maintenance DODGE RAM 2003 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2572 of 2895

center caps for more information refer to Owner's

Manual.

The tires on both wheels must be completely raised

off the ground when tightening the lug nuts. This

will ensure correct wheel centering and maximum

wheel clamping.

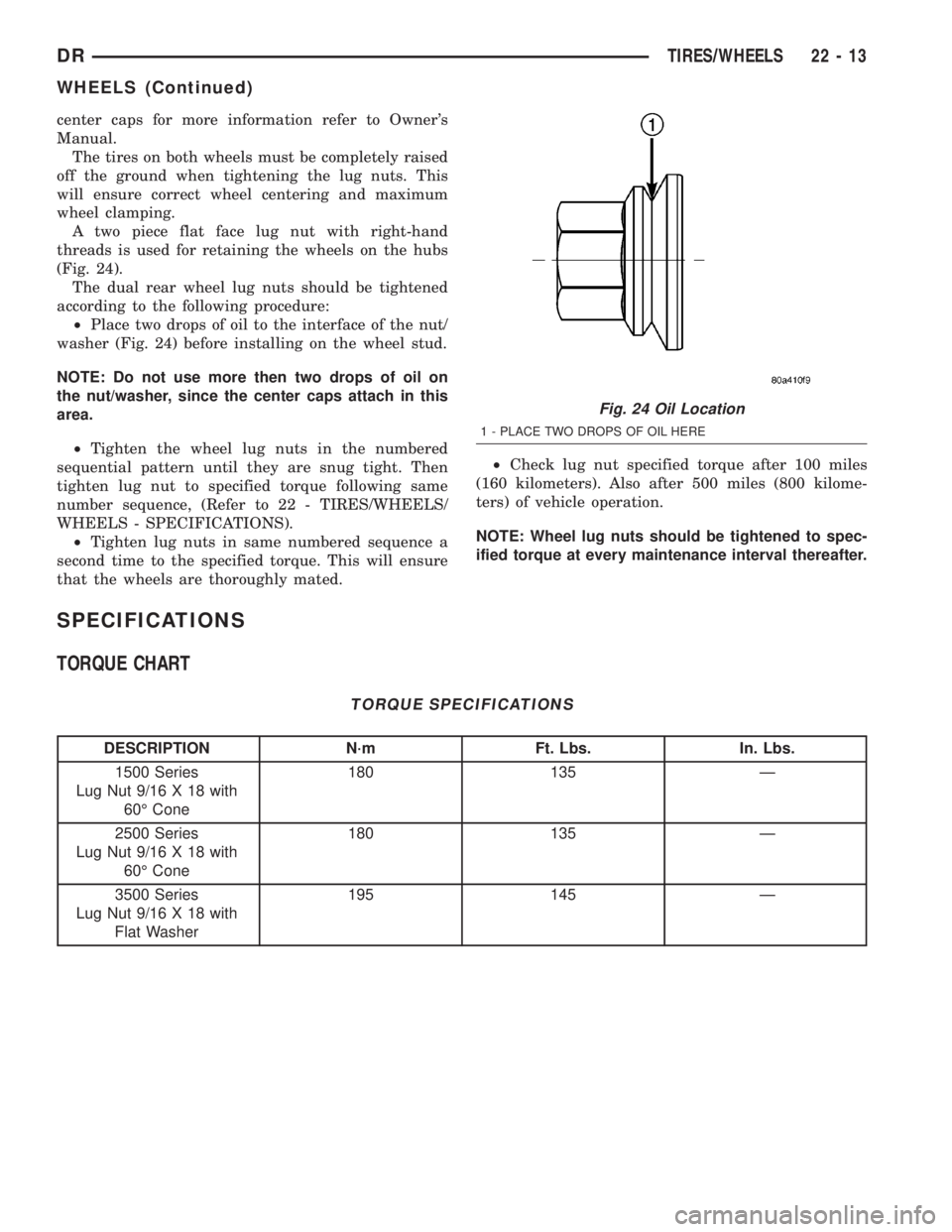

A two piece flat face lug nut with right-hand

threads is used for retaining the wheels on the hubs

(Fig. 24).

The dual rear wheel lug nuts should be tightened

according to the following procedure:

²Place two drops of oil to the interface of the nut/

washer (Fig. 24) before installing on the wheel stud.

NOTE: Do not use more then two drops of oil on

the nut/washer, since the center caps attach in this

area.

²Tighten the wheel lug nuts in the numbered

sequential pattern until they are snug tight. Then

tighten lug nut to specified torque following same

number sequence, (Refer to 22 - TIRES/WHEELS/

WHEELS - SPECIFICATIONS).

²Tighten lug nuts in same numbered sequence a

second time to the specified torque. This will ensure

that the wheels are thoroughly mated.²Check lug nut specified torque after 100 miles

(160 kilometers). Also after 500 miles (800 kilome-

ters) of vehicle operation.

NOTE: Wheel lug nuts should be tightened to spec-

ified torque at every maintenance interval thereafter.

