tailgate DODGE RAM 2002 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1029 of 2255

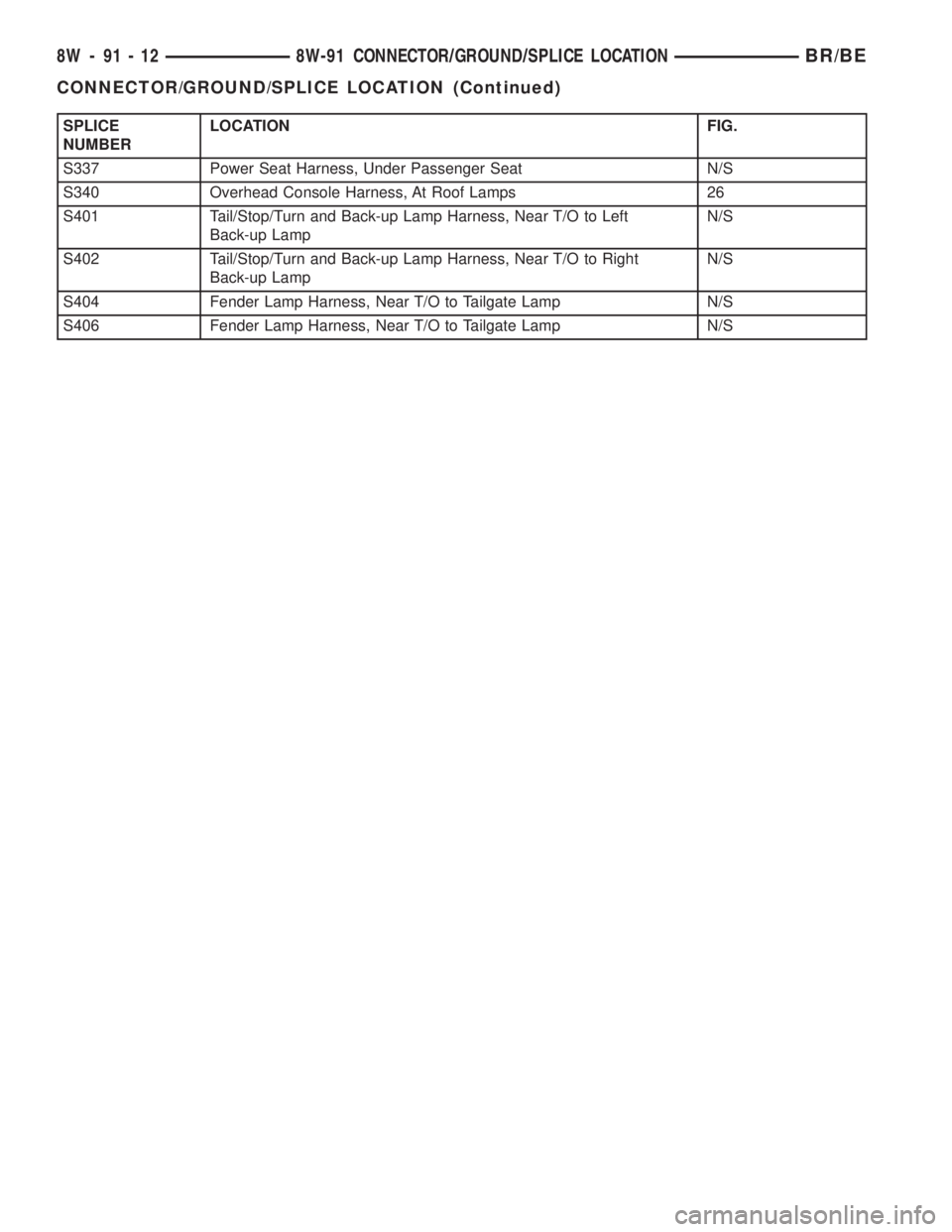

SPLICE

NUMBERLOCATION FIG.

S337 Power Seat Harness, Under Passenger Seat N/S

S340 Overhead Console Harness, At Roof Lamps 26

S401 Tail/Stop/Turn and Back-up Lamp Harness, Near T/O to Left

Back-up LampN/S

S402 Tail/Stop/Turn and Back-up Lamp Harness, Near T/O to Right

Back-up LampN/S

S404 Fender Lamp Harness, Near T/O to Tailgate Lamp N/S

S406 Fender Lamp Harness, Near T/O to Tailgate Lamp N/S

8W - 91 - 12 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONBR/BE

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1968 of 2255

BODY

TABLE OF CONTENTS

page page

BODY

WARNING

SAFETY PRECAUTIONS AND WARNINGS . . . 1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - WATER LEAKS . 2

DIAGNOSIS AND TESTING - WIND NOISE . . . 3

SPECIFICATIONS

WELD LOCATIONS.....................4

STRUCTURAL ADHESIVE LOCATIONS.....44

BODY SEALER LOCATIONS.............47

BODY GAP AND FLUSH MEASUREMENTS . . 56

BODY OPENING DIMENSIONS...........60TORQUE SPECIFICATIONS.............61

DECKLID/HATCH/LIFTGATE/TAILGATE.......63

DOOR - FRONT.........................68

DOOR - CARGO.........................77

EXTERIOR.............................86

HOOD................................100

INSTRUMENT PANEL SYSTEM............105

INTERIOR.............................118

PAINT................................129

SEATS...............................131

STATIONARY GLASS....................145

WEATHERSTRIP/SEALS..................151

BODY

WARNING

SAFETY PRECAUTIONS AND WARNINGS

WARNING: USE AN OSHA APPROVED BREATHING

FILTER WHEN SPRAYING PAINT OR SOLVENTS IN

A CONFINED AREA. PERSONAL INJURY CAN

RESULT.

²AVOID PROLONGED SKIN CONTACT WITH

PETROLEUM OR ALCOHOL ± BASED CLEANING

SOLVENTS. PERSONAL INJURY CAN RESULT.

²DO NOT STAND UNDER A HOISTED VEHICLE

THAT IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.CAUTION: When holes must be drilled or punched

in an inner body panel, verify depth of space to the

outer body panel, electrical wiring, or other compo-

nents. Damage to vehicle can result.

²Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

²Always have a fire extinguisher ready for use

when welding.

²Disconnect the negative (-) cable clamp from

the battery when servicing electrical components

that are live when the ignition is OFF. Damage to

electrical system can result.

²Do not use abrasive chemicals or compounds

on painted surfaces. Damage to finish can result.

²Do not use harsh alkaline based cleaning sol-

vents on painted or upholstered surfaces. Damage

to finish or color can result.

²Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

BR/BEBODY 23 - 1

Page 2026 of 2255

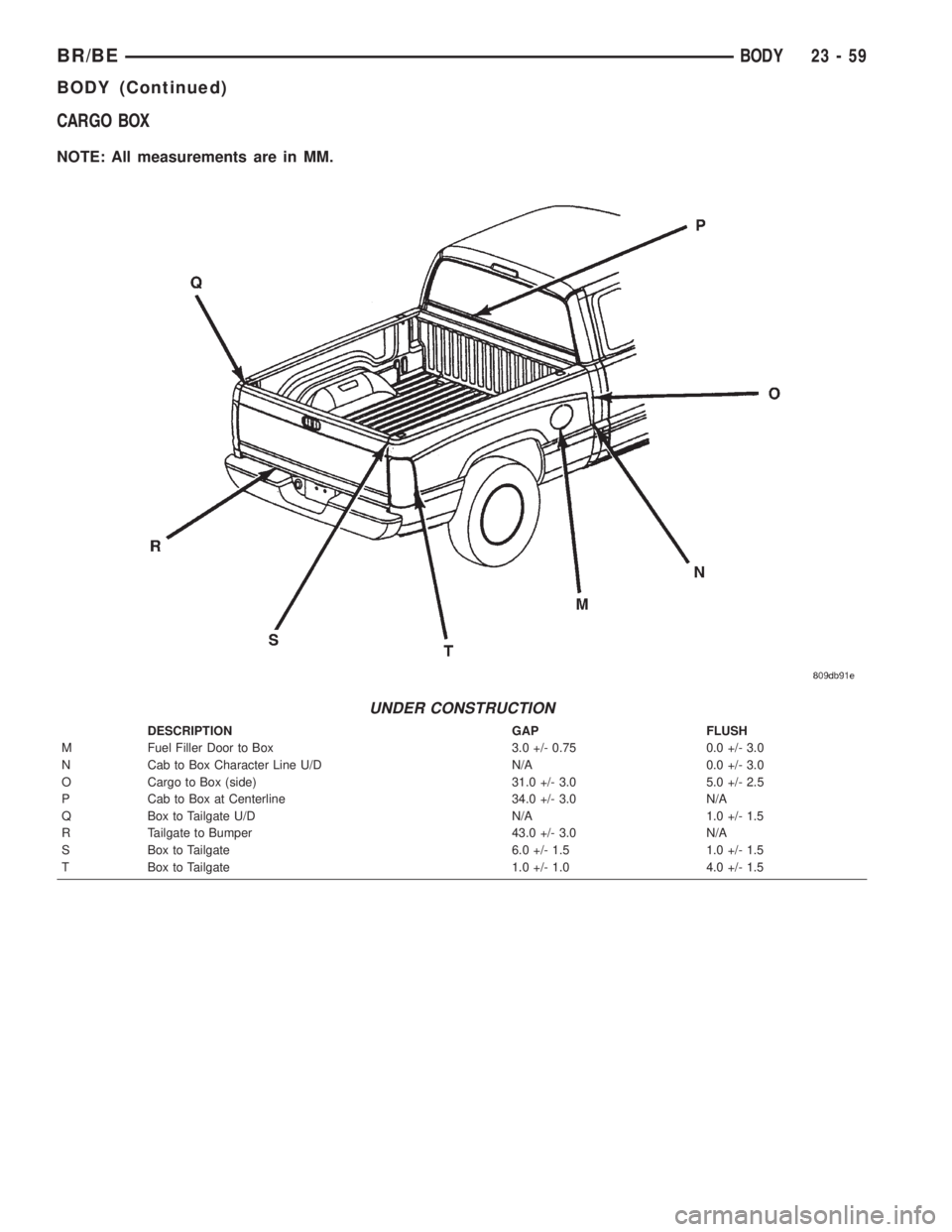

CARGO BOX

NOTE: All measurements are in MM.

UNDER CONSTRUCTION

DESCRIPTION GAP FLUSH

M Fuel Filler Door to Box 3.0 +/- 0.75 0.0 +/- 3.0

N Cab to Box Character Line U/D N/A 0.0 +/- 3.0

O Cargo to Box (side) 31.0 +/- 3.0 5.0 +/- 2.5

P Cab to Box at Centerline 34.0 +/- 3.0 N/A

Q Box to Tailgate U/D N/A 1.0 +/- 1.5

R Tailgate to Bumper 43.0 +/- 3.0 N/A

S Box to Tailgate 6.0 +/- 1.5 1.0 +/- 1.5

T Box to Tailgate 1.0 +/- 1.0 4.0 +/- 1.5

BR/BEBODY 23 - 59

BODY (Continued)

