check engine DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 2214 of 2255

(2) Install LDP filter to mounting bracket. Tighten

bolt to 7 N´m (65 in. lbs.) torque.

(3) Carefully install vapor/vacuum lines to LDP,

and install hose to LDP filter.The vapor/vacuum

lines and hoses must be firmly connected.

Check the vapor/vacuum lines at the LDP, LDP

filter and EVAP canister purge solenoid for

damage or leaks. If a leak is present, a Diagnos-

tic Trouble Code (DTC) may be set.

(4) Connect electrical connector to LDP.

PCV VALVE

DESCRIPTION - V-8 ENGINES

All 5.9L V-8 gas powered engines are equipped

with a closed crankcase ventilation system and a pos-

itive crankcase ventilation (PCV) valve. The 8.0L

V-10 engine is not equipped with a PCV valve. Refer

to Crankcase Ventilation SystemÐ8.0L V-10 Engine

for information.

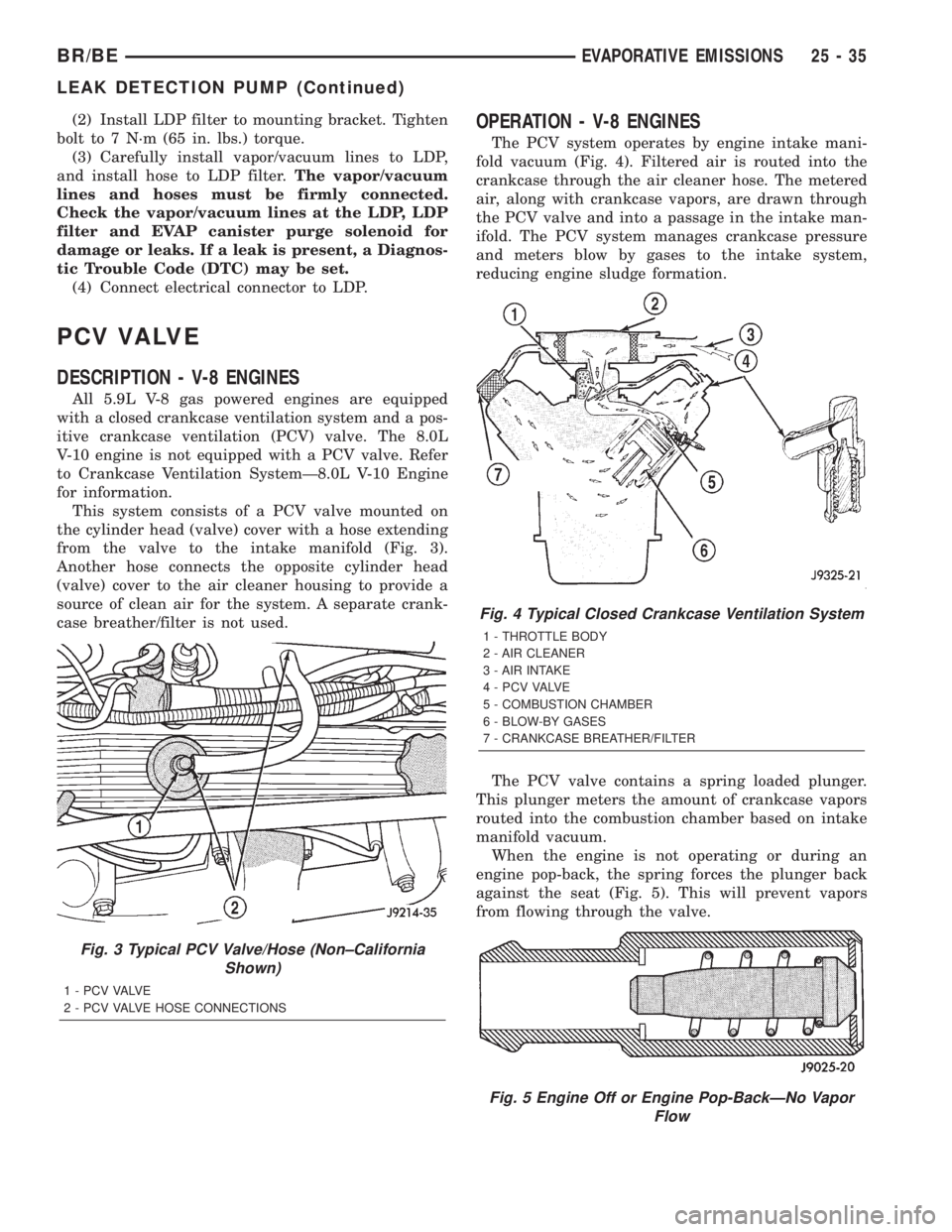

This system consists of a PCV valve mounted on

the cylinder head (valve) cover with a hose extending

from the valve to the intake manifold (Fig. 3).

Another hose connects the opposite cylinder head

(valve) cover to the air cleaner housing to provide a

source of clean air for the system. A separate crank-

case breather/filter is not used.

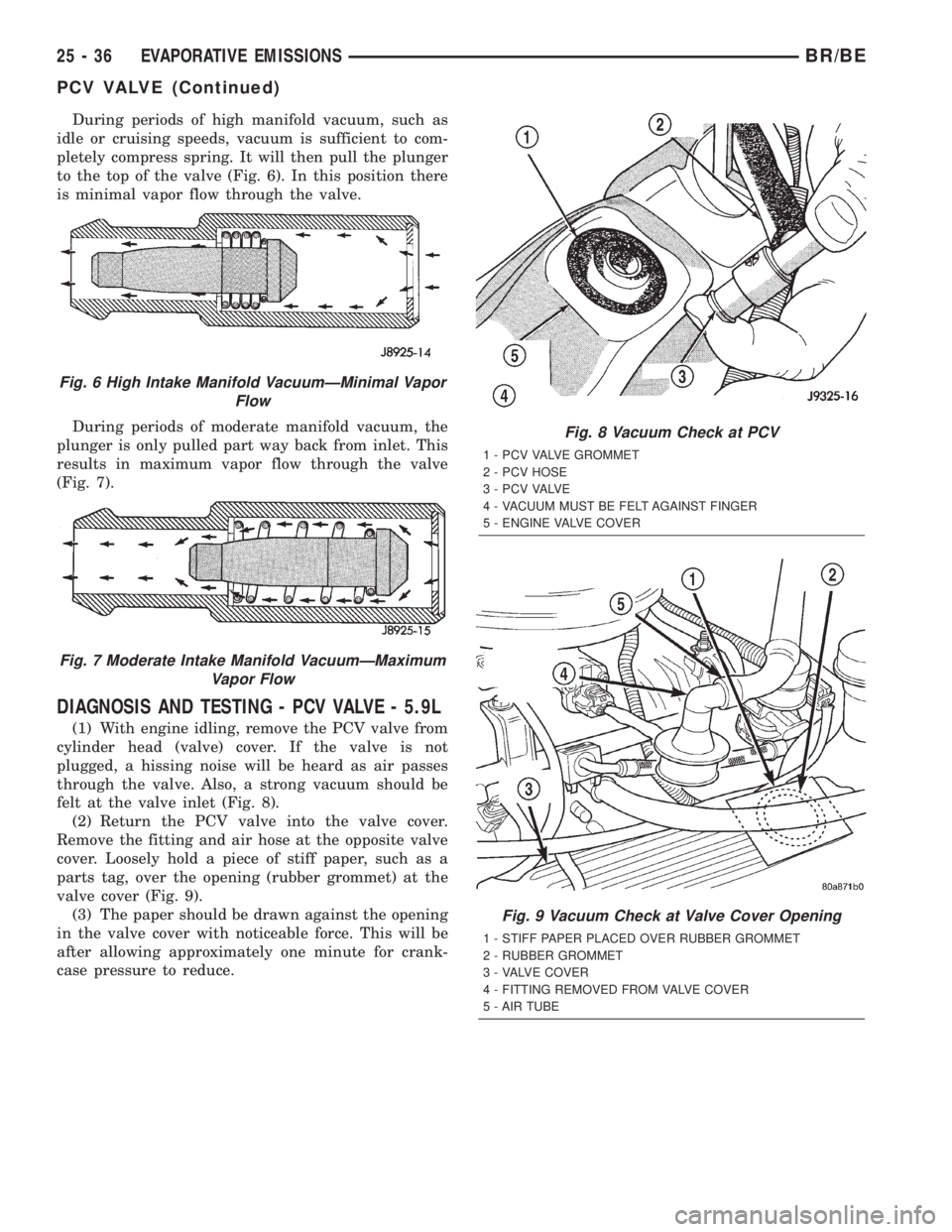

OPERATION - V-8 ENGINES

The PCV system operates by engine intake mani-

fold vacuum (Fig. 4). Filtered air is routed into the

crankcase through the air cleaner hose. The metered

air, along with crankcase vapors, are drawn through

the PCV valve and into a passage in the intake man-

ifold. The PCV system manages crankcase pressure

and meters blow by gases to the intake system,

reducing engine sludge formation.

The PCV valve contains a spring loaded plunger.

This plunger meters the amount of crankcase vapors

routed into the combustion chamber based on intake

manifold vacuum.

When the engine is not operating or during an

engine pop-back, the spring forces the plunger back

against the seat (Fig. 5). This will prevent vapors

from flowing through the valve.

Fig. 3 Typical PCV Valve/Hose (Non±California

Shown)

1 - P C V VA LV E

2 - PCV VALVE HOSE CONNECTIONS

Fig. 4 Typical Closed Crankcase Ventilation System

1 - THROTTLE BODY

2 - AIR CLEANER

3 - AIR INTAKE

4 - P C V VA LV E

5 - COMBUSTION CHAMBER

6 - BLOW-BY GASES

7 - CRANKCASE BREATHER/FILTER

Fig. 5 Engine Off or Engine Pop-BackÐNo Vapor

Flow

BR/BEEVAPORATIVE EMISSIONS 25 - 35

LEAK DETECTION PUMP (Continued)

Page 2215 of 2255

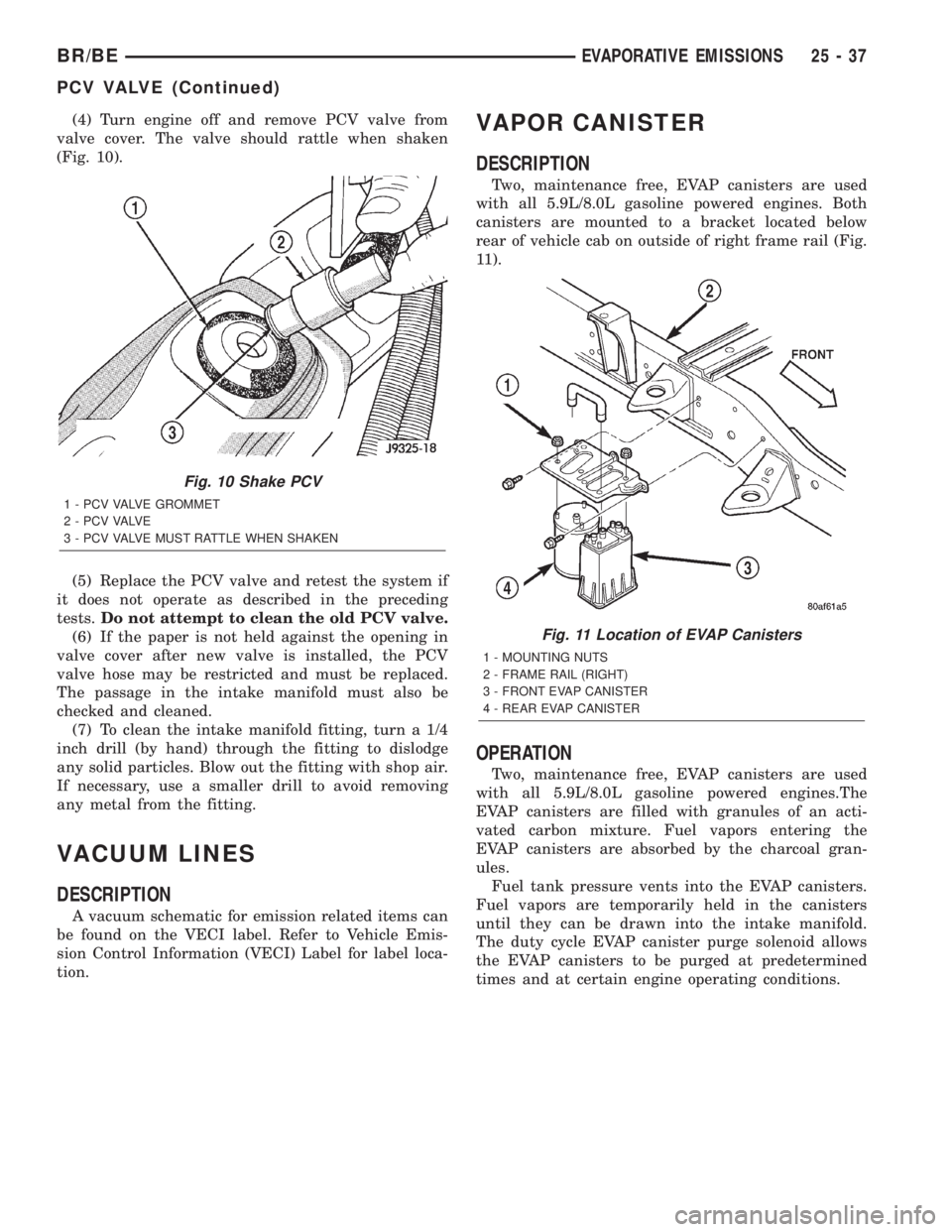

During periods of high manifold vacuum, such as

idle or cruising speeds, vacuum is sufficient to com-

pletely compress spring. It will then pull the plunger

to the top of the valve (Fig. 6). In this position there

is minimal vapor flow through the valve.