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

1500 Series

Lug Nut 9/16 X 18 with

60É Cone180 135 Ð

2500 Series

Lug Nut 9/16 X 18 with

60É Cone180 135 Ð

3500 Series

Lug Nut 9/16 X 18 with

Flat Washer195 145 Ð

Fig. 24 Oil Location

1 - PLACE TWO DROPS OF OIL HERE

DRTIRES/WHEELS 22 - 13

WHEELS (Continued)

Page 2577 of 2895

VISUAL INSPECTION BEFORE WATER LEAK TESTS

Verify that floor and body plugs are in place, body

drains are clear, and body components are properly

aligned and sealed. If component alignment or seal-

ing is necessary, refer to the appropriate section of

this group for proper procedures.

WATER LEAK TESTS

WARNING: DO NOT USE ELECTRIC SHOP LIGHTS

OR TOOLS IN WATER TEST AREA. PERSONAL

INJURY CAN RESULT.

When the conditions causing a water leak have

been determined, simulate the conditions as closely

as possible.

²If a leak occurs with the vehicle parked in a

steady light rain, flood the leak area with an open-

ended garden hose.

²If a leak occurs while driving at highway speeds

in a steady rain, test the leak area with a reasonable

velocity stream or fan spray of water. Direct the

spray in a direction comparable to actual conditions.

²If a leak occurs when the vehicle is parked on an

incline, hoist the end or side of the vehicle to simu-

late this condition. This method can be used when

the leak occurs when the vehicle accelerates, stops or

turns. If the leak occurs on acceleration, hoist the

front of the vehicle. If the leak occurs when braking,

hoist the back of the vehicle. If the leak occurs on left

turns, hoist the left side of the vehicle. If the leak

occurs on right turns, hoist the right side of the vehi-

cle. For hoisting recommendations (Refer to LUBRI-

CATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE).

WATER LEAK DETECTION

To detect a water leak point-of-entry, do a water

test and watch for water tracks or droplets forming

on the inside of the vehicle. If necessary, remove inte-

rior trim covers or panels to gain visual access to the

leak area. If the hose cannot be positioned without

being held, have someone help do the water test.

Some water leaks must be tested for a considerable

length of time to become apparent. When a leak

appears, find the highest point of the water track or

drop. The highest point usually will show the point of

entry. After leak point has been found, repair the

leak and water test to verify that the leak has

stopped.

Locating the entry point of water that is leaking

into a cavity between panels can be difficult. The

trapped water may splash or run from the cavity,

often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on an incline.MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use

a suitable mirror to gain visual access. A mirror can

also be used to deflect light to a limited-access area

to assist in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can

be detected without water testing. Position the vehi-

cle in a brightly lit area. From inside the darkened

luggage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop light

over the suspected leak areas around the luggage

compartment. If light is visible through a normally

sealed location, water could enter through the open-

ing.

PRESSURIZED LEAK TEST METHOD

When a water leak into the passenger compart-

ment cannot be detected by water testing, pressurize

the passenger compartment and soap test exterior of

the vehicle. To pressurize the passenger compart-

ment, close all doors and windows, start engine, and

set heater control to high blower in HEAT position. If

engine can not be started, connect a charger to the

battery to ensure adequate voltage to the blower.

With interior pressurized, apply dish detergent solu-

tion to suspected leak area on the exterior of the

vehicle. Apply detergent solution with spray device or

soft bristle brush. If soap bubbles occur at a body

seam, joint, seal or gasket, the leak entry point could

be at that location.

DIAGNOSIS AND TESTING - WIND NOISE

Wind noise is the result of most air leaks. Air leaks

can be caused by poor sealing, improper body compo-

nent alignment, body seam porosity, or missing plugs

in the engine compartment or door hinge pillar areas.

All body sealing points should be airtight in normal

driving conditions. Moving sealing surfaces will not

always seal airtight under all conditions. At times,

side glass or door seals will allow wind noise to be

noticed in the passenger compartment during high

cross winds. Over compensating on door or glass

adjustments to stop wind noise that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After a repair pro-

cedure has been performed, test vehicle to verify

noise has stopped before returning vehicle to use.

VISUAL INSPECTION BEFORE TESTS

Verify that floor and body plugs are in place and

body components are aligned and sealed. If compo-

nent alignment or sealing is necessary, refer to the

appropriate section of this group for proper proce-

dures.

23 - 2 BODYDR

BODY (Continued)

Page 2851 of 2895

tabs, valve must be pointed downward for

removal. Do not force valve from oil filler tube.

(3) After valve is removed, check condition of valve

o-ring (Fig. 25).

5.7L V-8

The PCV valve is mounted into the top of the

intake manifold, located to the right / rear of the

throttle body (Fig. 12). The PCV valve is sealed to

the intake manifold with 2 o-rings (Fig. 13).

(1) Remove PCV valve by rotating counter-clock-

wise 90 degrees until locating tabs have been freed.

After tabs have cleared, pull valve straight up from

intake manifold.

(2) After valve is removed, check condition of 2

valve o-rings.