Page 2030 of 2255

DECKLID/HATCH/LIFTGATE/TAILGATE

TABLE OF CONTENTS

page page

APPLIQUE

REMOVAL.............................63

INSTALLATION.........................63

DECALS

REMOVAL.............................64

INSTALLATION.........................64

HANDLE ESCUTCHEON

REMOVAL.............................64

INSTALLATION.........................64

LATCH

REMOVAL.............................65

INSTALLATION.........................65

LATCH HANDLE

REMOVAL.............................66INSTALLATION.........................66

LATCH STRIKER

REMOVAL.............................66

INSTALLATION.........................66

SLAM BUMPER

REMOVAL.............................67

INSTALLATION.........................67

CHECK CABLE

REMOVAL.............................67

INSTALLATION.........................67

TAILGATE

REMOVAL.............................67

INSTALLATION.........................67

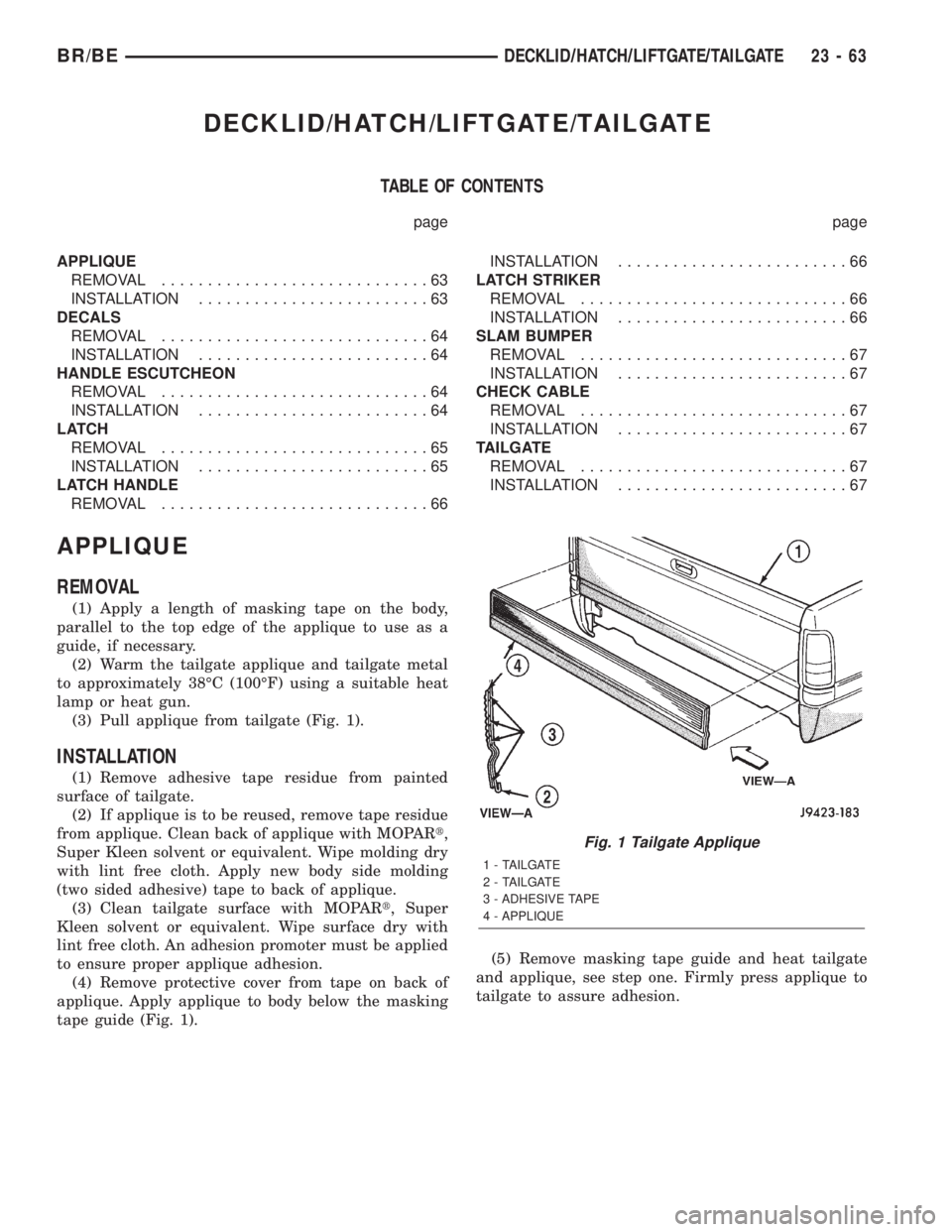

APPLIQUE

REMOVAL

(1) Apply a length of masking tape on the body,

parallel to the top edge of the applique to use as a

guide, if necessary.

(2) Warm the tailgate applique and tailgate metal

to approximately 38ÉC (100ÉF) using a suitable heat

lamp or heat gun.

(3) Pull applique from tailgate (Fig. 1).

INSTALLATION

(1) Remove adhesive tape residue from painted

surface of tailgate.

(2) If applique is to be reused, remove tape residue

from applique. Clean back of applique with MOPARt,

Super Kleen solvent or equivalent. Wipe molding dry

with lint free cloth. Apply new body side molding

(two sided adhesive) tape to back of applique.

(3) Clean tailgate surface with MOPARt, Super

Kleen solvent or equivalent. Wipe surface dry with

lint free cloth. An adhesion promoter must be applied

to ensure proper applique adhesion.

(4) Remove protective cover from tape on back of

applique. Apply applique to body below the masking

tape guide (Fig. 1).(5) Remove masking tape guide and heat tailgate

and applique, see step one. Firmly press applique to

tailgate to assure adhesion.

Fig. 1 Tailgate Applique

1 - TAILGATE

2 - TAILGATE

3 - ADHESIVE TAPE

4 - APPLIQUE

BR/BEDECKLID/HATCH/LIFTGATE/TAILGATE 23 - 63

Page 2031 of 2255

DECALS

REMOVAL

(1) Warm the panel to approximately 38ÉC (100ÉF)

using a suitable heat lamp or heat gun.

(2) Peel tape stripe from body panel using an even

pressure pull.

(3) Remove adhesive residue from body panel

using a suitable adhesive removing solvent.

INSTALLATION

(1) Clean painted body surface with MopartSuper

Clean solvent or equivalent and a lint free cloth.

(2) Remove protective cover from back side of

decal.

(3) Position decal properly on body.

(4) Press decal firmly to body with palm of hand.

(5) If temperature is below 21ÉC (70ÉF) warm decal

with a heat lamp or gun to assure adhesion. Do not

exceed 65ÉC (150ÉF) when heating emblem.

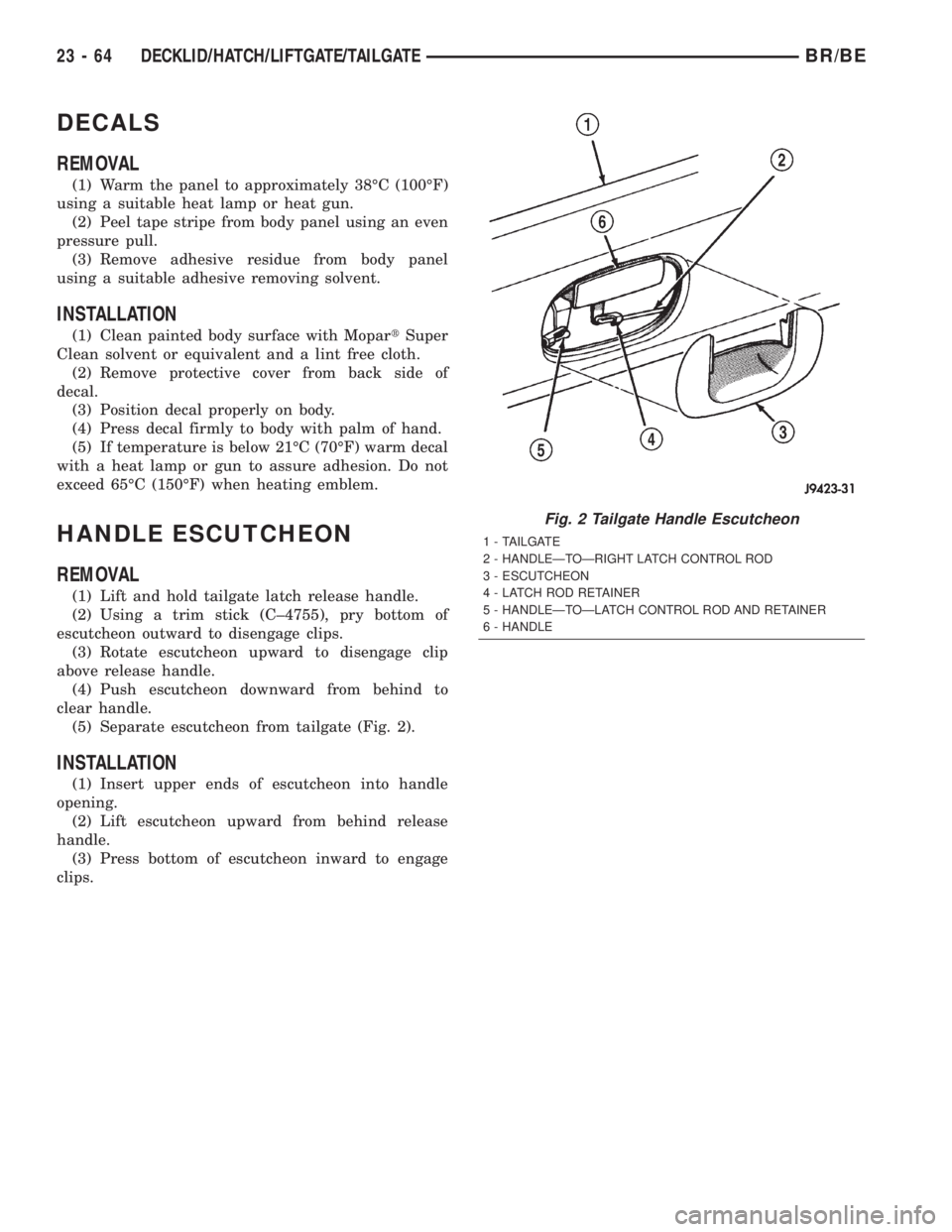

HANDLE ESCUTCHEON

REMOVAL

(1) Lift and hold tailgate latch release handle.

