differential DODGE RAM 2003 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 138 of 2895

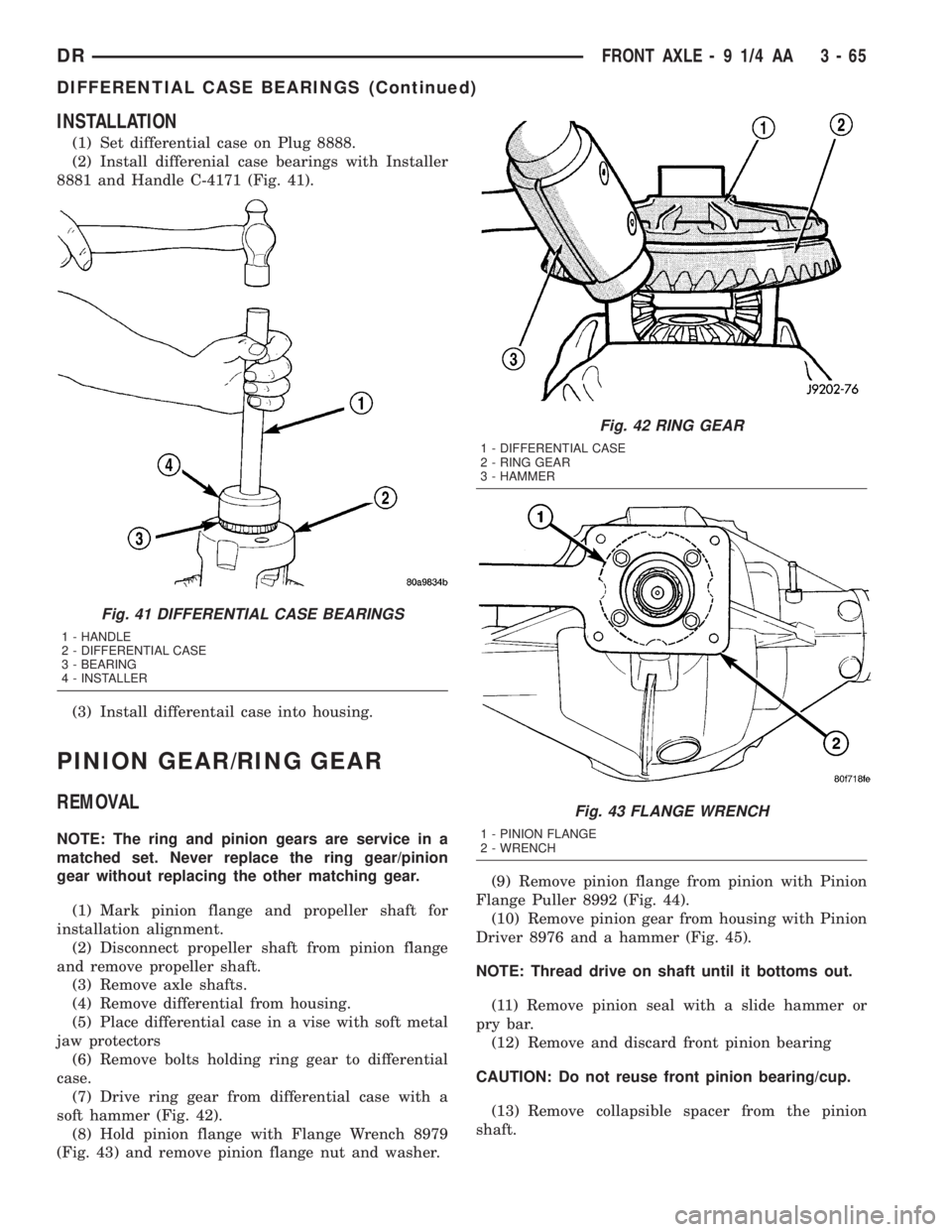

INSTALLATION

(1) Set differential case on Plug 8888.

(2) Install differenial case bearings with Installer

8881 and Handle C-4171 (Fig. 41).

(3) Install differentail case into housing.

PINION GEAR/RING GEAR

REMOVAL

NOTE: The ring and pinion gears are service in a

matched set. Never replace the ring gear/pinion

gear without replacing the other matching gear.

(1) Mark pinion flange and propeller shaft for

installation alignment.

(2) Disconnect propeller shaft from pinion flange

and remove propeller shaft.

(3) Remove axle shafts.

(4) Remove differential from housing.

(5) Place differential case in a vise with soft metal

jaw protectors

(6) Remove bolts holding ring gear to differential

case.

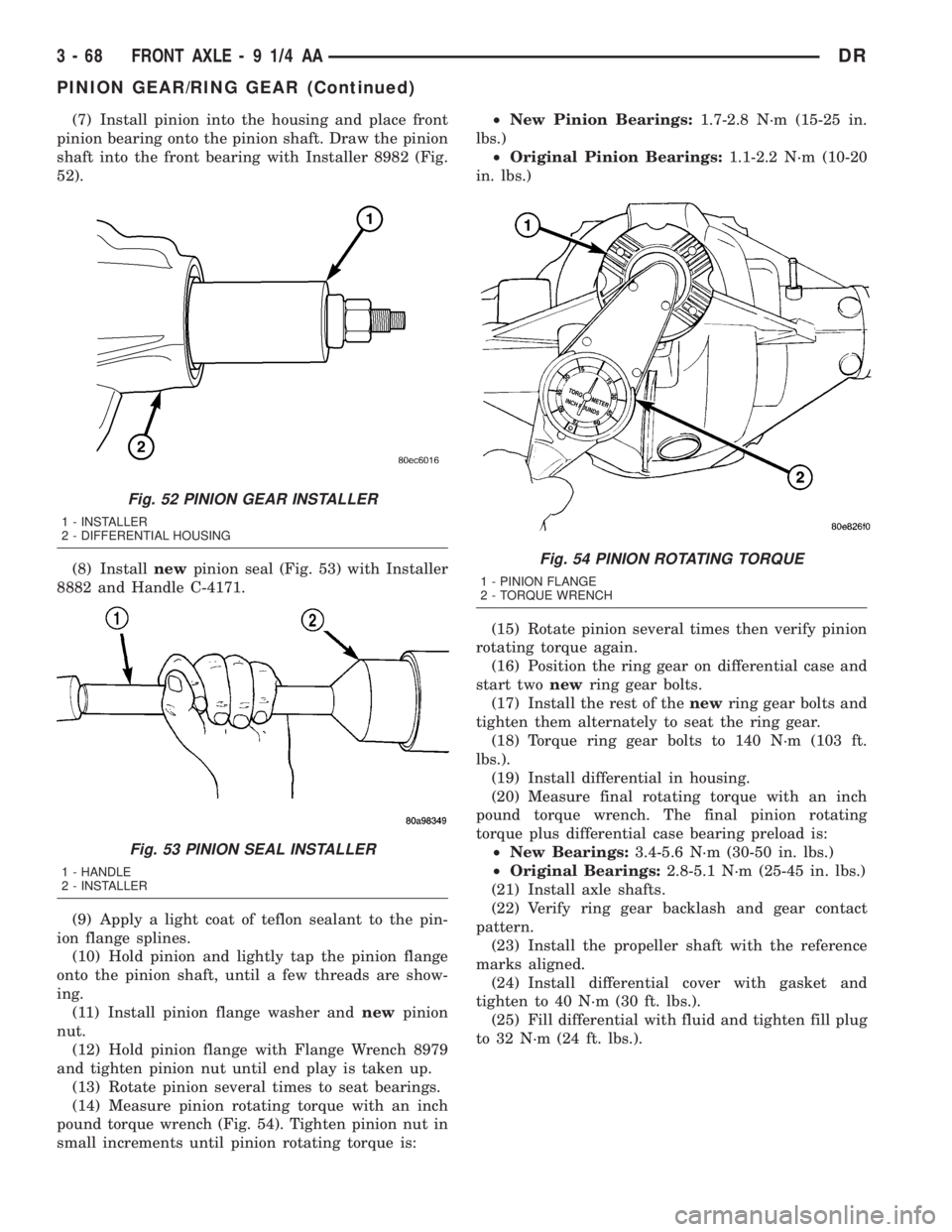

(7) Drive ring gear from differential case with a

soft hammer (Fig. 42).

