radiator cap DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 289 of 2895

DESCRIPTIONÐCOOLING SYSTEM FLOW -

5.9L DIESEL

The diesel engine cooling system consists of :

²Cross-flow radiator

²Belt driven water pump

²Belt driven mechanical cooling fan

²Electronic viscous fan drive

²Fan shroud

²Radiator pressure cap²Vertically mounted thermostat

²Coolant reserve/recovery system

²Transmission oil cooler

²Coolant

Coolant flow circuits for the 5.9L diesel engine are

shown in (Fig. 3).

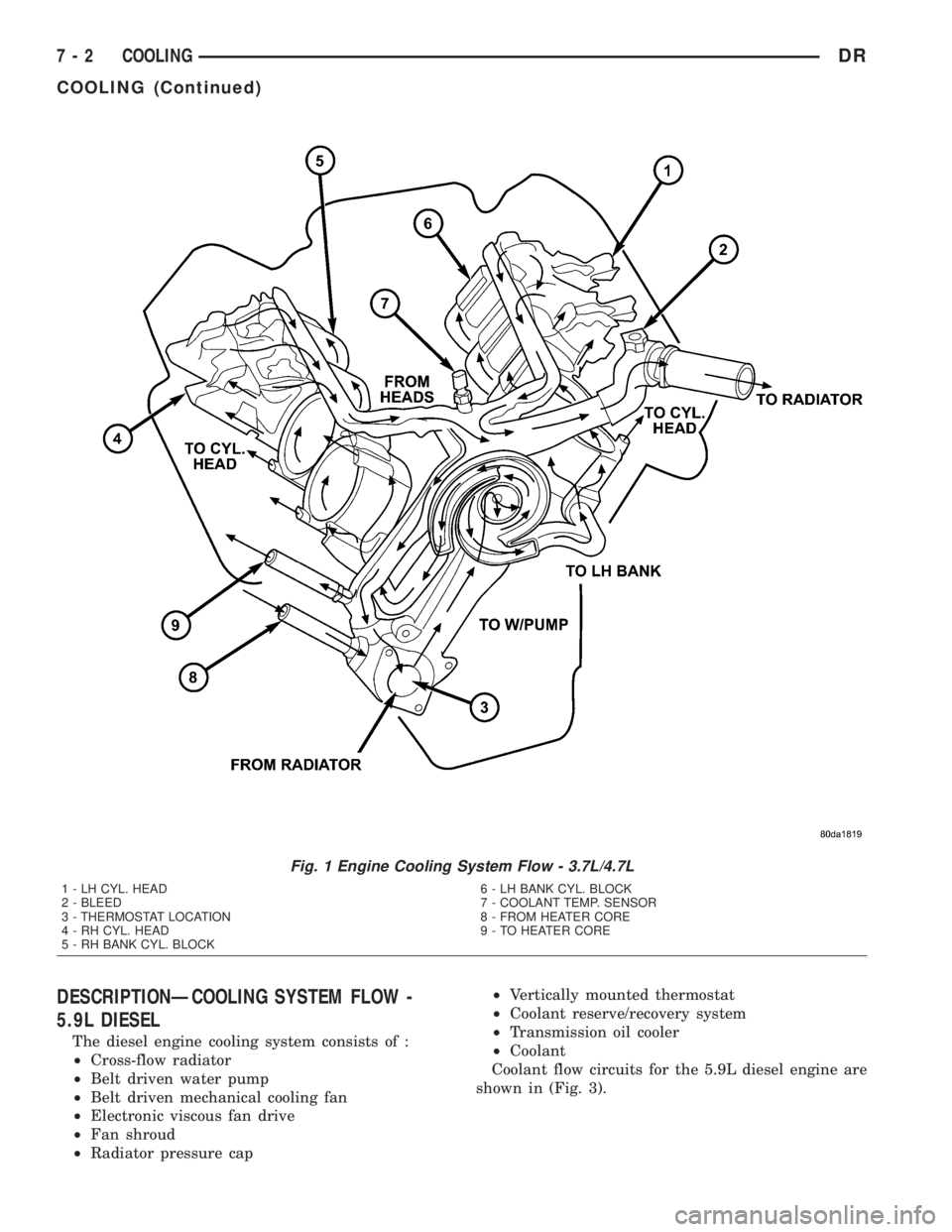

Fig. 1 Engine Cooling System Flow - 3.7L/4.7L

1 - LH CYL. HEAD

2 - BLEED

3 - THERMOSTAT LOCATION

4 - RH CYL. HEAD

5 - RH BANK CYL. BLOCK6 - LH BANK CYL. BLOCK

7 - COOLANT TEMP. SENSOR

8 - FROM HEATER CORE

9 - TO HEATER CORE

7 - 2 COOLINGDR

COOLING (Continued)

Page 292 of 2895

system is pressurized and uses a centrifugal water

pump to circulate coolant throughout the system.

5.9L, 5.9L Diesel, and 8.0L engines utilize an

ambient overflow bottle for coolant recovery/reserve.

The 3.7L and 4.7L engines utilize a pressurized

degas bottle for coolant deaeration and reserve. This

degas bottle has coolant flowing through it continu-

ously, supplied by a vent in the hot side radiator

tank and returning to the heater return hose.

An optional factory installed maximum duty cool-

ing package is available on most models. This pack-

age will provide additional cooling capacity for

vehicles used under extreme conditions such as

trailer towing in high ambient temperatures.

OPERATIONÐHOSE CLAMPS

The spring type hose clamp applies constant ten-

sion on a hose connection. To remove a spring type

hose clamp, only use constant tension clamp pliers

designed to compress the hose clamp.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐON-BOARD

DIAGNOSTICS (OBD)

COOLING SYSTEM RELATED DIAGNOSTICS

The Engine Control Module (ECM) has been pro-

grammed to monitor certain cooling system compo-

nents:

²If the engine has remained cool for too long a

period, such as with a stuck open thermostat, a Diag-

nostic Trouble Code (DTC) can be set.²If an open or shorted condition has developed in

the electronically controlled viscous fan clutch circuit,

a Diagnostic Trouble Code (DTC) can be set.

²If fan speed is not detected a DTC will be set.

²Coolant temperature sensor circuit problems can

set a DTC.

If the problem is sensed in a monitored circuit

often enough to indicated an actual problem, a DTC

is stored. The DTC will be stored in the ECM mem-

ory for eventual display to the service technician.

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

ACCESSING DIAGNOSTIC TROUBLE CODES

To read DTC's and to obtain cooling system data,

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

ERASING TROUBLE CODES

After the problem has been repaired, use the

DRBIIItscan tool to erase a DTC. Refer to the

appropriate Powertrain Diagnostic Procedures ser-

vice information for operation of the DRBIIItscan

tool.

