lumbar support DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 583 of 2255

POWER SEAT SYSTEM

TABLE OF CONTENTS

page page

POWER SEAT SYSTEM

DESCRIPTION.........................16

OPERATION...........................16

DIAGNOSIS AND TESTING - POWER SEAT

SYSTEM............................16

DRIVER POWER SEAT SWITCH

DESCRIPTION.........................17

OPERATION...........................17

DIAGNOSIS AND TESTING - DRIVER POWER

SEAT SWITCH........................17

REMOVAL.............................18

INSTALLATION.........................18

LUMBAR CONTROL SWITCH

DESCRIPTION.........................18

OPERATION...........................19

REMOVAL.............................19

LUMBAR MOTOR

DESCRIPTION.........................19OPERATION...........................19

DIAGNOSIS AND TESTING - LUMBAR MOTOR . 19

PASSENGER POWER SEAT SWITCH

DESCRIPTION.........................20

OPERATION...........................20

DIAGNOSIS AND TESTING - PASSENGER

POWER SEAT SWITCH.................20

REMOVAL.............................21

INSTALLATION.........................21

POWER SEAT TRACK

DESCRIPTION.........................21

OPERATION...........................22

DIAGNOSIS AND TESTING - POWER SEAT

TRACK.............................22

REMOVAL.............................22

INSTALLATION.........................22

POWER SEAT SYSTEM

DESCRIPTION

The power seat system option allows the driver (or

passenger on SLT Plus with power seats) to electri-

cally adjust the seat position for optimum control and

comfort using the power seat switches located on the

outboard seat cushion side shield. The power seat

system allows the seating position to be adjusted for-

ward, rearward, front up, front down, rear up, or

rear down. The power seat system receives battery

current through a fuse in the Power Distribution

Center and a circuit breaker in the junction block,

regardless of the ignition switch position.

The quad cab models equipped with the power seat

option also feature a power operated lumbar support

in the seat back. The power lumbar support allows

the user to inflate or deflate a bladder located in the

lower seat back to achieve optimum comfort and sup-

port in the lower lumbar region of the spinal column.

The power lumbar support shares the battery feed

circuit of the power seat system.

The power seat system includes the power seat

adjuster and motors unit, the power lumbar support

bladder and electric pump (quad cab only), the power

seat switch, and the circuit breaker. Following are

general descriptions of the major components in the

power seat system. Refer toHeated Seat Systemfor information on the individually controlled heated

front seats. Refer to the owner's manual in the vehi-

cle glove box for more information on the features,

use and operation of the power seat system.

OPERATION

The power seat system allows the driver and/or

front passenger seating positions to be adjusted elec-

trically and independently using the separate power

seat switches found on the outboard seat cushion

side shield of each front seat. See the owner's manual

in the vehicle glove box for more information on the

features, use and operation of the power seat system.

DIAGNOSIS AND TESTING - POWER SEAT

SYSTEM

Before any testing of the power seat system is

attempted, the battery should be fully-charged and

all wire harness connections and pins cleaned and

tightened to ensure proper continuity and grounds.

For circuit descriptions and diagrams, refer to Wiring

Diagrams.

With the dome lamp on, apply the power seat

switch in the direction of the failure. If the dome

lamp dims, the seat may be jamming. Check under

and behind the seat for binding or obstructions. If

the dome lamp does not dim, proceed with testing of

the individual components and circuits.

8N - 16 POWER SEAT SYSTEMBR/BE

Page 584 of 2255

DRIVER POWER SEAT SWITCH

DESCRIPTION

The power seat in standard cab models can be

adjusted in eight different directions, up, down, front

up, front down, rear up, rear down, rearward and for-

ward. The power seat switch for quad cab models has

an additional switch knob for adjusting the power

lumbar support. The switch is located on the lower

outboard side of the seat cushion on the seat cushion

side shield (Fig. 1) on all models. Refer to the owner's

manual in the vehicle glove box for more information

on the power seat switch functions and the seat

adjusting procedures.

The individual switches in the power seat switch

module cannot be repaired. If one switch is damaged

or faulty, the entire power seat switch module must

be replaced.

OPERATION

When a power switch control knob or knobs are

actuated, a battery feed and a ground path are

applied through the switch contacts to the power seat

track or recliner adjuster motor. The selected

adjuster motor operates to move the seat track or

recliner through its drive unit in the selected direc-

tion until the switch is released, or until the travel

limit of the adjuster is reached. When the switch is

moved in the opposite direction, the battery feed and

ground path to the motor are reversed through the

switch contacts. This causes the adjuster motor to

run in the opposite direction.No power seat switch should be held applied in any

direction after the adjuster has reached its travel

limit. The power seat adjuster motors each contain a

self-resetting circuit breaker to protect them from

overload. However, consecutive or frequent resetting

of the circuit breaker must not be allowed to con-

tinue, or the motor may be damaged.

DIAGNOSIS AND TESTING - DRIVER POWER

SEAT SWITCH

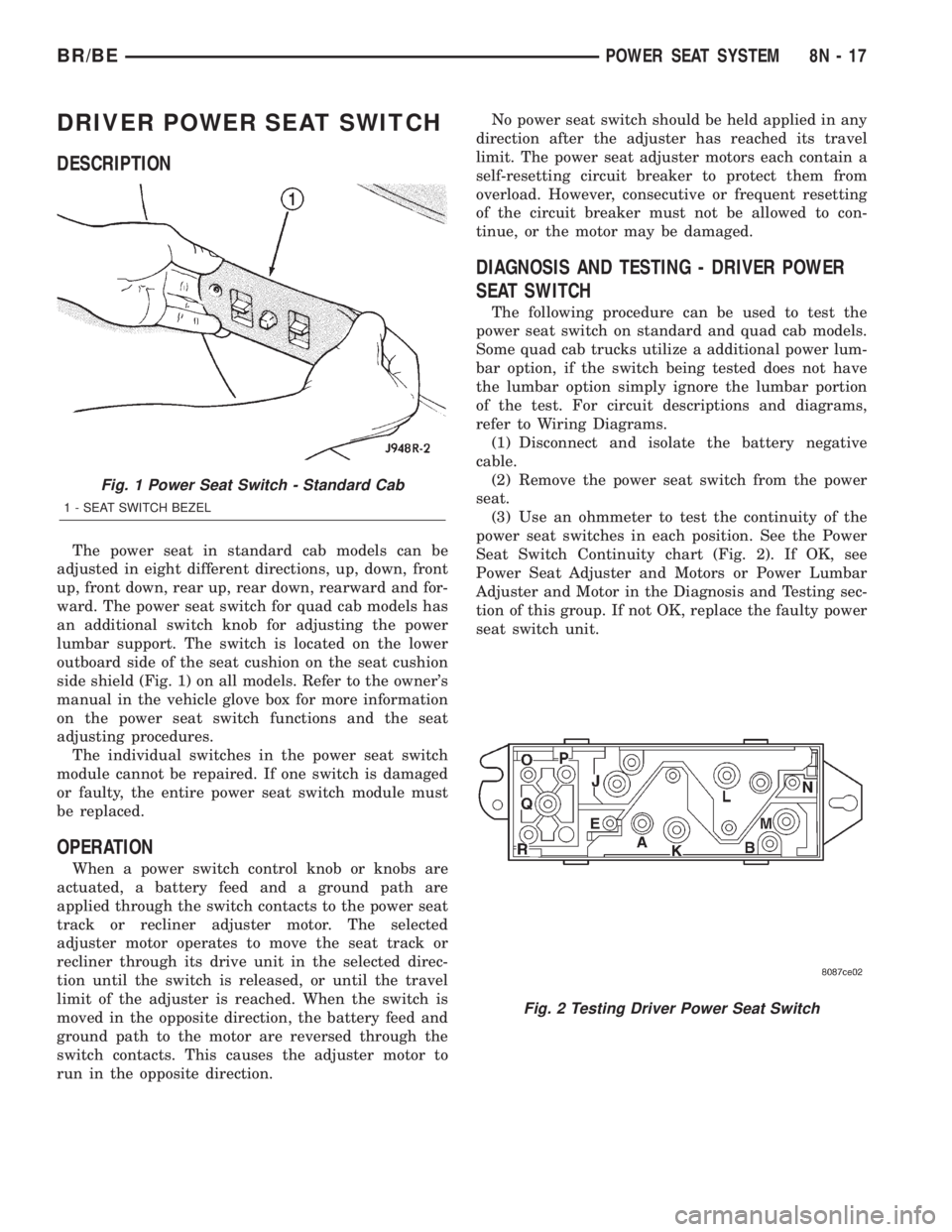

The following procedure can be used to test the

power seat switch on standard and quad cab models.

Some quad cab trucks utilize a additional power lum-

bar option, if the switch being tested does not have

the lumbar option simply ignore the lumbar portion

of the test. For circuit descriptions and diagrams,

refer to Wiring Diagrams.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the power seat switch from the power

seat.