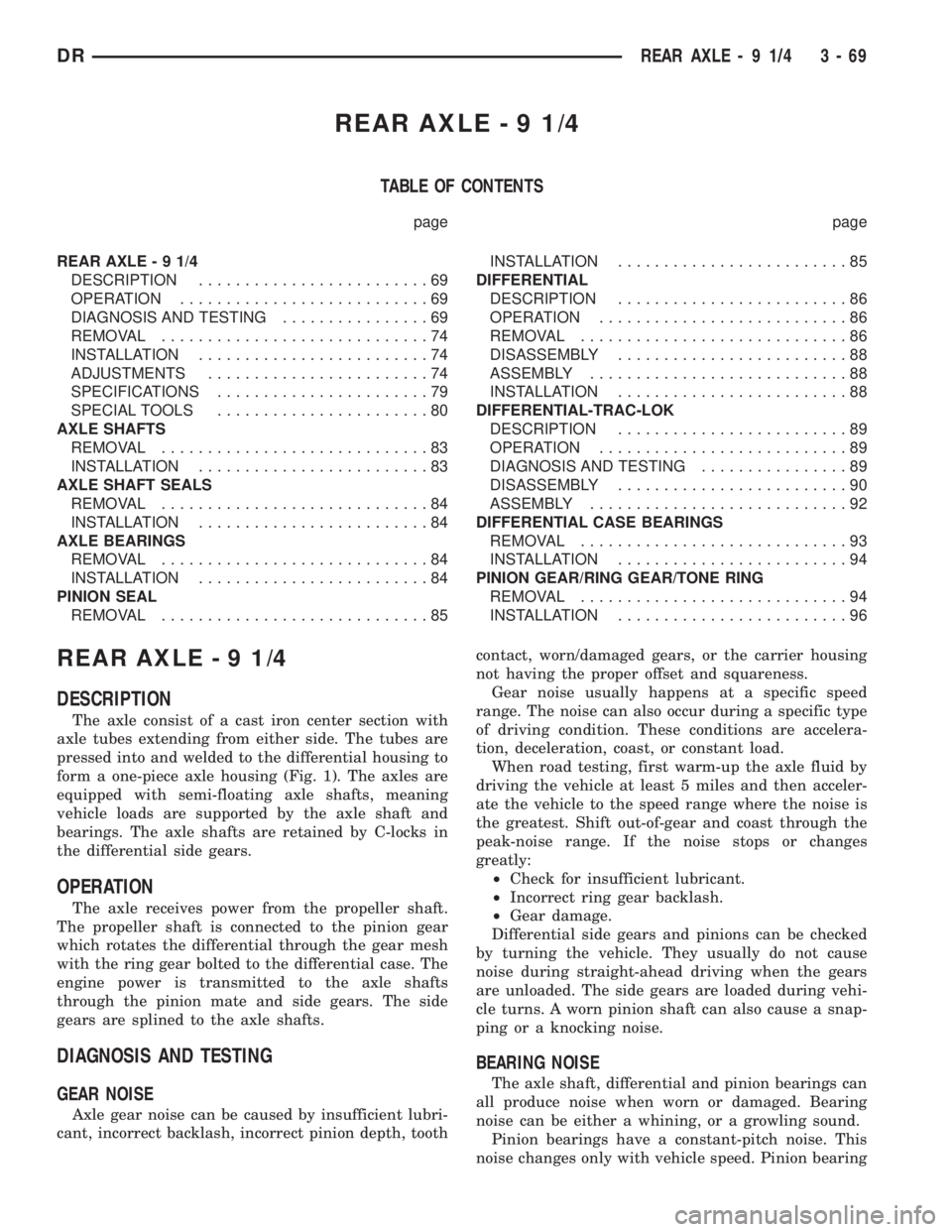

(8) Hold pinion flange with Flange Wrench 8979

(Fig. 43) and remove pinion flange nut and washer.(9) Remove pinion flange from pinion with Pinion

Flange Puller 8992 (Fig. 44).

(10) Remove pinion gear from housing with Pinion

Driver 8976 and a hammer (Fig. 45).

NOTE: Thread drive on shaft until it bottoms out.

(11) Remove pinion seal with a slide hammer or

pry bar.

(12) Remove and discard front pinion bearing

CAUTION: Do not reuse front pinion bearing/cup.

(13) Remove collapsible spacer from the pinion

shaft.

Fig. 41 DIFFERENTIAL CASE BEARINGS

1 - HANDLE

2 - DIFFERENTIAL CASE

3 - BEARING

4 - INSTALLER

Fig. 42 RING GEAR

1 - DIFFERENTIAL CASE

2 - RING GEAR

3 - HAMMER

Fig. 43 FLANGE WRENCH

1 - PINION FLANGE

2 - WRENCH

DRFRONT AXLE - 9 1/4 AA 3 - 65

DIFFERENTIAL CASE BEARINGS (Continued)

Page 141 of 2895

(7) Install pinion into the housing and place front

pinion bearing onto the pinion shaft. Draw the pinion

shaft into the front bearing with Installer 8982 (Fig.

52).

(8) Installnewpinion seal (Fig. 53) with Installer

8882 and Handle C-4171.

(9) Apply a light coat of teflon sealant to the pin-

ion flange splines.

(10) Hold pinion and lightly tap the pinion flange

onto the pinion shaft, until a few threads are show-

ing.

(11) Install pinion flange washer andnewpinion

nut.

(12) Hold pinion flange with Flange Wrench 8979

and tighten pinion nut until end play is taken up.

(13) Rotate pinion several times to seat bearings.

(14) Measure pinion rotating torque with an inch

pound torque wrench (Fig. 54). Tighten pinion nut in

small increments until pinion rotating torque is:²New Pinion Bearings:1.7-2.8 N´m (15-25 in.

lbs.)

²Original Pinion Bearings:1.1-2.2 N´m (10-20

in. lbs.)

(15) Rotate pinion several times then verify pinion

rotating torque again.

(16) Position the ring gear on differential case and

start twonewring gear bolts.

(17) Install the rest of thenewring gear bolts and

tighten them alternately to seat the ring gear.

(18) Torque ring gear bolts to 140 N´m (103 ft.

lbs.).

(19) Install differential in housing.

(20) Measure final rotating torque with an inch

pound torque wrench. The final pinion rotating

torque plus differential case bearing preload is:

²New Bearings:3.4-5.6 N´m (30-50 in. lbs.)

²Original Bearings:2.8-5.1 N´m (25-45 in. lbs.)

(21) Install axle shafts.

(22) Verify ring gear backlash and gear contact

pattern.

(23) Install the propeller shaft with the reference

marks aligned.

(24) Install differential cover with gasket and

tighten to 40 N´m (30 ft. lbs.).

(25) Fill differential with fluid and tighten fill plug

to 32 N´m (24 ft. lbs.).