DIAGNOSIS AND TESTINGÐCOOLING SYSTEM

- TESTING FOR LEAKS

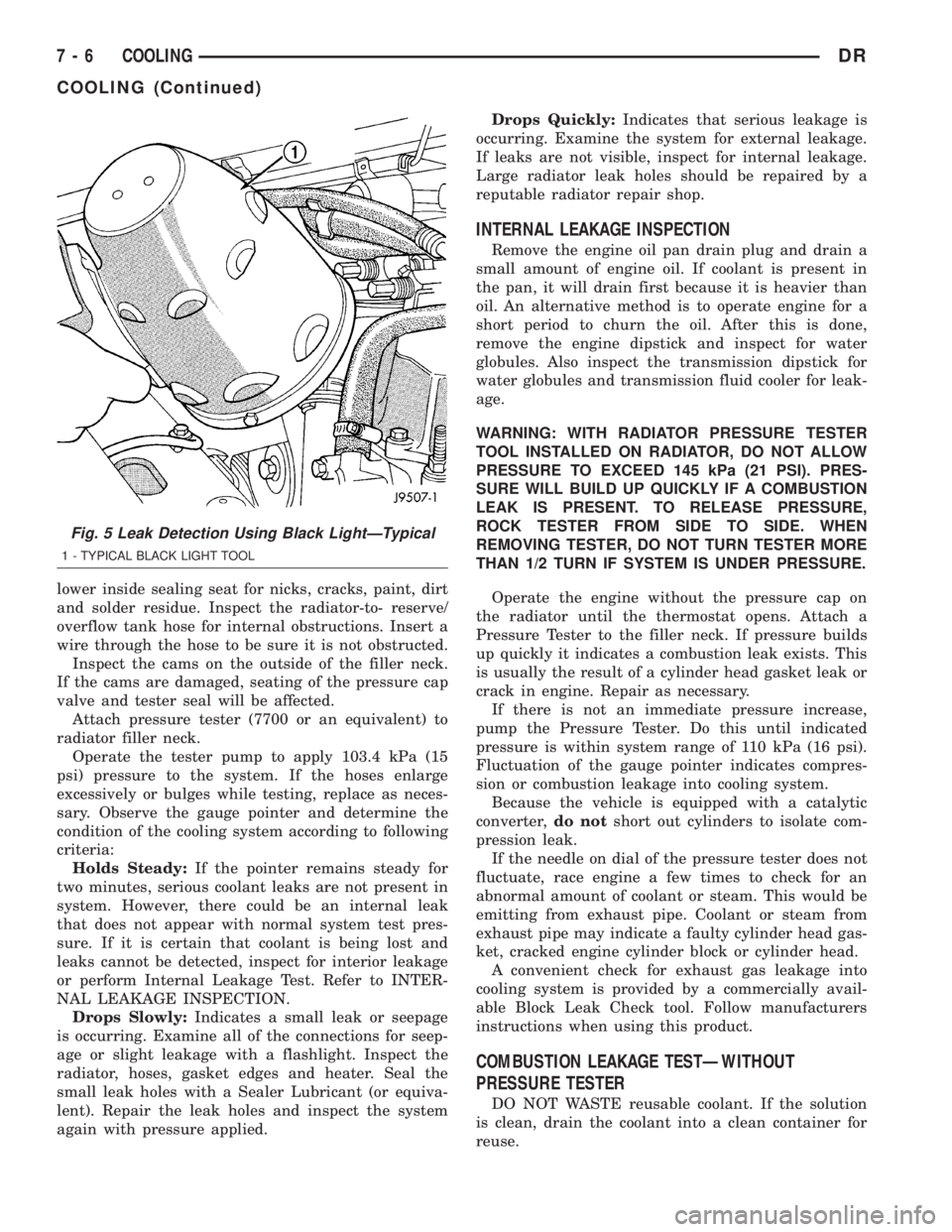

ULTRAVIOLET LIGHT METHOD

A leak detection additive is available through the

parts department that can be added to cooling sys-

tem. The additive is highly visible under ultraviolet

light (black light). Pour one ounce of additive into

cooling system. Place heater control unit in HEAT

position. Start and operate the engine until the radi-

ator upper hose is warm to the touch. Aim the com-

mercially available black light tool at the components

to be checked. If leaks are present, the black light

will cause the additive to glow a bright green color.

The black light can be used in conjunction with a

pressure tester to determine if any external leaks

exist (Fig. 5).

PRESSURE TESTER METHOD

The engine should be at normal operating temper-

ature. Recheck the system cold if the cause of coolant

loss is not located during the warm engine examina-

tion.

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING.

Carefully remove the radiator pressure cap from

the filler neck and check the coolant level. Push

down on the cap to disengage it from the stop tabs.

Wipe the inside of the filler neck and examine the

Fig. 4 Spring Clamp Size Location

1 - SPRING CLAMP SIZE LOCATION

DRCOOLING 7 - 5

COOLING (Continued)

Page 293 of 2895

lower inside sealing seat for nicks, cracks, paint, dirt

and solder residue. Inspect the radiator-to- reserve/

overflow tank hose for internal obstructions. Insert a

wire through the hose to be sure it is not obstructed.

Inspect the cams on the outside of the filler neck.

If the cams are damaged, seating of the pressure cap

valve and tester seal will be affected.

Attach pressure tester (7700 or an equivalent) to

radiator filler neck.

Operate the tester pump to apply 103.4 kPa (15

psi) pressure to the system. If the hoses enlarge

excessively or bulges while testing, replace as neces-

sary. Observe the gauge pointer and determine the

condition of the cooling system according to following

criteria:

Holds Steady:If the pointer remains steady for

two minutes, serious coolant leaks are not present in

system. However, there could be an internal leak

that does not appear with normal system test pres-

sure. If it is certain that coolant is being lost and

leaks cannot be detected, inspect for interior leakage

or perform Internal Leakage Test. Refer to INTER-

NAL LEAKAGE INSPECTION.

Drops Slowly:Indicates a small leak or seepage

is occurring. Examine all of the connections for seep-

age or slight leakage with a flashlight. Inspect the

radiator, hoses, gasket edges and heater. Seal the

small leak holes with a Sealer Lubricant (or equiva-

lent). Repair the leak holes and inspect the system

again with pressure applied.Drops Quickly:Indicates that serious leakage is

occurring. Examine the system for external leakage.

If leaks are not visible, inspect for internal leakage.

Large radiator leak holes should be repaired by a

reputable radiator repair shop.

INTERNAL LEAKAGE INSPECTION

Remove the engine oil pan drain plug and drain a

small amount of engine oil. If coolant is present in

the pan, it will drain first because it is heavier than

oil. An alternative method is to operate engine for a

short period to churn the oil. After this is done,

remove the engine dipstick and inspect for water

globules. Also inspect the transmission dipstick for

water globules and transmission fluid cooler for leak-

age.

WARNING: WITH RADIATOR PRESSURE TESTER

TOOL INSTALLED ON RADIATOR, DO NOT ALLOW

PRESSURE TO EXCEED 145 kPa (21 PSI). PRES-

SURE WILL BUILD UP QUICKLY IF A COMBUSTION

LEAK IS PRESENT. TO RELEASE PRESSURE,

ROCK TESTER FROM SIDE TO SIDE. WHEN

REMOVING TESTER, DO NOT TURN TESTER MORE

THAN 1/2 TURN IF SYSTEM IS UNDER PRESSURE.

Operate the engine without the pressure cap on

the radiator until the thermostat opens. Attach a

Pressure Tester to the filler neck. If pressure builds

up quickly it indicates a combustion leak exists. This

is usually the result of a cylinder head gasket leak or

crack in engine. Repair as necessary.

If there is not an immediate pressure increase,

pump the Pressure Tester. Do this until indicated

pressure is within system range of 110 kPa (16 psi).

Fluctuation of the gauge pointer indicates compres-

sion or combustion leakage into cooling system.

Because the vehicle is equipped with a catalytic

converter,do notshort out cylinders to isolate com-

pression leak.

If the needle on dial of the pressure tester does not

fluctuate, race engine a few times to check for an

abnormal amount of coolant or steam. This would be

emitting from exhaust pipe. Coolant or steam from

exhaust pipe may indicate a faulty cylinder head gas-

ket, cracked engine cylinder block or cylinder head.

