seat adjustment DODGE RAM 2003 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2145 of 2895

VALVE BODY FINAL

(1) Install boost valve, valve spring, retainer and

cover plate. Tighten cover plate screws to 4 N´m (35

in. lbs.) torque.

(2) Insert manual lever detent spring in upper

housing.

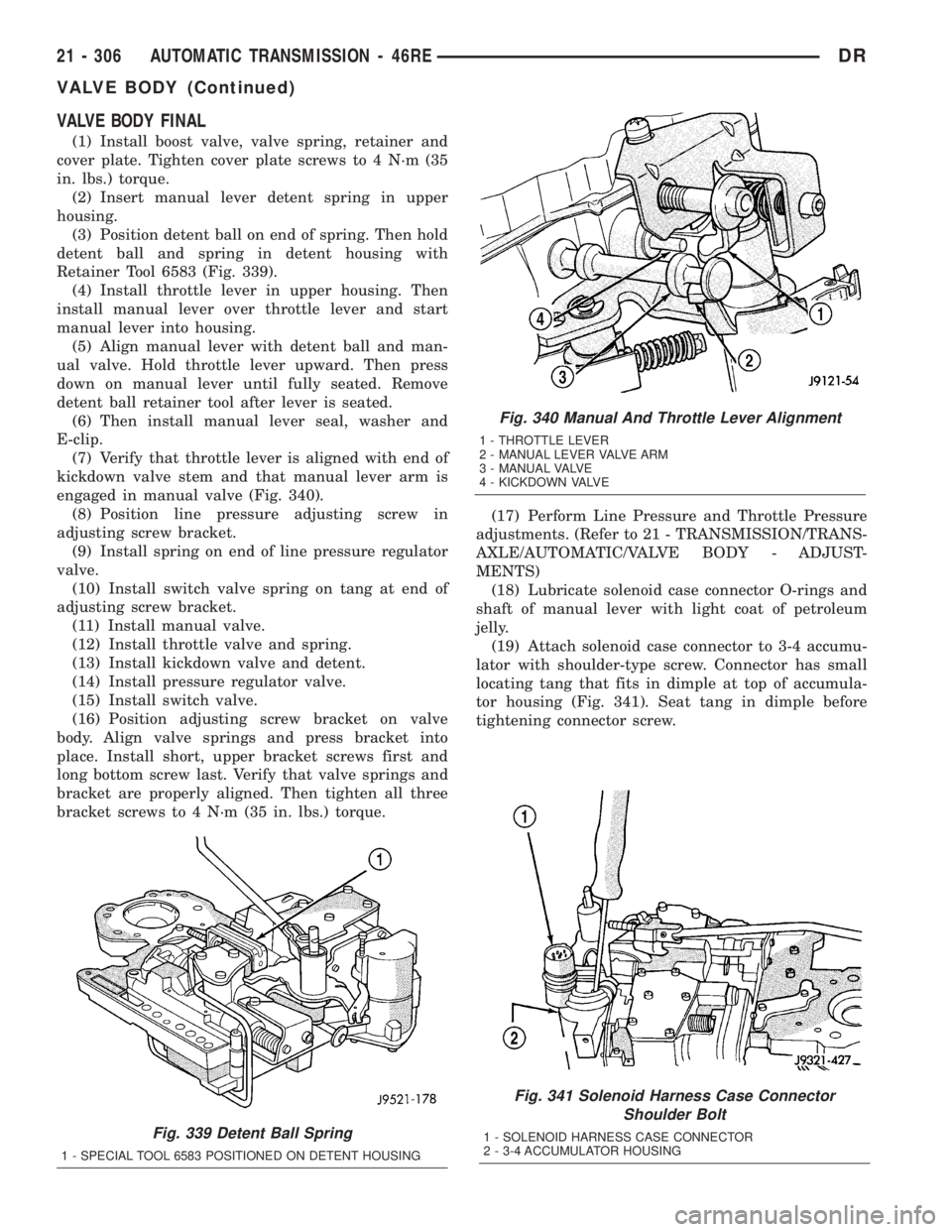

(3) Position detent ball on end of spring. Then hold

detent ball and spring in detent housing with

Retainer Tool 6583 (Fig. 339).

(4) Install throttle lever in upper housing. Then

install manual lever over throttle lever and start

manual lever into housing.

(5) Align manual lever with detent ball and man-

ual valve. Hold throttle lever upward. Then press

down on manual lever until fully seated. Remove

detent ball retainer tool after lever is seated.

(6) Then install manual lever seal, washer and

E-clip.

(7) Verify that throttle lever is aligned with end of

kickdown valve stem and that manual lever arm is

engaged in manual valve (Fig. 340).

(8) Position line pressure adjusting screw in

adjusting screw bracket.

(9) Install spring on end of line pressure regulator

valve.

(10) Install switch valve spring on tang at end of

adjusting screw bracket.

(11) Install manual valve.

(12) Install throttle valve and spring.

(13) Install kickdown valve and detent.

(14) Install pressure regulator valve.

(15) Install switch valve.

(16) Position adjusting screw bracket on valve

body. Align valve springs and press bracket into

place. Install short, upper bracket screws first and

long bottom screw last. Verify that valve springs and

bracket are properly aligned. Then tighten all three

bracket screws to 4 N´m (35 in. lbs.) torque.(17) Perform Line Pressure and Throttle Pressure

adjustments. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC/VALVE BODY - ADJUST-

MENTS)

(18) Lubricate solenoid case connector O-rings and

shaft of manual lever with light coat of petroleum

jelly.

(19) Attach solenoid case connector to 3-4 accumu-

lator with shoulder-type screw. Connector has small

locating tang that fits in dimple at top of accumula-

tor housing (Fig. 341). Seat tang in dimple before

tightening connector screw.

Fig. 339 Detent Ball Spring

1 - SPECIAL TOOL 6583 POSITIONED ON DETENT HOUSING

Fig. 340 Manual And Throttle Lever Alignment

1 - THROTTLE LEVER

2 - MANUAL LEVER VALVE ARM

3 - MANUAL VALVE

4 - KICKDOWN VALVE

Fig. 341 Solenoid Harness Case Connector

Shoulder Bolt

1 - SOLENOID HARNESS CASE CONNECTOR

2 - 3-4 ACCUMULATOR HOUSING

21 - 306 AUTOMATIC TRANSMISSION - 46REDR

VALVE BODY (Continued)

Page 2192 of 2895

(10) Install torque converter. Use C-clamp or metal

strap to hold converter in place for installation.

BAND ADJUSTMENT AND FINAL

(1) Adjust front and rear bands as follows:

(a) Loosen locknut on each band adjusting screw

4-5 turns.

(b) Tighten both adjusting screws to 8 N´m (72

in. lbs.).

(c) Back off front band adjusting screw 1-3/4

turns.

(d) Back off rear band adjusting screw 3 turns.

(e) Hold each adjusting screw in position and

tighten locknut to 34 N´m (25 ft. lbs.) torque.

(2) Install magnet in oil pan. Magnet seats on

small protrusion at corner of pan.

(3) Position new oil pan gasket on case and install

oil pan. Tighten pan bolts to 13.6 N´m (125 in. lbs.).

(4) Install throttle valve and shift selector levers

on valve body manual lever shaft.

(5) Apply small quantity of dielectric grease to ter-

minal pins of solenoid case connector and neutral

switch.

(6) Fill transmission with recommended fluid.

INSTALLATION

(1) Check torque converter hub inner and outer

diameters and hub drive notches for sharp edges

burrs, scratches, or nicks. Polish the hub and notches

with 320/400 grit paper and crocus cloth if necessary.

The hub must be smooth to avoid damaging pump

seal at installation.

(2) Lubricate pocket in the rear oil pump seal lip

with transmission fluid.

(3) Lubricate converter pilot hub of the crankshaft

with a light coating of MopartHigh Temp Grease.

(4) Align and install converter in oil pump.

(5) Carefully insert converter in oil pump. Then

rotate converter back and forth until fully seated in

pump gears.

(6) Check converter seating with steel scale and

straightedge (Fig. 65). Surface of converter lugs

should be 19mm (0.75 in.) to rear of straightedge

when converter is fully seated.

(7) Temporarily secure converter with C-clamp.

(8) Position transmission on jack and secure it

with chains.

(9) Check condition of converter driveplate.

Replace the plate if cracked, distorted or damaged.

Also be sure transmission dowel pins are seated

in engine block and protrude far enough to

hold transmission in alignment.

(10) Raise transmission and align converter with

drive plate and converter housing with engine block.

(11) Move transmission forward. Then raise, lower

or tilt transmission to align converter housing with

engine block dowels.

