fold seats DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 613 of 2255

(6) Install and tighten the screw that secures the

shoulder belt turning loop to the height adjuster.

Tighten the screw to 30 N´m (22 ft. lbs.).

(7) Fold and snap the cover over the front shoulder

belt turning loop to conceal the screw that secures

the turning loop to the height adjuster.

(8) Install and tighten the screw that secures the

lower seat belt anchor plate to the floor panel near

the base of the B-pillar. Tighten the screw to 40 N´m

(29 ft. lbs.).

INSTALLATION - CLUB/QUAD CAB

The front seat shoulder belt and retractor are inte-

gral to the driver and passenger front seat backs on

club cab and quad cab models.

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Position the front shoulder belt and retractor

onto the seat back frame.

(2) Install and tighten the two screws that secure

the seat belt retractor to the seat back frame (Fig.

16). Tighten the screws to 16 N´m (12 ft. lbs.).

(3) Position the retractor cover onto the seat back

frame.

(4) Install and tighten the screws that secure the

retractor cover to the seat back frame. Tighten the

screws to 2 N´m (17 in. lbs.).

(5) Reinstall the trim cover onto the front seat

back frame. (Refer to 23 - BODY/SEATS/SEAT BACK

COVER - INSTALLATION).

FRONT SEAT BELT BUCKLE

REMOVAL

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELTTHAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Move the front seat to its most forward position

for easiest access to the front seat belt buckle

anchors.

(2) Tilt both front seat backs forward far enough to

access the seat belt buckle anchor screws.

(3) On the driver's side only, disconnect the body

wire harness connector for the seat belt switch from

the seat belt switch pigtail wire connector on the seat

belt buckle.

(4) Remove the screw that secures the seat belt

buckle to the anchor on the seat cushion frame.

(5) Remove the front seat belt buckle from the seat

cushion frame.

INSTALLATION

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Position the front seat belt buckle onto the seat

cushion frame.

(2) On the driver's side only, reconnect the body

wire harness connector for the seat belt switch to the

seat belt switch pigtail wire connector on the seat

belt buckle.

(3) Install and tighten the screw that secures the

seat belt buckle to the anchor on the seat cushion

frame. Tighten the screw to 40 N´m (29 ft. lbs.).

8O - 20 RESTRAINTSBR/BE

FRONT SEAT BELT & RETRACTOR (Continued)

Page 620 of 2255

(2) Install and tighten the screw that secures the

retractor to the quarter inner panel. Tighten the

screw to 40 N´m (29 ft. lbs.).

(3) Engage the rear seat shoulder belt turning loop

and lower seat belt anchor plate with the quarter

trim panel.

(4) Reinstall the trim onto the quarter inner panel.

(Refer to 23 - BODY/INTERIOR/QUARTER TRIM

PANEL - INSTALLATION).

(5) Position the shoulder belt turning loop onto the

quarter inner panel near the top of the C-pillar.

(6) Install and tighten the screw that secures the

shoulder belt turning loop to the quarter inner panel.

Tighten the screw to 40 N´m (29 ft. lbs.).

(7) Fold and snap the cover over the rear shoulder

belt turning loop to conceal the screw that secures

the turning loop to the quarter inner panel.

(8) Position the lower seat belt anchor plate onto

the quarter inner panel near the base of the C-pillar.

(9) Install and tighten the screw that secures the

lower seat belt anchor plate to the quarter inner

panel near the base of the C-pillar. Tighten the screw

to 40 N´m (29 ft. lbs.).

(10) Reinstall the trim cover onto the door sill.

(Refer to 23 - BODY/INTERIOR/DOOR SILL TRIM -

INSTALLATION).

(11) Reinstall the rear seat into the passenger

compartment. (Refer to 23 - BODY/SEATS/REAR

SEAT - INSTALLATION).

REAR SEAT BELT BUCKLE

REMOVAL

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

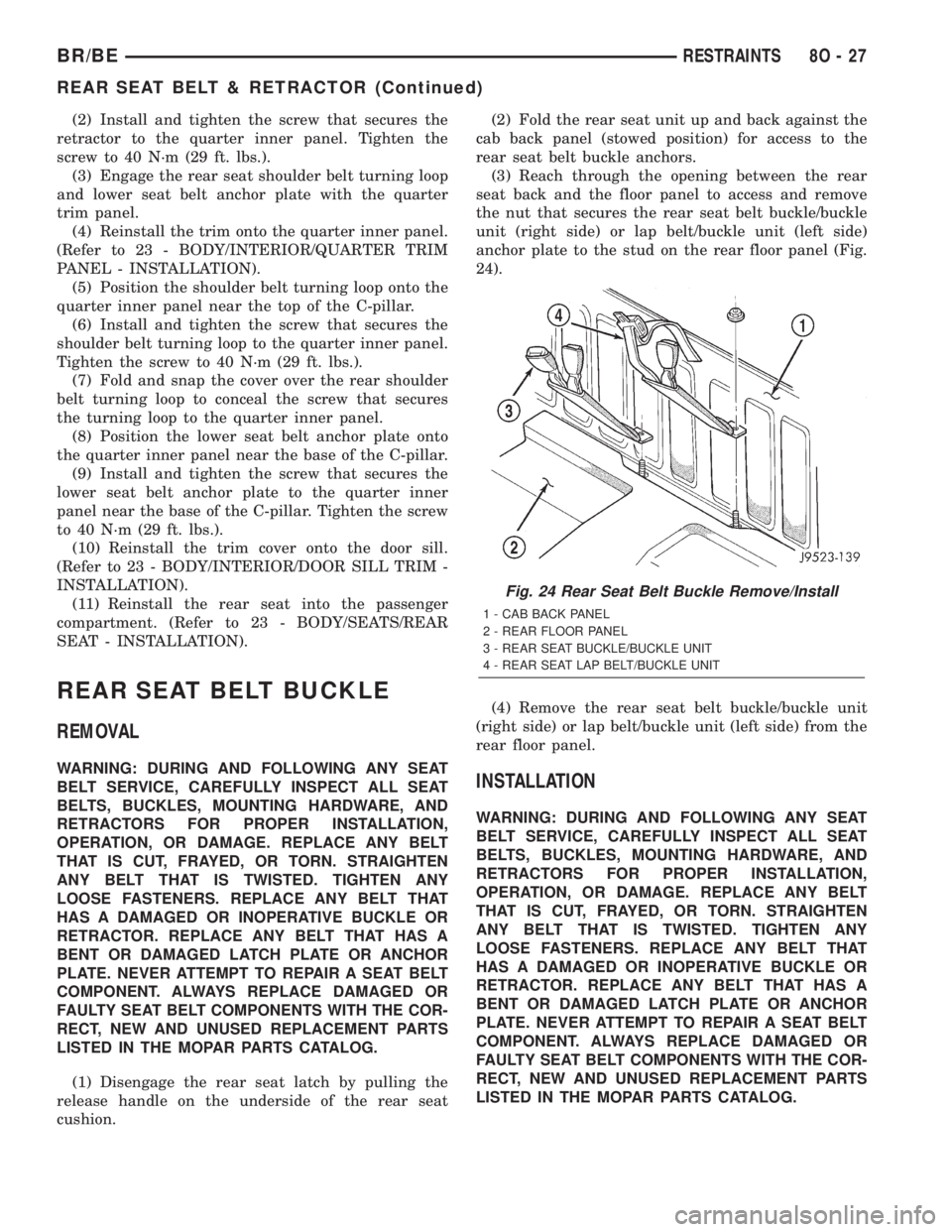

(1) Disengage the rear seat latch by pulling the

release handle on the underside of the rear seat

cushion.(2) Fold the rear seat unit up and back against the

cab back panel (stowed position) for access to the

rear seat belt buckle anchors.

(3) Reach through the opening between the rear

seat back and the floor panel to access and remove

the nut that secures the rear seat belt buckle/buckle

unit (right side) or lap belt/buckle unit (left side)

anchor plate to the stud on the rear floor panel (Fig.

24).

(4) Remove the rear seat belt buckle/buckle unit

(right side) or lap belt/buckle unit (left side) from the

rear floor panel.INSTALLATION

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

Fig. 24 Rear Seat Belt Buckle Remove/Install

1 - CAB BACK PANEL

2 - REAR FLOOR PANEL

3 - REAR SEAT BUCKLE/BUCKLE UNIT

4 - REAR SEAT LAP BELT/BUCKLE UNIT

BR/BERESTRAINTS 8O - 27

REAR SEAT BELT & RETRACTOR (Continued)

Page 1161 of 2255

INSTALLATION

INSTALLATIONÐCAMSHAFT BEARINGS

(1) Install new camshaft bearings using recom-

mended Tool 8544 Camshaft Bushing Remover

Installer, by sliding the new camshaft bearing shell

over proper adapter.

(2) Bearings must be carefully aligned to bring oil

holes into full register with oil passages from the

main bearing. If the camshaft bearing shell oil holes

are not in exact alignment, remove and install them

correctly. Install a new core hole plug at the rear of

camshaft.Be sure this plug does not leak.

