hvac DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1089 of 2895

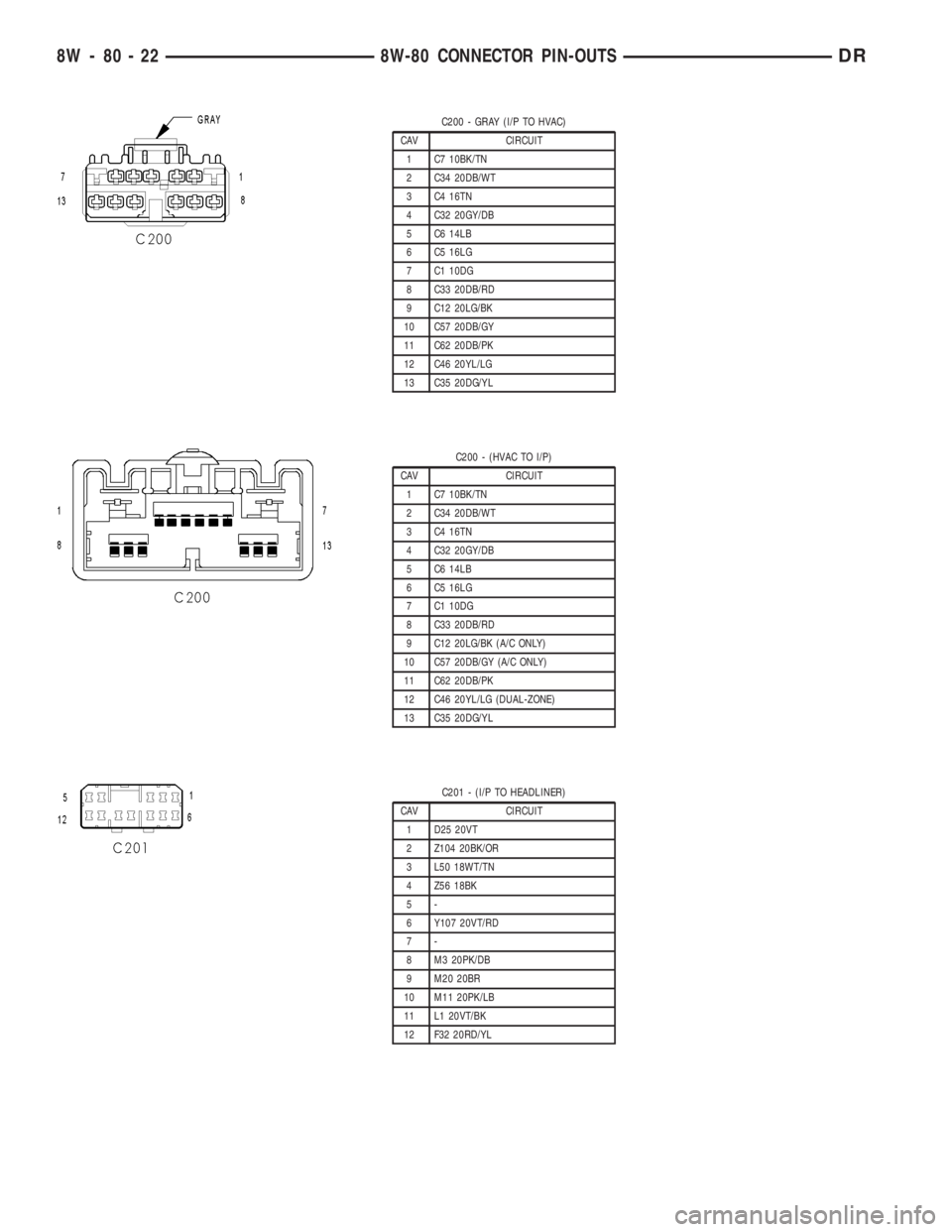

C200 - GRAY (I/P TO HVAC)

CAV CIRCUIT

1 C7 10BK/TN

2 C34 20DB/WT

3 C4 16TN

4 C32 20GY/DB

5 C6 14LB

6 C5 16LG

7 C1 10DG

8 C33 20DB/RD

9 C12 20LG/BK

10 C57 20DB/GY

11 C62 20DB/PK

12 C46 20YL/LG

13 C35 20DG/YL

C200 - (HVAC TO I/P)

CAV CIRCUIT

1 C7 10BK/TN

2 C34 20DB/WT

3 C4 16TN

4 C32 20GY/DB

5 C6 14LB

6 C5 16LG

7 C1 10DG

8 C33 20DB/RD

9 C12 20LG/BK (A/C ONLY)

10 C57 20DB/GY (A/C ONLY)

11 C62 20DB/PK

12 C46 20YL/LG (DUAL-ZONE)

13 C35 20DG/YL

C201 - (I/P TO HEADLINER)

