service indicator DODGE RAM 2002 Service Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1957 of 2255

METHOD 1 (RELOCATE WHEEL ON HUB)

(1) Drive vehicle a short distance to eliminate tire

flat spotting from a parked position.

(2) Check wheel bearings and adjust if adjustable

or replace if necessary.

(3) Check the wheel mounting surface.

(4) Relocate wheel on the mounting, two studs

over from the original position.

(5) Tighten wheel nuts until all are properly

torqued, to eliminate brake distortion.

(6) Check radial runout. If still excessive, mark

tire sidewall, wheel, and stud at point of maximum

runout and proceed to Method 2.

METHOD 2 (RELOCATE TIRE ON WHEEL)

NOTE: Rotating the tire on wheel is particularly

effective when there is runout in both tire and

wheel.

(1) Remove tire from wheel and mount wheel on

service dynamic balance machine.

(2) Check wheel radial runout (Fig. 2) and lateral

runout (Fig. 3).

²STEEL WHEELS: Radial runout 0.040 in., Lat-

eral runout 0.045 in. (maximum)

²ALUMINUM WHEELS: Radial runout 0.030 in.,

Lateral runout 0.035 in. (maximum)

(3)

If point of greatest wheel lateral runout is near

original chalk mark, remount tire 180 degrees. Recheck

runout, Refer to match mounting procedure.

STANDARD PROCEDURE

STANDARD PROCEDURE - TIRE ROTATION

Tires on the front and rear axles operate at differ-

ent loads and perform different steering, driving, and

braking functions. For these reasons, the tires wear

at unequal rates. They may also develop irregular

wear patterns. These effects can be reduced by rotat-

ing the tires according to the maintenance schedule

in the Owners Manual. This will improve tread life,

traction and maintain a smooth quiet ride.

The recommended method of tire rotation is (Fig.

4). Other methods can be used, but may not provide

the same tire longevity benefits.

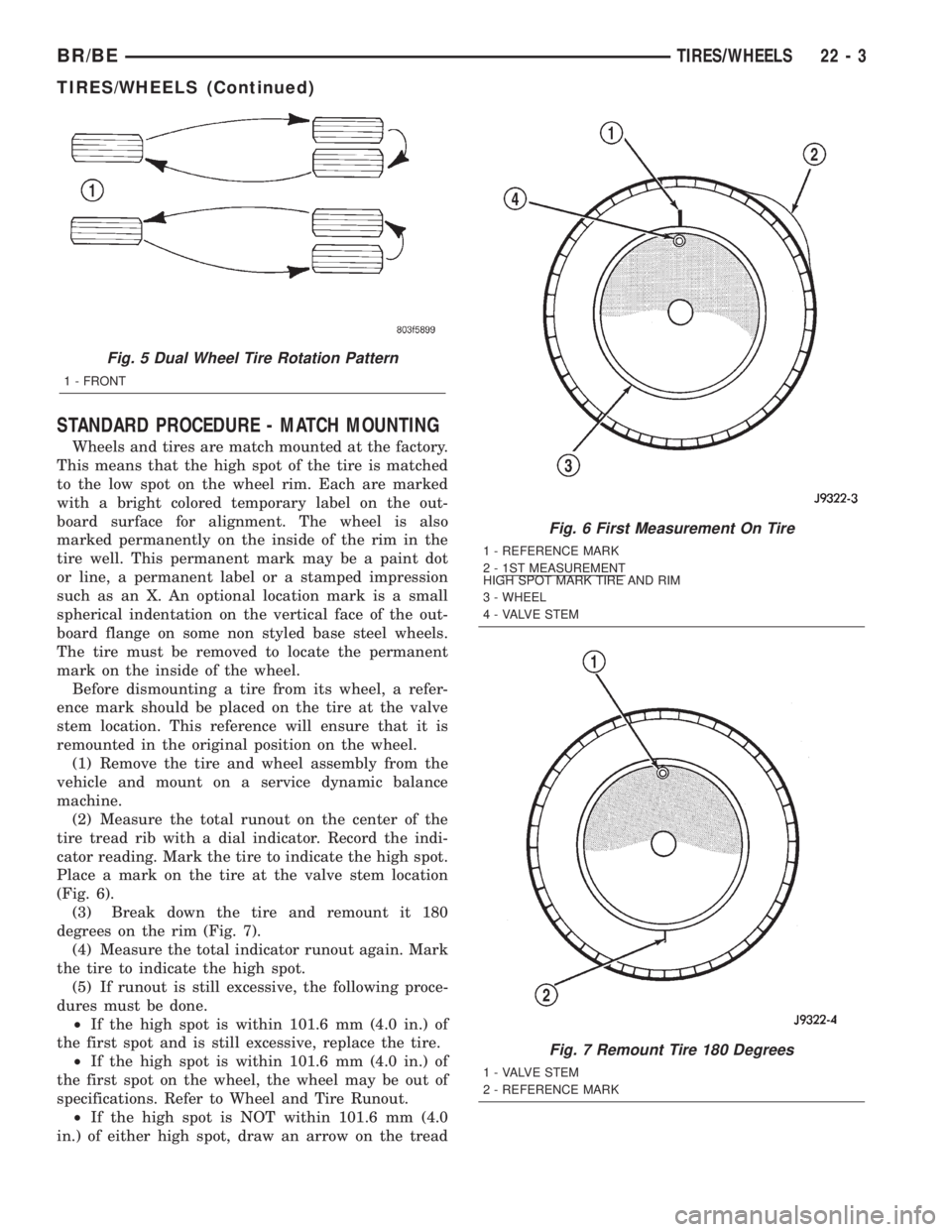

Dual wheel vehicles require a different tire rota-

tion pattern. Refer to (Fig. 5) for the proper tire rota-

tion with dual wheels.

Fig. 2 Radial Runout

1 - MOUNTING CONE

2 - SPINDLE SHAFT

3 - WING NUT

4 - PLASTIC CUP

5 - DIAL INDICATOR

6 - WHEEL

7 - DIAL INDICATOR

Fig. 3 Lateral Runout

1 - MOUNTING CONE

2 - SPINDLE SHAFT

3 - WING NUT

4 - PLASTIC CUP

5 - DIAL INDICATOR

6 - WHEEL

7 - DIAL INDICATOR

Fig. 4 Tire Rotation Pattern

22 - 2 TIRES/WHEELSBR/BE

TIRES/WHEELS (Continued)

Page 1958 of 2255

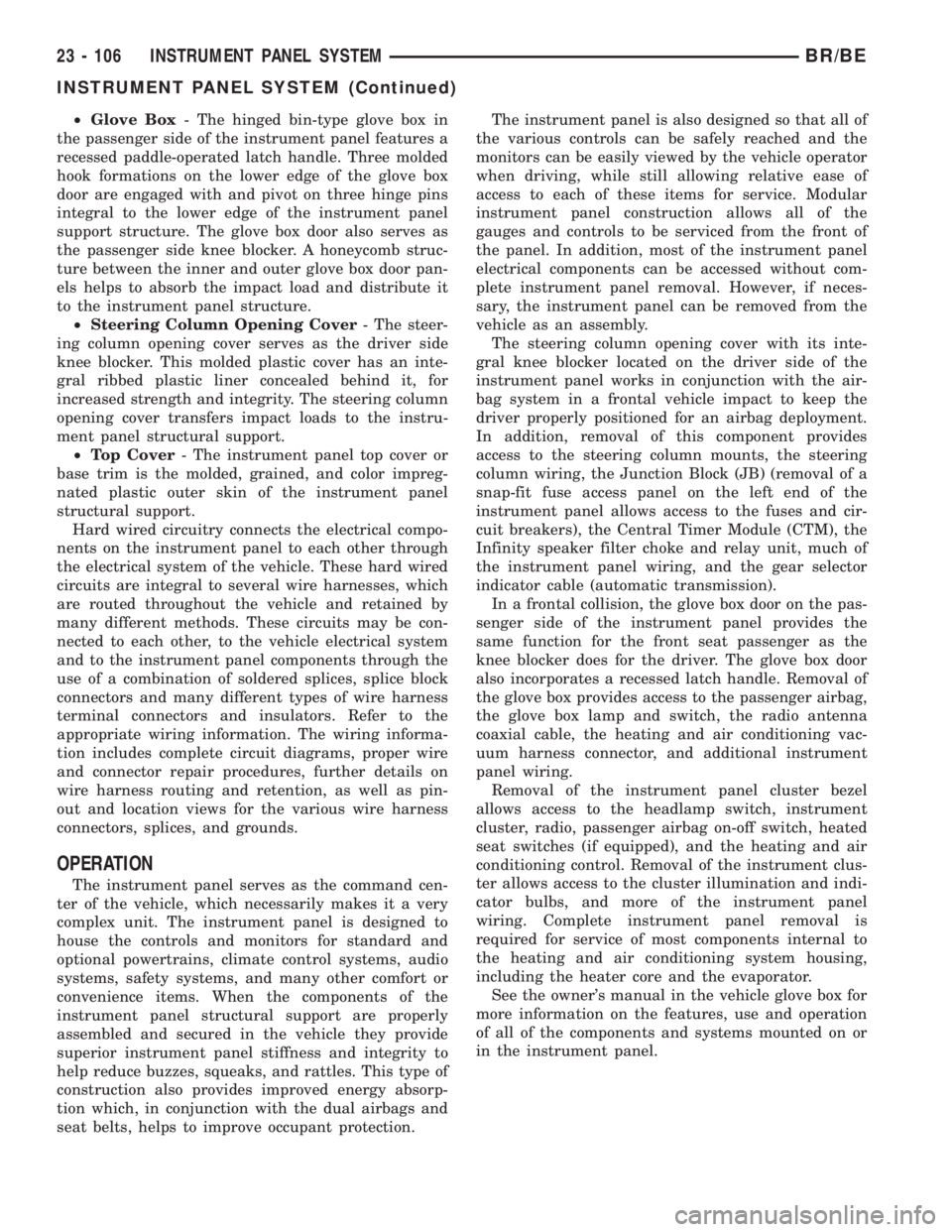

STANDARD PROCEDURE - MATCH MOUNTING

Wheels and tires are match mounted at the factory.

This means that the high spot of the tire is matched

to the low spot on the wheel rim. Each are marked

with a bright colored temporary label on the out-

board surface for alignment. The wheel is also

marked permanently on the inside of the rim in the

tire well. This permanent mark may be a paint dot

or line, a permanent label or a stamped impression

such as an X. An optional location mark is a small

spherical indentation on the vertical face of the out-

board flange on some non styled base steel wheels.

The tire must be removed to locate the permanent

mark on the inside of the wheel.

Before dismounting a tire from its wheel, a refer-

ence mark should be placed on the tire at the valve

stem location. This reference will ensure that it is

remounted in the original position on the wheel.

(1) Remove the tire and wheel assembly from the

vehicle and mount on a service dynamic balance

machine.

(2) Measure the total runout on the center of the

tire tread rib with a dial indicator. Record the indi-

cator reading. Mark the tire to indicate the high spot.

Place a mark on the tire at the valve stem location

(Fig. 6).

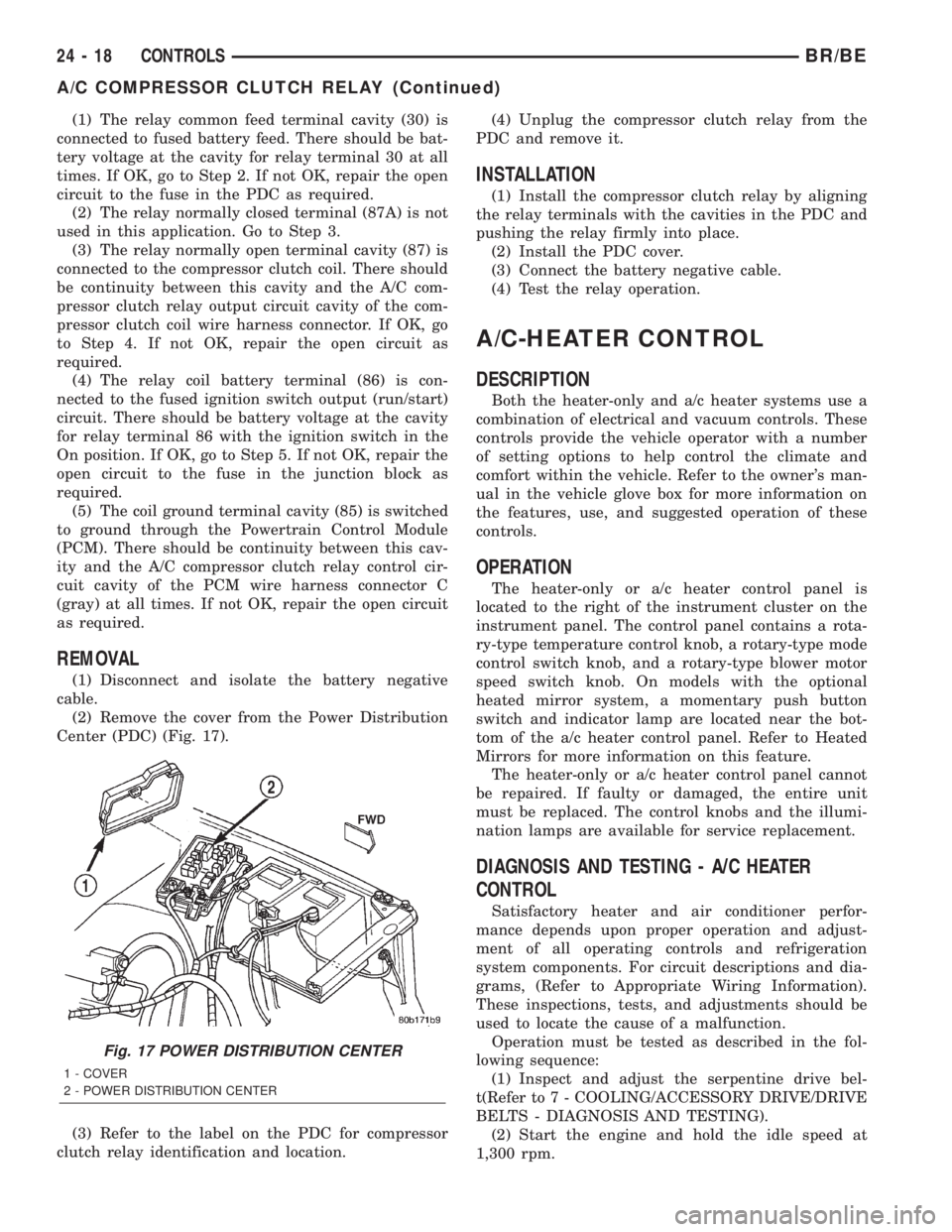

(3) Break down the tire and remount it 180

degrees on the rim (Fig. 7).