(2) Using a trim stick (C±4755), pry bottom of

escutcheon outward to disengage clips.

(3) Rotate escutcheon upward to disengage clip

above release handle.

(4) Push escutcheon downward from behind to

clear handle.

(5) Separate escutcheon from tailgate (Fig. 2).

INSTALLATION

(1) Insert upper ends of escutcheon into handle

opening.

(2) Lift escutcheon upward from behind release

handle.

(3) Press bottom of escutcheon inward to engage

clips.

Fig. 2 Tailgate Handle Escutcheon

1 - TAILGATE

2 - HANDLEÐTOÐRIGHT LATCH CONTROL ROD

3 - ESCUTCHEON

4 - LATCH ROD RETAINER

5 - HANDLEÐTOÐLATCH CONTROL ROD AND RETAINER

6 - HANDLE

23 - 64 DECKLID/HATCH/LIFTGATE/TAILGATEBR/BE

Page 2032 of 2255

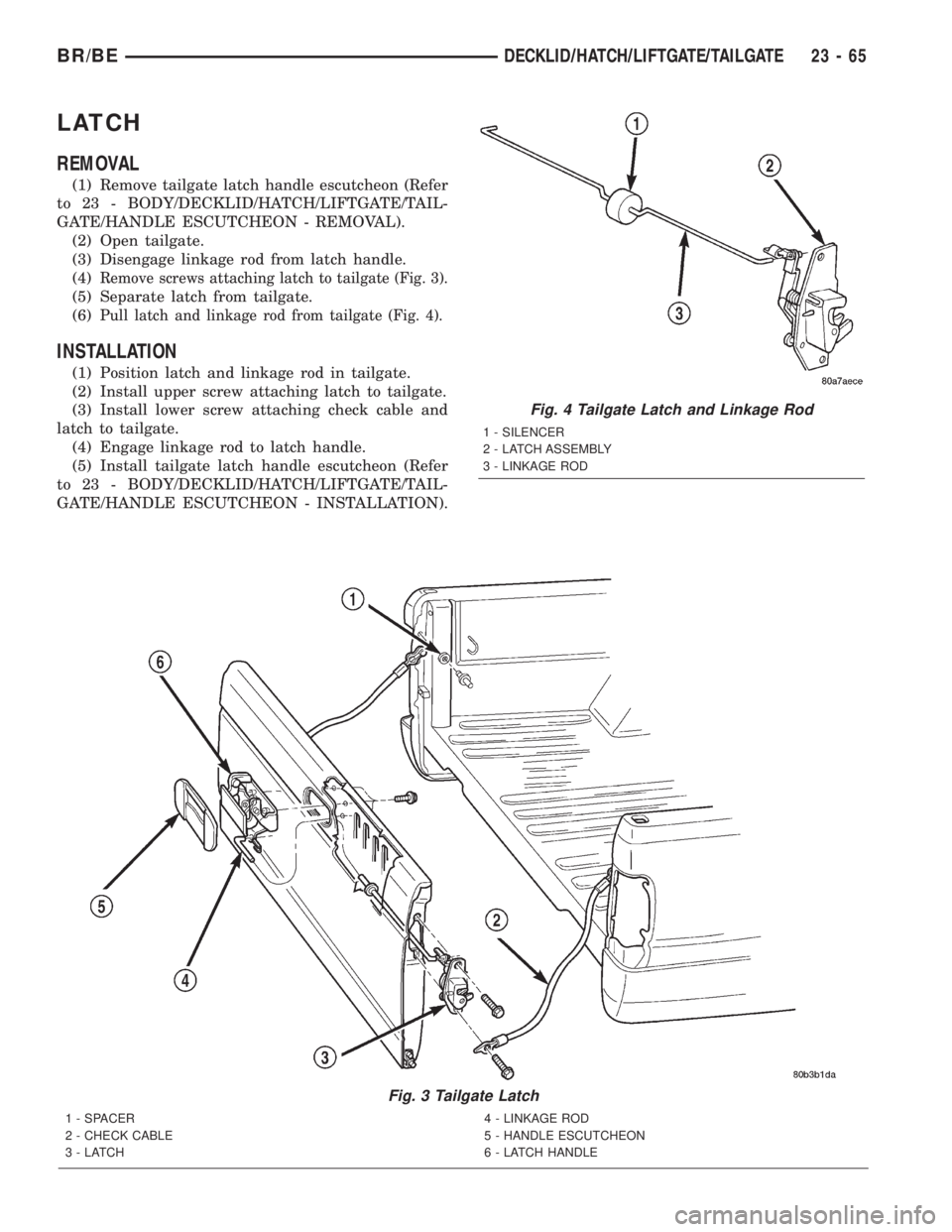

LATCH

REMOVAL

(1) Remove tailgate latch handle escutcheon (Refer

to 23 - BODY/DECKLID/HATCH/LIFTGATE/TAIL-

GATE/HANDLE ESCUTCHEON - REMOVAL).

(2) Open tailgate.

(3) Disengage linkage rod from latch handle.

(4)

Remove screws attaching latch to tailgate (Fig. 3).

(5) Separate latch from tailgate.

(6)

Pull latch and linkage rod from tailgate (Fig. 4).

INSTALLATION

(1) Position latch and linkage rod in tailgate.

(2) Install upper screw attaching latch to tailgate.

(3) Install lower screw attaching check cable and

latch to tailgate.

(4) Engage linkage rod to latch handle.

(5) Install tailgate latch handle escutcheon (Refer

to 23 - BODY/DECKLID/HATCH/LIFTGATE/TAIL-

GATE/HANDLE ESCUTCHEON - INSTALLATION).

