air filter DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 16 of 2255

²The use of leaded gas is prohibited by Federal

law. Using leaded gasoline can impair engine perfor-

mance, damage the emission control system, and

could result in loss of warranty coverage.

²An out-of-tune engine, or certain fuel or ignition

malfunctions, can cause the catalytic converter to

overheat. If you notice a pungent burning odor or

some light smoke, your engine may be out of tune or

malfunctioning and may require immediate service.

Contact your dealer for service assistance.

²When pulling a heavy load or driving a fully

loaded vehicle when the humidity is low and the tem-

perature is high, use a premium unleaded fuel to

help prevent spark knock. If spark knock persists,

lighten the load, or engine piston damage may result.

²The use of fuel additives which are now being

sold as octane enhancers is not recommended. Most

of these products contain high concentrations of

methanol. Fuel system damage or vehicle perfor-

mance problems resulting from the use of such fuels

or additives is not the responsibility of

DaimlerChrysler Corporation and may not be covered

under the new vehicle warranty.

NOTE: Intentional tampering with emissions control

systems can result in civil penalties being assessed

against you.

DESCRIPTION - FUEL REQUIREMENTS -

DIESEL ENGINE

DESCRIPTION

WARNING: Do not use alcohol or gasoline as a fuel

blending agent. They can be unstable under certain

conditions and hazardous or explosive when mixed

with diesel fuel.

Use good quality diesel fuel from a reputable sup-

plier in your Dodge truck. For most year-round ser-

vice, number 2 diesel fuel meeting ASTM

specification D-975 will provide good performance. If

the vehicle is exposed to extreme cold (below 0ÉF/-

18ÉC), or is required to operate at colder-than-normal

conditions for prolonged periods, use climatized No. 2

diesel fuel or dilute the No. 2 diesel fuel with 50%

No. 1 diesel fuel. This will provide better protection

from fuel gelling or wax-plugging of the fuel filters.

Diesel fuel is seldom completely free of water. To

prevent fuel system trouble, including fuel line freez-

ing in winter, drain the accumulated water from the

fuel/water separator using the fuel/water separator

drain provided. If you buy good-quality fuel and fol-

low the cold-weather advice above, fuel conditioners

should not be required in your vehicle. If available in

your area, a high cetane ªpremiumº diesel fuel mayoffer improved cold starting and warm-up perfor-

mance.

DESCRIPTION - ENGINE COOLANT

WARNING: ANTIFREEZE IS AN ETHYLENE GLYCOL

BASE COOLANT AND IS HARMFUL IF SWAL-

LOWED OR INHALED. IF SWALLOWED, DRINK

TWO GLASSES OF WATER AND INDUCE VOMIT-

ING. IF INHALED, MOVE TO FRESH AIR AREA.

SEEK MEDICAL ATTENTION IMMEDIATELY. DO NOT

STORE IN OPEN OR UNMARKED CONTAINERS.

WASH SKIN AND CLOTHING THOROUGHLY AFTER

COMING IN CONTACT WITH ETHYLENE GLYCOL.

KEEP OUT OF REACH OF CHILDREN. DISPOSE OF

GLYCOL BASE COOLANT PROPERLY, CONTACT

YOUR DEALER OR GOVERNMENT AGENCY FOR

LOCATION OF COLLECTION CENTER IN YOUR

AREA. DO NOT OPEN A COOLING SYSTEM WHEN

THE ENGINE IS AT OPERATING TEMPERATURE OR

HOT UNDER PRESSURE, PERSONAL INJURY CAN

RESULT. AVOID RADIATOR COOLING FAN WHEN

ENGINE COMPARTMENT RELATED SERVICE IS

PERFORMED, PERSONAL INJURY CAN RESULT.

CAUTION: Use of Propylene Glycol based coolants

is not recommended, as they provide less freeze

protection and less corrosion protection.

The cooling system is designed around the coolant.

The coolant must accept heat from engine metal, in

the cylinder head area near the exhaust valves and

engine block. Then coolant carries the heat to the

radiator where the tube/fin radiator can transfer the

heat to the air.

The use of aluminum cylinder blocks, cylinder

heads, and water pumps requires special corrosion

protection. MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769), or the equiva-

lent ethylene glycol base coolant with organic corro-

sion inhibitors (called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% Ethylene Glycol and 50% distilled

water to obtain a freeze point of -37ÉC (-35ÉF). If it

loses color or becomes contaminated, drain, flush,

and replace with fresh properly mixed coolant solu-

tion.

CAUTION: MoparTAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769) may not be

mixed with any other type of antifreeze. Mixing of

coolants other than specified (non-HOAT or other

HOAT), may result in engine damage that may not

be covered under the new vehicle warranty, and

decreased corrosion protection.

BR/BELUBRICATION & MAINTENANCE 0 - 3

FLUID TYPES (Continued)

