power steering fluid DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 19 of 2255

DESCRIPTION - AUTOMATIC TRANSMISSION

FLUID

NOTE: Refer to the maintenance schedules in this

group for the recommended maintenance (fluid/filter

change) intervals for this transmission.

NOTE: Refer to Service Procedures in this group for

fluid level checking procedures.

MopartATF +4, type 9602, Automatic Transmis-

sion Fluid is the recommended fluid for

DaimlerChrysler automatic transmissions.

Dexron II fluid IS NOT recommended. Clutch

chatter can result from the use of improper

fluid.

MopartATF +4, type 9602, Automatic Transmis-

sion Fluid when new is red in color. The ATF is dyed

red so it can be identified from other fluids used in

the vehicle such as engine oil or antifreeze. The red

color is not permanent and is not an indicator of fluid

condition. As the vehicle is driven, the ATF will begin

to look darker in color and may eventually become

brown.This is normal.A dark brown/black fluid

accompanied with a burnt odor and/or deterioration

in shift quality may indicate fluid deterioration or

transmission component failure.

FLUID ADDITIVES

DaimlerChrysler strongly recommends against the

addition of any fluids to the transmission, other than

those automatic transmission fluids listed above.

Exceptions to this policy are the use of special dyes

to aid in detecting fluid leaks.

Various ªspecialº additives and supplements exist

that claim to improve shift feel and/or quality. These

additives and others also claim to improve converter

clutch operation and inhibit overheating, oxidation,

varnish, and sludge. These claims have not been sup-

ported to the satisfaction of DaimlerChrysler and

these additivesmust not be used.The use of trans-

mission ªsealersº should also be avoided, since they

may adversely affect the integrity of transmission

seals.

OPERATION - AUTOMATIC TRANSMISSION

FLUID

The automatic transmission fluid is selected based

upon several qualities. The fluid must provide a high

level of protection for the internal components by

providing a lubricating film between adjacent metal

components. The fluid must also be thermally stable

so that it can maintain a consistent viscosity through

a large temperature range. If the viscosity stays con-

stant through the temperature range of operation,transmission operation and shift feel will remain con-

sistent. Transmission fluid must also be a good con-

ductor of heat. The fluid must absorb heat from the

internal transmission components and transfer that

heat to the transmission case.

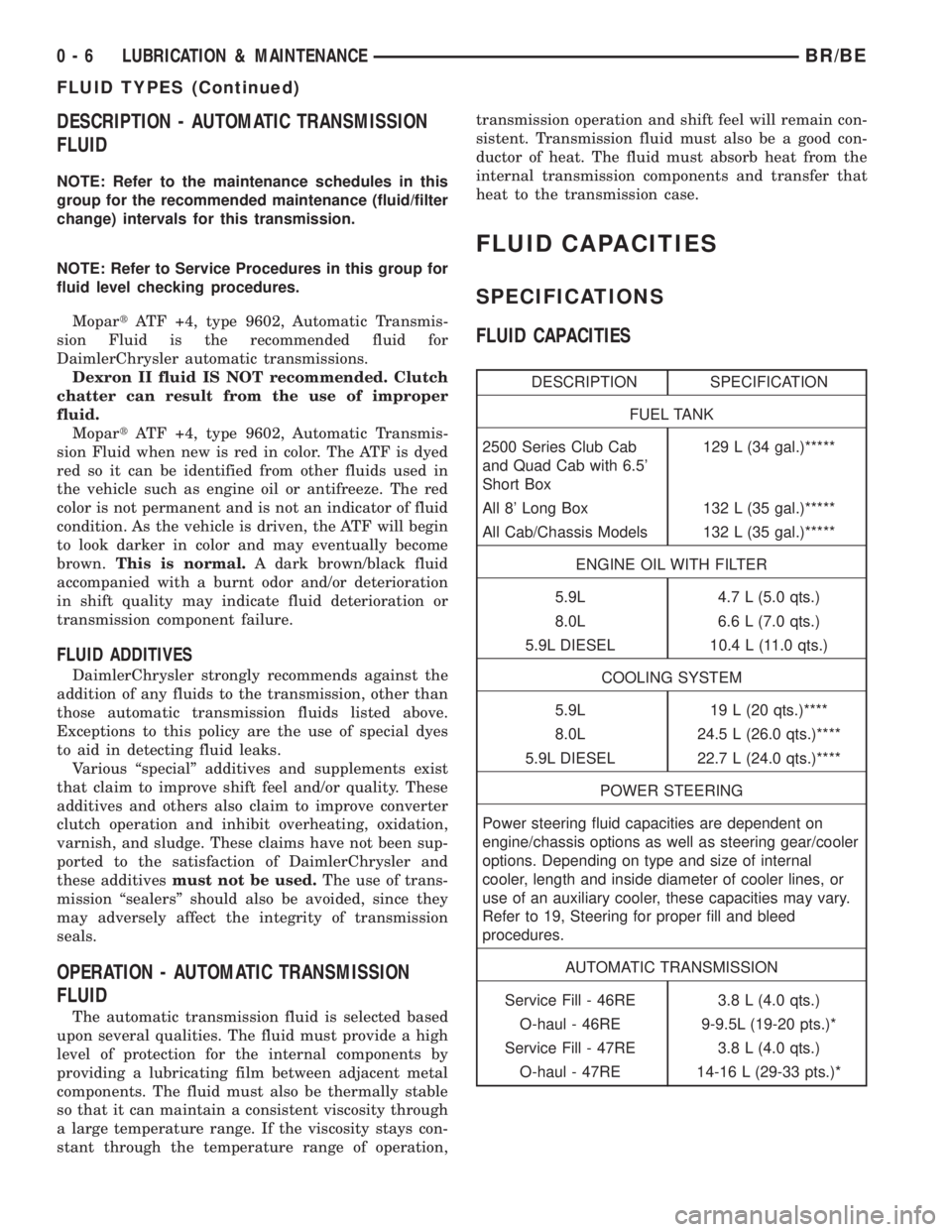

FLUID CAPACITIES

SPECIFICATIONS

FLUID CAPACITIES

DESCRIPTION SPECIFICATION

FUEL TANK

2500 Series Club Cab

and Quad Cab with 6.5'

Short Box129 L (34 gal.)*****

All 8' Long Box 132 L (35 gal.)*****

All Cab/Chassis Models 132 L (35 gal.)*****

ENGINE OIL WITH FILTER

5.9L 4.7 L (5.0 qts.)

8.0L 6.6 L (7.0 qts.)

5.9L DIESEL 10.4 L (11.0 qts.)

COOLING SYSTEM

5.9L 19 L (20 qts.)****

8.0L 24.5 L (26.0 qts.)****

5.9L DIESEL 22.7 L (24.0 qts.)****

POWER STEERING

Power steering fluid capacities are dependent on

engine/chassis options as well as steering gear/cooler

options. Depending on type and size of internal

cooler, length and inside diameter of cooler lines, or

use of an auxiliary cooler, these capacities may vary.

Refer to 19, Steering for proper fill and bleed

procedures.

AUTOMATIC TRANSMISSION

Service Fill - 46RE 3.8 L (4.0 qts.)

O-haul - 46RE 9-9.5L (19-20 pts.)*

Service Fill - 47RE 3.8 L (4.0 qts.)