Fig. 3 Tailgate Latch

1 - SPACER

2 - CHECK CABLE

3-LATCH4 - LINKAGE ROD

5 - HANDLE ESCUTCHEON

6 - LATCH HANDLE

Fig. 4 Tailgate Latch and Linkage Rod

1 - SILENCER

2 - LATCH ASSEMBLY

3 - LINKAGE ROD

BR/BEDECKLID/HATCH/LIFTGATE/TAILGATE 23 - 65

Page 2033 of 2255

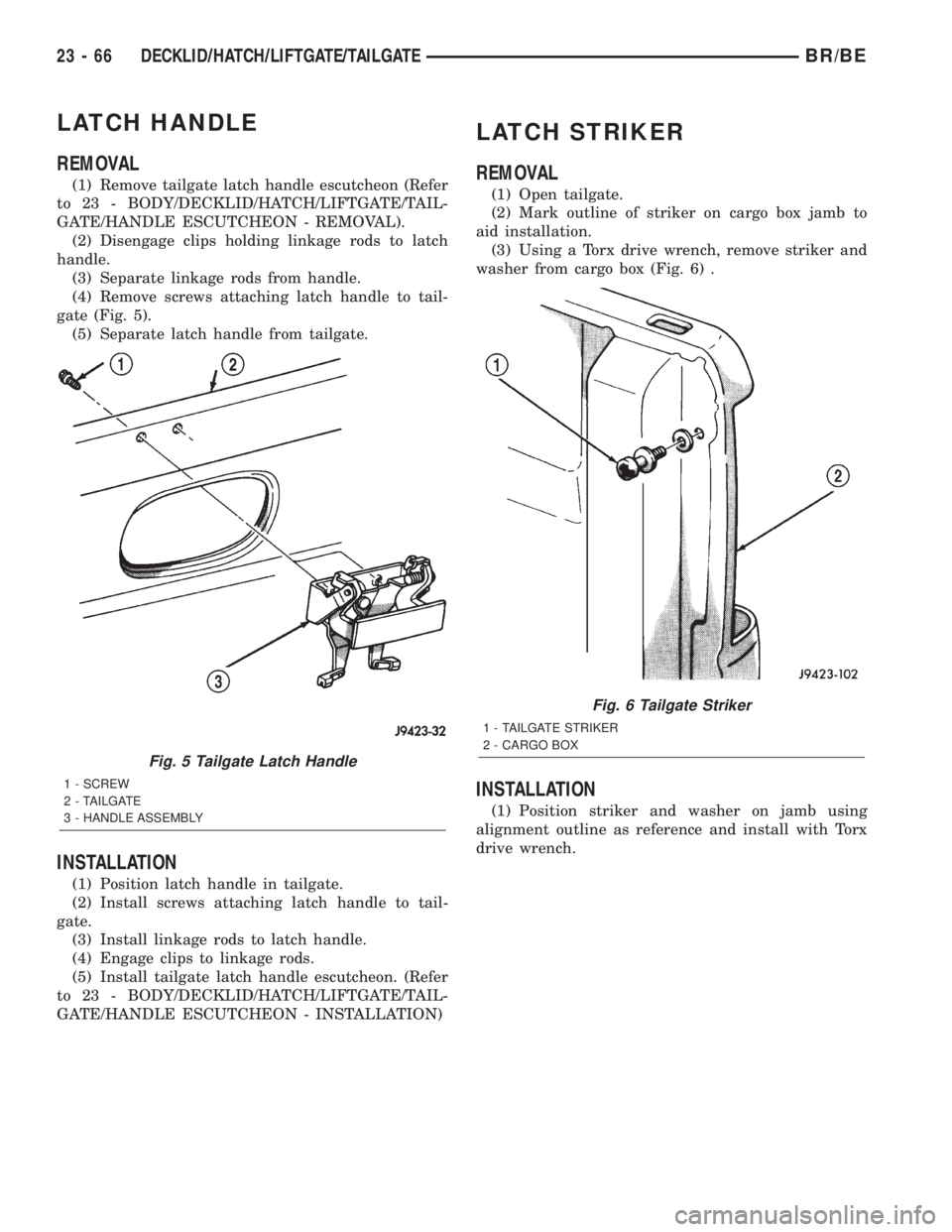

LATCH HANDLE

REMOVAL

(1) Remove tailgate latch handle escutcheon (Refer

to 23 - BODY/DECKLID/HATCH/LIFTGATE/TAIL-

GATE/HANDLE ESCUTCHEON - REMOVAL).

(2) Disengage clips holding linkage rods to latch

handle.

(3) Separate linkage rods from handle.

(4) Remove screws attaching latch handle to tail-

gate (Fig. 5).

(5) Separate latch handle from tailgate.

INSTALLATION

(1) Position latch handle in tailgate.

(2) Install screws attaching latch handle to tail-

gate.

(3) Install linkage rods to latch handle.

(4) Engage clips to linkage rods.

(5) Install tailgate latch handle escutcheon. (Refer

to 23 - BODY/DECKLID/HATCH/LIFTGATE/TAIL-

GATE/HANDLE ESCUTCHEON - INSTALLATION)

LATCH STRIKER

REMOVAL

(1) Open tailgate.

(2) Mark outline of striker on cargo box jamb to

aid installation.

(3) Using a Torx drive wrench, remove striker and

washer from cargo box (Fig. 6) .

INSTALLATION

(1) Position striker and washer on jamb using

alignment outline as reference and install with Torx

drive wrench.

