instrument panel DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 3 of 2255

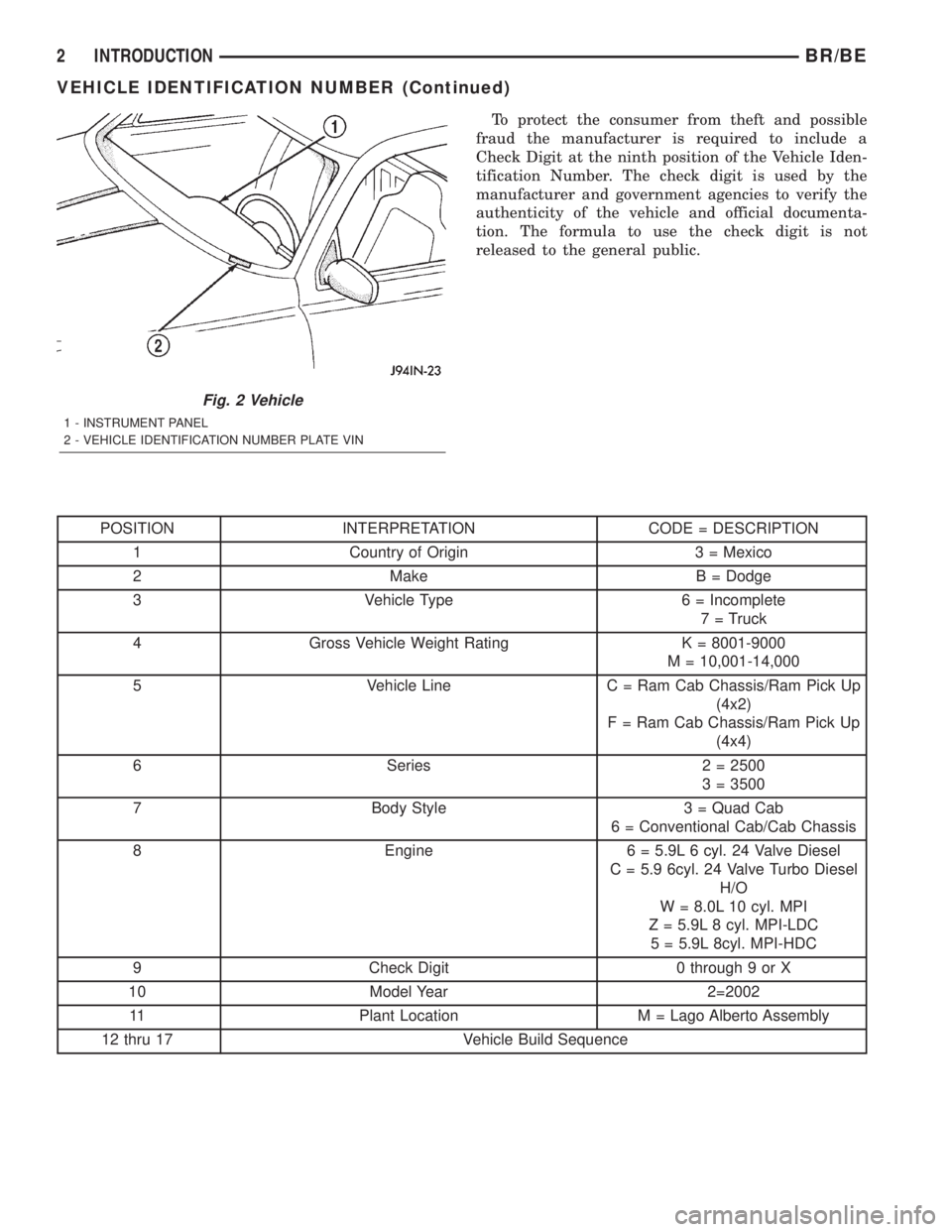

To protect the consumer from theft and possible

fraud the manufacturer is required to include a

Check Digit at the ninth position of the Vehicle Iden-

tification Number. The check digit is used by the

manufacturer and government agencies to verify the

authenticity of the vehicle and official documenta-

tion. The formula to use the check digit is not

released to the general public.

POSITION INTERPRETATION CODE = DESCRIPTION

1 Country of Origin 3 = Mexico

2 Make B = Dodge

3 Vehicle Type 6 = Incomplete

7 = Truck

4 Gross Vehicle Weight Rating K = 8001-9000

M = 10,001-14,000

5 Vehicle Line C = Ram Cab Chassis/Ram Pick Up

(4x2)

F = Ram Cab Chassis/Ram Pick Up

(4x4)

6 Series 2 = 2500

3 = 3500

7 Body Style 3 = Quad Cab

6 = Conventional Cab/Cab Chassis

8 Engine 6 = 5.9L 6 cyl. 24 Valve Diesel

C = 5.9 6cyl. 24 Valve Turbo Diesel

H/O

W = 8.0L 10 cyl. MPI

Z = 5.9L 8 cyl. MPI-LDC

5 = 5.9L 8cyl. MPI-HDC

9 Check Digit 0 through 9 or X

10 Model Year 2=2002

11 Plant Location M = Lago Alberto Assembly

12 thru 17 Vehicle Build Sequence

Fig. 2 Vehicle

1 - INSTRUMENT PANEL

2 - VEHICLE IDENTIFICATION NUMBER PLATE VIN

2 INTRODUCTIONBR/BE

VEHICLE IDENTIFICATION NUMBER (Continued)

Page 6 of 2255

²64 = Ram Truck Cab Chassis (162.7 in. Wheel

Base)

BODY CODE PLATEÐLINE 3

DIGITS 1,2, AND 3

Paint Procedure

²APA = Monotone

²AP9 = Special

²APB = Two-tone (Waterfall)

²APC = Two-tone (Centerband)

²APD = Two-tone (Lower break)

DIGIT 4

Open Space

DIGITS 5 THROUGH 8

Primary Paint

Refer to Group 23, Body for color codes.

DIGIT 9

Open Space

DIGITS 10 THROUGH 13

Secondary Paint

DIGIT 14

Open Space

DIGITS 15 THROUGH 18

Interior Trim Code

DIGIT 19

Open Space

DIGITS 20, 21, AND 22

Engine Code

²EML = 5.9 L 8 cyl. MPI Gasoline

²EMM = 5.9 L 8 cyl. MPI Gasoline (Heavy Duty)

²ETC = 5.9 L 6 cyl. Turbo Diesel

²EWA = 8.0 L 10 cyl. MPI Gasoline

BODY CODE PLATEÐLINE 2

DIGIT 1 Open Space

DIGITS 2 AND 3 Species Code. (Used for Manufacturing)

DIGIT 4

Open SpaceDIGIT 5

Market Code

²B = International

²C = Canada

²M = Mexico

²U = United States

DIGIT 6

Open Space

DIGITS 7 THROUGH 23

Vehicle Identification Number (VIN)

Refer to Vehicle Identification Number (VIN) para-

graph for proper breakdown of VIN code.