(4) Measure the total indicator runout again. Mark

the tire to indicate the high spot.

(5) If runout is still excessive, the following proce-

dures must be done.

²If the high spot is within 101.6 mm (4.0 in.) of

the first spot and is still excessive, replace the tire.

²If the high spot is within 101.6 mm (4.0 in.) of

the first spot on the wheel, the wheel may be out of

specifications. Refer to Wheel and Tire Runout.

²If the high spot is NOT within 101.6 mm (4.0

in.) of either high spot, draw an arrow on the tread

Fig. 5 Dual Wheel Tire Rotation Pattern

1 - FRONT

Fig. 6 First Measurement On Tire

1 - REFERENCE MARK

2 - 1ST MEASUREMENT

HIGH SPOT MARK TIRE AND RIM

3 - WHEEL

4 - VALVE STEM

Fig. 7 Remount Tire 180 Degrees

1 - VALVE STEM

2 - REFERENCE MARK

BR/BETIRES/WHEELS 22 - 3

TIRES/WHEELS (Continued)

Page 2073 of 2255

²Glove Box- The hinged bin-type glove box in

the passenger side of the instrument panel features a

recessed paddle-operated latch handle. Three molded

hook formations on the lower edge of the glove box

door are engaged with and pivot on three hinge pins

integral to the lower edge of the instrument panel

support structure. The glove box door also serves as

the passenger side knee blocker. A honeycomb struc-

ture between the inner and outer glove box door pan-

els helps to absorb the impact load and distribute it

to the instrument panel structure.

²Steering Column Opening Cover- The steer-

ing column opening cover serves as the driver side

knee blocker. This molded plastic cover has an inte-

gral ribbed plastic liner concealed behind it, for

increased strength and integrity. The steering column

opening cover transfers impact loads to the instru-

ment panel structural support.

²Top Cover- The instrument panel top cover or

base trim is the molded, grained, and color impreg-

nated plastic outer skin of the instrument panel

structural support.

Hard wired circuitry connects the electrical compo-

nents on the instrument panel to each other through

the electrical system of the vehicle. These hard wired

circuits are integral to several wire harnesses, which

are routed throughout the vehicle and retained by

many different methods. These circuits may be con-

nected to each other, to the vehicle electrical system

and to the instrument panel components through the

use of a combination of soldered splices, splice block

connectors and many different types of wire harness

terminal connectors and insulators. Refer to the

appropriate wiring information. The wiring informa-

tion includes complete circuit diagrams, proper wire

and connector repair procedures, further details on

wire harness routing and retention, as well as pin-

out and location views for the various wire harness

connectors, splices, and grounds.

OPERATION

The instrument panel serves as the command cen-

ter of the vehicle, which necessarily makes it a very

complex unit. The instrument panel is designed to

house the controls and monitors for standard and

optional powertrains, climate control systems, audio

systems, safety systems, and many other comfort or

convenience items. When the components of the

instrument panel structural support are properly

assembled and secured in the vehicle they provide

superior instrument panel stiffness and integrity to

help reduce buzzes, squeaks, and rattles. This type of

construction also provides improved energy absorp-

tion which, in conjunction with the dual airbags and

seat belts, helps to improve occupant protection.The instrument panel is also designed so that all of

the various controls can be safely reached and the

monitors can be easily viewed by the vehicle operator

when driving, while still allowing relative ease of

access to each of these items for service. Modular

instrument panel construction allows all of the

gauges and controls to be serviced from the front of

the panel. In addition, most of the instrument panel

electrical components can be accessed without com-

plete instrument panel removal. However, if neces-

sary, the instrument panel can be removed from the

vehicle as an assembly.

The steering column opening cover with its inte-

gral knee blocker located on the driver side of the

instrument panel works in conjunction with the air-

bag system in a frontal vehicle impact to keep the

driver properly positioned for an airbag deployment.

In addition, removal of this component provides

access to the steering column mounts, the steering

column wiring, the Junction Block (JB) (removal of a

snap-fit fuse access panel on the left end of the

instrument panel allows access to the fuses and cir-

cuit breakers), the Central Timer Module (CTM), the

Infinity speaker filter choke and relay unit, much of

the instrument panel wiring, and the gear selector

indicator cable (automatic transmission).

In a frontal collision, the glove box door on the pas-

senger side of the instrument panel provides the

same function for the front seat passenger as the

knee blocker does for the driver. The glove box door

also incorporates a recessed latch handle. Removal of

the glove box provides access to the passenger airbag,

the glove box lamp and switch, the radio antenna

coaxial cable, the heating and air conditioning vac-

uum harness connector, and additional instrument

panel wiring.

Removal of the instrument panel cluster bezel

allows access to the headlamp switch, instrument

cluster, radio, passenger airbag on-off switch, heated

seat switches (if equipped), and the heating and air

conditioning control. Removal of the instrument clus-

ter allows access to the cluster illumination and indi-

cator bulbs, and more of the instrument panel

wiring. Complete instrument panel removal is

required for service of most components internal to

the heating and air conditioning system housing,

including the heater core and the evaporator.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of all of the components and systems mounted on or

in the instrument panel.

23 - 106 INSTRUMENT PANEL SYSTEMBR/BE

INSTRUMENT PANEL SYSTEM (Continued)

Page 2139 of 2255

(1) The relay common feed terminal cavity (30) is

connected to fused battery feed. There should be bat-

tery voltage at the cavity for relay terminal 30 at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the fuse in the PDC as required.

(2) The relay normally closed terminal (87A) is not

used in this application. Go to Step 3.

(3) The relay normally open terminal cavity (87) is

connected to the compressor clutch coil. There should

be continuity between this cavity and the A/C com-

pressor clutch relay output circuit cavity of the com-

pressor clutch coil wire harness connector. If OK, go

to Step 4. If not OK, repair the open circuit as

required.

(4) The relay coil battery terminal (86) is con-

nected to the fused ignition switch output (run/start)

circuit. There should be battery voltage at the cavity

for relay terminal 86 with the ignition switch in the

On position. If OK, go to Step 5. If not OK, repair the

open circuit to the fuse in the junction block as

required.

(5) The coil ground terminal cavity (85) is switched

to ground through the Powertrain Control Module

(PCM). There should be continuity between this cav-

ity and the A/C compressor clutch relay control cir-

cuit cavity of the PCM wire harness connector C

(gray) at all times. If not OK, repair the open circuit

as required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Power Distribution

Center (PDC) (Fig. 17).

(3) Refer to the label on the PDC for compressor

clutch relay identification and location.(4) Unplug the compressor clutch relay from the

PDC and remove it.

INSTALLATION

(1) Install the compressor clutch relay by aligning

the relay terminals with the cavities in the PDC and

pushing the relay firmly into place.

(2) Install the PDC cover.

(3) Connect the battery negative cable.

(4) Test the relay operation.

A/C-HEATER CONTROL

DESCRIPTION

Both the heater-only and a/c heater systems use a

combination of electrical and vacuum controls. These

controls provide the vehicle operator with a number

of setting options to help control the climate and

comfort within the vehicle. Refer to the owner's man-

ual in the vehicle glove box for more information on

the features, use, and suggested operation of these

controls.

OPERATION

The heater-only or a/c heater control panel is

located to the right of the instrument cluster on the

instrument panel. The control panel contains a rota-

ry-type temperature control knob, a rotary-type mode

control switch knob, and a rotary-type blower motor

speed switch knob. On models with the optional

heated mirror system, a momentary push button

switch and indicator lamp are located near the bot-

tom of the a/c heater control panel. Refer to Heated

Mirrors for more information on this feature.

The heater-only or a/c heater control panel cannot

be repaired. If faulty or damaged, the entire unit

must be replaced. The control knobs and the illumi-

nation lamps are available for service replacement.

DIAGNOSIS AND TESTING - A/C HEATER

CONTROL

Satisfactory heater and air conditioner perfor-

mance depends upon proper operation and adjust-

ment of all operating controls and refrigeration

system components. For circuit descriptions and dia-

grams, (Refer to Appropriate Wiring Information).

These inspections, tests, and adjustments should be

used to locate the cause of a malfunction.

Operation must be tested as described in the fol-

lowing sequence:

(1) Inspect and adjust the serpentine drive bel-

t(Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE

BELTS - DIAGNOSIS AND TESTING).

(2) Start the engine and hold the idle speed at

1,300 rpm.

Fig. 17 POWER DISTRIBUTION CENTER

1 - COVER

2 - POWER DISTRIBUTION CENTER

24 - 18 CONTROLSBR/BE

A/C COMPRESSOR CLUTCH RELAY (Continued)

Page 2194 of 2255

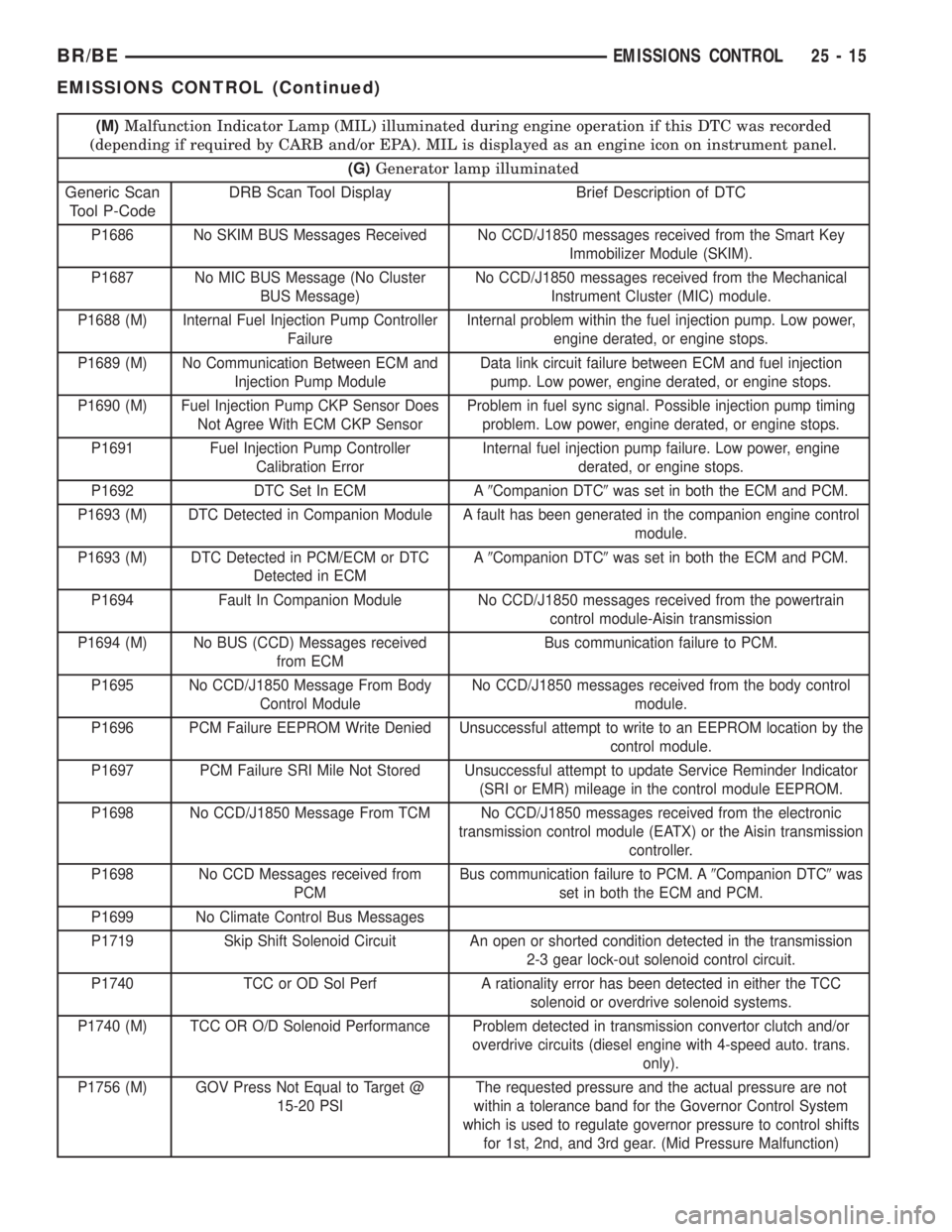

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P1686 No SKIM BUS Messages Received No CCD/J1850 messages received from the Smart Key

Immobilizer Module (SKIM).

P1687 No MIC BUS Message (No Cluster

BUS Message)No CCD/J1850 messages received from the Mechanical

Instrument Cluster (MIC) module.

P1688 (M) Internal Fuel Injection Pump Controller

FailureInternal problem within the fuel injection pump. Low power,

engine derated, or engine stops.

P1689 (M) No Communication Between ECM and

Injection Pump ModuleData link circuit failure between ECM and fuel injection

pump. Low power, engine derated, or engine stops.

P1690 (M) Fuel Injection Pump CKP Sensor Does

Not Agree With ECM CKP SensorProblem in fuel sync signal. Possible injection pump timing

problem. Low power, engine derated, or engine stops.

P1691 Fuel Injection Pump Controller

Calibration ErrorInternal fuel injection pump failure. Low power, engine

derated, or engine stops.

