remove seats DODGE RAM 2002 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1232 of 2255

Thrust Plate

Inspect the camshaft thrust plate for excessive

wear in the camshaft contact area. Measure thrust

plate thickness using the CAMSHAFT THRUST

PLATE THICKNESS CHART . Replace any thrust

plate that falls outside of these specifications:

CAMSHAFT THRUST PLATE THICKNESS CHART

9.34 mm (0.368 in.) MIN.

9.58 mm (0.377 in.) MAX.

INSTALLATION

INSTALLATIONÐCAMSHAFT BEARINGS

(1) Apply a coating of Loctitet640 Adhesive to the

backside of the new bushing. Avoid getting adhesive

in the oil hole.

(2) Use a universal cam bushing installation tool

and install the bushing so that it is even with the

front face of the cylinder block. The oil hole must be

aligned. A 3.2 mm (0.128 inch) diameter rod must be

able to pass through the hole (Fig. 97).

(3) Measure the installed bushing. The limit of the

inside diameter is 54.133 mm (2.1312 inch).

INSTALLATIONÐCAMSHAFT

(1) Lubricate the camshaft bushing and bores with

fresh engine oil or suitable equivalent.

(2) Liberally coat the camshaft lobes, journals, and

thrust washer with fresh engine oil or suitable equiv-

alent.

CAUTION: When installing the camshaft (Fig. 91),

DO NOT push it in farther than it will go with the

thrust washer in place. Pushing it too far can dis-

lodge the plug in the rear of the camshaft bore and

cause an oil leak.(3) Install the camshaft (Fig. 91) and thrust plate.

Align the timing marks as shown in (Fig. 89).

(4) Install the thrust plate bolts and tighten to 24

N´m (18 ft. lbs.) torque.

(5) Measure camshaft back lash and end clearance

(Fig. 98).

(6) Remove the wooden dowel rods and rubber

bands from the tappets.

(7) Lubricate the push rods with engine oil and

install in their original location (Fig. 87).Verify that

they are seated in the tappets.

(8) Lubricate the valve tips with engine oil and

install the crossheads in their original locations.

(9) Lubricate the crossheads and push rod sockets

with engine oil and install the rocker arms and ped-

estals in their original locations (Fig. 86). Tighten

bolts to 36 N´m (27 ft. lbs.) torque.

(10)Verify valve lash adjustment (Refer to 9 -

ENGINE/CYLINDER HEAD/INTAKE/EXHAUST

VALVES & SEATS - STANDARD PROCEDURE).

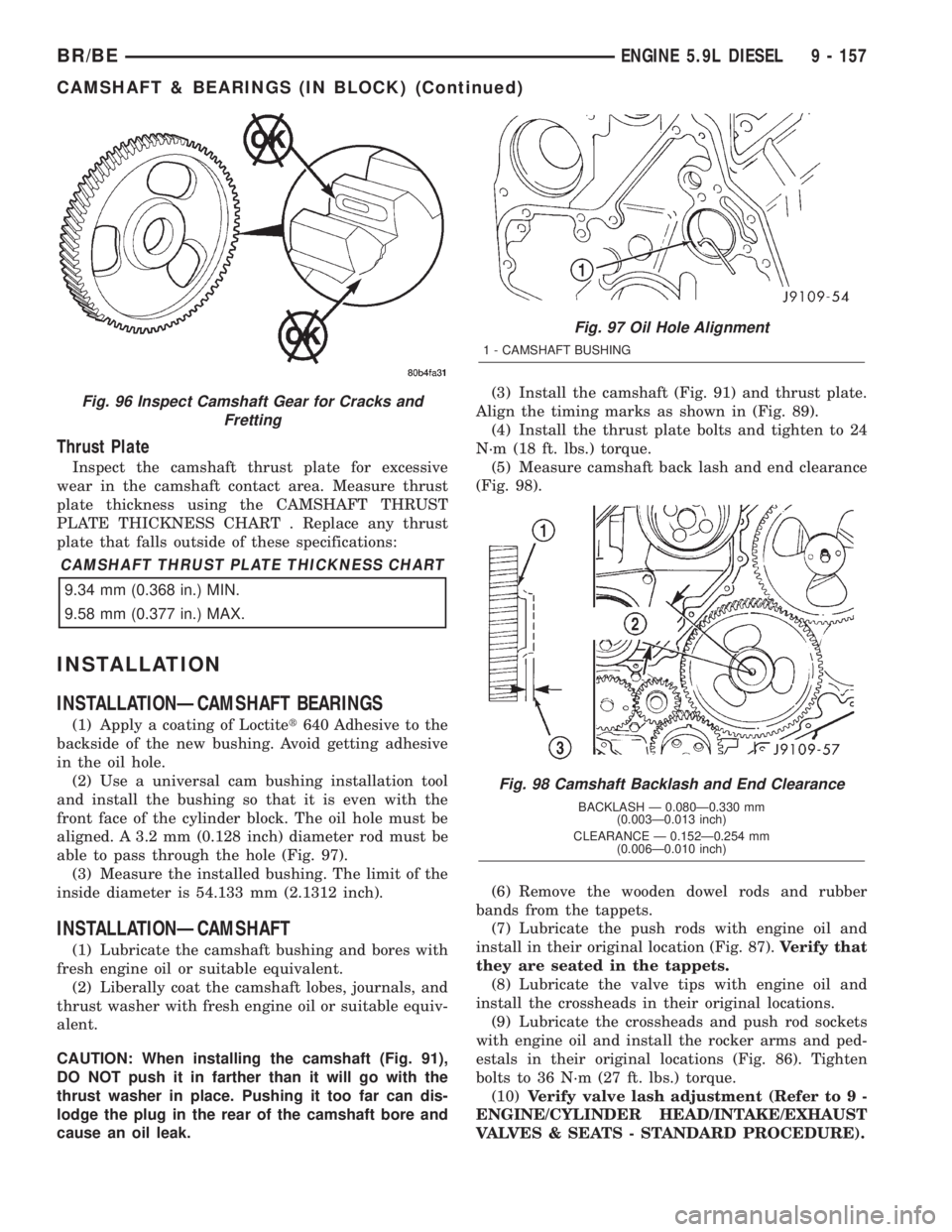

Fig. 96 Inspect Camshaft Gear for Cracks and

Fretting

Fig. 97 Oil Hole Alignment

1 - CAMSHAFT BUSHING

Fig. 98 Camshaft Backlash and End Clearance

BACKLASH Ð 0.080Ð0.330 mm

(0.003Ð0.013 inch)

CLEARANCE Ð 0.152Ð0.254 mm

(0.006Ð0.010 inch)

BR/BEENGINE 5.9L DIESEL 9 - 157

CAMSHAFT & BEARINGS (IN BLOCK) (Continued)

Page 1434 of 2255

INSTALLATION

(1) Install pitman shaft bearing into housing with

a bearing driver and handle.

(2) Coat the oil seal and washer withspecial

greasesupplied with the new seal.

(3) Install the oil seal with a driver and handle.

(4) Install backup washer.

(5) Install the retainer ring with snap ring pliers.

(6) Coat the dust seal withspecial greasesup-

plied with the new seal.

(7) Install dust seal with a driver and handle.

(8) Install pitman shaft to side cover by screwing

shaft in until it fully seats to side cover.

(9) Install preload adjuster nut.Do not tighten

nut until after Over-Center Rotation Torque

adjustment has been made.

(10) Install gasket to side cover and bend tabs

around edges of side cover (Fig. 11).

(11) Install pitman shaft assembly and side cover

to housing.

(12) Install side cover bolts and tighten to 60 N´m

(44 ft. lbs.).

(13) Perform over-center rotation torque adjust-

ment, (Refer to 19 - STEERING/GEAR - ADJUST-

MENTS).