Page 86 of 2255

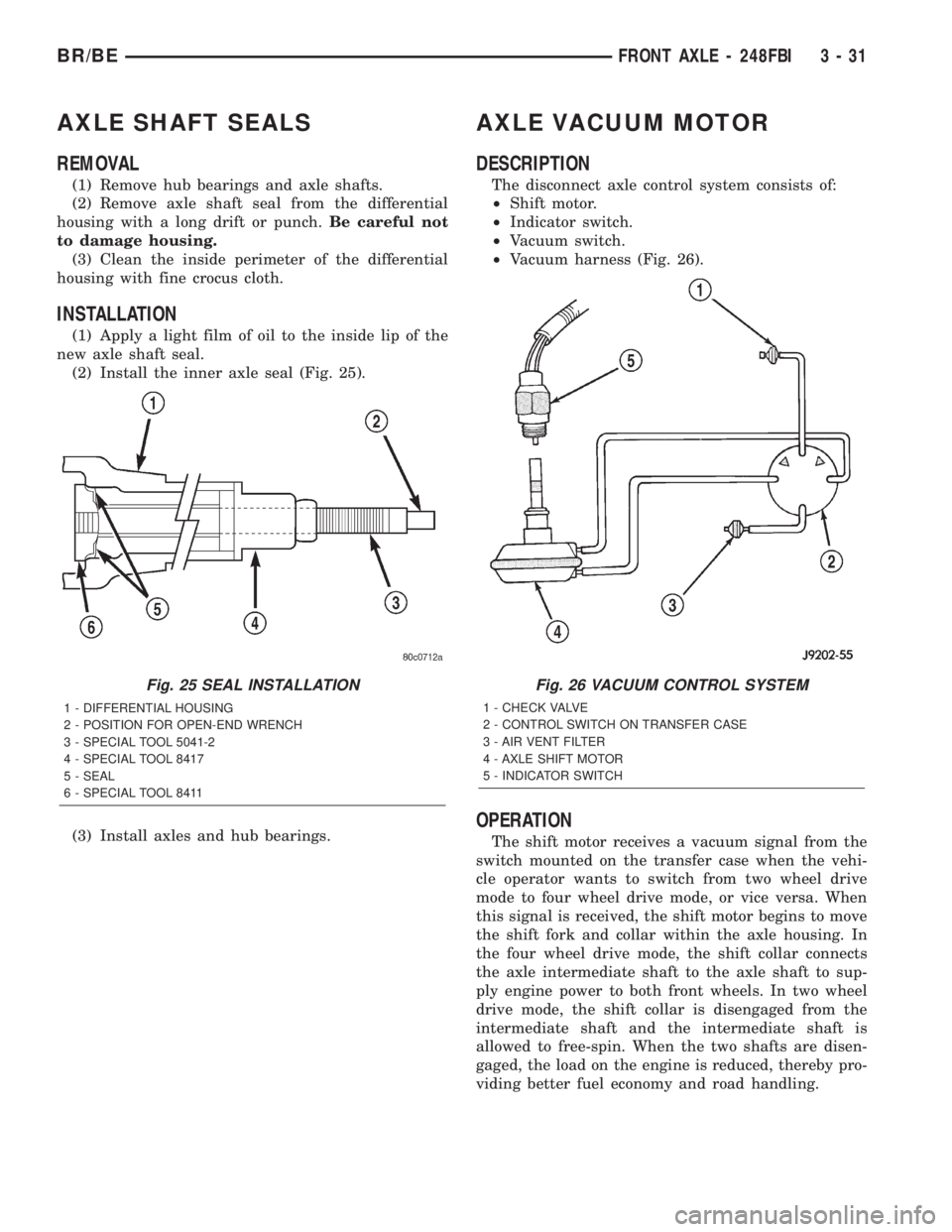

AXLE SHAFT SEALS

REMOVAL

(1) Remove hub bearings and axle shafts.

(2) Remove axle shaft seal from the differential

housing with a long drift or punch.Be careful not

to damage housing.

(3) Clean the inside perimeter of the differential

housing with fine crocus cloth.

INSTALLATION

(1) Apply a light film of oil to the inside lip of the

new axle shaft seal.

(2) Install the inner axle seal (Fig. 25).

(3) Install axles and hub bearings.

AXLE VACUUM MOTOR

DESCRIPTION

The disconnect axle control system consists of:

²Shift motor.

²Indicator switch.

²Vacuum switch.

²Vacuum harness (Fig. 26).

OPERATION

The shift motor receives a vacuum signal from the

switch mounted on the transfer case when the vehi-

cle operator wants to switch from two wheel drive

mode to four wheel drive mode, or vice versa. When

this signal is received, the shift motor begins to move

the shift fork and collar within the axle housing. In

the four wheel drive mode, the shift collar connects

the axle intermediate shaft to the axle shaft to sup-

ply engine power to both front wheels. In two wheel

drive mode, the shift collar is disengaged from the

intermediate shaft and the intermediate shaft is

allowed to free-spin. When the two shafts are disen-

gaged, the load on the engine is reduced, thereby pro-

viding better fuel economy and road handling.

Fig. 25 SEAL INSTALLATION

1 - DIFFERENTIAL HOUSING

2 - POSITION FOR OPEN-END WRENCH

3 - SPECIAL TOOL 5041-2

4 - SPECIAL TOOL 8417

5 - SEAL

6 - SPECIAL TOOL 8411

Fig. 26 VACUUM CONTROL SYSTEM

1 - CHECK VALVE

2 - CONTROL SWITCH ON TRANSFER CASE

3 - AIR VENT FILTER

4 - AXLE SHIFT MOTOR

5 - INDICATOR SWITCH

BR/BEFRONT AXLE - 248FBI 3 - 31

Page 344 of 2255

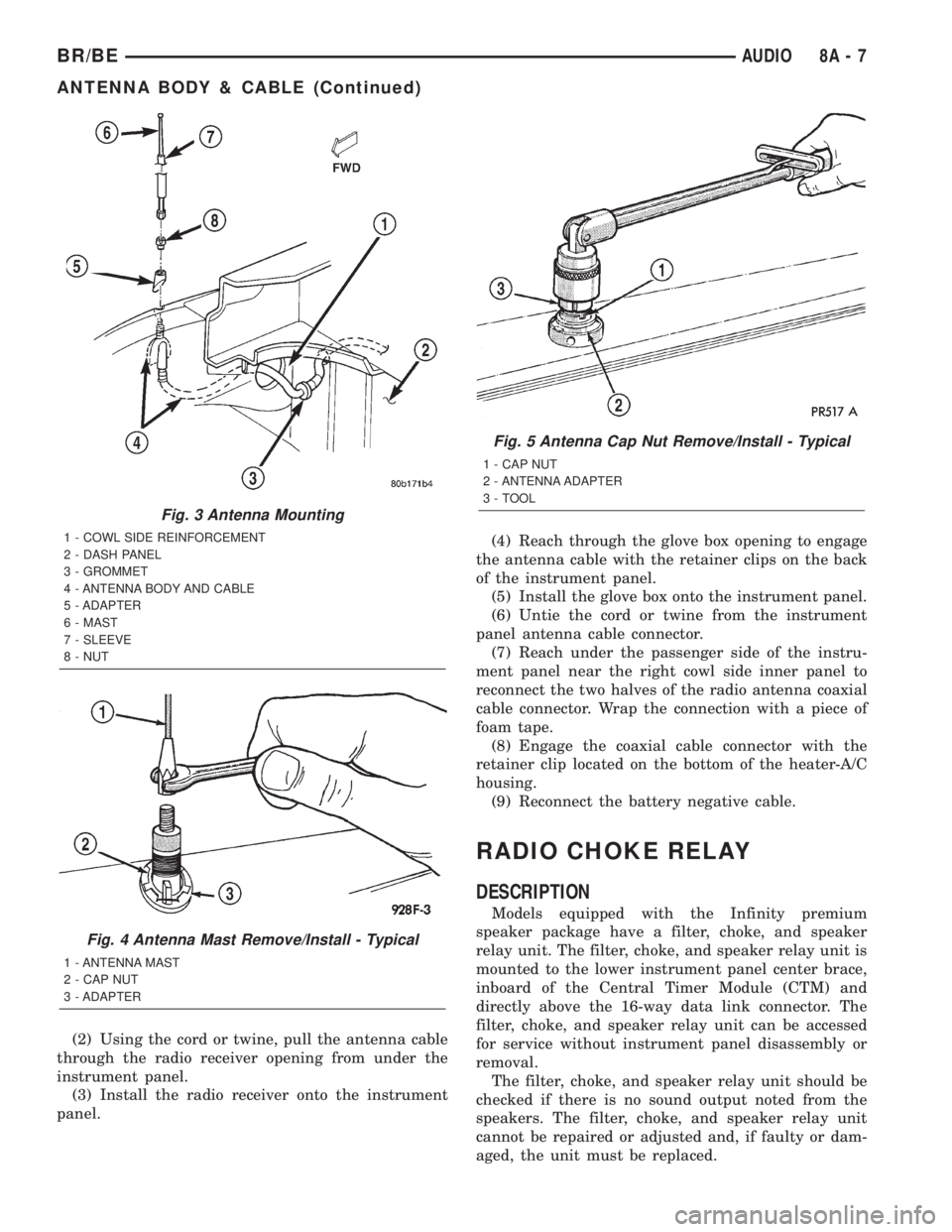

(2) Using the cord or twine, pull the antenna cable

through the radio receiver opening from under the

instrument panel.

