power systems DODGE RAM 2002 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 669 of 2255

DESCRIPTION - SECTION IDENTIFICATION AND

INFORMATION

The wiring diagrams are grouped into individual

sections. If a component is most likely found in a par-

ticular group, it will be shown complete (all wires,

connectors, and pins) within that group. For exam-

ple, the Auto Shutdown Relay is most likely to be

found in Group 30, so it is shown there complete. It

can, however, be shown partially in another group if

it contains some associated wiring.

Splice diagrams in Section 8W-70 show the entire

splice and provide references to other sections the

splices serves. Section 8W-70 only contains splice dia-

grams that are not shown in their entirety some-

where else in the wiring diagrams.

Section 8W-80 shows each connector and the cir-

cuits involved with that connector. The connectors

are identified using the name/number on the dia-

gram pages.

WIRING SECTION CHART

GROUP TOPIC

8W-01 thru

8W-09General information and Diagram

Overview

8W-10 thru

8W-19Main Sources of Power and

Vehicle Grounding

8W-20 thru

8W-29Starting and Charging

8W-30 thru

8W-39Powertrain/Drivetrain Systems

GROUP TOPIC

8W-40 thru

8W-49Body Electrical items and A/C

8W-50 thru

8W-59Exterior Lighting, Wipers and

Trailer Tow

8W-60 thru

8W-69Power Accessories

8W-70 Splice Information

8W-80 Connector Pin Outs

8W-91 Connector, Ground and Splice

Locations

DESCRIPTION - CONNECTOR, GROUND AND

SPLICE INFORMATION

CAUTION: Not all connectors are serviced. Some

connectors are serviced only with a harness. A typ-

ical example might be the Supplemental Restraint

System connectors. Always check parts availability

before attempting a repair.

IDENTIFICATION

In-line connectors are identified by a number, as

follows:

²In-line connectors located in the engine compart-

ment are C100 series numbers

²In-line connectors located in the Instrument

Panel area are C200 series numbers.

²In-line connectors located in the body are C300

series numbers.

²Jumper harness connectors are C400 series

numbers.

²Grounds and ground connectors are identified

with a ªGº and follow the same series numbering as

the in-line connectors.

²Splices are identified with an ªSº and follow the

same series numbering as the in-line connectors.

²Component connectors are identified by the com-

ponent name instead of a number. Multiple connec-

tors on a component use a C1, C2, etc. identifier.

LOCATIONS

Section 8W-91 contains connector/ground/splice

location illustrations. The illustrations contain the

connector name (or number)/ground number/splice

number and component identification. Connector/

ground/splice location charts in section 8W-91 refer-

ence the figure numbers of the illustrations.

The abbreviation T/O is used in the component

location section to indicate a point in which the wir-

ing harness branches out to a component. The abbre-

viation N/S means Not Shown in the illustrations

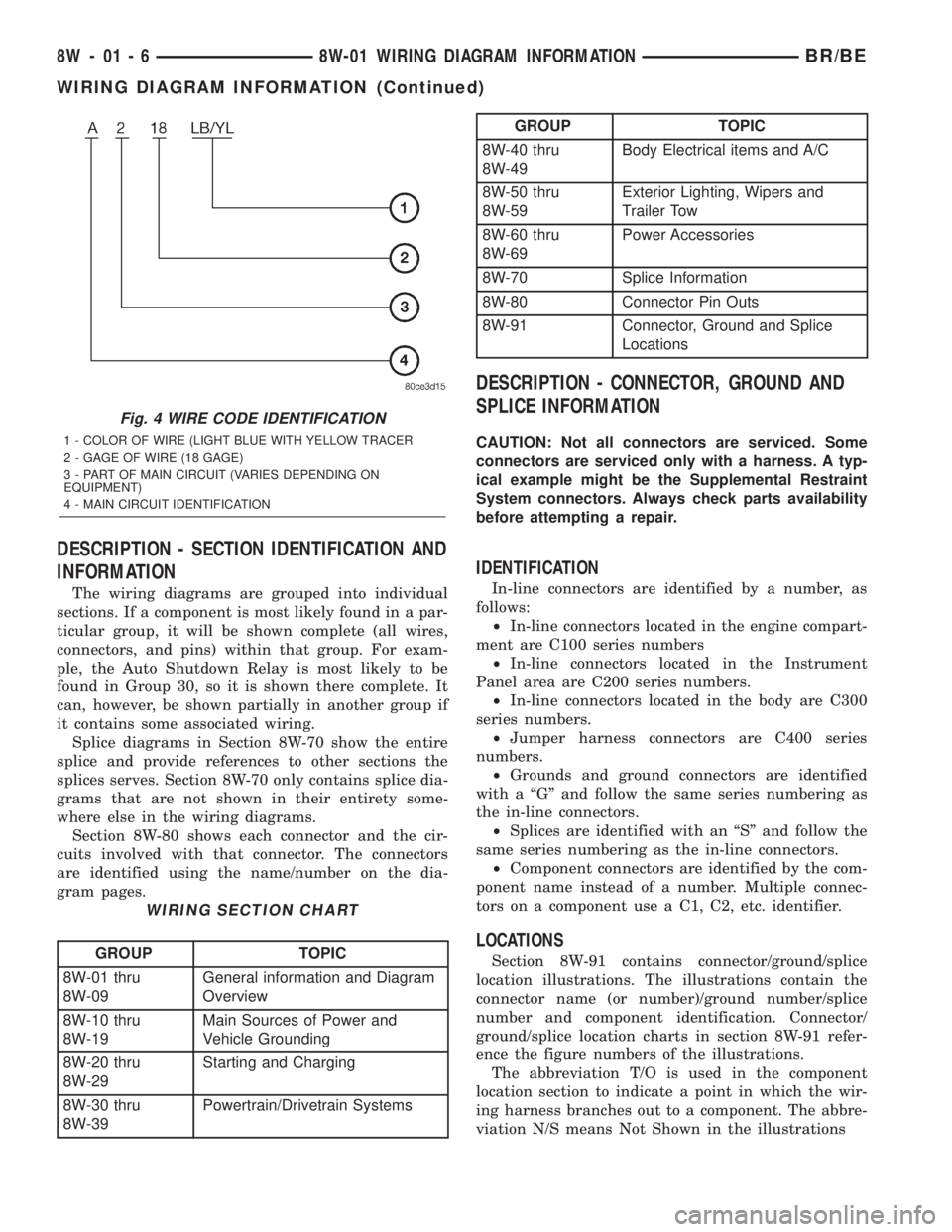

Fig. 4 WIRE CODE IDENTIFICATION

1 - COLOR OF WIRE (LIGHT BLUE WITH YELLOW TRACER

2 - GAGE OF WIRE (18 GAGE)

3 - PART OF MAIN CIRCUIT (VARIES DEPENDING ON

EQUIPMENT)

4 - MAIN CIRCUIT IDENTIFICATION

8W - 01 - 6 8W-01 WIRING DIAGRAM INFORMATIONBR/BE

WIRING DIAGRAM INFORMATION (Continued)

Page 1060 of 2255

8W-97 POWER DISTRIBUTION

TABLE OF CONTENTS

page page

POWER DISTRIBUTION

DESCRIPTION..........................1

OPERATION............................1

SPECIAL TOOLS

POWER DISTRIBUTION SYSTEMS.........2

CIGAR LIGHTER OUTLET

DESCRIPTION..........................2

OPERATION............................2

DIAGNOSIS AND TESTING - CIGAR LIGHTER

OUTLET.............................2

REMOVAL.............................3

INSTALLATION..........................4

CIRCUIT BREAKER

DESCRIPTION..........................4

DIAGNOSIS AND TESTING - CIRCUIT

BREAKER............................4

GENERATOR CARTRIDGE FUSE

DESCRIPTION..........................4

OPERATION............................4

REMOVAL.............................4

INSTALLATION..........................4

IOD FUSE

DESCRIPTION..........................5

OPERATION............................5

REMOVAL.............................6

INSTALLATION..........................6

JUNCTION BLOCK

DESCRIPTION..........................6

OPERATION............................7

DIAGNOSIS AND TESTING - JUNCTION

BLOCK..............................7

REMOVAL.............................7

INSTALLATION..........................8POWER DISTRIBUTION CENTER

DESCRIPTION..........................8

OPERATION............................8

REMOVAL.............................8

INSTALLATION.........................10

POWER OUTLET

DESCRIPTION.........................10

OPERATION...........................10

DIAGNOSIS AND TESTING - POWER OUTLET . 10

REMOVAL.............................11

INSTALLATION.........................11

HORN RELAY

DESCRIPTION.........................12

DIAGNOSIS AND TESTING - HORN RELAY . . . 12

REMOVAL.............................12

INSTALLATION.........................12

HEADLAMP RELAY

DESCRIPTION.........................13

REMOVAL.............................13

INSTALLATION.........................13

MICRO-RELAY

DESCRIPTION.........................13

OPERATION...........................14

DIAGNOSIS AND TESTING - MICRO-RELAY . . 14

REMOVAL.............................14

INSTALLATION.........................14

RELAY

DESCRIPTION.........................14

OPERATION...........................14

DIAGNOSIS AND TESTING - RELAY.........15

REMOVAL.............................15

INSTALLATION.........................15

POWER DISTRIBUTION

DESCRIPTION

This group covers the various standard and

optional power distribution components used on this

model. The power distribution system for this vehicle

consists of the following components:

²Power Distribution Center (PDC)

²Junction Block (JB).

