tow bar DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 28 of 2255

STANDARD PROCEDURE

STANDARD PROCEDURES - ALIGNMENT I.F.S.

Before each alignment reading the vehicle should

be jounced (rear first, then front). Grasp each

bumper at the center and jounce the vehicle up and

down several times. Always release the bumper in

the down position.Set the front end alignment to

specifications while the vehicle is in its NOR-

MALLY LOADED CONDITION.

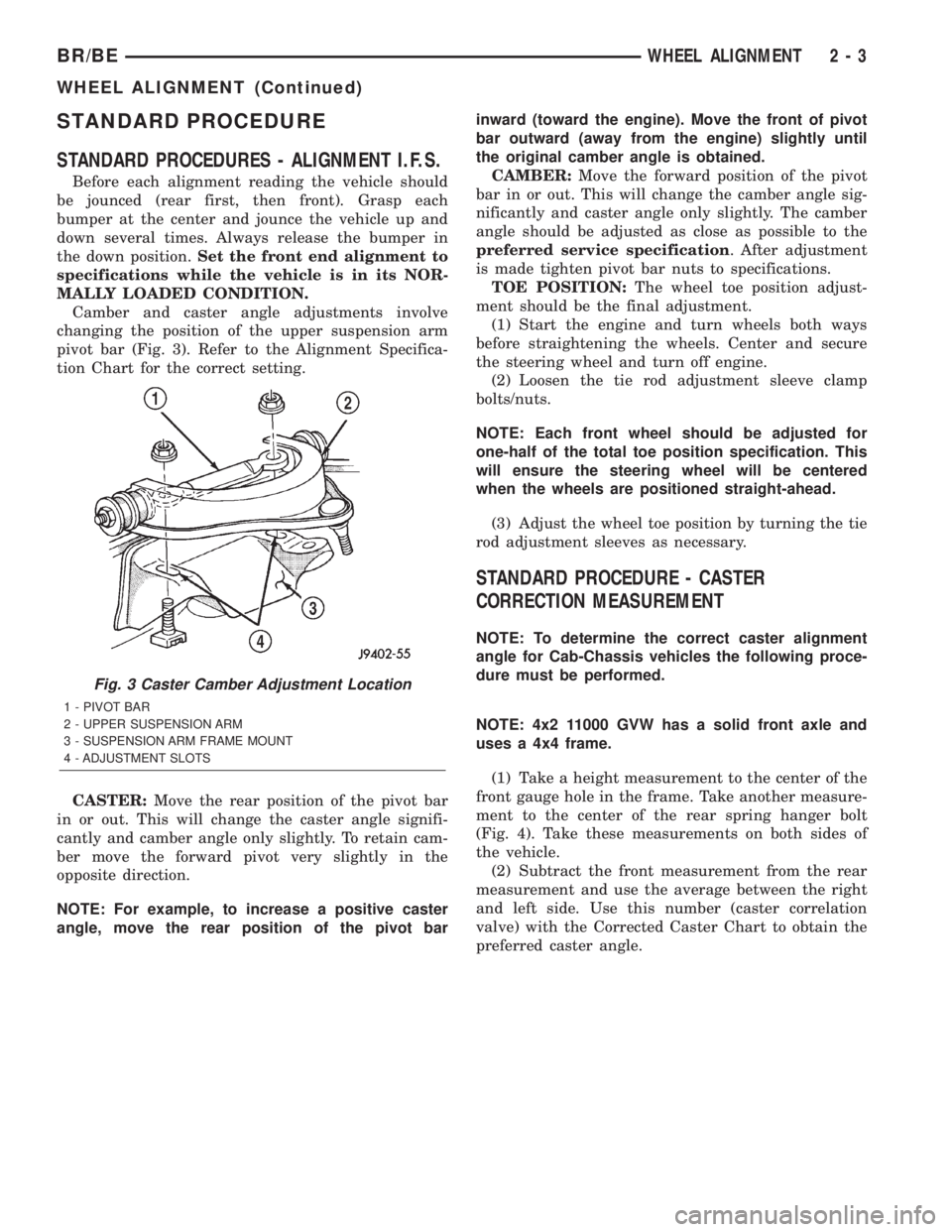

Camber and caster angle adjustments involve

changing the position of the upper suspension arm

pivot bar (Fig. 3). Refer to the Alignment Specifica-

tion Chart for the correct setting.

CASTER:Move the rear position of the pivot bar

in or out. This will change the caster angle signifi-

cantly and camber angle only slightly. To retain cam-

ber move the forward pivot very slightly in the

opposite direction.

NOTE: For example, to increase a positive caster

angle, move the rear position of the pivot barinward (toward the engine). Move the front of pivot

bar outward (away from the engine) slightly until

the original camber angle is obtained.

CAMBER:Move the forward position of the pivot

bar in or out. This will change the camber angle sig-

nificantly and caster angle only slightly. The camber

angle should be adjusted as close as possible to the

preferred service specification. After adjustment

is made tighten pivot bar nuts to specifications.

TOE POSITION:The wheel toe position adjust-

ment should be the final adjustment.

(1) Start the engine and turn wheels both ways

before straightening the wheels. Center and secure

the steering wheel and turn off engine.

(2) Loosen the tie rod adjustment sleeve clamp

bolts/nuts.

NOTE: Each front wheel should be adjusted for

one-half of the total toe position specification. This

will ensure the steering wheel will be centered

when the wheels are positioned straight-ahead.

(3) Adjust the wheel toe position by turning the tie

rod adjustment sleeves as necessary.

STANDARD PROCEDURE - CASTER

CORRECTION MEASUREMENT

NOTE: To determine the correct caster alignment

angle for Cab-Chassis vehicles the following proce-

dure must be performed.

NOTE: 4x2 11000 GVW has a solid front axle and

uses a 4x4 frame.

(1) Take a height measurement to the center of the

front gauge hole in the frame. Take another measure-

ment to the center of the rear spring hanger bolt

(Fig. 4). Take these measurements on both sides of

the vehicle.

(2) Subtract the front measurement from the rear

measurement and use the average between the right

and left side. Use this number (caster correlation

valve) with the Corrected Caster Chart to obtain the

preferred caster angle.

Fig. 3 Caster Camber Adjustment Location

1 - PIVOT BAR

2 - UPPER SUSPENSION ARM

3 - SUSPENSION ARM FRAME MOUNT

4 - ADJUSTMENT SLOTS

BR/BEWHEEL ALIGNMENT 2 - 3

WHEEL ALIGNMENT (Continued)

Page 292 of 2255

(4) Install fan blade/viscous fan drive assembly to

water pump shaft (Fig. 6).

(5) Except 8.0L V-10 Engine: Install coolant

reserve/overflow tank to fan shroud. Snaps into posi-

tion.

(6) Install throttle cable to fan shroud.

(7) Connect negative battery cable.

NOTE:

Viscous Fan Drive Fluid Pump Out Requirement:

After installing a new viscous fan drive, bring the

engine speed up to approximately 2000 rpm and

hold for approximately two minutes. This will

ensure proper fluid distribution within the drive.