PITMAN SHAFT SEAL

REMOVAL

(1) Clean exposed end of pitman shaft and housing

with a wire brush.

(2) Remove preload adjuster nut (Fig. 19).

(3) Rotate the stub shaft with a 12 point socket

from stop to stop and count the number of turns.

(4) Center the stub shaft by rotating it from the

stop 1/2 of the total amount of turns.

(5) Remove side cover bolts and remove side cover,

gasket and pitman shaft as an assembly (Fig. 19).

NOTE: The pitman shaft will not clear the housing if

it is not centered.

(6) Remove pitman shaft from the side cover.

(7) Remove dust seal from the housing with a seal

pick (Fig. 20).

CAUTION: Use care not to score the housing bore

when prying out seals and washer.

(8) Remove retaining ring with snap ring pliers.

(9) Remove washer from the housing.

(10) Remove oil seal from the housing with a seal

pick.

(11) Remove pitman shaft bearing from housing

with a bearing driver and handle (Fig. 21).

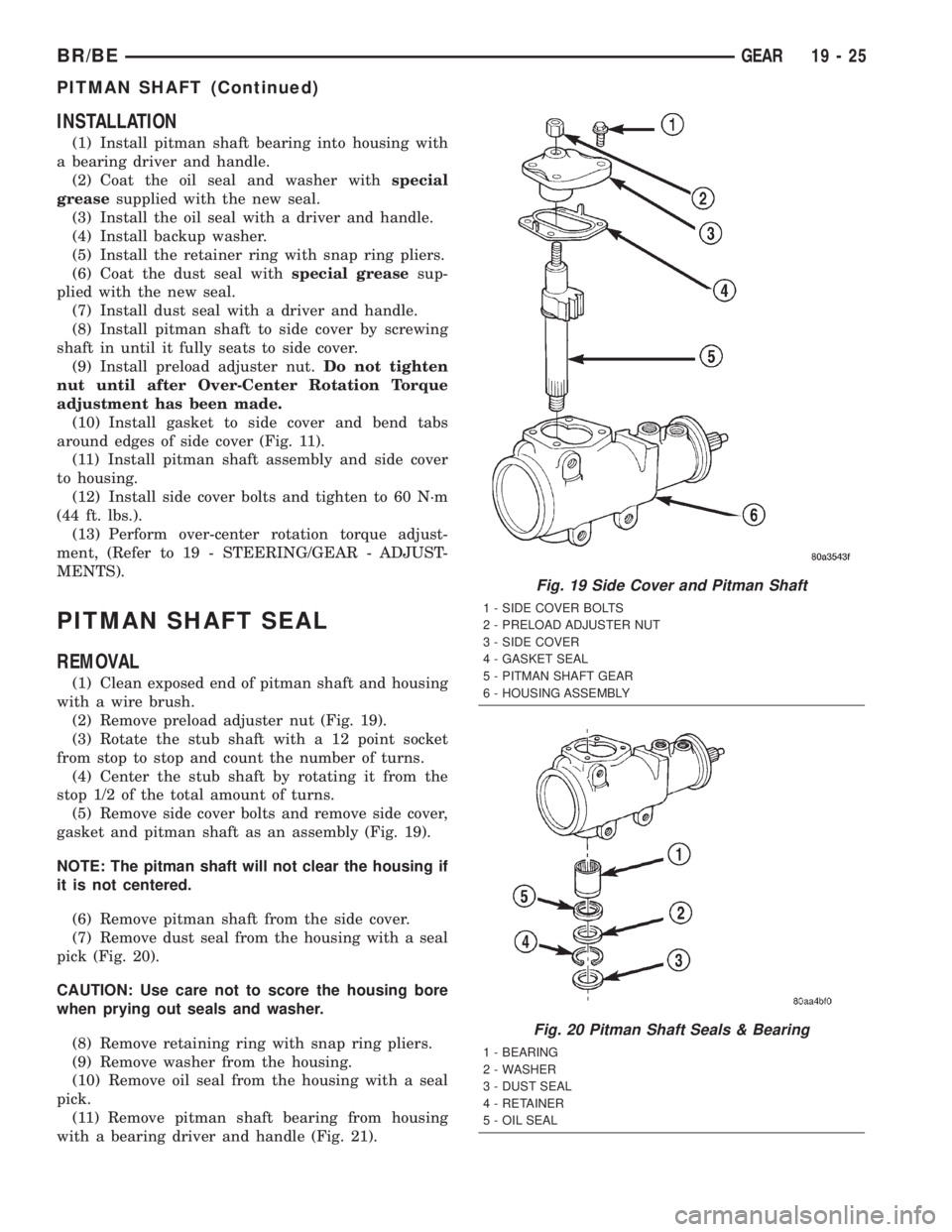

Fig. 19 Side Cover and Pitman Shaft

1 - SIDE COVER BOLTS

2 - PRELOAD ADJUSTER NUT

3 - SIDE COVER

4 - GASKET SEAL

5 - PITMAN SHAFT GEAR

6 - HOUSING ASSEMBLY

Fig. 20 Pitman Shaft Seals & Bearing

1 - BEARING

2 - WASHER

3 - DUST SEAL

4 - RETAINER

5 - OIL SEAL

BR/BEGEAR 19 - 25

PITMAN SHAFT (Continued)

Page 1583 of 2255

(a) Loosen locknut on each band adjusting screw

4-5 turns.

(b) Tighten both adjusting screws to 8 N´m (72

in. lbs.).

(c) Back off front band adjusting screw 2-7/8

turns.

(d) Back off rear band adjusting screw 2 turns.

(e) Hold each adjusting screw in position and

tighten locknut to 34 N´m (25 ft. lbs.) torque.

(2) Install magnet in oil pan. Magnet seats on

small protrusion at corner of pan.

(3) Position new oil pan gasket on case and install

oil pan. Tighten pan bolts to 13.6 N´m (125 in. lbs.).

(4) Install throttle valve and shift selector levers

on valve body manual lever shaft.

(5) Apply small quantity of dielectric grease to ter-

minal pins of solenoid case connector and neutral

switch.

(6) Fill transmission with recommended fluid.

Refer to Service Procedures section of this group.

INSTALLATION

(1) Check torque converter hub and hub drive

notches for sharp edges burrs, scratches, or nicks.

Polish the hub and notches with 320/400 grit paper

and crocus cloth if necessary. The hub must be

smooth to avoid damaging pump seal at installation.