During periods of moderate manifold vacuum, the

plunger is only pulled part way back from inlet. This

results in maximum vapor flow through the valve

(Fig. 7).

DIAGNOSIS AND TESTING - PCV VALVE - 5.9L

(1) With engine idling, remove the PCV valve from

cylinder head (valve) cover. If the valve is not

plugged, a hissing noise will be heard as air passes

through the valve. Also, a strong vacuum should be

felt at the valve inlet (Fig. 8).

(2) Return the PCV valve into the valve cover.

Remove the fitting and air hose at the opposite valve

cover. Loosely hold a piece of stiff paper, such as a

parts tag, over the opening (rubber grommet) at the

valve cover (Fig. 9).

(3) The paper should be drawn against the opening

in the valve cover with noticeable force. This will be

after allowing approximately one minute for crank-

case pressure to reduce.

Fig. 6 High Intake Manifold VacuumÐMinimal Vapor

Flow

Fig. 7 Moderate Intake Manifold VacuumÐMaximum

Vapor Flow

Fig. 8 Vacuum Check at PCV

1 - PCV VALVE GROMMET

2 - PCV HOSE

3 - P C V VA LV E

4 - VACUUM MUST BE FELT AGAINST FINGER

5 - ENGINE VALVE COVER

Fig. 9 Vacuum Check at Valve Cover Opening

1 - STIFF PAPER PLACED OVER RUBBER GROMMET

2 - RUBBER GROMMET

3 - VALVE COVER

4 - FITTING REMOVED FROM VALVE COVER

5 - AIR TUBE

25 - 36 EVAPORATIVE EMISSIONSBR/BE

PCV VALVE (Continued)

Page 2216 of 2255

(4) Turn engine off and remove PCV valve from

valve cover. The valve should rattle when shaken

(Fig. 10).

(5) Replace the PCV valve and retest the system if

it does not operate as described in the preceding

tests.Do not attempt to clean the old PCV valve.

(6) If the paper is not held against the opening in

valve cover after new valve is installed, the PCV

valve hose may be restricted and must be replaced.

The passage in the intake manifold must also be

checked and cleaned.

(7) To clean the intake manifold fitting, turn a 1/4

inch drill (by hand) through the fitting to dislodge

any solid particles. Blow out the fitting with shop air.

If necessary, use a smaller drill to avoid removing

any metal from the fitting.

VACUUM LINES

DESCRIPTION

A vacuum schematic for emission related items can

be found on the VECI label. Refer to Vehicle Emis-

sion Control Information (VECI) Label for label loca-

tion.

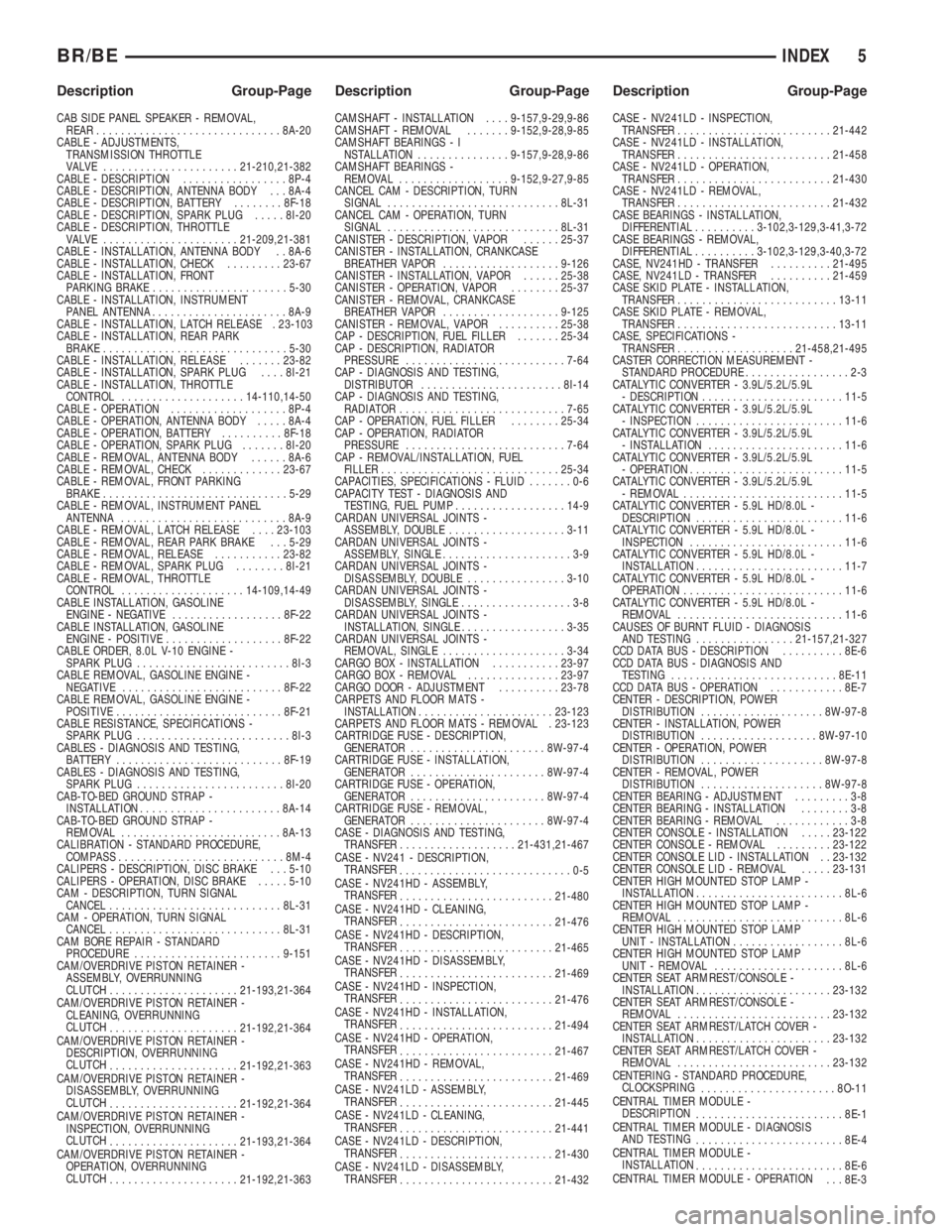

VAPOR CANISTER

DESCRIPTION

Two, maintenance free, EVAP canisters are used

with all 5.9L/8.0L gasoline powered engines. Both

canisters are mounted to a bracket located below

rear of vehicle cab on outside of right frame rail (Fig.

11).

OPERATION

Two, maintenance free, EVAP canisters are used

with all 5.9L/8.0L gasoline powered engines.The

EVAP canisters are filled with granules of an acti-

vated carbon mixture. Fuel vapors entering the

EVAP canisters are absorbed by the charcoal gran-

ules.

Fuel tank pressure vents into the EVAP canisters.

Fuel vapors are temporarily held in the canisters

until they can be drawn into the intake manifold.

The duty cycle EVAP canister purge solenoid allows

the EVAP canisters to be purged at predetermined

times and at certain engine operating conditions.

Fig. 10 Shake PCV

1 - PCV VALVE GROMMET

2 - P C V VA LV E

3 - PCV VALVE MUST RATTLE WHEN SHAKEN

Fig. 11 Location of EVAP Canisters

1 - MOUNTING NUTS

2 - FRAME RAIL (RIGHT)

3 - FRONT EVAP CANISTER

4 - REAR EVAP CANISTER

BR/BEEVAPORATIVE EMISSIONS 25 - 37

PCV VALVE (Continued)