Fig. 5 Tailgate Latch Handle

1 - SCREW

2 - TAILGATE

3 - HANDLE ASSEMBLY

Fig. 6 Tailgate Striker

1 - TAILGATE STRIKER

2 - CARGO BOX

23 - 66 DECKLID/HATCH/LIFTGATE/TAILGATEBR/BE

Page 2034 of 2255

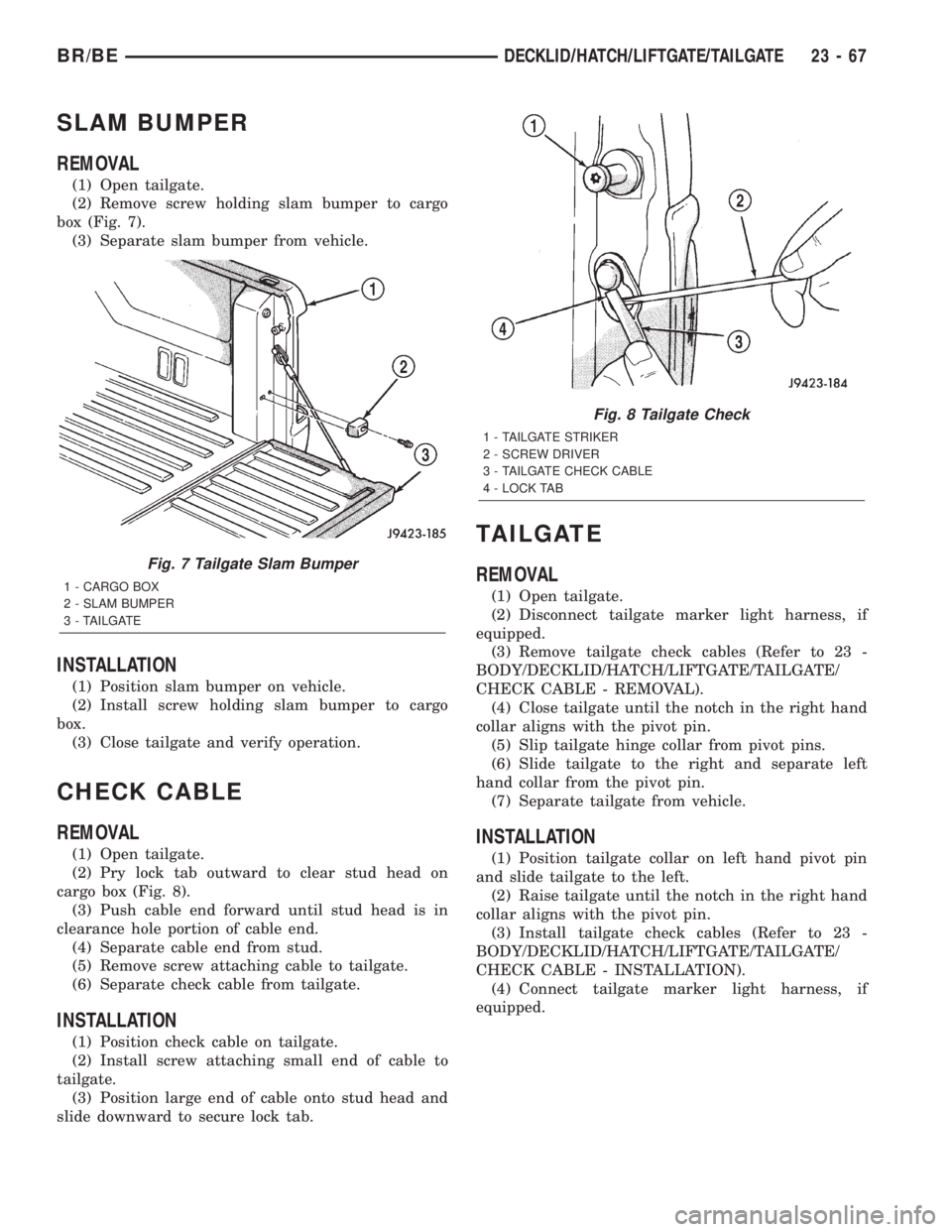

SLAM BUMPER

REMOVAL

(1) Open tailgate.

(2) Remove screw holding slam bumper to cargo

box (Fig. 7).

(3) Separate slam bumper from vehicle.

INSTALLATION

(1) Position slam bumper on vehicle.

(2) Install screw holding slam bumper to cargo

box.

(3) Close tailgate and verify operation.

CHECK CABLE

REMOVAL

(1) Open tailgate.

(2) Pry lock tab outward to clear stud head on

cargo box (Fig. 8).

(3) Push cable end forward until stud head is in

clearance hole portion of cable end.

(4) Separate cable end from stud.

(5) Remove screw attaching cable to tailgate.

(6) Separate check cable from tailgate.

INSTALLATION

(1) Position check cable on tailgate.

(2) Install screw attaching small end of cable to

tailgate.

(3) Position large end of cable onto stud head and

slide downward to secure lock tab.

TAILGATE

REMOVAL

(1) Open tailgate.

(2) Disconnect tailgate marker light harness, if

equipped.

(3) Remove tailgate check cables (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

CHECK CABLE - REMOVAL).

(4) Close tailgate until the notch in the right hand

collar aligns with the pivot pin.

(5) Slip tailgate hinge collar from pivot pins.

(6) Slide tailgate to the right and separate left

hand collar from the pivot pin.

(7) Separate tailgate from vehicle.

INSTALLATION

(1) Position tailgate collar on left hand pivot pin

and slide tailgate to the left.

(2) Raise tailgate until the notch in the right hand

collar aligns with the pivot pin.

(3) Install tailgate check cables (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

CHECK CABLE - INSTALLATION).

(4) Connect tailgate marker light harness, if

equipped.