The power distribution system also incorporates

various types of circuit control and protection fea-

tures, including:

²Automatic resetting circuit breakers

²Blade-type fuses²Cartridge fuses

²Circuit splice blocks

²Flashers

²Relays.

Following are general descriptions of the major

components in the power distribution system. See the

owner's manual in the vehicle glove box for more

information on the features and use of all of the

power distribution system components. Refer toWir-

ing Diagramsfor complete circuit diagrams for the

various power distribution system components.

OPERATION

The power distribution system for this vehicle is

designed to provide safe, reliable, and centralized dis-

BR/BE8W-97 POWER DISTRIBUTION 8W - 97 - 1

Page 1061 of 2255

tribution points for the electrical current required to

operate all of the many standard and optional facto-

ry-installed electrical and electronic powertrain,

chassis, safety, security, comfort and convenience sys-

tems. At the same time, the power distribution sys-

tem was designed to provide ready access to these

electrical distribution points for the vehicle techni-

cian to use when conducting diagnosis and repair of

faulty circuits. The power distribution system can

also prove useful for the sourcing of additional elec-

trical circuits that may be required to provide the

electrical current needed to operate many accessories

that the vehicle owner may choose to have installed

in the aftermarket.

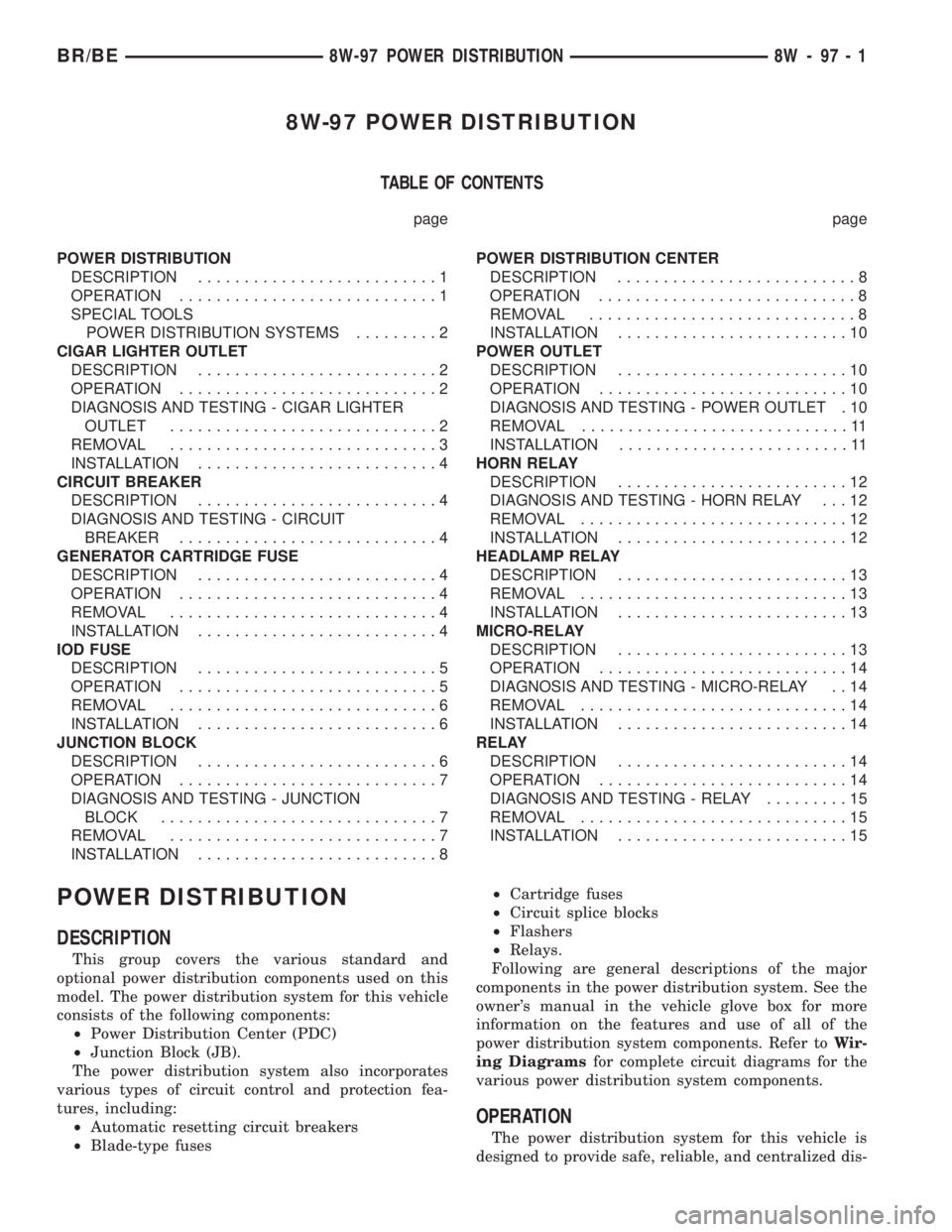

SPECIAL TOOLS

POWER DISTRIBUTION SYSTEMS

CIGAR LIGHTER OUTLET

DESCRIPTION

A cigar lighter is standard equipment on this

model. The cigar lighter is installed in the instru-

ment panel next to the ash receiver, which is located

near the center of the instrument panel, below the

radio. The cigar lighter base is secured by a snap fit

within the instrument panel.

The cigar lighter knob and heating element unit,

and the cigar lighter receptacle unit are available for

service. These components cannot be repaired and, if

faulty or damaged, they must be replaced.

OPERATION

The cigar lighter consists of two major components:

a knob and heating element unit, and the cigar

lighter base or receptacle shell. The receptacle shell

is connected to ground, and an insulated contact in

the bottom of the shell is connected to battery cur-

rent. The cigar lighter receives battery voltage from afuse in the junction block only when the ignition

switch is in the Accessory or On positions.

The knob and heating element are encased within

a spring-loaded housing, which also features a sliding

protective heat shield. When the knob and heating

element are inserted in the receptacle shell, the heat-

ing element resistor coil is grounded through its

housing to the receptacle shell. If the cigar lighter

knob is pushed inward, the heat shield slides up

toward the knob exposing the heating element, and

the heating element extends from the housing toward

the insulated contact in the bottom of the receptacle

shell.

Two small spring-clip retainers are located on

either side of the insulated contact inside the bottom

of the receptacle shell. These clips engage and hold

the heating element against the insulated contact

long enough for the resistor coil to heat up. When the

heating element is engaged with the contact, battery

current can flow through the resistor coil to ground,

causing the resistor coil to heat.

When the resistor coil becomes sufficiently heated,

excess heat radiates from the heating element caus-

ing the spring-clips to expand. Once the spring-clips

expand far enough to release the heating element,

the spring-loaded housing forces the knob and heat-

ing element to pop back outward to their relaxed

position. When the cigar lighter knob and element

are pulled out of the receptacle shell, the protective

heat shield slides downward on the housing so that

the heating element is recessed and shielded around

its circumference for safety.

DIAGNOSIS AND TESTING - CIGAR LIGHTER

OUTLET

For complete circuit diagrams, refer toCigar

Lighterin Wiring Diagrams.

WARNING: REFER TO THE PASSIVE RESTRAINT

SECTION OF THE SERVICE MANUAL BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Check the fused ignition switch output (run/ac-

cessory) fuse in the junction block. If OK, go to Step

2. If not OK, repair the shorted circuit or component

as required and replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/accessory) fuse in the junction block. If

OK, go to Step 3. If not OK, repair the open fused

Terminal Pick Kit 6680

8W - 97 - 2 8W-97 POWER DISTRIBUTIONBR/BE

POWER DISTRIBUTION (Continued)

Page 1065 of 2255

If a vehicle will be stored for more than about thirty

days, the battery negative cable should be discon-

nected to eliminate normal IOD; and, the battery

should be tested and recharged at regular intervals

during the vehicle storage period to prevent the bat-

tery from becoming discharged or damaged. Refer to

theBatterysection of the service manual for the

location of additional service information covering

the battery.