INSTALLATIONÐCAMSHAFT

(1) Lubricate camshaft lobes and camshaft bearing

journals. Using a long bolt, insert the camshaft into

the cylinder block.

NOTE: Whenever an engine has been rebuilt, a new

camshaft and/or new tappets installed, add 1 pint of

MoparTCrankcase Conditioner, or equivalent. The

oil mixture should be left in engine for a minimum

of 805 km (500 miles). Drain at the next normal oil

change.

(2) Install camshaft thrust plate. Tighten the torx

bolts to 22 N´m (16 ft. lbs.) torque.

(3) Check camshaft end play. The end play should

be 0.051-0.152 mm (0.002-0.006 inch) with a new

thrust plate and up to 0.254 mm (0.010 inch) with a

used thrust plate. If not within these limits install a

new thrust plate.

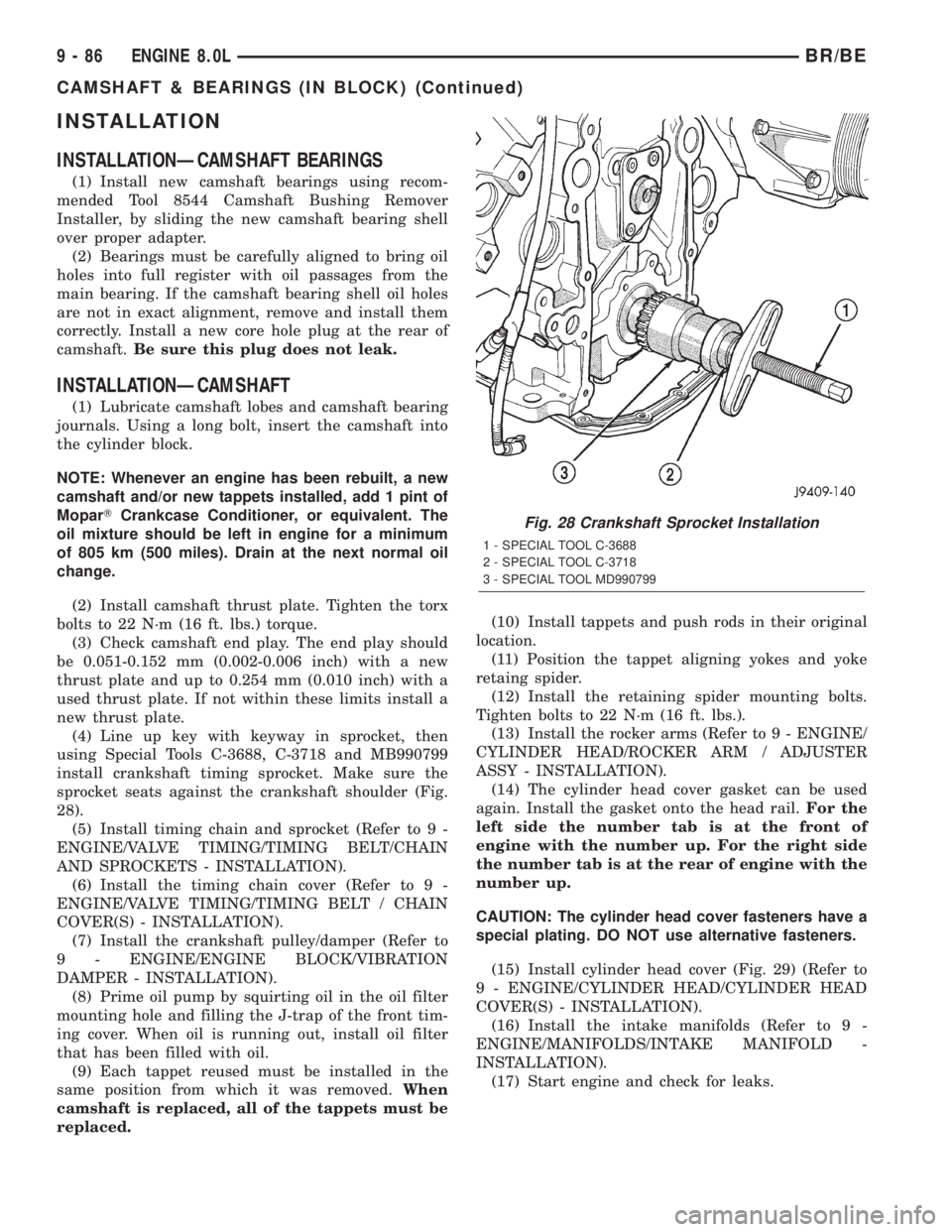

(4) Line up key with keyway in sprocket, then

using Special Tools C-3688, C-3718 and MB990799

install crankshaft timing sprocket. Make sure the

sprocket seats against the crankshaft shoulder (Fig.

28).

(5) Install timing chain and sprocket (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT/CHAIN

AND SPROCKETS - INSTALLATION).

(6) Install the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(7) Install the crankshaft pulley/damper (Refer to

9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - INSTALLATION).

(8) Prime oil pump by squirting oil in the oil filter

mounting hole and filling the J-trap of the front tim-

ing cover. When oil is running out, install oil filter

that has been filled with oil.

(9) Each tappet reused must be installed in the

same position from which it was removed.When

camshaft is replaced, all of the tappets must be

replaced.(10) Install tappets and push rods in their original

location.

(11) Position the tappet aligning yokes and yoke

retaing spider.

(12) Install the retaining spider mounting bolts.

Tighten bolts to 22 N´m (16 ft. lbs.).

(13) Install the rocker arms (Refer to 9 - ENGINE/

CYLINDER HEAD/ROCKER ARM / ADJUSTER

ASSY - INSTALLATION).

(14) The cylinder head cover gasket can be used

again. Install the gasket onto the head rail.For the

left side the number tab is at the front of

engine with the number up. For the right side

the number tab is at the rear of engine with the

number up.

CAUTION: The cylinder head cover fasteners have a

special plating. DO NOT use alternative fasteners.

(15) Install cylinder head cover (Fig. 29) (Refer to

9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(16) Install the intake manifolds (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

(17) Start engine and check for leaks.

Fig. 28 Crankshaft Sprocket Installation

1 - SPECIAL TOOL C-3688

2 - SPECIAL TOOL C-3718

3 - SPECIAL TOOL MD990799

9 - 86 ENGINE 8.0LBR/BE

CAMSHAFT & BEARINGS (IN BLOCK) (Continued)