CAV CIRCUIT

1 D25 20VT

2 Z104 20BK/OR

3 L50 18WT/TN

4 Z56 18BK

5-

6 Y107 20VT/RD

7-

8 M3 20PK/DB

9 M20 20BR

10 M11 20PK/LB

11 L1 20VT/BK

12 F32 20RD/YL

8W - 80 - 22 8W-80 CONNECTOR PIN-OUTSDR

Page 1181 of 2895

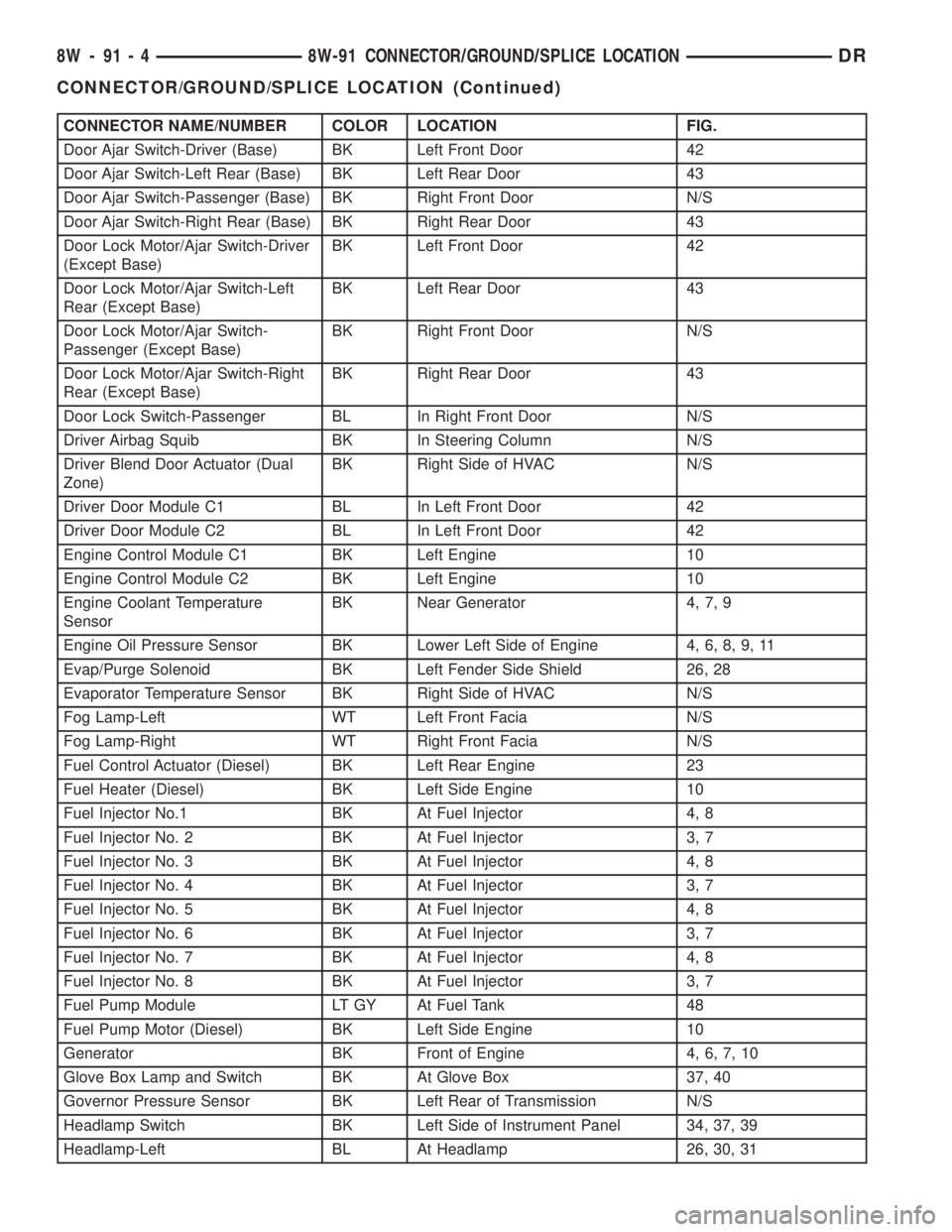

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Door Ajar Switch-Driver (Base) BK Left Front Door 42

Door Ajar Switch-Left Rear (Base) BK Left Rear Door 43

Door Ajar Switch-Passenger (Base) BK Right Front Door N/S

Door Ajar Switch-Right Rear (Base) BK Right Rear Door 43

Door Lock Motor/Ajar Switch-Driver

(Except Base)BK Left Front Door 42

Door Lock Motor/Ajar Switch-Left

Rear (Except Base)BK Left Rear Door 43

Door Lock Motor/Ajar Switch-

Passenger (Except Base)BK Right Front Door N/S

Door Lock Motor/Ajar Switch-Right

Rear (Except Base)BK Right Rear Door 43

Door Lock Switch-Passenger BL In Right Front Door N/S

Driver Airbag Squib BK In Steering Column N/S

Driver Blend Door Actuator (Dual

Zone)BK Right Side of HVAC N/S

Driver Door Module C1 BL In Left Front Door 42

Driver Door Module C2 BL In Left Front Door 42

Engine Control Module C1 BK Left Engine 10

Engine Control Module C2 BK Left Engine 10

Engine Coolant Temperature

SensorBK Near Generator 4, 7, 9

Engine Oil Pressure Sensor BK Lower Left Side of Engine 4, 6, 8, 9, 11

Evap/Purge Solenoid BK Left Fender Side Shield 26, 28

Evaporator Temperature Sensor BK Right Side of HVAC N/S

Fog Lamp-Left WT Left Front Facia N/S

Fog Lamp-Right WT Right Front Facia N/S

Fuel Control Actuator (Diesel) BK Left Rear Engine 23

Fuel Heater (Diesel) BK Left Side Engine 10

Fuel Injector No.1 BK At Fuel Injector 4, 8

Fuel Injector No. 2 BK At Fuel Injector 3, 7

Fuel Injector No. 3 BK At Fuel Injector 4, 8

Fuel Injector No. 4 BK At Fuel Injector 3, 7

Fuel Injector No. 5 BK At Fuel Injector 4, 8

Fuel Injector No. 6 BK At Fuel Injector 3, 7

Fuel Injector No. 7 BK At Fuel Injector 4, 8

Fuel Injector No. 8 BK At Fuel Injector 3, 7

Fuel Pump Module LT GY At Fuel Tank 48

Fuel Pump Motor (Diesel) BK Left Side Engine 10

Generator BK Front of Engine 4, 6, 7, 10

Glove Box Lamp and Switch BK At Glove Box 37, 40

Governor Pressure Sensor BK Left Rear of Transmission N/S

Headlamp Switch BK Left Side of Instrument Panel 34, 37, 39

Headlamp-Left BL At Headlamp 26, 30, 31

8W - 91 - 4 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONDR

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1183 of 2895

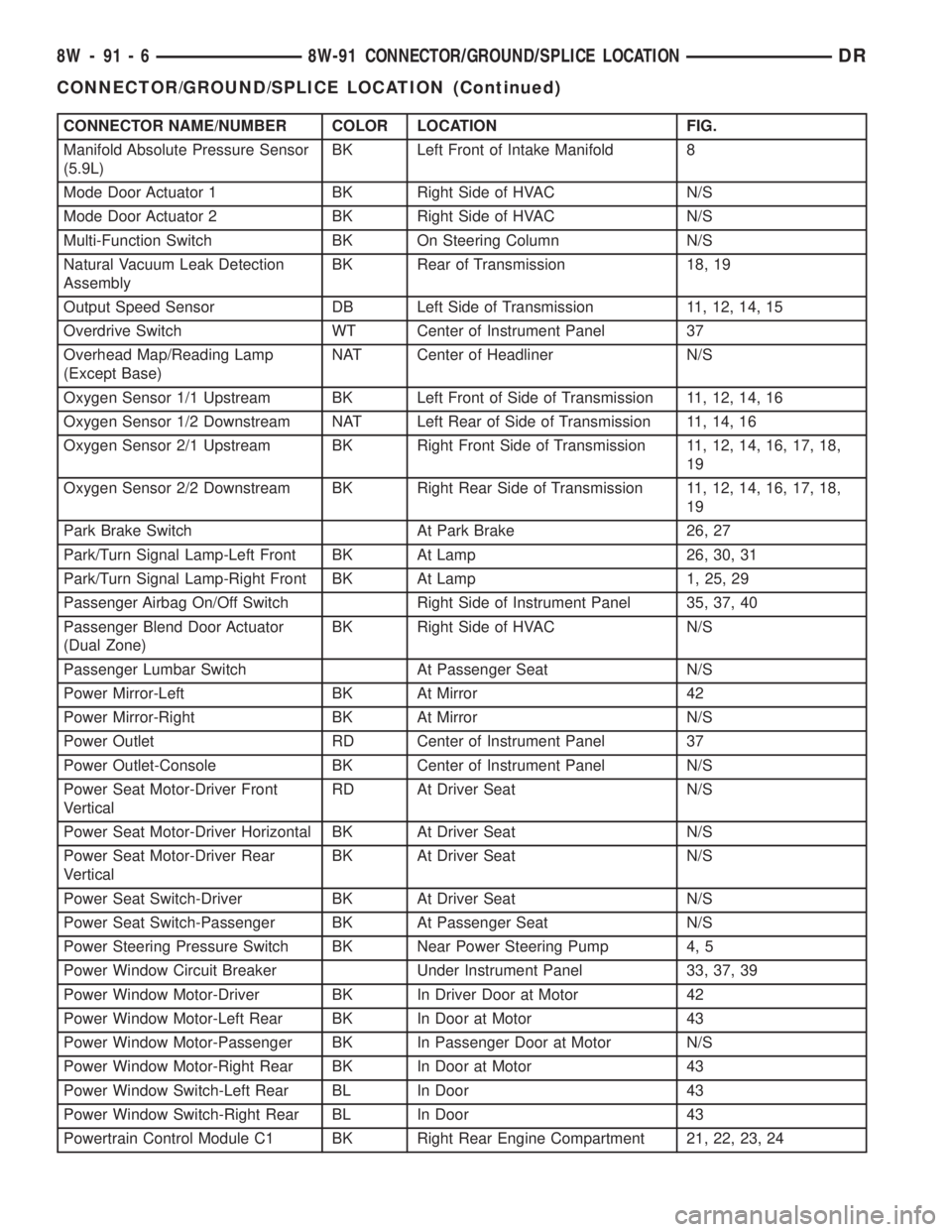

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Manifold Absolute Pressure Sensor