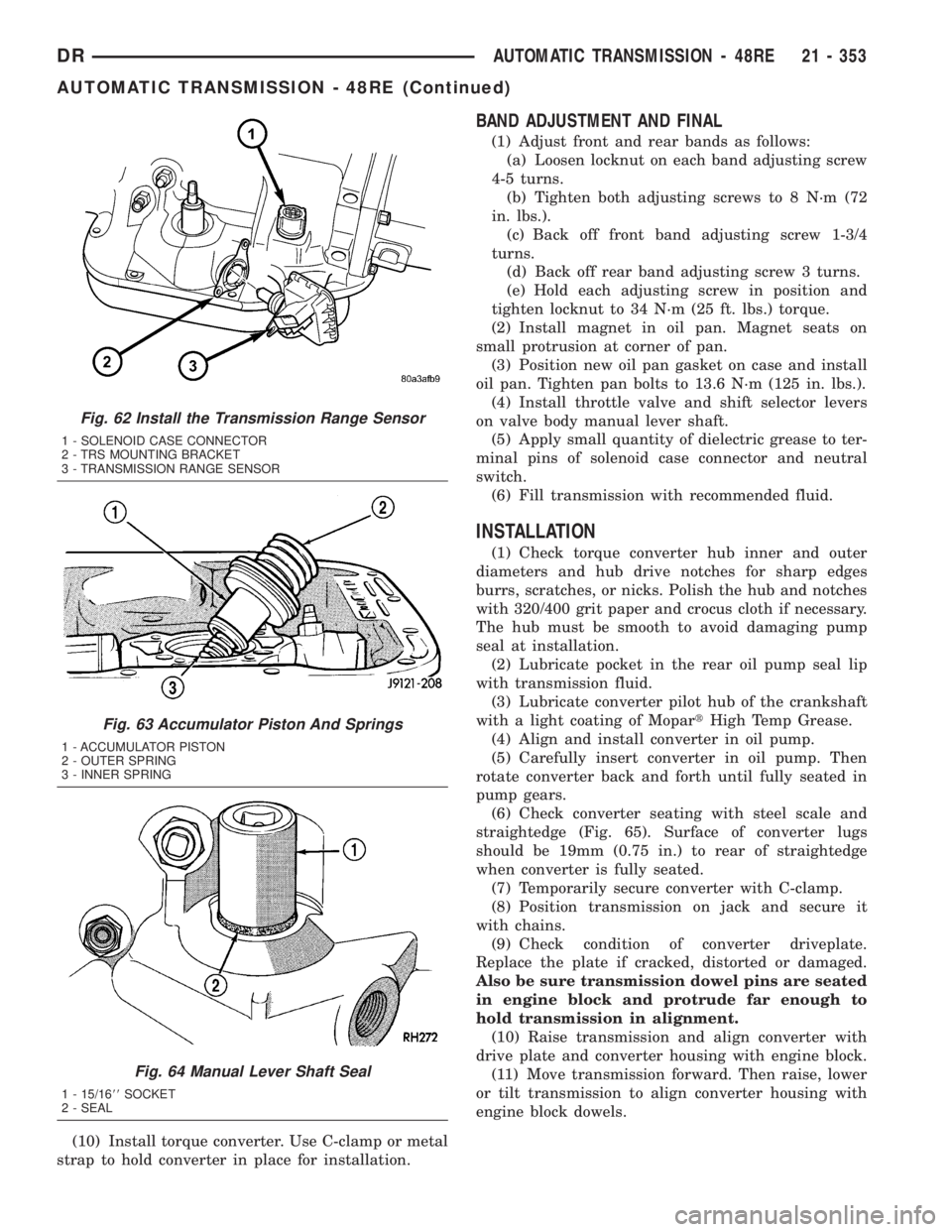

Fig. 62 Install the Transmission Range Sensor

1 - SOLENOID CASE CONNECTOR

2 - TRS MOUNTING BRACKET

3 - TRANSMISSION RANGE SENSOR

Fig. 63 Accumulator Piston And Springs

1 - ACCUMULATOR PISTON

2 - OUTER SPRING

3 - INNER SPRING

Fig. 64 Manual Lever Shaft Seal

1 - 15/1688SOCKET

2 - SEAL

DRAUTOMATIC TRANSMISSION - 48RE 21 - 353

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 2324 of 2895

VALVE BODY FINAL

(1) Install boost valve, valve spring, retainer and

cover plate. Tighten cover plate screws to 4 N´m (35

in. lbs.) torque.

(2) Insert manual lever detent spring in upper

housing.

(3) Position detent ball on end of spring. Then hold

detent ball and spring in detent housing with

Retainer Tool 6583 (Fig. 325).

(4) Install throttle lever in upper housing. Then

install manual lever over throttle lever and start

manual lever into housing.

(5) Align manual lever with detent ball and man-

ual valve. Hold throttle lever upward. Then press

down on manual lever until fully seated. Remove

detent ball retainer tool after lever is seated.

(6) Then install manual lever seal, washer and

E-clip.

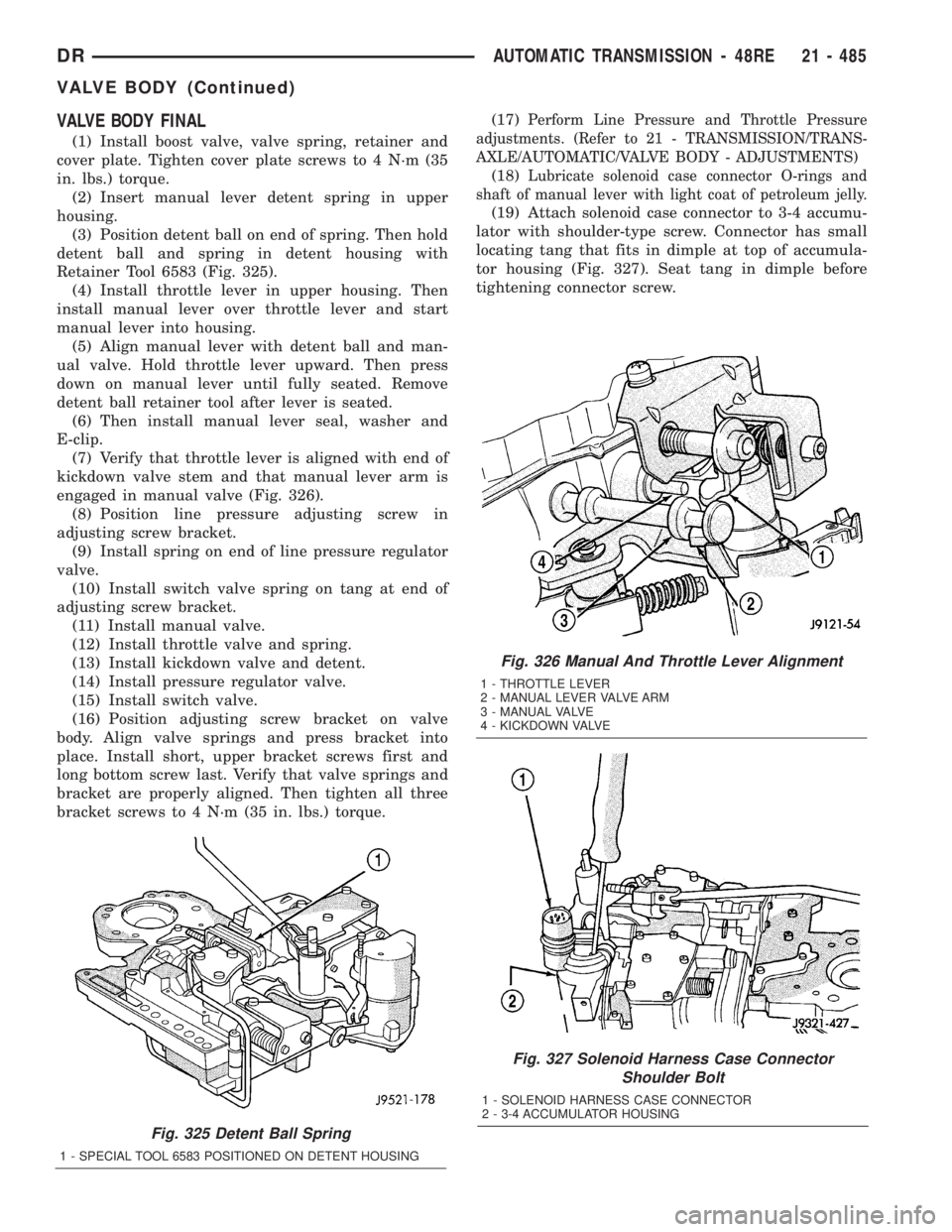

(7) Verify that throttle lever is aligned with end of

kickdown valve stem and that manual lever arm is

engaged in manual valve (Fig. 326).

(8) Position line pressure adjusting screw in

adjusting screw bracket.

(9) Install spring on end of line pressure regulator

valve.

(10) Install switch valve spring on tang at end of

adjusting screw bracket.

(11) Install manual valve.

(12) Install throttle valve and spring.

(13) Install kickdown valve and detent.

(14) Install pressure regulator valve.

(15) Install switch valve.

(16) Position adjusting screw bracket on valve

body. Align valve springs and press bracket into

place. Install short, upper bracket screws first and

long bottom screw last. Verify that valve springs and

bracket are properly aligned. Then tighten all three

bracket screws to 4 N´m (35 in. lbs.) torque.(17)

Perform Line Pressure and Throttle Pressure

adjustments. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC/VALVE BODY - ADJUSTMENTS)

(18)Lubricate solenoid case connector O-rings and

shaft of manual lever with light coat of petroleum jelly.

(19) Attach solenoid case connector to 3-4 accumu-

lator with shoulder-type screw. Connector has small

locating tang that fits in dimple at top of accumula-

tor housing (Fig. 327). Seat tang in dimple before

tightening connector screw.