Page 1195 of 2255

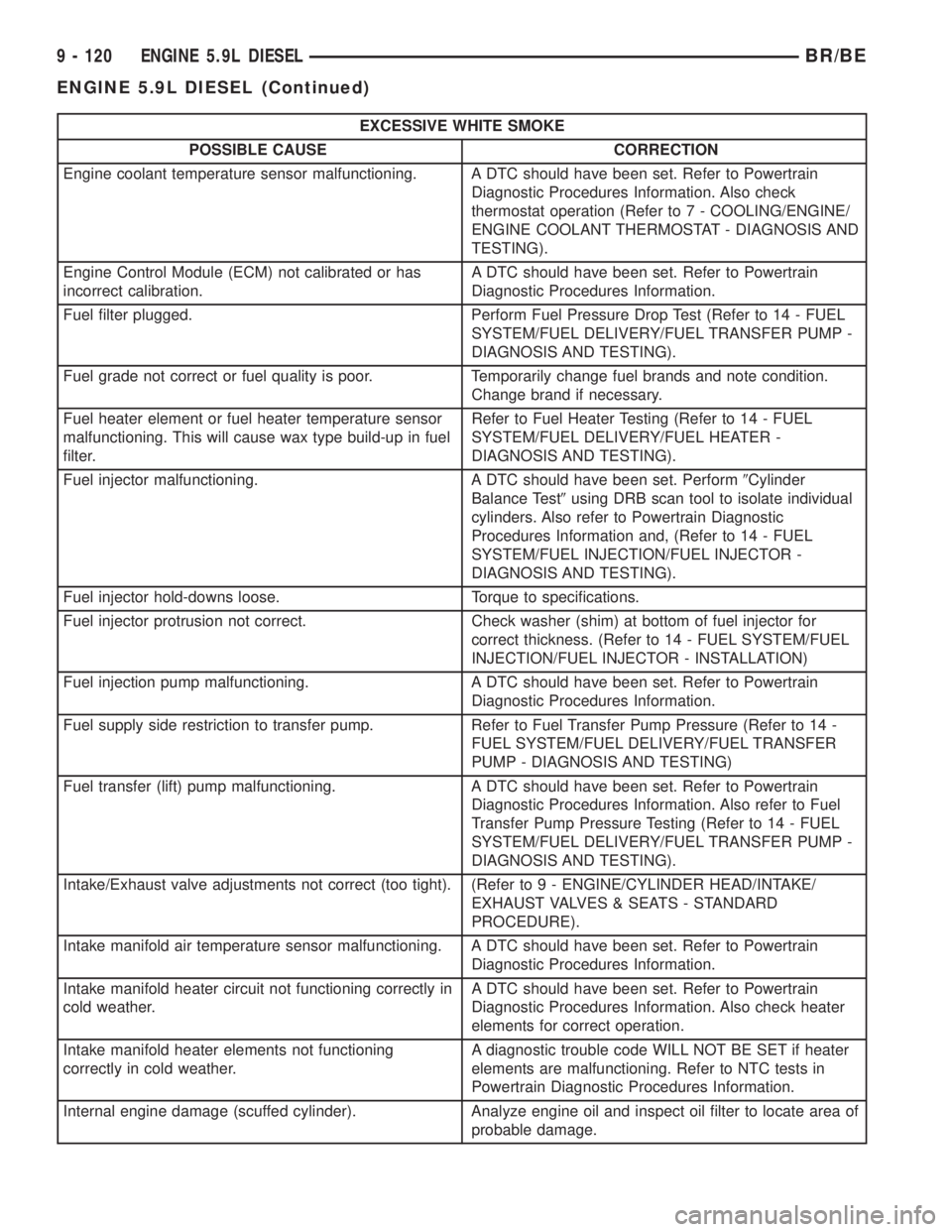

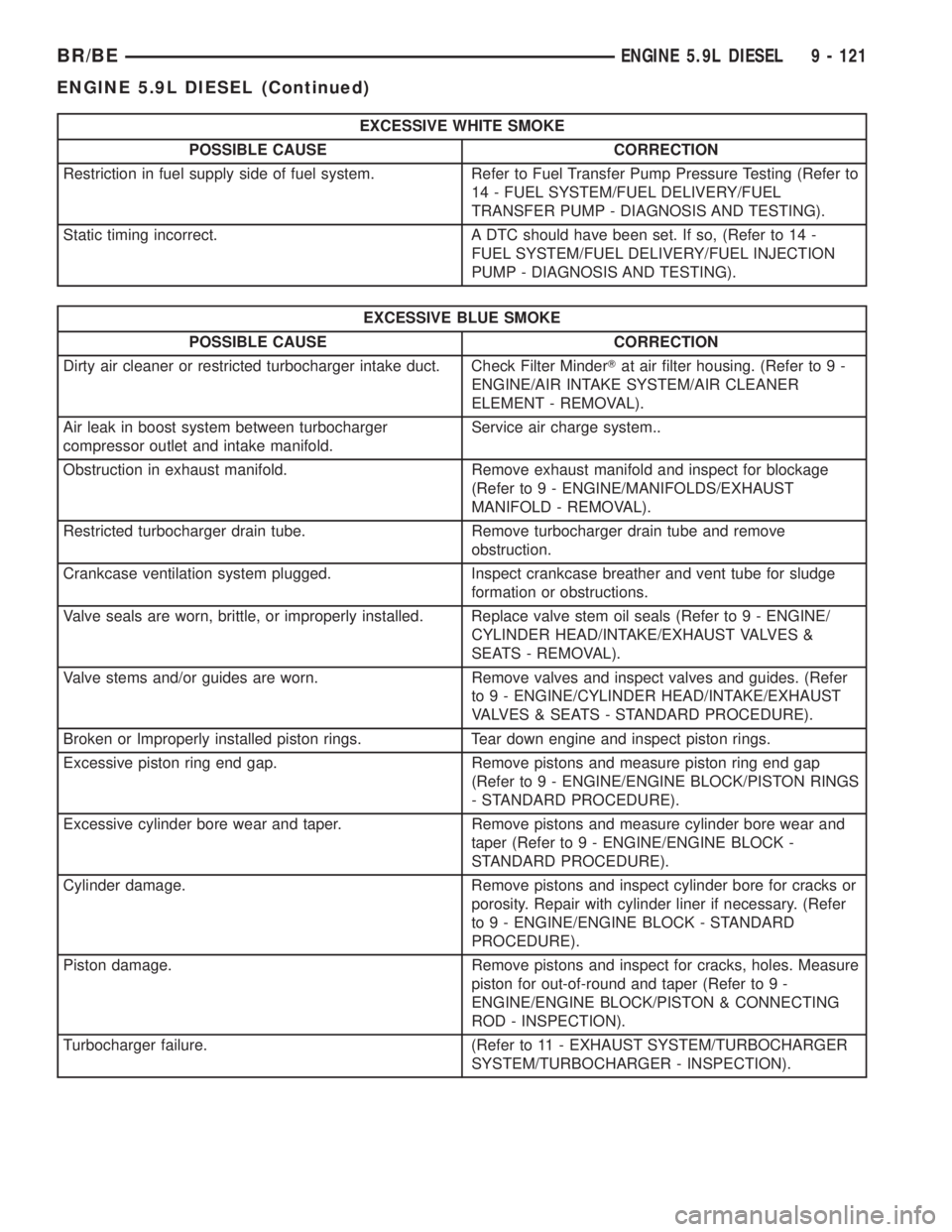

EXCESSIVE WHITE SMOKE

POSSIBLE CAUSE CORRECTION

Engine coolant temperature sensor malfunctioning. A DTC should have been set. Refer to Powertrain

Diagnostic Procedures Information. Also check

thermostat operation (Refer to 7 - COOLING/ENGINE/

ENGINE COOLANT THERMOSTAT - DIAGNOSIS AND

TESTING).

Engine Control Module (ECM) not calibrated or has

incorrect calibration.A DTC should have been set. Refer to Powertrain

Diagnostic Procedures Information.

Fuel filter plugged. Perform Fuel Pressure Drop Test (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/FUEL TRANSFER PUMP -

DIAGNOSIS AND TESTING).

Fuel grade not correct or fuel quality is poor. Temporarily change fuel brands and note condition.

Change brand if necessary.

Fuel heater element or fuel heater temperature sensor

malfunctioning. This will cause wax type build-up in fuel

filter.Refer to Fuel Heater Testing (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/FUEL HEATER -

DIAGNOSIS AND TESTING).

Fuel injector malfunctioning. A DTC should have been set. Perform9Cylinder

Balance Test9using DRB scan tool to isolate individual

cylinders. Also refer to Powertrain Diagnostic

Procedures Information and, (Refer to 14 - FUEL

SYSTEM/FUEL INJECTION/FUEL INJECTOR -

DIAGNOSIS AND TESTING).

Fuel injector hold-downs loose. Torque to specifications.

Fuel injector protrusion not correct. Check washer (shim) at bottom of fuel injector for

correct thickness. (Refer to 14 - FUEL SYSTEM/FUEL

INJECTION/FUEL INJECTOR - INSTALLATION)

Fuel injection pump malfunctioning. A DTC should have been set. Refer to Powertrain

Diagnostic Procedures Information.

Fuel supply side restriction to transfer pump. Refer to Fuel Transfer Pump Pressure (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/FUEL TRANSFER

PUMP - DIAGNOSIS AND TESTING)

Fuel transfer (lift) pump malfunctioning. A DTC should have been set. Refer to Powertrain

Diagnostic Procedures Information. Also refer to Fuel

Transfer Pump Pressure Testing (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/FUEL TRANSFER PUMP -

DIAGNOSIS AND TESTING).

Intake/Exhaust valve adjustments not correct (too tight). (Refer to 9 - ENGINE/CYLINDER HEAD/INTAKE/

EXHAUST VALVES & SEATS - STANDARD

PROCEDURE).

Intake manifold air temperature sensor malfunctioning. A DTC should have been set. Refer to Powertrain

Diagnostic Procedures Information.

Intake manifold heater circuit not functioning correctly in

cold weather.A DTC should have been set. Refer to Powertrain

Diagnostic Procedures Information. Also check heater

elements for correct operation.

Intake manifold heater elements not functioning

correctly in cold weather.A diagnostic trouble code WILL NOT BE SET if heater

elements are malfunctioning. Refer to NTC tests in

Powertrain Diagnostic Procedures Information.

Internal engine damage (scuffed cylinder). Analyze engine oil and inspect oil filter to locate area of

probable damage.

9 - 120 ENGINE 5.9L DIESELBR/BE

ENGINE 5.9L DIESEL (Continued)

Page 1196 of 2255

EXCESSIVE WHITE SMOKE

POSSIBLE CAUSE CORRECTION

Restriction in fuel supply side of fuel system. Refer to Fuel Transfer Pump Pressure Testing (Refer to

14 - FUEL SYSTEM/FUEL DELIVERY/FUEL

TRANSFER PUMP - DIAGNOSIS AND TESTING).

Static timing incorrect. A DTC should have been set. If so, (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/FUEL INJECTION

PUMP - DIAGNOSIS AND TESTING).

EXCESSIVE BLUE SMOKE

POSSIBLE CAUSE CORRECTION

Dirty air cleaner or restricted turbocharger intake duct. Check Filter MinderTat air filter housing. (Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

ELEMENT - REMOVAL).

Air leak in boost system between turbocharger

compressor outlet and intake manifold.Service air charge system..

