fuses DODGE RAM 2002 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 581 of 2255

INSTALLATION

(1) Insert the power mirror switch to the back of

the door trim panel.

(2) Connect the power mirror switch to the har-

ness connector.

(3) Install the trim panel to the inside of the

driver side door. (Refer to 23 - BODY/DOOR -

FRONT/TRIM PANEL - INSTALLATION).

(4) Install the nut that secures the power mirror

switch to the driver side front door.

(5) Push the control knob on to the power mirror

switch.

(6) Connect the battery negative cable.

SIDEVIEW MIRROR

DESCRIPTION

Each power mirror head contains two electric

motors, two drive mechanisms, and the mirror glass.

One motor and drive controls mirror up-and-down

movement, and the other controls right-and-left

movement.

OPERATION

The power mirrors in vehicles equipped with the

available heated mirror system option also include an

electric heating grid located behind the mirror glass.

This heating grid is energized by the heated mirror

relay in the heater and air conditioner control only

when the ignition switch is in the On position, and

the heated mirror system is turned on. (Refer to 8 -

ELECTRICAL/HEATED MIRRORS - DESCRIP-

TION) for more information.

The power mirror assembly cannot be repaired. If

any component of the power mirror unit is faulty or

damaged, the entire assembly must be replaced.

DIAGNOSIS AND TESTING - SIDEVIEW

MIRROR

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

(1) Check the fuses in the Power Distribution Cen-

ter (PDC) and the junction block. If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse(s).(2) Check for battery voltage at the fuse in the

junction block. If OK, go to Step 3. If not OK, repair

the open circuit to the PDC as required.

(3) Disconnect and isolate the battery negative

cable. Remove the driver side door trim panel and

unplug the wire harness connector from the power

mirror switch. Connect the battery negative cable.

Check for battery voltage at the fused B(+) circuit

cavity in the door wire harness half of the power mir-

ror switch wire harness connector. If OK, go to Step

4. If not OK, repair the open circuit to the junction

block as required.

(4) Disconnect and isolate the battery negative

cable. Check for continuity between the ground cir-

cuit cavity in the door wire harness half of the power

mirror switch wire harness connector and a good

ground. There should be continuity. If OK, go to Step

5. If not OK, repair the circuit to ground as required.

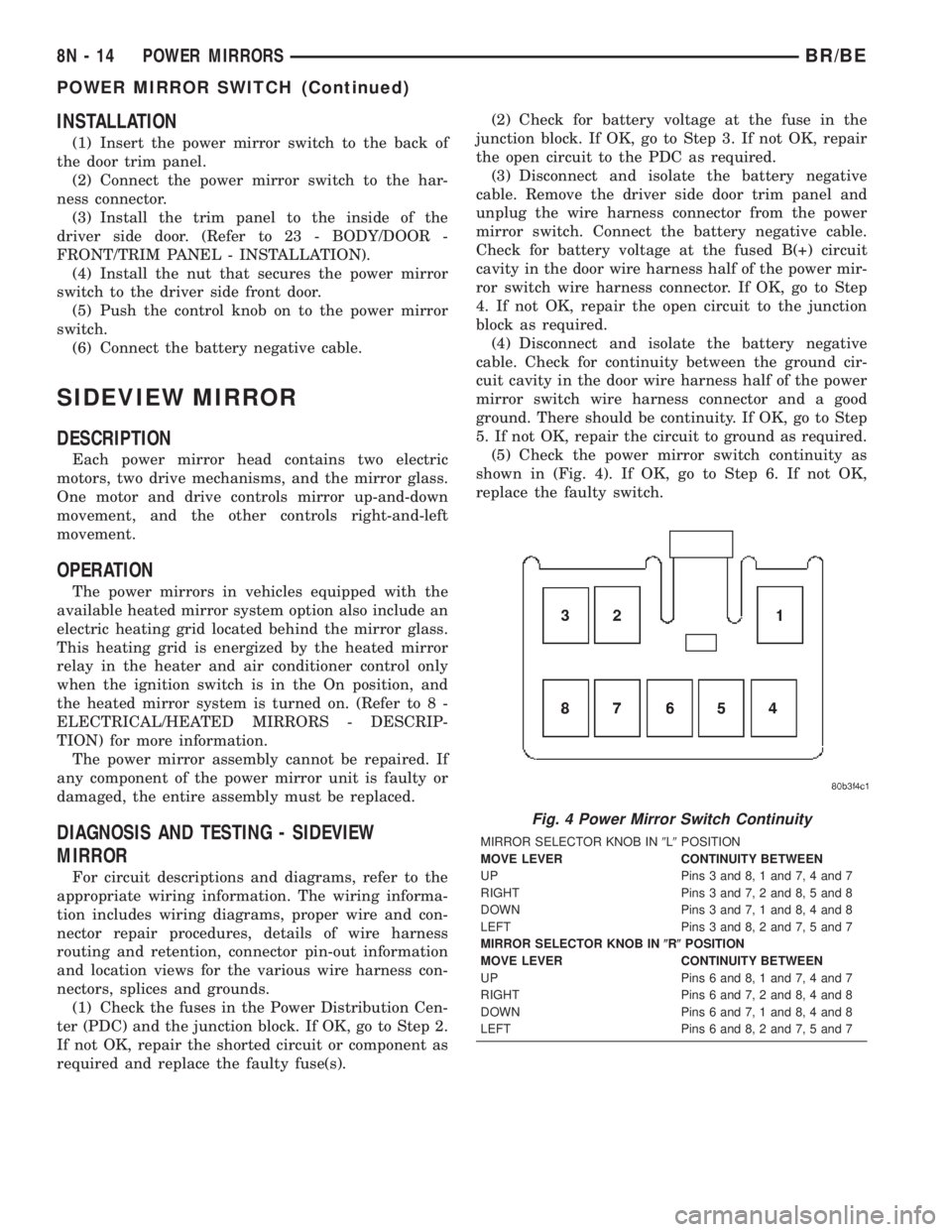

(5) Check the power mirror switch continuity as

shown in (Fig. 4). If OK, go to Step 6. If not OK,

replace the faulty switch.