Fig. 325 Detent Ball Spring

1 - SPECIAL TOOL 6583 POSITIONED ON DETENT HOUSING

Fig. 326 Manual And Throttle Lever Alignment

1 - THROTTLE LEVER

2 - MANUAL LEVER VALVE ARM

3 - MANUAL VALVE

4 - KICKDOWN VALVE

Fig. 327 Solenoid Harness Case Connector

Shoulder Bolt

1 - SOLENOID HARNESS CASE CONNECTOR

2 - 3-4 ACCUMULATOR HOUSING

DRAUTOMATIC TRANSMISSION - 48RE 21 - 485

VALVE BODY (Continued)

Page 2576 of 2895

BODY

TABLE OF CONTENTS

page page

BODY

WARNING

SAFETY PRECAUTIONS AND WARNINGS . . . 1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - WATER LEAKS . 1

DIAGNOSIS AND TESTING - WIND NOISE . . . 2

STANDARD PROCEDURE

STANDARD PROCEDURE - BODY

LUBRICATION.........................3

STANDARD PROCEDURE - HEAT STAKING . . 3

STANDARD PROCEDURE - PLASTIC BODY

PANEL REPAIR........................3

STANDARD PROCEDURE - BUZZ, SQUEAK

& RATTLE...........................11

SPECIFICATIONS - TORQUE..............12SPECIAL TOOLS

BODY..............................14

TAILGATE..............................15

DOOR - FRONT.........................18

DOORS - REAR.........................28

EXTERIOR.............................36

HOOD.................................46

INSTRUMENT PANEL.....................50

INTERIOR..............................63

PAINT.................................74

SEATS................................76

STATIONARY GLASS.....................86

WEATHERSTRIP/SEALS...................91

BODY STRUCTURE......................95

BODY

WARNING

SAFETY PRECAUTIONS AND WARNINGS

WARNING: USE AN OSHA APPROVED BREATHING

FILTER WHEN SPRAYING PAINT OR SOLVENTS IN

A CONFINED AREA. PERSONAL INJURY CAN

RESULT.

²AVOID PROLONGED SKIN CONTACT WITH

PETROLEUM OR ALCOHOL ± BASED CLEANING

SOLVENTS. PERSONAL INJURY CAN RESULT.

²DO NOT STAND UNDER A HOISTED VEHICLE

THAT IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION: When holes must be drilled or punched

in an inner body panel, verify depth of space to the

outer body panel, electrical wiring, or other compo-

nents. Damage to vehicle can result.

²Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

²Always have a fire extinguisher ready for use

when welding.

²Disconnect the negative (-) cable clamp from

the battery when servicing electrical components

that are live when the ignition is OFF. Damage to

electrical system can result.²Do not use abrasive chemicals or compounds

on painted surfaces. Damage to finish can result.

²Do not use harsh alkaline based cleaning sol-

vents on painted or upholstered surfaces. Damage

to finish or color can result.

²Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - WATER LEAKS

Water leaks can be caused by poor sealing,

improper body component alignment, body seam

porosity, missing plugs, or blocked drain holes. Cen-

trifugal and gravitational force can cause water to

drip from a location away from the actual leak point,

making leak detection difficult. All body sealing

points should be water tight in normal wet-driving

conditions. Water flowing downward from the front of

the vehicle should not enter the passenger or luggage

compartment. Moving sealing surfaces will not

always seal water tight under all conditions. At

times, side glass or door seals will allow water to

enter the passenger compartment during high pres-

sure washing or hard driving rain (severe) condi-

tions. Overcompensating on door or glass

adjustments to stop a water leak that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After completing

a repair, water test vehicle to verify leak has stopped

before returning vehicle to use.

DRBODY 23 - 1

Page 2587 of 2895

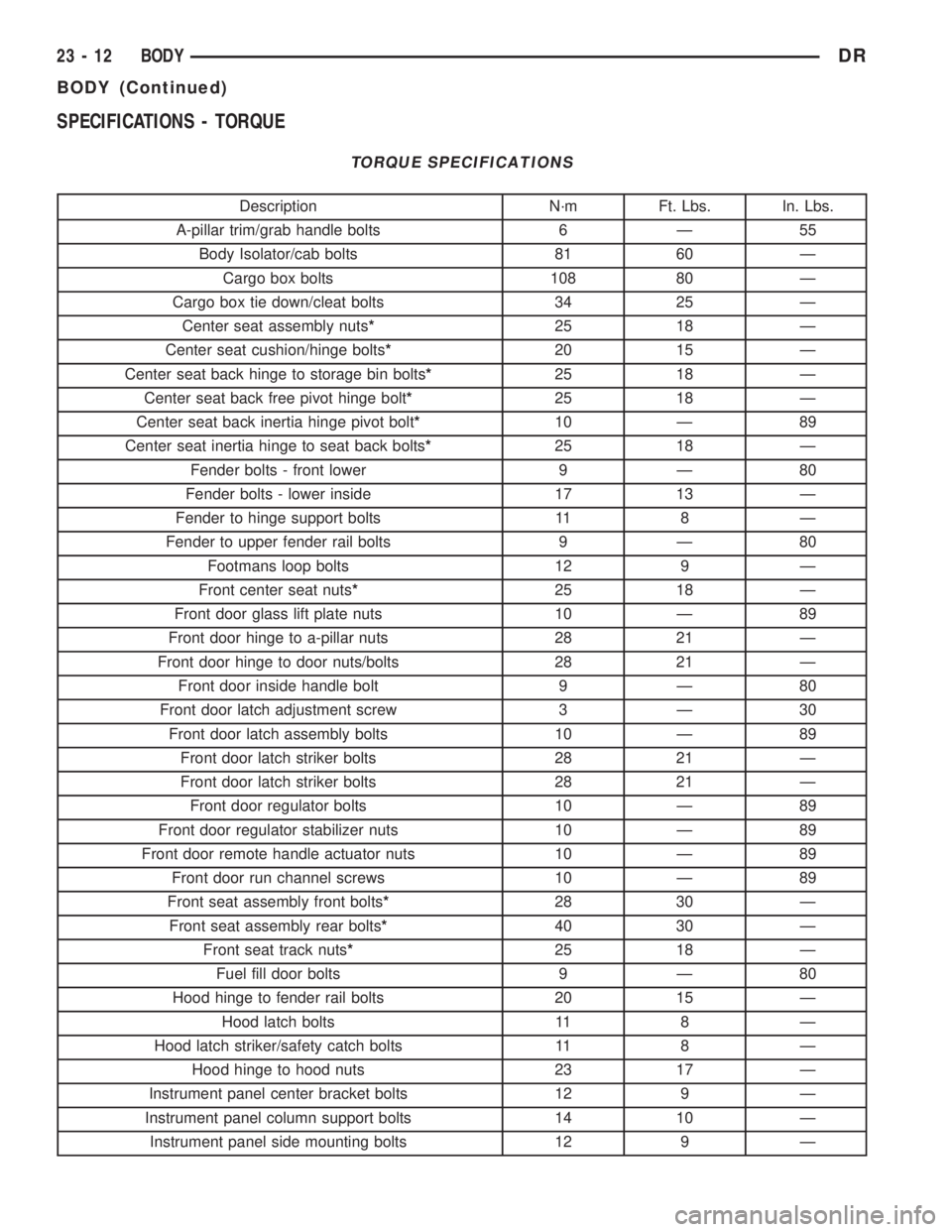

SPECIFICATIONS - TORQUE

TORQUE SPECIFICATIONS

Description N´m Ft. Lbs. In. Lbs.

A-pillar trim/grab handle bolts 6 Ð 55

Body Isolator/cab bolts 81 60 Ð

Cargo box bolts 108 80 Ð

Cargo box tie down/cleat bolts 34 25 Ð

Center seat assembly nuts*25 18 Ð

Center seat cushion/hinge bolts*20 15 Ð

Center seat back hinge to storage bin bolts*25 18 Ð

Center seat back free pivot hinge bolt*25 18 Ð

Center seat back inertia hinge pivot bolt*10 Ð 89

Center seat inertia hinge to seat back bolts*25 18 Ð

Fender bolts - front lower 9 Ð 80

Fender bolts - lower inside 17 13 Ð

Fender to hinge support bolts 11 8 Ð

Fender to upper fender rail bolts 9 Ð 80

Footmans loop bolts 12 9 Ð

Front center seat nuts*25 18 Ð

Front door glass lift plate nuts 10 Ð 89

Front door hinge to a-pillar nuts 28 21 Ð

Front door hinge to door nuts/bolts 28 21 Ð

Front door inside handle bolt 9 Ð 80

Front door latch adjustment screw 3 Ð 30

Front door latch assembly bolts 10 Ð 89

Front door latch striker bolts 28 21 Ð

Front door latch striker bolts 28 21 Ð

Front door regulator bolts 10 Ð 89

Front door regulator stabilizer nuts 10 Ð 89

Front door remote handle actuator nuts 10 Ð 89

Front door run channel screws 10 Ð 89

Front seat assembly front bolts*28 30 Ð

Front seat assembly rear bolts*40 30 Ð

Front seat track nuts*25 18 Ð

Fuel fill door bolts 9 Ð 80

Hood hinge to fender rail bolts 20 15 Ð

Hood latch bolts 11 8 Ð

Hood latch striker/safety catch bolts 11 8 Ð

Hood hinge to hood nuts 23 17 Ð

Instrument panel center bracket bolts 12 9 Ð

Instrument panel column support bolts 14 10 Ð

Instrument panel side mounting bolts 12 9 Ð

23 - 12 BODYDR

BODY (Continued)