Obstruction in exhaust manifold. Remove exhaust manifold and inspect for blockage

(Refer to 9 - ENGINE/MANIFOLDS/EXHAUST

MANIFOLD - REMOVAL).

Restricted turbocharger drain tube. Remove turbocharger drain tube and remove

obstruction.

Crankcase ventilation system plugged. Inspect crankcase breather and vent tube for sludge

formation or obstructions.

Valve seals are worn, brittle, or improperly installed. Replace valve stem oil seals (Refer to 9 - ENGINE/

CYLINDER HEAD/INTAKE/EXHAUST VALVES &

SEATS - REMOVAL).

Valve stems and/or guides are worn. Remove valves and inspect valves and guides. (Refer

to 9 - ENGINE/CYLINDER HEAD/INTAKE/EXHAUST

VALVES & SEATS - STANDARD PROCEDURE).

Broken or Improperly installed piston rings. Tear down engine and inspect piston rings.

Excessive piston ring end gap. Remove pistons and measure piston ring end gap

(Refer to 9 - ENGINE/ENGINE BLOCK/PISTON RINGS

- STANDARD PROCEDURE).

Excessive cylinder bore wear and taper. Remove pistons and measure cylinder bore wear and

taper (Refer to 9 - ENGINE/ENGINE BLOCK -

STANDARD PROCEDURE).

Cylinder damage. Remove pistons and inspect cylinder bore for cracks or

porosity. Repair with cylinder liner if necessary. (Refer

to 9 - ENGINE/ENGINE BLOCK - STANDARD

PROCEDURE).

Piston damage. Remove pistons and inspect for cracks, holes. Measure

piston for out-of-round and taper (Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON & CONNECTING

ROD - INSPECTION).

Turbocharger failure. (Refer to 11 - EXHAUST SYSTEM/TURBOCHARGER

SYSTEM/TURBOCHARGER - INSPECTION).

BR/BEENGINE 5.9L DIESEL 9 - 121

ENGINE 5.9L DIESEL (Continued)

Page 2090 of 2255

(4) Install the screws attaching the console to

mounting brackets.

(5) Install the transmission shifter boot, (Refer to

23 - BODY/INTERIOR/SHIFT BOOT - INSTALLA-

TION).

(6) Install the transfer case shifter boot, if

equipped. (Refer to 23 - BODY/INTERIOR/SHIFT

BOOT - INSTALLATION).

(7) Install cup holder in console, if equipped.

CARPETS AND FLOOR MATS

REMOVAL

STANDARD CAB

(1) Remove seat (Refer to 23 - BODY/SEATS/SEAT

- BENCH SEAT - REMOVAL) or(Refer to 23 - BODY/

SEATS/SEAT - SPLIT BENCH - REMOVAL).

(2) Remove door sill covers (Refer to 23 - BODY/

INTERIOR/DOOR SILL TRIM - REMOVAL).

(3) Remove cowl trim covers (Refer to 23 - BODY/

INTERIOR/COWL TRIM COVER - REMOVAL).

(4) Remove center console, if equipped.(Refer to 23

- BODY/INTERIOR/CENTER CONSOLE -

REMOVAL)

(5) If not equipped with a center console remove

the transfer case shifter boot (Refer to 23 - BODY/IN-

TERIOR/SHIFT BOOT/TRANSFER CASE - REMOV-

AL).

(6) Remove rear stowage tray (Refer to 23 - BODY/

INTERIOR/REAR FLOOR STOWAGE TRAY -

REMOVAL).

(7) Remove rear closure panel trim (Refer to 23 -

BODY/INTERIOR/REAR CLOSURE PANEL TRIM -

REMOVAL).

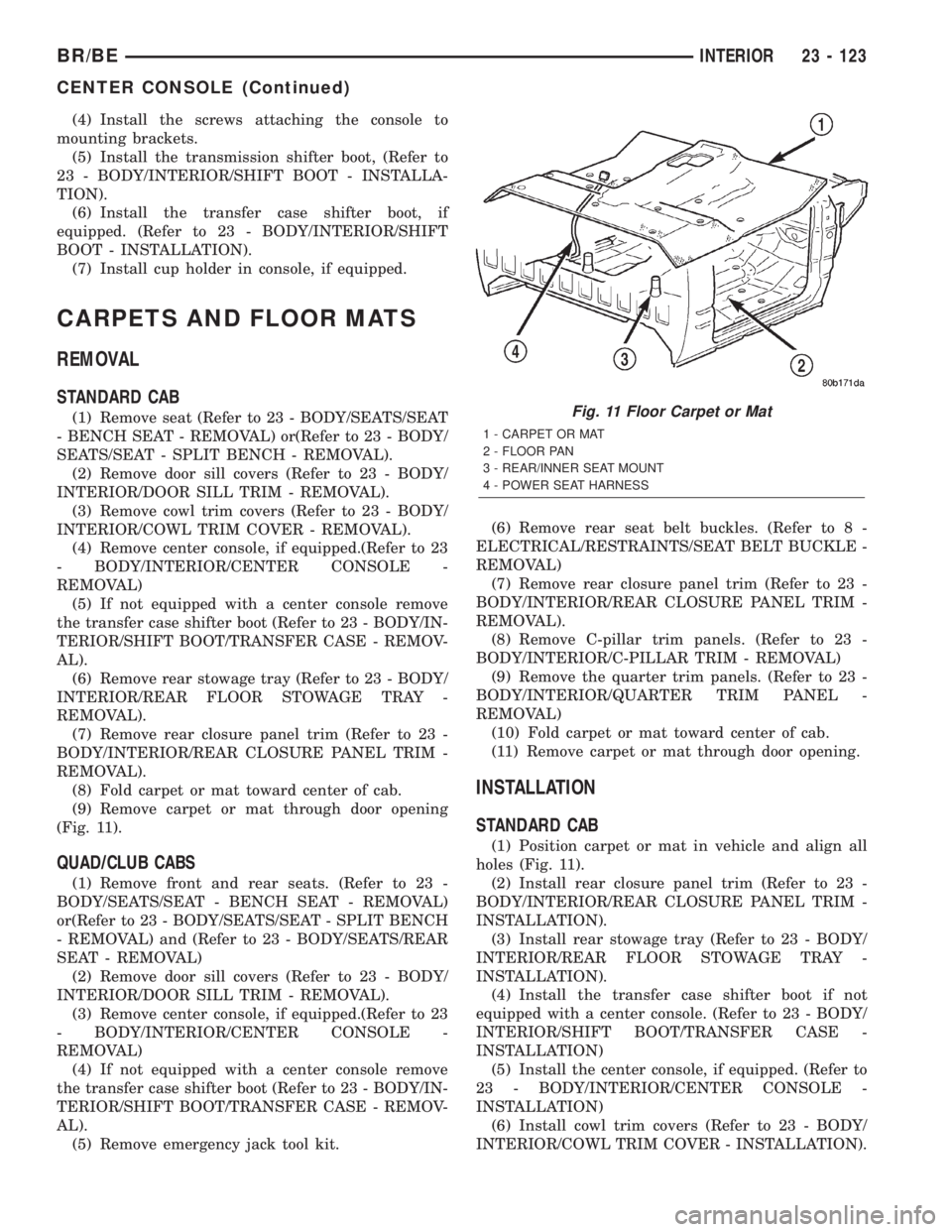

(8) Fold carpet or mat toward center of cab.

(9) Remove carpet or mat through door opening

(Fig. 11).

QUAD/CLUB CABS

(1) Remove front and rear seats. (Refer to 23 -

BODY/SEATS/SEAT - BENCH SEAT - REMOVAL)

or(Refer to 23 - BODY/SEATS/SEAT - SPLIT BENCH

- REMOVAL) and (Refer to 23 - BODY/SEATS/REAR

SEAT - REMOVAL)

(2) Remove door sill covers (Refer to 23 - BODY/

INTERIOR/DOOR SILL TRIM - REMOVAL).

(3) Remove center console, if equipped.(Refer to 23

- BODY/INTERIOR/CENTER CONSOLE -

REMOVAL)

(4) If not equipped with a center console remove

the transfer case shifter boot (Refer to 23 - BODY/IN-

TERIOR/SHIFT BOOT/TRANSFER CASE - REMOV-

AL).

(5) Remove emergency jack tool kit.(6) Remove rear seat belt buckles. (Refer to 8 -

ELECTRICAL/RESTRAINTS/SEAT BELT BUCKLE -

REMOVAL)

(7) Remove rear closure panel trim (Refer to 23 -

BODY/INTERIOR/REAR CLOSURE PANEL TRIM -

REMOVAL).

(8) Remove C-pillar trim panels. (Refer to 23 -

BODY/INTERIOR/C-PILLAR TRIM - REMOVAL)

(9) Remove the quarter trim panels. (Refer to 23 -

BODY/INTERIOR/QUARTER TRIM PANEL -

REMOVAL)

(10) Fold carpet or mat toward center of cab.

(11) Remove carpet or mat through door opening.

