fuse box DODGE RAM 2003 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1130 of 2895

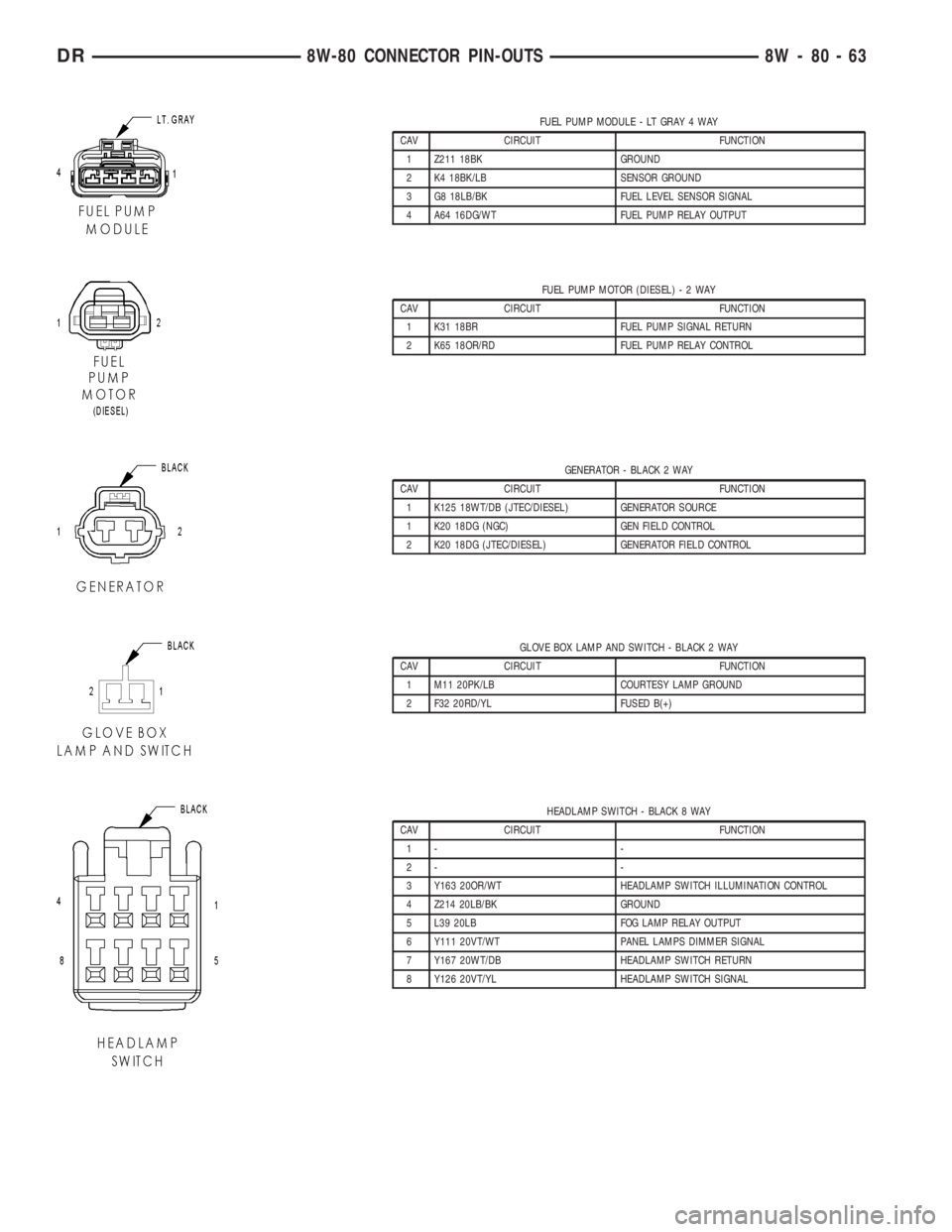

FUEL PUMP MODULE - LT GRAY 4 WAY

CAV CIRCUIT FUNCTION

1 Z211 18BK GROUND

2 K4 18BK/LB SENSOR GROUND

3 G8 18LB/BK FUEL LEVEL SENSOR SIGNAL

4 A64 16DG/WT FUEL PUMP RELAY OUTPUT

FUEL PUMP MOTOR (DIESEL)-2WAY

CAV CIRCUIT FUNCTION

1 K31 18BR FUEL PUMP SIGNAL RETURN

2 K65 18OR/RD FUEL PUMP RELAY CONTROL

GENERATOR - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 K125 18WT/DB (JTEC/DIESEL) GENERATOR SOURCE

1 K20 18DG (NGC) GEN FIELD CONTROL

2 K20 18DG (JTEC/DIESEL) GENERATOR FIELD CONTROL

GLOVE BOX LAMP AND SWITCH - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 M11 20PK/LB COURTESY LAMP GROUND

2 F32 20RD/YL FUSED B(+)

HEADLAMP SWITCH - BLACK 8 WAY

CAV CIRCUIT FUNCTION

1- -

2- -

3 Y163 20OR/WT HEADLAMP SWITCH ILLUMINATION CONTROL

4 Z214 20LB/BK GROUND

5 L39 20LB FOG LAMP RELAY OUTPUT

6 Y111 20VT/WT PANEL LAMPS DIMMER SIGNAL

7 Y167 20WT/DB HEADLAMP SWITCH RETURN

8 Y126 20VT/YL HEADLAMP SWITCH SIGNAL

DR8W-80 CONNECTOR PIN-OUTS 8W - 80 - 63

Page 1240 of 2895

8W-97 POWER DISTRIBUTION

TABLE OF CONTENTS

page page

POWER DISTRIBUTION

DESCRIPTION..........................1

OPERATION............................1

SPECIAL TOOLS

POWER DISTRIBUTION SYSTEMS.........2

CIGAR LIGHTER OUTLET

DESCRIPTION..........................2

OPERATION............................2

DIAGNOSIS AND TESTING - CIGAR LIGHTER

OUTLET.............................2

INTEGRATED POWER MODULE

DESCRIPTION..........................3

OPERATION............................3

REMOVAL.............................3

INSTALLATION..........................4

FRONT CONTROL MODULE

DESCRIPTION..........................4

OPERATION............................5

DIAGNOSIS AND TESTING - FRONT

CONTROL MODULE....................5

REMOVAL.............................5

INSTALLATION..........................5

IOD FUSE

DESCRIPTION..........................6OPERATION............................6

REMOVAL.............................6

INSTALLATION..........................7

POWER OUTLET

DESCRIPTION..........................7

OPERATION............................7

DIAGNOSIS AND TESTING - POWER OUTLET . 7

REMOVAL.............................7

INSTALLATION..........................7

RELAY

DESCRIPTION..........................8

OPERATION............................8

DIAGNOSIS AND TESTING - RELAY.........8

REMOVAL.............................9

INSTALLATION..........................9

MICRO RELAY

DESCRIPTION..........................9

OPERATION............................9

DIAGNOSIS AND TESTING - MICRO-RELAY . . . 9

REMOVAL.............................10

INSTALLATION.........................10

POWER DISTRIBUTION

DESCRIPTION

This group covers the various standard and

optional power distribution components used on this

model. The power distribution system for this vehicle

consists of the following components:

²Integrated Power Module (IPM)

²Front Control Module (FCM)

²Power Distribution Center (PDC)

²Power Outlets

²Cigar Lighter Outlets

²Relays

Refer to Wiring Diagrams for complete circuit sche-

matics.

The power distribution system also incorporates

various types of circuit control and protection fea-

tures, including:

²Automatic resetting circuit breakers

²Blade-type fuses

²Cartridge fuses

²RelaysFollowing are general descriptions of the major

components in the power distribution system. See the

owner's manual in the vehicle glove box for more

information on the features and use of all of the

power distribution system components.

OPERATION

The power distribution system for this vehicle is

designed to provide safe, reliable, and centralized dis-

tribution points for the electrical current required to

operate all of the many standard and optional facto-

ry-installed electrical and electronic powertrain,

chassis, safety, security, comfort and convenience sys-

tems. At the same time, the power distribution sys-

tem was designed to provide ready access to these

electrical distribution points for the vehicle techni-

cian to use when conducting diagnosis and repair of

faulty circuits. The power distribution system can

also prove useful for the sourcing of additional elec-

trical circuits that may be required to provide the

electrical current needed to operate many accessories

that the vehicle owner may choose to have installed

in the aftermarket.