RADIATOR FAN - 5.9L DIESEL

REMOVAL

CAUTION: If the viscous fan drive is replaced

because of mechanical damage, the cooling fan

blades should also be inspected. Inspect for fatigue

cracks, loose blades, or loose rivets that could

have resulted from excessive vibration. Replace fan

blade assembly if any of these conditions are

found. Also inspect water pump bearing and shaft

assembly for any related damage due to a viscous

fan drive malfunction.

(1) Disconnect the battery negative cables.

(2) Remove the fan shroud mounting bolts. Posi-

tion fan shroud towards engine.

CAUTION: Do not remove the fan pulley bolts. This

pulley is under spring tension.

(3) The thermal viscous fan drive/fan blade assem-

bly is attached (threaded) to the fan hub shaft (Fig.

7). Remove the fan blade/fan drive assembly from fan

pulley by turning the mounting nut clockwise (as

viewed from front). Threads on the viscous fan drive

areLEFT-HAND.A Snap-On 36 MM Fan Wrench

(number SP346 from Snap-On Cummins Diesel Tool

Set number 2017DSP) can be used. Place a bar or

screwdriver between the fan pulley bolts to prevent

pulley from rotating.

(4) Remove the fan shroud and the fan blade/vis-

cous drive as an assembly from vehicle.

(5) Remove fan blade-to-viscous fan drive mount-

ing bolts.

(6) Inspect the fan for cracks, loose rivets, loose or

bent fan blades.

CAUTION: Some engines equipped with serpentine

drive belts have reverse rotating fans and viscous

fan drives. They are marked with the wordREVERSE to designate their usage. Installation of

the wrong fan or viscous fan drive can result in

engine overheating.

CLEANING

Clean the fan blades using a mild soap and water.

Do not use an abrasive to clean the blades.

INSPECTION

WARNING: DO NOT ATTEMPT TO BEND OR

STRAIGHTEN FAN BLADES IF FAN IS NOT WITHIN

SPECIFICATIONS.

CAUTION: If fan blade assembly is replaced

because of mechanical damage, water pump and

viscous fan drive should also be inspected. These

components could have been damaged due to

excessive vibration.

(1) Remove fan blade assembly from viscous fan

drive unit (four bolts).

(2) Lay fan on a flat surface with leading edge fac-

ing down. With tip of blade touching flat surface,

replace fan if clearance between opposite blade and

surface is greater than 2.0 mm (.090 inch). Rocking

motion of opposite blades should not exceed 2.0 mm

(.090 inch). Test all blades in this manner.

(3) Inspect fan assembly for cracks, bends, loose

rivets or broken welds. Replace fan if any damage is

found.

Fig. 7 Fan Blade/Viscous Fan Drive

1 - THREADED SHAFT

2 - BOLT (4)

3 - FAN BLADE

4 - THREADED NUT

5 - VISCOUS FAN DRIVE

BR/BEENGINE 7 - 43

RADIATOR FAN - 5.9L/8.0L (Continued)

Page 652 of 2255

be routed away from hot, sharp, or moving parts;

and, sharp bends that might pinch the hose must be

avoided.

WASHER NOZZLE

DESCRIPTION

The two washer nozzles have integral snap fea-

tures that secure them in dedicated holes in the cowl

plenum cover/grille panel located near the base of the

windshield. The domed upper surface of the washer

nozzle is visible on the top of the plenum cover/grille

panel, and the nozzle orifice is oriented towards the

windshield glass. The washer plumbing fittings for

the washer nozzles are concealed beneath the cowl

plenum cover/grille panel. These fluidic washer noz-

zles are constructed of molded plastic. The cowl ple-

num cover/grille panel must be removed from the

vehicle to access the nozzles for service. The washer

nozzles cannot be adjusted or repaired and, if faulty

or damaged, they must be replaced.

OPERATION

The two washer nozzles are designed to dispense

washer fluid into the wiper pattern area on the out-

side of the windshield glass. Pressurized washer fluid

is fed to each nozzle from the washer reservoir by the

washer pump/motor through rubber hoses, which are

attached to a barbed nipple on each washer nozzle

below the cowl plenum cover/grille panel. The washer

nozzles incorporate a fluidic design, which causes the

nozzle to emit the pressurized washer fluid as an

oscillating stream to more effectively cover a larger

area of the glass area to be cleaned.

REMOVAL

(1) Remove the cowl plenum cover/grille panel

from the cowl top. (Refer to 23 - BODY/EXTERIOR/

COWL GRILLE - REMOVAL).

(2) From the underside of the cowl plenum cover/

grille panel, disconnect the washer hose from the

nozzle fitting.

(3) From the underside of the cowl plenum cover/

grille panel, compress the snap features of the

washer nozzle and push the nozzle out through the

top of the panel.

INSTALLATION

(1) From the top of the cowl plenum cover/grille

panel, insert the barbed nipple of the washer nozzle

through the nozzle mounting hole.

(2) With the orifice of the washer nozzle oriented

toward the windshield, use hand pressure to push

the nozzle into the mounting hole until the snap fea-tures of the nozzle are fully engaged with the under-

side of the cowl plenum cover/grille panel.

(3) From the underside of the cowl plenum cover/

grille panel, reconnect the washer hose to the washer

nozzle fitting.

(4) Reinstall the cowl plenum cover/grille panel

onto the cowl top. (Refer to 23 - BODY/EXTERIOR/

COWL GRILLE - INSTALLATION).

WASHER PUMP/MOTOR

DESCRIPTION

The washer pump/motor unit is located on the rear

of the washer reservoir, near the bottom in the left

front corner of the engine compartment. A small per-

manently lubricated and sealed electric motor is cou-

pled to the rotor-type washer pump. A seal flange

with a large barbed inlet nipple on the pump housing

passes through a rubber grommet seal installed in

the dedicated mounting hole near the bottom of the

washer reservoir. A smaller barbed outlet nipple on

the pump housing connects the unit to the washer

hose. The washer pump/motor unit is retained on the

reservoir by the interference fit between the barbed

pump inlet nipple and the grommet seal, which is a

light press fit. An integral electrical connector recep-

tacle is located on the motor housing. The washer

pump/motor unit cannot be repaired. If faulty or

damaged, the entire washer pump/motor unit must

be replaced.

OPERATION

The washer pump/motor unit is connected to the

vehicle electrical system through a single take out

and two-cavity connector of the headlamp and dash

wire harness. The washer pump/motor is grounded at

all times through a take out of the headlamp and

dash wire harness with a single eyelet terminal con-

nector that is secured by a nut to a ground stud

located on the forward extension of the left front

fender wheel housing in the engine compartment.

The washer pump/motor receives battery current on

a fused ignition switch output (run-acc) circuit

through the closed contacts of the momentary washer

switch within the multi-function switch only when

the washer button on the end of the switch control

stalk is depressed towards the steering column.