BODY CODE PLATEÐLINE 1

DIGITS 1 THROUGH 6 Body-in-white assembly sequence.

DIGIT 7

Open Space

DIGIT 8 Tailgate trim code.

DIGIT 9

Open Space

DIGITS 10 THROUGH 12 Cargo box code

²XBS = Sweptline

DIGIT 13

Open Space

DIGITS 14 THROUGH 16 Tailgate code

²MWD = Plain Tailgate

²MPB = Tailgate Applique (Black)

INTERNATIONAL VEHICLE

CONTROL & DISPLAY

SYMBOLS

DESCRIPTION - INTERNATIONAL SYMBOLS

The graphic symbols illustrated in the following

International Control and Display Symbols Chart are

used to identify various instrument controls. The

symbols correspond to the controls and displays that

are located on the instrument panel.

BR/BEINTRODUCTION 5

BODY CODE PLATE (Continued)

Page 217 of 2255

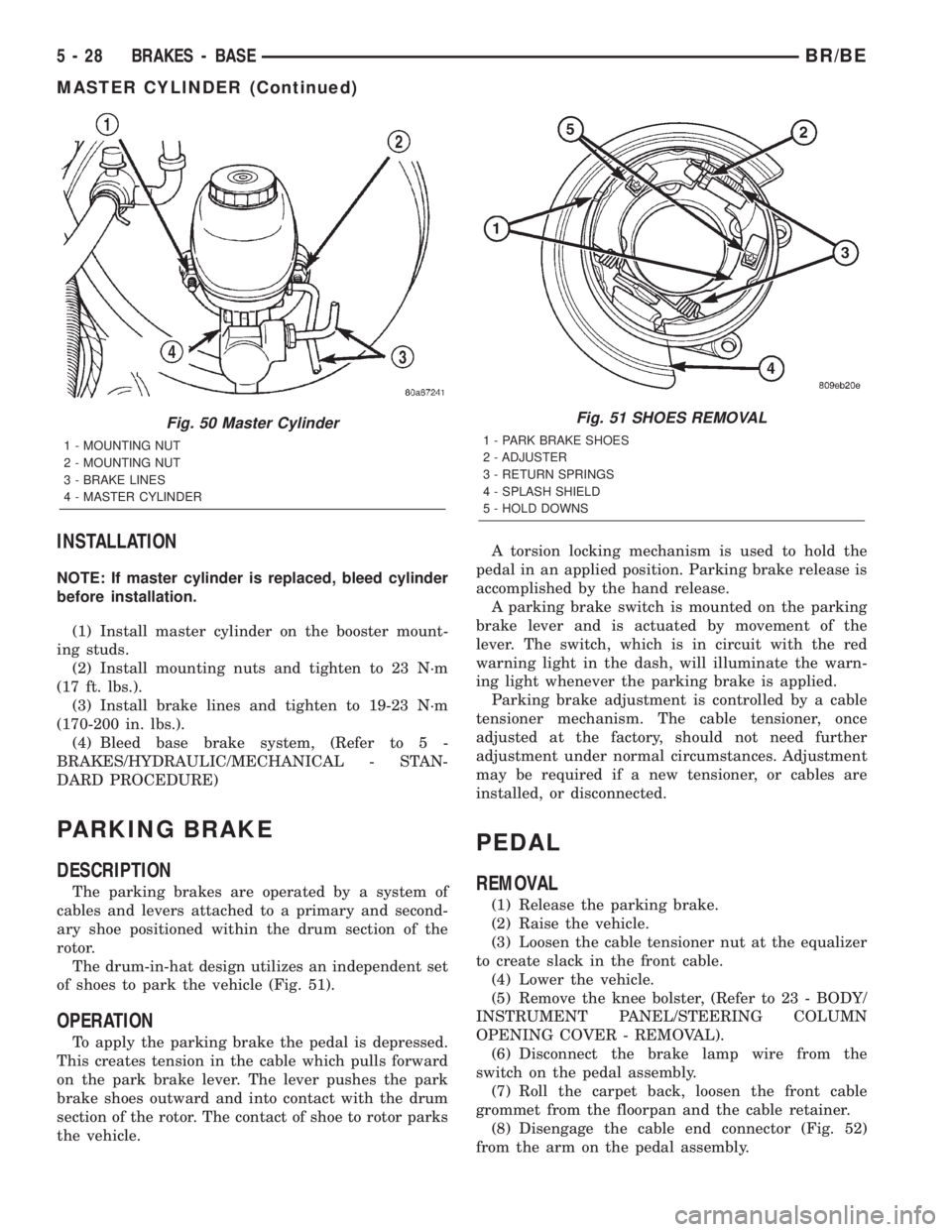

INSTALLATION

NOTE: If master cylinder is replaced, bleed cylinder

before installation.

(1) Install master cylinder on the booster mount-

ing studs.

(2) Install mounting nuts and tighten to 23 N´m

(17 ft. lbs.).

(3) Install brake lines and tighten to 19-23 N´m

(170-200 in. lbs.).

(4) Bleed base brake system, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL - STAN-

DARD PROCEDURE)

PARKING BRAKE

DESCRIPTION

The parking brakes are operated by a system of

cables and levers attached to a primary and second-

ary shoe positioned within the drum section of the

rotor.

The drum-in-hat design utilizes an independent set

of shoes to park the vehicle (Fig. 51).

OPERATION

To apply the parking brake the pedal is depressed.

This creates tension in the cable which pulls forward

on the park brake lever. The lever pushes the park

brake shoes outward and into contact with the drum

section of the rotor. The contact of shoe to rotor parks

the vehicle.A torsion locking mechanism is used to hold the

pedal in an applied position. Parking brake release is

accomplished by the hand release.

A parking brake switch is mounted on the parking

brake lever and is actuated by movement of the

lever. The switch, which is in circuit with the red

warning light in the dash, will illuminate the warn-

ing light whenever the parking brake is applied.

Parking brake adjustment is controlled by a cable

tensioner mechanism. The cable tensioner, once

adjusted at the factory, should not need further

adjustment under normal circumstances. Adjustment

may be required if a new tensioner, or cables are

installed, or disconnected.