DR8W-97 POWER DISTRIBUTION 8W - 97 - 1

Page 1245 of 2895

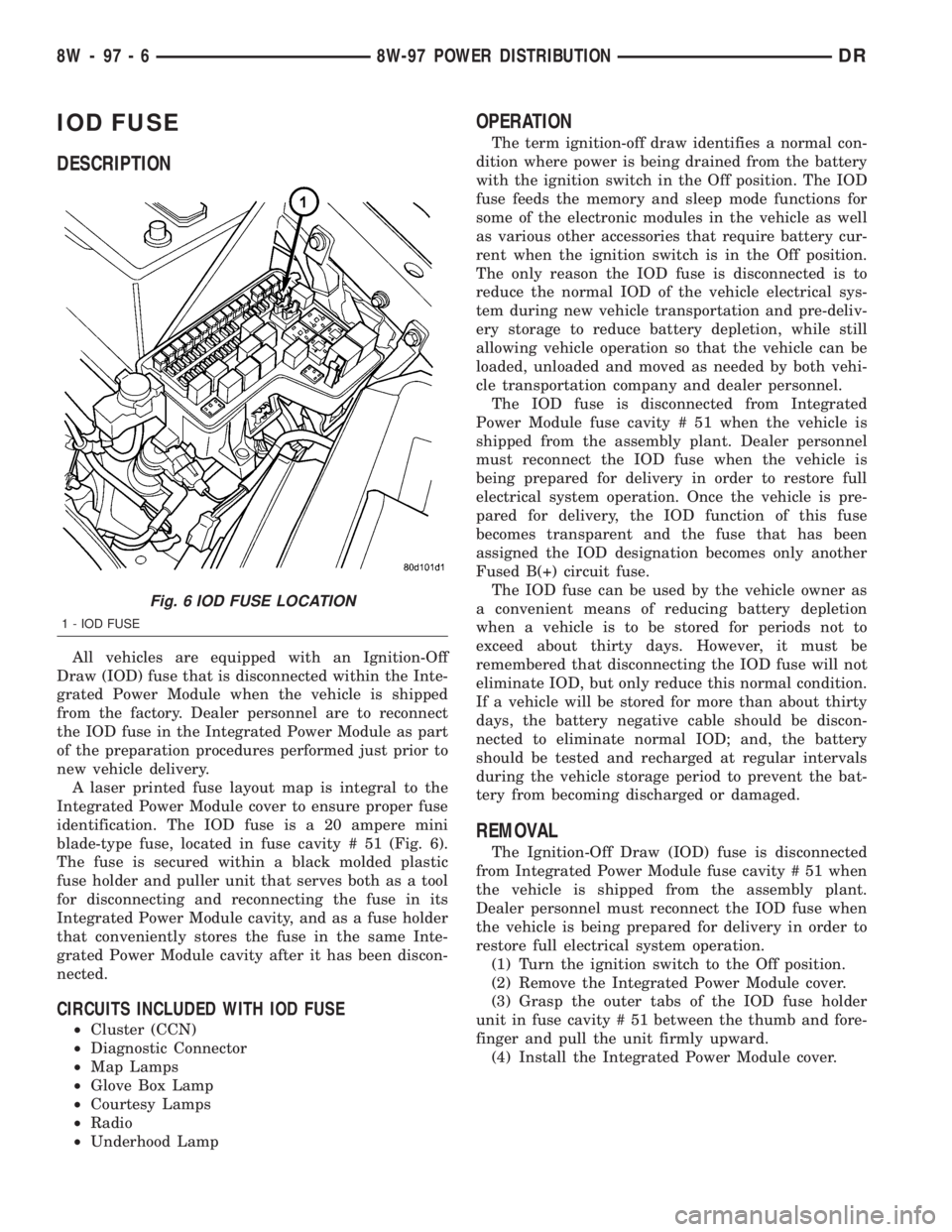

IOD FUSE

DESCRIPTION

All vehicles are equipped with an Ignition-Off

Draw (IOD) fuse that is disconnected within the Inte-

grated Power Module when the vehicle is shipped

from the factory. Dealer personnel are to reconnect

the IOD fuse in the Integrated Power Module as part

of the preparation procedures performed just prior to

new vehicle delivery.

A laser printed fuse layout map is integral to the

Integrated Power Module cover to ensure proper fuse

identification. The IOD fuse is a 20 ampere mini

blade-type fuse, located in fuse cavity # 51 (Fig. 6).

The fuse is secured within a black molded plastic

fuse holder and puller unit that serves both as a tool

for disconnecting and reconnecting the fuse in its

Integrated Power Module cavity, and as a fuse holder

that conveniently stores the fuse in the same Inte-

grated Power Module cavity after it has been discon-

nected.

CIRCUITS INCLUDED WITH IOD FUSE

²Cluster (CCN)

²Diagnostic Connector

²Map Lamps

²Glove Box Lamp

²Courtesy Lamps

²Radio

²Underhood Lamp

OPERATION

The term ignition-off draw identifies a normal con-

dition where power is being drained from the battery

with the ignition switch in the Off position. The IOD

fuse feeds the memory and sleep mode functions for

some of the electronic modules in the vehicle as well

as various other accessories that require battery cur-

rent when the ignition switch is in the Off position.

The only reason the IOD fuse is disconnected is to

reduce the normal IOD of the vehicle electrical sys-

tem during new vehicle transportation and pre-deliv-

ery storage to reduce battery depletion, while still

allowing vehicle operation so that the vehicle can be

loaded, unloaded and moved as needed by both vehi-

cle transportation company and dealer personnel.

The IOD fuse is disconnected from Integrated

Power Module fuse cavity # 51 when the vehicle is

shipped from the assembly plant. Dealer personnel

must reconnect the IOD fuse when the vehicle is

being prepared for delivery in order to restore full

electrical system operation. Once the vehicle is pre-

pared for delivery, the IOD function of this fuse

becomes transparent and the fuse that has been

assigned the IOD designation becomes only another

Fused B(+) circuit fuse.

The IOD fuse can be used by the vehicle owner as

a convenient means of reducing battery depletion

when a vehicle is to be stored for periods not to

exceed about thirty days. However, it must be

remembered that disconnecting the IOD fuse will not

eliminate IOD, but only reduce this normal condition.

If a vehicle will be stored for more than about thirty

days, the battery negative cable should be discon-

nected to eliminate normal IOD; and, the battery

should be tested and recharged at regular intervals

during the vehicle storage period to prevent the bat-

tery from becoming discharged or damaged.

REMOVAL

The Ignition-Off Draw (IOD) fuse is disconnected

from Integrated Power Module fuse cavity # 51 when

the vehicle is shipped from the assembly plant.

Dealer personnel must reconnect the IOD fuse when

the vehicle is being prepared for delivery in order to

restore full electrical system operation.

(1) Turn the ignition switch to the Off position.

(2) Remove the Integrated Power Module cover.

(3) Grasp the outer tabs of the IOD fuse holder

unit in fuse cavity # 51 between the thumb and fore-

finger and pull the unit firmly upward.

(4) Install the Integrated Power Module cover.

Fig. 6 IOD FUSE LOCATION

1 - IOD FUSE

8W - 97 - 6 8W-97 POWER DISTRIBUTIONDR

Page 2789 of 2895

for relay terminal 86 with the ignition switch in the

On position. If OK, go to Step 5. If not OK, repair the

open circuit to the fuse in the junction block as

required.