P1692 DTC Set In ECM A9Companion DTC9was set in both the ECM and PCM.

P1693 (M) DTC Detected in Companion Module A fault has been generated in the companion engine control

module.

P1693 (M) DTC Detected in PCM/ECM or DTC

Detected in ECMA9Companion DTC9was set in both the ECM and PCM.

P1694 Fault In Companion Module No CCD/J1850 messages received from the powertrain

control module-Aisin transmission

P1694 (M) No BUS (CCD) Messages received

from ECMBus communication failure to PCM.

P1695 No CCD/J1850 Message From Body

Control ModuleNo CCD/J1850 messages received from the body control

module.

P1696 PCM Failure EEPROM Write Denied Unsuccessful attempt to write to an EEPROM location by the

control module.

P1697 PCM Failure SRI Mile Not Stored Unsuccessful attempt to update Service Reminder Indicator

(SRI or EMR) mileage in the control module EEPROM.

P1698 No CCD/J1850 Message From TCM No CCD/J1850 messages received from the electronic

transmission control module (EATX) or the Aisin transmission

controller.

P1698 No CCD Messages received from

PCMBus communication failure to PCM. A9Companion DTC9was

set in both the ECM and PCM.

P1699 No Climate Control Bus Messages

P1719 Skip Shift Solenoid Circuit An open or shorted condition detected in the transmission

2-3 gear lock-out solenoid control circuit.

P1740 TCC or OD Sol Perf A rationality error has been detected in either the TCC

solenoid or overdrive solenoid systems.

P1740 (M) TCC OR O/D Solenoid Performance Problem detected in transmission convertor clutch and/or

overdrive circuits (diesel engine with 4-speed auto. trans.

only).

P1756 (M) GOV Press Not Equal to Target @

15-20 PSIThe requested pressure and the actual pressure are not

within a tolerance band for the Governor Control System

which is used to regulate governor pressure to control shifts

for 1st, 2nd, and 3rd gear. (Mid Pressure Malfunction)

BR/BEEMISSIONS CONTROL 25 - 15

EMISSIONS CONTROL (Continued)