A convenient check for exhaust gas leakage into

cooling system is provided by a commercially avail-

able Block Leak Check tool. Follow manufacturers

instructions when using this product.

COMBUSTION LEAKAGE TESTÐWITHOUT

PRESSURE TESTER

DO NOT WASTE reusable coolant. If the solution

is clean, drain the coolant into a clean container for

reuse.

Fig. 5 Leak Detection Using Black LightÐTypical

1 - TYPICAL BLACK LIGHT TOOL

7 - 6 COOLINGDR

COOLING (Continued)

Page 295 of 2895

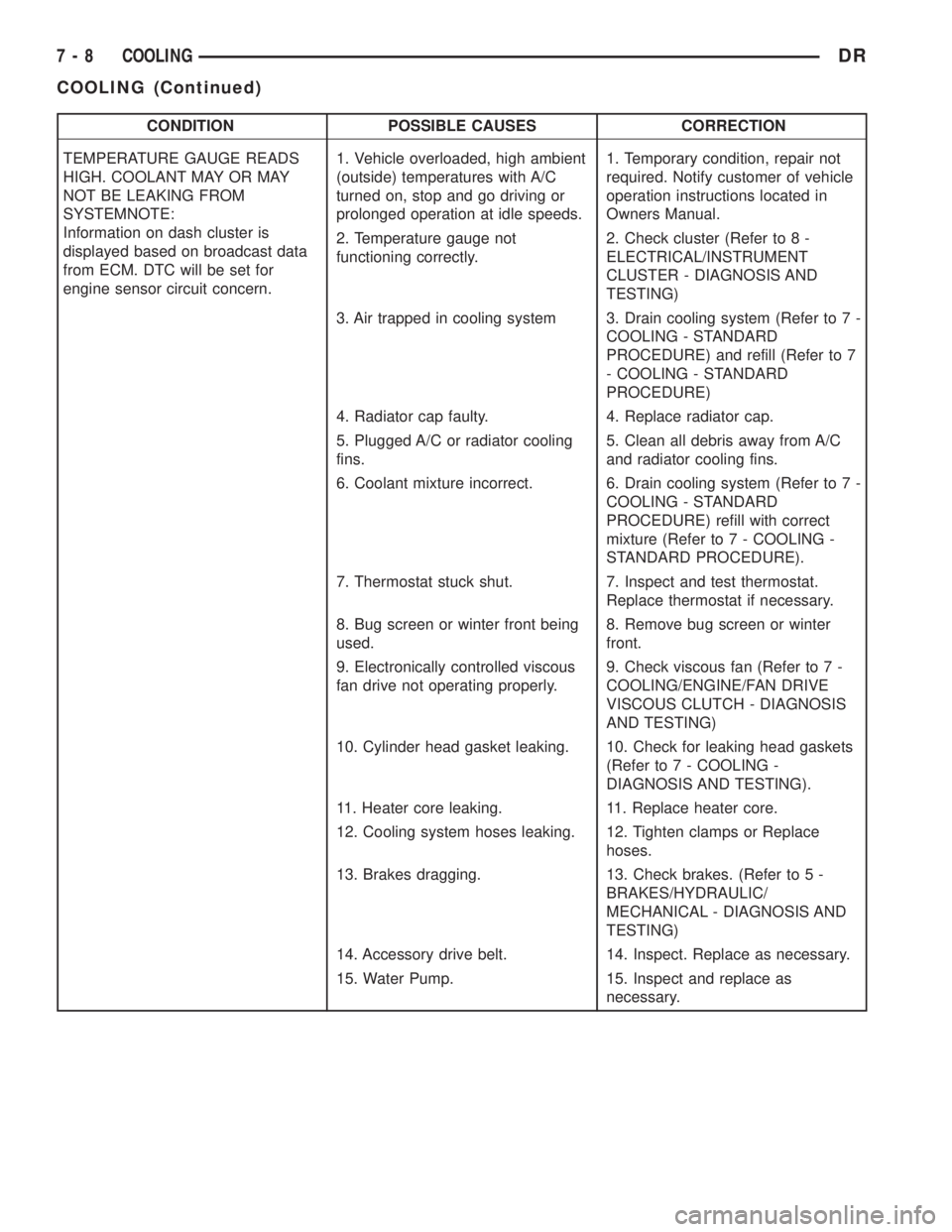

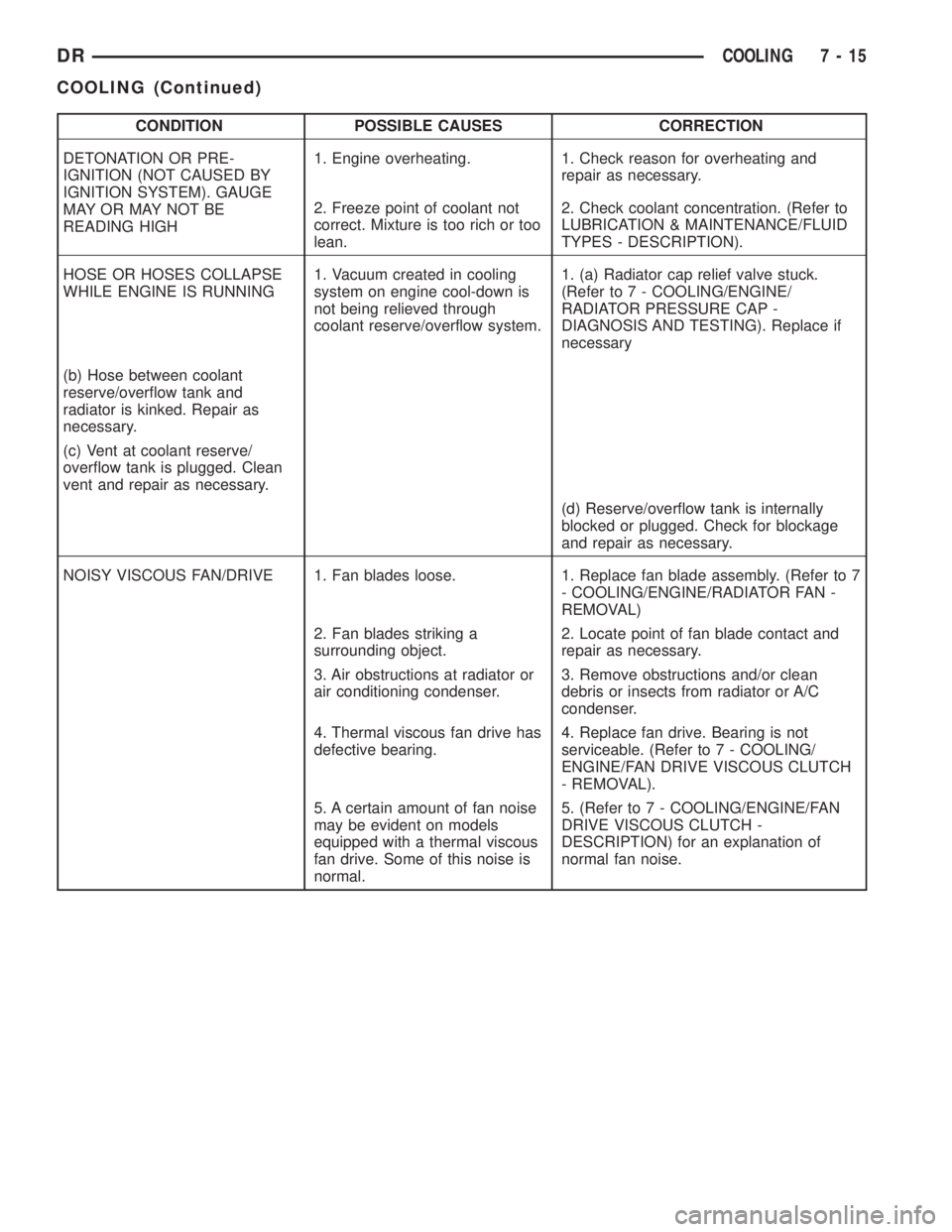

CONDITION POSSIBLE CAUSES CORRECTION

TEMPERATURE GAUGE READS

HIGH. COOLANT MAY OR MAY

NOT BE LEAKING FROM

SYSTEMNOTE:

Information on dash cluster is

displayed based on broadcast data

from ECM. DTC will be set for

engine sensor circuit concern.1. Vehicle overloaded, high ambient

(outside) temperatures with A/C

turned on, stop and go driving or

prolonged operation at idle speeds.1. Temporary condition, repair not

required. Notify customer of vehicle

operation instructions located in

Owners Manual.