(5.9L)BK Left Front of Intake Manifold 8

Mode Door Actuator 1 BK Right Side of HVAC N/S

Mode Door Actuator 2 BK Right Side of HVAC N/S

Multi-Function Switch BK On Steering Column N/S

Natural Vacuum Leak Detection

AssemblyBK Rear of Transmission 18, 19

Output Speed Sensor DB Left Side of Transmission 11, 12, 14, 15

Overdrive Switch WT Center of Instrument Panel 37

Overhead Map/Reading Lamp

(Except Base)NAT Center of Headliner N/S

Oxygen Sensor 1/1 Upstream BK Left Front of Side of Transmission 11, 12, 14, 16

Oxygen Sensor 1/2 Downstream NAT Left Rear of Side of Transmission 11, 14, 16

Oxygen Sensor 2/1 Upstream BK Right Front Side of Transmission 11, 12, 14, 16, 17, 18,

19

Oxygen Sensor 2/2 Downstream BK Right Rear Side of Transmission 11, 12, 14, 16, 17, 18,

19

Park Brake Switch At Park Brake 26, 27

Park/Turn Signal Lamp-Left Front BK At Lamp 26, 30, 31

Park/Turn Signal Lamp-Right Front BK At Lamp 1, 25, 29

Passenger Airbag On/Off Switch Right Side of Instrument Panel 35, 37, 40

Passenger Blend Door Actuator

(Dual Zone)BK Right Side of HVAC N/S

Passenger Lumbar Switch At Passenger Seat N/S

Power Mirror-Left BK At Mirror 42

Power Mirror-Right BK At Mirror N/S

Power Outlet RD Center of Instrument Panel 37

Power Outlet-Console BK Center of Instrument Panel N/S

Power Seat Motor-Driver Front

VerticalRD At Driver Seat N/S

Power Seat Motor-Driver Horizontal BK At Driver Seat N/S

Power Seat Motor-Driver Rear

VerticalBK At Driver Seat N/S

Power Seat Switch-Driver BK At Driver Seat N/S

Power Seat Switch-Passenger BK At Passenger Seat N/S

Power Steering Pressure Switch BK Near Power Steering Pump 4, 5

Power Window Circuit Breaker Under Instrument Panel 33, 37, 39

Power Window Motor-Driver BK In Driver Door at Motor 42

Power Window Motor-Left Rear BK In Door at Motor 43

Power Window Motor-Passenger BK In Passenger Door at Motor N/S

Power Window Motor-Right Rear BK In Door at Motor 43

Power Window Switch-Left Rear BL In Door 43

Power Window Switch-Right Rear BL In Door 43

Powertrain Control Module C1 BK Right Rear Engine Compartment 21, 22, 23, 24

8W - 91 - 6 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONDR

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1184 of 2895

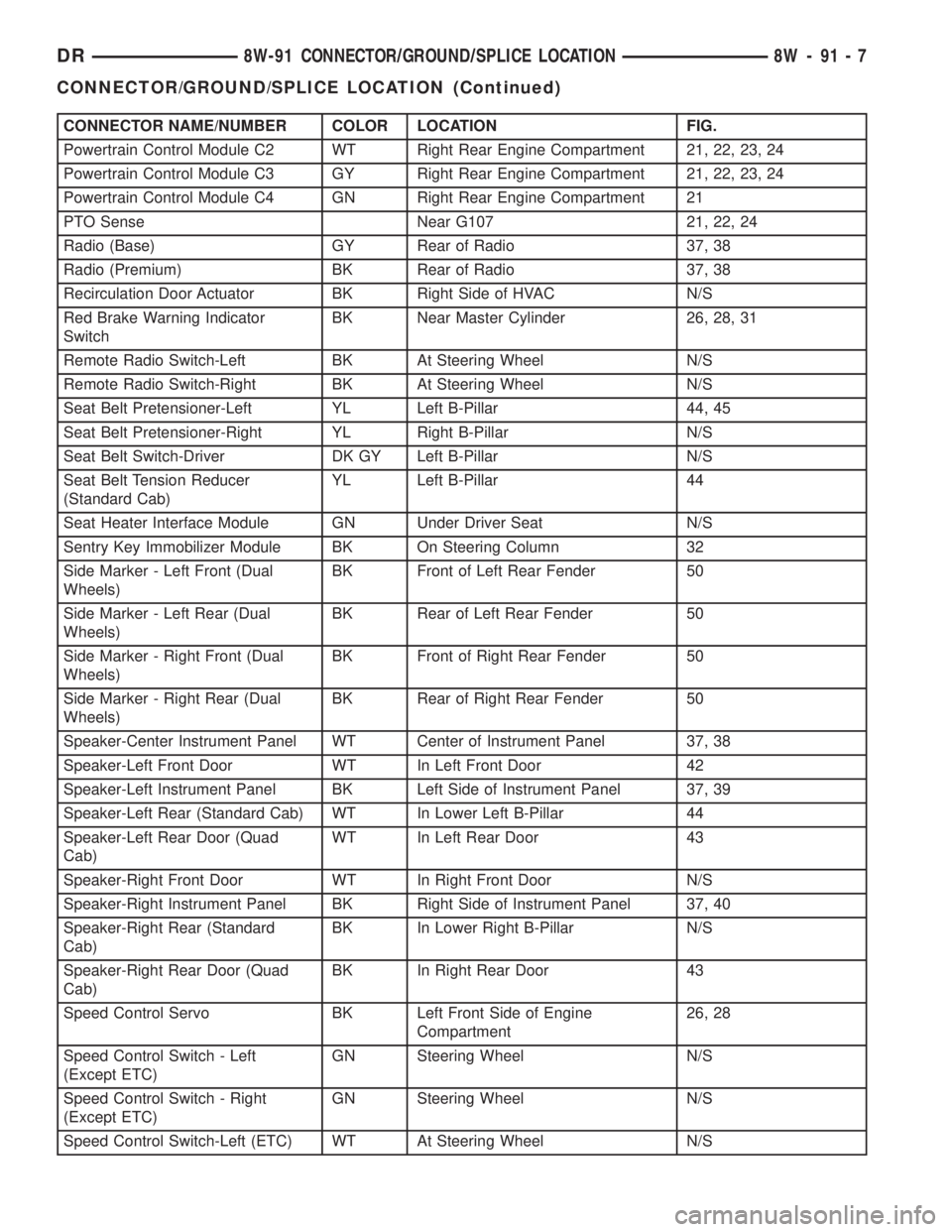

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Powertrain Control Module C2 WT Right Rear Engine Compartment 21, 22, 23, 24