INSTALLATION

3.7L V6 / 4.7L V-8

The PCV valve is located on the oil filler tube. Two

locating tabs are located on the side of the valve.

These 2 tabs fit into a cam lock in the oil filler tube.

An o-ring seals the valve to the filler tube.

(1) Return PCV valve back to oil filler tube by

placing valve locating tabs into cam lock. Press PCV

valve in and rotate valve upward. A slight click will

be felt when tabs have engaged cam lock. Valve

should be pointed towards rear of vehicle.

(2) Connect PCV line/hose and rubber hose to PCV

valve.

5.7L V-8

(1) Clean out intake manifold opening.

(2) Check condition of 2 o-rings on PCV valve.

(3) Apply engine oil to 2 o-rings.

(4) Place PCV valve into intake manifold and

rotate 90 degrees clockwise for installation.

VACUUM LINES

DESCRIPTION

A vacuum schematic for emission related items can

be found on the vehicles VECI label. Refer to Vehicle

Emission Control Information (VECI) Label for label

location.

VAPOR CANISTER

DESCRIPTION

Two, maintenance free, EVAP canisters are used.

Both canisters are mounted into a two-piece support

bracket located near the front of the fuel tank (Fig.

26).

OPERATION

Two, maintenance free, EVAP canisters are

used.The EVAP canisters are filled with granules of

an activated carbon mixture. Fuel vapors entering

the EVAP canisters are absorbed by the charcoal

granules.

Fuel tank pressure vents into the EVAP canisters.

Fuel vapors are temporarily held in the canisters

until they can be drawn into the intake manifold.

The duty cycle EVAP canister purge solenoid allows

the EVAP canisters to be purged at predetermined

times and at certain engine operating conditions.

REMOVAL

Two, maintenance free, EVAP canisters are used.

Both canisters are mounted into a two-piece support

bracket located near the front of the fuel tank (Fig.

26).

(1) Raise and support vehicle.

(2) Remove fuel tubes/lines at each EVAP canister.

Note location of tubes/lines before removal for easier

installation.

(3) Remove lower support bracket (Fig. 27).

(4) Remove mounting nuts at top of each canister

(Fig. 27).

Fig. 26 LOCATION, EVAP CANISTERS

1 - LDP

2 - LDP MOUNTING BOLT

3 - ELEC. CONNEC.

4 - FILTER MOUNTING BOLT

5 - LDP FILTER

6 - CONNECTING HOSE

7 - EVAP CANISTER MOUNTING BRACKET

8 - EVAP CANISTERS (2)

25 - 22 EVAPORATIVE EMISSIONSDR

PCV VALVE (Continued)