Page 2219 of 2255

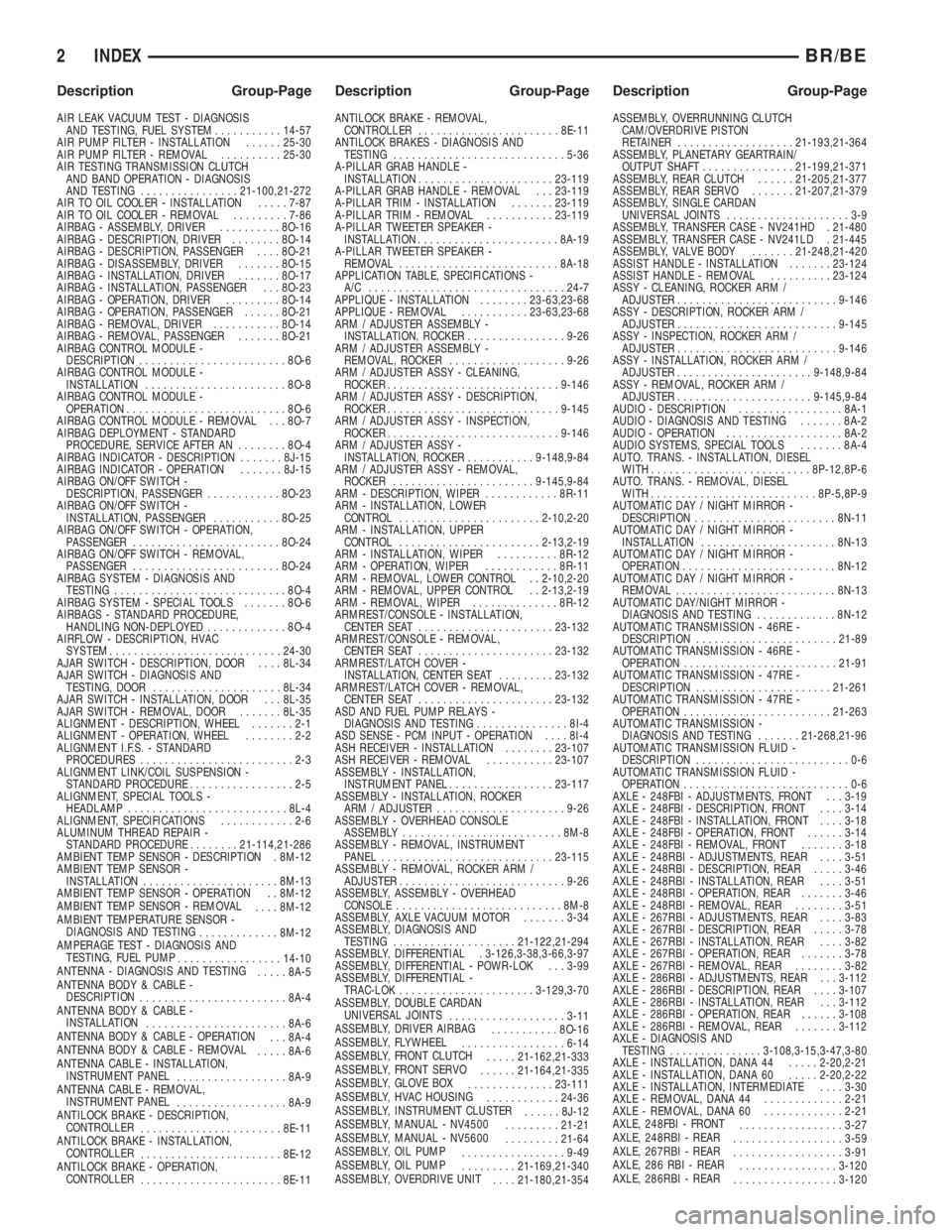

AIR LEAK VACUUM TEST - DIAGNOSIS

AND TESTING, FUEL SYSTEM...........14-57

AIR PUMP FILTER - INSTALLATION......25-30

AIR PUMP FILTER - REMOVAL..........25-30

AIR TESTING TRANSMISSION CLUTCH

AND BAND OPERATION - DIAGNOSIS

AND TESTING................21-100,21-272

AIR TO OIL COOLER - INSTALLATION.....7-87

AIR TO OIL COOLER - REMOVAL.........7-86

AIRBAG - ASSEMBLY, DRIVER..........8O-16

AIRBAG - DESCRIPTION, DRIVER........8O-14

AIRBAG - DESCRIPTION, PASSENGER....8O-21

AIRBAG - DISASSEMBLY, DRIVER.......8O-15

AIRBAG - INSTALLATION, DRIVER.......8O-17

AIRBAG - INSTALLATION, PASSENGER . . . 8O-23

AIRBAG - OPERATION, DRIVER.........8O-14

AIRBAG - OPERATION, PASSENGER......8O-21

AIRBAG - REMOVAL, DRIVER...........8O-14

AIRBAG - REMOVAL, PASSENGER.......8O-21

AIRBAG CONTROL MODULE -

DESCRIPTION........................8O-6

AIRBAG CONTROL MODULE -

INSTALLATION.......................8O-8

AIRBAG CONTROL MODULE -

OPERATION..........................8O-6

AIRBAG CONTROL MODULE - REMOVAL . . . 8O-7

AIRBAG DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER AN........8O-4

AIRBAG INDICATOR - DESCRIPTION.......8J-15

AIRBAG INDICATOR - OPERATION.......8J-15

AIRBAG ON/OFF SWITCH -

DESCRIPTION, PASSENGER............8O-23

AIRBAG ON/OFF SWITCH -

INSTALLATION, PASSENGER...........8O-25

AIRBAG ON/OFF SWITCH - OPERATION,

PASSENGER........................8O-24

AIRBAG ON/OFF SWITCH - REMOVAL,

PASSENGER........................8O-24

AIRBAG SYSTEM - DIAGNOSIS AND

TESTING............................8O-4

AIRBAG SYSTEM - SPECIAL TOOLS.......8O-6

AIRBAGS - STANDARD PROCEDURE,

HANDLING NON-DEPLOYED.............8O-4

AIRFLOW - DESCRIPTION, HVAC

SYSTEM............................24-30

AJAR SWITCH - DESCRIPTION, DOOR....8L-34

AJAR SWITCH - DIAGNOSIS AND

TESTING, DOOR.....................8L-34

AJAR SWITCH - INSTALLATION, DOOR . . . 8L-35

AJAR SWITCH - REMOVAL, DOOR.......8L-35

ALIGNMENT - DESCRIPTION, WHEEL.......2-1

ALIGNMENT - OPERATION, WHEEL........2-2

ALIGNMENT I.F.S. - STANDARD

PROCEDURES.........................2-3

ALIGNMENT LINK/COIL SUSPENSION -

STANDARD PROCEDURE.................2-5

ALIGNMENT, SPECIAL TOOLS -

HEADLAMP..........................8L-4

ALIGNMENT, SPECIFICATIONS............2-6

ALUMINUM THREAD REPAIR -

STANDARD PROCEDURE........21-114,21-286

AMBIENT TEMP SENSOR - DESCRIPTION . 8M-12

AMBIENT TEMP SENSOR -

INSTALLATION......................8M-13

AMBIENT TEMP SENSOR - OPERATION . . 8M-12

AMBIENT TEMP SENSOR - REMOVAL

....8M-12

AMBIENT TEMPERATURE SENSOR -

DIAGNOSIS AND TESTING

.............8M-12

AMPERAGE TEST - DIAGNOSIS AND

TESTING, FUEL PUMP

.................14-10

ANTENNA - DIAGNOSIS AND TESTING

.....8A-5

ANTENNA BODY & CABLE -

DESCRIPTION

........................8A-4

ANTENNA BODY & CABLE -

INSTALLATION

.......................8A-6

ANTENNA BODY & CABLE - OPERATION

. . . 8A-4

ANTENNA BODY & CABLE - REMOVAL

.....8A-6

ANTENNA CABLE - INSTALLATION,

INSTRUMENT PANEL

..................8A-9

ANTENNA CABLE - REMOVAL,

INSTRUMENT PANEL

..................8A-9

ANTILOCK BRAKE - DESCRIPTION,

CONTROLLER

.......................8E-11

ANTILOCK BRAKE - INSTALLATION,

CONTROLLER

.......................8E-12

ANTILOCK BRAKE - OPERATION,

CONTROLLER

.......................8E-11ANTILOCK BRAKE - REMOVAL,

CONTROLLER.......................8E-11

ANTILOCK BRAKES - DIAGNOSIS AND

TESTING............................5-36

A-PILLAR GRAB HANDLE -

INSTALLATION......................23-119

A-PILLAR GRAB HANDLE - REMOVAL . . . 23-119

A-PILLAR TRIM - INSTALLATION.......23-119

A-PILLAR TRIM - REMOVAL...........23-119

A-PILLAR TWEETER SPEAKER -

INSTALLATION.......................8A-19

A-PILLAR TWEETER SPEAKER -

REMOVAL..........................8A-18

APPLICATION TABLE, SPECIFICATIONS -

A/C ................................24-7

APPLIQUE - INSTALLATION........23-63,23-68

APPLIQUE - REMOVAL...........23-63,23-68

ARM / ADJUSTER ASSEMBLY -

INSTALLATION, ROCKER................9-26

ARM / ADJUSTER ASSEMBLY -

REMOVAL, ROCKER...................9-26

ARM / ADJUSTER ASSY - CLEANING,

ROCKER............................9-146

ARM / ADJUSTER ASSY - DESCRIPTION,

ROCKER............................9-145

ARM / ADJUSTER ASSY - INSPECTION,

ROCKER............................9-146

ARM / ADJUSTER ASSY -

INSTALLATION, ROCKER...........9-148,9-84

ARM / ADJUSTER ASSY - REMOVAL,

ROCKER.......................9-145,9-84

ARM - DESCRIPTION, WIPER............8R-11

ARM - INSTALLATION, LOWER

CONTROL.......................2-10,2-20

ARM - INSTALLATION, UPPER

CONTROL.......................2-13,2-19

ARM - INSTALLATION, WIPER..........8R-12

ARM - OPERATION, WIPER............8R-11

ARM - REMOVAL, LOWER CONTROL . . 2-10,2-20

ARM - REMOVAL, UPPER CONTROL . . 2-13,2-19

ARM - REMOVAL, WIPER..............8R-12

ARMREST/CONSOLE - INSTALLATION,

CENTER SEAT......................23-132

ARMREST/CONSOLE - REMOVAL,

CENTER SEAT......................23-132

ARMREST/LATCH COVER -

INSTALLATION, CENTER SEAT.........23-132

ARMREST/LATCH COVER - REMOVAL,

CENTER SEAT......................23-132

ASD AND FUEL PUMP RELAYS -

DIAGNOSIS AND TESTING...............8I-4

ASD SENSE - PCM INPUT - OPERATION....8I-4

ASH RECEIVER - INSTALLATION........23-107

ASH RECEIVER - REMOVAL...........23-107

ASSEMBLY - INSTALLATION,

INSTRUMENT PANEL.................23-117

ASSEMBLY - INSTALLATION, ROCKER

ARM / ADJUSTER.....................9-26

ASSEMBLY - OVERHEAD CONSOLE

ASSEMBLY..........................8M-8

ASSEMBLY - REMOVAL, INSTRUMENT

PANEL............................23-115

ASSEMBLY - REMOVAL, ROCKER ARM /

ADJUSTER...........................9-26

ASSEMBLY, ASSEMBLY - OVERHEAD

CONSOLE...........................8M-8

ASSEMBLY, AXLE VACUUM MOTOR.......3-34

ASSEMBLY, DIAGNOSIS AND

TESTING....................21-122,21-294

ASSEMBLY, DIFFERENTIAL . 3-126,3-38,3-66,3-97

ASSEMBLY, DIFFERENTIAL - POWR-LOK . . . 3-99

ASSEMBLY, DIFFERENTIAL -

TRAC-LOK......................3-129,3-70

ASSEMBLY, DOUBLE CARDAN

UNIVERSAL JOINTS

...................3-11

ASSEMBLY, DRIVER AIRBAG

...........8O-16

ASSEMBLY, FLYWHEEL

.................6-14

ASSEMBLY, FRONT CLUTCH

.....21-162,21-333

ASSEMBLY, FRONT SERVO

......21-164,21-335

ASSEMBLY, GLOVE BOX

..............23-111

ASSEMBLY, HVAC HOUSING

............24-36

ASSEMBLY, INSTRUMENT CLUSTER

......8J-12

ASSEMBLY, MANUAL - NV4500

.........21-21

ASSEMBLY, MANUAL - NV5600

.........21-64

ASSEMBLY, OIL PUMP

.................9-49

ASSEMBLY, OIL PUMP

.........21-169,21-340

ASSEMBLY, OVERDRIVE UNIT

....21-180,21-354ASSEMBLY, OVERRUNNING CLUTCH

CAM/OVERDRIVE PISTON

RETAINER...................21-193,21-364

ASSEMBLY, PLANETARY GEARTRAIN/

OUTPUT SHAFT...............21-199,21-371

ASSEMBLY, REAR CLUTCH......21-205,21-377

ASSEMBLY, REAR SERVO.......21-207,21-379

ASSEMBLY, SINGLE CARDAN

UNIVERSAL JOINTS....................3-9

ASSEMBLY, TRANSFER CASE - NV241HD . 21-480

ASSEMBLY, TRANSFER CASE - NV241LD . 21-445

ASSEMBLY, VALVE BODY.......21-248,21-420

ASSIST HANDLE - INSTALLATION.......23-124

ASSIST HANDLE - REMOVAL..........23-124

ASSY - CLEANING, ROCKER ARM /

ADJUSTER..........................9-146

ASSY - DESCRIPTION, ROCKER ARM /

ADJUSTER..........................9-145

ASSY - INSPECTION, ROCKER ARM /

ADJUSTER..........................9-146

ASSY - INSTALLATION, ROCKER ARM /

ADJUSTER......................9-148,9-84

ASSY - REMOVAL, ROCKER ARM /

ADJUSTER......................9-145,9-84

AUDIO - DESCRIPTION.................8A-1

AUDIO - DIAGNOSIS AND TESTING.......8A-2

AUDIO - OPERATION...................8A-2

AUDIO SYSTEMS, SPECIAL TOOLS.......8A-4

AUTO. TRANS. - INSTALLATION, DIESEL

WITH..........................8P-12,8P-6

AUTO. TRANS. - REMOVAL, DIESEL

WITH...........................8P-5,8P-9

AUTOMATIC DAY / NIGHT MIRROR -

DESCRIPTION.......................8N-11

AUTOMATIC DAY / NIGHT MIRROR -

INSTALLATION......................8N-13

AUTOMATIC DAY / NIGHT MIRROR -

OPERATION.........................8N-12

AUTOMATIC DAY / NIGHT MIRROR -

REMOVAL..........................8N-13

AUTOMATIC DAY/NIGHT MIRROR -

DIAGNOSIS AND TESTING.............8N-12

AUTOMATIC TRANSMISSION - 46RE -

DESCRIPTION.......................21-89

AUTOMATIC TRANSMISSION - 46RE -

OPERATION.........................21-91

AUTOMATIC TRANSMISSION - 47RE -

DESCRIPTION......................21-261

AUTOMATIC TRANSMISSION - 47RE -

OPERATION........................21-263

AUTOMATIC TRANSMISSION -

DIAGNOSIS AND TESTING.......21-268,21-96

AUTOMATIC TRANSMISSION FLUID -

DESCRIPTION.........................0-6

AUTOMATIC TRANSMISSION FLUID -

OPERATION...........................0-6

AXLE - 248FBI - ADJUSTMENTS, FRONT . . . 3-19

AXLE - 248FBI - DESCRIPTION, FRONT....3-14

AXLE - 248FBI - INSTALLATION, FRONT....3-18

AXLE - 248FBI - OPERATION, FRONT......3-14

AXLE - 248FBI - REMOVAL, FRONT.......3-18

AXLE - 248RBI - ADJUSTMENTS, REAR....3-51

AXLE - 248RBI - DESCRIPTION, REAR.....3-46

AXLE - 248RBI - INSTALLATION, REAR....3-51

AXLE - 248RBI - OPERATION, REAR.......3-46

AXLE - 248RBI - REMOVAL, REAR........3-51

AXLE - 267RBI - ADJUSTMENTS, REAR....3-83

AXLE - 267RBI - DESCRIPTION, REAR.....3-78

AXLE - 267RBI - INSTALLATION, REAR....3-82

AXLE - 267RBI - OPERATION, REAR.......3-78

AXLE - 267RBI - REMOVAL, REAR........3-82

AXLE - 286RBI - ADJUSTMENTS, REAR . . . 3-112

AXLE - 286RBI - DESCRIPTION, REAR....3-107

AXLE - 286RBI - INSTALLATION, REAR . . . 3-112

AXLE - 286RBI - OPERATION, REAR......3-108

AXLE - 286RBI - REMOVAL, REAR.......3-112

AXLE - DIAGNOSIS AND

TESTING...............3-108,3-15,3-47,3-80

AXLE - INSTALLATION, DANA 44.....2-20,2-21

AXLE - INSTALLATION, DANA 60.....2-20,2-22

AXLE - INSTALLATION, INTERMEDIATE....3-30

AXLE - REMOVAL, DANA 44.............2-21

AXLE - REMOVAL, DANA 60.............2-21

AXLE, 248FBI - FRONT

.................3-27

AXLE, 248RBI - REAR

..................3-59

AXLE, 267RBI - REAR

..................3-91

AXLE, 286 RBI - REAR

................3-120

AXLE, 286RBI - REAR

.................3-120

2 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2226 of 2255

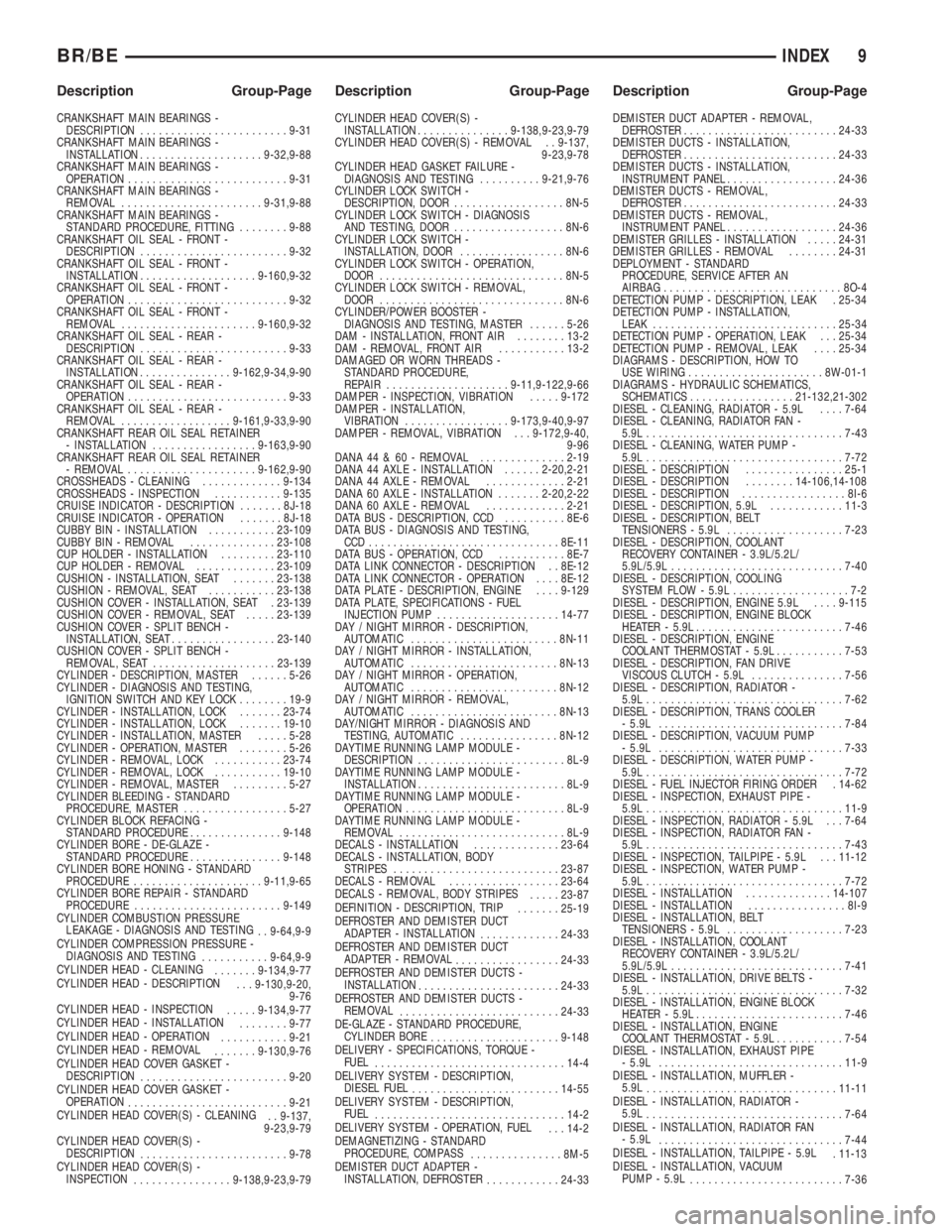

CRANKSHAFT MAIN BEARINGS -

DESCRIPTION........................9-31