(2) Lubricate pocket in the rear oil pump seal lip

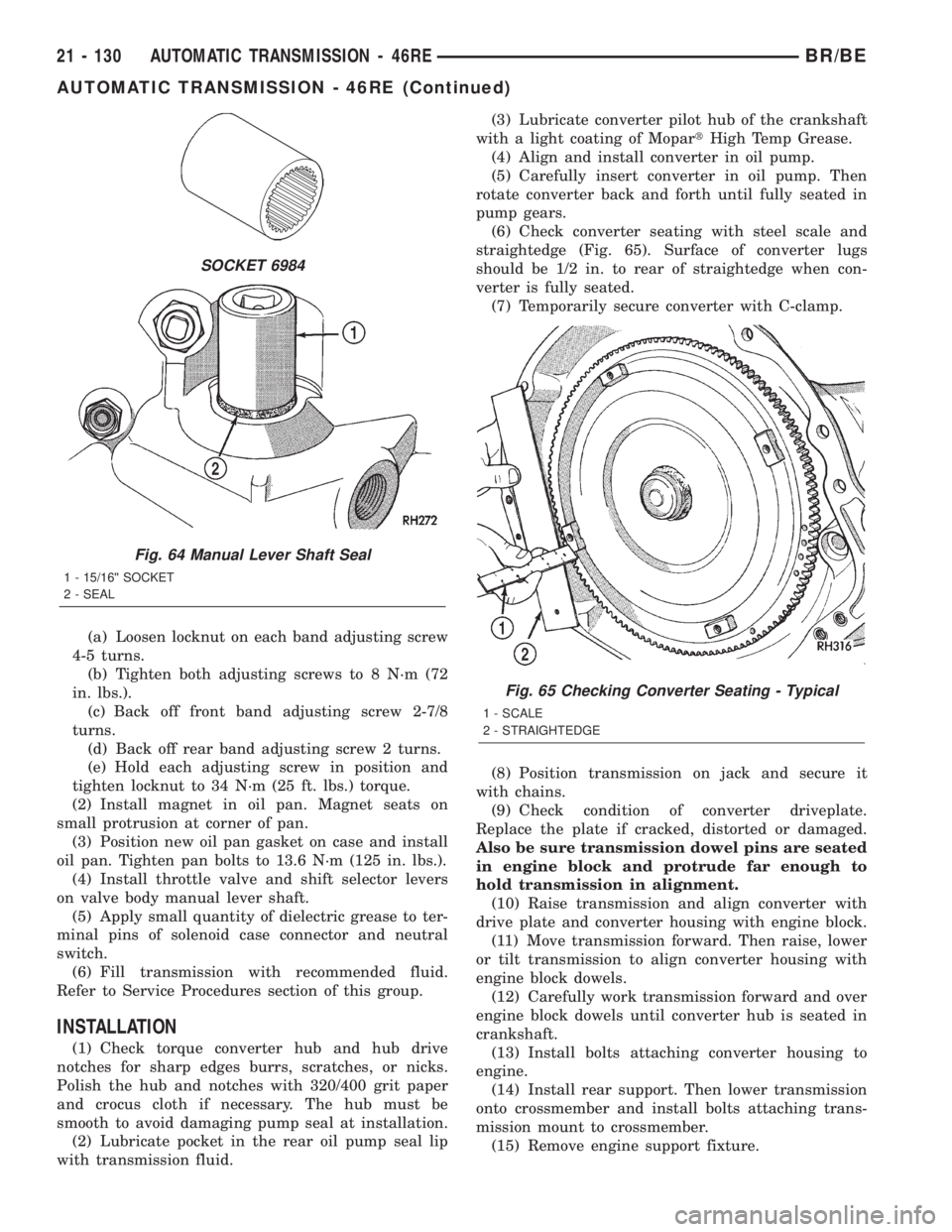

with transmission fluid.(3) Lubricate converter pilot hub of the crankshaft

with a light coating of MopartHigh Temp Grease.

(4) Align and install converter in oil pump.

(5) Carefully insert converter in oil pump. Then

rotate converter back and forth until fully seated in

pump gears.

(6) Check converter seating with steel scale and

straightedge (Fig. 65). Surface of converter lugs

should be 1/2 in. to rear of straightedge when con-

verter is fully seated.

(7) Temporarily secure converter with C-clamp.

(8) Position transmission on jack and secure it

with chains.

(9) Check condition of converter driveplate.

Replace the plate if cracked, distorted or damaged.

Also be sure transmission dowel pins are seated

in engine block and protrude far enough to

hold transmission in alignment.

(10) Raise transmission and align converter with

drive plate and converter housing with engine block.

(11) Move transmission forward. Then raise, lower

or tilt transmission to align converter housing with

engine block dowels.

(12) Carefully work transmission forward and over

engine block dowels until converter hub is seated in

crankshaft.

(13) Install bolts attaching converter housing to

engine.

(14) Install rear support. Then lower transmission

onto crossmember and install bolts attaching trans-

mission mount to crossmember.

(15) Remove engine support fixture.

SOCKET 6984

Fig. 64 Manual Lever Shaft Seal

1 - 15/16©© SOCKET

2 - SEAL

Fig. 65 Checking Converter Seating - Typical

1 - SCALE

2 - STRAIGHTEDGE

21 - 130 AUTOMATIC TRANSMISSION - 46REBR/BE

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 1873 of 2255

CAUTION: Many of the valves and plugs, such as

the throttle valve, shuttle valve plug, 1-2 shift valve

and 1-2 governor plug, are made of coated alumi-

num. Aluminum components are identified by the

dark color of the special coating applied to the sur-

face (or by testing with a magnet). Do not sand alu-

minum valves or plugs under any circumstances.

This practice could damage the special coating

causing the valves/plugs to stick and bind.

Inspect the valves and plugs for scratches, burrs,

nicks, or scores. Minor surface scratches on steel

valves and plugs can be removed with crocus cloth

butdo not round off the edges of the valve or

plug lands.Maintaining sharpness of these edges is

vitally important. The edges prevent foreign matter

from lodging between the valves and plugs and the

bore.

Inspect all the valve and plug bores in the valve

body. Use a penlight to view the bore interiors.

Replace the valve body if any bores are distorted or

scored. Inspect all of the valve body springs. The

springs must be free of distortion, warpage or broken

coils.