Powertrain Control Module C3 GY Right Rear Engine Compartment 21, 22, 23, 24

Powertrain Control Module C4 GN Right Rear Engine Compartment 21

PTO Sense Near G107 21, 22, 24

Radio (Base) GY Rear of Radio 37, 38

Radio (Premium) BK Rear of Radio 37, 38

Recirculation Door Actuator BK Right Side of HVAC N/S

Red Brake Warning Indicator

SwitchBK Near Master Cylinder 26, 28, 31

Remote Radio Switch-Left BK At Steering Wheel N/S

Remote Radio Switch-Right BK At Steering Wheel N/S

Seat Belt Pretensioner-Left YL Left B-Pillar 44, 45

Seat Belt Pretensioner-Right YL Right B-Pillar N/S

Seat Belt Switch-Driver DK GY Left B-Pillar N/S

Seat Belt Tension Reducer

(Standard Cab)YL Left B-Pillar 44

Seat Heater Interface Module GN Under Driver Seat N/S

Sentry Key Immobilizer Module BK On Steering Column 32

Side Marker - Left Front (Dual

Wheels)BK Front of Left Rear Fender 50

Side Marker - Left Rear (Dual

Wheels)BK Rear of Left Rear Fender 50

Side Marker - Right Front (Dual

Wheels)BK Front of Right Rear Fender 50

Side Marker - Right Rear (Dual

Wheels)BK Rear of Right Rear Fender 50

Speaker-Center Instrument Panel WT Center of Instrument Panel 37, 38

Speaker-Left Front Door WT In Left Front Door 42

Speaker-Left Instrument Panel BK Left Side of Instrument Panel 37, 39

Speaker-Left Rear (Standard Cab) WT In Lower Left B-Pillar 44

Speaker-Left Rear Door (Quad

Cab)WT In Left Rear Door 43

Speaker-Right Front Door WT In Right Front Door N/S

Speaker-Right Instrument Panel BK Right Side of Instrument Panel 37, 40

Speaker-Right Rear (Standard

Cab)BK In Lower Right B-Pillar N/S

Speaker-Right Rear Door (Quad

Cab)BK In Right Rear Door 43

Speed Control Servo BK Left Front Side of Engine

Compartment26, 28

Speed Control Switch - Left

(Except ETC)GN Steering Wheel N/S

Speed Control Switch - Right

(Except ETC)GN Steering Wheel N/S

Speed Control Switch-Left (ETC) WT At Steering Wheel N/S

DR8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 7

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1188 of 2895

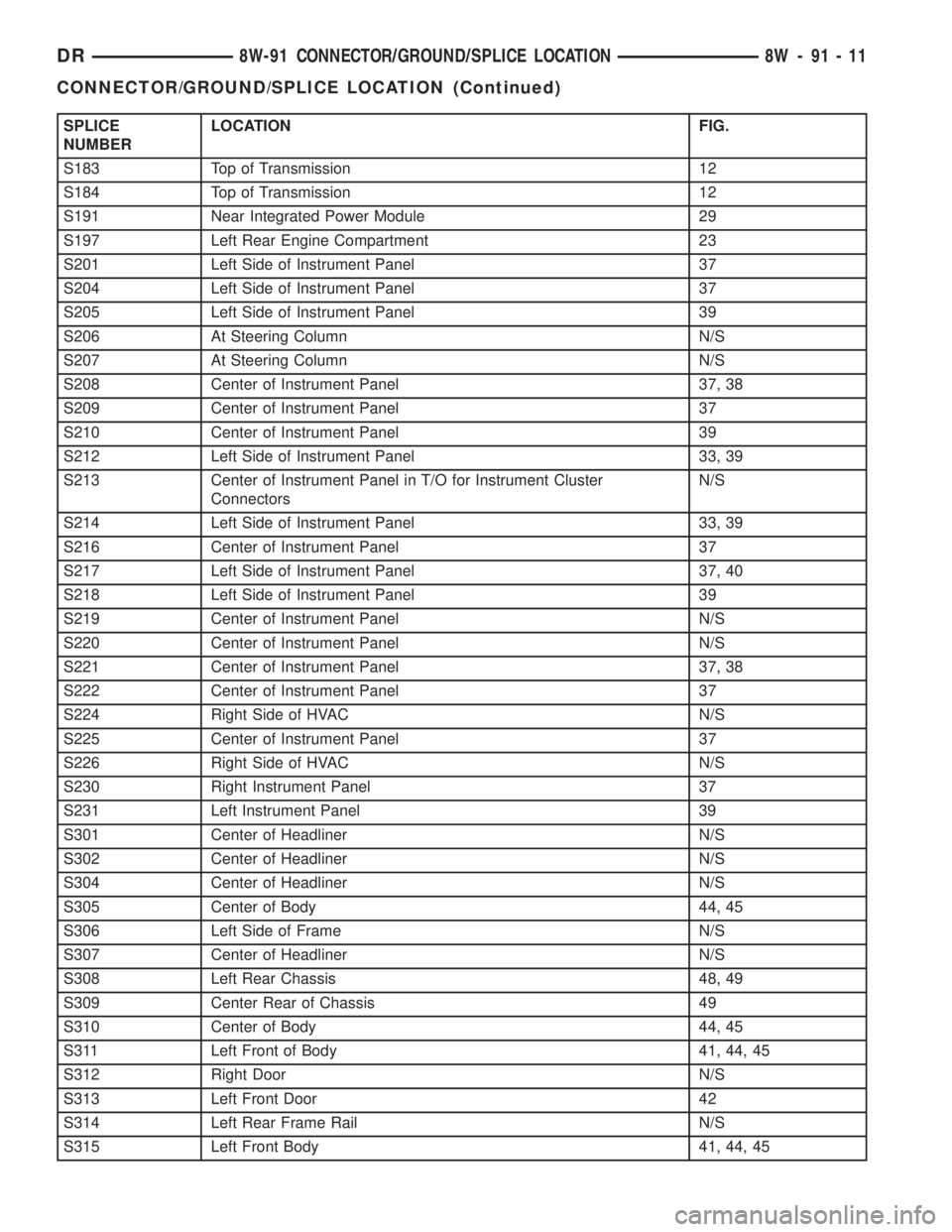

SPLICE

NUMBERLOCATION FIG.