Fig. 52 PINION GEAR INSTALLER

1 - INSTALLER

2 - DIFFERENTIAL HOUSING

Fig. 53 PINION SEAL INSTALLER

1 - HANDLE

2 - INSTALLER

Fig. 54 PINION ROTATING TORQUE

1 - PINION FLANGE

2 - TORQUE WRENCH

3 - 68 FRONT AXLE - 9 1/4 AADR

PINION GEAR/RING GEAR (Continued)

Page 142 of 2895

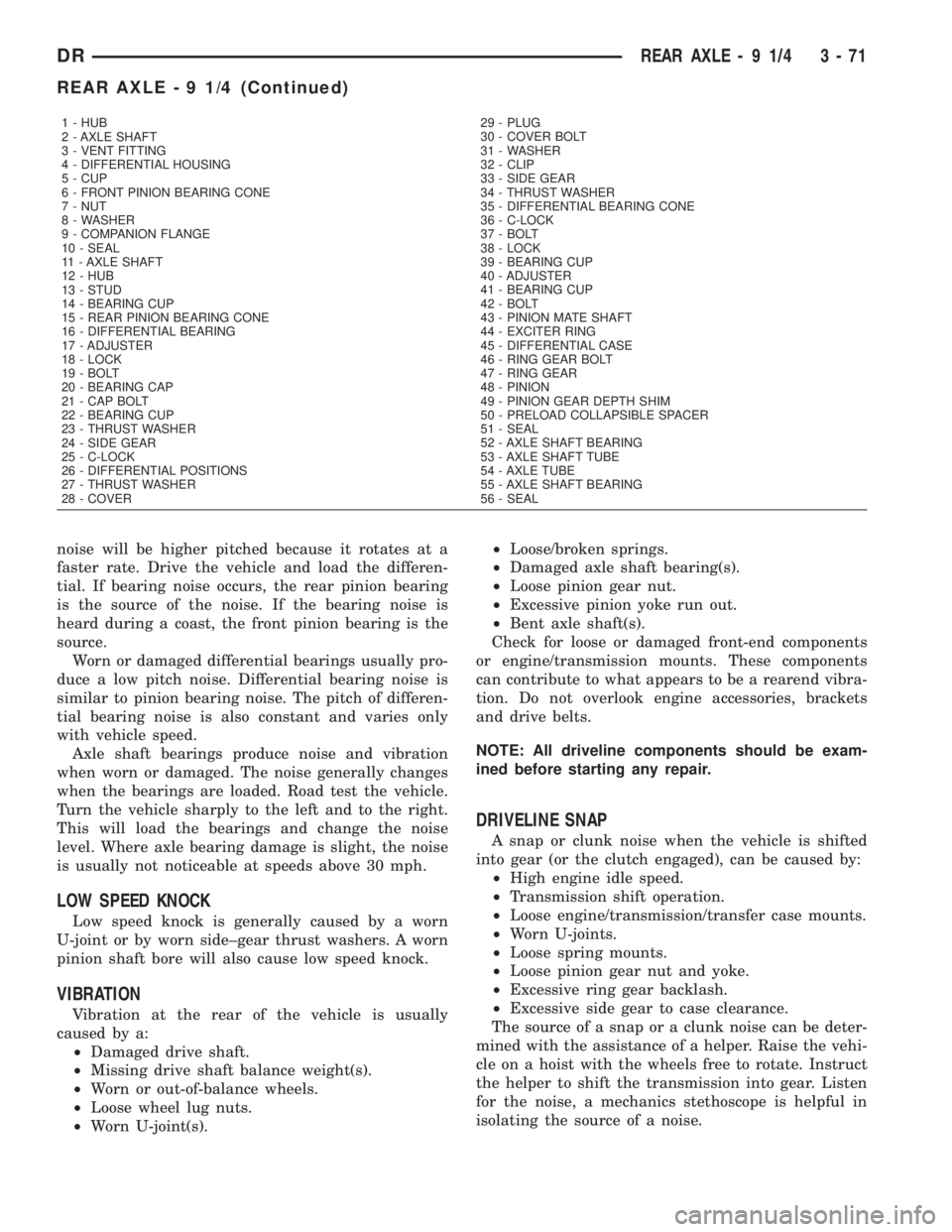

REAR AXLE-91/4

TABLE OF CONTENTS

page page

REAR AXLE-91/4

DESCRIPTION.........................69

OPERATION...........................69

DIAGNOSIS AND TESTING................69

REMOVAL.............................74

INSTALLATION.........................74

ADJUSTMENTS........................74

SPECIFICATIONS.......................79

SPECIAL TOOLS.......................80

AXLE SHAFTS

REMOVAL.............................83

INSTALLATION.........................83

AXLE SHAFT SEALS

REMOVAL.............................84

INSTALLATION.........................84

AXLE BEARINGS

REMOVAL.............................84

INSTALLATION.........................84

PINION SEAL

REMOVAL.............................85INSTALLATION.........................85

DIFFERENTIAL

DESCRIPTION.........................86

OPERATION...........................86

REMOVAL.............................86

DISASSEMBLY.........................88

ASSEMBLY............................88

INSTALLATION.........................88

DIFFERENTIAL-TRAC-LOK

DESCRIPTION.........................89

OPERATION...........................89

DIAGNOSIS AND TESTING................89

DISASSEMBLY.........................90

ASSEMBLY............................92

DIFFERENTIAL CASE BEARINGS

REMOVAL.............................93

INSTALLATION.........................94

PINION GEAR/RING GEAR/TONE RING

REMOVAL.............................94

INSTALLATION.........................96

REAR AXLE-91/4

DESCRIPTION

The axle consist of a cast iron center section with

axle tubes extending from either side. The tubes are

pressed into and welded to the differential housing to

form a one-piece axle housing (Fig. 1). The axles are

equipped with semi-floating axle shafts, meaning

vehicle loads are supported by the axle shaft and

bearings. The axle shafts are retained by C-locks in

the differential side gears.

OPERATION

The axle receives power from the propeller shaft.

The propeller shaft is connected to the pinion gear

which rotates the differential through the gear mesh

with the ring gear bolted to the differential case. The

engine power is transmitted to the axle shafts

through the pinion mate and side gears. The side

gears are splined to the axle shafts.

DIAGNOSIS AND TESTING

GEAR NOISE

Axle gear noise can be caused by insufficient lubri-

cant, incorrect backlash, incorrect pinion depth, toothcontact, worn/damaged gears, or the carrier housing

not having the proper offset and squareness.

Gear noise usually happens at a specific speed

range. The noise can also occur during a specific type

of driving condition. These conditions are accelera-

tion, deceleration, coast, or constant load.

When road testing, first warm-up the axle fluid by

driving the vehicle at least 5 miles and then acceler-

ate the vehicle to the speed range where the noise is

the greatest. Shift out-of-gear and coast through the

peak-noise range. If the noise stops or changes

greatly:

²Check for insufficient lubricant.

²Incorrect ring gear backlash.

²Gear damage.

Differential side gears and pinions can be checked

by turning the vehicle. They usually do not cause

noise during straight-ahead driving when the gears

are unloaded. The side gears are loaded during vehi-

cle turns. A worn pinion shaft can also cause a snap-

ping or a knocking noise.

BEARING NOISE

The axle shaft, differential and pinion bearings can

all produce noise when worn or damaged. Bearing

noise can be either a whining, or a growling sound.

Pinion bearings have a constant-pitch noise. This

noise changes only with vehicle speed. Pinion bearing

DRREAR AXLE - 9 1/4 3 - 69

Page 144 of 2895

noise will be higher pitched because it rotates at a

faster rate. Drive the vehicle and load the differen-

tial. If bearing noise occurs, the rear pinion bearing

is the source of the noise. If the bearing noise is

heard during a coast, the front pinion bearing is the

source.

Worn or damaged differential bearings usually pro-

duce a low pitch noise. Differential bearing noise is

similar to pinion bearing noise. The pitch of differen-

tial bearing noise is also constant and varies only

with vehicle speed.

Axle shaft bearings produce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by a worn

U-joint or by worn side±gear thrust washers. A worn

pinion shaft bore will also cause low speed knock.

VIBRATION

Vibration at the rear of the vehicle is usually

caused by a:

²Damaged drive shaft.

²Missing drive shaft balance weight(s).

²Worn or out-of-balance wheels.