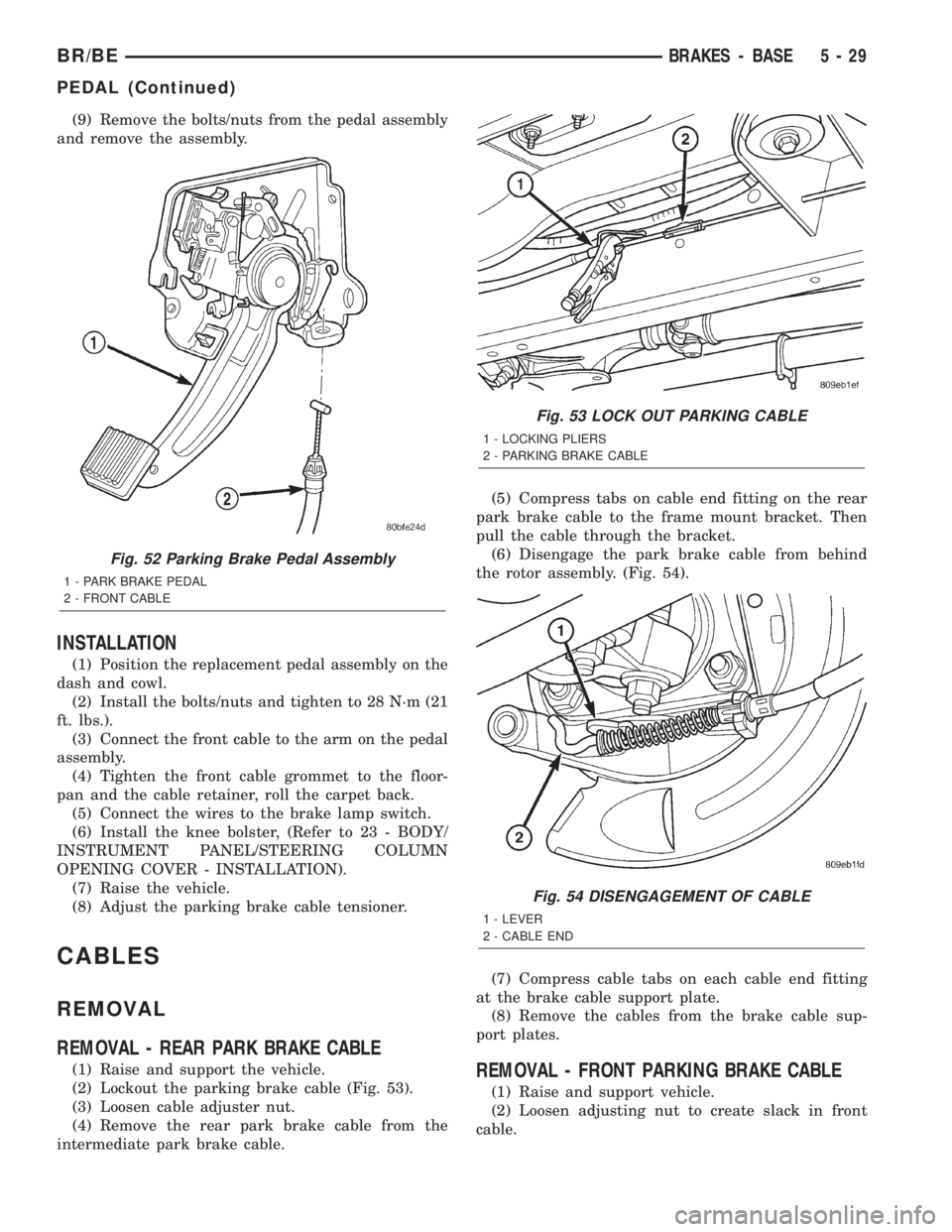

PEDAL

REMOVAL

(1) Release the parking brake.

(2) Raise the vehicle.

(3) Loosen the cable tensioner nut at the equalizer

to create slack in the front cable.

(4) Lower the vehicle.

(5) Remove the knee bolster, (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - REMOVAL).

(6) Disconnect the brake lamp wire from the

switch on the pedal assembly.

(7) Roll the carpet back, loosen the front cable

grommet from the floorpan and the cable retainer.

(8) Disengage the cable end connector (Fig. 52)

from the arm on the pedal assembly.

Fig. 50 Master Cylinder

1 - MOUNTING NUT

2 - MOUNTING NUT

3 - BRAKE LINES

4 - MASTER CYLINDER

Fig. 51 SHOES REMOVAL

1 - PARK BRAKE SHOES

2 - ADJUSTER

3 - RETURN SPRINGS

4 - SPLASH SHIELD

5 - HOLD DOWNS

5 - 28 BRAKES - BASEBR/BE

MASTER CYLINDER (Continued)

Page 218 of 2255

(9) Remove the bolts/nuts from the pedal assembly

and remove the assembly.

INSTALLATION

(1) Position the replacement pedal assembly on the

dash and cowl.

(2) Install the bolts/nuts and tighten to 28 N´m (21

ft. lbs.).

(3) Connect the front cable to the arm on the pedal

assembly.

(4) Tighten the front cable grommet to the floor-

pan and the cable retainer, roll the carpet back.

(5) Connect the wires to the brake lamp switch.

(6) Install the knee bolster, (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - INSTALLATION).

(7) Raise the vehicle.

(8) Adjust the parking brake cable tensioner.

CABLES

REMOVAL

REMOVAL - REAR PARK BRAKE CABLE

(1) Raise and support the vehicle.

(2) Lockout the parking brake cable (Fig. 53).

(3) Loosen cable adjuster nut.

(4) Remove the rear park brake cable from the

intermediate park brake cable.(5) Compress tabs on cable end fitting on the rear

park brake cable to the frame mount bracket. Then

pull the cable through the bracket.

(6) Disengage the park brake cable from behind

the rotor assembly. (Fig. 54).

(7) Compress cable tabs on each cable end fitting

at the brake cable support plate.

(8) Remove the cables from the brake cable sup-

port plates.REMOVAL - FRONT PARKING BRAKE CABLE

(1) Raise and support vehicle.

(2) Loosen adjusting nut to create slack in front

cable.

Fig. 52 Parking Brake Pedal Assembly

1 - PARK BRAKE PEDAL

2 - FRONT CABLE

Fig. 53 LOCK OUT PARKING CABLE

1 - LOCKING PLIERS

2 - PARKING BRAKE CABLE

Fig. 54 DISENGAGEMENT OF CABLE

1 - LEVER

2 - CABLE END

BR/BEBRAKES - BASE 5 - 29

PEDAL (Continued)

Page 220 of 2255

(7) Install the drum in hat assembly and verify

that the rotor rotates freely without drag.

(8) Install the wheel/tire assemblies, (Refer to 22 -

TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(9) Lower the vehicle enough for access to the park

brake foot pedal. Then fully apply the park brakes.

NOTE: Leave park brakes applied until adjustment

is complete.

(10) Raise the vehicle again.