Washer fluid is gravity-fed from the washer reservoir

to the inlet side of the washer pump. When the pump

motor is energized, the rotor-type pump pressurizes

the washer fluid and forces it through the pump out-

let nipple, the washer plumbing, and the washer noz-

zles onto the windshield glass.

BR/BEWIPERS/WASHERS 8R - 9

WASHER HOSES/TUBES (Continued)

Page 678 of 2255

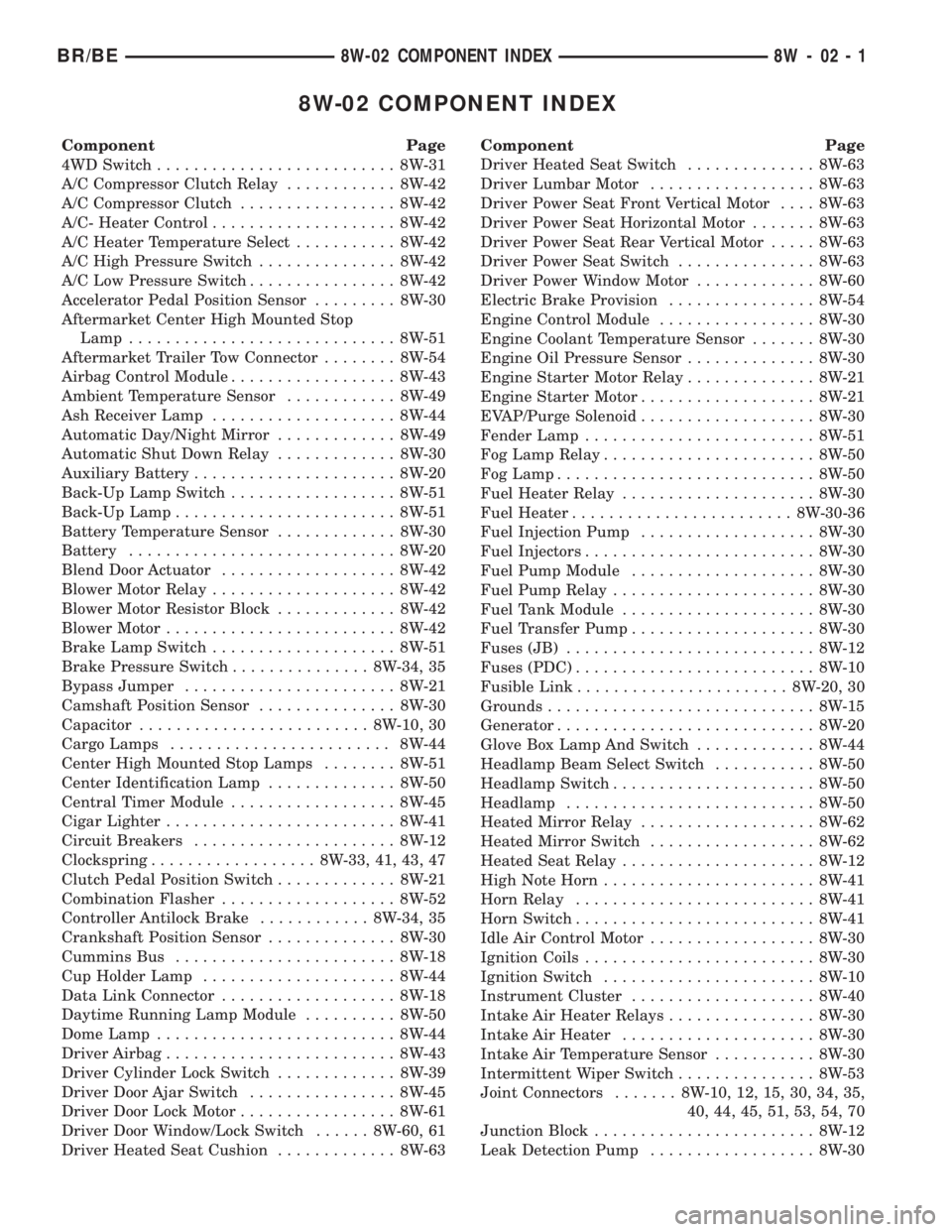

8W-02 COMPONENT INDEX

Component Page

4WD Switch.......................... 8W-31

A/C Compressor Clutch Relay............ 8W-42

A/C Compressor Clutch................. 8W-42

A/C- Heater Control.................... 8W-42

A/C Heater Temperature Select........... 8W-42

A/C High Pressure Switch............... 8W-42

A/C Low Pressure Switch................ 8W-42

Accelerator Pedal Position Sensor......... 8W-30

Aftermarket Center High Mounted Stop

Lamp............................. 8W-51

Aftermarket Trailer Tow Connector........ 8W-54

Airbag Control Module.................. 8W-43

Ambient Temperature Sensor............ 8W-49

Ash Receiver Lamp.................... 8W-44

Automatic Day/Night Mirror............. 8W-49

Automatic Shut Down Relay............. 8W-30

Auxiliary Battery...................... 8W-20

Back-Up Lamp Switch.................. 8W-51

Back-Up Lamp........................ 8W-51

Battery Temperature Sensor............. 8W-30

Battery............................. 8W-20

Blend Door Actuator................... 8W-42

Blower Motor Relay.................... 8W-42

Blower Motor Resistor Block............. 8W-42

Blower Motor......................... 8W-42

Brake Lamp Switch.................... 8W-51

Brake Pressure Switch............... 8W-34, 35

Bypass Jumper....................... 8W-21

Camshaft Position Sensor............... 8W-30

Capacitor......................... 8W-10, 30

Cargo Lamps........................ 8W-44

Center High Mounted Stop Lamps........ 8W-51

Center Identification Lamp.............. 8W-50

Central Timer Module.................. 8W-45

Cigar Lighter......................... 8W-41

Circuit Breakers...................... 8W-12

Clockspring.................. 8W-33, 41, 43, 47

Clutch Pedal Position Switch............. 8W-21

Combination Flasher................... 8W-52

Controller Antilock Brake............ 8W-34, 35

Crankshaft Position Sensor.............. 8W-30

Cummins Bus........................ 8W-18

Cup Holder Lamp..................... 8W-44

Data Link Connector................... 8W-18

Daytime Running Lamp Module.......... 8W-50

Dome Lamp.......................... 8W-44

Driver Airbag......................... 8W-43

Driver Cylinder Lock Switch............. 8W-39

Driver Door Ajar Switch................ 8W-45

Driver Door Lock Motor................. 8W-61

Driver Door Window/Lock Switch...... 8W-60, 61

Driver Heated Seat Cushion............. 8W-63Component Page

Driver Heated Seat Switch.............. 8W-63

Driver Lumbar Motor.................. 8W-63

Driver Power Seat Front Vertical Motor.... 8W-63

Driver Power Seat Horizontal Motor....... 8W-63

Driver Power Seat Rear Vertical Motor..... 8W-63

Driver Power Seat Switch............... 8W-63

Driver Power Window Motor............. 8W-60

Electric Brake Provision................ 8W-54

Engine Control Module................. 8W-30