(3) Use an ohmmeter to test the continuity of the

power seat switches in each position. See the Power

Seat Switch Continuity chart (Fig. 2). If OK, see

Power Seat Adjuster and Motors or Power Lumbar

Adjuster and Motor in the Diagnosis and Testing sec-

tion of this group. If not OK, replace the faulty power

seat switch unit.

Fig. 1 Power Seat Switch - Standard Cab

1 - SEAT SWITCH BEZEL

Fig. 2 Testing Driver Power Seat Switch

BR/BEPOWER SEAT SYSTEM 8N - 17

Page 585 of 2255

DRIVER POWER SEAT SWITCH TEST TABLE

DRIVER SWITCH

POSITIONCONTINUITY BETWEEN

OFF B-N, B-J, B-M

B-E, B-L, B-K

VERTICAL UP A-E, A-M, B-N, B-E

VERTICAL DOWN A-J, A-N, B-M, B-E

HORIZONTAL

FORWARDA-L, B-K

HORIZONTAL

REARWARDA-K, B-L

FRONT TILT UP A-M, B-N

FRONT TILT DOWN A-N, B-M

REAR TILT UP A-E, B-J

REAR TILT DOWN A-J, B-E

LUMBAR OFF O-P, O-R, P-R

LUMPAR UP (INFLATE) O-P, Q-R

LUMBAR DOWN

(DEFLATE)O-R, P-Q

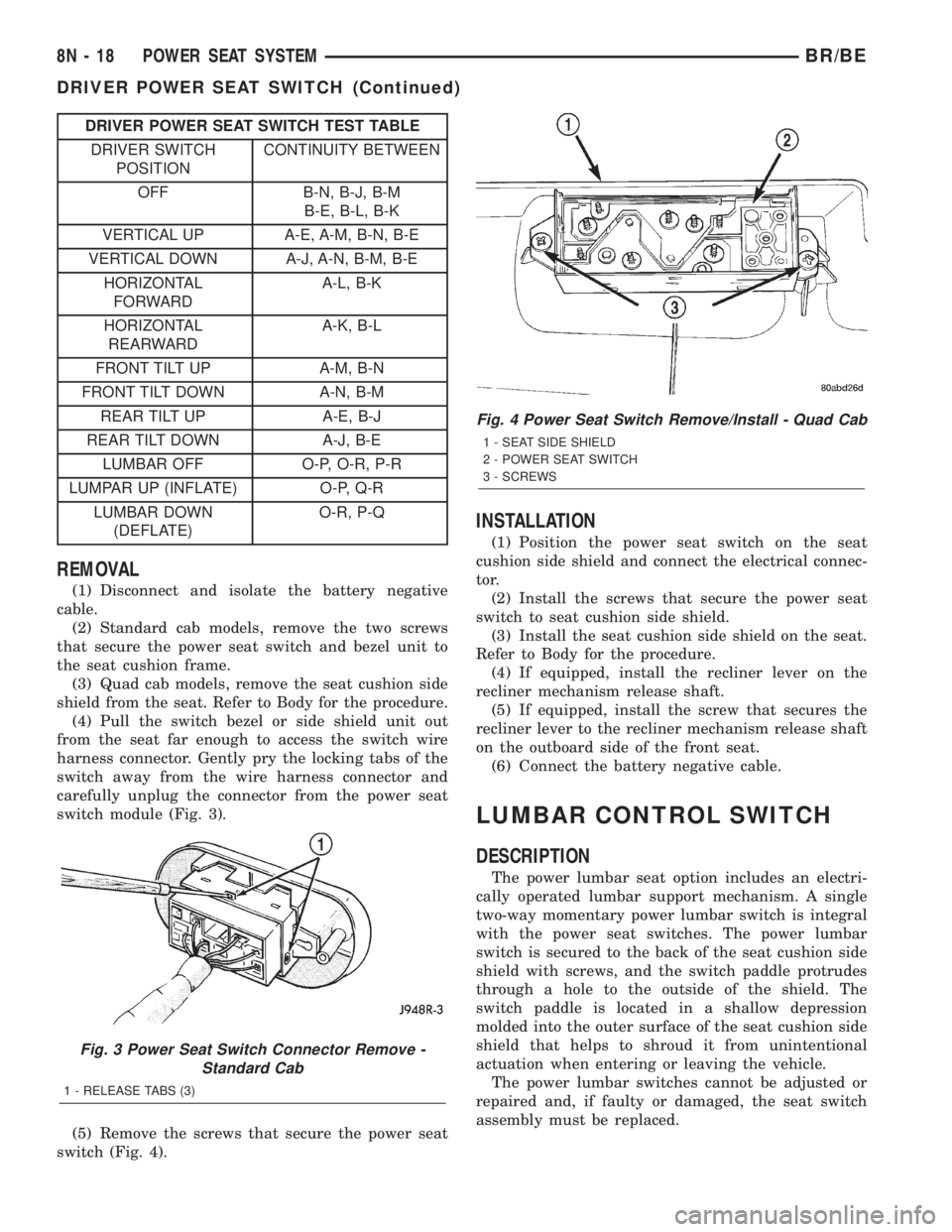

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Standard cab models, remove the two screws

that secure the power seat switch and bezel unit to

the seat cushion frame.

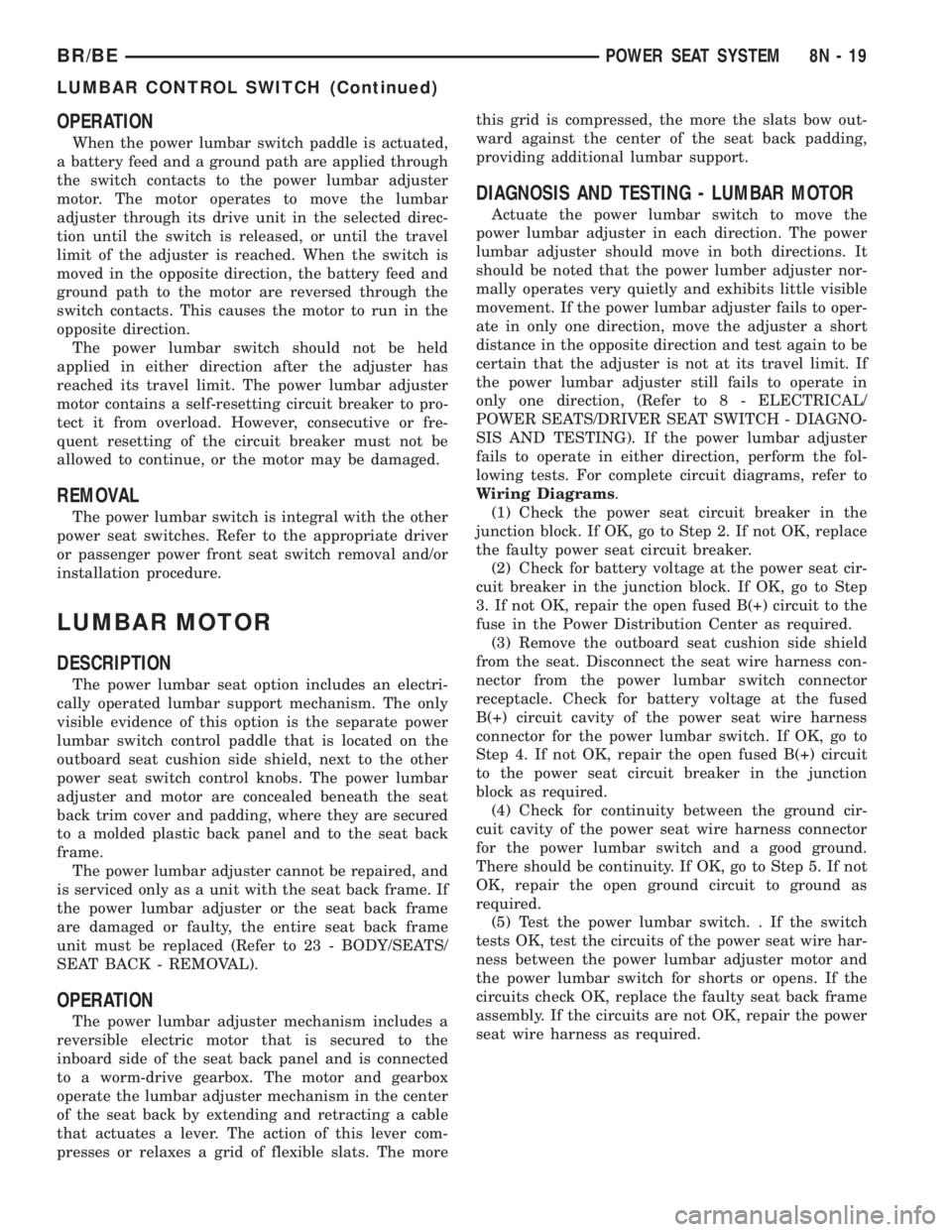

(3) Quad cab models, remove the seat cushion side

shield from the seat. Refer to Body for the procedure.