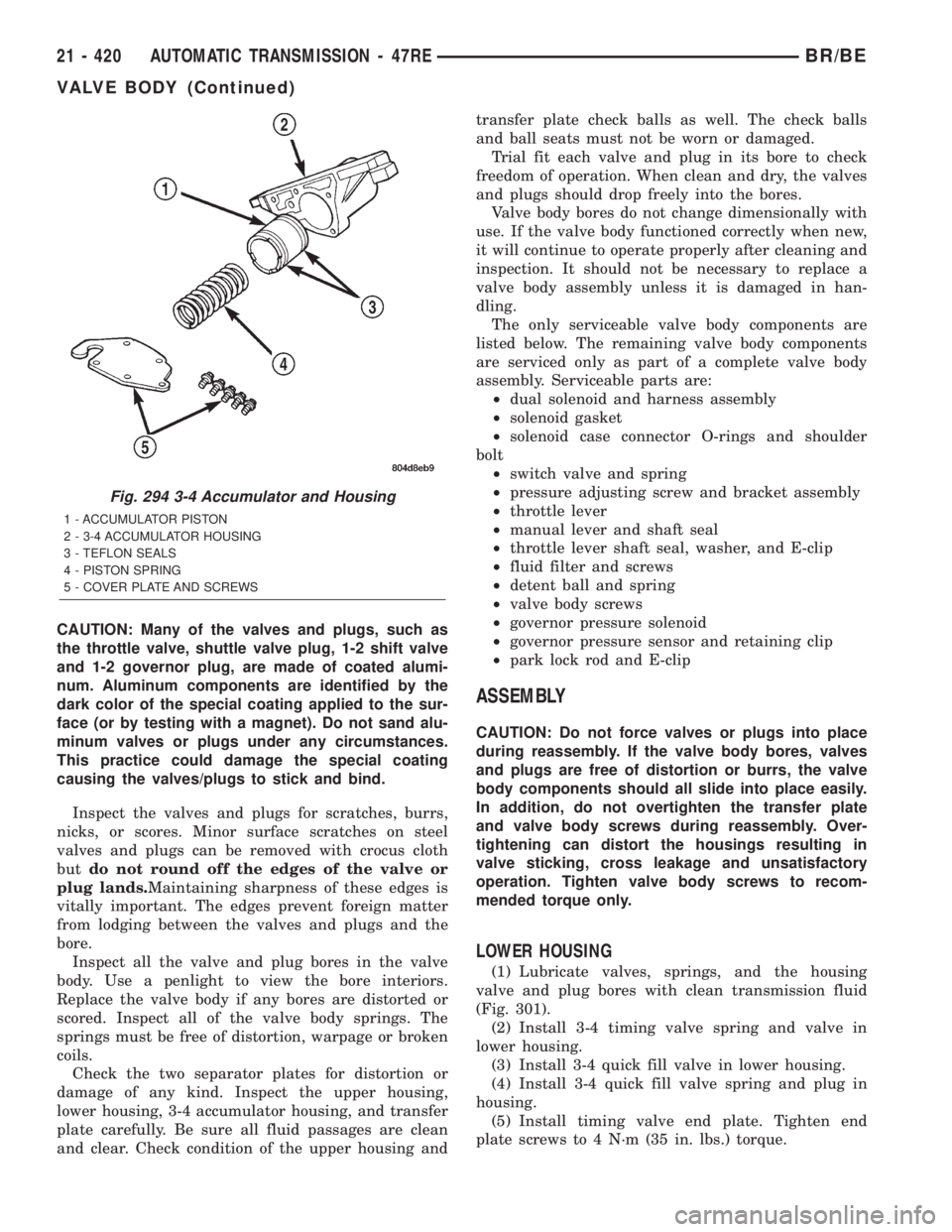

Check the two separator plates for distortion or

damage of any kind. Inspect the upper housing,

lower housing, 3-4 accumulator housing, and transfer

plate carefully. Be sure all fluid passages are clean

and clear. Check condition of the upper housing andtransfer plate check balls as well. The check balls

and ball seats must not be worn or damaged.

Trial fit each valve and plug in its bore to check

freedom of operation. When clean and dry, the valves

and plugs should drop freely into the bores.

Valve body bores do not change dimensionally with

use. If the valve body functioned correctly when new,

it will continue to operate properly after cleaning and

inspection. It should not be necessary to replace a

valve body assembly unless it is damaged in han-

dling.

The only serviceable valve body components are

listed below. The remaining valve body components

are serviced only as part of a complete valve body

assembly. Serviceable parts are:

²dual solenoid and harness assembly

²solenoid gasket

²solenoid case connector O-rings and shoulder

bolt

²switch valve and spring

²pressure adjusting screw and bracket assembly

²throttle lever

²manual lever and shaft seal

²throttle lever shaft seal, washer, and E-clip

²fluid filter and screws

²detent ball and spring

²valve body screws

²governor pressure solenoid

²governor pressure sensor and retaining clip

²park lock rod and E-clip

ASSEMBLY

CAUTION: Do not force valves or plugs into place

during reassembly. If the valve body bores, valves

and plugs are free of distortion or burrs, the valve

body components should all slide into place easily.

In addition, do not overtighten the transfer plate

and valve body screws during reassembly. Over-

tightening can distort the housings resulting in

valve sticking, cross leakage and unsatisfactory

operation. Tighten valve body screws to recom-

mended torque only.

LOWER HOUSING

(1) Lubricate valves, springs, and the housing

valve and plug bores with clean transmission fluid

(Fig. 301).

(2) Install 3-4 timing valve spring and valve in

lower housing.

(3) Install 3-4 quick fill valve in lower housing.

(4) Install 3-4 quick fill valve spring and plug in

housing.

(5) Install timing valve end plate. Tighten end

plate screws to 4 N´m (35 in. lbs.) torque.

Fig. 294 3-4 Accumulator and Housing

1 - ACCUMULATOR PISTON

2 - 3-4 ACCUMULATOR HOUSING

3 - TEFLON SEALS

4 - PISTON SPRING

5 - COVER PLATE AND SCREWS

21 - 420 AUTOMATIC TRANSMISSION - 47REBR/BE

VALVE BODY (Continued)

Page 1913 of 2255

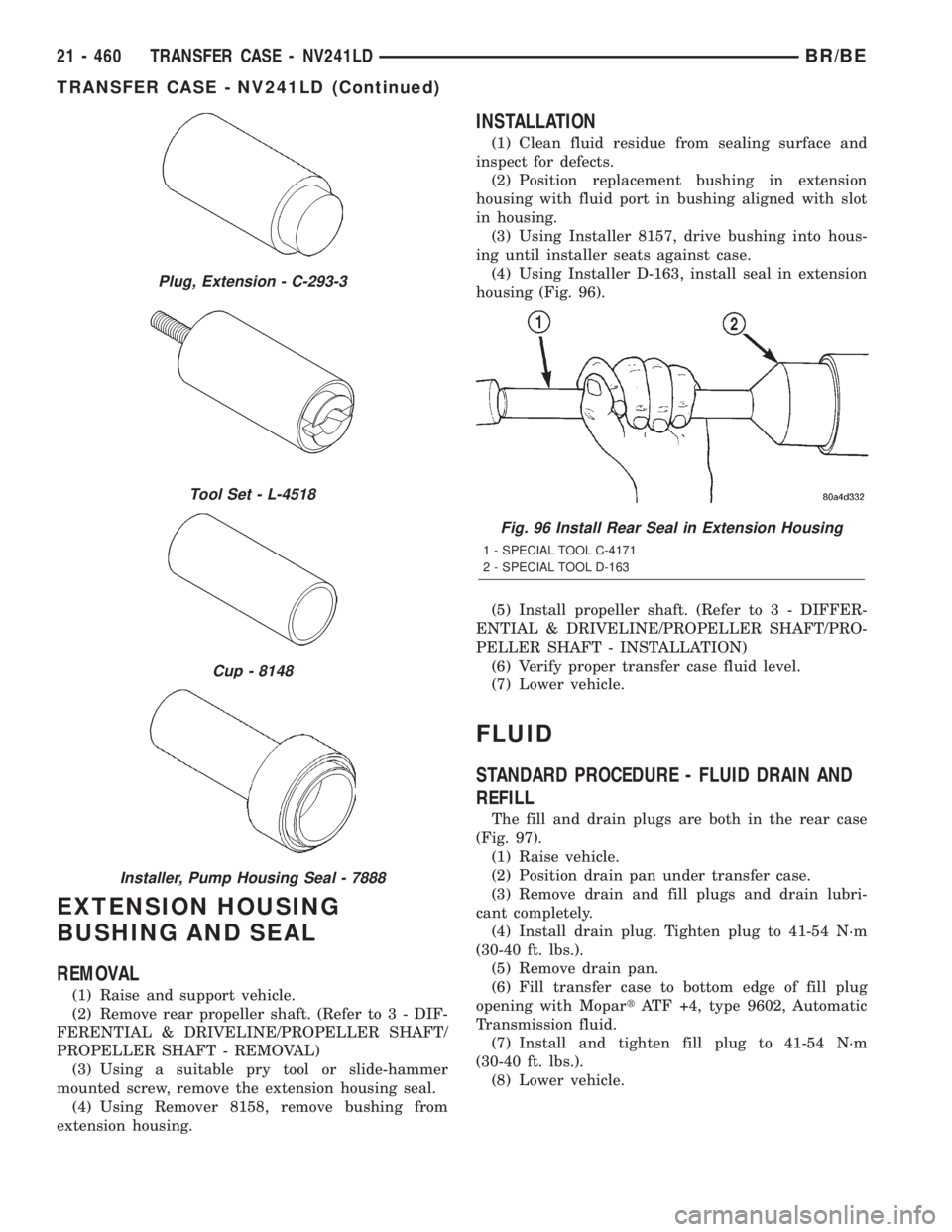

EXTENSION HOUSING

BUSHING AND SEAL

REMOVAL

(1) Raise and support vehicle.

(2) Remove rear propeller shaft. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - REMOVAL)

(3) Using a suitable pry tool or slide-hammer

mounted screw, remove the extension housing seal.

(4) Using Remover 8158, remove bushing from

extension housing.

INSTALLATION

(1) Clean fluid residue from sealing surface and

inspect for defects.