(5) The coil ground terminal cavity (85) is switched

to ground through the Powertrain Control Module

(PCM). There should be continuity between this cav-

ity and the A/C compressor clutch relay control cir-

cuit cavity of the PCM wire harness connector C

(gray) at all times. If not OK, repair the open circuit

as required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Power Distribution

Center (PDC).

(3) Refer to the label on the PDC for compressor

clutch relay identification and location.

(4) Unplug the compressor clutch relay from the

PDC.

INSTALLATION

(1) Install the compressor clutch relay by aligning

the relay terminals with the cavities in the PDC and

pushing the relay firmly into place.

(2) Install the PDC cover.

(3) Connect the battery negative cable.

(4) Test the relay operation.

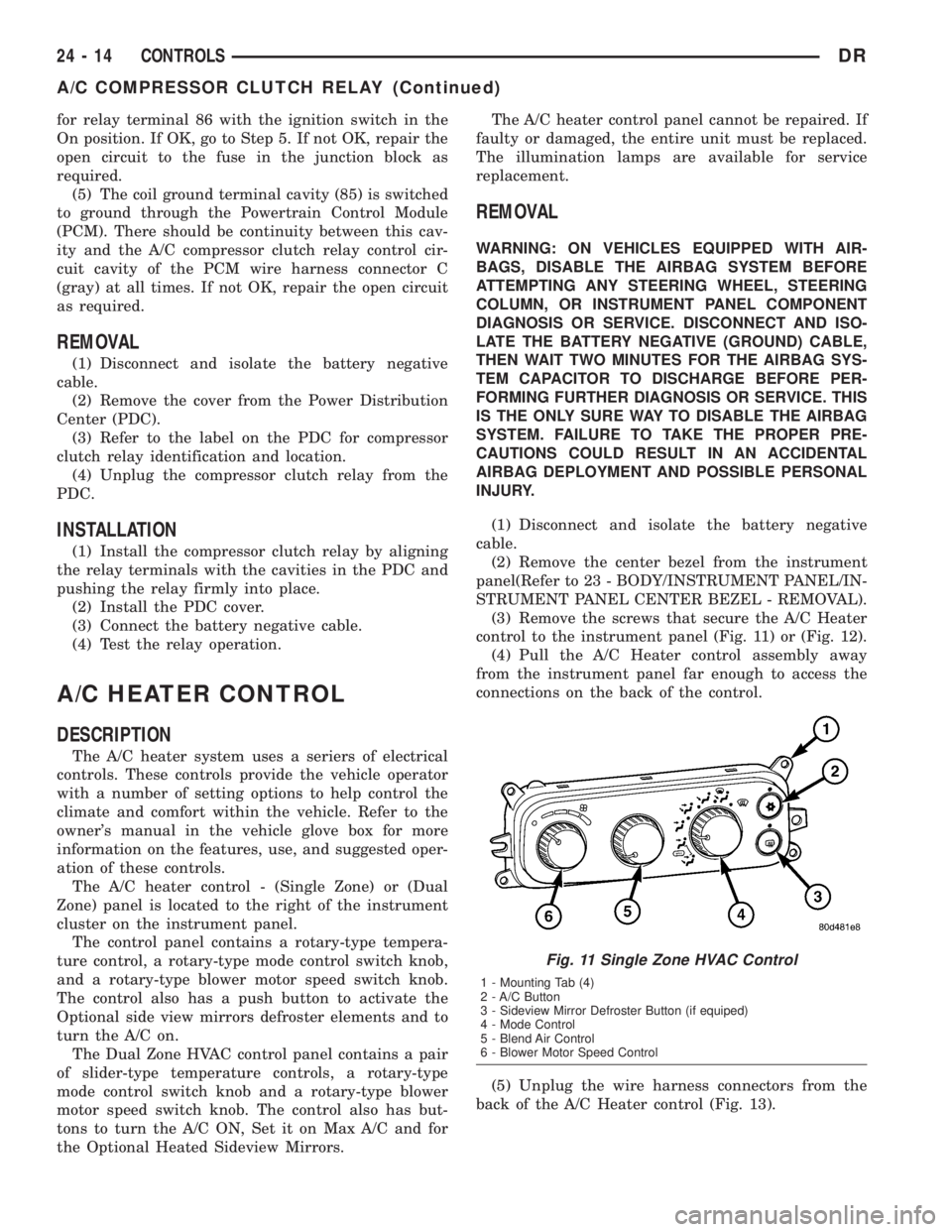

A/C HEATER CONTROL

DESCRIPTION

The A/C heater system uses a seriers of electrical

controls. These controls provide the vehicle operator

with a number of setting options to help control the

climate and comfort within the vehicle. Refer to the

owner's manual in the vehicle glove box for more

information on the features, use, and suggested oper-

ation of these controls.

The A/C heater control - (Single Zone) or (Dual

Zone) panel is located to the right of the instrument

cluster on the instrument panel.

The control panel contains a rotary-type tempera-

ture control, a rotary-type mode control switch knob,

and a rotary-type blower motor speed switch knob.

The control also has a push button to activate the

Optional side view mirrors defroster elements and to

turn the A/C on.

The Dual Zone HVAC control panel contains a pair

of slider-type temperature controls, a rotary-type

mode control switch knob and a rotary-type blower

motor speed switch knob. The control also has but-

tons to turn the A/C ON, Set it on Max A/C and for

the Optional Heated Sideview Mirrors.The A/C heater control panel cannot be repaired. If

faulty or damaged, the entire unit must be replaced.