(4) Pull the switch bezel or side shield unit out

from the seat far enough to access the switch wire

harness connector. Gently pry the locking tabs of the

switch away from the wire harness connector and

carefully unplug the connector from the power seat

switch module (Fig. 3).

(5) Remove the screws that secure the power seat

switch (Fig. 4).

INSTALLATION

(1) Position the power seat switch on the seat

cushion side shield and connect the electrical connec-

tor.

(2) Install the screws that secure the power seat

switch to seat cushion side shield.

(3) Install the seat cushion side shield on the seat.

Refer to Body for the procedure.

(4) If equipped, install the recliner lever on the

recliner mechanism release shaft.

(5) If equipped, install the screw that secures the

recliner lever to the recliner mechanism release shaft

on the outboard side of the front seat.

(6) Connect the battery negative cable.

LUMBAR CONTROL SWITCH

DESCRIPTION

The power lumbar seat option includes an electri-

cally operated lumbar support mechanism. A single

two-way momentary power lumbar switch is integral

with the power seat switches. The power lumbar

switch is secured to the back of the seat cushion side

shield with screws, and the switch paddle protrudes

through a hole to the outside of the shield. The

switch paddle is located in a shallow depression

molded into the outer surface of the seat cushion side

shield that helps to shroud it from unintentional

actuation when entering or leaving the vehicle.

The power lumbar switches cannot be adjusted or

repaired and, if faulty or damaged, the seat switch

assembly must be replaced.

Fig. 3 Power Seat Switch Connector Remove -

Standard Cab

1 - RELEASE TABS (3)

Fig. 4 Power Seat Switch Remove/Install - Quad Cab

1 - SEAT SIDE SHIELD

2 - POWER SEAT SWITCH

3 - SCREWS

8N - 18 POWER SEAT SYSTEMBR/BE

DRIVER POWER SEAT SWITCH (Continued)

Page 586 of 2255

OPERATION

When the power lumbar switch paddle is actuated,

a battery feed and a ground path are applied through

the switch contacts to the power lumbar adjuster

motor. The motor operates to move the lumbar

adjuster through its drive unit in the selected direc-

tion until the switch is released, or until the travel

limit of the adjuster is reached. When the switch is

moved in the opposite direction, the battery feed and

ground path to the motor are reversed through the

switch contacts. This causes the motor to run in the

opposite direction.

The power lumbar switch should not be held

applied in either direction after the adjuster has

reached its travel limit. The power lumbar adjuster

motor contains a self-resetting circuit breaker to pro-

tect it from overload. However, consecutive or fre-

quent resetting of the circuit breaker must not be

allowed to continue, or the motor may be damaged.

REMOVAL

The power lumbar switch is integral with the other

power seat switches. Refer to the appropriate driver

or passenger power front seat switch removal and/or

installation procedure.

LUMBAR MOTOR

DESCRIPTION

The power lumbar seat option includes an electri-

cally operated lumbar support mechanism. The only

visible evidence of this option is the separate power

lumbar switch control paddle that is located on the

outboard seat cushion side shield, next to the other

power seat switch control knobs. The power lumbar

adjuster and motor are concealed beneath the seat

back trim cover and padding, where they are secured

to a molded plastic back panel and to the seat back

frame.

The power lumbar adjuster cannot be repaired, and

is serviced only as a unit with the seat back frame. If

the power lumbar adjuster or the seat back frame

are damaged or faulty, the entire seat back frame

unit must be replaced (Refer to 23 - BODY/SEATS/

SEAT BACK - REMOVAL).

OPERATION

The power lumbar adjuster mechanism includes a

reversible electric motor that is secured to the

inboard side of the seat back panel and is connected

to a worm-drive gearbox. The motor and gearbox

operate the lumbar adjuster mechanism in the center

of the seat back by extending and retracting a cable

that actuates a lever. The action of this lever com-

presses or relaxes a grid of flexible slats. The morethis grid is compressed, the more the slats bow out-

ward against the center of the seat back padding,

providing additional lumbar support.

DIAGNOSIS AND TESTING - LUMBAR MOTOR

Actuate the power lumbar switch to move the

power lumbar adjuster in each direction. The power

lumbar adjuster should move in both directions. It

should be noted that the power lumber adjuster nor-

mally operates very quietly and exhibits little visible

movement. If the power lumbar adjuster fails to oper-

ate in only one direction, move the adjuster a short

distance in the opposite direction and test again to be

certain that the adjuster is not at its travel limit. If

the power lumbar adjuster still fails to operate in

only one direction, (Refer to 8 - ELECTRICAL/

POWER SEATS/DRIVER SEAT SWITCH - DIAGNO-

SIS AND TESTING). If the power lumbar adjuster

fails to operate in either direction, perform the fol-

lowing tests. For complete circuit diagrams, refer to

Wiring Diagrams.

(1) Check the power seat circuit breaker in the

junction block. If OK, go to Step 2. If not OK, replace

the faulty power seat circuit breaker.

(2) Check for battery voltage at the power seat cir-

cuit breaker in the junction block. If OK, go to Step

3. If not OK, repair the open fused B(+) circuit to the

fuse in the Power Distribution Center as required.

(3) Remove the outboard seat cushion side shield

from the seat. Disconnect the seat wire harness con-

nector from the power lumbar switch connector

receptacle. Check for battery voltage at the fused

B(+) circuit cavity of the power seat wire harness

connector for the power lumbar switch. If OK, go to

Step 4. If not OK, repair the open fused B(+) circuit

to the power seat circuit breaker in the junction

block as required.

(4) Check for continuity between the ground cir-

cuit cavity of the power seat wire harness connector

for the power lumbar switch and a good ground.

There should be continuity. If OK, go to Step 5. If not

OK, repair the open ground circuit to ground as

required.

(5) Test the power lumbar switch. . If the switch

tests OK, test the circuits of the power seat wire har-

ness between the power lumbar adjuster motor and

the power lumbar switch for shorts or opens. If the

circuits check OK, replace the faulty seat back frame

assembly. If the circuits are not OK, repair the power

seat wire harness as required.

BR/BEPOWER SEAT SYSTEM 8N - 19

LUMBAR CONTROL SWITCH (Continued)