(3) Install the radio receiver onto the instrument

panel.(4) Reach through the glove box opening to engage

the antenna cable with the retainer clips on the back

of the instrument panel.

(5) Install the glove box onto the instrument panel.

(6) Untie the cord or twine from the instrument

panel antenna cable connector.

(7) Reach under the passenger side of the instru-

ment panel near the right cowl side inner panel to

reconnect the two halves of the radio antenna coaxial

cable connector. Wrap the connection with a piece of

foam tape.

(8) Engage the coaxial cable connector with the

retainer clip located on the bottom of the heater-A/C

housing.

(9) Reconnect the battery negative cable.

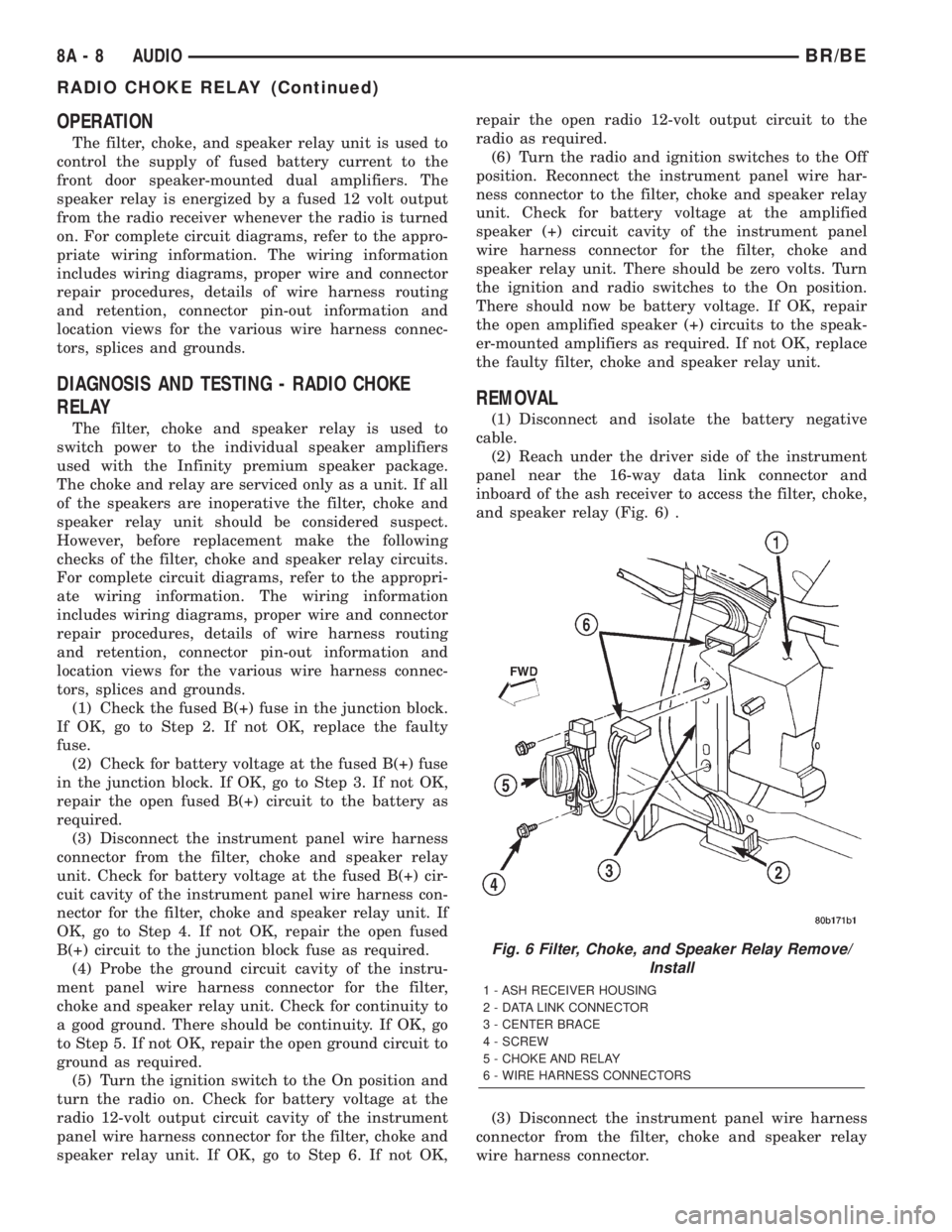

RADIO CHOKE RELAY

DESCRIPTION

Models equipped with the Infinity premium

speaker package have a filter, choke, and speaker

relay unit. The filter, choke, and speaker relay unit is

mounted to the lower instrument panel center brace,

inboard of the Central Timer Module (CTM) and

directly above the 16-way data link connector. The

filter, choke, and speaker relay unit can be accessed

for service without instrument panel disassembly or

removal.

The filter, choke, and speaker relay unit should be

checked if there is no sound output noted from the

speakers. The filter, choke, and speaker relay unit

cannot be repaired or adjusted and, if faulty or dam-

aged, the unit must be replaced.

Fig. 3 Antenna Mounting

1 - COWL SIDE REINFORCEMENT

2 - DASH PANEL

3 - GROMMET

4 - ANTENNA BODY AND CABLE

5 - ADAPTER

6 - MAST

7 - SLEEVE

8 - NUT

Fig. 4 Antenna Mast Remove/Install - Typical

1 - ANTENNA MAST

2 - CAP NUT

3 - ADAPTER

Fig. 5 Antenna Cap Nut Remove/Install - Typical

1 - CAP NUT

2 - ANTENNA ADAPTER

3 - TOOL

BR/BEAUDIO 8A - 7

ANTENNA BODY & CABLE (Continued)

Page 345 of 2255

OPERATION

The filter, choke, and speaker relay unit is used to

control the supply of fused battery current to the

front door speaker-mounted dual amplifiers. The

speaker relay is energized by a fused 12 volt output

from the radio receiver whenever the radio is turned

on. For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

DIAGNOSIS AND TESTING - RADIO CHOKE

RELAY

The filter, choke and speaker relay is used to

switch power to the individual speaker amplifiers

used with the Infinity premium speaker package.

The choke and relay are serviced only as a unit. If all

of the speakers are inoperative the filter, choke and

speaker relay unit should be considered suspect.

However, before replacement make the following

checks of the filter, choke and speaker relay circuits.