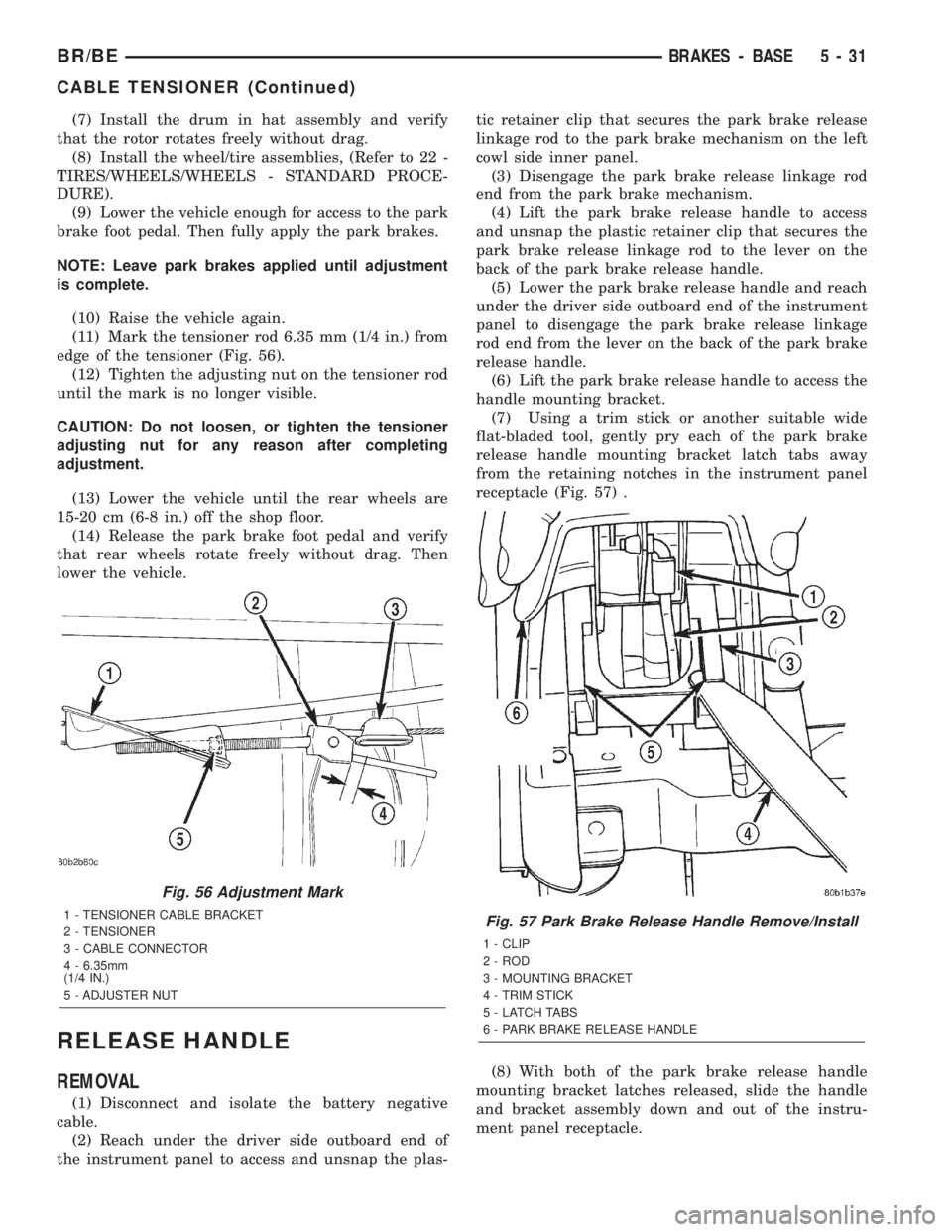

(11) Mark the tensioner rod 6.35 mm (1/4 in.) from

edge of the tensioner (Fig. 56).

(12) Tighten the adjusting nut on the tensioner rod

until the mark is no longer visible.

CAUTION: Do not loosen, or tighten the tensioner

adjusting nut for any reason after completing

adjustment.

(13) Lower the vehicle until the rear wheels are

15-20 cm (6-8 in.) off the shop floor.

(14) Release the park brake foot pedal and verify

that rear wheels rotate freely without drag. Then

lower the vehicle.

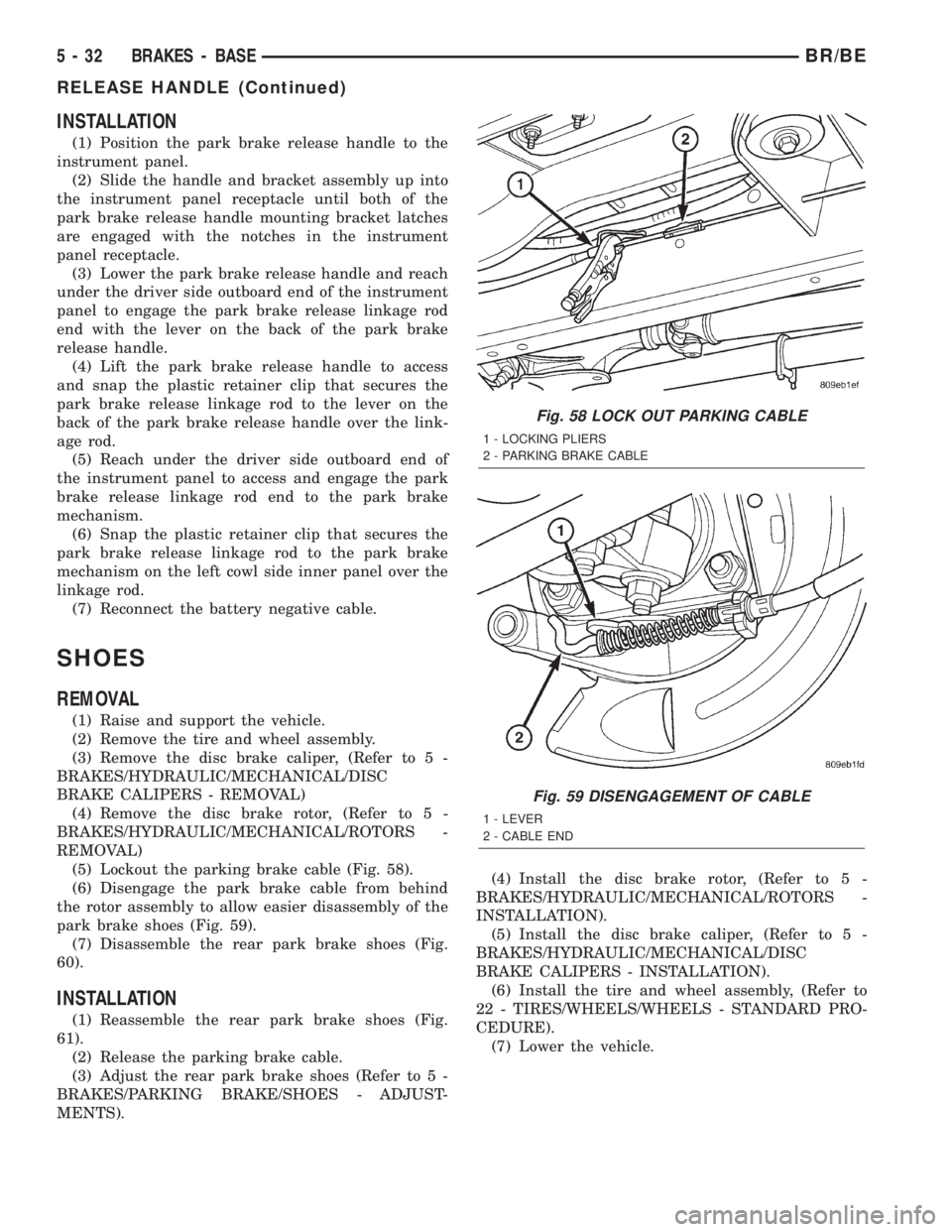

RELEASE HANDLE

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Reach under the driver side outboard end of

the instrument panel to access and unsnap the plas-tic retainer clip that secures the park brake release

linkage rod to the park brake mechanism on the left

cowl side inner panel.