Fig. 7 Tailgate Slam Bumper

1 - CARGO BOX

2 - SLAM BUMPER

3 - TAILGATE

Fig. 8 Tailgate Check

1 - TAILGATE STRIKER

2 - SCREW DRIVER

3 - TAILGATE CHECK CABLE

4 - LOCK TAB

BR/BEDECKLID/HATCH/LIFTGATE/TAILGATE 23 - 67

Page 2248 of 2255

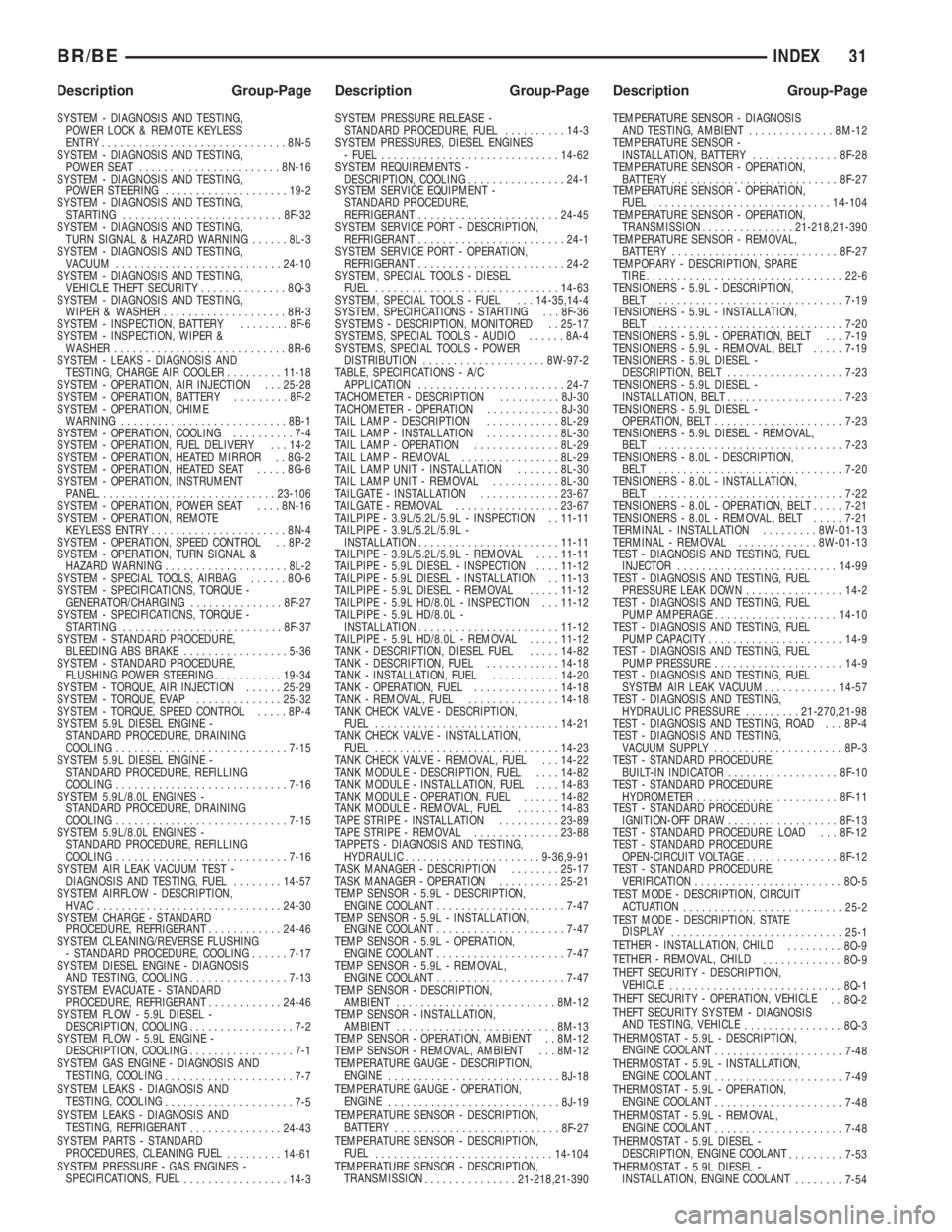

SYSTEM - DIAGNOSIS AND TESTING,

POWER LOCK & REMOTE KEYLESS

ENTRY..............................8N-5

SYSTEM - DIAGNOSIS AND TESTING,

POWER SEAT.......................8N-16

SYSTEM - DIAGNOSIS AND TESTING,

POWER STEERING....................19-2

SYSTEM - DIAGNOSIS AND TESTING,

STARTING..........................8F-32

SYSTEM - DIAGNOSIS AND TESTING,

TURN SIGNAL & HAZARD WARNING......8L-3

SYSTEM - DIAGNOSIS AND TESTING,

VACUUM...........................24-10

SYSTEM - DIAGNOSIS AND TESTING,

VEHICLE THEFT SECURITY..............8Q-3

SYSTEM - DIAGNOSIS AND TESTING,

WIPER & WASHER....................8R-3

SYSTEM - INSPECTION, BATTERY........8F-6

SYSTEM - INSPECTION, WIPER &

WASHER............................8R-6

SYSTEM - LEAKS - DIAGNOSIS AND

TESTING, CHARGE AIR COOLER.........11-18

SYSTEM - OPERATION, AIR INJECTION . . . 25-28

SYSTEM - OPERATION, BATTERY.........8F-2

SYSTEM - OPERATION, CHIME

WARNING...........................8B-1

SYSTEM - OPERATION, COOLING..........7-4

SYSTEM - OPERATION, FUEL DELIVERY . . . 14-2

SYSTEM - OPERATION, HEATED MIRROR . . 8G-2

SYSTEM - OPERATION, HEATED SEAT.....8G-6

SYSTEM - OPERATION, INSTRUMENT

PANEL..............................23-106

SYSTEM - OPERATION, POWER SEAT....8N-16

SYSTEM - OPERATION, REMOTE

KEYLESS ENTRY......................8N-4

SYSTEM - OPERATION, SPEED CONTROL . . 8P-2

SYSTEM - OPERATION, TURN SIGNAL &

HAZARD WARNING....................8L-2

SYSTEM - SPECIAL TOOLS, AIRBAG......8O-6

SYSTEM - SPECIFICATIONS, TORQUE -

GENERATOR/CHARGING...............8F-27

SYSTEM - SPECIFICATIONS, TORQUE -

STARTING..........................8F-37

SYSTEM - STANDARD PROCEDURE,

BLEEDING ABS BRAKE.................5-36

SYSTEM - STANDARD PROCEDURE,

FLUSHING POWER STEERING...........19-34

SYSTEM - TORQUE, AIR INJECTION......25-29

SYSTEM - TORQUE, EVAP..............25-32

SYSTEM - TORQUE, SPEED CONTROL.....8P-4

SYSTEM 5.9L DIESEL ENGINE -

STANDARD PROCEDURE, DRAINING

COOLING............................7-15

SYSTEM 5.9L DIESEL ENGINE -

STANDARD PROCEDURE, REFILLING

COOLING............................7-16

SYSTEM 5.9L/8.0L ENGINES -

STANDARD PROCEDURE, DRAINING

COOLING............................7-15

SYSTEM 5.9L/8.0L ENGINES -

STANDARD PROCEDURE, REFILLING

COOLING............................7-16

SYSTEM AIR LEAK VACUUM TEST -

DIAGNOSIS AND TESTING, FUEL........14-57

SYSTEM AIRFLOW - DESCRIPTION,

HVAC..............................24-30

SYSTEM CHARGE - STANDARD

PROCEDURE, REFRIGERANT............24-46

SYSTEM CLEANING/REVERSE FLUSHING

- STANDARD PROCEDURE, COOLING......7-17

SYSTEM DIESEL ENGINE - DIAGNOSIS

AND TESTING, COOLING................7-13

SYSTEM EVACUATE - STANDARD

PROCEDURE, REFRIGERANT............24-46

SYSTEM FLOW - 5.9L DIESEL -

DESCRIPTION, COOLING.................7-2

SYSTEM FLOW - 5.9L ENGINE -

DESCRIPTION, COOLING.................7-1

SYSTEM GAS ENGINE - DIAGNOSIS AND

TESTING, COOLING

.....................7-7

SYSTEM LEAKS - DIAGNOSIS AND

TESTING, COOLING

.....................7-5

SYSTEM LEAKS - DIAGNOSIS AND

TESTING, REFRIGERANT

...............24-43

SYSTEM PARTS - STANDARD

PROCEDURES, CLEANING FUEL

.........14-61

SYSTEM PRESSURE - GAS ENGINES -

SPECIFICATIONS, FUEL

.................14-3SYSTEM PRESSURE RELEASE -

STANDARD PROCEDURE, FUEL..........14-3

SYSTEM PRESSURES, DIESEL ENGINES

- FUEL.............................14-62

SYSTEM REQUIREMENTS -

DESCRIPTION, COOLING................24-1

SYSTEM SERVICE EQUIPMENT -

STANDARD PROCEDURE,

REFRIGERANT.......................24-45

SYSTEM SERVICE PORT - DESCRIPTION,

REFRIGERANT........................24-1

SYSTEM SERVICE PORT - OPERATION,

REFRIGERANT........................24-2

SYSTEM, SPECIAL TOOLS - DIESEL

FUEL..............................14-63

SYSTEM, SPECIAL TOOLS - FUEL . . . 14-35,14-4

SYSTEM, SPECIFICATIONS - STARTING . . . 8F-36

SYSTEMS - DESCRIPTION, MONITORED . . 25-17

SYSTEMS, SPECIAL TOOLS - AUDIO......8A-4

SYSTEMS, SPECIAL TOOLS - POWER

DISTRIBUTION....................8W-97-2

TABLE, SPECIFICATIONS - A/C

APPLICATION........................24-7

TACHOMETER - DESCRIPTION..........8J-30

TACHOMETER - OPERATION............8J-30

TAIL LAMP - DESCRIPTION............8L-29

TAIL LAMP - INSTALLATION............8L-30

TAIL LAMP - OPERATION..............8L-29

TAIL LAMP - REMOVAL................8L-29

TAIL LAMP UNIT - INSTALLATION.......8L-30

TAIL LAMP UNIT - REMOVAL...........8L-30

TAILGATE - INSTALLATION.............23-67

TAILGATE - REMOVAL.................23-67

TAILPIPE - 3.9L/5.2L/5.9L - INSPECTION . . 11-11

TAILPIPE - 3.9L/5.2L/5.9L -

INSTALLATION.......................11-11

TAILPIPE - 3.9L/5.2L/5.9L - REMOVAL....11-11

TAILPIPE - 5.9L DIESEL - INSPECTION....11-12

TAILPIPE - 5.9L DIESEL - INSTALLATION . . 11-13

TAILPIPE - 5.9L DIESEL - REMOVAL.....11-12

TAILPIPE - 5.9L HD/8.0L - INSPECTION . . . 11-12

TAILPIPE - 5.9L HD/8.0L -

INSTALLATION.......................11-12