2. Temperature gauge not

functioning correctly.2. Check cluster (Refer to 8 -

ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND

TESTING)

3. Air trapped in cooling system 3. Drain cooling system (Refer to 7 -

COOLING - STANDARD

PROCEDURE) and refill (Refer to 7

- COOLING - STANDARD

PROCEDURE)

4. Radiator cap faulty. 4. Replace radiator cap.

5. Plugged A/C or radiator cooling

fins.5. Clean all debris away from A/C

and radiator cooling fins.

6. Coolant mixture incorrect. 6. Drain cooling system (Refer to 7 -

COOLING - STANDARD

PROCEDURE) refill with correct

mixture (Refer to 7 - COOLING -

STANDARD PROCEDURE).

7. Thermostat stuck shut. 7. Inspect and test thermostat.

Replace thermostat if necessary.

8. Bug screen or winter front being

used.8. Remove bug screen or winter

front.

9. Electronically controlled viscous

fan drive not operating properly.9. Check viscous fan (Refer to 7 -

COOLING/ENGINE/FAN DRIVE

VISCOUS CLUTCH - DIAGNOSIS

AND TESTING)

10. Cylinder head gasket leaking. 10. Check for leaking head gaskets

(Refer to 7 - COOLING -

DIAGNOSIS AND TESTING).

11. Heater core leaking. 11. Replace heater core.

12. Cooling system hoses leaking. 12. Tighten clamps or Replace

hoses.

13. Brakes dragging. 13. Check brakes. (Refer to 5 -

BRAKES/HYDRAULIC/

MECHANICAL - DIAGNOSIS AND

TESTING)

14. Accessory drive belt. 14. Inspect. Replace as necessary.

15. Water Pump. 15. Inspect and replace as

necessary.

7 - 8 COOLINGDR

COOLING (Continued)

Page 296 of 2895

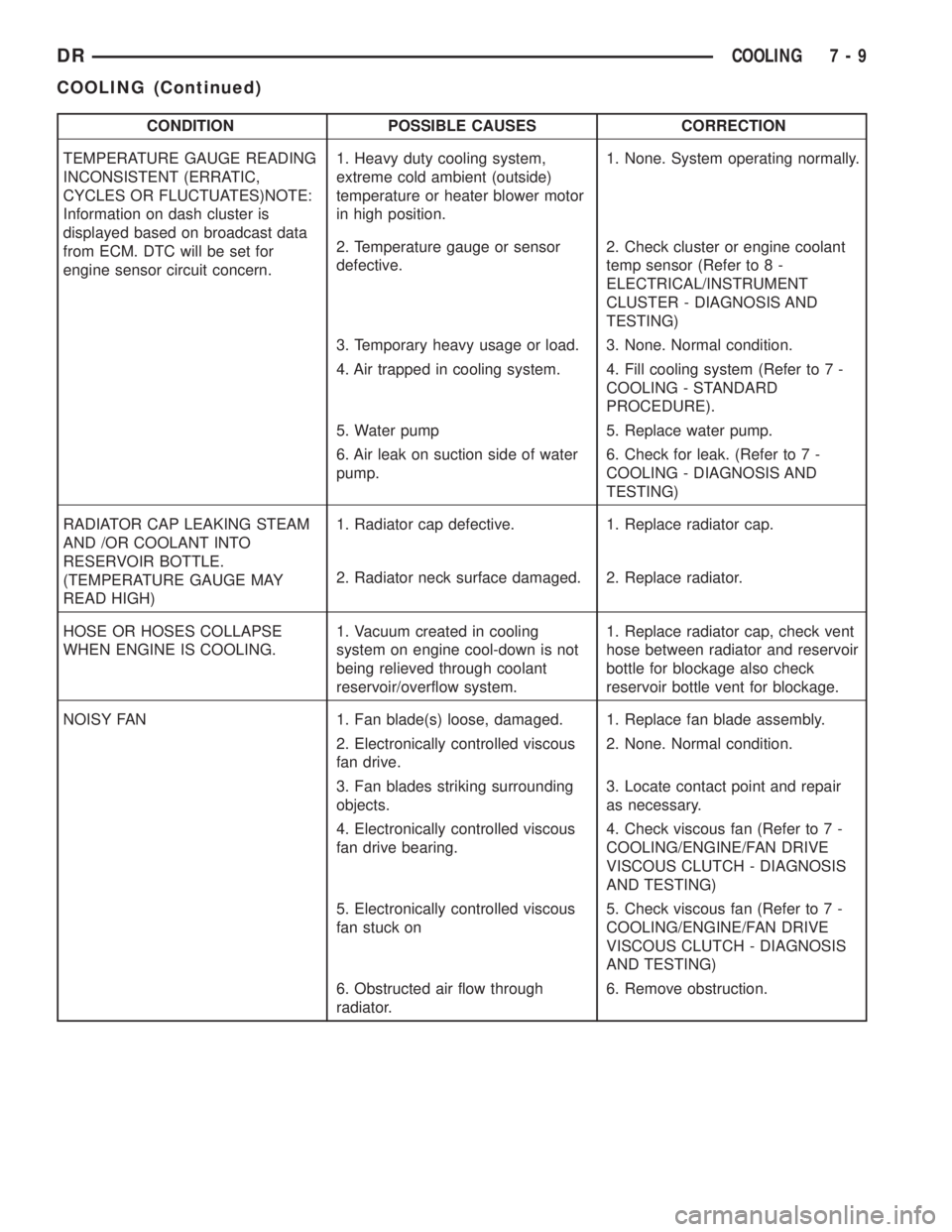

CONDITION POSSIBLE CAUSES CORRECTION

TEMPERATURE GAUGE READING

INCONSISTENT (ERRATIC,

CYCLES OR FLUCTUATES)NOTE:

Information on dash cluster is

displayed based on broadcast data

from ECM. DTC will be set for

engine sensor circuit concern.1. Heavy duty cooling system,

extreme cold ambient (outside)

temperature or heater blower motor

in high position.1. None. System operating normally.

2. Temperature gauge or sensor

defective.2. Check cluster or engine coolant

temp sensor (Refer to 8 -

ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND

TESTING)

3. Temporary heavy usage or load. 3. None. Normal condition.

4. Air trapped in cooling system. 4. Fill cooling system (Refer to 7 -

COOLING - STANDARD

PROCEDURE).

5. Water pump 5. Replace water pump.

6. Air leak on suction side of water

pump.6. Check for leak. (Refer to 7 -

COOLING - DIAGNOSIS AND

TESTING)

RADIATOR CAP LEAKING STEAM

AND /OR COOLANT INTO

RESERVOIR BOTTLE.