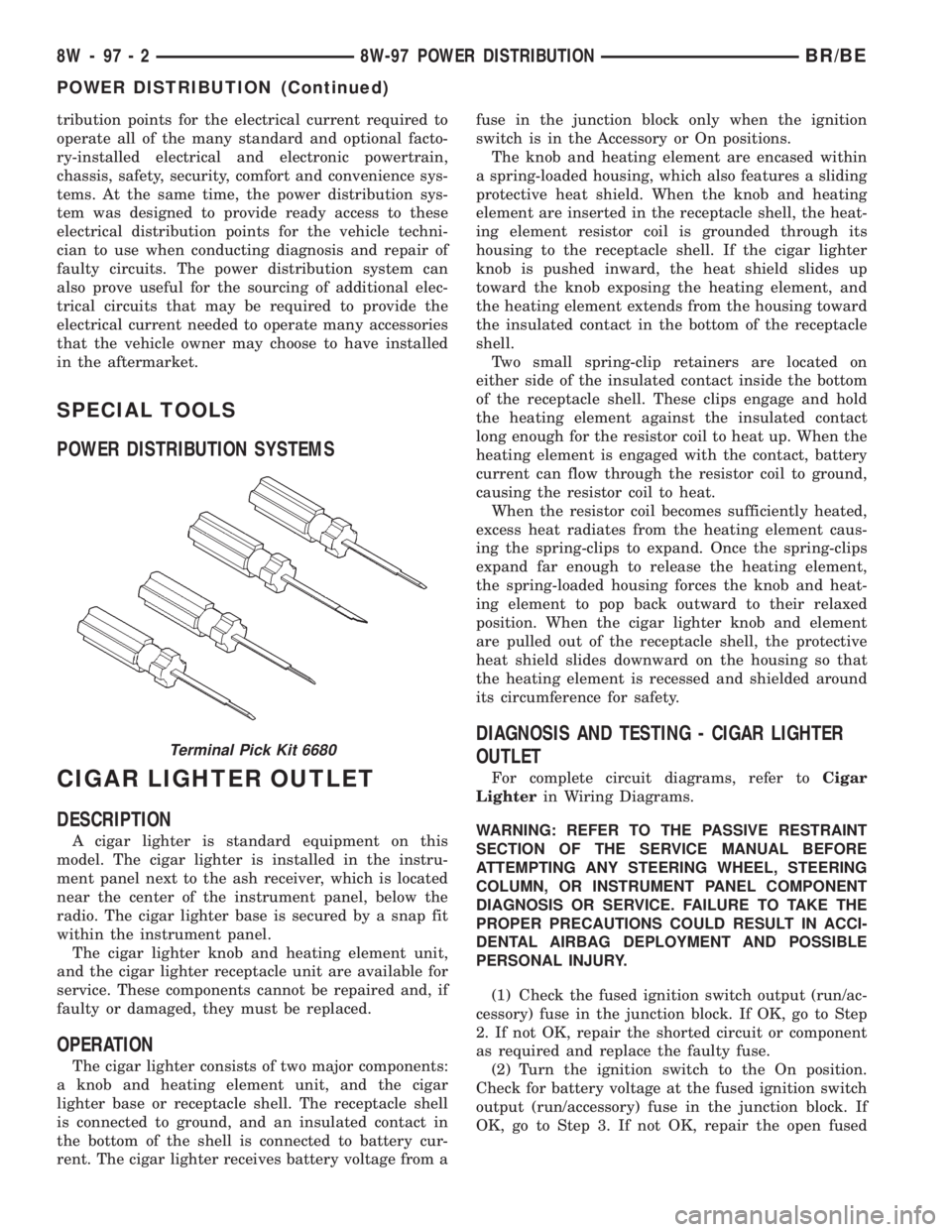

REMOVAL

The Ignition-Off Draw (IOD) fuse is disconnected

from Junction Block (JB) fuse cavity 12 when the

vehicle is shipped from the assembly plant. Dealer

personnel must reconnect the IOD fuse when the

vehicle is being prepared for delivery in order to

restore full electrical system operation.

(1) Turn the ignition switch to the Off position.

(2) Remove the fuse access panel by unsnapping it

from the left outboard end of the instrument panel.

(3) Grasp the upper and lower tabs of the IOD

fuse holder unit in fuse cavity 12 (Fig. 4) of the JB

between the thumb and forefinger and pull the unit

firmly outward.

(4) Install the fuse access panel by snapping it

onto the left outboard end of the instrument panel.

INSTALLATION

The Ignition-Off Draw (IOD) fuse is disconnected

from Junction Block (JB) fuse cavity 12 when the

vehicle is shipped from the assembly plant. Dealer

personnel must reconnect the IOD fuse when the

vehicle is being prepared for delivery in order to

restore full electrical system operation.

(1) Turn the ignition switch to the Off position.

(2) To install the IOD fuse, use a thumb to press

the IOD fuse holder unit in fuse cavity 12 firmly into

the JB.

(3) Install the fuse access panel by snapping it

onto the left outboard end of the instrument panel.

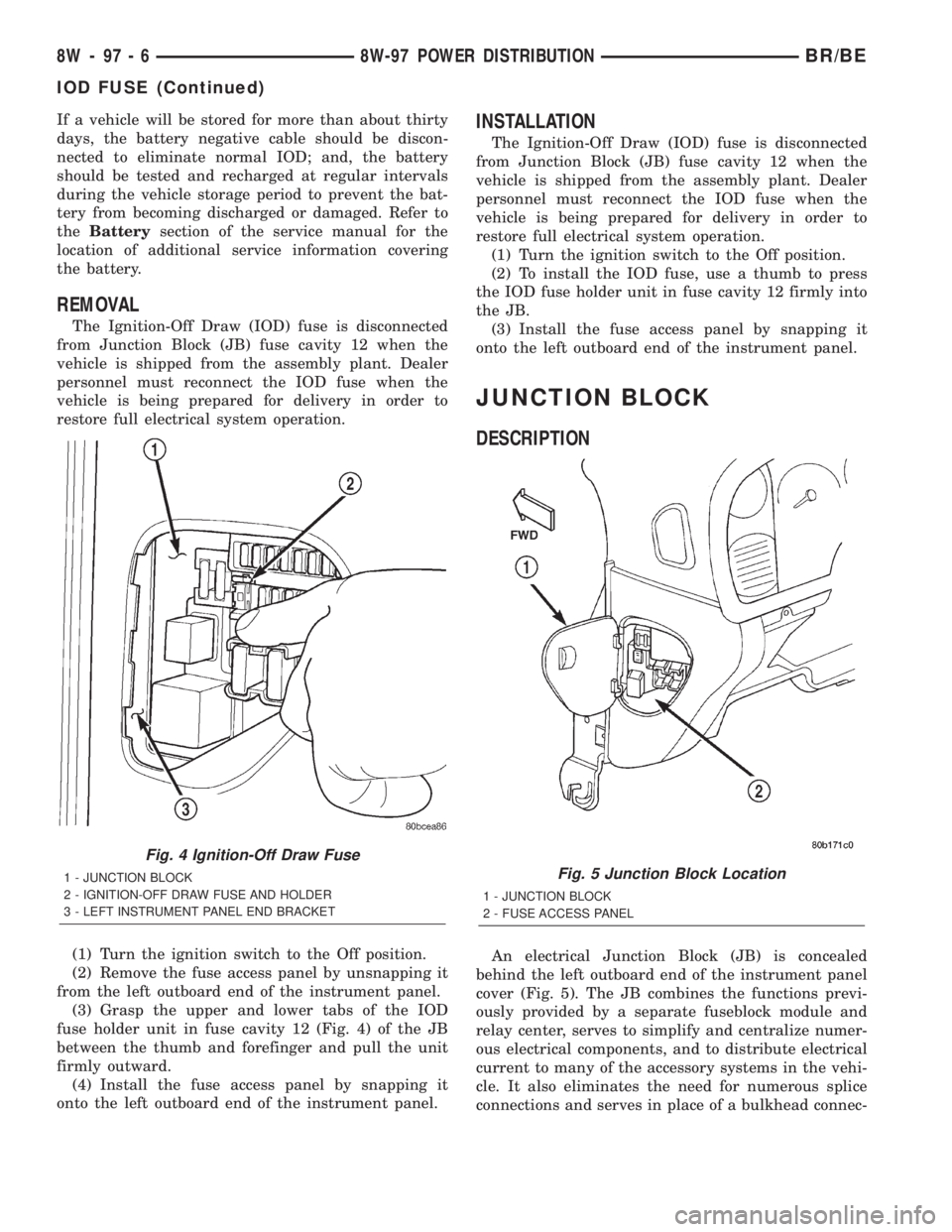

JUNCTION BLOCK

DESCRIPTION

An electrical Junction Block (JB) is concealed

behind the left outboard end of the instrument panel

cover (Fig. 5). The JB combines the functions previ-

ously provided by a separate fuseblock module and

relay center, serves to simplify and centralize numer-

ous electrical components, and to distribute electrical

current to many of the accessory systems in the vehi-

cle. It also eliminates the need for numerous splice

connections and serves in place of a bulkhead connec-

Fig. 4 Ignition-Off Draw Fuse

1 - JUNCTION BLOCK

2 - IGNITION-OFF DRAW FUSE AND HOLDER

3 - LEFT INSTRUMENT PANEL END BRACKETFig. 5 Junction Block Location

1 - JUNCTION BLOCK

2 - FUSE ACCESS PANEL

8W - 97 - 6 8W-97 POWER DISTRIBUTIONBR/BE

IOD FUSE (Continued)

Page 1281 of 2255

(4) Connect the DRBIIItto the pressure trans-

ducer following the instructions supplied with the

DRB IIIt.