Page 2588 of 2895

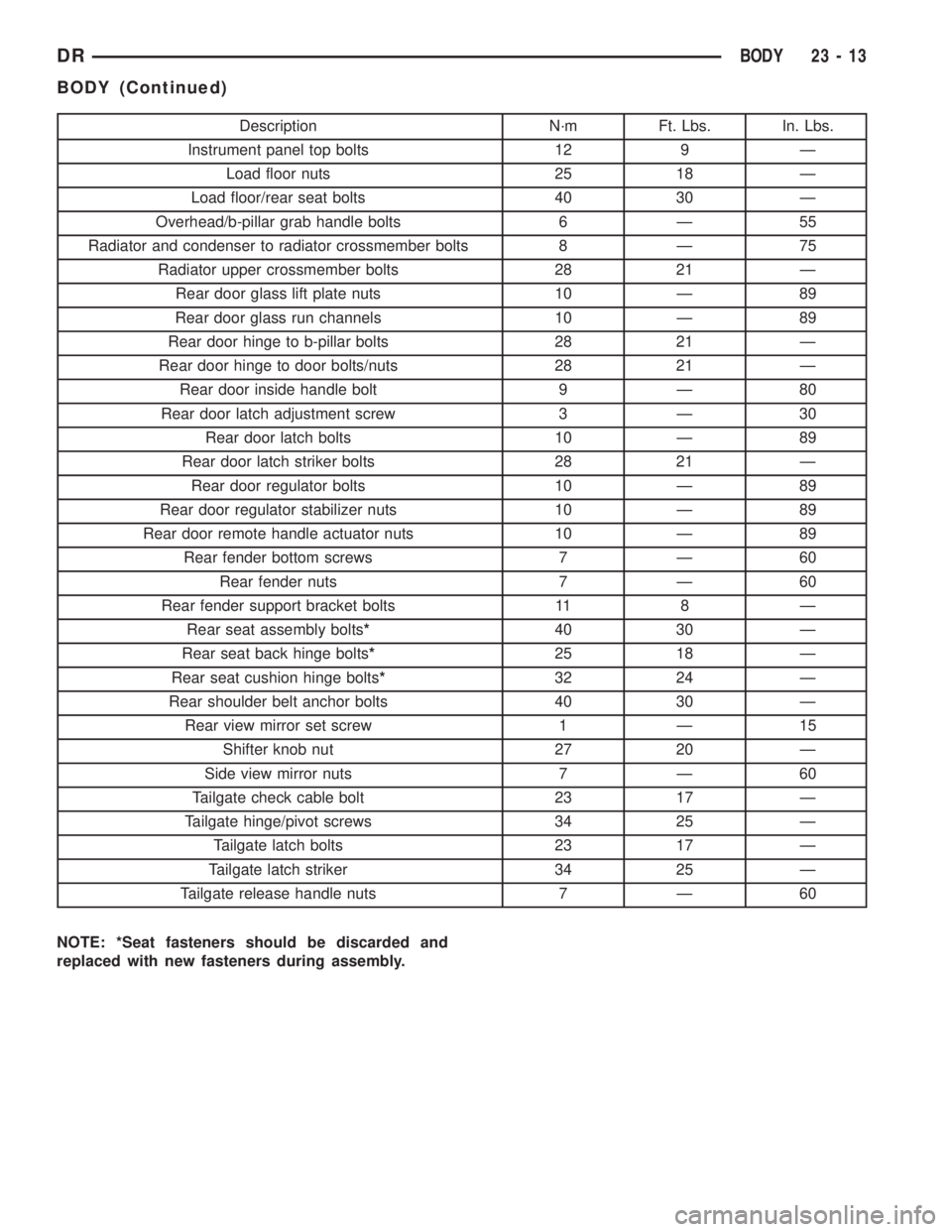

Description N´m Ft. Lbs. In. Lbs.

Instrument panel top bolts 12 9 Ð

Load floor nuts 25 18 Ð

Load floor/rear seat bolts 40 30 Ð

Overhead/b-pillar grab handle bolts 6 Ð 55

Radiator and condenser to radiator crossmember bolts 8 Ð 75

Radiator upper crossmember bolts 28 21 Ð

Rear door glass lift plate nuts 10 Ð 89

Rear door glass run channels 10 Ð 89

Rear door hinge to b-pillar bolts 28 21 Ð

Rear door hinge to door bolts/nuts 28 21 Ð

Rear door inside handle bolt 9 Ð 80

Rear door latch adjustment screw 3 Ð 30

Rear door latch bolts 10 Ð 89

Rear door latch striker bolts 28 21 Ð

Rear door regulator bolts 10 Ð 89

Rear door regulator stabilizer nuts 10 Ð 89

Rear door remote handle actuator nuts 10 Ð 89

Rear fender bottom screws 7 Ð 60

Rear fender nuts 7 Ð 60

Rear fender support bracket bolts 11 8 Ð

Rear seat assembly bolts*40 30 Ð

Rear seat back hinge bolts*25 18 Ð

Rear seat cushion hinge bolts*32 24 Ð

Rear shoulder belt anchor bolts 40 30 Ð

Rear view mirror set screw 1 Ð 15

Shifter knob nut 27 20 Ð

Side view mirror nuts 7 Ð 60

Tailgate check cable bolt 23 17 Ð

Tailgate hinge/pivot screws 34 25 Ð

Tailgate latch bolts 23 17 Ð

Tailgate latch striker 34 25 Ð

Tailgate release handle nuts 7 Ð 60

NOTE: *Seat fasteners should be discarded and

replaced with new fasteners during assembly.

DRBODY 23 - 13

BODY (Continued)

Page 2599 of 2895

LATCH STRIKER

REMOVAL

(1) Using a grease pencil or equivalent, mark the

position of the striker.

(2) Remove the bolts and remove the striker.

INSTALLATION

(1) Install the striker and install the bolts.

(2) Tighten the bolts to 28 N´m (21 ft. lbs.).

(3) Adjust the striker if needed. (Refer to 23 -

BODY/DOOR - FRONT/LATCH STRIKER - ADJUST-

MENTS)

ADJUSTMENTS

ADJUSTMENT

(1) Using a grease pencil or equivalent, mark the

position of the striker to aid in adjustment.

(2) Loosen the striker bolts.

(3) Change the striker position to adjust the rear

gap and flush measurement. (Refer to 23 - BODY/

BODY STRUCTURE/GAP AND FLUSH - SPECIFI-

CATIONS)

(4) Tighten the bolts to 28 N´m (21 ft. lbs.).

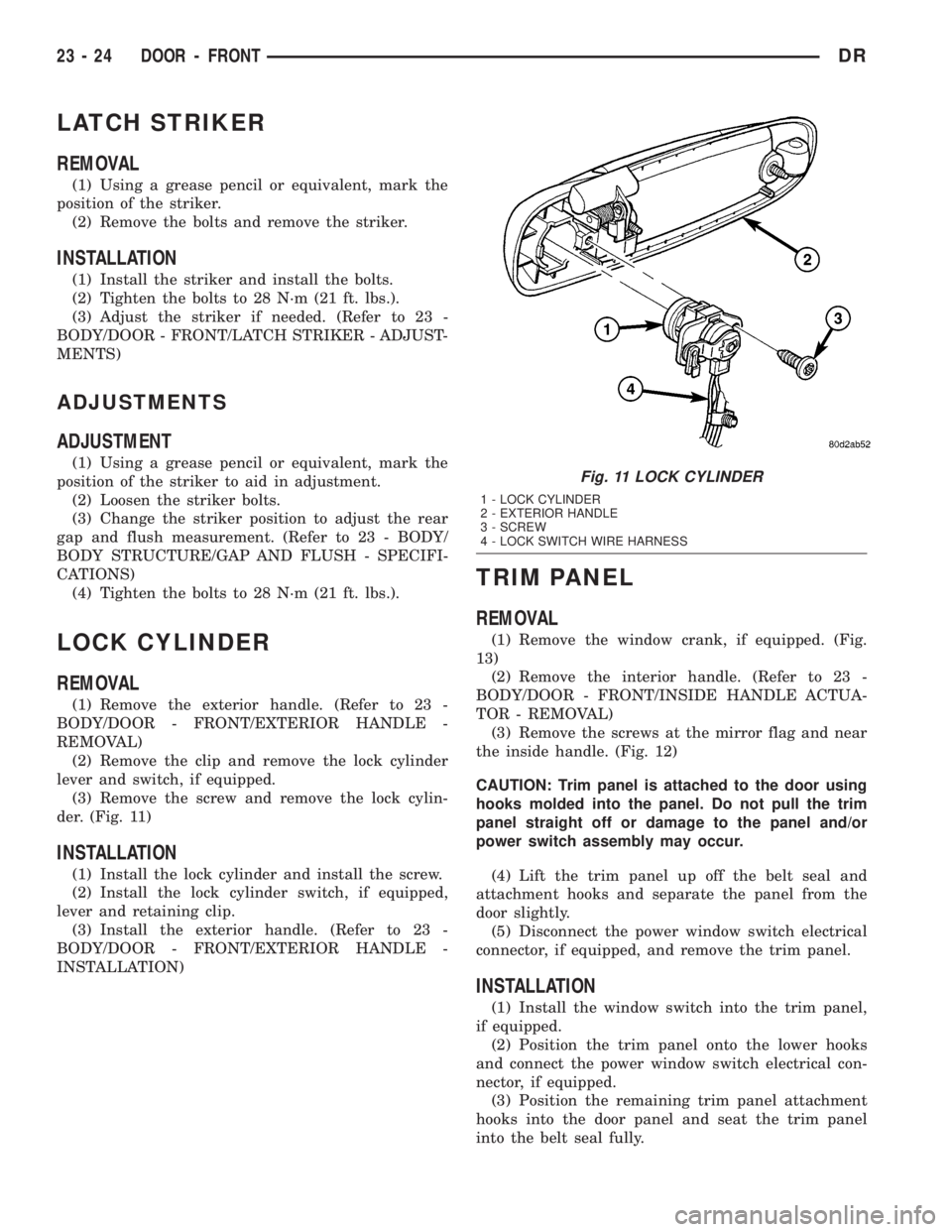

LOCK CYLINDER

REMOVAL

(1) Remove the exterior handle. (Refer to 23 -

BODY/DOOR - FRONT/EXTERIOR HANDLE -

REMOVAL)

(2) Remove the clip and remove the lock cylinder

lever and switch, if equipped.

(3) Remove the screw and remove the lock cylin-

der. (Fig. 11)

INSTALLATION

(1) Install the lock cylinder and install the screw.

(2) Install the lock cylinder switch, if equipped,

lever and retaining clip.

