warning DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 2175 of 2255

(2) Reassemble and reinstall the HVAC housing in

the vehicle. (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION/HVAC HOUSING -

ASSEMBLY) (Refer to 24 - HEATING & AIR CON-

DITIONING/DISTRIBUTION/HVAC HOUSING -

INSTALLATION)

NOTE: If the evaporator is replaced, add 60 millili-

ters (2 fluid ounces) of refrigerant oil to the refrig-

erant system.

A/C ORIFICE TUBE

DESCRIPTION

The fixed orifice tube is installed in the liquid line

between the outlet of the condenser and the inlet of

the evaporator. The fixed orifice tube is only serviced

as an integral part of the liquid line.

OPERATION

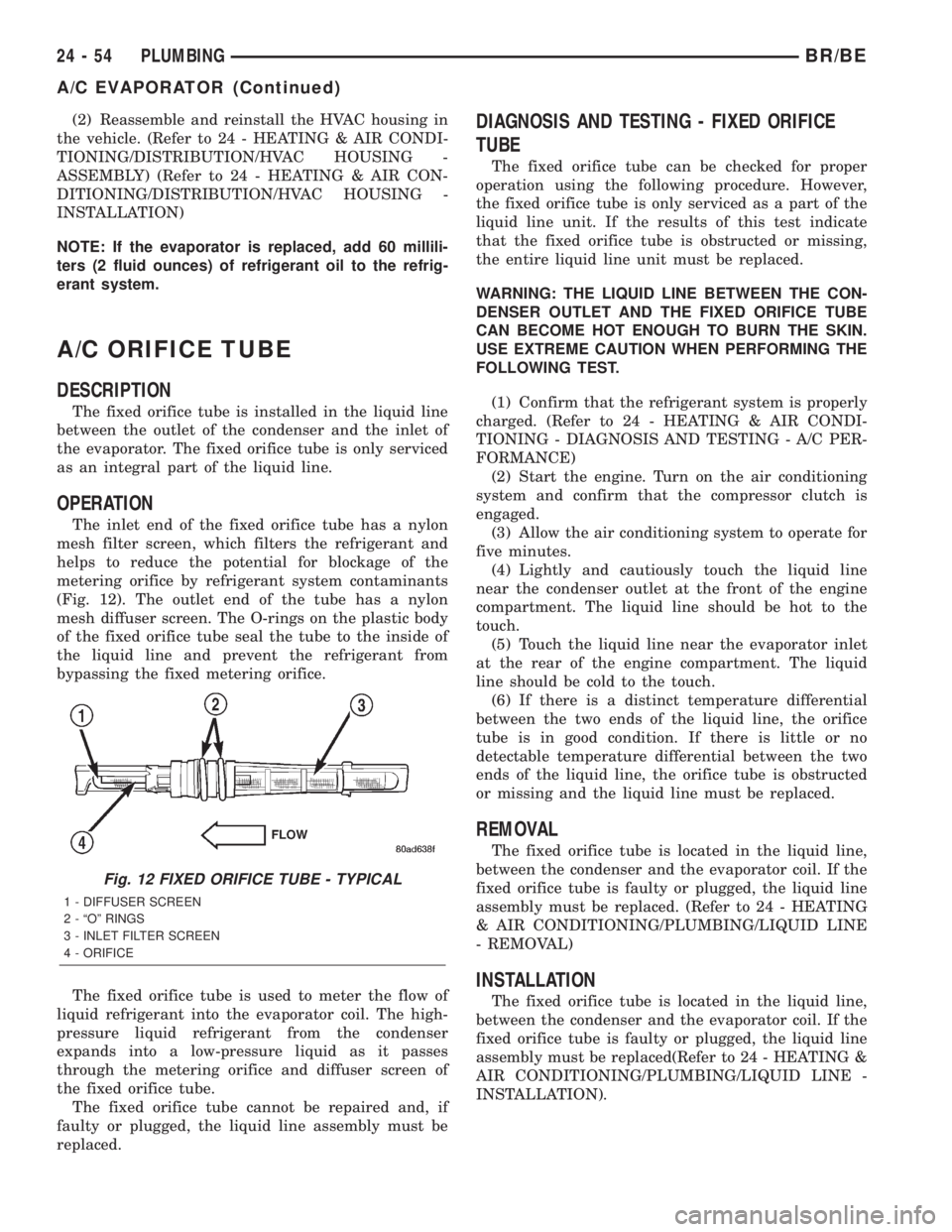

The inlet end of the fixed orifice tube has a nylon

mesh filter screen, which filters the refrigerant and

helps to reduce the potential for blockage of the

metering orifice by refrigerant system contaminants

(Fig. 12). The outlet end of the tube has a nylon

mesh diffuser screen. The O-rings on the plastic body

of the fixed orifice tube seal the tube to the inside of

the liquid line and prevent the refrigerant from

bypassing the fixed metering orifice.

The fixed orifice tube is used to meter the flow of

liquid refrigerant into the evaporator coil. The high-

pressure liquid refrigerant from the condenser

expands into a low-pressure liquid as it passes

through the metering orifice and diffuser screen of

the fixed orifice tube.

The fixed orifice tube cannot be repaired and, if

faulty or plugged, the liquid line assembly must be

replaced.

DIAGNOSIS AND TESTING - FIXED ORIFICE

TUBE

The fixed orifice tube can be checked for proper

operation using the following procedure. However,

the fixed orifice tube is only serviced as a part of the

liquid line unit. If the results of this test indicate

that the fixed orifice tube is obstructed or missing,

the entire liquid line unit must be replaced.

WARNING: THE LIQUID LINE BETWEEN THE CON-

DENSER OUTLET AND THE FIXED ORIFICE TUBE

CAN BECOME HOT ENOUGH TO BURN THE SKIN.

USE EXTREME CAUTION WHEN PERFORMING THE

FOLLOWING TEST.

(1) Confirm that the refrigerant system is properly

charged. (Refer to 24 - HEATING & AIR CONDI-

TIONING - DIAGNOSIS AND TESTING - A/C PER-

FORMANCE)

(2) Start the engine. Turn on the air conditioning

system and confirm that the compressor clutch is

engaged.

(3) Allow the air conditioning system to operate for

five minutes.

(4) Lightly and cautiously touch the liquid line

near the condenser outlet at the front of the engine

compartment. The liquid line should be hot to the

touch.

(5) Touch the liquid line near the evaporator inlet

at the rear of the engine compartment. The liquid

line should be cold to the touch.

(6) If there is a distinct temperature differential

between the two ends of the liquid line, the orifice

tube is in good condition. If there is little or no

detectable temperature differential between the two

ends of the liquid line, the orifice tube is obstructed

or missing and the liquid line must be replaced.

REMOVAL

The fixed orifice tube is located in the liquid line,

between the condenser and the evaporator coil. If the

fixed orifice tube is faulty or plugged, the liquid line

assembly must be replaced. (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/LIQUID LINE

- REMOVAL)

INSTALLATION

The fixed orifice tube is located in the liquid line,

between the condenser and the evaporator coil. If the

fixed orifice tube is faulty or plugged, the liquid line

assembly must be replaced(Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING/LIQUID LINE -

INSTALLATION).

Fig. 12 FIXED ORIFICE TUBE - TYPICAL

1 - DIFFUSER SCREEN

2 - ªOº RINGS

3 - INLET FILTER SCREEN

4 - ORIFICE

24 - 54 PLUMBINGBR/BE

A/C EVAPORATOR (Continued)

Page 2176 of 2255

ACCUMULATOR

DESCRIPTION

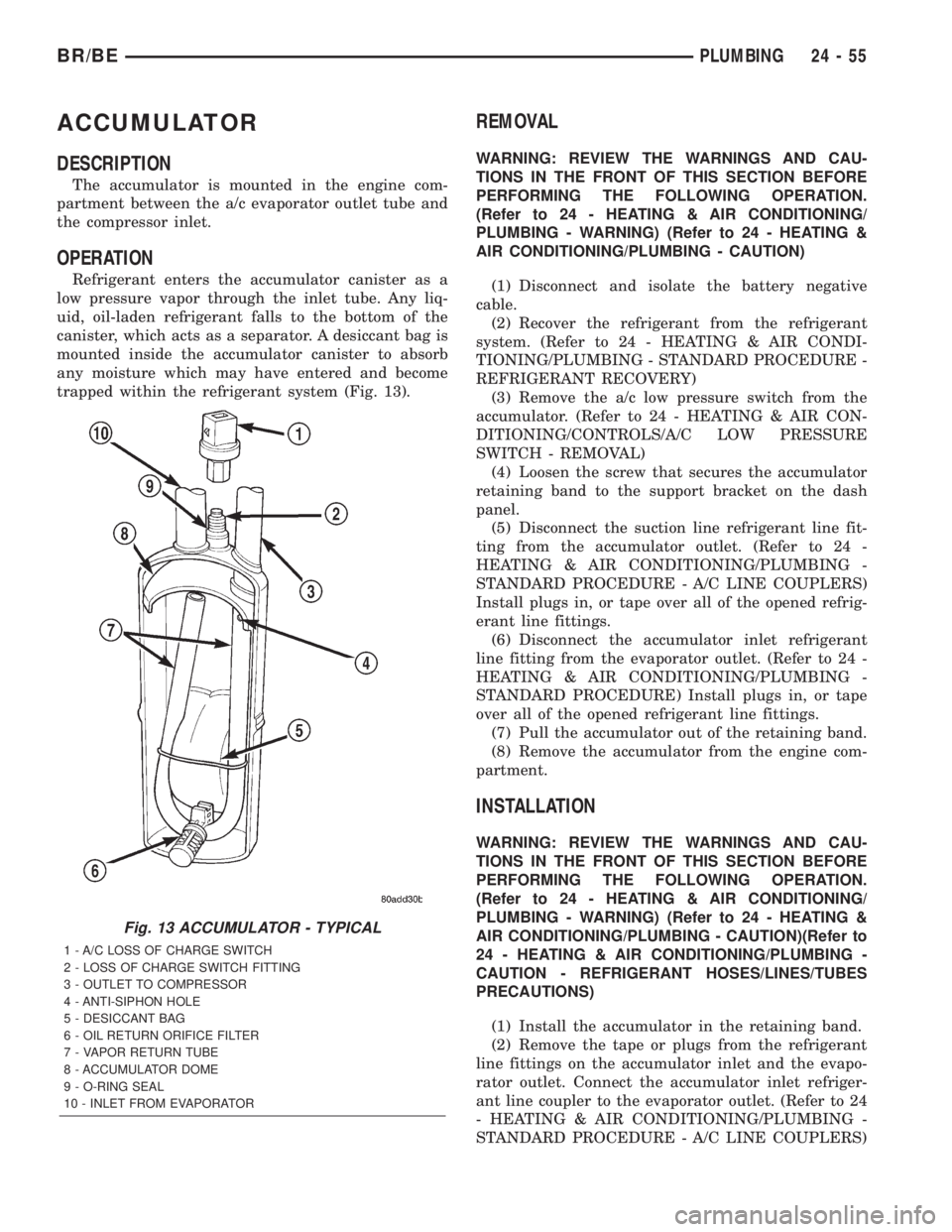

The accumulator is mounted in the engine com-

partment between the a/c evaporator outlet tube and

the compressor inlet.

OPERATION

Refrigerant enters the accumulator canister as a

low pressure vapor through the inlet tube. Any liq-

uid, oil-laden refrigerant falls to the bottom of the

canister, which acts as a separator. A desiccant bag is

mounted inside the accumulator canister to absorb

any moisture which may have entered and become

trapped within the refrigerant system (Fig. 13).

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

(3) Remove the a/c low pressure switch from the

accumulator. (Refer to 24 - HEATING & AIR CON-

DITIONING/CONTROLS/A/C LOW PRESSURE

SWITCH - REMOVAL)

(4) Loosen the screw that secures the accumulator

retaining band to the support bracket on the dash

panel.