Engine Coolant Temperature Sensor....... 8W-30

Engine Oil Pressure Sensor.............. 8W-30

Engine Starter Motor Relay.............. 8W-21

Engine Starter Motor................... 8W-21

EVAP/Purge Solenoid................... 8W-30

Fender Lamp......................... 8W-51

Fog Lamp Relay....................... 8W-50

Fog Lamp............................ 8W-50

Fuel Heater Relay..................... 8W-30

Fuel Heater........................ 8W-30-36

Fuel Injection Pump................... 8W-30

Fuel Injectors......................... 8W-30

Fuel Pump Module.................... 8W-30

Fuel Pump Relay...................... 8W-30

Fuel Tank Module..................... 8W-30

Fuel Transfer Pump.................... 8W-30

Fuses (JB)........................... 8W-12

Fuses (PDC).......................... 8W-10

Fusible Link....................... 8W-20, 30

Grounds............................. 8W-15

Generator............................ 8W-20

Glove Box Lamp And Switch............. 8W-44

Headlamp Beam Select Switch........... 8W-50

Headlamp Switch...................... 8W-50

Headlamp........................... 8W-50

Heated Mirror Relay................... 8W-62

Heated Mirror Switch.................. 8W-62

Heated Seat Relay..................... 8W-12

High Note Horn....................... 8W-41

Horn Relay.......................... 8W-41

Horn Switch.......................... 8W-41

Idle Air Control Motor.................. 8W-30

Ignition Coils......................... 8W-30

Ignition Switch....................... 8W-10

Instrument Cluster.................... 8W-40

Intake Air Heater Relays................ 8W-30

Intake Air Heater..................... 8W-30

Intake Air Temperature Sensor........... 8W-30

Intermittent Wiper Switch............... 8W-53

Joint Connectors....... 8W-10, 12, 15, 30, 34, 35,

40, 44, 45, 51, 53, 54, 70

Junction Block........................ 8W-12

Leak Detection Pump.................. 8W-30

BR/BE8W-02 COMPONENT INDEX 8W - 02 - 1

Page 679 of 2255

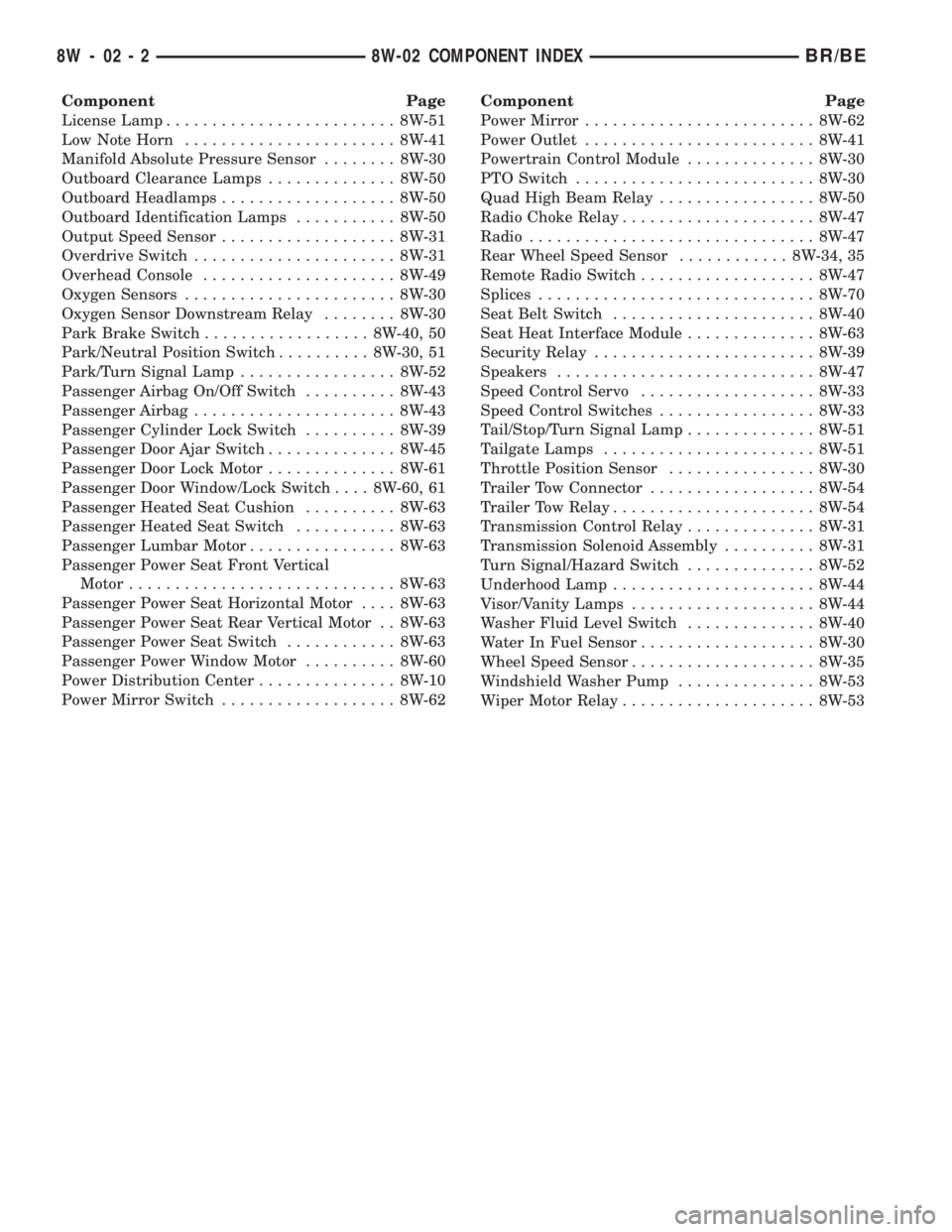

Component Page

License Lamp......................... 8W-51

Low Note Horn....................... 8W-41

Manifold Absolute Pressure Sensor........ 8W-30

Outboard Clearance Lamps.............. 8W-50

Outboard Headlamps................... 8W-50

Outboard Identification Lamps........... 8W-50

Output Speed Sensor................... 8W-31

Overdrive Switch...................... 8W-31

Overhead Console..................... 8W-49

Oxygen Sensors....................... 8W-30

Oxygen Sensor Downstream Relay........ 8W-30

Park Brake Switch.................. 8W-40, 50

Park/Neutral Position Switch.......... 8W-30, 51

Park/Turn Signal Lamp................. 8W-52

Passenger Airbag On/Off Switch.......... 8W-43

Passenger Airbag...................... 8W-43

Passenger Cylinder Lock Switch.......... 8W-39

Passenger Door Ajar Switch.............. 8W-45

Passenger Door Lock Motor.............. 8W-61

Passenger Door Window/Lock Switch.... 8W-60, 61

Passenger Heated Seat Cushion.......... 8W-63

Passenger Heated Seat Switch........... 8W-63

Passenger Lumbar Motor................ 8W-63

Passenger Power Seat Front Vertical

Motor............................. 8W-63

Passenger Power Seat Horizontal Motor.... 8W-63

Passenger Power Seat Rear Vertical Motor . . 8W-63