INSTALLATION

STANDARD CAB

(1) Position carpet or mat in vehicle and align all

holes (Fig. 11).

(2) Install rear closure panel trim (Refer to 23 -

BODY/INTERIOR/REAR CLOSURE PANEL TRIM -

INSTALLATION).

(3) Install rear stowage tray (Refer to 23 - BODY/

INTERIOR/REAR FLOOR STOWAGE TRAY -

INSTALLATION).

(4) Install the transfer case shifter boot if not

equipped with a center console. (Refer to 23 - BODY/

INTERIOR/SHIFT BOOT/TRANSFER CASE -

INSTALLATION)

(5) Install the center console, if equipped. (Refer to

23 - BODY/INTERIOR/CENTER CONSOLE -

INSTALLATION)

(6) Install cowl trim covers (Refer to 23 - BODY/

INTERIOR/COWL TRIM COVER - INSTALLATION).

Fig. 11 Floor Carpet or Mat

1 - CARPET OR MAT

2 - FLOOR PAN

3 - REAR/INNER SEAT MOUNT

4 - POWER SEAT HARNESS

BR/BEINTERIOR 23 - 123

CENTER CONSOLE (Continued)

Page 2168 of 2255

replaced. The compressor clutch, pulley and clutch

coil are available for service.

OPERATION - HIGH PRESSURE RELIEF VALVE

The high pressure relief valve vents the system

when a discharge pressure of 3445 to 4135 kPa (500

to 600 psi) or above is reached. The valve closes with

a minimum discharge pressure of 2756 kPa (400 psi)

is reached.

The high pressure relief valve vents only enough

refrigerant to reduce the system pressure, and then

re-seats itself. The majority of the refrigerant is con-

served in the system. If the valve vents refrigerant, it

does not mean the valve is faulty.

The high pressure relief valve is a factory-cali-

brated unit. The valve cannot be adjusted or

repaired, and must not be removed or otherwise dis-

turbed. The valve is only serviced as a part of the

compressor assembly.

DIAGNOSIS AND TESTING - A/C COMPRESSOR

When investigating an air conditioning related

noise, you must first know the conditions under

which the noise occurs. These conditions include:

weather, vehicle speed, transmission in gear or neu-

tral, engine speed, engine operating temperature,

and any other special conditions. Noises that develop

during air conditioning operation can often be mis-

leading. For example: What sounds like a failed front

bearing or connecting rod, may be caused by loose

bolts, nuts, mounting brackets, or a loose compressor

clutch assembly.

Drive belts are speed sensitive. At different engine

speeds and depending upon belt tension, belts can

develop noises that are mistaken for a compressor

noise. Improper belt tension can cause a misleading

noise when the compressor clutch is engaged, which

may not occur when the compressor clutch is disen-

gaged. Check the serpentine drive belt condition and

tension before beginning this procedure(Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

DIAGNOSIS AND TESTING).

(1) Select a quiet area for testing. Duplicate the

complaint conditions as much as possible. Switch the

compressor on and off several times to clearly iden-

tify the compressor noise. Listen to the compressor

while the clutch is engaged and disengaged. Probe

the compressor with an engine stethoscope or a long

screwdriver with the handle held to your ear to bet-

ter localize the source of the noise.

(2) Loosen all of the compressor mounting hard-

ware and retighten. Tighten the compressor clutch

mounting nut. Be certain that the clutch coil is

mounted securely to the compressor, and that the

clutch plate and pulley are properly aligned and have

the correct air gap. (Refer to 24 - HEATING & AIRCONDITIONING/CONTROLS/A/C COMPRESSOR

CLUTCH - INSTALLATION)

(3) To duplicate a high-ambient temperature condi-

tion (high head pressure), restrict the air flow

through the condenser. Install a manifold gauge set

to be certain that the discharge pressure does not

exceed 2760 kPa (400 psi).

(4) Check the refrigerant system plumbing for

incorrect routing, rubbing or interference, which can

cause unusual noises. Also check the refrigerant lines

for kinks or sharp bends that will restrict refrigerant

flow, which can cause noises. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAU-

TION)

(5) If the noise is from opening and closing of the

high pressure relief valve, recover, evacuate, and

recharge the refrigerant system. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE - REFRIGERANT RECOVERY)

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE - REFRIG-

ERANT SYSTEM EVACUATE) (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE) If the high pressure relief valve still

does not seat properly, replace the compressor.

(6) If the noise is from liquid slugging on the suc-

tion line, replace the accumulator. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/AC-

CUMULATOR - REMOVAL) Check the refrigerant oil

level and the refrigerant system charge. (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING/

REFRIGERANT OIL - STANDARD PROCEDURE -

REFRIGERANT OIL LEVEL) (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - SPECI-

FICATIONS - CHARGE CAPACITY) If the liquid

slugging condition continues following accumulator

replacement, replace the compressor.

(7) If the noise continues, replace the compressor

and repeat Step 1.

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

The compressor may be removed and repositioned

without disconnecting the refrigerant lines or dis-

charging the refrigerant system. Discharging is not

necessary if servicing the compressor clutch or clutch

coil, the engine, the cylinder head, or the generator.

(1) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

BR/BEPLUMBING 24 - 47

A/C COMPRESSOR (Continued)