Page 587 of 2255

PASSENGER POWER SEAT

SWITCH

DESCRIPTION

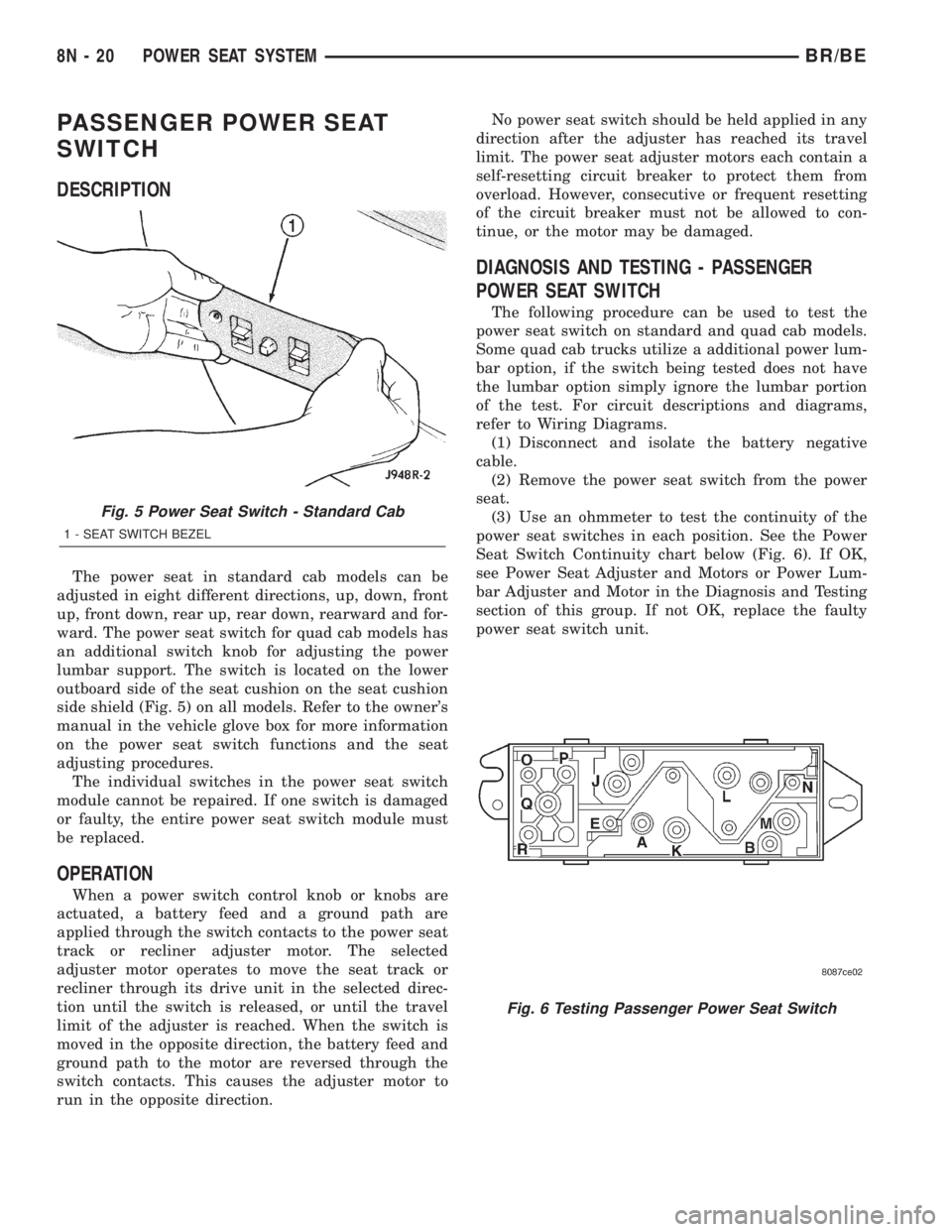

The power seat in standard cab models can be

adjusted in eight different directions, up, down, front

up, front down, rear up, rear down, rearward and for-

ward. The power seat switch for quad cab models has

an additional switch knob for adjusting the power

lumbar support. The switch is located on the lower

outboard side of the seat cushion on the seat cushion

side shield (Fig. 5) on all models. Refer to the owner's

manual in the vehicle glove box for more information

on the power seat switch functions and the seat

adjusting procedures.

The individual switches in the power seat switch

module cannot be repaired. If one switch is damaged

or faulty, the entire power seat switch module must

be replaced.

OPERATION

When a power switch control knob or knobs are

actuated, a battery feed and a ground path are

applied through the switch contacts to the power seat

track or recliner adjuster motor. The selected

adjuster motor operates to move the seat track or

recliner through its drive unit in the selected direc-

tion until the switch is released, or until the travel

limit of the adjuster is reached. When the switch is

moved in the opposite direction, the battery feed and

ground path to the motor are reversed through the

switch contacts. This causes the adjuster motor to

run in the opposite direction.No power seat switch should be held applied in any

direction after the adjuster has reached its travel

limit. The power seat adjuster motors each contain a

self-resetting circuit breaker to protect them from

overload. However, consecutive or frequent resetting

of the circuit breaker must not be allowed to con-

tinue, or the motor may be damaged.

DIAGNOSIS AND TESTING - PASSENGER

POWER SEAT SWITCH

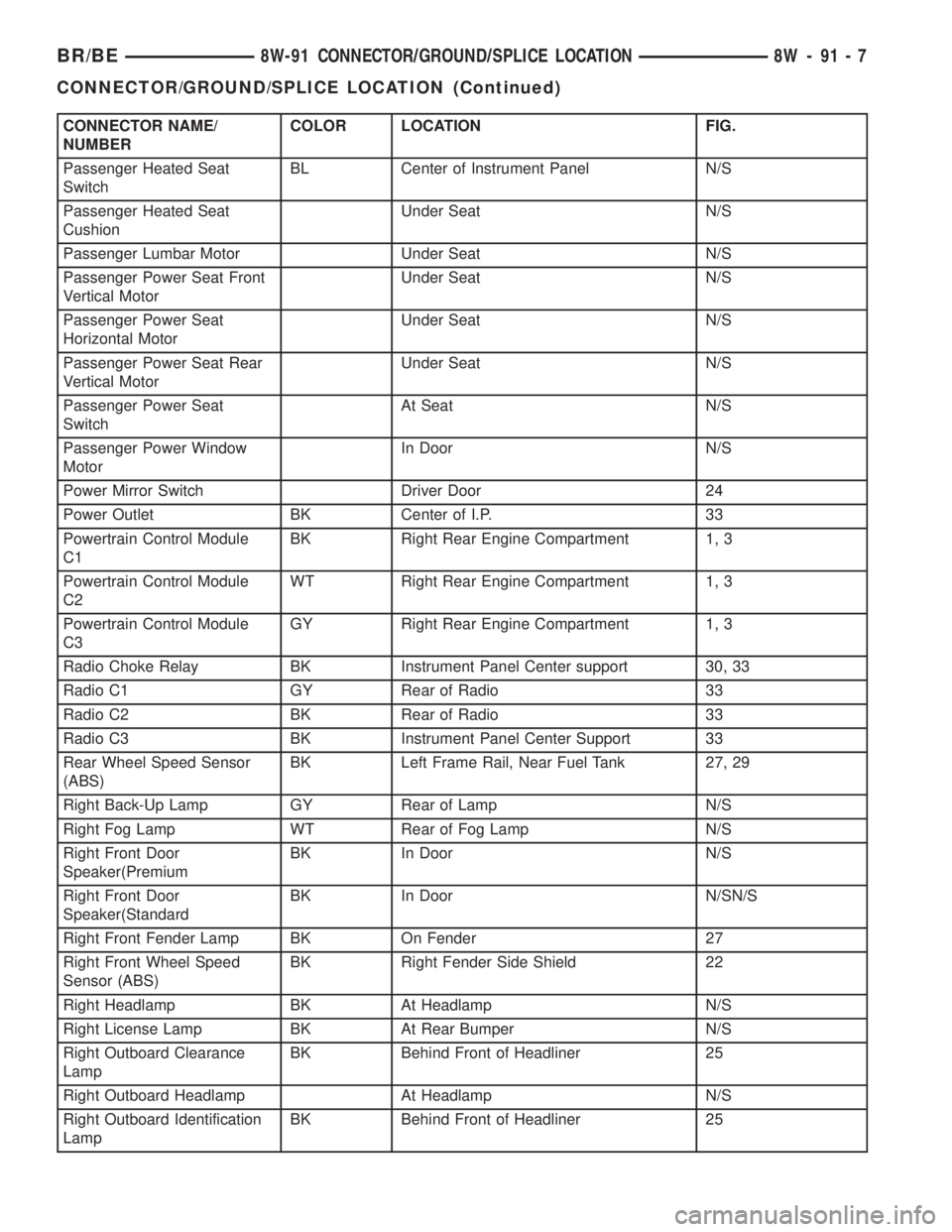

The following procedure can be used to test the

power seat switch on standard and quad cab models.

Some quad cab trucks utilize a additional power lum-

bar option, if the switch being tested does not have

the lumbar option simply ignore the lumbar portion

of the test. For circuit descriptions and diagrams,

refer to Wiring Diagrams.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the power seat switch from the power

seat.

(3) Use an ohmmeter to test the continuity of the

power seat switches in each position. See the Power

Seat Switch Continuity chart below (Fig. 6). If OK,

see Power Seat Adjuster and Motors or Power Lum-

bar Adjuster and Motor in the Diagnosis and Testing

section of this group. If not OK, replace the faulty

power seat switch unit.