Fig. 4 Power Mirror Switch Continuity

MIRROR SELECTOR KNOB IN9L9POSITION

MOVE LEVER CONTINUITY BETWEEN

UP Pins 3 and 8, 1 and 7, 4 and 7

RIGHT Pins 3 and 7, 2 and 8, 5 and 8

DOWN Pins 3 and 7, 1 and 8, 4 and 8

LEFT Pins 3 and 8, 2 and 7, 5 and 7

MIRROR SELECTOR KNOB IN(R(POSITION

MOVE LEVER CONTINUITY BETWEEN

UP Pins 6 and 8, 1 and 7, 4 and 7

RIGHT Pins 6 and 7, 2 and 8, 4 and 8

DOWN Pins 6 and 7, 1 and 8, 4 and 8

LEFT Pins 6 and 8, 2 and 7, 5 and 7

8N - 14 POWER MIRRORSBR/BE

POWER MIRROR SWITCH (Continued)

Page 664 of 2255

8W-01 WIRING DIAGRAM INFORMATION

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION

DESCRIPTION

DESCRIPTION - HOW TO USE WIRING

DIAGRAMS...........................1

DESCRIPTION - CIRCUIT INFORMATION....4

DESCRIPTION - CIRCUIT FUNCTIONS......4

DESCRIPTION - SECTION IDENTIFICATION

AND INFORMATION....................6

DESCRIPTION - CONNECTOR, GROUND

AND SPLICE INFORMATION..............6

WARNINGS - GENERAL...................7

DIAGNOSIS AND TESTING - WIRING

HARNESS............................7

STANDARD PROCEDURE

STANDARD PROCEDURE -

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE DEVICES...................8

STANDARD PROCEDURE - TESTING OF

VOLTAGE POTENTIAL...................8

STANDARD PROCEDURE - TESTING FOR

CONTINUITY..........................9STANDARD PROCEDURE - TESTING FOR A

SHORT TO GROUND...................9

STANDARD PROCEDURE - TESTING FOR A

SHORT TO GROUND ON FUSES

POWERING SEVERAL LOADS............9

STANDARD PROCEDURE - TESTING FOR A

VOLTAGE DROP.......................9

SPECIAL TOOLS

WIRING/TERMINAL.....................9

CONNECTOR

REMOVAL.............................10

INSTALLATION.........................10

DIODE

REMOVAL.............................13

INSTALLATION.........................13

TERMINAL

REMOVAL.............................13

INSTALLATION.........................13

WIRE

STANDARD PROCEDURE - WIRE SPLICING . . 13

WIRING DIAGRAM

INFORMATION

DESCRIPTION

DESCRIPTION - HOW TO USE WIRING

DIAGRAMS

DaimlerChrysler Corporation wiring diagrams are

designed to provide information regarding the vehi-

cles wiring content. In order to effectively use the

wiring diagrams to diagnose and repair

DaimlerChrysler Corporation vehicles, it is important

to understand all of their features and characteris-

tics.

Diagrams are arranged such that the power (B+)

side of the circuit is placed near the top of the page,

and the ground (B-) side of the circuit is placed near

the bottom of the page (Fig. 1).All switches, components, and modules are shown

in the at rest position with the doors closed and the

key removed from the ignition (Fig. 2).

Components are shown two ways. A solid line

around a component indicates that the component is

complete. A dashed line around the component indi-

cates that the component is being shown is not com-

plete. Incomplete components have a reference

number to indicate the page where the component is

shown complete.

It is important to realize that no attempt is made

on the diagrams to represent components and wiring

as they appear on the vehicle. For example, a short

piece of wire is treated the same as a long one. In

addition, switches and other components are shown

as simply as possible, with regard to function only.

BR/BE8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 1

Page 672 of 2255

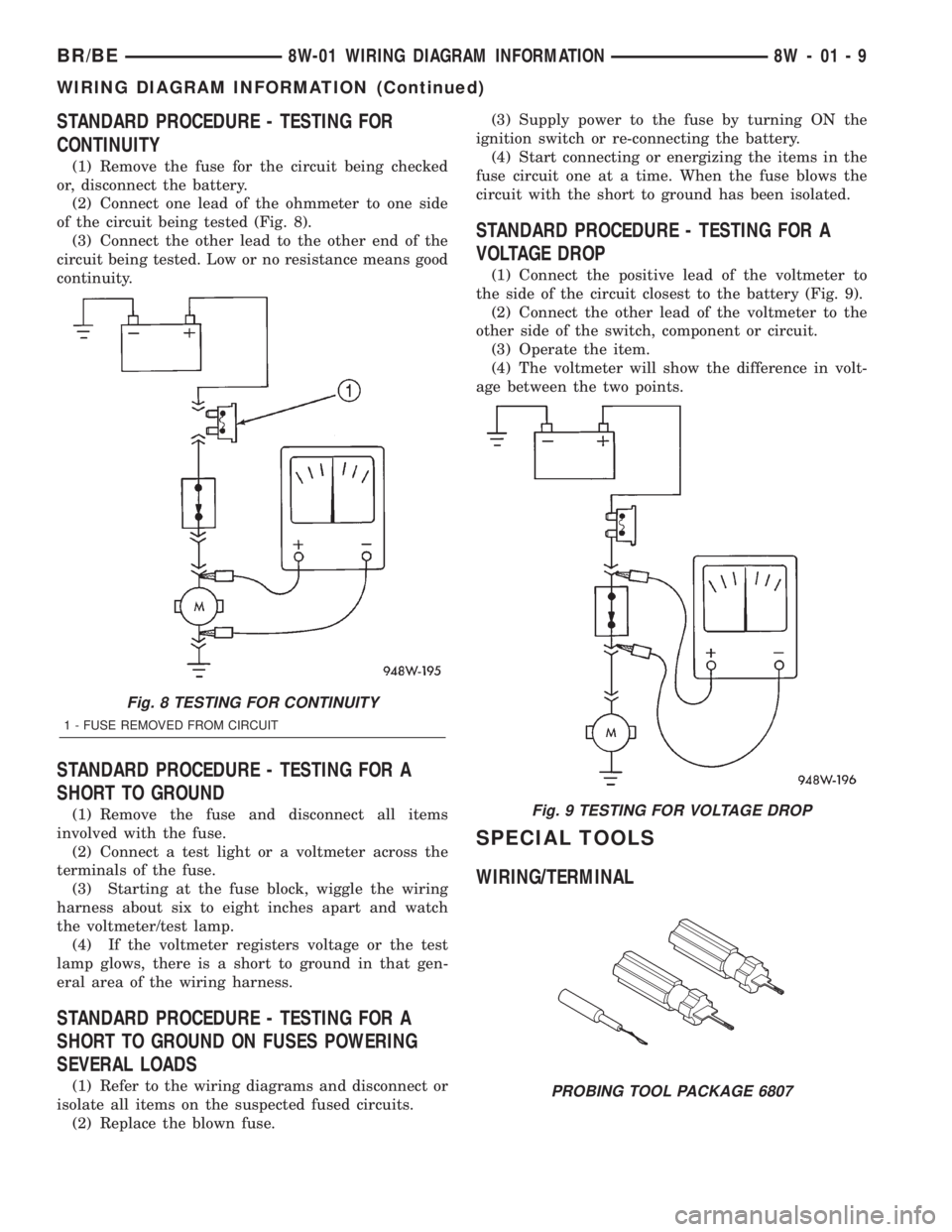

STANDARD PROCEDURE - TESTING FOR

CONTINUITY

(1) Remove the fuse for the circuit being checked

or, disconnect the battery.