(3) Disengage the park brake release linkage rod

end from the park brake mechanism.

(4) Lift the park brake release handle to access

and unsnap the plastic retainer clip that secures the

park brake release linkage rod to the lever on the

back of the park brake release handle.

(5) Lower the park brake release handle and reach

under the driver side outboard end of the instrument

panel to disengage the park brake release linkage

rod end from the lever on the back of the park brake

release handle.

(6) Lift the park brake release handle to access the

handle mounting bracket.

(7) Using a trim stick or another suitable wide

flat-bladed tool, gently pry each of the park brake

release handle mounting bracket latch tabs away

from the retaining notches in the instrument panel

receptacle (Fig. 57) .

(8) With both of the park brake release handle

mounting bracket latches released, slide the handle

and bracket assembly down and out of the instru-

ment panel receptacle.

Fig. 56 Adjustment Mark

1 - TENSIONER CABLE BRACKET

2 - TENSIONER

3 - CABLE CONNECTOR

4 - 6.35mm

(1/4 IN.)

5 - ADJUSTER NUTFig. 57 Park Brake Release Handle Remove/Install

1 - CLIP

2 - ROD

3 - MOUNTING BRACKET

4 - TRIM STICK

5 - LATCH TABS

6 - PARK BRAKE RELEASE HANDLE

BR/BEBRAKES - BASE 5 - 31

CABLE TENSIONER (Continued)

Page 221 of 2255

INSTALLATION

(1) Position the park brake release handle to the

instrument panel.

(2) Slide the handle and bracket assembly up into

the instrument panel receptacle until both of the

park brake release handle mounting bracket latches

are engaged with the notches in the instrument

panel receptacle.

(3) Lower the park brake release handle and reach

under the driver side outboard end of the instrument

panel to engage the park brake release linkage rod

end with the lever on the back of the park brake

release handle.

(4) Lift the park brake release handle to access

and snap the plastic retainer clip that secures the

park brake release linkage rod to the lever on the

back of the park brake release handle over the link-

age rod.

(5) Reach under the driver side outboard end of

the instrument panel to access and engage the park

brake release linkage rod end to the park brake

mechanism.

(6) Snap the plastic retainer clip that secures the

park brake release linkage rod to the park brake

mechanism on the left cowl side inner panel over the

linkage rod.

(7) Reconnect the battery negative cable.

SHOES

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the tire and wheel assembly.

(3) Remove the disc brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL)

(4) Remove the disc brake rotor, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

REMOVAL)

(5) Lockout the parking brake cable (Fig. 58).

(6) Disengage the park brake cable from behind

the rotor assembly to allow easier disassembly of the

park brake shoes (Fig. 59).

(7) Disassemble the rear park brake shoes (Fig.

60).

INSTALLATION

(1) Reassemble the rear park brake shoes (Fig.

61).

(2) Release the parking brake cable.

(3) Adjust the rear park brake shoes (Refer to 5 -

BRAKES/PARKING BRAKE/SHOES - ADJUST-

MENTS).(4) Install the disc brake rotor, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

INSTALLATION).

(5) Install the disc brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION).

(6) Install the tire and wheel assembly, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

(7) Lower the vehicle.

Fig. 58 LOCK OUT PARKING CABLE

1 - LOCKING PLIERS

2 - PARKING BRAKE CABLE

Fig. 59 DISENGAGEMENT OF CABLE

1 - LEVER

2 - CABLE END

5 - 32 BRAKES - BASEBR/BE

RELEASE HANDLE (Continued)