Page 2875 of 2895

LEVEL - STANDARD PROCEDURE,

REFRIGERANT OIL...................24-54

LEVEL CHECK - STANDARD

PROCEDURE, COOLANT................7-17

LEVEL CHECK - STANDARD

PROCEDURE, FLUID.....21-201,21-381,21-542

LEVEL CHECKING - STANDARD

PROCEDURE, POWER STEERING FLUID . . . 19-42

LEVEL SENDING UNIT / SENSOR -

DESCRIPTION, FUEL..............14-68,14-7

LEVEL SENDING UNIT / SENSOR -

INSTALLATION, FUEL..................14-8

LEVEL SENDING UNIT / SENSOR -

OPERATION, FUEL................14-68,14-7

LEVEL SENDING UNIT / SENSOR -

REMOVAL, FUEL......................14-7

LEVEL SWITCH - DESCRIPTION,

WASHER FLUID......................8R-9

LEVEL SWITCH - INSTALLATION,

WASHER FLUID.....................8R-11

LEVEL SWITCH - OPERATION, WASHER

FLUID..............................8R-9

LEVEL SWITCH - REMOVAL, WASHER

FLUID.............................8R-10

LEVER - ADJUSTMENT, SHIFT . . . 21-622,21-657

LEVER - INSTALLATION, GEAR SHIFT.....19-12

LEVER - INSTALLATION, SHIFT . . . 21-621,21-656

LEVER - REMOVAL, GEAR SHIFT........19-12

LEVER - REMOVAL, SHIFT......21-620,21-655

LICENSE PLATE LAMP - INSTALLATION . . . 8L-16

LICENSE PLATE LAMP - REMOVAL.......8L-16

LICENSE PLATE LAMP UNIT -

INSTALLATION.......................8L-16

LICENSE PLATE LAMP UNIT - REMOVAL . . 8L-16

LID - INSTALLATION, CENTER SEAT

BACK..............................23-80

LID - REMOVAL, CENTER SEAT BACK....23-80

LIFTERS - CLEANING, HYDRAULIC . . 9-260,9-388

LIFTERS - INSTALLATION, HYDRAULIC . . . 9-260,

9-388

LIFTERS - REMOVAL, HYDRAULIC . . 9-259,9-387

LIFTERS/TAPPETS - CLEANING, SOLID....9-328

LIFTERS/TAPPETS - INSPECTION, SOLID . . 9-328

LIFTERS/TAPPETS - INSTALLATION,

SOLID.............................9-328

LIFTERS/TAPPETS - REMOVAL, SOLID....9-327

LIGHT DUTY FRONT FRAME RAIL TIP

REPLACEMENT - STANDARD

PROCEDURE.........................13-4

LIGHTER OUTLET - DESCRIPTION,

CIGAR...........................8W-97-2

LIGHTER OUTLET - DIAGNOSIS AND

TESTING, CIGAR...................8W-97-2

LIGHTER OUTLET - OPERATION, CIGAR . 8W-97-2

LIMITING VALVE - DESCRIPTION, FUEL

PRESSURE.........................14-72

LIMITING VALVE - INSTALLATION, FUEL

PRESSURE.........................14-73

LIMITING VALVE - OPERATION, FUEL

PRESSURE.........................14-72

LIMITING VALVE - REMOVAL, FUEL

PRESSURE.........................14-72

LINE - DESCRIPTION, REFRIGERANT.....24-32

LINE - INSTALLATION, LIQUID..........24-45

LINE - REMOVAL, LIQUID..............24-45

LINE COUPLER - DESCRIPTION,

REFRIGERANT.......................24-52

LINE COUPLER - INSTALLATION,

REFRIGERANT.......................24-53

LINE COUPLER - OPERATION,

REFRIGERANT.......................24-52

LINE COUPLER - REMOVAL,

REFRIGERANT.......................24-52

LINE LEAKS - DIAGNOSIS AND TESTING,

HIGH-PRESSURE FUEL................14-69

LINE PRESSURE (LP) SENSOR -

DESCRIPTION......................21-559

LINE PRESSURE (LP) SENSOR -

INSTALLATION......................21-560

LINE PRESSURE (LP) SENSOR -

OPERATION........................21-559

LINE PRESSURE (LP) SENSOR -

REMOVAL.........................21-559

LINES - DESCRIPTION, FUEL

.......14-69,14-8

LINES - DESCRIPTION, VACUUM

........25-22

LINES - INSTALLATION, FUEL

...........14-71

LINES - OPERATION, FUEL

.............14-69

LINES - OPERATION, REFRIGERANT

......24-32LINES - REMOVAL, FUEL..............14-69

LINK - INSTALLATION, DRAG...........19-35

LINK - REMOVAL, DRAG...............19-35

LINK CONNECTOR - DESCRIPTION, DATA . . 8E-3

LINK CONNECTOR - OPERATION, DATA....8E-3

LINKAGE - INSTALLATION...............6-13