Fig. 5 Power Seat Switch - Standard Cab

1 - SEAT SWITCH BEZEL

Fig. 6 Testing Passenger Power Seat Switch

8N - 20 POWER SEAT SYSTEMBR/BE

Page 1024 of 2255

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Passenger Heated Seat

SwitchBL Center of Instrument Panel N/S

Passenger Heated Seat

CushionUnder Seat N/S

Passenger Lumbar Motor Under Seat N/S

Passenger Power Seat Front

Vertical MotorUnder Seat N/S

Passenger Power Seat

Horizontal MotorUnder Seat N/S

Passenger Power Seat Rear

Vertical MotorUnder Seat N/S

Passenger Power Seat

SwitchAt Seat N/S

Passenger Power Window

MotorIn Door N/S

Power Mirror Switch Driver Door 24

Power Outlet BK Center of I.P. 33

Powertrain Control Module

C1BK Right Rear Engine Compartment 1, 3

Powertrain Control Module

C2WT Right Rear Engine Compartment 1, 3

Powertrain Control Module

C3GY Right Rear Engine Compartment 1, 3

Radio Choke Relay BK Instrument Panel Center support 30, 33

Radio C1 GY Rear of Radio 33

Radio C2 BK Rear of Radio 33

Radio C3 BK Instrument Panel Center Support 33

Rear Wheel Speed Sensor

(ABS)BK Left Frame Rail, Near Fuel Tank 27, 29

Right Back-Up Lamp GY Rear of Lamp N/S

Right Fog Lamp WT Rear of Fog Lamp N/S

Right Front Door

Speaker(PremiumBK In Door N/S

Right Front Door

Speaker(StandardBK In Door N/SN/S

Right Front Fender Lamp BK On Fender 27

Right Front Wheel Speed

Sensor (ABS)BK Right Fender Side Shield 22

Right Headlamp BK At Headlamp N/S

Right License Lamp BK At Rear Bumper N/S

Right Outboard Clearance

LampBK Behind Front of Headliner 25

Right Outboard Headlamp At Headlamp N/S

Right Outboard Identification

LampBK Behind Front of Headliner 25

BR/BE8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 7

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 2098 of 2255

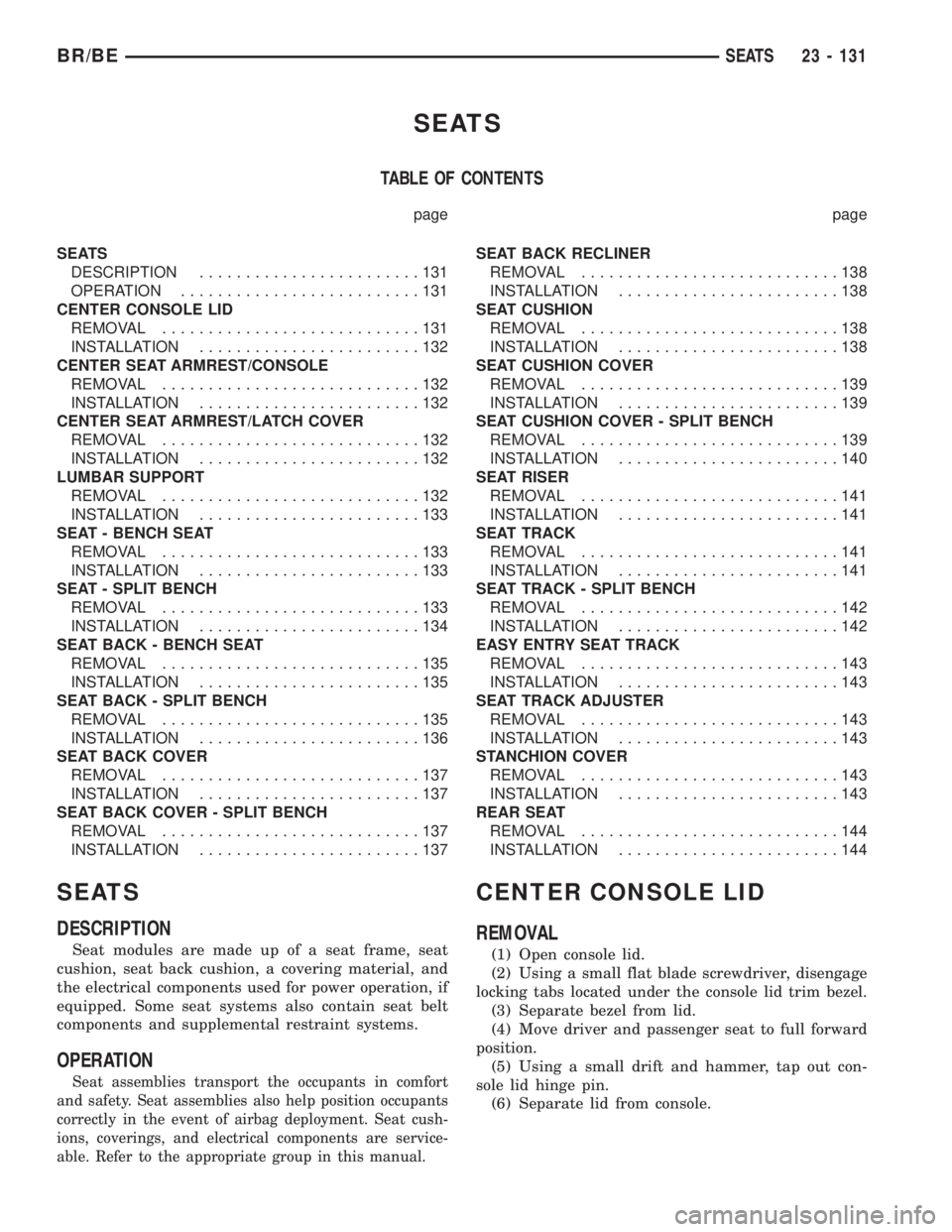

SEATS

TABLE OF CONTENTS

page page

SEATS

DESCRIPTION........................131

OPERATION..........................131

CENTER CONSOLE LID

REMOVAL............................131

INSTALLATION........................132

CENTER SEAT ARMREST/CONSOLE

REMOVAL............................132

INSTALLATION........................132

CENTER SEAT ARMREST/LATCH COVER

REMOVAL............................132

INSTALLATION........................132

LUMBAR SUPPORT

REMOVAL............................132

INSTALLATION........................133

SEAT - BENCH SEAT

REMOVAL............................133

INSTALLATION........................133

SEAT - SPLIT BENCH

REMOVAL............................133

INSTALLATION........................134

SEAT BACK - BENCH SEAT

REMOVAL............................135

INSTALLATION........................135

SEAT BACK - SPLIT BENCH

REMOVAL............................135

INSTALLATION........................136

SEAT BACK COVER

REMOVAL............................137

INSTALLATION........................137

SEAT BACK COVER - SPLIT BENCH

REMOVAL............................137

INSTALLATION........................137SEAT BACK RECLINER

REMOVAL............................138

INSTALLATION........................138

SEAT CUSHION

REMOVAL............................138

INSTALLATION........................138

SEAT CUSHION COVER

REMOVAL............................139

INSTALLATION........................139

SEAT CUSHION COVER - SPLIT BENCH

REMOVAL............................139

INSTALLATION........................140

SEAT RISER

REMOVAL............................141

INSTALLATION........................141

SEAT TRACK

REMOVAL............................141

INSTALLATION........................141

SEAT TRACK - SPLIT BENCH

REMOVAL............................142

INSTALLATION........................142

EASY ENTRY SEAT TRACK

REMOVAL............................143

INSTALLATION........................143

SEAT TRACK ADJUSTER

REMOVAL............................143

INSTALLATION........................143

STANCHION COVER

REMOVAL............................143

INSTALLATION........................143

REAR SEAT

REMOVAL............................144

INSTALLATION........................144

SEATS

DESCRIPTION

Seat modules are made up of a seat frame, seat

cushion, seat back cushion, a covering material, and

the electrical components used for power operation, if

equipped. Some seat systems also contain seat belt

components and supplemental restraint systems.

OPERATION

Seat assemblies transport the occupants in comfort

and safety. Seat assemblies also help position occupants

correctly in the event of airbag deployment. Seat cush-

ions, coverings, and electrical components are service-

able. Refer to the appropriate group in this manual.

CENTER CONSOLE LID

REMOVAL

(1) Open console lid.

(2) Using a small flat blade screwdriver, disengage

locking tabs located under the console lid trim bezel.

(3) Separate bezel from lid.

(4) Move driver and passenger seat to full forward

position.

(5) Using a small drift and hammer, tap out con-

sole lid hinge pin.

(6) Separate lid from console.

BR/BESEATS 23 - 131

Page 2099 of 2255

INSTALLATION

(1) Align console lid with console. Verify lid tension

spring is in position.

(2) Install hinge pin.

(3) Position trim bezel on lid and snap into place.

CENTER SEAT ARMREST/

CONSOLE

REMOVAL

(1) Remove bolts on driver and passenger seat

inboard seat tracks.

(2) Separate center section.

INSTALLATION

(1) Position and align center section on driver and

passenger seat inboard seat tracks.

(2) Install bolts. Tighten to 19.5 N´m (14 ft. lbs.)

torque.