(5) Disconnect the suction line refrigerant line fit-

ting from the accumulator outlet. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - A/C LINE COUPLERS)

Install plugs in, or tape over all of the opened refrig-

erant line fittings.

(6) Disconnect the accumulator inlet refrigerant

line fitting from the evaporator outlet. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE) Install plugs in, or tape

over all of the opened refrigerant line fittings.

(7) Pull the accumulator out of the retaining band.

(8) Remove the accumulator from the engine com-

partment.

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)(Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTION - REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS)

(1) Install the accumulator in the retaining band.

(2) Remove the tape or plugs from the refrigerant

line fittings on the accumulator inlet and the evapo-

rator outlet. Connect the accumulator inlet refriger-

ant line coupler to the evaporator outlet. (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - A/C LINE COUPLERS)

Fig. 13 ACCUMULATOR - TYPICAL

1 - A/C LOSS OF CHARGE SWITCH

2 - LOSS OF CHARGE SWITCH FITTING

3 - OUTLET TO COMPRESSOR

4 - ANTI-SIPHON HOLE

5 - DESICCANT BAG

6 - OIL RETURN ORIFICE FILTER

7 - VAPOR RETURN TUBE

8 - ACCUMULATOR DOME

9 - O-RING SEAL

10 - INLET FROM EVAPORATOR

BR/BEPLUMBING 24 - 55

Page 2201 of 2255

MIL Illumination

The PCM Task Manager carries out the illumina-

tion of the MIL. The Task Manager triggers MIL illu-

mination upon test failure, depending on monitor

failure criteria.

The Task Manager Screen shows both a Requested

MIL state and an Actual MIL state. When the MIL is

illuminated upon completion of a test for a third trip,

the Requested MIL state changes to OFF. However,

the MIL remains illuminated until the next key

cycle. (On some vehicles, the MIL will actually turn

OFF during the third key cycle) During the key cycle

for the third good trip, the Requested MIL state is

OFF, while the Actual MILL state is ON. After the

next key cycle, the MIL is not illuminated and both

MIL states read OFF.

Diagnostic Trouble Codes (DTCs)

With OBD II, different DTC faults have different

priorities according to regulations. As a result, the

priorities determine MIL illumination and DTC era-

sure. DTCs are entered according to individual prior-

ity. DTCs with a higher priority overwrite lower

priority DTCs.

Priorities

²Priority 0 ÐNon-emissions related trouble codes

²Priority 1 Ð One trip failure of a two trip fault

for non-fuel system and non-misfire.

²Priority 2 Ð One trip failure of a two trip fault

for fuel system (rich/lean) or misfire.

²Priority3ÐTwotrip failure for a non-fuel sys-

tem and non-misfire or matured one trip comprehen-

sive component fault.

²Priority4ÐTwotrip failure or matured fault

for fuel system (rich/lean) and misfire or one trip cat-

alyst damaging misfire.

Non-emissions related failures have no priority.

One trip failures of two trip faults have low priority.

Two trip failures or matured faults have higher pri-

ority. One and two trip failures of fuel system and

misfire monitor take precedence over non-fuel system

and non-misfire failures.

DTC Self Erasure

With one trip components or systems, the MIL is

illuminated upon test failure and DTCs are stored.

Two trip monitors are components requiring failure

in two consecutive trips for MIL illumination. Upon

failure of the first test, the Task Manager enters a

maturing code. If the component fails the test for a

second time the code matures and a DTC is set.

After three good trips the MIL is extinguished and

the Task Manager automatically switches the trip

counter to a warm-up cycle counter. DTCs are auto-matically erased following 40 warm-up cycles if the

component does not fail again.

For misfire and fuel system monitors, the compo-

nent must pass the test under a Similar Conditions

Window in order to record a good trip. A Similar Con-

ditions Window is when engine RPM is within 375

RPM and load is within 10% of when the fault

occurred.

NOTE: It is important to understand that a compo-

nent does not have to fail under a similar window of

operation to mature. It must pass the test under a

Similar Conditions Window when it failed to record

a Good Trip for DTC erasure for misfire and fuel

system monitors.

DTCs can be erased anytime with a DRB III. Eras-

ing the DTC with the DRB III erases all OBD II

information. The DRB III automatically displays a

warning that erasing the DTC will also erase all

OBD II monitor data. This includes all counter infor-

mation for warm-up cycles, trips and Freeze Frame.

Trip Indicator

TheTripis essential for running monitors and

extinguishing the MIL. In OBD II terms, a trip is a

set of vehicle operating conditions that must be met

for a specific monitor to run. All trips begin with a

key cycle.

Good Trip

The Good Trip counters are as follows:

²Specific Good Trip

²Fuel System Good Trip

²Misfire Good Trip

²Alternate Good Trip (appears as a Global Good

Trip on DRB III)

²Comprehensive Components

²Major Monitor

²Warm-Up Cycles

Specific Good Trip

The term Good Trip has different meanings

depending on the circumstances:

²If the MIL is OFF, a trip is defined as when the

Oxygen Sensor Monitor and the Catalyst Monitor

have been completed in the same drive cycle.

²If the MIL is ON and a DTC was set by the Fuel

Monitor or Misfire Monitor (both continuous moni-

tors), the vehicle must be operated in the Similar

Condition Window for a specified amount of time.

²If the MIL is ON and a DTC was set by a Task

Manager commanded once-per-trip monitor (such as

the Oxygen Sensor Monitor, Catalyst Monitor, Purge

Flow Monitor, Leak Detection Pump Monitor, EGR

Monitor or Oxygen Sensor Heater Monitor), a good

trip is when the monitor is passed on the next start-

up.

25 - 22 EMISSIONS CONTROLBR/BE

EMISSIONS CONTROL (Continued)