LINKAGE - LINK/COIL - DESCRIPTION....19-33

LINKAGE - REMOVAL..................6-13

LINKAGE, SPECIAL TOOLS - STEERING . . . 19-35

LINK/COIL - DESCRIPTION, GEAR........19-19

LINK/COIL - DESCRIPTION, LINKAGE.....19-33

LINK/COIL - INSTALLATION, GEAR.......19-20

LINK/COIL - OPERATION, GEAR.........19-19

LINK/COIL - REMOVAL, GEAR...........19-19

LINK/COIL SUSPENSION - STANDARD

PROCEDURE, ALIGNMENT...............2-5

LIQUID LINE - INSTALLATION...........24-45

LIQUID LINE - REMOVAL..............24-45

LOAD FLOOR - INSTALLATION..........23-73

LOAD FLOOR - REMOVAL..............23-73

LOAD FLOOR SUPPORT CYLINDER -

INSTALLATION.......................23-73

LOAD FLOOR SUPPORT CYLINDER -

REMOVAL..........................23-73

LOADS - STANDARD PROCEDURE,

TESTING FOR A SHORT TO GROUND

ON FUSES POWERING SEVERAL.....8W-01-10

LOCATION - DESCRIPTION, CONNECTOR/

GROUND/SPLICE...................8W-91-1

LOCATIONS - SPECIFICATIONS, SEALER . 23-103

LOCATIONS - SPECIFICATIONS,

STRUCTURAL ADHESIVE..............23-113

LOCATIONS - SPECIFICATIONS, WELD . . . 23-122

LOCK - STANDARD PROCEDURE,

HYDROSTATIC........9-186,9-232,9-290,9-361

LOCK CYLINDER - DIAGNOSIS AND

TESTING, IGNITION SWITCH AND KEY....19-11

LOCK CYLINDER - INSTALLATION.......23-24

LOCK CYLINDER - REMOVAL...........23-24

LOCK MOTOR - DESCRIPTION, DOOR.....8N-5

LOCK MOTOR - DIAGNOSIS AND

TESTING, DOOR......................8N-5

LOCK MOTOR - OPERATION, DOOR.......8N-5

LOCK SWITCH - DIAGNOSIS AND

TESTING, POWER.....................8N-4

LOCK SWITCH - INSTALLATION, POWER . . . 8N-4

LOCK SWITCH - REMOVAL, POWER......8N-4

LOCKING RETRACTOR - DESCRIPTION,

AUTOMATIC........................8O-13

LOCKING RETRACTOR - OPERATION,

AUTOMATIC........................8O-14

LOCKS - DESCRIPTION, POWER.........8N-1

LOCKS - DIAGNOSIS AND TESTING,

POWER.............................8N-3

LOCKS - OPERATION, POWER...........8N-2

LOOP ADJUSTER - INSTALLATION, SEAT

BELT TURNING......................8O-50

LOOP ADJUSTER - REMOVAL, SEAT

BELT TURNING......................8O-50

LOOP BRACKETS - INSTALLATION, SEAT

BACK REAR - FOOTMANS..............23-85

LOOP BRACKETS - REMOVAL, SEAT

BACK REAR - FOOTMANS..............23-85

LOW FUEL INDICATOR - DESCRIPTION . . . 8J-29

LOW FUEL INDICATOR - OPERATION.....8J-29

LOWER BALL JOINT - DIAGNOSIS AND

TESTING............................2-18

LOWER BALL JOINT - INSTALLATION . 2-19,2-33

LOWER BALL JOINT - REMOVAL.....2-18,2-32

LOWER CONTROL ARM BUSHINGS -

2WD (LD) - INSTALLATION..............2-14

LOWER CONTROL ARM BUSHINGS -

2WD (LD) - REMOVAL.................2-12

LOWER CONTROL ARM BUSHINGS -

4WD (LD) - INSTALLATION..............2-13

LOWER CONTROL ARM BUSHINGS -

4WD (LD) - REMOVAL.................2-12

LOWER SURROUND - INSTALLATION,

INSTRUMENT PANEL..................23-60

LOWER SURROUND - REMOVAL,

INSTRUMENT PANEL

..................23-60

LOWER SUSPENSION ARM -

INSTALLATION

........................2-35

LOWER SUSPENSION ARM - REMOVAL

....2-35

LOWER TRIM - INSTALLATION,

B-PILLAR

...........................23-65

LOWER TRIM - INSTALLATION,

C-PILLAR

...........................23-68LOWER TRIM - REMOVAL, B-PILLAR.....23-64

LOWER TRIM - REMOVAL, C-PILLAR.....23-67

LOW/REVERSE CLUTCH - ASSEMBLY....21-561

LOW/REVERSE CLUTCH - CLEANING....21-561

LOW/REVERSE CLUTCH - DISASSEMBLY . 21-560

LOW/REVERSE CLUTCH - INSPECTION . . 21-561

LUBRICANTS - DESCRIPTION, ENGINE

OIL .................................0-2

LUBRICATION - DESCRIPTION.....9-148,9-214,

9-267,9-337,9-393,9-60

LUBRICATION - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS.....9-183,9-230,