(3) Install the exterior handle. (Refer to 23 -

BODY/DOOR - FRONT/EXTERIOR HANDLE -

INSTALLATION)

TRIM PANEL

REMOVAL

(1) Remove the window crank, if equipped. (Fig.

13)

(2) Remove the interior handle. (Refer to 23 -

BODY/DOOR - FRONT/INSIDE HANDLE ACTUA-

TOR - REMOVAL)

(3) Remove the screws at the mirror flag and near

the inside handle. (Fig. 12)

CAUTION: Trim panel is attached to the door using

hooks molded into the panel. Do not pull the trim

panel straight off or damage to the panel and/or

power switch assembly may occur.

(4) Lift the trim panel up off the belt seal and

attachment hooks and separate the panel from the

door slightly.

(5) Disconnect the power window switch electrical

connector, if equipped, and remove the trim panel.

INSTALLATION

(1) Install the window switch into the trim panel,

if equipped.

(2) Position the trim panel onto the lower hooks

and connect the power window switch electrical con-

nector, if equipped.

(3) Position the remaining trim panel attachment

hooks into the door panel and seat the trim panel

into the belt seal fully.

Fig. 11 LOCK CYLINDER

1 - LOCK CYLINDER

2 - EXTERIOR HANDLE

3 - SCREW

4 - LOCK SWITCH WIRE HARNESS

23 - 24 DOOR - FRONTDR

Page 2608 of 2895

(2) Insert a 5/32-inch hex-wrench through hole and

into adjustment screw. Loosen screw.

(3) Operate outside handle several times to release

any restriction because of mis-alignment.

(4) Tighten adjustment screw to 3 N´m (30 in.

lbs.).

(5) Test handle for proper operation.

LATCH STRIKER

REMOVAL

(1) Using a grease pencil or equivalent, mark the

position of the striker.

(2) Remove the bolts and remove the striker.

INSTALLATION

(1) Install the striker and install the bolts.

(2) Tighten the bolts to 28 N´m (21 ft. lbs.).

(3) Adjust the striker if needed. (Refer to 23 -

BODY/DOOR - FRONT/LATCH STRIKER - ADJUST-

MENTS)

ADJUSTMENTS

ADJUSTMENT

(1) Using a grease pencil or equivalent, mark the

position of the striker to aid in adjustment.

(2) Loosen the striker bolts.

(3) Change the striker position to adjust the rear

gap and flush measurement. (Refer to 23 - BODY/

BODY STRUCTURE/GAP AND FLUSH - SPECIFI-

CATIONS)

(4) Tighten the bolts to 28 N´m (21 ft. lbs.).

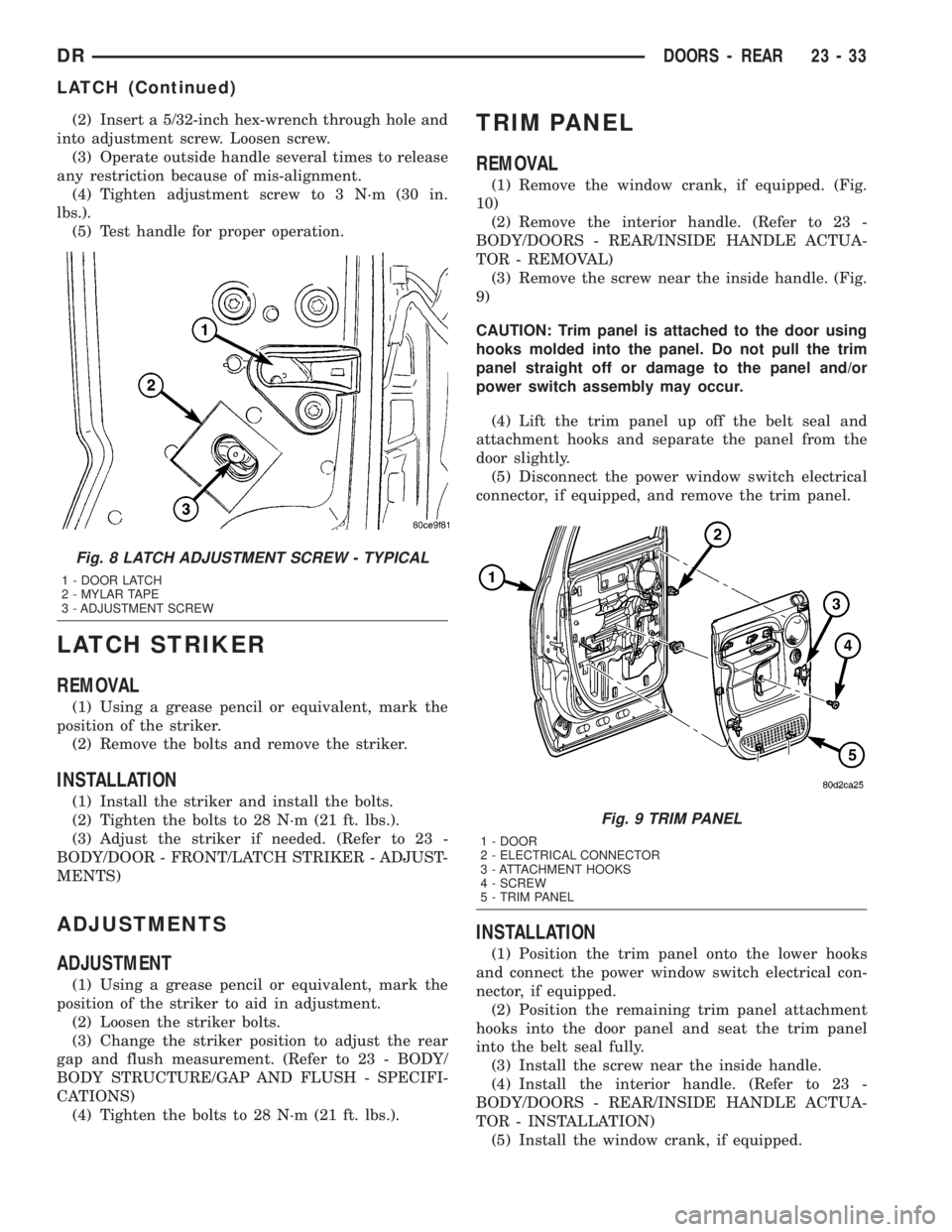

TRIM PANEL

REMOVAL

(1) Remove the window crank, if equipped. (Fig.

10)

(2) Remove the interior handle. (Refer to 23 -

BODY/DOORS - REAR/INSIDE HANDLE ACTUA-

TOR - REMOVAL)

(3) Remove the screw near the inside handle. (Fig.

9)

CAUTION: Trim panel is attached to the door using

hooks molded into the panel. Do not pull the trim

panel straight off or damage to the panel and/or

power switch assembly may occur.

(4) Lift the trim panel up off the belt seal and

attachment hooks and separate the panel from the

door slightly.

(5) Disconnect the power window switch electrical

connector, if equipped, and remove the trim panel.

INSTALLATION

(1) Position the trim panel onto the lower hooks

and connect the power window switch electrical con-

nector, if equipped.

(2) Position the remaining trim panel attachment

hooks into the door panel and seat the trim panel

into the belt seal fully.

(3) Install the screw near the inside handle.

(4) Install the interior handle. (Refer to 23 -

BODY/DOORS - REAR/INSIDE HANDLE ACTUA-

TOR - INSTALLATION)

(5) Install the window crank, if equipped.

Fig. 8 LATCH ADJUSTMENT SCREW - TYPICAL

1 - DOOR LATCH

2 - MYLAR TAPE

3 - ADJUSTMENT SCREW

Fig. 9 TRIM PANEL

1 - DOOR

2 - ELECTRICAL CONNECTOR

3 - ATTACHMENT HOOKS

4 - SCREW

5 - TRIM PANEL

DRDOORS - REAR 23 - 33

LATCH (Continued)