(5) Enter DRBIIItinto pressure reading mode and

test drive vehicle.

(6) The turbocharger boost pressure must be

between 110 - 138 kpa (16 - 20 psi.). If pressure read-

ings are lower than 110 kpa (16 psi.) inspect for the

following:

²Restricted air inlet system

²Leak in the charge air cooler system (Refer to 11

- EXHAUST SYSTEM/TURBOCHARGER SYSTEM/

CHARGE AIR COOLER AND PLUMBING - DIAG-

NOSIS AND TESTING)

²Turbocharger wastegate broken or misadjusted

²Turbocharger damaged (Refer to 11 - EXHAUST

SYSTEM/TURBOCHARGER SYSTEM/TURBO-

CHARGER - INSPECTION)

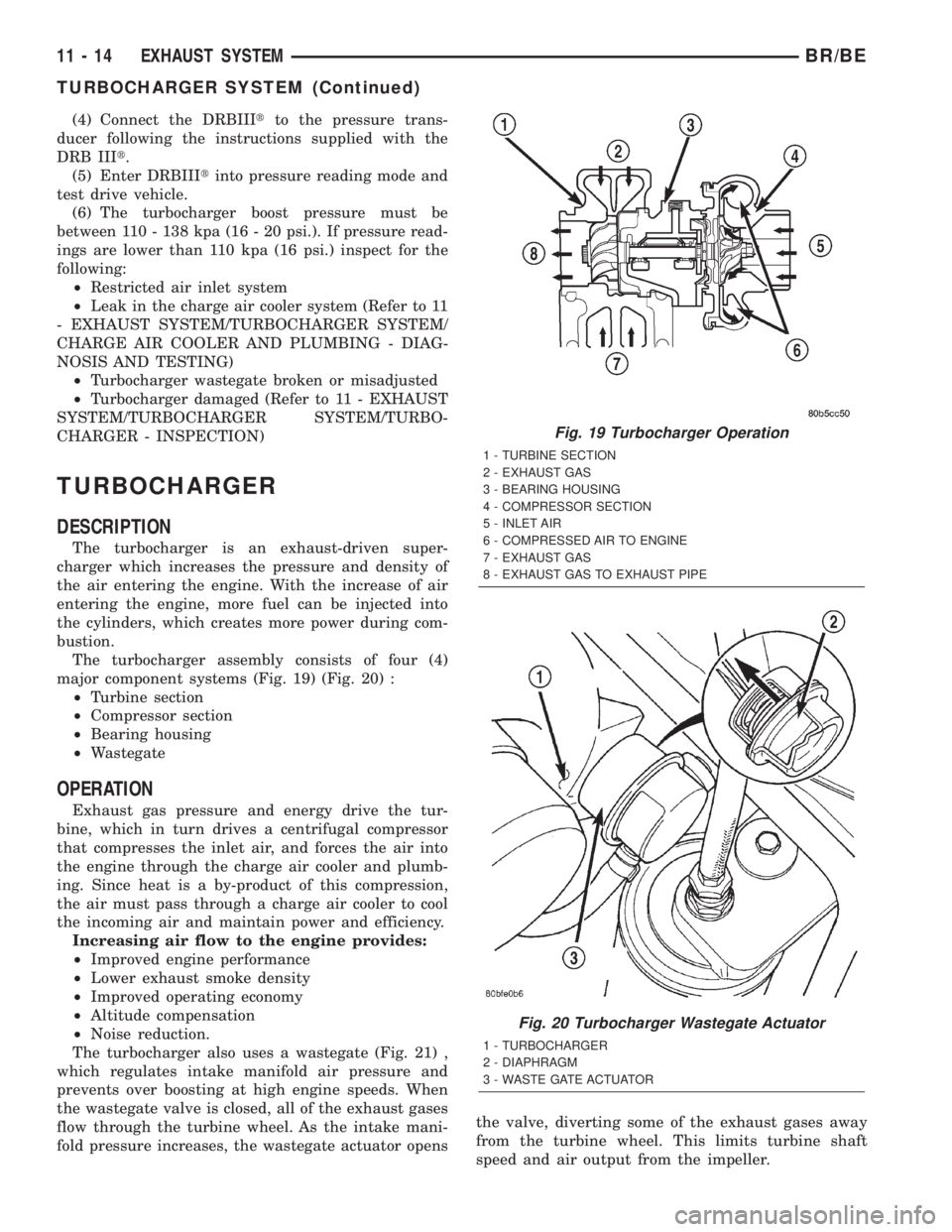

TURBOCHARGER

DESCRIPTION

The turbocharger is an exhaust-driven super-

charger which increases the pressure and density of

the air entering the engine. With the increase of air

entering the engine, more fuel can be injected into

the cylinders, which creates more power during com-

bustion.

The turbocharger assembly consists of four (4)

major component systems (Fig. 19) (Fig. 20) :

²Turbine section

²Compressor section

²Bearing housing

²Wastegate

OPERATION

Exhaust gas pressure and energy drive the tur-

bine, which in turn drives a centrifugal compressor

that compresses the inlet air, and forces the air into

the engine through the charge air cooler and plumb-

ing. Since heat is a by-product of this compression,

the air must pass through a charge air cooler to cool

the incoming air and maintain power and efficiency.

Increasing air flow to the engine provides:

²Improved engine performance

²Lower exhaust smoke density

²Improved operating economy

²Altitude compensation

²Noise reduction.