For complete circuit diagrams, refer to the appropri-

ate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

(1) Check the fused B(+) fuse in the junction block.

If OK, go to Step 2. If not OK, replace the faulty

fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the junction block. If OK, go to Step 3. If not OK,

repair the open fused B(+) circuit to the battery as

required.

(3) Disconnect the instrument panel wire harness

connector from the filter, choke and speaker relay

unit. Check for battery voltage at the fused B(+) cir-

cuit cavity of the instrument panel wire harness con-

nector for the filter, choke and speaker relay unit. If

OK, go to Step 4. If not OK, repair the open fused

B(+) circuit to the junction block fuse as required.

(4) Probe the ground circuit cavity of the instru-

ment panel wire harness connector for the filter,

choke and speaker relay unit. Check for continuity to

a good ground. There should be continuity. If OK, go

to Step 5. If not OK, repair the open ground circuit to

ground as required.

(5) Turn the ignition switch to the On position and

turn the radio on. Check for battery voltage at the

radio 12-volt output circuit cavity of the instrument

panel wire harness connector for the filter, choke and

speaker relay unit. If OK, go to Step 6. If not OK,repair the open radio 12-volt output circuit to the

radio as required.

(6) Turn the radio and ignition switches to the Off

position. Reconnect the instrument panel wire har-

ness connector to the filter, choke and speaker relay

unit. Check for battery voltage at the amplified

speaker (+) circuit cavity of the instrument panel

wire harness connector for the filter, choke and

speaker relay unit. There should be zero volts. Turn

the ignition and radio switches to the On position.

There should now be battery voltage. If OK, repair

the open amplified speaker (+) circuits to the speak-

er-mounted amplifiers as required. If not OK, replace

the faulty filter, choke and speaker relay unit.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Reach under the driver side of the instrument

panel near the 16-way data link connector and

inboard of the ash receiver to access the filter, choke,

and speaker relay (Fig. 6) .

(3) Disconnect the instrument panel wire harness

connector from the filter, choke and speaker relay

wire harness connector.

Fig. 6 Filter, Choke, and Speaker Relay Remove/

Install

1 - ASH RECEIVER HOUSING

2 - DATA LINK CONNECTOR

3 - CENTER BRACE

4 - SCREW

5 - CHOKE AND RELAY

6 - WIRE HARNESS CONNECTORS

8A - 8 AUDIOBR/BE

RADIO CHOKE RELAY (Continued)

Page 354 of 2255

(5) Install the driver side airbag module onto the

steering wheel. Refer to Electrical, Restraints for the

procedures.

(6) Reconnect the battery negative cable.

SPEAKER

DESCRIPTION

STANDARD

The standard equipment speaker system includes

speakers in four locations. One full-range 15.2 by

22.9 centimeter (6.0 by 9.0 inch) speaker is located in

each front door. There is also one full-range 13.3 cen-

timeter (5.25 inch) diameter speaker located in each

rear cab side panel for the standard cab and the club

cab models, or in each rear door of the quad cab mod-

els.

PREMIUM

The optional premium speaker system features

Infinity model speakers in six locations. Each of the

standard front door speakers are replaced with Infin-

ity model speakers that include integral dual 30 watt

amplifiers. Each of the standard rear speakers is also

replaced by an Infinity model speaker. The premium

speaker system also includes an additional Infinity

tweeter mounted in the A-pillar garnish molding. The

total available power of the premium speaker system

is about 120 watts.

OPERATION

STANDARD

Each of the four full-range speakers used in the

standard speaker system is driven by the amplifier

that is integral to the factory-installed radio receiver.

For complete circuit diagrams, refer to the appropri-

ate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

PREMIUM

The Infinity speakers used in the premium speaker

system are driven by dual amplifiers that are inte-

gral to each of the front door speakers. One of these

dual amplifiers drives the front door speaker and the

A-pillar mounted tweeter for that side of the vehicle,

while the other amplifier drives the rear speaker for

that side of the vehicle. For complete circuit dia-

grams, to refer to the appropriate wiring information.

The wiring information includes wiring diagrams,proper wire and connector repair procedures, details

of wire harness routing and retention, connector pin-

out information and location views for the various

wire harness connectors, splices and grounds.

DIAGNOSIS AND TESTING - SPEAKER

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

CAUTION: The speaker output of the radio receiver

is a ªfloating groundº system. Do not allow any

speaker lead to short to ground, as damage to the

radio receiver may result.

(1) Turn the ignition switch to the On position.

Turn the radio receiver on. Adjust the balance and

fader controls to check the performance of each indi-

vidual speaker. Note the speaker locations that are

not performing correctly. If only an Infinity A-pillar

or an Infinity rear speaker is inoperative, go to Step

8. If any other speaker is inoperative, go to Step 2.

NOTE: If the vehicle is equipped with the Infinity

premium speaker package and all of the speakers

are inoperative, refer to Filter, Choke, and Speaker

Relay in the Diagnosis and Testing section of this

group.

(2) Turn the radio receiver off. Turn the ignition

switch to the Off position. Disconnect and isolate the

battery negative cable. Remove the radio receiver

from the instrument panel. Check both the feed (+)

circuit and return (±) circuit cavities for the inopera-

tive speaker location(s) in the radio receiver wire

harness connectors for continuity to ground. In each

case, there should be no continuity. If OK, go to Step

3. If not OK, repair the shorted speaker feed (+)

and/or return (±) circuit(s) to the speaker as required.

(3) If the inoperative speaker is an Infinity-ampli-

fied speaker, go to Step 5. If the vehicle is equipped

with the standard speaker system, check the resis-

tance between the speaker feed (+) circuit and return

BR/BEAUDIO 8A - 17

REMOTE SWITCHES (Continued)

Page 355 of 2255

(±) circuit cavities of the radio receiver wire harness

connectors for the inoperative speaker location(s).

The meter should read between 2.5 and 4 ohms

(speaker resistance). If OK, go to Step 4. If not OK,

go to Step 5.

(4) Install a known good radio receiver. Connect

the battery negative cable. Turn the ignition switch

to the On position. Turn on the radio receiver and

test the speaker operation. If OK, replace the faulty

radio receiver. If not OK, turn the radio receiver off,

turn the ignition switch to the Off position, discon-

nect and isolate the battery negative cable, remove

the test radio receiver, and go to Step 5.

(5) Disconnect the wire harness connector at the

inoperative standard speaker system speaker or at

the Infinity-amplified front door-mounted speaker.

Check for continuity between the speaker feed (+) cir-

cuit cavities of the radio receiver wire harness con-

nector and the speaker wire harness connector for

the inoperative speaker location. Repeat the check

between the speaker return (±) circuit cavities of the

radio receiver wire harness connector and the

speaker wire harness connector for the inoperative

speaker location. In each case, there should be conti-

nuity. If OK with an Infinity-amplified front door-

mounted speaker, go to Step 6. If OK with the

standard speaker system, replace the faulty speaker.