CENTER SEAT ARMREST/

LATCH COVER

REMOVAL

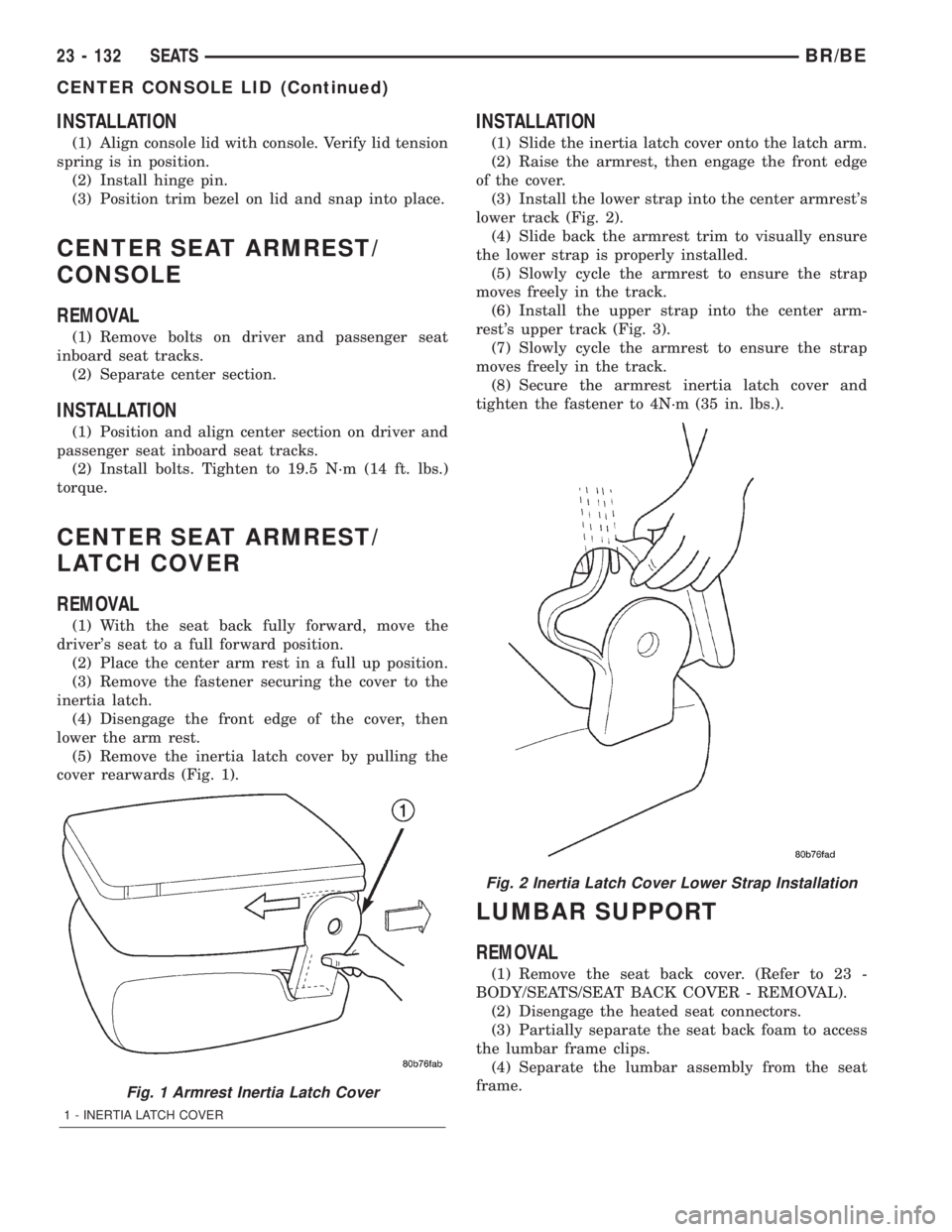

(1) With the seat back fully forward, move the

driver's seat to a full forward position.

(2) Place the center arm rest in a full up position.

(3) Remove the fastener securing the cover to the

inertia latch.

(4) Disengage the front edge of the cover, then

lower the arm rest.

(5) Remove the inertia latch cover by pulling the

cover rearwards (Fig. 1).

INSTALLATION

(1) Slide the inertia latch cover onto the latch arm.

(2) Raise the armrest, then engage the front edge

of the cover.

(3) Install the lower strap into the center armrest's

lower track (Fig. 2).

(4) Slide back the armrest trim to visually ensure

the lower strap is properly installed.

(5) Slowly cycle the armrest to ensure the strap

moves freely in the track.

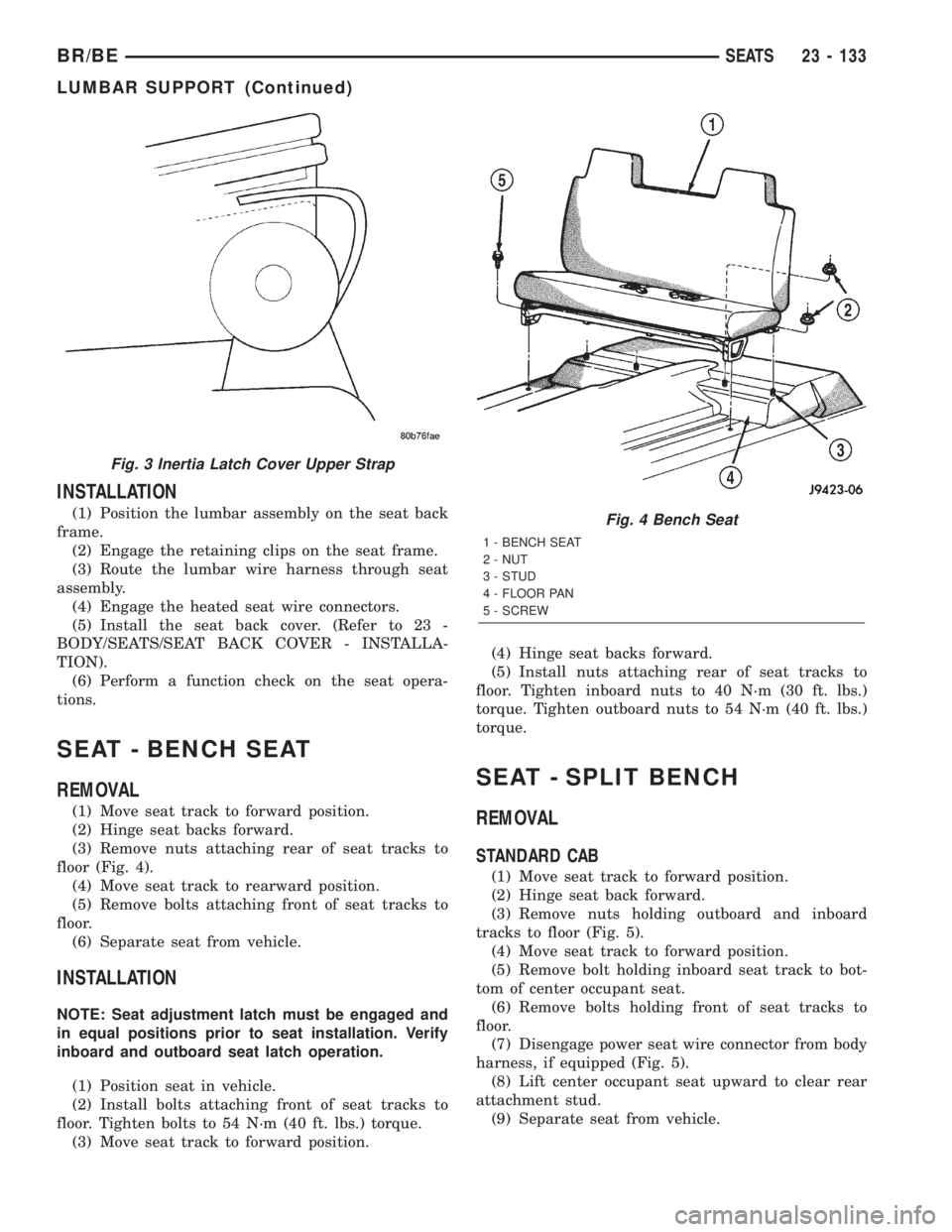

(6) Install the upper strap into the center arm-

rest's upper track (Fig. 3).

(7) Slowly cycle the armrest to ensure the strap

moves freely in the track.

(8) Secure the armrest inertia latch cover and

tighten the fastener to 4N´m (35 in. lbs.).

LUMBAR SUPPORT

REMOVAL

(1) Remove the seat back cover. (Refer to 23 -

BODY/SEATS/SEAT BACK COVER - REMOVAL).

(2) Disengage the heated seat connectors.

(3) Partially separate the seat back foam to access

the lumbar frame clips.

(4) Separate the lumbar assembly from the seat

frame.

Fig. 1 Armrest Inertia Latch Cover

1 - INERTIA LATCH COVER

Fig. 2 Inertia Latch Cover Lower Strap Installation

23 - 132 SEATSBR/BE

CENTER CONSOLE LID (Continued)

Page 2100 of 2255

INSTALLATION

(1) Position the lumbar assembly on the seat back

frame.

(2) Engage the retaining clips on the seat frame.

(3) Route the lumbar wire harness through seat

assembly.

(4) Engage the heated seat wire connectors.

(5) Install the seat back cover. (Refer to 23 -

BODY/SEATS/SEAT BACK COVER - INSTALLA-

TION).

(6) Perform a function check on the seat opera-

tions.