²Loose wheel lug nuts.

²Worn U-joint(s).²Loose/broken springs.

²Damaged axle shaft bearing(s).

²Loose pinion gear nut.

²Excessive pinion yoke run out.

²Bent axle shaft(s).

Check for loose or damaged front-end components

or engine/transmission mounts. These components

can contribute to what appears to be a rearend vibra-

tion. Do not overlook engine accessories, brackets

and drive belts.

NOTE: All driveline components should be exam-

ined before starting any repair.

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged), can be caused by:

²High engine idle speed.

²Transmission shift operation.

²Loose engine/transmission/transfer case mounts.

²Worn U-joints.

²Loose spring mounts.

²Loose pinion gear nut and yoke.

²Excessive ring gear backlash.

²Excessive side gear to case clearance.

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the vehi-

cle on a hoist with the wheels free to rotate. Instruct

the helper to shift the transmission into gear. Listen

for the noise, a mechanics stethoscope is helpful in

isolating the source of a noise.

1 - HUB

2 - AXLE SHAFT

3 - VENT FITTING

4 - DIFFERENTIAL HOUSING

5 - CUP

6 - FRONT PINION BEARING CONE

7 - NUT

8 - WASHER

9 - COMPANION FLANGE

10 - SEAL

11 - AXLE SHAFT

12 - HUB

13 - STUD

14 - BEARING CUP

15 - REAR PINION BEARING CONE

16 - DIFFERENTIAL BEARING

17 - ADJUSTER

18 - LOCK

19 - BOLT

20 - BEARING CAP

21 - CAP BOLT

22 - BEARING CUP

23 - THRUST WASHER

24 - SIDE GEAR

25 - C-LOCK

26 - DIFFERENTIAL POSITIONS

27 - THRUST WASHER

28 - COVER29 - PLUG

30 - COVER BOLT

31 - WASHER

32 - CLIP

33 - SIDE GEAR

34 - THRUST WASHER

35 - DIFFERENTIAL BEARING CONE

36 - C-LOCK

37 - BOLT

38 - LOCK

39 - BEARING CUP

40 - ADJUSTER

41 - BEARING CUP

42 - BOLT

43 - PINION MATE SHAFT

44 - EXCITER RING

45 - DIFFERENTIAL CASE

46 - RING GEAR BOLT

47 - RING GEAR

48 - PINION

49 - PINION GEAR DEPTH SHIM

50 - PRELOAD COLLAPSIBLE SPACER

51 - SEAL

52 - AXLE SHAFT BEARING

53 - AXLE SHAFT TUBE

54 - AXLE TUBE

55 - AXLE SHAFT BEARING

56 - SEAL

DRREAR AXLE - 9 1/4 3 - 71

REAR AXLE - 9 1/4 (Continued)

Page 145 of 2895

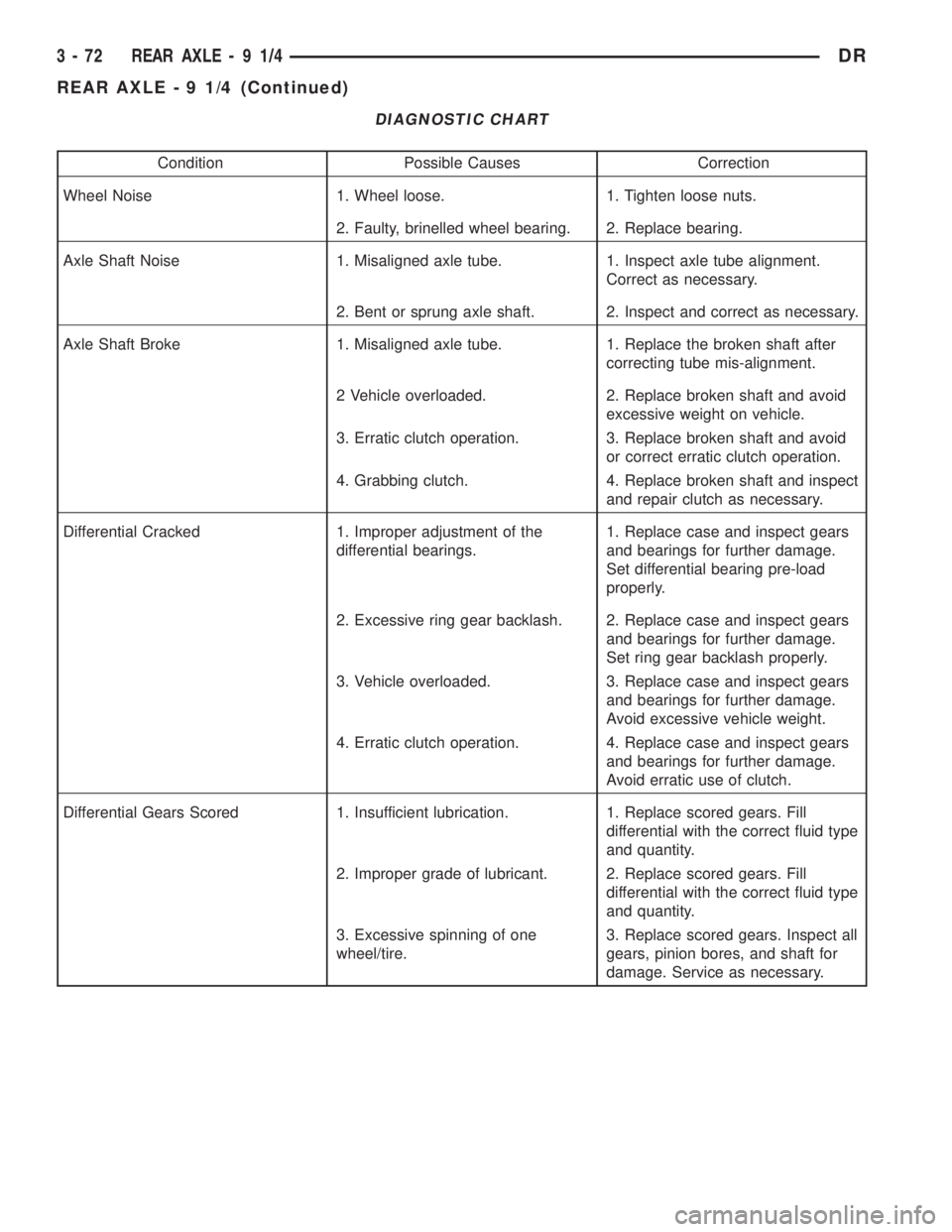

DIAGNOSTIC CHART

Condition Possible Causes Correction

Wheel Noise 1. Wheel loose. 1. Tighten loose nuts.

2. Faulty, brinelled wheel bearing. 2. Replace bearing.

Axle Shaft Noise 1. Misaligned axle tube. 1. Inspect axle tube alignment.

Correct as necessary.

2. Bent or sprung axle shaft. 2. Inspect and correct as necessary.

Axle Shaft Broke 1. Misaligned axle tube. 1. Replace the broken shaft after

correcting tube mis-alignment.

2 Vehicle overloaded. 2. Replace broken shaft and avoid

excessive weight on vehicle.

3. Erratic clutch operation. 3. Replace broken shaft and avoid

or correct erratic clutch operation.

4. Grabbing clutch. 4. Replace broken shaft and inspect

and repair clutch as necessary.

Differential Cracked 1. Improper adjustment of the

differential bearings.1. Replace case and inspect gears

and bearings for further damage.

Set differential bearing pre-load

properly.

2. Excessive ring gear backlash. 2. Replace case and inspect gears

and bearings for further damage.

Set ring gear backlash properly.

3. Vehicle overloaded. 3. Replace case and inspect gears

and bearings for further damage.

Avoid excessive vehicle weight.

4. Erratic clutch operation. 4. Replace case and inspect gears

and bearings for further damage.