Page 2223 of 2255

CENTRAL TIMER MODULE - REMOVAL....8E-5

CERTIFICATION LABEL - DESCRIPTION,

VEHICLE SAFETY...................Intro.-1

CHAIN COVER(S) - INSTALLATION,

TIMING BELT....................9-110,9-54

CHAIN COVER(S) - REMOVAL, TIMING

BELT ..........................9-110,9-53

CHAIN STRETCH - INSPECTION,

MEASURING TIMING..............9-111,9-54

CHANNEL - INSTALLATION, GLASS RUN . . 23-71

CHANNEL - REMOVAL, GLASS RUN......23-71

CHARGE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM...............24-46

CHARGE AIR COOLER AND PLUMBING -

CLEANING..........................11-19

CHARGE AIR COOLER AND PLUMBING -

DESCRIPTION.......................11-18

CHARGE AIR COOLER AND PLUMBING -

INSPECTION........................11-19

CHARGE AIR COOLER AND PLUMBING -

INSTALLATION.......................11-20

CHARGE AIR COOLER AND PLUMBING -

OPERATION.........................11-18

CHARGE AIR COOLER AND PLUMBING -

REMOVAL..........................11-18

CHARGE AIR COOLER SYSTEM - LEAKS

- DIAGNOSIS AND TESTING............11-18

CHARGING - DESCRIPTION.............8F-25

CHARGING - OPERATION..............8F-25

CHARGING - STANDARD PROCEDURE,

BATTERY............................8F-8

CHARGING SYSTEM - DIAGNOSIS AND

TESTING...........................8F-25

CHART, SPECIFICATIONS - TORQUE....5-3,5-37

CHART, SPECIFICATIONS -

TORQUE.............19-21,19-41,19-43,19-9

CHART, SPECIFICATIONS -

TORQUE.....................2-15,2-26,2-8

CHART, SPECIFICATIONS - TORQUE......22-11

CHARTS - DIAGNOSIS AND TESTING,

DIAGNOSIS..................21-102,21-274

CHARTS - DIAGNOSIS AND TESTING,

SMOKE DIAGNOSIS...................9-118

CHASSIS ADAPTER BRACKET -

INSTALLATION, CAB..................13-10

CHASSIS ADAPTER BRACKET -

REMOVAL, CAB......................13-10

CHECK - INSTALLATION...............23-78

CHECK - REMOVAL...................23-78

CHECK - STANDARD PROCEDURE,

COOLANT LEVEL......................7-16

CHECK - STANDARD PROCEDURE, FLUID

LEVEL......................21-157,21-328

CHECK - STANDARD PROCEDURE, OIL

PUMP VOLUME...............21-166,21-336

CHECK CABLE - INSTALLATION.........23-67

CHECK CABLE - REMOVAL.............23-67

CHECK GAUGES INDICATOR -

DESCRIPTION.......................8J-17

CHECK GAUGES INDICATOR -

OPERATION.........................8J-17

CHECK VALVE - DESCRIPTION, FUEL

TANK ..............................14-21

CHECK VALVE - DESCRIPTION, ONE WAY . 25-31

CHECK VALVE - DESCRIPTION, VACUUM . . 24-28

CHECK VALVE - DIAGNOSIS AND

TESTING, ONE-WAY..................25-31

CHECK VALVE - INSTALLATION, FUEL

TANK ..............................14-23

CHECK VALVE - INSTALLATION, ONE

WAY...............................25-31

CHECK VALVE - INSTALLATION, VACUUM

. 24-29

CHECK VALVE - OPERATION, ONE WAY

. . . 25-31

CHECK VALVE - OPERATION, VACUUM

....24-28

CHECK VALVE - REMOVAL, FUEL TANK

. . . 14-22

CHECK VALVE - REMOVAL, ONE WAY

....25-31

CHECK VALVE - REMOVAL, VACUUM

.....24-29

CHECKS - DIAGNOSIS AND TESTING,

PRELIMINARY

.........................7-4

CHILD TETHER - INSTALLATION

..........8O-9

CHILD TETHER - REMOVAL

.............8O-9

CHIME WARNING SYSTEM -

DESCRIPTION

........................8B-1

CHIME WARNING SYSTEM - DIAGNOSIS

AND TESTING

........................8B-2

CHIME WARNING SYSTEM - OPERATION

. . . 8B-1

CHOKE RELAY - DESCRIPTION, RADIO

....8A-7CHOKE RELAY - DIAGNOSIS AND

TESTING, RADIO......................8A-8

CHOKE RELAY - INSTALLATION, RADIO....8A-9

CHOKE RELAY - OPERATION, RADIO......8A-8

CHOKE RELAY - REMOVAL, RADIO.......8A-8

CIGAR LIGHTER OUTLET - DESCRIPTION . 8W-97-2

CIGAR LIGHTER OUTLET - DIAGNOSIS

AND TESTING.....................8W-97-2

CIGAR LIGHTER OUTLET -

INSTALLATION....................8W-97-4

CIGAR LIGHTER OUTLET - OPERATION . 8W-97-2

CIGAR LIGHTER OUTLET - REMOVAL . . 8W-97-3

CIRCUIT ACTUATION TEST MODE -

DESCRIPTION........................25-2

CIRCUIT BREAKER - DESCRIPTION....8W-97-4

CIRCUIT BREAKER - DIAGNOSIS AND

TESTING.........................8W-97-4

CIRCUIT FUNCTIONS - DESCRIPTION . . 8W-01-4

CIRCUIT INFORMATION - DESCRIPTION . 8W-01-4

CIRCUIT SENSE - DESCRIPTION,

IGNITION...........................8E-17

CIRCUIT SENSE - OPERATION, IGNITION . . 8E-19

CIRCUITS - DIESEL - OPERATION,

NON-MONITORED....................25-24

CIRCUITS - GAS ENGINES - OPERATION,

NON-MONITORED....................25-24

CLAMPS - DESCRIPTION, HOSE...........7-4

CLAMPS - OPERATION, HOSE.............7-4

CLASSIFICATION OF LUBRICANTS -

STANDARD PROCEDURE..................0-1

CLEANER ELEMENT - INSTALLATION,

AIR ...............................9-130

CLEANER ELEMENT - REMOVAL, AIR.....9-129

CLEANING AND INSPECTION, OIL

COOLER & LINES....................9-179

CLEANING, BATTERY SYSTEM...........8F-5

CLEANING, CHARGE AIR COOLER AND

PLUMBING.........................11-19

CLEANING, CROSSHEADS..............9-134

CLEANING, CYLINDER HEAD.......9-134,9-77

CLEANING, CYLINDER HEAD

COVER(S)..................9-137,9-23,9-79

CLEANING, ENGINE BLOCK..........9-27,9-85

CLEANING, EXHAUST

MANIFOLD.................9-109,9-185,9-53

CLEANING, FRONT SERVO......21-164,21-334

CLEANING FUEL SYSTEM PARTS -

STANDARD PROCEDURES..............14-61

CLEANING, HYDRAULIC LIFTERS.....9-37,9-92

CLEANING, INTAKE MANIFOLD . 9-107,9-184,9-51

CLEANING, INTAKE/EXHAUST VALVES &

SEATS ..............................9-26

CLEANING, MANUAL - NV4500..........21-20

CLEANING, MANUAL - NV5600..........21-63

CLEANING, OIL PAN.........9-103,9-179,9-46

CLEANING, OIL PRESSURE RELIEF

VALVE .............................9-180

CLEANING, OIL PUMP............9-104,9-181

CLEANING, OIL PUMP..........21-168,21-338

CLEANING, OPERATION.................9-22

CLEANING, OVERDRIVE UNIT....21-179,21-353

CLEANING, OVERRUNNING CLUTCH

CAM/OVERDRIVE PISTON

RETAINER...................21-192,21-364

CLEANING, PISTON & CONNECTING

ROD.......................9-169,9-39,9-94

CLEANING, PUSHRODS................9-134

CLEANING, RADIATOR - 5.9L............7-59

CLEANING, RADIATOR - 5.9L DIESEL......7-64

CLEANING, RADIATOR - 8.0L............7-61

CLEANING, RADIATOR FAN - 5.9L

DIESEL.............................7-43

CLEANING, RADIATOR FAN - 5.9L/8.0L....7-42

CLEANING, REAR CLUTCH

......21-204,21-377

CLEANING, REAR SERVO

.......21-207,21-379

CLEANING, ROCKER ARM / ADJUSTER

ASSY

..............................9-146

CLEANING, SOLID LIFTERS/TAPPETS

.....9-164

CLEANING, SPARK PLUG

...............8I-20

CLEANING, TRANSFER CASE - NV241HD

. 21-476

CLEANING, TRANSFER CASE - NV241LD

. 21-441

CLEANING, TURBOCHARGER

...........11-16

CLEANING, VALVE BODY

........21-244,21-418

CLEANING, WATER PUMP - 5.9L

.........7-68

CLEANING, WATER PUMP - 5.9L DIESEL

. . . 7-72

CLEANING, WATER PUMP - 8.0L

.........7-71

CLEANING, WIPER & WASHER SYSTEM

. . . 8R-6CLEANING/REVERSE FLUSHING -

STANDARD PROCEDURE, COOLING

SYSTEM............................7-17

CLEARANCE - STANDARD PROCEDURE,

CONNECTING ROD BEARING AND

CRANKSHAFT JOURNAL...............9-158

CLEARANCE - STANDARD PROCEDURE,

MAIN BEARING......................9-159

CLEARANCE LAMP - INSTALLATION.......8L-7

CLEARANCE LAMP - REMOVAL..........8L-7

CLOCKSPRING - DESCRIPTION.........8O-10

CLOCKSPRING - INSTALLATION.........8O-13

CLOCKSPRING - OPERATION...........8O-10

CLOCKSPRING - REMOVAL............8O-12

CLOCKSPRING CENTERING - STANDARD

PROCEDURE........................8O-11

CLOSURE PANEL TRIM - INSTALLATION,

REAR.............................23-121

CLOSURE PANEL TRIM - REMOVAL,

REAR.............................23-120

CLUB/QUAD CAB - INSTALLATION.......8O-20

CLUB/QUAD CAB - REMOVAL...........8O-19

CLUSTER - ASSEMBLY, INSTRUMENT....8J-12

CLUSTER - DESCRIPTION, INSTRUMENT . . . 8J-2

CLUSTER - DIAGNOSIS AND TESTING,

INSTRUMENT........................8J-6

CLUSTER - DISASSEMBLY, INSTRUMENT . . 8J-10

CLUSTER - INSTALLATION, INSTRUMENT . 8J-13

CLUSTER - OPERATION, INSTRUMENT.....8J-3

CLUSTER - REMOVAL, INSTRUMENT......8J-10

CLUSTER BEZEL - INSTALLATION.......23-108

CLUSTER BEZEL - REMOVAL..........23-108

CLUTCH - 5.9L DIESEL - DESCRIPTION,

FAN DRIVE VISCOUS...................7-56

CLUTCH - 5.9L DIESEL - OPERATION,

FAN DRIVE VISCOUS...................7-56

CLUTCH - 5.9L/8.0L - DESCRIPTION,

FAN DRIVE VISCOUS...................7-55

CLUTCH - 5.9L/8.0L - OPERATION, FAN

DRIVE VISCOUS......................7-55

CLUTCH - ASSEMBLY, FRONT....21-162,21-333

CLUTCH - ASSEMBLY, REAR.....21-205,21-377

CLUTCH - CLEANING, REAR.....21-204,21-377

CLUTCH - DESCRIPTION.................6-1

CLUTCH - DESCRIPTION, A/C

COMPRESSOR.......................24-11

CLUTCH - DESCRIPTION, FRONT . 21-160,21-330

CLUTCH - DESCRIPTION, OVERDRIVE . . . 21-172,

21-343

CLUTCH - DESCRIPTION, REAR . . 21-203,21-375

CLUTCH - DIAGNOSIS AND TESTING

.......6-2

CLUTCH - DISASSEMBLY, FRONT

. 21-161,21-331

CLUTCH - DISASSEMBLY, REAR

. . 21-204,21-376

CLUTCH - INSPECTION, A/C

COMPRESSOR

.......................24-15

CLUTCH - INSPECTION, FRONT

. . 21-162,21-332

CLUTCH - INSPECTION, REAR

. . . 21-204,21-377

CLUTCH - INSTALLATION, A/C

COMPRESSOR

.......................24-15

CLUTCH - OPERATION

..................6-2

CLUTCH - OPERATION, A/C

COMPRESSOR

.......................24-13

CLUTCH - OPERATION, FRONT

. . . 21-160,21-330

CLUTCH - OPERATION, OVERDRIVE

....21-172,

21-343

CLUTCH - OPERATION, REAR

....21-203,21-375

CLUTCH - REMOVAL, A/C COMPRESSOR

. . 24-13

CLUTCH - SPECIFICATIONS

...............6-7

CLUTCH - WARNING

....................6-2

CLUTCH AND BAND OPERATION -

DIAGNOSIS AND TESTING, AIR

TESTING TRANSMISSION

.......21-100,21-272

CLUTCH BREAK-IN - STANDARD

PROCEDURE, A/C COMPRESSOR

........24-13

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - ASSEMBLY,

OVERRUNNING

...............21-193,21-364

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - CLEANING, OVERRUNNING

. 21-192,

21-364

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - DESCRIPTION,

OVERRUNNING

...............21-192,21-363

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - DISASSEMBLY,

OVERRUNNING

...............21-192,21-364

6 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2231 of 2255

FUEL INJECTION PUMP RELAY -

DESCRIPTION......................14-103

FUEL INJECTION PUMP RELAY -

OPERATION........................14-103

FUEL INJECTION PUMP TIMING -

DIAGNOSIS AND TESTING.............14-70

FUEL INJECTION SYSTEM -

DESCRIPTION, DIESEL................14-91

FUEL INJECTOR - DESCRIPTION....14-52,14-97

FUEL INJECTOR - DIAGNOSIS AND

TESTING...........................14-53

FUEL INJECTOR - INSTALLATION.......14-102

FUEL INJECTOR - OPERATION..........14-98

FUEL INJECTOR - REMOVAL...........14-101

FUEL INJECTOR FIRING ORDER, DIESEL . . 14-62

FUEL INJECTOR TEST - DIAGNOSIS AND

TESTING...........................14-99

FUEL LEVEL SENDING UNIT / SENSOR -

DESCRIPTION...................14-7,14-77

FUEL LEVEL SENDING UNIT / SENSOR -

INSTALLATION........................14-8

FUEL LEVEL SENDING UNIT / SENSOR -

OPERATION.....................14-7,14-77

FUEL LEVEL SENDING UNIT / SENSOR -

REMOVAL...........................14-7

FUEL LINE LEAKS - DIAGNOSIS AND

TESTING, HIGH-PRESSURE.............14-78

FUEL LINES - DESCRIPTION.............14-8

FUEL LINES - DESCRIPTION, HIGH

PRESSURE.........................14-78

FUEL LINES - OPERATION, HIGH

PRESSURE...........................14-78

FUEL PRESSURE LEAK DOWN TEST -

DIAGNOSIS AND TESTING..............14-2

FUEL PUMP - DESCRIPTION.............14-9

FUEL PUMP - OPERATION..............14-9

FUEL PUMP 235 H.P. - DESCRIPTION....14-69

FUEL PUMP 245 H.P. - DESCRIPTION....14-69

FUEL PUMP AMPERAGE TEST -

DIAGNOSIS AND TESTING.............14-10

FUEL PUMP CAPACITY TEST -

DIAGNOSIS AND TESTING..............14-9

FUEL PUMP MODULE - DESCRIPTION....14-12

FUEL PUMP MODULE - INSTALLATION . . . 14-13

FUEL PUMP MODULE - OPERATION......14-13

FUEL PUMP MODULE - REMOVAL.......14-13

FUEL PUMP PRESSURE TEST -

DIAGNOSIS AND TESTING..............14-9

FUEL PUMP RELAY - DESCRIPTION......14-40

FUEL PUMP RELAY - INSTALLATION.....14-40

FUEL PUMP RELAY - OPERATION........14-40

FUEL PUMP RELAY - REMOVAL.........14-40

FUEL PUMP RELAYS - DIAGNOSIS AND

TESTING, ASD........................8I-4

FUEL REQUIREMENTS - DIESEL ENGINE

- DESCRIPTION........................0-3

FUEL REQUIREMENTS - GAS ENGINES -

DESCRIPTION.........................0-2

FUEL SENSOR - DESCRIPTION, WATER

IN ................................14-89

FUEL SENSOR - OPERATION, WATER IN . . 14-89

FUEL SENSOR - REMOVAL, WATER IN....14-89

FUEL SUPPLY RESTRICTIONS -

DIAGNOSIS AND TESTING.............14-60

FUEL SYSTEM - DIAGNOSIS AND

TESTING, AIR IN.....................14-60

FUEL SYSTEM AIR LEAK VACUUM TEST

- DIAGNOSIS AND TESTING............14-57

FUEL SYSTEM PARTS - STANDARD

PROCEDURES, CLEANING..............14-61

FUEL SYSTEM PRESSURE - GAS

ENGINES - SPECIFICATIONS.............14-3

FUEL SYSTEM PRESSURE RELEASE -

STANDARD PROCEDURE................14-3

FUEL SYSTEM PRESSURES, DIESEL

ENGINES...........................14-62

FUEL SYSTEM, SPECIAL TOOLS.....14-35,14-4

FUEL SYSTEM, SPECIAL TOOLS -

DIESEL............................14-63

FUEL TANK - DESCRIPTION............14-18

FUEL TANK - DESCRIPTION, DIESEL.....14-82

FUEL TANK - INSTALLATION

............14-20

FUEL TANK - OPERATION

..............14-18

FUEL TANK - REMOVAL

...............14-18

FUEL TANK CHECK VALVE -

DESCRIPTION

.......................14-21

FUEL TANK CHECK VALVE -

INSTALLATION

.......................14-23FUEL TANK CHECK VALVE - REMOVAL....14-22

FUEL TANK MODULE - DESCRIPTION.....14-82

FUEL TANK MODULE - INSTALLATION....14-83

FUEL TANK MODULE - OPERATION......14-82

FUEL TANK MODULE - REMOVAL........14-83

FUEL TEMPERATURE SENSOR -

DESCRIPTION......................14-104

FUEL TEMPERATURE SENSOR -

OPERATION........................14-104

FUEL TRANSFER PUMP - DESCRIPTION . . 14-83

FUEL TRANSFER PUMP - INSTALLATION . . 14-87

FUEL TRANSFER PUMP - OPERATION....14-83

FUEL TRANSFER PUMP - REMOVAL......14-86

FUEL TRANSFER PUMP PRESSURE -

DIAGNOSIS AND TESTING.............14-84

FUSE - DESCRIPTION, GENERATOR

CARTRIDGE.......................8W-97-4

FUSE - DESCRIPTION, IOD...........8W-97-5

FUSE - INSTALLATION, GENERATOR

CARTRIDGE.......................8W-97-4

FUSE - INSTALLATION, IOD..........8W-97-6

FUSE - OPERATION, GENERATOR

CARTRIDGE.......................8W-97-4

FUSE - OPERATION, IOD.............8W-97-5

FUSE - REMOVAL, GENERATOR

CARTRIDGE.......................8W-97-4

FUSE - REMOVAL, IOD..............8W-97-6

FUSES POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A SHORT TO GROUND ON.........8W-01-9