Page 2222 of 2255

CAB SIDE PANEL SPEAKER - REMOVAL,

REAR..............................8A-20

CABLE - ADJUSTMENTS,

TRANSMISSION THROTTLE

VALVE ......................21-210,21-382

CABLE - DESCRIPTION.................8P-4

CABLE - DESCRIPTION, ANTENNA BODY . . . 8A-4

CABLE - DESCRIPTION, BATTERY........8F-18

CABLE - DESCRIPTION, SPARK PLUG.....8I-20

CABLE - DESCRIPTION, THROTTLE

VALVE ......................21-209,21-381

CABLE - INSTALLATION, ANTENNA BODY . . 8A-6

CABLE - INSTALLATION, CHECK.........23-67

CABLE - INSTALLATION, FRONT

PARKING BRAKE......................5-30

CABLE - INSTALLATION, INSTRUMENT

PANEL ANTENNA......................8A-9

CABLE - INSTALLATION, LATCH RELEASE . 23-103

CABLE - INSTALLATION, REAR PARK

BRAKE..............................5-30

CABLE - INSTALLATION, RELEASE.......23-82

CABLE - INSTALLATION, SPARK PLUG....8I-21

CABLE - INSTALLATION, THROTTLE

CONTROL....................14-110,14-50

CABLE - OPERATION...................8P-4

CABLE - OPERATION, ANTENNA BODY.....8A-4

CABLE - OPERATION, BATTERY..........8F-18

CABLE - OPERATION, SPARK PLUG.......8I-20

CABLE - REMOVAL, ANTENNA BODY......8A-6

CABLE - REMOVAL, CHECK.............23-67

CABLE - REMOVAL, FRONT PARKING

BRAKE..............................5-29

CABLE - REMOVAL, INSTRUMENT PANEL

ANTENNA...........................8A-9

CABLE - REMOVAL, LATCH RELEASE....23-103

CABLE - REMOVAL, REAR PARK BRAKE . . . 5-29

CABLE - REMOVAL, RELEASE...........23-82

CABLE - REMOVAL, SPARK PLUG........8I-21

CABLE - REMOVAL, THROTTLE

CONTROL....................14-109,14-49

CABLE INSTALLATION, GASOLINE

ENGINE - NEGATIVE..................8F-22

CABLE INSTALLATION, GASOLINE

ENGINE - POSITIVE...................8F-22

CABLE ORDER, 8.0L V-10 ENGINE -

SPARK PLUG.........................8I-3

CABLE REMOVAL, GASOLINE ENGINE -

NEGATIVE..........................8F-22

CABLE REMOVAL, GASOLINE ENGINE -

POSITIVE...........................8F-21

CABLE RESISTANCE, SPECIFICATIONS -

SPARK PLUG.........................8I-3

CABLES - DIAGNOSIS AND TESTING,

BATTERY...........................8F-19

CABLES - DIAGNOSIS AND TESTING,

SPARK PLUG........................8I-20

CAB-TO-BED GROUND STRAP -

INSTALLATION.......................8A-14

CAB-TO-BED GROUND STRAP -

REMOVAL..........................8A-13

CALIBRATION - STANDARD PROCEDURE,

COMPASS...........................8M-4

CALIPERS - DESCRIPTION, DISC BRAKE . . . 5-10

CALIPERS - OPERATION, DISC BRAKE.....5-10

CAM - DESCRIPTION, TURN SIGNAL

CANCEL............................8L-31

CAM - OPERATION, TURN SIGNAL

CANCEL............................8L-31

CAM BORE REPAIR - STANDARD

PROCEDURE........................9-151

CAM/OVERDRIVE PISTON RETAINER -

ASSEMBLY, OVERRUNNING

CLUTCH.....................21-193,21-364

CAM/OVERDRIVE PISTON RETAINER -

CLEANING, OVERRUNNING

CLUTCH

.....................21-192,21-364

CAM/OVERDRIVE PISTON RETAINER -

DESCRIPTION, OVERRUNNING

CLUTCH

.....................21-192,21-363

CAM/OVERDRIVE PISTON RETAINER -

DISASSEMBLY, OVERRUNNING

CLUTCH

.....................21-192,21-364

CAM/OVERDRIVE PISTON RETAINER -

INSPECTION, OVERRUNNING

CLUTCH

.....................21-193,21-364

CAM/OVERDRIVE PISTON RETAINER -

OPERATION, OVERRUNNING

CLUTCH

.....................21-192,21-363CAMSHAFT - INSTALLATION....9-157,9-29,9-86

CAMSHAFT - REMOVAL.......9-152,9-28,9-85

CAMSHAFT BEARINGS - I

NSTALLATION...............9-157,9-28,9-86

CAMSHAFT BEARINGS -

REMOVAL..................9-152,9-27,9-85

CANCEL CAM - DESCRIPTION, TURN

SIGNAL............................8L-31

CANCEL CAM - OPERATION, TURN

SIGNAL............................8L-31

CANISTER - DESCRIPTION, VAPOR......25-37

CANISTER - INSTALLATION, CRANKCASE

BREATHER VAPOR...................9-126

CANISTER - INSTALLATION, VAPOR......25-38

CANISTER - OPERATION, VAPOR........25-37

CANISTER - REMOVAL, CRANKCASE

BREATHER VAPOR...................9-125

CANISTER - REMOVAL, VAPOR..........25-38

CAP - DESCRIPTION, FUEL FILLER.......25-34

CAP - DESCRIPTION, RADIATOR

PRESSURE..........................7-64

CAP - DIAGNOSIS AND TESTING,

DISTRIBUTOR.......................8I-14

CAP - DIAGNOSIS AND TESTING,

RADIATOR...........................7-65

CAP - OPERATION, FUEL FILLER........25-34

CAP - OPERATION, RADIATOR

PRESSURE..........................7-64

CAP - REMOVAL/INSTALLATION, FUEL

FILLER.............................25-34

CAPACITIES, SPECIFICATIONS - FLUID.......0-6

CAPACITY TEST - DIAGNOSIS AND

TESTING, FUEL PUMP..................14-9

CARDAN UNIVERSAL JOINTS -

ASSEMBLY, DOUBLE...................3-11

CARDAN UNIVERSAL JOINTS -

ASSEMBLY, SINGLE.....................3-9

CARDAN UNIVERSAL JOINTS -

DISASSEMBLY, DOUBLE................3-10

CARDAN UNIVERSAL JOINTS -

DISASSEMBLY, SINGLE..................3-8

CARDAN UNIVERSAL JOINTS -

INSTALLATION, SINGLE.................3-35

CARDAN UNIVERSAL JOINTS -

REMOVAL, SINGLE....................3-34

CARGO BOX - INSTALLATION...........23-97

CARGO BOX - REMOVAL...............23-97

CARGO DOOR - ADJUSTMENT..........23-78

CARPETS AND FLOOR MATS -

INSTALLATION......................23-123

CARPETS AND FLOOR MATS - REMOVAL . 23-123

CARTRIDGE FUSE - DESCRIPTION,

GENERATOR......................8W-97-4

CARTRIDGE FUSE - INSTALLATION,

GENERATOR......................8W-97-4

CARTRIDGE FUSE - OPERATION,

GENERATOR......................8W-97-4

CARTRIDGE FUSE - REMOVAL,

GENERATOR......................8W-97-4

CASE - DIAGNOSIS AND TESTING,

TRANSFER...................21-431,21-467

CASE - NV241 - DESCRIPTION,

TRANSFER

............................0-5

CASE - NV241HD - ASSEMBLY,

TRANSFER

.........................21-480

CASE - NV241HD - CLEANING,

TRANSFER

.........................21-476

CASE - NV241HD - DESCRIPTION,

TRANSFER

.........................21-465

CASE - NV241HD - DISASSEMBLY,

TRANSFER

.........................21-469

CASE - NV241HD - INSPECTION,

TRANSFER

.........................21-476

CASE - NV241HD - INSTALLATION,

TRANSFER

.........................21-494

CASE - NV241HD - OPERATION,

TRANSFER

.........................21-467

CASE - NV241HD - REMOVAL,

TRANSFER

.........................21-469

CASE - NV241LD - ASSEMBLY,

TRANSFER

.........................21-445

CASE - NV241LD - CLEANING,

TRANSFER

.........................21-441

CASE - NV241LD - DESCRIPTION,

TRANSFER

.........................21-430

CASE - NV241LD - DISASSEMBLY,

TRANSFER

.........................21-432CASE - NV241LD - INSPECTION,

TRANSFER.........................21-442

CASE - NV241LD - INSTALLATION,

TRANSFER.........................21-458

CASE - NV241LD - OPERATION,

TRANSFER.........................21-430

CASE - NV241LD - REMOVAL,

TRANSFER.........................21-432

CASE BEARINGS - INSTALLATION,

DIFFERENTIAL..........3-102,3-129,3-41,3-72

CASE BEARINGS - REMOVAL,

DIFFERENTIAL..........3-102,3-129,3-40,3-72

CASE, NV241HD - TRANSFER..........21-495

CASE, NV241LD - TRANSFER..........21-459

CASE SKID PLATE - INSTALLATION,

TRANSFER..........................13-11

CASE SKID PLATE - REMOVAL,

TRANSFER..........................13-11

CASE, SPECIFICATIONS -

TRANSFER...................21-458,21-495

CASTER CORRECTION MEASUREMENT -

STANDARD PROCEDURE.................2-3

CATALYTIC CONVERTER - 3.9L/5.2L/5.9L

- DESCRIPTION.......................11-5

CATALYTIC CONVERTER - 3.9L/5.2L/5.9L

- INSPECTION........................11-6

CATALYTIC CONVERTER - 3.9L/5.2L/5.9L

- INSTALLATION......................11-6

CATALYTIC CONVERTER - 3.9L/5.2L/5.9L

- OPERATION.........................11-5

CATALYTIC CONVERTER - 3.9L/5.2L/5.9L

- REMOVAL..........................11-5

CATALYTIC CONVERTER - 5.9L HD/8.0L -

DESCRIPTION........................11-6

CATALYTIC CONVERTER - 5.9L HD/8.0L -

INSPECTION.........................11-6

CATALYTIC CONVERTER - 5.9L HD/8.0L -

INSTALLATION........................11-7

CATALYTIC CONVERTER - 5.9L HD/8.0L -

OPERATION..........................11-6

CATALYTIC CONVERTER - 5.9L HD/8.0L -

REMOVAL...........................11-6

CAUSES OF BURNT FLUID - DIAGNOSIS

AND TESTING................21-157,21-327

CCD DATA BUS - DESCRIPTION..........8E-6

CCD DATA BUS - DIAGNOSIS AND

TESTING...........................8E-11

CCD DATA BUS - OPERATION............8E-7

CENTER - DESCRIPTION, POWER

DISTRIBUTION....................8W-97-8

CENTER - INSTALLATION, POWER

DISTRIBUTION...................8W-97-10

CENTER - OPERATION, POWER

DISTRIBUTION....................8W-97-8

CENTER - REMOVAL, POWER

DISTRIBUTION....................8W-97-8

CENTER BEARING - ADJUSTMENT.........3-8

CENTER BEARING - INSTALLATION........3-8

CENTER BEARING - REMOVAL............3-8

CENTER CONSOLE - INSTALLATION.....23-122

CENTER CONSOLE - REMOVAL.........23-122

CENTER CONSOLE LID - INSTALLATION . . 23-132

CENTER CONSOLE LID - REMOVAL.....23-131

CENTER HIGH MOUNTED STOP LAMP -

INSTALLATION........................8L-6

CENTER HIGH MOUNTED STOP LAMP -

REMOVAL...........................8L-6

CENTER HIGH MOUNTED STOP LAMP

UNIT - INSTALLATION..................8L-6

CENTER HIGH MOUNTED STOP LAMP

UNIT - REMOVAL.....................8L-6

CENTER SEAT ARMREST/CONSOLE -

INSTALLATION......................23-132

CENTER SEAT ARMREST/CONSOLE -

REMOVAL.........................23-132

CENTER SEAT ARMREST/LATCH COVER -

INSTALLATION......................23-132

CENTER SEAT ARMREST/LATCH COVER -

REMOVAL.........................23-132

CENTERING - STANDARD PROCEDURE,

CLOCKSPRING

......................8O-11

CENTRAL TIMER MODULE -

DESCRIPTION

........................8E-1

CENTRAL TIMER MODULE - DIAGNOSIS

AND TESTING

........................8E-4

CENTRAL TIMER MODULE -

INSTALLATION

........................8E-6

CENTRAL TIMER MODULE - OPERATION

. . . 8E-3

BR/BEINDEX 5

Description Group-Page Description Group-Page Description Group-Page

Page 2223 of 2255

CENTRAL TIMER MODULE - REMOVAL....8E-5

CERTIFICATION LABEL - DESCRIPTION,

VEHICLE SAFETY...................Intro.-1

CHAIN COVER(S) - INSTALLATION,

TIMING BELT....................9-110,9-54

CHAIN COVER(S) - REMOVAL, TIMING

BELT ..........................9-110,9-53

CHAIN STRETCH - INSPECTION,

MEASURING TIMING..............9-111,9-54

CHANNEL - INSTALLATION, GLASS RUN . . 23-71

CHANNEL - REMOVAL, GLASS RUN......23-71

CHARGE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM...............24-46

CHARGE AIR COOLER AND PLUMBING -

CLEANING..........................11-19

CHARGE AIR COOLER AND PLUMBING -

DESCRIPTION.......................11-18

CHARGE AIR COOLER AND PLUMBING -

INSPECTION........................11-19

CHARGE AIR COOLER AND PLUMBING -

INSTALLATION.......................11-20

CHARGE AIR COOLER AND PLUMBING -

OPERATION.........................11-18

CHARGE AIR COOLER AND PLUMBING -

REMOVAL..........................11-18

CHARGE AIR COOLER SYSTEM - LEAKS

- DIAGNOSIS AND TESTING............11-18

CHARGING - DESCRIPTION.............8F-25

CHARGING - OPERATION..............8F-25

CHARGING - STANDARD PROCEDURE,

BATTERY............................8F-8

CHARGING SYSTEM - DIAGNOSIS AND

TESTING...........................8F-25

CHART, SPECIFICATIONS - TORQUE....5-3,5-37

CHART, SPECIFICATIONS -

TORQUE.............19-21,19-41,19-43,19-9

CHART, SPECIFICATIONS -

TORQUE.....................2-15,2-26,2-8

CHART, SPECIFICATIONS - TORQUE......22-11

CHARTS - DIAGNOSIS AND TESTING,

DIAGNOSIS..................21-102,21-274