Avoid erratic use of clutch.

Differential Gears Scored 1. Insufficient lubrication. 1. Replace scored gears. Fill

differential with the correct fluid type

and quantity.

2. Improper grade of lubricant. 2. Replace scored gears. Fill

differential with the correct fluid type

and quantity.

3. Excessive spinning of one

wheel/tire.3. Replace scored gears. Inspect all

gears, pinion bores, and shaft for

damage. Service as necessary.

3 - 72 REAR AXLE-91/4DR

REAR AXLE - 9 1/4 (Continued)

Page 146 of 2895

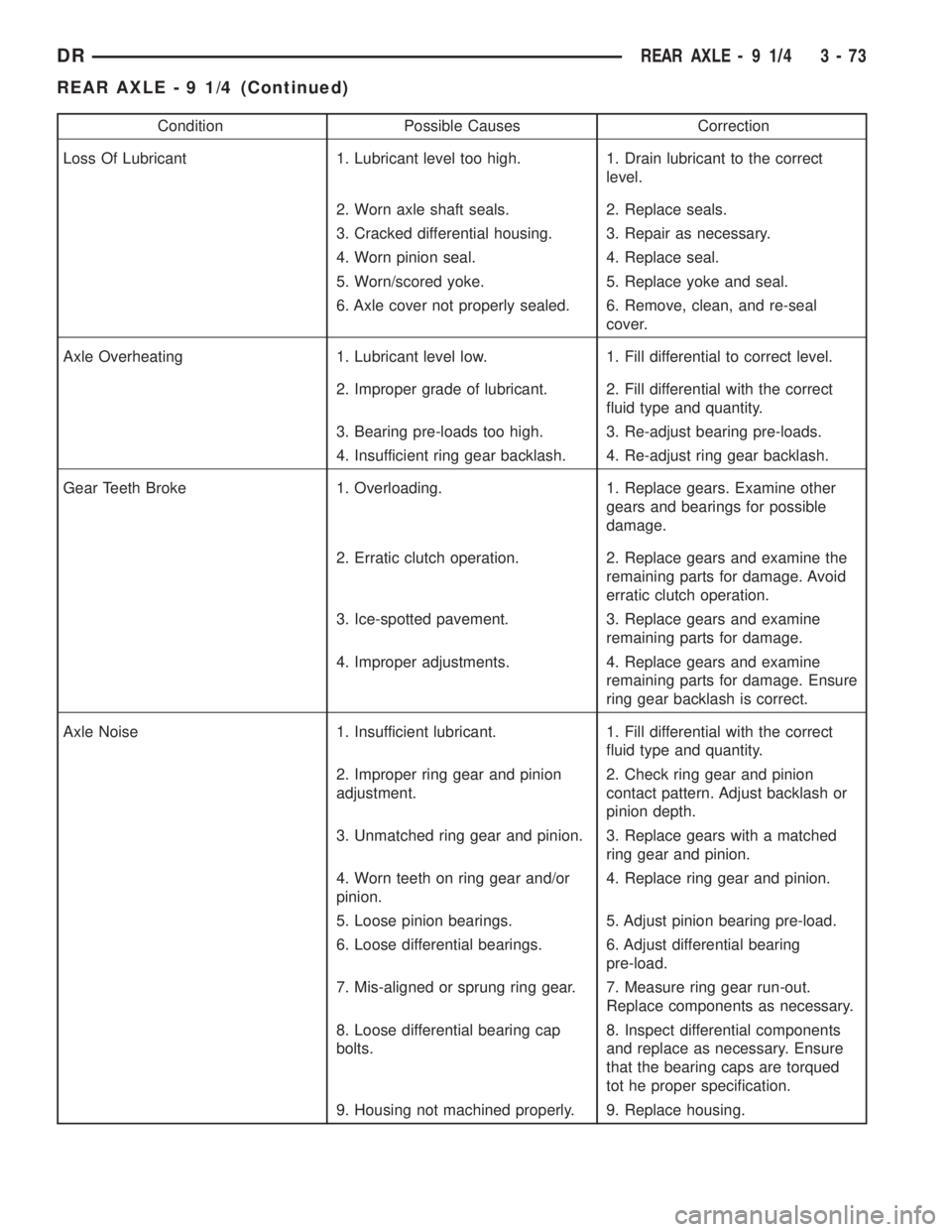

Condition Possible Causes Correction

Loss Of Lubricant 1. Lubricant level too high. 1. Drain lubricant to the correct

level.

2. Worn axle shaft seals. 2. Replace seals.

3. Cracked differential housing. 3. Repair as necessary.

4. Worn pinion seal. 4. Replace seal.

5. Worn/scored yoke. 5. Replace yoke and seal.

6. Axle cover not properly sealed. 6. Remove, clean, and re-seal

cover.

Axle Overheating 1. Lubricant level low. 1. Fill differential to correct level.

2. Improper grade of lubricant. 2. Fill differential with the correct

fluid type and quantity.

3. Bearing pre-loads too high. 3. Re-adjust bearing pre-loads.

4. Insufficient ring gear backlash. 4. Re-adjust ring gear backlash.

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern. Adjust backlash or

pinion depth.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

DRREAR AXLE - 9 1/4 3 - 73

REAR AXLE - 9 1/4 (Continued)

Page 147 of 2895

REMOVAL

(1) Raise and support the vehicle.

(2) Position a lifting device under the axle.

(3) Secure axle to device.

(4) Remove wheels and tires assemblies.

(5) Remove RWAL sensor from the differential

housing.

(6) Remove brake hose at the axle junction block.

(7) Disconnect parking brake cables and cable

brackets.

(8) Remove brake calipers and rotors.

(9) Remove axle vent hose.

(10) Mark propeller shaft and companion flange

for installation alignment reference.

(11) Remove propeller shaft.

(12) Remove shock absorbers from axle.

(13) Remove U-bolets from axle.

(14) Separate the axle from the vehicle.

INSTALLATION

(1) Raise axle with lifting device and align to the

leaf spring centering bolts.

(2) Install axle U-bolts and tighten to 149 N´m

(110 ft. lbs.).

(3) Install shock absorbers to axle and tighten to

specification.

(4) Install the RWAL sensor to the differential

housing.

(5) Connect the parking brake cables and cable

brackets.

(6) Install brake rotors and calipers.

(7) Connect brake hose to the axle junction block.

(8) Install axle vent hose.

(9) Align propeller shaft and pinion companion

flange reference marks and tighten companion flange

bolts to 115 N´m (85 ft. lbs.).

(10) Install the wheels and tires.

(11) Fill differential to specifications.

(12) Remove lifting device from axle and lower the

vehicle.