(2) Connect one lead of the ohmmeter to one side

of the circuit being tested (Fig. 8).

(3) Connect the other lead to the other end of the

circuit being tested. Low or no resistance means good

continuity.

STANDARD PROCEDURE - TESTING FOR A

SHORT TO GROUND

(1) Remove the fuse and disconnect all items

involved with the fuse.

(2) Connect a test light or a voltmeter across the

terminals of the fuse.

(3) Starting at the fuse block, wiggle the wiring

harness about six to eight inches apart and watch

the voltmeter/test lamp.

(4) If the voltmeter registers voltage or the test

lamp glows, there is a short to ground in that gen-

eral area of the wiring harness.

STANDARD PROCEDURE - TESTING FOR A

SHORT TO GROUND ON FUSES POWERING

SEVERAL LOADS

(1) Refer to the wiring diagrams and disconnect or

isolate all items on the suspected fused circuits.

(2) Replace the blown fuse.(3) Supply power to the fuse by turning ON the

ignition switch or re-connecting the battery.

(4) Start connecting or energizing the items in the

fuse circuit one at a time. When the fuse blows the

circuit with the short to ground has been isolated.

STANDARD PROCEDURE - TESTING FOR A

VOLTAGE DROP

(1) Connect the positive lead of the voltmeter to

the side of the circuit closest to the battery (Fig. 9).

(2) Connect the other lead of the voltmeter to the

other side of the switch, component or circuit.

(3) Operate the item.

(4) The voltmeter will show the difference in volt-

age between the two points.

SPECIAL TOOLS

WIRING/TERMINAL

Fig. 8 TESTING FOR CONTINUITY

1 - FUSE REMOVED FROM CIRCUIT

Fig. 9 TESTING FOR VOLTAGE DROP

PROBING TOOL PACKAGE 6807

BR/BE8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 9

WIRING DIAGRAM INFORMATION (Continued)