Page 2223 of 2255

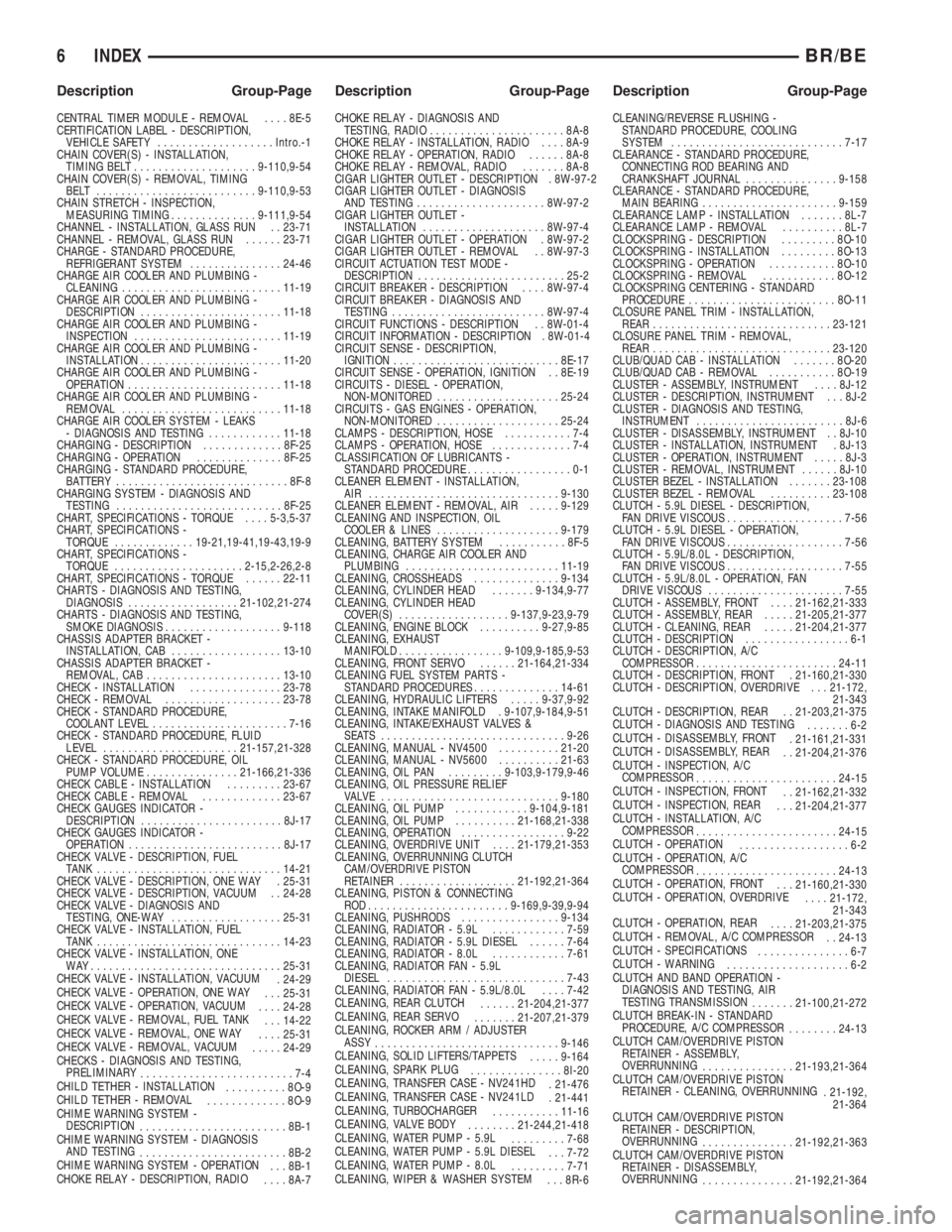

CENTRAL TIMER MODULE - REMOVAL....8E-5

CERTIFICATION LABEL - DESCRIPTION,

VEHICLE SAFETY...................Intro.-1

CHAIN COVER(S) - INSTALLATION,

TIMING BELT....................9-110,9-54

CHAIN COVER(S) - REMOVAL, TIMING

BELT ..........................9-110,9-53

CHAIN STRETCH - INSPECTION,

MEASURING TIMING..............9-111,9-54

CHANNEL - INSTALLATION, GLASS RUN . . 23-71

CHANNEL - REMOVAL, GLASS RUN......23-71

CHARGE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM...............24-46

CHARGE AIR COOLER AND PLUMBING -

CLEANING..........................11-19

CHARGE AIR COOLER AND PLUMBING -

DESCRIPTION.......................11-18

CHARGE AIR COOLER AND PLUMBING -

INSPECTION........................11-19

CHARGE AIR COOLER AND PLUMBING -

INSTALLATION.......................11-20

CHARGE AIR COOLER AND PLUMBING -

OPERATION.........................11-18

CHARGE AIR COOLER AND PLUMBING -

REMOVAL..........................11-18

CHARGE AIR COOLER SYSTEM - LEAKS

- DIAGNOSIS AND TESTING............11-18

CHARGING - DESCRIPTION.............8F-25

CHARGING - OPERATION..............8F-25

CHARGING - STANDARD PROCEDURE,

BATTERY............................8F-8

CHARGING SYSTEM - DIAGNOSIS AND

TESTING...........................8F-25

CHART, SPECIFICATIONS - TORQUE....5-3,5-37

CHART, SPECIFICATIONS -

TORQUE.............19-21,19-41,19-43,19-9

CHART, SPECIFICATIONS -

TORQUE.....................2-15,2-26,2-8

CHART, SPECIFICATIONS - TORQUE......22-11

CHARTS - DIAGNOSIS AND TESTING,

DIAGNOSIS..................21-102,21-274

CHARTS - DIAGNOSIS AND TESTING,

SMOKE DIAGNOSIS...................9-118

CHASSIS ADAPTER BRACKET -

INSTALLATION, CAB..................13-10

CHASSIS ADAPTER BRACKET -

REMOVAL, CAB......................13-10

CHECK - INSTALLATION...............23-78

CHECK - REMOVAL...................23-78

CHECK - STANDARD PROCEDURE,

COOLANT LEVEL......................7-16

CHECK - STANDARD PROCEDURE, FLUID

LEVEL......................21-157,21-328

CHECK - STANDARD PROCEDURE, OIL

PUMP VOLUME...............21-166,21-336

CHECK CABLE - INSTALLATION.........23-67

CHECK CABLE - REMOVAL.............23-67

CHECK GAUGES INDICATOR -

DESCRIPTION.......................8J-17

CHECK GAUGES INDICATOR -

OPERATION.........................8J-17

CHECK VALVE - DESCRIPTION, FUEL

TANK ..............................14-21

CHECK VALVE - DESCRIPTION, ONE WAY . 25-31

CHECK VALVE - DESCRIPTION, VACUUM . . 24-28

CHECK VALVE - DIAGNOSIS AND

TESTING, ONE-WAY..................25-31

CHECK VALVE - INSTALLATION, FUEL

TANK ..............................14-23

CHECK VALVE - INSTALLATION, ONE

WAY...............................25-31

CHECK VALVE - INSTALLATION, VACUUM

. 24-29

CHECK VALVE - OPERATION, ONE WAY

. . . 25-31

CHECK VALVE - OPERATION, VACUUM

....24-28

CHECK VALVE - REMOVAL, FUEL TANK

. . . 14-22

CHECK VALVE - REMOVAL, ONE WAY

....25-31

CHECK VALVE - REMOVAL, VACUUM

.....24-29

CHECKS - DIAGNOSIS AND TESTING,

PRELIMINARY

.........................7-4

CHILD TETHER - INSTALLATION

..........8O-9

CHILD TETHER - REMOVAL

.............8O-9

CHIME WARNING SYSTEM -

DESCRIPTION

........................8B-1

CHIME WARNING SYSTEM - DIAGNOSIS

AND TESTING

........................8B-2

CHIME WARNING SYSTEM - OPERATION

. . . 8B-1

CHOKE RELAY - DESCRIPTION, RADIO

....8A-7CHOKE RELAY - DIAGNOSIS AND

TESTING, RADIO......................8A-8

CHOKE RELAY - INSTALLATION, RADIO....8A-9

CHOKE RELAY - OPERATION, RADIO......8A-8

CHOKE RELAY - REMOVAL, RADIO.......8A-8

CIGAR LIGHTER OUTLET - DESCRIPTION . 8W-97-2

CIGAR LIGHTER OUTLET - DIAGNOSIS

AND TESTING.....................8W-97-2

CIGAR LIGHTER OUTLET -

INSTALLATION....................8W-97-4

CIGAR LIGHTER OUTLET - OPERATION . 8W-97-2

CIGAR LIGHTER OUTLET - REMOVAL . . 8W-97-3

CIRCUIT ACTUATION TEST MODE -

DESCRIPTION........................25-2

CIRCUIT BREAKER - DESCRIPTION....8W-97-4

CIRCUIT BREAKER - DIAGNOSIS AND

TESTING.........................8W-97-4

CIRCUIT FUNCTIONS - DESCRIPTION . . 8W-01-4

CIRCUIT INFORMATION - DESCRIPTION . 8W-01-4

CIRCUIT SENSE - DESCRIPTION,

IGNITION...........................8E-17

CIRCUIT SENSE - OPERATION, IGNITION . . 8E-19

CIRCUITS - DIESEL - OPERATION,

NON-MONITORED....................25-24

CIRCUITS - GAS ENGINES - OPERATION,

NON-MONITORED....................25-24

CLAMPS - DESCRIPTION, HOSE...........7-4

CLAMPS - OPERATION, HOSE.............7-4

CLASSIFICATION OF LUBRICANTS -

STANDARD PROCEDURE..................0-1

CLEANER ELEMENT - INSTALLATION,

AIR ...............................9-130

CLEANER ELEMENT - REMOVAL, AIR.....9-129

CLEANING AND INSPECTION, OIL

COOLER & LINES....................9-179

CLEANING, BATTERY SYSTEM...........8F-5

CLEANING, CHARGE AIR COOLER AND

PLUMBING.........................11-19

CLEANING, CROSSHEADS..............9-134

CLEANING, CYLINDER HEAD.......9-134,9-77

CLEANING, CYLINDER HEAD

COVER(S)..................9-137,9-23,9-79

CLEANING, ENGINE BLOCK..........9-27,9-85

CLEANING, EXHAUST

MANIFOLD.................9-109,9-185,9-53

CLEANING, FRONT SERVO......21-164,21-334

CLEANING FUEL SYSTEM PARTS -

STANDARD PROCEDURES..............14-61

CLEANING, HYDRAULIC LIFTERS.....9-37,9-92

CLEANING, INTAKE MANIFOLD . 9-107,9-184,9-51

CLEANING, INTAKE/EXHAUST VALVES &

SEATS ..............................9-26

CLEANING, MANUAL - NV4500..........21-20

CLEANING, MANUAL - NV5600..........21-63

CLEANING, OIL PAN.........9-103,9-179,9-46

CLEANING, OIL PRESSURE RELIEF

VALVE .............................9-180

CLEANING, OIL PUMP............9-104,9-181

CLEANING, OIL PUMP..........21-168,21-338

CLEANING, OPERATION.................9-22

CLEANING, OVERDRIVE UNIT....21-179,21-353

CLEANING, OVERRUNNING CLUTCH

CAM/OVERDRIVE PISTON

RETAINER...................21-192,21-364

CLEANING, PISTON & CONNECTING

ROD.......................9-169,9-39,9-94

CLEANING, PUSHRODS................9-134

CLEANING, RADIATOR - 5.9L............7-59

CLEANING, RADIATOR - 5.9L DIESEL......7-64

CLEANING, RADIATOR - 8.0L............7-61

CLEANING, RADIATOR FAN - 5.9L

DIESEL.............................7-43

CLEANING, RADIATOR FAN - 5.9L/8.0L....7-42

CLEANING, REAR CLUTCH

......21-204,21-377

CLEANING, REAR SERVO

.......21-207,21-379

CLEANING, ROCKER ARM / ADJUSTER

ASSY

..............................9-146

CLEANING, SOLID LIFTERS/TAPPETS

.....9-164

CLEANING, SPARK PLUG

...............8I-20

CLEANING, TRANSFER CASE - NV241HD

. 21-476

CLEANING, TRANSFER CASE - NV241LD

. 21-441

CLEANING, TURBOCHARGER

...........11-16

CLEANING, VALVE BODY

........21-244,21-418

CLEANING, WATER PUMP - 5.9L

.........7-68

CLEANING, WATER PUMP - 5.9L DIESEL