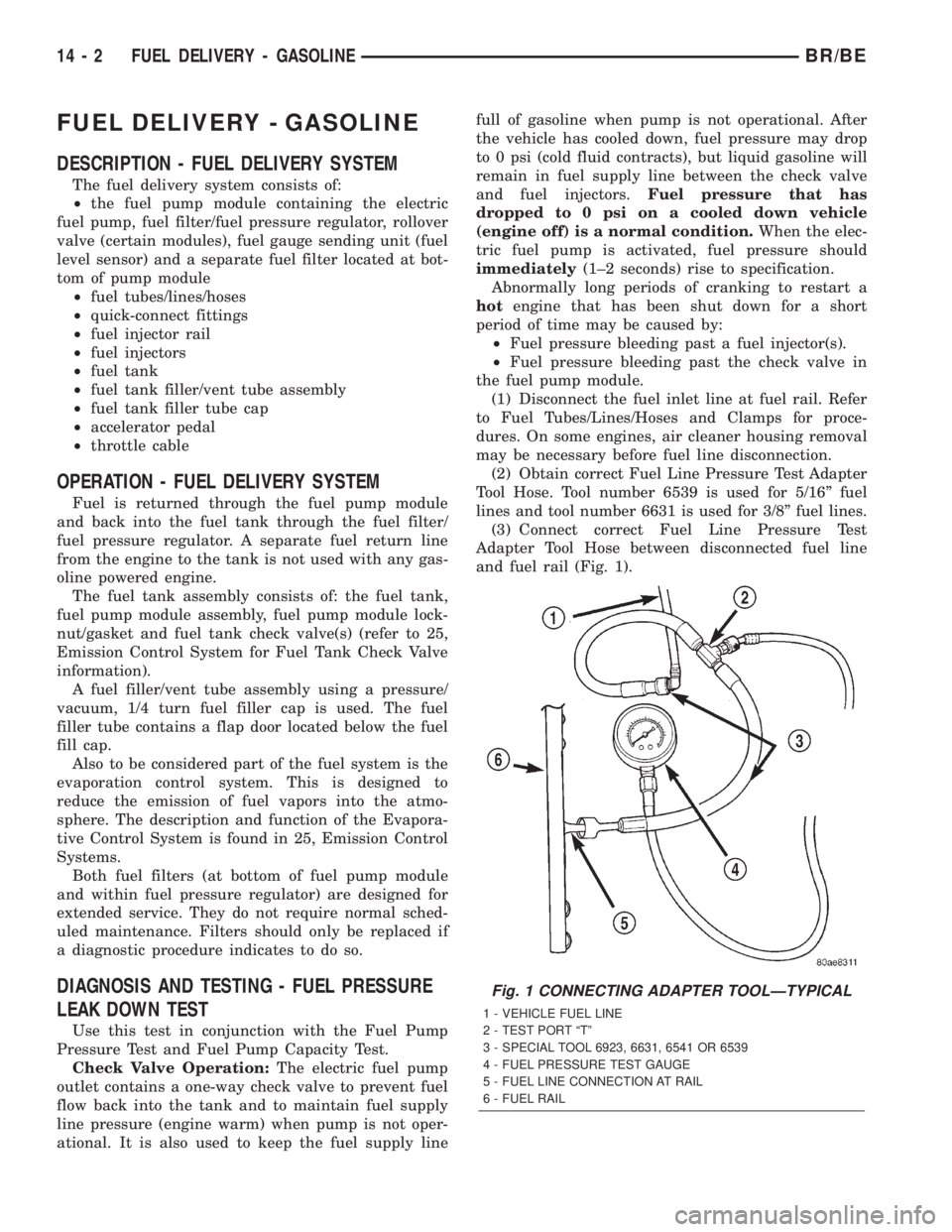

The turbocharger also uses a wastegate (Fig. 21) ,

which regulates intake manifold air pressure and

prevents over boosting at high engine speeds. When

the wastegate valve is closed, all of the exhaust gases

flow through the turbine wheel. As the intake mani-

fold pressure increases, the wastegate actuator opensthe valve, diverting some of the exhaust gases away

from the turbine wheel. This limits turbine shaft

speed and air output from the impeller.

Fig. 19 Turbocharger Operation

1 - TURBINE SECTION

2 - EXHAUST GAS

3 - BEARING HOUSING

4 - COMPRESSOR SECTION

5 - INLET AIR

6 - COMPRESSED AIR TO ENGINE

7 - EXHAUST GAS

8 - EXHAUST GAS TO EXHAUST PIPE

Fig. 20 Turbocharger Wastegate Actuator

1 - TURBOCHARGER

2 - DIAPHRAGM

3 - WASTE GATE ACTUATOR

11 - 14 EXHAUST SYSTEMBR/BE

TURBOCHARGER SYSTEM (Continued)

Page 1301 of 2255

FUEL DELIVERY - GASOLINE

DESCRIPTION - FUEL DELIVERY SYSTEM

The fuel delivery system consists of:

²the fuel pump module containing the electric

fuel pump, fuel filter/fuel pressure regulator, rollover

valve (certain modules), fuel gauge sending unit (fuel

level sensor) and a separate fuel filter located at bot-

tom of pump module

²fuel tubes/lines/hoses

²quick-connect fittings

²fuel injector rail

²fuel injectors

²fuel tank

²fuel tank filler/vent tube assembly

²fuel tank filler tube cap

²accelerator pedal

²throttle cable

OPERATION - FUEL DELIVERY SYSTEM

Fuel is returned through the fuel pump module

and back into the fuel tank through the fuel filter/

fuel pressure regulator. A separate fuel return line

from the engine to the tank is not used with any gas-

oline powered engine.

The fuel tank assembly consists of: the fuel tank,

fuel pump module assembly, fuel pump module lock-

nut/gasket and fuel tank check valve(s) (refer to 25,

Emission Control System for Fuel Tank Check Valve

information).

A fuel filler/vent tube assembly using a pressure/

vacuum, 1/4 turn fuel filler cap is used. The fuel

filler tube contains a flap door located below the fuel

fill cap.

Also to be considered part of the fuel system is the

evaporation control system. This is designed to

reduce the emission of fuel vapors into the atmo-

sphere. The description and function of the Evapora-

tive Control System is found in 25, Emission Control

Systems.

Both fuel filters (at bottom of fuel pump module

and within fuel pressure regulator) are designed for

extended service. They do not require normal sched-

uled maintenance. Filters should only be replaced if

a diagnostic procedure indicates to do so.

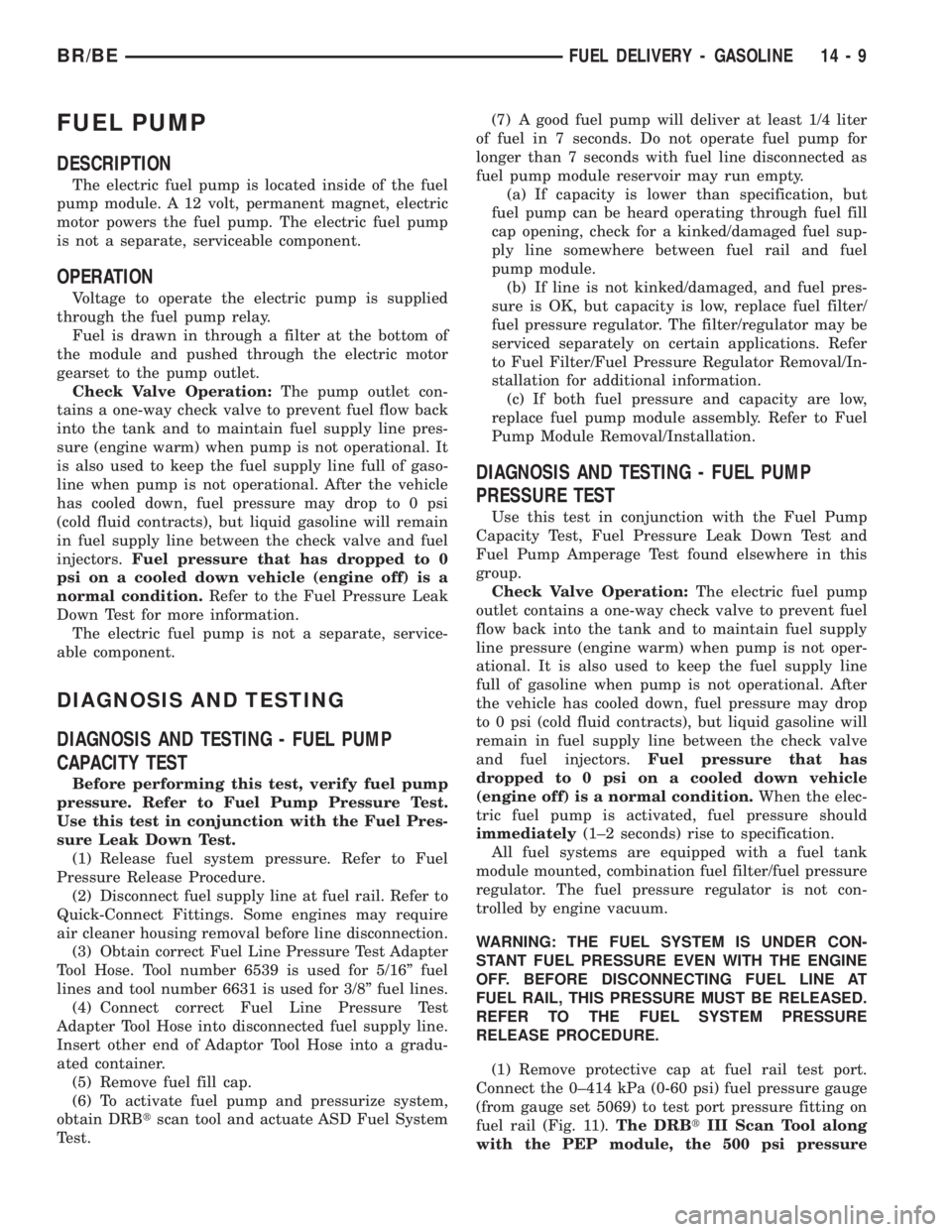

DIAGNOSIS AND TESTING - FUEL PRESSURE

LEAK DOWN TEST

Use this test in conjunction with the Fuel Pump

Pressure Test and Fuel Pump Capacity Test.

Check Valve Operation:The electric fuel pump

outlet contains a one-way check valve to prevent fuel

flow back into the tank and to maintain fuel supply

line pressure (engine warm) when pump is not oper-

ational. It is also used to keep the fuel supply linefull of gasoline when pump is not operational. After

the vehicle has cooled down, fuel pressure may drop

to 0 psi (cold fluid contracts), but liquid gasoline will

remain in fuel supply line between the check valve

and fuel injectors.Fuel pressure that has

dropped to 0 psi on a cooled down vehicle

(engine off) is a normal condition.When the elec-

tric fuel pump is activated, fuel pressure should

immediately(1±2 seconds) rise to specification.

Abnormally long periods of cranking to restart a

hotengine that has been shut down for a short

period of time may be caused by:

²Fuel pressure bleeding past a fuel injector(s).