CRANKSHAFT MAIN BEARINGS -

INSTALLATION....................9-32,9-88

CRANKSHAFT MAIN BEARINGS -

OPERATION..........................9-31

CRANKSHAFT MAIN BEARINGS -

REMOVAL.......................9-31,9-88

CRANKSHAFT MAIN BEARINGS -

STANDARD PROCEDURE, FITTING........9-88

CRANKSHAFT OIL SEAL - FRONT -

DESCRIPTION........................9-32

CRANKSHAFT OIL SEAL - FRONT -

INSTALLATION...................9-160,9-32

CRANKSHAFT OIL SEAL - FRONT -

OPERATION..........................9-32

CRANKSHAFT OIL SEAL - FRONT -

REMOVAL......................9-160,9-32

CRANKSHAFT OIL SEAL - REAR -

DESCRIPTION........................9-33

CRANKSHAFT OIL SEAL - REAR -

INSTALLATION...............9-162,9-34,9-90

CRANKSHAFT OIL SEAL - REAR -

OPERATION..........................9-33

CRANKSHAFT OIL SEAL - REAR -

REMOVAL..................9-161,9-33,9-90

CRANKSHAFT REAR OIL SEAL RETAINER

- INSTALLATION.................9-163,9-90

CRANKSHAFT REAR OIL SEAL RETAINER

- REMOVAL.....................9-162,9-90

CROSSHEADS - CLEANING.............9-134

CROSSHEADS - INSPECTION...........9-135

CRUISE INDICATOR - DESCRIPTION.......8J-18

CRUISE INDICATOR - OPERATION.......8J-18

CUBBY BIN - INSTALLATION...........23-109

CUBBY BIN - REMOVAL..............23-108

CUP HOLDER - INSTALLATION.........23-110

CUP HOLDER - REMOVAL.............23-109

CUSHION - INSTALLATION, SEAT.......23-138

CUSHION - REMOVAL, SEAT...........23-138

CUSHION COVER - INSTALLATION, SEAT . 23-139

CUSHION COVER - REMOVAL, SEAT.....23-139

CUSHION COVER - SPLIT BENCH -

INSTALLATION, SEAT.................23-140

CUSHION COVER - SPLIT BENCH -

REMOVAL, SEAT....................23-139

CYLINDER - DESCRIPTION, MASTER......5-26

CYLINDER - DIAGNOSIS AND TESTING,

IGNITION SWITCH AND KEY LOCK........19-9

CYLINDER - INSTALLATION, LOCK.......23-74

CYLINDER - INSTALLATION, LOCK.......19-10

CYLINDER - INSTALLATION, MASTER.....5-28

CYLINDER - OPERATION, MASTER........5-26

CYLINDER - REMOVAL, LOCK...........23-74

CYLINDER - REMOVAL, LOCK...........19-10

CYLINDER - REMOVAL, MASTER.........5-27

CYLINDER BLEEDING - STANDARD

PROCEDURE, MASTER.................5-27

CYLINDER BLOCK REFACING -

STANDARD PROCEDURE...............9-148

CYLINDER BORE - DE-GLAZE -

STANDARD PROCEDURE...............9-148

CYLINDER BORE HONING - STANDARD

PROCEDURE.....................9-11,9-65

CYLINDER BORE REPAIR - STANDARD

PROCEDURE........................9-149

CYLINDER COMBUSTION PRESSURE

LEAKAGE - DIAGNOSIS AND TESTING

. . 9-64,9-9

CYLINDER COMPRESSION PRESSURE -

DIAGNOSIS AND TESTING

...........9-64,9-9

CYLINDER HEAD - CLEANING

.......9-134,9-77

CYLINDER HEAD - DESCRIPTION

. . . 9-130,9-20,

9-76

CYLINDER HEAD - INSPECTION

.....9-134,9-77

CYLINDER HEAD - INSTALLATION

........9-77

CYLINDER HEAD - OPERATION

...........9-21

CYLINDER HEAD - REMOVAL

.......9-130,9-76

CYLINDER HEAD COVER GASKET -

DESCRIPTION

........................9-20

CYLINDER HEAD COVER GASKET -

OPERATION

..........................9-21

CYLINDER HEAD COVER(S) - CLEANING

. . 9-137,

9-23,9-79

CYLINDER HEAD COVER(S) -

DESCRIPTION

........................9-78

CYLINDER HEAD COVER(S) -

INSPECTION

................9-138,9-23,9-79CYLINDER HEAD COVER(S) -

INSTALLATION...............9-138,9-23,9-79

CYLINDER HEAD COVER(S) - REMOVAL . . 9-137,

9-23,9-78

CYLINDER HEAD GASKET FAILURE -

DIAGNOSIS AND TESTING..........9-21,9-76

CYLINDER LOCK SWITCH -

DESCRIPTION, DOOR..................8N-5

CYLINDER LOCK SWITCH - DIAGNOSIS

AND TESTING, DOOR..................8N-6

CYLINDER LOCK SWITCH -

INSTALLATION, DOOR.................8N-6

CYLINDER LOCK SWITCH - OPERATION,

DOOR..............................8N-5

CYLINDER LOCK SWITCH - REMOVAL,

DOOR..............................8N-6

CYLINDER/POWER BOOSTER -

DIAGNOSIS AND TESTING, MASTER......5-26

DAM - INSTALLATION, FRONT AIR........13-2

DAM - REMOVAL, FRONT AIR...........13-2

DAMAGED OR WORN THREADS -

STANDARD PROCEDURE,

REPAIR ....................9-11,9-122,9-66

DAMPER - INSPECTION, VIBRATION.....9-172

DAMPER - INSTALLATION,

VIBRATION.................9-173,9-40,9-97

DAMPER - REMOVAL, VIBRATION . . . 9-172,9-40,

9-96

DANA 44 & 60 - REMOVAL..............2-19

DANA 44 AXLE - INSTALLATION......2-20,2-21

DANA 44 AXLE - REMOVAL.............2-21

DANA 60 AXLE - INSTALLATION.......2-20,2-22

DANA 60 AXLE - REMOVAL.............2-21

DATA BUS - DESCRIPTION, CCD..........8E-6

DATA BUS - DIAGNOSIS AND TESTING,

CCD ...............................8E-11

DATA BUS - OPERATION, CCD...........8E-7

DATA LINK CONNECTOR - DESCRIPTION . . 8E-12

DATA LINK CONNECTOR - OPERATION....8E-12

DATA PLATE - DESCRIPTION, ENGINE....9-129

DATA PLATE, SPECIFICATIONS - FUEL

INJECTION PUMP....................14-77

DAY / NIGHT MIRROR - DESCRIPTION,

AUTOMATIC........................8N-11

DAY / NIGHT MIRROR - INSTALLATION,

AUTOMATIC........................8N-13

DAY / NIGHT MIRROR - OPERATION,

AUTOMATIC........................8N-12

DAY / NIGHT MIRROR - REMOVAL,

AUTOMATIC........................8N-13

DAY/NIGHT MIRROR - DIAGNOSIS AND

TESTING, AUTOMATIC................8N-12

DAYTIME RUNNING LAMP MODULE -

DESCRIPTION........................8L-9

DAYTIME RUNNING LAMP MODULE -

INSTALLATION........................8L-9

DAYTIME RUNNING LAMP MODULE -

OPERATION..........................8L-9

DAYTIME RUNNING LAMP MODULE -

REMOVAL...........................8L-9

DECALS - INSTALLATION..............23-64

DECALS - INSTALLATION, BODY

STRIPES...........................23-87

DECALS - REMOVAL..................23-64

DECALS - REMOVAL, BODY STRIPES

.....23-87

DEFINITION - DESCRIPTION, TRIP

.......25-19

DEFROSTER AND DEMISTER DUCT

ADAPTER - INSTALLATION

.............24-33

DEFROSTER AND DEMISTER DUCT

ADAPTER - REMOVAL

.................24-33

DEFROSTER AND DEMISTER DUCTS -

INSTALLATION

.......................24-33

DEFROSTER AND DEMISTER DUCTS -

REMOVAL

..........................24-33

DE-GLAZE - STANDARD PROCEDURE,

CYLINDER BORE

.....................9-148

DELIVERY - SPECIFICATIONS, TORQUE -

FUEL

...............................14-4

DELIVERY SYSTEM - DESCRIPTION,

DIESEL FUEL

........................14-55

DELIVERY SYSTEM - DESCRIPTION,

FUEL

...............................14-2

DELIVERY SYSTEM - OPERATION, FUEL

. . . 14-2

DEMAGNETIZING - STANDARD

PROCEDURE, COMPASS

...............8M-5

DEMISTER DUCT ADAPTER -

INSTALLATION, DEFROSTER

............24-33DEMISTER DUCT ADAPTER - REMOVAL,

DEFROSTER.........................24-33

DEMISTER DUCTS - INSTALLATION,

DEFROSTER.........................24-33

DEMISTER DUCTS - INSTALLATION,

INSTRUMENT PANEL..................24-36

DEMISTER DUCTS - REMOVAL,

DEFROSTER.........................24-33

DEMISTER DUCTS - REMOVAL,

INSTRUMENT PANEL..................24-36

DEMISTER GRILLES - INSTALLATION.....24-31

DEMISTER GRILLES - REMOVAL........24-31

DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER AN

AIRBAG.............................8O-4

DETECTION PUMP - DESCRIPTION, LEAK . 25-34

DETECTION PUMP - INSTALLATION,

LEAK..............................25-34

DETECTION PUMP - OPERATION, LEAK . . . 25-34

DETECTION PUMP - REMOVAL, LEAK....25-34

DIAGRAMS - DESCRIPTION, HOW TO

USE WIRING......................8W-01-1

DIAGRAMS - HYDRAULIC SCHEMATICS,

SCHEMATICS.................21-132,21-302

DIESEL - CLEANING, RADIATOR - 5.9L....7-64

DIESEL - CLEANING, RADIATOR FAN -

5.9L................................7-43

DIESEL - CLEANING, WATER PUMP -

5.9L................................7-72

DIESEL - DESCRIPTION................25-1

DIESEL - DESCRIPTION........14-106,14-108

DIESEL - DESCRIPTION.................8I-6

DIESEL - DESCRIPTION, 5.9L............11-3

DIESEL - DESCRIPTION, BELT

TENSIONERS - 5.9L...................7-23

DIESEL - DESCRIPTION, COOLANT

RECOVERY CONTAINER - 3.9L/5.2L/

5.9L/5.9L............................7-40

DIESEL - DESCRIPTION, COOLING

SYSTEM FLOW - 5.9L...................7-2

DIESEL - DESCRIPTION, ENGINE 5.9L....9-115

DIESEL - DESCRIPTION, ENGINE BLOCK

HEATER - 5.9L........................7-46

DIESEL - DESCRIPTION, ENGINE

COOLANT THERMOSTAT - 5.9L...........7-53

DIESEL - DESCRIPTION, FAN DRIVE

VISCOUS CLUTCH - 5.9L...............7-56

DIESEL - DESCRIPTION, RADIATOR -

5.9L................................7-62

DIESEL - DESCRIPTION, TRANS COOLER

- 5.9L..............................7-84

DIESEL - DESCRIPTION, VACUUM PUMP

- 5.9L..............................7-33

DIESEL - DESCRIPTION, WATER PUMP -

5.9L................................7-72

DIESEL - FUEL INJECTOR FIRING ORDER . 14-62

DIESEL - INSPECTION, EXHAUST PIPE -

5.9L................................11-9

DIESEL - INSPECTION, RADIATOR - 5.9L . . . 7-64

DIESEL - INSPECTION, RADIATOR FAN -

5.9L................................7-43

DIESEL - INSPECTION, TAILPIPE - 5.9L . . . 11-12

DIESEL - INSPECTION, WATER PUMP -

5.9L................................7-72

DIESEL - INSTALLATION..............14-107

DIESEL - INSTALLATION................8I-9

DIESEL - INSTALLATION, BELT

TENSIONERS - 5.9L...................7-23

DIESEL - INSTALLATION, COOLANT

RECOVERY CONTAINER - 3.9L/5.2L/

5.9L/5.9L............................7-41

DIESEL - INSTALLATION, DRIVE BELTS -

5.9L................................7-32

DIESEL - INSTALLATION, ENGINE BLOCK

HEATER - 5.9L........................7-46

DIESEL - INSTALLATION, ENGINE

COOLANT THERMOSTAT - 5.9L...........7-54

DIESEL - INSTALLATION, EXHAUST PIPE

- 5.9L..............................11-9

DIESEL - INSTALLATION, MUFFLER -

5.9L

...............................11-11

DIESEL - INSTALLATION, RADIATOR -

5.9L

................................7-64

DIESEL - INSTALLATION, RADIATOR FAN

- 5.9L

..............................7-44

DIESEL - INSTALLATION, TAILPIPE - 5.9L

. 11-13

DIESEL - INSTALLATION, VACUUM

PUMP - 5.9L

.........................7-36

BR/BEINDEX 9

Description Group-Page Description Group-Page Description Group-Page

Page 2228 of 2255

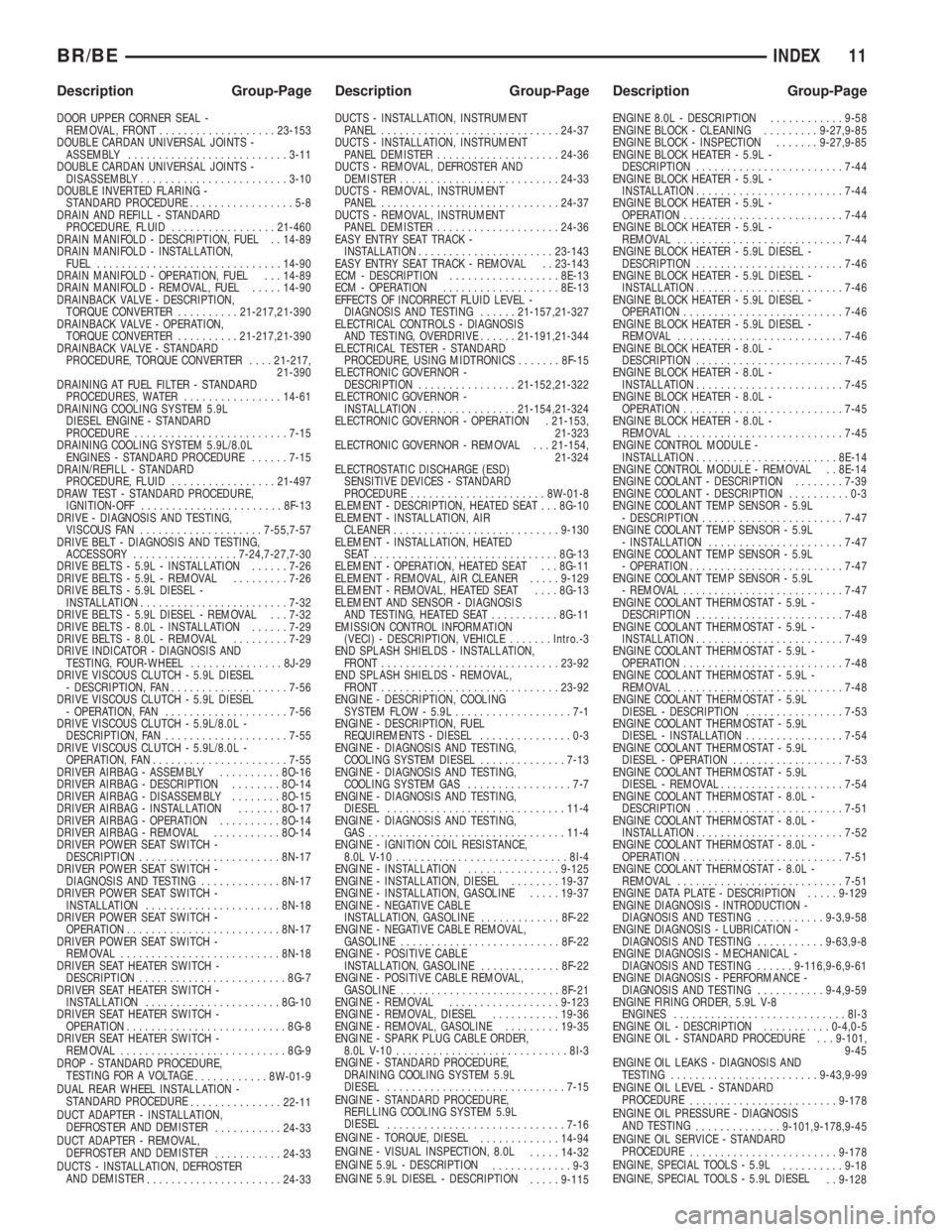

DOOR UPPER CORNER SEAL -

REMOVAL, FRONT...................23-153

DOUBLE CARDAN UNIVERSAL JOINTS -

ASSEMBLY..........................3-11

DOUBLE CARDAN UNIVERSAL JOINTS -

DISASSEMBLY........................3-10

DOUBLE INVERTED FLARING -

STANDARD PROCEDURE.................5-8

DRAIN AND REFILL - STANDARD

PROCEDURE, FLUID.................21-460