O-haul - 47RE 14-16 L (29-33 pts.)*

0 - 6 LUBRICATION & MAINTENANCEBR/BE

FLUID TYPES (Continued)

Page 194 of 2255

CAUTION: Never use gasoline, kerosene, alcohol,

motor oil, transmission fluid, or any fluid containing

mineral oil to clean the system components. These

fluids damage rubber cups and seals. Use only

fresh brake fluid or Mopar brake cleaner to clean or

flush brake system components. These are the only

cleaning materials recommended. If system contam-

ination is suspected, check the fluid for dirt, discol-

oration, or separation into distinct layers. Also

check the reservoir cap seal for distortion. Drain

and flush the system with new brake fluid if con-

tamination is suspected.

CAUTION: Use Mopar brake fluid, or an equivalent

quality fluid meeting SAE/DOT standards J1703 and

DOT 3. Brake fluid must be clean and free of con-

taminants. Use fresh fluid from sealed containers

only to ensure proper antilock component opera-

tion.

CAUTION: Use Mopar multi-mileage or high temper-

ature grease to lubricate caliper slide surfaces,

drum brake pivot pins, and shoe contact points on

the backing plates. Use multi-mileage grease or GE

661 or Dow 111 silicone grease on caliper slide pins

to ensure proper operation.

DIAGNOSIS AND TESTING - BASE BRAKE

SYSTEM

Base brake components consist of the brake shoes,

calipers, wheel cylinders, brake drums, rotors, brake

lines, master cylinder, booster, and parking brake

components.

Brake diagnosis involves determining if the prob-

lem is related to a mechanical, hydraulic, or vacuum

operated component.

The first diagnosis step is the preliminary check.

PRELIMINARY BRAKE CHECK

(1) Check condition of tires and wheels. Damaged

wheels and worn, damaged, or underinflated tires

can cause pull, shudder, vibration, and a condition

similar to grab.

(2) If complaint was based on noise when braking,

check suspension components. Jounce front and rear

of vehicle and listen for noise that might be caused

by loose, worn or damaged suspension or steering

components.

(3) Inspect brake fluid level and condition. Note

that the brake reservoir fluid level will decrease in

proportion to normal lining wear.Also note that

brake fluid tends to darken over time. This is

normal and should not be mistaken for contam-

ination.(a) If fluid level is abnormally low, look for evi-

dence of leaks at calipers, wheel cylinders, brake

lines, and master cylinder.

(b) If fluid appears contaminated, drain out a

sample to examine. System will have to be flushed

if fluid is separated into layers, or contains a sub-

stance other than brake fluid. The system seals

and cups will also have to be replaced after flush-

ing. Use clean brake fluid to flush the system.

(4) Check parking brake operation. Verify free

movement and full release of cables and pedal. Also

note if vehicle was being operated with parking

brake partially applied.

(5) Check brake pedal operation. Verify that pedal

does not bind and has adequate free play. If pedal

lacks free play, check pedal and power booster for

being loose or for bind condition. Do not road test

until condition is corrected.

(6) Check booster vacuum check valve and hose.

(7) If components checked appear OK, road test

the vehicle.

ROAD TESTING

(1) If complaint involved low brake pedal, pump

pedal and note if it comes back up to normal height.

(2) Check brake pedal response with transmission

in Neutral and engine running. Pedal should remain

firm under constant foot pressure.

(3) During road test, make normal and firm brake

stops in 25-40 mph range. Note faulty brake opera-

tion such as low pedal, hard pedal, fade, pedal pulsa-

tion, pull, grab, drag, noise, etc.

(4) Attempt to stop the vehicle with the parking

brake only and note grab, drag, noise, etc.

PEDAL FALLS AWAY

A brake pedal that falls away under steady foot

pressure is generally the result of a system leak. The

leak point could be at a brake line, fitting, hose, or

caliper/wheel cylinder. If leakage is severe, fluid will

be evident at or around the leaking component.

Internal leakage (seal by-pass) in the master cylin-

der caused by worn or damaged piston cups, may

also be the problem cause.

An internal leak in the ABS or RWAL system may

also be the problem with no physical evidence.

LOW PEDAL

If a low pedal is experienced, pump the pedal sev-

eral times. If the pedal comes back up, worn linings,

rotors, drums, or rear brakes out of adjustment are

the most likely causes. The proper course of action is

to inspect and replace all worn component and make

the proper adjustments.

BR/BEBRAKES - BASE 5 - 5

HYDRAULIC/MECHANICAL (Continued)

Page 204 of 2255

(8) Remove the supports and lower the vehicle.

(9) Verify a firm pedal before moving the vehicle.

FLUID

DIAGNOSIS AND TESTING - BRAKE FLUID

CONTAMINATION

Indications of fluid contamination are swollen or

deteriorated rubber parts.

Swollen rubber parts indicate the presence of

petroleum in the brake fluid.

To test for contamination, put a small amount of

drained brake fluid in clear glass jar. If fluid sepa-

rates into layers, there is mineral oil or other fluid

contamination of the brake fluid.

If brake fluid is contaminated, drain and thor-

oughly flush system. Replace master cylinder, propor-

tioning valve, caliper seals, wheel cylinder seals,

Antilock Brakes hydraulic unit and all hydraulic

fluid hoses.