Passenger Power Seat Switch............ 8W-63

Passenger Power Window Motor.......... 8W-60

Power Distribution Center............... 8W-10

Power Mirror Switch................... 8W-62Component Page

Power Mirror......................... 8W-62

Power Outlet......................... 8W-41

Powertrain Control Module.............. 8W-30

PTO Switch.......................... 8W-30

Quad High Beam Relay................. 8W-50

Radio Choke Relay..................... 8W-47

Radio............................... 8W-47

Rear Wheel Speed Sensor............ 8W-34, 35

Remote Radio Switch................... 8W-47

Splices.............................. 8W-70

Seat Belt Switch...................... 8W-40

Seat Heat Interface Module.............. 8W-63

Security Relay........................ 8W-39

Speakers............................ 8W-47

Speed Control Servo................... 8W-33

Speed Control Switches................. 8W-33

Tail/Stop/Turn Signal Lamp.............. 8W-51

Tailgate Lamps....................... 8W-51

Throttle Position Sensor................ 8W-30

Trailer Tow Connector.................. 8W-54

Trailer Tow Relay...................... 8W-54

Transmission Control Relay.............. 8W-31

Transmission Solenoid Assembly.......... 8W-31

Turn Signal/Hazard Switch.............. 8W-52

Underhood Lamp...................... 8W-44

Visor/Vanity Lamps.................... 8W-44

Washer Fluid Level Switch.............. 8W-40

Water In Fuel Sensor................... 8W-30

Wheel Speed Sensor.................... 8W-35

Windshield Washer Pump............... 8W-53

Wiper Motor Relay..................... 8W-53

8W - 02 - 2 8W-02 COMPONENT INDEXBR/BE

Page 938 of 2255

Component Page

Left Rear Fender Lamp

(Dual Rear Wheels)................ 8W-80-59

Left Rear Speaker (Premium 2 Door).... 8W-80-59

Left Rear Speaker (Premium 4 Door).... 8W-80-60

Left Rear Speaker (Standard 2 Door).... 8W-80-60

Left Rear Speaker (Standard 4 Door).... 8W-80-60

Left Remote Radio Switch............. 8W-80-60

Left Speed Control Switch............ 8W-80-60

Left Tail/Stop/Turn Signal Lamp........ 8W-80-61

Left Tweeter (Premium).............. 8W-80-61

Left Visor/Vanity Lamp............... 8W-80-61

Low Note Horn..................... 8W-80-61

Manifold Absolute Pressure Sensor

(3.9L/5.2L/5.9L)................... 8W-80-61

Manifold Absolute Pressure Sensor

(8.0L).......................... 8W-80-62

Manifold Air Pressure Sensor (Diesel).... 8W-80-62

Multi-Function Switch............... 8W-80-62

Output Speed Sensor................ 8W-80-63

Overdrive Switch................... 8W-80-63

Overhead Console (Base).............. 8W-80-63

Overhead Console (Highline)........... 8W-80-63

Oxygen Sensor 1/1 Left Bank Up

(5.9L HD/8.0L)................... 8W-80-63

Oxygen Sensor 1/1 Left Bank Up

(California)...................... 8W-80-64

Oxygen Sensor 1/1 Upstream

(A/T Except 8.0L)................. 8W-80-64

Oxygen Sensor 1/1 Upstream

(M/T Except 8.0L)................. 8W-80-64

Oxygen Sensor 1/2 Downstream

(3.9L/5.2L)....................... 8W-80-64

Oxygen Sensor 1/2 Left Bank Down

(California)...................... 8W-80-64

Oxygen Sensor 1/2 Pre-Catalyst (8.0L) . . . 8W-80-65

Oxygen Sensor 1/3 Post Catalyst (8.0L) . . 8W-80-65

Oxygen Sensor 2/1 Right Bank Up (5.9l HD)