Page 678 of 2255

8W-02 COMPONENT INDEX

Component Page

4WD Switch.......................... 8W-31

A/C Compressor Clutch Relay............ 8W-42

A/C Compressor Clutch................. 8W-42

A/C- Heater Control.................... 8W-42

A/C Heater Temperature Select........... 8W-42

A/C High Pressure Switch............... 8W-42

A/C Low Pressure Switch................ 8W-42

Accelerator Pedal Position Sensor......... 8W-30

Aftermarket Center High Mounted Stop

Lamp............................. 8W-51

Aftermarket Trailer Tow Connector........ 8W-54

Airbag Control Module.................. 8W-43

Ambient Temperature Sensor............ 8W-49

Ash Receiver Lamp.................... 8W-44

Automatic Day/Night Mirror............. 8W-49

Automatic Shut Down Relay............. 8W-30

Auxiliary Battery...................... 8W-20

Back-Up Lamp Switch.................. 8W-51

Back-Up Lamp........................ 8W-51

Battery Temperature Sensor............. 8W-30

Battery............................. 8W-20

Blend Door Actuator................... 8W-42

Blower Motor Relay.................... 8W-42

Blower Motor Resistor Block............. 8W-42

Blower Motor......................... 8W-42

Brake Lamp Switch.................... 8W-51

Brake Pressure Switch............... 8W-34, 35

Bypass Jumper....................... 8W-21

Camshaft Position Sensor............... 8W-30

Capacitor......................... 8W-10, 30

Cargo Lamps........................ 8W-44

Center High Mounted Stop Lamps........ 8W-51

Center Identification Lamp.............. 8W-50

Central Timer Module.................. 8W-45

Cigar Lighter......................... 8W-41

Circuit Breakers...................... 8W-12

Clockspring.................. 8W-33, 41, 43, 47

Clutch Pedal Position Switch............. 8W-21

Combination Flasher................... 8W-52

Controller Antilock Brake............ 8W-34, 35

Crankshaft Position Sensor.............. 8W-30

Cummins Bus........................ 8W-18

Cup Holder Lamp..................... 8W-44

Data Link Connector................... 8W-18

Daytime Running Lamp Module.......... 8W-50

Dome Lamp.......................... 8W-44

Driver Airbag......................... 8W-43

Driver Cylinder Lock Switch............. 8W-39

Driver Door Ajar Switch................ 8W-45

Driver Door Lock Motor................. 8W-61

Driver Door Window/Lock Switch...... 8W-60, 61

Driver Heated Seat Cushion............. 8W-63Component Page

Driver Heated Seat Switch.............. 8W-63

Driver Lumbar Motor.................. 8W-63

Driver Power Seat Front Vertical Motor.... 8W-63

Driver Power Seat Horizontal Motor....... 8W-63

Driver Power Seat Rear Vertical Motor..... 8W-63

Driver Power Seat Switch............... 8W-63

Driver Power Window Motor............. 8W-60

Electric Brake Provision................ 8W-54

Engine Control Module................. 8W-30

Engine Coolant Temperature Sensor....... 8W-30

Engine Oil Pressure Sensor.............. 8W-30

Engine Starter Motor Relay.............. 8W-21

Engine Starter Motor................... 8W-21

EVAP/Purge Solenoid................... 8W-30

Fender Lamp......................... 8W-51

Fog Lamp Relay....................... 8W-50

Fog Lamp............................ 8W-50

Fuel Heater Relay..................... 8W-30

Fuel Heater........................ 8W-30-36

Fuel Injection Pump................... 8W-30

Fuel Injectors......................... 8W-30

Fuel Pump Module.................... 8W-30

Fuel Pump Relay...................... 8W-30

Fuel Tank Module..................... 8W-30

Fuel Transfer Pump.................... 8W-30

Fuses (JB)........................... 8W-12

Fuses (PDC).......................... 8W-10

Fusible Link....................... 8W-20, 30

Grounds............................. 8W-15

Generator............................ 8W-20

Glove Box Lamp And Switch............. 8W-44

Headlamp Beam Select Switch........... 8W-50

Headlamp Switch...................... 8W-50

Headlamp........................... 8W-50

Heated Mirror Relay................... 8W-62

Heated Mirror Switch.................. 8W-62

Heated Seat Relay..................... 8W-12

High Note Horn....................... 8W-41

Horn Relay.......................... 8W-41

Horn Switch.......................... 8W-41

Idle Air Control Motor.................. 8W-30

Ignition Coils......................... 8W-30

Ignition Switch....................... 8W-10

Instrument Cluster.................... 8W-40

Intake Air Heater Relays................ 8W-30

Intake Air Heater..................... 8W-30

Intake Air Temperature Sensor........... 8W-30

Intermittent Wiper Switch............... 8W-53

Joint Connectors....... 8W-10, 12, 15, 30, 34, 35,

40, 44, 45, 51, 53, 54, 70

Junction Block........................ 8W-12

Leak Detection Pump.................. 8W-30

BR/BE8W-02 COMPONENT INDEX 8W - 02 - 1

Page 1060 of 2255

8W-97 POWER DISTRIBUTION

TABLE OF CONTENTS

page page

POWER DISTRIBUTION

DESCRIPTION..........................1

OPERATION............................1

SPECIAL TOOLS

POWER DISTRIBUTION SYSTEMS.........2

CIGAR LIGHTER OUTLET

DESCRIPTION..........................2

OPERATION............................2

DIAGNOSIS AND TESTING - CIGAR LIGHTER

OUTLET.............................2

REMOVAL.............................3

INSTALLATION..........................4

CIRCUIT BREAKER

DESCRIPTION..........................4

DIAGNOSIS AND TESTING - CIRCUIT

BREAKER............................4

GENERATOR CARTRIDGE FUSE

DESCRIPTION..........................4

OPERATION............................4

REMOVAL.............................4

INSTALLATION..........................4

IOD FUSE

DESCRIPTION..........................5

OPERATION............................5

REMOVAL.............................6

INSTALLATION..........................6

JUNCTION BLOCK

DESCRIPTION..........................6

OPERATION............................7

DIAGNOSIS AND TESTING - JUNCTION

BLOCK..............................7

REMOVAL.............................7

INSTALLATION..........................8POWER DISTRIBUTION CENTER

DESCRIPTION..........................8

OPERATION............................8

REMOVAL.............................8

INSTALLATION.........................10

POWER OUTLET

DESCRIPTION.........................10

OPERATION...........................10

DIAGNOSIS AND TESTING - POWER OUTLET . 10

REMOVAL.............................11

INSTALLATION.........................11

HORN RELAY

DESCRIPTION.........................12

DIAGNOSIS AND TESTING - HORN RELAY . . . 12

REMOVAL.............................12

INSTALLATION.........................12

HEADLAMP RELAY

DESCRIPTION.........................13

REMOVAL.............................13

INSTALLATION.........................13

MICRO-RELAY

DESCRIPTION.........................13

OPERATION...........................14

DIAGNOSIS AND TESTING - MICRO-RELAY . . 14

REMOVAL.............................14

INSTALLATION.........................14

RELAY

DESCRIPTION.........................14

OPERATION...........................14

DIAGNOSIS AND TESTING - RELAY.........15

REMOVAL.............................15

INSTALLATION.........................15

POWER DISTRIBUTION

DESCRIPTION

This group covers the various standard and

optional power distribution components used on this

model. The power distribution system for this vehicle

consists of the following components:

²Power Distribution Center (PDC)

²Junction Block (JB).

The power distribution system also incorporates

various types of circuit control and protection fea-

tures, including:

²Automatic resetting circuit breakers

²Blade-type fuses²Cartridge fuses

²Circuit splice blocks

²Flashers

²Relays.

Following are general descriptions of the major

components in the power distribution system. See the

owner's manual in the vehicle glove box for more

information on the features and use of all of the

power distribution system components. Refer toWir-

ing Diagramsfor complete circuit diagrams for the

various power distribution system components.

OPERATION

The power distribution system for this vehicle is

designed to provide safe, reliable, and centralized dis-

BR/BE8W-97 POWER DISTRIBUTION 8W - 97 - 1

Page 1063 of 2255

(8) Remove the cigar lighter or power outlet mount

from the instrument panel.

INSTALLATION

(1) Reconnect the instrument panel wire harness

connector to the cigar lighter or power outlet recep-

tacle base connector receptacle.

(2) Install the cigar lighter or power outlet mount

into the instrument panel.

(3) Align the splines on the outside of the cigar

lighter or power outlet receptacle base connector

receptacle with the grooves on the inside of the

mount.

(4) Press firmly on the cigar lighter or power out-

let receptacle base until the retaining bosses of the

mount are fully engaged in their receptacles.

(5) Install the cigar lighter knob and element into

the cigar lighter receptacle base, or the protective cap

into the power outlet receptacle base.

(6) Reconnect the battery negative cable.

CIRCUIT BREAKER

DESCRIPTION

Automatic resetting circuit breakers are used to

protect a system circuit from a short circuit or over-

load. Some examples of his condition can be caused

by an obstructed or stuck seat adjuster or power win-

dow motor.

The circuit breaker cannot be repaired and, if

faulty or damaged, it must be replaced.

DIAGNOSIS AND TESTING - CIRCUIT BREAKER

For circuit descriptions and diagrams, refer to Wir-

ing Diagrams.

(1) Locate the correct circuit breaker in the junc-

tion block. Pull out the circuit breaker slightly, but

be certain that the circuit breaker terminals still con-

tact the terminals in the junction block cavities.

(2) Connect the negative lead of a 12-volt DC volt-

meter to a good ground.

(3) With the voltmeter positive lead, check both

terminals of the circuit breaker for battery voltage.

If only one terminal has battery voltage, the circuit

breaker is faulty and must be replaced. If neither ter-

minal has battery voltage, repair the open circuit

from the Power Distribution Center (PDC) as

required.

GENERATOR CARTRIDGE

FUSE

DESCRIPTION

A 140 ampere generator cartridge fuse is used on

this model. The generator cartridge fuse is similar to

other cartridge fuses found in the Power Distribution

Center (PDC). This fuse has a color-coded plastic

housing and a clear plastic fuse conductor inspection

cover like other cartridge fuses, but has a higher cur-

rent rating and is connected and secured with screws

instead of being pushed onto male spade-type termi-

nals. The generator cartridge fuse cannot be repaired

and, if faulty or damaged, it must be replaced.

OPERATION

The generator cartridge fuse is secured between

the two B(+) terminal stud connection bus bars

within the Power Distribution Center (PDC). This

fuse protects the vehicle electrical system from dam-

age that could be caused by excessive charging sys-

tem output and/or excessive electrical system current

levels resulting from a faulty generator or faulty

charging system control circuits. If the current rating

of the fuse is exceeded, the fuse conductor melts to

open the generator output circuit connection to the

PDC. If a generator cartridge fuse fails, be certain to

completely inspect and test the vehicle charging sys-

tem before replacing the fuse and returning the vehi-

cle to service. Refer toCharging Systemfor the

charging system diagnostic procedures. Refer toWir-

ing Diagramsfor the location of complete PDC cir-

cuit diagrams.