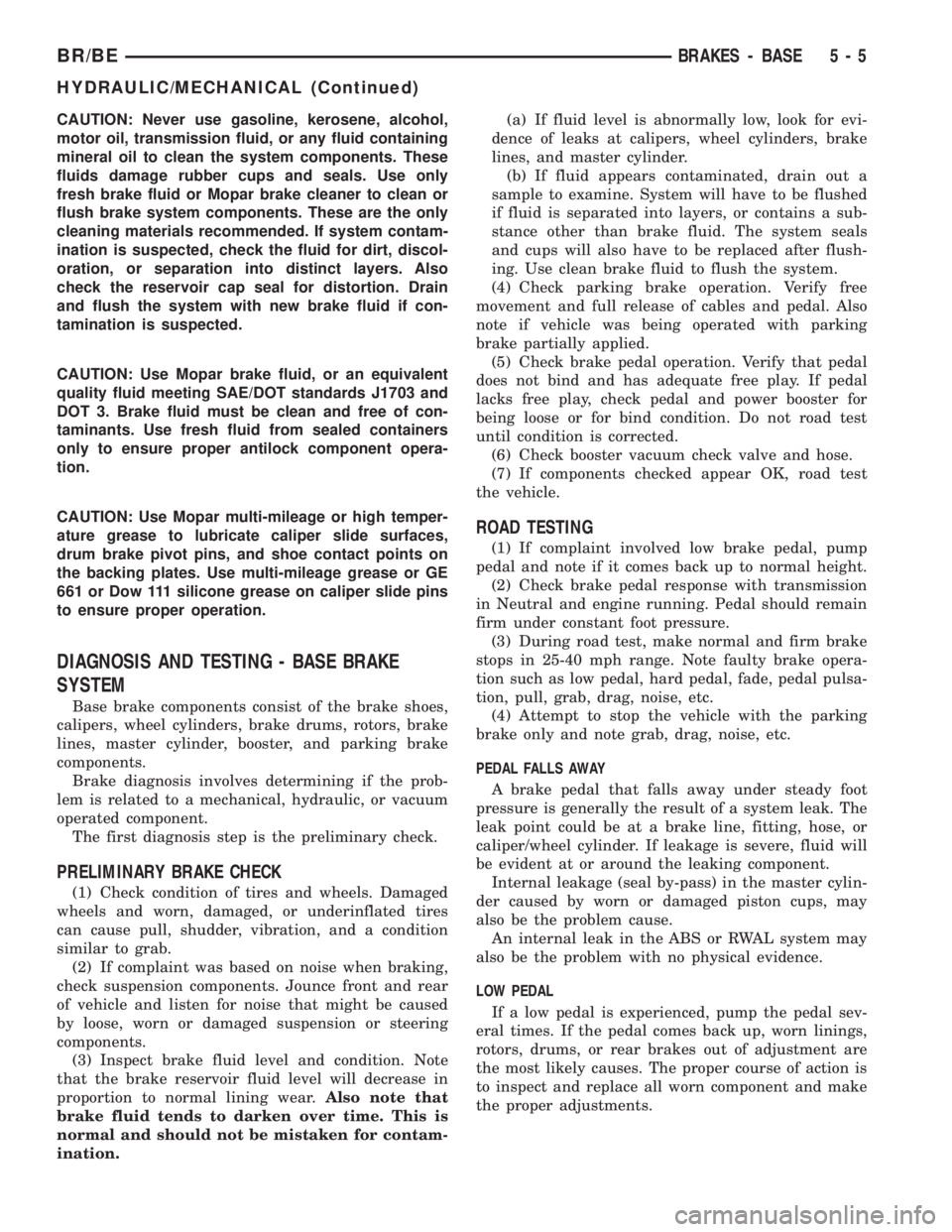

STANDARD PROCEDURE - BRAKE FLUID

LEVEL

Always clean the master cylinder reservoir and

caps before checking fluid level. If not cleaned, dirt

could enter the fluid.

The fluid fill level is indicated on the side of the

master cylinder reservoir (Fig. 19).

The correct fluid level is to the FULL indicator on

the side of the reservoir. If necessary, add fluid to the

proper level.

SPECIFICATIONS

BRAKE FLUID

The brake fluid used in this vehicle must conform

to DOT 3 specifications and SAE J1703 standards.

No other type of brake fluid is recommended or

approved for usage in the vehicle brake system. Use

only Mopar brake fluid or an equivalent from a

tightly sealed container.

CAUTION: Never use reclaimed brake fluid or fluid

from an container which has been left open. An

open container of brake fluid will absorb moisture

from the air and contaminate the fluid.

CAUTION: Never use any type of a petroleum-based

fluid in the brake hydraulic system. Use of such

type fluids will result in seal damage of the vehicle

brake hydraulic system causing a failure of the

vehicle brake system. Petroleum based fluids would

be items such as engine oil, transmission fluid,

power steering fluid, etc.

FLUID RESERVOIR

REMOVAL

(1) Remove reservoir cap and empty fluid into

drain container.

(2) Clamp cylinder body in vise with brass protec-

tive jaws.

(3) Remove pins that retain reservoir to master

cylinder. Use hammer and pin punch to remove pins

(Fig. 20).

(4) Loosen reservoir from grommets with pry tool

(Fig. 21).

(5) Remove reservoir by rocking it to one side and

pulling free of grommets (Fig. 22).

(6) Remove old grommets from cylinder body (Fig.

23).

INSTALLATION

CAUTION: Do not use any type of tool to install the

grommets. Tools may cut, or tear the grommets cre-

ating a leak problem after installation. Install the

grommets using finger pressure only.

(1) Lubricate new grommets with clean brake fluid

and Install new grommets in cylinder body (Fig. 24).

Use finger pressure to install and seat grommets.

(2) Start reservoir in grommets. Then rock reser-

voir back and forth while pressing downward to seat

it in grommets.

Fig. 19 Master Cylinder Fluid Level - Typical

1 - INDICATOR

2 - RESERVOIR

BR/BEBRAKES - BASE 5 - 15

DISC BRAKE CALIPERS (Continued)

Page 207 of 2255

EXTERIOR/BRAKE LAMP SWITCH - INSTALLA-

TION).

(10) Install knee bolster, (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - INSTALLATION).

POWER BRAKE BOOSTER

DIAGNOSIS AND TESTING - HYDRAULIC

BOOSTER

The hydraulic booster uses hydraulic pressure from

the power steering pump. Before diagnosing a

booster problem, first verify the power steering pump

is operating properly. Perform the following checks.

²Check the power steering fluid level.

²Check the brake fluid level.

²Check all power steering hoses and lines for

leaks and restrictions.

²Check power steering pump pressure.

NOISES

The hydraulic booster unit will produce certain

characteristic booster noises. The noises may occur

when the brake pedal is used in a manner not asso-

ciated with normal braking or driving habits.

HISSING

A hissing noise may be noticed when above normal

brake pedal pressure is applied, 40 lbs. or above. The

noise will be more noticeable if the vehicle is not

moving. The noise will increase with the brake pedal

pressure and an increase of system operating temper-

ature.

CLUNK-CHATTER-CLICKING

A clunk-chatter-clicking may be noticed when the

brake pedal is released quickly, after above normal

brake pedal pressure is applied 50-100 lbs..

BOOSTER FUNCTION TEST

With the engine off depress the brake pedal several

times to discharge the accumulator. Then depress the

brake pedal using 40 lbs. of force and start the

engine. The brake pedal should fall and then push

back against your foot. This indicates the booster is

operating properly.

ACCUMULATOR LEAKDOWN

(1) Start the engine, apply the brakes and turn the

steering wheel from lock to lock. This will ensure the

accumulator is charged. Turn off the engine and let

the vehicle sit for one hour. After one hour there

should be at least two power assisted brake applica-

tion with the engine off. If the system does not retain

a charge the booster must be replaced.(2) With the engine off depress the brake pedal

several times to discharge the accumulator. Grasp

the accumulator and see if it wobbles or turns. If it

does the accumulator has lost a gas charge and the

booster must be replaced.