The illumination lamps are available for service

replacement.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the center bezel from the instrument

panel(Refer to 23 - BODY/INSTRUMENT PANEL/IN-

STRUMENT PANEL CENTER BEZEL - REMOVAL).

(3) Remove the screws that secure the A/C Heater

control to the instrument panel (Fig. 11) or (Fig. 12).

(4) Pull the A/C Heater control assembly away

from the instrument panel far enough to access the

connections on the back of the control.

(5) Unplug the wire harness connectors from the

back of the A/C Heater control (Fig. 13).

Fig. 11 Single Zone HVAC Control

1 - Mounting Tab (4)

2 - A/C Button

3 - Sideview Mirror Defroster Button (if equiped)

4 - Mode Control

5 - Blend Air Control

6 - Blower Motor Speed Control

24 - 14 CONTROLSDR

A/C COMPRESSOR CLUTCH RELAY (Continued)

Page 2800 of 2895

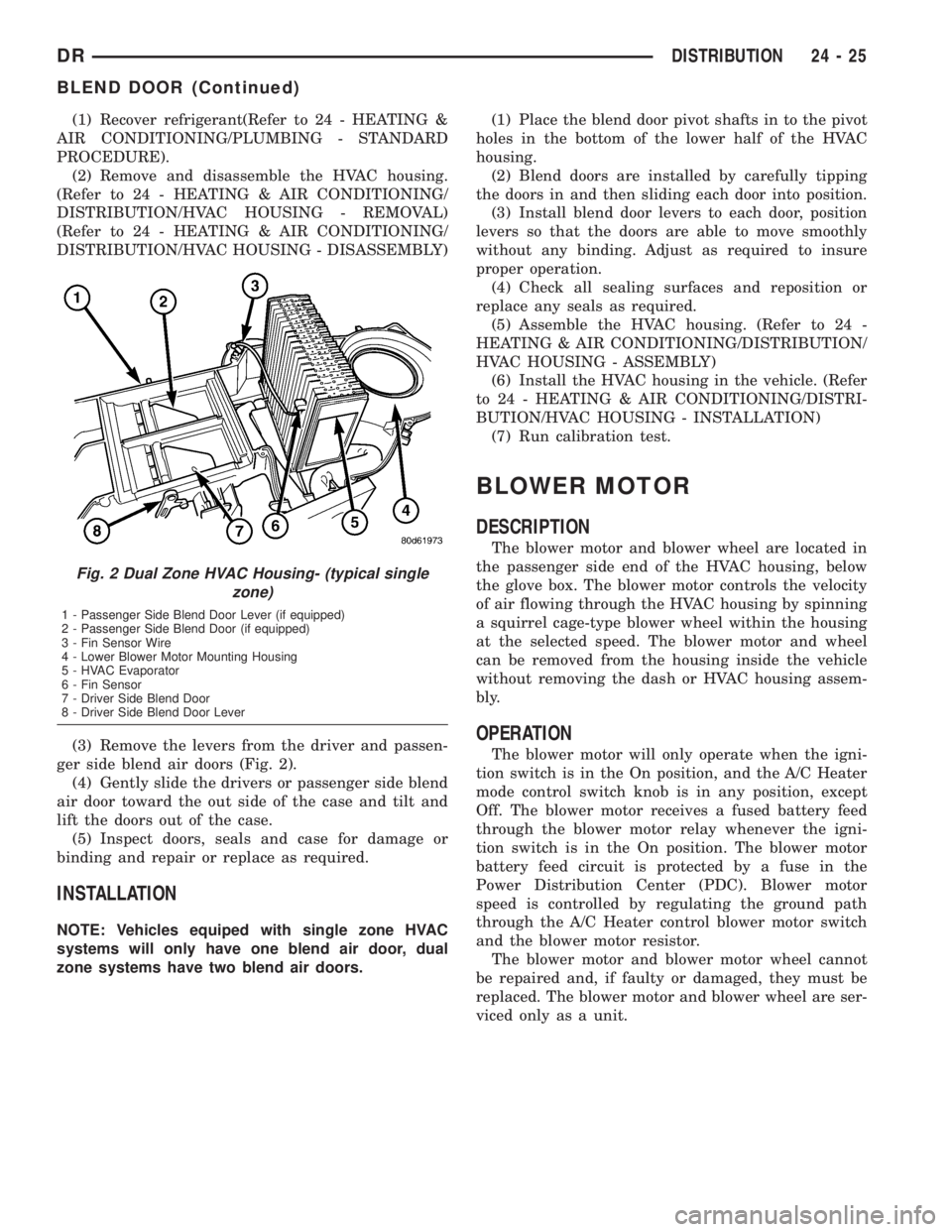

(1) Recover refrigerant(Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - STANDARD

PROCEDURE).

(2) Remove and disassemble the HVAC housing.

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL)

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - DISASSEMBLY)

(3) Remove the levers from the driver and passen-

ger side blend air doors (Fig. 2).

(4) Gently slide the drivers or passenger side blend

air door toward the out side of the case and tilt and

lift the doors out of the case.

(5) Inspect doors, seals and case for damage or

binding and repair or replace as required.

INSTALLATION

NOTE: Vehicles equiped with single zone HVAC

systems will only have one blend air door, dual

zone systems have two blend air doors.(1) Place the blend door pivot shafts in to the pivot

holes in the bottom of the lower half of the HVAC

housing.