If not OK, repair the open speaker feed (+) and/or

return (±) circuit(s) as required.

(6) Check for continuity between the ground cir-

cuit cavity in the body half of the wire harness con-

nector for the Infinity-amplified front door-mounted

speaker on the same side of the vehicle as the inop-

erative speaker and a good ground. There should be

continuity. If OK, go to Step 7. If not OK, repair the

open ground circuit to ground as required.

(7) Install the radio receiver. Connect the battery

negative cable. Turn the ignition switch to the On

position. Turn the radio receiver on. Check for bat-

tery voltage at the radio choke output circuit cavity

of the wire harness connector for the Infinity-ampli-

fied front door-mounted speaker on the same side of

the vehicle as the inoperative speaker. If OK, go to

Step 8. If not OK, repair the open radio choke output

circuit to the filter, choke, and speaker relay as

required.

(8) Turn the radio receiver off. Turn the ignition

switch to the Off position. Disconnect and isolate the

battery negative cable. Disconnect the wire harness

connector for the Infinity-amplified front door-

mounted speaker on the same side of the vehicle as

the inoperative speaker. Check both the amplified

feed (+) circuit and amplified return (±) circuit cavi-

ties for the inoperative speaker location in the body

half of the front door speaker wire harness connector

for continuity to ground. In each case, there shouldbe no continuity. If OK, go to Step 9. If not OK,

repair the shorted amplified feed (+) and/or amplified

return (±) circuit(s) as required.

(9) Disconnect the wire harness connector at the

inoperative speaker. Check for continuity between

the amplified feed (+) circuit cavities in the body half

of the wire harness connector for the Infinity-ampli-

fied front door-mounted speaker on the same side of

the vehicle as the inoperative speaker and the inop-

erative speaker wire harness connector. Repeat the

check between the amplified return (±) circuit cavi-

ties in the body half of the wire harness connector for

the Infinity-amplified front door-mounted speaker on

the same side of the vehicle as the inoperative

speaker and the inoperative speaker wire harness

connector. In each case, there should be continuity. If

OK, go to Step 10. If not OK, repair the open ampli-

fied feed (+) and/or amplified return (±) circuit(s) as

required.

(10) Check the resistance between the amplified

feed (+) circuit and amplified return (±) circuit cavi-

ties for the inoperative speaker in the body half of

the wire harness connector for the Infinity-amplified

front door-mounted speaker on the same side of the

vehicle as the inoperative speaker. The meter should

read between 2.5 and 4 ohms (speaker resistance). If

OK, replace the faulty front door-mounted Infinity

speaker and amplifier unit. If not OK, replace the

faulty A-pillar or rear-mounted Infinity speaker.

A-PILLAR TWEETER SPEAKER

REMOVAL

The A-pillar-mounted tweeters are used only with

the optional Infinity premium speaker package.

(1) Disconnect and isolate the battery negative

cable.

(2) If the vehicle is so equipped, remove the grab

handle from the A-pillar. Refer to Body, Interior for

the procedures.

(3) Disengage the trim from the A-pillar. Refer to

Body, Interior for the procedures.

(4) Pull the trim away from the A-pillar far enough

to access the tweeter wire harness connector (Fig.

18).

(5) Disconnect the body wire harness connector

from the A-pillar tweeter wire harness connector.

(6) Remove the trim and tweeter from the A-pillar

as a unit.

(7) Disengage the tweeter wire harness retainers

from the heat stakes on the back of the A-pillar trim.

(8) Disengage the tweeter from the A-pillar trim

by pushing out on the tweeter firmly and evenly from

the inside of the trim until it unsnaps from the

mounting hole.

8A - 18 AUDIOBR/BE

SPEAKER (Continued)

Page 378 of 2255

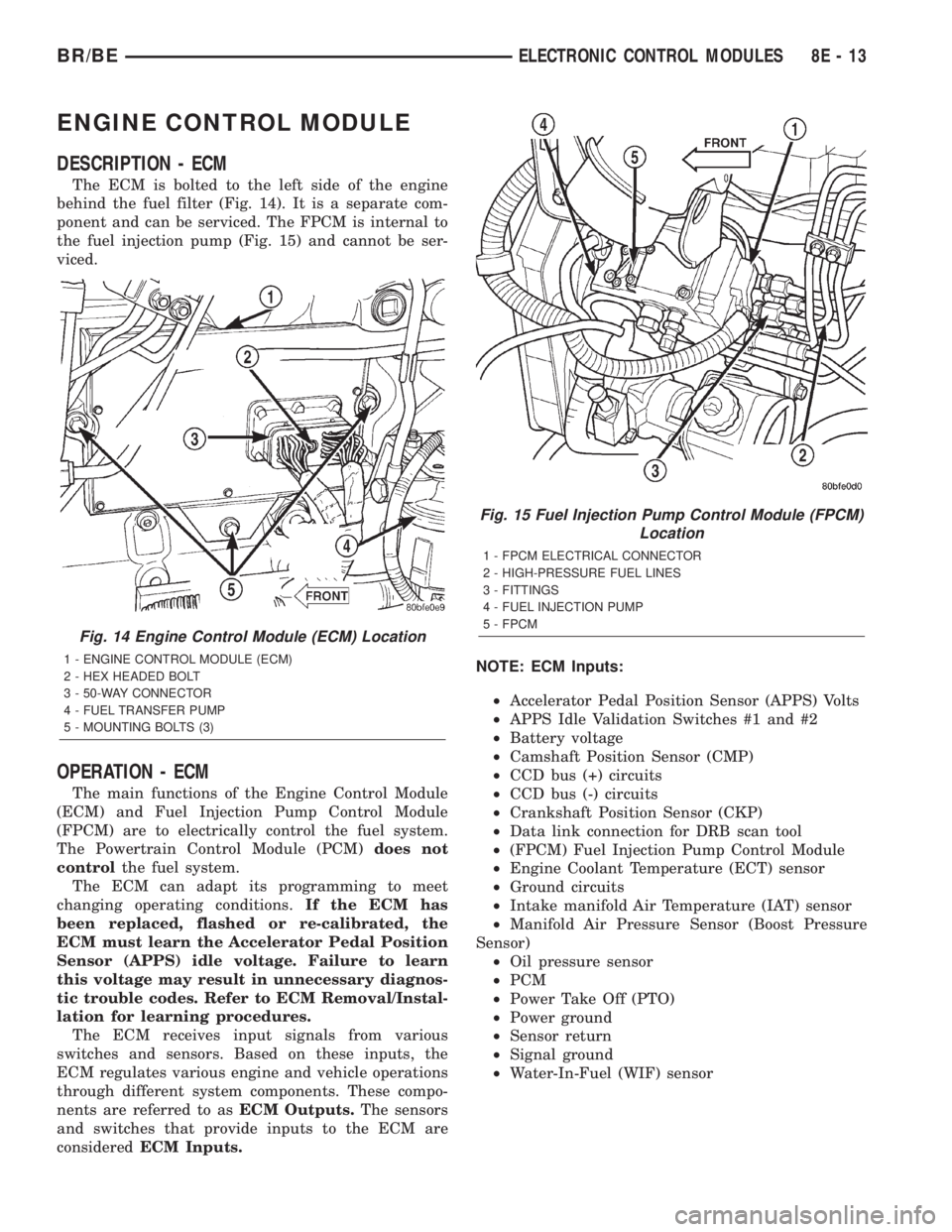

ENGINE CONTROL MODULE

DESCRIPTION - ECM

The ECM is bolted to the left side of the engine

behind the fuel filter (Fig. 14). It is a separate com-

ponent and can be serviced. The FPCM is internal to

the fuel injection pump (Fig. 15) and cannot be ser-

viced.