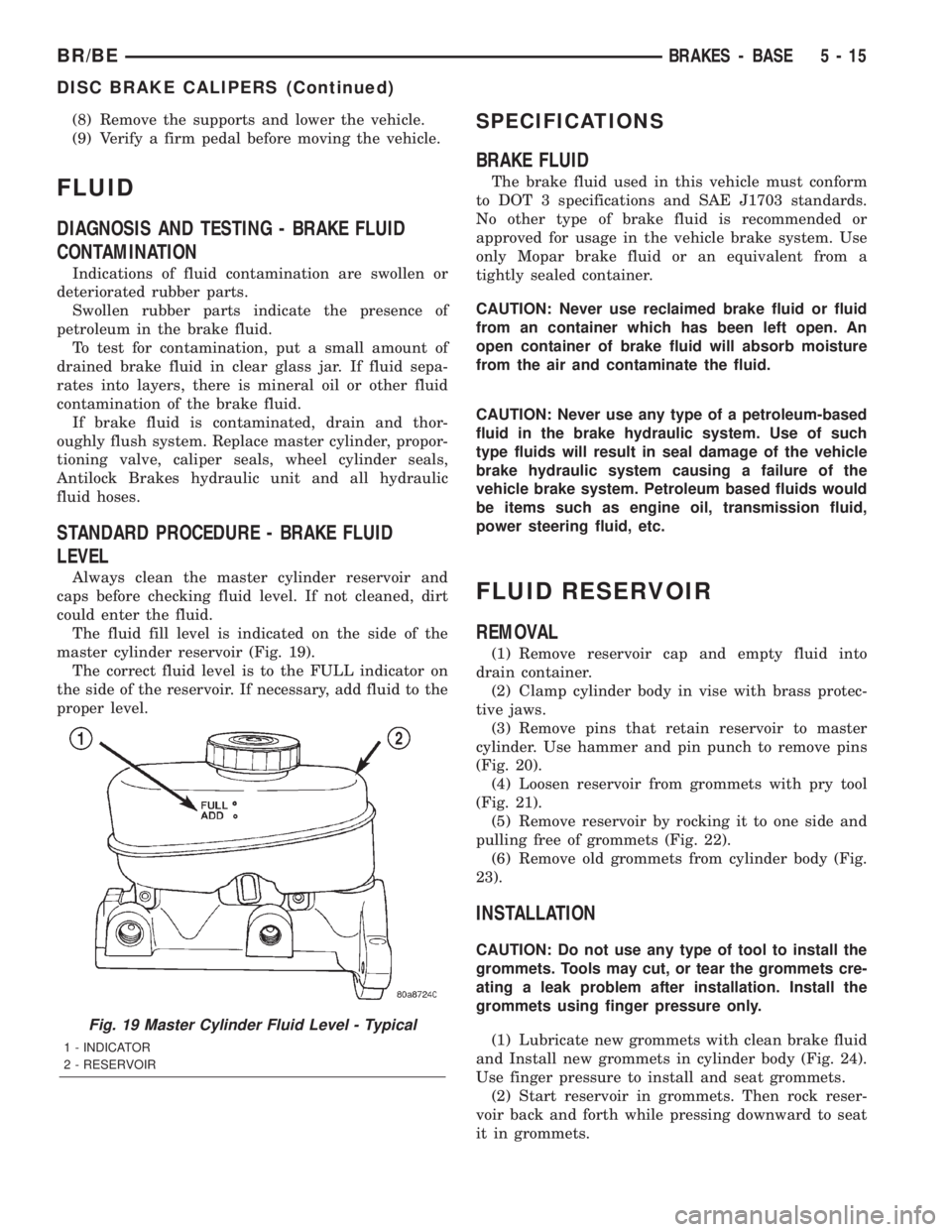

SEAL LEAKAGE

If the booster leaks from any of the seals the

booster assembly must be replaced (Fig. 27).

²INPUT ROD SEAL:Fluid leakage from rear

end of the booster.

²PISTON SEAL:Fluid leakage from vent at

front of booster.

²HOUSING SEAL:Fluid leakage between hous-

ing and housing cover.

²SPOOL VALVE SEAL:Fluid leakage near

spool plug.

²RETURN PORT FITTING SEAL:Fluid leak-

age from port fitting.

Fig. 27 Hydraulic Booster Seals

1 - PUMP

2 - GEAR

3 - INPUT SEAL

4 - HOUSING SEAL

5 - ACCUMULATOR SEAL

6 - PISTON SEAL

7 - SPOOL PLUG SEAL

8 - RETURN

5 - 18 BRAKES - BASEBR/BE

PEDAL (Continued)

Page 208 of 2255

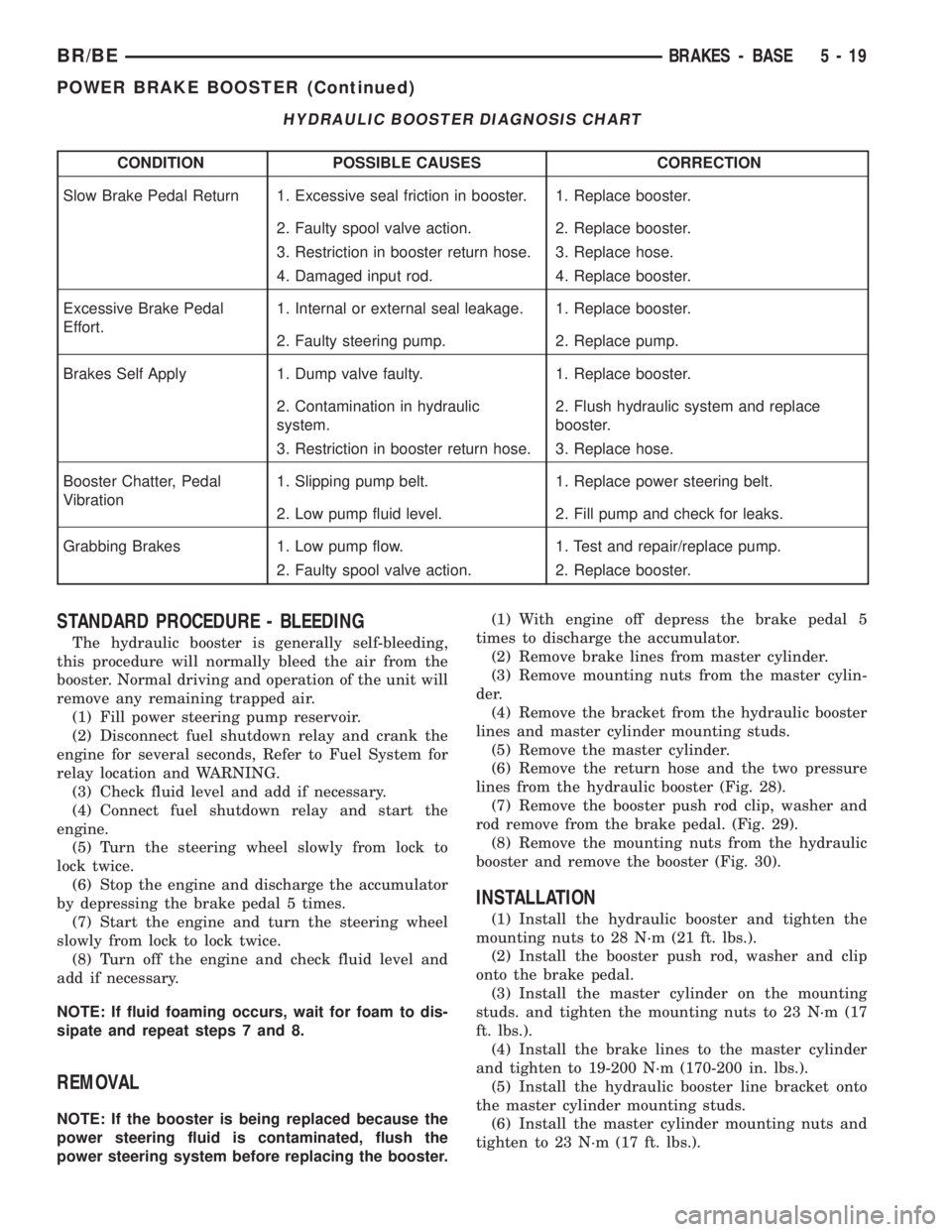

HYDRAULIC BOOSTER DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

Slow Brake Pedal Return 1. Excessive seal friction in booster. 1. Replace booster.

2. Faulty spool valve action. 2. Replace booster.

3. Restriction in booster return hose. 3. Replace hose.

4. Damaged input rod. 4. Replace booster.

Excessive Brake Pedal

Effort.1. Internal or external seal leakage. 1. Replace booster.