Page 2856 of 2895

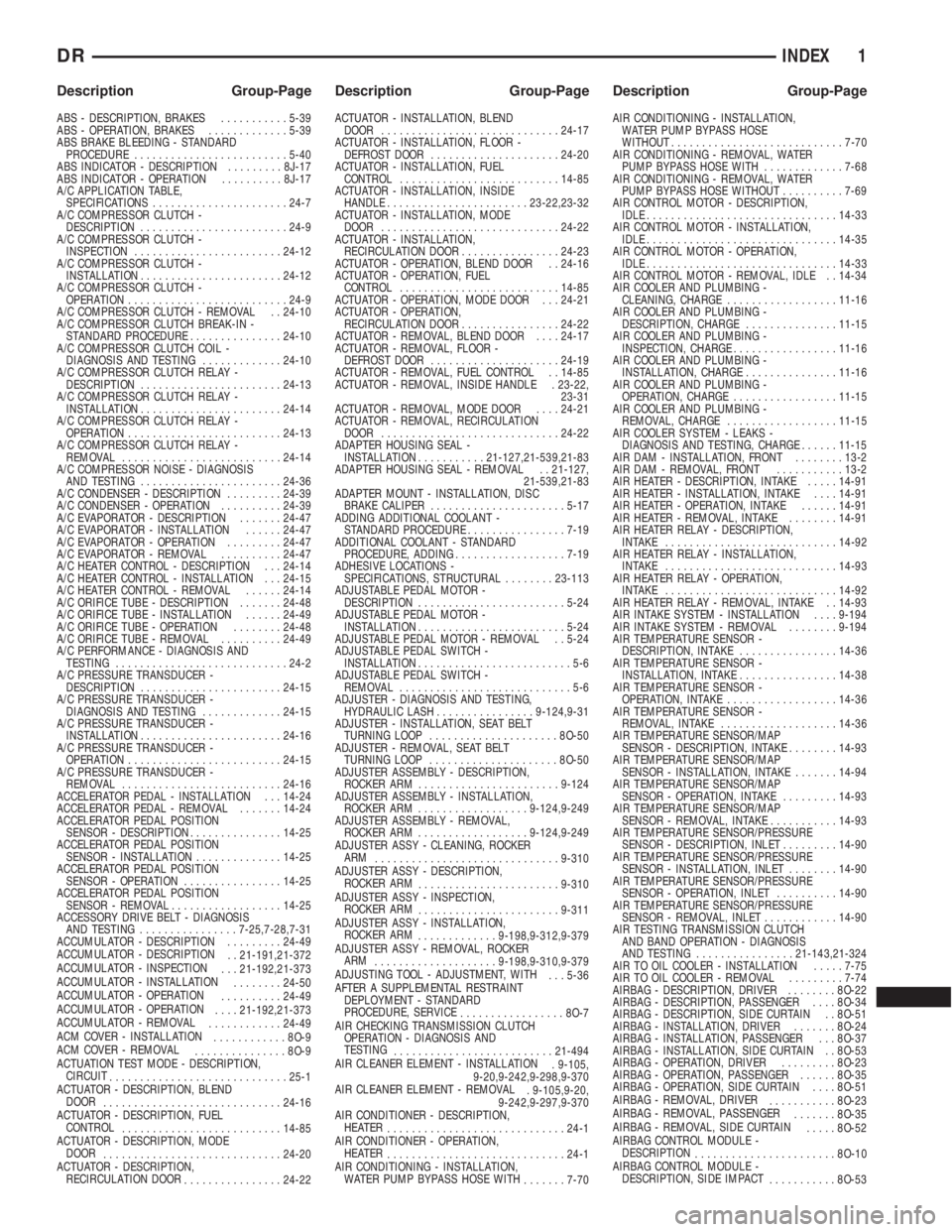

ABS - DESCRIPTION, BRAKES...........5-39

ABS - OPERATION, BRAKES.............5-39

ABS BRAKE BLEEDING - STANDARD

PROCEDURE.........................5-40

ABS INDICATOR - DESCRIPTION.........8J-17

ABS INDICATOR - OPERATION..........8J-17

A/C APPLICATION TABLE,

SPECIFICATIONS......................24-7

A/C COMPRESSOR CLUTCH -

DESCRIPTION........................24-9

A/C COMPRESSOR CLUTCH -

INSPECTION........................24-12

A/C COMPRESSOR CLUTCH -

INSTALLATION.......................24-12

A/C COMPRESSOR CLUTCH -

OPERATION..........................24-9

A/C COMPRESSOR CLUTCH - REMOVAL . . 24-10

A/C COMPRESSOR CLUTCH BREAK-IN -

STANDARD PROCEDURE...............24-10

A/C COMPRESSOR CLUTCH COIL -

DIAGNOSIS AND TESTING.............24-10

A/C COMPRESSOR CLUTCH RELAY -

DESCRIPTION.......................24-13

A/C COMPRESSOR CLUTCH RELAY -

INSTALLATION.......................24-14

A/C COMPRESSOR CLUTCH RELAY -

OPERATION.........................24-13

A/C COMPRESSOR CLUTCH RELAY -

REMOVAL..........................24-14

A/C COMPRESSOR NOISE - DIAGNOSIS

AND TESTING.......................24-36

A/C CONDENSER - DESCRIPTION.........24-39

A/C CONDENSER - OPERATION..........24-39

A/C EVAPORATOR - DESCRIPTION.......24-47

A/C EVAPORATOR - INSTALLATION......24-47

A/C EVAPORATOR - OPERATION.........24-47

A/C EVAPORATOR - REMOVAL..........24-47

A/C HEATER CONTROL - DESCRIPTION . . . 24-14

A/C HEATER CONTROL - INSTALLATION . . . 24-15

A/C HEATER CONTROL - REMOVAL......24-14

A/C ORIFICE TUBE - DESCRIPTION.......24-48

A/C ORIFICE TUBE - INSTALLATION......24-49

A/C ORIFICE TUBE - OPERATION........24-48

A/C ORIFICE TUBE - REMOVAL..........24-49

A/C PERFORMANCE - DIAGNOSIS AND

TESTING............................24-2

A/C PRESSURE TRANSDUCER -

DESCRIPTION.......................24-15

A/C PRESSURE TRANSDUCER -

DIAGNOSIS AND TESTING.............24-15

A/C PRESSURE TRANSDUCER -

INSTALLATION.......................24-16

A/C PRESSURE TRANSDUCER -

OPERATION.........................24-15

A/C PRESSURE TRANSDUCER -

REMOVAL..........................24-16

ACCELERATOR PEDAL - INSTALLATION . . . 14-24

ACCELERATOR PEDAL - REMOVAL.......14-24

ACCELERATOR PEDAL POSITION

SENSOR - DESCRIPTION...............14-25

ACCELERATOR PEDAL POSITION

SENSOR - INSTALLATION..............14-25

ACCELERATOR PEDAL POSITION

SENSOR - OPERATION................14-25

ACCELERATOR PEDAL POSITION

SENSOR - REMOVAL..................14-25

ACCESSORY DRIVE BELT - DIAGNOSIS

AND TESTING................7-25,7-28,7-31

ACCUMULATOR - DESCRIPTION.........24-49

ACCUMULATOR - DESCRIPTION

. . 21-191,21-372

ACCUMULATOR - INSPECTION

. . . 21-192,21-373

ACCUMULATOR - INSTALLATION

........24-50

ACCUMULATOR - OPERATION

..........24-49

ACCUMULATOR - OPERATION

....21-192,21-373

ACCUMULATOR - REMOVAL

............24-49

ACM COVER - INSTALLATION

............8O-9

ACM COVER - REMOVAL

...............8O-9

ACTUATION TEST MODE - DESCRIPTION,

CIRCUIT

.............................25-1

ACTUATOR - DESCRIPTION, BLEND

DOOR

.............................24-16

ACTUATOR - DESCRIPTION, FUEL

CONTROL

..........................14-85

ACTUATOR - DESCRIPTION, MODE

DOOR

.............................24-20

ACTUATOR - DESCRIPTION,

RECIRCULATION DOOR

................24-22ACTUATOR - INSTALLATION, BLEND

DOOR.............................24-17

ACTUATOR - INSTALLATION, FLOOR -

DEFROST DOOR.....................24-20

ACTUATOR - INSTALLATION, FUEL

CONTROL..........................14-85

ACTUATOR - INSTALLATION, INSIDE

HANDLE.......................23-22,23-32

ACTUATOR - INSTALLATION, MODE

DOOR.............................24-22

ACTUATOR - INSTALLATION,

RECIRCULATION DOOR................24-23

ACTUATOR - OPERATION, BLEND DOOR . . 24-16

ACTUATOR - OPERATION, FUEL

CONTROL..........................14-85

ACTUATOR - OPERATION, MODE DOOR . . . 24-21

ACTUATOR - OPERATION,

RECIRCULATION DOOR................24-22

ACTUATOR - REMOVAL, BLEND DOOR....24-17

ACTUATOR - REMOVAL, FLOOR -

DEFROST DOOR.....................24-19

ACTUATOR - REMOVAL, FUEL CONTROL . . 14-85

ACTUATOR - REMOVAL, INSIDE HANDLE . 23-22,

23-31

ACTUATOR - REMOVAL, MODE DOOR....24-21

ACTUATOR - REMOVAL, RECIRCULATION

DOOR.............................24-22

ADAPTER HOUSING SEAL -

INSTALLATION...........21-127,21-539,21-83

ADAPTER HOUSING SEAL - REMOVAL . . 21-127,

21-539,21-83

ADAPTER MOUNT - INSTALLATION, DISC

BRAKE CALIPER......................5-17

ADDING ADDITIONAL COOLANT -

STANDARD PROCEDURE................7-19

ADDITIONAL COOLANT - STANDARD

PROCEDURE, ADDING..................7-19

ADHESIVE LOCATIONS -

SPECIFICATIONS, STRUCTURAL........23-113

ADJUSTABLE PEDAL MOTOR -

DESCRIPTION........................5-24

ADJUSTABLE PEDAL MOTOR -

INSTALLATION........................5-24

ADJUSTABLE PEDAL MOTOR - REMOVAL . . 5-24

ADJUSTABLE PEDAL SWITCH -

INSTALLATION.........................5-6

ADJUSTABLE PEDAL SWITCH -

REMOVAL............................5-6

ADJUSTER - DIAGNOSIS AND TESTING,

HYDRAULIC LASH................9-124,9-31

ADJUSTER - INSTALLATION, SEAT BELT

TURNING LOOP.....................8O-50

ADJUSTER - REMOVAL, SEAT BELT

TURNING LOOP.....................8O-50

ADJUSTER ASSEMBLY - DESCRIPTION,

ROCKER ARM.......................9-124

ADJUSTER ASSEMBLY - INSTALLATION,

ROCKER ARM..................9-124,9-249

ADJUSTER ASSEMBLY - REMOVAL,

ROCKER ARM..................9-124,9-249

ADJUSTER ASSY - CLEANING, ROCKER

ARM

..............................9-310

ADJUSTER ASSY - DESCRIPTION,

ROCKER ARM

.......................9-310

ADJUSTER ASSY - INSPECTION,

ROCKER ARM

.......................9-311

ADJUSTER ASSY - INSTALLATION,

ROCKER ARM

.............9-198,9-312,9-379

ADJUSTER ASSY - REMOVAL, ROCKER

ARM

....................9-198,9-310,9-379

ADJUSTING TOOL - ADJUSTMENT, WITH

. . . 5-36

AFTER A SUPPLEMENTAL RESTRAINT

DEPLOYMENT - STANDARD

PROCEDURE, SERVICE

.................8O-7

AIR CHECKING TRANSMISSION CLUTCH

OPERATION - DIAGNOSIS AND

TESTING

..........................21-494

AIR CLEANER ELEMENT - INSTALLATION

. 9-105,

9-20,9-242,9-298,9-370

AIR CLEANER ELEMENT - REMOVAL

. 9-105,9-20,

9-242,9-297,9-370

AIR CONDITIONER - DESCRIPTION,

HEATER

.............................24-1

AIR CONDITIONER - OPERATION,

HEATER

.............................24-1

AIR CONDITIONING - INSTALLATION,

WATER PUMP BYPASS HOSE WITH

.......7-70AIR CONDITIONING - INSTALLATION,

WATER PUMP BYPASS HOSE

WITHOUT............................7-70

AIR CONDITIONING - REMOVAL, WATER