S183 Top of Transmission 12

S184 Top of Transmission 12

S191 Near Integrated Power Module 29

S197 Left Rear Engine Compartment 23

S201 Left Side of Instrument Panel 37

S204 Left Side of Instrument Panel 37

S205 Left Side of Instrument Panel 39

S206 At Steering Column N/S

S207 At Steering Column N/S

S208 Center of Instrument Panel 37, 38

S209 Center of Instrument Panel 37

S210 Center of Instrument Panel 39

S212 Left Side of Instrument Panel 33, 39

S213 Center of Instrument Panel in T/O for Instrument Cluster

ConnectorsN/S

S214 Left Side of Instrument Panel 33, 39

S216 Center of Instrument Panel 37

S217 Left Side of Instrument Panel 37, 40

S218 Left Side of Instrument Panel 39

S219 Center of Instrument Panel N/S

S220 Center of Instrument Panel N/S

S221 Center of Instrument Panel 37, 38

S222 Center of Instrument Panel 37

S224 Right Side of HVAC N/S

S225 Center of Instrument Panel 37

S226 Right Side of HVAC N/S

S230 Right Instrument Panel 37

S231 Left Instrument Panel 39

S301 Center of Headliner N/S

S302 Center of Headliner N/S

S304 Center of Headliner N/S

S305 Center of Body 44, 45

S306 Left Side of Frame N/S

S307 Center of Headliner N/S

S308 Left Rear Chassis 48, 49

S309 Center Rear of Chassis 49

S310 Center of Body 44, 45

S311 Left Front of Body 41, 44, 45

S312 Right Door N/S

S313 Left Front Door 42

S314 Left Rear Frame Rail N/S

S315 Left Front Body 41, 44, 45

DR8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 11

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 2630 of 2895

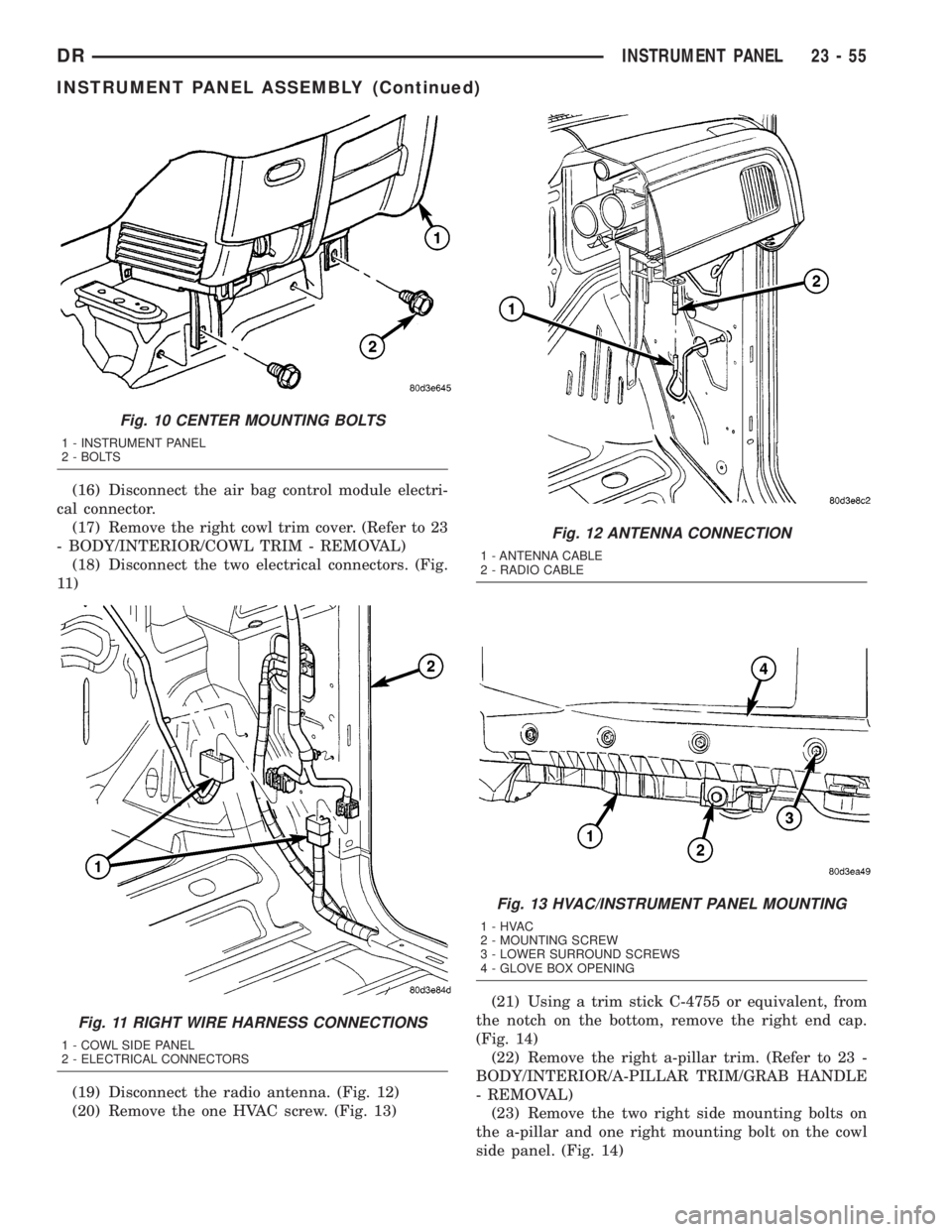

(16) Disconnect the air bag control module electri-

cal connector.

(17) Remove the right cowl trim cover. (Refer to 23

- BODY/INTERIOR/COWL TRIM - REMOVAL)

(18) Disconnect the two electrical connectors. (Fig.

11 )

(19) Disconnect the radio antenna. (Fig. 12)

(20) Remove the one HVAC screw. (Fig. 13)(21) Using a trim stick C-4755 or equivalent, from

the notch on the bottom, remove the right end cap.

(Fig. 14)

(22) Remove the right a-pillar trim. (Refer to 23 -

BODY/INTERIOR/A-PILLAR TRIM/GRAB HANDLE

- REMOVAL)

(23) Remove the two right side mounting bolts on

the a-pillar and one right mounting bolt on the cowl

side panel. (Fig. 14)

Fig. 10 CENTER MOUNTING BOLTS

1 - INSTRUMENT PANEL

2 - BOLTS

Fig. 11 RIGHT WIRE HARNESS CONNECTIONS

1 - COWL SIDE PANEL

2 - ELECTRICAL CONNECTORS

Fig. 12 ANTENNA CONNECTION

1 - ANTENNA CABLE

2 - RADIO CABLE

Fig. 13 HVAC/INSTRUMENT PANEL MOUNTING

1-HVAC

2 - MOUNTING SCREW

3 - LOWER SURROUND SCREWS

4 - GLOVE BOX OPENING

DRINSTRUMENT PANEL 23 - 55

INSTRUMENT PANEL ASSEMBLY (Continued)

Page 2632 of 2895

(11) Install the right a-pillar trim panel. (Refer to

23 - BODY/INTERIOR/A-PILLAR TRIM - INSTAL-

LATION)

(12) Position the right end cap and seat the

attachment clips fully.

(13) Install the one HVAC mounting screw.

(14) Connect the radio antenna.

(15) Connect the two electrical connectors at the

right cowl panel.

(16) Install the right cowl trim cover. (Refer to 23 -

BODY/INTERIOR/COWL TRIM - INSTALLATION)

(17) Connect the air bag control module electrical

connector.

(18) Install the center bracket bolts and tighten to

12 N´m (9 ft. lbs.).

(19) Install the floor console, if equipped. (Refer to

23 - BODY/INTERIOR/FLOOR CONSOLE - INSTAL-

LATION)

(20) Install the air bag control module cover, if

equipped.

(21) Connect the park brake release handle actua-

tor rod.

(22) Install the hood release handle and tighten

the screws.

(23) Install the two bolts at the column support

bracket and tighten to 14 N´m (10 ft. lbs.).