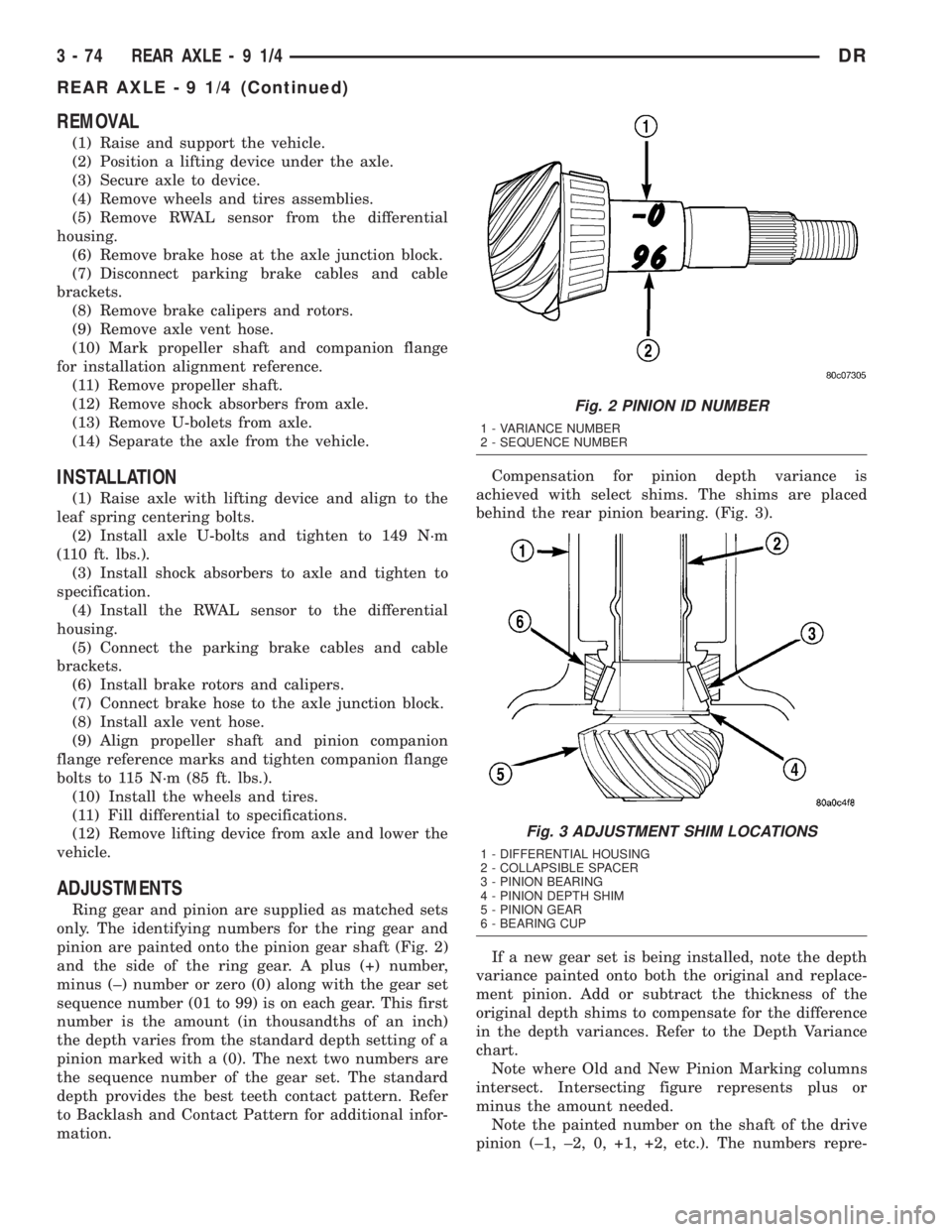

ADJUSTMENTS

Ring gear and pinion are supplied as matched sets

only. The identifying numbers for the ring gear and

pinion are painted onto the pinion gear shaft (Fig. 2)

and the side of the ring gear. A plus (+) number,

minus (±) number or zero (0) along with the gear set

sequence number (01 to 99) is on each gear. This first

number is the amount (in thousandths of an inch)

the depth varies from the standard depth setting of a

pinion marked with a (0). The next two numbers are

the sequence number of the gear set. The standard

depth provides the best teeth contact pattern. Refer

to Backlash and Contact Pattern for additional infor-

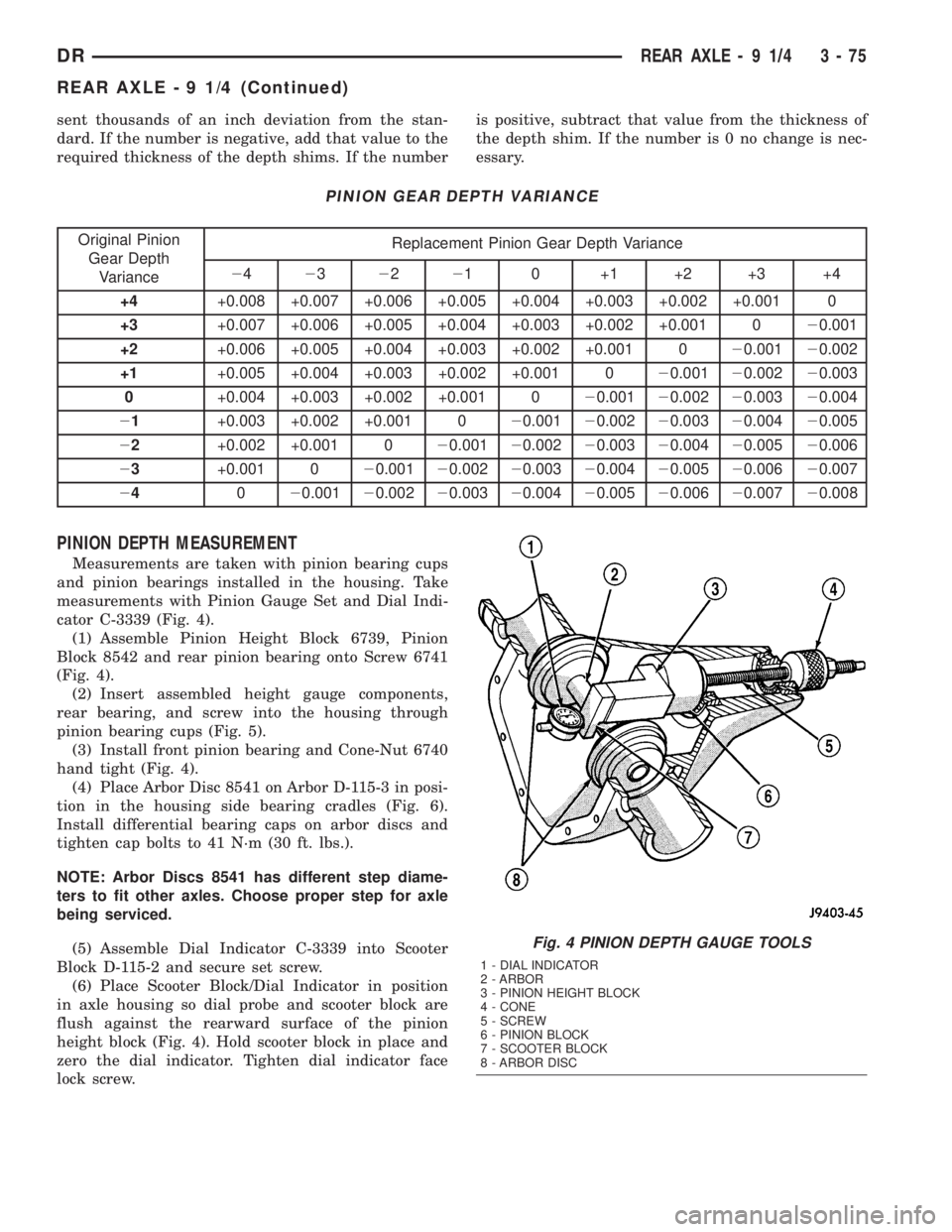

mation.Compensation for pinion depth variance is

achieved with select shims. The shims are placed

behind the rear pinion bearing. (Fig. 3).

If a new gear set is being installed, note the depth

variance painted onto both the original and replace-

ment pinion. Add or subtract the thickness of the

original depth shims to compensate for the difference

in the depth variances. Refer to the Depth Variance

chart.

Note where Old and New Pinion Marking columns

intersect. Intersecting figure represents plus or

minus the amount needed.

Note the painted number on the shaft of the drive

pinion (±1, ±2, 0, +1, +2, etc.). The numbers repre-

Fig. 2 PINION ID NUMBER

1 - VARIANCE NUMBER

2 - SEQUENCE NUMBER

Fig. 3 ADJUSTMENT SHIM LOCATIONS

1 - DIFFERENTIAL HOUSING

2 - COLLAPSIBLE SPACER

3 - PINION BEARING

4 - PINION DEPTH SHIM

5 - PINION GEAR

6 - BEARING CUP

3 - 74 REAR AXLE-91/4DR

REAR AXLE - 9 1/4 (Continued)

Page 148 of 2895

sent thousands of an inch deviation from the stan-

dard. If the number is negative, add that value to the

required thickness of the depth shims. If the numberis positive, subtract that value from the thickness of

the depth shim. If the number is 0 no change is nec-

essary.