OPERATION - ECM

The main functions of the Engine Control Module

(ECM) and Fuel Injection Pump Control Module

(FPCM) are to electrically control the fuel system.

The Powertrain Control Module (PCM)does not

controlthe fuel system.

The ECM can adapt its programming to meet

changing operating conditions.If the ECM has

been replaced, flashed or re-calibrated, the

ECM must learn the Accelerator Pedal Position

Sensor (APPS) idle voltage. Failure to learn

this voltage may result in unnecessary diagnos-

tic trouble codes. Refer to ECM Removal/Instal-

lation for learning procedures.

The ECM receives input signals from various

switches and sensors. Based on these inputs, the

ECM regulates various engine and vehicle operations

through different system components. These compo-

nents are referred to asECM Outputs.The sensors

and switches that provide inputs to the ECM are

consideredECM Inputs.NOTE: ECM Inputs:

²Accelerator Pedal Position Sensor (APPS) Volts

²APPS Idle Validation Switches #1 and #2

²Battery voltage

²Camshaft Position Sensor (CMP)

²CCD bus (+) circuits

²CCD bus (-) circuits

²Crankshaft Position Sensor (CKP)

²Data link connection for DRB scan tool

²(FPCM) Fuel Injection Pump Control Module

²Engine Coolant Temperature (ECT) sensor

²Ground circuits

²Intake manifold Air Temperature (IAT) sensor

²Manifold Air Pressure Sensor (Boost Pressure

Sensor)

²Oil pressure sensor

²PCM

²Power Take Off (PTO)

²Power ground

²Sensor return

²Signal ground

²Water-In-Fuel (WIF) sensor

Fig. 14 Engine Control Module (ECM) Location

1 - ENGINE CONTROL MODULE (ECM)

2 - HEX HEADED BOLT

3 - 50-WAY CONNECTOR

4 - FUEL TRANSFER PUMP

5 - MOUNTING BOLTS (3)

Fig. 15 Fuel Injection Pump Control Module (FPCM)

Location

1 - FPCM ELECTRICAL CONNECTOR

2 - HIGH-PRESSURE FUEL LINES

3 - FITTINGS

4 - FUEL INJECTION PUMP

5 - FPCM

BR/BEELECTRONIC CONTROL MODULES 8E - 13

Page 379 of 2255

NOTE: ECM Outputs:

After inputs are received by the ECM, certain sen-

sors, switches and components are controlled or reg-

ulated by the ECM. These are consideredECM

Outputs.These outputs are for:

²CCD bus (+) circuits

²CCD bus (-) circuits

²CKP and APPS outputs to the PCM

²Data link connection for DRB scan tool

²Five volt sensor supply

²Fuel injection pump

²Fuel injection pump relay

²(FPCM) Fuel Pump Control Module

²Fuel transfer (lift) pump

²Intake manifold air heater relays #1 and #2 con-

trol circuits

²Malfunction indicator lamp (Check engine lamp)

²Oil pressure gauge/warning lamp

²PCM

²Wait-to-start warning lamp

²Water-In-Fuel (WIF) warning lamp

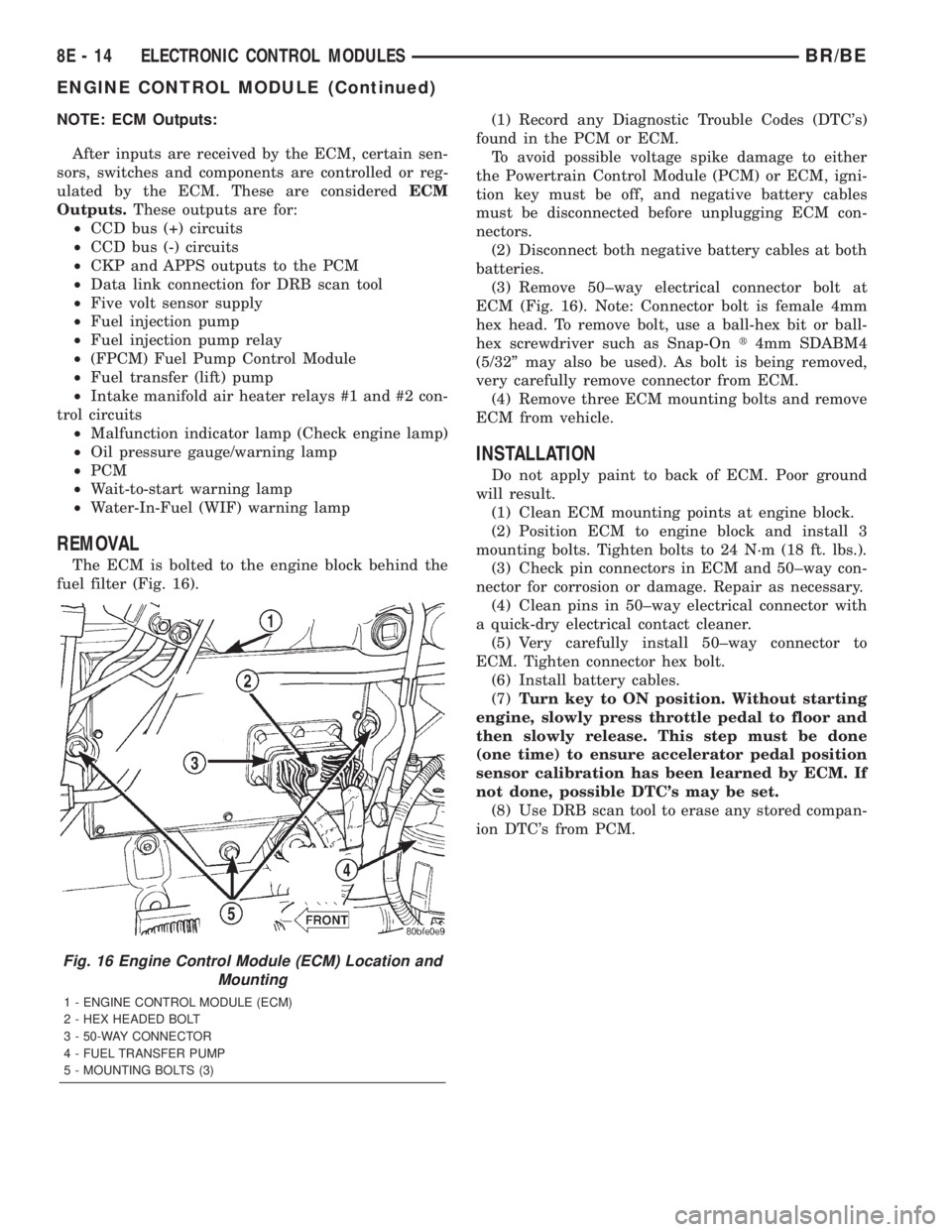

REMOVAL

The ECM is bolted to the engine block behind the

fuel filter (Fig. 16).(1) Record any Diagnostic Trouble Codes (DTC's)

found in the PCM or ECM.