2. Faulty steering pump. 2. Replace pump.

Brakes Self Apply 1. Dump valve faulty. 1. Replace booster.

2. Contamination in hydraulic

system.2. Flush hydraulic system and replace

booster.

3. Restriction in booster return hose. 3. Replace hose.

Booster Chatter, Pedal

Vibration1. Slipping pump belt. 1. Replace power steering belt.

2. Low pump fluid level. 2. Fill pump and check for leaks.

Grabbing Brakes 1. Low pump flow. 1. Test and repair/replace pump.

2. Faulty spool valve action. 2. Replace booster.

STANDARD PROCEDURE - BLEEDING

The hydraulic booster is generally self-bleeding,

this procedure will normally bleed the air from the

booster. Normal driving and operation of the unit will

remove any remaining trapped air.

(1) Fill power steering pump reservoir.

(2) Disconnect fuel shutdown relay and crank the

engine for several seconds, Refer to Fuel System for

relay location and WARNING.

(3) Check fluid level and add if necessary.

(4) Connect fuel shutdown relay and start the

engine.

(5) Turn the steering wheel slowly from lock to

lock twice.

(6) Stop the engine and discharge the accumulator

by depressing the brake pedal 5 times.

(7) Start the engine and turn the steering wheel

slowly from lock to lock twice.

(8) Turn off the engine and check fluid level and

add if necessary.

NOTE: If fluid foaming occurs, wait for foam to dis-

sipate and repeat steps 7 and 8.

REMOVAL

NOTE: If the booster is being replaced because the

power steering fluid is contaminated, flush the

power steering system before replacing the booster.(1) With engine off depress the brake pedal 5

times to discharge the accumulator.

(2) Remove brake lines from master cylinder.

(3) Remove mounting nuts from the master cylin-

der.

(4) Remove the bracket from the hydraulic booster

lines and master cylinder mounting studs.

(5) Remove the master cylinder.

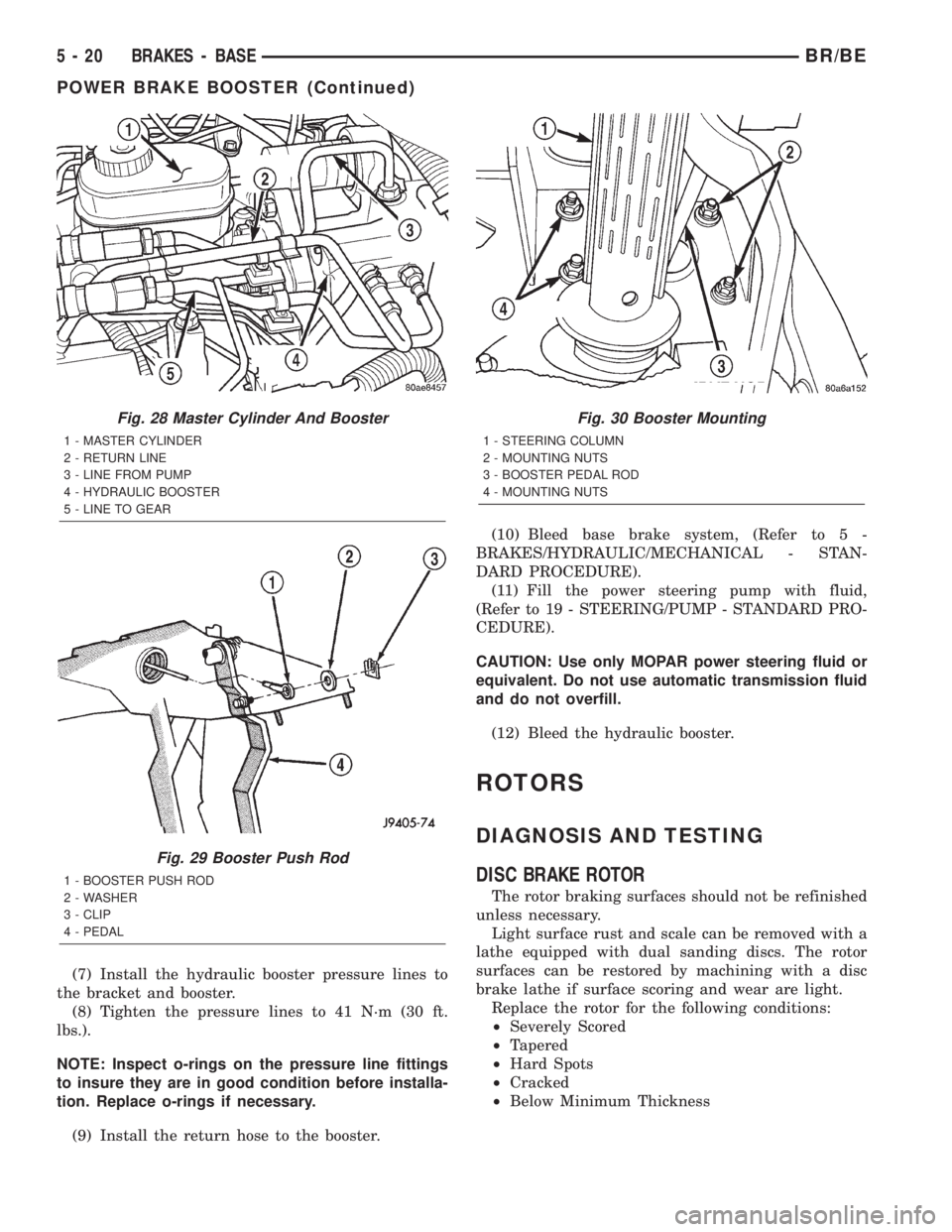

(6) Remove the return hose and the two pressure

lines from the hydraulic booster (Fig. 28).

(7) Remove the booster push rod clip, washer and

rod remove from the brake pedal. (Fig. 29).

(8) Remove the mounting nuts from the hydraulic

booster and remove the booster (Fig. 30).

INSTALLATION

(1) Install the hydraulic booster and tighten the

mounting nuts to 28 N´m (21 ft. lbs.).

(2) Install the booster push rod, washer and clip

onto the brake pedal.

(3) Install the master cylinder on the mounting

studs. and tighten the mounting nuts to 23 N´m (17

ft. lbs.).

(4) Install the brake lines to the master cylinder

and tighten to 19-200 N´m (170-200 in. lbs.).

(5) Install the hydraulic booster line bracket onto

the master cylinder mounting studs.

(6) Install the master cylinder mounting nuts and

tighten to 23 N´m (17 ft. lbs.).

BR/BEBRAKES - BASE 5 - 19

POWER BRAKE BOOSTER (Continued)

Page 209 of 2255

(7) Install the hydraulic booster pressure lines to

the bracket and booster.

(8) Tighten the pressure lines to 41 N´m (30 ft.

lbs.).

NOTE: Inspect o-rings on the pressure line fittings

to insure they are in good condition before installa-

tion. Replace o-rings if necessary.

(9) Install the return hose to the booster.(10) Bleed base brake system, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL - STAN-

DARD PROCEDURE).

(11) Fill the power steering pump with fluid,

(Refer to 19 - STEERING/PUMP - STANDARD PRO-

CEDURE).

CAUTION: Use only MOPAR power steering fluid or

equivalent. Do not use automatic transmission fluid

and do not overfill.

(12) Bleed the hydraulic booster.