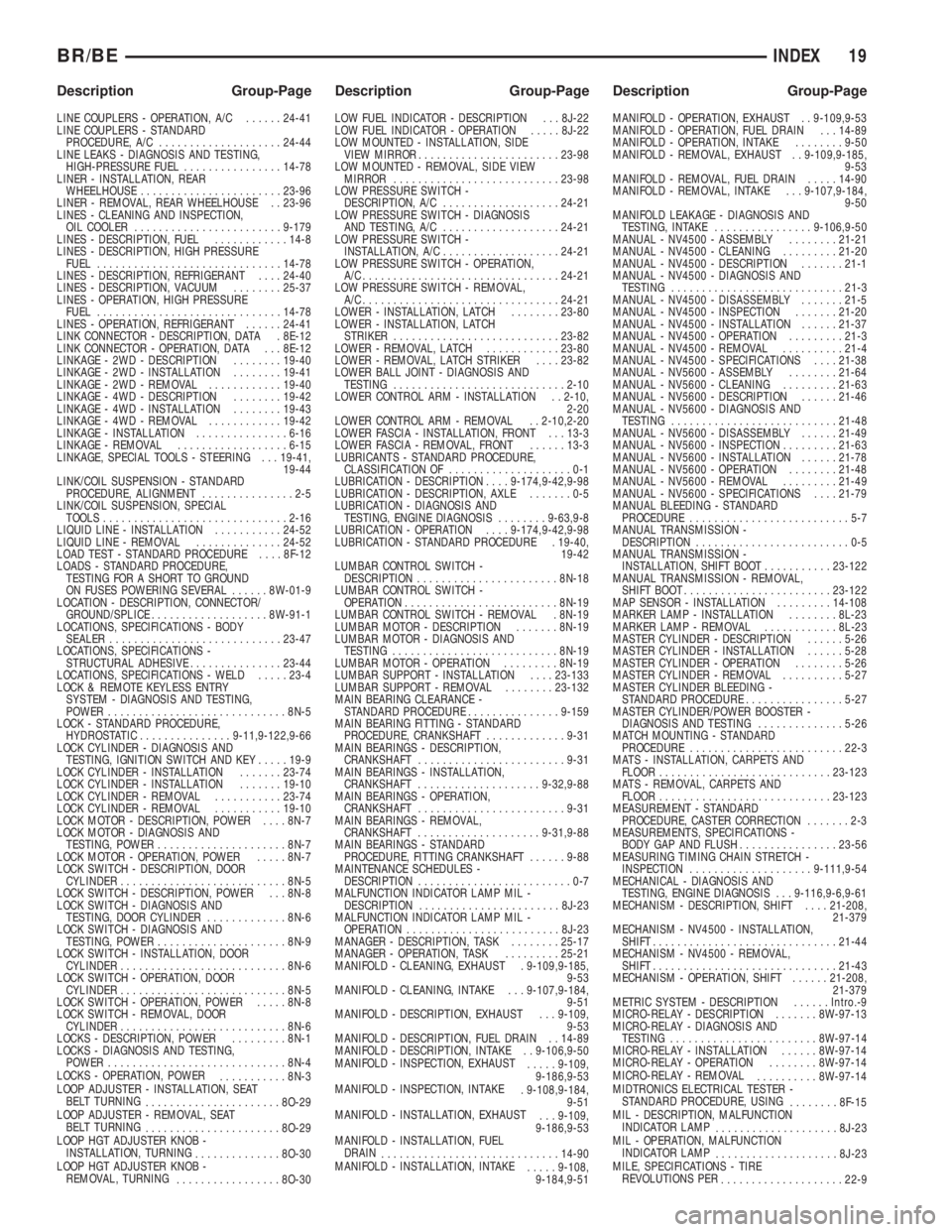

SEAT - BENCH SEAT

REMOVAL

(1) Move seat track to forward position.

(2) Hinge seat backs forward.

(3) Remove nuts attaching rear of seat tracks to

floor (Fig. 4).

(4) Move seat track to rearward position.

(5) Remove bolts attaching front of seat tracks to

floor.

(6) Separate seat from vehicle.

INSTALLATION

NOTE: Seat adjustment latch must be engaged and

in equal positions prior to seat installation. Verify

inboard and outboard seat latch operation.

(1) Position seat in vehicle.

(2) Install bolts attaching front of seat tracks to

floor. Tighten bolts to 54 N´m (40 ft. lbs.) torque.

(3) Move seat track to forward position.(4) Hinge seat backs forward.

(5) Install nuts attaching rear of seat tracks to

floor. Tighten inboard nuts to 40 N´m (30 ft. lbs.)

torque. Tighten outboard nuts to 54 N´m (40 ft. lbs.)

torque.

SEAT - SPLIT BENCH

REMOVAL

STANDARD CAB

(1) Move seat track to forward position.

(2) Hinge seat back forward.

(3) Remove nuts holding outboard and inboard

tracks to floor (Fig. 5).

(4) Move seat track to forward position.

(5) Remove bolt holding inboard seat track to bot-

tom of center occupant seat.

(6) Remove bolts holding front of seat tracks to

floor.

(7) Disengage power seat wire connector from body

harness, if equipped (Fig. 5).

(8) Lift center occupant seat upward to clear rear

attachment stud.

(9) Separate seat from vehicle.

Fig. 3 Inertia Latch Cover Upper Strap

Fig. 4 Bench Seat

1 - BENCH SEAT

2 - NUT

3 - STUD

4 - FLOOR PAN

5 - SCREW

BR/BESEATS 23 - 133

LUMBAR SUPPORT (Continued)