. . . 7-72

CLEANING, WATER PUMP - 8.0L

.........7-71

CLEANING, WIPER & WASHER SYSTEM

. . . 8R-6CLEANING/REVERSE FLUSHING -

STANDARD PROCEDURE, COOLING

SYSTEM............................7-17

CLEARANCE - STANDARD PROCEDURE,

CONNECTING ROD BEARING AND

CRANKSHAFT JOURNAL...............9-158

CLEARANCE - STANDARD PROCEDURE,

MAIN BEARING......................9-159

CLEARANCE LAMP - INSTALLATION.......8L-7

CLEARANCE LAMP - REMOVAL..........8L-7

CLOCKSPRING - DESCRIPTION.........8O-10

CLOCKSPRING - INSTALLATION.........8O-13

CLOCKSPRING - OPERATION...........8O-10

CLOCKSPRING - REMOVAL............8O-12

CLOCKSPRING CENTERING - STANDARD

PROCEDURE........................8O-11

CLOSURE PANEL TRIM - INSTALLATION,

REAR.............................23-121

CLOSURE PANEL TRIM - REMOVAL,

REAR.............................23-120

CLUB/QUAD CAB - INSTALLATION.......8O-20

CLUB/QUAD CAB - REMOVAL...........8O-19

CLUSTER - ASSEMBLY, INSTRUMENT....8J-12

CLUSTER - DESCRIPTION, INSTRUMENT . . . 8J-2

CLUSTER - DIAGNOSIS AND TESTING,

INSTRUMENT........................8J-6

CLUSTER - DISASSEMBLY, INSTRUMENT . . 8J-10

CLUSTER - INSTALLATION, INSTRUMENT . 8J-13

CLUSTER - OPERATION, INSTRUMENT.....8J-3

CLUSTER - REMOVAL, INSTRUMENT......8J-10

CLUSTER BEZEL - INSTALLATION.......23-108

CLUSTER BEZEL - REMOVAL..........23-108

CLUTCH - 5.9L DIESEL - DESCRIPTION,

FAN DRIVE VISCOUS...................7-56

CLUTCH - 5.9L DIESEL - OPERATION,

FAN DRIVE VISCOUS...................7-56

CLUTCH - 5.9L/8.0L - DESCRIPTION,

FAN DRIVE VISCOUS...................7-55

CLUTCH - 5.9L/8.0L - OPERATION, FAN

DRIVE VISCOUS......................7-55

CLUTCH - ASSEMBLY, FRONT....21-162,21-333

CLUTCH - ASSEMBLY, REAR.....21-205,21-377

CLUTCH - CLEANING, REAR.....21-204,21-377

CLUTCH - DESCRIPTION.................6-1

CLUTCH - DESCRIPTION, A/C

COMPRESSOR.......................24-11

CLUTCH - DESCRIPTION, FRONT . 21-160,21-330

CLUTCH - DESCRIPTION, OVERDRIVE . . . 21-172,

21-343

CLUTCH - DESCRIPTION, REAR . . 21-203,21-375

CLUTCH - DIAGNOSIS AND TESTING

.......6-2

CLUTCH - DISASSEMBLY, FRONT

. 21-161,21-331

CLUTCH - DISASSEMBLY, REAR

. . 21-204,21-376

CLUTCH - INSPECTION, A/C

COMPRESSOR

.......................24-15

CLUTCH - INSPECTION, FRONT

. . 21-162,21-332

CLUTCH - INSPECTION, REAR

. . . 21-204,21-377

CLUTCH - INSTALLATION, A/C

COMPRESSOR

.......................24-15

CLUTCH - OPERATION

..................6-2

CLUTCH - OPERATION, A/C

COMPRESSOR

.......................24-13

CLUTCH - OPERATION, FRONT

. . . 21-160,21-330

CLUTCH - OPERATION, OVERDRIVE

....21-172,

21-343

CLUTCH - OPERATION, REAR

....21-203,21-375

CLUTCH - REMOVAL, A/C COMPRESSOR

. . 24-13

CLUTCH - SPECIFICATIONS

...............6-7

CLUTCH - WARNING

....................6-2

CLUTCH AND BAND OPERATION -

DIAGNOSIS AND TESTING, AIR

TESTING TRANSMISSION

.......21-100,21-272

CLUTCH BREAK-IN - STANDARD

PROCEDURE, A/C COMPRESSOR

........24-13

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - ASSEMBLY,

OVERRUNNING

...............21-193,21-364

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - CLEANING, OVERRUNNING

. 21-192,

21-364

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - DESCRIPTION,

OVERRUNNING

...............21-192,21-363

CLUTCH CAM/OVERDRIVE PISTON

RETAINER - DISASSEMBLY,

OVERRUNNING

...............21-192,21-364

6 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2234 of 2255

INDICATOR - OPERATION, SERVICE

REMINDER..........................8J-28

INDICATOR - OPERATION, TRANS

OVERTEMP.........................8J-31

INDICATOR - OPERATION, TURN SIGNAL . . 8J-32

INDICATOR - OPERATION, UPSHIFT......8J-33

INDICATOR - OPERATION, VTSS.........8Q-3

INDICATOR - OPERATION, WAIT-TO-

START .............................8J-34

INDICATOR - OPERATION, WASHER

FLUID..............................8J-35

INDICATOR - OPERATION, WATER-IN-

FUEL..............................8J-36

INDICATOR LAMP MIL - DESCRIPTION,

MALFUNCTION.......................8J-23

INDICATOR LAMP MIL - OPERATION,

MALFUNCTION.......................8J-23

INDICATOR TEST - STANDARD

PROCEDURE, BUILT-IN................8F-10

INDICATOR (TRANSFER CASE) -

DESCRIPTION, SHIFT.................8J-28

INDICATOR (TRANSFER CASE) -

OPERATION, SHIFT...................8J-28

INDICATORS - DIAGNOSIS AND

TESTING, TREAD WEAR................22-8

INFLATION PRESSURES - DESCRIPTION,

TIRE................................22-7

INITIAL OPERATION - STANDARD

PROCEDURE, POWER STEERING

PUMP.............................19-33

INJECTION - SPECIFICATIONS, TORQUE -

GAS FUEL..........................14-35

INJECTION PUMP - DESCRIPTION, AIR.....25-29

INJECTION PUMP - DIAGNOSIS AND

TESTING, AIR.......................25-29

INJECTION PUMP - INSTALLATION, AIR . . . 25-30

INJECTION PUMP - OPERATION, AIR.....25-29

INJECTION PUMP - REMOVAL, AIR......25-30

INJECTION PUMP DATA PLATE,

SPECIFICATIONS - FUEL...............14-77

INJECTION PUMP RELAY -

DESCRIPTION, FUEL.................14-103

INJECTION PUMP RELAY - OPERATION,

FUEL.............................14-103

INJECTION PUMP TIMING - DIAGNOSIS

AND TESTING, FUEL..................14-70

INJECTION SYSTEM - DESCRIPTION, AIR . 25-26

INJECTION SYSTEM - DESCRIPTION,

DIESEL FUEL........................14-91

INJECTION SYSTEM - OPERATION, AIR . . . 25-28

INJECTION SYSTEM - TORQUE, AIR......25-29

INJECTOR - DESCRIPTION, FUEL . . . 14-52,14-97

INJECTOR - DIAGNOSIS AND TESTING,

FUEL..............................14-53

INJECTOR - INSTALLATION, FUEL.......14-102

INJECTOR - OPERATION, FUEL..........14-98

INJECTOR - REMOVAL, FUEL..........14-101

INJECTOR FIRING ORDER, DIESEL -

FUEL..............................14-62

INJECTOR TEST - DIAGNOSIS AND

TESTING, FUEL......................14-99

INLET BAFFLE - INSTALLATION, HVAC

HOUSING...........................24-36

INLET BAFFLE - REMOVAL, HVAC

HOUSING...........................24-35

INLET FILTER - INSTALLATION..........14-23

INLET FILTER - REMOVAL..............14-23

INNER BELT WEATHERSTRIP -

INSTALLATION, FRONT DOOR..........23-153

INNER BELT WEATHERSTRIP -

REMOVAL, FRONT DOOR.............23-153

IN/OUT - ADJUSTMENT, FRONT DOOR

....23-70

INPUT - DESCRIPTION, VEHICLE SPEED

. . . 8P-2

INPUT - OPERATION, ASD SENSE - PCM

. . . 8I-4

INSIDE HANDLE ACTUATOR -

INSTALLATION

..................23-72,23-80

INSIDE HANDLE ACTUATOR - REMOVAL

. . 23-72,

23-80

INSPECTION - CONNECTING RODS

......9-169

INSPECTION - INSPECTION

.............9-169

INSPECTION - INSTALLATION

......9-136,9-170

INSPECTION, 5.9L ENGINES - VISUAL

....14-29

INSPECTION, 8.0L ENGINE - VISUAL

.....14-32

INSPECTION, A/C COMPRESSOR

CLUTCH

............................24-15

INSPECTION, ACCUMULATOR