ROTORS

DIAGNOSIS AND TESTING

DISC BRAKE ROTOR

The rotor braking surfaces should not be refinished

unless necessary.

Light surface rust and scale can be removed with a

lathe equipped with dual sanding discs. The rotor

surfaces can be restored by machining with a disc

brake lathe if surface scoring and wear are light.

Replace the rotor for the following conditions:

²Severely Scored

²Tapered

²Hard Spots

²Cracked

²Below Minimum Thickness

Fig. 28 Master Cylinder And Booster

1 - MASTER CYLINDER

2 - RETURN LINE

3 - LINE FROM PUMP

4 - HYDRAULIC BOOSTER

5 - LINE TO GEAR

Fig. 29 Booster Push Rod

1 - BOOSTER PUSH ROD

2 - WASHER

3 - CLIP

4 - PEDAL

Fig. 30 Booster Mounting

1 - STEERING COLUMN

2 - MOUNTING NUTS

3 - BOOSTER PEDAL ROD

4 - MOUNTING NUTS

5 - 20 BRAKES - BASEBR/BE

POWER BRAKE BOOSTER (Continued)

Page 224 of 2255

BRAKES - ABS

TABLE OF CONTENTS

page page

BRAKES - ABS

DESCRIPTION.........................35

OPERATION...........................36

DIAGNOSIS AND TESTING - ANTILOCK

BRAKES............................36

STANDARD PROCEDURE

STANDARD PROCEDURE - RWAL SERVICE

PRECAUTIONS.......................36

STANDARD PROCEDURE - BLEEDING ABS

BRAKE SYSTEM......................36

SPECIFICATIONS

TORQUE CHART......................37

FRONT WHEEL SPEED SENSOR

DESCRIPTION.........................38

OPERATION...........................38

REMOVAL

REMOVAL - 4X2......................39REMOVAL - 4X4......................39

INSTALLATION

INSTALLATION - 4X2...................39

INSTALLATION - 4X4...................39

REAR WHEEL SPEED SENSOR

DIAGNOSIS AND TESTING - REAR WHEEL

SPEED SENSOR......................40

REMOVAL.............................40

INSTALLATION.........................40

HCU (HYDRAULIC CONTROL UNIT)

DESCRIPTION.........................40

OPERATION...........................40

REMOVAL.............................41

INSTALLATION.........................41

BRAKES - ABS

DESCRIPTION

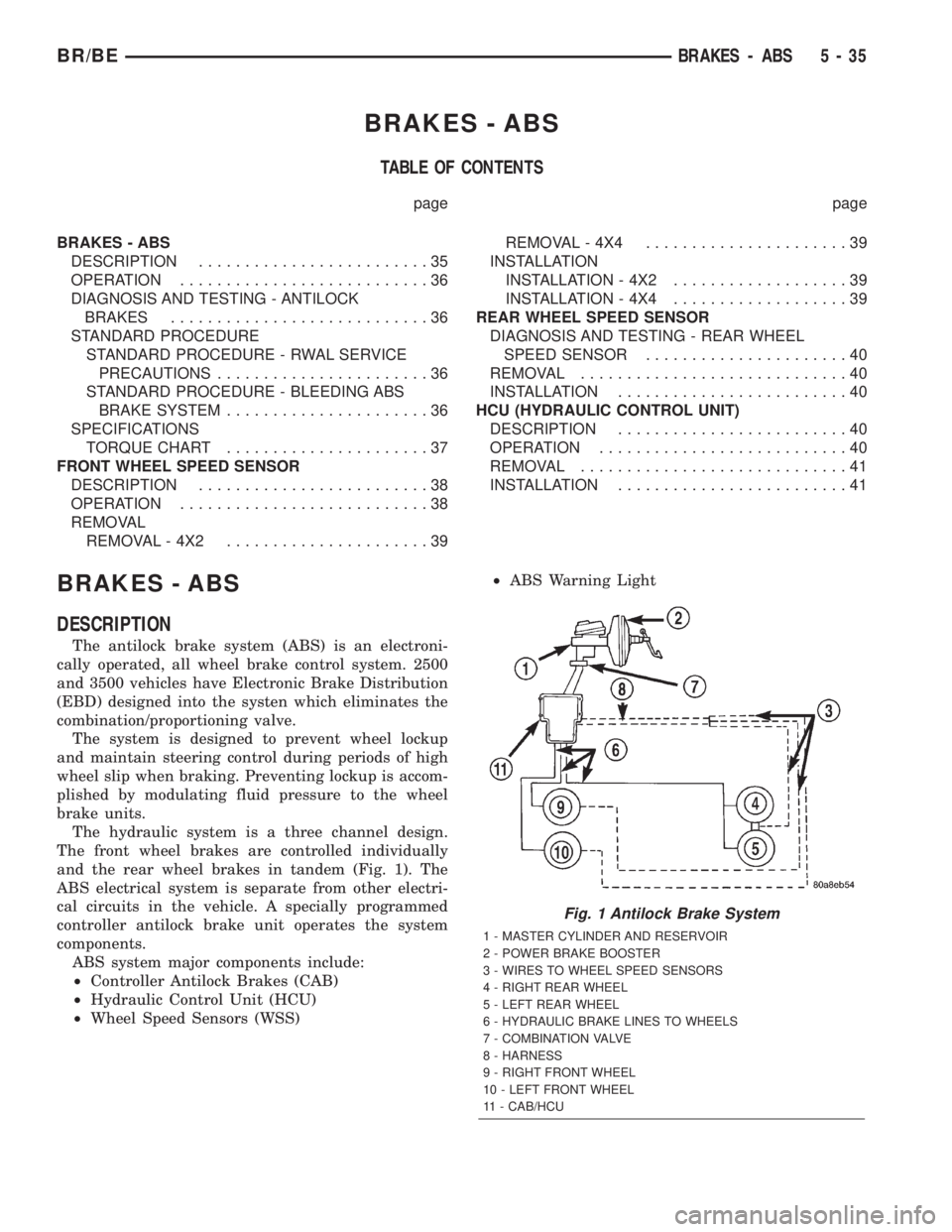

The antilock brake system (ABS) is an electroni-

cally operated, all wheel brake control system. 2500

and 3500 vehicles have Electronic Brake Distribution

(EBD) designed into the systen which eliminates the

combination/proportioning valve.

The system is designed to prevent wheel lockup

and maintain steering control during periods of high

wheel slip when braking. Preventing lockup is accom-

plished by modulating fluid pressure to the wheel

brake units.

The hydraulic system is a three channel design.

The front wheel brakes are controlled individually

and the rear wheel brakes in tandem (Fig. 1). The

ABS electrical system is separate from other electri-

cal circuits in the vehicle. A specially programmed

controller antilock brake unit operates the system

components.

ABS system major components include:

²Controller Antilock Brakes (CAB)

²Hydraulic Control Unit (HCU)

²Wheel Speed Sensors (WSS)²ABS Warning Light

Fig. 1 Antilock Brake System

1 - MASTER CYLINDER AND RESERVOIR

2 - POWER BRAKE BOOSTER

3 - WIRES TO WHEEL SPEED SENSORS

4 - RIGHT REAR WHEEL

5 - LEFT REAR WHEEL

6 - HYDRAULIC BRAKE LINES TO WHEELS

7 - COMBINATION VALVE

8 - HARNESS

9 - RIGHT FRONT WHEEL

10 - LEFT FRONT WHEEL

11 - CAB/HCU

BR/BEBRAKES - ABS 5 - 35

Page 225 of 2255

OPERATION

Battery voltage is supplied to the CAB when a

speed of 15 miles per hour is reached. The CAB per-

forms a system initialization procedure at this point.

