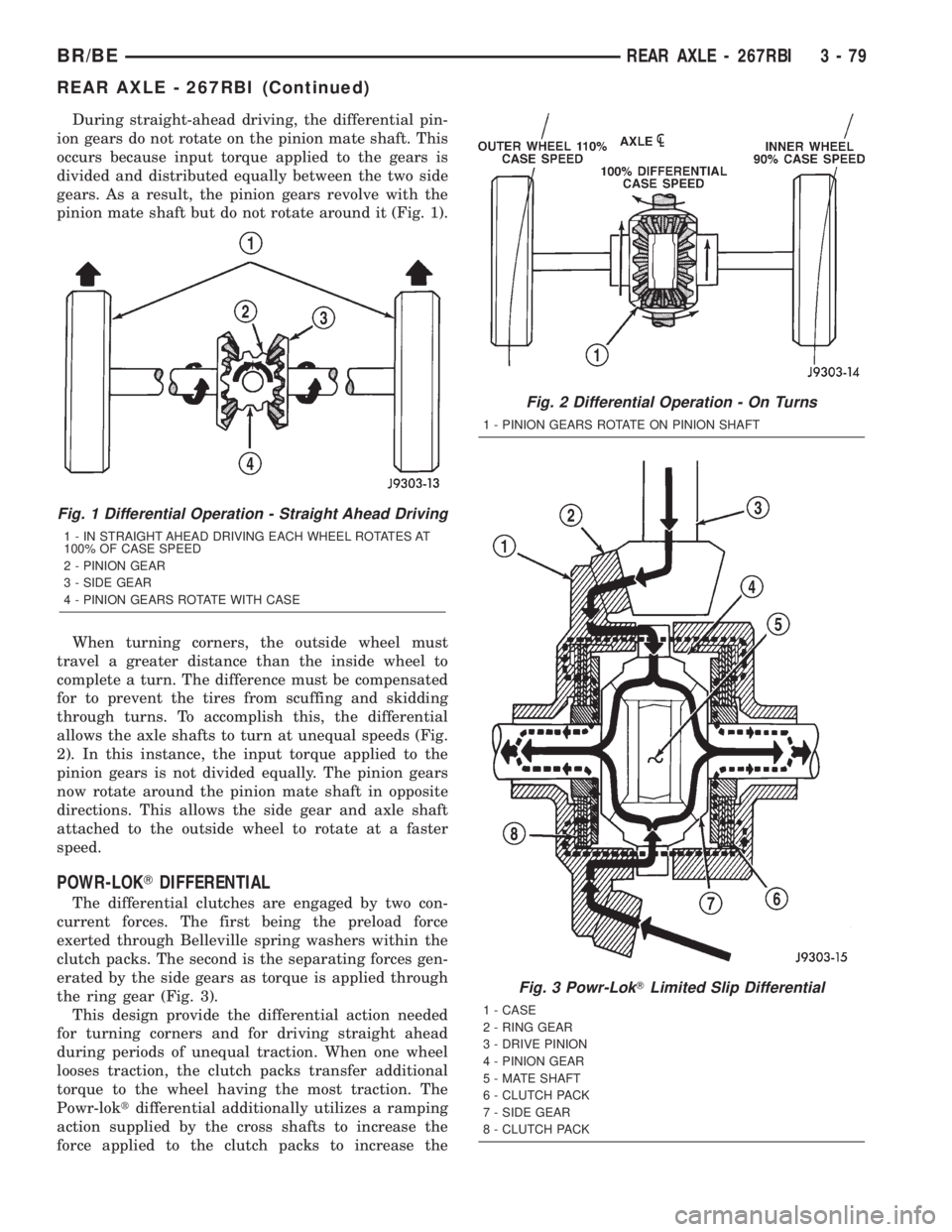

POWR-LOKTDIFFERENTIAL

The differential clutches are engaged by two con-

current forces. The first being the preload force

exerted through Belleville spring washers within the

clutch packs. The second is the separating forces gen-

erated by the side gears as torque is applied through

the ring gear (Fig. 3).

This design provide the differential action needed

for turning corners and for driving straight ahead

during periods of unequal traction. When one wheel

looses traction, the clutch packs transfer additional

torque to the wheel having the most traction. The

Powr-loktdifferential additionally utilizes a ramping

action supplied by the cross shafts to increase the

force applied to the clutch packs to increase the

Fig. 1 Differential Operation - Straight Ahead Driving

1 - IN STRAIGHT AHEAD DRIVING EACH WHEEL ROTATES AT

100% OF CASE SPEED

2 - PINION GEAR

3 - SIDE GEAR

4 - PINION GEARS ROTATE WITH CASE

Fig. 2 Differential Operation - On Turns

1 - PINION GEARS ROTATE ON PINION SHAFT

Fig. 3 Powr-LokTLimited Slip Differential

1 - CASE

2 - RING GEAR

3 - DRIVE PINION

4 - PINION GEAR

5 - MATE SHAFT

6 - CLUTCH PACK

7 - SIDE GEAR

8 - CLUTCH PACK

BR/BEREAR AXLE - 267RBI 3 - 79

REAR AXLE - 267RBI (Continued)