GAP AND FLUSH MEASUREMENTS,

SPECIFICATIONS - BODY...............23-56

GASKET - DESCRIPTION, CYLINDER

HEAD COVER.........................9-20

GASKET - OPERATION, CYLINDER HEAD

COVER..............................9-21

GASKET FAILURE - DIAGNOSIS AND

TESTING, CYLINDER HEAD..........9-21,9-76

GASKETS AND SEALERS - STANDARD

PROCEDURE, FORM-IN-PLACE . . 9-10,9-122,9-66

GASOLINE ENGINE - INSTALLATION......19-37

GASOLINE ENGINE - NEGATIVE CABLE

INSTALLATION.......................8F-22

GASOLINE ENGINE - NEGATIVE CABLE

REMOVAL..........................8F-22

GASOLINE ENGINE - POSITIVE CABLE

INSTALLATION.......................8F-22

GASOLINE ENGINE - POSITIVE CABLE

REMOVAL..........................8F-21

GASOLINE ENGINE - REMOVAL.........19-35

GAUGE - DESCRIPTION, ENGINE

TEMPERATURE......................8J-18

GAUGE - DESCRIPTION, FUEL...........8J-19

GAUGE - DESCRIPTION, OIL PRESSURE . . 8J-25

GAUGE - DESCRIPTION, VOLTAGE.......8J-33

GAUGE - OPERATION, ENGINE

TEMPERATURE......................8J-19

GAUGE - OPERATION, FUEL............8J-20

GAUGE - OPERATION, OIL PRESSURE....8J-25

GAUGE - OPERATION, VOLTAGE.........8J-33

GAUGE SENDING UNIT - DIAGNOSIS

AND TESTING, FUEL...................14-7

GAUGES - DIAGNOSIS AND TESTING,

PRESSURE..........................22-8

GAUGES INDICATOR - DESCRIPTION,

CHECK.............................8J-17

GAUGES INDICATOR - OPERATION,

CHECK.............................8J-17

GEAR - ADJUSTMENTS................19-18

GEAR - DESCRIPTION.................19-16

GEAR - INSTALLATION................19-18

GEAR - INSTALLATION, PINION

GEAR/RING..........................3-43

GEAR - OPERATION...................19-16

GEAR - REMOVAL....................19-18

GEAR - REMOVAL, PINION GEAR/RING....3-41

GEAR HOUSING - INSTALLATION........9-188

GEAR HOUSING - REMOVAL............9-187

GEAR HOUSING COVER - INSTALLATION . . 9-190

GEAR HOUSING COVER - REMOVAL

.....9-189

GEAR HOUSING PLUG - INSTALLATION,

STEERING

..........................19-30

GEAR HOUSING PLUG - REMOVAL,

STEERING

..........................19-29

GEAR LEAKAGE - DIAGNOSIS AND

TESTING, POWER STEERING

...........19-16

GEAR SELECTOR INDICATOR -

DESCRIPTION

.......................8J-20GEAR SELECTOR INDICATOR -

OPERATION.........................8J-21

GEAR SHIFT LEVER - INSTALLATION.....19-15

GEAR SHIFT LEVER - REMOVAL.........19-14

GEAR, SPECIAL TOOLS - POWER

STEERING..........................19-22

GEAR, SPECIFICATIONS - POWER

STEERING..........................19-21

GEAR/RING GEAR - INSTALLATION,

PINION.............................3-43

GEAR/RING GEAR - REMOVAL, PINION....3-41

GEAR/RING GEAR/TONE RING -

INSTALLATION, PINION.......3-104,3-132,3-75

GEAR/RING GEAR/TONE RING -

REMOVAL, PINION..........3-103,3-131,3-73

GEAR/TONE RING - INSTALLATION,

PINION GEAR/RING..........3-104,3-132,3-75

GEAR/TONE RING - REMOVAL, PINION

GEAR/RING................3-103,3-131,3-73

GEARTRAIN/OUTPUT SHAFT -

ASSEMBLY, PLANETARY........21-199,21-371

GEARTRAIN/OUTPUT SHAFT -

DESCRIPTION, PLANETARY......21-197,21-369

GEARTRAIN/OUTPUT SHAFT -

DISASSEMBLY, PLANETARY.....21-198,21-369

GEARTRAIN/OUTPUT SHAFT -

INSPECTION, PLANETARY.......21-199,21-371

GEARTRAIN/OUTPUT SHAFT -

OPERATION, PLANETARY.......21-197,21-369

GENERAL - WARNINGS.............8W-01-7

GENERATOR - DESCRIPTION...........8F-28

GENERATOR - INSTALLATION............8F-30

GENERATOR - OPERATION.............8F-28

GENERATOR - REMOVAL...............8F-28

GENERATOR CARTRIDGE FUSE -

DESCRIPTION.....................8W-97-4

GENERATOR CARTRIDGE FUSE -

INSTALLATION....................8W-97-4

GENERATOR CARTRIDGE FUSE -

OPERATION.......................8W-97-4

GENERATOR CARTRIDGE FUSE -

REMOVAL........................8W-97-4

GENERATOR RATINGS, SPECIFICATIONS . . 8F-26

GENERATOR/CHARGING SYSTEM -

SPECIFICATIONS, TORQUE.............8F-27

GLASS - DESCRIPTION, STATIONARY....23-145

GLASS - INSTALLATION, BACKLITE VENT . 23-146

GLASS - INSTALLATION, DOOR.........23-70

GLASS - INSTALLATION, SIDE VIEW

MIRROR...........................23-98

GLASS - OPERATION, STATIONARY.....23-145

GLASS - REMOVAL, BACKLITE VENT....23-146

GLASS - REMOVAL, DOOR.............23-70

GLASS - REMOVAL, SIDE VIEW MIRROR . . 23-98

GLASS RUN CHANNEL - INSTALLATION . . . 23-71

GLASS RUN CHANNEL - REMOVAL......23-71

GLASS RUN WEATHERSTRIP -

INSTALLATION, FRONT DOOR..........23-153

GLASS RUN WEATHERSTRIP -

REMOVAL, FRONT DOOR.............23-152

GLOVE BOX - ASSEMBLY.............23-111

GLOVE BOX - DISASSEMBLY..........23-110

GLOVE BOX LAMP AND SWITCH -

INSTALLATION.......................8L-36

GLOVE BOX LAMP AND SWITCH -

REMOVAL

..........................8L-35

GLOVE BOX LATCH STRIKER -

INSTALLATION

......................23-112

GLOVE BOX LATCH STRIKER - REMOVAL

. 23-111

GLOVE BOX OPENING UPPER TRIM -

INSTALLATION

......................23-112

GLOVE BOX OPENING UPPER TRIM -

REMOVAL

.........................23-112

GOVERNOR - DESCRIPTION,

ELECTRONIC

.................21-152,21-322

GOVERNOR - INSTALLATION,

ELECTRONIC

.................21-154,21-324

GOVERNOR - OPERATION, ELECTRONIC

. 21-153,

21-323

GOVERNOR - REMOVAL, ELECTRONIC

. . 21-154,

21-324

GRAB HANDLE - INSTALLATION,

A-PILLAR

..........................23-119

GRAB HANDLE - REMOVAL, A-PILLAR

. . . 23-119

GRADING - STANDARD PROCEDURE,

PISTON

............................9-166

GRID - DESCRIPTION, HEATED MIRROR

. . . 8G-4

14 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2232 of 2255

GRID - DIAGNOSIS AND TESTING,

HEATED MIRROR.....................8G-4

GRID - OPERATION, HEATED MIRROR.....8G-4

GRILLE - INSTALLATION...............23-91

GRILLE - INSTALLATION, COWL.........23-90

GRILLE - REMOVAL..................23-91

GRILLE - REMOVAL, COWL............23-90

GRILLE FRAME - INSTALLATION.........23-92

GRILLE FRAME - REMOVAL............23-91

GRILLES - INSTALLATION, DEMISTER....24-31

GRILLES - REMOVAL, DEMISTER........24-31

GROUND STRAP - INSTALLATION,

CAB-TO-BED........................8A-14

GROUND STRAP - INSTALLATION,

ENGINE-TO-BODY....................8A-13

GROUND STRAP - INSTALLATION,

HEATER CORE.......................8A-14

GROUND STRAP - REMOVAL,

CAB-TO-BED........................8A-13

GROUND STRAP - REMOVAL,

ENGINE-TO-BODY....................8A-12

GROUND STRAP - REMOVAL, HEATER

CORE..............................8A-14

GUIDES AND SPRINGS - STANDARD

PROCEDURE, VALVES..................9-23

HANDLE - INSTALLATION, A-PILLAR

GRAB.............................23-119

HANDLE - INSTALLATION, ASSIST......23-124

HANDLE - INSTALLATION, EXTERIOR.....23-71

HANDLE - INSTALLATION, LATCH.........23-66

HANDLE - INSTALLATION, RELEASE.......5-32

HANDLE - INSTALLATION, SHUTFACE.....23-83

HANDLE - REMOVAL, A-PILLAR GRAB . . . 23-119

HANDLE - REMOVAL, ASSIST..........23-124

HANDLE - REMOVAL, EXTERIOR........23-71

HANDLE - REMOVAL, LATCH...........23-66

HANDLE - REMOVAL, RELEASE..........5-31

HANDLE - REMOVAL, SHUTFACE........23-83

HANDLE ACTUATOR - INSTALLATION,

INSIDE........................23-72,23-80

HANDLE ACTUATOR - REMOVAL, INSIDE . 23-72,

23-80

HANDLE ESCUTCHEON - INSTALLATION . . 23-64

HANDLE ESCUTCHEON - REMOVAL......23-64

HANDLING NON-DEPLOYED AIRBAGS -

STANDARD PROCEDURE...............8O-4

HARNESS - DIAGNOSIS AND TESTING,

WIRING..........................8W-01-7

HAZARD WARNING SYSTEM -

DESCRIPTION, TURN SIGNAL............8L-2

HAZARD WARNING SYSTEM -

DIAGNOSIS AND TESTING, TURN

SIGNAL.............................8L-3

HAZARD WARNING SYSTEM -

OPERATION, TURN SIGNAL.............8L-2

HCU (HYDRAULIC CONTROL UNIT) -

DESCRIPTION........................5-40

HCU (HYDRAULIC CONTROL UNIT) -

INSTALLATION........................5-41

HCU (HYDRAULIC CONTROL UNIT) -

OPERATION..........................5-40

HCU (HYDRAULIC CONTROL UNIT) -

REMOVAL...........................5-41

HD/8.0L - DESCRIPTION, CATALYTIC

CONVERTER - 5.9L....................11-6

HD/8.0L - INSPECTION, CATALYTIC

CONVERTER - 5.9L....................11-6

HD/8.0L - INSPECTION, EXHAUST PIPE -

5.9L................................11-8

HD/8.0L - INSPECTION, TAILPIPE - 5.9L . . 11-12

HD/8.0L - INSTALLATION, CATALYTIC

CONVERTER - 5.9L....................11-7