(5.2L/5.9L/8.0L California).......... 8W-80-65

Oxygen Sensor 2/2 Right Bank Down

(California)...................... 8W-80-65

Park/Neutral Position Switch (A/T)...... 8W-80-65

Passenger Airbag................... 8W-80-66

Passenger Airbag On/Off Switch C1..... 8W-80-66

Passenger Airbag On/Off Switch C2..... 8W-80-66

Passenger Cylinder Lock Switch........ 8W-80-66

Passenger Door Ajar Switch........... 8W-80-66

Passenger Door Lock Motor........... 8W-80-66

Passenger Door Window/Lock Switch.... 8W-80-67

Passenger Heated Seat Cushion........ 8W-80-67

Passenger Heated Seat Switch......... 8W-80-67

Passenger Lumbar Motor............. 8W-80-67

Passenger Power Seat Front Vertical Motor

(Club Cab)....................... 8W-80-68

Passenger Power Seat Horizontal Motor

(Club Cab)....................... 8W-80-68Component Page

Passenger Power Seat Rear Vertical Motor

(Club Cab)....................... 8W-80-68

Passenger Power Seat Switch (Club Cab) . 8W-80-68

Passenger Power Window Motor........ 8W-80-68

Power Mirror Switch................. 8W-80-69

Power Outlet....................... 8W-80-69

Powertrain Control Module C1 (Diesel) . . . 8W-80-69

Powertrain Control Module C1 (Gas).... 8W-80-70

Powertrain Control Module C2 (Diesel) . . . 8W-80-71

Powertrain Control Module C2 (Gas).... 8W-80-71

Powertrain Control Module C3 (Diesel) . . . 8W-80-72

Powertrain Control Module C3 (Gas).... 8W-80-73

Radio C1.......................... 8W-80-74

Radio C2.......................... 8W-80-74

Radio C3.......................... 8W-80-74

Radio Choke Relay.................. 8W-80-74

Rear Wheel Speed Sensor (ABS)........ 8W-80-74

Right Back-Up Lamp................ 8W-80-75

Right Fog Lamp.................... 8W-80-75

Right Front Door Speaker (Premium).... 8W-80-75

Right Front Door Speaker (Standard).... 8W-80-75

Right Front Fender Lamp

(Dual Rear Wheels)................ 8W-80-75

Right Front Wheel Speed Sensor (ABS) . . 8W-80-76

Right Headlamp.................... 8W-80-76

Right License Lamp................. 8W-80-76

Right Outboard Clearance Lamp....... 8W-80-76

Right Outboard Headlamp............ 8W-80-76

Right Outboard Identification Lamp..... 8W-80-77

Right Park/Turn Signal Lamp.......... 8W-80-77

Right Power Mirror.................. 8W-80-77

Right Rear Fender Lamp

(Dual Rear Wheels)................ 8W-80-77

Right Rear Speaker (2 Door Premium) . . . 8W-80-77

Right Rear Speaker (4 Door Premium) . . . 8W-80-78

Right Rear Speaker (Standard 2 Door) . . . 8W-80-78

Right Rear Speaker (Standard 4 Door) . . . 8W-80-78

Right Remote Radio Switch........... 8W-80-78

Right Speed Control Switch........... 8W-80-78

Right Tail/Stop/Turn Signal Lamp...... 8W-80-78

Right Tweeter (Premium)............. 8W-80-79

Right Visor/Vanity Lamp.............. 8W-80-79

Seat Belt Switch (Club Cab)........... 8W-80-79

Seat Belt Switch (Standard Cab)....... 8W-80-79

Seat Heat Interface Module........... 8W-80-79

Speed Control Servo................. 8W-80-80

Tailgate Lamp (Dual Rear Wheels)...... 8W-80-80

Throttle Position Sensor (Gas)......... 8W-80-80

Trailer Tow Connector................ 8W-80-80

Transmission Solenoid Assembly........ 8W-80-80

Underhood Lamp................... 8W-80-81

Washer Fluid Level Switch............ 8W-80-81

Water In Fuel Sensor (Diesel).......... 8W-80-81

Wiper Motor....................... 8W-80-81

BR/BE8W-80 CONNECTOR PIN-OUTS 8W - 80 - 3

Page 1063 of 2255

(8) Remove the cigar lighter or power outlet mount

from the instrument panel.

INSTALLATION

(1) Reconnect the instrument panel wire harness

connector to the cigar lighter or power outlet recep-

tacle base connector receptacle.

(2) Install the cigar lighter or power outlet mount

into the instrument panel.

(3) Align the splines on the outside of the cigar

lighter or power outlet receptacle base connector

receptacle with the grooves on the inside of the

mount.

(4) Press firmly on the cigar lighter or power out-

let receptacle base until the retaining bosses of the

mount are fully engaged in their receptacles.

(5) Install the cigar lighter knob and element into

the cigar lighter receptacle base, or the protective cap

into the power outlet receptacle base.

(6) Reconnect the battery negative cable.

CIRCUIT BREAKER

DESCRIPTION

Automatic resetting circuit breakers are used to

protect a system circuit from a short circuit or over-

load. Some examples of his condition can be caused

by an obstructed or stuck seat adjuster or power win-

dow motor.

The circuit breaker cannot be repaired and, if

faulty or damaged, it must be replaced.

DIAGNOSIS AND TESTING - CIRCUIT BREAKER

For circuit descriptions and diagrams, refer to Wir-

ing Diagrams.

(1) Locate the correct circuit breaker in the junc-

tion block. Pull out the circuit breaker slightly, but

be certain that the circuit breaker terminals still con-

tact the terminals in the junction block cavities.

(2) Connect the negative lead of a 12-volt DC volt-

meter to a good ground.

(3) With the voltmeter positive lead, check both

terminals of the circuit breaker for battery voltage.

If only one terminal has battery voltage, the circuit

breaker is faulty and must be replaced. If neither ter-

minal has battery voltage, repair the open circuit

from the Power Distribution Center (PDC) as

required.

GENERATOR CARTRIDGE

FUSE

DESCRIPTION

A 140 ampere generator cartridge fuse is used on

this model. The generator cartridge fuse is similar to

other cartridge fuses found in the Power Distribution

Center (PDC). This fuse has a color-coded plastic

housing and a clear plastic fuse conductor inspection

cover like other cartridge fuses, but has a higher cur-

rent rating and is connected and secured with screws

instead of being pushed onto male spade-type termi-

nals. The generator cartridge fuse cannot be repaired

and, if faulty or damaged, it must be replaced.

OPERATION

The generator cartridge fuse is secured between

the two B(+) terminal stud connection bus bars

within the Power Distribution Center (PDC). This

fuse protects the vehicle electrical system from dam-

age that could be caused by excessive charging sys-

tem output and/or excessive electrical system current

levels resulting from a faulty generator or faulty

charging system control circuits. If the current rating

of the fuse is exceeded, the fuse conductor melts to

open the generator output circuit connection to the

PDC. If a generator cartridge fuse fails, be certain to

completely inspect and test the vehicle charging sys-

tem before replacing the fuse and returning the vehi-

cle to service. Refer toCharging Systemfor the

charging system diagnostic procedures. Refer toWir-

ing Diagramsfor the location of complete PDC cir-

cuit diagrams.

REMOVAL

If a generator cartridge fuse fails, be certain to

inspect and test the vehicle charging system before

replacing the cartridge fuse and returning the vehicle

to service. Refer toCharging Systemin the index of

this service manual for the charging system diagnos-

tic procedures.

(1) Disconnect and isolate the battery negative

cable.

(2) Unlatch and remove the cover from the Power

Distribution Center (PDC).

(3) Remove the two screws that secure the genera-

tor cartridge fuse to the two B(+) terminal stud bus

bars within the PDC.

(4) Remove the generator cartridge fuse from the

PDC.

INSTALLATION

If a generator cartridge fuse fails, be certain to

inspect and test the vehicle charging system before

replacing the cartridge fuse and returning the vehicle

8W - 97 - 4 8W-97 POWER DISTRIBUTIONBR/BE

CIGAR LIGHTER OUTLET (Continued)

Page 1066 of 2255

tor between many of the engine compartment, instru-

ment panel, and body wire harnesses. The JB houses

up to nineteen blade-type fuses (two standard-type

and seventeen mini-type), up to two blade-type auto-

matic resetting circuit breakers, the electronic combi-

nation turn signal and hazard warning flasher, and

one International Standards Organization (ISO)

micro-relay.

The molded plastic JB housing has integral mount-

ing brackets that are secured with two screws to the

left instrument panel end bracket. The left end of the

instrument panel cover has a snap-fit fuse access

panel that can be removed for service of the JB. A

fuse puller and spare fuse holders are located on the

back of the fuse access cover, as well as an adhesive-

backed fuse layout map to ensure proper fuse identi-

fication.

The JB unit cannot be repaired and is only ser-

viced as an assembly. If any internal circuit or the JB

housing is faulty or damaged, the entire JB unit

must be replaced.

OPERATION

All of the circuits entering and leaving the JB do

so through up to nine wire harness connectors, which

are connected to the JB through integral connector

receptacles molded into the JB housing. Internal con-

nection of all of the JB circuits is accomplished by an

intricate combination of hard wiring and bus bars.

Refer toWiring Diagramsfor the location of com-

plete JB circuit diagrams.

DIAGNOSIS AND TESTING - JUNCTION BLOCK

The junction block does not incorporate any self

diagnostic capability. Most of the electrical circuits

incorporated into the vehicle must pass through the

junction block at one point or another. The most effi-

cient means of diagnosing a suspected junction block

problem involves a simple continuity tester or ohm

meter. Using the Wiring Diagrams as a guide trace

the problem circuit to the proper junction block cav-

ity and test all circuits in the effected circuit for

proper continuity. A open or high resistance circuit is

a sign of a problem. Some other possible junction

block problems to look for are:

²Loose fuse receptacle terminals.

²Loose relay / circuit breaker receptacle termi-

nals.

²Bent or distorted electrical circuit pins.