DRAIN MANIFOLD - DESCRIPTION, FUEL . . 14-89

DRAIN MANIFOLD - INSTALLATION,

FUEL..............................14-90

DRAIN MANIFOLD - OPERATION, FUEL . . . 14-89

DRAIN MANIFOLD - REMOVAL, FUEL.....14-90

DRAINBACK VALVE - DESCRIPTION,

TORQUE CONVERTER..........21-217,21-390

DRAINBACK VALVE - OPERATION,

TORQUE CONVERTER..........21-217,21-390

DRAINBACK VALVE - STANDARD

PROCEDURE, TORQUE CONVERTER....21-217,

21-390

DRAINING AT FUEL FILTER - STANDARD

PROCEDURES, WATER................14-61

DRAINING COOLING SYSTEM 5.9L

DIESEL ENGINE - STANDARD

PROCEDURE.........................7-15

DRAINING COOLING SYSTEM 5.9L/8.0L

ENGINES - STANDARD PROCEDURE......7-15

DRAIN/REFILL - STANDARD

PROCEDURE, FLUID.................21-497

DRAW TEST - STANDARD PROCEDURE,

IGNITION-OFF.......................8F-13

DRIVE - DIAGNOSIS AND TESTING,

VISCOUS FAN....................7-55,7-57

DRIVE BELT - DIAGNOSIS AND TESTING,

ACCESSORY.................7-24,7-27,7-30

DRIVE BELTS - 5.9L - INSTALLATION......7-26

DRIVE BELTS - 5.9L - REMOVAL.........7-26

DRIVE BELTS - 5.9L DIESEL -

INSTALLATION........................7-32

DRIVE BELTS - 5.9L DIESEL - REMOVAL . . . 7-32

DRIVE BELTS - 8.0L - INSTALLATION......7-29

DRIVE BELTS - 8.0L - REMOVAL.........7-29

DRIVE INDICATOR - DIAGNOSIS AND

TESTING, FOUR-WHEEL...............8J-29

DRIVE VISCOUS CLUTCH - 5.9L DIESEL

- DESCRIPTION, FAN...................7-56

DRIVE VISCOUS CLUTCH - 5.9L DIESEL

- OPERATION, FAN....................7-56

DRIVE VISCOUS CLUTCH - 5.9L/8.0L -

DESCRIPTION, FAN....................7-55

DRIVE VISCOUS CLUTCH - 5.9L/8.0L -

OPERATION, FAN......................7-55

DRIVER AIRBAG - ASSEMBLY..........8O-16

DRIVER AIRBAG - DESCRIPTION........8O-14

DRIVER AIRBAG - DISASSEMBLY........8O-15

DRIVER AIRBAG - INSTALLATION.......8O-17

DRIVER AIRBAG - OPERATION..........8O-14

DRIVER AIRBAG - REMOVAL...........8O-14

DRIVER POWER SEAT SWITCH -

DESCRIPTION.......................8N-17

DRIVER POWER SEAT SWITCH -

DIAGNOSIS AND TESTING.............8N-17

DRIVER POWER SEAT SWITCH -

INSTALLATION......................8N-18

DRIVER POWER SEAT SWITCH -

OPERATION.........................8N-17

DRIVER POWER SEAT SWITCH -

REMOVAL..........................8N-18

DRIVER SEAT HEATER SWITCH -

DESCRIPTION........................8G-7

DRIVER SEAT HEATER SWITCH -

INSTALLATION......................8G-10

DRIVER SEAT HEATER SWITCH -

OPERATION..........................8G-8

DRIVER SEAT HEATER SWITCH -

REMOVAL...........................8G-9

DROP - STANDARD PROCEDURE,

TESTING FOR A VOLTAGE

............8W-01-9

DUAL REAR WHEEL INSTALLATION -

STANDARD PROCEDURE

...............22-11

DUCT ADAPTER - INSTALLATION,

DEFROSTER AND DEMISTER

...........24-33

DUCT ADAPTER - REMOVAL,

DEFROSTER AND DEMISTER

...........24-33

DUCTS - INSTALLATION, DEFROSTER

AND DEMISTER

......................24-33DUCTS - INSTALLATION, INSTRUMENT

PANEL.............................24-37

DUCTS - INSTALLATION, INSTRUMENT

PANEL DEMISTER....................24-36

DUCTS - REMOVAL, DEFROSTER AND

DEMISTER..........................24-33

DUCTS - REMOVAL, INSTRUMENT

PANEL.............................24-37

DUCTS - REMOVAL, INSTRUMENT

PANEL DEMISTER....................24-36

EASY ENTRY SEAT TRACK -

INSTALLATION......................23-143

EASY ENTRY SEAT TRACK - REMOVAL . . 23-143

ECM - DESCRIPTION..................8E-13

ECM - OPERATION...................8E-13

EFFECTS OF INCORRECT FLUID LEVEL -

DIAGNOSIS AND TESTING......21-157,21-327

ELECTRICAL CONTROLS - DIAGNOSIS

AND TESTING, OVERDRIVE......21-191,21-344

ELECTRICAL TESTER - STANDARD

PROCEDURE, USING MIDTRONICS.......8F-15

ELECTRONIC GOVERNOR -

DESCRIPTION................21-152,21-322

ELECTRONIC GOVERNOR -

INSTALLATION................21-154,21-324

ELECTRONIC GOVERNOR - OPERATION . 21-153,

21-323

ELECTRONIC GOVERNOR - REMOVAL . . . 21-154,

21-324

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE DEVICES - STANDARD

PROCEDURE......................8W-01-8

ELEMENT - DESCRIPTION, HEATED SEAT . . . 8G-10

ELEMENT - INSTALLATION, AIR

CLEANER...........................9-130

ELEMENT - INSTALLATION, HEATED

SEAT ..............................8G-13

ELEMENT - OPERATION, HEATED SEAT . . . 8G-11

ELEMENT - REMOVAL, AIR CLEANER.....9-129

ELEMENT - REMOVAL, HEATED SEAT....8G-13

ELEMENT AND SENSOR - DIAGNOSIS

AND TESTING, HEATED SEAT...........8G-11

EMISSION CONTROL INFORMATION

(VECI) - DESCRIPTION, VEHICLE.......Intro.-3

END SPLASH SHIELDS - INSTALLATION,

FRONT.............................23-92

END SPLASH SHIELDS - REMOVAL,

FRONT.............................23-92

ENGINE - DESCRIPTION, COOLING

SYSTEM FLOW - 5.9L...................7-1

ENGINE - DESCRIPTION, FUEL

REQUIREMENTS - DIESEL...............0-3

ENGINE - DIAGNOSIS AND TESTING,

COOLING SYSTEM DIESEL..............7-13

ENGINE - DIAGNOSIS AND TESTING,

COOLING SYSTEM GAS.................7-7

ENGINE - DIAGNOSIS AND TESTING,

DIESEL.............................11-4

ENGINE - DIAGNOSIS AND TESTING,

GAS................................11-4

ENGINE - IGNITION COIL RESISTANCE,

8.0L V-10............................8I-4

ENGINE - INSTALLATION...............9-125

ENGINE - INSTALLATION, DIESEL........19-37

ENGINE - INSTALLATION, GASOLINE.....19-37

ENGINE - NEGATIVE CABLE

INSTALLATION, GASOLINE.............8F-22

ENGINE - NEGATIVE CABLE REMOVAL,

GASOLINE..........................8F-22

ENGINE - POSITIVE CABLE

INSTALLATION, GASOLINE.............8F-22

ENGINE - POSITIVE CABLE REMOVAL,

GASOLINE..........................8F-21

ENGINE - REMOVAL..................9-123

ENGINE - REMOVAL, DIESEL...........19-36

ENGINE - REMOVAL, GASOLINE.........19-35

ENGINE - SPARK PLUG CABLE ORDER,

8.0L V-10............................8I-3

ENGINE - STANDARD PROCEDURE,

DRAINING COOLING SYSTEM 5.9L

DIESEL.............................7-15

ENGINE - STANDARD PROCEDURE,

REFILLING COOLING SYSTEM 5.9L

DIESEL

.............................7-16

ENGINE - TORQUE, DIESEL

.............14-94

ENGINE - VISUAL INSPECTION, 8.0L

.....14-32

ENGINE 5.9L - DESCRIPTION

.............9-3

ENGINE 5.9L DIESEL - DESCRIPTION

.....9-115ENGINE 8.0L - DESCRIPTION............9-58

ENGINE BLOCK - CLEANING.........9-27,9-85

ENGINE BLOCK - INSPECTION.......9-27,9-85

ENGINE BLOCK HEATER - 5.9L -

DESCRIPTION........................7-44

ENGINE BLOCK HEATER - 5.9L -

INSTALLATION........................7-44

ENGINE BLOCK HEATER - 5.9L -

OPERATION..........................7-44

ENGINE BLOCK HEATER - 5.9L -

REMOVAL...........................7-44

ENGINE BLOCK HEATER - 5.9L DIESEL -

DESCRIPTION........................7-46

ENGINE BLOCK HEATER - 5.9L DIESEL -

INSTALLATION........................7-46

ENGINE BLOCK HEATER - 5.9L DIESEL -

OPERATION..........................7-46

ENGINE BLOCK HEATER - 5.9L DIESEL -

REMOVAL...........................7-46

ENGINE BLOCK HEATER - 8.0L -

DESCRIPTION........................7-45

ENGINE BLOCK HEATER - 8.0L -

INSTALLATION........................7-45

ENGINE BLOCK HEATER - 8.0L -

OPERATION..........................7-45

ENGINE BLOCK HEATER - 8.0L -

REMOVAL...........................7-45

ENGINE CONTROL MODULE -

INSTALLATION.......................8E-14

ENGINE CONTROL MODULE - REMOVAL . . 8E-14

ENGINE COOLANT - DESCRIPTION........7-39

ENGINE COOLANT - DESCRIPTION..........0-3

ENGINE COOLANT TEMP SENSOR - 5.9L

- DESCRIPTION.......................7-47

ENGINE COOLANT TEMP SENSOR - 5.9L

- INSTALLATION......................7-47

ENGINE COOLANT TEMP SENSOR - 5.9L

- OPERATION.........................7-47

ENGINE COOLANT TEMP SENSOR - 5.9L

- REMOVAL..........................7-47

ENGINE COOLANT THERMOSTAT - 5.9L -

DESCRIPTION........................7-48

ENGINE COOLANT THERMOSTAT - 5.9L -

INSTALLATION........................7-49

ENGINE COOLANT THERMOSTAT - 5.9L -

OPERATION..........................7-48

ENGINE COOLANT THERMOSTAT - 5.9L -

REMOVAL...........................7-48

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - DESCRIPTION................7-53

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - INSTALLATION................7-54

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - OPERATION..................7-53

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL - REMOVAL....................7-54

ENGINE COOLANT THERMOSTAT - 8.0L -

DESCRIPTION........................7-51

ENGINE COOLANT THERMOSTAT - 8.0L -

INSTALLATION........................7-52

ENGINE COOLANT THERMOSTAT - 8.0L -

OPERATION..........................7-51

ENGINE COOLANT THERMOSTAT - 8.0L -

REMOVAL...........................7-51

ENGINE DATA PLATE - DESCRIPTION.....9-129

ENGINE DIAGNOSIS - INTRODUCTION -

DIAGNOSIS AND TESTING...........9-3,9-58

ENGINE DIAGNOSIS - LUBRICATION -

DIAGNOSIS AND TESTING...........9-63,9-8

ENGINE DIAGNOSIS - MECHANICAL -

DIAGNOSIS AND TESTING......9-116,9-6,9-61

ENGINE DIAGNOSIS - PERFORMANCE -

DIAGNOSIS AND TESTING...........9-4,9-59

ENGINE FIRING ORDER, 5.9L V-8

ENGINES............................8I-3

ENGINE OIL - DESCRIPTION...........0-4,0-5

ENGINE OIL - STANDARD PROCEDURE . . . 9-101,

9-45

ENGINE OIL LEAKS - DIAGNOSIS AND

TESTING........................9-43,9-99

ENGINE OIL LEVEL - STANDARD

PROCEDURE

........................9-178

ENGINE OIL PRESSURE - DIAGNOSIS

AND TESTING

..............9-101,9-178,9-45

ENGINE OIL SERVICE - STANDARD

PROCEDURE

........................9-178

ENGINE, SPECIAL TOOLS - 5.9L

..........9-18

ENGINE, SPECIAL TOOLS - 5.9L DIESEL

. . 9-128

BR/BEINDEX 11

Description Group-Page Description Group-Page Description Group-Page

Page 2230 of 2255

FLOW - DIAGNOSIS AND TESTING,

RADIATOR COOLANT..........7-58,7-60,7-62

FLOW AND PRESSURE - DIAGNOSIS

AND TESTING, POWER STEERING........19-4

FLUID - DESCRIPTION, AUTOMATIC

TRANSMISSION.......................0-6

FLUID - DIAGNOSIS AND TESTING,

CAUSES OF BURNT............21-157,21-327

FLUID - OPERATION, AUTOMATIC

TRANSMISSION.......................0-6

FLUID AND FILTER REPLACEMENT -

STANDARD PROCEDURE........21-158,21-329

FLUID CAPACITIES, SPECIFICATIONS.......0-6

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING................21-157,21-327

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING, BRAKE..................5-15