Page 297 of 2255

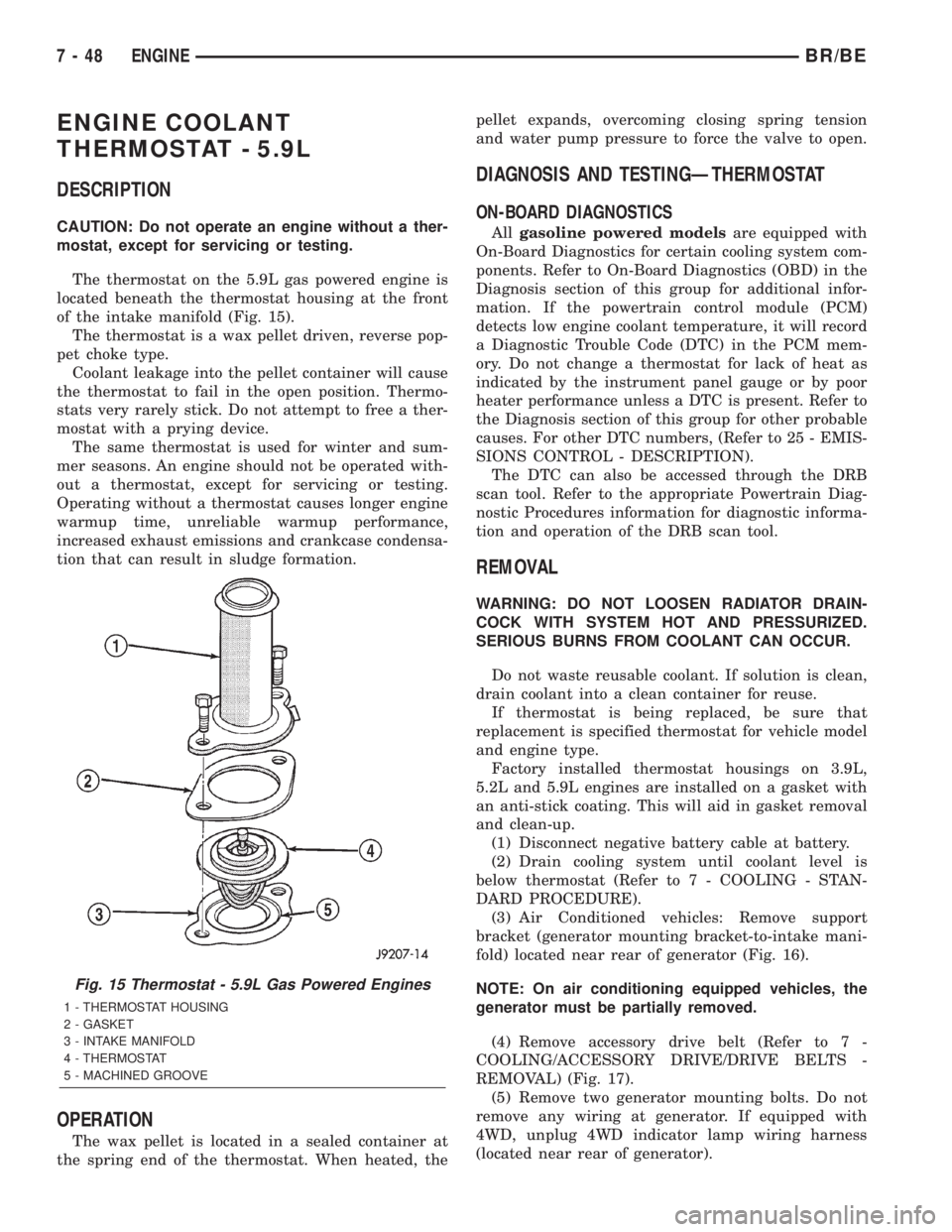

ENGINE COOLANT

THERMOSTAT - 5.9L

DESCRIPTION

CAUTION: Do not operate an engine without a ther-

mostat, except for servicing or testing.

The thermostat on the 5.9L gas powered engine is

located beneath the thermostat housing at the front

of the intake manifold (Fig. 15).

The thermostat is a wax pellet driven, reverse pop-

pet choke type.

Coolant leakage into the pellet container will cause

the thermostat to fail in the open position. Thermo-

stats very rarely stick. Do not attempt to free a ther-

mostat with a prying device.

The same thermostat is used for winter and sum-

mer seasons. An engine should not be operated with-

out a thermostat, except for servicing or testing.

Operating without a thermostat causes longer engine

warmup time, unreliable warmup performance,

increased exhaust emissions and crankcase condensa-

tion that can result in sludge formation.

OPERATION

The wax pellet is located in a sealed container at

the spring end of the thermostat. When heated, thepellet expands, overcoming closing spring tension

and water pump pressure to force the valve to open.

DIAGNOSIS AND TESTINGÐTHERMOSTAT

ON-BOARD DIAGNOSTICS

Allgasoline powered modelsare equipped with

On-Board Diagnostics for certain cooling system com-

ponents. Refer to On-Board Diagnostics (OBD) in the

Diagnosis section of this group for additional infor-

mation. If the powertrain control module (PCM)

detects low engine coolant temperature, it will record

a Diagnostic Trouble Code (DTC) in the PCM mem-

ory. Do not change a thermostat for lack of heat as

indicated by the instrument panel gauge or by poor

heater performance unless a DTC is present. Refer to

the Diagnosis section of this group for other probable

causes. For other DTC numbers, (Refer to 25 - EMIS-

SIONS CONTROL - DESCRIPTION).

The DTC can also be accessed through the DRB

scan tool. Refer to the appropriate Powertrain Diag-

nostic Procedures information for diagnostic informa-

tion and operation of the DRB scan tool.

REMOVAL

WARNING: DO NOT LOOSEN RADIATOR DRAIN-

COCK WITH SYSTEM HOT AND PRESSURIZED.

SERIOUS BURNS FROM COOLANT CAN OCCUR.

Do not waste reusable coolant. If solution is clean,

drain coolant into a clean container for reuse.

If thermostat is being replaced, be sure that

replacement is specified thermostat for vehicle model

and engine type.

Factory installed thermostat housings on 3.9L,

5.2L and 5.9L engines are installed on a gasket with

an anti-stick coating. This will aid in gasket removal

and clean-up.

(1) Disconnect negative battery cable at battery.

(2) Drain cooling system until coolant level is

below thermostat (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(3) Air Conditioned vehicles: Remove support

bracket (generator mounting bracket-to-intake mani-

fold) located near rear of generator (Fig. 16).

NOTE: On air conditioning equipped vehicles, the

generator must be partially removed.

(4) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL) (Fig. 17).

(5) Remove two generator mounting bolts. Do not

remove any wiring at generator. If equipped with

4WD, unplug 4WD indicator lamp wiring harness

(located near rear of generator).