9-358,9-7

LUBRICATION - OPERATION . 9-148,9-267,9-337,

9-393,9-60

LUBRICATION - STANDARD PROCEDURE . . 19-34

LUBRICATION - STANDARD PROCEDURE,

BODY...............................23-3

LUMBAR CONTROL SWITCH -

DESCRIPTION.......................8N-19

LUMBAR CONTROL SWITCH -

OPERATION.........................8N-19

LUMBAR CONTROL SWITCH - REMOVAL . 8N-19

LUMBAR MOTOR - DESCRIPTION.......8N-19

LUMBAR MOTOR - DIAGNOSIS AND

TESTING...........................8N-20

LUMBAR MOTOR - OPERATION.........8N-20

MAIN BEARING - FITTING - STANDARD

PROCEDURE, CRANKSHAFT.......9-133,9-202

MAIN BEARING CLEARANCE -

STANDARD PROCEDURE................9-322

MAIN BEARING FITTING - STANDARD

PROCEDURE, CRANKSHAFT............9-253

MAIN BEARING FITTING, STANDARD

PROCEDURE.........................9-43

MAIN BEARINGS - DESCRIPTION,

CRANKSHAFT.......................9-253

MAIN BEARINGS - INSPECTION,

CRANKSHAFT..................9-133,9-203

MAIN BEARINGS - INSTALLATION,

CRANKSHAFT..................9-254,9-383

MAIN BEARINGS - OPERATION,

CRANKSHAFT.......................9-253

MAIN BEARINGS - REMOVAL,

CRANKSHAFT..................9-254,9-383

MAIN BEARINGS - STANDARD

PROCEDURE, FITTING CRANKSHAFT.....9-383

MAINTENANCE SCHEDULES -

DESCRIPTION.........................0-6

MALFUNCTION INDICATOR LAMP (MIL) -

DESCRIPTION.......................8J-30

MALFUNCTION INDICATOR LAMP (MIL) -

OPERATION.........................8J-30

MANAGER - DESCRIPTION, TASK.........25-1

MANAGER - OPERATION, TASK..........25-5

MANIFOLD - CLEANING, EXHAUST . 9-161,9-220,

9-277,9-347,9-404

MANIFOLD - CLEANING, INTAKE . . . 9-158,9-219,

9-275,9-346,9-402

MANIFOLD - DESCRIPTION, EXHAUST . . . 9-159,

9-220,9-277,9-403,9-73

MANIFOLD - DESCRIPTION, INTAKE.....9-157,

9-219,9-274,9-401,9-71

MANIFOLD - INSPECTION, EXHAUST.....9-161,

9-220,9-277,9-347,9-404

MANIFOLD - INSPECTION, INTAKE . 9-158,9-219,

9-275,9-346,9-402

MANIFOLD - INSTALLATION, EXHAUST . . . 9-162,

9-220,9-277,9-347,9-404,9-74

MANIFOLD - INSTALLATION, INTAKE.....9-158,

9-219,9-275,9-346,9-402,9-72

MANIFOLD - OPERATION, EXHAUST.....9-220,

9-277,9-403

MANIFOLD - OPERATION, INTAKE........9-274

MANIFOLD - REMOVAL, EXHAUST . . 9-159,9-220,

9-277,9-347,9-404,9-73

MANIFOLD - REMOVAL, INTAKE . . . 9-157,9-219,

9-275,9-345,9-401,9-72

MANIFOLD LEAKAGE - DIAGNOSIS AND

TESTING, INTAKE

.....9-157,9-219,9-274,9-401

MANIFOLD LEAKS - DIAGNOSIS AND

TESTING, INTAKE

.....................9-71

MANUAL - INSTALLATION, WINDOW

REGULATOR

...................23-26,23-35

MANUAL - REMOVAL, WINDOW

REGULATOR

...................23-26,23-35

MANUAL BLEEDING - STANDARD

PROCEDURE

..........................5-5

20 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2884 of 2895

RETURN - DESCRIPTION, SENSOR.......8E-10

RETURN HOSE - GEAR TO COOLER -

INSTALLATION..................19-43,19-44

RETURN HOSE - GEAR TO COOLER -

REMOVAL..........................19-43

RETURN HOSE - RESERVOIR TO

COOLER - INSTALLATION.........19-43,19-44

RETURN HOSE - RESERVOIR TO

COOLER - REMOVAL.............19-43,19-44

REVOLUTIONS PER MILE,

SPECIFICATIONS - TIRE...............22-10

RFE TRANSMISSION, SPECIAL TOOLS . . . 21-535

RIGHT - DESCRIPTION, CAMSHAFT(S)....9-117

RIGHT - INSTALLATION.................2-34

RIGHT - INSTALLATION, CAMSHAFT(S) . . . 9-118

RIGHT - INSTALLATION, CYLINDER

HEAD...............................9-32

RIGHT - REMOVAL....................2-34

RIGHT - REMOVAL, CAMSHAFT(S).......9-117

RIGHT - REMOVAL, CYLINDER HEAD......9-32

RIGHT CYLINDER HEAD - INSTALLATION . . 9-111

RIGHT CYLINDER HEAD - REMOVAL.....9-108

RIGHT OUTBOARD - INSTALLATION,

CENTER ANCHOR....................8O-45

RIGHT OUTBOARD - REMOVAL, CENTER

ANCHOR...........................8O-43

RIGHT REAR CABLE - INSTALLATION......5-32

RIGHT REAR CABLE - REMOVAL.........5-31

RIGHT SIDE - INSTALLATION...........9-121

RIGHT SIDE - REMOVAL...............9-121

RING - INSTALLATION, PINION

GEAR/RING GEAR/TONE......3-123,3-150,3-96

RING - REMOVAL, PINION GEAR/RING

GEAR/TONE................3-122,3-149,3-94

RING FITTING - STANDARD

PROCEDURE, PISTON . 9-140,9-207,9-262,9-333,

9-52

RINGS - STANDARD PROCEDURE,