FLUID DRAIN AND REFILL - STANDARD

PROCEDURE.......................21-460

FLUID DRAIN/REFILL - STANDARD

PROCEDURE.......................21-497

FLUID INDICATOR - DESCRIPTION,

WASHER...........................8J-35

FLUID INDICATOR - DIAGNOSIS AND

TESTING, WASHER...................8J-35

FLUID INDICATOR - OPERATION,

WASHER...........................8J-35

FLUID LEAK - DIAGNOSIS AND TESTING,

CONVERTER HOUSING.........21-101,21-273

FLUID LEVEL - DIAGNOSIS AND

TESTING, EFFECTS OF INCORRECT.....21-157,

21-327

FLUID LEVEL - STANDARD PROCEDURE,

BRAKE...............................5-15

FLUID LEVEL CHECK - STANDARD

PROCEDURE.................21-157,21-328

FLUID LEVEL SWITCH - DESCRIPTION,

WASHER............................8R-7

FLUID LEVEL SWITCH - INSTALLATION,

WASHER............................8R-8

FLUID LEVEL SWITCH - OPERATION,

WASHER............................8R-7

FLUID LEVEL SWITCH - REMOVAL,

WASHER............................8R-8

FLUID RESERVOIR - INSTALLATION.......5-15

FLUID RESERVOIR - REMOVAL..........5-15

FLUID, SPECIFICATIONS - BRAKE.........5-15

FLUSH MEASUREMENTS,

SPECIFICATIONS - BODY GAP..........23-56

FLUSHING - STANDARD PROCEDURE,

COOLING SYSTEM CLEANING/

REVERSE............................7-17

FLUSHING COOLERS AND TUBES - WITH

RADIATOR IN-TANK TRANSMISSION

OIL COOLER - STANDARD

PROCEDURE.................7-78,7-82,7-84

FLUSHING COOLERS AND TUBES -

WITHOUT RADIATOR IN-TANK

TRANSMISSION OIL COOLER -

STANDARD PROCEDURE.......7-79,7-82,7-85

FLUSHING POWER STEERING SYSTEM -

STANDARD PROCEDURE...............19-34

FLYWHEEL - ASSEMBLY................6-14

FLYWHEEL - DIAGNOSIS AND TESTING....6-13

FLYWHEEL - DISASSEMBLY.............6-13

FOG LAMP - DIAGNOSIS AND TESTING . . . 8L-10

FOG LAMP - INSTALLATION............8L-11

FOG LAMP - REMOVAL................8L-11

FOG LAMP UNIT - ADJUSTMENTS.......8L-13

FOG LAMP UNIT - INSTALLATION........8L-12

FOG LAMP UNIT - REMOVAL...........8L-12

FORE/AFT - ADJUSTMENT, FRONT DOOR . . 23-69

FORM-IN-PLACE GASKETS AND

SEALERS - STANDARD PROCEDURE . 9-10,9-122,

9-66

FOUR-WHEEL DRIVE INDICATOR -

DIAGNOSIS AND TESTING..............8J-29

FRAME - INSTALLATION, GRILLE........23-92

FRAME - REMOVAL, GRILLE............23-91

FRAME DIMENSION, SPECIFICATIONS.....13-8

FRAME SERVICE, DESCRIPTION..........13-7

FRONT - 2500 - INSTALLATION..........5-23

FRONT - 2500 - REMOVAL

..............5-22

FRONT - 3500 - INSTALLATION

..........5-23

FRONT - 3500 - REMOVAL

..............5-22

FRONT - DESCRIPTION, CRANKSHAFT

OIL SEAL

............................9-32

FRONT - INSTALLATION

............5-14,5-26FRONT - INSTALLATION...............22-12

FRONT - INSTALLATION, CRANKSHAFT

OIL SEAL.......................9-160,9-32

FRONT - INSTALLATION, PROPELLER

SHAFT...............................3-7

FRONT - OPERATION, CRANKSHAFT OIL

SEAL...............................9-32

FRONT - REMOVAL................5-11,5-24

FRONT - REMOVAL, CRANKSHAFT OIL

SEAL..........................9-160,9-32

FRONT - REMOVAL, PROPELLER SHAFT....3-6

FRONT AIR DAM - INSTALLATION........13-2

FRONT AIR DAM - REMOVAL............13-2

FRONT AXLE - 248FBI - ADJUSTMENTS....3-19

FRONT AXLE - 248FBI - DESCRIPTION.....3-14

FRONT AXLE - 248FBI - INSTALLATION....3-18

FRONT AXLE - 248FBI - OPERATION......3-14

FRONT AXLE - 248FBI - REMOVAL........3-18

FRONT AXLE, 248FBI..................3-27

FRONT AXLE, SPECIAL TOOLS...........3-27

FRONT BEARING - INSTALLATION,

OUTPUT SHAFT...............21-171,21-342

FRONT BEARING - REMOVAL, OUTPUT

SHAFT......................21-171,21-342

FRONT BUMPER - INSTALLATION.........13-4

FRONT BUMPER - REMOVAL............13-4

FRONT BUMPER - SPORT -

INSTALLATION........................13-5

FRONT BUMPER - SPORT - REMOVAL......13-5

FRONT CLUTCH - ASSEMBLY....21-162,21-333

FRONT CLUTCH - DESCRIPTION . . 21-160,21-330

FRONT CLUTCH - DISASSEMBLY . 21-161,21-331

FRONT CLUTCH - INSPECTION . . . 21-162,21-332

FRONT CLUTCH - OPERATION . . . 21-160,21-330

FRONT COVER INSTALLED -

INSTALLATION, FRONT OIL SEAL.........9-89

FRONT COVER INSTALLED - REMOVAL,

FRONT OIL SEAL......................9-89

FRONT COVER REMOVED -

INSTALLATION, FRONT OIL SEAL.........9-90

FRONT COVER REMOVED - REMOVAL,

FRONT OIL SEAL......................9-89

FRONT DOOR FORE/AFT - ADJUSTMENT . . 23-69

FRONT DOOR GLASS RUN

WEATHERSTRIP - INSTALLATION.......23-153

FRONT DOOR GLASS RUN

WEATHERSTRIP - REMOVAL...........23-152

FRONT DOOR INNER BELT

WEATHERSTRIP - INSTALLATION.......23-153

FRONT DOOR INNER BELT

WEATHERSTRIP - REMOVAL...........23-153

FRONT DOOR IN/OUT - ADJUSTMENT....23-70

FRONT DOOR LATCH - ADJUSTMENT.....23-73

FRONT DOOR OUTER BELT

WEATHERSTRIP - INSTALLATION.......23-153

FRONT DOOR OUTER BELT

WEATHERSTRIP - REMOVAL...........23-153

FRONT DOOR SECOND WEATHERSTRIP -

INSTALLATION......................23-154

FRONT DOOR SECOND WEATHERSTRIP -

REMOVAL.........................23-154

FRONT DOOR SPEAKER - INSTALLATION . . 8A-19

FRONT DOOR SPEAKER - REMOVAL.....8A-19

FRONT DOOR UP/DOWN - ADJUSTMENT . . 23-70

FRONT DOOR UPPER CORNER SEAL -

INSTALLATION......................23-154

FRONT DOOR UPPER CORNER SEAL -

REMOVAL.........................23-153

FRONT END SPLASH SHIELDS -

INSTALLATION.......................23-92

FRONT END SPLASH SHIELDS -

REMOVAL..........................23-92

FRONT FASCIA - INSTALLATION

..........13-2

FRONT FASCIA - REMOVAL

..............13-2

FRONT FASCIA - SPORT - INSTALLATION

. . 13-3

FRONT FASCIA - SPORT - REMOVAL

......13-3

FRONT FENDER - INSTALLATION, LEFT

. . . 23-93

FRONT FENDER - INSTALLATION, RIGHT

. . 23-94

FRONT FENDER - REMOVAL, LEFT

.......23-93

FRONT FENDER - REMOVAL, RIGHT

......23-94

FRONT LOWER FASCIA - INSTALLATION

. . . 13-3

FRONT LOWER FASCIA - REMOVAL

.......13-3

FRONT MOUNT - INSTALLATION

....9-174,9-42,

9-98

FRONT MOUNT - REMOVAL

....9-173,9-41,9-97

FRONT OIL SEAL - FRONT COVER

INSTALLED - INSTALLATION

.............9-89FRONT OIL SEAL - FRONT COVER

INSTALLED - REMOVAL................9-89

FRONT OIL SEAL - FRONT COVER

REMOVED - INSTALLATION..............9-90

FRONT OIL SEAL - FRONT COVER

REMOVED - REMOVAL.................9-89

FRONT OUTPUT SHAFT SEAL -

INSTALLATION................21-461,21-498

FRONT OUTPUT SHAFT SEAL -

REMOVAL...................21-461,21-498

FRONT PARKING BRAKE CABLE -

INSTALLATION........................5-30

FRONT PARKING BRAKE CABLE -

REMOVAL...........................5-29

FRONT SEAT BELT BUCKLE -

INSTALLATION......................8O-20

FRONT SEAT BELT BUCKLE - REMOVAL . . 8O-20

FRONT SERVO - ASSEMBLY.....21-164,21-335

FRONT SERVO - CLEANING.....21-164,21-334

FRONT SERVO - DESCRIPTION . . . 21-164,21-334

FRONT SERVO - DISASSEMBLY . . 21-164,21-334

FRONT SERVO - INSPECTION....21-164,21-335

FRONT SERVO - OPERATION....21-164,21-334

FRONT SUSPENSION, SPECIAL TOOLS -

INDEPENDENT.........................2-9

FRONT TOW HOOK - INSTALLATION......13-10

FRONT TOW HOOK - REMOVAL.........13-10

FRONT WHEEL SPEED SENSOR -

DESCRIPTION........................5-38

FRONT WHEEL SPEED SENSOR -

OPERATION...........................5-38

FUEL DELIVERY - SPECIFICATIONS,

TORQUE............................14-4

FUEL DELIVERY SYSTEM -

DESCRIPTION........................14-2

FUEL DELIVERY SYSTEM -

DESCRIPTION, DIESEL................14-55

FUEL DELIVERY SYSTEM - OPERATION....14-2

FUEL DRAIN MANIFOLD - DESCRIPTION . . 14-89

FUEL DRAIN MANIFOLD - INSTALLATION . . 14-90

FUEL DRAIN MANIFOLD - OPERATION....14-89

FUEL DRAIN MANIFOLD - REMOVAL.....14-90

FUEL FILL DOOR - INSTALLATION.......23-95

FUEL FILL DOOR - REMOVAL...........23-95

FUEL FILLER CAP - DESCRIPTION.......25-34

FUEL FILLER CAP - OPERATION.........25-34

FUEL FILLER CAP - REMOVAL/

INSTALLATION.......................25-34

FUEL FILTER - STANDARD

PROCEDURES, WATER DRAINING AT.....14-61

FUEL FILTER / WATER SEPARATOR -

DESCRIPTION.......................14-63

FUEL FILTER / WATER SEPARATOR -

INSTALLATION.......................14-65

FUEL FILTER / WATER SEPARATOR -

OPERATION.........................14-63

FUEL FILTER / WATER SEPARATOR -

REMOVAL..........................14-64

FUEL FILTER/PRESSURE REGULATOR -

DESCRIPTION........................14-5

FUEL FILTER/PRESSURE REGULATOR -

INSTALLATION........................14-7

FUEL FILTER/PRESSURE REGULATOR -

OPERATION..........................14-5

FUEL FILTER/PRESSURE REGULATOR -

REMOVAL...........................14-5

FUEL GAUGE - DESCRIPTION...........8J-19

FUEL GAUGE - OPERATION.............8J-20

FUEL GAUGE SENDING UNIT -

DIAGNOSIS AND TESTING..............14-7

FUEL HEATER - DESCRIPTION

..........14-66

FUEL HEATER - DIAGNOSIS AND

TESTING

...........................14-66

FUEL HEATER - OPERATION

............14-66

FUEL HEATER - REMOVAL/INSTALLATION

. 14-67

FUEL HEATER RELAY - DESCRIPTION

....14-67

FUEL HEATER RELAY - DIAGNOSIS AND

TESTING

...........................14-68

FUEL HEATER RELAY - INSTALLATION

....14-69

FUEL HEATER RELAY - OPERATION

......14-67

FUEL HEATER RELAY - REMOVAL

........14-69

FUEL INDICATOR - DESCRIPTION, LOW

. . . 8J-22

FUEL INDICATOR - OPERATION, LOW

.....8J-22

FUEL INJECTION - SPECIFICATIONS,

TORQUE - GAS

......................14-35

FUEL INJECTION PUMP DATA PLATE,

SPECIFICATIONS

.....................14-77

BR/BEINDEX 13

Description Group-Page Description Group-Page Description Group-Page

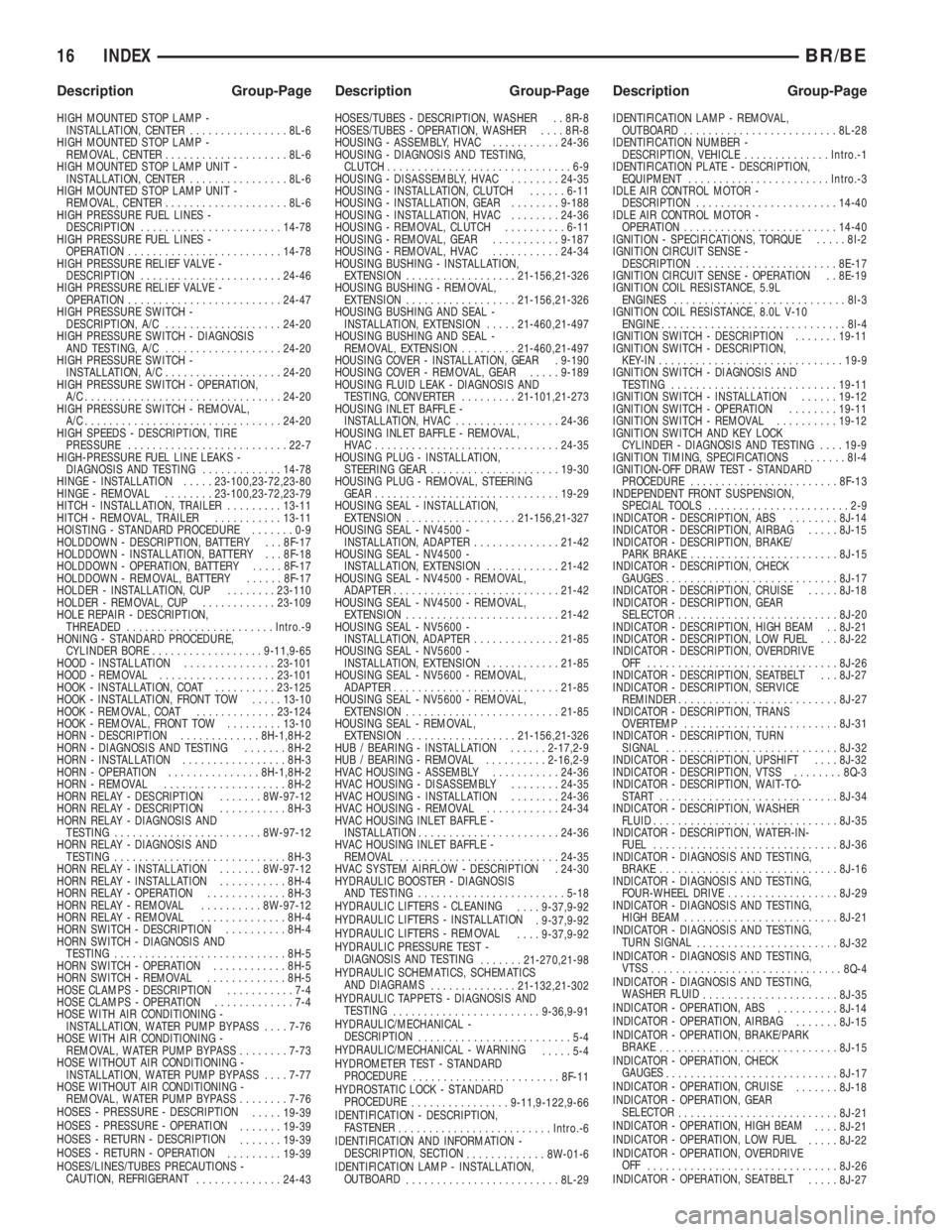

Page 2233 of 2255

HIGH MOUNTED STOP LAMP -

INSTALLATION, CENTER................8L-6

HIGH MOUNTED STOP LAMP -

REMOVAL, CENTER....................8L-6

HIGH MOUNTED STOP LAMP UNIT -

INSTALLATION, CENTER................8L-6

HIGH MOUNTED STOP LAMP UNIT -

REMOVAL, CENTER....................8L-6

HIGH PRESSURE FUEL LINES -