(2) Blend doors are installed by carefully tipping

the doors in and then sliding each door into position.

(3) Install blend door levers to each door, position

levers so that the doors are able to move smoothly

without any binding. Adjust as required to insure

proper operation.

(4) Check all sealing surfaces and reposition or

replace any seals as required.

(5) Assemble the HVAC housing. (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - ASSEMBLY)

(6) Install the HVAC housing in the vehicle. (Refer

to 24 - HEATING & AIR CONDITIONING/DISTRI-

BUTION/HVAC HOUSING - INSTALLATION)

(7) Run calibration test.

BLOWER MOTOR

DESCRIPTION

The blower motor and blower wheel are located in

the passenger side end of the HVAC housing, below

the glove box. The blower motor controls the velocity

of air flowing through the HVAC housing by spinning

a squirrel cage-type blower wheel within the housing

at the selected speed. The blower motor and wheel

can be removed from the housing inside the vehicle

without removing the dash or HVAC housing assem-

bly.

OPERATION

The blower motor will only operate when the igni-

tion switch is in the On position, and the A/C Heater

mode control switch knob is in any position, except

Off. The blower motor receives a fused battery feed

through the blower motor relay whenever the igni-

tion switch is in the On position. The blower motor

battery feed circuit is protected by a fuse in the

Power Distribution Center (PDC). Blower motor

speed is controlled by regulating the ground path

through the A/C Heater control blower motor switch

and the blower motor resistor.

The blower motor and blower motor wheel cannot

be repaired and, if faulty or damaged, they must be

replaced. The blower motor and blower wheel are ser-

viced only as a unit.

Fig. 2 Dual Zone HVAC Housing- (typical single

zone)

1 - Passenger Side Blend Door Lever (if equipped)

2 - Passenger Side Blend Door (if equipped)

3 - Fin Sensor Wire

4 - Lower Blower Motor Mounting Housing

5 - HVAC Evaporator

6 - Fin Sensor

7 - Driver Side Blend Door

8 - Driver Side Blend Door Lever

DRDISTRIBUTION 24 - 25

BLEND DOOR (Continued)