(TEMPERATURE GAUGE MAY

READ HIGH)1. Radiator cap defective. 1. Replace radiator cap.

2. Radiator neck surface damaged. 2. Replace radiator.

HOSE OR HOSES COLLAPSE

WHEN ENGINE IS COOLING.1. Vacuum created in cooling

system on engine cool-down is not

being relieved through coolant

reservoir/overflow system.1. Replace radiator cap, check vent

hose between radiator and reservoir

bottle for blockage also check

reservoir bottle vent for blockage.

NOISY FAN 1. Fan blade(s) loose, damaged. 1. Replace fan blade assembly.

2. Electronically controlled viscous

fan drive.2. None. Normal condition.

3. Fan blades striking surrounding

objects.3. Locate contact point and repair

as necessary.

4. Electronically controlled viscous

fan drive bearing.4. Check viscous fan (Refer to 7 -

COOLING/ENGINE/FAN DRIVE

VISCOUS CLUTCH - DIAGNOSIS

AND TESTING)

5. Electronically controlled viscous

fan stuck on5. Check viscous fan (Refer to 7 -

COOLING/ENGINE/FAN DRIVE

VISCOUS CLUTCH - DIAGNOSIS

AND TESTING)

6. Obstructed air flow through

radiator.6. Remove obstruction.

DRCOOLING 7 - 9

COOLING (Continued)

Page 298 of 2895

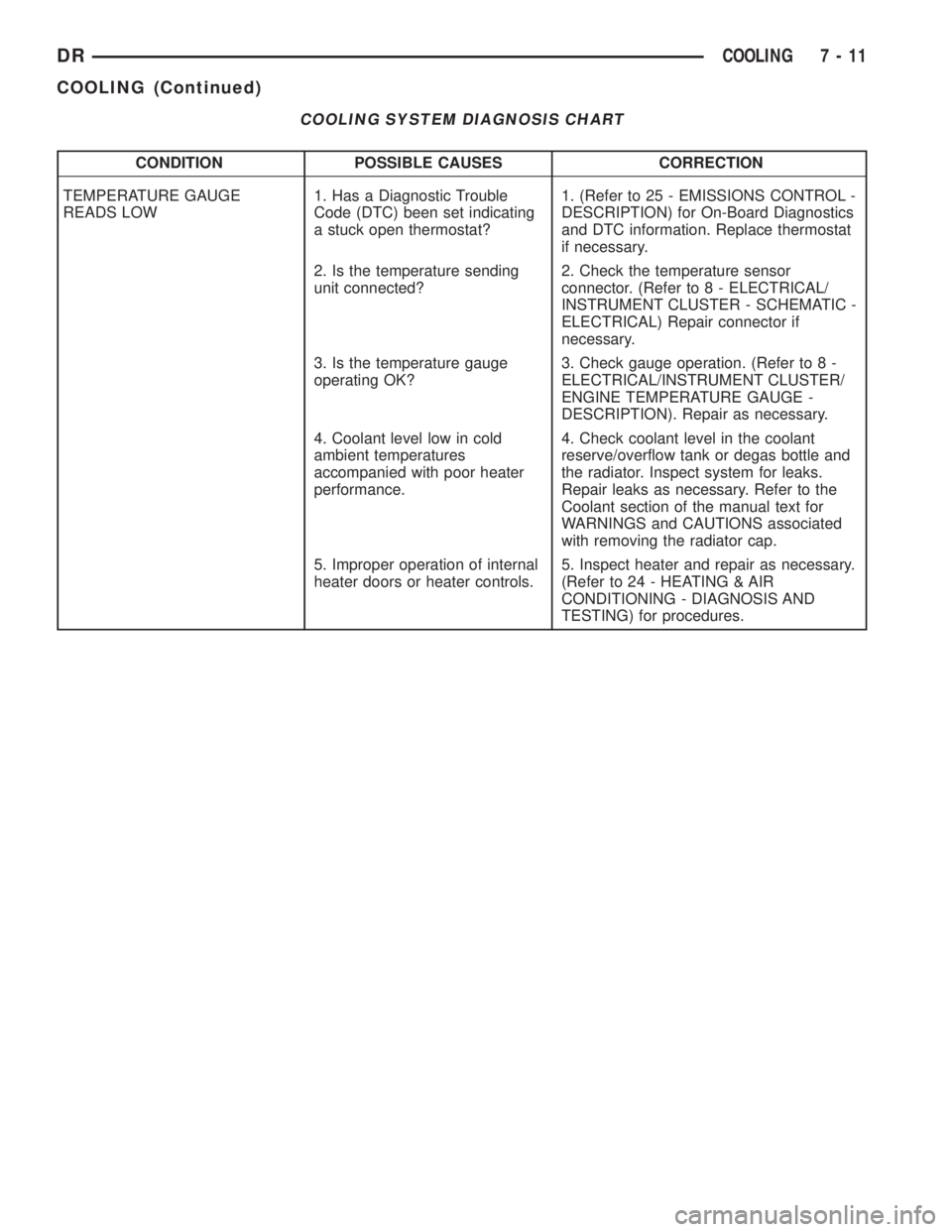

COOLING SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

TEMPERATURE GAUGE

READS LOW1. Has a Diagnostic Trouble

Code (DTC) been set indicating

a stuck open thermostat?1. (Refer to 25 - EMISSIONS CONTROL -

DESCRIPTION) for On-Board Diagnostics

and DTC information. Replace thermostat

if necessary.

2. Is the temperature sending

unit connected?2. Check the temperature sensor

connector. (Refer to 8 - ELECTRICAL/

INSTRUMENT CLUSTER - SCHEMATIC -

ELECTRICAL) Repair connector if

necessary.

3. Is the temperature gauge

operating OK?3. Check gauge operation. (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER/

ENGINE TEMPERATURE GAUGE -

DESCRIPTION). Repair as necessary.

4. Coolant level low in cold

ambient temperatures

accompanied with poor heater

performance.4. Check coolant level in the coolant

reserve/overflow tank or degas bottle and

the radiator. Inspect system for leaks.

Repair leaks as necessary. Refer to the

Coolant section of the manual text for

WARNINGS and CAUTIONS associated

with removing the radiator cap.

5. Improper operation of internal

heater doors or heater controls.5. Inspect heater and repair as necessary.

(Refer to 24 - HEATING & AIR

CONDITIONING - DIAGNOSIS AND

TESTING) for procedures.