PINION GEAR DEPTH VARIANCE

Original Pinion

Gear Depth

VarianceReplacement Pinion Gear Depth Variance

24232221 0 +1 +2 +3 +4

+4+0.008 +0.007 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 0

+3+0.007 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 020.001

+2+0.006 +0.005 +0.004 +0.003 +0.002 +0.001 020.00120.002

+1+0.005 +0.004 +0.003 +0.002 +0.001 020.00120.00220.003

0+0.004 +0.003 +0.002 +0.001 020.00120.00220.00320.004

21+0.003 +0.002 +0.001 020.00120.00220.00320.00420.005

22+0.002 +0.001 020.00120.00220.00320.00420.00520.006

23+0.001 020.00120.00220.00320.00420.00520.00620.007

24020.00120.00220.00320.00420.00520.00620.00720.008

PINION DEPTH MEASUREMENT

Measurements are taken with pinion bearing cups

and pinion bearings installed in the housing. Take

measurements with Pinion Gauge Set and Dial Indi-

cator C-3339 (Fig. 4).

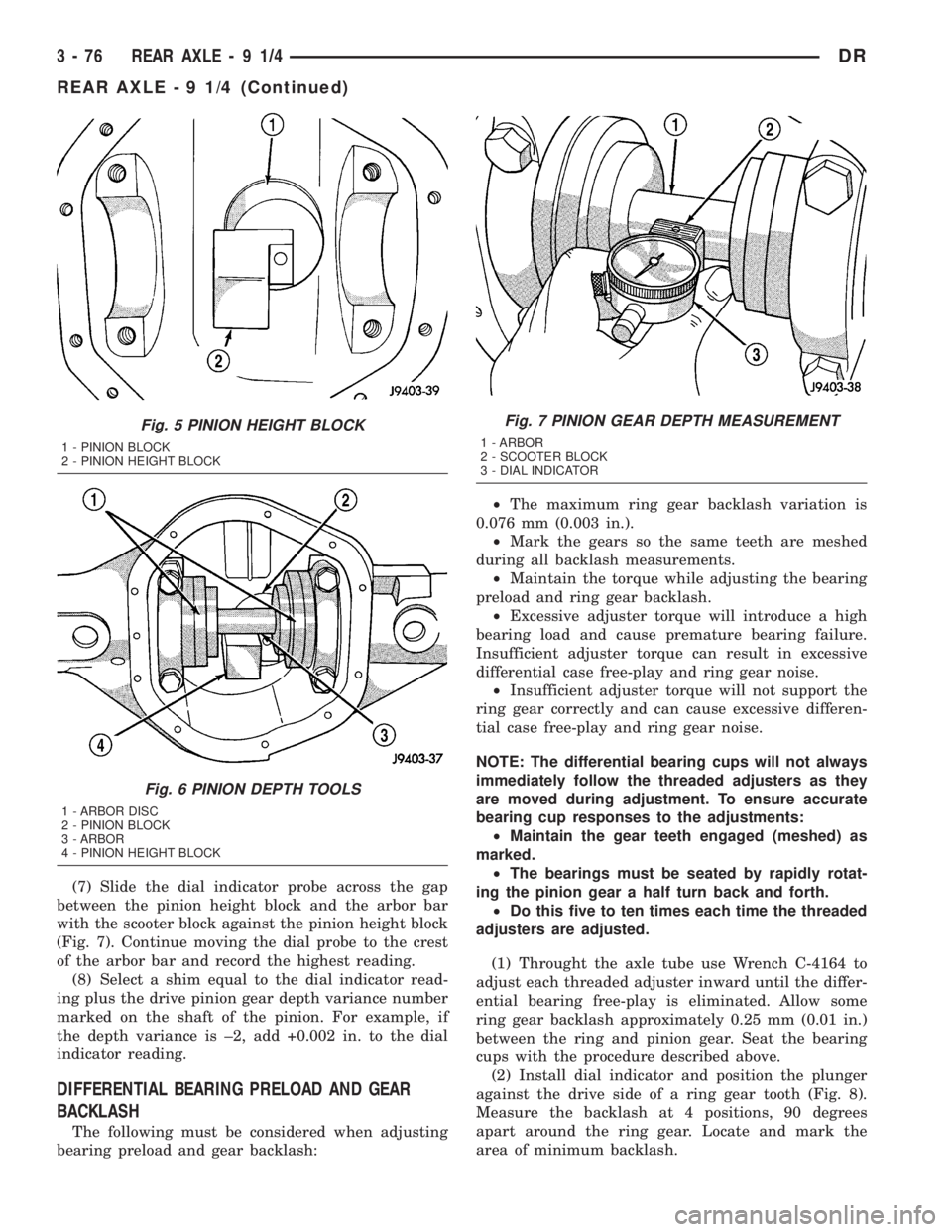

(1) Assemble Pinion Height Block 6739, Pinion

Block 8542 and rear pinion bearing onto Screw 6741

(Fig. 4).

(2) Insert assembled height gauge components,

rear bearing, and screw into the housing through

pinion bearing cups (Fig. 5).

(3) Install front pinion bearing and Cone-Nut 6740

hand tight (Fig. 4).

(4) Place Arbor Disc 8541 on Arbor D-115-3 in posi-

tion in the housing side bearing cradles (Fig. 6).

Install differential bearing caps on arbor discs and

tighten cap bolts to 41 N´m (30 ft. lbs.).

NOTE: Arbor Discs 8541 has different step diame-

ters to fit other axles. Choose proper step for axle

being serviced.

(5) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.

(6) Place Scooter Block/Dial Indicator in position

in axle housing so dial probe and scooter block are

flush against the rearward surface of the pinion

height block (Fig. 4). Hold scooter block in place and

zero the dial indicator. Tighten dial indicator face

lock screw.

Fig. 4 PINION DEPTH GAUGE TOOLS

1 - DIAL INDICATOR

2 - ARBOR

3 - PINION HEIGHT BLOCK

4 - CONE

5 - SCREW

6 - PINION BLOCK

7 - SCOOTER BLOCK

8 - ARBOR DISC

DRREAR AXLE - 9 1/4 3 - 75

REAR AXLE - 9 1/4 (Continued)

Page 149 of 2895

(7) Slide the dial indicator probe across the gap

between the pinion height block and the arbor bar

with the scooter block against the pinion height block

(Fig. 7). Continue moving the dial probe to the crest

of the arbor bar and record the highest reading.

(8) Select a shim equal to the dial indicator read-

ing plus the drive pinion gear depth variance number

marked on the shaft of the pinion. For example, if

the depth variance is ±2, add +0.002 in. to the dial

indicator reading.

DIFFERENTIAL BEARING PRELOAD AND GEAR

BACKLASH

The following must be considered when adjusting

bearing preload and gear backlash:²The maximum ring gear backlash variation is

0.076 mm (0.003 in.).

²Mark the gears so the same teeth are meshed

during all backlash measurements.

²Maintain the torque while adjusting the bearing

preload and ring gear backlash.

²Excessive adjuster torque will introduce a high

bearing load and cause premature bearing failure.

Insufficient adjuster torque can result in excessive

differential case free-play and ring gear noise.

²Insufficient adjuster torque will not support the

ring gear correctly and can cause excessive differen-

tial case free-play and ring gear noise.

NOTE: The differential bearing cups will not always

immediately follow the threaded adjusters as they

are moved during adjustment. To ensure accurate

bearing cup responses to the adjustments:

²Maintain the gear teeth engaged (meshed) as

marked.