To avoid possible voltage spike damage to either

the Powertrain Control Module (PCM) or ECM, igni-

tion key must be off, and negative battery cables

must be disconnected before unplugging ECM con-

nectors.

(2) Disconnect both negative battery cables at both

batteries.

(3) Remove 50±way electrical connector bolt at

ECM (Fig. 16). Note: Connector bolt is female 4mm

hex head. To remove bolt, use a ball-hex bit or ball-

hex screwdriver such as Snap-Ont4mm SDABM4

(5/32º may also be used). As bolt is being removed,

very carefully remove connector from ECM.

(4) Remove three ECM mounting bolts and remove

ECM from vehicle.

INSTALLATION

Do not apply paint to back of ECM. Poor ground

will result.

(1) Clean ECM mounting points at engine block.

(2) Position ECM to engine block and install 3

mounting bolts. Tighten bolts to 24 N´m (18 ft. lbs.).

(3) Check pin connectors in ECM and 50±way con-

nector for corrosion or damage. Repair as necessary.

(4) Clean pins in 50±way electrical connector with

a quick-dry electrical contact cleaner.

(5) Very carefully install 50±way connector to

ECM. Tighten connector hex bolt.

(6) Install battery cables.

(7)Turn key to ON position. Without starting

engine, slowly press throttle pedal to floor and

then slowly release. This step must be done

(one time) to ensure accelerator pedal position

sensor calibration has been learned by ECM. If

not done, possible DTC's may be set.

(8) Use DRB scan tool to erase any stored compan-

ion DTC's from PCM.

Fig. 16 Engine Control Module (ECM) Location and

Mounting

1 - ENGINE CONTROL MODULE (ECM)

2 - HEX HEADED BOLT

3 - 50-WAY CONNECTOR

4 - FUEL TRANSFER PUMP

5 - MOUNTING BOLTS (3)

8E - 14 ELECTRONIC CONTROL MODULESBR/BE

ENGINE CONTROL MODULE (Continued)

Page 515 of 2255

INDICATOR DOES NOT ILLUMINATE WITH WASHER

RESERVOIR EMPTY

(1) Disconnect and isolate the battery negative

cable. Disconnect the headlamp and dash wire har-

ness connector for the washer fluid level switch from

the washer fluid level switch connector receptacle.

Check for continuity between the ground circuit cav-

ity of the headlamp and dash wire harness connector

for the washer fluid level switch and a good ground.

There should be continuity. If OK, go to Step 2. If not

OK, repair the open ground circuit to ground (G100)

as required.

(2) Remove the instrument cluster from the instru-

ment panel. Check for continuity between the washer

fluid switch sense circuit cavities of the headlamp

and dash wire harness connector for the washer fluid

level switch and the instrument panel wire harness

connector (Connector C2) for the instrument cluster.

If OK, replace the faulty washer fluid level switch. If

not OK, repair the open washer fluid switch sense

circuit between the washer fluid level switch and the

instrument cluster as required.

INDICATOR STAYS ILLUMINATED WITH WASHER

RESERVOIR FULL

(1) Disconnect and isolate the battery negative

cable. Disconnect the headlamp and dash wire har-

ness connector for the washer fluid level switch from

the washer fluid level switch connector receptacle.

Check for continuity between the ground circuit ter-

minal and the washer fluid switch sense terminal in

the washer fluid level switch connector receptacle.

There should be no continuity. If OK, go to Step 2. If

not OK, replace the faulty washer fluid level switch.

(2) Remove the instrument cluster from the instru-

ment panel. Check for continuity between the washer

fluid switch sense circuit cavity of the headlamp and

dash wire harness connector for the washer fluid

level switch and a good ground. There should be no

continuity. If not OK, repair the shorted washer fluid

switch sense circuit between the washer fluid level

switch and the instrument cluster as required.

WATER-IN-FUEL INDICATOR

DESCRIPTION

A water-in-fuel indicator is standard equipment on

all instrument clusters, but is only functional in vehi-

cles equipped with an optional diesel engine. The

water-in-fuel indicator is located near the lower edge

of the instrument cluster overlay, to the left of center.

The water-in-fuel indicator consists of a stencilled

cutout of the text ªWATER IN FUELº in the opaque

layer of the instrument cluster overlay. The dark

outer layer of the overlay prevents the indicator from

being clearly visible when it is not illuminated. A redlens located behind the cutout causes the ªWATER

IN FUELº text to appear in red through the translu-

cent outer layer of the overlay when the indicator is

illuminated from behind by a Light Emitting Diode

(LED) soldered onto the instrument cluster electronic

circuit board. The water-in-fuel indicator is serviced

as a unit with the instrument cluster.

OPERATION

The water-in-fuel indicator gives an indication to

the vehicle operator when the water accumulated in

the diesel engine fuel filter/separator filter bowl

requires draining. This indicator is controlled by a

transistor on the instrument cluster circuit board

based upon cluster programming and electronic mes-

sages received by the cluster from the Engine Control

Module (ECM) over the Chrysler Collision Detection

(CCD) data bus. The water-in-fuel indicator Light

Emitting Diode (LED) receives battery current on the

instrument cluster electronic circuit board through

the fused ignition switch output (st-run) circuit

whenever the ignition switch is in the On or Start

positions; therefore, the indicator will always be off

when the ignition switch is in any position except On

or Start. The LED only illuminates when it is

switched to ground by the instrument cluster transis-

tor. The instrument cluster will turn on the water-in-

fuel indicator for the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the indicator is illuminated

for about two seconds as a bulb test.

²Water-In-Fuel Lamp-On Message- Each time

the cluster receives a water-in-fuel lamp-on message

from the ECM, the indicator will be illuminated. The

indicator remains illuminated until the cluster

receives a water-in-fuel lamp-off message from the

ECM or until the ignition switch is turned to the Off

position, whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the indicator will be

turned on during the bulb check portion of the test to

confirm the functionality of the LED and the cluster

control circuitry.