CHARTS - DIAGNOSIS AND TESTING,

SMOKE DIAGNOSIS...................9-118

CHASSIS ADAPTER BRACKET -

INSTALLATION, CAB..................13-10

CHASSIS ADAPTER BRACKET -

REMOVAL, CAB......................13-10

CHECK - INSTALLATION...............23-78

CHECK - REMOVAL...................23-78

CHECK - STANDARD PROCEDURE,

COOLANT LEVEL......................7-16

CHECK - STANDARD PROCEDURE, FLUID

LEVEL......................21-157,21-328

CHECK - STANDARD PROCEDURE, OIL

PUMP VOLUME...............21-166,21-336

CHECK CABLE - INSTALLATION.........23-67

CHECK CABLE - REMOVAL.............23-67

CHECK GAUGES INDICATOR -

DESCRIPTION.......................8J-17

CHECK GAUGES INDICATOR -

OPERATION.........................8J-17

CHECK VALVE - DESCRIPTION, FUEL

TANK ..............................14-21

CHECK VALVE - DESCRIPTION, ONE WAY . 25-31

CHECK VALVE - DESCRIPTION, VACUUM . . 24-28

CHECK VALVE - DIAGNOSIS AND

TESTING, ONE-WAY..................25-31

CHECK VALVE - INSTALLATION, FUEL

TANK ..............................14-23

CHECK VALVE - INSTALLATION, ONE

WAY...............................25-31

CHECK VALVE - INSTALLATION, VACUUM

. 24-29

CHECK VALVE - OPERATION, ONE WAY

. . . 25-31

CHECK VALVE - OPERATION, VACUUM

....24-28

CHECK VALVE - REMOVAL, FUEL TANK

. . . 14-22

CHECK VALVE - REMOVAL, ONE WAY

....25-31

CHECK VALVE - REMOVAL, VACUUM

.....24-29

CHECKS - DIAGNOSIS AND TESTING,

PRELIMINARY

.........................7-4

CHILD TETHER - INSTALLATION

..........8O-9

CHILD TETHER - REMOVAL

.............8O-9

CHIME WARNING SYSTEM -

DESCRIPTION

........................8B-1

CHIME WARNING SYSTEM - DIAGNOSIS

AND TESTING

........................8B-2

CHIME WARNING SYSTEM - OPERATION

. . . 8B-1

CHOKE RELAY - DESCRIPTION, RADIO

....8A-7CHOKE RELAY - DIAGNOSIS AND

TESTING, RADIO......................8A-8

CHOKE RELAY - INSTALLATION, RADIO....8A-9

CHOKE RELAY - OPERATION, RADIO......8A-8

CHOKE RELAY - REMOVAL, RADIO.......8A-8

CIGAR LIGHTER OUTLET - DESCRIPTION . 8W-97-2

CIGAR LIGHTER OUTLET - DIAGNOSIS

AND TESTING.....................8W-97-2

CIGAR LIGHTER OUTLET -

INSTALLATION....................8W-97-4

CIGAR LIGHTER OUTLET - OPERATION . 8W-97-2

CIGAR LIGHTER OUTLET - REMOVAL . . 8W-97-3

CIRCUIT ACTUATION TEST MODE -

DESCRIPTION........................25-2

CIRCUIT BREAKER - DESCRIPTION....8W-97-4

CIRCUIT BREAKER - DIAGNOSIS AND

TESTING.........................8W-97-4

CIRCUIT FUNCTIONS - DESCRIPTION . . 8W-01-4

CIRCUIT INFORMATION - DESCRIPTION . 8W-01-4

CIRCUIT SENSE - DESCRIPTION,

IGNITION...........................8E-17

CIRCUIT SENSE - OPERATION, IGNITION . . 8E-19

CIRCUITS - DIESEL - OPERATION,

NON-MONITORED....................25-24

CIRCUITS - GAS ENGINES - OPERATION,

NON-MONITORED....................25-24

CLAMPS - DESCRIPTION, HOSE...........7-4

CLAMPS - OPERATION, HOSE.............7-4

CLASSIFICATION OF LUBRICANTS -

STANDARD PROCEDURE..................0-1

CLEANER ELEMENT - INSTALLATION,

AIR ...............................9-130

CLEANER ELEMENT - REMOVAL, AIR.....9-129

CLEANING AND INSPECTION, OIL

COOLER & LINES....................9-179

CLEANING, BATTERY SYSTEM...........8F-5

CLEANING, CHARGE AIR COOLER AND

PLUMBING.........................11-19

CLEANING, CROSSHEADS..............9-134

CLEANING, CYLINDER HEAD.......9-134,9-77

CLEANING, CYLINDER HEAD

COVER(S)..................9-137,9-23,9-79

CLEANING, ENGINE BLOCK..........9-27,9-85

CLEANING, EXHAUST

MANIFOLD.................9-109,9-185,9-53

CLEANING, FRONT SERVO......21-164,21-334

CLEANING FUEL SYSTEM PARTS -

STANDARD PROCEDURES..............14-61

CLEANING, HYDRAULIC LIFTERS.....9-37,9-92

CLEANING, INTAKE MANIFOLD . 9-107,9-184,9-51

CLEANING, INTAKE/EXHAUST VALVES &

SEATS ..............................9-26

CLEANING, MANUAL - NV4500..........21-20

CLEANING, MANUAL - NV5600..........21-63

CLEANING, OIL PAN.........9-103,9-179,9-46

CLEANING, OIL PRESSURE RELIEF

VALVE .............................9-180

CLEANING, OIL PUMP............9-104,9-181

CLEANING, OIL PUMP..........21-168,21-338

CLEANING, OPERATION.................9-22

CLEANING, OVERDRIVE UNIT....21-179,21-353

CLEANING, OVERRUNNING CLUTCH

CAM/OVERDRIVE PISTON

RETAINER...................21-192,21-364

CLEANING, PISTON & CONNECTING

ROD.......................9-169,9-39,9-94

CLEANING, PUSHRODS................9-134

CLEANING, RADIATOR - 5.9L............7-59

CLEANING, RADIATOR - 5.9L DIESEL......7-64

CLEANING, RADIATOR - 8.0L............7-61

CLEANING, RADIATOR FAN - 5.9L

DIESEL.............................7-43

CLEANING, RADIATOR FAN - 5.9L/8.0L....7-42

CLEANING, REAR CLUTCH

......21-204,21-377

CLEANING, REAR SERVO

.......21-207,21-379

CLEANING, ROCKER ARM / ADJUSTER

ASSY

..............................9-146

CLEANING, SOLID LIFTERS/TAPPETS

.....9-164

CLEANING, SPARK PLUG

...............8I-20

CLEANING, TRANSFER CASE - NV241HD

. 21-476

CLEANING, TRANSFER CASE - NV241LD

. 21-441

CLEANING, TURBOCHARGER

...........11-16

CLEANING, VALVE BODY

........21-244,21-418

CLEANING, WATER PUMP - 5.9L

.........7-68

CLEANING, WATER PUMP - 5.9L DIESEL

. . . 7-72

CLEANING, WATER PUMP - 8.0L

.........7-71

CLEANING, WIPER & WASHER SYSTEM

. . . 8R-6CLEANING/REVERSE FLUSHING -

STANDARD PROCEDURE, COOLING

SYSTEM............................7-17

CLEARANCE - STANDARD PROCEDURE,

CONNECTING ROD BEARING AND

CRANKSHAFT JOURNAL...............9-158

CLEARANCE - STANDARD PROCEDURE,

MAIN BEARING......................9-159

CLEARANCE LAMP - INSTALLATION.......8L-7

CLEARANCE LAMP - REMOVAL..........8L-7

CLOCKSPRING - DESCRIPTION.........8O-10

CLOCKSPRING - INSTALLATION.........8O-13

CLOCKSPRING - OPERATION...........8O-10

CLOCKSPRING - REMOVAL............8O-12

CLOCKSPRING CENTERING - STANDARD

PROCEDURE........................8O-11

CLOSURE PANEL TRIM - INSTALLATION,

REAR.............................23-121

CLOSURE PANEL TRIM - REMOVAL,

REAR.............................23-120

CLUB/QUAD CAB - INSTALLATION.......8O-20

CLUB/QUAD CAB - REMOVAL...........8O-19

CLUSTER - ASSEMBLY, INSTRUMENT....8J-12

CLUSTER - DESCRIPTION, INSTRUMENT . . . 8J-2

CLUSTER - DIAGNOSIS AND TESTING,

INSTRUMENT........................8J-6

CLUSTER - DISASSEMBLY, INSTRUMENT . . 8J-10

CLUSTER - INSTALLATION, INSTRUMENT . 8J-13

CLUSTER - OPERATION, INSTRUMENT.....8J-3

CLUSTER - REMOVAL, INSTRUMENT......8J-10

CLUSTER BEZEL - INSTALLATION.......23-108

CLUSTER BEZEL - REMOVAL..........23-108

CLUTCH - 5.9L DIESEL - DESCRIPTION,

FAN DRIVE VISCOUS...................7-56

CLUTCH - 5.9L DIESEL - OPERATION,

FAN DRIVE VISCOUS...................7-56

CLUTCH - 5.9L/8.0L - DESCRIPTION,

FAN DRIVE VISCOUS...................7-55

CLUTCH - 5.9L/8.0L - OPERATION, FAN

DRIVE VISCOUS......................7-55

CLUTCH - ASSEMBLY, FRONT....21-162,21-333

CLUTCH - ASSEMBLY, REAR.....21-205,21-377

CLUTCH - CLEANING, REAR.....21-204,21-377

CLUTCH - DESCRIPTION.................6-1

CLUTCH - DESCRIPTION, A/C

COMPRESSOR.......................24-11

CLUTCH - DESCRIPTION, FRONT . 21-160,21-330

CLUTCH - DESCRIPTION, OVERDRIVE . . . 21-172,

21-343

CLUTCH - DESCRIPTION, REAR . . 21-203,21-375

CLUTCH - DIAGNOSIS AND TESTING

.......6-2

CLUTCH - DISASSEMBLY, FRONT

. 21-161,21-331

CLUTCH - DISASSEMBLY, REAR

. . 21-204,21-376

CLUTCH - INSPECTION, A/C

COMPRESSOR

.......................24-15

CLUTCH - INSPECTION, FRONT

. . 21-162,21-332

CLUTCH - INSPECTION, REAR

. . . 21-204,21-377

CLUTCH - INSTALLATION, A/C

COMPRESSOR

.......................24-15

CLUTCH - OPERATION

..................6-2

CLUTCH - OPERATION, A/C

COMPRESSOR

.......................24-13

CLUTCH - OPERATION, FRONT

. . . 21-160,21-330

CLUTCH - OPERATION, OVERDRIVE

....21-172,

21-343

CLUTCH - OPERATION, REAR

....21-203,21-375

CLUTCH - REMOVAL, A/C COMPRESSOR

. . 24-13

CLUTCH - SPECIFICATIONS

...............6-7

CLUTCH - WARNING

....................6-2

CLUTCH AND BAND OPERATION -

DIAGNOSIS AND TESTING, AIR

TESTING TRANSMISSION

.......21-100,21-272

CLUTCH BREAK-IN - STANDARD

PROCEDURE, A/C COMPRESSOR

........24-13

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - ASSEMBLY,

OVERRUNNING

...............21-193,21-364

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - CLEANING, OVERRUNNING

. 21-192,

21-364

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - DESCRIPTION,

OVERRUNNING

...............21-192,21-363

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - DISASSEMBLY,

OVERRUNNING

...............21-192,21-364

6 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2225 of 2255

CONTROLS - DIAGNOSIS AND TESTING,

OVERDRIVE ELECTRICAL.......21-191,21-344

CONVERTER - 3.9L/5.2L/5.9L -

DESCRIPTION, CATALYTIC...............11-5

CONVERTER - 3.9L/5.2L/5.9L -

INSPECTION, CATALYTIC................11-6

CONVERTER - 3.9L/5.2L/5.9L -

INSTALLATION, CATALYTIC..............11-6

CONVERTER - 3.9L/5.2L/5.9L -

OPERATION, CATALYTIC................11-5

CONVERTER - 3.9L/5.2L/5.9L -

REMOVAL, CATALYTIC..................11-5

CONVERTER - 5.9L HD/8.0L -

DESCRIPTION, CATALYTIC...............11-6

CONVERTER - 5.9L HD/8.0L -

INSPECTION, CATALYTIC................11-6

CONVERTER - 5.9L HD/8.0L -

INSTALLATION, CATALYTIC..............11-7

CONVERTER - 5.9L HD/8.0L -

OPERATION, CATALYTIC................11-6

CONVERTER - 5.9L HD/8.0L - REMOVAL,

CATALYTIC...........................11-6

CONVERTER - DESCRIPTION,

TORQUE.....................21-212,21-384

CONVERTER - INSTALLATION,

TORQUE.....................21-217,21-389

CONVERTER - OPERATION,

TORQUE.....................21-215,21-388

CONVERTER - REMOVAL,

TORQUE.....................21-216,21-389

CONVERTER DRAINBACK VALVE -

DESCRIPTION, TORQUE........21-217,21-390

CONVERTER DRAINBACK VALVE -

OPERATION, TORQUE............21-217,21-390

CONVERTER DRAINBACK VALVE -

STANDARD PROCEDURE,

TORQUE.....................21-217,21-390

CONVERTER HOUSING FLUID LEAK -

DIAGNOSIS AND TESTING......21-101,21-273

COOLANT - DESCRIPTION, ENGINE.......7-39

COOLANT - DESCRIPTION, ENGINE........0-3

COOLANT - OPERATION................7-40

COOLANT - STANDARD PROCEDURE,

ADDING ADDITIONAL..................7-16

COOLANT FLOW - DIAGNOSIS AND

TESTING, RADIATOR...........7-58,7-60,7-62

COOLANT LEVEL CHECK - STANDARD

PROCEDURE.........................7-16

COOLANT RECOVERY CONTAINER -

3.9L/5.2L/5.9L/5.9L DIESEL -

DESCRIPTION........................7-40

COOLANT RECOVERY CONTAINER -

3.9L/5.2L/5.9L/5.9L DIESEL -

INSTALLATION........................7-41

COOLANT RECOVERY CONTAINER -

3.9L/5.2L/5.9L/5.9L DIESEL -

OPERATION..........................7-40

COOLANT RECOVERY CONTAINER -

3.9L/5.2L/5.9L/5.9L DIESEL -

REMOVAL...........................7-40

COOLANT RECOVERY CONTAINER - 8.0L

- DESCRIPTION.......................7-41

COOLANT RECOVERY CONTAINER - 8.0L

- OPERATION.........................7-41

COOLANT SELECTION - ADDITIVES -

STANDARD PROCEDURE................7-17

COOLANT TEMP SENSOR - 5.9L -

DESCRIPTION, ENGINE.................7-47

COOLANT TEMP SENSOR - 5.9L -

INSTALLATION, ENGINE................7-47

COOLANT TEMP SENSOR - 5.9L -

OPERATION, ENGINE...................7-47

COOLANT TEMP SENSOR - 5.9L -

REMOVAL, ENGINE....................7-47

COOLANT THERMOSTAT - 5.9L -

DESCRIPTION, ENGINE.................7-48

COOLANT THERMOSTAT - 5.9L -

INSTALLATION, ENGINE................7-49

COOLANT THERMOSTAT - 5.9L -

OPERATION, ENGINE

...................7-48

COOLANT THERMOSTAT - 5.9L -