(2) Position replacement bushing in extension

housing with fluid port in bushing aligned with slot

in housing.

(3) Using Installer 8157, drive bushing into hous-

ing until installer seats against case.

(4) Using Installer D-163, install seal in extension

housing (Fig. 96).

(5) Install propeller shaft. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/PROPELLER SHAFT/PRO-

PELLER SHAFT - INSTALLATION)

(6) Verify proper transfer case fluid level.

(7) Lower vehicle.

FLUID

STANDARD PROCEDURE - FLUID DRAIN AND

REFILL

The fill and drain plugs are both in the rear case

(Fig. 97).

(1) Raise vehicle.

(2) Position drain pan under transfer case.

(3) Remove drain and fill plugs and drain lubri-

cant completely.

(4) Install drain plug. Tighten plug to 41-54 N´m

(30-40 ft. lbs.).

(5) Remove drain pan.

(6) Fill transfer case to bottom edge of fill plug

opening with MopartATF +4, type 9602, Automatic

Transmission fluid.

(7) Install and tighten fill plug to 41-54 N´m

(30-40 ft. lbs.).

(8) Lower vehicle.

Plug, Extension - C-293-3

Tool Set - L-4518

Cup - 8148

Installer, Pump Housing Seal - 7888

Fig. 96 Install Rear Seal in Extension Housing

1 - SPECIAL TOOL C-4171

2 - SPECIAL TOOL D-163

21 - 460 TRANSFER CASE - NV241LDBR/BE

TRANSFER CASE - NV241LD (Continued)

Page 1950 of 2255

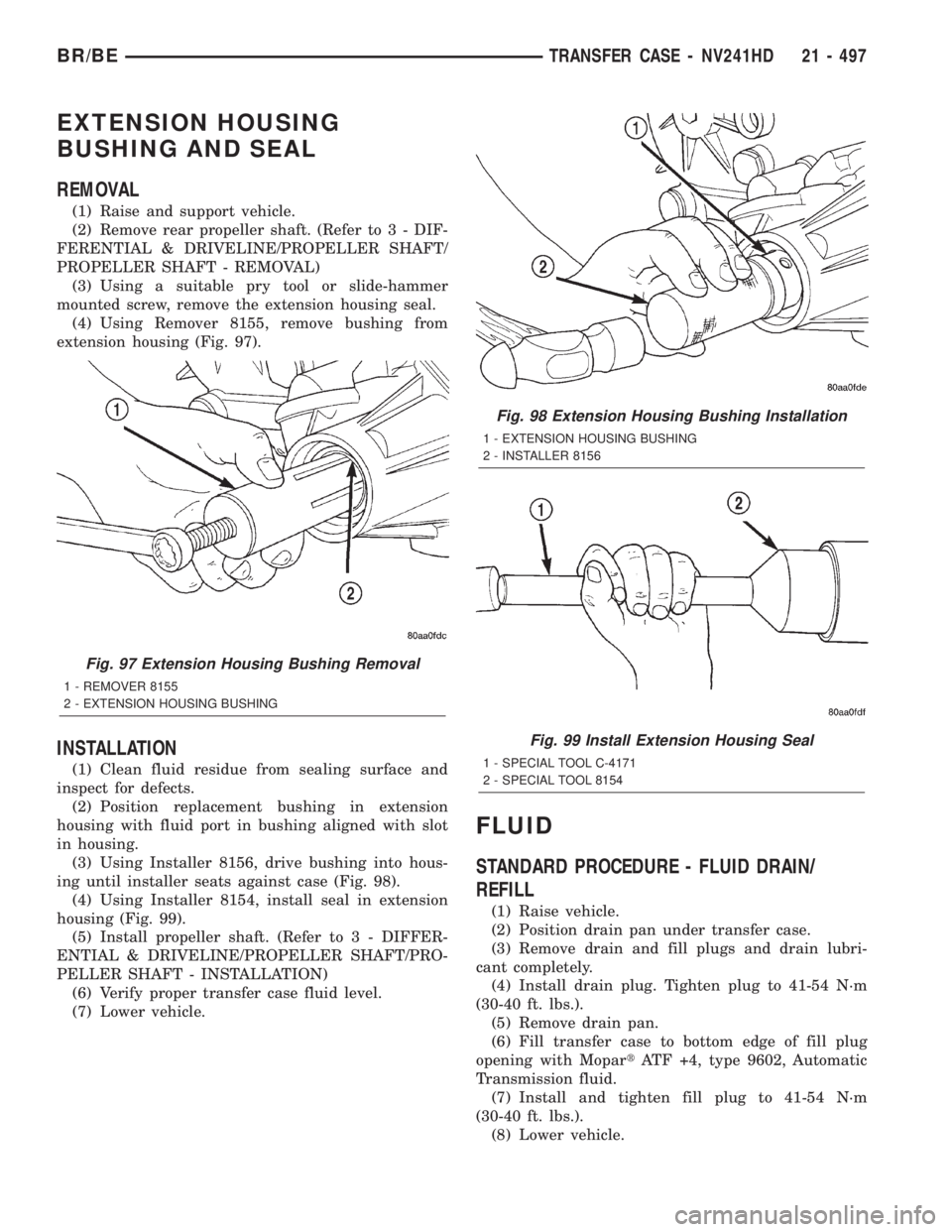

EXTENSION HOUSING

BUSHING AND SEAL

REMOVAL

(1) Raise and support vehicle.

(2) Remove rear propeller shaft. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - REMOVAL)

(3) Using a suitable pry tool or slide-hammer

mounted screw, remove the extension housing seal.

(4) Using Remover 8155, remove bushing from

extension housing (Fig. 97).

INSTALLATION

(1) Clean fluid residue from sealing surface and

inspect for defects.

(2) Position replacement bushing in extension

housing with fluid port in bushing aligned with slot

in housing.

(3) Using Installer 8156, drive bushing into hous-

ing until installer seats against case (Fig. 98).

(4) Using Installer 8154, install seal in extension

housing (Fig. 99).

(5) Install propeller shaft. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/PROPELLER SHAFT/PRO-

PELLER SHAFT - INSTALLATION)

(6) Verify proper transfer case fluid level.

(7) Lower vehicle.

FLUID

STANDARD PROCEDURE - FLUID DRAIN/

REFILL

(1) Raise vehicle.

(2) Position drain pan under transfer case.

(3) Remove drain and fill plugs and drain lubri-

cant completely.

(4) Install drain plug. Tighten plug to 41-54 N´m

(30-40 ft. lbs.).

(5) Remove drain pan.

(6) Fill transfer case to bottom edge of fill plug

opening with MopartATF +4, type 9602, Automatic

Transmission fluid.

(7) Install and tighten fill plug to 41-54 N´m

(30-40 ft. lbs.).

(8) Lower vehicle.

Fig. 97 Extension Housing Bushing Removal

1 - REMOVER 8155

2 - EXTENSION HOUSING BUSHING

Fig. 98 Extension Housing Bushing Installation

1 - EXTENSION HOUSING BUSHING

2 - INSTALLER 8156

Fig. 99 Install Extension Housing Seal

1 - SPECIAL TOOL C-4171

2 - SPECIAL TOOL 8154

BR/BETRANSFER CASE - NV241HD 21 - 497

Page 1968 of 2255

BODY

TABLE OF CONTENTS

page page

BODY

WARNING

SAFETY PRECAUTIONS AND WARNINGS . . . 1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - WATER LEAKS . 2

DIAGNOSIS AND TESTING - WIND NOISE . . . 3

SPECIFICATIONS

WELD LOCATIONS.....................4

STRUCTURAL ADHESIVE LOCATIONS.....44

BODY SEALER LOCATIONS.............47

BODY GAP AND FLUSH MEASUREMENTS . . 56

BODY OPENING DIMENSIONS...........60TORQUE SPECIFICATIONS.............61

DECKLID/HATCH/LIFTGATE/TAILGATE.......63

DOOR - FRONT.........................68

DOOR - CARGO.........................77

EXTERIOR.............................86

HOOD................................100

INSTRUMENT PANEL SYSTEM............105

INTERIOR.............................118

PAINT................................129

SEATS...............................131

STATIONARY GLASS....................145

WEATHERSTRIP/SEALS..................151

BODY

WARNING

SAFETY PRECAUTIONS AND WARNINGS

WARNING: USE AN OSHA APPROVED BREATHING

FILTER WHEN SPRAYING PAINT OR SOLVENTS IN

A CONFINED AREA. PERSONAL INJURY CAN

RESULT.