DRCOOLING 7 - 11

COOLING (Continued)

Page 299 of 2895

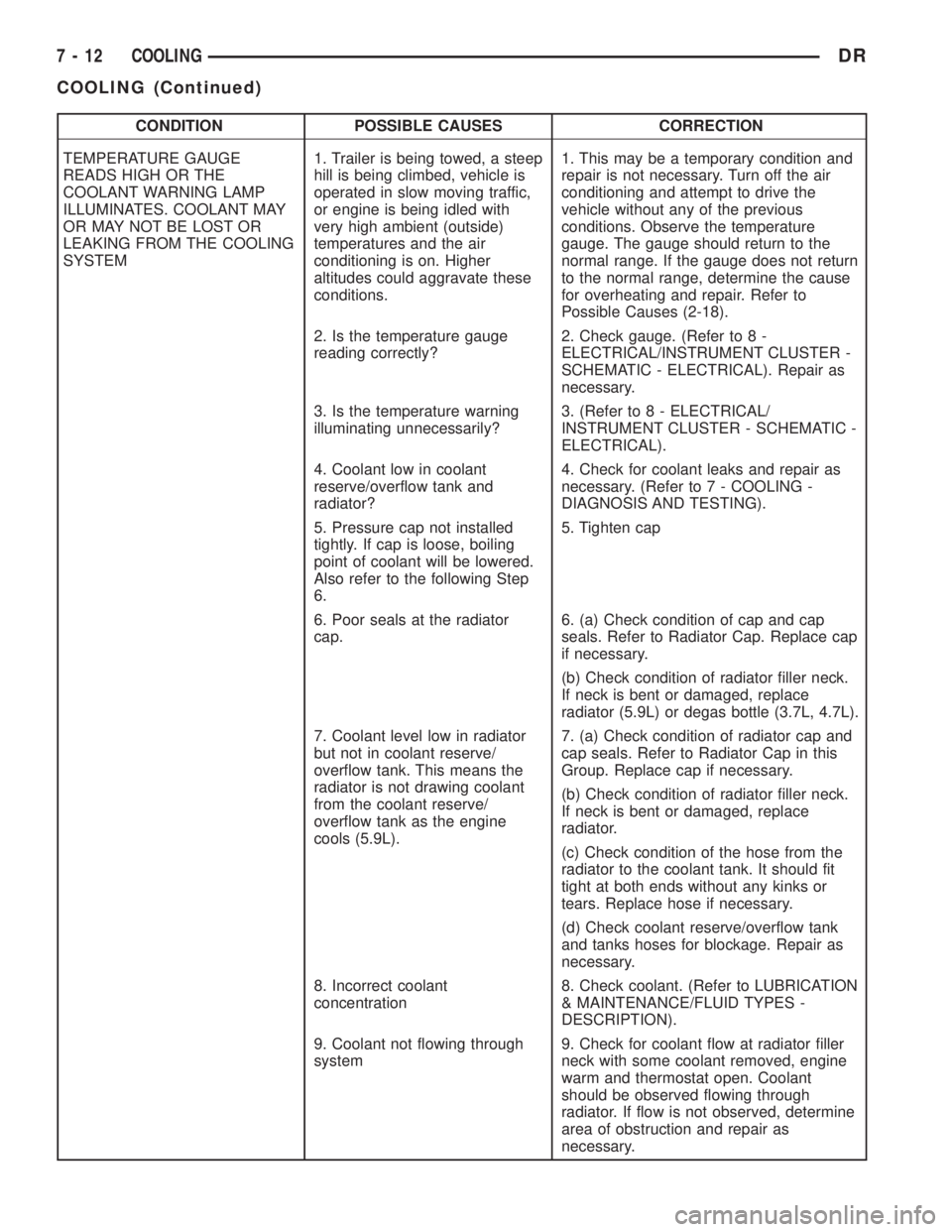

CONDITION POSSIBLE CAUSES CORRECTION

TEMPERATURE GAUGE

READS HIGH OR THE

COOLANT WARNING LAMP

ILLUMINATES. COOLANT MAY

OR MAY NOT BE LOST OR

LEAKING FROM THE COOLING

SYSTEM1. Trailer is being towed, a steep

hill is being climbed, vehicle is

operated in slow moving traffic,

or engine is being idled with

very high ambient (outside)

temperatures and the air

conditioning is on. Higher

altitudes could aggravate these

conditions.1. This may be a temporary condition and

repair is not necessary. Turn off the air

conditioning and attempt to drive the

vehicle without any of the previous

conditions. Observe the temperature

gauge. The gauge should return to the

normal range. If the gauge does not return

to the normal range, determine the cause

for overheating and repair. Refer to

Possible Causes (2-18).

2. Is the temperature gauge

reading correctly?2. Check gauge. (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER -

SCHEMATIC - ELECTRICAL). Repair as

necessary.

3. Is the temperature warning

illuminating unnecessarily?3. (Refer to 8 - ELECTRICAL/

INSTRUMENT CLUSTER - SCHEMATIC -

ELECTRICAL).

4. Coolant low in coolant

reserve/overflow tank and

radiator?4. Check for coolant leaks and repair as

necessary. (Refer to 7 - COOLING -

DIAGNOSIS AND TESTING).

5. Pressure cap not installed

tightly. If cap is loose, boiling

point of coolant will be lowered.

Also refer to the following Step

6.5. Tighten cap

6. Poor seals at the radiator

cap.6. (a) Check condition of cap and cap

seals. Refer to Radiator Cap. Replace cap

if necessary.

(b) Check condition of radiator filler neck.

If neck is bent or damaged, replace

radiator (5.9L) or degas bottle (3.7L, 4.7L).

7. Coolant level low in radiator

but not in coolant reserve/

overflow tank. This means the

radiator is not drawing coolant

from the coolant reserve/

overflow tank as the engine

cools (5.9L).7. (a) Check condition of radiator cap and

cap seals. Refer to Radiator Cap in this

Group. Replace cap if necessary.

(b) Check condition of radiator filler neck.

If neck is bent or damaged, replace

radiator.

(c) Check condition of the hose from the

radiator to the coolant tank. It should fit

tight at both ends without any kinks or

tears. Replace hose if necessary.

(d) Check coolant reserve/overflow tank

and tanks hoses for blockage. Repair as

necessary.

8. Incorrect coolant

concentration8. Check coolant. (Refer to LUBRICATION

& MAINTENANCE/FLUID TYPES -

DESCRIPTION).

9. Coolant not flowing through

system9. Check for coolant flow at radiator filler

neck with some coolant removed, engine

warm and thermostat open. Coolant

should be observed flowing through

radiator. If flow is not observed, determine

area of obstruction and repair as

necessary.

7 - 12 COOLINGDR

COOLING (Continued)