PUMP BYPASS HOSE WITH.............7-68

AIR CONDITIONING - REMOVAL, WATER

PUMP BYPASS HOSE WITHOUT..........7-69

AIR CONTROL MOTOR - DESCRIPTION,

IDLE...............................14-33

AIR CONTROL MOTOR - INSTALLATION,

IDLE...............................14-35

AIR CONTROL MOTOR - OPERATION,

IDLE...............................14-33

AIR CONTROL MOTOR - REMOVAL, IDLE . . 14-34

AIR COOLER AND PLUMBING -

CLEANING, CHARGE..................11-16

AIR COOLER AND PLUMBING -

DESCRIPTION, CHARGE...............11-15

AIR COOLER AND PLUMBING -

INSPECTION, CHARGE.................11-16

AIR COOLER AND PLUMBING -

INSTALLATION, CHARGE...............11-16

AIR COOLER AND PLUMBING -

OPERATION, CHARGE.................11-15

AIR COOLER AND PLUMBING -

REMOVAL, CHARGE..................11-15

AIR COOLER SYSTEM - LEAKS -

DIAGNOSIS AND TESTING, CHARGE......11-15

AIR DAM - INSTALLATION, FRONT........13-2

AIR DAM - REMOVAL, FRONT...........13-2

AIR HEATER - DESCRIPTION, INTAKE.....14-91

AIR HEATER - INSTALLATION, INTAKE....14-91

AIR HEATER - OPERATION, INTAKE......14-91

AIR HEATER - REMOVAL, INTAKE........14-91

AIR HEATER RELAY - DESCRIPTION,

INTAKE ............................14-92

AIR HEATER RELAY - INSTALLATION,

INTAKE ............................14-93

AIR HEATER RELAY - OPERATION,

INTAKE ............................14-92

AIR HEATER RELAY - REMOVAL, INTAKE . . 14-93

AIR INTAKE SYSTEM - INSTALLATION....9-194

AIR INTAKE SYSTEM - REMOVAL........9-194

AIR TEMPERATURE SENSOR -

DESCRIPTION, INTAKE................14-36

AIR TEMPERATURE SENSOR -

INSTALLATION, INTAKE................14-38

AIR TEMPERATURE SENSOR -

OPERATION, INTAKE..................14-36

AIR TEMPERATURE SENSOR -

REMOVAL, INTAKE...................14-36

AIR TEMPERATURE SENSOR/MAP

SENSOR - DESCRIPTION, INTAKE........14-93

AIR TEMPERATURE SENSOR/MAP

SENSOR - INSTALLATION, INTAKE.......14-94

AIR TEMPERATURE SENSOR/MAP

SENSOR - OPERATION, INTAKE.........14-93

AIR TEMPERATURE SENSOR/MAP

SENSOR - REMOVAL, INTAKE...........14-93

AIR TEMPERATURE SENSOR/PRESSURE

SENSOR - DESCRIPTION, INLET.........14-90

AIR TEMPERATURE SENSOR/PRESSURE

SENSOR - INSTALLATION, INLET........14-90

AIR TEMPERATURE SENSOR/PRESSURE

SENSOR - OPERATION, INLET..........14-90

AIR TEMPERATURE SENSOR/PRESSURE

SENSOR - REMOVAL, INLET............14-90

AIR TESTING TRANSMISSION CLUTCH

AND BAND OPERATION - DIAGNOSIS

AND TESTING................21-143,21-324

AIR TO OIL COOLER - INSTALLATION.....7-75

AIR TO OIL COOLER - REMOVAL.........7-74

AIRBAG - DESCRIPTION, DRIVER........8O-22

AIRBAG - DESCRIPTION, PASSENGER....8O-34

AIRBAG - DESCRIPTION, SIDE CURTAIN . . 8O-51

AIRBAG - INSTALLATION, DRIVER.......8O-24

AIRBAG - INSTALLATION, PASSENGER . . . 8O-37

AIRBAG - INSTALLATION, SIDE CURTAIN . . 8O-53

AIRBAG - OPERATION, DRIVER.........8O-23

AIRBAG - OPERATION, PASSENGER......8O-35

AIRBAG - OPERATION, SIDE CURTAIN....8O-51

AIRBAG - REMOVAL, DRIVER

...........8O-23

AIRBAG - REMOVAL, PASSENGER

.......8O-35

AIRBAG - REMOVAL, SIDE CURTAIN

.....8O-52

AIRBAG CONTROL MODULE -

DESCRIPTION

.......................8O-10

AIRBAG CONTROL MODULE -

DESCRIPTION, SIDE IMPACT

...........8O-53

DRINDEX 1

Description Group-Page Description Group-Page Description Group-Page

Page 2857 of 2895

AIRBAG CONTROL MODULE -

INSTALLATION......................8O-12

AIRBAG CONTROL MODULE -

OPERATION.........................8O-10

AIRBAG CONTROL MODULE -

OPERATION, SIDE IMPACT.............8O-54

AIRBAG CONTROL MODULE - REMOVAL . . 8O-11

AIRBAG INDICATOR - DESCRIPTION......8J-18

AIRBAG INDICATOR - OPERATION.......8J-18

AIRBAG ON/OFF SWITCH -

DESCRIPTION, PASSENGER............8O-38

AIRBAG ON/OFF SWITCH -

INSTALLATION, PASSENGER...........8O-39

AIRBAG ON/OFF SWITCH - OPERATION,

PASSENGER........................8O-38

AIRBAG ON/OFF SWITCH - REMOVAL,

PASSENGER........................8O-39

AJAR INDICATOR - DESCRIPTION, DOOR . . 8J-23

AJAR INDICATOR - OPERATION, DOOR . . . 8J-23

AJAR SWITCH - DESCRIPTION, DOOR....8L-25

AJAR SWITCH - OPERATION, DOOR......8L-25

ALIGNMENT - DESCRIPTION, WHEEL.......2-1

ALIGNMENT - OPERATION, WHEEL........2-2

ALIGNMENT - SPECIAL TOOLS,

HEADLAMP..........................8L-7

ALIGNMENT LINK/COIL SUSPENSION -

STANDARD PROCEDURE.................2-5

ALIGNMENT, SPECIAL TOOLS - WHEEL.....2-7

ALIGNMENT, SPECIFICATIONS............2-6

ALUMINUM THREAD REPAIR -

STANDARD PROCEDURE . . 21-156,21-337,21-495

AMBIENT TEMP SENSOR - DESCRIPTION . 8M-10

AMBIENT TEMP SENSOR - OPERATION . . 8M-10

AMBIENT TEMPERATURE SENSOR -

DIAGNOSIS AND TESTING.............8M-11

AMBIENT TEMPERATURE SENSOR

CIRCUIT - DIAGNOSIS AND TESTING....8M-11

AMPLIFIER - DESCRIPTION.............8A-3

AMPLIFIER - INSTALLATION.............8A-4

AMPLIFIER - OPERATION...............8A-3

AMPLIFIER - REMOVAL................8A-3

ANCHOR - DESCRIPTION, CHILD

RESTRAINT.........................8O-14

ANCHOR - INSTALLATION, CHILD

RESTRAINT.........................8O-17

ANCHOR - OPERATION, CHILD

RESTRAINT.........................8O-16

ANCHOR - REMOVAL, CHILD RESTRAINT . 8O-16

ANCHOR & RIGHT OUTBOARD -

INSTALLATION, CENTER...............8O-45

ANCHOR & RIGHT OUTBOARD -

REMOVAL, CENTER...................8O-43

ANTENNA BODY & CABLE -

DESCRIPTION........................8A-4

ANTENNA BODY & CABLE -

INSTALLATION.......................8A-6

ANTENNA BODY & CABLE - OPERATION . . . 8A-4

ANTENNA BODY & CABLE - REMOVAL.....8A-6

ANTENNA BODY AND CABLE -

DIAGNOSIS AND TESTING..............8A-4

ANTENNA CABLE - INSTALLATION,

INSTRUMENT PANEL..................8A-7

ANTENNA CABLE - REMOVAL,

INSTRUMENT PANEL..................8A-6

ANTILOCK - DIAGNOSIS AND TESTING,

REAR WHEEL........................5-42

ANTILOCK BRAKE - DESCRIPTION,

CONTROLLER........................8E-3

ANTILOCK BRAKE - INSTALLATION,

CONTROLLER........................8E-3

ANTILOCK BRAKE - OPERATION,

CONTROLLER........................8E-3

ANTILOCK BRAKE - REMOVAL,

CONTROLLER........................8E-3

A-PILLAR TRIM/GRAB HANDLE -

INSTALLATION.......................23-64

A-PILLAR TRIM/GRAB HANDLE -

REMOVAL..........................23-64

A-PILLAR WEATHERSTRIP RETAINER -

INSTALLATION

.......................23-91

A-PILLAR WEATHERSTRIP RETAINER -

REMOVAL

..........................23-91

APPLICATION TABLE, SPECIFICATIONS -

A/C

................................24-7

AREA LEAKS - DIAGNOSIS AND

TESTING, REAR SEAL

........9-135,9-204,9-64

ARM / ADJUSTER ASSEMBLY -

DESCRIPTION, ROCKER

...............9-124ARM / ADJUSTER ASSEMBLY -

INSTALLATION, ROCKER..........9-124,9-249

ARM / ADJUSTER ASSEMBLY -