The ECM continually monitors the water-in-fuel

sensor, then sends the proper messages to the instru-

ment cluster. For further diagnosis of the water-in-

fuel indicator or the instrument cluster circuitry that

controls the indicator, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND TEST-

ING). For proper diagnosis of the water-in-fuel

sensor, the ECM, the CCD data bus, or the message

inputs to the instrument cluster that control the

water-in-fuel indicator, a DRBIIItscan tool is

required. Refer to the appropriate diagnostic

information.

8J - 36 INSTRUMENT CLUSTERBR/BE

WASHER FLUID INDICATOR (Continued)

Page 1021 of 2255

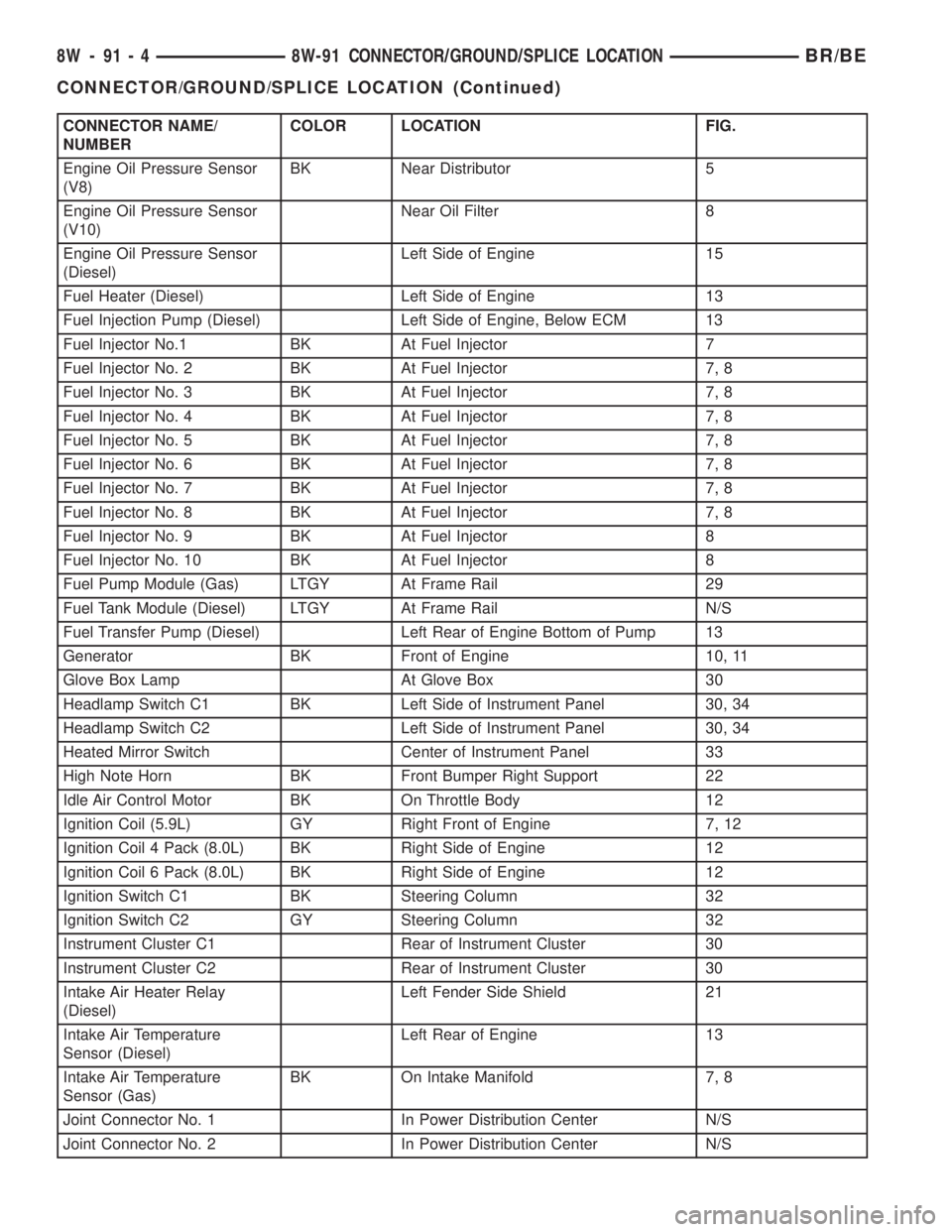

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Engine Oil Pressure Sensor

(V8)BK Near Distributor 5

Engine Oil Pressure Sensor

(V10)Near Oil Filter 8

Engine Oil Pressure Sensor

(Diesel)Left Side of Engine 15

Fuel Heater (Diesel) Left Side of Engine 13

Fuel Injection Pump (Diesel) Left Side of Engine, Below ECM 13

Fuel Injector No.1 BK At Fuel Injector 7

Fuel Injector No. 2 BK At Fuel Injector 7, 8

Fuel Injector No. 3 BK At Fuel Injector 7, 8

Fuel Injector No. 4 BK At Fuel Injector 7, 8

Fuel Injector No. 5 BK At Fuel Injector 7, 8

Fuel Injector No. 6 BK At Fuel Injector 7, 8

Fuel Injector No. 7 BK At Fuel Injector 7, 8

Fuel Injector No. 8 BK At Fuel Injector 7, 8

Fuel Injector No. 9 BK At Fuel Injector 8

Fuel Injector No. 10 BK At Fuel Injector 8

Fuel Pump Module (Gas) LTGY At Frame Rail 29

Fuel Tank Module (Diesel) LTGY At Frame Rail N/S

Fuel Transfer Pump (Diesel) Left Rear of Engine Bottom of Pump 13

Generator BK Front of Engine 10, 11

Glove Box Lamp At Glove Box 30

Headlamp Switch C1 BK Left Side of Instrument Panel 30, 34

Headlamp Switch C2 Left Side of Instrument Panel 30, 34

Heated Mirror Switch Center of Instrument Panel 33

High Note Horn BK Front Bumper Right Support 22

Idle Air Control Motor BK On Throttle Body 12

Ignition Coil (5.9L) GY Right Front of Engine 7, 12

Ignition Coil 4 Pack (8.0L) BK Right Side of Engine 12

Ignition Coil 6 Pack (8.0L) BK Right Side of Engine 12

Ignition Switch C1 BK Steering Column 32

Ignition Switch C2 GY Steering Column 32

Instrument Cluster C1 Rear of Instrument Cluster 30

Instrument Cluster C2 Rear of Instrument Cluster 30

Intake Air Heater Relay

(Diesel)Left Fender Side Shield 21

Intake Air Temperature

Sensor (Diesel)Left Rear of Engine 13

Intake Air Temperature

Sensor (Gas)BK On Intake Manifold 7, 8

Joint Connector No. 1 In Power Distribution Center N/S

Joint Connector No. 2 In Power Distribution Center N/S

8W - 91 - 4 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONBR/BE

CONNECTOR/GROUND/SPLICE LOCATION (Continued)