Page 301 of 2895

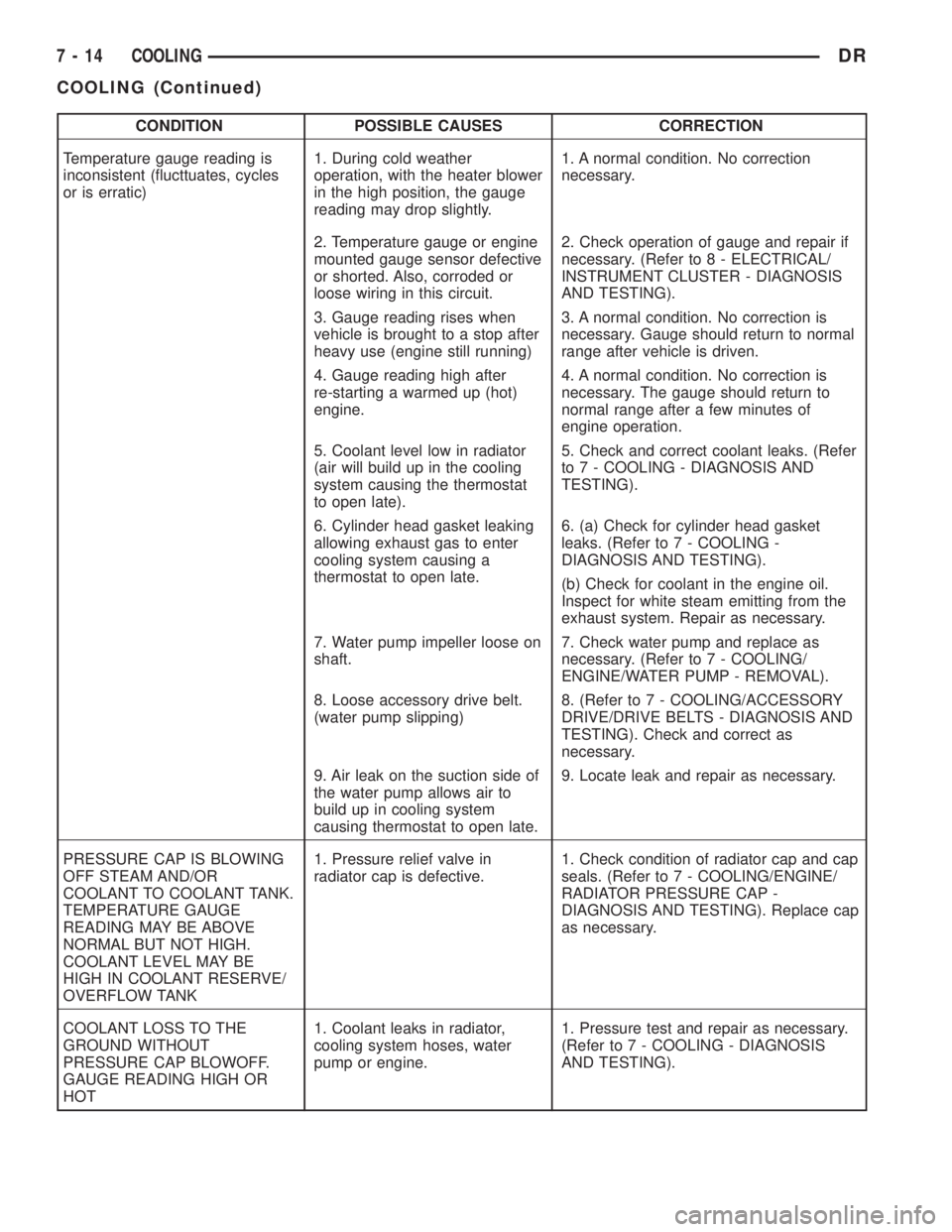

CONDITION POSSIBLE CAUSES CORRECTION

Temperature gauge reading is

inconsistent (flucttuates, cycles

or is erratic)1. During cold weather

operation, with the heater blower

in the high position, the gauge

reading may drop slightly.1. A normal condition. No correction

necessary.

2. Temperature gauge or engine

mounted gauge sensor defective

or shorted. Also, corroded or

loose wiring in this circuit.2. Check operation of gauge and repair if

necessary. (Refer to 8 - ELECTRICAL/

INSTRUMENT CLUSTER - DIAGNOSIS

AND TESTING).

3. Gauge reading rises when

vehicle is brought to a stop after

heavy use (engine still running)3. A normal condition. No correction is

necessary. Gauge should return to normal

range after vehicle is driven.

4. Gauge reading high after

re-starting a warmed up (hot)

engine.4. A normal condition. No correction is

necessary. The gauge should return to

normal range after a few minutes of

engine operation.

5. Coolant level low in radiator

(air will build up in the cooling

system causing the thermostat

to open late).5. Check and correct coolant leaks. (Refer

to 7 - COOLING - DIAGNOSIS AND

TESTING).

6. Cylinder head gasket leaking

allowing exhaust gas to enter

cooling system causing a

thermostat to open late.6. (a) Check for cylinder head gasket

leaks. (Refer to 7 - COOLING -

DIAGNOSIS AND TESTING).

(b) Check for coolant in the engine oil.

Inspect for white steam emitting from the

exhaust system. Repair as necessary.

7. Water pump impeller loose on

shaft.7. Check water pump and replace as

necessary. (Refer to 7 - COOLING/

ENGINE/WATER PUMP - REMOVAL).

8. Loose accessory drive belt.

(water pump slipping)8. (Refer to 7 - COOLING/ACCESSORY

DRIVE/DRIVE BELTS - DIAGNOSIS AND

TESTING). Check and correct as

necessary.

9. Air leak on the suction side of

the water pump allows air to

build up in cooling system

causing thermostat to open late.9. Locate leak and repair as necessary.

PRESSURE CAP IS BLOWING

OFF STEAM AND/OR

COOLANT TO COOLANT TANK.

TEMPERATURE GAUGE

READING MAY BE ABOVE

NORMAL BUT NOT HIGH.

COOLANT LEVEL MAY BE

HIGH IN COOLANT RESERVE/

OVERFLOW TANK1. Pressure relief valve in

radiator cap is defective.1. Check condition of radiator cap and cap

seals. (Refer to 7 - COOLING/ENGINE/

RADIATOR PRESSURE CAP -

DIAGNOSIS AND TESTING). Replace cap

as necessary.

COOLANT LOSS TO THE

GROUND WITHOUT

PRESSURE CAP BLOWOFF.

GAUGE READING HIGH OR

HOT1. Coolant leaks in radiator,

cooling system hoses, water

pump or engine.1. Pressure test and repair as necessary.

(Refer to 7 - COOLING - DIAGNOSIS

AND TESTING).

7 - 14 COOLINGDR

COOLING (Continued)

Page 302 of 2895

CONDITION POSSIBLE CAUSES CORRECTION

DETONATION OR PRE-

IGNITION (NOT CAUSED BY

IGNITION SYSTEM). GAUGE

MAY OR MAY NOT BE

READING HIGH1. Engine overheating. 1. Check reason for overheating and

repair as necessary.

2. Freeze point of coolant not

correct. Mixture is too rich or too

lean.2. Check coolant concentration. (Refer to

LUBRICATION & MAINTENANCE/FLUID

TYPES - DESCRIPTION).

HOSE OR HOSES COLLAPSE

WHILE ENGINE IS RUNNING1. Vacuum created in cooling

system on engine cool-down is

not being relieved through

coolant reserve/overflow system.1. (a) Radiator cap relief valve stuck.

(Refer to 7 - COOLING/ENGINE/

RADIATOR PRESSURE CAP -

DIAGNOSIS AND TESTING). Replace if

necessary

(b) Hose between coolant

reserve/overflow tank and

radiator is kinked. Repair as

necessary.

(c) Vent at coolant reserve/

overflow tank is plugged. Clean

vent and repair as necessary.

(d) Reserve/overflow tank is internally

blocked or plugged. Check for blockage

and repair as necessary.

NOISY VISCOUS FAN/DRIVE 1. Fan blades loose. 1. Replace fan blade assembly. (Refer to 7

- COOLING/ENGINE/RADIATOR FAN -

REMOVAL)

2. Fan blades striking a

surrounding object.2. Locate point of fan blade contact and

repair as necessary.

3. Air obstructions at radiator or

air conditioning condenser.3. Remove obstructions and/or clean

debris or insects from radiator or A/C

condenser.

4. Thermal viscous fan drive has

defective bearing.4. Replace fan drive. Bearing is not

serviceable. (Refer to 7 - COOLING/

ENGINE/FAN DRIVE VISCOUS CLUTCH

- REMOVAL).

5. A certain amount of fan noise

may be evident on models

equipped with a thermal viscous

fan drive. Some of this noise is

normal.5. (Refer to 7 - COOLING/ENGINE/FAN

DRIVE VISCOUS CLUTCH -

DESCRIPTION) for an explanation of

normal fan noise.