REMOVAL, ENGINE

....................7-48

COOLANT THERMOSTAT - 5.9L DIESEL -

DESCRIPTION, ENGINE

.................7-53

COOLANT THERMOSTAT - 5.9L DIESEL -

INSTALLATION, ENGINE

................7-54

COOLANT THERMOSTAT - 5.9L DIESEL -

OPERATION, ENGINE

...................7-53COOLANT THERMOSTAT - 5.9L DIESEL -

REMOVAL, ENGINE....................7-54

COOLANT THERMOSTAT - 8.0L -

DESCRIPTION, ENGINE.................7-51

COOLANT THERMOSTAT - 8.0L -

INSTALLATION, ENGINE................7-52

COOLANT THERMOSTAT - 8.0L -

OPERATION, ENGINE...................7-51

COOLANT THERMOSTAT - 8.0L -

REMOVAL, ENGINE....................7-51

COOLER - 5.9L - DESCRIPTION, TRANS....7-78

COOLER - 5.9L - OPERATION, TRANS.....7-78

COOLER - 5.9L DIESEL - DESCRIPTION,

TRANS..............................7-84

COOLER - 5.9L DIESEL - OPERATION,

TRANS..............................7-84

COOLER - 8.0L - DESCRIPTION, TRANS....7-81

COOLER - 8.0L - OPERATION, TRANS.....7-81

COOLER - INSTALLATION, AIR TO OIL.....7-87

COOLER & LINES - CLEANING AND

INSPECTION, OIL.....................9-179

COOLER - REMOVAL, AIR TO OIL.........7-86

COOLER - REMOVAL, WATER TO OIL......7-86

COOLER - STANDARD PROCEDURE,

FLUSHING COOLERS AND TUBES -

WITH RADIATOR IN-TANK

TRANSMISSION OIL...........7-78,7-82,7-84

COOLER - STANDARD PROCEDURE,

FLUSHING COOLERS AND TUBES -

WITHOUT RADIATOR IN-TANK

TRANSMISSION OIL...........7-79,7-82,7-85

COOLER AND PLUMBING - CLEANING,

CHARGE AIR..........................11-19

COOLER AND PLUMBING -

DESCRIPTION, CHARGE AIR............11-18

COOLER AND PLUMBING - INSPECTION,

CHARGE AIR........................11-19

COOLER AND PLUMBING -

INSTALLATION, CHARGE AIR...........11-20

COOLER AND PLUMBING - OPERATION,

CHARGE AIR........................11-18

COOLER AND PLUMBING - REMOVAL,

CHARGE AIR........................11-18

COOLER SYSTEM - LEAKS - DIAGNOSIS

AND TESTING, CHARGE AIR............11-18

COOLERS AND TUBES - WITH

RADIATOR IN-TANK TRANSMISSION

OIL COOLER - STANDARD

PROCEDURE, FLUSHING........7-78,7-82,7-84

COOLERS AND TUBES - WITHOUT

RADIATOR IN-TANK TRANSMISSION

OIL COOLER - STANDARD

PROCEDURE, FLUSHING........7-79,7-82,7-85

COOLING, SPECIAL TOOLS..............7-18

COOLING SYSTEM - OPERATION..........7-4

COOLING SYSTEM 5.9L DIESEL ENGINE

- STANDARD PROCEDURE, DRAINING.....7-15

COOLING SYSTEM 5.9L DIESEL ENGINE

- STANDARD PROCEDURE, REFILLING.....7-16

COOLING SYSTEM 5.9L/8.0L ENGINES -

STANDARD PROCEDURE, DRAINING......7-15

COOLING SYSTEM 5.9L/8.0L ENGINES -

STANDARD PROCEDURE, REFILLING......7-16

COOLING SYSTEM CLEANING/REVERSE

FLUSHING - STANDARD PROCEDURE.....7-17

COOLING SYSTEM DIESEL ENGINE -

DIAGNOSIS AND TESTING

..............7-13

COOLING SYSTEM FLOW - 5.9L DIESEL

- DESCRIPTION

........................7-2

COOLING SYSTEM FLOW - 5.9L ENGINE

- DESCRIPTION

........................7-1

COOLING SYSTEM GAS ENGINE -

DIAGNOSIS AND TESTING

...............7-7

COOLING SYSTEM LEAKS - DIAGNOSIS

AND TESTING

.........................7-5

COOLING SYSTEM REQUIREMENTS -

DESCRIPTION

........................24-1

CORE - DESCRIPTION, HEATER

.........24-56

CORE - INSTALLATION, HEATER

.........24-56

CORE - OPERATION, HEATER

...........24-56

CORE - REMOVAL, HEATER

............24-56

CORE GROUND STRAP - INSTALLATION,

HEATER

............................8A-14

CORE GROUND STRAP - REMOVAL,

HEATER

............................8A-14

CORNER SEAL - INSTALLATION, FRONT

DOOR UPPER

......................23-154CORNER SEAL - REMOVAL, FRONT

DOOR UPPER......................23-153

COUPLERS - DESCRIPTION, A/C LINE....24-40

COUPLERS - OPERATION, A/C LINE......24-41

COUPLERS - STANDARD PROCEDURE,

A/C LINE...........................24-44

COVER - INSTALLATION, CENTER SEAT

ARMREST/LATCH...................23-132

COVER - INSTALLATION, COWL TRIM . . . 23-120

COVER - INSTALLATION, GEAR HOUSING . 9-190

COVER - INSTALLATION, INSTRUMENT

PANEL TOP........................23-113

COVER - INSTALLATION, SEAT BACK....23-137

COVER - INSTALLATION, SEAT CUSHION . 23-139

COVER - INSTALLATION, STANCHION....23-143

COVER - INSTALLATION, STEERING

COLUMN OPENING..................23-114

COVER - NV4500 - INSTALLATION, SHIFT . 21-45

COVER - NV4500 - REMOVAL, SHIFT.....21-45

COVER - NV5600 - INSTALLATION, SHIFT . 21-86

COVER - NV5600 - REMOVAL, SHIFT.....21-86

COVER - REMOVAL, CENTER SEAT

ARMREST/LATCH...................23-132

COVER - REMOVAL, COWL TRIM.......23-119

COVER - REMOVAL, GEAR HOUSING.....9-189

COVER - REMOVAL, INSTRUMENT

PANEL TOP........................23-113

COVER - REMOVAL, SEAT BACK........23-137

COVER - REMOVAL, SEAT CUSHION......23-139

COVER - REMOVAL, STANCHION.......23-143

COVER - REMOVAL, STEERING COLUMN

OPENING..........................23-113

COVER - REMOVAL, WHEEL............22-12

COVER - SPLIT BENCH - INSTALLATION,

SEAT BACK........................23-137

COVER - SPLIT BENCH - INSTALLATION,

SEAT CUSHION.....................23-140

COVER - SPLIT BENCH - REMOVAL,

SEAT BACK........................23-137

COVER - SPLIT BENCH - REMOVAL,

SEAT CUSHION.....................23-139

COVER GASKET - DESCRIPTION,

CYLINDER HEAD......................9-20

COVER GASKET - OPERATION,

CYLINDER HEAD......................9-21

COVER INSTALLED - INSTALLATION,

FRONT OIL SEAL - FRONT..............9-89

COVER INSTALLED - REMOVAL, FRONT

OIL SEAL - FRONT....................9-89

COVER REMOVED - INSTALLATION,

FRONT OIL SEAL - FRONT..............9-90

COVER REMOVED - REMOVAL, FRONT

OIL SEAL - FRONT....................9-89

COVER(S) - CLEANING, CYLINDER HEAD . 9-137,

9-23,9-79

COVER(S) - DESCRIPTION, CYLINDER

HEAD...............................9-78

COVER(S) - INSPECTION, CYLINDER

HEAD......................9-138,9-23,9-79

COVER(S) - INSTALLATION, CYLINDER

HEAD......................9-138,9-23,9-79

COVER(S) - INSTALLATION, TIMING

BELT / CHAIN...................9-110,9-54

COVER(S) - REMOVAL, CYLINDER HEAD . 9-137,

9-23,9-78

COVER(S) - REMOVAL, TIMING BELT /

CHAIN.........................9-110,9-53

COWL GRILLE - INSTALLATION.........23-90

COWL GRILLE - REMOVAL.............23-90

COWL TRIM COVER - INSTALLATION....23-120

COWL TRIM COVER - REMOVAL.......23-119

COWL WEATHERSTRIP - INSTALLATION . 23-152

COWL WEATHERSTRIP - REMOVAL.....23-152

C-PILLAR TRIM - INSTALLATION.......23-128

C-PILLAR TRIM - REMOVAL...........23-128

CRANKCASE BREATHER VAPOR

CANISTER - INSTALLATION.............9-126

CRANKCASE BREATHER VAPOR

CANISTER - REMOVAL................9-125

CRANKSHAFT - DESCRIPTION......9-159,9-29

CRANKSHAFT - INSTALLATION

.......9-30,9-88

CRANKSHAFT - OPERATION

.............9-29

CRANKSHAFT - REMOVAL

..........9-30,9-87

CRANKSHAFT JOURNAL CLEARANCE -

STANDARD PROCEDURE, CONNECTING

ROD BEARING

.......................9-158

CRANKSHAFT MAIN BEARING FITTING -

STANDARD PROCEDURE

................9-31

8 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2231 of 2255

FUEL INJECTION PUMP RELAY -

DESCRIPTION......................14-103

FUEL INJECTION PUMP RELAY -

OPERATION........................14-103

FUEL INJECTION PUMP TIMING -

DIAGNOSIS AND TESTING.............14-70

FUEL INJECTION SYSTEM -

DESCRIPTION, DIESEL................14-91

FUEL INJECTOR - DESCRIPTION....14-52,14-97

FUEL INJECTOR - DIAGNOSIS AND

TESTING...........................14-53

FUEL INJECTOR - INSTALLATION.......14-102

FUEL INJECTOR - OPERATION..........14-98

FUEL INJECTOR - REMOVAL...........14-101

FUEL INJECTOR FIRING ORDER, DIESEL . . 14-62

FUEL INJECTOR TEST - DIAGNOSIS AND

TESTING...........................14-99

FUEL LEVEL SENDING UNIT / SENSOR -

DESCRIPTION...................14-7,14-77

FUEL LEVEL SENDING UNIT / SENSOR -

INSTALLATION........................14-8

FUEL LEVEL SENDING UNIT / SENSOR -

OPERATION.....................14-7,14-77

FUEL LEVEL SENDING UNIT / SENSOR -

REMOVAL...........................14-7

FUEL LINE LEAKS - DIAGNOSIS AND

TESTING, HIGH-PRESSURE.............14-78

FUEL LINES - DESCRIPTION.............14-8

FUEL LINES - DESCRIPTION, HIGH

PRESSURE.........................14-78

FUEL LINES - OPERATION, HIGH

PRESSURE...........................14-78

FUEL PRESSURE LEAK DOWN TEST -

DIAGNOSIS AND TESTING..............14-2

FUEL PUMP - DESCRIPTION.............14-9

FUEL PUMP - OPERATION..............14-9

FUEL PUMP 235 H.P. - DESCRIPTION....14-69

FUEL PUMP 245 H.P. - DESCRIPTION....14-69

FUEL PUMP AMPERAGE TEST -

DIAGNOSIS AND TESTING.............14-10

FUEL PUMP CAPACITY TEST -

DIAGNOSIS AND TESTING..............14-9

FUEL PUMP MODULE - DESCRIPTION....14-12

FUEL PUMP MODULE - INSTALLATION . . . 14-13

FUEL PUMP MODULE - OPERATION......14-13

FUEL PUMP MODULE - REMOVAL.......14-13

FUEL PUMP PRESSURE TEST -

DIAGNOSIS AND TESTING..............14-9

FUEL PUMP RELAY - DESCRIPTION......14-40

FUEL PUMP RELAY - INSTALLATION.....14-40

FUEL PUMP RELAY - OPERATION........14-40

FUEL PUMP RELAY - REMOVAL.........14-40

FUEL PUMP RELAYS - DIAGNOSIS AND

TESTING, ASD........................8I-4

FUEL REQUIREMENTS - DIESEL ENGINE

- DESCRIPTION........................0-3

FUEL REQUIREMENTS - GAS ENGINES -

DESCRIPTION.........................0-2

FUEL SENSOR - DESCRIPTION, WATER

IN ................................14-89

FUEL SENSOR - OPERATION, WATER IN . . 14-89

FUEL SENSOR - REMOVAL, WATER IN....14-89

FUEL SUPPLY RESTRICTIONS -

DIAGNOSIS AND TESTING.............14-60

FUEL SYSTEM - DIAGNOSIS AND

TESTING, AIR IN.....................14-60

FUEL SYSTEM AIR LEAK VACUUM TEST

- DIAGNOSIS AND TESTING............14-57

FUEL SYSTEM PARTS - STANDARD

PROCEDURES, CLEANING..............14-61

FUEL SYSTEM PRESSURE - GAS

ENGINES - SPECIFICATIONS.............14-3

FUEL SYSTEM PRESSURE RELEASE -

STANDARD PROCEDURE................14-3

FUEL SYSTEM PRESSURES, DIESEL

ENGINES...........................14-62

FUEL SYSTEM, SPECIAL TOOLS.....14-35,14-4

FUEL SYSTEM, SPECIAL TOOLS -

DIESEL............................14-63

FUEL TANK - DESCRIPTION............14-18

FUEL TANK - DESCRIPTION, DIESEL.....14-82

FUEL TANK - INSTALLATION

............14-20

FUEL TANK - OPERATION

..............14-18

FUEL TANK - REMOVAL

...............14-18

FUEL TANK CHECK VALVE -

DESCRIPTION

.......................14-21

FUEL TANK CHECK VALVE -

INSTALLATION

.......................14-23FUEL TANK CHECK VALVE - REMOVAL....14-22

FUEL TANK MODULE - DESCRIPTION.....14-82

FUEL TANK MODULE - INSTALLATION....14-83

FUEL TANK MODULE - OPERATION......14-82

FUEL TANK MODULE - REMOVAL........14-83

FUEL TEMPERATURE SENSOR -

DESCRIPTION......................14-104

FUEL TEMPERATURE SENSOR -

OPERATION........................14-104

FUEL TRANSFER PUMP - DESCRIPTION . . 14-83

FUEL TRANSFER PUMP - INSTALLATION . . 14-87

FUEL TRANSFER PUMP - OPERATION....14-83

FUEL TRANSFER PUMP - REMOVAL......14-86

FUEL TRANSFER PUMP PRESSURE -

DIAGNOSIS AND TESTING.............14-84

FUSE - DESCRIPTION, GENERATOR

CARTRIDGE.......................8W-97-4

FUSE - DESCRIPTION, IOD...........8W-97-5

FUSE - INSTALLATION, GENERATOR

CARTRIDGE.......................8W-97-4

FUSE - INSTALLATION, IOD..........8W-97-6

FUSE - OPERATION, GENERATOR

CARTRIDGE.......................8W-97-4

FUSE - OPERATION, IOD.............8W-97-5

FUSE - REMOVAL, GENERATOR

CARTRIDGE.......................8W-97-4

FUSE - REMOVAL, IOD..............8W-97-6

FUSES POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A SHORT TO GROUND ON.........8W-01-9