HD/8.0L - INSTALLATION, EXHAUST PIPE

- 5.9L..............................11-8

HD/8.0L - INSTALLATION, TAILPIPE -

5.9L...............................11-12

HD/8.0L - OPERATION, CATALYTIC

CONVERTER - 5.9L....................11-6

HD/8.0L - REMOVAL, CATALYTIC

CONVERTER - 5.9L....................11-6

HD/8.0L - REMOVAL, EXHAUST PIPE -

5.9L................................11-7

HD/8.0L - REMOVAL, TAILPIPE - 5.9L

....11-12

HEAD - CLEANING, CYLINDER

......9-134,9-77

HEAD - DESCRIPTION, CYLINDER

. . . 9-130,9-20,

9-76

HEAD - INSPECTION, CYLINDER

.....9-134,9-77

HEAD - INSTALLATION, CYLINDER

........9-77HEAD - OPERATION, CYLINDER..........9-21

HEAD - REMOVAL, CYLINDER......9-130,9-76

HEAD COVER GASKET - DESCRIPTION,

CYLINDER...........................9-20

HEAD COVER GASKET - OPERATION,

CYLINDER...........................9-21

HEAD COVER(S) - CLEANING, CYLINDER . 9-137,

9-23,9-79

HEAD COVER(S) - DESCRIPTION,

CYLINDER...........................9-78

HEAD COVER(S) - INSPECTION,

CYLINDER..................9-138,9-23,9-79

HEAD COVER(S) - INSTALLATION,

CYLINDER..................9-138,9-23,9-79

HEAD COVER(S) - REMOVAL, CYLINDER . 9-137,

9-23,9-78

HEAD GASKET FAILURE - DIAGNOSIS

AND TESTING, CYLINDER...........9-21,9-76

HEADLAMP - DESCRIPTION............8L-13

HEADLAMP - DIAGNOSIS AND TESTING . . 8L-14

HEADLAMP - INSTALLATION............8L-16

HEADLAMP - OPERATION..............8L-13

HEADLAMP - REMOVAL...............8L-16

HEADLAMP ALIGNMENT, SPECIAL

TOOLS..............................8L-4

HEADLAMP RELAY - DESCRIPTION . . . 8W-97-13

HEADLAMP RELAY - DESCRIPTION......8L-17

HEADLAMP RELAY - DIAGNOSIS AND

TESTING...........................8L-17

HEADLAMP RELAY - INSTALLATION . . . 8W-97-13

HEADLAMP RELAY - INSTALLATION......8L-18

HEADLAMP RELAY - OPERATION........8L-17

HEADLAMP RELAY - REMOVAL......8W-97-13

HEADLAMP RELAY - REMOVAL.........8L-18

HEADLAMP SWITCH - DESCRIPTION.....8L-18

HEADLAMP SWITCH - DIAGNOSIS AND

TESTING...........................8L-19

HEADLAMP SWITCH - INSTALLATION....8L-20

HEADLAMP SWITCH - OPERATION.......8L-18

HEADLAMP SWITCH - REMOVAL........8L-19

HEADLAMP UNIT - ADJUSTMENTS......8L-21

HEADLAMP UNIT - INSTALLATION.......8L-21

HEADLAMP UNIT - REMOVAL...........8L-20

HEADLINER - INSTALLATION..........23-125

HEADLINER - REMOVAL..............23-125

HEAT SHIELDS - DESCRIPTION.........11-10

HEAT SHIELDS - INSTALLATION.........11-10

HEAT SHIELDS - REMOVAL.............11-10

HEAT/DEFROST DOOR - INSTALLATION . . . 24-38

HEAT/DEFROST DOOR - REMOVAL.......24-37

HEAT/DEFROST DOOR ACTUATOR -

INSTALLATION.......................24-27

HEAT/DEFROST DOOR ACTUATOR -

REMOVAL..........................24-26

HEATED MIRROR GRID - DESCRIPTION . . . 8G-4

HEATED MIRROR GRID - DIAGNOSIS

AND TESTING........................8G-4

HEATED MIRROR GRID - OPERATION.....8G-4

HEATED MIRROR SWITCH - DIAGNOSIS

AND TESTING........................8G-3

HEATED MIRROR SYSTEM -

DESCRIPTION........................8G-1

HEATED MIRROR SYSTEM - DIAGNOSIS

AND TESTING........................8G-2

HEATED MIRROR SYSTEM - OPERATION . . . 8G-2

HEATED SEAT ELEMENT - DESCRIPTION . . 8G-10

HEATED SEAT ELEMENT - INSTALLATION . 8G-13

HEATED SEAT ELEMENT - OPERATION....8G-11

HEATED SEAT ELEMENT - REMOVAL.....8G-13

HEATED SEAT ELEMENT AND SENSOR -

DIAGNOSIS AND TESTING.............8G-11

HEATED SEAT MODULE - DESCRIPTION . . . 8E-20

HEATED SEAT MODULE - DIAGNOSIS

AND TESTING.......................8E-21

HEATED SEAT MODULE - INSTALLATION . . 8E-23

HEATED SEAT MODULE - OPERATION....8E-20

HEATED SEAT MODULE - REMOVAL......8E-23

HEATED SEAT RELAY - DESCRIPTION....8G-14

HEATED SEAT RELAY - DIAGNOSIS AND

TESTING...........................8G-15

HEATED SEAT RELAY - INSTALLATION....8G-16

HEATED SEAT RELAY - OPERATION

......8G-15

HEATED SEAT RELAY - REMOVAL

.......8G-16

HEATED SEAT SWITCH - DIAGNOSIS

AND TESTING

...................8G-17,8G-8

HEATED SEAT SYSTEM - DESCRIPTION

....8G-5

HEATED SEAT SYSTEM - DIAGNOSIS

AND TESTING

........................8G-6HEATED SEAT SYSTEM - OPERATION.....8G-6

HEATER - 5.9L - DESCRIPTION, ENGINE

BLOCK..............................7-44

HEATER - 5.9L - INSTALLATION, ENGINE

BLOCK..............................7-44

HEATER - 5.9L - OPERATION, ENGINE

BLOCK..............................7-44

HEATER - 5.9L - REMOVAL, ENGINE

BLOCK..............................7-44

HEATER - 5.9L DIESEL - DESCRIPTION,

ENGINE BLOCK.......................7-46

HEATER - 5.9L DIESEL - INSTALLATION,

ENGINE BLOCK.......................7-46

HEATER - 5.9L DIESEL - OPERATION,

ENGINE BLOCK.......................7-46

HEATER - 5.9L DIESEL - REMOVAL,

ENGINE BLOCK.......................7-46

HEATER - 8.0L - DESCRIPTION, ENGINE

BLOCK..............................7-45

HEATER - 8.0L - INSTALLATION, ENGINE

BLOCK..............................7-45

HEATER - 8.0L - OPERATION, ENGINE

BLOCK..............................7-45

HEATER - 8.0L - REMOVAL, ENGINE

BLOCK..............................7-45

HEATER - DESCRIPTION, FUEL..........14-66

HEATER - DESCRIPTION, INTAKE AIR....14-104

HEATER - DIAGNOSIS AND TESTING,

FUEL..............................14-66

HEATER - INSTALLATION, INTAKE AIR . . . 14-105

HEATER - OPERATION, FUEL............14-66

HEATER - OPERATION, INTAKE AIR.......14-104

HEATER - REMOVAL, INTAKE AIR.......14-104

HEATER - REMOVAL/INSTALLATION,

FUEL..............................14-67

HEATER AND AIR CONDITIONER -

DESCRIPTION........................24-1

HEATER AND AIR CONDITIONER -

OPERATION..........................24-1

HEATER CONTROL - DIAGNOSIS AND

TESTING, A/C.......................24-18

HEATER CORE - DESCRIPTION..........24-56

HEATER CORE - INSTALLATION.........24-56

HEATER CORE - OPERATION............24-56

HEATER CORE - REMOVAL.............24-56

HEATER CORE GROUND STRAP -

INSTALLATION.......................8A-14

HEATER CORE GROUND STRAP -

REMOVAL..........................8A-14

HEATER PERFORMANCE - DIAGNOSIS

AND TESTING........................24-6

HEATER RELAY - DESCRIPTION, FUEL....14-67

HEATER RELAY - DESCRIPTION, INTAKE

AIR ..............................14-105

HEATER RELAY - DIAGNOSIS AND

TESTING, FUEL......................14-68

HEATER RELAY - INSTALLATION, FUEL . . . 14-69

HEATER RELAY - INSTALLATION, INTAKE

AIR ..............................14-106

HEATER RELAY - OPERATION, FUEL......14-67

HEATER RELAY - OPERATION, INTAKE

AIR ..............................14-105

HEATER RELAY - REMOVAL, FUEL.......14-69

HEATER RELAY - REMOVAL, INTAKE AIR . 14-106

HEATER SWITCH - DESCRIPTION,

DRIVER SEAT........................8G-7

HEATER SWITCH - DESCRIPTION,

PASSENGER SEAT....................8G-16

HEATER SWITCH - INSTALLATION,

DRIVER SEAT.......................8G-10

HEATER SWITCH - INSTALLATION,

PASSENGER SEAT....................8G-19

HEATER SWITCH - OPERATION, DRIVER

SEAT ...............................8G-8

HEATER SWITCH - OPERATION,

PASSENGER SEAT....................8G-17

HEATER SWITCH - REMOVAL, DRIVER

SEAT ...............................8G-9

HEATER SWITCH - REMOVAL,

PASSENGER SEAT....................8G-18

HGT ADJUSTER KNOB - INSTALLATION,

TURNING LOOP

.....................8O-30

HGT ADJUSTER KNOB - REMOVAL,

TURNING LOOP

.....................8O-30

HIGH BEAM INDICATOR - DESCRIPTION

. . 8J-21

HIGH BEAM INDICATOR - DIAGNOSIS

AND TESTING

.......................8J-21

HIGH BEAM INDICATOR - OPERATION

....8J-21

BR/BEINDEX 15

Description Group-Page Description Group-Page Description Group-Page

Page 2233 of 2255

HIGH MOUNTED STOP LAMP -

INSTALLATION, CENTER................8L-6

HIGH MOUNTED STOP LAMP -

REMOVAL, CENTER....................8L-6

HIGH MOUNTED STOP LAMP UNIT -

INSTALLATION, CENTER................8L-6

HIGH MOUNTED STOP LAMP UNIT -

REMOVAL, CENTER....................8L-6

HIGH PRESSURE FUEL LINES -

DESCRIPTION.......................14-78

HIGH PRESSURE FUEL LINES -

OPERATION.........................14-78

HIGH PRESSURE RELIEF VALVE -

DESCRIPTION.......................24-46

HIGH PRESSURE RELIEF VALVE -

OPERATION.........................24-47

HIGH PRESSURE SWITCH -

DESCRIPTION, A/C...................24-20

HIGH PRESSURE SWITCH - DIAGNOSIS

AND TESTING, A/C...................24-20

HIGH PRESSURE SWITCH -