TAILPIPE - 5.9L HD/8.0L - REMOVAL.....11-12

TANK - DESCRIPTION, DIESEL FUEL.....14-82

TANK - DESCRIPTION, FUEL............14-18

TANK - INSTALLATION, FUEL...........14-20

TANK - OPERATION, FUEL..............14-18

TANK - REMOVAL, FUEL...............14-18

TANK CHECK VALVE - DESCRIPTION,

FUEL..............................14-21

TANK CHECK VALVE - INSTALLATION,

FUEL..............................14-23

TANK CHECK VALVE - REMOVAL, FUEL . . . 14-22

TANK MODULE - DESCRIPTION, FUEL....14-82

TANK MODULE - INSTALLATION, FUEL....14-83

TANK MODULE - OPERATION, FUEL......14-82

TANK MODULE - REMOVAL, FUEL.......14-83

TAPE STRIPE - INSTALLATION..........23-89

TAPE STRIPE - REMOVAL..............23-88

TAPPETS - DIAGNOSIS AND TESTING,

HYDRAULIC......................9-36,9-91

TASK MANAGER - DESCRIPTION........25-17

TASK MANAGER - OPERATION..........25-21

TEMP SENSOR - 5.9L - DESCRIPTION,

ENGINE COOLANT.....................7-47

TEMP SENSOR - 5.9L - INSTALLATION,

ENGINE COOLANT.....................7-47

TEMP SENSOR - 5.9L - OPERATION,

ENGINE COOLANT.....................7-47

TEMP SENSOR - 5.9L - REMOVAL,

ENGINE COOLANT.....................7-47

TEMP SENSOR - DESCRIPTION,

AMBIENT..........................8M-12

TEMP SENSOR - INSTALLATION,

AMBIENT..........................8M-13

TEMP SENSOR - OPERATION, AMBIENT . . 8M-12

TEMP SENSOR - REMOVAL, AMBIENT . . . 8M-12

TEMPERATURE GAUGE - DESCRIPTION,

ENGINE

............................8J-18

TEMPERATURE GAUGE - OPERATION,

ENGINE

............................8J-19

TEMPERATURE SENSOR - DESCRIPTION,

BATTERY

...........................8F-27

TEMPERATURE SENSOR - DESCRIPTION,

FUEL

.............................14-104

TEMPERATURE SENSOR - DESCRIPTION,

TRANSMISSION

...............21-218,21-390TEMPERATURE SENSOR - DIAGNOSIS

AND TESTING, AMBIENT..............8M-12

TEMPERATURE SENSOR -

INSTALLATION, BATTERY..............8F-28

TEMPERATURE SENSOR - OPERATION,

BATTERY...........................8F-27

TEMPERATURE SENSOR - OPERATION,

FUEL.............................14-104

TEMPERATURE SENSOR - OPERATION,

TRANSMISSION...............21-218,21-390

TEMPERATURE SENSOR - REMOVAL,

BATTERY...........................8F-27

TEMPORARY - DESCRIPTION, SPARE

TIRE................................22-6

TENSIONERS - 5.9L - DESCRIPTION,

BELT ...............................7-19

TENSIONERS - 5.9L - INSTALLATION,

BELT ...............................7-20

TENSIONERS - 5.9L - OPERATION, BELT . . . 7-19

TENSIONERS - 5.9L - REMOVAL, BELT.....7-19

TENSIONERS - 5.9L DIESEL -

DESCRIPTION, BELT...................7-23

TENSIONERS - 5.9L DIESEL -

INSTALLATION, BELT...................7-23

TENSIONERS - 5.9L DIESEL -

OPERATION, BELT.....................7-23

TENSIONERS - 5.9L DIESEL - REMOVAL,

BELT ...............................7-23

TENSIONERS - 8.0L - DESCRIPTION,

BELT ...............................7-20

TENSIONERS - 8.0L - INSTALLATION,

BELT ...............................7-22

TENSIONERS - 8.0L - OPERATION, BELT.....7-21

TENSIONERS - 8.0L - REMOVAL, BELT.....7-21

TERMINAL - INSTALLATION.........8W-01-13

TERMINAL - REMOVAL.............8W-01-13

TEST - DIAGNOSIS AND TESTING, FUEL

INJECTOR..........................14-99

TEST - DIAGNOSIS AND TESTING, FUEL

PRESSURE LEAK DOWN................14-2

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP AMPERAGE....................14-10

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP CAPACITY......................14-9

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP PRESSURE.....................14-9

TEST - DIAGNOSIS AND TESTING, FUEL

SYSTEM AIR LEAK VACUUM............14-57

TEST - DIAGNOSIS AND TESTING,

HYDRAULIC PRESSURE.........21-270,21-98

TEST - DIAGNOSIS AND TESTING, ROAD . . . 8P-4

TEST - DIAGNOSIS AND TESTING,

VACUUM SUPPLY.....................8P-3

TEST - STANDARD PROCEDURE,

BUILT-IN INDICATOR..................8F-10

TEST - STANDARD PROCEDURE,

HYDROMETER.......................8F-11

TEST - STANDARD PROCEDURE,

IGNITION-OFF DRAW..................8F-13

TEST - STANDARD PROCEDURE, LOAD . . . 8F-12

TEST - STANDARD PROCEDURE,

OPEN-CIRCUIT VOLTAGE...............8F-12

TEST - STANDARD PROCEDURE,

VERIFICATION........................8O-5

TEST MODE - DESCRIPTION, CIRCUIT

ACTUATION

..........................25-2

TEST MODE - DESCRIPTION, STATE

DISPLAY

............................25-1

TETHER - INSTALLATION, CHILD

.........8O-9

TETHER - REMOVAL, CHILD

.............8O-9

THEFT SECURITY - DESCRIPTION,

VEHICLE

............................8Q-1

THEFT SECURITY - OPERATION, VEHICLE

. . 8Q-2

THEFT SECURITY SYSTEM - DIAGNOSIS

AND TESTING, VEHICLE

................8Q-3

THERMOSTAT - 5.9L - DESCRIPTION,

ENGINE COOLANT

.....................7-48

THERMOSTAT - 5.9L - INSTALLATION,

ENGINE COOLANT

.....................7-49

THERMOSTAT - 5.9L - OPERATION,

ENGINE COOLANT

.....................7-48

THERMOSTAT - 5.9L - REMOVAL,

ENGINE COOLANT

.....................7-48

THERMOSTAT - 5.9L DIESEL -

DESCRIPTION, ENGINE COOLANT

.........7-53

THERMOSTAT - 5.9L DIESEL -

INSTALLATION, ENGINE COOLANT

........7-54

BR/BEINDEX 31

Description Group-Page Description Group-Page Description Group-Page