GAP AND FLUSH MEASUREMENTS,

SPECIFICATIONS - BODY...............23-56

GASKET - DESCRIPTION, CYLINDER

HEAD COVER.........................9-20

GASKET - OPERATION, CYLINDER HEAD

COVER..............................9-21

GASKET FAILURE - DIAGNOSIS AND

TESTING, CYLINDER HEAD..........9-21,9-76

GASKETS AND SEALERS - STANDARD

PROCEDURE, FORM-IN-PLACE . . 9-10,9-122,9-66

GASOLINE ENGINE - INSTALLATION......19-37

GASOLINE ENGINE - NEGATIVE CABLE

INSTALLATION.......................8F-22

GASOLINE ENGINE - NEGATIVE CABLE

REMOVAL..........................8F-22

GASOLINE ENGINE - POSITIVE CABLE

INSTALLATION.......................8F-22

GASOLINE ENGINE - POSITIVE CABLE

REMOVAL..........................8F-21

GASOLINE ENGINE - REMOVAL.........19-35

GAUGE - DESCRIPTION, ENGINE

TEMPERATURE......................8J-18

GAUGE - DESCRIPTION, FUEL...........8J-19

GAUGE - DESCRIPTION, OIL PRESSURE . . 8J-25

GAUGE - DESCRIPTION, VOLTAGE.......8J-33

GAUGE - OPERATION, ENGINE

TEMPERATURE......................8J-19

GAUGE - OPERATION, FUEL............8J-20

GAUGE - OPERATION, OIL PRESSURE....8J-25

GAUGE - OPERATION, VOLTAGE.........8J-33

GAUGE SENDING UNIT - DIAGNOSIS

AND TESTING, FUEL...................14-7

GAUGES - DIAGNOSIS AND TESTING,

PRESSURE..........................22-8

GAUGES INDICATOR - DESCRIPTION,

CHECK.............................8J-17

GAUGES INDICATOR - OPERATION,

CHECK.............................8J-17

GEAR - ADJUSTMENTS................19-18

GEAR - DESCRIPTION.................19-16

GEAR - INSTALLATION................19-18

GEAR - INSTALLATION, PINION

GEAR/RING..........................3-43

GEAR - OPERATION...................19-16

GEAR - REMOVAL....................19-18

GEAR - REMOVAL, PINION GEAR/RING....3-41

GEAR HOUSING - INSTALLATION........9-188

GEAR HOUSING - REMOVAL............9-187

GEAR HOUSING COVER - INSTALLATION . . 9-190

GEAR HOUSING COVER - REMOVAL

.....9-189

GEAR HOUSING PLUG - INSTALLATION,

STEERING

..........................19-30

GEAR HOUSING PLUG - REMOVAL,

STEERING

..........................19-29

GEAR LEAKAGE - DIAGNOSIS AND

TESTING, POWER STEERING

...........19-16

GEAR SELECTOR INDICATOR -

DESCRIPTION

.......................8J-20GEAR SELECTOR INDICATOR -

OPERATION.........................8J-21

GEAR SHIFT LEVER - INSTALLATION.....19-15

GEAR SHIFT LEVER - REMOVAL.........19-14

GEAR, SPECIAL TOOLS - POWER

STEERING..........................19-22

GEAR, SPECIFICATIONS - POWER

STEERING..........................19-21

GEAR/RING GEAR - INSTALLATION,

PINION.............................3-43

GEAR/RING GEAR - REMOVAL, PINION....3-41

GEAR/RING GEAR/TONE RING -

INSTALLATION, PINION.......3-104,3-132,3-75

GEAR/RING GEAR/TONE RING -

REMOVAL, PINION..........3-103,3-131,3-73

GEAR/TONE RING - INSTALLATION,

PINION GEAR/RING..........3-104,3-132,3-75

GEAR/TONE RING - REMOVAL, PINION

GEAR/RING................3-103,3-131,3-73

GEARTRAIN/OUTPUT SHAFT -

ASSEMBLY, PLANETARY........21-199,21-371

GEARTRAIN/OUTPUT SHAFT -

DESCRIPTION, PLANETARY......21-197,21-369

GEARTRAIN/OUTPUT SHAFT -

DISASSEMBLY, PLANETARY.....21-198,21-369

GEARTRAIN/OUTPUT SHAFT -

INSPECTION, PLANETARY.......21-199,21-371

GEARTRAIN/OUTPUT SHAFT -

OPERATION, PLANETARY.......21-197,21-369

GENERAL - WARNINGS.............8W-01-7

GENERATOR - DESCRIPTION...........8F-28

GENERATOR - INSTALLATION............8F-30

GENERATOR - OPERATION.............8F-28

GENERATOR - REMOVAL...............8F-28

GENERATOR CARTRIDGE FUSE -

DESCRIPTION.....................8W-97-4

GENERATOR CARTRIDGE FUSE -

INSTALLATION....................8W-97-4

GENERATOR CARTRIDGE FUSE -

OPERATION.......................8W-97-4

GENERATOR CARTRIDGE FUSE -

REMOVAL........................8W-97-4

GENERATOR RATINGS, SPECIFICATIONS . . 8F-26

GENERATOR/CHARGING SYSTEM -

SPECIFICATIONS, TORQUE.............8F-27

GLASS - DESCRIPTION, STATIONARY....23-145

GLASS - INSTALLATION, BACKLITE VENT . 23-146

GLASS - INSTALLATION, DOOR.........23-70

GLASS - INSTALLATION, SIDE VIEW

MIRROR...........................23-98

GLASS - OPERATION, STATIONARY.....23-145

GLASS - REMOVAL, BACKLITE VENT....23-146

GLASS - REMOVAL, DOOR.............23-70

GLASS - REMOVAL, SIDE VIEW MIRROR . . 23-98

GLASS RUN CHANNEL - INSTALLATION . . . 23-71

GLASS RUN CHANNEL - REMOVAL......23-71

GLASS RUN WEATHERSTRIP -

INSTALLATION, FRONT DOOR..........23-153

GLASS RUN WEATHERSTRIP -

REMOVAL, FRONT DOOR.............23-152

GLOVE BOX - ASSEMBLY.............23-111

GLOVE BOX - DISASSEMBLY..........23-110

GLOVE BOX LAMP AND SWITCH -

INSTALLATION.......................8L-36

GLOVE BOX LAMP AND SWITCH -

REMOVAL

..........................8L-35

GLOVE BOX LATCH STRIKER -

INSTALLATION

......................23-112

GLOVE BOX LATCH STRIKER - REMOVAL

. 23-111

GLOVE BOX OPENING UPPER TRIM -

INSTALLATION

......................23-112

GLOVE BOX OPENING UPPER TRIM -

REMOVAL

.........................23-112

GOVERNOR - DESCRIPTION,

ELECTRONIC

.................21-152,21-322

GOVERNOR - INSTALLATION,

ELECTRONIC

.................21-154,21-324

GOVERNOR - OPERATION, ELECTRONIC

. 21-153,

21-323

GOVERNOR - REMOVAL, ELECTRONIC

. . 21-154,

21-324

GRAB HANDLE - INSTALLATION,

A-PILLAR

..........................23-119

GRAB HANDLE - REMOVAL, A-PILLAR

. . . 23-119

GRADING - STANDARD PROCEDURE,

PISTON

............................9-166

GRID - DESCRIPTION, HEATED MIRROR

. . . 8G-4

14 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2233 of 2255

HIGH MOUNTED STOP LAMP -

INSTALLATION, CENTER................8L-6

HIGH MOUNTED STOP LAMP -

REMOVAL, CENTER....................8L-6

HIGH MOUNTED STOP LAMP UNIT -

INSTALLATION, CENTER................8L-6

HIGH MOUNTED STOP LAMP UNIT -

REMOVAL, CENTER....................8L-6

HIGH PRESSURE FUEL LINES -

DESCRIPTION.......................14-78

HIGH PRESSURE FUEL LINES -

OPERATION.........................14-78

HIGH PRESSURE RELIEF VALVE -

DESCRIPTION.......................24-46

HIGH PRESSURE RELIEF VALVE -

OPERATION.........................24-47

HIGH PRESSURE SWITCH -

DESCRIPTION, A/C...................24-20

HIGH PRESSURE SWITCH - DIAGNOSIS

AND TESTING, A/C...................24-20

HIGH PRESSURE SWITCH -

INSTALLATION, A/C...................24-20

HIGH PRESSURE SWITCH - OPERATION,

A/C................................24-20

HIGH PRESSURE SWITCH - REMOVAL,

A/C................................24-20

HIGH SPEEDS - DESCRIPTION, TIRE

PRESSURE..........................22-7

HIGH-PRESSURE FUEL LINE LEAKS -

DIAGNOSIS AND TESTING.............14-78

HINGE - INSTALLATION.....23-100,23-72,23-80

HINGE - REMOVAL........23-100,23-72,23-79

HITCH - INSTALLATION, TRAILER.........13-11

HITCH - REMOVAL, TRAILER...........13-11

HOISTING - STANDARD PROCEDURE.......0-9

HOLDDOWN - DESCRIPTION, BATTERY . . . 8F-17

HOLDDOWN - INSTALLATION, BATTERY . . . 8F-18

HOLDDOWN - OPERATION, BATTERY.....8F-17

HOLDDOWN - REMOVAL, BATTERY......8F-17

HOLDER - INSTALLATION, CUP........23-110

HOLDER - REMOVAL, CUP............23-109

HOLE REPAIR - DESCRIPTION,

THREADED........................Intro.-9

HONING - STANDARD PROCEDURE,

CYLINDER BORE..................9-11,9-65

HOOD - INSTALLATION...............23-101

HOOD - REMOVAL...................23-101

HOOK - INSTALLATION, COAT..........23-125

HOOK - INSTALLATION, FRONT TOW.....13-10

HOOK - REMOVAL, COAT.............23-124

HOOK - REMOVAL, FRONT TOW.........13-10

HORN - DESCRIPTION.............8H-1,8H-2

HORN - DIAGNOSIS AND TESTING.......8H-2

HORN - INSTALLATION.................8H-3

HORN - OPERATION...............8H-1,8H-2

HORN - REMOVAL....................8H-2

HORN RELAY - DESCRIPTION.......8W-97-12

HORN RELAY - DESCRIPTION...........8H-3

HORN RELAY - DIAGNOSIS AND

TESTING........................8W-97-12

HORN RELAY - DIAGNOSIS AND

TESTING............................8H-3

HORN RELAY - INSTALLATION.......8W-97-12

HORN RELAY - INSTALLATION...........8H-4

HORN RELAY - OPERATION.............8H-3

HORN RELAY - REMOVAL..........8W-97-12

HORN RELAY - REMOVAL..............8H-4

HORN SWITCH - DESCRIPTION..........8H-4

HORN SWITCH - DIAGNOSIS AND

TESTING............................8H-5

HORN SWITCH - OPERATION............8H-5

HORN SWITCH - REMOVAL.............8H-5

HOSE CLAMPS - DESCRIPTION...........7-4

HOSE CLAMPS - OPERATION.............7-4

HOSE WITH AIR CONDITIONING -

INSTALLATION, WATER PUMP BYPASS....7-76

HOSE WITH AIR CONDITIONING -

REMOVAL, WATER PUMP BYPASS........7-73

HOSE WITHOUT AIR CONDITIONING -

INSTALLATION, WATER PUMP BYPASS....7-77

HOSE WITHOUT AIR CONDITIONING -

REMOVAL, WATER PUMP BYPASS........7-76

HOSES - PRESSURE - DESCRIPTION

.....19-39

HOSES - PRESSURE - OPERATION

.......19-39

HOSES - RETURN - DESCRIPTION

.......19-39

HOSES - RETURN - OPERATION

.........19-39

HOSES/LINES/TUBES PRECAUTIONS -

CAUTION, REFRIGERANT

..............24-43HOSES/TUBES - DESCRIPTION, WASHER . . 8R-8

HOSES/TUBES - OPERATION, WASHER....8R-8

HOUSING - ASSEMBLY, HVAC...........24-36

HOUSING - DIAGNOSIS AND TESTING,

CLUTCH..............................6-9

HOUSING - DISASSEMBLY, HVAC........24-35

HOUSING - INSTALLATION, CLUTCH......6-11

HOUSING - INSTALLATION, GEAR........9-188

HOUSING - INSTALLATION, HVAC........24-36

HOUSING - REMOVAL, CLUTCH..........6-11

HOUSING - REMOVAL, GEAR...........9-187

HOUSING - REMOVAL, HVAC...........24-34

HOUSING BUSHING - INSTALLATION,

EXTENSION..................21-156,21-326

HOUSING BUSHING - REMOVAL,

EXTENSION..................21-156,21-326