(24) Install the steering column. (Refer to 19 -

STEERING/COLUMN - INSTALLATION)

(25) Connect the wire harness electrical connectors

above the brake pedal.

(26) Install the two top instrument panel bolts and

tighten to 12 N´m (9 ft. lbs.).

(27) Install the four top instrument panel screws.

(28) Install the instrument panel top cover. (Refer

to 23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL TOP COVER - INSTALLATION)

INSTRUMENT PANEL

HEADLAMP SWITCH BEZEL

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULDRESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

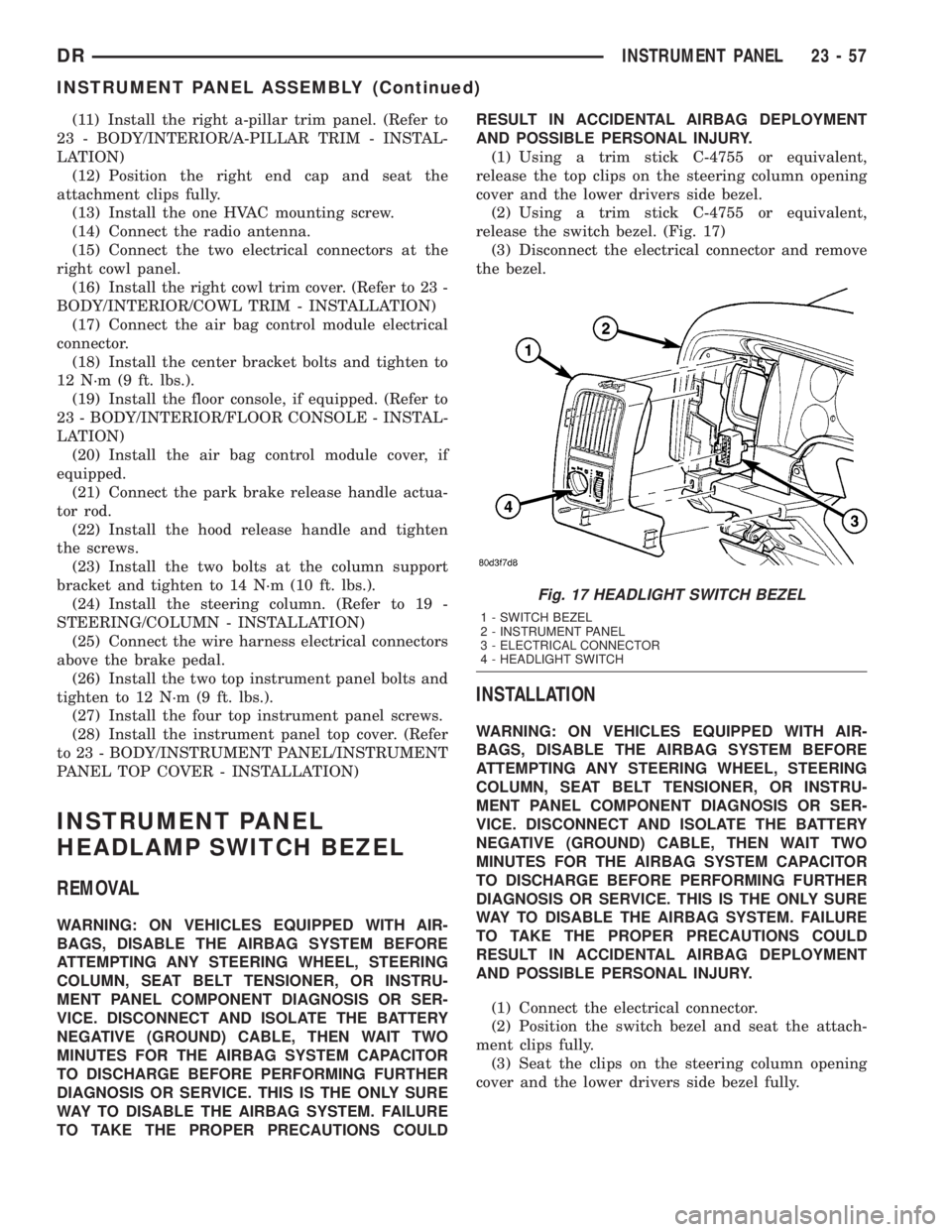

(1) Using a trim stick C-4755 or equivalent,

release the top clips on the steering column opening

cover and the lower drivers side bezel.

(2) Using a trim stick C-4755 or equivalent,

release the switch bezel. (Fig. 17)

(3) Disconnect the electrical connector and remove

the bezel.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Connect the electrical connector.

(2) Position the switch bezel and seat the attach-

ment clips fully.

(3) Seat the clips on the steering column opening

cover and the lower drivers side bezel fully.

Fig. 17 HEADLIGHT SWITCH BEZEL

1 - SWITCH BEZEL

2 - INSTRUMENT PANEL

3 - ELECTRICAL CONNECTOR

4 - HEADLIGHT SWITCH

DRINSTRUMENT PANEL 23 - 57

INSTRUMENT PANEL ASSEMBLY (Continued)

Page 2776 of 2895

HEATING & AIR CONDITIONING

TABLE OF CONTENTS

page page

HEATING & AIR CONDITIONING

DESCRIPTION

DESCRIPTION - HEATER AND AIR

CONDITIONER........................1

DESCRIPTION - COOLING SYSTEM

REQUIREMENTS.......................1

DESCRIPTION - REFRIGERANT SYSTEM

SERVICE PORT........................1

OPERATION

OPERATION - HEATER AND AIR

CONDITIONER........................1

OPERATION - REFRIGERANT SYSTEM

SERVICE PORT........................2DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C