....21-150,21-320

INSPECTION, BATTERY SYSTEM

..........8F-6INSPECTION, CATALYTIC CONVERTER -

3.9L/5.2L/5.9L........................11-6

INSPECTION, CATALYTIC CONVERTER -

5.9L HD/8.0L.........................11-6

INSPECTION, CHARGE AIR COOLER AND

PLUMBING.........................11-19

INSPECTION, CROSSHEADS............9-135

INSPECTION, CYLINDER HEAD......9-134,9-77

INSPECTION, CYLINDER HEAD COVER(S) . 9-138,

9-23,9-79

INSPECTION, DIAGNOSIS AND TESTING . . . 7-66

INSPECTION, DIAGNOSIS AND TESTING . 21-122,

21-293

INSPECTION, DIAGNOSIS AND TESTING

- WHEEL...........................22-11

INSPECTION, ENGINE BLOCK........9-27,9-85

INSPECTION, EXHAUST MANIFOLD . 9-109,9-186,

9-53

INSPECTION, EXHAUST PIPE -

3.9L/5.2L/5.9L........................11-7

INSPECTION, EXHAUST PIPE - 5.9L

DIESEL.............................11-9

INSPECTION, EXHAUST PIPE - 5.9L

HD/8.0L.............................11-8

INSPECTION, FRONT CLUTCH....21-162,21-332

INSPECTION, FRONT SERVO.....21-164,21-335

INSPECTION, INSPECTION.............9-169

INSPECTION, INTAKE MANIFOLD . . . 9-108,9-184,

9-51

INSPECTION, INTAKE/EXHAUST VALVES

& SEATS ............................9-26

INSPECTION, MANUAL - NV4500........21-20

INSPECTION, MANUAL - NV5600........21-63

INSPECTION, MEASURING TIMING

CHAIN STRETCH.................9-111,9-54

INSPECTION, OIL COOLER & LINES -

CLEANING..........................9-179

INSPECTION, OIL PAN.......9-103,9-179,9-46

INSPECTION, OIL PRESSURE RELIEF

VALVE .............................9-180

INSPECTION, OIL PUMP......9-104,9-181,9-47

INSPECTION, OIL PUMP........21-168,21-339

INSPECTION, OPERATION...............9-22

INSPECTION, OVERDRIVE UNIT . . 21-180,21-353

INSPECTION, OVERRUNNING CLUTCH

CAM/OVERDRIVE PISTON RETAINER....21-193,

21-364

INSPECTION, PISTON & CONNECTING

ROD............................9-39,9-94

INSPECTION, PLANETARY GEARTRAIN/

OUTPUT SHAFT...............21-199,21-371

INSPECTION, PUSHRODS..............9-135

INSPECTION, RADIATOR - 5.9L..........7-60

INSPECTION, RADIATOR - 5.9L DIESEL....7-64

INSPECTION, RADIATOR - 8.0L..........7-61

INSPECTION, RADIATOR FAN - 5.9L

DIESEL.............................7-43

INSPECTION, RADIATOR FAN - 5.9L/8.0L . . . 7-42

INSPECTION, REAR CLUTCH.....21-204,21-377

INSPECTION, REMOVAL................5-12

INSPECTION, REMOVAL...........9-155,9-83

INSPECTION, ROCKER ARM / ADJUSTER

ASSY..............................9-146

INSPECTION, SOLID LIFTERS/TAPPETS . . . 9-165

INSPECTION, STANDARD PROCEDURE....9-151

INSPECTION, TAILPIPE - 3.9L/5.2L/5.9L . . . 11-11

INSPECTION, TAILPIPE - 5.9L DIESEL....11-12

INSPECTION, TAILPIPE - 5.9L HD/8.0L....11-12

INSPECTION, TRANSFER CASE -

NV241HD..........................21-476

INSPECTION, TRANSFER CASE -

NV241LD..........................21-442

INSPECTION, TURBOCHARGER..........11-16

INSPECTION, VALVE BODY......21-244,21-419

INSPECTION, VIBRATION DAMPER.......9-172

INSPECTION, WATER PUMP - 5.9L........7-68

INSPECTION, WATER PUMP - 5.9L

DIESEL.............................7-72

INSPECTION, WATER PUMP - 8.0L........7-71

INSPECTION, WIPER & WASHER

SYSTEM............................8R-6

INSTRUMENT CLUSTER - ASSEMBLY.....8J-12

INSTRUMENT CLUSTER - DESCRIPTION

. . . 8J-2

INSTRUMENT CLUSTER - DIAGNOSIS

AND TESTING

........................8J-6

INSTRUMENT CLUSTER - DISASSEMBLY

. . 8J-10

INSTRUMENT CLUSTER - INSTALLATION

. . 8J-13

INSTRUMENT CLUSTER - OPERATION

.....8J-3INSTRUMENT CLUSTER - REMOVAL.....8J-10

INSTRUMENT PANEL ANTENNA CABLE -

INSTALLATION.......................8A-9

INSTRUMENT PANEL ANTENNA CABLE -

REMOVAL...........................8A-9

INSTRUMENT PANEL ASSEMBLY -

INSTALLATION......................23-117

INSTRUMENT PANEL ASSEMBLY -

REMOVAL.........................23-115

INSTRUMENT PANEL DEMISTER DUCTS

- INSTALLATION.....................24-36

INSTRUMENT PANEL DEMISTER DUCTS

- REMOVAL.........................24-36

INSTRUMENT PANEL DUCTS -

INSTALLATION.......................24-37

INSTRUMENT PANEL DUCTS - REMOVAL . 24-37

INSTRUMENT PANEL SYSTEM -

DESCRIPTION......................23-105

INSTRUMENT PANEL SYSTEM -

OPERATION........................23-106

INSTRUMENT PANEL TOP COVER -

INSTALLATION......................23-113

INSTRUMENT PANEL TOP COVER -

REMOVAL.........................23-113

INTAKE AIR HEATER - DESCRIPTION....14-104

INTAKE AIR HEATER - INSTALLATION....14-105

INTAKE AIR HEATER - OPERATION......14-104

INTAKE AIR HEATER - REMOVAL.......14-104

INTAKE AIR HEATER RELAY -

DESCRIPTION......................14-105

INTAKE AIR HEATER RELAY -

INSTALLATION.......................14-106

INTAKE AIR HEATER RELAY -

OPERATION........................14-105

INTAKE AIR HEATER RELAY - REMOVAL . 14-106

INTAKE MANIFOLD - CLEANING....9-107,9-184,

9-51

INTAKE MANIFOLD - DESCRIPTION . . 9-106,9-50

INTAKE MANIFOLD - INSPECTION . . 9-108,9-184,

9-51

INTAKE MANIFOLD - INSTALLATION.....9-108,

9-184,9-51

INTAKE MANIFOLD - OPERATION.........9-50

INTAKE MANIFOLD - REMOVAL....9-107,9-184,

9-50

INTAKE MANIFOLD LEAKAGE -

DIAGNOSIS AND TESTING.........9-106,9-50

INTAKE/EXHAUST VALVES & SEATS -

CLEANING...........................9-26

INTAKE/EXHAUST VALVES & SEATS -

DESCRIPTION...............9-138,9-23,9-80

INTAKE/EXHAUST VALVES & SEATS -

INSPECTION.........................9-26

INTAKE/EXHAUST VALVES & SEATS -

INSTALLATION........................9-26

INTAKE/EXHAUST VALVES & SEATS -

REMOVAL...........................9-25

IN-TANK TRANSMISSION OIL COOLER -

STANDARD PROCEDURE, FLUSHING

COOLERS AND TUBES - WITH

RADIATOR...................7-78,7-82,7-84

IN-TANK TRANSMISSION OIL COOLER -

STANDARD PROCEDURE, FLUSHING

COOLERS AND TUBES - WITHOUT

RADIATOR...................7-79,7-82,7-85

INTERIOR - CAUTION................23-118

INTERIOR LAMPS, SPECIFICATIONS......8L-33

INTERMEDIATE - REMOVAL, AXLE

SHAFTS.............................3-30

INTERMEDIATE AXLE - INSTALLATION.....3-30

INTERNATIONAL SYMBOLS -

DESCRIPTION......................Intro.-5

INTERNATIONAL SYMBOLS -

DESCRIPTION.........................0-1

INTRODUCTION - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS........9-3,9-58

INVERTED FLARING - STANDARD

PROCEDURE, DOUBLE..................5-8

IOD FUSE - DESCRIPTION...........8W-97-5

IOD FUSE - INSTALLATION...........8W-97-6

IOD FUSE - OPERATION.............8W-97-5

IOD FUSE - REMOVAL

..............8W-97-6

ISO FLARING - STANDARD PROCEDURE

....5-8

JOINT - DIAGNOSIS AND TESTING,

LOWER BALL

........................2-10

JOINT - DIAGNOSIS AND TESTING,

UPPER BALL

.........................2-12

JOINT MOLDING - INSTALLATION, ROOF

. . 23-91

BR/BEINDEX 17

Description Group-Page Description Group-Page Description Group-Page