FITTING PISTON.....................9-390

RKE TRANSMITTER BATTERIES -

STANDARD PROCEDURE...............8N-9

RKE TRANSMITTER CUSTOMER

PREFERENCES - STANDARD

PROCEDURE.........................8N-9

RKE TRANSMITTER PROGRAMING -

STANDARD PROCEDURE..............8N-10

ROAD TEST - DIAGNOSIS AND TESTING . . . 8P-3

ROAD TESTING - DIAGNOSIS AND

TESTING..............21-139,21-320,21-491

ROCKER ARM / ADJUSTER ASSEMBLY -

DESCRIPTION.......................9-124

ROCKER ARM / ADJUSTER ASSEMBLY -

INSTALLATION..................9-124,9-249

ROCKER ARM / ADJUSTER ASSEMBLY -

REMOVAL.....................9-124,9-249

ROCKER ARM / ADJUSTER ASSY -

CLEANING..........................9-310

ROCKER ARM / ADJUSTER ASSY -

DESCRIPTION.......................9-310

ROCKER ARM / ADJUSTER ASSY -

INSPECTION........................9-311

ROCKER ARM / ADJUSTER ASSY -

INSTALLATION.............9-198,9-312,9-379

ROCKER ARM / ADJUSTER ASSY -

REMOVAL................9-198,9-310,9-379

ROCKER ARM - DESCRIPTION

.......9-30,9-36

ROCKER ARM - INSTALLATION

..........9-30

ROCKER ARM - REMOVAL

..........9-30,9-36

ROCKER HOUSING - INSTALLATION

......9-304

ROCKER HOUSING - REMOVAL

.........9-304

ROD - CLEANING, PISTON &

CONNECTING

........9-138,9-206,9-261,9-389

ROD - CLEANING, PISTON AND

CONNECTING

........................9-331

ROD - DESCRIPTION, PISTON &

CONNECTING

. . . 9-137,9-205,9-260,9-329,9-388,

9-47

ROD - INSPECTION, CONNECTING

.......9-332

ROD - INSPECTION, PISTON &

CONNECTING

........9-138,9-206,9-261,9-389

ROD - INSTALLATION, PISTON &

CONNECTING

........9-139,9-207,9-261,9-389

ROD - REMOVAL, PISTON &

CONNECTING

. . . 9-137,9-205,9-261,9-330,9-389

ROD BEARING AND CRANKSHAFT

JOURNAL CLEARANCE - STANDARD

PROCEDURE, CONNECTING

............9-321ROD BEARING FITTING - STANDARD

PROCEDURE, CONNECTING . . 9-128,9-251,9-382

ROD BEARING FITTING, STANDARD

PROCEDURE - CONNECTING.............9-48

ROD END - DIAGNOSIS AND TESTING,

OUTER TIE..........................19-31

ROD END - INSTALLATION, OUTER TIE . . . 19-32

ROD END - INSTALLATION, TIE.........19-37

ROD END - REMOVAL, OUTER TIE.......19-31

ROD END - REMOVAL, TIE.............19-36

ROTATION - STANDARD PROCEDURE,

TIRE................................22-2

ROTOR - 5.9L V-8 - DIAGNOSIS AND

TESTING, DISTRIBUTOR...............8I-19

ROUTING, 5.7L V-8 ENGINE - FIRING

ORDER / CABLE.......................8I-4

RUN CHANNEL - INSTALLATION, GLASS . . 23-21,

23-31

RUN CHANNEL - REMOVAL, GLASS . 23-21,23-30

RUN WEATHERSTRIP - INSTALLATION,

FRONT DOOR GLASS.................23-92

RUN WEATHERSTRIP - INSTALLATION,

REAR DOOR GLASS..................23-93

RUN WEATHERSTRIP - REMOVAL,

FRONT DOOR GLASS.................23-92

RUN WEATHERSTRIP - REMOVAL, REAR

DOOR GLASS.......................23-93

RUNOUT - DIAGNOSIS AND TESTING,

TIRE AND WHEEL.....................22-1

RWAL VALVE - DESCRIPTION............5-44

RWAL VALVE - INSTALLATION...........5-45

RWAL VALVE - OPERATION.............5-44

RWAL VALVE - REMOVAL...............5-45

SAFETY CERTIFICATION LABEL -

DESCRIPTION, VEHICLE..............Intro.-1

SAFETY PRECAUTIONS AND WARNINGS,

WARNING...........................23-1

SAFETY PRECAUTIONS, STANDARD

PROCEDURE.........................8L-7

SAFETY PRECAUTIONS, WARNING -

WINDSHIELD........................23-88

SANDING/BUFFING & POLISHING -

DESCRIPTION, FINESSE...............23-75

SCHEDULES - DESCRIPTION,

MAINTENANCE........................0-6

SCHEMATICS AND DIAGRAMS -

HYDRAULIC SCHEMATICS . 21-175,21-355,21-513

SCHEMATICS, SCHEMATICS AND

DIAGRAMS - HYDRAULIC . 21-175,21-355,21-513

SEAL - DIAGNOSIS AND TESTING,

RADIATOR CAP-TO-FILLER NECK.........7-61

SEAL - FRONT - DESCRIPTION,

CRANKSHAFT OIL....................9-254

SEAL - FRONT - INSTALLATION,

CRANKSHAFT OIL . 9-134,9-203,9-255,9-324,9-45

SEAL - FRONT - OPERATION,

CRANKSHAFT OIL....................9-254

SEAL - FRONT - REMOVAL,

CRANKSHAFT OIL . 9-134,9-203,9-254,9-323,9-44

SEAL - FRONT COVER INSTALLED -

INSTALLATION, FRONT OIL.............9-384

SEAL - FRONT COVER INSTALLED -

REMOVAL, FRONT OIL................9-384

SEAL - FRONT COVER REMOVED -

INSTALLATION, FRONT OIL.............9-384