Fig. 15 Thermostat - 5.9L Gas Powered Engines

1 - THERMOSTAT HOUSING

2 - GASKET

3 - INTAKE MANIFOLD

4 - THERMOSTAT

5 - MACHINED GROOVE

7 - 48 ENGINEBR/BE

Page 300 of 2255

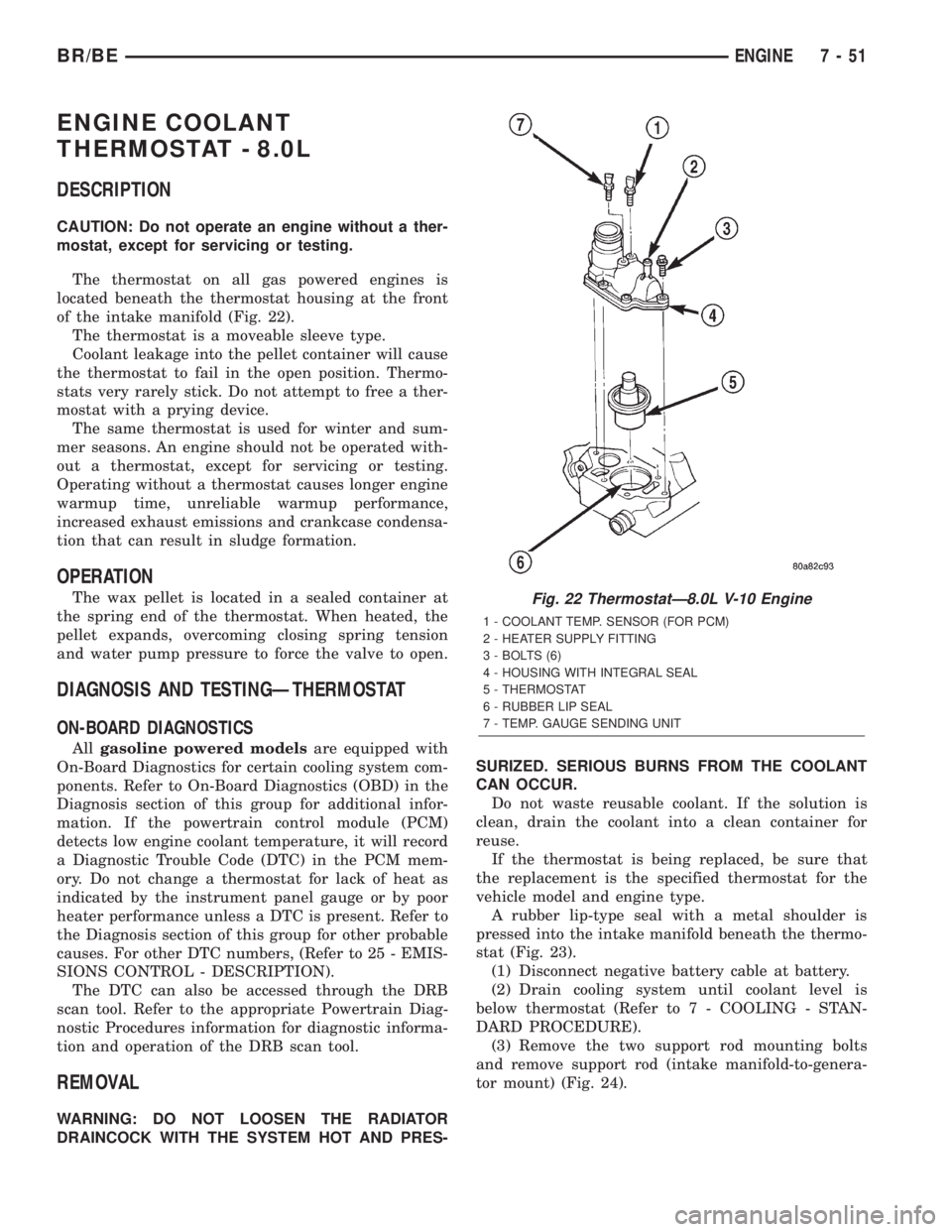

ENGINE COOLANT

THERMOSTAT - 8.0L

DESCRIPTION

CAUTION: Do not operate an engine without a ther-

mostat, except for servicing or testing.

The thermostat on all gas powered engines is

located beneath the thermostat housing at the front

of the intake manifold (Fig. 22).

The thermostat is a moveable sleeve type.

Coolant leakage into the pellet container will cause

the thermostat to fail in the open position. Thermo-

stats very rarely stick. Do not attempt to free a ther-

mostat with a prying device.

The same thermostat is used for winter and sum-

mer seasons. An engine should not be operated with-

out a thermostat, except for servicing or testing.

Operating without a thermostat causes longer engine

warmup time, unreliable warmup performance,

increased exhaust emissions and crankcase condensa-

tion that can result in sludge formation.

OPERATION

The wax pellet is located in a sealed container at

the spring end of the thermostat. When heated, the

pellet expands, overcoming closing spring tension

and water pump pressure to force the valve to open.

DIAGNOSIS AND TESTINGÐTHERMOSTAT

ON-BOARD DIAGNOSTICS

Allgasoline powered modelsare equipped with

On-Board Diagnostics for certain cooling system com-

ponents. Refer to On-Board Diagnostics (OBD) in the

Diagnosis section of this group for additional infor-

mation. If the powertrain control module (PCM)

detects low engine coolant temperature, it will record

a Diagnostic Trouble Code (DTC) in the PCM mem-

ory. Do not change a thermostat for lack of heat as

indicated by the instrument panel gauge or by poor

heater performance unless a DTC is present. Refer to

the Diagnosis section of this group for other probable

causes. For other DTC numbers, (Refer to 25 - EMIS-

SIONS CONTROL - DESCRIPTION).

The DTC can also be accessed through the DRB

scan tool. Refer to the appropriate Powertrain Diag-

nostic Procedures information for diagnostic informa-

tion and operation of the DRB scan tool.

REMOVAL

WARNING: DO NOT LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND PRES-SURIZED. SERIOUS BURNS FROM THE COOLANT

CAN OCCUR.

Do not waste reusable coolant. If the solution is

clean, drain the coolant into a clean container for

reuse.

If the thermostat is being replaced, be sure that

the replacement is the specified thermostat for the

vehicle model and engine type.

A rubber lip-type seal with a metal shoulder is

pressed into the intake manifold beneath the thermo-

stat (Fig. 23).

(1) Disconnect negative battery cable at battery.

(2) Drain cooling system until coolant level is

below thermostat (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(3) Remove the two support rod mounting bolts

and remove support rod (intake manifold-to-genera-

tor mount) (Fig. 24).

Fig. 22 ThermostatÐ8.0L V-10 Engine

1 - COOLANT TEMP. SENSOR (FOR PCM)

2 - HEATER SUPPLY FITTING

3 - BOLTS (6)

4 - HOUSING WITH INTEGRAL SEAL

5 - THERMOSTAT

6 - RUBBER LIP SEAL

7 - TEMP. GAUGE SENDING UNIT

BR/BEENGINE 7 - 51

Page 338 of 2255

AUDIO

TABLE OF CONTENTS

page page

AUDIO

DESCRIPTION..........................1

OPERATION............................2

DIAGNOSIS AND TESTING - AUDIO..........2

SPECIAL TOOLS

AUDIO SYSTEMS......................4

ANTENNA BODY & CABLE

DESCRIPTION..........................4

OPERATION............................4

DIAGNOSIS AND TESTING - ANTENNA.......5

REMOVAL.............................6

INSTALLATION..........................6

RADIO CHOKE RELAY

DESCRIPTION..........................7

OPERATION............................8

DIAGNOSIS AND TESTING - RADIO CHOKE

RELAY...............................8

REMOVAL.............................8

INSTALLATION..........................9

INSTRUMENT PANEL ANTENNA CABLE

REMOVAL.............................9

INSTALLATION..........................9

RADIO

DESCRIPTION.........................10

OPERATION...........................10

DIAGNOSIS AND TESTING - RADIO.........10

REMOVAL.............................11

INSTALLATION.........................11

RADIO NOISE SUPPRESSION COMPONENTS

DESCRIPTION.........................12

DIAGNOSIS AND TESTING - RADIO NOISE

SUPPRESSION COMPONENTS...........12ENGINE-TO-BODY GROUND STRAP

REMOVAL.............................12

INSTALLATION.........................13

CAB-TO- BED GROUND STRAP

REMOVAL.............................13

INSTALLATION.........................14

HEATER CORE GROUND STRAP

REMOVAL.............................14

INSTALLATION.........................14

REMOTE SWITCHES

DESCRIPTION.........................14

OPERATION...........................15

DIAGNOSIS AND TESTING - REMOTE

SWITCHES..........................15

REMOVAL.............................16

INSTALLATION.........................16

SPEAKER

DESCRIPTION.........................17

OPERATION...........................17

DIAGNOSIS AND TESTING - SPEAKER......17

A-PILLAR TWEETER SPEAKER

REMOVAL.............................18

INSTALLATION.........................19

FRONT DOOR SPEAKER

REMOVAL.............................19

INSTALLATION.........................19

REAR CAB SIDE PANEL SPEAKER

REMOVAL.............................20

INSTALLATION.........................20

REAR DOOR SPEAKER

REMOVAL.............................20

INSTALLATION.........................21

AUDIO

DESCRIPTION

An audio system is standard factory-installed

equipment on this model, unless the vehicle is

ordered with an available radio delete option. The

standard equipment audio system includes an

AM/FM/cassette (RAS sales code) receiver, and

speakers in four locations. Several combinations of

radio receivers and speaker systems are offered as

optional equipment on this model. The audio system

uses an ignition switched source of battery current so

that the system will only operate when the ignition

switch is in the On or Accessory positions. The audio

system includes the following components:²Antenna

²Clockspring (with remote radio switches only)

²Filter, choke and speaker relay (with premium

speaker system only)

²High-line or premium Central Timer Module

(CTM) (with remote radio switches)

²Radio noise suppression components

²Radio receiver

²Remote radio switches (optional with RAZ radio

receiver only)

²Speakers

Refer to Electrical, Restraints for more information

on the clockspring. Refer to Electrical, Body Control/

Central Control Module for more information on the

Central Timer Module. Refer to the appropriate wir-

ing information. The wiring information includes wir-

BR/BEAUDIO 8A - 1

Page 339 of 2255

ing diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds. Following are general descriptions of

the remaining major components in the standard and

optional factory-installed audio systems.