Page 2236 of 2255

LINE COUPLERS - OPERATION, A/C......24-41

LINE COUPLERS - STANDARD

PROCEDURE, A/C....................24-44

LINE LEAKS - DIAGNOSIS AND TESTING,

HIGH-PRESSURE FUEL................14-78

LINER - INSTALLATION, REAR

WHEELHOUSE.......................23-96

LINER - REMOVAL, REAR WHEELHOUSE . . 23-96

LINES - CLEANING AND INSPECTION,

OIL COOLER........................9-179

LINES - DESCRIPTION, FUEL............14-8

LINES - DESCRIPTION, HIGH PRESSURE

FUEL..............................14-78

LINES - DESCRIPTION, REFRIGERANT....24-40

LINES - DESCRIPTION, VACUUM........25-37

LINES - OPERATION, HIGH PRESSURE

FUEL..............................14-78

LINES - OPERATION, REFRIGERANT......24-41

LINK CONNECTOR - DESCRIPTION, DATA . 8E-12

LINK CONNECTOR - OPERATION, DATA . . . 8E-12

LINKAGE - 2WD - DESCRIPTION........19-40

LINKAGE - 2WD - INSTALLATION........19-41

LINKAGE - 2WD - REMOVAL............19-40

LINKAGE - 4WD - DESCRIPTION........19-42

LINKAGE - 4WD - INSTALLATION........19-43

LINKAGE - 4WD - REMOVAL............19-42

LINKAGE - INSTALLATION...............6-16

LINKAGE - REMOVAL..................6-15

LINKAGE, SPECIAL TOOLS - STEERING . . . 19-41,

19-44

LINK/COIL SUSPENSION - STANDARD

PROCEDURE, ALIGNMENT...............2-5

LINK/COIL SUSPENSION, SPECIAL

TOOLS..............................2-16

LIQUID LINE - INSTALLATION...........24-52

LIQUID LINE - REMOVAL..............24-52

LOAD TEST - STANDARD PROCEDURE....8F-12

LOADS - STANDARD PROCEDURE,

TESTING FOR A SHORT TO GROUND

ON FUSES POWERING SEVERAL......8W-01-9

LOCATION - DESCRIPTION, CONNECTOR/

GROUND/SPLICE...................8W-91-1

LOCATIONS, SPECIFICATIONS - BODY

SEALER............................23-47

LOCATIONS, SPECIFICATIONS -

STRUCTURAL ADHESIVE...............23-44

LOCATIONS, SPECIFICATIONS - WELD.....23-4

LOCK & REMOTE KEYLESS ENTRY

SYSTEM - DIAGNOSIS AND TESTING,

POWER.............................8N-5

LOCK - STANDARD PROCEDURE,

HYDROSTATIC...............9-11,9-122,9-66

LOCK CYLINDER - DIAGNOSIS AND

TESTING, IGNITION SWITCH AND KEY.....19-9

LOCK CYLINDER - INSTALLATION.......23-74

LOCK CYLINDER - INSTALLATION.......19-10

LOCK CYLINDER - REMOVAL...........23-74

LOCK CYLINDER - REMOVAL...........19-10

LOCK MOTOR - DESCRIPTION, POWER....8N-7

LOCK MOTOR - DIAGNOSIS AND

TESTING, POWER.....................8N-7

LOCK MOTOR - OPERATION, POWER.....8N-7

LOCK SWITCH - DESCRIPTION, DOOR

CYLINDER...........................8N-5

LOCK SWITCH - DESCRIPTION, POWER . . . 8N-8

LOCK SWITCH - DIAGNOSIS AND

TESTING, DOOR CYLINDER.............8N-6

LOCK SWITCH - DIAGNOSIS AND

TESTING, POWER.....................8N-9

LOCK SWITCH - INSTALLATION, DOOR

CYLINDER...........................8N-6

LOCK SWITCH - OPERATION, DOOR

CYLINDER...........................8N-5

LOCK SWITCH - OPERATION, POWER.....8N-8

LOCK SWITCH - REMOVAL, DOOR

CYLINDER...........................8N-6

LOCKS - DESCRIPTION, POWER.........8N-1

LOCKS - DIAGNOSIS AND TESTING,

POWER.............................8N-4

LOCKS - OPERATION, POWER

...........8N-3

LOOP ADJUSTER - INSTALLATION, SEAT

BELT TURNING

......................8O-29

LOOP ADJUSTER - REMOVAL, SEAT

BELT TURNING

......................8O-29

LOOP HGT ADJUSTER KNOB -

INSTALLATION, TURNING

..............8O-30

LOOP HGT ADJUSTER KNOB -

REMOVAL, TURNING

.................8O-30LOW FUEL INDICATOR - DESCRIPTION . . . 8J-22

LOW FUEL INDICATOR - OPERATION.....8J-22

LOW MOUNTED - INSTALLATION, SIDE

VIEW MIRROR.......................23-98

LOW MOUNTED - REMOVAL, SIDE VIEW

MIRROR...........................23-98

LOW PRESSURE SWITCH -

DESCRIPTION, A/C...................24-21

LOW PRESSURE SWITCH - DIAGNOSIS

AND TESTING, A/C...................24-21

LOW PRESSURE SWITCH -

INSTALLATION, A/C...................24-21

LOW PRESSURE SWITCH - OPERATION,

A/C................................24-21

LOW PRESSURE SWITCH - REMOVAL,

A/C................................24-21

LOWER - INSTALLATION, LATCH........23-80

LOWER - INSTALLATION, LATCH

STRIKER...........................23-82

LOWER - REMOVAL, LATCH............23-80

LOWER - REMOVAL, LATCH STRIKER....23-82

LOWER BALL JOINT - DIAGNOSIS AND

TESTING............................2-10

LOWER CONTROL ARM - INSTALLATION . . 2-10,

2-20

LOWER CONTROL ARM - REMOVAL . . 2-10,2-20

LOWER FASCIA - INSTALLATION, FRONT . . . 13-3

LOWER FASCIA - REMOVAL, FRONT......13-3

LUBRICANTS - STANDARD PROCEDURE,

CLASSIFICATION OF....................0-1

LUBRICATION - DESCRIPTION....9-174,9-42,9-98

LUBRICATION - DESCRIPTION, AXLE.......0-5

LUBRICATION - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS........9-63,9-8

LUBRICATION - OPERATION....9-174,9-42,9-98

LUBRICATION - STANDARD PROCEDURE . 19-40,

19-42

LUMBAR CONTROL SWITCH -

DESCRIPTION.......................8N-18

LUMBAR CONTROL SWITCH -

OPERATION.........................8N-19

LUMBAR CONTROL SWITCH - REMOVAL . 8N-19

LUMBAR MOTOR - DESCRIPTION.......8N-19

LUMBAR MOTOR - DIAGNOSIS AND

TESTING...........................8N-19

LUMBAR MOTOR - OPERATION.........8N-19

LUMBAR SUPPORT - INSTALLATION....23-133

LUMBAR SUPPORT - REMOVAL........23-132

MAIN BEARING CLEARANCE -

STANDARD PROCEDURE...............9-159

MAIN BEARING FITTING - STANDARD

PROCEDURE, CRANKSHAFT.............9-31

MAIN BEARINGS - DESCRIPTION,

CRANKSHAFT........................9-31

MAIN BEARINGS - INSTALLATION,

CRANKSHAFT....................9-32,9-88

MAIN BEARINGS - OPERATION,

CRANKSHAFT........................9-31

MAIN BEARINGS - REMOVAL,

CRANKSHAFT....................9-31,9-88

MAIN BEARINGS - STANDARD

PROCEDURE, FITTING CRANKSHAFT......9-88

MAINTENANCE SCHEDULES -

DESCRIPTION.........................0-7

MALFUNCTION INDICATOR LAMP MIL -

DESCRIPTION.......................8J-23

MALFUNCTION INDICATOR LAMP MIL -

OPERATION.........................8J-23

MANAGER - DESCRIPTION, TASK........25-17

MANAGER - OPERATION, TASK.........25-21

MANIFOLD - CLEANING, EXHAUST . 9-109,9-185,

9-53

MANIFOLD - CLEANING, INTAKE . . . 9-107,9-184,

9-51

MANIFOLD - DESCRIPTION, EXHAUST . . . 9-109,

9-53

MANIFOLD - DESCRIPTION, FUEL DRAIN . . 14-89

MANIFOLD - DESCRIPTION, INTAKE . . 9-106,9-50

MANIFOLD - INSPECTION, EXHAUST

.....9-109,

9-186,9-53

MANIFOLD - INSPECTION, INTAKE

. 9-108,9-184,

9-51

MANIFOLD - INSTALLATION, EXHAUST

. . . 9-109,

9-186,9-53

MANIFOLD - INSTALLATION, FUEL

DRAIN

.............................14-90

MANIFOLD - INSTALLATION, INTAKE

.....9-108,

9-184,9-51MANIFOLD - OPERATION, EXHAUST . . 9-109,9-53

MANIFOLD - OPERATION, FUEL DRAIN . . . 14-89

MANIFOLD - OPERATION, INTAKE........9-50

MANIFOLD - REMOVAL, EXHAUST . . 9-109,9-185,

9-53

MANIFOLD - REMOVAL, FUEL DRAIN.....14-90

MANIFOLD - REMOVAL, INTAKE . . . 9-107,9-184,

9-50

MANIFOLD LEAKAGE - DIAGNOSIS AND

TESTING, INTAKE................9-106,9-50

MANUAL - NV4500 - ASSEMBLY........21-21

MANUAL - NV4500 - CLEANING.........21-20

MANUAL - NV4500 - DESCRIPTION.......21-1

MANUAL - NV4500 - DIAGNOSIS AND

TESTING............................21-3

MANUAL - NV4500 - DISASSEMBLY.......21-5

MANUAL - NV4500 - INSPECTION.......21-20

MANUAL - NV4500 - INSTALLATION......21-37

MANUAL - NV4500 - OPERATION.........21-3

MANUAL - NV4500 - REMOVAL..........21-4

MANUAL - NV4500 - SPECIFICATIONS....21-38

MANUAL - NV5600 - ASSEMBLY........21-64

MANUAL - NV5600 - CLEANING.........21-63

MANUAL - NV5600 - DESCRIPTION......21-46

MANUAL - NV5600 - DIAGNOSIS AND

TESTING...........................21-48

MANUAL - NV5600 - DISASSEMBLY......21-49

MANUAL - NV5600 - INSPECTION.........21-63

MANUAL - NV5600 - INSTALLATION......21-78

MANUAL - NV5600 - OPERATION........21-48

MANUAL - NV5600 - REMOVAL.........21-49

MANUAL - NV5600 - SPECIFICATIONS....21-79

MANUAL BLEEDING - STANDARD

PROCEDURE..........................5-7

MANUAL TRANSMISSION -

DESCRIPTION.........................0-5

MANUAL TRANSMISSION -

INSTALLATION, SHIFT BOOT...........23-122

MANUAL TRANSMISSION - REMOVAL,

SHIFT BOOT........................23-122

MAP SENSOR - INSTALLATION.........14-108

MARKER LAMP - INSTALLATION........8L-23

MARKER LAMP - REMOVAL............8L-23

MASTER CYLINDER - DESCRIPTION......5-26

MASTER CYLINDER - INSTALLATION......5-28

MASTER CYLINDER - OPERATION........5-26

MASTER CYLINDER - REMOVAL..........5-27

MASTER CYLINDER BLEEDING -

STANDARD PROCEDURE................5-27

MASTER CYLINDER/POWER BOOSTER -

DIAGNOSIS AND TESTING..............5-26

MATCH MOUNTING - STANDARD

PROCEDURE.........................22-3

MATS - INSTALLATION, CARPETS AND

FLOOR............................23-123

MATS - REMOVAL, CARPETS AND

FLOOR............................23-123

MEASUREMENT - STANDARD

PROCEDURE, CASTER CORRECTION.......2-3

MEASUREMENTS, SPECIFICATIONS -

BODY GAP AND FLUSH................23-56

MEASURING TIMING CHAIN STRETCH -

INSPECTION....................9-111,9-54

MECHANICAL - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS . . . 9-116,9-6,9-61

MECHANISM - DESCRIPTION, SHIFT....21-208,

21-379

MECHANISM - NV4500 - INSTALLATION,

SHIFT..............................21-44

MECHANISM - NV4500 - REMOVAL,

SHIFT..............................21-43

MECHANISM - OPERATION, SHIFT......21-208,

21-379

METRIC SYSTEM - DESCRIPTION......Intro.-9

MICRO-RELAY - DESCRIPTION.......8W-97-13

MICRO-RELAY - DIAGNOSIS AND

TESTING........................8W-97-14

MICRO-RELAY - INSTALLATION......8W-97-14

MICRO-RELAY - OPERATION........8W-97-14

MICRO-RELAY - REMOVAL

..........8W-97-14

MIDTRONICS ELECTRICAL TESTER -

STANDARD PROCEDURE, USING

........8F-15

MIL - DESCRIPTION, MALFUNCTION

INDICATOR LAMP

....................8J-23

MIL - OPERATION, MALFUNCTION

INDICATOR LAMP

....................8J-23

MILE, SPECIFICATIONS - TIRE

REVOLUTIONS PER

....................22-9

BR/BEINDEX 19

Description Group-Page Description Group-Page Description Group-Page