REMOVAL

If a generator cartridge fuse fails, be certain to

inspect and test the vehicle charging system before

replacing the cartridge fuse and returning the vehicle

to service. Refer toCharging Systemin the index of

this service manual for the charging system diagnos-

tic procedures.

(1) Disconnect and isolate the battery negative

cable.

(2) Unlatch and remove the cover from the Power

Distribution Center (PDC).

(3) Remove the two screws that secure the genera-

tor cartridge fuse to the two B(+) terminal stud bus

bars within the PDC.

(4) Remove the generator cartridge fuse from the

PDC.

INSTALLATION

If a generator cartridge fuse fails, be certain to

inspect and test the vehicle charging system before

replacing the cartridge fuse and returning the vehicle

8W - 97 - 4 8W-97 POWER DISTRIBUTIONBR/BE

CIGAR LIGHTER OUTLET (Continued)

Page 1064 of 2255

to service. Refer toCharging Systemin the index of

this service manual for the charging system diagnos-

tic procedures.

(1) Position the generator cartridge fuse onto the

two B(+) terminal stud bus bars within the PDC.

(2) Install and tighten the two screws that secure

the generator cartridge fuse to the two B(+) terminal

stud bus bars within the PDC. Tighten the screws to

3.4 N´m (30 in. lbs.).Be certain that both screws

are tightened to the proper torque value.

(3) Install and latch the cover onto the PDC.

(4) Reconnect the battery negative cable.

IOD FUSE

DESCRIPTION

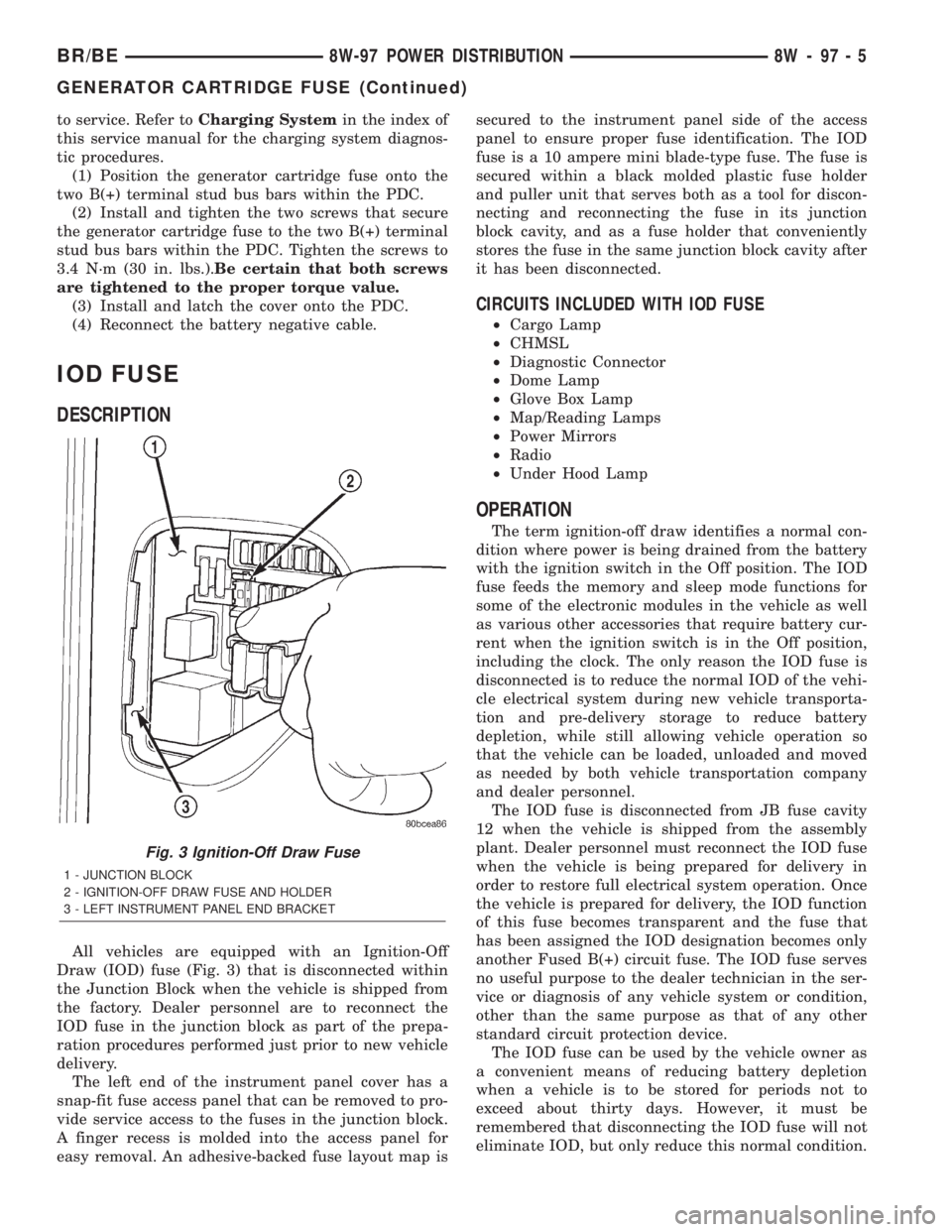

All vehicles are equipped with an Ignition-Off

Draw (IOD) fuse (Fig. 3) that is disconnected within

the Junction Block when the vehicle is shipped from

the factory. Dealer personnel are to reconnect the

IOD fuse in the junction block as part of the prepa-

ration procedures performed just prior to new vehicle

delivery.

The left end of the instrument panel cover has a

snap-fit fuse access panel that can be removed to pro-

vide service access to the fuses in the junction block.

A finger recess is molded into the access panel for

easy removal. An adhesive-backed fuse layout map issecured to the instrument panel side of the access

panel to ensure proper fuse identification. The IOD

fuse is a 10 ampere mini blade-type fuse. The fuse is

secured within a black molded plastic fuse holder

and puller unit that serves both as a tool for discon-

necting and reconnecting the fuse in its junction

block cavity, and as a fuse holder that conveniently

stores the fuse in the same junction block cavity after

it has been disconnected.

CIRCUITS INCLUDED WITH IOD FUSE

²Cargo Lamp

²CHMSL

²Diagnostic Connector

²Dome Lamp

²Glove Box Lamp

²Map/Reading Lamps

²Power Mirrors

²Radio

²Under Hood Lamp

OPERATION

The term ignition-off draw identifies a normal con-

dition where power is being drained from the battery

with the ignition switch in the Off position. The IOD

fuse feeds the memory and sleep mode functions for

some of the electronic modules in the vehicle as well

as various other accessories that require battery cur-

rent when the ignition switch is in the Off position,

including the clock. The only reason the IOD fuse is

disconnected is to reduce the normal IOD of the vehi-

cle electrical system during new vehicle transporta-

tion and pre-delivery storage to reduce battery

depletion, while still allowing vehicle operation so

that the vehicle can be loaded, unloaded and moved

as needed by both vehicle transportation company

and dealer personnel.