Initialization consists of a static and dynamic self

check of system electrical components.

The static and dynamic checks occurs at ignition

start up. During the dynamic check, the CAB briefly

cycles the pump and solenoids to verify operation. An

audible noise may be heard during this self check.

This noise should be considered normal.

If an ABS component exhibits a fault during ini-

tialization, the CAB illuminates the amber warning

light and registers a fault code in the microprocessor

memory.

The CAB monitors wheel speed sensor inputs con-

tinuously while the vehicle is in motion. However,

the CAB will not activate any ABS components as

long as sensor inputs indicate normal braking.

During normal braking, the master cylinder, power

booster and wheel brake units all function as they

would in a vehicle without ABS. The HCU compo-

nents are not activated.

The purpose of the antilock system is to prevent

wheel lockup during periods of high wheel slip. Pre-

venting lockup helps maintain vehicle braking action

and steering control.

The antilock CAB activates the system whenever

sensor signals indicate periods of wheel slip. Periods

of wheel slip occur when brake stops involve high

pedal pressure and rate of vehicle deceleration.

The antilock system prevents lockup during a

wheel slip condition by modulating fluid apply pres-

sure to the wheel brake units.

Brake fluid apply pressure is modulated according

to wheel speed, degree of slip and rate of decelera-

tion. Sensors at each front wheel convert wheel speed

into electrical signals. These signals are transmitted

to the CAB for processing and determination of

wheel slip and deceleration rate.

The ABS system has three fluid pressure control

channels. The front brakes are controlled separately

and the rear brakes in tandem. A speed sensor input

signal indicating a wheel slip condition activates the

CAB antilock program.

There are Two solenoid valves (Isolation and Dump

valve) which are used in each antilock control chan-

nel. The valves are all located within the HCU valve

body and work in pairs to either increase, hold, or

decrease apply pressure as needed in the individual

control channels.

During an ABS stop the ISO valve actuates, Stop-

ping anymore pressure build Ðup to the calipers.

Then the Dump valve dumps off pressure until the

wheel unlocks. This will continue until the wheels

quit slipping altogether.

DIAGNOSIS AND TESTING - ANTILOCK

BRAKES

The ABS brake system performs several self-tests

every time the ignition switch is turned on and the

vehicle is driven. The CAB monitors the systems

input and output circuits to verify the system is oper-

ating correctly. If the on board diagnostic system

senses that a circuit is malfunctioning the system

will set a trouble code in its memory.

NOTE: An audible noise may be heard during the

self-test. This noise should be considered normal.

NOTE: The MDS or DRB III scan tool is used to

diagnose the ABS system. For additional informa-

tion refer to the Antilock Brake section in Group

8W. For test procedures refer to the Chassis Diag-

nostic Manual.

STANDARD PROCEDURE

STANDARD PROCEDURE - RWAL SERVICE

PRECAUTIONS

The RWAL uses an electronic control module, the

CAB. This module is designed to withstand normal

current draws associated with vehicle operation.

Care must be taken to avoid overloading the CAB

circuits.In testing for open or short circuits, do

not ground or apply voltage to any of the cir-

cuits unless instructed to do so for a diagnostic

procedure.These circuits should only be tested

using a high impedance multi-meter or the DRB

tester as described in this section. Power should

never be removed or applied to any control module

with the ignition in the ON position. Before removing

or connecting battery cables, fuses, or connectors,

always turn the ignition to the OFF position.

CAUTION: Use only factory wiring harnesses. Do

not cut or splice wiring to the brake circuits. The

addition of after-market electrical equipment (car

phone, radar detector, citizen band radio, trailer

lighting, trailer brakes, ect.) on a vehicle equipped

with antilock brakes may affect the function of the

antilock brake system.

STANDARD PROCEDURE - BLEEDING ABS

BRAKE SYSTEM

ABS system bleeding requires conventional bleed-

ing methods plus use of the DRB scan tool. The pro-

cedure involves performing a base brake bleeding,

followed by use of the scan tool to cycle and bleed the

5 - 36 BRAKES - ABSBR/BE

BRAKES - ABS (Continued)

Page 645 of 2255

contains all of the switches for both the wiper and

washer systems.

²Washer Fluid Level Switch- The washer fluid

level switch is located in a dedicated hole on the

lower rear side of the washer reservoir, above the

washer pump/motor unit near the left front corner of

the engine compartment.

²Washer Nozzles- The dual fluidic washer noz-

zles are secured with integral snap features to dedi-

cated openings in the cowl plenum cover/grille panel

located near the base of the windshield. The washer

plumbing fittings for the washer nozzles are con-

cealed beneath the cowl plenum cover/grille panel.

²Washer Pump/Motor- The washer pump/mo-

tor unit is located in a dedicated hole on the lower

rear side of the washer reservoir near the left front

corner of the engine compartment.

²Washer Reservoir- The washer reservoir is

secured to the left side of the radiator fan shroud in

the left front corner of the engine compartment.

²Wiper Arms- The two wiper arms are secured

to the two wiper pivots, which extend through the

cowl plenum cover/grille panel located near the base

of the windshield.

²Wiper Blades- The two wiper blades are

secured to the two wiper arms, and are parked on

the glass near the bottom of the windshield when the

wiper system is not in operation.

²Wiper Module- The wiper pivots are the only

visible components of the wiper module. The remain-

der of the module is concealed within the cowl ple-

num beneath the cowl plenum cover/grille panel. The

wiper module includes the module bracket, the single

wiper motor, the wiper linkage, and the two wiper

pivots.

²Wiper Relay- The wiper relay is located in the

Power Distribution Center (PDC) in the engine com-

partment near the battery.

Features of the wiper and washer system include

the following:

²Continuous Wipe Modes- The two-speed

wiper motor and the internal circuitry of the multi-

function switch work in concert to provide two con-

tinuous wipe cycles, low speed or high speed.

²Intermittent Wipe Mode- The internal cir-

cuitry of the multi-function switch, the CTM, and the

wiper relay work in concert to provide an intermit-

tent wipe mode with multiple delay interval selec-

tions. On models with a high-line or premium CTM,

the CTM also automatically adjusts each manually

selected delay interval to compensate for vehicle

speed.

²Washer Mode- When the washer system is

activated with the multi-function switch while the

wiper system is operating, washer fluid will be dis-

pensed onto the windshield glass through the washernozzles for as long as the washer pump/motor is

energized.

²Wipe-After-Wash Mode- The internal circuitry

of the CTM provides a wipe-after-wash feature

which, if the wipers are turned Off, will operate the

washer pump/motor and the wipers for as long as the

washer system is activated, then provide several

additional wipe cycles after the washer system is

deactivated before parking the wiper blades near the

base of the windshield.

Hard wired circuitry connects the wiper and

washer system components to the electrical system of

the vehicle. These hard wired circuits are integral to

several wire harnesses, which are routed throughout

the vehicle and retained by many different methods.