²AVOID PROLONGED SKIN CONTACT WITH

PETROLEUM OR ALCOHOL ± BASED CLEANING

SOLVENTS. PERSONAL INJURY CAN RESULT.

²DO NOT STAND UNDER A HOISTED VEHICLE

THAT IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.CAUTION: When holes must be drilled or punched

in an inner body panel, verify depth of space to the

outer body panel, electrical wiring, or other compo-

nents. Damage to vehicle can result.

²Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

²Always have a fire extinguisher ready for use

when welding.

²Disconnect the negative (-) cable clamp from

the battery when servicing electrical components

that are live when the ignition is OFF. Damage to

electrical system can result.

²Do not use abrasive chemicals or compounds

on painted surfaces. Damage to finish can result.

²Do not use harsh alkaline based cleaning sol-

vents on painted or upholstered surfaces. Damage

to finish or color can result.

²Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

BR/BEBODY 23 - 1

Page 2090 of 2255

(4) Install the screws attaching the console to

mounting brackets.

(5) Install the transmission shifter boot, (Refer to

23 - BODY/INTERIOR/SHIFT BOOT - INSTALLA-

TION).

(6) Install the transfer case shifter boot, if

equipped. (Refer to 23 - BODY/INTERIOR/SHIFT

BOOT - INSTALLATION).

(7) Install cup holder in console, if equipped.

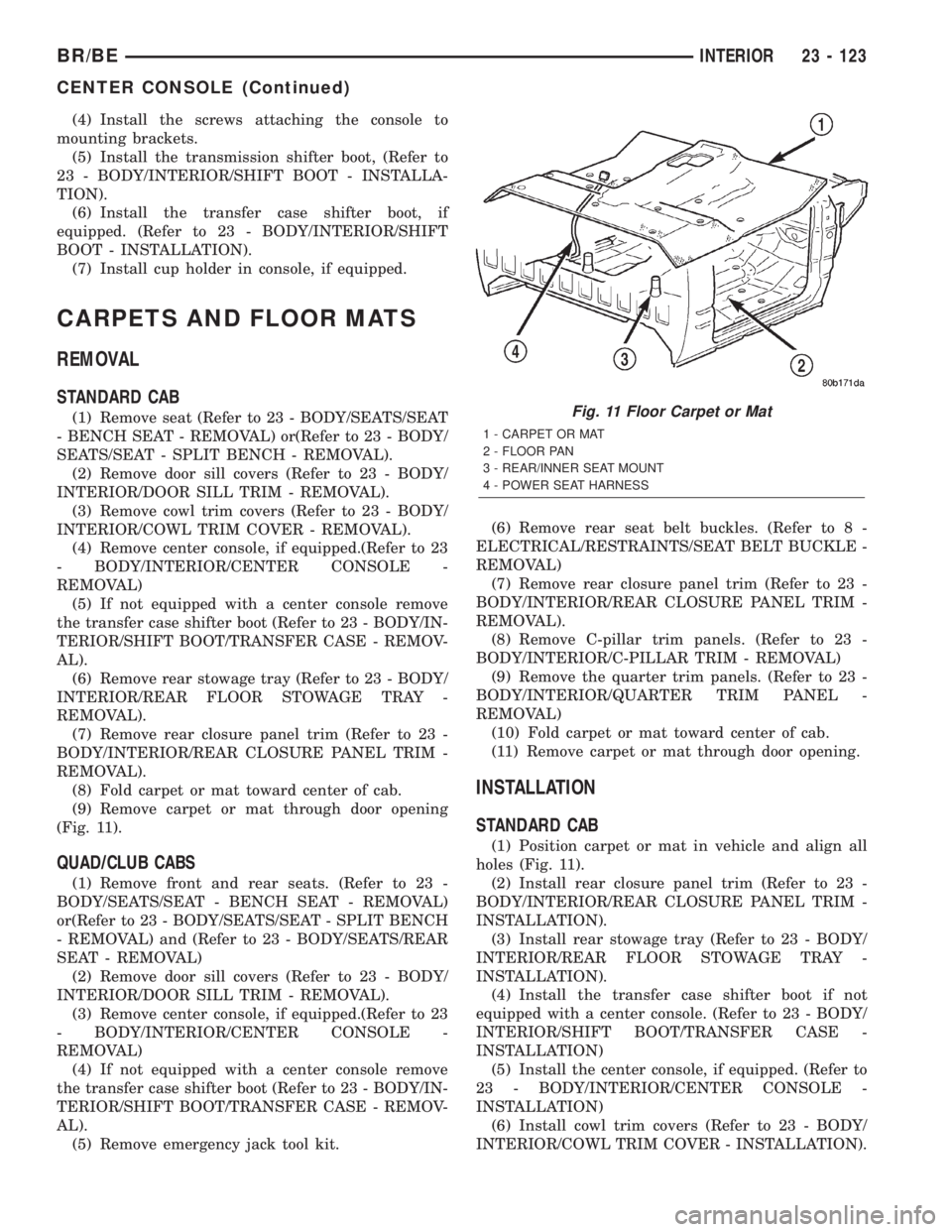

CARPETS AND FLOOR MATS

REMOVAL

STANDARD CAB

(1) Remove seat (Refer to 23 - BODY/SEATS/SEAT

- BENCH SEAT - REMOVAL) or(Refer to 23 - BODY/

SEATS/SEAT - SPLIT BENCH - REMOVAL).

(2) Remove door sill covers (Refer to 23 - BODY/

INTERIOR/DOOR SILL TRIM - REMOVAL).

(3) Remove cowl trim covers (Refer to 23 - BODY/

INTERIOR/COWL TRIM COVER - REMOVAL).

(4) Remove center console, if equipped.(Refer to 23

- BODY/INTERIOR/CENTER CONSOLE -

REMOVAL)

(5) If not equipped with a center console remove

the transfer case shifter boot (Refer to 23 - BODY/IN-

TERIOR/SHIFT BOOT/TRANSFER CASE - REMOV-

AL).

(6) Remove rear stowage tray (Refer to 23 - BODY/

INTERIOR/REAR FLOOR STOWAGE TRAY -

REMOVAL).

(7) Remove rear closure panel trim (Refer to 23 -

BODY/INTERIOR/REAR CLOSURE PANEL TRIM -

REMOVAL).

(8) Fold carpet or mat toward center of cab.

(9) Remove carpet or mat through door opening

(Fig. 11).

QUAD/CLUB CABS

(1) Remove front and rear seats. (Refer to 23 -

BODY/SEATS/SEAT - BENCH SEAT - REMOVAL)

or(Refer to 23 - BODY/SEATS/SEAT - SPLIT BENCH

- REMOVAL) and (Refer to 23 - BODY/SEATS/REAR

SEAT - REMOVAL)

(2) Remove door sill covers (Refer to 23 - BODY/

INTERIOR/DOOR SILL TRIM - REMOVAL).