²Incorrect size fuse installed in junction block

fuse cavity.

²Dark areas identifying a source of excess heat.

²Defective fuse, relay or circuit breaker installed

in junction block cavity.

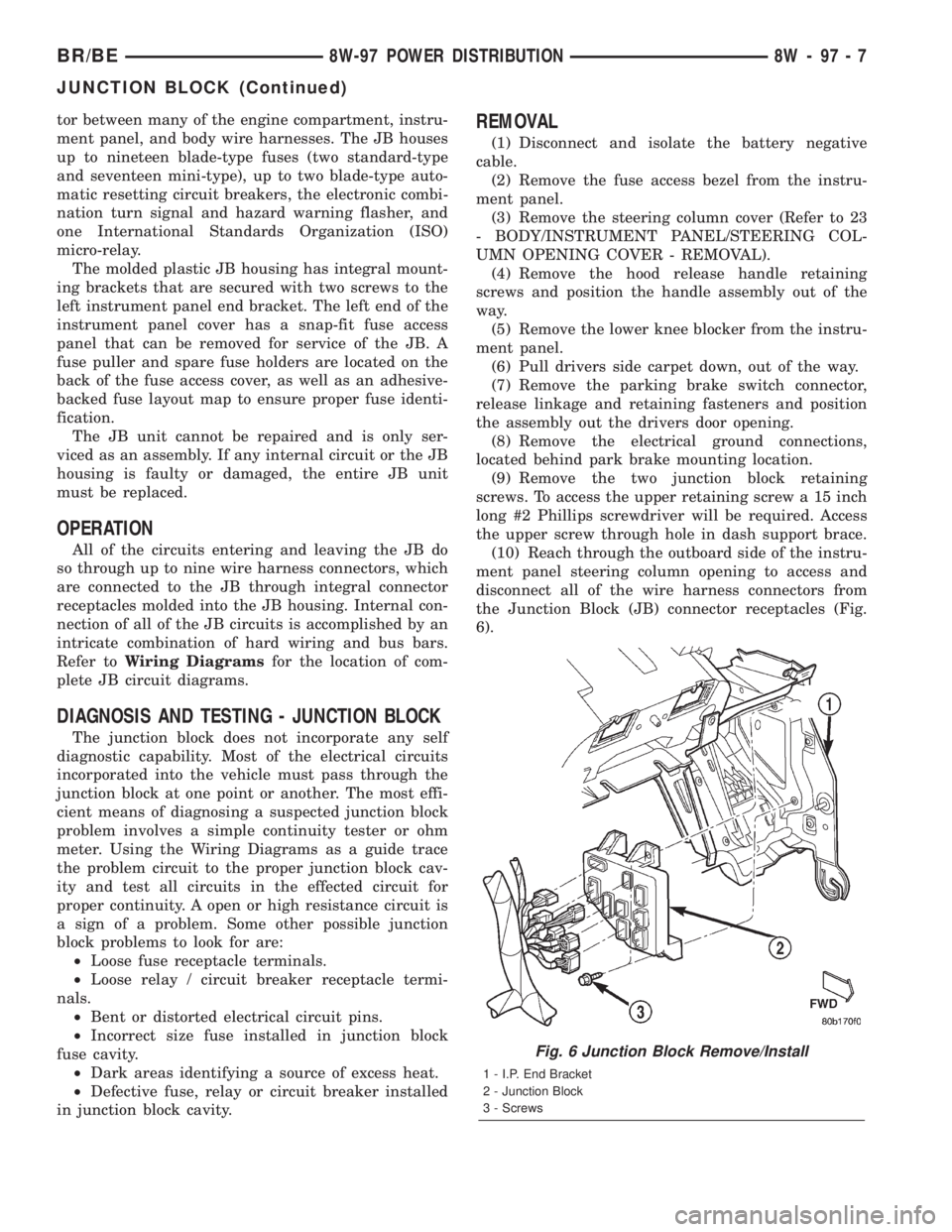

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the fuse access bezel from the instru-

ment panel.

(3) Remove the steering column cover (Refer to 23

- BODY/INSTRUMENT PANEL/STEERING COL-

UMN OPENING COVER - REMOVAL).

(4) Remove the hood release handle retaining

screws and position the handle assembly out of the

way.

(5) Remove the lower knee blocker from the instru-

ment panel.

(6) Pull drivers side carpet down, out of the way.

(7) Remove the parking brake switch connector,

release linkage and retaining fasteners and position

the assembly out the drivers door opening.

(8) Remove the electrical ground connections,

located behind park brake mounting location.

(9) Remove the two junction block retaining

screws. To access the upper retaining screw a 15 inch

long #2 Phillips screwdriver will be required. Access

the upper screw through hole in dash support brace.

(10) Reach through the outboard side of the instru-

ment panel steering column opening to access and

disconnect all of the wire harness connectors from

the Junction Block (JB) connector receptacles (Fig.

6).

Fig. 6 Junction Block Remove/Install

1 - I.P. End Bracket

2 - Junction Block

3 - Screws

BR/BE8W-97 POWER DISTRIBUTION 8W - 97 - 7

JUNCTION BLOCK (Continued)

Page 1067 of 2255

(11) Remove the junction block from under the

instrument panel.

INSTALLATION

NOTE: If the Junction Block (JB) is being replaced

with a new unit, be certain to transfer each of the

fuses, circuit breakers and relays from the faulty JB

to the proper cavities of the replacement JB. Refer

to Junction Block in the index of this service man-

ual for the location of complete circuit diagrams

and cavity assignments for the JB.

(1) Position the junction block under the instru-

ment panel.

(2) Connect all of the wire harness connectors on

the Junction Block (JB) connector receptacles.

(3) Install the two junction block retaining screws.

(4) Install the electrical ground connections,

located behind park brake mounting location.

(5) Install the parking brake switch connector,

release linkage and retaining fasteners.

(6) Reposition drivers side carpet.

(7) Install the lower knee blocker on the instru-

ment panel.

(8) Install the hood release handle retaining

screws.

(9) Install the steering column cover.

(10) Install the fuse access bezel on the instrument

panel.

(11) Connect the battery negative cable.