HOUSING BUSHING AND SEAL -

INSTALLATION, EXTENSION.....21-460,21-497

HOUSING BUSHING AND SEAL -

REMOVAL, EXTENSION.........21-460,21-497

HOUSING COVER - INSTALLATION, GEAR . 9-190

HOUSING COVER - REMOVAL, GEAR.....9-189

HOUSING FLUID LEAK - DIAGNOSIS AND

TESTING, CONVERTER.........21-101,21-273

HOUSING INLET BAFFLE -

INSTALLATION, HVAC.................24-36

HOUSING INLET BAFFLE - REMOVAL,

HVAC..............................24-35

HOUSING PLUG - INSTALLATION,

STEERING GEAR.......................19-30

HOUSING PLUG - REMOVAL, STEERING

GEAR..............................19-29

HOUSING SEAL - INSTALLATION,

EXTENSION..................21-156,21-327

HOUSING SEAL - NV4500 -

INSTALLATION, ADAPTER..............21-42

HOUSING SEAL - NV4500 -

INSTALLATION, EXTENSION............21-42

HOUSING SEAL - NV4500 - REMOVAL,

ADAPTER...........................21-42

HOUSING SEAL - NV4500 - REMOVAL,

EXTENSION.........................21-42

HOUSING SEAL - NV5600 -

INSTALLATION, ADAPTER..............21-85

HOUSING SEAL - NV5600 -

INSTALLATION, EXTENSION............21-85

HOUSING SEAL - NV5600 - REMOVAL,

ADAPTER...........................21-85

HOUSING SEAL - NV5600 - REMOVAL,

EXTENSION.........................21-85

HOUSING SEAL - REMOVAL,

EXTENSION..................21-156,21-326

HUB / BEARING - INSTALLATION......2-17,2-9

HUB / BEARING - REMOVAL..........2-16,2-9

HVAC HOUSING - ASSEMBLY...........24-36

HVAC HOUSING - DISASSEMBLY........24-35

HVAC HOUSING - INSTALLATION........24-36

HVAC HOUSING - REMOVAL............24-34

HVAC HOUSING INLET BAFFLE -

INSTALLATION.......................24-36

HVAC HOUSING INLET BAFFLE -

REMOVAL..........................24-35

HVAC SYSTEM AIRFLOW - DESCRIPTION . 24-30

HYDRAULIC BOOSTER - DIAGNOSIS

AND TESTING........................5-18

HYDRAULIC LIFTERS - CLEANING

....9-37,9-92

HYDRAULIC LIFTERS - INSTALLATION

. 9-37,9-92

HYDRAULIC LIFTERS - REMOVAL

....9-37,9-92

HYDRAULIC PRESSURE TEST -

DIAGNOSIS AND TESTING

.......21-270,21-98

HYDRAULIC SCHEMATICS, SCHEMATICS

AND DIAGRAMS

..............21-132,21-302

HYDRAULIC TAPPETS - DIAGNOSIS AND

TESTING

........................9-36,9-91

HYDRAULIC/MECHANICAL -

DESCRIPTION

.........................5-4

HYDRAULIC/MECHANICAL - WARNING

.....5-4

HYDROMETER TEST - STANDARD

PROCEDURE

........................8F-11

HYDROSTATIC LOCK - STANDARD

PROCEDURE

................9-11,9-122,9-66

IDENTIFICATION - DESCRIPTION,

FASTENER

.........................Intro.-6

IDENTIFICATION AND INFORMATION -

DESCRIPTION, SECTION

.............8W-01-6

IDENTIFICATION LAMP - INSTALLATION,

OUTBOARD

.........................8L-29IDENTIFICATION LAMP - REMOVAL,

OUTBOARD.........................8L-28

IDENTIFICATION NUMBER -

DESCRIPTION, VEHICLE..............Intro.-1

IDENTIFICATION PLATE - DESCRIPTION,

EQUIPMENT.......................Intro.-3

IDLE AIR CONTROL MOTOR -

DESCRIPTION.......................14-40

IDLE AIR CONTROL MOTOR -

OPERATION.........................14-40

IGNITION - SPECIFICATIONS, TORQUE.....8I-2

IGNITION CIRCUIT SENSE -

DESCRIPTION.......................8E-17

IGNITION CIRCUIT SENSE - OPERATION . . 8E-19

IGNITION COIL RESISTANCE, 5.9L

ENGINES............................8I-3

IGNITION COIL RESISTANCE, 8.0L V-10

ENGINE..............................8I-4

IGNITION SWITCH - DESCRIPTION.......19-11

IGNITION SWITCH - DESCRIPTION,

KEY-IN..............................19-9

IGNITION SWITCH - DIAGNOSIS AND

TESTING...........................19-11

IGNITION SWITCH - INSTALLATION......19-12

IGNITION SWITCH - OPERATION........19-11

IGNITION SWITCH - REMOVAL..........19-12

IGNITION SWITCH AND KEY LOCK

CYLINDER - DIAGNOSIS AND TESTING....19-9

IGNITION TIMING, SPECIFICATIONS.......8I-4

IGNITION-OFF DRAW TEST - STANDARD

PROCEDURE........................8F-13

INDEPENDENT FRONT SUSPENSION,

SPECIAL TOOLS.......................2-9

INDICATOR - DESCRIPTION, ABS........8J-14

INDICATOR - DESCRIPTION, AIRBAG.....8J-15

INDICATOR - DESCRIPTION, BRAKE/

PARK BRAKE........................8J-15

INDICATOR - DESCRIPTION, CHECK

GAUGES............................8J-17

INDICATOR - DESCRIPTION, CRUISE.....8J-18

INDICATOR - DESCRIPTION, GEAR

SELECTOR..........................8J-20

INDICATOR - DESCRIPTION, HIGH BEAM . . 8J-21

INDICATOR - DESCRIPTION, LOW FUEL . . . 8J-22

INDICATOR - DESCRIPTION, OVERDRIVE

OFF ...............................8J-26

INDICATOR - DESCRIPTION, SEATBELT . . . 8J-27

INDICATOR - DESCRIPTION, SERVICE

REMINDER..........................8J-27

INDICATOR - DESCRIPTION, TRANS

OVERTEMP.........................8J-31

INDICATOR - DESCRIPTION, TURN

SIGNAL............................8J-32

INDICATOR - DESCRIPTION, UPSHIFT....8J-32

INDICATOR - DESCRIPTION, VTSS........8Q-3

INDICATOR - DESCRIPTION, WAIT-TO-

START .............................8J-34

INDICATOR - DESCRIPTION, WASHER

FLUID..............................8J-35

INDICATOR - DESCRIPTION, WATER-IN-

FUEL..............................8J-36

INDICATOR - DIAGNOSIS AND TESTING,

BRAKE.............................8J-16

INDICATOR - DIAGNOSIS AND TESTING,

FOUR-WHEEL DRIVE..................8J-29

INDICATOR - DIAGNOSIS AND TESTING,

HIGH BEAM.........................8J-21

INDICATOR - DIAGNOSIS AND TESTING,

TURN SIGNAL

.......................8J-32

INDICATOR - DIAGNOSIS AND TESTING,

VTSS

...............................8Q-4

INDICATOR - DIAGNOSIS AND TESTING,

WASHER FLUID

......................8J-35

INDICATOR - OPERATION, ABS

..........8J-14

INDICATOR - OPERATION, AIRBAG

.......8J-15

INDICATOR - OPERATION, BRAKE/PARK

BRAKE

.............................8J-15

INDICATOR - OPERATION, CHECK

GAUGES

............................8J-17

INDICATOR - OPERATION, CRUISE

.......8J-18

INDICATOR - OPERATION, GEAR

SELECTOR

..........................8J-21

INDICATOR - OPERATION, HIGH BEAM

....8J-21

INDICATOR - OPERATION, LOW FUEL

.....8J-22

INDICATOR - OPERATION, OVERDRIVE

OFF

...............................8J-26

INDICATOR - OPERATION, SEATBELT

.....8J-27

16 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2235 of 2255

JOINT MOLDING - REMOVAL, ROOF......23-91

JOINTS - ASSEMBLY, DOUBLE CARDAN

UNIVERSAL..........................3-11

JOINTS - ASSEMBLY, SINGLE CARDAN

UNIVERSAL...........................3-9

JOINTS - DISASSEMBLY, DOUBLE

CARDAN UNIVERSAL..................3-10

JOINTS - DISASSEMBLY, SINGLE

CARDAN UNIVERSAL...................3-8

JOINTS - INSTALLATION, SINGLE

CARDAN UNIVERSAL..................3-35

JOINTS - REMOVAL, SINGLE CARDAN

UNIVERSAL..........................3-34

JOURNAL CLEARANCE - STANDARD

PROCEDURE, CONNECTING ROD

BEARING AND CRANKSHAFT...........9-158

JUMP STARTING - STANDARD

PROCEDURE..........................0-7

JUNCTION BLOCK - DESCRIPTION.....8W-97-6

JUNCTION BLOCK - DIAGNOSIS AND

TESTING.........................8W-97-7

JUNCTION BLOCK - INSTALLATION....8W-97-8

JUNCTION BLOCK - OPERATION......8W-97-7

JUNCTION BLOCK - REMOVAL........8W-97-7

KEEPER - INSTALLATION, BACKLITE

LATCH ............................23-146

KEEPER - REMOVAL, BACKLITE LATCH . . 23-146

KEY LOCK CYLINDER - DIAGNOSIS AND

TESTING, IGNITION SWITCH.............19-9

KEY-IN IGNITION SWITCH -

DESCRIPTION........................19-9

KEYLESS ENTRY SYSTEM -

DESCRIPTION, REMOTE................8N-2

KEYLESS ENTRY SYSTEM - DIAGNOSIS

AND TESTING, POWER LOCK &

REMOTE............................8N-5

KEYLESS ENTRY SYSTEM - OPERATION,

REMOTE............................8N-4

KEYLESS ENTRY TRANSMITTER -

DESCRIPTION, REMOTE................8N-7

KEYLESS ENTRY TRANSMITTER -

DIAGNOSIS AND TESTING, REMOTE......8N-8

KEYLESS ENTRY TRANSMITTER -

OPERATION, REMOTE..................8N-8

KEYLESS ENTRY TRANSMITTER

BATTERIES - STANDARD PROCEDURE,

REMOTE............................8N-8

KNOB - INSTALLATION, TURNING LOOP

HGT ADJUSTER.....................8O-30

KNOB - REMOVAL, TURNING LOOP HGT

ADJUSTER.........................8O-30

KNUCKLE - INSTALLATION..........2-10,2-19

KNUCKLE - REMOVAL..............2-10,2-19

LABEL - DESCRIPTION, VEHICLE SAFETY

CERTIFICATION.....................Intro.-1

LAMP - DESCRIPTION, READING........8L-36

LAMP - DESCRIPTION, TAIL............8L-29

LAMP - DIAGNOSIS AND TESTING, FOG . . 8L-10

LAMP - INSTALLATION, CENTER HIGH

MOUNTED STOP......................8L-6

LAMP - INSTALLATION, CLEARANCE......8L-7

LAMP - INSTALLATION, DOME..........8L-34

LAMP - INSTALLATION, FOG............8L-11

LAMP - INSTALLATION, LICENSE PLATE . . 8L-22

LAMP - INSTALLATION, MARKER........8L-23

LAMP - INSTALLATION, OUTBOARD

IDENTIFICATION.....................8L-29

LAMP - INSTALLATION, PARK/TURN

SIGNAL............................8L-29

LAMP - INSTALLATION, READING........8L-37

LAMP - INSTALLATION, TAIL...........8L-30

LAMP - INSTALLATION, UNDERHOOD....8L-32

LAMP - INSTALLATION, VANITY.........8L-37

LAMP - OPERATION, READING..........8L-36

LAMP - OPERATION, TAIL..............8L-29

LAMP - REMOVAL, CENTER HIGH

MOUNTED STOP......................8L-6

LAMP - REMOVAL, CLEARANCE..........8L-7

LAMP - REMOVAL, DOME..............8L-34

LAMP - REMOVAL, FOG...............8L-11

LAMP - REMOVAL, LICENSE PLATE......8L-22

LAMP - REMOVAL, MARKER...........8L-23

LAMP - REMOVAL, OUTBOARD

IDENTIFICATION

.....................8L-28

LAMP - REMOVAL, PARK/TURN SIGNAL

. . 8L-29

LAMP - REMOVAL, READING

...........8L-36

LAMP - REMOVAL, TAIL

...............8L-29

LAMP - REMOVAL, UNDERHOOD

........8L-31LAMP - REMOVAL, VANITY.............8L-37