²Fuel pressure bleeding past the check valve in

the fuel pump module.

(1) Disconnect the fuel inlet line at fuel rail. Refer

to Fuel Tubes/Lines/Hoses and Clamps for proce-

dures. On some engines, air cleaner housing removal

may be necessary before fuel line disconnection.

(2) Obtain correct Fuel Line Pressure Test Adapter

Tool Hose. Tool number 6539 is used for 5/16º fuel

lines and tool number 6631 is used for 3/8º fuel lines.

(3) Connect correct Fuel Line Pressure Test

Adapter Tool Hose between disconnected fuel line

and fuel rail (Fig. 1).

Fig. 1 CONNECTING ADAPTER TOOLÐTYPICAL

1 - VEHICLE FUEL LINE

2 - TEST PORT ªTº

3 - SPECIAL TOOL 6923, 6631, 6541 OR 6539

4 - FUEL PRESSURE TEST GAUGE

5 - FUEL LINE CONNECTION AT RAIL

6 - FUEL RAIL

14 - 2 FUEL DELIVERY - GASOLINEBR/BE

Page 1308 of 2255

FUEL PUMP

DESCRIPTION

The electric fuel pump is located inside of the fuel

pump module. A 12 volt, permanent magnet, electric

motor powers the fuel pump. The electric fuel pump

is not a separate, serviceable component.

OPERATION

Voltage to operate the electric pump is supplied

through the fuel pump relay.

Fuel is drawn in through a filter at the bottom of

the module and pushed through the electric motor

gearset to the pump outlet.

Check Valve Operation:The pump outlet con-

tains a one-way check valve to prevent fuel flow back

into the tank and to maintain fuel supply line pres-

sure (engine warm) when pump is not operational. It

is also used to keep the fuel supply line full of gaso-

line when pump is not operational. After the vehicle

has cooled down, fuel pressure may drop to 0 psi

(cold fluid contracts), but liquid gasoline will remain

in fuel supply line between the check valve and fuel

injectors.Fuel pressure that has dropped to 0

psi on a cooled down vehicle (engine off) is a

normal condition.Refer to the Fuel Pressure Leak

Down Test for more information.

The electric fuel pump is not a separate, service-

able component.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - FUEL PUMP

CAPACITY TEST

Before performing this test, verify fuel pump

pressure. Refer to Fuel Pump Pressure Test.

Use this test in conjunction with the Fuel Pres-

sure Leak Down Test.

(1) Release fuel system pressure. Refer to Fuel

Pressure Release Procedure.

(2) Disconnect fuel supply line at fuel rail. Refer to

Quick-Connect Fittings. Some engines may require

air cleaner housing removal before line disconnection.

(3) Obtain correct Fuel Line Pressure Test Adapter

Tool Hose. Tool number 6539 is used for 5/16º fuel

lines and tool number 6631 is used for 3/8º fuel lines.

(4) Connect correct Fuel Line Pressure Test

Adapter Tool Hose into disconnected fuel supply line.

Insert other end of Adaptor Tool Hose into a gradu-

ated container.

(5) Remove fuel fill cap.

(6) To activate fuel pump and pressurize system,

obtain DRBtscan tool and actuate ASD Fuel System

Test.(7) A good fuel pump will deliver at least 1/4 liter

of fuel in 7 seconds. Do not operate fuel pump for

longer than 7 seconds with fuel line disconnected as

fuel pump module reservoir may run empty.

(a) If capacity is lower than specification, but

fuel pump can be heard operating through fuel fill

cap opening, check for a kinked/damaged fuel sup-

ply line somewhere between fuel rail and fuel

pump module.

(b) If line is not kinked/damaged, and fuel pres-

sure is OK, but capacity is low, replace fuel filter/

fuel pressure regulator. The filter/regulator may be

serviced separately on certain applications. Refer

to Fuel Filter/Fuel Pressure Regulator Removal/In-

stallation for additional information.

(c) If both fuel pressure and capacity are low,

replace fuel pump module assembly. Refer to Fuel

Pump Module Removal/Installation.

DIAGNOSIS AND TESTING - FUEL PUMP

PRESSURE TEST

Use this test in conjunction with the Fuel Pump

Capacity Test, Fuel Pressure Leak Down Test and

Fuel Pump Amperage Test found elsewhere in this

group.

Check Valve Operation:The electric fuel pump

outlet contains a one-way check valve to prevent fuel

flow back into the tank and to maintain fuel supply

line pressure (engine warm) when pump is not oper-

ational. It is also used to keep the fuel supply line

full of gasoline when pump is not operational. After

the vehicle has cooled down, fuel pressure may drop

to 0 psi (cold fluid contracts), but liquid gasoline will

remain in fuel supply line between the check valve

and fuel injectors.Fuel pressure that has

dropped to 0 psi on a cooled down vehicle

(engine off) is a normal condition.When the elec-

tric fuel pump is activated, fuel pressure should

immediately(1±2 seconds) rise to specification.

All fuel systems are equipped with a fuel tank

module mounted, combination fuel filter/fuel pressure

regulator. The fuel pressure regulator is not con-

trolled by engine vacuum.

WARNING: THE FUEL SYSTEM IS UNDER CON-

STANT FUEL PRESSURE EVEN WITH THE ENGINE

OFF. BEFORE DISCONNECTING FUEL LINE AT

FUEL RAIL, THIS PRESSURE MUST BE RELEASED.

REFER TO THE FUEL SYSTEM PRESSURE

RELEASE PROCEDURE.

(1) Remove protective cap at fuel rail test port.

Connect the 0±414 kPa (0-60 psi) fuel pressure gauge

(from gauge set 5069) to test port pressure fitting on

fuel rail (Fig. 11).The DRBtIII Scan Tool along

with the PEP module, the 500 psi pressure

BR/BEFUEL DELIVERY - GASOLINE 14 - 9

Page 1345 of 2255

around 70ÉF, the resistance of the heating element is

approximately 4.5 ohms. As the sensor's temperature

increases, resistance in the heater element increases.

This allows the heater to maintain the optimum

operating temperature of approximately 930É-1100ÉF

(500É-600É C). Although the sensors operate the

same, there are physical differences, due to the envi-

ronment that they operate in, that keep them from

being interchangeable.

Maintaining correct sensor temperature at all

times allows the system to enter into closed loop

operation sooner. Also, it allows the system to remain

in closed loop operation during periods of extended

idle.

In Closed Loop operation, the PCM monitors cer-

tain O2 sensor input(s) along with other inputs, and

adjusts the injector pulse width accordingly. During

Open Loop operation, the PCM ignores the O2 sensor

input. The PCM adjusts injector pulse width based

on preprogrammed (fixed) values and inputs from

other sensors.

Upstream Sensors:Two upstream sensors are

used (1/1 and 2/1). The 1/1 sensor is the first sensor

to receive exhaust gases from the #1 cylinder. They

provide an input voltage to the PCM. The input tells

the PCM the oxygen content of the exhaust gas. The

PCM uses this information to fine tune fuel delivery

to maintain the correct oxygen content at the down-

stream oxygen sensors. The PCM will change the air/

fuel ratio until the upstream sensors input a voltage

that the PCM has determined will make the down-

stream sensors output (oxygen content) correct.

The upstream oxygen sensors also provide an input

to determine mini-catalyst efficiency. Main catalytic

convertor efficiency is not calculated with this pack-

age.

Downstream Sensors:Two downstream sensors

are used (1/2 and 2/2). The downstream sensors are

used to determine the correct air-fuel ratio. As the

oxygen content changes at the downstream sensor,

the PCM calculates how much air-fuel ratio change is

required. The PCM then looks at the upstream oxy-

gen sensor voltage, and changes fuel delivery until

the upstream sensor voltage changes enough to cor-

rect the downstream sensor voltage (oxygen content).

The downstream oxygen sensors also provide an

input to determine mini-catalyst efficiency. Main cat-

alytic convertor efficiency is not calculated with this

package.

Medium and Heavy Duty 8.0L V-10 Engine:

Four oxygen sensors are used (2 upstream, 1 pre-cat-

alyst and 1 post-catalyst). The upstream sensors (1/1

and 2/1) will fine-tune the air-fuel ratio through the

Powertrain Control Module (PCM). The pre-catalyst

(1/2) and post-catalyst (1/3) sensors will determine

catalytic convertor efficiency (efficiency of the maincatalytic convertor). This is also done through the

PCM.

Heavy Duty 5.9L Engine:Downstream sensors

are not used with this emissions package, meaning

catalytic convertor efficiency is not calculated with

this package. Two upstream sensors are used. The

left upstream sensor (1/1) will monitor cylinders 1, 3,

5 and 7. The right upstream sensor (2/1) will monitor

cylinders 2, 4, 6 and 8. The PCM monitors the oxy-

gen content of the sensors, and will fine-tune the air-

fuel ratio.