INSTALLATION, A/C...................24-20

HIGH PRESSURE SWITCH - OPERATION,

A/C................................24-20

HIGH PRESSURE SWITCH - REMOVAL,

A/C................................24-20

HIGH SPEEDS - DESCRIPTION, TIRE

PRESSURE..........................22-7

HIGH-PRESSURE FUEL LINE LEAKS -

DIAGNOSIS AND TESTING.............14-78

HINGE - INSTALLATION.....23-100,23-72,23-80

HINGE - REMOVAL........23-100,23-72,23-79

HITCH - INSTALLATION, TRAILER.........13-11

HITCH - REMOVAL, TRAILER...........13-11

HOISTING - STANDARD PROCEDURE.......0-9

HOLDDOWN - DESCRIPTION, BATTERY . . . 8F-17

HOLDDOWN - INSTALLATION, BATTERY . . . 8F-18

HOLDDOWN - OPERATION, BATTERY.....8F-17

HOLDDOWN - REMOVAL, BATTERY......8F-17

HOLDER - INSTALLATION, CUP........23-110

HOLDER - REMOVAL, CUP............23-109

HOLE REPAIR - DESCRIPTION,

THREADED........................Intro.-9

HONING - STANDARD PROCEDURE,

CYLINDER BORE..................9-11,9-65

HOOD - INSTALLATION...............23-101

HOOD - REMOVAL...................23-101

HOOK - INSTALLATION, COAT..........23-125

HOOK - INSTALLATION, FRONT TOW.....13-10

HOOK - REMOVAL, COAT.............23-124

HOOK - REMOVAL, FRONT TOW.........13-10

HORN - DESCRIPTION.............8H-1,8H-2

HORN - DIAGNOSIS AND TESTING.......8H-2

HORN - INSTALLATION.................8H-3

HORN - OPERATION...............8H-1,8H-2

HORN - REMOVAL....................8H-2

HORN RELAY - DESCRIPTION.......8W-97-12

HORN RELAY - DESCRIPTION...........8H-3

HORN RELAY - DIAGNOSIS AND

TESTING........................8W-97-12

HORN RELAY - DIAGNOSIS AND

TESTING............................8H-3

HORN RELAY - INSTALLATION.......8W-97-12

HORN RELAY - INSTALLATION...........8H-4

HORN RELAY - OPERATION.............8H-3

HORN RELAY - REMOVAL..........8W-97-12

HORN RELAY - REMOVAL..............8H-4

HORN SWITCH - DESCRIPTION..........8H-4

HORN SWITCH - DIAGNOSIS AND

TESTING............................8H-5

HORN SWITCH - OPERATION............8H-5

HORN SWITCH - REMOVAL.............8H-5

HOSE CLAMPS - DESCRIPTION...........7-4

HOSE CLAMPS - OPERATION.............7-4

HOSE WITH AIR CONDITIONING -

INSTALLATION, WATER PUMP BYPASS....7-76

HOSE WITH AIR CONDITIONING -

REMOVAL, WATER PUMP BYPASS........7-73

HOSE WITHOUT AIR CONDITIONING -

INSTALLATION, WATER PUMP BYPASS....7-77

HOSE WITHOUT AIR CONDITIONING -

REMOVAL, WATER PUMP BYPASS........7-76

HOSES - PRESSURE - DESCRIPTION

.....19-39

HOSES - PRESSURE - OPERATION

.......19-39

HOSES - RETURN - DESCRIPTION

.......19-39

HOSES - RETURN - OPERATION

.........19-39

HOSES/LINES/TUBES PRECAUTIONS -

CAUTION, REFRIGERANT

..............24-43HOSES/TUBES - DESCRIPTION, WASHER . . 8R-8

HOSES/TUBES - OPERATION, WASHER....8R-8

HOUSING - ASSEMBLY, HVAC...........24-36

HOUSING - DIAGNOSIS AND TESTING,

CLUTCH..............................6-9

HOUSING - DISASSEMBLY, HVAC........24-35

HOUSING - INSTALLATION, CLUTCH......6-11

HOUSING - INSTALLATION, GEAR........9-188

HOUSING - INSTALLATION, HVAC........24-36

HOUSING - REMOVAL, CLUTCH..........6-11

HOUSING - REMOVAL, GEAR...........9-187

HOUSING - REMOVAL, HVAC...........24-34

HOUSING BUSHING - INSTALLATION,

EXTENSION..................21-156,21-326

HOUSING BUSHING - REMOVAL,

EXTENSION..................21-156,21-326

HOUSING BUSHING AND SEAL -

INSTALLATION, EXTENSION.....21-460,21-497

HOUSING BUSHING AND SEAL -

REMOVAL, EXTENSION.........21-460,21-497

HOUSING COVER - INSTALLATION, GEAR . 9-190

HOUSING COVER - REMOVAL, GEAR.....9-189

HOUSING FLUID LEAK - DIAGNOSIS AND

TESTING, CONVERTER.........21-101,21-273

HOUSING INLET BAFFLE -

INSTALLATION, HVAC.................24-36

HOUSING INLET BAFFLE - REMOVAL,

HVAC..............................24-35

HOUSING PLUG - INSTALLATION,

STEERING GEAR.......................19-30

HOUSING PLUG - REMOVAL, STEERING

GEAR..............................19-29

HOUSING SEAL - INSTALLATION,

EXTENSION..................21-156,21-327

HOUSING SEAL - NV4500 -

INSTALLATION, ADAPTER..............21-42

HOUSING SEAL - NV4500 -

INSTALLATION, EXTENSION............21-42

HOUSING SEAL - NV4500 - REMOVAL,

ADAPTER...........................21-42

HOUSING SEAL - NV4500 - REMOVAL,

EXTENSION.........................21-42

HOUSING SEAL - NV5600 -

INSTALLATION, ADAPTER..............21-85

HOUSING SEAL - NV5600 -

INSTALLATION, EXTENSION............21-85

HOUSING SEAL - NV5600 - REMOVAL,

ADAPTER...........................21-85

HOUSING SEAL - NV5600 - REMOVAL,

EXTENSION.........................21-85

HOUSING SEAL - REMOVAL,

EXTENSION..................21-156,21-326

HUB / BEARING - INSTALLATION......2-17,2-9

HUB / BEARING - REMOVAL..........2-16,2-9

HVAC HOUSING - ASSEMBLY...........24-36

HVAC HOUSING - DISASSEMBLY........24-35

HVAC HOUSING - INSTALLATION........24-36

HVAC HOUSING - REMOVAL............24-34

HVAC HOUSING INLET BAFFLE -

INSTALLATION.......................24-36

HVAC HOUSING INLET BAFFLE -

REMOVAL..........................24-35

HVAC SYSTEM AIRFLOW - DESCRIPTION . 24-30

HYDRAULIC BOOSTER - DIAGNOSIS

AND TESTING........................5-18

HYDRAULIC LIFTERS - CLEANING

....9-37,9-92

HYDRAULIC LIFTERS - INSTALLATION

. 9-37,9-92

HYDRAULIC LIFTERS - REMOVAL

....9-37,9-92

HYDRAULIC PRESSURE TEST -

DIAGNOSIS AND TESTING

.......21-270,21-98

HYDRAULIC SCHEMATICS, SCHEMATICS

AND DIAGRAMS

..............21-132,21-302

HYDRAULIC TAPPETS - DIAGNOSIS AND

TESTING

........................9-36,9-91

HYDRAULIC/MECHANICAL -

DESCRIPTION

.........................5-4

HYDRAULIC/MECHANICAL - WARNING

.....5-4

HYDROMETER TEST - STANDARD

PROCEDURE

........................8F-11

HYDROSTATIC LOCK - STANDARD

PROCEDURE

................9-11,9-122,9-66

IDENTIFICATION - DESCRIPTION,

FASTENER

.........................Intro.-6

IDENTIFICATION AND INFORMATION -

DESCRIPTION, SECTION

.............8W-01-6

IDENTIFICATION LAMP - INSTALLATION,

OUTBOARD

.........................8L-29IDENTIFICATION LAMP - REMOVAL,

OUTBOARD.........................8L-28

IDENTIFICATION NUMBER -

DESCRIPTION, VEHICLE..............Intro.-1

IDENTIFICATION PLATE - DESCRIPTION,

EQUIPMENT.......................Intro.-3

IDLE AIR CONTROL MOTOR -

DESCRIPTION.......................14-40

IDLE AIR CONTROL MOTOR -

OPERATION.........................14-40

IGNITION - SPECIFICATIONS, TORQUE.....8I-2

IGNITION CIRCUIT SENSE -

DESCRIPTION.......................8E-17

IGNITION CIRCUIT SENSE - OPERATION . . 8E-19

IGNITION COIL RESISTANCE, 5.9L

ENGINES............................8I-3

IGNITION COIL RESISTANCE, 8.0L V-10

ENGINE..............................8I-4

IGNITION SWITCH - DESCRIPTION.......19-11

IGNITION SWITCH - DESCRIPTION,

KEY-IN..............................19-9

IGNITION SWITCH - DIAGNOSIS AND

TESTING...........................19-11

IGNITION SWITCH - INSTALLATION......19-12

IGNITION SWITCH - OPERATION........19-11

IGNITION SWITCH - REMOVAL..........19-12

IGNITION SWITCH AND KEY LOCK

CYLINDER - DIAGNOSIS AND TESTING....19-9

IGNITION TIMING, SPECIFICATIONS.......8I-4

IGNITION-OFF DRAW TEST - STANDARD

PROCEDURE........................8F-13

INDEPENDENT FRONT SUSPENSION,

SPECIAL TOOLS.......................2-9

INDICATOR - DESCRIPTION, ABS........8J-14

INDICATOR - DESCRIPTION, AIRBAG.....8J-15

INDICATOR - DESCRIPTION, BRAKE/

PARK BRAKE........................8J-15

INDICATOR - DESCRIPTION, CHECK

GAUGES............................8J-17

INDICATOR - DESCRIPTION, CRUISE.....8J-18

INDICATOR - DESCRIPTION, GEAR

SELECTOR..........................8J-20

INDICATOR - DESCRIPTION, HIGH BEAM . . 8J-21

INDICATOR - DESCRIPTION, LOW FUEL . . . 8J-22

INDICATOR - DESCRIPTION, OVERDRIVE

OFF ...............................8J-26

INDICATOR - DESCRIPTION, SEATBELT . . . 8J-27

INDICATOR - DESCRIPTION, SERVICE

REMINDER..........................8J-27

INDICATOR - DESCRIPTION, TRANS

OVERTEMP.........................8J-31

INDICATOR - DESCRIPTION, TURN

SIGNAL............................8J-32

INDICATOR - DESCRIPTION, UPSHIFT....8J-32

INDICATOR - DESCRIPTION, VTSS........8Q-3

INDICATOR - DESCRIPTION, WAIT-TO-

START .............................8J-34

INDICATOR - DESCRIPTION, WASHER

FLUID..............................8J-35

INDICATOR - DESCRIPTION, WATER-IN-