OPERATION

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of each of the available audio systems.

CENTRAL TIMER MODULE

The high-line or premium Central Timer Module

(CTM) can also control some features of the audio

system when the vehicle is equipped with the

optional RAZ radio receiver and remote radio

switches. A high-line CTM is used on high-line ver-

sions of this vehicle. A premium CTM is used on

vehicles equipped with the optional heated seats. The

CTM combines the functions of a chime/buzzer mod-

ule, an intermittent wipe module, an illuminated

entry module, a remote keyless entry module, and a

vehicle theft security system module in a single unit.

The high-line or premium CTM also controls and

integrates many of the additional electronic functions

and features included on models with this option.

The RAZ radio receiver with a remote radio switch

option is one of the features that the CTM controls.

The CTM is programmed to send switch status mes-sages over the Chrysler Collision Detection (CCD)

data bus to control the volume, seek, and pre-set sta-

tion advance functions of the RAZ radio receiver. The

CTM monitors the status of the remote radio

switches located on the steering wheel through a

hard wired circuit. The CTM then sends the proper

switch status messages to the radio receiver. The

electronic circuitry within the radio receiver responds

to the switch status messages it receives by adjusting

the radio settings as requested.

Refer to Electrical, Body Control/Central Timer

Module for more information on the high-line CTM.

Refer to Remote Radio Switch in Description and

Operation for more information on this component.

In addition, radio receivers connected to the CCD

data bus have several audio system functions that

can be diagnosed using a DRBIIItscan tool. Refer to

the proper Diagnostic Procedures manual for more

information on DRBIIIttesting of the audio systems.

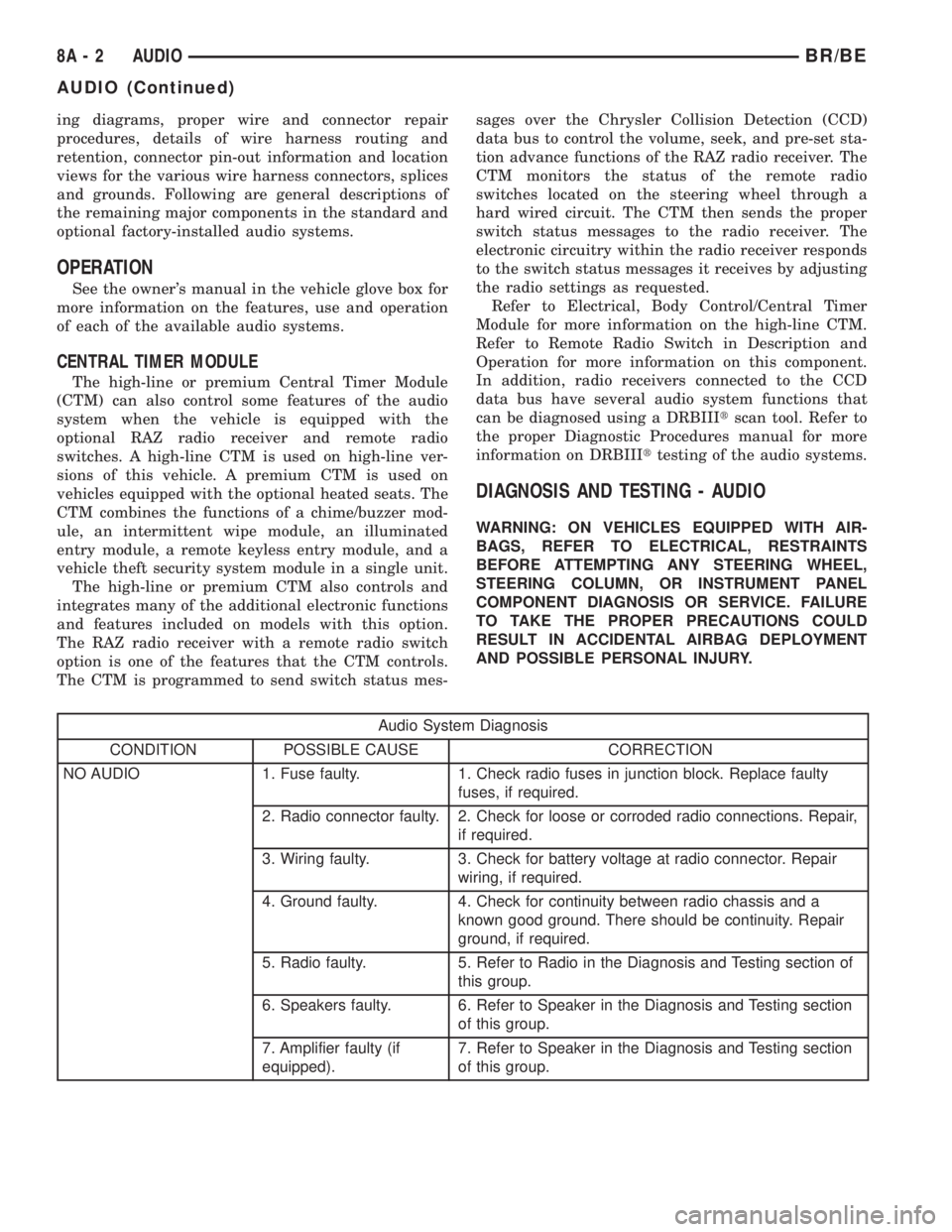

DIAGNOSIS AND TESTING - AUDIO

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Audio System Diagnosis

CONDITION POSSIBLE CAUSE CORRECTION

NO AUDIO 1. Fuse faulty. 1. Check radio fuses in junction block. Replace faulty

fuses, if required.

2. Radio connector faulty. 2. Check for loose or corroded radio connections. Repair,

if required.

3. Wiring faulty. 3. Check for battery voltage at radio connector. Repair

wiring, if required.

4. Ground faulty. 4. Check for continuity between radio chassis and a

known good ground. There should be continuity. Repair

ground, if required.

5. Radio faulty. 5. Refer to Radio in the Diagnosis and Testing section of

this group.

6. Speakers faulty. 6. Refer to Speaker in the Diagnosis and Testing section

of this group.

7. Amplifier faulty (if

equipped).7. Refer to Speaker in the Diagnosis and Testing section

of this group.

8A - 2 AUDIOBR/BE

AUDIO (Continued)