The IOD fuse is disconnected from JB fuse cavity

12 when the vehicle is shipped from the assembly

plant. Dealer personnel must reconnect the IOD fuse

when the vehicle is being prepared for delivery in

order to restore full electrical system operation. Once

the vehicle is prepared for delivery, the IOD function

of this fuse becomes transparent and the fuse that

has been assigned the IOD designation becomes only

another Fused B(+) circuit fuse. The IOD fuse serves

no useful purpose to the dealer technician in the ser-

vice or diagnosis of any vehicle system or condition,

other than the same purpose as that of any other

standard circuit protection device.

The IOD fuse can be used by the vehicle owner as

a convenient means of reducing battery depletion

when a vehicle is to be stored for periods not to

exceed about thirty days. However, it must be

remembered that disconnecting the IOD fuse will not

eliminate IOD, but only reduce this normal condition.

Fig. 3 Ignition-Off Draw Fuse

1 - JUNCTION BLOCK

2 - IGNITION-OFF DRAW FUSE AND HOLDER

3 - LEFT INSTRUMENT PANEL END BRACKET

BR/BE8W-97 POWER DISTRIBUTION 8W - 97 - 5

GENERATOR CARTRIDGE FUSE (Continued)

Page 1066 of 2255

tor between many of the engine compartment, instru-

ment panel, and body wire harnesses. The JB houses

up to nineteen blade-type fuses (two standard-type

and seventeen mini-type), up to two blade-type auto-

matic resetting circuit breakers, the electronic combi-

nation turn signal and hazard warning flasher, and

one International Standards Organization (ISO)

micro-relay.

The molded plastic JB housing has integral mount-

ing brackets that are secured with two screws to the

left instrument panel end bracket. The left end of the

instrument panel cover has a snap-fit fuse access

panel that can be removed for service of the JB. A

fuse puller and spare fuse holders are located on the

back of the fuse access cover, as well as an adhesive-

backed fuse layout map to ensure proper fuse identi-

fication.

The JB unit cannot be repaired and is only ser-

viced as an assembly. If any internal circuit or the JB

housing is faulty or damaged, the entire JB unit

must be replaced.

OPERATION

All of the circuits entering and leaving the JB do

so through up to nine wire harness connectors, which

are connected to the JB through integral connector

receptacles molded into the JB housing. Internal con-

nection of all of the JB circuits is accomplished by an

intricate combination of hard wiring and bus bars.

Refer toWiring Diagramsfor the location of com-

plete JB circuit diagrams.

DIAGNOSIS AND TESTING - JUNCTION BLOCK

The junction block does not incorporate any self

diagnostic capability. Most of the electrical circuits

incorporated into the vehicle must pass through the

junction block at one point or another. The most effi-

cient means of diagnosing a suspected junction block

problem involves a simple continuity tester or ohm

meter. Using the Wiring Diagrams as a guide trace

the problem circuit to the proper junction block cav-

ity and test all circuits in the effected circuit for

proper continuity. A open or high resistance circuit is

a sign of a problem. Some other possible junction

block problems to look for are:

²Loose fuse receptacle terminals.

²Loose relay / circuit breaker receptacle termi-

nals.

²Bent or distorted electrical circuit pins.

²Incorrect size fuse installed in junction block

fuse cavity.

²Dark areas identifying a source of excess heat.

²Defective fuse, relay or circuit breaker installed

in junction block cavity.

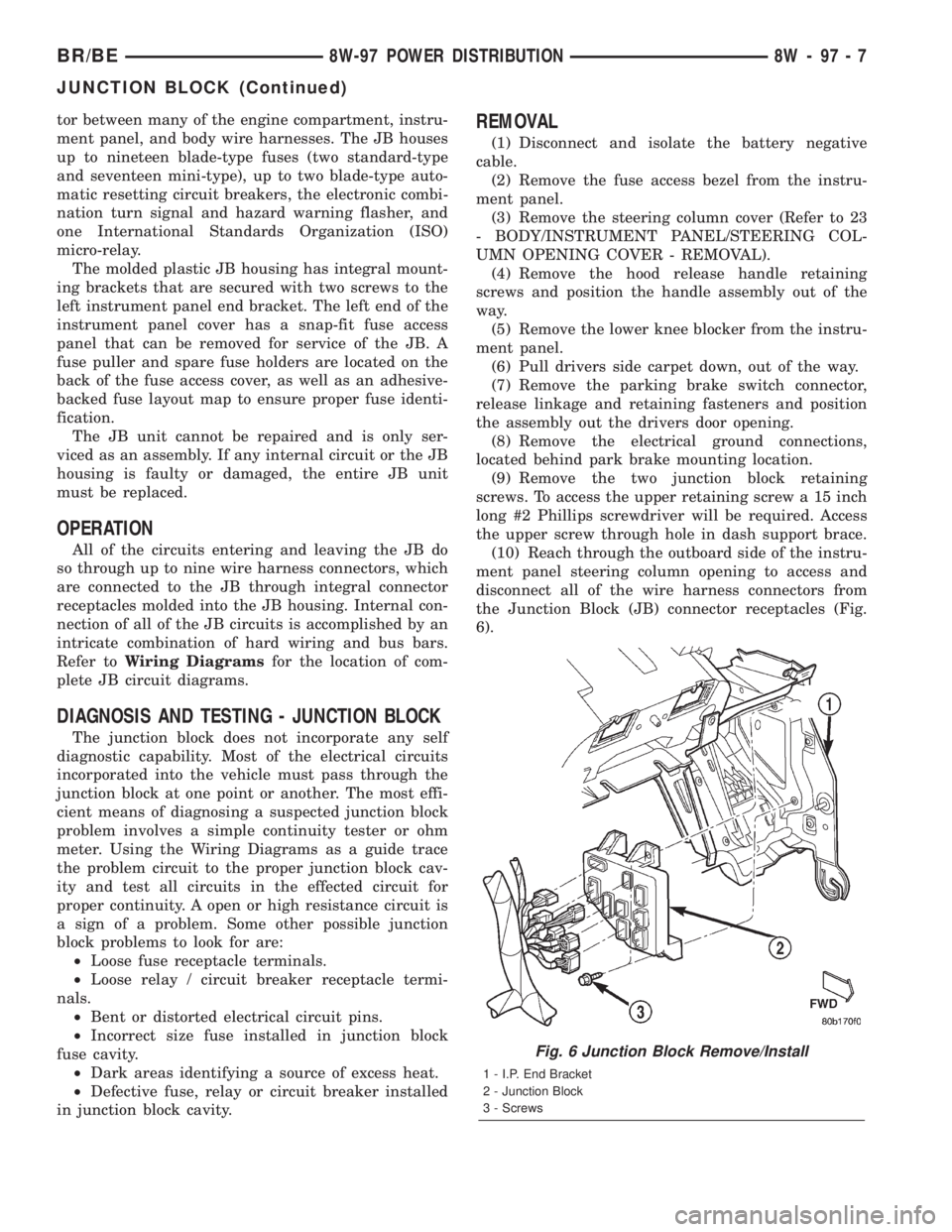

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the fuse access bezel from the instru-

ment panel.