PERFORMANCE.......................2

DIAGNOSIS AND TESTING - HEATER

PERFORMANCE.......................5

STANDARD PROCEDURE - DIODE

REPLACEMENT.......................7

SPECIFICATIONS

A/C APPLICATION TABLE................7

SPECIFICATIONS......................8

CONTROLS.............................9

DISTRIBUTION..........................24

PLUMBING.............................31

HEATING & AIR

CONDITIONING

DESCRIPTION

DESCRIPTION - HEATER AND AIR

CONDITIONER

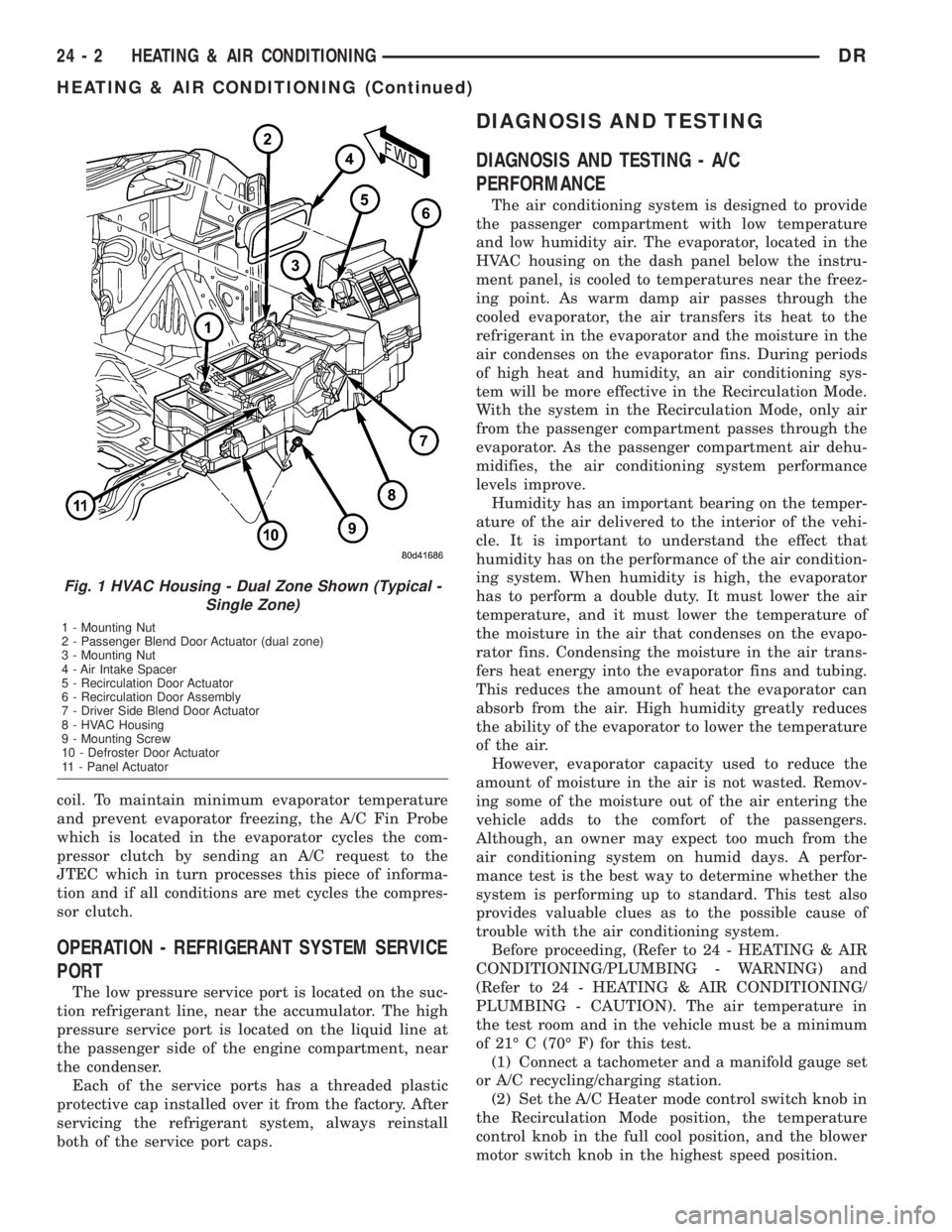

All vehicles are equipped with a common HVAC

housing assembly (Fig. 1). The system combines air

conditioning, heating, and ventilating capabilities in

a single unit housing mounted under the instrument

panel.

DESCRIPTION - COOLING SYSTEM

REQUIREMENTS

To maintain the performance level of the HVAC

system, the engine cooling system must be properly

maintained. The use of a bug screen is not recom-

mended. Any obstructions in front of the radiator or

condenser will reduce the performance of the air con-

ditioning and engine cooling systems.

The engine cooling system includes the heater core

and the heater hoses. Refer to Engine Cooling for

more information before the opening of, or attempt-

ing any service to the engine cooling system.

DESCRIPTION - REFRIGERANT SYSTEM

SERVICE PORT

The two refrigerant system service ports are used

to charge, recover/recycle, evacuate, and test the air

conditioning refrigerant system. Unique service port

coupler sizes are used on the R-134a system, toensure that the refrigerant system is not accidentally

contaminated by the use of the wrong refrigerant

(R-12), or refrigerant system service equipment.

OPERATION

OPERATION - HEATER AND AIR CONDITIONER

The heater air conditioner are blend-air type sys-

tems. In a blend-air system, a blend door controls the

amount of unconditioned air (or cooled air from the

evaporator on models with air conditioning) that is

allowed to flow through, or around, the heater core. A

temperature control knob on the A/C Heater control

panel determines the discharge air temperature by

controlling an electric actuator, which moves the

blend door. This allows an almost immediate control

of the output air temperature of the system.

The mode control knob on the A/C Heater control

panel is used to direct the conditioned air to the

selected system outlets. Both mode control switches

use electric actuators to control the mode doors.

On all vehicles, the outside air intake can be shut

off by selecting the Recirculation Mode with the

mode control knob. This will operate a electric actu-

ated recirculation door that closes off the outside

fresh air intake and recirculates the air that is

already inside the vehicle.

The air conditioner for all models is designed for

the use of non-CFC, R-134a refrigerant. The air con-

ditioning system has an evaporator to cool and dehu-

midify the incoming air prior to blending it with the

heated air. This air conditioning system uses a fixed

orifice tube in the liquid line near the condenser out-

let tube to meter refrigerant flow to the evaporator

DRHEATING & AIR CONDITIONING 24 - 1

Page 2777 of 2895

coil. To maintain minimum evaporator temperature

and prevent evaporator freezing, the A/C Fin Probe

which is located in the evaporator cycles the com-

pressor clutch by sending an A/C request to the

JTEC which in turn processes this piece of informa-

tion and if all conditions are met cycles the compres-

sor clutch.

OPERATION - REFRIGERANT SYSTEM SERVICE

PORT

The low pressure service port is located on the suc-

tion refrigerant line, near the accumulator. The high

pressure service port is located on the liquid line at

the passenger side of the engine compartment, near

the condenser.

Each of the service ports has a threaded plastic

protective cap installed over it from the factory. After

servicing the refrigerant system, always reinstall

both of the service port caps.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C

PERFORMANCE

The air conditioning system is designed to provide

the passenger compartment with low temperature

and low humidity air. The evaporator, located in the

HVAC housing on the dash panel below the instru-

ment panel, is cooled to temperatures near the freez-

ing point. As warm damp air passes through the

cooled evaporator, the air transfers its heat to the

refrigerant in the evaporator and the moisture in the

air condenses on the evaporator fins. During periods

of high heat and humidity, an air conditioning sys-

tem will be more effective in the Recirculation Mode.

With the system in the Recirculation Mode, only air

from the passenger compartment passes through the

evaporator. As the passenger compartment air dehu-

midifies, the air conditioning system performance

levels improve.

Humidity has an important bearing on the temper-

ature of the air delivered to the interior of the vehi-

cle. It is important to understand the effect that

humidity has on the performance of the air condition-

ing system. When humidity is high, the evaporator

has to perform a double duty. It must lower the air

temperature, and it must lower the temperature of

the moisture in the air that condenses on the evapo-

rator fins. Condensing the moisture in the air trans-

fers heat energy into the evaporator fins and tubing.

This reduces the amount of heat the evaporator can

absorb from the air. High humidity greatly reduces

the ability of the evaporator to lower the temperature

of the air.

However, evaporator capacity used to reduce the

amount of moisture in the air is not wasted. Remov-

ing some of the moisture out of the air entering the

vehicle adds to the comfort of the passengers.

Although, an owner may expect too much from the

air conditioning system on humid days. A perfor-

mance test is the best way to determine whether the

system is performing up to standard. This test also

provides valuable clues as to the possible cause of

trouble with the air conditioning system.

Before proceeding, (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - WARNING) and

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - CAUTION). The air temperature in

the test room and in the vehicle must be a minimum

of 21É C (70É F) for this test.