DESCRIPTION.......................14-78

HIGH PRESSURE FUEL LINES -

OPERATION.........................14-78

HIGH PRESSURE RELIEF VALVE -

DESCRIPTION.......................24-46

HIGH PRESSURE RELIEF VALVE -

OPERATION.........................24-47

HIGH PRESSURE SWITCH -

DESCRIPTION, A/C...................24-20

HIGH PRESSURE SWITCH - DIAGNOSIS

AND TESTING, A/C...................24-20

HIGH PRESSURE SWITCH -

INSTALLATION, A/C...................24-20

HIGH PRESSURE SWITCH - OPERATION,

A/C................................24-20

HIGH PRESSURE SWITCH - REMOVAL,

A/C................................24-20

HIGH SPEEDS - DESCRIPTION, TIRE

PRESSURE..........................22-7

HIGH-PRESSURE FUEL LINE LEAKS -

DIAGNOSIS AND TESTING.............14-78

HINGE - INSTALLATION.....23-100,23-72,23-80

HINGE - REMOVAL........23-100,23-72,23-79

HITCH - INSTALLATION, TRAILER.........13-11

HITCH - REMOVAL, TRAILER...........13-11

HOISTING - STANDARD PROCEDURE.......0-9

HOLDDOWN - DESCRIPTION, BATTERY . . . 8F-17

HOLDDOWN - INSTALLATION, BATTERY . . . 8F-18

HOLDDOWN - OPERATION, BATTERY.....8F-17

HOLDDOWN - REMOVAL, BATTERY......8F-17

HOLDER - INSTALLATION, CUP........23-110

HOLDER - REMOVAL, CUP............23-109

HOLE REPAIR - DESCRIPTION,

THREADED........................Intro.-9

HONING - STANDARD PROCEDURE,

CYLINDER BORE..................9-11,9-65

HOOD - INSTALLATION...............23-101

HOOD - REMOVAL...................23-101

HOOK - INSTALLATION, COAT..........23-125

HOOK - INSTALLATION, FRONT TOW.....13-10

HOOK - REMOVAL, COAT.............23-124

HOOK - REMOVAL, FRONT TOW.........13-10

HORN - DESCRIPTION.............8H-1,8H-2

HORN - DIAGNOSIS AND TESTING.......8H-2

HORN - INSTALLATION.................8H-3

HORN - OPERATION...............8H-1,8H-2

HORN - REMOVAL....................8H-2

HORN RELAY - DESCRIPTION.......8W-97-12

HORN RELAY - DESCRIPTION...........8H-3

HORN RELAY - DIAGNOSIS AND

TESTING........................8W-97-12

HORN RELAY - DIAGNOSIS AND

TESTING............................8H-3

HORN RELAY - INSTALLATION.......8W-97-12

HORN RELAY - INSTALLATION...........8H-4

HORN RELAY - OPERATION.............8H-3

HORN RELAY - REMOVAL..........8W-97-12

HORN RELAY - REMOVAL..............8H-4

HORN SWITCH - DESCRIPTION..........8H-4

HORN SWITCH - DIAGNOSIS AND

TESTING............................8H-5

HORN SWITCH - OPERATION............8H-5

HORN SWITCH - REMOVAL.............8H-5

HOSE CLAMPS - DESCRIPTION...........7-4

HOSE CLAMPS - OPERATION.............7-4

HOSE WITH AIR CONDITIONING -

INSTALLATION, WATER PUMP BYPASS....7-76

HOSE WITH AIR CONDITIONING -

REMOVAL, WATER PUMP BYPASS........7-73

HOSE WITHOUT AIR CONDITIONING -

INSTALLATION, WATER PUMP BYPASS....7-77

HOSE WITHOUT AIR CONDITIONING -

REMOVAL, WATER PUMP BYPASS........7-76

HOSES - PRESSURE - DESCRIPTION

.....19-39

HOSES - PRESSURE - OPERATION

.......19-39

HOSES - RETURN - DESCRIPTION

.......19-39

HOSES - RETURN - OPERATION

.........19-39

HOSES/LINES/TUBES PRECAUTIONS -

CAUTION, REFRIGERANT

..............24-43HOSES/TUBES - DESCRIPTION, WASHER . . 8R-8

HOSES/TUBES - OPERATION, WASHER....8R-8

HOUSING - ASSEMBLY, HVAC...........24-36

HOUSING - DIAGNOSIS AND TESTING,

CLUTCH..............................6-9

HOUSING - DISASSEMBLY, HVAC........24-35

HOUSING - INSTALLATION, CLUTCH......6-11

HOUSING - INSTALLATION, GEAR........9-188

HOUSING - INSTALLATION, HVAC........24-36

HOUSING - REMOVAL, CLUTCH..........6-11

HOUSING - REMOVAL, GEAR...........9-187

HOUSING - REMOVAL, HVAC...........24-34

HOUSING BUSHING - INSTALLATION,

EXTENSION..................21-156,21-326

HOUSING BUSHING - REMOVAL,

EXTENSION..................21-156,21-326

HOUSING BUSHING AND SEAL -

INSTALLATION, EXTENSION.....21-460,21-497

HOUSING BUSHING AND SEAL -

REMOVAL, EXTENSION.........21-460,21-497

HOUSING COVER - INSTALLATION, GEAR . 9-190

HOUSING COVER - REMOVAL, GEAR.....9-189

HOUSING FLUID LEAK - DIAGNOSIS AND

TESTING, CONVERTER.........21-101,21-273

HOUSING INLET BAFFLE -

INSTALLATION, HVAC.................24-36

HOUSING INLET BAFFLE - REMOVAL,

HVAC..............................24-35

HOUSING PLUG - INSTALLATION,

STEERING GEAR.......................19-30

HOUSING PLUG - REMOVAL, STEERING

GEAR..............................19-29

HOUSING SEAL - INSTALLATION,

EXTENSION..................21-156,21-327

HOUSING SEAL - NV4500 -

INSTALLATION, ADAPTER..............21-42

HOUSING SEAL - NV4500 -

INSTALLATION, EXTENSION............21-42

HOUSING SEAL - NV4500 - REMOVAL,

ADAPTER...........................21-42

HOUSING SEAL - NV4500 - REMOVAL,

EXTENSION.........................21-42

HOUSING SEAL - NV5600 -

INSTALLATION, ADAPTER..............21-85

HOUSING SEAL - NV5600 -

INSTALLATION, EXTENSION............21-85

HOUSING SEAL - NV5600 - REMOVAL,

ADAPTER...........................21-85

HOUSING SEAL - NV5600 - REMOVAL,

EXTENSION.........................21-85

HOUSING SEAL - REMOVAL,

EXTENSION..................21-156,21-326

HUB / BEARING - INSTALLATION......2-17,2-9

HUB / BEARING - REMOVAL..........2-16,2-9

HVAC HOUSING - ASSEMBLY...........24-36

HVAC HOUSING - DISASSEMBLY........24-35

HVAC HOUSING - INSTALLATION........24-36

HVAC HOUSING - REMOVAL............24-34

HVAC HOUSING INLET BAFFLE -

INSTALLATION.......................24-36

HVAC HOUSING INLET BAFFLE -

REMOVAL..........................24-35

HVAC SYSTEM AIRFLOW - DESCRIPTION . 24-30

HYDRAULIC BOOSTER - DIAGNOSIS

AND TESTING........................5-18

HYDRAULIC LIFTERS - CLEANING

....9-37,9-92

HYDRAULIC LIFTERS - INSTALLATION

. 9-37,9-92

HYDRAULIC LIFTERS - REMOVAL

....9-37,9-92

HYDRAULIC PRESSURE TEST -

DIAGNOSIS AND TESTING

.......21-270,21-98

HYDRAULIC SCHEMATICS, SCHEMATICS

AND DIAGRAMS

..............21-132,21-302

HYDRAULIC TAPPETS - DIAGNOSIS AND

TESTING

........................9-36,9-91

HYDRAULIC/MECHANICAL -

DESCRIPTION

.........................5-4

HYDRAULIC/MECHANICAL - WARNING

.....5-4

HYDROMETER TEST - STANDARD

PROCEDURE

........................8F-11

HYDROSTATIC LOCK - STANDARD

PROCEDURE

................9-11,9-122,9-66

IDENTIFICATION - DESCRIPTION,

FASTENER

.........................Intro.-6

IDENTIFICATION AND INFORMATION -

DESCRIPTION, SECTION

.............8W-01-6

IDENTIFICATION LAMP - INSTALLATION,

OUTBOARD

.........................8L-29IDENTIFICATION LAMP - REMOVAL,

OUTBOARD.........................8L-28

IDENTIFICATION NUMBER -

DESCRIPTION, VEHICLE..............Intro.-1

IDENTIFICATION PLATE - DESCRIPTION,

EQUIPMENT.......................Intro.-3

IDLE AIR CONTROL MOTOR -

DESCRIPTION.......................14-40

IDLE AIR CONTROL MOTOR -

OPERATION.........................14-40

IGNITION - SPECIFICATIONS, TORQUE.....8I-2

IGNITION CIRCUIT SENSE -

DESCRIPTION.......................8E-17

IGNITION CIRCUIT SENSE - OPERATION . . 8E-19

IGNITION COIL RESISTANCE, 5.9L

ENGINES............................8I-3

IGNITION COIL RESISTANCE, 8.0L V-10

ENGINE..............................8I-4

IGNITION SWITCH - DESCRIPTION.......19-11

IGNITION SWITCH - DESCRIPTION,

KEY-IN..............................19-9

IGNITION SWITCH - DIAGNOSIS AND

TESTING...........................19-11

IGNITION SWITCH - INSTALLATION......19-12

IGNITION SWITCH - OPERATION........19-11

IGNITION SWITCH - REMOVAL..........19-12

IGNITION SWITCH AND KEY LOCK

CYLINDER - DIAGNOSIS AND TESTING....19-9

IGNITION TIMING, SPECIFICATIONS.......8I-4

IGNITION-OFF DRAW TEST - STANDARD

PROCEDURE........................8F-13

INDEPENDENT FRONT SUSPENSION,

SPECIAL TOOLS.......................2-9

INDICATOR - DESCRIPTION, ABS........8J-14

INDICATOR - DESCRIPTION, AIRBAG.....8J-15

INDICATOR - DESCRIPTION, BRAKE/

PARK BRAKE........................8J-15

INDICATOR - DESCRIPTION, CHECK

GAUGES............................8J-17

INDICATOR - DESCRIPTION, CRUISE.....8J-18

INDICATOR - DESCRIPTION, GEAR

SELECTOR..........................8J-20

INDICATOR - DESCRIPTION, HIGH BEAM . . 8J-21

INDICATOR - DESCRIPTION, LOW FUEL . . . 8J-22

INDICATOR - DESCRIPTION, OVERDRIVE

OFF ...............................8J-26

INDICATOR - DESCRIPTION, SEATBELT . . . 8J-27

INDICATOR - DESCRIPTION, SERVICE

REMINDER..........................8J-27

INDICATOR - DESCRIPTION, TRANS

OVERTEMP.........................8J-31

INDICATOR - DESCRIPTION, TURN

SIGNAL............................8J-32

INDICATOR - DESCRIPTION, UPSHIFT....8J-32

INDICATOR - DESCRIPTION, VTSS........8Q-3

INDICATOR - DESCRIPTION, WAIT-TO-

START .............................8J-34

INDICATOR - DESCRIPTION, WASHER

FLUID..............................8J-35

INDICATOR - DESCRIPTION, WATER-IN-

FUEL..............................8J-36

INDICATOR - DIAGNOSIS AND TESTING,

BRAKE.............................8J-16

INDICATOR - DIAGNOSIS AND TESTING,

FOUR-WHEEL DRIVE..................8J-29

INDICATOR - DIAGNOSIS AND TESTING,

HIGH BEAM.........................8J-21

INDICATOR - DIAGNOSIS AND TESTING,

TURN SIGNAL

.......................8J-32

INDICATOR - DIAGNOSIS AND TESTING,

VTSS

...............................8Q-4

INDICATOR - DIAGNOSIS AND TESTING,

WASHER FLUID

......................8J-35

INDICATOR - OPERATION, ABS

..........8J-14

INDICATOR - OPERATION, AIRBAG

.......8J-15

INDICATOR - OPERATION, BRAKE/PARK

BRAKE

.............................8J-15

INDICATOR - OPERATION, CHECK

GAUGES

............................8J-17

INDICATOR - OPERATION, CRUISE

.......8J-18

INDICATOR - OPERATION, GEAR

SELECTOR

..........................8J-21

INDICATOR - OPERATION, HIGH BEAM

....8J-21

INDICATOR - OPERATION, LOW FUEL

.....8J-22

INDICATOR - OPERATION, OVERDRIVE

OFF

...............................8J-26

INDICATOR - OPERATION, SEATBELT

.....8J-27

16 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page