SEAL - FRONT COVER REMOVED -

REMOVAL, FRONT OIL................9-384

SEAL - INSTALLATION, ADAPTER

HOUSING...............21-127,21-539,21-83

SEAL - INSTALLATION, DOOR OPENING . . . 23-92

SEAL - INSTALLATION, EXTENSION

HOUSING.........21-127,21-200,21-380,21-83

SEAL - INSTALLATION, EXTENSION

HOUSING BUSHING............21-616,21-682

SEAL - INSTALLATION, FRONT OUTPUT

SHAFT..........21-618,21-653,21-683,21-717

SEAL - INSTALLATION, OIL PUMP

FRONT............................21-567

SEAL - INSTALLATION, PINION

....3-113,3-140,

3-35,3-60,3-85

SEAL - INSTALLATION, STEERING GEAR

INPUT SHAFT

.......................19-28

SEAL - INSTALLATION, VALVE STEM

.....9-378

SEAL - REAR - DESCRIPTION,

CRANKSHAFT OIL

....................9-255

SEAL - REAR - INSTALLATION,

CRANKSHAFT OIL

....9-136,9-204,9-256,9-325,

9-385,9-46SEAL - REAR - OPERATION,

CRANKSHAFT OIL....................9-255

SEAL - REAR - REMOVAL, CRANKSHAFT

OIL .......9-135,9-204,9-255,9-325,9-385,9-45

SEAL - REMOVAL, ADAPTER HOUSING . . 21-127,

21-539,21-83

SEAL - REMOVAL, DOOR OPENING......23-92

SEAL - REMOVAL, EXTENSION

HOUSING.........21-127,21-200,21-380,21-83

SEAL - REMOVAL, EXTENSION HOUSING

BUSHING....................21-616,21-682

SEAL - REMOVAL, FRONT OUTPUT

SHAFT..........21-617,21-653,21-683,21-717

SEAL - REMOVAL, OIL PUMP FRONT....21-567

SEAL - REMOVAL, PINION....3-113,3-140,3-34,

3-60,3-85

SEAL - REMOVAL, STEERING GEAR

INPUT SHAFT.......................19-25

SEAL AND DUST BOOT - INSTALLATION,

EXTENSION HOUSING..........21-652,21-716

SEAL AND DUST BOOT - REMOVAL,

EXTENSION HOUSING..........21-652,21-716

SEAL AREA LEAKS - DIAGNOSIS AND

TESTING, REAR.............9-135,9-204,9-64

SEAL RETAINER - INSTALLATION,

CRANKSHAFT REAR OIL.....9-205,9-326,9-386

SEAL RETAINER - REMOVAL,

CRANKSHAFT REAR OIL.....9-204,9-326,9-386

SEALER LOCATIONS - SPECIFICATIONS . . 23-103

SEALERS - STANDARD PROCEDURE,

FORM-IN-PLACE GASKETS . . . 9-232,9-289,9-360,

9-9,9-93

SEALS - DESCRIPTION, VALVE GUIDE . . . 9-31,9-36

SEALS - DESCRIPTION, VALVE STEM....9-126,

9-198

SEALS - INSTALLATION, AXLE SHAFT . 3-33,3-58,

3-84

SEALS - REMOVAL, AXLE SHAFT . 3-33,3-58,3-84

SEALS - REMOVAL, VALVE SPRINGS.....9-308

SEALS - REMOVAL, VALVE STEM........9-377

SEAT - FRONT - INSTALLATION.........23-82

SEAT - FRONT - REMOVAL.............23-82

SEAT - INSTALLATION, CENTER.........23-77

SEAT - REAR - INSTALLATION..........23-84

SEAT - REAR - REMOVAL..............23-84

SEAT - REMOVAL, CENTER.............23-76

SEAT BACK - INSTALLATION, CENTER

ARMREST..........................23-78

SEAT BACK - REAR - INSTALLATION.....23-84

SEAT BACK - REAR - REMOVAL.........23-84

SEAT BACK - REMOVAL, CENTER

ARMREST..........................23-77

SEAT BACK CUSHION / COVER - FRONT

- INSTALLATION.....................23-83

SEAT BACK CUSHION / COVER - FRONT

- REMOVAL.........................23-83

SEAT BACK CUSHION / COVER - REAR -

INSTALLATION.......................23-85

SEAT BACK CUSHION / COVER - REAR -

REMOVAL..........................23-85

SEAT BACK HINGE - INSTALLATION,

CENTER............................23-80

SEAT BACK HINGE - REMOVAL, CENTER . . 23-79

SEAT BACK INERTIA HINGE COVER -

INSTALLATION, CENTER

...............23-78

SEAT BACK INERTIA HINGE COVER -

REMOVAL, CENTER

...................23-78

SEAT BACK LID - INSTALLATION,

CENTER

............................23-80

SEAT BACK LID - REMOVAL, CENTER

....23-80

SEAT BACK REAR - FOOTMANS LOOP

BRACKETS - INSTALLATION

............23-85

SEAT BACK REAR - FOOTMANS LOOP

BRACKETS - REMOVAL

................23-85

SEAT BELT - INSTALLATION, FRONT

CENTER

............................8O-27

SEAT BELT - REMOVAL, FRONT CENTER

. . 8O-26

SEAT BELT & RETRACTOR -

INSTALLATION, FRONT CENTER

.........8O-26

SEAT BELT & RETRACTOR -

INSTALLATION, REAR CENTER

..........8O-40

SEAT BELT & RETRACTOR -

INSTALLATION, REAR OUTBOARD

.......8O-42

SEAT BELT & RETRACTOR - REMOVAL,

FRONT CENTER

......................8O-25

SEAT BELT & RETRACTOR - REMOVAL,

REAR CENTER

.......................8O-39

DRINDEX 29

Description Group-Page Description Group-Page Description Group-Page