(3) Remove center console, if equipped.(Refer to 23

- BODY/INTERIOR/CENTER CONSOLE -

REMOVAL)

(4) If not equipped with a center console remove

the transfer case shifter boot (Refer to 23 - BODY/IN-

TERIOR/SHIFT BOOT/TRANSFER CASE - REMOV-

AL).

(5) Remove emergency jack tool kit.(6) Remove rear seat belt buckles. (Refer to 8 -

ELECTRICAL/RESTRAINTS/SEAT BELT BUCKLE -

REMOVAL)

(7) Remove rear closure panel trim (Refer to 23 -

BODY/INTERIOR/REAR CLOSURE PANEL TRIM -

REMOVAL).

(8) Remove C-pillar trim panels. (Refer to 23 -

BODY/INTERIOR/C-PILLAR TRIM - REMOVAL)

(9) Remove the quarter trim panels. (Refer to 23 -

BODY/INTERIOR/QUARTER TRIM PANEL -

REMOVAL)

(10) Fold carpet or mat toward center of cab.

(11) Remove carpet or mat through door opening.

INSTALLATION

STANDARD CAB

(1) Position carpet or mat in vehicle and align all

holes (Fig. 11).

(2) Install rear closure panel trim (Refer to 23 -

BODY/INTERIOR/REAR CLOSURE PANEL TRIM -

INSTALLATION).

(3) Install rear stowage tray (Refer to 23 - BODY/

INTERIOR/REAR FLOOR STOWAGE TRAY -

INSTALLATION).

(4) Install the transfer case shifter boot if not

equipped with a center console. (Refer to 23 - BODY/

INTERIOR/SHIFT BOOT/TRANSFER CASE -

INSTALLATION)

(5) Install the center console, if equipped. (Refer to

23 - BODY/INTERIOR/CENTER CONSOLE -

INSTALLATION)

(6) Install cowl trim covers (Refer to 23 - BODY/

INTERIOR/COWL TRIM COVER - INSTALLATION).

Fig. 11 Floor Carpet or Mat

1 - CARPET OR MAT

2 - FLOOR PAN

3 - REAR/INNER SEAT MOUNT

4 - POWER SEAT HARNESS

BR/BEINTERIOR 23 - 123

CENTER CONSOLE (Continued)

Page 2091 of 2255

(7) Install door sill covers (Refer to 23 - BODY/IN-

TERIOR/DOOR SILL TRIM - INSTALLATION).

(8) Install seat, (Refer to 23 - BODY/SEATS/SEAT

- INSTALLATION) or (Refer to 23 - BODY/SEATS/

SEAT/SPLIT BENCH - INSTALLATION).

QUAD/CLUB CABS

(1) Position carpet or mat in vehicle.

(2) Install quarter trim panels. (Refer to 23 -

BODY/INTERIOR/QUARTER TRIM PANEL -

INSTALLATION)

(3) Install rear seat belt buckles.

(4) Install the C-pillar trim panels, if equipped.

(Refer to 23 - BODY/INTERIOR/C-PILLAR TRIM -

INSTALLATION)

(5) Install rear closure panel trim (Refer to 23 -

BODY/INTERIOR/REAR CLOSURE PANEL TRIM -

INSTALLATION).

(6) Install the rear seat belt buckles. (Refer to 8 -

ELECTRICAL/RESTRAINTS/SEAT BELT BUCKLE -

INSTALLATION)

(7) Install emergency jack tool kit.

(8) Install the transfer case shifter boot if not

equipped with a center console. (Refer to 23 - BODY/

INTERIOR/SHIFT BOOT/TRANSFER CASE -

INSTALLATION)

(9) Install the center console, if equipped. (Refer to

23 - BODY/INTERIOR/CENTER CONSOLE -

INSTALLATION)

(10) Install floor shift boot, if equipped.

(11) Install cowl trim covers (Refer to 23 - BODY/

INTERIOR/COWL TRIM COVER - INSTALLATION).

(12) Install door sill covers (Refer to 23 - BODY/

INTERIOR/DOOR SILL TRIM - INSTALLATION).

(13) Install front and rear seats. (Refer to 23 -

BODY/SEATS/SEAT - BENCH SEAT - INSTALLA-

TION) or (Refer to 23 - BODY/SEATS/SEAT - SPLIT

BENCH - INSTALLATION) and (Refer to 23 - BODY/

SEATS/REAR SEAT - INSTALLATION)

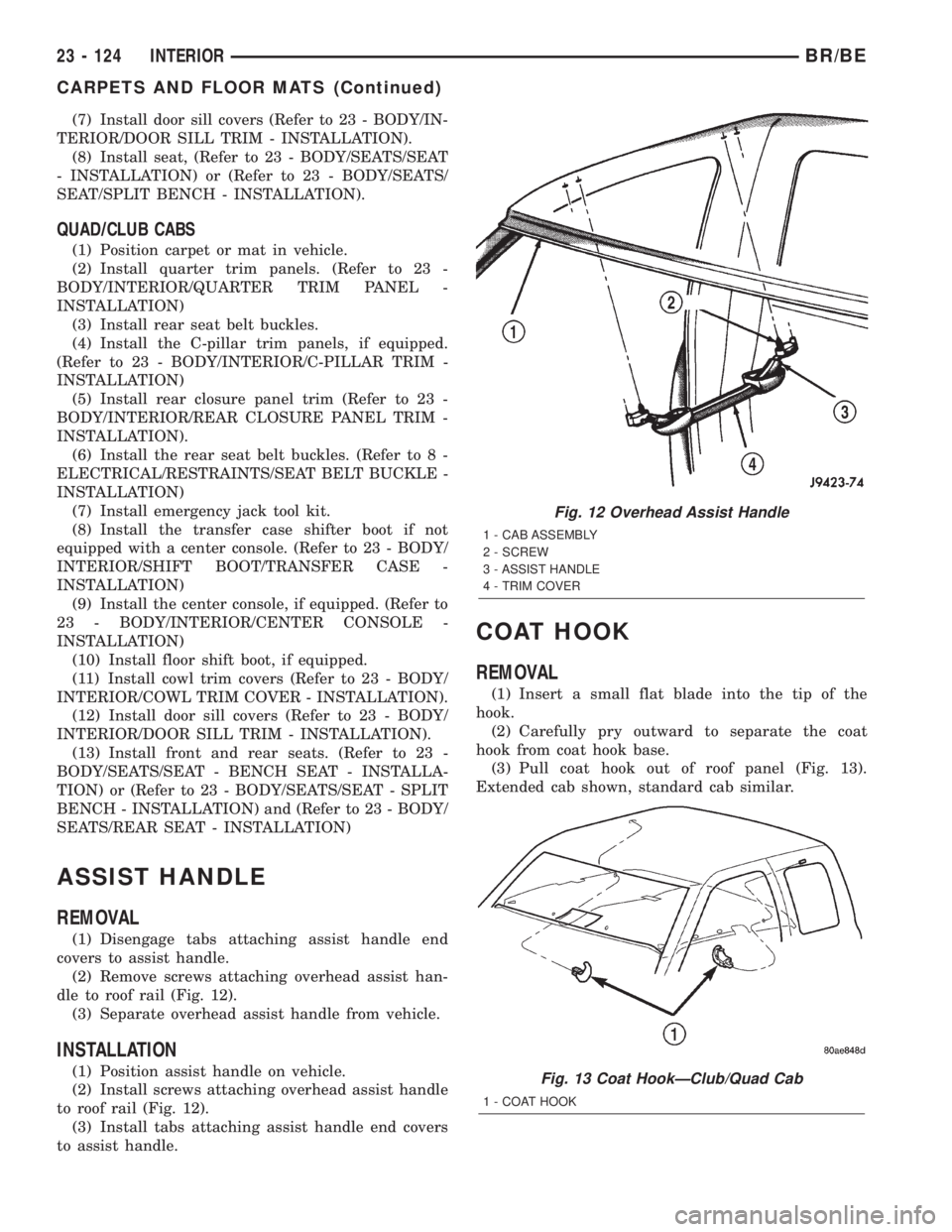

ASSIST HANDLE

REMOVAL

(1) Disengage tabs attaching assist handle end

covers to assist handle.