Engines equipped with either a downstream sen-

sor(s), or a post-catalytic sensor, will monitor cata-

lytic convertor efficiency. If efficiency is below

emission standards, the Malfunction Indicator Lamp

(MIL) will be illuminated and a Diagnostic Trouble

Code (DTC) will be set. Refer to Monitored Systems

in Emission Control Systems for additional informa-

tion.

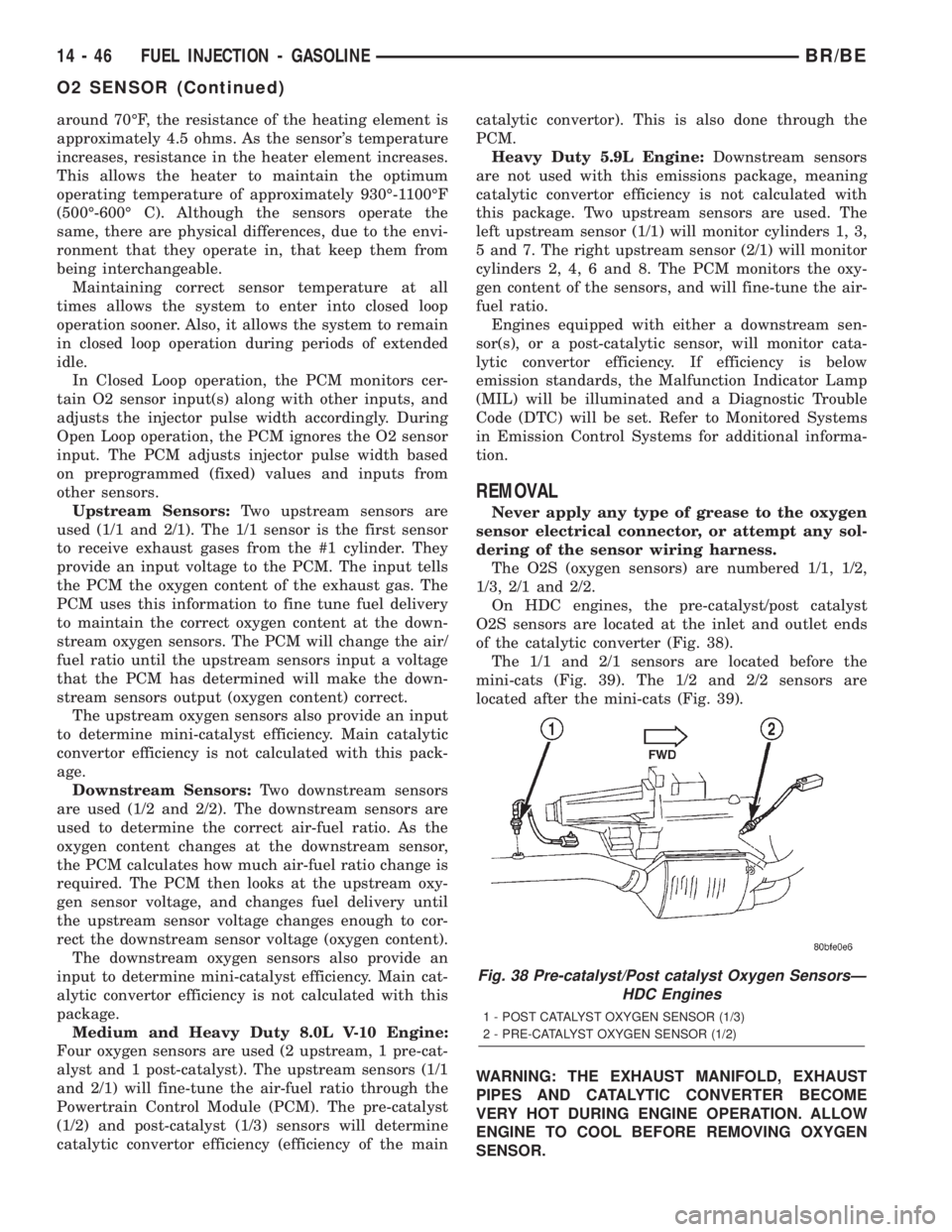

REMOVAL

Never apply any type of grease to the oxygen

sensor electrical connector, or attempt any sol-

dering of the sensor wiring harness.

The O2S (oxygen sensors) are numbered 1/1, 1/2,

1/3, 2/1 and 2/2.

On HDC engines, the pre-catalyst/post catalyst

O2S sensors are located at the inlet and outlet ends

of the catalytic converter (Fig. 38).

The 1/1 and 2/1 sensors are located before the

mini-cats (Fig. 39). The 1/2 and 2/2 sensors are

located after the mini-cats (Fig. 39).

WARNING: THE EXHAUST MANIFOLD, EXHAUST

PIPES AND CATALYTIC CONVERTER BECOME

VERY HOT DURING ENGINE OPERATION. ALLOW

ENGINE TO COOL BEFORE REMOVING OXYGEN

SENSOR.

Fig. 38 Pre-catalyst/Post catalyst Oxygen SensorsÐ

HDC Engines

1 - POST CATALYST OXYGEN SENSOR (1/3)

2 - PRE-CATALYST OXYGEN SENSOR (1/2)

14 - 46 FUEL INJECTION - GASOLINEBR/BE

O2 SENSOR (Continued)