These circuits may be connected to each other, to the

vehicle electrical system and to the wiper and washer

system components through the use of a combination

of soldered splices, splice block connectors, and many

different types of wire harness terminal connectors

and insulators. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

OPERATION

The wiper and washer system is intended to pro-

vide the vehicle operator with a convenient, safe, and

reliable means of maintaining visibility through the

windshield glass. The various components of this sys-

tem are designed to convert electrical energy pro-

duced by the vehicle electrical system into the

mechanical action of the wiper blades to wipe the

outside surface of the glass, as well as into the

hydraulic action of the washer system to apply

washer fluid stored in an on-board reservoir to the

area of the glass to be wiped. When combined, these

components provide the means to effectively main-

tain clear visibility for the vehicle operator by remov-

ing excess accumulations of rain, snow, bugs, mud, or

other minor debris from the outside windshield glass

surface that might be encountered while driving the

vehicle under numerous types of inclement operating

conditions. The vehicle operator initiates all wiper

and washer system functions with the multi-function

switch control stalk that extends from the left side of

the steering column, just below the steering wheel.

Rotating the knob on the end of the multi-function

switch control stalk selects the desired wiper system

operating mode. The wiper system allows the vehicle

operator to select from two continuous wiper speeds,

Hi or Lo, or one of several intermittent wipe Delay

mode intervals. Pushing the button on the end of the

control stalk downwards towards the steering column

8R - 2 WIPERS/WASHERSBR/BE

WIPERS/WASHERS (Continued)

Page 1025 of 2255

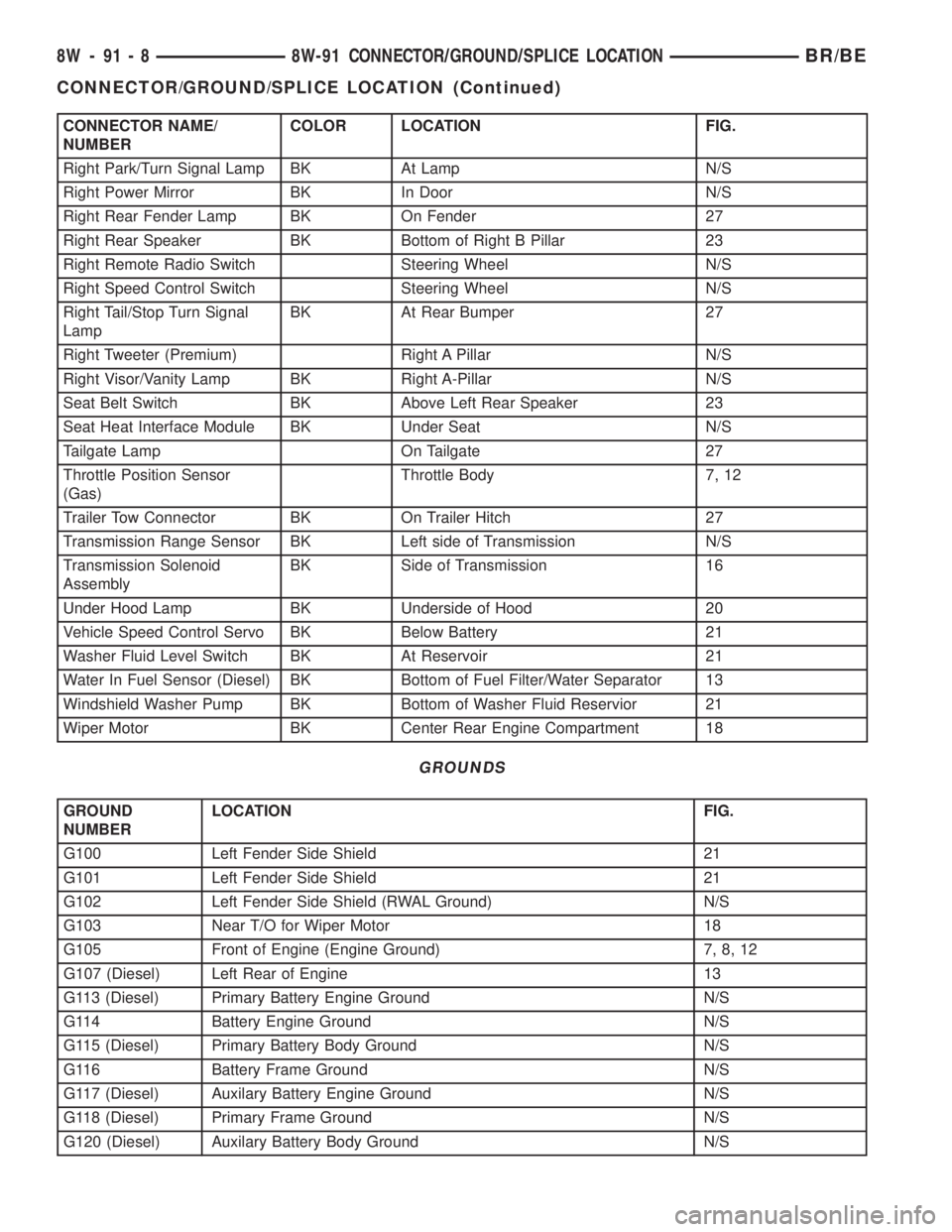

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Right Park/Turn Signal Lamp BK At Lamp N/S

Right Power Mirror BK In Door N/S

Right Rear Fender Lamp BK On Fender 27

Right Rear Speaker BK Bottom of Right B Pillar 23

Right Remote Radio Switch Steering Wheel N/S

Right Speed Control Switch Steering Wheel N/S

Right Tail/Stop Turn Signal

LampBK At Rear Bumper 27

Right Tweeter (Premium) Right A Pillar N/S

Right Visor/Vanity Lamp BK Right A-Pillar N/S

Seat Belt Switch BK Above Left Rear Speaker 23

Seat Heat Interface Module BK Under Seat N/S

Tailgate Lamp On Tailgate 27

Throttle Position Sensor

(Gas)Throttle Body 7, 12

Trailer Tow Connector BK On Trailer Hitch 27

Transmission Range Sensor BK Left side of Transmission N/S

Transmission Solenoid

AssemblyBK Side of Transmission 16

Under Hood Lamp BK Underside of Hood 20

Vehicle Speed Control Servo BK Below Battery 21

Washer Fluid Level Switch BK At Reservoir 21

Water In Fuel Sensor (Diesel) BK Bottom of Fuel Filter/Water Separator 13

Windshield Washer Pump BK Bottom of Washer Fluid Reservior 21

Wiper Motor BK Center Rear Engine Compartment 18

GROUNDS

GROUND

NUMBERLOCATION FIG.

G100 Left Fender Side Shield 21

G101 Left Fender Side Shield 21

G102 Left Fender Side Shield (RWAL Ground) N/S

G103 Near T/O for Wiper Motor 18

G105 Front of Engine (Engine Ground) 7, 8, 12

G107 (Diesel) Left Rear of Engine 13

G113 (Diesel) Primary Battery Engine Ground N/S

G114 Battery Engine Ground N/S

G115 (Diesel) Primary Battery Body Ground N/S

G116 Battery Frame Ground N/S

G117 (Diesel) Auxilary Battery Engine Ground N/S

G118 (Diesel) Primary Frame Ground N/S

G120 (Diesel) Auxilary Battery Body Ground N/S

8W - 91 - 8 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONBR/BE

CONNECTOR/GROUND/SPLICE LOCATION (Continued)