²The bearings must be seated by rapidly rotat-

ing the pinion gear a half turn back and forth.

²Do this five to ten times each time the threaded

adjusters are adjusted.

(1) Throught the axle tube use Wrench C-4164 to

adjust each threaded adjuster inward until the differ-

ential bearing free-play is eliminated. Allow some

ring gear backlash approximately 0.25 mm (0.01 in.)

between the ring and pinion gear. Seat the bearing

cups with the procedure described above.

(2) Install dial indicator and position the plunger

against the drive side of a ring gear tooth (Fig. 8).

Measure the backlash at 4 positions, 90 degrees

apart around the ring gear. Locate and mark the

area of minimum backlash.

Fig. 5 PINION HEIGHT BLOCK

1 - PINION BLOCK

2 - PINION HEIGHT BLOCK

Fig. 6 PINION DEPTH TOOLS

1 - ARBOR DISC

2 - PINION BLOCK

3 - ARBOR

4 - PINION HEIGHT BLOCK

Fig. 7 PINION GEAR DEPTH MEASUREMENT

1 - ARBOR

2 - SCOOTER BLOCK

3 - DIAL INDICATOR

3 - 76 REAR AXLE-91/4DR

REAR AXLE - 9 1/4 (Continued)

Page 150 of 2895

(3) Rotate the ring gear to the position of the least

backlash. Mark the gear so that all future backlash

measurements will be taken with the same gear

teeth meshed.

(4) Loosen the right-side, tighten the left-side

threaded adjuster. Obtain backlash of 0.076 to 0.102

mm (0.003-0.004 in.) with each adjuster tightened to

14 N´m (10 ft. lbs.). Seat the bearing cups with the

procedure described above.

(5) Tighten the differential bearing cap bolts 136

N´m (100 ft. lbs.).

(6) Tighten the right-side threaded adjuster to 102

N´m (75 ft. lbs.). Seat the bearing cups with the pro-

cedure described above. Continue to tighten the

right-side adjuster and seat bearing cups until the

torque remains constant at 102 N´m (75 ft. lbs.)

(7) Measure the ring gear backlash. The range of

backlash is 0.15 to 0.203 mm (0.006 to 0.008 in.).

(8) Continue increasing the torque at the right-

side threaded adjuster until the specified backlash is

obtained.

NOTE: The left-side threaded adjuster torque

should have approximately 102 N´m (75 ft. lbs.). If

the torque is considerably less, the complete

adjustment procedure must be repeated.

(9) Tighten the left-side threaded adjuster until

102 N´m (75 ft. lbs.) torque is indicated. Seat the

bearing rollers with the procedure described above.

Do this until the torque remains constant.

(10) Install the threaded adjuster locks and

tighten the lock screws to 10 N´m (90 in. lbs.).GEAR CONTACT PATTERN

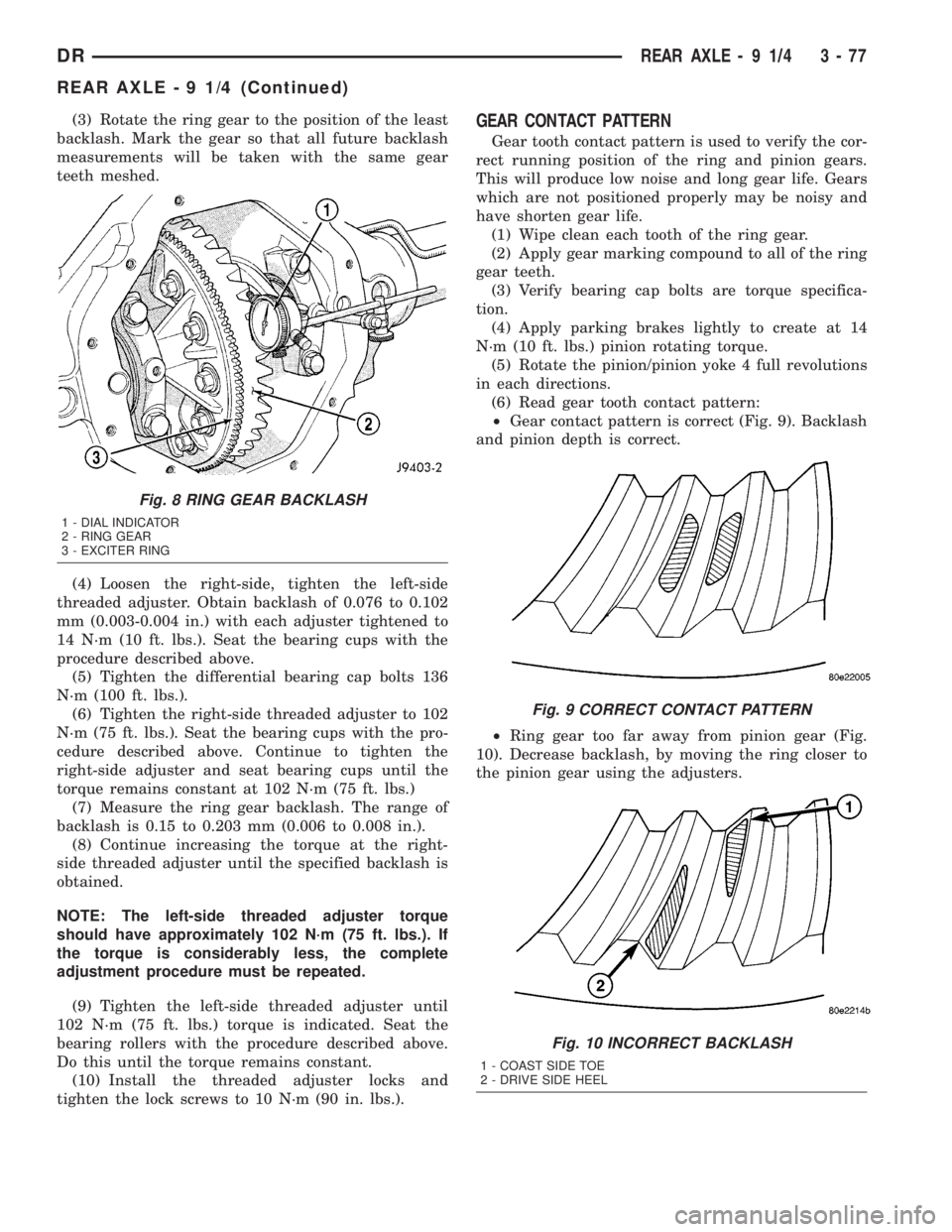

Gear tooth contact pattern is used to verify the cor-

rect running position of the ring and pinion gears.

This will produce low noise and long gear life. Gears

which are not positioned properly may be noisy and

have shorten gear life.

(1) Wipe clean each tooth of the ring gear.

(2) Apply gear marking compound to all of the ring

gear teeth.

(3) Verify bearing cap bolts are torque specifica-

tion.

(4) Apply parking brakes lightly to create at 14

N´m (10 ft. lbs.) pinion rotating torque.

(5) Rotate the pinion/pinion yoke 4 full revolutions

in each directions.

(6) Read gear tooth contact pattern:

²Gear contact pattern is correct (Fig. 9). Backlash

and pinion depth is correct.

²Ring gear too far away from pinion gear (Fig.

10). Decrease backlash, by moving the ring closer to

the pinion gear using the adjusters.

Fig. 8 RING GEAR BACKLASH

1 - DIAL INDICATOR

2 - RING GEAR

3 - EXCITER RING

Fig. 9 CORRECT CONTACT PATTERN

Fig. 10 INCORRECT BACKLASH

1 - COAST SIDE TOE

2 - DRIVE SIDE HEEL

DRREAR AXLE - 9 1/4 3 - 77

REAR AXLE - 9 1/4 (Continued)