(1) Connect a tachometer and a manifold gauge set

or A/C recycling/charging station.

(2) Set the A/C Heater mode control switch knob in

the Recirculation Mode position, the temperature

control knob in the full cool position, and the blower

motor switch knob in the highest speed position.

Fig. 1 HVAC Housing - Dual Zone Shown (Typical -

Single Zone)

1 - Mounting Nut

2 - Passenger Blend Door Actuator (dual zone)

3 - Mounting Nut

4 - Air Intake Spacer

5 - Recirculation Door Actuator

6 - Recirculation Door Assembly

7 - Driver Side Blend Door Actuator

8 - HVAC Housing

9 - Mounting Screw

10 - Defroster Door Actuator

11 - Panel Actuator

24 - 2 HEATING & AIR CONDITIONINGDR

HEATING & AIR CONDITIONING (Continued)

Page 2780 of 2895

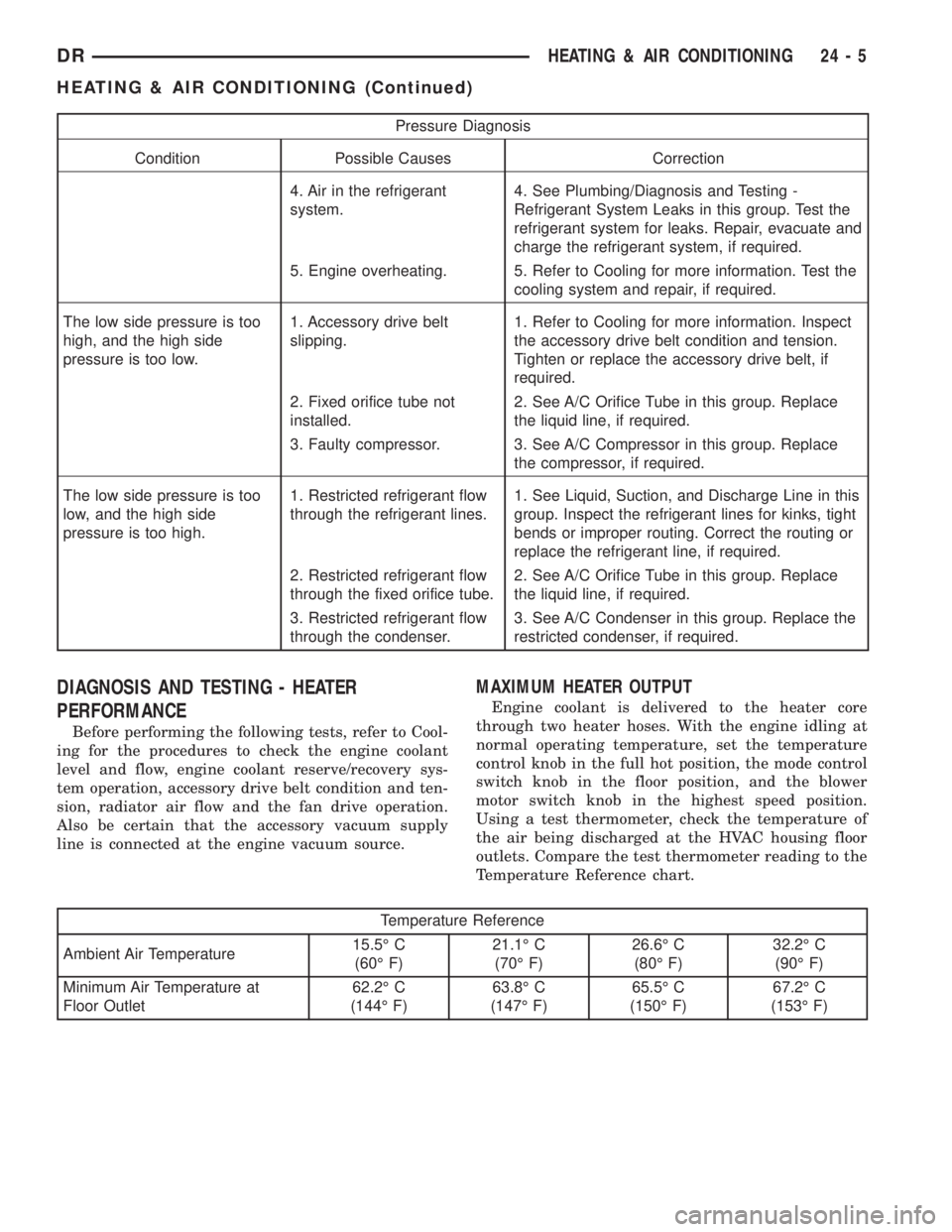

Pressure Diagnosis

Condition Possible Causes Correction

4. Air in the refrigerant

system.4. See Plumbing/Diagnosis and Testing -

Refrigerant System Leaks in this group. Test the

refrigerant system for leaks. Repair, evacuate and

charge the refrigerant system, if required.

5. Engine overheating. 5. Refer to Cooling for more information. Test the

cooling system and repair, if required.

The low side pressure is too

high, and the high side

pressure is too low.1. Accessory drive belt

slipping.1. Refer to Cooling for more information. Inspect

the accessory drive belt condition and tension.

Tighten or replace the accessory drive belt, if

required.

2. Fixed orifice tube not

installed.2. See A/C Orifice Tube in this group. Replace

the liquid line, if required.

3. Faulty compressor. 3. See A/C Compressor in this group. Replace

the compressor, if required.

The low side pressure is too

low, and the high side

pressure is too high.1. Restricted refrigerant flow

through the refrigerant lines.1. See Liquid, Suction, and Discharge Line in this

group. Inspect the refrigerant lines for kinks, tight

bends or improper routing. Correct the routing or

replace the refrigerant line, if required.

2. Restricted refrigerant flow

through the fixed orifice tube.2. See A/C Orifice Tube in this group. Replace

the liquid line, if required.

3. Restricted refrigerant flow

through the condenser.3. See A/C Condenser in this group. Replace the

restricted condenser, if required.

DIAGNOSIS AND TESTING - HEATER

PERFORMANCE

Before performing the following tests, refer to Cool-

ing for the procedures to check the engine coolant

level and flow, engine coolant reserve/recovery sys-

tem operation, accessory drive belt condition and ten-

sion, radiator air flow and the fan drive operation.

Also be certain that the accessory vacuum supply

line is connected at the engine vacuum source.

MAXIMUM HEATER OUTPUT

Engine coolant is delivered to the heater core

through two heater hoses. With the engine idling at

normal operating temperature, set the temperature

control knob in the full hot position, the mode control

switch knob in the floor position, and the blower

motor switch knob in the highest speed position.

Using a test thermometer, check the temperature of

the air being discharged at the HVAC housing floor

outlets. Compare the test thermometer reading to the

Temperature Reference chart.

Temperature Reference

Ambient Air Temperature15.5É C

(60É F)21.1É C

(70É F)26.6É C

(80É F)32.2É C

(90É F)

Minimum Air Temperature at

Floor Outlet62.2É C

(144É F)63.8É C

(147É F)65.5É C

(150É F)67.2É C

(153É F)

DRHEATING & AIR CONDITIONING 24 - 5

HEATING & AIR CONDITIONING (Continued)