FUEL..............................8J-36

INDICATOR - DIAGNOSIS AND TESTING,

BRAKE.............................8J-16

INDICATOR - DIAGNOSIS AND TESTING,

FOUR-WHEEL DRIVE..................8J-29

INDICATOR - DIAGNOSIS AND TESTING,

HIGH BEAM.........................8J-21

INDICATOR - DIAGNOSIS AND TESTING,

TURN SIGNAL

.......................8J-32

INDICATOR - DIAGNOSIS AND TESTING,

VTSS

...............................8Q-4

INDICATOR - DIAGNOSIS AND TESTING,

WASHER FLUID

......................8J-35

INDICATOR - OPERATION, ABS

..........8J-14

INDICATOR - OPERATION, AIRBAG

.......8J-15

INDICATOR - OPERATION, BRAKE/PARK

BRAKE

.............................8J-15

INDICATOR - OPERATION, CHECK

GAUGES

............................8J-17

INDICATOR - OPERATION, CRUISE

.......8J-18

INDICATOR - OPERATION, GEAR

SELECTOR

..........................8J-21

INDICATOR - OPERATION, HIGH BEAM

....8J-21

INDICATOR - OPERATION, LOW FUEL

.....8J-22

INDICATOR - OPERATION, OVERDRIVE

OFF

...............................8J-26

INDICATOR - OPERATION, SEATBELT

.....8J-27

16 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2240 of 2255

PLATE - INSTALLATION, TRANSFER

CASE SKID.........................13-11

PLATE - REMOVAL, TRANSFER CASE

SKID..............................13-11

PLATE LAMP - INSTALLATION, LICENSE . . 8L-22

PLATE LAMP - REMOVAL, LICENSE......8L-22

PLATE LAMP UNIT - INSTALLATION,

LICENSE...........................8L-22

PLATE LAMP UNIT - REMOVAL, LICENSE . . 8L-22

PLATE, SPECIFICATIONS - FUEL

INJECTION PUMP DATA...............14-77

PLATES - INSTALLATION, EXTERIOR

NAME.............................23-89

PLATES - REMOVAL, EXTERIOR NAME....23-89

PLUG - CLEANING, SPARK.............8I-20

PLUG - DESCRIPTION, SPARK...........8I-16

PLUG - INSTALLATION, SPARK..........8I-20

PLUG - INSTALLATION, STEERING GEAR

HOUSING...........................19-30

PLUG - OPERATION, SPARK............8I-16

PLUG - REMOVAL, SPARK..............8I-19

PLUG - REMOVAL, STEERING GEAR

HOUSING...........................19-29

PLUG CABLE - DESCRIPTION, SPARK.....8I-20

PLUG CABLE - INSTALLATION, SPARK....8I-21

PLUG CABLE - OPERATION, SPARK.......8I-20

PLUG CABLE - REMOVAL, SPARK........8I-21

PLUG CABLE ORDER, 8.0L V-10 ENGINE

- SPARK .............................8I-3

PLUG CABLE RESISTANCE,

SPECIFICATIONS - SPARK...............8I-3

PLUG CABLES - DIAGNOSIS AND

TESTING, SPARK.....................8I-20

PLUG CONDITIONS - DIAGNOSIS AND

TESTING, SPARK.....................8I-17

PLUGS, SPECIFICATIONS - SPARK........8I-3

PLUMBING - CLEANING, CHARGE AIR

COOLER............................11-19

PLUMBING - DESCRIPTION, CHARGE

AIR COOLER........................11-18

PLUMBING - INSPECTION, CHARGE AIR

COOLER............................11-19

PLUMBING - INSTALLATION, CHARGE

AIR COOLER........................11-20

PLUMBING - OPERATION, CHARGE AIR

COOLER............................11-18

PLUMBING - REMOVAL, CHARGE AIR

COOLER............................11-18

PLUMBING - SERVICE CAUTIONS........24-42

PLUMBING - SERVICE WARNINGS.......24-42

POLISHING - DESCRIPTION, WET

SANDING/BUFFING..................23-130

PORT - DESCRIPTION, REFRIGERANT

SYSTEM SERVICE.....................24-1

PORT - OPERATION, REFRIGERANT

SYSTEM SERVICE.....................24-2

POSITION SENSOR - DESCRIPTION,

ACCELERATOR PEDAL.................14-95

POSITION SENSOR - DESCRIPTION,

THROTTLE..........................14-50

POSITION SENSOR - INSTALLATION,

ACCELERATOR PEDAL.................14-97

POSITION SENSOR - OPERATION,

ACCELERATOR PEDAL.................14-95

POSITION SENSOR - OPERATION,

THROTTLE..........................14-50

POSITION SENSOR - REMOVAL,

ACCELERATOR PEDAL.................14-95

POSITION SWITCH - DESCRIPTION,

CLUTCH PEDAL.......................6-17

POSITION SWITCH - DIAGNOSIS AND

TESTING, PARK/NEUTRAL.......21-195,21-367

POSITION SWITCH - INSTALLATION,

PARK/NEUTRAL...............21-195,21-367

POSITION SWITCH - OPERATION,

CLUTCH PEDAL.......................6-17

POSITION SWITCH - REMOVAL,

PARK/NEUTRAL...............21-195,21-367

POSITIVE CABLE INSTALLATION,

GASOLINE ENGINE...................8F-22

POSITIVE CABLE REMOVAL, GASOLINE

ENGINE

............................8F-21

POTENTIAL - STANDARD PROCEDURE,

TESTING OF VOLTAGE

..............8W-01-8

POWER BRAKE BOOSTER -

INSTALLATION

........................5-19

POWER BRAKE BOOSTER - REMOVAL

.....5-19

POWER DISTRIBUTION - DESCRIPTION

. 8W-97-1POWER DISTRIBUTION - OPERATION . . 8W-97-1

POWER DISTRIBUTION CENTER -

DESCRIPTION.....................8W-97-8

POWER DISTRIBUTION CENTER -

INSTALLATION...................8W-97-10

POWER DISTRIBUTION CENTER -

OPERATION.......................8W-97-8

POWER DISTRIBUTION CENTER -

REMOVAL........................8W-97-8

POWER DISTRIBUTION SYSTEMS,

SPECIAL TOOLS...................8W-97-2

POWER GROUNDS - DESCRIPTION......8E-17

POWER LOCK & REMOTE KEYLESS

ENTRY SYSTEM - DIAGNOSIS AND

TESTING............................8N-5

POWER LOCK MOTOR - DESCRIPTION....8N-7

POWER LOCK MOTOR - DIAGNOSIS AND

TESTING............................8N-7

POWER LOCK MOTOR - OPERATION......8N-7

POWER LOCK SWITCH - DESCRIPTION....8N-8

POWER LOCK SWITCH - DIAGNOSIS

AND TESTING........................8N-9

POWER LOCK SWITCH - OPERATION......8N-8

POWER LOCKS - DESCRIPTION..........8N-1

POWER LOCKS - DIAGNOSIS AND

TESTING............................8N-4

POWER LOCKS - OPERATION............8N-3

POWER MIRROR SWITCH -

DESCRIPTION.......................8N-13

POWER MIRROR SWITCH -

INSTALLATION......................8N-14

POWER MIRROR SWITCH - OPERATION . . 8N-13

POWER MIRROR SWITCH - REMOVAL . . . 8N-13

POWER MIRRORS - DESCRIPTION......8N-11

POWER MIRRORS - OPERATION........8N-11

POWER OUTLET - DESCRIPTION.....8W-97-10

POWER OUTLET - DIAGNOSIS AND

TESTING........................8W-97-10

POWER OUTLET - INSTALLATION....8W-97-11

POWER OUTLET - OPERATION.......8W-97-10

POWER OUTLET - REMOVAL........8W-97-11

POWER SEAT SWITCH - DESCRIPTION,

DRIVER............................8N-17

POWER SEAT SWITCH - DESCRIPTION,

PASSENGER........................8N-20

POWER SEAT SWITCH - DIAGNOSIS

AND TESTING, DRIVER................8N-17

POWER SEAT SWITCH - DIAGNOSIS

AND TESTING, PASSENGER............8N-20

POWER SEAT SWITCH - INSTALLATION,

DRIVER............................8N-18

POWER SEAT SWITCH - INSTALLATION,

PASSENGER........................8N-21

POWER SEAT SWITCH - OPERATION,

DRIVER............................8N-17

POWER SEAT SWITCH - OPERATION,

PASSENGER........................8N-20

POWER SEAT SWITCH - REMOVAL,

DRIVER............................8N-18

POWER SEAT SWITCH - REMOVAL,

PASSENGER........................8N-21

POWER SEAT SYSTEM - DESCRIPTION . . . 8N-16

POWER SEAT SYSTEM - DIAGNOSIS

AND TESTING.......................8N-16

POWER SEAT SYSTEM - OPERATION.....8N-16

POWER SEAT TRACK - DESCRIPTION....8N-21

POWER SEAT TRACK - DIAGNOSIS AND

TESTING...........................8N-22

POWER SEAT TRACK - INSTALLATION....8N-22

POWER SEAT TRACK - OPERATION......8N-22

POWER SEAT TRACK - REMOVAL.......8N-22

POWER STEERING FLOW AND

PRESSURE - DIAGNOSIS AND

TESTING............................19-4

POWER STEERING GEAR LEAKAGE -

DIAGNOSIS AND TESTING.............19-16

POWER STEERING GEAR, SPECIAL

TOOLS.............................19-22

POWER STEERING GEAR,

SPECIFICATIONS

.....................19-21

POWER STEERING PUMP - INITIAL

OPERATION - STANDARD PROCEDURE

. . . 19-33

POWER STEERING PUMP, SPECIAL

TOOLS

.............................19-38

POWER STEERING SYSTEM -

DIAGNOSIS AND TESTING

..............19-2

POWER STEERING SYSTEM -

STANDARD PROCEDURE, FLUSHING

.....19-34POWER WINDOW SWITCH -

DESCRIPTION.......................8N-24

POWER WINDOW SWITCH - DIAGNOSIS

AND TESTING.......................8N-24

POWER WINDOW SWITCH -

INSTALLATION......................8N-26

POWER WINDOW SWITCH - OPERATION . . 8N-24

POWER WINDOW SWITCH - REMOVAL . . . 8N-25

POWER WINDOWS - DESCRIPTION......8N-23

POWER WINDOWS - DIAGNOSIS AND

TESTING...........................8N-23

POWER WINDOWS - OPERATION........8N-23

POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A SHORT TO GROUND ON FUSES . 8W-01-9