LAMP AND SWITCH - INSTALLATION,

GLOVE BOX.........................8L-36

LAMP AND SWITCH - REMOVAL, GLOVE

BOX ...............................8L-35

LAMP MIL - DESCRIPTION,

MALFUNCTION INDICATOR.............8J-23

LAMP MIL - OPERATION, MALFUNCTION

INDICATOR.........................8J-23

LAMP MODULE - DESCRIPTION,

DAYTIME RUNNING....................8L-9

LAMP MODULE - INSTALLATION,

DAYTIME RUNNING....................8L-9

LAMP MODULE - OPERATION, DAYTIME

RUNNING............................8L-9

LAMP MODULE - REMOVAL, DAYTIME

RUNNING............................8L-9

LAMP SWITCH - DESCRIPTION, BRAKE....8L-4

LAMP SWITCH - DIAGNOSIS AND

TESTING, BRAKE......................8L-5

LAMP SWITCH - INSTALLATION, BRAKE . . . 8L-6

LAMP SWITCH - OPERATION, BRAKE......8L-4

LAMP SWITCH - REMOVAL, BRAKE.......8L-5

LAMP UNIT - ADJUSTMENTS, FOG.......8L-13

LAMP UNIT - INSTALLATION, CENTER

HIGH MOUNTED STOP.................8L-6

LAMP UNIT - INSTALLATION, FOG.......8L-12

LAMP UNIT - INSTALLATION, LICENSE

PLATE .............................8L-22

LAMP UNIT - INSTALLATION, PARK/

TURN SIGNAL.......................8L-29

LAMP UNIT - INSTALLATION, TAIL.......8L-30

LAMP UNIT - INSTALLATION,

UNDERHOOD........................8L-32

LAMP UNIT - REMOVAL, CENTER HIGH

MOUNTED STOP......................8L-6

LAMP UNIT - REMOVAL, FOG...........8L-12

LAMP UNIT - REMOVAL, LICENSE PLATE . . 8L-22

LAMP UNIT - REMOVAL, PARK/TURN

SIGNAL............................8L-29

LAMP UNIT - REMOVAL, TAIL...........8L-30

LAMP UNIT - REMOVAL, UNDERHOOD . . . 8L-32

LAMPS, SPECIFICATIONS - EXTERIOR.....8L-4

LAMPS, SPECIFICATIONS - INTERIOR....8L-33

LASH ADJUSTMENT AND VERIFICATION

- STANDARD PROCEDURE, VALVE.......9-141

LATCH - ADJUSTMENT, FRONT DOOR....23-73

LATCH - INSTALLATION....23-102,23-65,23-73

LATCH - INSTALLATION, SAFETY.......23-104

LATCH - LOWER - INSTALLATION........23-80

LATCH - LOWER - REMOVAL...........23-80

LATCH - REMOVAL........23-102,23-65,23-72

LATCH - REMOVAL, SAFETY...........23-104

LATCH - UPPER - INSTALLATION........23-81

LATCH - UPPER - REMOVAL............23-81

LATCH AND KEEPER - INSTALLATION,

BACKLITE.........................23-146

LATCH AND KEEPER - REMOVAL,

BACKLITE.........................23-146

LATCH HANDLE - INSTALLATION........23-66

LATCH HANDLE - REMOVAL............23-66

LATCH RELEASE CABLE - INSTALLATION . 23-103

LATCH RELEASE CABLE - REMOVAL....23-103

LATCH STRIKER - INSTALLATION . 23-103,23-66,

23-73

LATCH STRIKER - INSTALLATION, GLOVE

BOX ..............................23-112

LATCH STRIKER - LOWER -

INSTALLATION

.......................23-82

LATCH STRIKER - LOWER - REMOVAL

....23-82

LATCH STRIKER - REMOVAL

.....23-103,23-66,

23-73

LATCH STRIKER - REMOVAL, GLOVE

BOX

..............................23-111

LATCH STRIKER - UPPER -

INSTALLATION

.......................23-82

LATCH STRIKER - UPPER - REMOVAL

....23-82

LEAK - DIAGNOSIS AND TESTING,

CONVERTER HOUSING FLUID

....21-101,21-273

LEAK DETECTION PUMP - DESCRIPTION

. . 25-34

LEAK DETECTION PUMP - INSTALLATION

. 25-34

LEAK DETECTION PUMP - OPERATION

....25-34

LEAK DETECTION PUMP - REMOVAL

.....25-34

LEAK DOWN TEST - DIAGNOSIS AND

TESTING, FUEL PRESSURE

..............14-2

LEAK VACUUM TEST - DIAGNOSIS AND

TESTING, FUEL SYSTEM AIR

...........14-57LEAKAGE - DIAGNOSIS AND TESTING,

CYLINDER COMBUSTION PRESSURE . . . 9-64,9-9

LEAKAGE - DIAGNOSIS AND TESTING,

INTAKE MANIFOLD...............9-106,9-50

LEAKAGE - DIAGNOSIS AND TESTING,

POWER STEERING GEAR..............19-16

LEAKAGE - DIAGNOSIS AND TESTING,

PUMP.............................19-33

LEAKS - DIAGNOSIS AND TESTING,

CHARGE AIR COOLER SYSTEM.........11-18

LEAKS - DIAGNOSIS AND TESTING,

COOLING SYSTEM.....................7-5

LEAKS - DIAGNOSIS AND TESTING,

ENGINE OIL......................9-43,9-99

LEAKS - DIAGNOSIS AND TESTING,

HIGH-PRESSURE FUEL LINE............14-78

LEAKS - DIAGNOSIS AND TESTING,

REFRIGERANT SYSTEM...............24-43

LEAKS - DIAGNOSIS AND TESTING,

WATER .............................23-2

LEAKS - STANDARD PROCEDURE,

REPAIRING..........................22-9

LEFT FRONT FENDER - INSTALLATION....23-93

LEFT FRONT FENDER - REMOVAL.......23-93

LEVEL - DIAGNOSIS AND TESTING,

EFFECTS OF INCORRECT FLUID . . 21-157,21-327

LEVEL - STANDARD PROCEDURE,

BRAKE FLUID........................5-15

LEVEL - STANDARD PROCEDURE,

ENGINE OIL.........................9-178

LEVEL - STANDARD PROCEDURE,

REFRIGERANT OIL...................24-57

LEVEL CHECK - STANDARD

PROCEDURE, COOLANT................7-16

LEVEL CHECK - STANDARD

PROCEDURE, FLUID...........21-157,21-328

LEVEL SENDING UNIT / SENSOR -

DESCRIPTION, FUEL..............14-7,14-77

LEVEL SENDING UNIT / SENSOR -

INSTALLATION, FUEL..................14-8

LEVEL SENDING UNIT / SENSOR -

OPERATION, FUEL................14-7,14-77

LEVEL SENDING UNIT / SENSOR -

REMOVAL, FUEL......................14-7

LEVEL SWITCH - DESCRIPTION,

WASHER FLUID......................8R-7

LEVEL SWITCH - INSTALLATION,

WASHER FLUID......................8R-8

LEVEL SWITCH - OPERATION, WASHER

FLUID..............................8R-7

LEVEL SWITCH - REMOVAL, WASHER

FLUID..............................8R-8

LEVER - ADJUSTMENT, SHIFT . . . 21-463,21-500

LEVER - INSTALLATION, GEAR SHIFT.....19-15

LEVER - INSTALLATION, SHIFT . . . 21-462,21-500

LEVER - REMOVAL, GEAR SHIFT........19-14

LEVER - REMOVAL, SHIFT......21-462,21-499

LICENSE PLATE LAMP - INSTALLATION . . . 8L-22

LICENSE PLATE LAMP - REMOVAL.......8L-22

LICENSE PLATE LAMP UNIT -

INSTALLATION.......................8L-22

LICENSE PLATE LAMP UNIT - REMOVAL . . 8L-22

LID - INSTALLATION, CENTER CONSOLE . 23-132

LID - REMOVAL, CENTER CONSOLE.....23-131

LIFTERS - CLEANING, HYDRAULIC....9-37,9-92

LIFTERS - INSTALLATION, HYDRAULIC....9-37,

9-92

LIFTERS - REMOVAL, HYDRAULIC....9-37,9-92

LIFTERS/TAPPETS - CLEANING, SOLID....9-164

LIFTERS/TAPPETS - INSPECTION, SOLID . . 9-165

LIFTERS/TAPPETS - INSTALLATION,

SOLID.............................9-165

LIFTERS/TAPPETS - REMOVAL, SOLID....9-164

LIGHTER OUTLET - DESCRIPTION,

CIGAR...........................8W-97-2

LIGHTER OUTLET - DIAGNOSIS AND

TESTING, CIGAR...................8W-97-2

LIGHTER OUTLET - INSTALLATION,

CIGAR...........................8W-97-4

LIGHTER OUTLET - OPERATION, CIGAR . 8W-97-2

LIGHTER OUTLET - REMOVAL, CIGAR . . 8W-97-3

LINE - INSTALLATION, LIQUID

..........24-52

LINE - INSTALLATION, SUCTION AND

DISCHARGE

.........................24-52

LINE - REMOVAL, LIQUID

..............24-52

LINE - REMOVAL, SUCTION AND

DISCHARGE

.........................24-51

LINE COUPLERS - DESCRIPTION, A/C

....24-40

18 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2238 of 2255

NV241LD - CLEANING, TRANSFER CASE . 21-441

NV241LD - DESCRIPTION, TRANSFER

CASE.............................21-430

NV241LD - DISASSEMBLY, TRANSFER

CASE.............................21-432

NV241LD - INSPECTION, TRANSFER

CASE.............................21-442

NV241LD - INSTALLATION, TRANSFER

CASE.............................21-458

NV241LD - OPERATION, TRANSFER

CASE.............................21-430

NV241LD - REMOVAL, TRANSFER CASE . 21-432

NV241LD - TRANSFER CASE...........21-459

NV4500 - ASSEMBLY, MANUAL.........21-21

NV4500 - CLEANING, MANUAL..........21-20

NV4500 - DESCRIPTION, MANUAL........21-1

NV4500 - DIAGNOSIS AND TESTING,

MANUAL............................21-3

NV4500 - DISASSEMBLY, MANUAL........21-5

NV4500 - INSPECTION, MANUAL........21-20

NV4500 - INSTALLATION, ADAPTER

HOUSING SEAL......................21-42

NV4500 - INSTALLATION, EXTENSION

HOUSING SEAL......................21-42

NV4500 - INSTALLATION, MANUAL......21-37

NV4500 - INSTALLATION, SHIFT COVER . . . 21-45

NV4500 - INSTALLATION, SHIFT

MECHANISM........................21-44

NV4500 - OPERATION, MANUAL..........21-3

NV4500 - REMOVAL, ADAPTER

HOUSING SEAL......................21-42

NV4500 - REMOVAL, EXTENSION

HOUSING SEAL......................21-42

NV4500 - REMOVAL, MANUAL...........21-4

NV4500 - REMOVAL, SHIFT COVER......21-45

NV4500 - REMOVAL, SHIFT MECHANISM . . 21-43

NV4500 - SPECIFICATIONS, MANUAL.....21-38

NV5600 - ASSEMBLY, MANUAL.........21-64

NV5600 - CLEANING, MANUAL..........21-63

NV5600 - DESCRIPTION, MANUAL.......21-46

NV5600 - DIAGNOSIS AND TESTING,

MANUAL...........................21-48

NV5600 - DISASSEMBLY, MANUAL.......21-49

NV5600 - INSPECTION, MANUAL........21-63

NV5600 - INSTALLATION, ADAPTER

HOUSING SEAL......................21-85

NV5600 - INSTALLATION, EXTENSION

HOUSING SEAL......................21-85

NV5600 - INSTALLATION, MANUAL......21-78

NV5600 - INSTALLATION, SHIFT COVER . . . 21-86

NV5600 - OPERATION, MANUAL.........21-48

NV5600 - REMOVAL, ADAPTER

HOUSING SEAL......................21-85

NV5600 - REMOVAL, EXTENSION

HOUSING SEAL......................21-85

NV5600 - REMOVAL, MANUAL..........21-49

NV5600 - REMOVAL, SHIFT COVER......21-86

NV5600 - SPECIFICATIONS, MANUAL.....21-79

O2 SENSOR - DESCRIPTION............14-45

O2 SENSOR - INSTALLATION...........14-47

O2 SENSOR - OPERATION.............14-45

O2 SENSOR - REMOVAL...............14-46

ODOMETER - DESCRIPTION............8J-24

ODOMETER - OPERATION..............8J-24

OFF INDICATOR - DESCRIPTION,

OVERDRIVE.........................8J-26

OFF INDICATOR - OPERATION,

OVERDRIVE.........................8J-26

OIL - DESCRIPTION, ENGINE..........0-4,0-5

OIL - DESCRIPTION, REFRIGERANT......24-57

OIL - OPERATION, REFRIGERANT........24-57