(3) Remove the steering column cover (Refer to 23

- BODY/INSTRUMENT PANEL/STEERING COL-

UMN OPENING COVER - REMOVAL).

(4) Remove the hood release handle retaining

screws and position the handle assembly out of the

way.

(5) Remove the lower knee blocker from the instru-

ment panel.

(6) Pull drivers side carpet down, out of the way.

(7) Remove the parking brake switch connector,

release linkage and retaining fasteners and position

the assembly out the drivers door opening.

(8) Remove the electrical ground connections,

located behind park brake mounting location.

(9) Remove the two junction block retaining

screws. To access the upper retaining screw a 15 inch

long #2 Phillips screwdriver will be required. Access

the upper screw through hole in dash support brace.

(10) Reach through the outboard side of the instru-

ment panel steering column opening to access and

disconnect all of the wire harness connectors from

the Junction Block (JB) connector receptacles (Fig.

6).

Fig. 6 Junction Block Remove/Install

1 - I.P. End Bracket

2 - Junction Block

3 - Screws

BR/BE8W-97 POWER DISTRIBUTION 8W - 97 - 7

JUNCTION BLOCK (Continued)

Page 1067 of 2255

(11) Remove the junction block from under the

instrument panel.

INSTALLATION

NOTE: If the Junction Block (JB) is being replaced

with a new unit, be certain to transfer each of the

fuses, circuit breakers and relays from the faulty JB

to the proper cavities of the replacement JB. Refer

to Junction Block in the index of this service man-

ual for the location of complete circuit diagrams

and cavity assignments for the JB.

(1) Position the junction block under the instru-

ment panel.

(2) Connect all of the wire harness connectors on

the Junction Block (JB) connector receptacles.

(3) Install the two junction block retaining screws.

(4) Install the electrical ground connections,

located behind park brake mounting location.

(5) Install the parking brake switch connector,

release linkage and retaining fasteners.

(6) Reposition drivers side carpet.

(7) Install the lower knee blocker on the instru-

ment panel.

(8) Install the hood release handle retaining

screws.

(9) Install the steering column cover.

(10) Install the fuse access bezel on the instrument

panel.

(11) Connect the battery negative cable.

POWER DISTRIBUTION

CENTER

DESCRIPTION

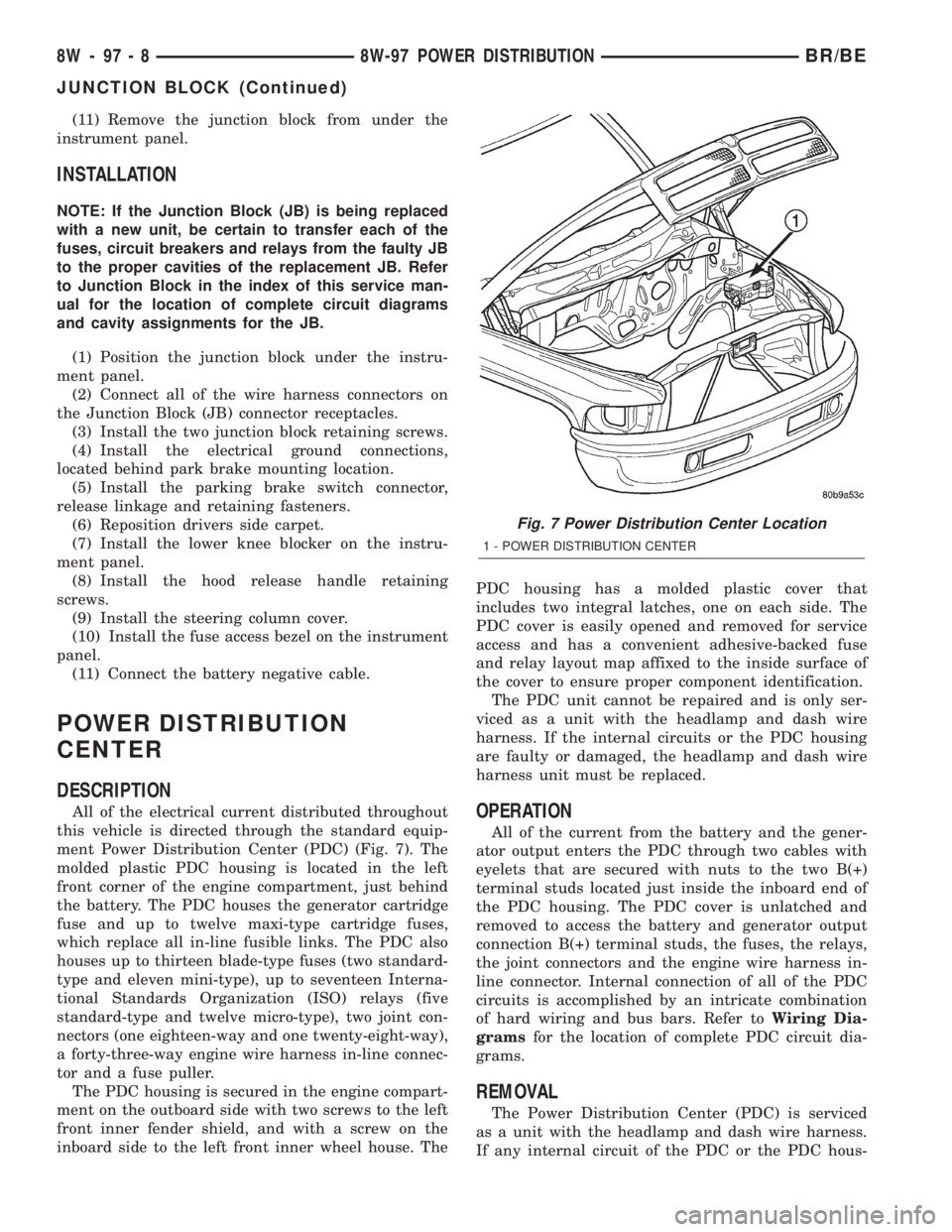

All of the electrical current distributed throughout

this vehicle is directed through the standard equip-

ment Power Distribution Center (PDC) (Fig. 7). The

molded plastic PDC housing is located in the left

front corner of the engine compartment, just behind

the battery. The PDC houses the generator cartridge

fuse and up to twelve maxi-type cartridge fuses,

which replace all in-line fusible links. The PDC also

houses up to thirteen blade-type fuses (two standard-

type and eleven mini-type), up to seventeen Interna-

tional Standards Organization (ISO) relays (five

standard-type and twelve micro-type), two joint con-

nectors (one eighteen-way and one twenty-eight-way),

a forty-three-way engine wire harness in-line connec-

tor and a fuse puller.