(2) Remove screws attaching overhead assist han-

dle to roof rail (Fig. 12).

(3) Separate overhead assist handle from vehicle.

INSTALLATION

(1) Position assist handle on vehicle.

(2) Install screws attaching overhead assist handle

to roof rail (Fig. 12).

(3) Install tabs attaching assist handle end covers

to assist handle.

COAT HOOK

REMOVAL

(1) Insert a small flat blade into the tip of the

hook.

(2) Carefully pry outward to separate the coat

hook from coat hook base.

(3) Pull coat hook out of roof panel (Fig. 13).

Extended cab shown, standard cab similar.

Fig. 12 Overhead Assist Handle

1 - CAB ASSEMBLY

2 - SCREW

3 - ASSIST HANDLE

4 - TRIM COVER

Fig. 13 Coat HookÐClub/Quad Cab

1 - COAT HOOK

23 - 124 INTERIORBR/BE

CARPETS AND FLOOR MATS (Continued)

Page 2095 of 2255

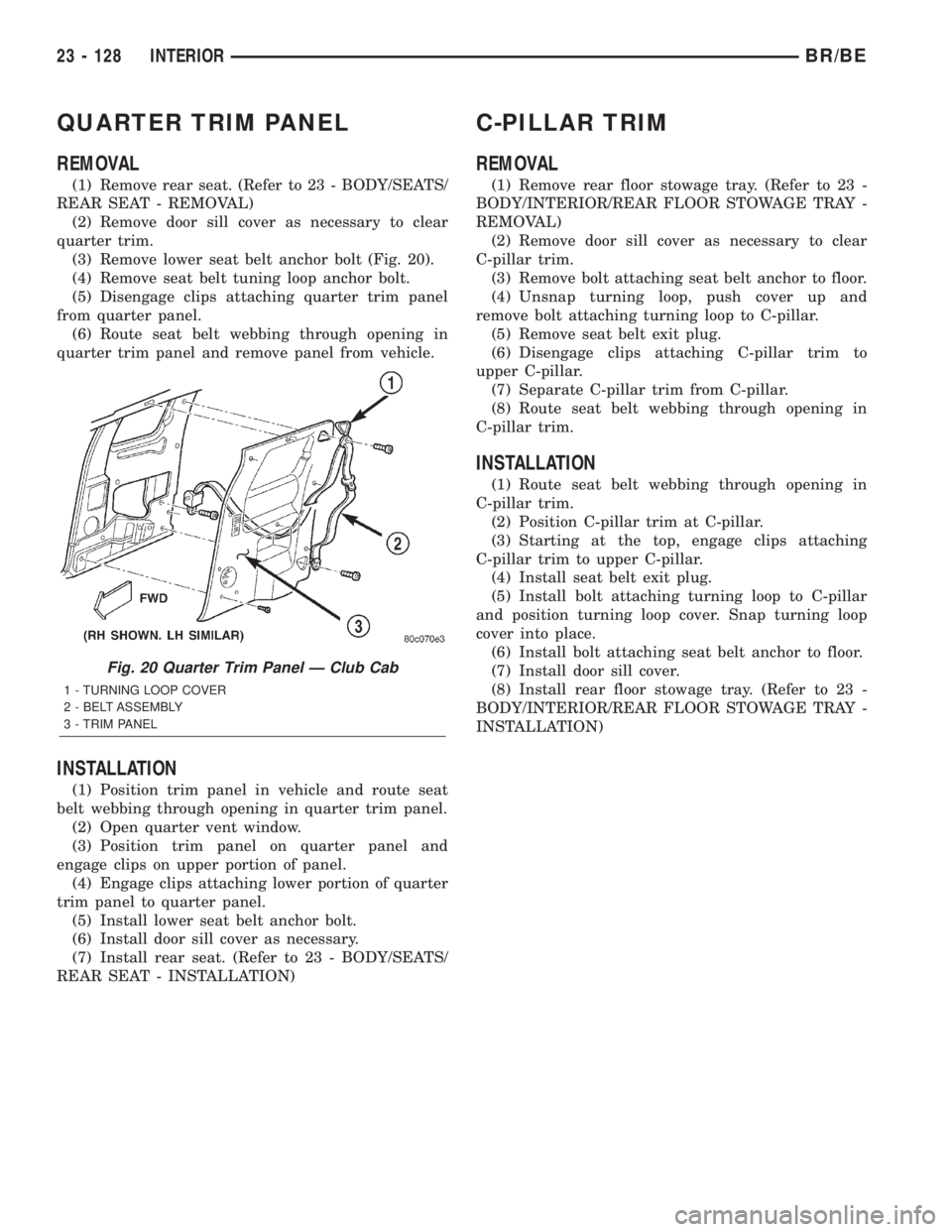

QUARTER TRIM PANEL

REMOVAL

(1) Remove rear seat. (Refer to 23 - BODY/SEATS/

REAR SEAT - REMOVAL)

(2) Remove door sill cover as necessary to clear

quarter trim.

(3) Remove lower seat belt anchor bolt (Fig. 20).

(4) Remove seat belt tuning loop anchor bolt.

(5) Disengage clips attaching quarter trim panel

from quarter panel.

(6) Route seat belt webbing through opening in

quarter trim panel and remove panel from vehicle.

INSTALLATION

(1) Position trim panel in vehicle and route seat

belt webbing through opening in quarter trim panel.

(2) Open quarter vent window.

(3) Position trim panel on quarter panel and

engage clips on upper portion of panel.

(4) Engage clips attaching lower portion of quarter

trim panel to quarter panel.

(5) Install lower seat belt anchor bolt.

(6) Install door sill cover as necessary.

(7) Install rear seat. (Refer to 23 - BODY/SEATS/

REAR SEAT - INSTALLATION)

C-PILLAR TRIM

REMOVAL

(1) Remove rear floor stowage tray. (Refer to 23 -

BODY/INTERIOR/REAR FLOOR STOWAGE TRAY -

REMOVAL)

(2) Remove door sill cover as necessary to clear

C-pillar trim.

(3) Remove bolt attaching seat belt anchor to floor.

(4) Unsnap turning loop, push cover up and

remove bolt attaching turning loop to C-pillar.

(5) Remove seat belt exit plug.

(6) Disengage clips attaching C-pillar trim to

upper C-pillar.

(7) Separate C-pillar trim from C-pillar.

(8) Route seat belt webbing through opening in

C-pillar trim.

INSTALLATION

(1) Route seat belt webbing through opening in

C-pillar trim.

(2) Position C-pillar trim at C-pillar.

(3) Starting at the top, engage clips attaching

C-pillar trim to upper C-pillar.

(4) Install seat belt exit plug.

(5) Install bolt attaching turning loop to C-pillar

and position turning loop cover. Snap turning loop

cover into place.

(6) Install bolt attaching seat belt anchor to floor.

(7) Install door sill cover.

(8) Install rear floor stowage tray. (Refer to 23 -

BODY/INTERIOR/REAR FLOOR STOWAGE TRAY -

INSTALLATION)

Fig. 20 Quarter Trim Panel Ð Club Cab

1 - TURNING LOOP COVER

2 - BELT ASSEMBLY

3 - TRIM PANEL

23 - 128 INTERIORBR/BE