Page 2870 of 2895

FUEL INJECTOR RAIL - DESCRIPTION....14-89

FUEL INJECTOR RAIL - INSTALLATION....14-90

FUEL INJECTOR RAIL - OPERATION......14-89

FUEL INJECTOR RAIL - REMOVAL.......14-89

FUEL LEVEL SENDING UNIT / SENSOR -

DESCRIPTION...................14-68,14-7

FUEL LEVEL SENDING UNIT / SENSOR -

INSTALLATION........................14-8

FUEL LEVEL SENDING UNIT / SENSOR -

OPERATION.....................14-68,14-7

FUEL LEVEL SENDING UNIT / SENSOR -

REMOVAL...........................14-7

FUEL LINE LEAKS - DIAGNOSIS AND

TESTING, HIGH-PRESSURE.............14-69

FUEL LINES - DESCRIPTION........14-69,14-8

FUEL LINES - INSTALLATION...........14-71

FUEL LINES - OPERATION..............14-69

FUEL LINES - REMOVAL...............14-69

FUEL PRESSURE LIMITING VALVE -

DESCRIPTION.......................14-72

FUEL PRESSURE LIMITING VALVE -

INSTALLATION.......................14-73

FUEL PRESSURE LIMITING VALVE -

OPERATION.........................14-72

FUEL PRESSURE LIMITING VALVE -

REMOVAL..........................14-72

FUEL PRESSURE SENSOR -

DESCRIPTION.......................14-72

FUEL PRESSURE SENSOR -

INSTALLATION.......................14-72

FUEL PRESSURE SENSOR - OPERATION....14-72

FUEL PRESSURE SENSOR - REMOVAL....14-72

FUEL PUMP - DESCRIPTION............14-12

FUEL PUMP - OPERATION.............14-12

FUEL PUMP MODULE - DESCRIPTION....14-12

FUEL PUMP MODULE - INSTALLATION . . . 14-13

FUEL PUMP MODULE - OPERATION......14-12

FUEL PUMP MODULE - REMOVAL.......14-12

FUEL PUMP RELAY - DESCRIPTION......14-33

FUEL PUMP RELAY - INSTALLATION.....14-33

FUEL PUMP RELAY - OPERATION........14-33

FUEL PUMP RELAY - REMOVAL.........14-33

FUEL PUMP RELAYS - DIAGNOSIS AND

TESTING, ASD........................8I-7

FUEL RAIL - DESCRIPTION.............14-13

FUEL RAIL - INSTALLATION............14-18

FUEL RAIL - OPERATION...............14-13

FUEL RAIL - REMOVAL................14-13

FUEL REQUIREMENTS - DIESEL ENGINE

- DESCRIPTION........................0-1

FUEL SENSOR - DESCRIPTION, WATER

IN ................................14-77

FUEL SENSOR - OPERATION, WATER IN . . 14-78

FUEL SENSOR - REMOVAL, WATER IN....14-78

FUEL SYSTEM - DESCRIPTION, DIESEL . . . 14-57

FUEL SYSTEM - TORQUE...............14-3

FUEL SYSTEM PARTS - STANDARD

PROCEDURES, CLEANING..............14-58

FUEL SYSTEM PRESSURE, DIESEL.......14-60

FUEL SYSTEM PRESSURE RELEASE -

STANDARD PROCEDURE................14-2

FUEL SYSTEM PRESSURE,

SPECIFICATIONS......................14-3

FUEL SYSTEM PRIMING - STANDARD

PROCEDURE........................14-59

FUEL SYSTEM, SPECIAL TOOLS..........14-5

FUEL SYSTEM, SPECIAL TOOLS -

DIESEL............................14-60

FUEL TANK - DESCRIPTION............14-20

FUEL TANK - OPERATION..............14-20

FUEL TANK MODULE - DESCRIPTION.....14-75

FUEL TANK MODULE - INSTALLATION....14-75

FUEL TANK MODULE - OPERATION......14-75

FUEL TANK MODULE - REMOVAL........14-75

FUEL TRANSFER PUMP - DESCRIPTION . . 14-75

FUEL TRANSFER PUMP - INSTALLATION . . 14-76

FUEL TRANSFER PUMP - OPERATION....14-76

FUEL TRANSFER PUMP - REMOVAL......14-76

FULL SIZE, SPARE WHEEL WITH

MATCHING TIRE - DESCRIPTION........22-15

FUNCTIONS - DESCRIPTION, CIRCUIT . . 8W-01-6

FUSE - DESCRIPTION, IOD

...........8W-97-6

FUSE - INSTALLATION, IOD

..........8W-97-7

FUSE - OPERATION, IOD

.............8W-97-6

FUSE - REMOVAL, IOD

..............8W-97-6

FUSES POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A SHORT TO GROUND ON