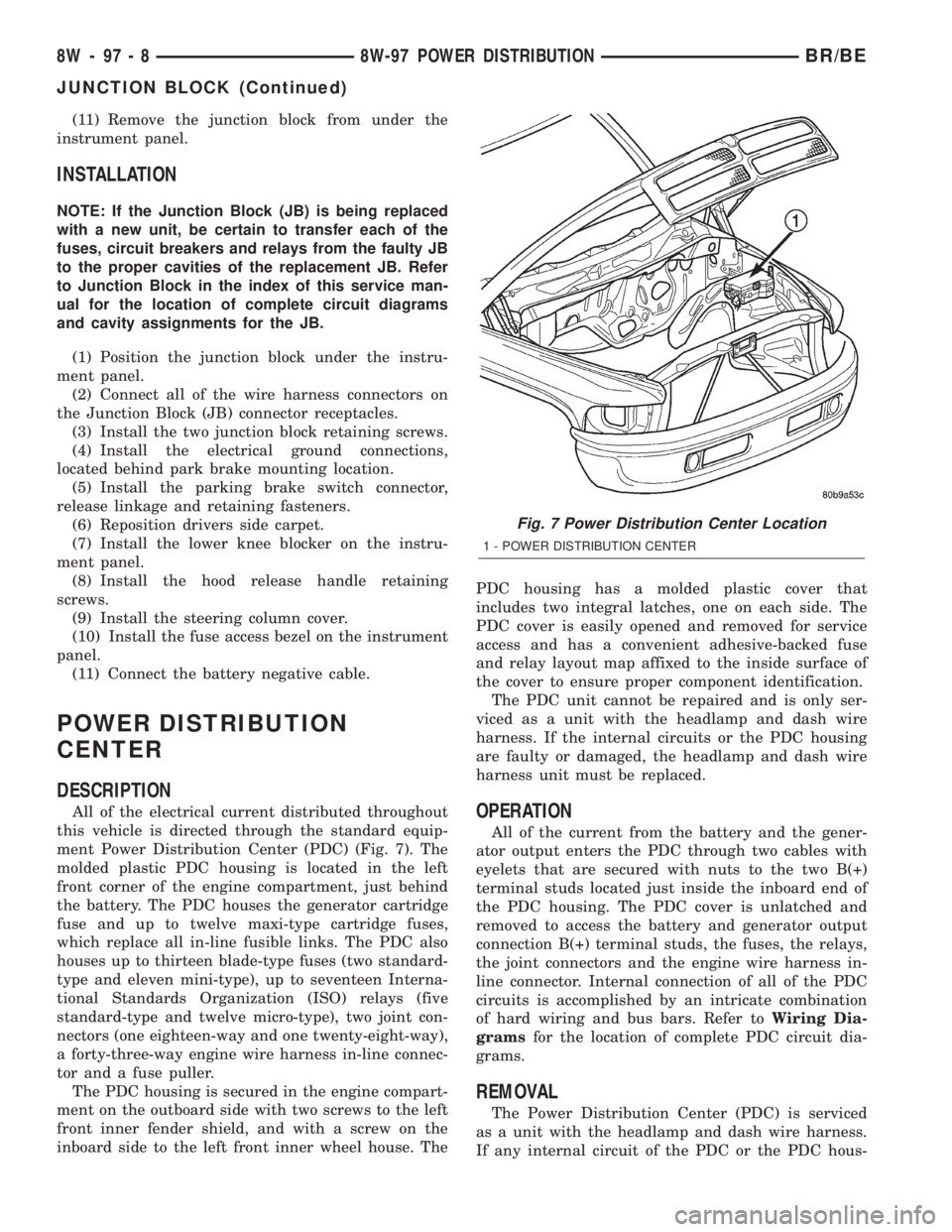

POWER DISTRIBUTION

CENTER

DESCRIPTION

All of the electrical current distributed throughout

this vehicle is directed through the standard equip-

ment Power Distribution Center (PDC) (Fig. 7). The

molded plastic PDC housing is located in the left

front corner of the engine compartment, just behind

the battery. The PDC houses the generator cartridge

fuse and up to twelve maxi-type cartridge fuses,

which replace all in-line fusible links. The PDC also

houses up to thirteen blade-type fuses (two standard-

type and eleven mini-type), up to seventeen Interna-

tional Standards Organization (ISO) relays (five

standard-type and twelve micro-type), two joint con-

nectors (one eighteen-way and one twenty-eight-way),

a forty-three-way engine wire harness in-line connec-

tor and a fuse puller.

The PDC housing is secured in the engine compart-

ment on the outboard side with two screws to the left

front inner fender shield, and with a screw on the

inboard side to the left front inner wheel house. ThePDC housing has a molded plastic cover that

includes two integral latches, one on each side. The

PDC cover is easily opened and removed for service

access and has a convenient adhesive-backed fuse

and relay layout map affixed to the inside surface of

the cover to ensure proper component identification.

The PDC unit cannot be repaired and is only ser-

viced as a unit with the headlamp and dash wire

harness. If the internal circuits or the PDC housing

are faulty or damaged, the headlamp and dash wire

harness unit must be replaced.OPERATION

All of the current from the battery and the gener-

ator output enters the PDC through two cables with

eyelets that are secured with nuts to the two B(+)

terminal studs located just inside the inboard end of

the PDC housing. The PDC cover is unlatched and

removed to access the battery and generator output

connection B(+) terminal studs, the fuses, the relays,

the joint connectors and the engine wire harness in-

line connector. Internal connection of all of the PDC

circuits is accomplished by an intricate combination

of hard wiring and bus bars. Refer toWiring Dia-

gramsfor the location of complete PDC circuit dia-

grams.

REMOVAL

The Power Distribution Center (PDC) is serviced

as a unit with the headlamp and dash wire harness.

If any internal circuit of the PDC or the PDC hous-

Fig. 7 Power Distribution Center Location

1 - POWER DISTRIBUTION CENTER

8W - 97 - 8 8W-97 POWER DISTRIBUTIONBR/BE

JUNCTION BLOCK (Continued)

Page 1086 of 2255

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDURE - REPAIR DAMAGED

OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDUREÐHYDROSTATIC

LOCK

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Perform the Fuel Pressure Release Procedure

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).

(2) Disconnect the negative cable(s) from the bat-

tery.

(3) Inspect air cleaner, induction system, and

intake manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the spark plugs.

(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

(6) Identify the fluid in the cylinders (coolant, fuel,

oil, etc.).

(7) Be sure all fluid has been removed from the

cylinders.(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt a small amount of engine oil into the

cylinders to lubricate the walls. This will prevent

damage on restart.

(10) Install new spark plugs. Tighten the spark

plugs to 41 N´m (30 ft. lbs.) torque.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

N´m (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil. (Refer to LUBRICATION &

MAINTENANCE - SPECIFICATIONS).

(15) Connect the negative cable(s) to the battery.

(16) Start the engine and check for any leaks.

STANDARD PROCEDURE - CYLINDER BORE

HONING

Before honing, stuff plenty of clean shop towels

under the bores and over the crankshaft to keep

abrasive materials from entering the crankshaft

area.

(1) Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round, as well as removing light

scuffing, scoring and scratches. Usually, a few strokes

will clean up a bore and maintain the required lim-

its.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin-

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). about 20-60

strokes, depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Using honing

oil C-3501-3880, or a light honing oil, available from

major oil distributors.

CAUTION: DO NOT use engine or transmission oil,

mineral spirits, or kerosene.

(3) Honing should be done by moving the hone up

and down fast enough to get a crosshatch pattern.

The hone marks should INTERSECT at 40É to 60É

for proper seating of rings (Fig. 3).

(4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 40É to 60É

angle. Faster up and down strokes increase the cross-

hatch angle.

BR/BEENGINE 5.9L 9 - 11

ENGINE 5.9L (Continued)