DRCOOLING 7 - 15

COOLING (Continued)

Page 304 of 2895

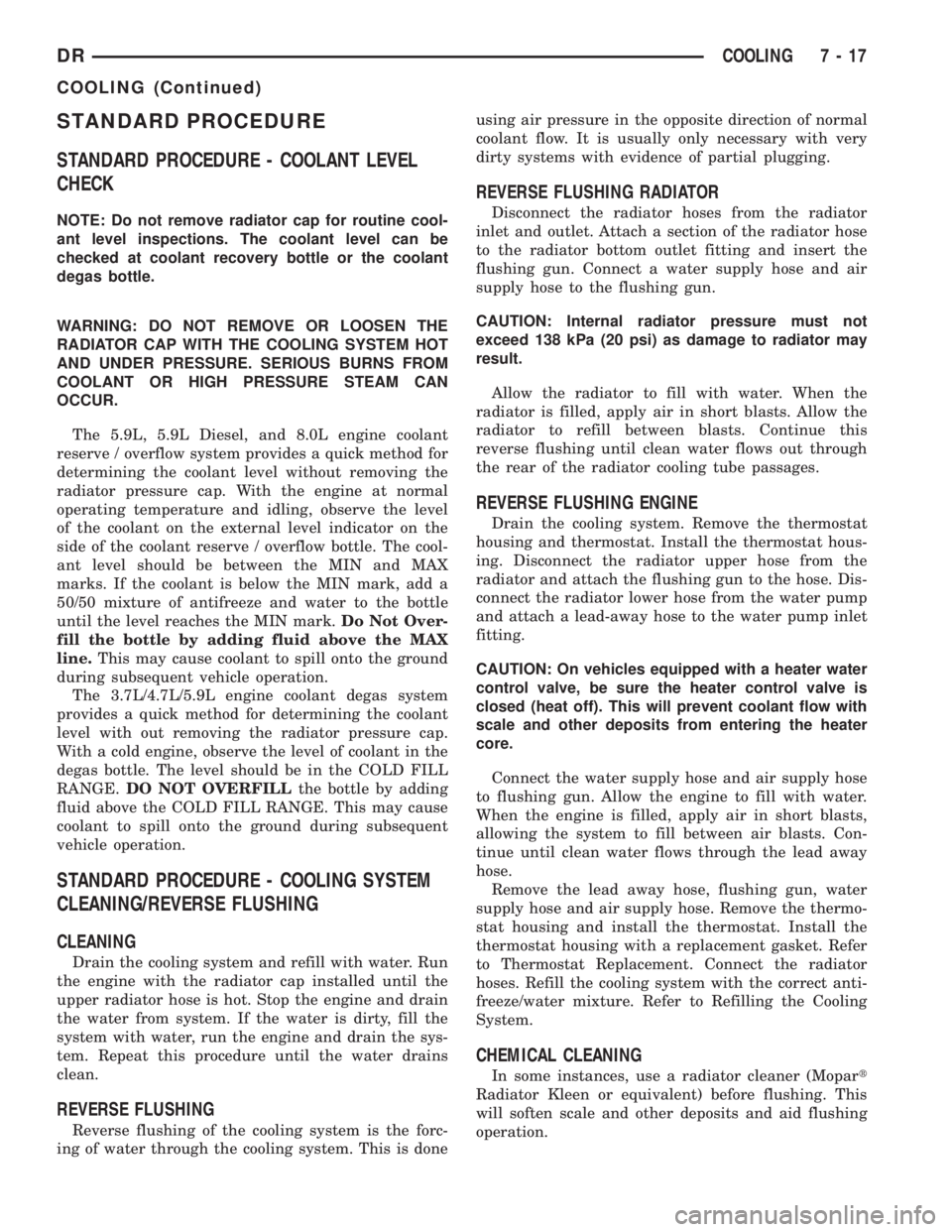

STANDARD PROCEDURE

STANDARD PROCEDURE - COOLANT LEVEL

CHECK

NOTE: Do not remove radiator cap for routine cool-

ant level inspections. The coolant level can be

checked at coolant recovery bottle or the coolant

degas bottle.

WARNING: DO NOT REMOVE OR LOOSEN THE

RADIATOR CAP WITH THE COOLING SYSTEM HOT

AND UNDER PRESSURE. SERIOUS BURNS FROM

COOLANT OR HIGH PRESSURE STEAM CAN

OCCUR.

The 5.9L, 5.9L Diesel, and 8.0L engine coolant

reserve / overflow system provides a quick method for

determining the coolant level without removing the

radiator pressure cap. With the engine at normal

operating temperature and idling, observe the level

of the coolant on the external level indicator on the

side of the coolant reserve / overflow bottle. The cool-

ant level should be between the MIN and MAX

marks. If the coolant is below the MIN mark, add a

50/50 mixture of antifreeze and water to the bottle

until the level reaches the MIN mark.Do Not Over-

fill the bottle by adding fluid above the MAX

line.This may cause coolant to spill onto the ground

during subsequent vehicle operation.

The 3.7L/4.7L/5.9L engine coolant degas system

provides a quick method for determining the coolant

level with out removing the radiator pressure cap.

With a cold engine, observe the level of coolant in the

degas bottle. The level should be in the COLD FILL

RANGE.DO NOT OVERFILLthe bottle by adding

fluid above the COLD FILL RANGE. This may cause

coolant to spill onto the ground during subsequent

vehicle operation.

STANDARD PROCEDURE - COOLING SYSTEM

CLEANING/REVERSE FLUSHING

CLEANING

Drain the cooling system and refill with water. Run

the engine with the radiator cap installed until the

upper radiator hose is hot. Stop the engine and drain

the water from system. If the water is dirty, fill the

system with water, run the engine and drain the sys-

tem. Repeat this procedure until the water drains

clean.

REVERSE FLUSHING

Reverse flushing of the cooling system is the forc-

ing of water through the cooling system. This is doneusing air pressure in the opposite direction of normal

coolant flow. It is usually only necessary with very

dirty systems with evidence of partial plugging.

REVERSE FLUSHING RADIATOR

Disconnect the radiator hoses from the radiator

inlet and outlet. Attach a section of the radiator hose

to the radiator bottom outlet fitting and insert the

flushing gun. Connect a water supply hose and air

supply hose to the flushing gun.

CAUTION: Internal radiator pressure must not

exceed 138 kPa (20 psi) as damage to radiator may

result.

Allow the radiator to fill with water. When the

radiator is filled, apply air in short blasts. Allow the

radiator to refill between blasts. Continue this

reverse flushing until clean water flows out through

the rear of the radiator cooling tube passages.

REVERSE FLUSHING ENGINE

Drain the cooling system. Remove the thermostat

housing and thermostat. Install the thermostat hous-

ing. Disconnect the radiator upper hose from the

radiator and attach the flushing gun to the hose. Dis-

connect the radiator lower hose from the water pump

and attach a lead-away hose to the water pump inlet

fitting.

CAUTION: On vehicles equipped with a heater water

control valve, be sure the heater control valve is

closed (heat off). This will prevent coolant flow with

scale and other deposits from entering the heater

core.

Connect the water supply hose and air supply hose

to flushing gun. Allow the engine to fill with water.

When the engine is filled, apply air in short blasts,

allowing the system to fill between air blasts. Con-

tinue until clean water flows through the lead away

hose.

Remove the lead away hose, flushing gun, water

supply hose and air supply hose. Remove the thermo-

stat housing and install the thermostat. Install the

thermostat housing with a replacement gasket. Refer

to Thermostat Replacement. Connect the radiator

hoses. Refill the cooling system with the correct anti-

freeze/water mixture. Refer to Refilling the Cooling

System.

CHEMICAL CLEANING

In some instances, use a radiator cleaner (Mopart

Radiator Kleen or equivalent) before flushing. This

will soften scale and other deposits and aid flushing

operation.

DRCOOLING 7 - 17

COOLING (Continued)