REMOVAL, ROCKER.............9-124,9-249

ARM / ADJUSTER ASSY - CLEANING,

ROCKER............................9-310

ARM / ADJUSTER ASSY - DESCRIPTION,

ROCKER............................9-310

ARM / ADJUSTER ASSY - INSPECTION,

ROCKER............................9-311

ARM / ADJUSTER ASSY -

INSTALLATION, ROCKER.....9-198,9-312,9-379

ARM / ADJUSTER ASSY - REMOVAL,

ROCKER.................9-198,9-310,9-379

ARM - DESCRIPTION, ROCKER......9-30,9-36

ARM - DESCRIPTION, WIPER...........8R-18

ARM - INSTALLATION, LOWER

SUSPENSION.........................2-35

ARM - INSTALLATION, PITMAN.........19-36

ARM - INSTALLATION, ROCKER..........9-30

ARM - INSTALLATION, UPPER CONTROL . . . 2-27

ARM - INSTALLATION, WIPER..........8R-19

ARM - OPERATION, WIPER............8R-18

ARM - REMOVAL, LOWER SUSPENSION . . . 2-35

ARM - REMOVAL, PITMAN.............19-35

ARM - REMOVAL, ROCKER..........9-30,9-36

ARM - REMOVAL, UPPER CONTROL......2-27

ARM - REMOVAL, WIPER..............8R-18

ARM BUSHINGS - 2WD (LD) -

INSTALLATION, LOWER CONTROL..........2-14

ARM BUSHINGS - 2WD (LD) -

REMOVAL, LOWER CONTROL............2-12

ARM BUSHINGS - 4WD (LD) -

INSTALLATION, LOWER CONTROL........2-13

ARM BUSHINGS - 4WD (LD) -

REMOVAL, LOWER CONTROL............2-12

ARMREST / SEAT BACK - INSTALLATION,

CENTER............................23-78

ARMREST / SEAT BACK - REMOVAL,

CENTER............................23-77

ASD AND FUEL PUMP RELAYS -

DIAGNOSIS AND TESTING...............8I-7

ASD SENSE - PCM INPUT - OPERATION....8I-6

ASH RECEIVER - INSTALLATION.........23-52

ASH RECEIVER - REMOVAL............23-51

AUDIO - DESCRIPTION.................8A-1

AUDIO - DIAGNOSIS AND TESTING.......8A-2

AUDIO - OPERATION...................8A-1

AUTOMATIC DAY / NIGHT MIRROR -

DESCRIPTION.......................8N-12

AUTOMATIC DAY / NIGHT MIRROR -

DIAGNOSIS AND TESTING.............8N-12

AUTOMATIC DAY / NIGHT MIRROR -

OPERATION.........................8N-12

AUTOMATIC DAY / NIGHT MIRROR -

REMOVAL..........................8N-13

AUTOMATIC LOCKING RETRACTOR -

DESCRIPTION.......................8O-13

AUTOMATIC LOCKING RETRACTOR -

OPERATION.........................8O-14

AUTOMATIC TRANSMISSION -

45RFE/545RFE - DESCRIPTION.........21-489

AUTOMATIC TRANSMISSION -

45RFE/545RFE - OPERATION...........21-490

AUTOMATIC TRANSMISSION - 46RE -

DESCRIPTION......................21-131

AUTOMATIC TRANSMISSION - 46RE -

OPERATION........................21-133

AUTOMATIC TRANSMISSION - 48RE -

DESCRIPTION......................21-312

AUTOMATIC TRANSMISSION - 48RE -

OPERATION........................21-314

AUTOMATIC TRANSMISSION -

DIAGNOSIS AND TESTING......21-139,21-320,

21-491

AUTOMATIC TRANSMISSION FLUID -

DESCRIPTION.........................0-4

AUTOMATIC TRANSMISSION FLUID -

OPERATION...........................0-5

AUXILIARY SPRING BUMPERS (3500) -

INSTALLATION

........................2-40

AUXILIARY SPRING BUMPERS (3500) -

REMOVAL

...........................2-40

AXLE - 10 1/2 AA - ADJUSTMENTS,

REAR

..............................3-104

AXLE - 10 1/2 AA - DESCRIPTION, REAR

. . 3-100

AXLE - 10 1/2 AA - DIAGNOSIS AND

TESTING, REAR

......................3-100AXLE - 10 1/2 AA - INSTALLATION,

REAR..............................3-103

AXLE - 10 1/2 AA - OPERATION, REAR . . . 3-100

AXLE - 10 1/2 AA - REMOVAL, REAR.....3-103

AXLE - 10 1/2 AA - SPECIAL TOOLS,

REAR..............................3-108

AXLE - 10 1/2 AA - SPECIFICATIONS,

REAR..............................3-108

AXLE - 11 1/2 AA - ADJUSTMENTS,

REAR..............................3-131

AXLE - 11 1/2 AA - DESCRIPTION, REAR . . 3-127

AXLE - 11 1/2 AA - DIAGNOSIS AND

TESTING, REAR......................3-127

AXLE - 11 1/2 AA - INSTALLATION,

REAR..............................3-130

AXLE - 11 1/2 AA - OPERATION, REAR . . . 3-127

AXLE - 11 1/2 AA - REMOVAL, REAR.....3-130

AXLE - 11 1/2 AA - SPECIAL TOOLS,

REAR..............................3-135

AXLE - 11 1/2 AA - SPECIFICATIONS,

REAR..............................3-135

AXLE - 9 1/4 - ADJUSTMENTS, REAR.....3-74

AXLE - 9 1/4 - DESCRIPTION, REAR......3-69

AXLE - 9 1/4 - DIAGNOSIS AND

TESTING, REAR.......................3-69

AXLE - 9 1/4 - INSTALLATION, REAR......3-74

AXLE - 9 1/4 - OPERATION, REAR........3-69

AXLE - 9 1/4 - REMOVAL, REAR..........3-74

AXLE - 9 1/4 - SPECIAL TOOLS, REAR.....3-80

AXLE - 9 1/4 - SPECIFICATIONS, REAR......3-79

AXLE - 9 1/4 AA - ADJUSTMENTS,

FRONT..............................3-49

AXLE - 9 1/4 AA - DESCRIPTION, FRONT . . . 3-45

AXLE - 9 1/4 AA - DIAGNOSIS AND

TESTING, FRONT......................3-45

AXLE - 9 1/4 AA - INSTALLATION,

FRONT..............................3-48

AXLE - 9 1/4 AA - OPERATION, FRONT....3-45

AXLE - 9 1/4 AA - REMOVAL, FRONT......3-48

AXLE - 9 1/4 AA - SPECIAL TOOLS,

FRONT..............................3-53

AXLE - 9 1/4 AA - SPECIFICATIONS,

FRONT..............................3-53

AXLE - C205F - ADJUSTMENTS, FRONT....3-21

AXLE - C205F - DESCRIPTION, FRONT.....3-18

AXLE - C205F - DIAGNOSIS AND

TESTING, FRONT......................3-18

AXLE - C205F - INSTALLATION, FRONT....3-21

AXLE - C205F - OPERATION, FRONT......3-18

AXLE - C205F - REMOVAL, FRONT........3-21

AXLE - C205F - SPECIAL TOOLS, FRONT . . . 3-30

AXLE - C205F - SPECIFICATIONS, FRONT . . . 3-29

AXLE - DESCRIPTION...................0-4

AXLE BEARINGS - INSTALLATION . . 3-112,3-139,

3-34,3-84

AXLE BEARINGS - REMOVAL . . 3-112,3-138,3-33,

3-84

AXLE SHAFT SEALS - INSTALLATION . 3-33,3-58,

3-84

AXLE SHAFT SEALS - REMOVAL . 3-33,3-58,3-84

AXLE SHAFTS - ASSEMBLY.............3-58

AXLE SHAFTS - DISASSEMBLY...........3-56

AXLE SHAFTS - INSTALLATION....3-111,3-138,

3-33,3-58,3-83

AXLE SHAFTS - REMOVAL

....3-111,3-138,3-33,

3-56,3-83

BACK - INSTALLATION, CENTER

ARMREST / SEAT

....................23-78

BACK - REAR - INSTALLATION, SEAT

.....23-84

BACK - REAR - REMOVAL, SEAT

........23-84

BACK - REMOVAL, CENTER ARMREST /

SEAT

..............................23-77

BACK CUSHION / COVER - FRONT -

INSTALLATION, SEAT

.................23-83

BACK CUSHION / COVER - FRONT -

REMOVAL, SEAT

.....................23-83

BACK CUSHION / COVER - REAR -

INSTALLATION, SEAT

.................23-85

BACK CUSHION / COVER - REAR -

REMOVAL, SEAT

.....................23-85

BACK HINGE - INSTALLATION, CENTER

SEAT

..............................23-80

BACK HINGE - REMOVAL, CENTER SEAT

. . 23-79

BACK INERTIA HINGE COVER -

INSTALLATION, CENTER SEAT

..........23-78

BACK INERTIA HINGE COVER -

REMOVAL, CENTER SEAT

..............23-78

2 INDEXDR

Description Group-Page Description Group-Page Description Group-Page