POWR-LOK - ASSEMBLY, DIFFERENTIAL . . . 3-99

POWR-LOK - DISASSEMBLY,

DIFFERENTIAL........................3-99

POWR-LOK - DIAGNOSIS AND TESTING . . . 3-99

PRELIMINARY CHECKS - DIAGNOSIS

AND TESTING.........................7-4

PRESSURE - DESCRIPTION, HOSES......19-39

PRESSURE - DIAGNOSIS AND TESTING,

BOOST.............................14-93

PRESSURE - DIAGNOSIS AND TESTING,

CYLINDER COMPRESSION...........9-64,9-9

PRESSURE - DIAGNOSIS AND TESTING,

ENGINE OIL................9-101,9-178,9-45

PRESSURE - DIAGNOSIS AND TESTING,

FUEL TRANSFER PUMP...............14-84

PRESSURE - DIAGNOSIS AND TESTING,

POWER STEERING FLOW.................19-4

PRESSURE - DIAGNOSIS AND TESTING,

TURBOCHARGER BOOST...............11-13

PRESSURE - GAS ENGINES -

SPECIFICATIONS, FUEL SYSTEM.........14-3

PRESSURE - OPERATION, HOSES........19-39

PRESSURE BLEEDING - STANDARD

PROCEDURE..........................5-8

PRESSURE CAP - DESCRIPTION,

RADIATOR...........................7-64

PRESSURE CAP - OPERATION,

RADIATOR...........................7-64

PRESSURE FOR HIGH SPEEDS -

DESCRIPTION, TIRE...................22-7

PRESSURE FUEL LINES - DESCRIPTION,

HIGH..............................14-78

PRESSURE FUEL LINES - OPERATION,

HIGH..............................14-78

PRESSURE GAUGE - DESCRIPTION, OIL . . 8J-25

PRESSURE GAUGE - OPERATION, OIL....8J-25

PRESSURE GAUGES - DIAGNOSIS AND

TESTING............................22-8

PRESSURE LEAK DOWN TEST -

DIAGNOSIS AND TESTING, FUEL.........14-2

PRESSURE LEAKAGE - DIAGNOSIS AND

TESTING, CYLINDER COMBUSTION....9-64,9-9

PRESSURE RELEASE - STANDARD

PROCEDURE, FUEL SYSTEM.............14-3

PRESSURE RELIEF VALVE - CLEANING,

OIL................................9-180

PRESSURE RELIEF VALVE -

DESCRIPTION, HIGH

..................24-46

PRESSURE RELIEF VALVE - INSPECTION,

OIL

................................9-180

PRESSURE RELIEF VALVE -

INSTALLATION, OIL

...................9-180

PRESSURE RELIEF VALVE - OPERATION,

HIGH

..............................24-47

PRESSURE RELIEF VALVE - REMOVAL,

OIL

................................9-180

PRESSURE SENSOR/SWITCH -

INSTALLATION, OIL

...................9-181

PRESSURE SENSOR/SWITCH -

REMOVAL, OIL

......................9-181

PRESSURE SWITCH - DESCRIPTION, A/C

HIGH

..............................24-20

PRESSURE SWITCH - DESCRIPTION, A/C

LOW

..............................24-21

PRESSURE SWITCH - DIAGNOSIS AND

TESTING, A/C HIGH

...................24-20

PRESSURE SWITCH - DIAGNOSIS AND

TESTING, A/C LOW

...................24-21

PRESSURE SWITCH - INSTALLATION,

A/C HIGH

...........................24-20

PRESSURE SWITCH - INSTALLATION,

A/C LOW

...........................24-21

BR/BEINDEX 23

Description Group-Page Description Group-Page Description Group-Page

Page 2243 of 2255

REMOTE KEYLESS ENTRY SYSTEM -

DESCRIPTION........................8N-2

REMOTE KEYLESS ENTRY SYSTEM -

DIAGNOSIS AND TESTING, POWER

LOCK...............................8N-5

REMOTE KEYLESS ENTRY SYSTEM -

OPERATION..........................8N-4

REMOTE KEYLESS ENTRY

TRANSMITTER - DESCRIPTION..........8N-7

REMOTE KEYLESS ENTRY

TRANSMITTER - DIAGNOSIS AND

TESTING............................8N-8

REMOTE KEYLESS ENTRY

TRANSMITTER - OPERATION............8N-8

REMOTE KEYLESS ENTRY

TRANSMITTER BATTERIES -

STANDARD PROCEDURE...............8N-8

REMOTE SWITCHES - DESCRIPTION.....8A-14

REMOTE SWITCHES - DIAGNOSIS AND

TESTING...........................8A-15

REMOTE SWITCHES - INSTALLATION.....8A-16

REMOTE SWITCHES - OPERATION.......8A-15

REMOTE SWITCHES - REMOVAL........8A-16

REPAIR - STANDARD PROCEDURE,

ALUMINUM THREAD...........21-114,21-286

REPAIR - STANDARD PROCEDURE, CAM

BORE..............................9-151

REPAIR - STANDARD PROCEDURE,

CYLINDER BORE.....................9-149

REPAIR DAMAGED OR WORN THREADS

- STANDARD PROCEDURE.....9-11,9-122,9-66

REPAIRING LEAKS - STANDARD

PROCEDURE.........................22-9

REQUIREMENTS - DESCRIPTION,

COOLING SYSTEM....................24-1

REQUIREMENTS - DIESEL ENGINE -

DESCRIPTION, FUEL....................0-3

REQUIREMENTS - GAS ENGINES -

DESCRIPTION, FUEL....................0-2

RESERVOIR - DESCRIPTION, VACUUM . . . 8P-14

RESERVOIR - DESCRIPTION, WASHER . . . 8R-10

RESERVOIR - INSTALLATION, FLUID......5-15

RESERVOIR - INSTALLATION, VACUUM . . . 8P-15

RESERVOIR - INSTALLATION, WASHER . . . 8R-11

RESERVOIR - OPERATION, WASHER.....8R-10

RESERVOIR - REMOVAL, FLUID..........5-15

RESERVOIR - REMOVAL, VACUUM.......8P-14

RESERVOIR - REMOVAL, WASHER......8R-10

RESISTANCE, 5.9L ENGINES - IGNITION

COIL................................8I-3

RESISTANCE, 8.0L V-10 ENGINE -

IGNITION COIL........................8I-4

RESISTANCE, SPECIFICATIONS - SPARK

PLUG CABLE.........................8I-3

RESISTOR BLOCK - DESCRIPTION,

BLOWER MOTOR....................24-23

RESISTOR BLOCK - DIAGNOSIS AND

TESTING, BLOWER MOTOR............24-23

RESISTOR BLOCK - INSTALLATION,

BLOWER MOTOR....................24-24

RESISTOR BLOCK - OPERATION,

BLOWER MOTOR....................24-23

RESISTOR BLOCK - REMOVAL, BLOWER

MOTOR............................24-24

RESONATOR - INSTALLATION...........11-13

RESONATOR - REMOVAL..............11-13

RESTRAINTS - DESCRIPTION............8O-1

RESTRAINTS - OPERATION.............8O-2

RESTRAINTS - WARNING...............8O-3

RESTRICTIONS - DIAGNOSIS AND

TESTING, FUEL SUPPLY...............14-60

RETAINER - ASSEMBLY, OVERRUNNING

CLUTCH CAM/OVERDRIVE PISTON.....21-193,

21-364

RETAINER - CLEANING, OVERRUNNING

CLUTCH CAM/OVERDRIVE PISTON

.....21-192,

21-364

RETAINER - DESCRIPTION,

OVERRUNNING CLUTCH CAM/

OVERDRIVE PISTON

...........21-192,21-363

RETAINER - DISASSEMBLY,

OVERRUNNING CLUTCH CAM/

OVERDRIVE PISTON

...........21-192,21-364

RETAINER - INSPECTION,

OVERRUNNING CLUTCH CAM/

OVERDRIVE PISTON

...........21-193,21-364

RETAINER - INSTALLATION,

CRANKSHAFT REAR OIL SEAL

......9-163,9-90RETAINER - OPERATION, OVERRUNNING

CLUTCH CAM/OVERDRIVE PISTON.....21-192,

21-363

RETAINER - REMOVAL, CRANKSHAFT

REAR OIL SEAL..................9-162,9-90

RETRACTOR - INSTALLATION, REAR

SEAT BELT .........................8O-26

RETRACTOR - REMOVAL, REAR SEAT

BELT ..............................8O-26

RETURN - DESCRIPTION, HOSES........19-39

RETURN - DESCRIPTION, SENSOR.......8E-17

RETURN - OPERATION, HOSES..........19-39

REVOLUTIONS PER MILE,

SPECIFICATIONS - TIRE................22-9

RIGHT FRONT FENDER - INSTALLATION . . 23-94

RIGHT FRONT FENDER - REMOVAL......23-94

RING - INSTALLATION, PINION

GEAR/RING GEAR/TONE......3-104,3-132,3-75

RING - REMOVAL, PINION GEAR/RING

GEAR/TONE................3-103,3-131,3-73

RING FITTING - STANDARD

PROCEDURE, PISTON.............9-171,9-39

RINGS - STANDARD PROCEDURE,

FITTING PISTON......................9-95

RISER - INSTALLATION, SEAT..........23-141

RISER - REMOVAL, SEAT.............23-141

RKE TRANSMITTER PROGRAMMING -

STANDARD PROCEDURE...............8N-8

ROAD TEST - DIAGNOSIS AND TESTING . . . 8P-4

ROAD TESTING - DIAGNOSIS AND

TESTING.....................21-269,21-97

ROCKER ARM / ADJUSTER ASSEMBLY -

INSTALLATION........................9-26

ROCKER ARM / ADJUSTER ASSEMBLY -

REMOVAL...........................9-26

ROCKER ARM / ADJUSTER ASSY -

CLEANING..........................9-146

ROCKER ARM / ADJUSTER ASSY -

DESCRIPTION.......................9-145

ROCKER ARM / ADJUSTER ASSY -

INSPECTION........................9-146

ROCKER ARM / ADJUSTER ASSY -

INSTALLATION...................9-148,9-84

ROCKER ARM / ADJUSTER ASSY -

REMOVAL......................9-145,9-84

ROD - CLEANING, PISTON &

CONNECTING...............9-169,9-39,9-94

ROD - DESCRIPTION, PISTON &

CONNECTING...............9-165,9-38,9-93

ROD - INSPECTION, PISTON &

CONNECTING.....................9-39,9-94

ROD - INSTALLATION, PISTON &

CONNECTING.....................9-39,9-94

ROD - REMOVAL, PISTON &

CONNECTING...............9-168,9-38,9-94

ROD BEARING AND CRANKSHAFT

JOURNAL CLEARANCE - STANDARD

PROCEDURE, CONNECTING............9-158

ROD BEARING FITTING - STANDARD

PROCEDURE, CONNECTING.........9-29,9-87

RODS, INSPECTION - CONNECTING......9-169

ROOF JOINT MOLDING - INSTALLATION . . 23-91

ROOF JOINT MOLDING - REMOVAL......23-91

ROTATION - STANDARD PROCEDURE,

TIRE

................................22-2

ROTOR - DIAGNOSIS AND TESTING,

DISTRIBUTOR

.......................8I-14

ROTOR, DIAGNOSIS AND TESTING -

DISC BRAKE

.........................5-20

RUN CHANNEL - INSTALLATION, GLASS

. . 23-71

RUN CHANNEL - REMOVAL, GLASS

......23-71

RUN WEATHERSTRIP - INSTALLATION,

FRONT DOOR GLASS

................23-153

RUN WEATHERSTRIP - REMOVAL,

FRONT DOOR GLASS

................23-152

RUNNING LAMP MODULE -

DESCRIPTION, DAYTIME

................8L-9

RUNNING LAMP MODULE -

INSTALLATION, DAYTIME

...............8L-9

RUNNING LAMP MODULE - OPERATION,

DAYTIME

............................8L-9

RUNNING LAMP MODULE - REMOVAL,

DAYTIME

............................8L-9

RUNOUT - DIAGNOSIS AND TESTING,

TIRE AND WHEEL

.....................22-1

RWAL SERVICE PRECAUTIONS -

STANDARD PROCEDURE

................5-36SAFETY CERTIFICATION LABEL -

DESCRIPTION, VEHICLE..............Intro.-1

SAFETY LATCH - INSTALLATION........23-104

SAFETY LATCH - REMOVAL...........23-104

SAFETY PRECAUTIONS AND WARNINGS,

WARNING...........................23-1

SANDING/BUFFING & POLISHING -

DESCRIPTION, WET.................23-130

SCHEDULES - DESCRIPTION,

MAINTENANCE........................0-7

SCHEMATICS AND DIAGRAMS -

HYDRAULIC SCHEMATICS.......21-132,21-302

SCHEMATICS, SCHEMATICS AND

DIAGRAMS - HYDRAULIC.......21-132,21-302

SEAL - DIAGNOSIS AND TESTING,

RADIATOR CAP-TO-FILLER NECK.........7-65

SEAL - FRONT - DESCRIPTION,

CRANKSHAFT OIL.....................9-32

SEAL - FRONT - INSTALLATION,

CRANKSHAFT OIL................9-160,9-32

SEAL - FRONT - OPERATION,

CRANKSHAFT OIL.....................9-32

SEAL - FRONT - REMOVAL,

CRANKSHAFT OIL................9-160,9-32

SEAL - FRONT COVER INSTALLED -

INSTALLATION, FRONT OIL..............9-89

SEAL - FRONT COVER INSTALLED -

REMOVAL, FRONT OIL.................9-89

SEAL - FRONT COVER REMOVED -

INSTALLATION, FRONT OIL..............9-90

SEAL - FRONT COVER REMOVED -