......8W-01-10GAP AND FLUSH - SPECIFICATIONS......23-95

GAS - DESCRIPTION, FUEL DELIVERY.....14-1

GAS - INSTALLATION............19-30,19-41

GAS - OPERATION, FUEL DELIVERY.......14-2

GAS - REMOVAL................19-29,19-40

GAS ENGINE - DIAGNOSIS AND TESTING . . 11-2

GAS ENGINE - INSTALLATION...........19-24

GAS ENGINE - REMOVAL..............19-23

GASKET - DESCRIPTION, CYLINDER

HEAD COVER........................9-243

GASKET - DIAGNOSIS AND TESTING,

CYLINDER HEAD......................9-20

GASKET - OPERATION, CYLINDER HEAD

COVER.............................9-243

GASKET FAILURE - DIAGNOSIS AND

TESTING, CYLINDER HEAD . . . 9-194,9-243,9-370

GASKET SELECTION - STANDARD

PROCEDURE, HEAD...................9-330

GASKET SURFACE PREPARATION -

STANDARD PROCEDURE, ENGINE........9-10

GASKETS AND SEALERS - STANDARD

PROCEDURE, FORM-IN-PLACE....9-232,9-289,

9-360,9-9,9-93

GAUGE - DESCRIPTION, ENGINE

TEMPERATURE......................8J-23

GAUGE - DESCRIPTION, FUEL...........8J-25

GAUGE - DESCRIPTION, OIL PRESSURE . . 8J-32

GAUGE - DESCRIPTION, VOLTAGE.......8J-40

GAUGE - OPERATION, ENGINE

TEMPERATURE......................8J-23

GAUGE - OPERATION, FUEL............8J-26

GAUGE - OPERATION, OIL PRESSURE....8J-32

GAUGE - OPERATION, VOLTAGE.........8J-41

GAUGES - DIAGNOSIS AND TESTING,

PRESSURE..........................22-7

GAUGES INDICATOR - DESCRIPTION,

CHECK.............................8J-21

GAUGES INDICATOR - OPERATION,

CHECK.............................8J-21

GEAR - DESCRIPTION, CRANKSHAFT.....9-322

GEAR - INDEPENDENT FRONT

SUSPENSION - DESCRIPTION...........19-16

GEAR - INDEPENDENT FRONT

SUSPENSION - INSTALLATION..........19-17

GEAR - INDEPENDENT FRONT

SUSPENSION - REMOVAL..............19-16

GEAR - INSTALLATION................9-322

GEAR - INSTALLATION, PINION

GEAR/RING......................3-42,3-66

GEAR - LINK/COIL - DESCRIPTION.......19-19

GEAR - LINK/COIL - INSTALLATION......19-20

GEAR - LINK/COIL - OPERATION........19-19

GEAR - LINK/COIL - REMOVAL..........19-19

GEAR - REMOVAL....................9-322

GEAR - REMOVAL, PINION GEAR/RING....3-40,

3-65

GEAR HOUSING - INSTALLATION........9-349

GEAR HOUSING - REMOVAL............9-348

GEAR HOUSING COVER - INSTALLATION . . 9-350

GEAR HOUSING COVER - REMOVAL.....9-349

GEAR INPUT SHAFT SEAL -

INSTALLATION, STEERING.............19-28

GEAR INPUT SHAFT SEAL - REMOVAL,

STEERING..........................19-25

GEAR SELECTOR INDICATOR -

DESCRIPTION.......................8J-26

GEAR SELECTOR INDICATOR -

OPERATION.........................8J-27

GEAR SHIFT LEVER - INSTALLATION.....19-12

GEAR SHIFT LEVER - REMOVAL.........19-12

GEAR, SPECIAL TOOLS - POWER

STEERING..........................19-22

GEAR, SPECIFICATIONS - POWER

STEERING..........................19-21

GEAR TO COOLER - INSTALLATION,

RETURN HOSE.................19-43,19-44

GEAR TO COOLER - REMOVAL, RETURN

HOSE..............................19-43

GEAR/RING GEAR - INSTALLATION,

PINION

.........................3-42,3-66

GEAR/RING GEAR - REMOVAL, PINION

....3-40,

3-65

GEAR/RING GEAR/TONE RING -

INSTALLATION, PINION

.......3-123,3-150,3-96

GEAR/RING GEAR/TONE RING -

REMOVAL, PINION

..........3-122,3-149,3-94

GEARSHIFT CABLE - DIAGNOSIS AND

TESTING

..............21-209,21-389,21-544GEARSHIFT CABLE - INSTALLATION....21-210,