The PDC housing is secured in the engine compart-

ment on the outboard side with two screws to the left

front inner fender shield, and with a screw on the

inboard side to the left front inner wheel house. ThePDC housing has a molded plastic cover that

includes two integral latches, one on each side. The

PDC cover is easily opened and removed for service

access and has a convenient adhesive-backed fuse

and relay layout map affixed to the inside surface of

the cover to ensure proper component identification.

The PDC unit cannot be repaired and is only ser-

viced as a unit with the headlamp and dash wire

harness. If the internal circuits or the PDC housing

are faulty or damaged, the headlamp and dash wire

harness unit must be replaced.OPERATION

All of the current from the battery and the gener-

ator output enters the PDC through two cables with

eyelets that are secured with nuts to the two B(+)

terminal studs located just inside the inboard end of

the PDC housing. The PDC cover is unlatched and

removed to access the battery and generator output

connection B(+) terminal studs, the fuses, the relays,

the joint connectors and the engine wire harness in-

line connector. Internal connection of all of the PDC

circuits is accomplished by an intricate combination

of hard wiring and bus bars. Refer toWiring Dia-

gramsfor the location of complete PDC circuit dia-

grams.

REMOVAL

The Power Distribution Center (PDC) is serviced

as a unit with the headlamp and dash wire harness.

If any internal circuit of the PDC or the PDC hous-

Fig. 7 Power Distribution Center Location

1 - POWER DISTRIBUTION CENTER

8W - 97 - 8 8W-97 POWER DISTRIBUTIONBR/BE

JUNCTION BLOCK (Continued)

Page 1069 of 2255

INSTALLATION

The Power Distribution Center (PDC) is serviced

as a unit with the headlamp and dash wire harness.

If any internal circuit of the PDC or the PDC hous-

ing is faulty or damaged, the entire PDC and head-

lamp and dash wire harness unit must be replaced.

NOTE: If the PDC is being replaced with a new unit,

be certain to transfer each of the blade-type fuses,

cartridge fuses and relays from the faulty PDC to

the proper cavities of the replacement PDC. Refer

to Power Distribution in the index of this service

manual for the location of complete PDC circuit dia-

grams and cavity assignments.

(1) Position the PDC and the headlamp and dash

wire harness unit in the engine compartment.

(2) Install and tighten the two screws that secure

the PDC housing to the left front fender inner shield.

Tighten the screws to 8.4 N´m (75 in. lbs.).

(3) Install and tighten the screw that secures the

PDC housing to the left front fender wheel housing.

Tighten the screw to 2.2 N´m (20 in. lbs.).

(4) Install the eyelet of the battery positive cable

PDC take out onto the forward B(+) terminal stud in

the PDC.

(5) Install and tighten the nut that secures the

eyelet of the battery positive cable PDC take out to

the forward B(+) terminal stud in the PDC. Tighten

the nut to 8.4 N´m (75 in. lbs.).

(6) Install the eyelet of the battery negative cable

generator output take out onto the rearward B(+) ter-

minal stud in the PDC.

(7) Install and tighten the nut that secures the

eyelet of the battery negative cable generator output

take out to the rearward B(+) terminal stud in the

PDC. Tighten the nut to 75 in. lbs.

(8) Reconnect the engine wire harness in-line con-

nector to the PDC.

(9) Install and tighten the screw that secures the

engine wire harness in-line connector to the PDC.

Tighten the screw until a distinct audible click is

heard.

(10) Install and latch the cover onto the PDC.

(11) Engage each of the retainers that secure the

headlamp and dash wire harness to the vehicle body

and chassis components. Refer toConnector Loca-

tionsin Wiring for the location of more information

on the headlamp and dash wire harness retainer

locations.

(12) Install all of the fasteners that secure each of

the headlamp and dash wire harness ground eyelets

to the vehicle body and chassis components. Refer to

Connector Locationsin Wiring for the location of

more information on the ground eyelet locations.(13) Reconnect each of the headlamp and dash

wire harness connectors. Refer toConnector Loca-

tionsin Wiring for the location of more information

on the headlamp and dash wire harness connector

locations.

(14) Reconnect the battery negative cable.

POWER OUTLET

DESCRIPTION

Two power outlets are installed in the vehicle. One

in the instrument panel next to the cigar lighter and

the other in the right rear quarter trim panel. The

power outlet bases are secured by a snap fit within

the instrument panel or trim panel. A plastic protec-

tive cap snaps into the power outlet base when the

power outlet is not being used, and hangs from the

power outlet base mount by an integral bail strap

while the power outlet is in use.

The power outlet receptacle unit and the accessory

power outlet protective cap are available for service.

The power outlet receptacle cannot be repaired and,

if faulty or damaged, it must be replaced.

OPERATION

The power outlet base or receptacle shell is con-

nected to ground, and an insulated contact in the

bottom of the shell is connected to battery current.

The power outlet receives battery voltage from a fuse

in the Junction Block at all times.

While the power outlet is very similar to a cigar

lighter base unit, it does not include the two small

spring-clip retainers inside the bottom of the recepta-

cle shell that are used to secure the cigar lighter

heating element to the insulated contact.

DIAGNOSIS AND TESTING - POWER OUTLET

For complete circuit diagrams, refer toPower

Outletin Wiring Diagrams.

(1) Check the fused B(+) fuse in the junction block.

If OK, go to Step 2. If not OK, repair the shorted cir-

cuit or component as required and replace the faulty

fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the junction block. If OK, go to Step 3. If not OK,

repair the open fused B(+) circuit to the battery as

required.

(3) Remove the plastic protective cap from the

power outlet receptacle. Check for continuity between

the inside circumference of the power outlet recepta-

cle and a good ground. There should be continuity. If

OK, go to Step 4. If not OK, go to Step 5.

(4) Check for battery voltage at the insulated con-

tact located at the back of the power outlet recepta-

cle. If not OK, go to Step 5.

8W - 97 - 10 8W-97 POWER DISTRIBUTIONBR/BE

POWER DISTRIBUTION CENTER (Continued)