Page 1390 of 2255

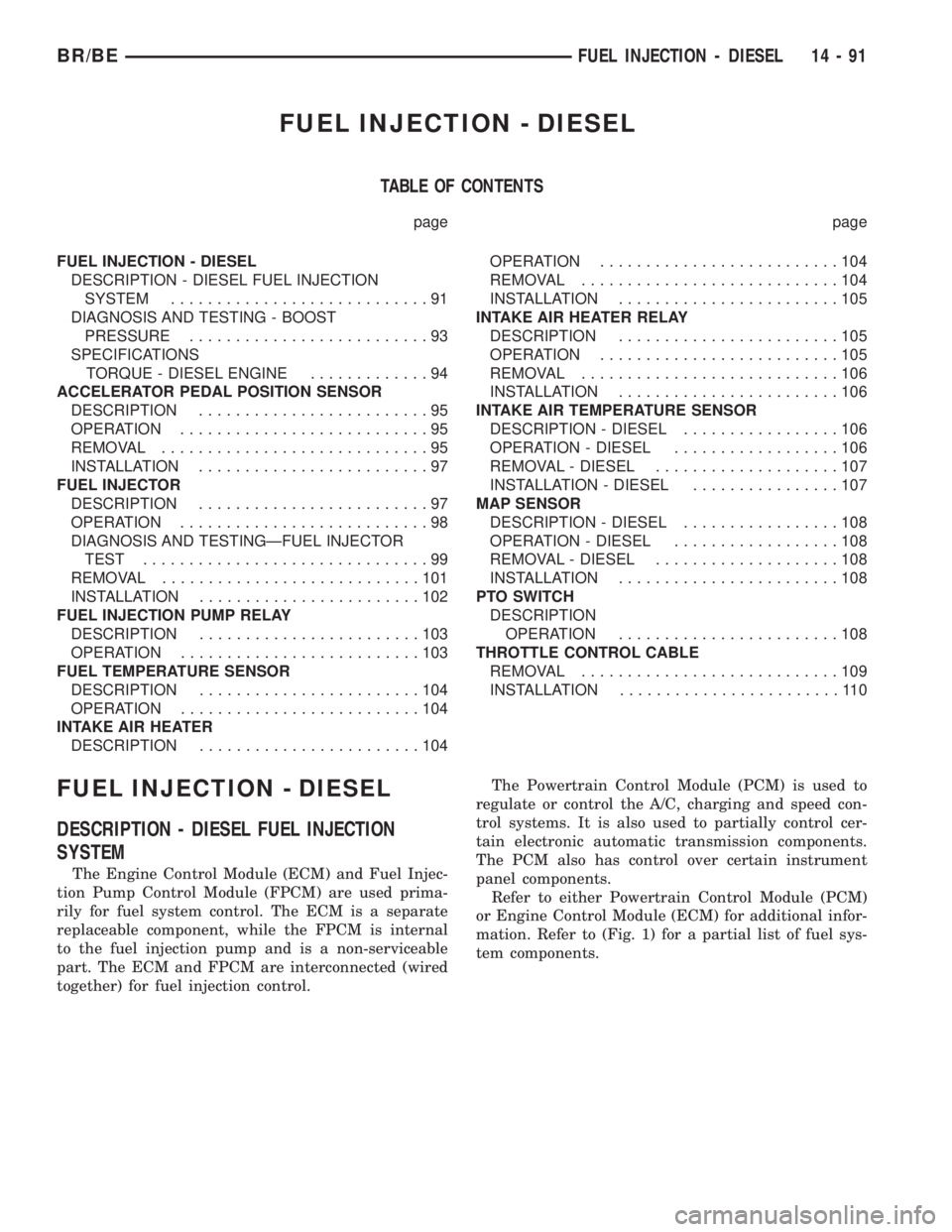

FUEL INJECTION - DIESEL

TABLE OF CONTENTS

page page

FUEL INJECTION - DIESEL

DESCRIPTION - DIESEL FUEL INJECTION

SYSTEM............................91

DIAGNOSIS AND TESTING - BOOST

PRESSURE..........................93

SPECIFICATIONS

TORQUE - DIESEL ENGINE.............94

ACCELERATOR PEDAL POSITION SENSOR

DESCRIPTION.........................95

OPERATION...........................95

REMOVAL.............................95

INSTALLATION.........................97

FUEL INJECTOR

DESCRIPTION.........................97

OPERATION...........................98

DIAGNOSIS AND TESTINGÐFUEL INJECTOR

TEST...............................99

REMOVAL............................101

INSTALLATION........................102

FUEL INJECTION PUMP RELAY

DESCRIPTION........................103

OPERATION..........................103

FUEL TEMPERATURE SENSOR

DESCRIPTION........................104

OPERATION..........................104

INTAKE AIR HEATER

DESCRIPTION........................104OPERATION..........................104

REMOVAL............................104

INSTALLATION........................105

INTAKE AIR HEATER RELAY

DESCRIPTION........................105

OPERATION..........................105

REMOVAL............................106

INSTALLATION........................106

INTAKE AIR TEMPERATURE SENSOR

DESCRIPTION - DIESEL.................106

OPERATION - DIESEL..................106

REMOVAL - DIESEL....................107

INSTALLATION - DIESEL................107

MAP SENSOR

DESCRIPTION - DIESEL.................108

OPERATION - DIESEL..................108

REMOVAL - DIESEL....................108

INSTALLATION........................108

PTO SWITCH

DESCRIPTION

OPERATION........................108

THROTTLE CONTROL CABLE

REMOVAL............................109

INSTALLATION........................110

FUEL INJECTION - DIESEL

DESCRIPTION - DIESEL FUEL INJECTION

SYSTEM

The Engine Control Module (ECM) and Fuel Injec-

tion Pump Control Module (FPCM) are used prima-

rily for fuel system control. The ECM is a separate

replaceable component, while the FPCM is internal

to the fuel injection pump and is a non-serviceable

part. The ECM and FPCM are interconnected (wired

together) for fuel injection control.The Powertrain Control Module (PCM) is used to

regulate or control the A/C, charging and speed con-

trol systems. It is also used to partially control cer-

tain electronic automatic transmission components.

The PCM also has control over certain instrument

panel components.

Refer to either Powertrain Control Module (PCM)

or Engine Control Module (ECM) for additional infor-

mation. Refer to (Fig. 1) for a partial list of fuel sys-

tem components.

BR/BEFUEL INJECTION - DIESEL 14 - 91

Page 1411 of 2255

DIAGNOSIS AND TESTING

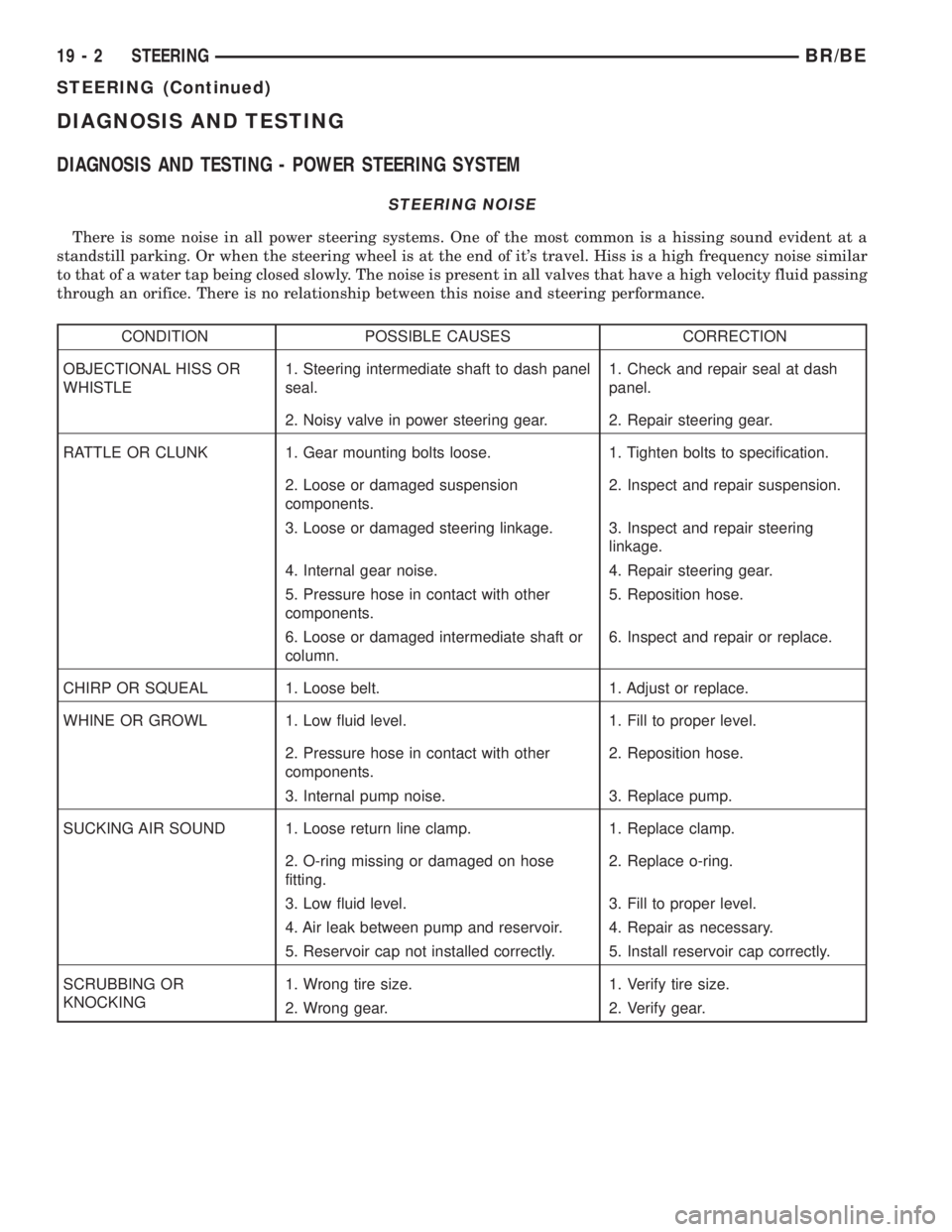

DIAGNOSIS AND TESTING - POWER STEERING SYSTEM

STEERING NOISE

There is some noise in all power steering systems. One of the most common is a hissing sound evident at a

standstill parking. Or when the steering wheel is at the end of it's travel. Hiss is a high frequency noise similar

to that of a water tap being closed slowly. The noise is present in all valves that have a high velocity fluid passing

through an orifice. There is no relationship between this noise and steering performance.

CONDITION POSSIBLE CAUSES CORRECTION

OBJECTIONAL HISS OR

WHISTLE1. Steering intermediate shaft to dash panel

seal.1. Check and repair seal at dash

panel.

2. Noisy valve in power steering gear. 2. Repair steering gear.

RATTLE OR CLUNK 1. Gear mounting bolts loose. 1. Tighten bolts to specification.

2. Loose or damaged suspension

components.2. Inspect and repair suspension.

3. Loose or damaged steering linkage. 3. Inspect and repair steering

linkage.

4. Internal gear noise. 4. Repair steering gear.

5. Pressure hose in contact with other

components.5. Reposition hose.

6. Loose or damaged intermediate shaft or

column.6. Inspect and repair or replace.

CHIRP OR SQUEAL 1. Loose belt. 1. Adjust or replace.

WHINE OR GROWL 1. Low fluid level. 1. Fill to proper level.

2. Pressure hose in contact with other

components.2. Reposition hose.

3. Internal pump noise. 3. Replace pump.

SUCKING AIR SOUND 1. Loose return line clamp. 1. Replace clamp.

2. O-ring missing or damaged on hose

fitting.2. Replace o-ring.

3. Low fluid level. 3. Fill to proper level.

4. Air leak between pump and reservoir. 4. Repair as necessary.

5. Reservoir cap not installed correctly. 5. Install reservoir cap correctly.

SCRUBBING OR

KNOCKING1. Wrong tire size. 1. Verify tire size.

2. Wrong gear. 2. Verify gear.

19 - 2 STEERINGBR/BE

STEERING (Continued)