21-390,21-545

GEARSHIFT CABLE - REMOVAL . . 21-209,21-389,

21-544

GEARSHIFT CABLE, ADJUSTMENTS.....21-211,

21-391,21-546

GEAR/TONE RING - INSTALLATION,

PINION GEAR/RING..........3-123,3-150,3-96

GEAR/TONE RING - REMOVAL, PINION

GEAR/RING................3-122,3-149,3-94

GEARTRAIN - ASSEMBLY, PLANETARY . . . 21-573

GEARTRAIN - CLEANING, PLANETARY . . . 21-573

GEARTRAIN - DESCRIPTION,

PLANETARY........................21-571

GEARTRAIN - DISASSEMBLY,

PLANETARY........................21-573

GEARTRAIN - INSPECTION, PLANETARY . 21-573

GEARTRAIN - OPERATION, PLANETARY . . 21-571

GEARTRAIN/OUTPUT SHAFT -

ASSEMBLY, PLANETARY........21-245,21-423

GEARTRAIN/OUTPUT SHAFT -

DESCRIPTION, PLANETARY......21-242,21-420

GEARTRAIN/OUTPUT SHAFT -

DISASSEMBLY, PLANETARY.....21-243,21-421

GEARTRAIN/OUTPUT SHAFT -

INSPECTION, PLANETARY.......21-245,21-422

GEARTRAIN/OUTPUT SHAFT -

OPERATION, PLANETARY.......21-243,21-420

GENERAL - WARNINGS.............8W-01-7

GENERATOR / CHARGING SYSTEM -

SPECIFICATIONS, TORQUE.............8F-20

GENERATOR - DESCRIPTION.............8F-22

GENERATOR - INSTALLATION...........8F-25

GENERATOR - OPERATION.............8F-22

GENERATOR - REMOVAL...............8F-22

GENERATOR RATINGS, SPECIFICATIONS . . 8F-20

GENII - ASSEMBLY, TRANSFER CASE -

NV241............................21-604

GENII - CLEANING, TRANSFER CASE -

NV241............................21-602

GENII - DESCRIPTION, TRANSFER CASE

- NV241..............................0-4

GENII - DESCRIPTION, TRANSFER CASE

- NV241...........................21-591

GENII - DIAGNOSIS AND TESTING,

TRANSFER CASE - NV241.............21-592

GENII - DISASSEMBLY, TRANSFER CASE

- NV241...........................21-593

GENII - INSPECTION, TRANSFER CASE -

NV241............................21-602

GENII - INSTALLATION, TRANSFER CASE

- NV241...........................21-614

GENII - OPERATION, TRANSFER CASE -

NV241............................21-591

GENII - REMOVAL, TRANSFER CASE -

NV241............................21-593

GENII - TRANSFER CASE, NV241.......21-614

GLASS - INSTALLATION, BACKLITE VENT . 23-87

GLASS - INSTALLATION, DOOR....23-20,23-30

GLASS - INSTALLATION, SIDE VIEW

MIRROR...........................23-44

GLASS - REMOVAL, BACKLITE VENT.....23-87

GLASS - REMOVAL, DOOR........23-20,23-30

GLASS - REMOVAL, SIDE VIEW MIRROR . . 23-42

GLASS RUN CHANNEL - INSTALLATION . . 23-21,

23-31

GLASS RUN CHANNEL - REMOVAL . 23-21,23-30

GLASS RUN WEATHERSTRIP -

INSTALLATION, FRONT DOOR...........23-92

GLASS RUN WEATHERSTRIP -

INSTALLATION, REAR DOOR............23-93

GLASS RUN WEATHERSTRIP -

REMOVAL, FRONT DOOR..............23-92

GLASS RUN WEATHERSTRIP -

REMOVAL, REAR DOOR...............23-93

GLOVE BOX - INSTALLATION...........23-53

GLOVE BOX - REMOVAL...............23-53

GLOVE BOX LAMP/SWITCH -

INSTALLATION.......................8L-25

GLOVE BOX LAMP/SWITCH - REMOVAL . . . 8L-25

GLOVE BOX LATCH - INSTALLATION

.....23-53

GLOVE BOX LATCH - REMOVAL

.........23-53

GOVERNOR - DESCRIPTION,

ELECTRONIC

.................21-196,21-376

GOVERNOR - INSTALLATION,

ELECTRONIC

.................21-199,21-379

GOVERNOR - OPERATION, ELECTRONIC

. 21-196,

21-377

DRINDEX 15

Description Group-Page Description Group-Page Description Group-Page